SunStar SPS/D-B1201 Series, SPS/C-B1201 Series, SPS/D(C)-B1202-01, SPS/D(C)-B1202-02, SPS/D(C)-B1202-03 User Manual

Page 1

USER S MANUAL

SPS/D-B1201

SERIES

SPS/C-B1201

SERIES

R

Electronically Controlled

Button Sewing Machine

(Mechanical Part)

Page 2

Best Quality

Best Price

Best Service

SunStar CO., LTD.

R

1.

Thank you for purchasing our product. Based on the rich expertise and

experience accumulated in industrial sewing machine production, SUNSTAR

will manufacture industrial sewing machines, which deliver more diverse

functions, high performance, powerful operation, enhanced durability, and

more sophisticated design to meet a number of user’s needs.

2. Please read this user’s manual thoroughly before using the machine. Make

sure to properly use the machine to enjoy its full performance.

3. The specifications of the machine are subject to change, aimed to enhance

product performance, without prior notice.

4.

This product is designed, manufactured, and sold as an industrial sewing

machine. It should not be used for other than industrial purpose.

Page 3

SPS/D-B1202-01

④ Button Type

01 : Small-Size Button

(Mechanical Type Wiper)

02: Large-Size Button

(Mechanical Type Wiper)

03 : Small & Large Size Button

(Solenoid wiper Type Wiper)

① Sunstar

Pattern

System

② Series

C: Motor belt-type

D: Motor direct drive-type

③ Button S/M Model Name

Page 4

Contents

1. Machine safety regulations 6

2. Machine Specifications 9

3. Machine Structure 10

1) Names of each part of the machine 10

4. Machine Installation 11

1) Machine installation conditions 11

2) Electric installation conditions 11

3) How to install the table 11

4) The assembly of peripheral parts 14

5) Change of parameters according to setting of thread wiper specifications 15

5. Preparations before operating the machine 16

1) How to supply oil 16

2) How to grease 16

3) How to attach needle 17

4) Checking needle and thread 17

5) How to pass upper thread 17

6) Threading the lower thread 17

7) How to take the bobbin case on and off 18

8) How to adjust the tension of the upper thread and the lower thread 18

9) How to wind the lower thread 19

10) How to operate a pedal 19

11) Disposing the waste oil 19

6. How to repair the machine 20

1) Adjusting the height of the needle bar 20

2) Adjusting the needle and the shuttle 20

3) How to adjust the eccentricity of thread take-up crank axis 21

4) Adjusting the lower shaft gear and the rocking shaft gear 21

5) Adjusting the position of shuttle upper spring 22

6) How to adjust the ascending range of button clamp 22

7) How to adjust the button clamp holder tension 23

Page 5

8) Adjusting the parts of thread release 23

9) Adjusting the parts of wiper 24

10) Adjusting the parts for trimming 27

11) Adjusting the devices for main thread adjustment 29

12) Adjusting the winder devices 29

13) Setting up the synchro position(C Series) 30

14) Mounting the Direct Motor and Adjusting Method(D Series) 31

15) Setting up the X-Y origin 31

16) How to adjust the feeding plate 32

17) Checking the setting position of button clamp 32

18) How to set up the button clamp adjusting plate 33

19) How to attach the spacer spring plate 33

7. Cause of Breakdown and Troubleshooting 34

8. Pattern List 36

9. Drawing of Table 37

1) SPS/D-B1202 37

2) SPS/C-B1202 38

10. Gauge List 39

11. Option List 39

Page 6

6

11

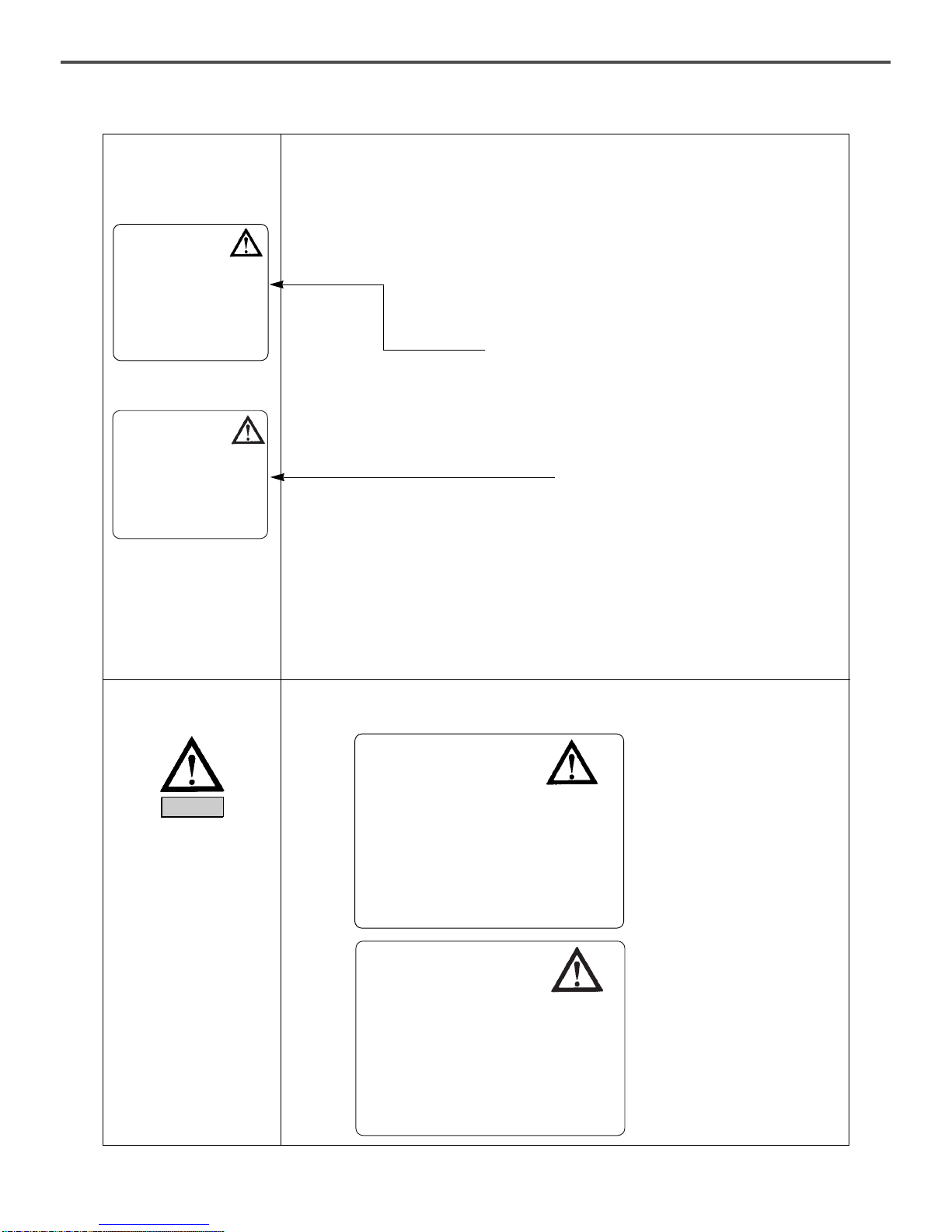

MACHINE SAFETY REGULATIONS

Safety instruction on this manual are defined as Danger, Warning and Notice.

If you do not keep the instructoins, physical injury on the human body and machine damage might be occurred.

: This indication should be observed definitely. If not, danger could be happen during the installation,

conveyance and maintenance of machines.

: When you keep this indication, injury from the machine can be prevented.

: When you keep this indication, error on the machine can be prevented.

Danger

Warning

Notice

1-1) Machine Transportation

Danger

1-2) Machine Installation

Notice

1-3) Machine Repair

Danger

Only trained and experienced people should treat the machine who are fully

understand the safety rules.

For conveyance, follow the below directions.

ⓐ More than two people to a minimum should convey the machine.

ⓑ For a protection of safety accident, wipe away the oil stained on machine.

Owing to the improper environment for machine installation, physical damages on

the human body and machine can be occurred. Please follow below conditions.

ⓐ When you unwrap the packing of the machine, try from above in order.

Especially careful of nails put into edges of wood box packing.

ⓑ Since dust and humidity can cause pollution and abrasion, you should install

airconditioner with regular cleaning.

ⓒ Put in a place of no direct ray of light.

If the machine is exposed in direct ray of light for a long time, transformation

of color and shape can be happened.

ⓓ To get enough space in case of repair, make the machine 50cm apart from the

right and left and back side of wall to a minimum.

ⓔ EXPLOSION HAZARDS

Do not operate in explosive atmospheres. To avoid explosion, do not operate

this machine in an explosive atomosphere including a place where large

quantities of aerosot spray product are being used or where oxygen is being

administered unless it has been specifically certified for such operation.

ⓕ The machines where not provided with a local lighting due to the feature of

machine. Therefore the illumination of the working area must be fuifilled by

end user.

[Refer] Details for installation of machine is described in ‘4. Machine Installation.’

If you have any problems on the machine, troubleshooting should be handled by

the designated A/S engineers.

ⓐ Before cleaning and repairing machine, cut off the main power and wait for 4

minutes until the machine comes to be completely discharged.

ⓑ You should not change the specification of machine and any part of machine

without consulting with our company. Those changes can threaten the safety of

machine during the operation.

ⓒ You should exchange from the used one into SWF guaranteed devices.

ⓓ After finishing troubleshooting, cover the all covers that are uncovered during

repairing.

Page 7

7

SPS/D(C)-1202 Series are made for industrial use to perform button sewing to

fabrics or its similar materials. Please observe the following principles.

ⓐ Read the manual to understand on the operation of machine perfectly.

ⓑ Wear suitable clothes and cap for safe operation.

ⓒ During operation, don’t make you body close to operating part of machine such

as needle, hook, take-up lever or pulley.

ⓓ Do not remove a safety plate and covers during operation

ⓔ Be sure the grounding lines in connected.

ⓕ Before opening electricity box such as control box, cut off the supply of

electricity and confirm if the switch is “off”.

ⓖ When inserting thread into a needle or before inspecting after sewing, be sure

the machine is stopped.

ⓗ Do not turn on the power during pedaling.

ⓘ Do not use several motor per a electric outlet.

ⓙ Install the machine apart from noise occurrence area such as high frequency

welding machines as far as possible.

ⓚ Be careful- When the upper feed plate comes down to press. Otherwise, the

finger or hand hight be hurt at smacking.

1-4) Machine Operation

Warning

ⓐ Safety label : It describes cautions during operating the machine.

ⓑ Thread take-up cover : It prevents from any contact between body and take-up lever.

ⓒ Motor Cover(D Series) : It prevents from insertion of hands, feet or clothes by Motor.

Belt Cover(C Series) : It prevents from insertion of hands, feet or clothes by V-belt Motor.

ⓓ Label for specification of power : It describes cautions for safety to protect against

electric shock during rotating the motors.

ⓔ Finger guard : It prevent from contacts between a finger and needle.

ⓕ Safety plate : It protects eyes against needle breaks.

1-5)

Devices for safety

Notice

Belt will crush or amputate finger or hand, keep cover in place

before operating, turn off power before inspecting or adjusting.

Warning

ⓑ

ⓐ

ⓕ

ⓔ

ⓓ

ⓒ

Page 8

8

Caution mark is attached on the machine for safety.

When you operate the machine, observe the directions on the mark.

Position of Warning Mark

1-6) Caution Mark Position

1-7) Contents of Marks

Warning

CAUTION

경고

Do not operate without finger guard and

safety devices. Before threading, changing

bobbin and needle, cleaning etc. switch off

main switch.

손가락 보호대와 안전장치 없이 작동하지

마십시오.

실, 보빈, 바늘교환시나 청소전에는 반드시 주

전원의 스위치를 꺼 주십시오.

CAUTION

경고

Hazardous voltage will cause injury.

Be sure to wait at least 360 seconds before

opening this cover after turn off main switch

and unplug a power cord.

고압 전류에 의해 감전될 수 있으므로 커버를

열 때는 전원을 내리고 전원 플러그를 뽑고 나

서 360초간 기다린 후 여십시오.

CAUTION

경고

Do not operate without finger guard

and safety devices. Before threading,

changing bobbin and needle, cleaning

etc. switch off main switch.

손가락 보호대와 안전장치 없이 작동하지 마

십시오.

실, 보빈, 바늘교환시나 청소전에는 반드시

주전원의 스위치를 꺼 주십시오.

CAUTION

경고

Hazardous voltage will cause injury.

Be sure to wait at least 360 seconds

before opening this cover after turn

off main switch and unplug a power

cord.

고압 전류에 의해 감전될 수 있으므로 커버

를 열 때는 전원을 내리고 전원 플러그를 뽑

고 나서 360초간 기다린 후 여십시오.

Caution

1)

2)

Warning

Page 9

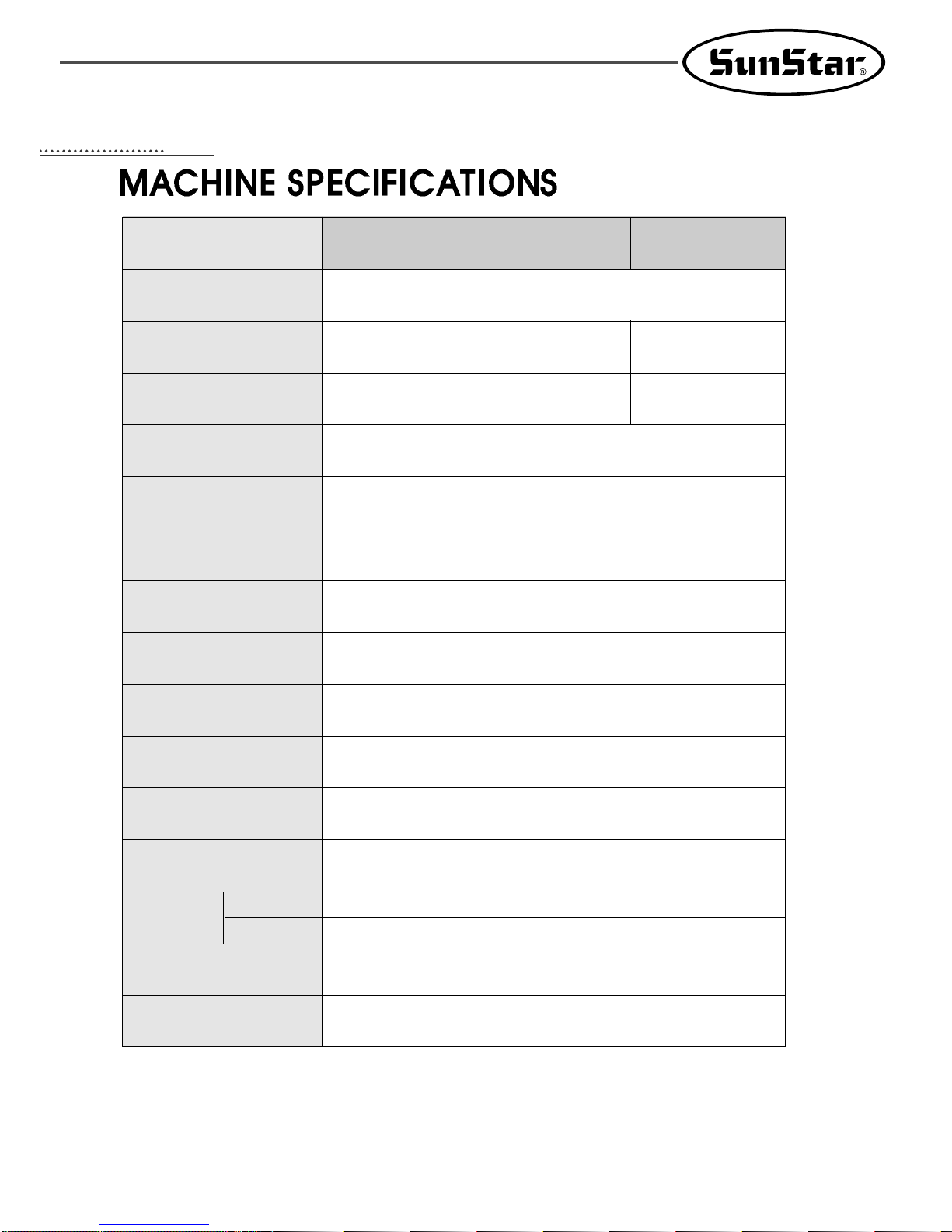

9

Max. 2,500spm (Standard : 2,200spm)

DP×17 #14

Semi-Rotary Standard Shuttle Hook

Max. 13mm

Max. 99 Patterns (Standard: 33 Patterns)

Max. 10,000 Stitches

20%~200%

P-ROM

5℃~40℃ (41℉~104℉)

20%~80%

1ф : 100~240V / 3ф : 200V~440V, 50/60Hz

600VA

Name of Model

Speed

Button Size

Wiper Specification

Needle

Hook

Button Clamp Lift

No. of Patterns

No. of Stitches

Enlargement / Reduction

Memory

Main Motor

Power

Consumption Power

22

SPS/D(C)-B1202-01 SPS/D(C)-B1202-02 SPS/D(C)-B1202-03

ф8~ф20mm

D Series

C Series

Direct Drive AC Servo Motor

AC Servo Motor

ф8~ф32mm ф8~ф32mm

Mechanical Type Wiper Solenoid Type Wiper

Proper Temperatare of

machine running

Proper Humidity of

machine running

Page 10

10

33

MACHINE STRUCTURE

1) Names of each part of the machine

Arm

Mortor Cover

Thread

Stand

Safety Plate

Operation Box

Power Switch

Control Box

Pedal Switch

Page 11

11

44

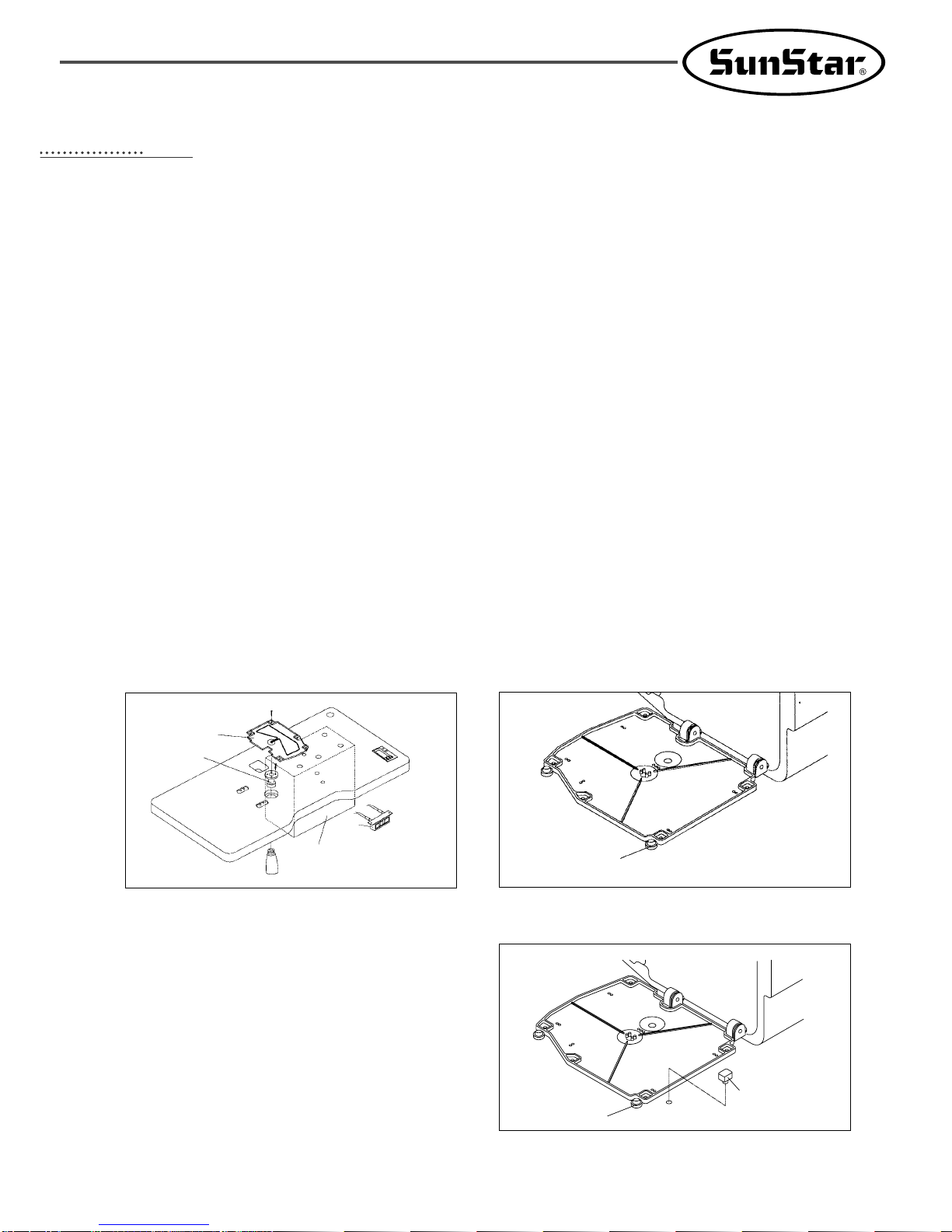

[ Fig. 1 ]

[ Fig. 2 ]

B. In case of SPS/C-B1202 series, attach the

bed cushion rubber to the table.

③

④

②

①

MACHINE INSTALLATION

1) Machine installation conditions

A. Do not use the machine where the voltage is over regular voltage ±10% to prevent accidents.

B. For safe operation of the machine, use the machine under the following conditions.

Surrounding Temperature During Operation : 5℃~40℃

Surrounding Temperature During Maintenance : -10℃~60℃

C. Humidity : Between 20~80%(Relative humidit

y)

2) Electric installation conditions

A. Power Voltage

·The power voltage must be between regular voltage ±10%.

·The frequency of the power should be regular frequency (50/60HZ)±1%.

B. Electromagnetic Wave Noise

Use separate power with strong magnetics or high frequency products, and do not leave the machine

near them.

C. Use low voltage when supplements or accessories are being adhered.

D. Be careful not to have water or coffee be spilled into the Controller and Motor.

E. Do not drop the Controller or Motor.

3) How to install the table

A. Fix the oil tub holder ①, oil holder ②,

control box ③, and main switch ④ on

the table.

Cushion Rubber

①

②

C. In case of SPS/D-B1202 series, attach the

bed cushion rubber ① and safety switch

supporting rubber ② to the table.

[ Fig. 3 ]

Page 12

12

[ Fig. 6 ]

①

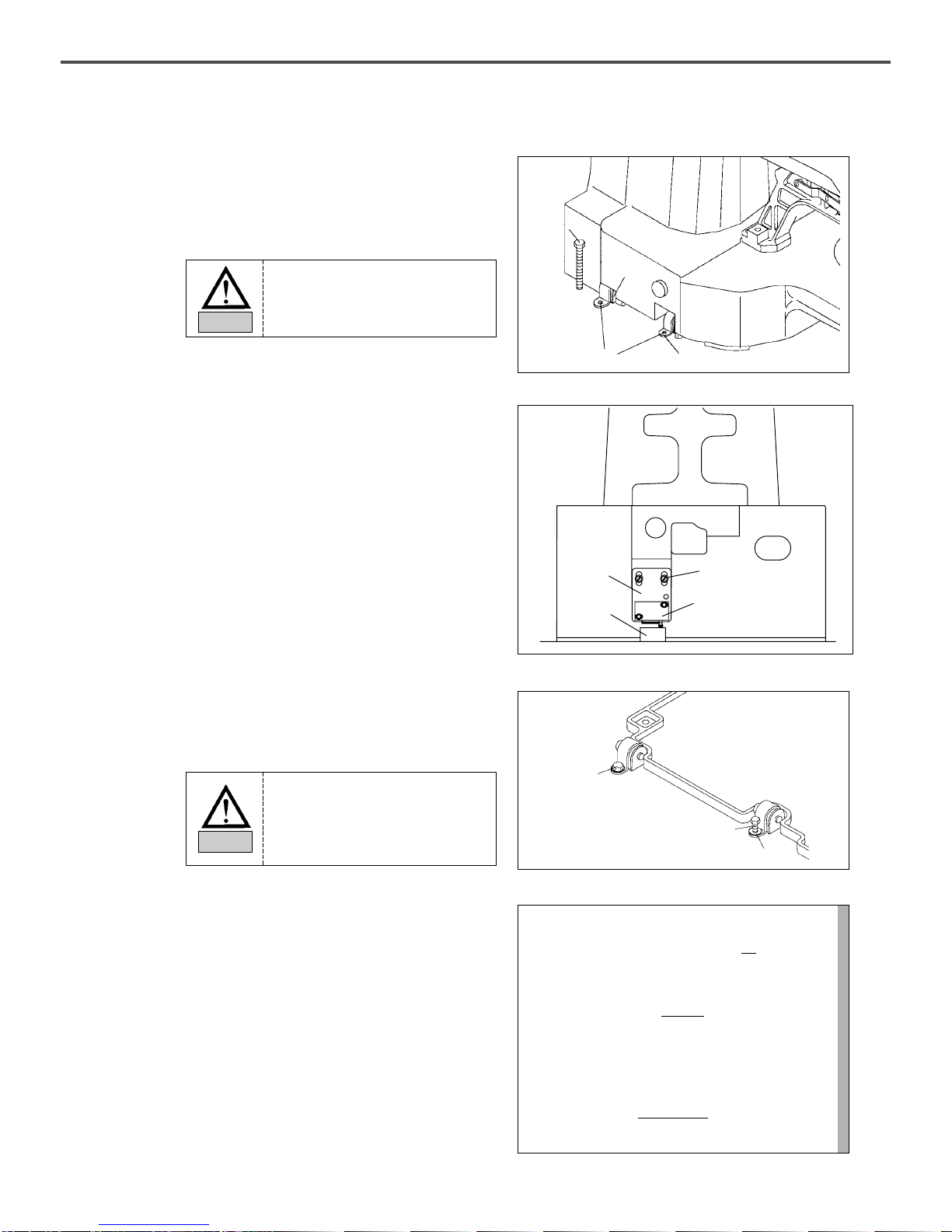

①

F. Stand the machine as shown in the picture,

and then fix the machine on the table after

inserting the fixing bolts into the hinge metal

holes of point ①.

Bolt

[ Fig. 7 ]

G. Put the “V”-Belt in between the pulley and

the motor while the machine is standing as

in the picture.(C Series)

Pulley

V-Belt

Motor Cover

[ Fig. 4 ]

①

D. Add the hinge metal and hinge rubber to the

bed. Then insert the fixing bolt into the

hinge

metal hole of point ① and fix the table

as shown

in the picture.

Bolt

Hinge

Rubber

Hinge

E. In case of SPS/D-B1202 series, assemble the

safety switch bracket ① on the bed as in the

figure. Move the safety switch bracket up

and down to make sure that the safety

switch supporting rubber② is tightly pressed

by the safety switch③, and then fasten the

screw④.

[ Fig. 5 ]

②

④

③

①

The machine should be carried

by more 2 people for safety

Danger

Since the machine is not perfectly

installed on the table, extreme care is

needed when you make the machine

stand up not to have any accident

occurred.

Danger

Page 13

13

[ Fig. 9 ]

I.Be sure to connect the earthing conductor

(green)between the sewing machine and the

motor. And also, connect the earthing conduct

or between the control box and the motor.

(C Series)

Conductor

[ Fig. 10 ]

J.In case of D series, connect the conduct of

sewing machine and control box as in the

picture.

Conductor

[ Fig. 8 ]

D

C

①

②

H. After connecting the “V”-Belt, if the fixing

nuts① and ② are vertically unfastened

sufficiently tension occurs in belt D due to

the weight of motor C. At this point, first

screw in fixing nut ① A, then nut ② in

fixing screw B tightly. And, finish the cable

connection between the embroidery machine

and the control box, then fix the cable

wiring under the table as shown in the

Figure. (The length of cable should be set

up considering when the machine is put

aside.) (C Series)

Page 14

14

A. Attach the motor cover to the back side of machine and sides by using fixing bolts

(In case of C series, attach the belt cover by using fixing screws for the rear (3EA) and the side (2EA).)

4) The assembly of peripheral parts

[ Fig. 11 ]

[ Fig. 12 ]

Motor Cover

Velt Cover

Fixing Screw

Fixing Screw

Fixing

Screw

D series

C series

③

④

①

②

B. Install the thread stand on the table.

[ Fig. 13 ]

C. Fix the button case base① in the bottom of

flat table to the easy working position using a

screw②. And insert the button case③ into the

button case base①, then fix it with a fixed

screw④.

[ Fig. 14 ]

For safety, motor cover and safety plate should be attached to the machine.

Caution

Page 15

15

5) Change of parameters according to setting of thread wiper specifications

·Parameters are changed according to mechanical thread wiper specifications upon initialization.

·For change of parameters according to setting of thread wiper specifications, refer to the following

table :

·For more information, refer to “Memory Switch Function Table”.

Mechanical Type

Electronic Type

Function No.

Wiper Specification

0

1

A14 A31

1

0

Page 16

16

55

[ Fig. 16 ]

PREPARATIONS BEFORE OPERATING THE MACHINE

1) How to supply oil

A. Check the remaining oil in the oil tank in the

arm and bed, and supply the oil sufficiently

on the arrowed parts on the Figure 16 with

a lubricator.

[ Fig. 17 ]

B. Open the hook cover and supply oil till the

shuttle race ring is surrounded by oil. Put

the hook cover closed after finishing.

Shuttle Race Ring

Hook Cover

2) How to grease

Supply a little grease on the arrowed parts in

the Figure16. Too much grease prevents the

clamp from moving up and down, therefore an

error message

-[“Er 05”] is displayed.

[ Fig. 18 ]

Be sure to supply oil when

operating the machine for the

first time and when the machine

has not been used for a long

time.

Caution

For safety, keep the hook cover

closed during operating.

Caution

Page 17

17

5) How to pass upper thread

Place the thread take-up lever on the top

position, and hang the upper thread as shown in

the Figure20. About 40mm of the upper thread

should come out from the needle eye.

[ Fig. 20 ]

3) How to attach needle

Loosen the needle fixing screw① in the needle

bar, place the long groove of needle② toward to

user and push it until the needle upper point

gets to the needle insert hole, then fix it with

the needle fixing screw①.

[ Fig. 19 ]

①

4) Checking needle and thread

Refer to the right table when selecting the

needle and thread to use according to working

conditions.

(Cotton thread or span thread is available.)

②

Needle

DP×17 #14

Upper Thread

#60

#50

#40

#60

#80

#60

#60

#60

Lower Thread

6) Threading the lower thread

A. Insert bobbin ① into bobbin case ② as

shown in the Figure21.

B. After setting the lower thread through the

crack of the bobbin case, insert the thread

through thread hole ③.

C. Adjust the lower thread to hang 25mm out

of thread hole ③.

[ Fig. 21 ]

③

25mm

②

①

Insert the bobbin to turn clockwise

when seen from behind the bobbin

case

Caution

Page 18

18

[ Fig. 24 ]

①

[ Fig. 22 ]

[ Fig. 23 ]

①

8) How to adjust the tension of the upper thread and the lower thread

A. Adjusting the Tension of the Upper Thread

When the tension adjusting nuts ③ and ④,

of thread tension adjusting unit ① and subtension adjusting unit ②, are turned

clockwise the upper thread is tightened. And

loosens when turned the other way around.

B. Adjusting the Tension of the Lower Thread

The lower thread becomes tight when tension

adjusting screw ① is turned clockwise, as

shown in the picture. When the screw is

turned the other way the lower thread is

loosened.

7)

How to take the bobbin case on and off

Opening the hook cover, hold the knob ① of

bobbin case and push into the shuttle until

sounding.

Bobbin Case

②

④

①

③

If you start operating the machine

when a bobbin case is not perfectly

installed, thread can be tangled of the

bobbin case would be protruded.

Caution

Page 19

19

9) How to wind the lower thread

A. Press SELECT on operation box and select .

B. Insert the bobbin into the thread winder drive shaft ② on thread winder base ①, attched to the

upper cap.

C. Adhere the bobbin winder lever ③ closely to a bobbin, then let the machine run by pressing pedal.

D. After the bobbin winder lever takes off from a bobbin, cut the thread of bobbin by using bobbin

winder knife ④.

[ Fig. 25 ]

10)

How to operate a pedal

A. Install a pedal switch in the proper position

for the convenience of work.

B. If you step on pedal one step, the button

clamp descends, and if take off your feet

from the pedal, it ascends.

C. If you step on two step the pedal switch

after stepping on it one step, the sewing

starts, and after finishing it,the button clamp

ascends.

[ Fig. 26 ]

[ Fig. 27 ]

11) Disposing the waste oil

When the oil receiving oiler at the bottom of

the table is full, take it off to empty.

↓

→

Oiler

Spread out some fabrics or papers

on the floor when you attach or

remove the oil receiving container.

Caution

Page 20

20

66

HOW TO REPAIR THE MACHINE

1) Adjusting the height of the needle bar

Loosen the needle bar clamp screw① at its

lowest point, adjust the upper punched mark of

the needle bar to conform to the bottom of the

needle bar bushing as shown in the Figure28,

then tighten the needle bar clamp screw①.

2) Adjusting the needle and the shuttle

B. After unfastening the shuttle drive screw①, open the inner hook pressure bar ② left to right and remove

the shuttle Race ring ③ from the (large) shuttle ④.

C. Make the shuttle hook point accord with the center of the needle. And make the needle and the front

face of the shuttle drive connect each other to prevent the needle from curving. Then, tighten the drive

screw ① firmly.

D. After unfastening the (large) shuttle screw⑤, turn the large hook adjustment shaft ⑥ to the left to right

and adjust the (large) shuttle ④ so that the needle and the shuttle hook point is 0.05~0.1mm apart

from each other.

E. After adjusting the (large) shuttle ④ in place, adjust the rotary direction of the (large) shuttle ④ so the

needle and the (large) shuttle ④ is 7.5mm apart from each other.

Then, tighten the (large) shuttle screw ①.

A. As shown in the Figure29, go up the needle

bar from its lowest point, and conform the

lower-left punched mark of the needle bar to

the lower bushing of the needle bar.

7.5mm

②

②

⑥

③

→

→

0.05~0.1mm

→

⑤

①

④

0mm

[ Fig. 28 ]

[ Fig. 29 ]

Needle Bar

Lower Bushing

Lower

punched mark

Upper

punched

mark

①

The machine is set to be the best condition at the factory. Do not make any discrete

adjustments on the machine and replace genuine parts approved by the company only.

Caution

For safety, make sure all the screws are tightened firmly after adjusting the (large) shuttle.

Caution

Page 21

21

[ Fig. 31 ]

3) How to adjust the eccentricity of thread take-up crank axis

③

②

①

4) Adjusting the lower shaft gear and the rocking shaft gear

A. Unfasten screws ①, ②and ③.

B. While having the upper shaft turning, move the rocking shaft gear in the direction of the arrow to

the position where it will move easily without load.

C. Have the oscillator shaft collar(right) stick to the bed surface , and then tighten the collar screw.

D. Turn the oscillator shaft collar(right), still sticking to the bed surface , in the direction of the

arrow and make adjustments so the end of the shuttle drive will rotate smoothly with the backlash

of under 0.1mm.

E. Tighten screw ① and ③ back on firmly.

[ Fig. 32 ]

below 0.1mm

②

Oscillator Shaft

Collar(R)

①

③

→←

A. Disassemble the face plate from an

embroidery machine, then remove a clamp

screw in the thread take-up crank axis.

B. Loosen a fixed screw of the thread take-up

crank axis in the left of arm.

C. Rotate the thread take-up crankshaft③ to

place its eccentric part to the upper

direction. And adjust the driver’s groove

horizontally.

D. Tighten the fixed screw of the thread take-

up crank axis, then reassemble the clamp

screw of the thread take-up crank axis.

The machine may not operate when the rocking shaft gear in not in the right position.

Caution

If there is too much backlash the machine may make more noise than usual during

operation. And if there is not enough backlash, the machine may not operate.

Caution

Page 22

22

[ Fig. 30 ]

5) Adjusting the position of shuttle upper spring

After removing the lower feed plate and the needle plate from the machine, unfasten the screw of the

shuttle upper spring

. Then, adjust the shuttle upper spring so that the backside of the needle

and comes

to point in the vertical direction, and the center of the needle will come to the middle of interval

horizontally. After the adjustment is done, tighten the screw back on firmly.

[ Fig. 33 ]

①

①

①

①

③

②

6) How to adjust the ascending range of button clamp

To adjust the ascending range of button clamp, take out its tension adjusting screw①, loosen the fixed

screw②, adjust the holder bar of button clamp up and down to place it to the suitable position, then

tighten the fixed screw②. And attach the tension adjusting screw① on the original position again.

※ The maximum rising height of button clamp is 13mm from the presser foot.

(The rising height of button clamp upon delivery is adjusted to 10~11mm.)

[ Fig. 34 ]

13mm

The thread may be disconnected or the thread strand may be unfastened if there are scratches or if

the surface is rough around the Shuttle upper spring. Always check the surface of the spring before

operating the machine.

Caution

Page 23

23

8) Adjusting the parts of thread release

A. How to Set the Thread release Notch

Place the notch so that the right side of the

slot of the thread release notch ① touches

circumference of the notch screw ②, and then

fix with a screw.

[ Fig. 36 ]

①

①

Thread

Trimmer

Cam

②

②

7) How to adjust the button clamp holder tension

Adjust it smoothly to the extent that sewing

cloth does not move during sewing, and fix it

with the tension adjusting nuts - ① and ②.

[ Fig. 35 ]

[ Fig. 37 ]

B. How to Set the Thread Release Stopper

ⓐ Remove the thread release return spring.

ⓑ After unfastening the thread release stopper screw, adjust the trimming drive link and the thread

release lever pin 0.3mm apart from each other. Then, attach the arm to the thread delay stopper

completely. When the thread release stopper is pushed to the right, the space between the

trimming drive link and the thread release lever pin is reduced. And it is enlarged when the stopper

is pushed to the left.

ⓒ Hang on the thread release return spring.

→

→

0.3mm

Thread Release

Lever Pin

Thread

Trimming

Driving Link

Thread Release

Stopper

Return Spring

Screw

Widen

Narrow

For safety, use a tool when removing or attaching the thread release return spring.

Caution

The remaining amount of thread

may not be enough or not be

regular and the thread may be

unfastened from the needle if the

notch is not set in the right position.

Caution

Page 24

24

C. How to adjust the opening capacity of the thread guide disk

ⓐ Unfasten the thread release adjusting plate screw.

ⓑ Open the thread guide disk by operating the trimming devices.

ⓒ Adjust the opening capacity to 0.6~0.8mm for normal material and 0.8~1mm for heavy material.

To increase the opening capacity, widen the angle between the thread release plate and narrow

the angle to reduce the opening capacity.

ⓓ Tighten the screw after the adjustment.

[ Fig. 38 ]

Widen

Narrow

Floating Amount

Screw

Upper Shaft

To Thread Tension

Adjusting Ass’y

To Tension Release Link

Thread Tension Adjusting Plate

→

→

9) Adjusting the parts of wiper

A. Adjusting method of kinematic type wiper(SPS/D(C)-B1202-01, 02)

ⓐ Unfasten the wiper base plate bolt ②.

ⓑ When the thread wiper and the needle center are in a straight line, adjust the thread wiper base③

up and down that the interval between the needle① and the thread wiper can be 2.5mm, then

tighten the clamp②.

ⓒ Unfasten the wiper rod bolt ④.

ⓓ Adjust the thread connecting rod⑤ up and down that the thread wiper under sewing standby can

have the interval of 15~17mm from the needle center, then tighten the thread wiper rod clamp④.

ⓔ The thread wiper spring attached on the thread wiper base has the function to hold upper thread

after thread trimming, and its proper tension is about 20~30g. (A little stronger than the tension of

lower thread in the bobbin case)

[ Fig. 39 ]

[ Fig. 40 ]

③

②

Needle ①

2.5mm

④

⑤

⑥

15~17mm

If the disk is not opened appropriately, the amount of remaining thread may be not enough or

not regular, and the disk may not be closed completely.

Caution

If the wiper is not placed in the right position, the wiper may collide with the presser foot

or needle during the operation, and the wiper may not move properly.

Caution

Page 25

25

B. Installation and adjusting method of solenoid wiper (SPS/D(C)-B1202-03)

ⓐ Fix the wiper base plate with screw as

shown in the figure41.

ⓑ Fix the wiper base at the opposite

direction with two screws as shown in the

figure42.

ⓒ Connect the connector located at solenoid

with the connector came out from arm.

[ Fig. 41 ]

[ Fig. 42 ]

[ Fig. 43 ]

Page 26

26

ⓓ Loosen the base clamp②, adjust

the thread base③ up and down

that the interval between the

thread wiper and the needle

center can be 2.5mm when the

thread wiper and the needle center

are in a straight line, then tighten

the clamp②

ⓔ Loosen the thread crank clamp④,

adjust the thread wiper crank⑤

that the thread wiper under sewing

standby can have the interval of

15~17mm from the needle center,

then tighten the wiper crank

clamp④.

ⓕ Finally, after arranging the

connector as shown in the

figure48, attach the wiper cover

⑥ by using wiper cover joint

screw⑦.

ⓖ The thread wiper spring⑧ attached on the thread wiper base has the function to hold upper thread after

thread trimming, and its proper tension is about 20~30g. (A little stronger than the tension of lower thread

in the bobbin case)If the tension of the thread wiper spring is strong, the thread may come upward the

button.

[ Fig. 44 ] [ Fig. 45 ]

[ Fig. 46 ]

[ Fig. 47 ]

[ Fig. 48 ]

②

①

2.5mm

③

④

⑤

15~17

To use the thread wiper solenoid, the sewing related function number, A-18 should be set up to

“100”. In addition to, check if A-14 is set up to “1”and A-31 to “0”.

Caution

Page 27

27

10) Adjusting the parts for trimming

A. Setting the position of the trimming Cam

Set the upper shaft collar and the trimming cam 1.7mm apart from each other and place the

trimming cam where the trimming cam carving line accords with the upper shaft carving point.

Then, tighten screw ①.

[ Fig. 49 ]

Upper Shaft

Upper

Shaft

Collar

①

1.7mm

Thread Trimmer Cam

Carving

Line

Carving Point

Upper Shaft

→

→

B. How to adjust the link stopper

ⓐ With the needle bar in its lowest position, check if there is enough clearance between thetrimming

cam roller and both ends of the trimming cam when the trimming drive link is pushed in the

direction of the arrow() within the trimming cam moving part.

ⓑ Make the end of the link stopper screw touch part of the trimming link stick when the

trimming cam roller is inserted into the trimming cam moving part. Then, tighten the nut.

[ Fig. 50 ]

Thread

Trimmer

Cam Roller

Clearance

Clearance

Thread Trimmer Cam

Thread Trimmer

Connecting Rod

Thread Trimmer

Connecting Rod

Link Stopper Screw

Link Stopper Screw

Thread Trimming Driving Link

Nut

→

→

→

→

If the trimming cam is not placed in the right position, the trimming operation may not

be made correctly or the machine may be lock.

Caution

If there is not enough clearance between the trimming cam roller and both ends of the

trimming cam,

trimming may not be operated correctly or the machine may be lock when

beginning to sew or trimming.

Caution

If the position is not set appropriately, the return to the previous point after trimming may be

delayed and the first stitch may not be tight enough.

Caution

Page 28

28

C. Setting the trimming shaft in place

ⓐ Unfasten the trimming drive link screw and the trimming shaft collar screw.

ⓑ Make the trimming shaft step accord with part of the arm.

ⓒ Tighten the screws.

[ Fig. 51 ]

Thread Trimmer Shaft

Thread Trimmer Cam

Screw

Thread Trimming

Driving Link

Collar for

Thread Trimmer Shaft

D. Setting the Link Stopper in Place

ⓐ Unfasten the trimming drive link stopper

screw while trimming is not operated and

have the trimming drive link and the

trimming drive link stopper notch 0.3mm

apart from each other.

ⓑ Tighten the screw.

[ Fig. 52 ]

→

→

0.3mm

Thread

Trimmer

Driving

Link

Screw

Thread Trimmer Driving

Link Stopper

→

→

0.3mm

E. Setting the Thread Trimming Solenoid in Place

ⓐ After unfastening the thread trimming solenoid bracket screw, have the trimming shaft and the thread

trimming solenoid rotary link 0.5mm apart from each other and tighten the screw back on.

ⓑ Unfasten the thread trimming solenoid rotary link screw and drive the thread trimming solenoid rotary

link manually to move the trimming shaft collar 6.8mm in the direction of the arrow. Then, tighten the

screw back on.

ⓒ Check if the trimming shaft collar returns to its place when the thread trimming solenoid rotary

link returns.

[ Fig. 53 ]

→

→

0.5mm

Solenoid

Thread

Trimming

Rotation Link

Thread Trimmer Solenoid Bracket

Screw

Screw

Thread Trimmer Shaft

Thread Trimming Rotation Link

6.8mm

→

→

If the position is not adjusted appropriately, trimming may not be operated correctly or

the machine may be lock.

Caution

If the position is not set right, the trimming return or the thread delay may be delayed to bring poor

sewing quality.

Caution

If the link stopper is not set in the

right position, trimming may not be

operated correctly and the machine

may be lock.

Caution

Page 29

29

F. Adjusting the Moving Knife and the Fixed Knife

ⓐ When the needle bar stops at the upper position, use the trimming lever adjustment screw to

adjust space A between the thread separation point of the moving knife and the needle plate hole

as indicated in the table.(4.5mm)

ⓑ Use the fixed knife screw to adjust space B between the fixed knife and the needle plate cover as

indicated in the table. (0.5mm)

ⓒ after the adjustment, check the position of the mes by manual trimming operation.

[ Fig. 54 ]

4.5mm 0.5mm

AB

Needle

Plate Cover

Fixed knife

Moving Knife

→

→

→

B

A

→

B. Place the winding drive wheel 4mm away

from the upper shaft bushing(F) and tighten

the screw.

[ Fig. 57 ]

Bobbin Winder

Driving Wheel

Upper Shaft

Bushing(F)

Upper Shaft

4mm

12) Adjusting the winder devices

A. To adjust the winding capacity of the bobbin,

use the beginning position of the winding

control plate, and after unfastening the screw,

turn the plate in direction A for large winding

capacity and turn in direction B for small

winding capacity.

[ Fig. 56 ]

Bobbin Winder

Adjusting Plate

Bobbin

A

B

11) Adjusting the devices for main thread adjustment

A. When the tension control nut ① of the thread

control device is turned clockwise, the upper

thread is tightened and becomes loose as the

nut is turned counterclockwise. Adjust the

tension according to the sewing conditions such

as material, thread, number of stitches etc.

B. To tighten the take-up lever spring, use a

driver to turn the groove ② on the edge face

of the thread tension control device shaft

clockwise. And to make the spring relax, turn

it counerclockwise.

(Standard operating quantity is 6∼8mm,

and tension is about 30g∼50g.

)

[ Fig. 55 ]

①

Thread

Take-up

Spring

②

Trimming may not be operated or there may not be enough remaining thread if the knife is not set

inappropriately

Caution

Page 30

30

13) Setting up the synchro position(C Series)

A. Installing the synchronizer

ⓐ Fix the synchoronizer on the back side of

arm.

ⓑ Adjust the gap between pulley and synchronizer

to be 2.5mm, then fasten the fixing screw for

pulley.

[ Fig. 58 ]

Upper Shaft

Bushing(R)

Sychronizer

Upper

Shaft

Pulley

2.5mm

Pulley

Screw

Magnetic

Holder

[ Fig. 60 ]

[ Fig. 59 ]

[ Fig. 61 ]

B. Adjusting the position of position detector

ⓐ Adjust the position of take-up lever to be same as Fig. 61 by turning the pulley. At this time, the

white carving sign of pulley should be straight line with the carving sign of arm.

ⓑ Adjust the clamp screw① in the pulley’s punched point, and tighten the clamp screw① where the

pulley’s punched pointⓐ conforms to its inscribed pointⓑ.

ⓒ Unfasten the screw ② on the N.D carving sign and move to the right and left, then let it suspen

on the place where the needle bar just start ascending from the bottom.

Direct

ion of

Rotati

on

About 3mm

Direction of

Rotation

①

②

Page 31

31

15) Setting up the X-Y Origin

A. How to set up X-axis Origin

ⓐ Separate a bed cover (left).

ⓑ Move the button inserted into the button clamp to the center of X-axis.

ⓒ As seen in the figure, unfasten the bolts of X-sensor plate and let the end of X-sensor

plate locate on the center of sensor, then fasten the bolts with screw-driver.

[ Fig. 63 ]

Screw

X-sensor plate

Sensor

14)

Mounting the Direct Motor and Adjsuting Method(D Series)

[ Fig. 62 ]

Screw NO.1

Servo Motor

Flat

Surface

Upper Shaft

O-ring

ARM

2 0.7

Upper Shaft

Rear

Bushing

Coupling

A. When you mount the coupling on the servo-motor, fit the screw No.1 of coupling to the flat surface of the

servo motor shaft and make the clearance between the coupling and servo motor 0.7mm.

B. When you mount the coupling on the upper shaft, fit the screw No.1 of coupling to the flat surface of the

upper shaft and make the clearance between the coupling and upper shaft bushing(R) 2mm.

C. After mounting both couplings, check the positions of each screws to the aligned.

※ If the positions of each screws are not aligned, the needle does not stop normal position.

Page 32

32

B. How to set up Y-axis Origin

ⓐ Separate a bed cover ( right ).

ⓑ Move the center of work clamp foot to be placed on the center of Y-axis.

ⓒ As seen in the figure, unfasten the bolts of Y-sensor plate and let the end of X-sensor

plate locate on the center of sensor, then fasten the bolts with screw-driver.

[ Fig. 64 ]

Screw

Sensor

Y-sensor plate

①

Button

needle point

conform

17) Checking the setting position of button clamp

A. Select Pattern No. “0”at the operation box.

B. Press [Ready] key to ascend the button clamp

that the machine can return to the origin.

C. Insert the button into the button clamp①.

D. Press the button clam of Step 1 to descend

its holder. At this time, turn the pulley for the

error message [

“Er 03”] to display on the LCD.

E. Remove your foot from the pedal, and turn

the pulley to check if the needle point

conforms to the button’s center.

F. If the needle point does not insert into the

button’s center, loosen the fixed screw② of the

button clamp bracket, and fix it that the needle

point can be inserted into the button’s center.

G. After adjusting, check the pattern form that the

needle is exactly inserted into the button hole.

[ Fig. 66 ]

②

②

①

16) How to adjust the feeding plate

A. Select Pattern No. “0”at the operation box.

B. Press [Ready] key to ascend the button

clamp that the machine can return to the

origin.

C. Adjust the feeding plate① that its center can

place to the center of presser bar cover②.

[ Fig. 65 ]

Page 33

33

①

③

②

18) How to set up the button clamp adjusting plate

A. Insert the button into its clamp while the

machine stops, and check that it is exactly

inserted.

B. Loosen the button clamp adjusting screw①,

and adjust that the space between the

button clamp adjusting plate② and its

adjusting screw① can be 0.5~1mm.

[ Fig. 67 ]

0.5~1.0mm

A. Place the spacer spring to the button’s

center, adjust it to be projected to

3.5~4mm from the button’s center to the

spring’s edge, and fix the spacer spring plate

③ to the button clamp bracket①.

B. To adjust the height of spacer spring, loosen

the screw④, place the spring to the suitable

position, and fix the screw④.

[ Fig. 68 ]

19) How to attach the spacer spring plate

②

③

④

3.5~4mm

①

Page 34

34

77

CAUSE OF BREAKDOWN AND TROUBLESHOOTING

No.

1

2

3

Condition of Breakdown

Error on operation or

drive of machine

Cause of Breakdown

Loosing of belt tension and damage

on belt

Fuse shortage for main power or

circuit

Deviation from Y and Y limit of

feed bracket

Troubleshooting

Adjust the belt tension or exchange it

Check the fuse shortage of main shaft

drive motor in a controller box or

exchange it

Bad position of

stopping position

Slackness of main drive belt

Due to improper synchro position

Adjust the belt tension

Adjust setting position of synchro

Needle bent

4

Thread is cut

5

Stitch skipping

Damage on needle(Bending of

needle, cracks on needle hole or

groove, and abrasion or

transformation of needle tip)

Exchange the needle

Move the feed bracket to normal place

(inside limit switch)

Wrong installation of needle

Install the needle properly

Contact of needle with shuttle

Adjust the distance properly between a needle and shuttle

Wrong insertion of thread Insert the thread properly

Wrong installation of needle (Height

of needle or direction of needle)

Reinstall the needle.

Damage on needle (Bending of

needle, cracks on needle hole or

groove, and abrasion or

transformation of needle tip)

Exchange the needle.

Excessive tension of upper thread and under thread

Adjust the tension

Excessive tension and stroke of

take-up lever spring

Adjust the tension and stroke of takeup lever spring

Crack on the controlling hole of

shuttle surface spring

Exchange the shuttle surface spring

Use of bending needle

Exchange the needle.

Use of improper sized needle compared with using thread

Exchange the needle.

Wrong installation of needle Reinstall the needle.

Improper timing for needle and shuttle

Readjust the timing for needle and shuttle

Improper gap between groove and shuttle point

Readjust the timing for needle and shuttle

Excessive tension of take-up lever

spring and stroke

Adjust the tension of take-up lever

spring and stroke

Page 35

35

No.

6

7

Condition of Breakdown Cause of Breakdown

Weak tension of upper thread

Weak tension of lower thread

Troubleshooting

Readjust the tension of upper thread.

Errorin thread tightening

Improper timing for needle and

shuttle

Laxity of exchanging tension between

movable mes and fixed mes

Readjust the timing for needle and shuttle

Readjust the tension of fixed mes.

Error in trimming

Abrasion and crack on blade of movable mes

and fixed mes

Exchange the movable mes and fixed mes.

Readjust the tension of lower thread.

Wrong position of trimming cam.

Readjust the position of trimming cam

Page 36

36

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Pattern

No.

Pattern

No of

Threads

Range of Sewing

X (mm) Y (mm)

Range of Sewing

X (mm) Y (mm)

Pattern

No of

Threads

Pattern

No.

※

The magnifying and reduction range (X and Y) of standard sewing shown above is 100%

66 patterns including 33 patterns can be additionally provided.

※

In case of the pattern of “*”mark of Sewing Pattern No., a thread is trimmed after finish of first sewing to

remove a line through sewing patterns. In case of SPS/C-B1202-01 and 02, press the pedal once more after finish

of first sewing, or continuously press and release the pedal until second sewing begins.

In case of SPS/C-B1202-03, just one time pressing of the pedal will do.

A. If the central distance between use buttonholes does not conform for the standard sewing range of Sewing

Pattern No., magnify or reduce the sewing range to adjust it.

B. After the Sewing Pattern Number and the sewing range (X, Y) are changed, don’t forget to check if the

needlepoint conforms to the buttonhole with regard to [Checking Pattern Shape].

C. Rate of magnifying and reduction according to the sewing range

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

0

0

0

3.4

3.4

3.4

3.4

2.9

2.9

2.9

2.9

0

0

0

0

0

3.4

3.4

3.4

3.4

3.4

3.4

3.4

2.5

2.5

2.5

2.5

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

3.4

6-6

8-8

10-10

12-12

6-6

8-8

10-10

12-12

6-6

8-8

10-10

6-6

8-8

10-10

6-6

8-8

10-10

6

8

10

12

16

6

10

12

6-6

10-10

6-6

10-10

5-5-5

8-8-8

5-5-5

8-8-8

Sewing Area

X,Y(mm)

2.4

71 76 82 88 94 100 106 118 126 132 138 153 165 176 182 188

2.6 2.8 3.0 3.2 3.4 3.6 4.0 4.3 4.5 4.7 5.2 5.6 6.0 6.2 6.4

Expansion &

Reduction (%)

*

*

*

*

*

*

*

*

*

88

PATTERN LIST

Page 37

37

99

DRAWING OF TABLE

1) SPS/D-B1202

Page 38

38

2) SPS/C-B1202

Page 39

39

1111

NAME Code No.

Button Spacer Ass’y

Feed Guide Bracket

Feed Plate

Small Button

Midium Button

Large Button

23-182A-120B

20-149A-120B

23-094A-120B

23-095A-120B

23-096A-120B

1100

GAUGE LIST

Button Size

External diameter of Button

(mm)

ф8~ф15

0~3.5 0~4.5

0~4.5

0~6.5

0~6.5

0~3.5

1.3 (2.2)

23-033A-120B

23-026A-120B 23-053A-120B 23-066A-120B

23-056A-120B 23-063A-120B

2 (2.7) 2.7 (3.2)

(23-050A-120B) (23-063A-120B) (23-076A-120B)

(23-047A-120B) (23-060A-120B) (23-073A-120B)

Punched mark

ф10~ф20 ф15~ф32

(Y)

(X)

Thickness

Code

No.

Right

Left

Stitch Size

(mm)

Button Clamp

Ass’y

Needle Plate Cover 10-042A-120B

23-043A-120B 23-058A-120B 23-071A-120B

10-043A-120B 10-044A-120B

Feed Plate

※ ( ): Special Option

Small Button Midium Button

Large Button

Punched mark Punched mark

A

1

A

1

B

2

B

2

C

3

C

3

MODEL SPS/D(C)-B1202

Loading...

Loading...