1) FOR AT MOST USE WITH EASINESS,

PLEASE CERTAINLY READ THIS MANUAL

BEFORE STARTING USE.

2) KEEP THIS MANUAL IN SAFE PLACE

FOR REFERENCE WHEN THE MACHINE

BREAKS DOWN.

MMEEEE--110011002200

USER

’’

S MANUAL

R

SSuunnSSttaarr CCOO..,, LLTTDD..

SPS/A-Pattern Series

SPS/B-Pattern Series

SPS/C-Pattern Series

Electronically Controlled

Pattern Sewing Machine

(Electronic Control Part)

Best Quality

Best Price

Best Service

SSUUNNSSTTAARR CCOO..,, LLTTDD..

R

1.

Thank you for purchasing our product. Based on the rich expertise and

experience accumulated in industrial sewing machine production, SUNSTAR

will manufacture industrial sewing machines, which deliver more diverse

functions, high performance, powerful operation, enhanced durability, and

more sophisticated design to meet a number of user’s needs.

2. Please read this user’s manual thoroughly before using the machine. Make

sure to properly use the machine to enjoy its full performance.

3. The specifications of the machine are subject to change, aimed to enhance

product performance, without prior notice.

4.

This product is designed, manufactured, and sold as an industrial sewing

machine. It should not be used for other than industrial purpose.

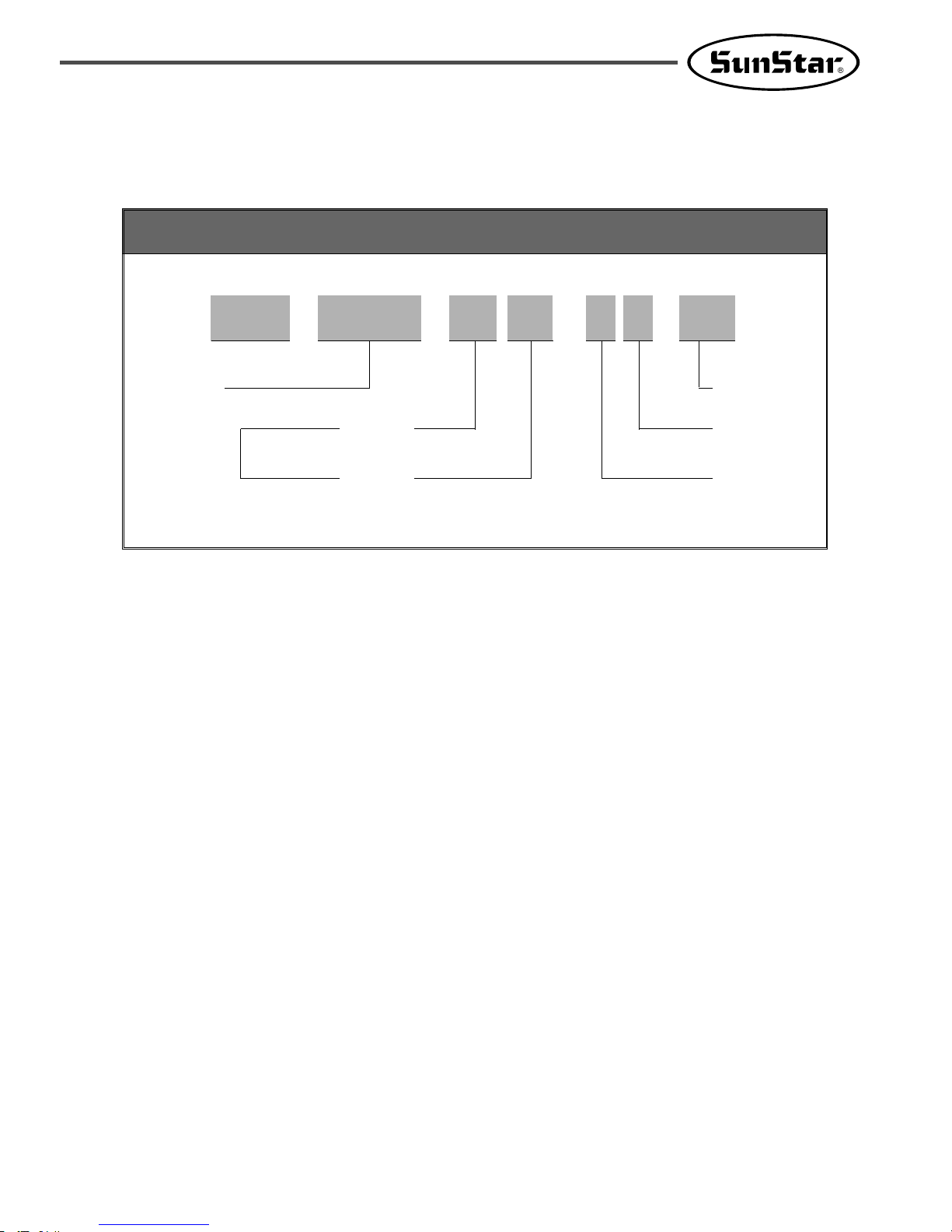

Pattern Type

A : Belt Type

B : Direct Type

C :

Separated upper and lower operation type

Sewing Type

1306 : X(130mm), Y(60mm)

1310 : X(130mm), Y(100mm)

1507 : X(150mm), Y(70mm)

1811 : X(180mm), Y(110mm)

2211 : X(220mm), Y(110mm)

2516 : X(250mm), Y(160mm)

3020 : X(300mm), Y(200mm)

5030 : X(500mm), Y(300mm)

5050 : X(500mm), Y(500mm)

8050 : X(800mm), Y(500mm)

Material Type

G:General Material

H:Heavy Material

Stitch

S:Standard Stitch

P:Perfect Stich

Feed Frame

10:Electronic

20:Pneumatic Monolithic Feeding Frame

22:Pneumatic Separately-Driven Feeding

23:Pneumatic Reverse Device

Attach/Separate Feed Frame

SPS/C-Series

01:Arm Lifting Type

02:Fixed Arm Type

Organization of the Pattern S/M Model

Series

Sewing Area

SPS / A,B,C - 13 0 6 - H S-10

(X)×10mm

(Y)×10mm

Feeding Frame

Type

Stitch Type

Material Type

1. Machine Safety Regulations …………………………………………………………… 6

2. I/O Board Dip Switch Setting ………………………………………………………… 9

3. Basic Operational Method ……………………………………………………………… 10

1) Name and roles of each key on operation unit……………………………………………… 10

2) Name and description of each display contents on general operation mode …………… 11

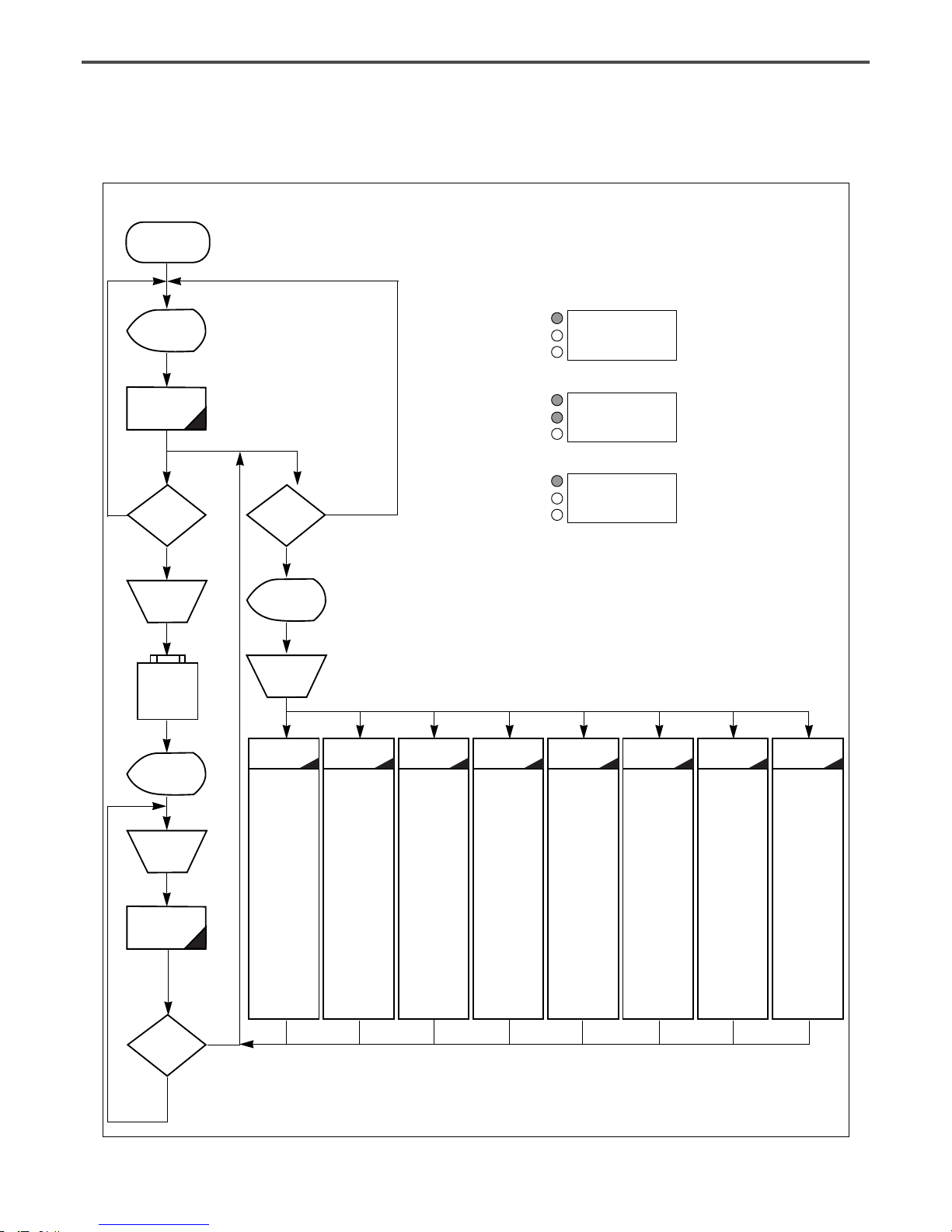

3) Flow chart of general operation ……………………………………………………………… 12

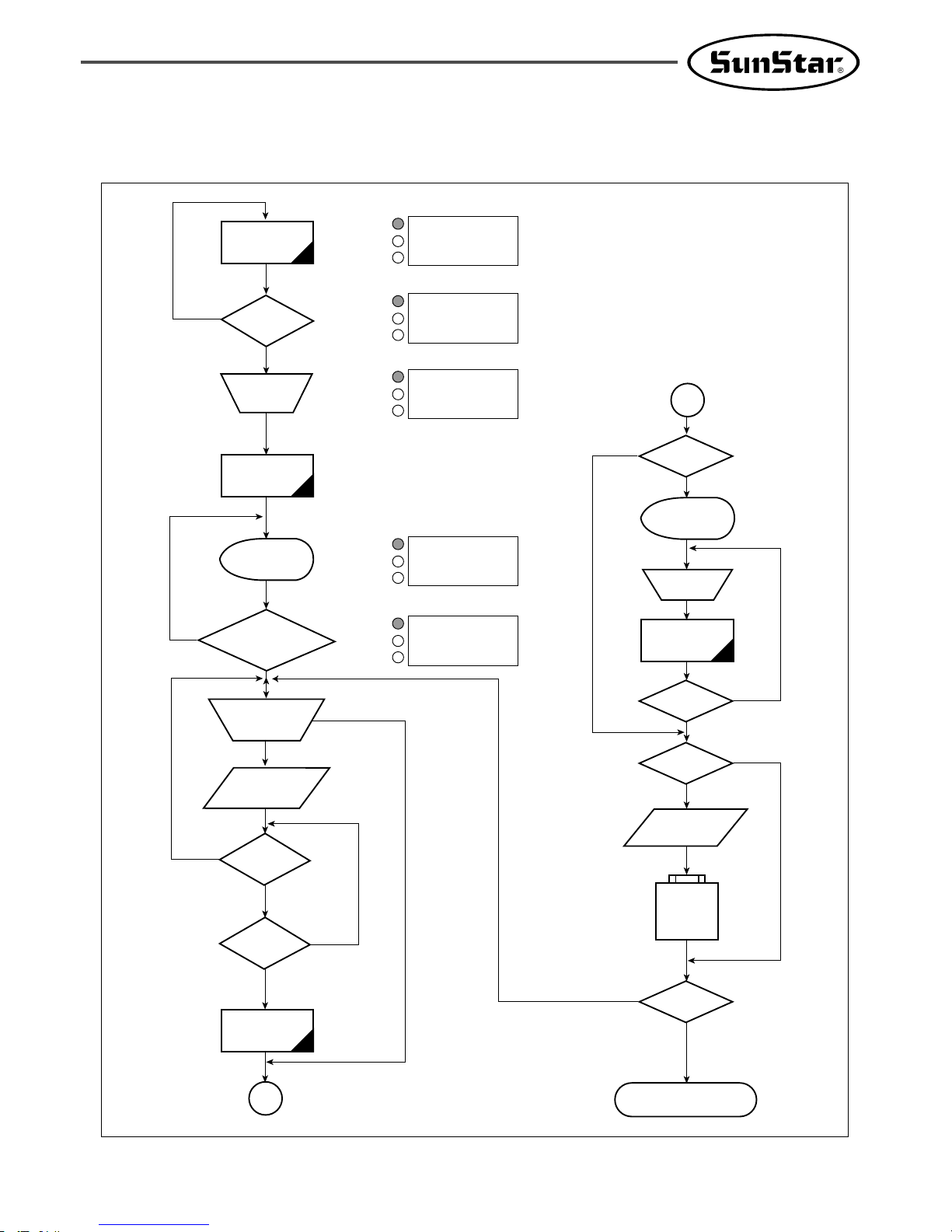

4) Work flow of pattern programming …………………………………………………………… 13

5) Operating after reading the patterns from USB flash drive ……………………………… 14

6) Confirming the working pattern read from the USB flash drive ………………………… 14

7) When a machine stops operating during sewing by the thread cut ……………………… 15

8) Emergency stop during operation ……………………………………………………………… 15

9) Winding the thread …………………………………………………………………………… 15

10) Safety Functions ………………………………………………………………………………… 16

4. Applicable Operation ……………………………………………………………………… 19

1) Pattern Data Generation Function………………………………………………………………………… 19

1-1) Program example 1 : Generating the square pattern ………………………………… 19

1-2) Program example 2 : Generating the circle pattern ………………………………… 21

1-3) Program example 3 : Generating the double curve pattern ………………………… 23

1-4) Program example 4 :

Pattern generation by using the second origin and pause

…… 26

1-5) Zigzag shape selecting function to generate zigzag …………………………………… 30

2) Pattern Data Edit Function …………………………………………………………………… 32

2-1) One stitch movement function …………………………………………………………… 32

2-2) Partial movement function of pattern data …………………………………………… 33

2-3) A fix number of stitch delete function ………………………………………………… 35

2-4) Partial pattern data delete function …………………………………………………… 36

2-5) Partial stitch width changing function ………………………………………………… 38

2-6) Pattern partial copy function …………………………………………………………… 39

2-7) Pattern data inserting function…………………………………………………………… 41

3) Pattern Data Application Function …………………………………………………………… 43

3-1) Operation after reading pattern data from USB flash drive and moving the second

temporary start point ……………………………………………………………………… 43

3-2) Program example 5 : Change of sewing speed within a pattern …………………… 44

3-2-1) Changing the sewing speed from an existing pattern data ………………… 44

3-2-2) Changing the sewing speed by making new pattern data…………………… 47

3-3) Program example 6 : Use of reversal ………………………………………………… 49

3-3-1) Pattern programming by using reversal………………………………………… 49

3-3-2) Adding the code to already programmed pattern …………………………… 52

3-4) Using the extension/reduction modes …………………………………………………… 54

3-5) Using the chain sewing mode …………………………………………………………… 56

3-6) Change/saving function of pattern data start point ………………………………… 58

3-7) Change/saving function of pattern 2nd original point ………………………………… 60

3-8)

Change/saving function of maximum pattern sewing speed and extension/reduction rate

…… 61

3-9) Symmetrical shape creating function of pattern ……………………………………… 63

3-10) Condensed sewing stitch inserting function …………………………………………… 64

3-11) Automatic Back Tack(B/T) inserting function ………………………………………66

3-12) OverLap sewing stitch inserting function ………………………………………………67

3-13) Automatic insertion of thread trimmer code when deleting stitches ……………… 69

3-14) Setting-up reference point for zooming ………………………………………………… 70

3-15) Embroidery design call function ………………………………………………………… 72

3-16) JUKI Design Call ………………………………………………………………………… 73

3-17) Sewing limit function …………………………………………………………………… 74

3-18) Quick origin search motion function for 1811 machines …………………………… 76

3-19) Setting origin search function of upper and lower shafts after finishing sewing

[only applied for SPS/C-Series]………………………………………………………… 77

3-20) Setting machine Head up or down function [Only for SPS/C-

Series

] …………… 78

3-21)

Setting reverse rotation after trimming [Only applied for SPS/

B/

C-Series]

………… 79

CONTENT

3-22)

Setting the angle of reverse rotation after trimming [

O

nly applied for SPS/B/C-Series]

…80

3-23) Setting output port [Only applied for SPS/C-Series] ……………………………… 81

3-24)

Setting time delay when output port is being used [

O

nly applied for SPS/C-Series]

…84

3-25) 3rd Thread Adjusting Device (TR3) Setting ………………………………………… 85

3-26) Basic Clamp Position Setting …………………………………………………………… 88

4) Pattern Data General Function ……………………………………………………………… 89

4-1) Checking and deleting the pattern number …………………………………………… 89

4-2) Making a copy the pattern to another number or diskette ………………………… 90

4-3) Function to copy saved patternS from interior memory to USB flash drive …… 91

4-4) Pattern information displaying function ………………………………………………… 92

4-5) Change of parameter related to general sewing ……………………………………… 93

4-6) Initialization of parameter related to general sewing ………………………………… 94

4-7) System program update …………………………………………………………………… 95

4-8) Confirmation for version of system program ……………………………………………96

4-9) Bobbin counter setting by design………………………………………………………… 97

4-10) Saving in the Internal Memory after Creating Pattern Designs…………………… 99

5. High Operating Method …………………………………………………………………100

1) Understanding the function of machine test ………………………………………………… 100

1-1) Encoder test …………………………………………………………………………………100

1-2) Step motor-main shaft motor test (X-Y Main Test) ……………………………… 100

1-3) Main motor test …………………………………………………………………………… 101

1-4) Interrupt test ……………………………………………………………………………… 102

1-5) PWM test…………………………………………………………………………………… 102

1-6) LCD test …………………………………………………………………………………… 103

1-7) Keyboard test ……………………………………………………………………………… 104

1-8) Input 0 test ………………………………………………………………………………… 104

1-9) Input 1 test ………………………………………………………………………………… 105

1-10) Input 2 Test ……………………………………………………………………………… 106

1-11) Input 3 Test ……………………………………………………………………………… 106

1-12) Input 4 Test [Only applied for SPS/C-Series] ……………………………………… 107

1-13) Input 5 Test [Only applied for SPS/C-Series] ……………………………………… 107

1-14) Input 6 Test [Only applied for SPS/C-Series] ……………………………………… 108

1-15)

Lower Shaft Encoder Test (Encoder1 Test) [Only applied for SPS/C-Series]

………… 109

1-16) Solenoid Test ……………………………………………………………………………… 109

1-17) Output 4 Test [Only applied for SPS/C-Series] ……………………………………110

1-18) Output 5 Test [Only applied for SPS/C-Series] ……………………………………111

1-19) Other output ports[only applied for SPS/C-Series] ………………………………… 111

1-20) Manual operation test of step motor (XY Jog Test) ……………………………… 112

1-21) Origin Test ………………………………………………………………………………… 112

1-22) Jump Test ………………………………………………………………………………… 113

1-23)

Communication test between the main shaft board and the CPU/IO board (Async Test)

…… 113

6. Description on Parameter Related to General Sewing Operation ………………115

1) Function no. related pattern programming …………………………………………………… 164

2) Pattern chart……………………………………………………………………………………… 166

3) Parameter number related to general sewing ………………………………………………… 167

4) Error list …………………………………………………………………………………………172

5) SPS/A/B/C-Series block diagram……………………………………………………………… 174

6) Table drawing …………………………………………………………………………………… 178

7) Basic Manual …………………………………………………………………………………… 179

7. Emergency Recovery………………………………………………………………………181

1) Emergency recovery when problems occur in flash memory ……………………………… 181

2) User's emergency self-restoration and operating program installation …………………… 182

8. Special Functions …………………………………………………………………………183

1) Auto Call Function ……………………………………………………………………………… 183

2) Design auto call through handy barcode……………………………………………………… 191

9. Parameter save function …………………………………………………………………194

1) Parameter Write ………………………………………………………………………………… 194

2) Parameter Read …………………………………………………………………………………195

6

11

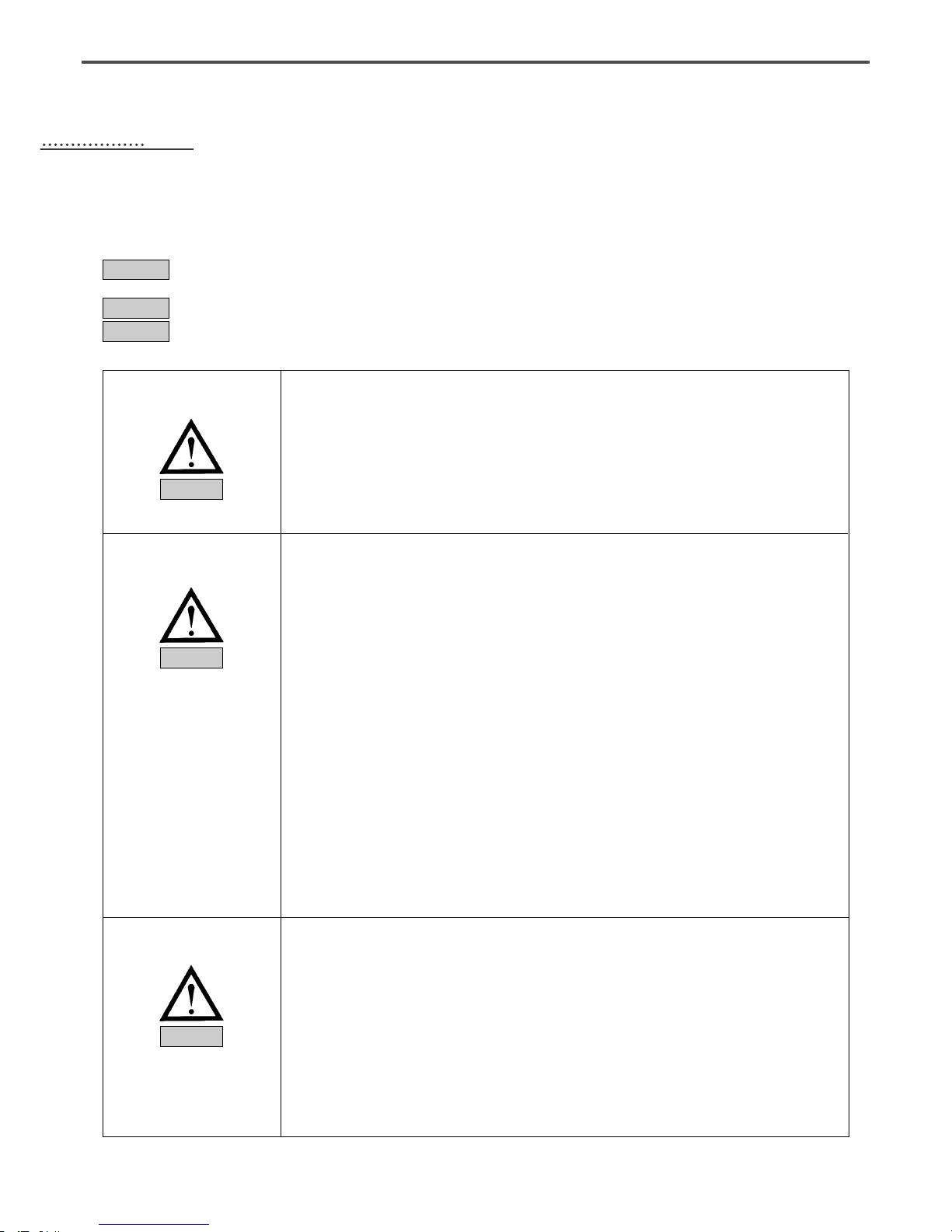

MACHINE SAFETY REGULATIONS

Safety instruction on this manual are defined as Danger, Warning and Notice.

If you do not keep the instructions, physical injury on the human body and machine damage might be occurred.

: This indication should be observed definitely. If not, danger could be happen during the installation,

conveyance and maintenance of machines.

: When you keep this indication, injury from the machine can be prevented.

: When you keep this indication, error on the machine can be prevented.

Danger

Warning

Notice

1-1) Machine

Transportation

Danger

1-2) Machine Installation

Warning

1-3) Machine Repair

Notice

Those in charge of transporting the machine should know the safety regulations very well.

The following indications should be followed when the machine is being transported.

ⓐ More than 2 people must transport the machine.

ⓑ To prevent accidents from occurring during transportation, wipe off the oil on the machine

well.

The machine may not work well or breakdown if installed in certain places, Install the machine

where the following qualifications agree.

ⓐ Remove the package and wrappings starting from the top. Take special notice on the nails

on the wooden boxes.

ⓑ Dust and moisture stains and rusts the machine. Install an airconditioner and clean the

machine regularly.

ⓒ Keep the machine out of the sun.

ⓓ Leave sufficient space of more than 50cm behind, and on the right and left side of the

machine for repairing.

ⓔ EXPLOSION HAZARDS

Do not operate in explosive atmospheres. To avoid explosion, do not operate this machine

in an explosive atmosphere including a place where large quantities of aerosol spray

product are being used or where oxygen is being administered unless it has been

specifically certified for such operation.

ⓕ The machine were not provided with a local lighting due to the feature of machine.

Therefore the illumination of the working area must be fulfilled by end user.

[Refer] Details for machine installment are described in Mechanical Structure Manual

4. Machine Installment.

When the machine needs to be repaired, only the assigned troubleshooting engineer educated at

the company should take charge.

ⓐ Before cleaning or repairing the machine, close down the motive power and wait 5

minutes till the machine is completely out of power.

ⓑ Not any of the machine specifications or parts should be changed without consulting the

company. Such changes may make the operation dangerous.

ⓒ Spare parts produced by the company should only be used for replacements.

ⓓ Put all the safety covers back on after the machine has been repaired.

7

A(B) Pattern Series is made to sew patterns on fabrics and other similar material for

manufacturing.

Follow the following indications when operating the machine.

ⓐ Read through this manual carefully and completely before operating the machine.

ⓑ Wear the proper clothes for work.

ⓒ Keep hands or other parts of the body away from the machine operation parts(needle,

shuttle, thread take-up lever, and pulley etc.) when the machine is being operated.

ⓓ Keep the covers and safety plates on the machine during operation.

ⓔ Be sure to connect the earthing conductor.

ⓕ Close down the electric motive power and check if the switch is turned “off”before opening

electric boxes such as the control box.

ⓖ Stop the machine before threading the needle or checking after work.

ⓗ Do not step on the pedal when turning the power on.

ⓘ Do not connect several motors to the same concent.

ⓙ If possible, install the machine away from loud noise such as high frequency welding

machines

ⓚ Be careful when the upper feed plate comes down to press. Otherwise, the finger or hand

might be hurt at smacking.

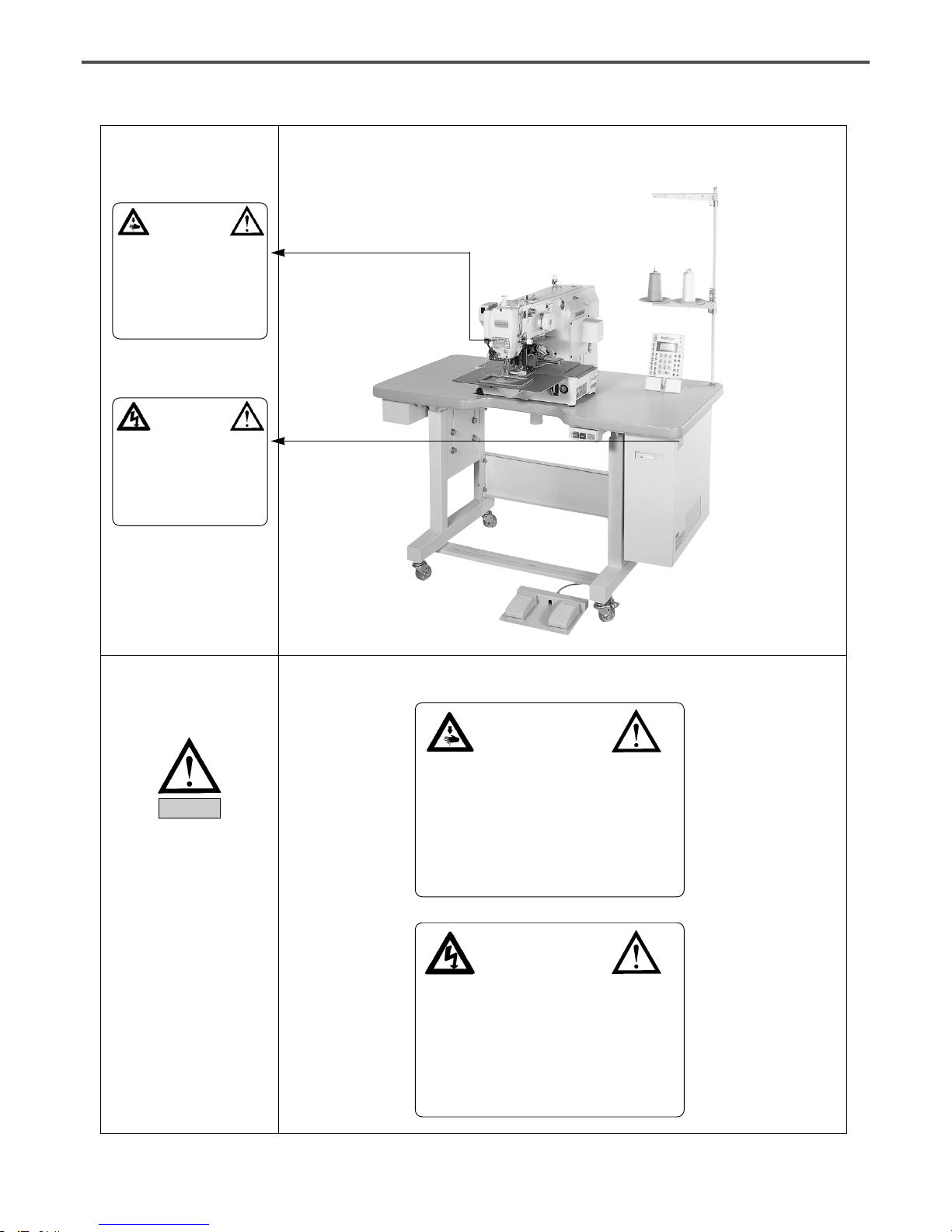

1-4) Machine Operation

Warning

ⓐ Safety label : It describes cautions during operating the machine.

ⓑ Thread take-up cover : It prevents from any contact between body and take-up lever.

ⓒ Belt Cover : It prevents from insertion of hands, feet or clothes by V-belt Motor.

ⓓ Step motor cover : It prevents from accidents during rotation of step motors.

ⓔ Label for specification of power : It describes cautions for safety to protect electric shock

during the motors’ rotation. (Voltage input / use Hz)

ⓕ Safety plate : It protects eyes against needle breaks.

ⓖ Finger guard : It prevent from contacts between a finger and needle.

1-5) Devices for Safety

[Warning]

Belt will crush or amputate finger or hand, keep cover in place before operating, turn off

power before inspecting or adjusting.

Notice

ⓐ

ⓑ

ⓓ

ⓐ

ⓔ

ⓒ

ⓕ

ⓖ

8

Caution

1)

2)

1-7) Contents of Marks

Warning

Caution mark is attached on the machine for safety.

When you operate the machine, observe the directions on the mark.

Position of Warning Mark

[View from the right-front]

1-6) Caution Mark

Position

CAUTION

경고

Do not operate without finger guard and

safety devices. Before threading, changing

bobbin and needle, cleaning etc. switch off

main switch.

손가락 보호대와 안전장치 없이 작동하지

마십시오.

실, 보빈, 바늘교환시나 청소전에는 반드시 주

전원의 스위치를 꺼 주십시오.

WARNING

경고

Hazardous voltage will cause injury.

Be sure to wait at least 360 seconds before

opening this cover after turn off main switch

and unplug a power cord.

고압 전류에 의해 감전될 수 있으므로 커버를

열 때는 전원을 내리고 전원 플러그를 뽑고 나

서 360초간 기다린 후 여십시오.

CAUTION

경고

Do not operate without finger guard

and safety devices. Before threading,

changing bobbin and needle, cleaning

etc. switch off main switch.

손가락 보호대와 안전장치 없이 작동하지 마

십시오.

실, 보빈, 바늘교환시나 청소전에는 반드시

주전원의 스위치를 꺼 주십시오.

WARNING

경고

Hazardous voltage will cause injury.

Be sure to wait at least 360 seconds

before opening this cover after turn

off main switch and unplug a power

cord.

고압 전류에 의해 감전될 수 있으므로 커버

를 열 때는 전원을 내리고 전원 플러그를 뽑

고 나서 360초간 기다린 후 여십시오.

9

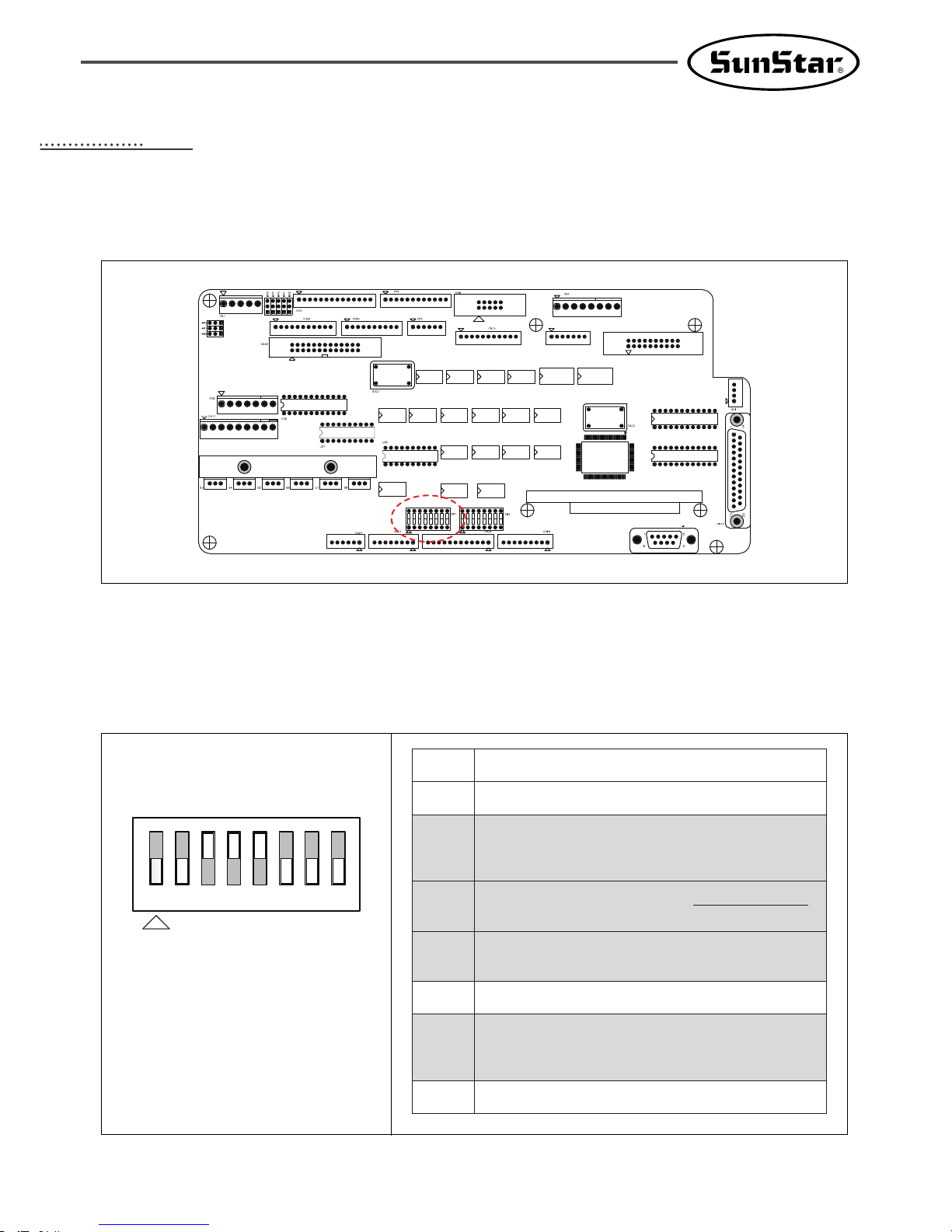

22

I/O Board Dip Switch Setting

This shows how to set up the dip switch(SW1) on the I/O board.

The figure above is based on the SPS/C-5050 I/O board.

The following describes each dip switch number.

SW1

1

2

Not used

Not used

3

Main shaft motor type

ON : Direct drive

OFF : Belt type

4

If the main shaft motor is a

ddiirreecctt ddrriivvee ttyyppee

,

activate the serial communication witht he CPU card.

5

6

7

8

New I/O board setting

(After REV 21)

Not used

Distinction between integrated and non-integrated versions

ON : Non-integrated version setting

OFF : Integrated version setting

Not used

10

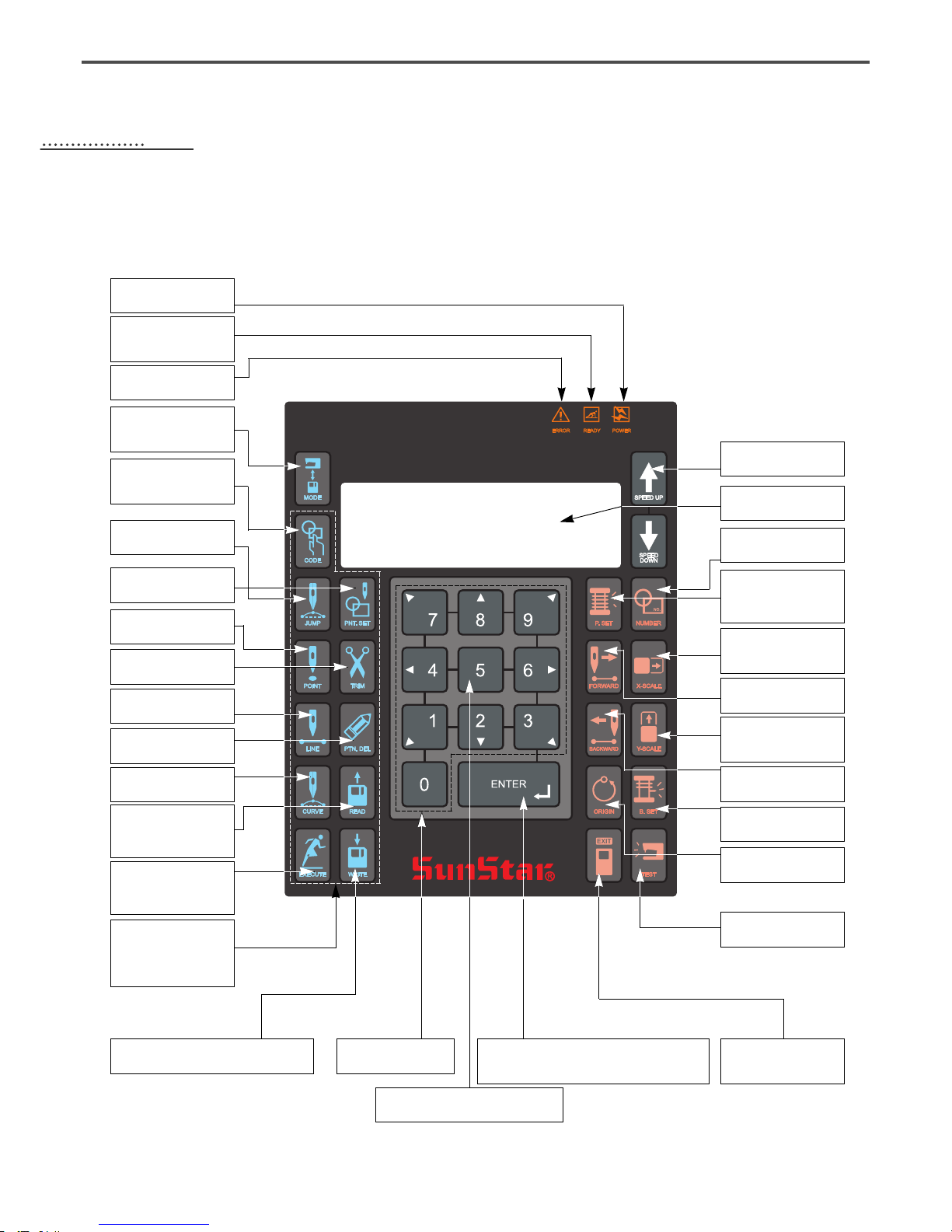

33

BASIC OPERATIONAL METHOD

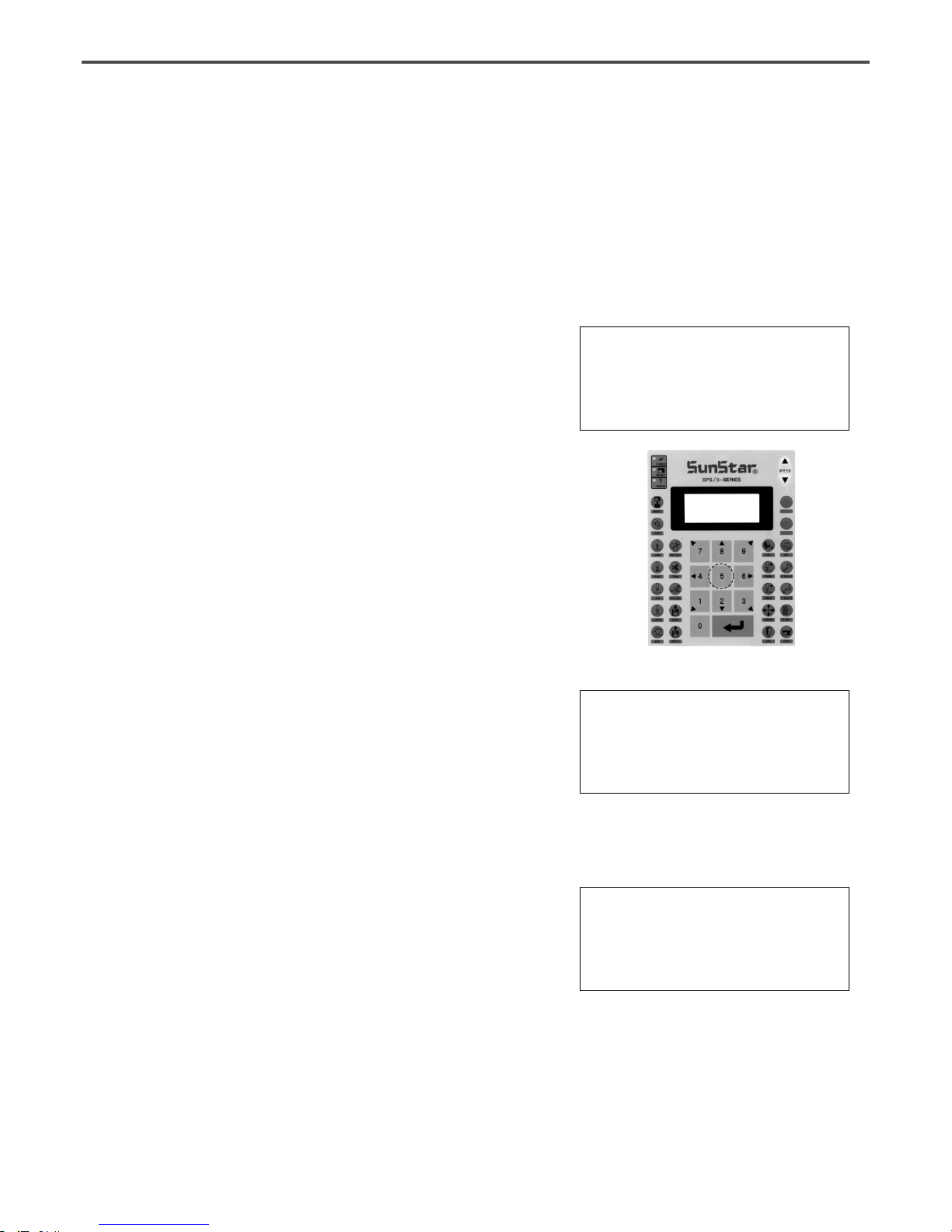

1) Name and Roles of Each Key on Operation Unit

POWER LED

Input of power

READY LED

Sewing available

condition

ERROR LED

Errors occurred

MODE KEY

Change of working

mode

CODE KEY

Selection of function

code

POINT KEY

Input of point code

JUMP KEY

Input of jump code

POINT-SET KEY

Input of point

TRIM KEY

Input of trim code

LINE KEY

Input of straight code

PATTERN-DELETE KEY

Delection of pattern code

CURVE KEY

Input of curve key

PUNCHING RELATED KEY

It can be used for pattern data generation

ENTER KEY

Pressed to cancle sewing function setups

or to end input

DIRECTION/DIGIT KEY

Threading and Unthreading Key

ESCAPE KEY

Cancle of function to

be selected

EXECUTION KEY

Designation of start

for code generation

WRITE KEY

Used to write the

pattern onto the

USB Flash Drive

READ KEY

Reading patterns from

a USB Flash Drive

NO. KEY

Input of pattern NO.

X_SCALE KEY

Use when it is extended or

reduced to the X direction

Y_SCALE KEY

Use when it is extended or

reduced to the Y direction

P. SET KEY

Counter setting for

working capacity

FORW KEY

1 Stitch forward

BACK KEY

1 Stitch backward

B. SET KEY

Counter setting of bottom thread

SPEED KEY

Change of sewing speed

LCD DISPLAY

Indication of contents

TEST KEY

Change to test sewing mode

ORIGIN KEY

Returning to origin

11

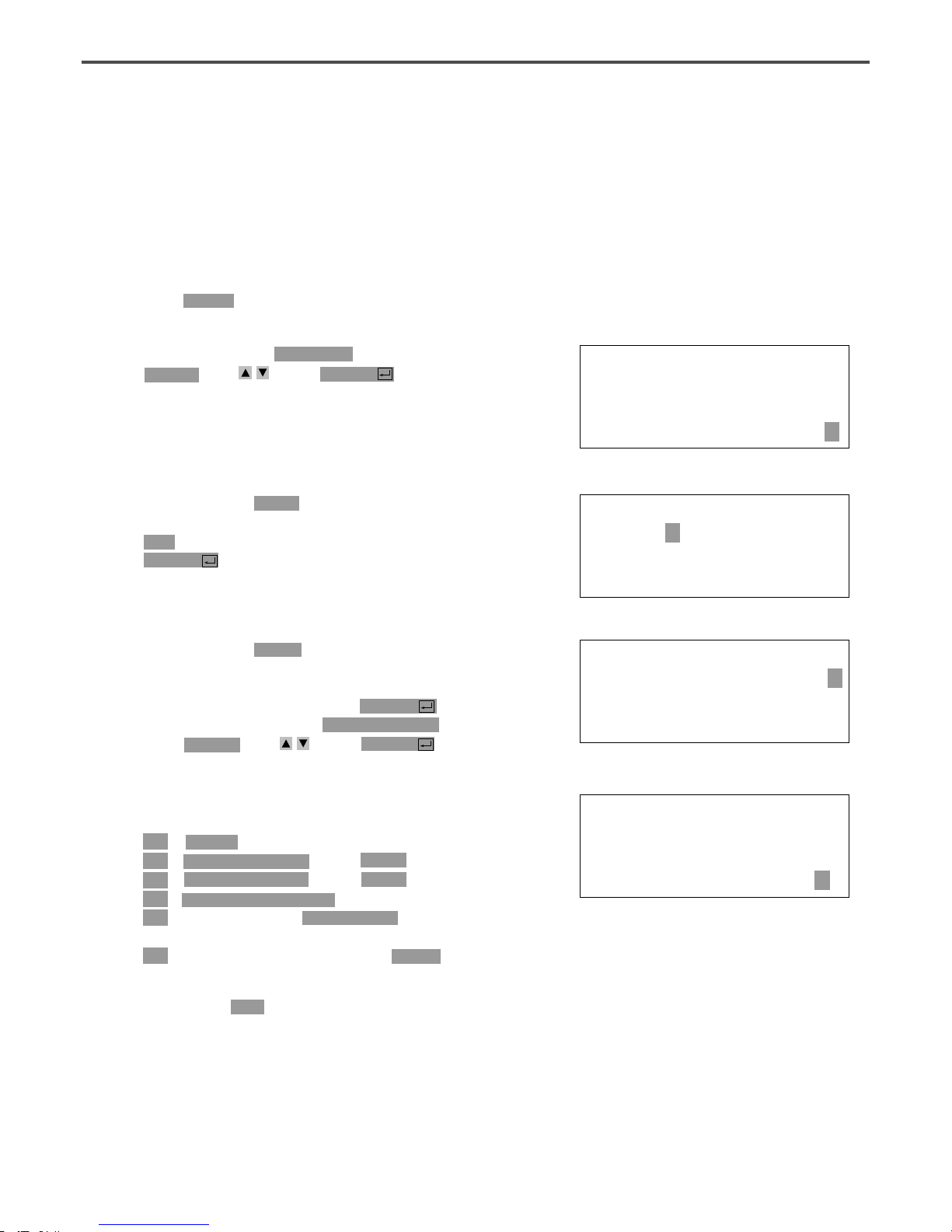

2) Name and Description of Each Display Contents on General Operation Mode

It is an initial screen when power is on for the first time, but display of screen can be changed according

to the general sewing related parameter.

A.

“POWER LED”:

When you turn on the power, this lamp also comes to light on.

B.“READY LED”:

This lamp comes to light on when a machine is ready to work by reading patterns.

During reading or writing the patterns, the lamp flickers. If you press ENTER, you

can get out of the “READY”state.

C.“ERROR LED”: When errors including sensing thread and emergency stop happen this lamp comes

to light on.

D.“NO”: It indicates pattern No. Press NO key and input the pattern number you want by pressing

digit keys. (000 ∼ 999)

E.“XS”: It indicates a rate of enlargement and reduction for width. You can change the value at your

option by using digit keys after pressing down X SCALE key. (001[%] ∼400[%])

F.“YS”: It indicates a rate of enlargement and reduction for length. You can change the value at your

option by using digit keys after pressing down Y SCALE key. (001[%] ∼400[%])

G.“SP”: It indicates sewing speed. You can change the speed you want by pressing down SPEED key.

(200[SPM] ∼2500[SPM])

※ Maximum sewing speed varies depending on the sewing machine. See “Setting-Up the Speed”.

H.“BC”: It indicates setting value of bottom thread exchange counter. You can change the value at

your option by using digit key after pressing down B. SET key. (000 ∼ 999)

I. “PC” : It indicates setting value of working capacity. You can change the value at your option by

using digit keys after pressing down P. SET key. (0000 ∼9999)

J. “NOR_SEW”: It shows working condition. General sewing and chain sewing are available.

“ NOR_SEW”indicates the general sewing and “CHN_XX”means chain sewing.

※ Reference : 00~15 are available in XX of “CHN_XX”

※ In case of SPS/C-series :

※ In case of SPS/C-series, when the power is on first, upper-lower shaft origin search motion will start. After

origin search motion, the highest position of thread take- up is set as the different way from the existing

pattern. Because origin search motion will perform to set upper-lower shaft hook time. This will not cause

problem during sewing or trimming. The position will be set as the existing pattern when the machine stops

or trims during sewing.

NO:000 NOR_SEW

XS:100%

YS:100% SP:1500

BC:000 PC:0000

POWER LED

READY LED

ERROR LED

Needle & Hook

Origin....

12

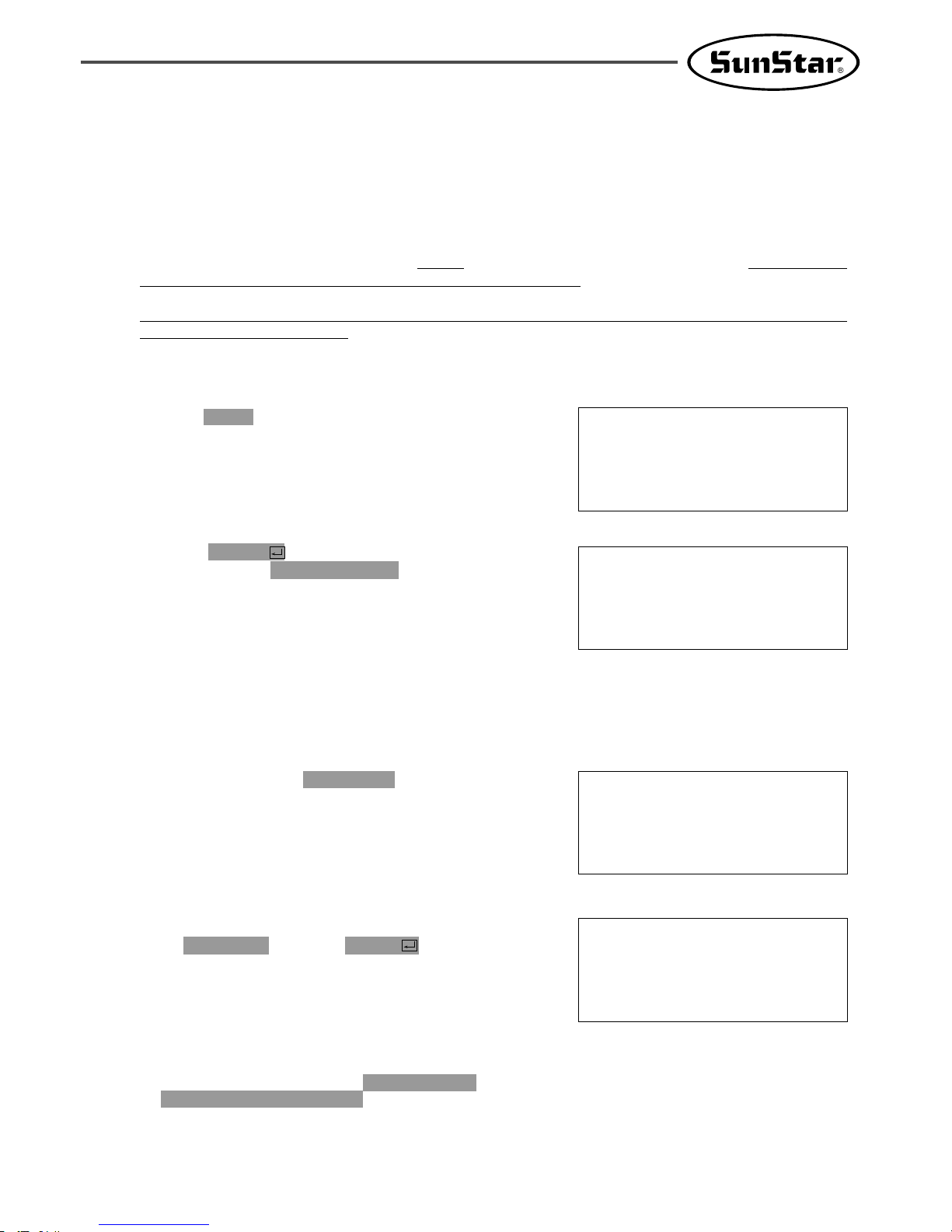

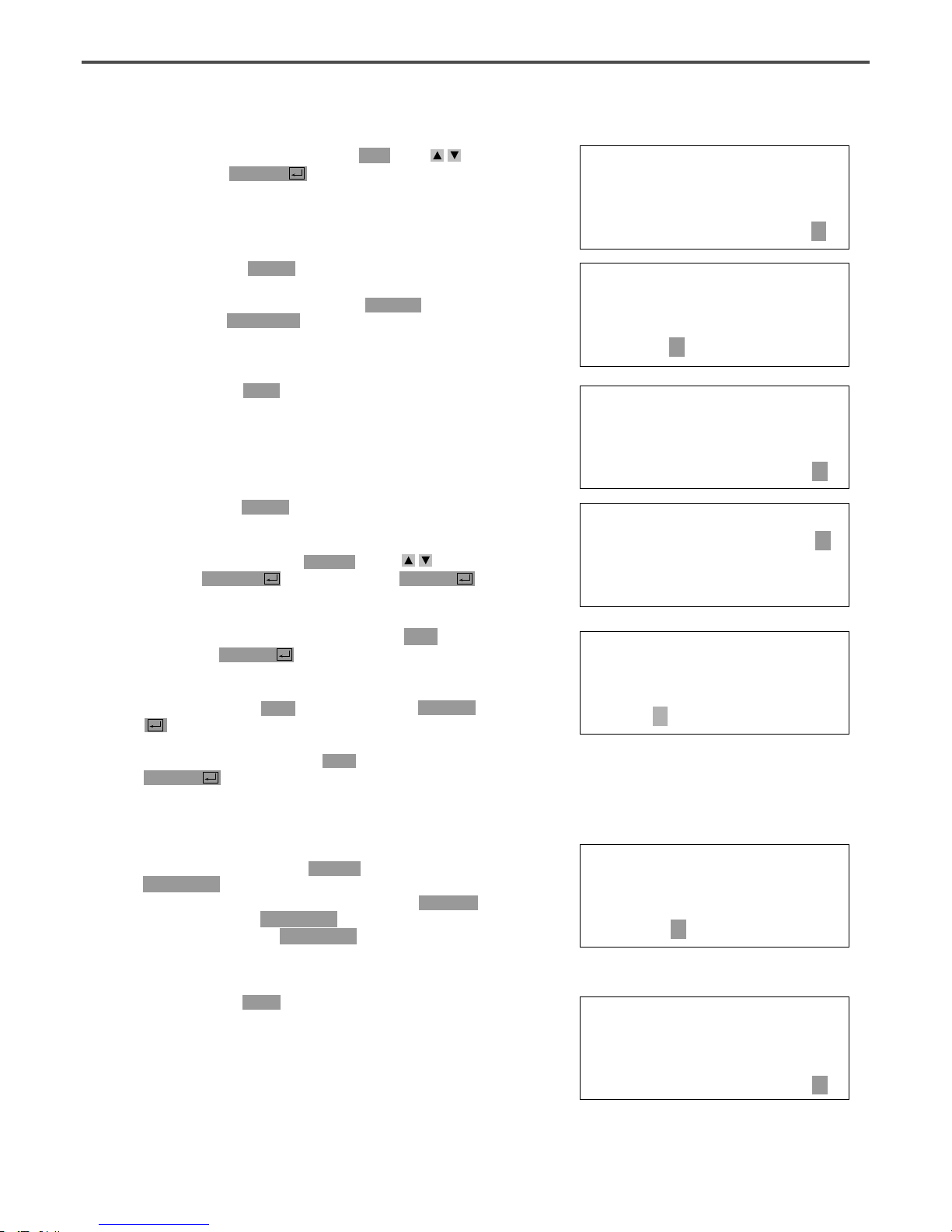

3) Flow Chart of General Operation

Power On

NO

NO

YES

NO

YES

YES

Indication of

general sewing

mode

General Sewing

mode

Is NO key

pressed?

Selection of

pattern No.

Read

USB flash

drive

Indication of

special working

mode

Selection of

working

mode

0:Initialization

1. S/W Version

2. Para. Init.

3. Sys. UpDate

4. Para Ptrn

1:Parameter

setting

0. JOG En/Dis

1. JOG Mode

2. Machine Org1

3. Machine Org2

4. Strt Ret Mod

5. Bobbin Counter

6. Prodct Counter

7. Pattern Read

8. Trim EM Stop

9. Slow Start

10. Max Speed

11. Feed End Pos

12. FF Operation

.

.

◎ Refer the

appendix 3.

2:Pattern

programming

0. TRIM

1. SEC_ORG

2. PAUSE

3. EMPTY

4. JUMP

5. POINT

6. LINE/CURVE

7. LINE

8. CURVE

9. ARC

10. CIRCLE

11. UMP SPD

12. STI SPD

.

.

◎ Refer the

appendix 4.

3:

Thread winding

4:Machine test

5:Pattern list

6:Embroidery

data conversion

7:JUKI Data

Conversion

0. Encoder Test

1. XY Main Test

2. MainMotor Test

3. Interrupt Test

4. PWM Test

5. LCD Test

6. Keyboard Test

7. Input0 Test

8. Input1 Test

9. Input2 Test

10. XY Jog Test

11. Solenoid Test

12. Origin Test

13. Jump Test

14. Asyne Test

(Direct Type)

0. Memory

1. USB

0. SWF

1. TAJIMA

JUKI(0)

Light On for

preparation

Operation of

pedal switch

Sewing

Is ENTER

key pressed?

Is MODE

key pressed?

NO:000 NOR_SEW

XS:100

%

YS:100%SP:2000

BC:000 PC:0000

POWER LED

READY LED

ERROR LED

POWER LED

READY LED

ERROR LED

POWER LED

READY LED

ERROR LED

NO:000 NOR_SEW

XS:100

%

YS:100%SP:2000

BC:000 PC:0000

<< Main Menu >>

0.Initialize

1.Parameter Set

2.Program

13

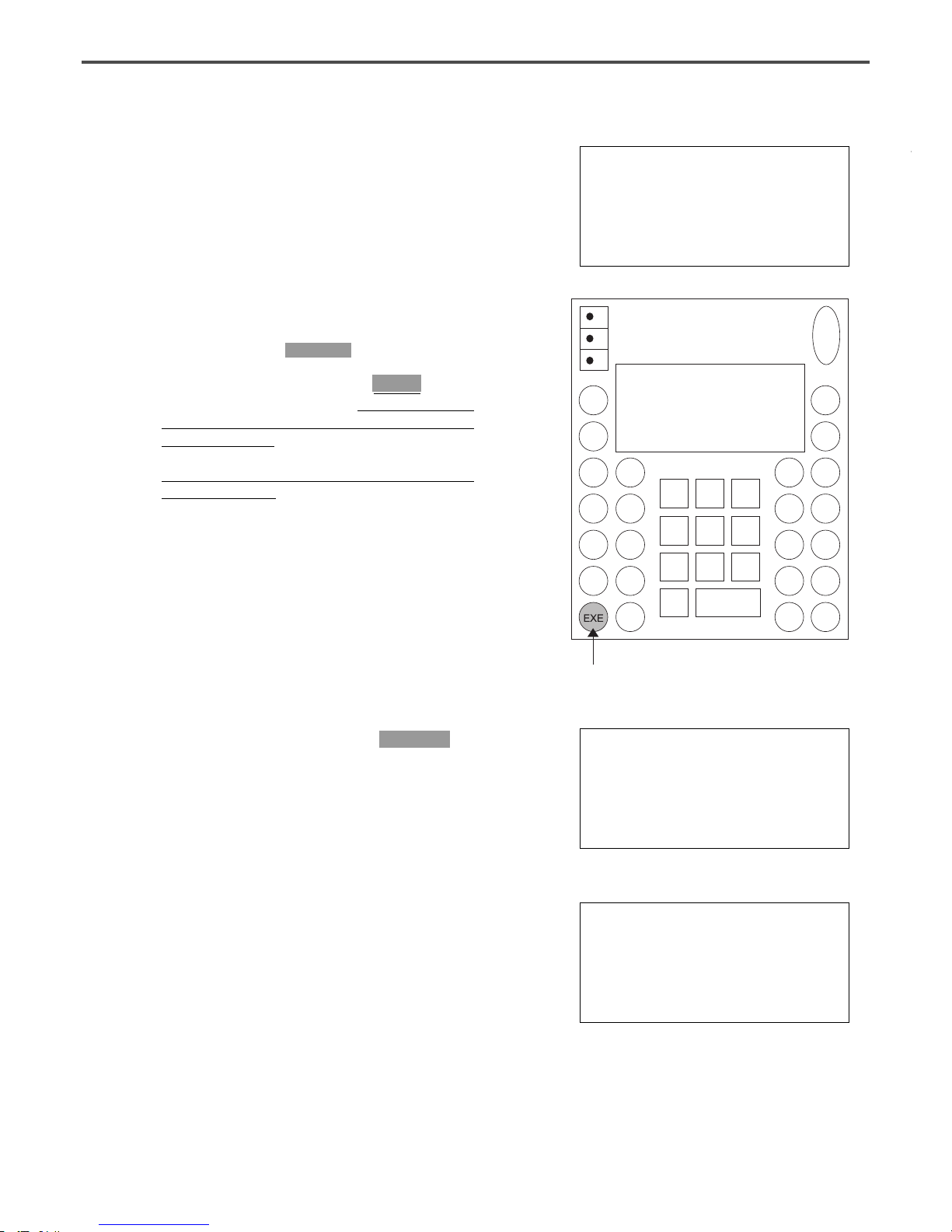

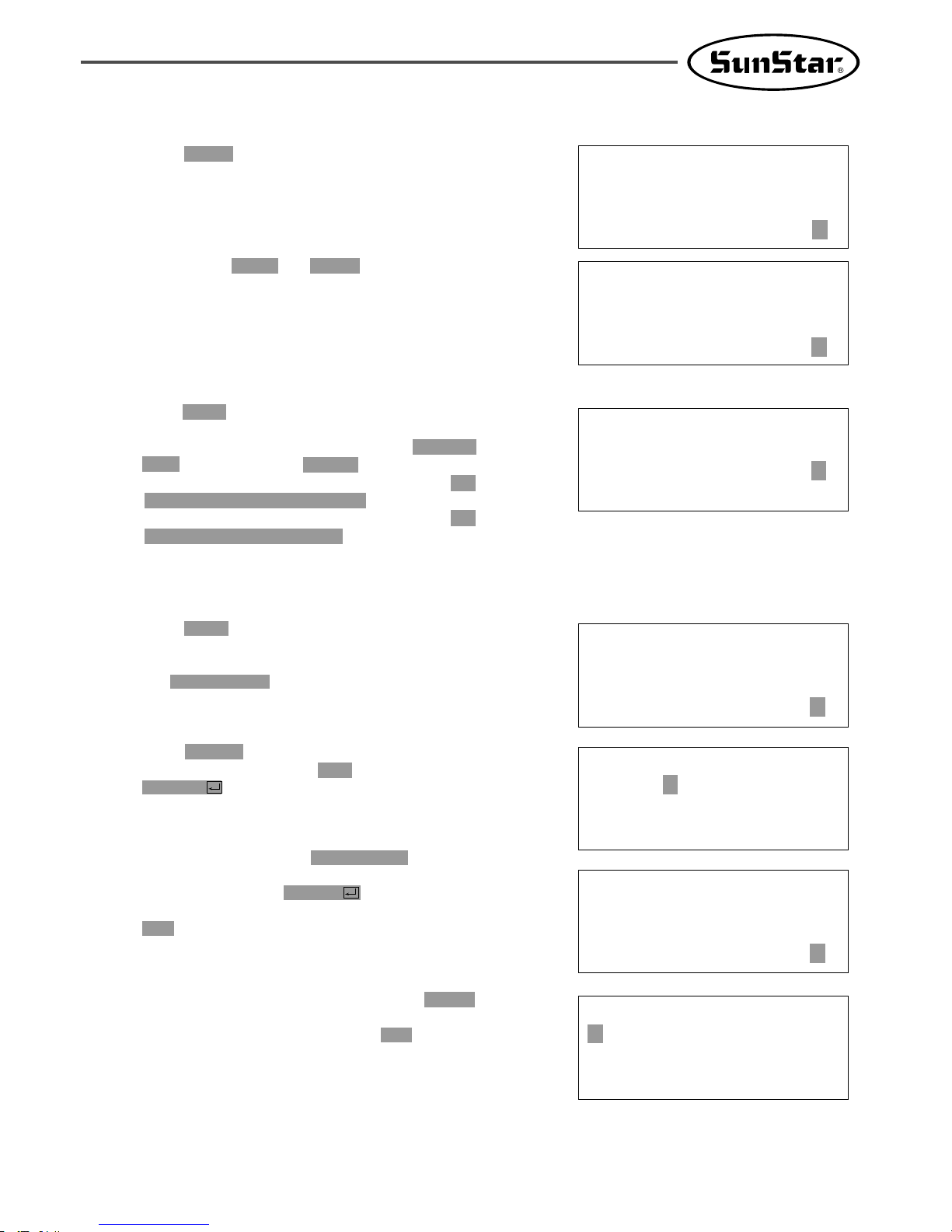

4) Work Flow of Pattern Programming

YES

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

NO

NO

NO

General

sewing mode

A

Is TEST key

pressed?

Light On for

preparation

Operation of

pedal switch

Test Sewing

Is TEST key

pressed?

Is WRITE key

pressed?

Input of Pattern

No.

Read

USB flash

drive

Is MODE key

pressed?

End of Programming Mode

Selection of

working mode

Pattern

Programming

Mode

Is CODE key or

punching related

key pressed?

Indication of

Programming

Mode

Selection of

Programming Code

Information Input of

Stitch Width and

Coordinates

Is ESC key

pressed?

Is EXE key

pressed?

Pattern Data

Generation

A

Is MODE key

pressed?

NO:000 NOR_SEW

XS:100

%

YS:100%SP:2000

BC:000 PC:0000

POWER LED

READY LED

ERROR LED

POWER LED

READY LED

ERROR LED

POWER LED

READY LED

ERROR LED

POWER LED

READY LED

ERROR LED

POWER LED

READY LED

ERROR LED

<< Main Menu >>

0.Initialize

1.Parameter Set

2.Program

<< Main Menu >>

2.Program

3.Bobbin Wind

4.Machine Test

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

<Function Code>

000:TRIM

001:SEC_ORG

002:PAUSE

14

5) Operating After Reading the Patterns from USB flash drive

A. Insert the USB flash drive stored sewing

patterns into the terminal.

B. After pressing NO key, input the pattern

number by using digit keys. (If you want to

work with “001”pattern, press [0][0][1])

C. Press ENTER key. Read the pattern and

change to sewing available mode.

D. At the moment, the upper thread plate comes

to descend, then ascend again after moving to

the sewing start point. The READY LED

comes to light on.

E.

Press SPEED key and adjust the speed properly.

F. If you step on the pedal switch on the right

side, the upper feed plate comes to descend, and

if you step on the pedal switch on the left side,

the machine starts relevant work.

G. When you finish operating, the machine backs to

the origin or sewing start point, and the upper

feed plate comes to ascend.

6) Confirming the Working Pattern Read from the USB flash drive

A. Insert a USB flash drive into the terminal.

B.

After pressing NO key, input the pattern number

by using digit keys. (If you want to work with

“001”pattern, press [0][0][1])

C. Press ENTER key. Read the pattern and

change to sewing available mode.

D. At the moment, the upper thread plate comes

to descend, then ascend again after moving to

the sewing start point. The READY LED

comes to light on.

E.

Press SPEED key and adjust the speed properly.

F. If you step on the pedal switch on the right

side, the upper feed plate comes to descend.

G.

If you press FORW and BACK keys to progress

and reverse 1 stitch, you can confirm the real

shape to be sewn. If you press continuously, it

moves to the start or to the end of pattern

data consecutively.

H.

If you want to finish working, press ORIGIN key.

I. If you want to continue sewing at the forward

or backward point, step on the left pedal switch.

J. When you finish operating, the machine backs to

the origin or sewing start point, and the upper

feed plate comes to ascend.

NO:001 NOR_SEW

XS:100%

YS:100% SP:2000

BC:000 PC:0000

NO:001 NOR_SEW

XS:100%

YS:100% SP:1500

BC:000 PC:0000

NO:001 NOR_SEW

XS:100%

YS:100% SP:2000

BC:000 PC:0000

NO:001 NOR_SEW

XS:100%

YS:100% SP:1500

BC:000 PC:0000

※ Caution : If READY LED turns on or upper feed plate is under, some keys are not available.

It happened, operate the keys after lifting the upper feed plate or pressing ENTER key.

15

7) When a Machine Stops Operating During Sewing by the Thread Cut

A.

You can get the screen like a figure on the right side.

B. If you want to sew continuously at the same

position, insert thread again, then step on the

left pedal switch. If you want to sew at the 1

stitch forward or backward point, after moving

by using FORW and BACK key and step on

the left pedal switch.

C. If you want to stop operation and restart

sewing from the beginning, press ORIGIN key.

The feed plate moves to the origin or sewing

start point and ascend.

D. When you finish operating, the machine backs to

the origin or sewing start point, and the upper

feed plate comes to ascend.

8) Emergency Stop During Operation

A. The machine stops operating immediately by

pressing EMERGENCY STOP switch during

sewing. Then you can get the screen like a figure

on the right side.

B.

If you want to restart sewing from the beginning

after discontinuing it, Press the EMERGENCY

STOP switch once more to perform trimming.

(When manual trimming is set after emergency

stop) then press ORIGIN key. The feed plate

moves to origin then comes to ascend.

C. If you want to continue sewing, step on the left

pedal switch. If you finish every working, a

needle moves to origin and the upper feed plate

ascends.

Err18

Thread Broken!

NO:001 NOR_SEW

XS:100%

YS:100% SP:2000

BC:000 PC:0000

Err17

Emergency Stop!

NO:001 NOR_SEW

XS:100%

YS:100% SP:2000

BC:000 PC:0000

9) Winding the Thread

A. Inset the empty bobbin into a head of the

sewing machine.

B. Press MODE key.

C. Move to “3. Bobbin Wind” by using direction

keys , then press ENTER key. At this

time, the upper feed plate comes to descend.

D. If you step on the left pedal switch, thread

winding starts to progress, and if you step on

the left pedal switch one more time, thread

winding comes to discontinue temporarily.

E. If you finish the thread winding work, complete

the thread winding with the left pedal switch

or ESC key.

<< Main Menu >>

3. Bobbin Wind

4. Machine Test

5. Pattern List

<<Bobbin Wind>>

16

A. Sewing ready position

NO:001 NOR_SEW

XS:100%

YS:100% SP:1500

BC:001 PC:0001

10) Safety Functions

10-1) Threading and Cancellation Key

When the sewing machine is in the ready position, press No. 5 key for threading (the presser foot and

the clamp descend). While threading, a user might mistakenly step on the operation pedal, and start the

operation, causing a safety problem. To prevent accidents, the function to freeze the operation after

threading was added.

However, the operation freeze status can be canceled by pressing the same No. 5 key again.

B. Press No. 5 key for threading. The following

message is displayed on the screen, and all keys

become disabled. The sewing operation pedal

switch is also disabled.

Threading...

To Release...

Press(5) again!

C. To cancel the freeze mode, press No. 5 key again.

D. When the safety mode is cancelled, the screen

returns to the original status.

NO:001 NOR_SEW

XS:100%

YS:100% SP:1500

BC:001 PC:0001

17

A. Press MODE and move to “Parameter Set”

on the Main Menu.

B. Press ENTER to get into “Parameter

Set”. Move to “095. Safety Mode”.

<< Main Menu >>

1. Parameter Set

2. Program

3. Bobbin Wind

<Parameter Set>

095.Safety Mode

096.Jump Speed

097.Auto Call

10-2) Emergency Stop, Thread Sensing or Pause Code.

In order to provide maximum safety to users, when a sewing machine is stopped due to emergency stop,

thread sensing or pause code, the operation of the pedal start switch, the clamp up/down switch and

the operation box keys become disabled. When the safety mode is cancelled, the keys are enabled again

and the sewing machine operation is back to normal.

To cancel the safety function, press the “

EXE”key on the left bottom of the OP Box. When this key

is pressed, the sewing machine operation will go back to normal.

When the sewing machine is stopped in relation to emergency stop, thread sensing or pause code, the

clamp takes the down position.

The safety mode can be set as follows:

C. The default value is 1) DISABLE.

095.Safety Mode

1) DISABLE <-

2) ENABLE

D. To activate the safety mode, move the cursor

to 2) ENABLE and press ENTER .

E. If the setting is completed, the safety mode

will be enabled in time of emergency stop,

thread sensing or pause code while sewing is

conducted.

095.Safety Mode

1) DISABLE

2) ENABLE <-

18

F. The following shows an example of situations

where the safety mode is activated. Thread is

broken in the middle of sewing.

When the thread is sensed, an alarm is issued

and the OP Box displays the following

message. While the message is displayed on

the OP Box screen, Pedal Start Switch,

Clamp Up/Down Switch, and Keys of the OP

Box remain disabled in order to protect users.

Only when the exit key is entered, the

functions mentioned above are operable. To

cancel the safety mode, press “

EXE” on the

left bottom of the OP Box. When this key is

pressed, the sewing machine operation will go

back to normal.

While the safety mode is effective, the clamp

is located down.

G. To cancel this function, press EXE Key on

the OP Box. This is the message you can

see on the OP Box screen.

After the function is cancelled, the sewing

machine can be operated again.

Err18

Thread Broken!

Press EXE Key

Sewing is ready

OK!

H. Sewing can be started by pressing the Pedal

Start Switch.

NO:003 NOR_SEW

XS:100%

YS:100% SP:2000

BC:100 PC:0000

NO:123 NOR_SEW

XS:100%

YS:100% SP:1500

BC:004 PC:9084

19

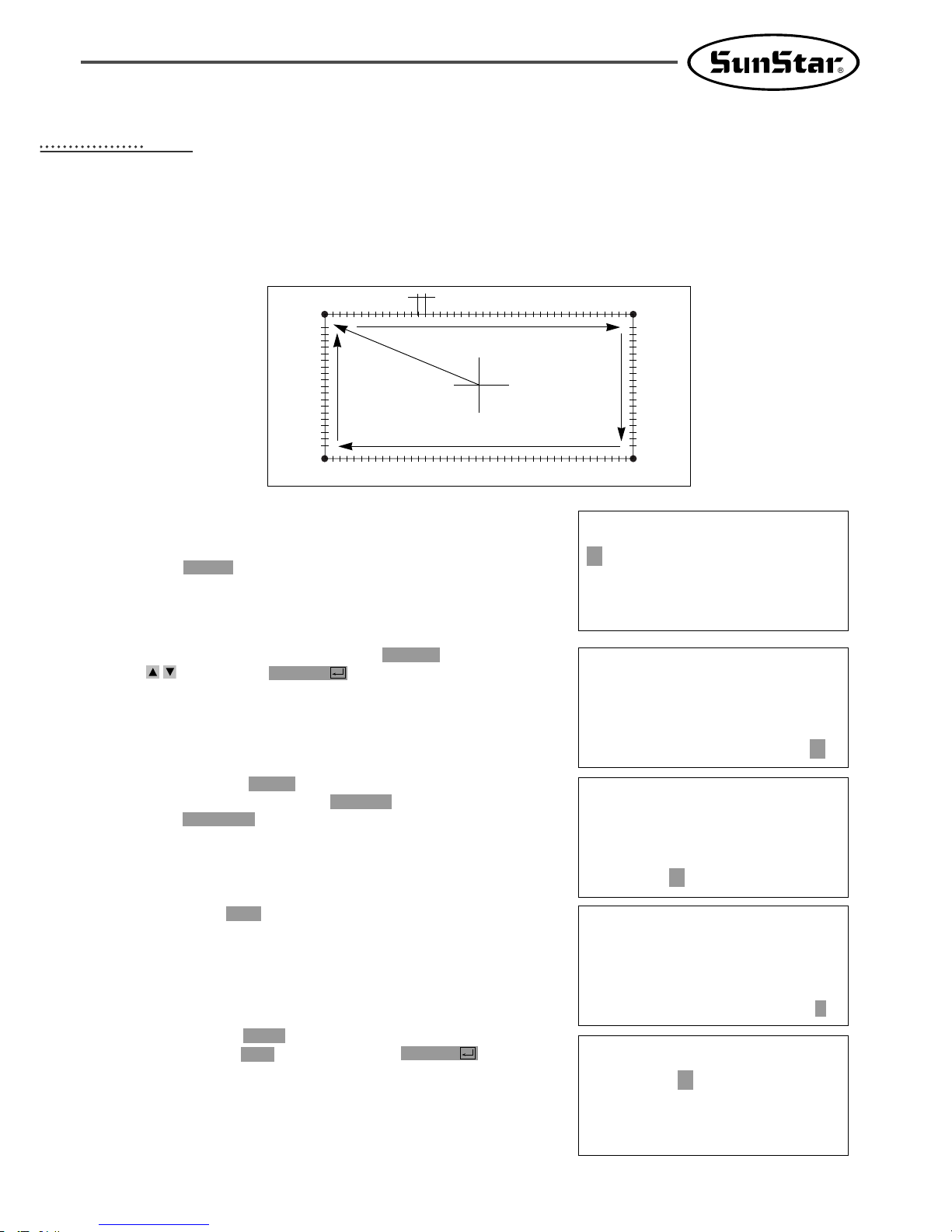

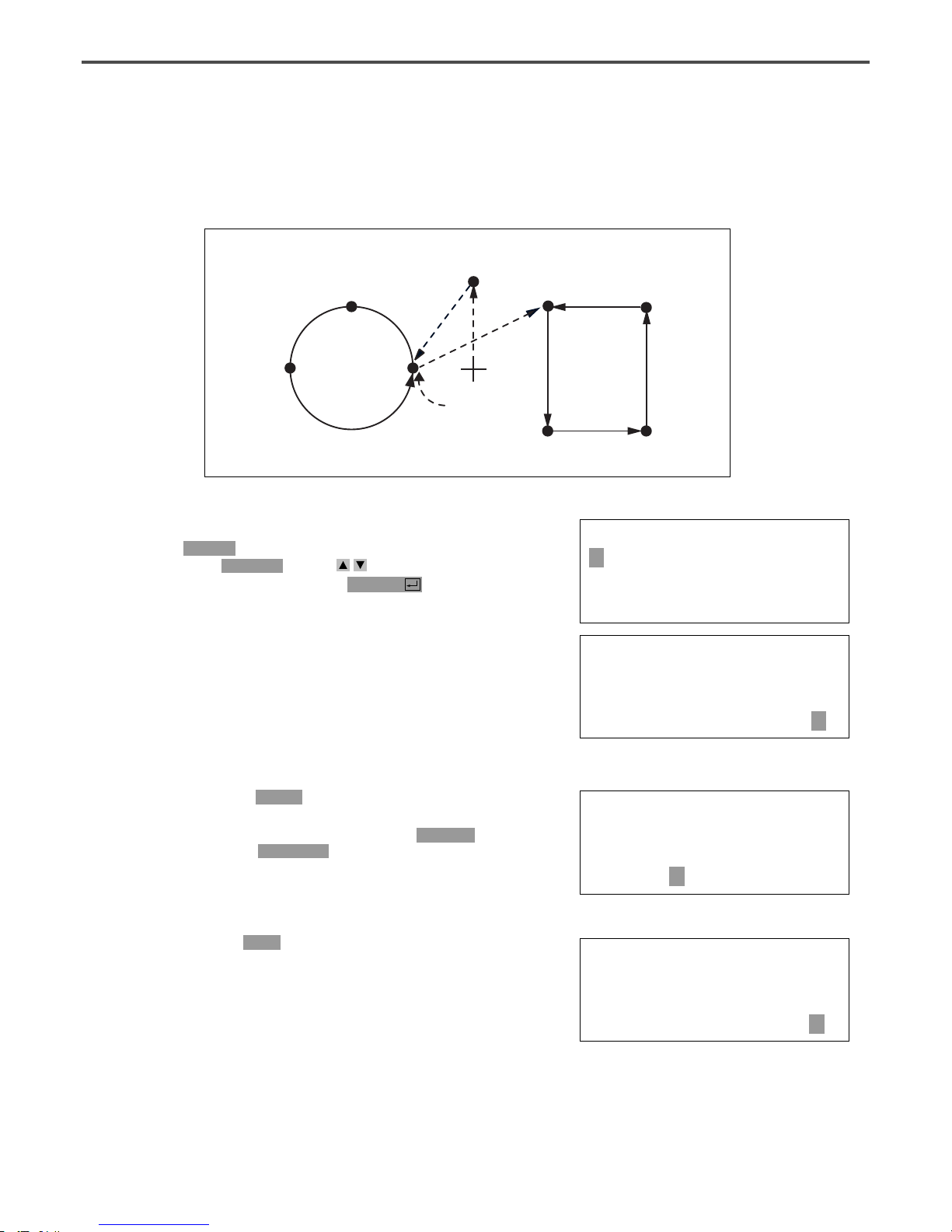

1) Pattern Data Generation Function

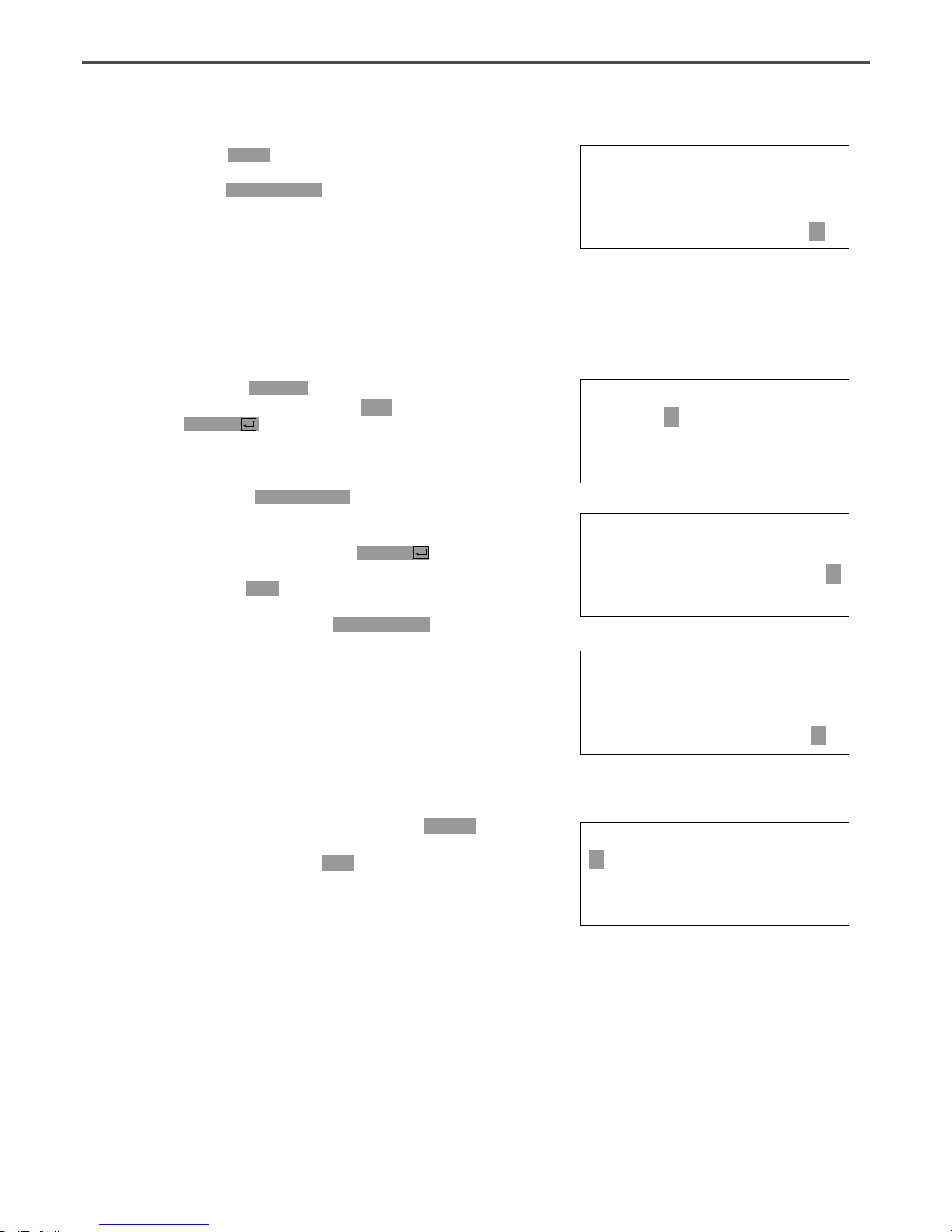

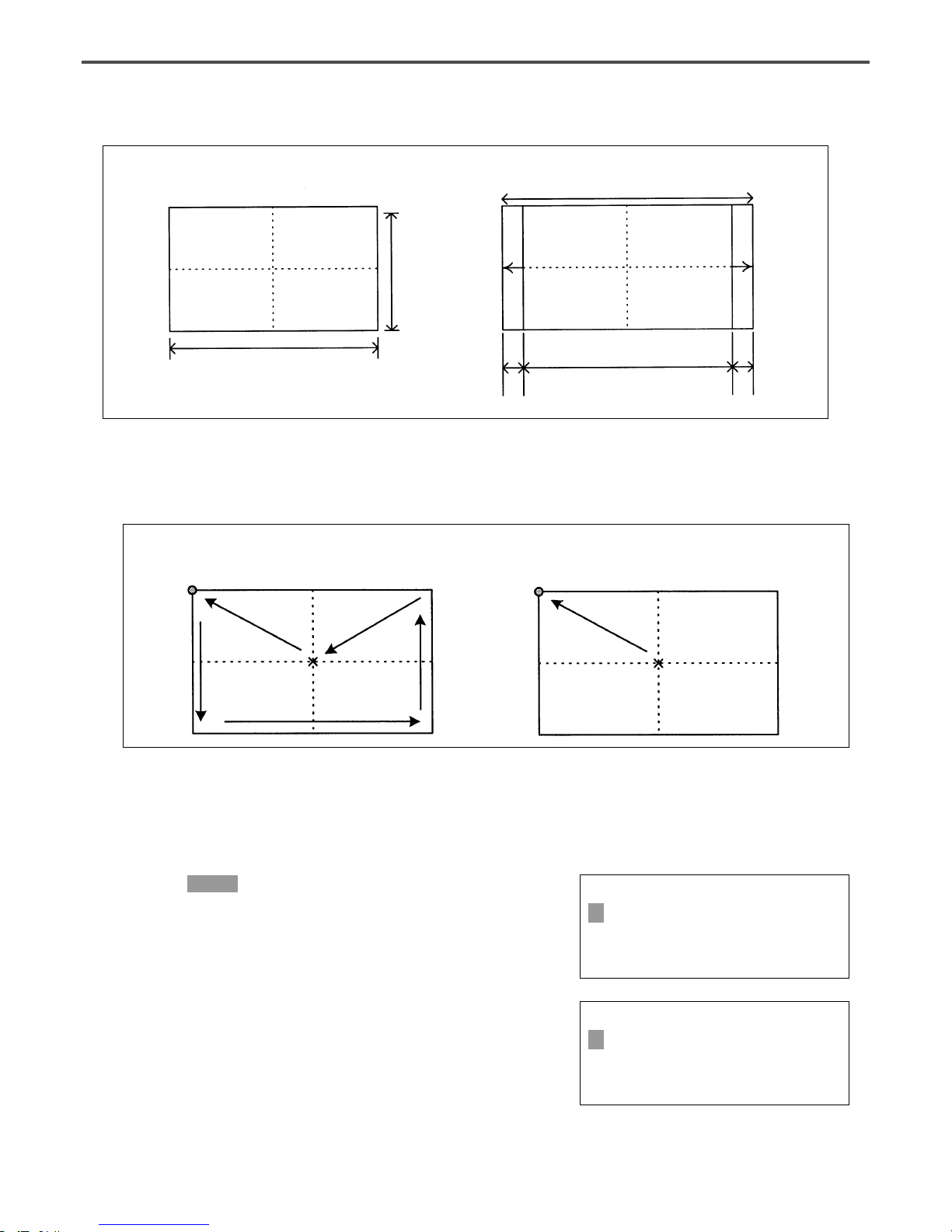

1-1) Program Example 1 : Generating the Square Pattern

(0,0)

Move

3mm

→

→

JUMP

P1

P4

P2

P3

(-650,-300) (650,-300)

(-650,300)

(650,300)

A. Insert a USB flash drive into the terminal.

B. Press MODE key.

C. Move to “2. Program” by using direction keys

, then press ENTER key. At this time,

the upper feed plate comes to descend.

D. After pressing JUMP key, move to the initial

point of square by using direction keys. Then,

press PNT SET key.

E.

If you press EXE key, the machine operates pattern

data, then the feed plate moves according to the

operated data.

F

.

After pressing LINE key, input the stitch width

by using the digit keys, then press ENTER

key. (For example, if you want to set the

stitch width as 3mm, input [0][3][0].)

<< Main Menu >>

2. Program

3. Bobbin Wind

4. Machine Test

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

JUMP NONE

X:-0650A N:00065

Y:00300A

Function Code?

007:LINE

WIDTH:030[0.1mm]

004:JUMP

X:-0650

Y:00300

N:001

44

APPLICABLE OPERATION

20

G. Move to each edge of the square by using

direction keys, then press PNT SET key to input

coordinates of each edge point. Whenever you

press the PNT SET key, the number on screen

will be increased.

H. If you press EXE key, the machine operates

pattern data, then the feed plate moves according

to the operated data.

I. Press TRIM key to input the trimming code.

Then, “000:TRIM”appears on the screen for a

little while, and you can see the screen like

a figure on the right side.

J.

If you press FORW and BACK keys to progress

and reverse 1 stitch, you can confirm the real

shape to be sewn. Whenever you once press the

keys, you can see the operating form and

coordinates

at that time. If you want to perform

test sewing, goes to the next step directly. If

you press continuously, it moves to the start or

to the end of pattern data consecutively.

K. Press TEST key.

The upper feed plate moves to origin and to the

sewing start point, then goes up again. READY

LED lights up. Press SPEED key and adjust

the speed properly. Then if you step on the

pedal switch on the right side, the upper feed

plate comes to descend, and if you step on the

pedal switch on the left side, the machine starts

test sewing. If the test sewing is finished, the

upper feed plate moves to the sewing start

point, then comes to ascend.

L. Press TEST key one more time and finish the

test sewing. Then, the upper feed plate comes to

descend and moves to origin with the turning

off the READY LED.

M. Press WRITE key and input the number you

want to save by using digit keys, then press

ENTER key. (For example, if you want to

save a pattern number as 300, input [3][0][0].)

It you do that, the generated pattern data will

be saved in a floppy disk to that number.

During

saving the pattern, the READY LED

flickers.

LINE NONE

X:-0650A N:00193

Y:00300A

Function Code?

TRIM NONE

X:-0650A N:00194

Y:00300A

Function Code?

<Test Sewing>

SP:1200

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

LINE NONE

X:-0650A N:00193

Y:00300A

Function Code?

015:PTRN WRITE

NO :300

007:LINE

X:-0650

Y:00300

N:004

21

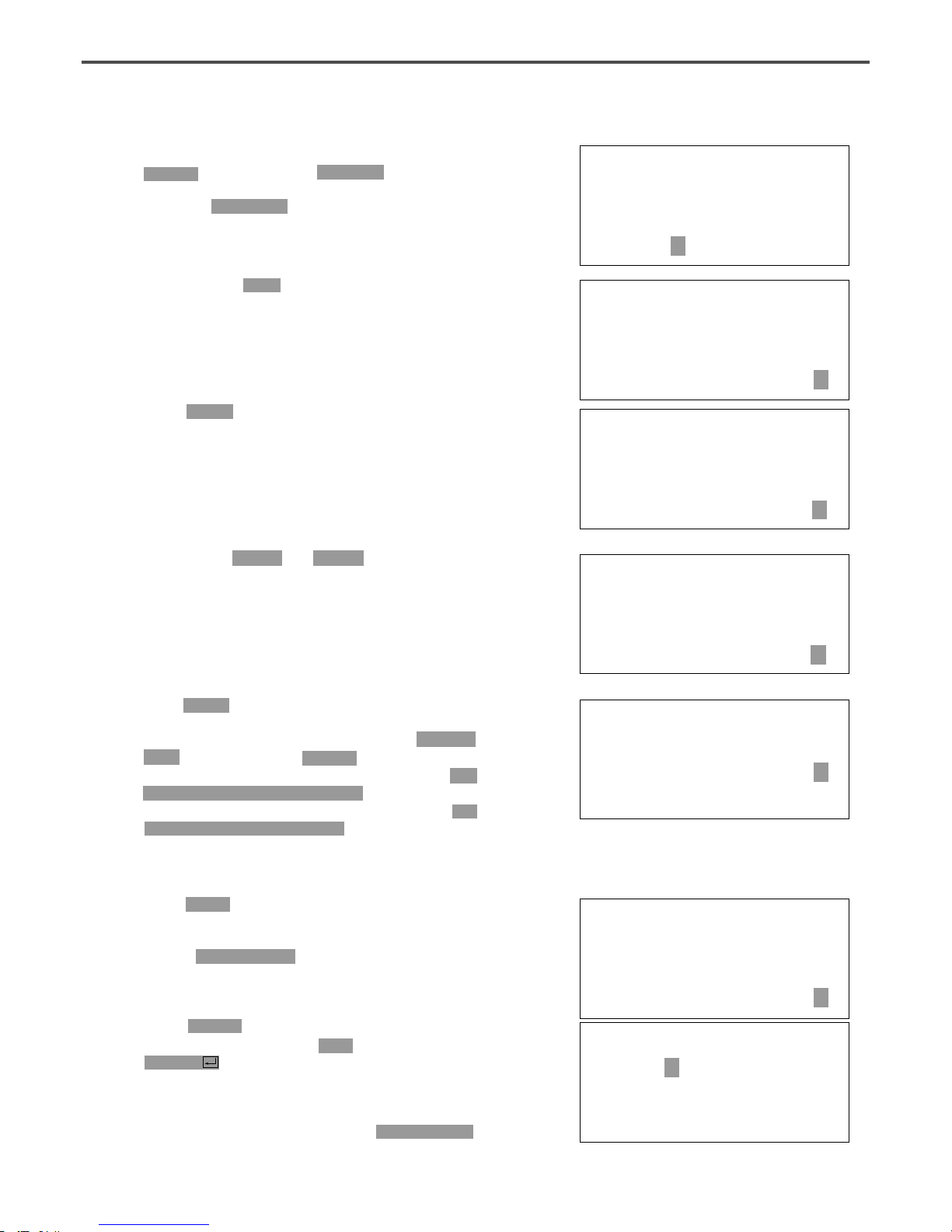

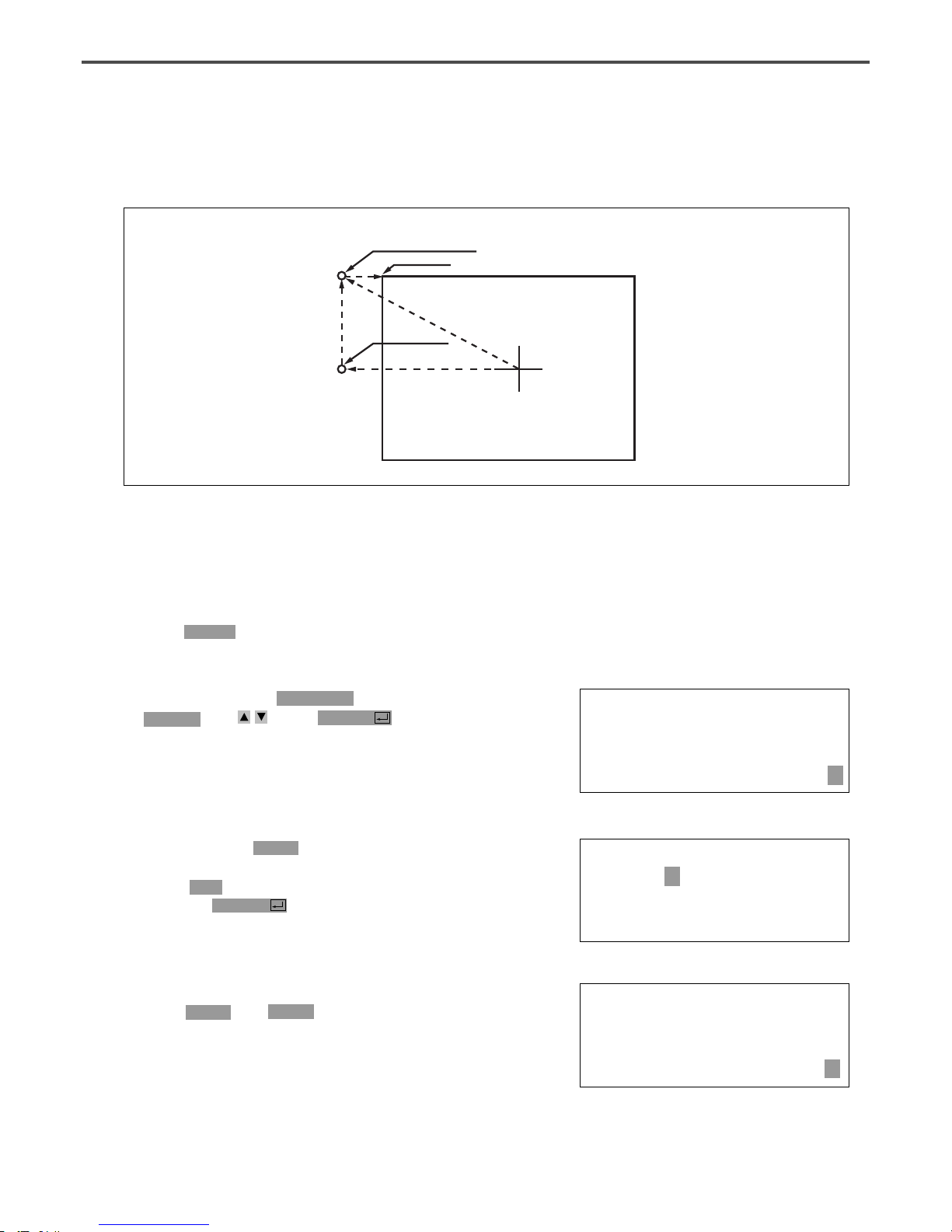

1-2) Program Example 2 : Generating the Circle Pattern

To generate circle patterns, input 3 random coordinates that pass on the circle.

A. Insert a USB flash drive into the terminal.

B. Press MODE key.

C. Move to “2. Program”by using direction keys

, then press ENTER key. At this time,

the upper feed plate comes to descend.

D. After pressing JUMP key, move to a random

coordinates (For example, X:00000, Y:00300)

that passes on circle by using direction keys.

Then, press PNT SET key.

O. For finishing a pattern generation, press MODE

key. Then, the upper feed plate moves to the

origin and comes to ascend. Press ESC key to

back to the initial screen.

N. If there already exists the pattern number that

you want to save in a USB flash drive, you can

see the screen like a figure on the right side. If

you

want to save the pattern with the same

number,

just press ENTER key, but if you

want to save it with another number, press ESC

key and save to the other number.

<< Main Menu >>

2. Program

3. Bobbin Wind

4. Machine Test

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

004:JUMP

X:00000

Y:00300

N:001

P1(0,300)

P1(0,-300)

P2(300,0)

(0,0)

↔

3mm

JUMP

Pattern Exist!

OverWrite?

Y(ENTER)/N(ESC)

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

22

JUMP NONE

X:00000A N:00027

Y:00300A

Function Code?

E. If you press EXE key, the machine operates

pattern data, then the feed plate moves according

to the operated data.

F. After pressing CODE key, if you know function

codes related to pattern programming, input three

digit number, but if not, move to “10. Circle”

by using direction keys after pressing

ENTER key, then press ENTER key again.

G. Input the stitch width by using the digit keys,

then press ENTER key. (For example, if you

want to set the stitch width as 3mm, input

[0][3][0].)

H. Move to the second random coordinates that

passes on a circle (For example, X:00300

Y:00000) by using direction keys, then press PNT

SET key.

Same as above,

move to the third

random coordinates that passes on a circle (For

example, X:00000 Y:-00300), then press PNT

SET key. Whenever you press PNT SET key,

the number of screen increases.

I. If you press EXE key, the machine operates

pattern data, then the feed plate moves according

to the operated data.

J. Press TRIM key to input the trimming code.

Then, “000:TRIM”appears on the screen for a

little while, and replace the screen like a

figure on the right side.

K.

If you press FORW and BACK keys to progress

and reverse 1 stitch, you can confirm the real

shape to be sewn. Whenever you once press the

keys, you can see the operating form and

coordinates

at that time. If you want to perform

test sewing, goes to the next step directly.

If you

press continuously, it moves to the start or to

the end of pattern data consecutively.

L. Press TEST key.

The upper feed plate comes to ascend and

moves to the origin or sewing start point, then

goes up. After that, READY LED turns on.

Press SPEED key and adjust the speed properly.

Then if you step on the pedal switch on the

right side, the upper feed plate comes to descend,

and if you step on the pedal switch on the left

side, the machine starts test sewing. If the test

sewing is finished, the upper feed plate moves to

origin and comes to ascend.

<Function Code>

010:CIRCLE <

011:JUMP SPD

012:STI SPD

010:CIRCLE

WIDTH:030[0.1mm]

010:CIRCLE

X:00000

Y:-0300

N:002

CIRCLE NONE

X:00000A N:00090

Y:00300A

Function Code?

CIRCLE NONE

X:00000A N:00090

Y:00300A

Function Code?

<Test Sewing>

SP:1500

TRIM NONE

X:00000A N:00091

Y:00300A

Function Code?

23

O. For finishing a pattern generation, press MODE

key. Then, the upper feed plate moves to the

origin and comes to ascend. Press ESC key to

back to the initial screen.

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

<< Main Menu >>

2. Program

3. Bobbin Wind

4. Machine Test

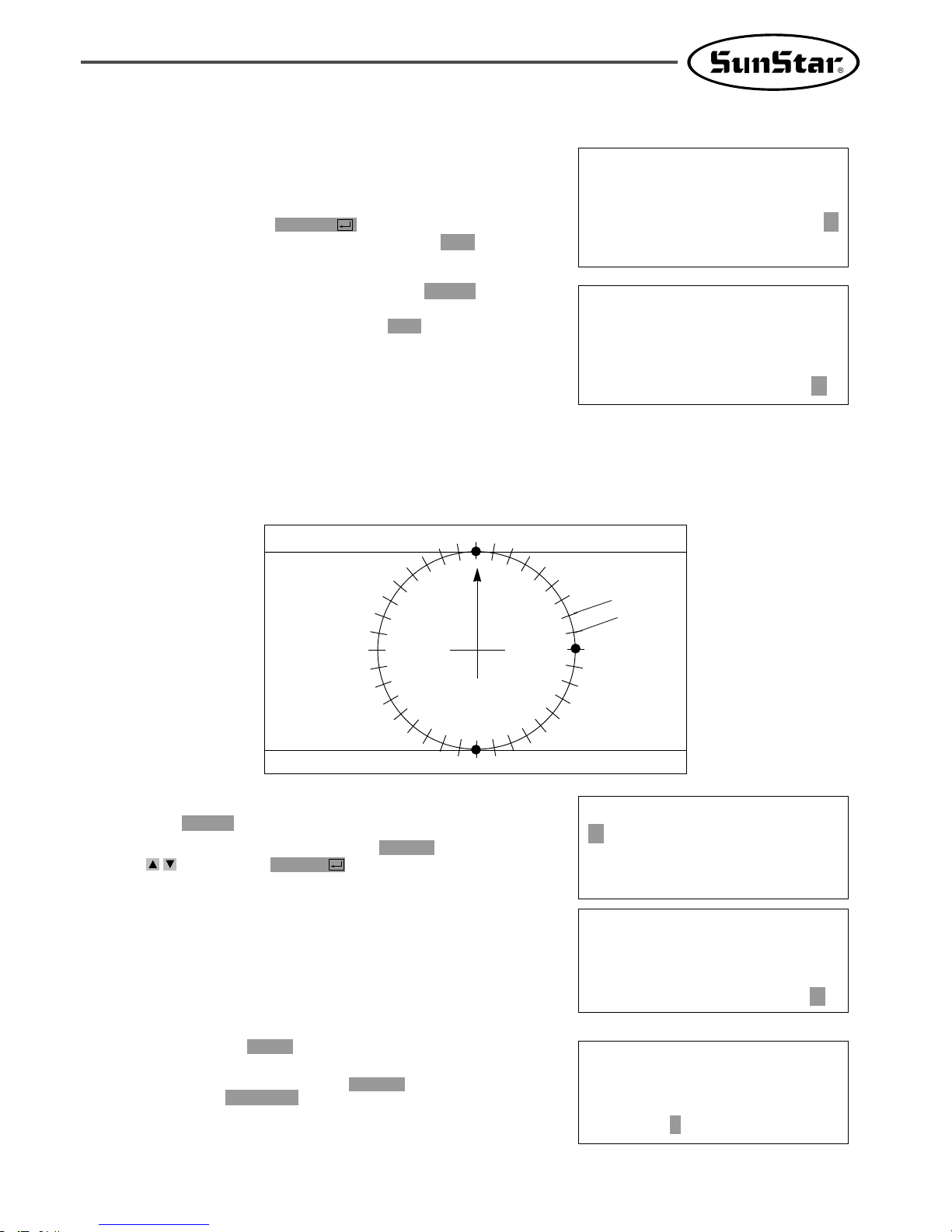

1-3) Program Example 3 : Generating the Double Curve Pattern

Input a curving spot that inclines largely among spots that pass on a curve. We give 5 curving lines for

examples here.

(-600,0)

(600,0)

(-300,200)

(300,-200)

(0,0)

A. Insert a USB flash drive into the terminal.

B. Press MODE key.

<< Main Menu >>

2. Program

3. Bobbin Wind

4. Machine Test

M.Press TEST key one more time and finish the

test sewing. Then, the upper feed plate comes to

descend and move to origin with the turning off

the READY LED.

N. Press WRITE key and input the number you

want to save by using digit keys, then press

ENTER key. Then, save the generated pattern

data in a USB flash drive as a relevant number.

(For example, if you want to save a pattern

number as 301, input [3][0][1].)

During saving the data, READY LED flickers.

If you want to save the pattern with the same

number, just press ENTER key, but if you

want to save it with another number, press ESC

key and save to the other number. After

finishing saving process, the upper feed plate

backs to the origin.

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

015:PTRN WRITE

NO :301

24

D. After pressing JUMP key, move to a random

coordinates (For example X:-0600, Y:00000)

that passes on a circle by using direction keys.

Then, press PNT SET key.

E. If you press EXE key, the machine operates

pattern data, then the feed plate moves according

to the operated data.

F. After pressing CODE key, If you know function

codes related to pattern programming, input

three digit number, but if not, move to “28.

Curve DBL”by using direction keys , after

pressing ENTER key, then press ENTER

key again.

G. Input the stitch width by using the digit keys,

then press ENTER key. (For example, if you

want to set the stitch width as 3mm, input

[0][3][0].) Input the distance between the two

curves by using digit keys, then press ENTER

key. (For example, if you want to set 5mm,

input [0][5][0].) Input a direction

from

standard curve by using digit keys, then

press

ENTER key. (For example, if you want to

place another curve on above the standard

curve, input [0].)

H. Move to the next coordinates (For example, X:-

0300 Y:00200) by using direction keys, then press

PNT SET key. Same as above, move to the

other three coordinates in turns by using direction

keys and press PNT SET key. At this time,

whenever you press PNT SET key, the number

of screen increases.

I. If you press EXE key, the machine operates

pattern data, then the feed plate moves

according to the operated data. At this time, the

sewing machine discontinues for a while.

JUMP NONE

X:-0600A N:00054

Y:00000A

Function Code?

<Function Code>

028:CURVE DBL <

029:ARC DBL

030:CIRCLE DBL

028:CURVE DBL

WIDTH:030[0.1mm]

OFSET:050[0.1mm]

DIR:0[0/1]

004:JUMP

X:-0600

Y:00000

N:001

028:CURVE DBL

X:00600

Y:00000

N:004

CURVE DBL NONE

X:-0635A N:00157

Y:00035A

Function Code?

C. Move to “2. Program”by using digit keys ,

then press ENTER key. At this time, the

upper feed plate comes to descend and moves to

the origin.

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

25

J. Press TRIM key to input the trimming code.

Then, “000:TRIM”appears on the screen for a

little while, and you can see the screen like

a figure on the right side.

K.

If you press FORW and BACK keys to progress

and reverse 1 stitch, you can confirm the real

shape to be sewn. Whenever you once press the

keys, you can see the operating form and

coordinates at that time. If you want to perform

test sewing, goes to the next step directly. If

you press continuously, it moves to the start or

to the end of pattern data consecutively.

L. Press TEST key.

The upper feed plate comes to ascend and moves

to origin, then goes up. After that, READY

LED lights up. Press SPEED key and adjust

the speed properly. Then if you step on the

pedal switch on the right side, the upper feed

plate comes to descend, and if you step on the

pedal switch on the left side, the machine starts

test sewing. If the test sewing is finished, the

upper feed plate moves to origin or sewing start

point and comes to ascend.

M. Press TEST key one more time and finish the

test sewing. Then, the upper feed plate comes to

descend and moves to origin with the turning on

the READY LED.

N. Press WRITE key and input the number you

want to save by using digit keys, then press

ENTER key. Then, save the generated

pattern data in a USB flash drive as a relevant

number.(For example, if you want to save a

pattern number as 302, input [3][0][2].)

During saving the data, READY LED flickers.

If you want to save the pattern with the same

number, just press ENTER key, but if you

want to save it with another number, press

ESC key and save to the other number. After

finishing saving process, the upper feed plate

backs to the origin.

O.

For finishing a pattern generation, press MODE

key. Then, the upper feed plate comes to ascend

after moving to origin. Press ESC key to

back to the initial screen.

CURVE DBL NONE

X:00600A N:00103

Y:00000A

Function Code?

<Test Sewing>

SP:1500

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

015:PTRN WRITE

NO :302

<< Main Menu >>

2. Program

3. Bobbin Wind

4. Machine Test

TRIM NONE

X:-0635A N:00158

Y:00035A

Function Code?

26

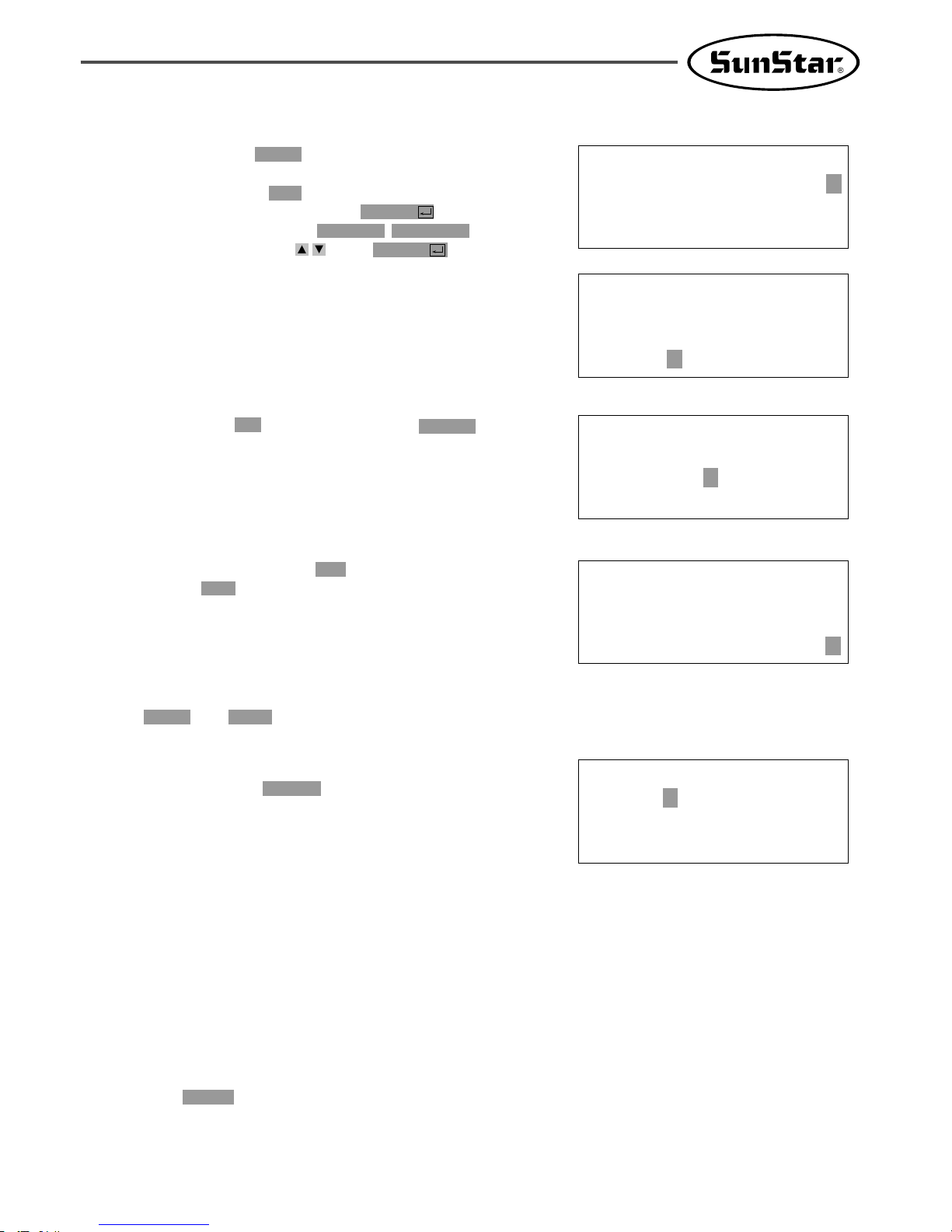

1-4) Program Example 4 : Pattern Generation by Using the Second Origin and Pause

To program as below, input as the following orders : JUMP → SEC_Org → JUMP → CIRCLE →

TRIM → PAUSE → JUMP → LINE → TRIM

P1

(PAUSE)

(0,0)

(JUMP)

D. After pressing JUMP key, make the second

origin move to the coordinates (For example,

X:00000 Y:00300) you want by using direction

keys, then press PNT SET key.

E. By pressing EXE key, after operating the

pattern data, the feed plate moves according to

the operated pattern data.

004:JUMP

X:00000

Y:00300

N:001

JUMP NONE

X:00000A N:00027

Y:00300A

Function Code?

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

A. Insert a USB flash drive into the terminal.

B. Press MODE key.

C. By using direction keys , move to “2.

Program” menu, then press ENTER key. At

this time the upper feed plate descends, and

moves to the origin.

<< Main Menu >>

2. Program

3. Bobbin Wind

4. Machine Test

(SEC_ORG)

P2

P3

(CIRCLE)

(LINE)

P5

P7

P4

P6

27

<Function Code>

001:SEC_ORG <

002:PAUSE

003:EMPTY

F. After pressing CODE key, input the three digit

numbers if you know the pattern programming

related function code, but if you don’t know it,

press ENTER key and move to “001: SEC_

ORG”by using direction keys , then press

ENTER key again.

G. After pressing JUMP key, move to one random

coordinates that passes through circle (for

example, X:-0100, Y:00000), then press PNT

SET key.

H. By pressing EXE key, the feed plate moves

according to the operated data after operating

the pattern data.

I. After pressing CODE key, input the three digit

numbers if you know the pattern programming

related function code, but if you don’t know it,

press ENTER key and move to “010: Circle”

by using direction keys , then press ENTER

key again.

J. By using digit keys, input the stitch width and

press ENTER key.

(For example, if you set up the stitch width as

3mm, input [0][3][0].)

K. By using direction keys, move to the second

random coordinates that passes through circle

(for example, X:-0300 Y:00200), then press

PNT SET key.

Likewise move to the third coordinates that

passes through circle (for example, X:-0500

Y:00000), then press PNT SET key.

At this time the number on screen increases

whenever you press PNT SET key.

JUMP NONE

X:-0100A N:00056

Y:00000A

Function Code?

<Function Code>

010:CIRCLE <

011:JUMP SPD

012:STI SPD

010:CIRCLE

WIDTH:030[0.1mm]

010:CIRCLE

X:-0500

Y:00000

N:002

004:JUMP

X:-0100

Y:00000

N:001

28

CIRCLE NONE

X:-0100A N:00098

Y:00000A

Function Code?

TRIM NONE

X:-0100A N:00099

Y:00000A

Function Code?

<Function Code>

002:PAUSE <

003:EMPTY

004:JUMP

004:JUMP

X:00100

Y:00200

N:001

JUMP NONE

X:00100A N:00125

Y:00200A

Function Code?

<Function Code>

007:LINE <

008:CURVE

009:ARC

L.

By pressing EXE key, the feed plate moves

according to the operated data after operating

the pattern data.

M.

By pressing TRIM key, input the code for trim.

Then, after appearing “00:TRIM”on the screen

for a moment, then a screen of the right side

appears.

N.

After pressing CODE key, input the three digit

numbers if you know the pattern programming

related function code, but if you don’t know it,

press ENTER key and move to “002: PAUSE”

by using direction keys , then press ENTER

key.

O.

After pressing JUMP key, move to the one

random coordinates of straight line (for example,

X:00100 Y:00200)by using direction keys, then

press PNT SET key.

P.

By pressing EXE key, the feed plate moves

according to the operated data after operating

the pattern data.

Q. After pressing CODE key.

If you know the function number related to

pattern programming, input three-figure number

and if you do not know the number, press

ENTER key and transfer to “007:Line”menu

by using direction key , and then press

ENTER key.

Ref.)“LINE”and “CURVE”function is set to

use with hot key on the operation

panel and so you may press this key.

29

007:LINE

WIDETH:030[0.1mm]

007:LINE

X:00100

Y:00200

N:004

LINE NONE

X:00100A N:00181

Y:00200A

Function Code?

TRIM NONE

X:00100A N:00182

Y:00200A

Function Code?

015:PTRN WRITE

NO :303

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

<< Main Menu >>

2. Program

3. Bobbin Wind

4. Machine Test

R.

By using the digit keys, input the stitch width

and press ENTER key.

(For example, if you set up the stitch width as

3mm, input [0][3][0].)

S.

By using direction key, move to the another

coordinates in turns that passes through line,

then press PNT SET key.

At this time the number on screen increases

whenever you press PNT SET key.

T.

By pressing EXE key, the feed plate moves

according to the operated data after operating

the pattern data.

U.

By pressing TRIM key, input the code for trim.

Then, after appearing “00:TRIM”on the screen

for a moment, then a screen of the right side

appears.

V.

After pressing WRITE key, input the number

you want to save by using digit keys. then

press ENTER key. Save the generated pattern

data in a USB flash drive as a relevant number.

(For example, if you want to save the pattern

number as 303, input [3][0][3].) During saving

the pattern, the READY LED flickers. When a

pattern of same number is in a USB flash drive

and if you want to save another pattern as

same number, press ENTER key. If you want

to save the pattern as another number, press

ESC key and save it as another number. After

finishing saving, the upper feed plate moves to

the origin again.

W.

For finishing pattern generation, press MODE

key. Then the upper feed plate moves to the

origin and ascends. Press ESC key to back to

the initial screen.

30

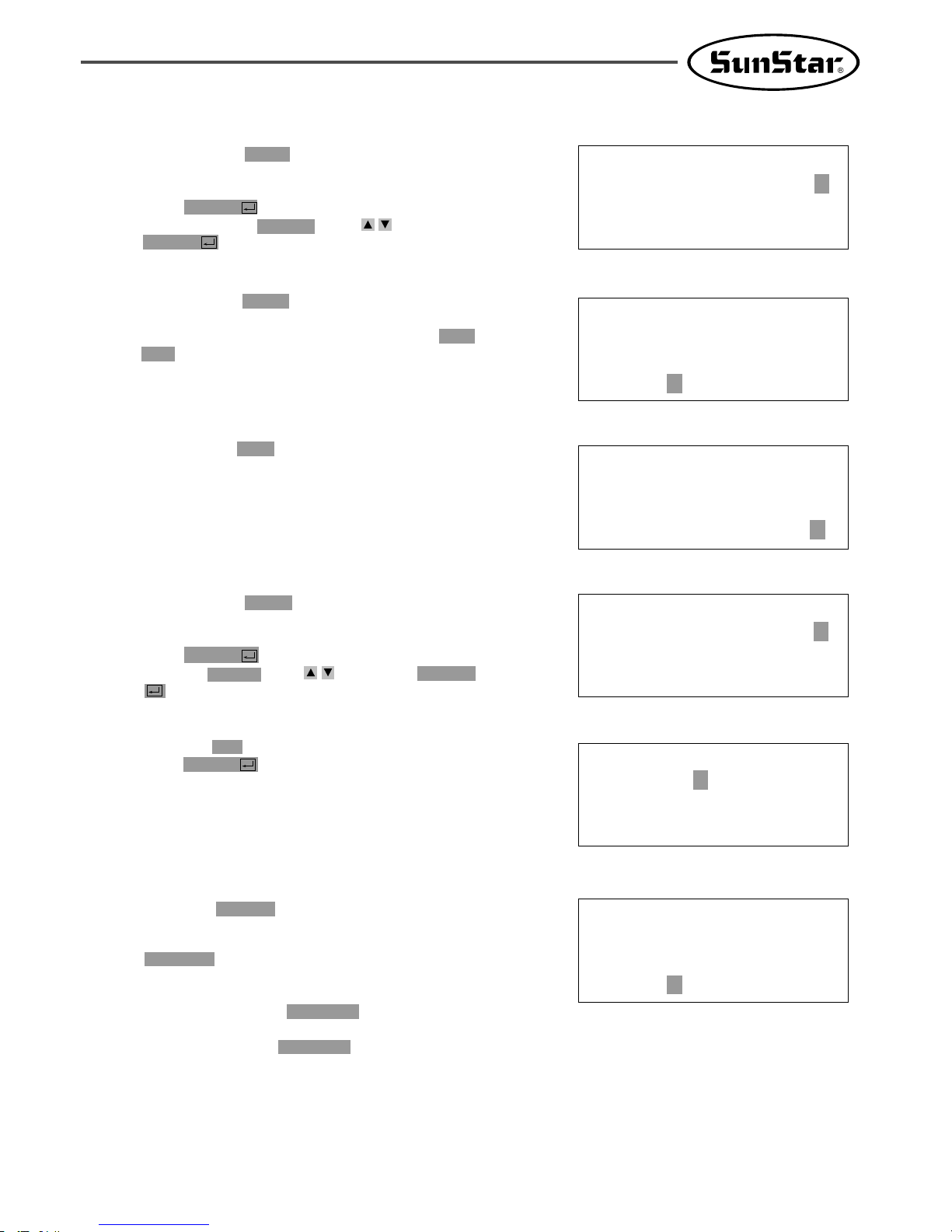

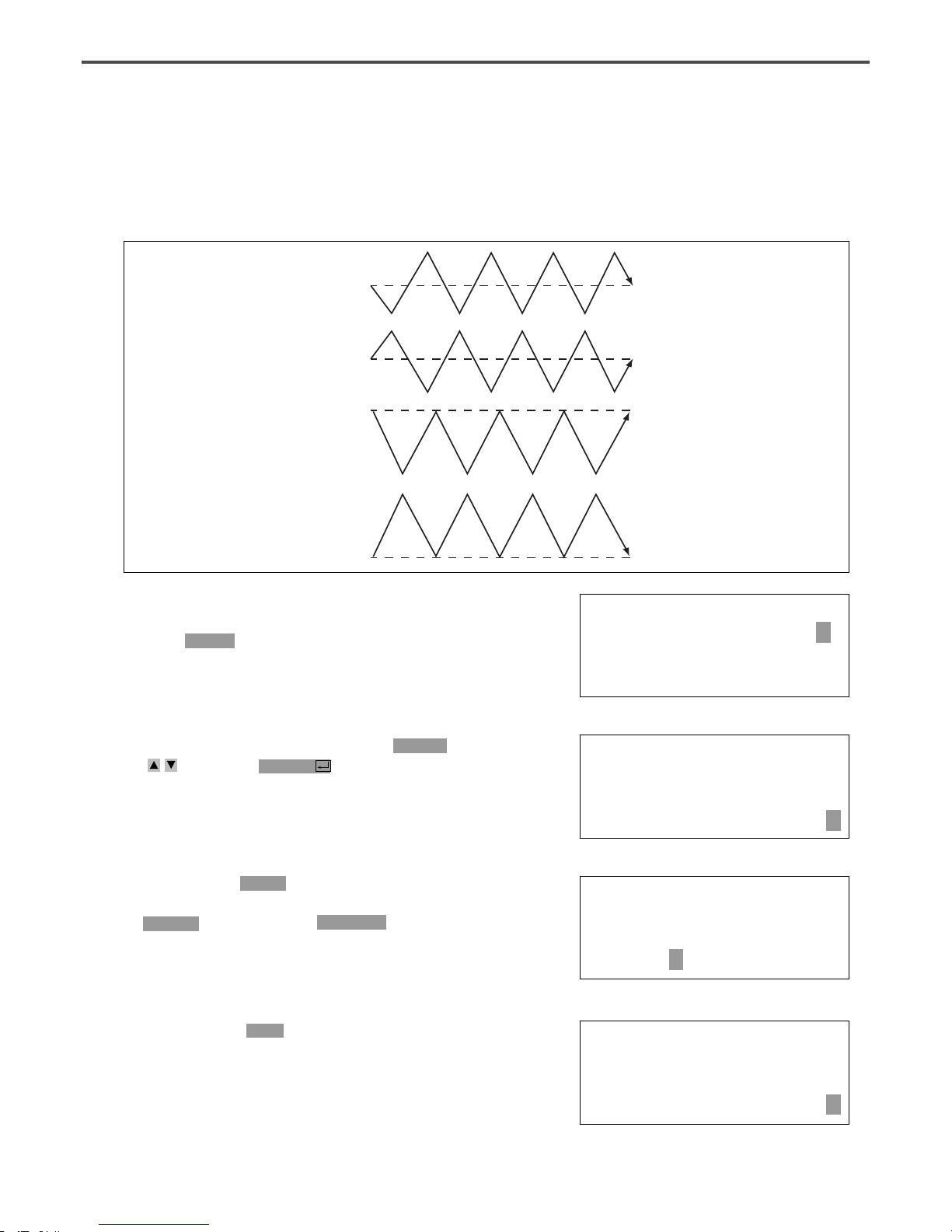

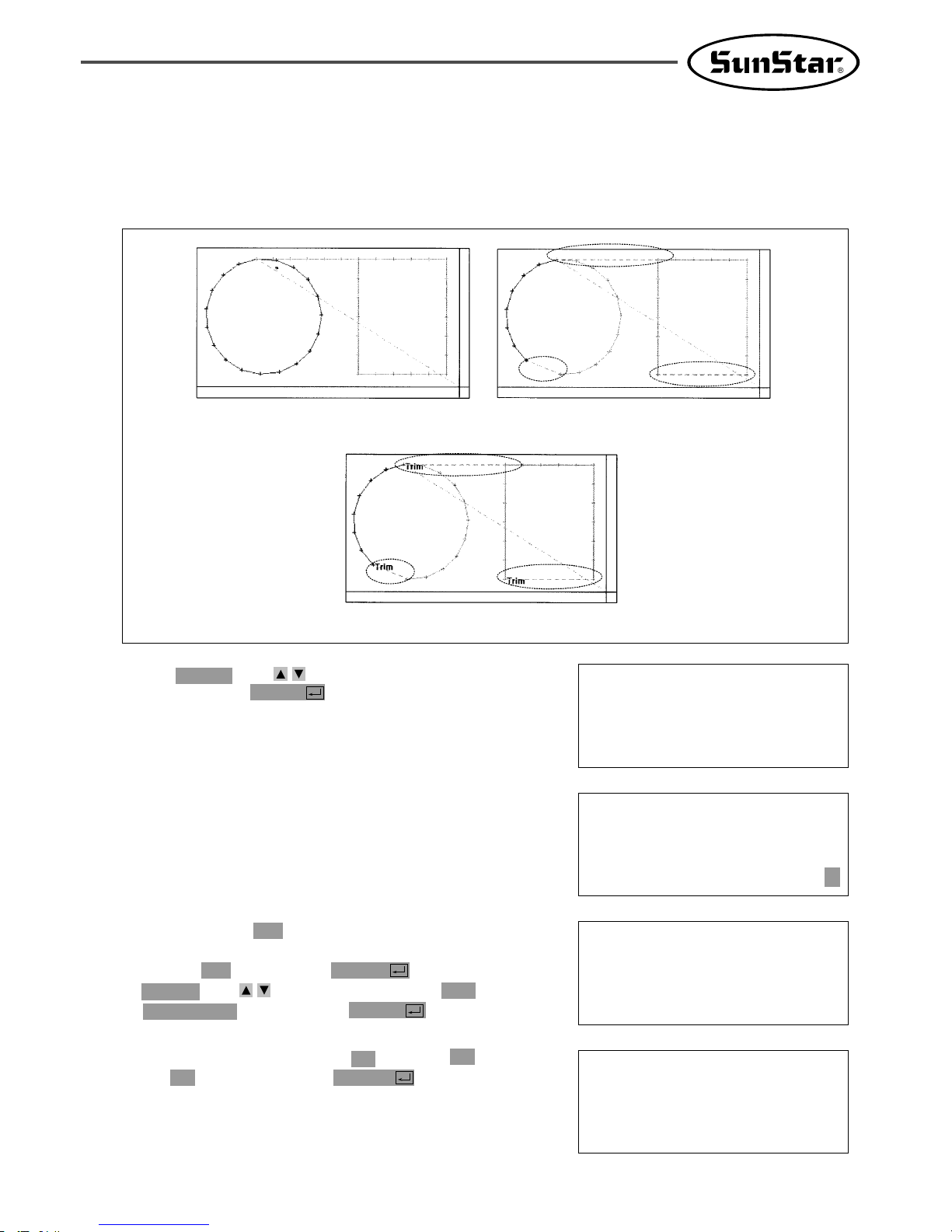

1-5) ZigZag Shape Selecting Function to Generate ZigZag

It was made to select 4 kinds of “DIR” values from existing 0/1 to 0/1/2/3 among three parameters

inputting to create Line ZigZag, Curve ZigZag, Arc ZigZag, Circle ZigZag and accordingly ZigZag shapes

are classified into 4 type.

JUMP

X:-0650A

Y:00000A

N:001

JUMP NONE

X:-0650A N:00000

Y:00000A

Function Code?

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

C. Move to “2. Program”menu by using direction key

and press ENTER key. Then, the upper

feed plate comes down and moves the original

point.

A. Insert a USB flash drive into the terminal.

B. Press MODE key.

D. After pressing JUMP key, move to the coordinate

(for example:X:-0650 Y:00000) to locate by using

direction key. Then, press PNT SET key.

E. If you press EXE key, after calculation on

pattern data, feed plate moves according to the

calculated data.

<< Main Menu >>

2. Program <

3. Bobbin Wind

4. Machine Test

For DIR=0

For DIR=1

For DIR=2

For DIR=3

31

<Function Code>

019:LINE ZIG <

020:CURVE ZIG

021:ARC ZIG

G. Input ZigZag width by using digit key, press

ENTER key and input ZigZag stitch width.

Then, press ENTER key and input DIR value

by using digit key to select ZigZag shape to

create. And press ENTER key.

H. Move ZigZag line (Ex: X: 00650 Y: 00000) to

the last sewing coordinate by using direction key

again and press PNT SET key.

F. After pressing CODE key, if you know the

function number related to pattern programming,

input three figure digit number and if you do

not know the number, press ENTER key. Then

after moving to “019: LINE ZIG” menu by

using direction key, press ENTER key.

J. Input thread trimmer key by pressing TRIM

key. Then “00:TRIM” screen appears for a

second and then the screen like the figure in the

right side appears again.

I. If you press EXE key, after calculation on

pattern data, feed plate moves according to the

calculated data.

K. You can confirm the shape to be actually sewed

by pressing FORW key and BACK key. Every

time you press once, it moves by one stitch and

show work mode and coordinate at the moment.

When you want to actually do initial sewing,

skip to next. If you press continuously, it moves

to the start or to the end of pattern data

consecutively.

L. Press TEST key. The upper feed plate moves to the

original point or sewing start point and goes up

and READY LED is turned on. After adjusting

appropriate initial sewing speed by pressing SPEED

key, step on the pedal switch in the right. Then, the

upper feed plate comes down and stepping on the left

pedal, it performs initial sewing. The upper feed plate

that completed initial sewing moves to the original

point or sewing start point and then goes up.

M. The order of saving and completion is the same

as the previous example.

017:LINE ZIG

X:00650

Y:00000

N:001

LINE ZIG NONE

X:00650A N:00000

Y:00000A

Function Code?

TRIM NONE

X:00650A N:00000

Y:00000A

Function Code?

LINE ZIG NONE

X:00650A N:00000

Y:00000A

Function Code?

<Test Sewing>

SP:1500

010:LINE ZIG

WIDTH:030[0.1mm]

PITCH:030[0.1mm]

DIR:3[0->3]

32

2) Pattern Data Edit Function

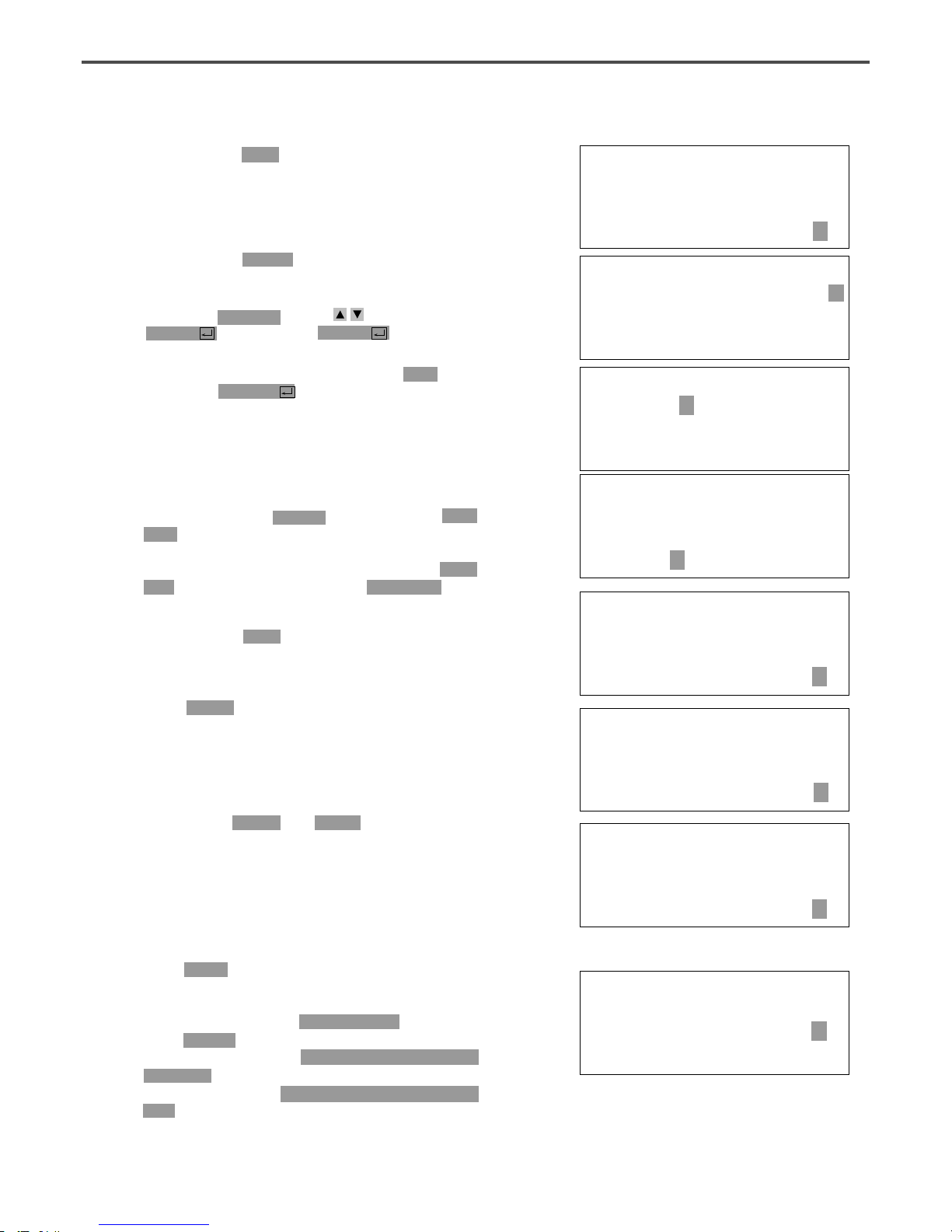

2-1) One Stitch Movement Function

It uses when correcting the location of one stitch in the formed sewing shape.

014:PTRN READ

NO :001

LINE

X:-0001A N:00059

Y:00000A

Function Code?

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

A. Insert USB flash drive containing the pattern to

change movement of a stitch.

B. Press MODE key.

C. After moving to “2. Program” menu by using

direction key , press ENTER key. At this

time, the upper feed plate comes down and

move the original point.

D. After pressing READ key, input the pattern

number to change movement of a stitch by

moving the digit key and read in the pattern by

pressing ENTER key. (For example, to read

pattern number 001, input [0][0][1]).

E. Go to the location of stitch to correct by using

FORW and BACK key.

<Function Code>

051:STITCH DRAG<

052:STITCH DEL

053:MOV SEWSTAR

F. After pressing CODE key, if you know the

function number 051 related to pattern

programming, input three figure of digit number

and if you do not know the number, press

ENTER key and move to “051:STITCH

DRAG”by using direction key . Then, press

ENTER key.

<< Main Menu >>

2. Program <

3. Bobbin Wind

4. Machine Test

Existing Location

Location Movement

New Location

< Before Location Change > < After Location Change >

33

051:STITCH DRAG

X:-00001

Y:-00060

N:000

H. If you press EXE key, change to new needle

location is completed.

I. Confirm if needle location was changed to the

desired location by using FORW and BACK

key.

G. Move to the location desired movement of one

stitch by using direction key.

※

X-Y coordinate value is different according

to location of needle.

A. Insert partial pattern data into the USB flash

drive containing the pattern to move and

change.

B. Press MODE key.

<< Main Menu >>

2. Program <

3. Bobbin Wind

4. Machine Test

LINE

X:-0001A N:00059

Y:-0060A

Function Code?

2-2) Partial Movement Function of Pattern Data

Move part of pattern to different location among the sewing shape.

End Point of Movement ScopeStart Point of Movement Scope

Scope to Move

Location to Move

< Before Movement > < After Movement >

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

C. After moving to “2. Program” menu by using

direction key , press ENTER key. At this

time, the upper feed plate comes down and

moves to the original point.

34

D. After pressing READ key, input the pattern

number to move and change partial pattern

data by using digit key and read in the pattern

by pressing ENTER key. (For example, input

[0][0][1] to read the pattern number 001.)

E. Go to the needle location to partially move by

using FORW and BACK key.

014:PTRN READ

NO :001

JUMP

X:00174A N:00070

Y:00183A

Function Code?

Reference) Location of the needle for partial movement

should be placed at the first start needle location that

actually sews. Therefore, if the sewing data that has

line property after jump appears, the last location of

JUMP data is the first start location of needle correction.

F. After pressing CODE key, if you know the

function number related to pattern programming,

input three figure digit number 046, but if you

do not know the number, press ENTER key.

Then after move to “046:MOV PTRN” by

using direction key , press ENTER key.

<Function Code>

046:MOV PTRN<

052:COPY PTRN

053:DEL PTRN

G. Go to the last location of pattern to move by

using FORW key.

※ The indicated values are different according

to current location.

<RANGE SETTING>

X:00174A N:00088

Y:00183A

H. If you press EXE key, it becomes the state

that the selected pattern for partial movement

can move to the optional location.

046:MOV PTRN

X:00174

Y:00183

N:000

I. Move to the location to move by pressing direction

key.

046:MOV PTRN

X:00174

Y:-0101

N:000

J. If you press EXE key, movement is completed.

K. Confirm if movement was properly made by

using FORW and BACK key.

LINE

X:00174A N:00096

Y:-00101A

Function Code?

35

A. Insert USB flash drive containing the pattern to

delete stitches.

B. Press MODE key.

2-3) A Fixed Number of Stitch Delete Function

Delete 1-99 stitch in the pattern data shape after the start point to delete at present.

Delete Start PointDelete Start Point

Number of Stitch to delete Number of deleted Stitch

JUMP

< Before Delete > < After Delete >

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

C. After moving to “2. Program” menu by using

direction key , press ENTER key. At this

time, the upper feed plate comes down and

moves to the original point.

014:PTRN READ

NO :001

D. After pressing READ key, input the pattern

number to delete stitch by using the digit key

and read in the pattern by pressing ENTER

key. (For example, input [0][0][1] to read the

pattern 001.)

LINE

X:-0025A N:00059

Y:00000A

Function Code?

E. Go to needle location to delete by using FORW

and BACK key.

※ X-Y coordinate value is different according to

needle location.

<Function Code>

052:STITCH_DEL <

053:MOV SEWSTRT

054:MOV 2ndORG

F. After pressing CODE key, if you know the

function number 052 related to pattern

programming, input three-figure digit number

and if you do not know, press ENTER key.

Then after moving to “052:STITCH_DEL”by

using direction key , press ENTER key.

36

052:STITCH DEL

NUM:10[STITCH]

TRIM

X:-0233A N:00033

Y:00120A

Function Code?

G. Input the number of stitch to delete behind

from current location.

H. Press ENTER key.

I. Stitch is deleted as many as the input number.

J. Confirm if the stitches were deleted as many as

desired number by using FORW and BACK

key.

A. Insert USB flash drive containing the partial

pattern to delete.

B. Press MODE key.

Reference) After deleting as much as the number of

defined stitches, if end point and start point of two

sewing data existing at both sides do not match and

have distances, a jump is automatically made between

the two sewing data. If you want to input automatic

thread trimming, you can set up at “057:AUTO TRM”.

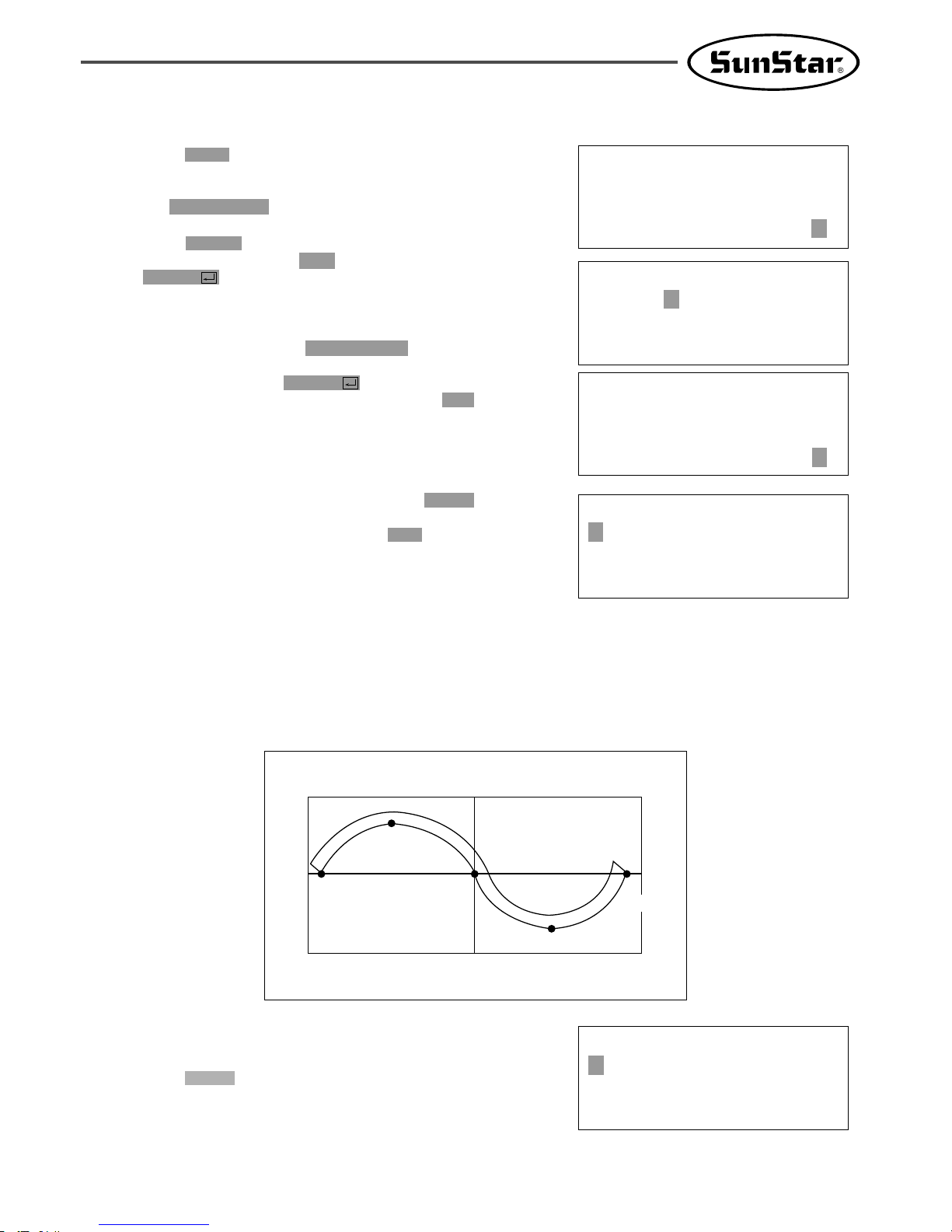

2-4) Partial Pattern Data Delete Function

Delete one of the generated pattern data shapes selectively (For example: Jump, Line, Curve, Arc, Circle).

LINELINE

LINE

LINE

LINE

CIRCLE

LINE

Needle Position

Needle Position

LINE

LINE

LINE

LINE

LINE LINE

LINE LINE

ARC ARC

ARC

CURVECURVE

CURVE CURVE

JUMP

< CIRCLE Delete > < LINE Delete >

< ARC Delete >

Needle Position

37

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

014:PTRN READ

NO :001

CIRCLE

X:-0067A N:00052

Y:-0092A

Function Code?

TRIM

X:-0220A N:00029

Y:00040A

Function Code?

C. After moving to “2. Program” menu by using

direction key press ENTER key. At this

time, the upper feed plate comes down and

moves to the original point.

D. After pressing READ key, input the pattern

number to delete partial pattern by using digit

key and read in the pattern by pressing

ENTER key. (For example, input [0][0][1] to

read the pattern number 001).

E. Go to the pattern that the shape to delete

exists by using FORW and BACK key.

※ X-Y coordinate value is different according

to needle location.

F. Delete is available by two methods as below.

- After pressing CODE key, input Function code

039 and press ENTER key.

- Or press PTN. DEL key of OP.

G. Press PTN.DEL key on operation box (OP).

Reference) After deleting as much as the number of

defined stitches, if end point and start point of two

sewing data existing at both sides do not match and

have distances, a jump is automatically made between

the two sewing data. If you want to input automatic

thread trimming, you can set up at “057:AUTO TRM”.

H. Confirm if desired partial pattern shape was

deleted by using FORW and BACK key. (Line

is deleted by once.)

I. Delete the partial pattern data to delete

repeatedly in the order of E-F-G.

38

2-5) Partial Stitch Width Changing Function

Change stitch width by selecting a fixed part from the pattern shape.

End Point of Stitch

Width Change

Start Point of Stitch

Width Change

End Point of Stitch

Width Change

Start Point of Stitch

width Change

Current Stitch Width 3.0mm

Current Stitch Width 2.0mm

< Before Partial Stitch Width Change > < After Partial Stitch Width Change >

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

014:PTRN READ

NO :001

A. Insert USB flash drive containing the pattern to

change stitch width.

B. Press MODE key.

C. After moving to “2. Program” menu by using

direction key , press ENTER key. At this

time, the upper feed plate comes to descend.

D. After pressing READ key, input the pattern

number to change stitch width by using digit

key and read in the pattern by pressing

ENTER key. (For example, input [0][0][1] to

read the pattern number 001.)

LINE

X:-0070A N:00021

Y:00140A

Function Code?

E. Go to the location to start change of stitch

width by using FORW and BACK key.

※ X-Y coordinate value is different according

to needle location.

39

<Function Code>

013:STI WIDT<

014:PTRN READ

015:PTRN WRITE

013:STI READ

WIDTH:020[0.1mm]

<RANGE SETTING>

X:00142A N:00029

Y:00089A

F. After pressing CODE key, if you know the

function number related to pattern programming,

input three-figure digit number 013, and if you

do not know, press ENTER key. Then after

moving to “013:STI WIDT”by using direction key

, press ENTER key.

G. Input the stitch width value to change and

press ENTER key.

H. Move to the location to complete stitch width

change by using FORW and BACK key.

ARC

X:00133A N:00052

Y:00061A

Function Code?

I. If you press EXE key, change of stitch width is

completed.

※ X-Y coordinate values are different

according to current location.

J. Confirm if change of stitch width was made

properly by using FORW and BACK key.

2-6) Pattern Partial Copy Function

Set a fixed part of pattern shape and copy to desired location.

Copy End Point

Copy Start Point

Scope to Copy

Location to Copy

40

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

014:PTRN READ

NO :001

A. Insert USB flash drive containing partial pattern

to make partial copy.

B. Press MODE key.

C. After moving to “2. Program” menu by using

direction key , press ENTER key. At this

time, the upper feed plate comes down and

moves to the original point.

D. After pressing READ key, input the pattern

number to copy partial pattern by using digit

key and read in the pattern by pressing

ENTER key. (For example, input [0][0][1] to

read the pattern number 001.)

JUMP

X:00174A N:00070

Y:00183A

Function Code?

<Function Code>

047:COPY PTRN<

048:DEL PTRN

049:REV SET

E. Go to copy start location by using FORW and

BACK key.

F. After pressing CODE key, if you know the

function number related to pattern programming,

input three-figure digit number 047, and if you

do not know the number, press ENTER ey.

Then, after moving to “047:COPY PTRN” by

using direction key , press ENTER key.

<RANGE SETTING>

X:00174A N:00088

Y:00183A

G. Go to the copy completing location of pattern

by using FORW key.

※ X-Y coordinate values are different

according to current location.

047:COPY PTRN

X:00174

Y:00183

N:000

H. If you press EXE key, it becomes the state to

move to the location to copy.

Reference) Location of the needle for partial copy should be

placed at the first start needle location that actually sews.

Therefore, if the sewing data that has line property next

jump appears, the last location of JUMP data is the first

start location of needle correction.

41

047:COPY PTRN

X:00174

Y:-0133

N:000

I. Move to the location to copy by pressing direction

key.

※ The indicated values are different according

to current location.

LINE

X:00174A N:00088

Y:00183A

Function Code?

J. If you press EXE key, copy is completed.

K. Confirm if copy was made properly by using

FORW and BACK key.

2-7) Pattern Data Inserting Function

It is the function made that pattern data inserting is available because the behind data is protected

though new pattern data is added in the middle of pattern data.

Inserting Point

Pattern Data

End Point

Pattern Data

Start Point

< After Pattern Data Insertion >

ORIGIN

X:00000A N:00000

Y:00000A

Function Code?

A. Insert USB flash drive containing the pattern to

insert.

B. Press MODE key.

C. After moving to “2. Program” menu by using

direction key , press ENTER key. At this

time, the upper feed plate comes down and

moves to the original point.

Inserting Point

Pattern Data

End Point

Pattern Data

Start Point

< Before Pattern Data Insertion >

42

014:PTRN READ

NO :001

D. After pressing READ key, input the pattern

number to insert pattern by using digit key and

read in the pattern by pressing ENTER key.

(For example, input [0][0][1] to read the

pattern number 001.)

LINE

X:-0012A N:00032

Y:00000A

Function Code?

<Function Code>

047:LINE <

048:CURVE

049:CIRCLE

E. Go to the location of data to insert by using

FORW and BACK key.

F. Select LINE of operation box (OP) of the

function code to insert. After pressing CODE

key, if you know the function number related to

pattern programming, input three-figure digit

number and if you do not know the number,

press ENTER key. Then after selecting the

function number by using direction key ,

press ENTER key.

007:LINE

WIDTH:020[01.mm]

G. Input stitch width and press ENTER key.

007:LINE

X:-0203

Y:-0207

N:001

H. Insert data of the shape to insert by using

direction key. (Same as sewing data generation by

using LINE)

LINE

X:-0209A N:00071

Y:00000A

Function Code?

I. If you input data of the shape to insert each,

press EXE key.

J. Confirm if new pattern data was inserted

properly by using FORW and BACK key.

43

3-1) Operation after reading pattern data from USB flash drive and moving the second temporary start point

It is possible to move to the sewing start point or the second origin by using direction keys in the sewing

available state. To decide the moving point, whether it is the sewing start point or the second origin, set

up 1) PNT_STR_POS or 2) SECND_ORG at the general sewing related parameter No. “001. Move to

starting point/the second origin manually.”

※ Note : It is available when READY LED turns on, and this function is used for movement to the

temporary sewing start point or the second origin. By setting up the second origin within

pattern data, the same position can be set up as the second origin.

A. Insert a USB flash drive into the terminal.

B. Press NO key, then input the pattern number

by using digit keys. (If you want to work with

“001”pattern, input [0][0][1].)

C. Press ENTER key to read a pattern and to

change to sewing available mode.

D. The upper feed plate comes to descend and

moves to the origin or sewing start point then

ascends. READY LED lights up.

E. Press SPEED key to adjust speed properly.

F.

If you step on the pedal switch on the right side,

the upper feed plate comes to descend.

G. After moving to a random second origin by

using direction keys, if you step on the pedal

switch on the left side, the machine moves to