Sunstar SPS A-1306, SPS A-1811, SPS B-1507 User Manual

SuiiHtar

USSR'S

INVERTING

MRNURL

ClflMPD^VIC^S

SPS/R(B)-S€RI€S

Electronic

Pattern

Sewing

Machine

1)

2)

FOR

PLEASE

BEFORE

KE?

FOR

BREAKS

AT

MOST

CERTAINLY

STARTING

TH»

MANUAL

REF5)ENCE

DOWN.

USE

WHEN

WITH

READ

USE

IN

SAFE

EASINESS,

THIS

MANUAL

PLACE

THE

MACHINE

1.

Thank

experience

will

functions,

more

2.

Please

sure

3.

The

product

4.

This

machine.

you

manufacture

sophisticated

read

to

properly

specifications

product

for

purchasing

accumulated

industrial

high

performance,

design

this

user's

use

performance,

Is

designed,

It

should

manual

the

of

the

without

not

be

our

product.

in

industrial

sewing

powerful

to

meet a number

machine

machine

prior

manufactured,

used

for

sewing

machines,

thoroughly

to

enjoy

are

subject

notice.

other

Based

operation,

its

and

than

on

the

machine

which

enhanced

of

user's

before

using

full

performance.

to

change,

sold

as

industrial

rich

expertise

production,

deliver

needs.

the

aimed

an

industrial

purpose.

SUNSTAR

more

durability,

machine.

to

enhance

and

diverse

and

Make

sewing

SUNSTAR

CO.,

LTD.

COMTEMTS

1.

Notice

Before

2.

Inverting

1.

Installing

2.

Adjusting

3.

Installation

4.

Adjusting

5.

Removing

3.

Inverting

1.

Installing

2.

Adjusting

3.

Adjusting

4.

Adjusting

5.

Adjusting

6.

Adjusting

7.

Removing

Clamp

Clamp

Using

Devices

the

Inverting

the

Wiper

and

Adjustment

the

Reversal

the

Inverting

Devices

the

Inverting

the

Wiper

the

Inverting

the

Middle

the

Position

the

Label

the

Inverting

of

SPS/A-1306

Clamp

Devices

Parts

of

Pneumatic

Feeding

Clamp

Devices

of

SPS/A-1811

Clamp

Devices

Parts

Presser

Stop

Position

of

the

Inverting

Guide

Clamp

Devices

Frame

Plate

Feeding

of

Series

Control

Series

Frame

Reversal

Clamp

Feeding

Devices

Parts

Crank

Frame

-

-

4

5

5

6

7

8

9

10

10

10

10

12

12

13

13

4.

SPS/B-1507

1,

Specifications

2.

Structure

2,

Installation

5.

The

Use

of

1.

2.

6.

Parts

A.

B.

C.

D.

E.

F.

G.

H.

I.

Pattem

Adding

Programming

the

Book

Inverting

Inverting

Wiper & Presser

Pneumatic

Pneumatic

Pneumatic

Inverting

Inverting

Pneumatic

Series

Inverting

of

unit

of

machine

Inverting

Codes

Clamp

Clamp

Control

Control

Control

Clamp

Clamp

Control

Functions

by

for

Reversal

Devices

Devices

Foot

Mechanism

Mechanism

Mechanism

Mechanism

Devices

Devices

Mechanism

Clamp

Using

Mechanism

Mechanism

Mechanism

Mechanism

Devices

the

Inverting

to

the

Pattems

(SPS/A-1306

(SPS/A-1811

(SPS/A-1306

(SPS/A-1306

(SPS/A-1811

(SPS/A-2516

(SPS/B-1507HJ)

(SPS/B-1507HJ)

Code

Already

Programmed

Series)

Series)

Pneumatic

Electronic

Series)

Machine

Machine

Series)

Seires)

Series)

14

14

15

16

18

18

21

23

25

26

28

30

32

34

36

38

42

Attachments

1.

Pneumatic

2.

Pneumatic

3.

Pneumatic

circuit

diagram

circuit

diagram

circuit

diagram

for

SPS/A-1306

for

SPS/A-1811

for

SPS/B-1507

series

tumover

series

tumover

series

tumover

device

device

device

42

48

52

1

Notice

1)

Before

2)

Before

3)

Using

you

range.

inputting

A

reading

A

presser

should

If

that a needle

If

ascend

be

Before

air

pressure

the

up-feed

patterns,

you

foot

careful

use

read

during

is

not

since

plate

is

put

check

patterns,

sewing

available

the

Using

by

air

pressure

and

reversal

over

the

reversal

the

pattern

incorretly a needle

or

after

finishing

for

sewing

range

control

feeding

feeding

number

sewing.

normal

inverting

around

devices,

frame

ascend

frame,

once

can

reversal

check

simultaneously

the

needle

more.

be

broken

working.

In

crank

if a needle

can

when

case

differs

be

of

from

is

with

broken

the

reversal

using

not

air

pressure

the

the

normal

attached.

Input

feeding

presser

frame

foot,

sewing

so

Inverting

1.

Installing

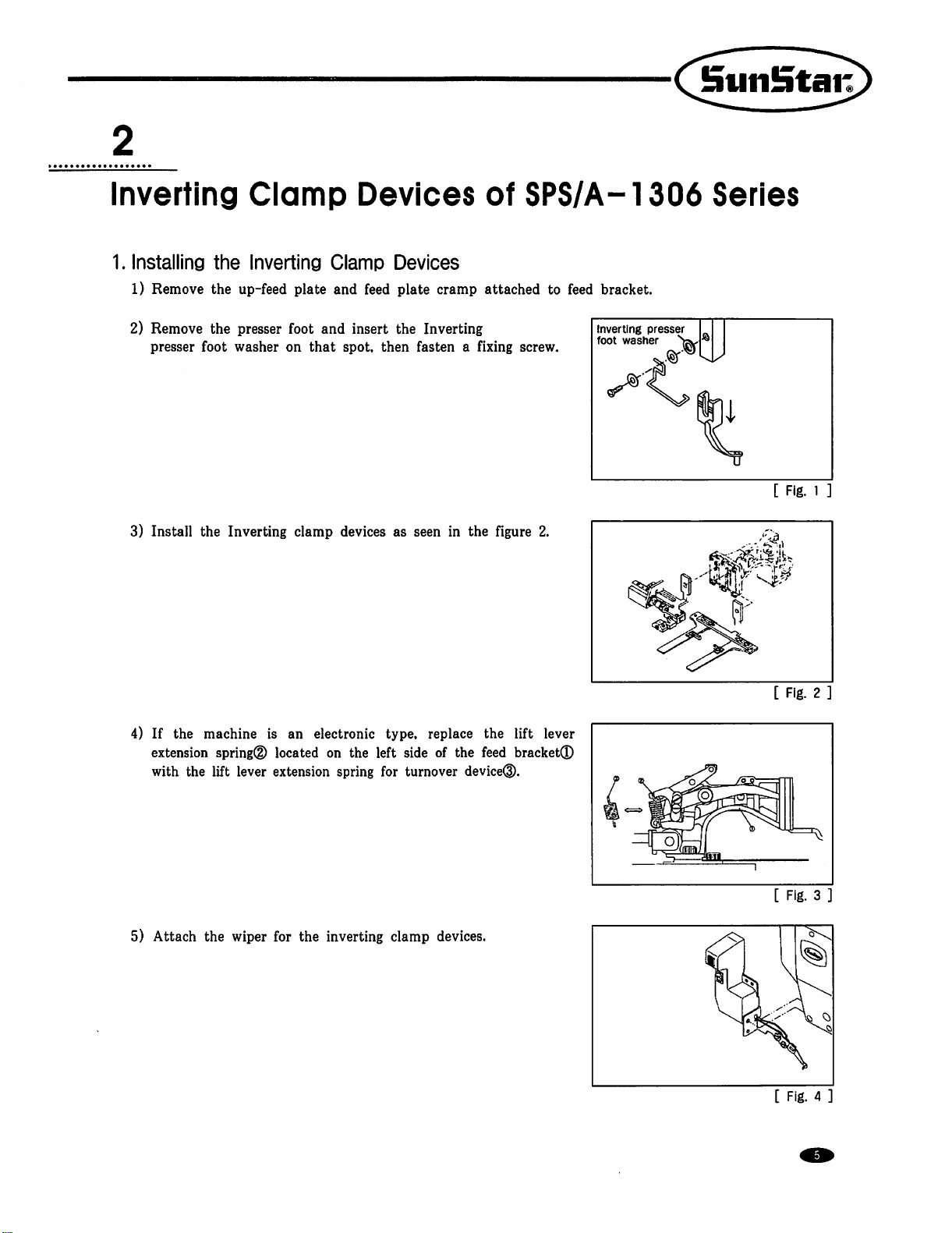

1)

Remove

Clamp

the

Inverting

the

up-feed

Clamp

plate

and

Devices

of

Devices

feed

plate

cramp

attached

SPS/A-1306

to

feed

bracket.

Series

2)

Remove

presser

3)

Install

4)

If

the

extension

with

the

the

presser

foot

washer

the

Inverting

machine

spring®

lift

lever

foot

and

on

that

clamp

is

an

electronic

located

extension

on

spring

insert

the

spot,

then

devices

the

as

type,

left

side

for

Inverting

fasten a fixing

seen

in

the

figure

replace

of

turnover

the

the

feed

device®.

screw.

2.

lift

lever

bracket®

Inverting

foot

washer

presser

[

[

Fig.

1

Fig.

2

5)

Attach

the

wiper

for

the

inverting

clamp

devices.

[

Fig. 3 .

Fig. 4 ]

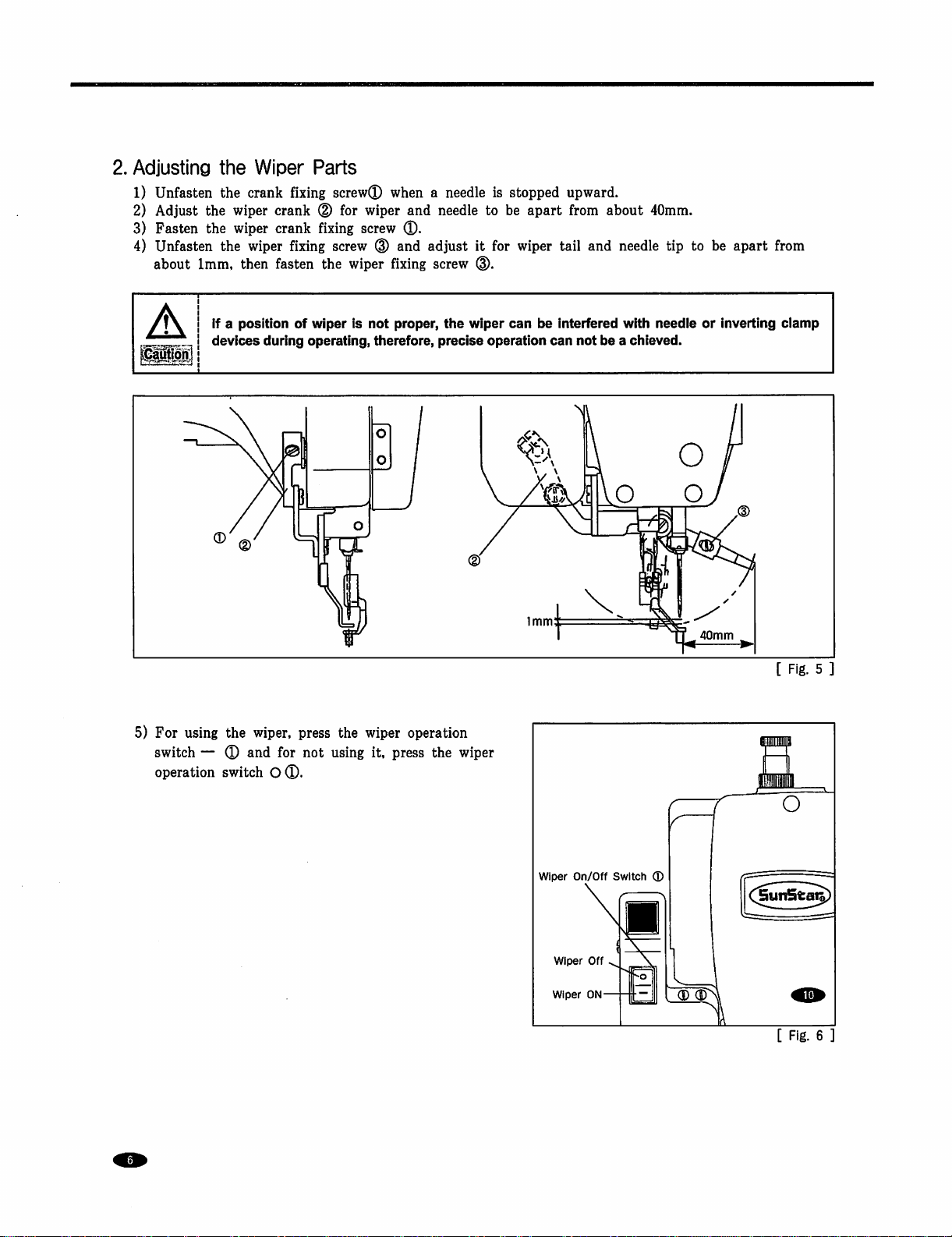

2.

Adjusting

1)

Unfasten

2)

Adjust

3)

Fasten

4)

Unfasten

about

the

the

the

the

the

1mm,

Wiper

crank

wiper

crank

wiper

crank

wiper

then

fasten

Parts

fixing

screw®

(D

for

fixing

fixing

screw

the

when a needle

wiper

and

screw

®.

(D

and

adjust

wiper fixing

screw

is

needle

to

it

for

d).

stopped

be

apart

wiper

tail

upward.

from

about

and

needle

40mm.

tip

to

be

apart

from

5)

For

using

switch — ®

operation

If a position

devices

the

and

switch

of

during

wiper,

press

for

O®.

wiper

is

not

operating,

not

therefore,

the

wiper

using

it,

proper,

the

precise

operation

press

the

wiper

operation

wiper

can

be

interfered

can

not

with

needle

be a chieved.

or

inverting

40mm

clamp

[

Fig. 5 ]

wiper

Wiper

Wiper

On/Off

Off

ON-

Switch

S

®

[

Fig.

6

3.

Installation

A

A.

For

1)

2)

3)

4)

5)

Make

safety

pneumatic

Attach

Remove

figure

Connect

Open

Pull

the

turned

pressure

6)

Pull

the

the ( + ) direction,

decreases.

and

Adjustment

sure

that

the

power

accidents.

type

the

pressure

the

plug®

below.

the

air

the

finger

pressure

in

the ( + ) direction,

decreases.

pressure

Set

adjusterQ

attached

hoses®,®

valve®

adjuster®

Set

adjuster®

the

the

air

pressure

the

pressure

Hand

to

and

handle

air

handle

e

of

Pneumatic

is

turned

off

during

to

the

rear

to

T(D,

and

the

corresponding

pass

the

air

for

the

the

pressure

pressure

for

at

upper

increases.

at

the

appropriate

Control

parts

instaiiation

side

of

the

table

insert

it

into

solenoid

to

move

in.

reverse

increases.

the

When

device

When

appropriate

feed

in

the

it

is

turned

level

Solenoid

Reverse

(0.5~0.55MPa)

Valve

Device

Parts

and

leg

using

T®.

Connect

entrances.

in

the

arrow

it

is

turned

level

of

0.5~0.55MPa

arrow

direction.

in

the

of

0.4-0.45MPa

for

adjustment

the

the

in

order

screw.

air

hose®

direction.

in

the

(-)

When

(-)

direction,

(4~4.5Kfg/crf).

Solenoid

Reverse

(0.4~0.45MPa)

to

prevent

as

in

the

When

it

is

direction,

the

(5~5.5Kgf/cril).

it

is

turned

the

pressure

Valve

Device

in

for

Handle

[

Fig. 7 ]

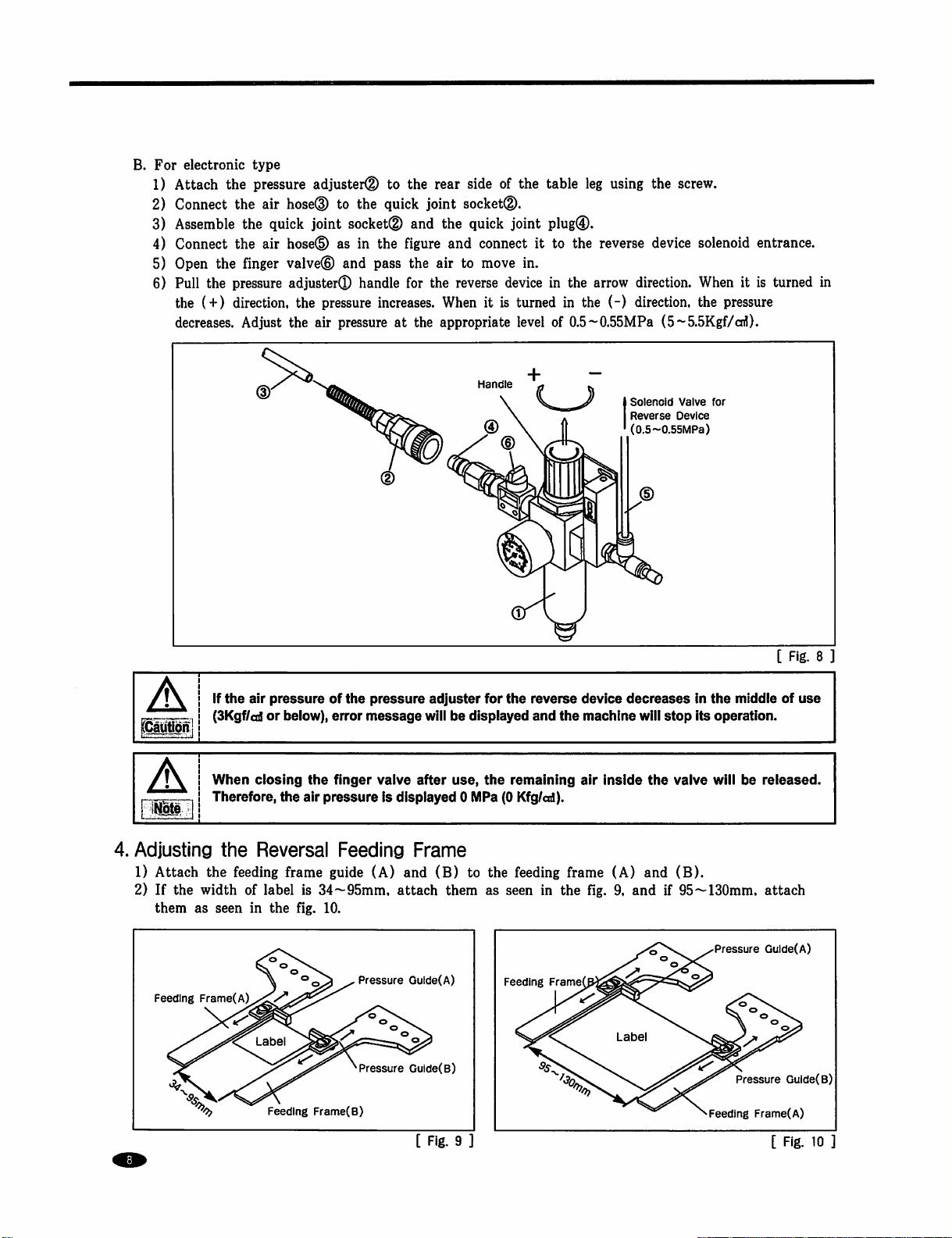

B.

For

electronic

1)

Attach

2)

Connect

3)

Assemble

4)

Connect

5)

Open

6)

Pull

the

decreases.

type

the

the

the

the

the

finger

the

pressure

(+)

direction,

Adjust

pressure

air

air

adjuster(D

hosed)

quick

joint

hosed)

valve®

adjuster®

the

pressure

the

air

to

the

to

the

quick

socket®

as

in

the

figure

and

pass

handle

for

increases.

pressure

at

rear

side

joint

socketd).

and

the

quick

and

connect

the

air

to

the

reverse

When

the

appropriate

Handle

of

joint

move

device

it

is

turned

the

table

plug®.

it

to

in.

in

level

of

leg

using

the

the

reverse

the

arrow

in

the

(-)

0.5~0.55MPa

device

direction.

direction,

(5~5.5Kgf/cnl).

Solenoid

Reverse

(0.5~0.55MPa)

screw.

solenoid

When

the

pressure

Valve

for

Device

entrance.

it

is

turned

in

aunon

A

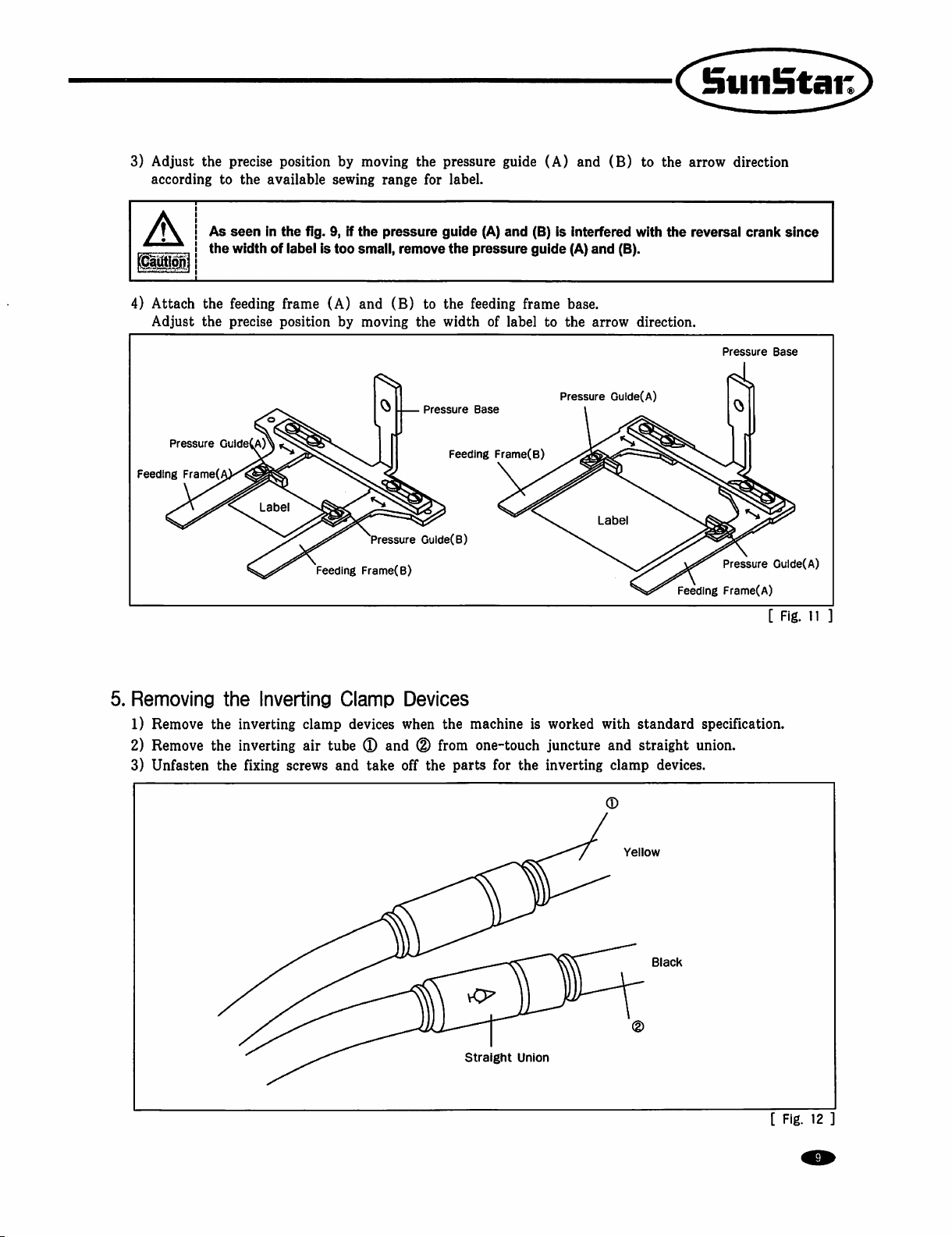

4.

Adjusting

1)

Attach

2)

If

the

them

Feeding

•KN,.

If

the

air

(3Kgf/cd

When

ciosing

Therefore,

the

the

feeding

width

of

as

seen

in

Frame(A)

^

pressure

or

the

of

below),

error

the

finger

air

pressure

Reversal

frame

guide

label

is

34~95mm,

the fig.

10.

^

Label

Feeding

Frame(B)

the

pressure

message

valve

is

Feeding

(A)

adjuster

will

after

displayed 0 MPa

Frame

and

(B)

attach

^Pressure

^Pressure

Gulde(A)

Gulde(B)

for

be

displayed

use,

the

to

the

them

as

the

reverse

and

remaining

(0

Kfg/cd).

feeding

seen

in

Feeding

Frame

device

the

machine

air

Inside

frame

(A)

the fig.

decreases

will

stop

the

and

9,

and

if

Labe

In

the

middle

Its

operation.

valve

will

be

(B).

95~130mm,

Pressure

Pressure

Feeding

[

Fig.

of

use

released.

attach

Gulde(A)

Guide(B)

Frame(A)

8

[

Fig.

9

[

Fig.

10

3)

Adjust

according

the

precise

to

position

the

available

by

moving

sewing

the

range

pressure

for

label.

guide

(A)

and

(B)

to

the

arrow

direction

f\ I As

A

4)

Attach

Adjust

Pressure

Feeding

I the

the

the

GuideCA)^

Frame(

seen

in

the

width

of

label

feeding

precise

frame

position

fig.

9,

if

is

too

(A)

by

Feeding

the

pressure

small,

remove

and

(B)

to

moving

Frame(B)

the

Pressure

Pressure

Gulde(B)

guide

(A)

and

the

pressure

the

feeding

width

of

Base

Feeding

Frame(B)

(B)

guide

frame

label

is

interfered

(A)

base.

to

the

Pressure

and

(8).

arrow

Guide(A)

Labe

with

direction.

the

reversal

Pressure

Pressure

Feeding

Frame(A)

crank

since

Base

Gulde(A)

[

Fig.

11

5.

Removing

1)

Remove

2)

Remove

3)

Unfasten

the

Inverting

the

inverting

the

inverting

the fixing

clamp

air

tube

screws

and

—

Clamp

devices

(D

and

take

Devices

when

the

(D

from

off

the

parts

machine

is

one-touch

for

the

straight

Union

worked

juncture

inverting

with

and

clamp

/

standard

straight

devices.

Yellow

Black

specification.

union.

[

Fig.

12

Inverting

1.

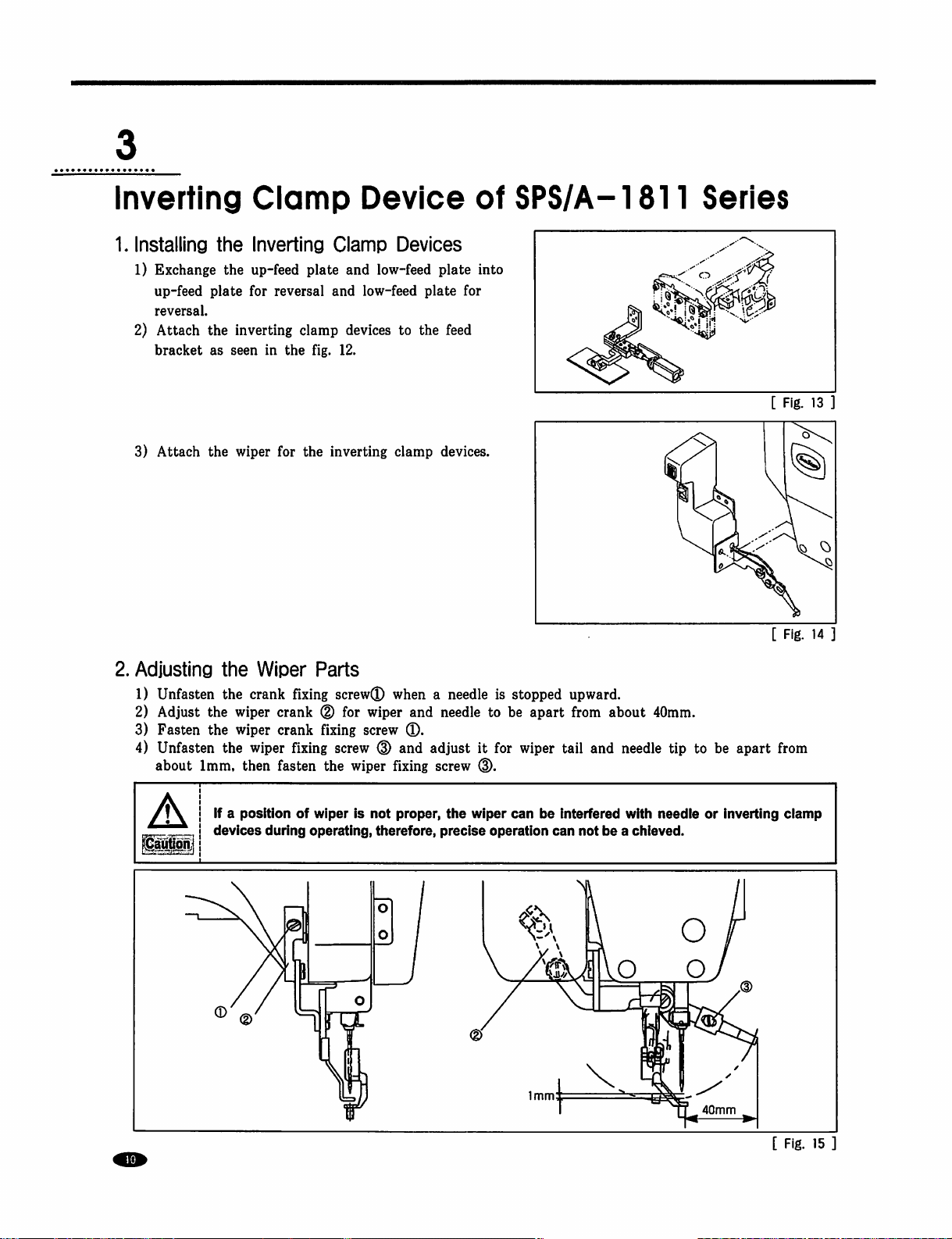

Installing

1)

Exchange

up-feed

reversal.

2)

Attach

bracket

3)

Attach

Clamp

the

Inverting

the

up-feed

plate

for

the

inverting

as

seen

the

wiper

reversal

in

for

plate

clamp

the

fig.

the

Device

Clamp

and

and

devices

12.

inverting

Devices

low-feed

low-feed

to

clamp

plate

plate

the

feed

devices.

of

into

for

SPS/A-1811

Series

[

Fig.

[

Fig.

13

14

2.

Adjusting

1)

Unfasten

2)

Adjust

3)

Fasten

4)

Unfasten

about

A

the

Wiper

the

crank fixing

the

wiper

the

wiper

the

wiper

1mm,

then

If a position

devices

during

Parts

screw®

crank ® for

crank

fixing

screw

fixing

screw

fasten

the

wiper

of

wiper

is

operating,

when a needle

wiper

and

needle

®.

(D

and

adjust

fixing

screw

not

proper,

therefore,

the wiper

precise

is

stopped

to

be

it

for

wiper

(D.

can

operation

upward.

apart

from

tail

be

interfered

can

about

and

needle

with

not

be a chieved.

40mm.

tip

needie

to

be

apart

or

inverting

40mm

from

ciamp

[

Fig.

15

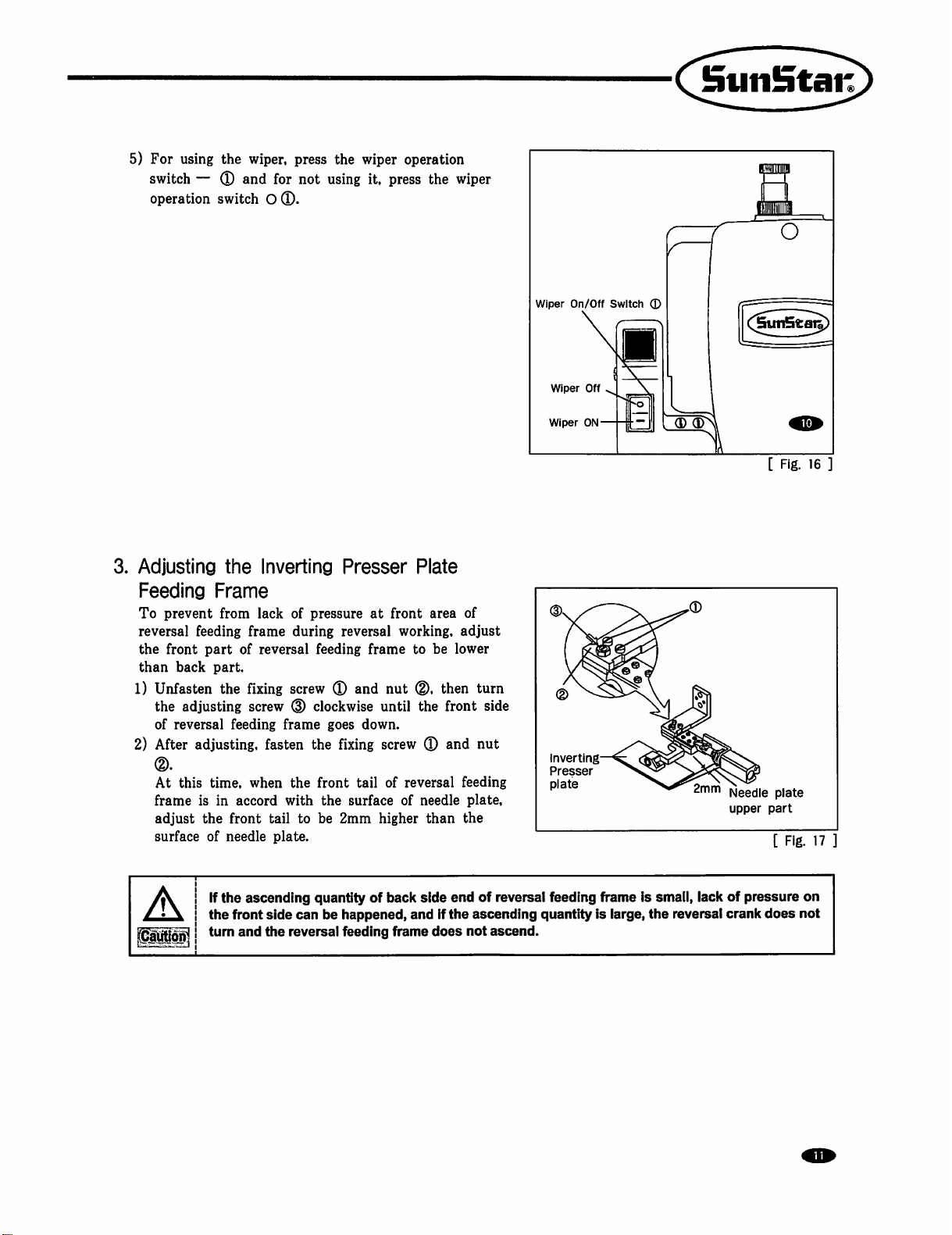

5)

For

switch — ®

operation

3.

Adjusting

Feeding

To

prevent

reversal

the

front

than

back

1)

Unfasten

the

of

reversal

2)

After

(D.

At

this

frame

adjust

surface

using

the

wiper,

and

switch O ®.

the

Frame

from

lack

feeding

adjusting

adjusting,

is

part

part.

the

feeding

time,

in

the

front

of

needle

frame

of

fixing

screw

when

accord

press

the

for

not

using

Inverting

of

during

reversal

Presser

pressure

reversal

feeding

screw ® and

(D

clockwise

frame

goes

fasten

the

with

tail

to

plate.

the

fixing

front

the

be

2mm

surface

wiper

operation

it,

press

Plate

at

front

working,

frame

down.

tail

to

nut

(D.

until

the

screw ® and

of

reversal

of

needle

higher

the

area

be

lower

then

front

than

wiper

of

adjust

turn

side

nut

feeding

plate,

the

Wiper

On/Off

Wiper

Wiper

ON-

(D

^<2^

Inverting—

Presser

plate

Off

Switch

■

c;

©

C[5un5t^)

(D

(D

[

Fig.

16

]

Needle

plate

upper

part

[

Fig.

17

If

the

aunon

ascending

the

front

turn

and

side

the

quantity

can

be

happened,

reversal

feeding

of

back

and

frame

side

end

If

the

does

of

reversal

ascending

not

ascend.

feeding

quantity

frame

is

is

smali,

large,

the

lack

of

reversal

crank

pressure

does

on

not

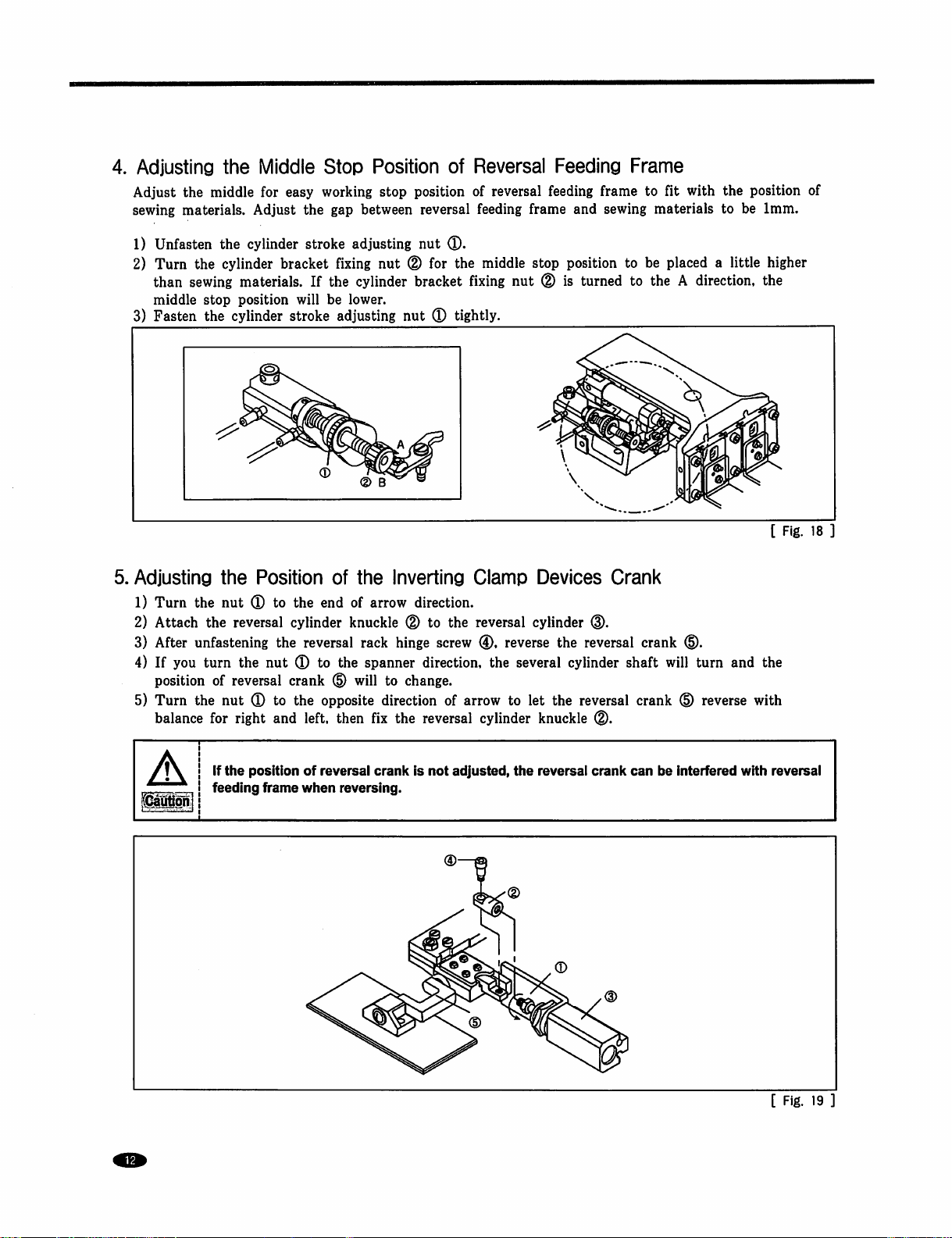

4.

Adjusting

Adjust

sewing

1)

2)

the

materials.

Unfasten

Turn

than

middle

3)

Fasten

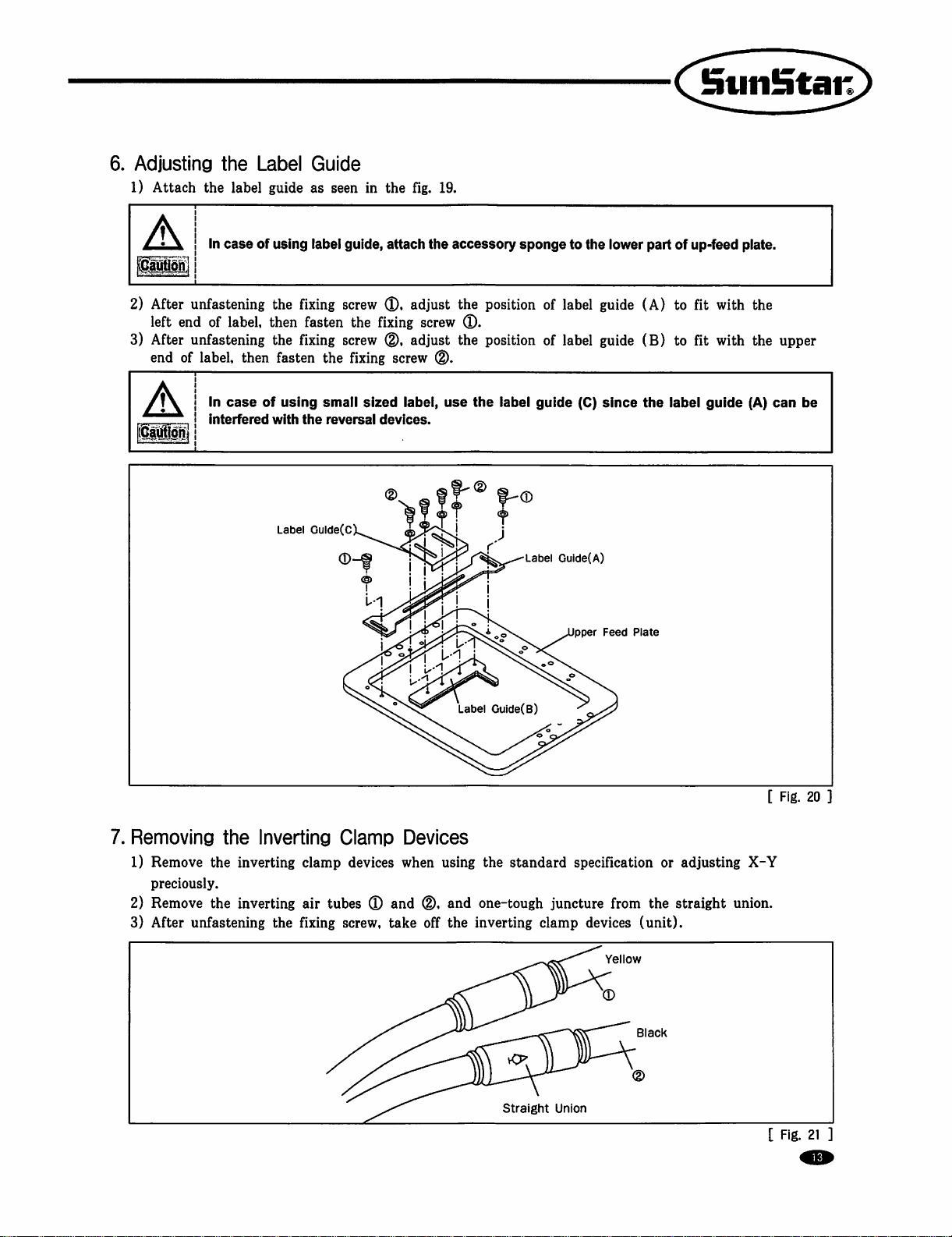

5.

Adjusting

1)

Turn

2)

Attach

3)

After

4)

If

you

position

5)

Turn

balance

the

Middle

middle

the

sewing

stop

the

the

the

unfastening

turn

of

the

for

for

Adjust

the

cylinder

cylinder

bracket

materials.

position

cylinder

the

Position

nut ® to

reversal

the

the

nut ® to

reversal

nut ® to

right

and

Stop

easy

working

the

gap

stroke

will

stroke

the

cylinder

reversal

crank

the

left,

adjusting

fixing

If

the

be

lower.

adjusting

of

end

of

knuckle

the

d)

opposite

then

Position

stop

position

between

cylinder

the

arrow

rack

spanner

will

fix

reversal

nut

nut

(D

for

bracket

nut

(D

Inverting

direction.

(D

to

hinge

direction,

to

change.

direction

the

reversal

of

Reversal

of

feeding

®.

the

middle

fixing

tightly.

Clamp

the

reversal

screw

(D,

of

arrow

cylinder

Feeding

reversal

the

feeding

frame

stop

nut ® is

Devices

cylinder

reverse

several

to

let

the

knuckle

frame

and

sewing

position

turned

Crank

the

reversal

cylinder

reversal

(D.

Frame

to

fit

with

the

materials

to

be

placed a little

to

the A direction,

crank

shaft

will

crank

d).

turn

d)

reverse

to

and

position

be

1mm.

higher

the

[

Fig.

the

with

of

18

If

the

position

feeding

frame

of

reversal

when

reversing.

crank

is

not

adjusted,

the

reversal

crank

can

be

interfered

with

reversal

[

Fig.

19

]

6.

Adjusting

1)

Attach

A

ICaliW]

2)

After

left

3)

After

end

A

the

Label

the

label

guide

In

case

of

unfastening

end

of

label,

then

unfastening

of

label,

then

In

case

of

interfered

Guide

as

using

label

the

fixing

fasten

the

fixing

fasten

using

with

the

Label

Gulde(C

seen

guide,

screw

the

screw

the

fixing

small

sized

reversal

in

the

attach

(D.

fixing

0,

screw

label,

devices.

fig.

19.

the

accessory

adjust

the

screw

0.

adjust

the

0.

use

sponge

position

position

the

label

guide

to

of

label

of

label

the

(C)

lower

guide

(A)

guide

(B)

since

the

C^^nSta^

part

of

up-feed

to

fit

to fit

iabel

plate.

with

with

guide

the

the

(A)

upper

can

be

7.

Removing

1)

Remove

preciously.

2)

Remove

3)

After

the

Inverting

the

inverting

the

inverting

unfastening

the

Clamp

clamp

air

fixing

devices

tubes ® and

screw,

Devices

when

(D,

take

off

Label

Guide(B)

using

the

and

one-tough

the

inverting

Label

Guide(A)

pper

standard

specification

juncture

clamp

Feed

Plate

from

the

devices

Ye

ow

(unit).

or

adjusting

straight

[

X-Y

union.

Fig.

20

Straight

Union

B

ack

[

Fig.

21

SPS/B-1507

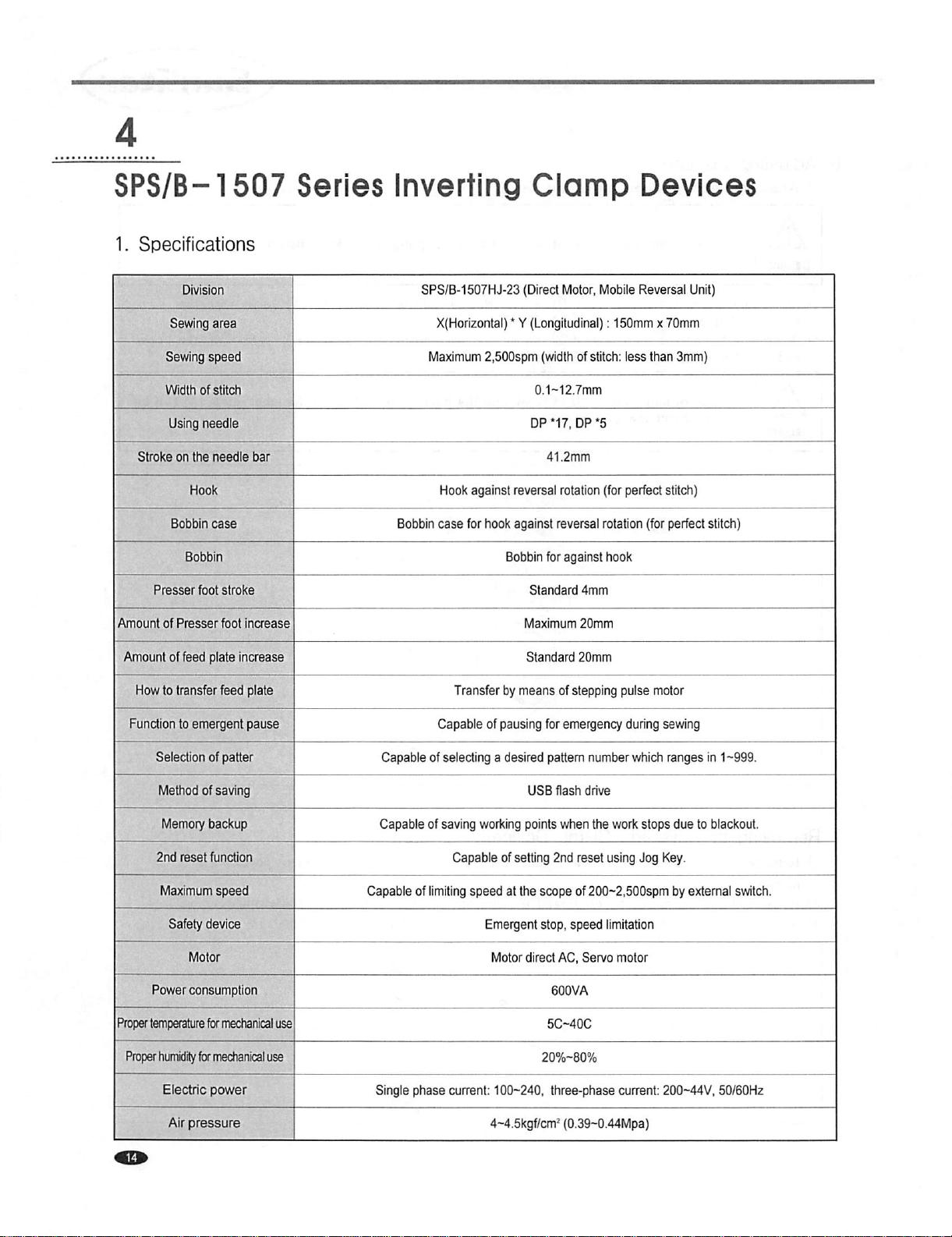

1.

Specifications

Series

Inverting

Clamp

Devices

Sewing

Stroke

Presser

Amount

of

Amount

How

to

Function

Sewing

area

speed

Width

of

stitch

Using

needle

on

the

needle

Bobbin

case

foot

Presser

of

feed

plate

transfer

to

emergent

stroke

foot

increase

increase

feed

piate

pause

bar

SPS/B-1507HJ-23

X(Horizontal) * Y

Maximum

Bobbin

Hook

case

2,500spm

against

for

hook

Transfer

Capable

of

(Direct

Motor,

(Longitudinal):

(width

of

DP

*17,

DP

reversal

rotation

against

reversal

Bobbin

for

against

Standard

Maximum

Standard

by

means

pausing

4mm

20mm

20mm

of

stepping

for

emergency

Mobile

Reversal

150mm x 70mm

stitch:

less

*5

(for

perfect

rotation

hook

puise

during

than

stitch)

(for

perfect

motor

sewing

Unit)

3mm)

stitch)

Selection

Method

Memory

2nd

Maximum

Safety

Power

Proper

temperature

Proper

humidity

Electric

of

patter

of

saving

backup

reset

function

speed

device

consumption

for

mechanical

for

mechanicai

power

use

use

Capable

Capable

Capable

of

Single

phase

of

selecting a desired

of

saving

working

Capable

limiting

of

speed

setting

at

the

Emergent

Motor

current:

100-240,

4-4.5kgf/cm^

pattern

number

USB

flash

drive

points

when

2nd

reset

scope

of

200-2,500spm

stop,

speed

direct

AC,

Servo

5C-40C

20%-80%

three-phase

(0.39-0.44Mpa)

which

the

work

stops

using

Jog

limitation

motor

current:

ranges

in 1 ~999.

due

to

blackout.

Key.

by

external

200-44V,

50/60H2

switch.

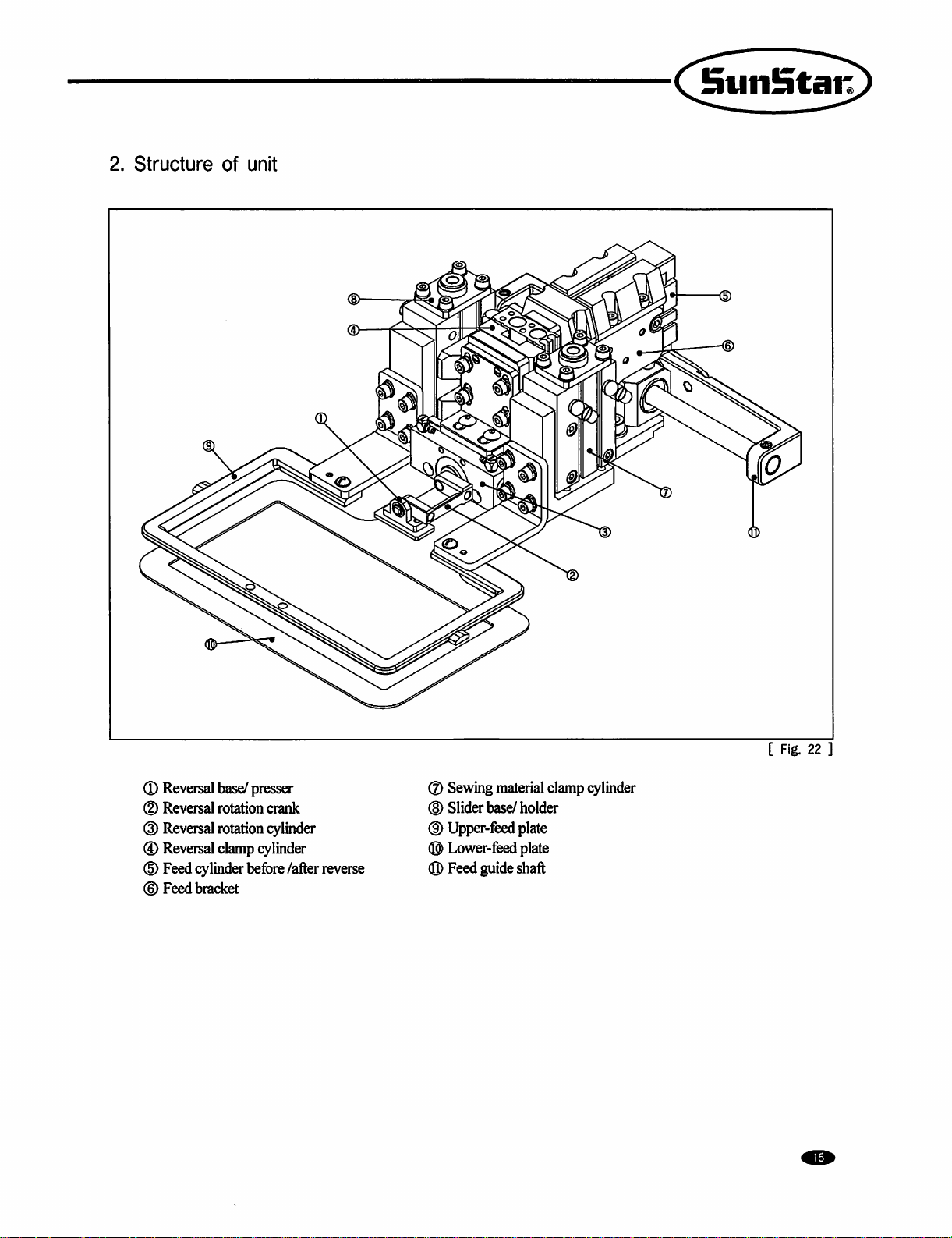

2.

Structure

of

unit

®

Reversal

(D

Reversal

(D

Reversal

®

Reversal

(D

Feed

(©

Feed

base/

presser

rotation

rotation

clamp

cylinder

bracket

before

crank

cylinder

Under

/after

reverse

®

Sewing

(H)

Slider

base/

(D

Upper-feed

®

Lower-feed

(Q)

Feed

guide

material

clamp

holder

plate

plate

shaft

cylinder

[

Fig.

22

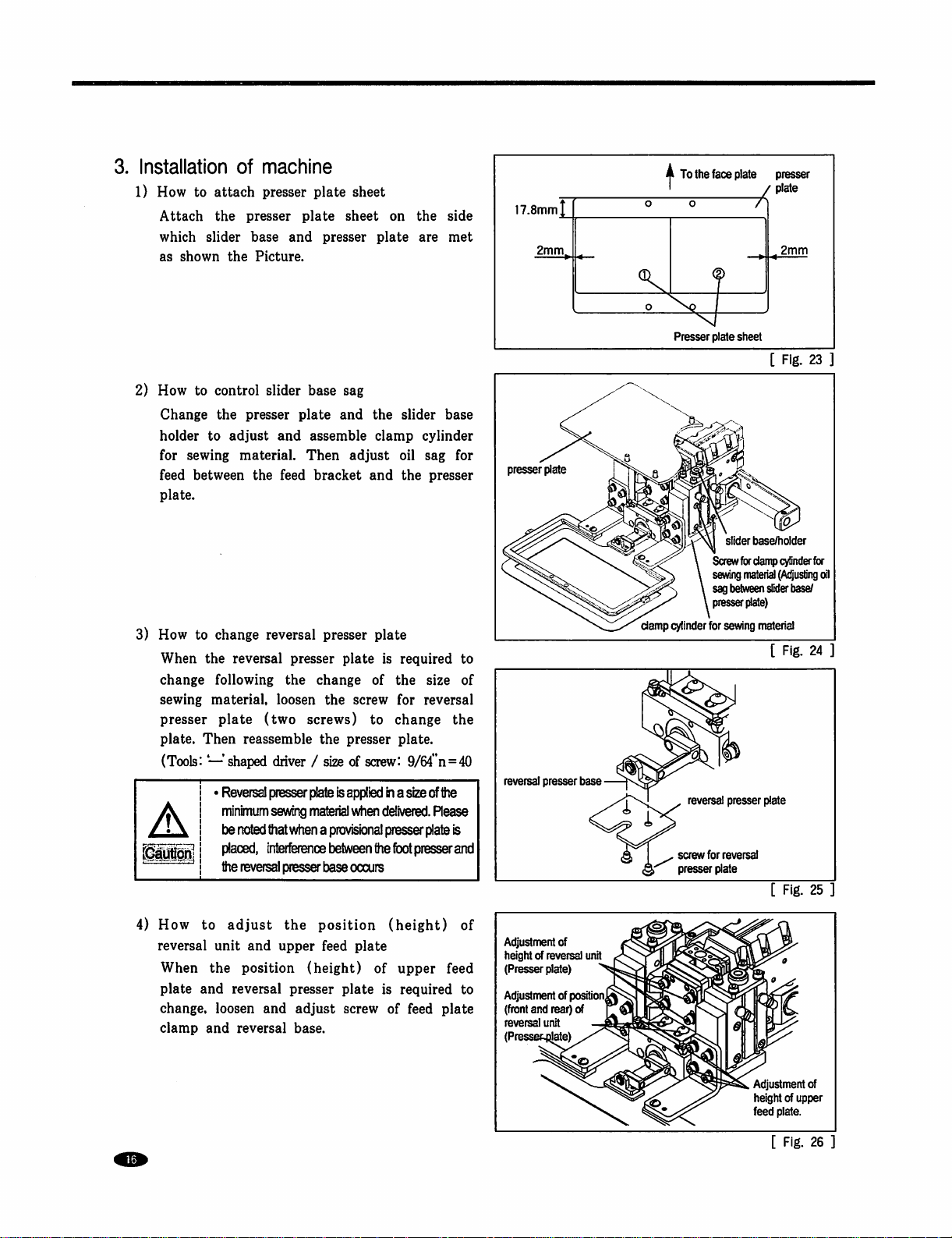

3.

Installation

1)

How

to

Attach

which

as

shown

2)

How

to

Change

holder

for

sewing

feed

between

plate.

of

attach

the

presser

slider

base

the

Picture.

control

the

presser

to

adjust

material.

the

machine

presser

slider

plate

and

plate

and

feed

plate

base

assemble

Then

bracket

sheet

sheet

presser

sag

and

the

adjust

and

on

plate

slider

clamp

oil

the

the

side

are

met

base

cylinder

sag

for

presser

17.8mm|_

2mm^

presser

plate

o

A

To

the

'

o

Presser

face

plate

plate

sheet

slider

Screw

for

presser

/ plate

2mm

[

Fig.

base/holder

damp

cylinder

23

for

3)

How

to

change

When

the

reversal

change

sewing

presser

plate.

following

material,

plate

Then

(Tools: — shaped

Reversal

minimum

be

placed,

the

4)

How

to

adjust

reversal

When

plate

change,

clamp

unit

the

and

loosen

and

reversal

reversal

presser

the

loosen

(two

screws)

reassemble

driver / size

presser

plate

sevwng

material

noted

that

when a provisional

'(nterference

reversal

presser

the

and

upper

position

reversal

presser

and

(height)

adjust

base.

presser

change

the

plate

plate

of

screw

is

to

the

presser

of

screw:

Is

appl'ed

when

delivered.

presser

between

the

base

occurs

position

feed

(height)

plate

of

plate

is

screw

required

the

size

for

reversal

change

plate.

9/64"n=40

in a size

of

Rease

plate

toot

presser

upper

required

of

feed

to

of

the

the

is

and

of

feed

to

plate

reversal

presser

base

Adjustment

height

(Presser

Adjustment

(front

reversal

(Presse

of

of

reversal

plate)

of

and

rear)

unit

position^

of

unit

damp

cylinder

for

sewing

matenal

[

Fig.

24

—

J

1 ,

screw

presser

reversal

presser

for

reversal

plate

plate

[

Fig.

25

Adjustment

height

feed

plate.

[

Fig.

of

of

upper

26

Loading...

Loading...