Page 1

SuiiHtar

USSR'S

INVERTING

MRNURL

ClflMPD^VIC^S

SPS/R(B)-S€RI€S

Electronic

Pattern

Sewing

Machine

1)

2)

FOR

PLEASE

BEFORE

KE?

FOR

BREAKS

AT

MOST

CERTAINLY

STARTING

TH»

MANUAL

REF5)ENCE

DOWN.

USE

WHEN

WITH

READ

USE

IN

SAFE

EASINESS,

THIS

MANUAL

PLACE

THE

MACHINE

Page 2

1.

Thank

experience

will

functions,

more

2.

Please

sure

3.

The

product

4.

This

machine.

you

manufacture

sophisticated

read

to

properly

specifications

product

for

purchasing

accumulated

industrial

high

performance,

design

this

user's

use

performance,

Is

designed,

It

should

manual

the

of

the

without

not

be

our

product.

in

industrial

sewing

powerful

to

meet a number

machine

machine

prior

manufactured,

used

for

sewing

machines,

thoroughly

to

enjoy

are

subject

notice.

other

Based

operation,

its

and

than

on

the

machine

which

enhanced

of

user's

before

using

full

performance.

to

change,

sold

as

industrial

rich

expertise

production,

deliver

needs.

the

aimed

an

industrial

purpose.

SUNSTAR

more

durability,

machine.

to

enhance

and

diverse

and

Make

sewing

SUNSTAR

CO.,

LTD.

Page 3

COMTEMTS

1.

Notice

Before

2.

Inverting

1.

Installing

2.

Adjusting

3.

Installation

4.

Adjusting

5.

Removing

3.

Inverting

1.

Installing

2.

Adjusting

3.

Adjusting

4.

Adjusting

5.

Adjusting

6.

Adjusting

7.

Removing

Clamp

Clamp

Using

Devices

the

Inverting

the

Wiper

and

Adjustment

the

Reversal

the

Inverting

Devices

the

Inverting

the

Wiper

the

Inverting

the

Middle

the

Position

the

Label

the

Inverting

of

SPS/A-1306

Clamp

Devices

Parts

of

Pneumatic

Feeding

Clamp

Devices

of

SPS/A-1811

Clamp

Devices

Parts

Presser

Stop

Position

of

the

Inverting

Guide

Clamp

Devices

Frame

Plate

Feeding

of

Series

Control

Series

Frame

Reversal

Clamp

Feeding

Devices

Parts

Crank

Frame

-

-

4

5

5

6

7

8

9

10

10

10

10

12

12

13

13

4.

SPS/B-1507

1,

Specifications

2.

Structure

2,

Installation

5.

The

Use

of

1.

2.

6.

Parts

A.

B.

C.

D.

E.

F.

G.

H.

I.

Pattem

Adding

Programming

the

Book

Inverting

Inverting

Wiper & Presser

Pneumatic

Pneumatic

Pneumatic

Inverting

Inverting

Pneumatic

Series

Inverting

of

unit

of

machine

Inverting

Codes

Clamp

Clamp

Control

Control

Control

Clamp

Clamp

Control

Functions

by

for

Reversal

Devices

Devices

Foot

Mechanism

Mechanism

Mechanism

Mechanism

Devices

Devices

Mechanism

Clamp

Using

Mechanism

Mechanism

Mechanism

Mechanism

Devices

the

Inverting

to

the

Pattems

(SPS/A-1306

(SPS/A-1811

(SPS/A-1306

(SPS/A-1306

(SPS/A-1811

(SPS/A-2516

(SPS/B-1507HJ)

(SPS/B-1507HJ)

Code

Already

Programmed

Series)

Series)

Pneumatic

Electronic

Series)

Machine

Machine

Series)

Seires)

Series)

14

14

15

16

18

18

21

23

25

26

28

30

32

34

36

38

42

Attachments

1.

Pneumatic

2.

Pneumatic

3.

Pneumatic

circuit

diagram

circuit

diagram

circuit

diagram

for

SPS/A-1306

for

SPS/A-1811

for

SPS/B-1507

series

tumover

series

tumover

series

tumover

device

device

device

42

48

52

Page 4

1

Notice

1)

Before

2)

Before

3)

Using

you

range.

inputting

A

reading

A

presser

should

If

that a needle

If

ascend

be

Before

air

pressure

the

up-feed

patterns,

you

foot

careful

use

read

during

is

not

since

plate

is

put

check

patterns,

sewing

available

the

Using

by

air

pressure

and

reversal

over

the

reversal

the

pattern

incorretly a needle

or

after

finishing

for

sewing

range

control

feeding

feeding

number

sewing.

normal

inverting

around

devices,

frame

ascend

frame,

once

can

reversal

check

simultaneously

the

needle

more.

be

broken

working.

In

crank

if a needle

can

when

case

differs

be

of

from

is

with

broken

the

reversal

using

not

air

pressure

the

the

normal

attached.

Input

feeding

presser

frame

foot,

sewing

so

Page 5

Inverting

1.

Installing

1)

Remove

Clamp

the

Inverting

the

up-feed

Clamp

plate

and

Devices

of

Devices

feed

plate

cramp

attached

SPS/A-1306

to

feed

bracket.

Series

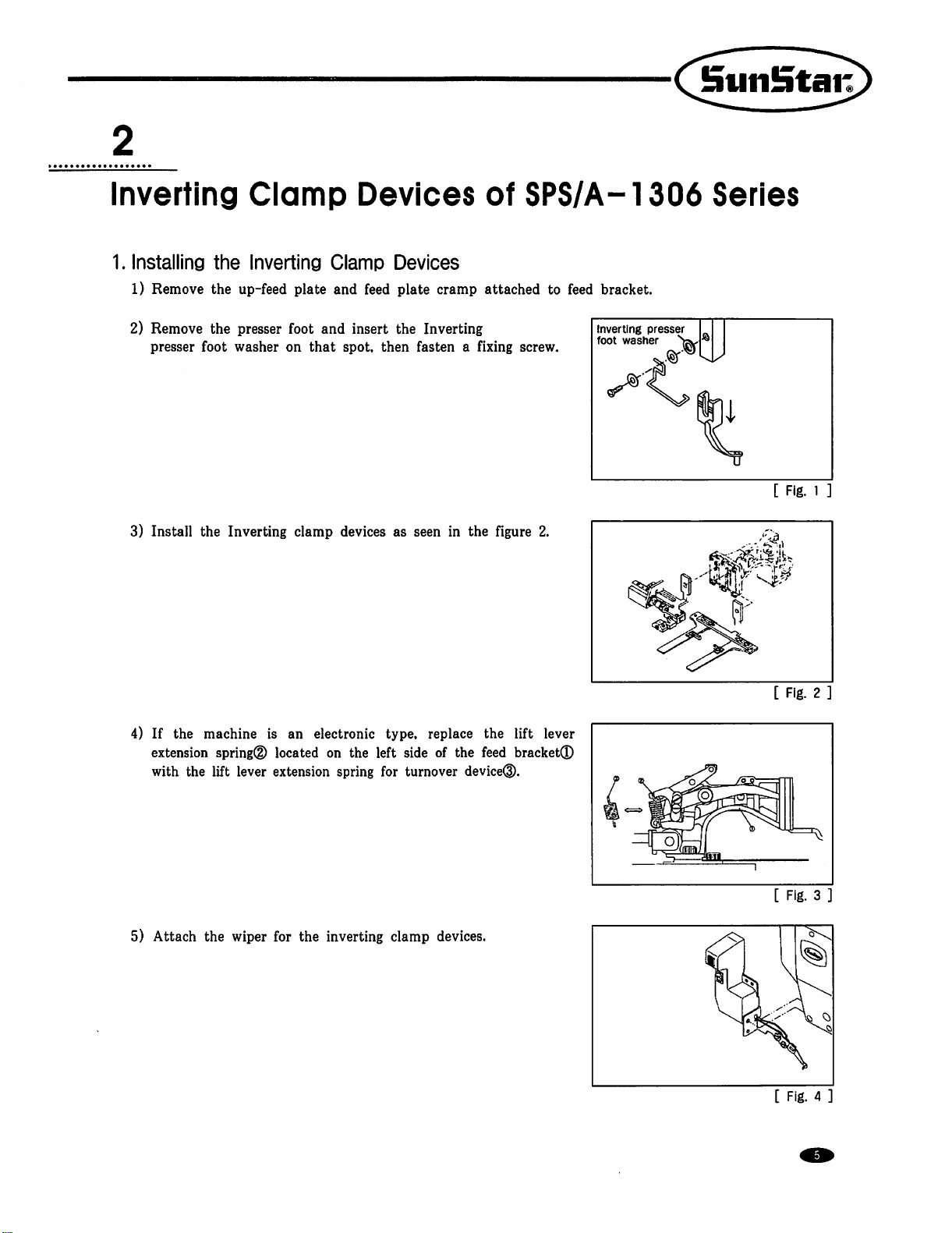

2)

Remove

presser

3)

Install

4)

If

the

extension

with

the

the

presser

foot

washer

the

Inverting

machine

spring®

lift

lever

foot

and

on

that

clamp

is

an

electronic

located

extension

on

spring

insert

the

spot,

then

devices

the

as

type,

left

side

for

Inverting

fasten a fixing

seen

in

the

figure

replace

of

turnover

the

the

feed

device®.

screw.

2.

lift

lever

bracket®

Inverting

foot

washer

presser

[

[

Fig.

1

Fig.

2

5)

Attach

the

wiper

for

the

inverting

clamp

devices.

[

Fig. 3 .

Fig. 4 ]

Page 6

2.

Adjusting

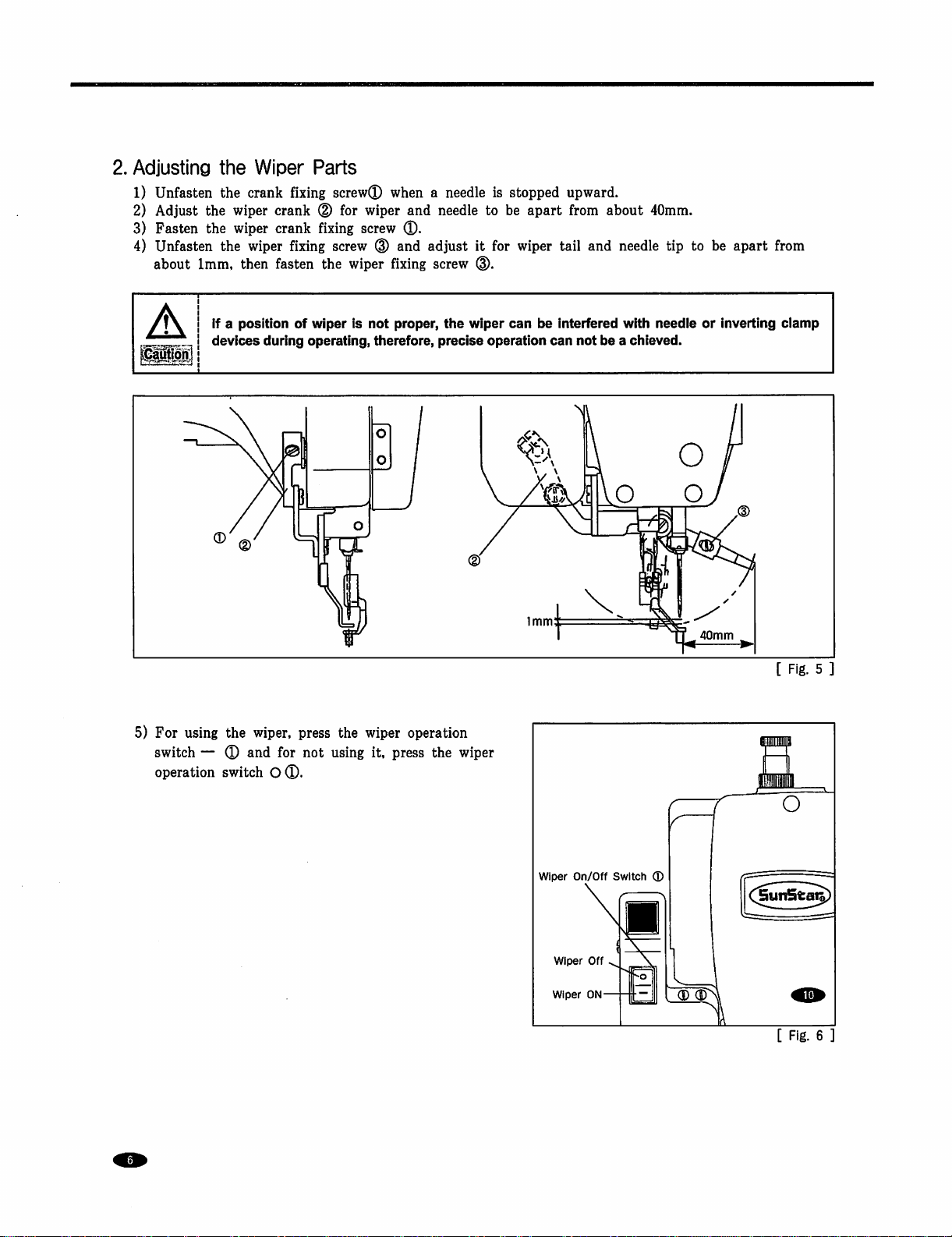

1)

Unfasten

2)

Adjust

3)

Fasten

4)

Unfasten

about

the

the

the

the

the

1mm,

Wiper

crank

wiper

crank

wiper

crank

wiper

then

fasten

Parts

fixing

screw®

(D

for

fixing

fixing

screw

the

when a needle

wiper

and

screw

®.

(D

and

adjust

wiper fixing

screw

is

needle

to

it

for

d).

stopped

be

apart

wiper

tail

upward.

from

about

and

needle

40mm.

tip

to

be

apart

from

5)

For

using

switch — ®

operation

If a position

devices

the

and

switch

of

during

wiper,

press

for

O®.

wiper

is

not

operating,

not

therefore,

the

wiper

using

it,

proper,

the

precise

operation

press

the

wiper

operation

wiper

can

be

interfered

can

not

with

needle

be a chieved.

or

inverting

40mm

clamp

[

Fig. 5 ]

wiper

Wiper

Wiper

On/Off

Off

ON-

Switch

S

®

[

Fig.

6

Page 7

3.

Installation

A

A.

For

1)

2)

3)

4)

5)

Make

safety

pneumatic

Attach

Remove

figure

Connect

Open

Pull

the

turned

pressure

6)

Pull

the

the ( + ) direction,

decreases.

and

Adjustment

sure

that

the

power

accidents.

type

the

pressure

the

plug®

below.

the

air

the

finger

pressure

in

the ( + ) direction,

decreases.

pressure

Set

adjusterQ

attached

hoses®,®

valve®

adjuster®

Set

adjuster®

the

the

air

pressure

the

pressure

Hand

to

and

handle

air

handle

e

of

Pneumatic

is

turned

off

during

to

the

rear

to

T(D,

and

the

corresponding

pass

the

air

for

the

the

pressure

pressure

for

at

upper

increases.

at

the

appropriate

Control

parts

instaiiation

side

of

the

table

insert

it

into

solenoid

to

move

in.

reverse

increases.

the

When

device

When

appropriate

feed

in

the

it

is

turned

level

Solenoid

Reverse

(0.5~0.55MPa)

Valve

Device

Parts

and

leg

using

T®.

Connect

entrances.

in

the

arrow

it

is

turned

level

of

0.5~0.55MPa

arrow

direction.

in

the

of

0.4-0.45MPa

for

adjustment

the

the

in

order

screw.

air

hose®

direction.

in

the

(-)

When

(-)

direction,

(4~4.5Kfg/crf).

Solenoid

Reverse

(0.4~0.45MPa)

to

prevent

as

in

the

When

it

is

direction,

the

(5~5.5Kgf/cril).

it

is

turned

the

pressure

Valve

Device

in

for

Handle

[

Fig. 7 ]

Page 8

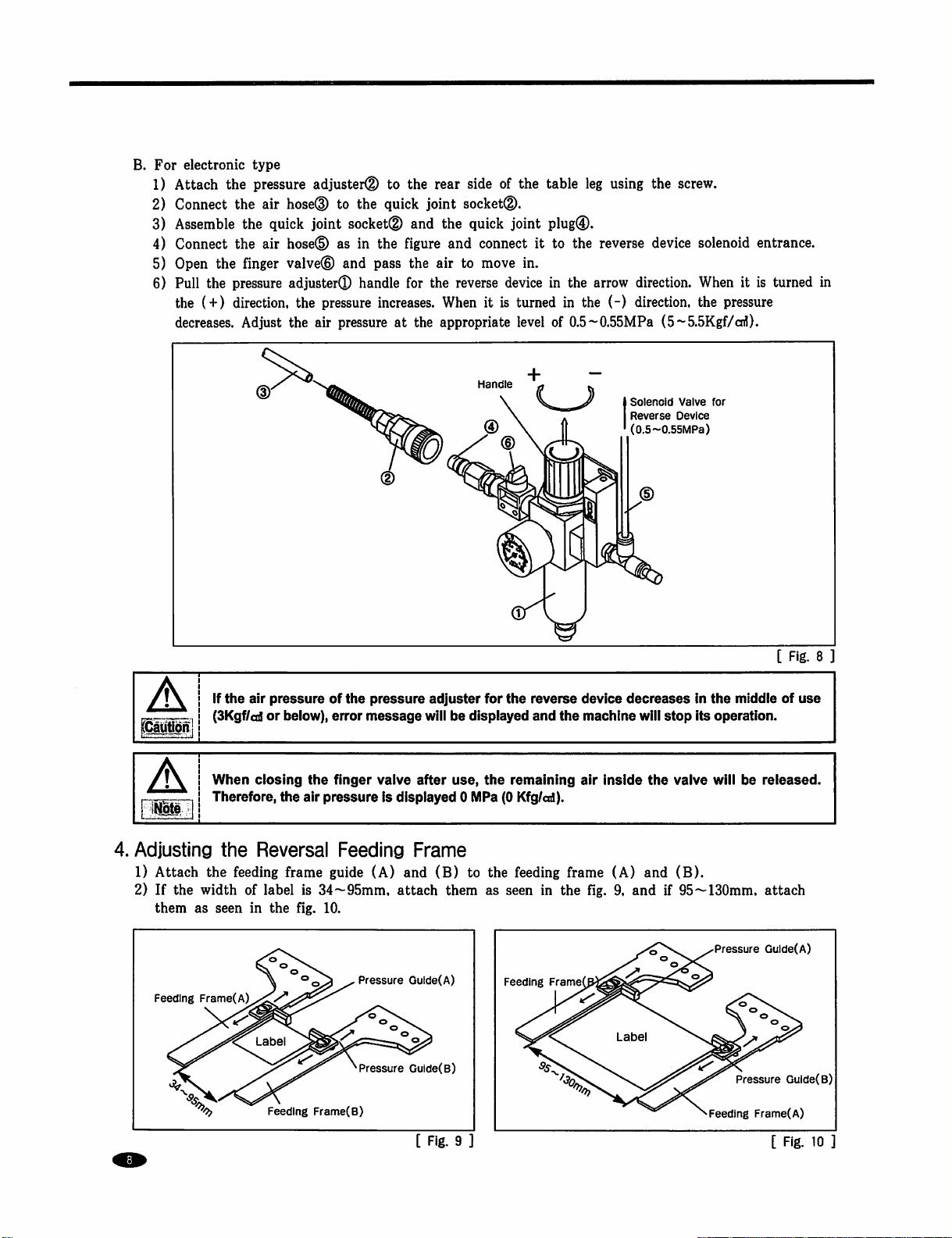

B.

For

electronic

1)

Attach

2)

Connect

3)

Assemble

4)

Connect

5)

Open

6)

Pull

the

decreases.

type

the

the

the

the

the

finger

the

pressure

(+)

direction,

Adjust

pressure

air

air

adjuster(D

hosed)

quick

joint

hosed)

valve®

adjuster®

the

pressure

the

air

to

the

to

the

quick

socket®

as

in

the

figure

and

pass

handle

for

increases.

pressure

at

rear

side

joint

socketd).

and

the

quick

and

connect

the

air

to

the

reverse

When

the

appropriate

Handle

of

joint

move

device

it

is

turned

the

table

plug®.

it

to

in.

in

level

of

leg

using

the

the

reverse

the

arrow

in

the

(-)

0.5~0.55MPa

device

direction.

direction,

(5~5.5Kgf/cnl).

Solenoid

Reverse

(0.5~0.55MPa)

screw.

solenoid

When

the

pressure

Valve

for

Device

entrance.

it

is

turned

in

aunon

A

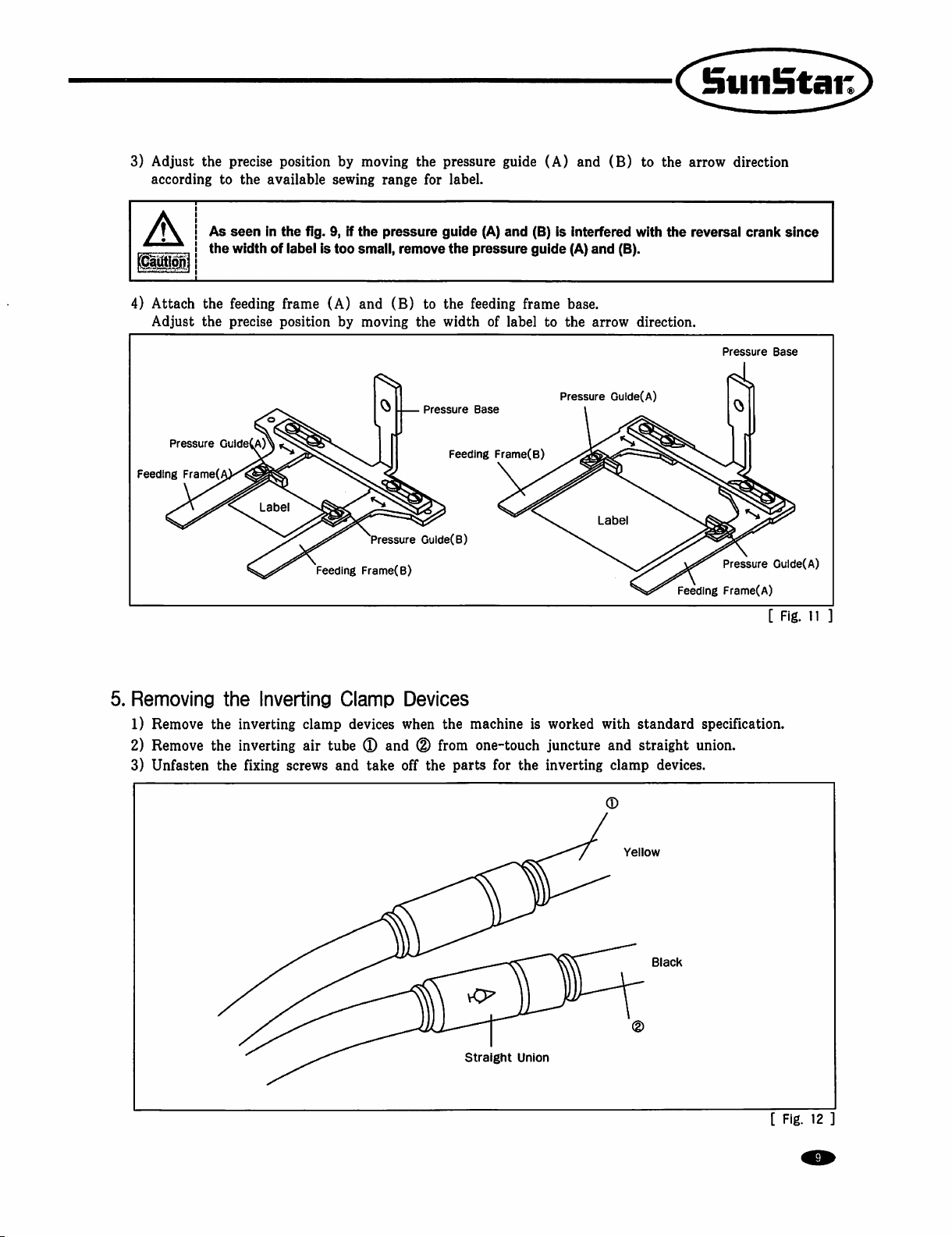

4.

Adjusting

1)

Attach

2)

If

the

them

Feeding

•KN,.

If

the

air

(3Kgf/cd

When

ciosing

Therefore,

the

the

feeding

width

of

as

seen

in

Frame(A)

^

pressure

or

the

of

below),

error

the

finger

air

pressure

Reversal

frame

guide

label

is

34~95mm,

the fig.

10.

^

Label

Feeding

Frame(B)

the

pressure

message

valve

is

Feeding

(A)

adjuster

will

after

displayed 0 MPa

Frame

and

(B)

attach

^Pressure

^Pressure

Gulde(A)

Gulde(B)

for

be

displayed

use,

the

to

the

them

as

the

reverse

and

remaining

(0

Kfg/cd).

feeding

seen

in

Feeding

Frame

device

the

machine

air

Inside

frame

(A)

the fig.

decreases

will

stop

the

and

9,

and

if

Labe

In

the

middle

Its

operation.

valve

will

be

(B).

95~130mm,

Pressure

Pressure

Feeding

[

Fig.

of

use

released.

attach

Gulde(A)

Guide(B)

Frame(A)

8

[

Fig.

9

[

Fig.

10

Page 9

3)

Adjust

according

the

precise

to

position

the

available

by

moving

sewing

the

range

pressure

for

label.

guide

(A)

and

(B)

to

the

arrow

direction

f\ I As

A

4)

Attach

Adjust

Pressure

Feeding

I the

the

the

GuideCA)^

Frame(

seen

in

the

width

of

label

feeding

precise

frame

position

fig.

9,

if

is

too

(A)

by

Feeding

the

pressure

small,

remove

and

(B)

to

moving

Frame(B)

the

Pressure

Pressure

Gulde(B)

guide

(A)

and

the

pressure

the

feeding

width

of

Base

Feeding

Frame(B)

(B)

guide

frame

label

is

interfered

(A)

base.

to

the

Pressure

and

(8).

arrow

Guide(A)

Labe

with

direction.

the

reversal

Pressure

Pressure

Feeding

Frame(A)

crank

since

Base

Gulde(A)

[

Fig.

11

5.

Removing

1)

Remove

2)

Remove

3)

Unfasten

the

Inverting

the

inverting

the

inverting

the fixing

clamp

air

tube

screws

and

—

Clamp

devices

(D

and

take

Devices

when

the

(D

from

off

the

parts

machine

is

one-touch

for

the

straight

Union

worked

juncture

inverting

with

and

clamp

/

standard

straight

devices.

Yellow

Black

specification.

union.

[

Fig.

12

Page 10

Inverting

1.

Installing

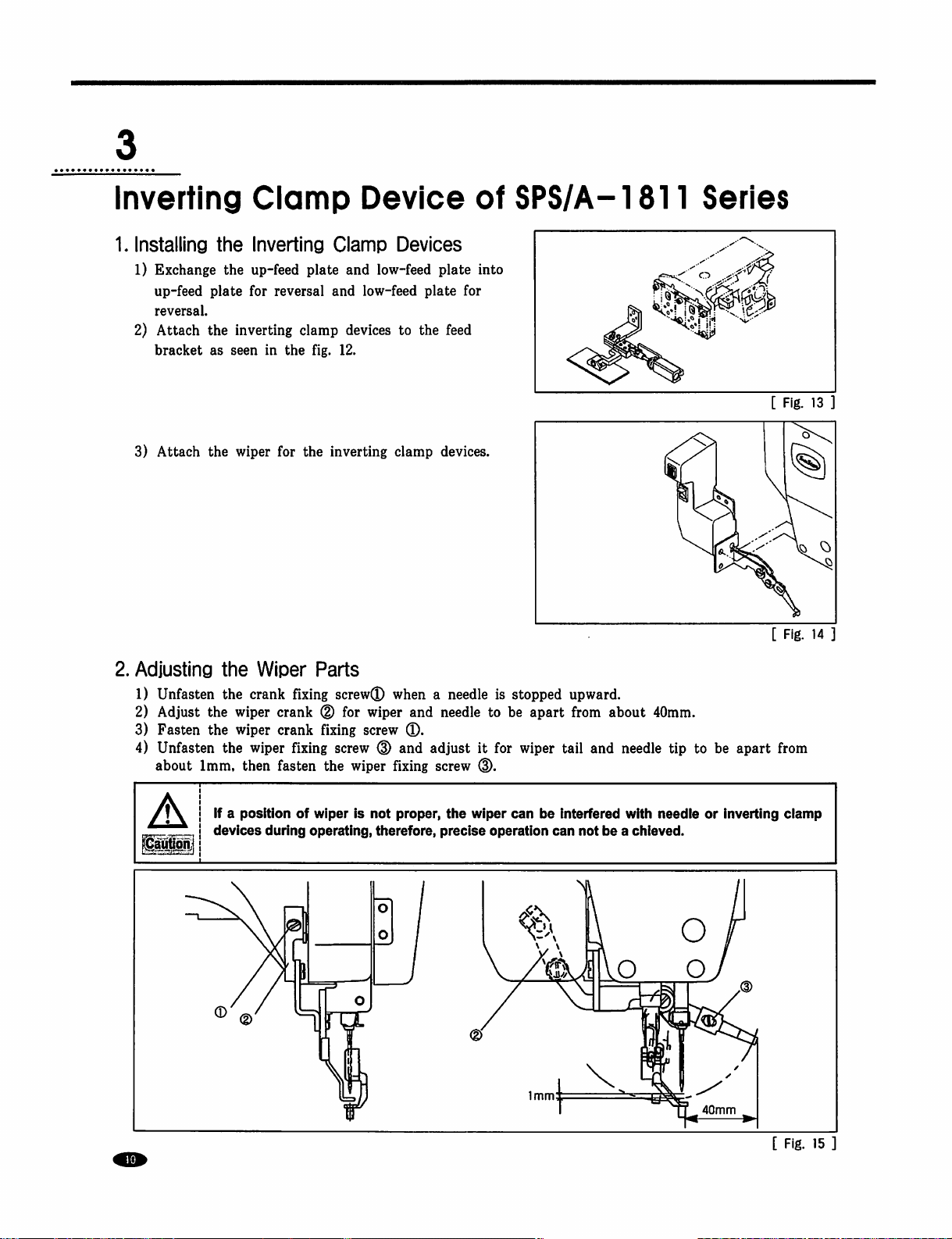

1)

Exchange

up-feed

reversal.

2)

Attach

bracket

3)

Attach

Clamp

the

Inverting

the

up-feed

plate

for

the

inverting

as

seen

the

wiper

reversal

in

for

plate

clamp

the

fig.

the

Device

Clamp

and

and

devices

12.

inverting

Devices

low-feed

low-feed

to

clamp

plate

plate

the

feed

devices.

of

into

for

SPS/A-1811

Series

[

Fig.

[

Fig.

13

14

2.

Adjusting

1)

Unfasten

2)

Adjust

3)

Fasten

4)

Unfasten

about

A

the

Wiper

the

crank fixing

the

wiper

the

wiper

the

wiper

1mm,

then

If a position

devices

during

Parts

screw®

crank ® for

crank

fixing

screw

fixing

screw

fasten

the

wiper

of

wiper

is

operating,

when a needle

wiper

and

needle

®.

(D

and

adjust

fixing

screw

not

proper,

therefore,

the wiper

precise

is

stopped

to

be

it

for

wiper

(D.

can

operation

upward.

apart

from

tail

be

interfered

can

about

and

needle

with

not

be a chieved.

40mm.

tip

needie

to

be

apart

or

inverting

40mm

from

ciamp

[

Fig.

15

Page 11

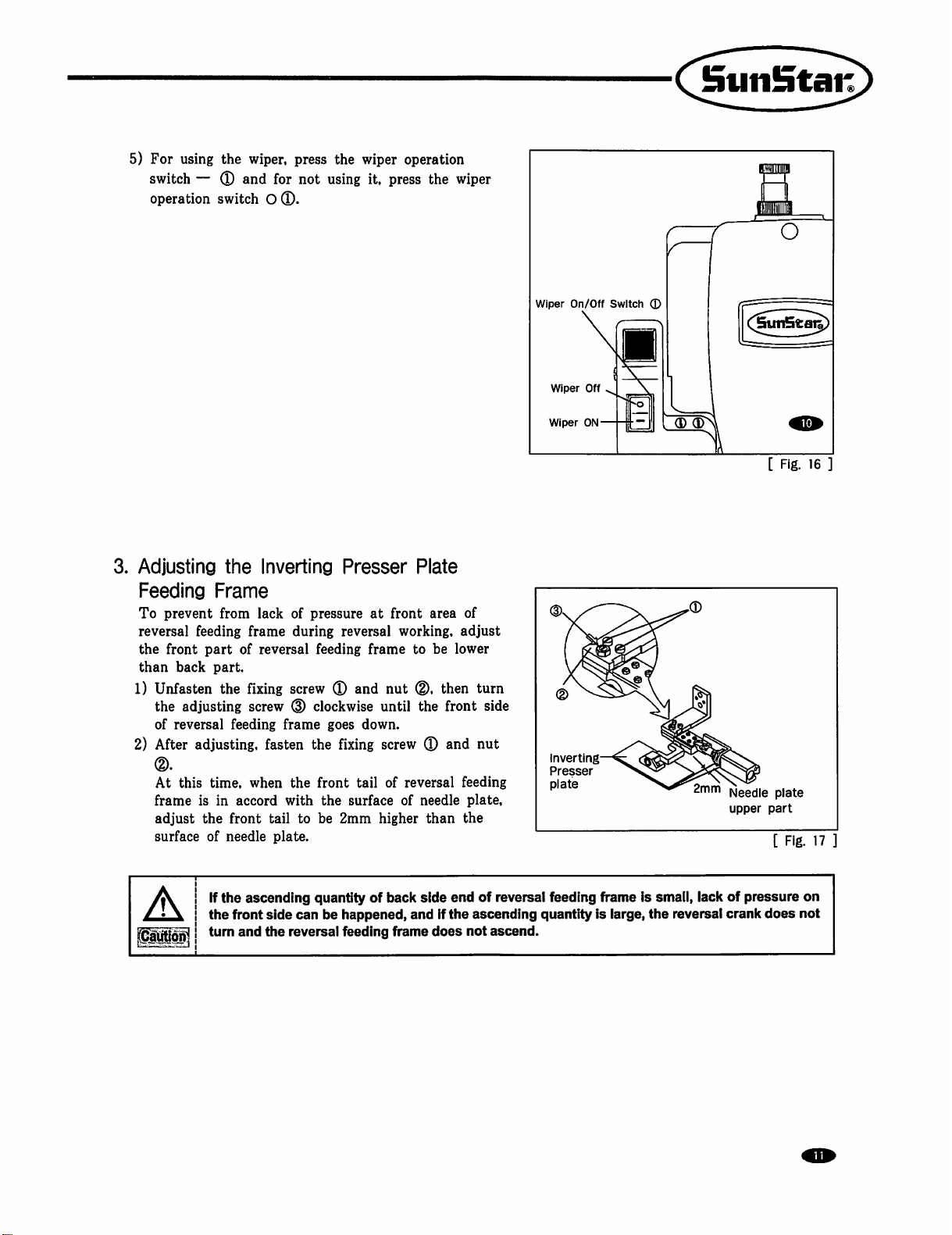

5)

For

switch — ®

operation

3.

Adjusting

Feeding

To

prevent

reversal

the

front

than

back

1)

Unfasten

the

of

reversal

2)

After

(D.

At

this

frame

adjust

surface

using

the

wiper,

and

switch O ®.

the

Frame

from

lack

feeding

adjusting

adjusting,

is

part

part.

the

feeding

time,

in

the

front

of

needle

frame

of

fixing

screw

when

accord

press

the

for

not

using

Inverting

of

during

reversal

Presser

pressure

reversal

feeding

screw ® and

(D

clockwise

frame

goes

fasten

the

with

tail

to

plate.

the

fixing

front

the

be

2mm

surface

wiper

operation

it,

press

Plate

at

front

working,

frame

down.

tail

to

nut

(D.

until

the

screw ® and

of

reversal

of

needle

higher

the

area

be

lower

then

front

than

wiper

of

adjust

turn

side

nut

feeding

plate,

the

Wiper

On/Off

Wiper

Wiper

ON-

(D

^<2^

Inverting—

Presser

plate

Off

Switch

■

c;

©

C[5un5t^)

(D

(D

[

Fig.

16

]

Needle

plate

upper

part

[

Fig.

17

If

the

aunon

ascending

the

front

turn

and

side

the

quantity

can

be

happened,

reversal

feeding

of

back

and

frame

side

end

If

the

does

of

reversal

ascending

not

ascend.

feeding

quantity

frame

is

is

smali,

large,

the

lack

of

reversal

crank

pressure

does

on

not

Page 12

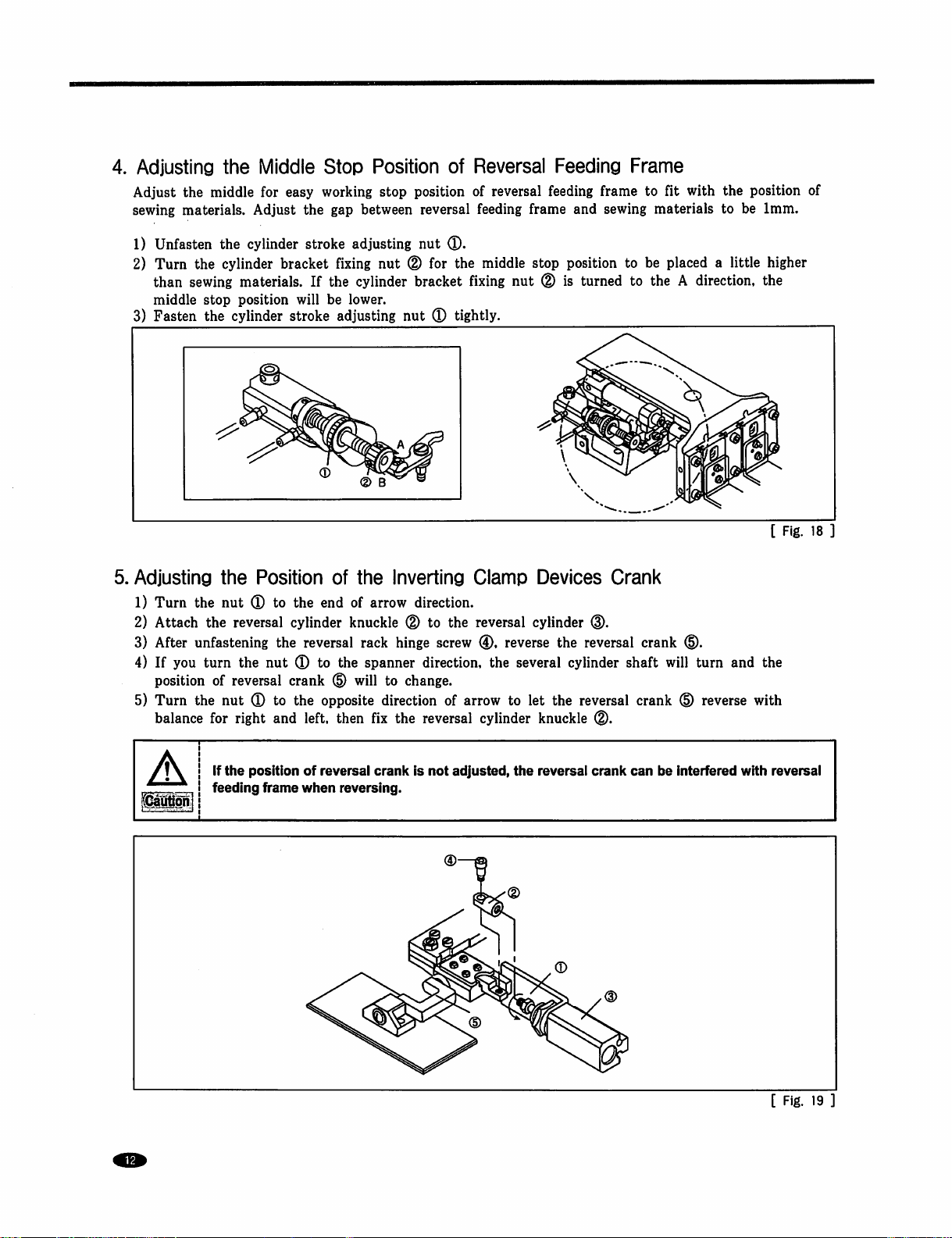

4.

Adjusting

Adjust

sewing

1)

2)

the

materials.

Unfasten

Turn

than

middle

3)

Fasten

5.

Adjusting

1)

Turn

2)

Attach

3)

After

4)

If

you

position

5)

Turn

balance

the

Middle

middle

the

sewing

stop

the

the

the

unfastening

turn

of

the

for

for

Adjust

the

cylinder

cylinder

bracket

materials.

position

cylinder

the

Position

nut ® to

reversal

the

the

nut ® to

reversal

nut ® to

right

and

Stop

easy

working

the

gap

stroke

will

stroke

the

cylinder

reversal

crank

the

left,

adjusting

fixing

If

the

be

lower.

adjusting

of

end

of

knuckle

the

d)

opposite

then

Position

stop

position

between

cylinder

the

arrow

rack

spanner

will

fix

reversal

nut

nut

(D

for

bracket

nut

(D

Inverting

direction.

(D

to

hinge

direction,

to

change.

direction

the

reversal

of

Reversal

of

feeding

®.

the

middle

fixing

tightly.

Clamp

the

reversal

screw

(D,

of

arrow

cylinder

Feeding

reversal

the

feeding

frame

stop

nut ® is

Devices

cylinder

reverse

several

to

let

the

knuckle

frame

and

sewing

position

turned

Crank

the

reversal

cylinder

reversal

(D.

Frame

to

fit

with

the

materials

to

be

placed a little

to

the A direction,

crank

shaft

will

crank

d).

turn

d)

reverse

to

and

position

be

1mm.

higher

the

[

Fig.

the

with

of

18

If

the

position

feeding

frame

of

reversal

when

reversing.

crank

is

not

adjusted,

the

reversal

crank

can

be

interfered

with

reversal

[

Fig.

19

]

Page 13

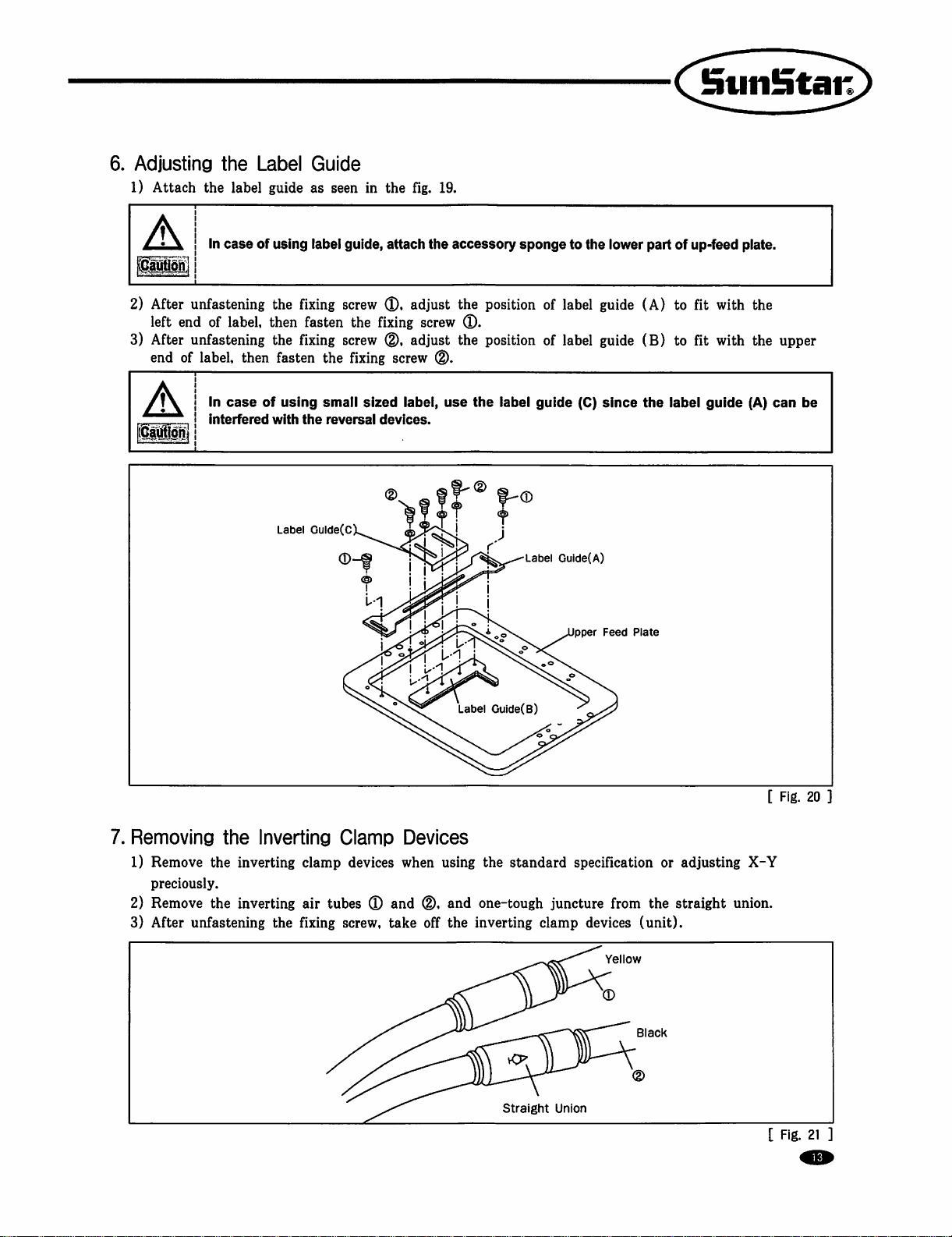

6.

Adjusting

1)

Attach

A

ICaliW]

2)

After

left

3)

After

end

A

the

Label

the

label

guide

In

case

of

unfastening

end

of

label,

then

unfastening

of

label,

then

In

case

of

interfered

Guide

as

using

label

the

fixing

fasten

the

fixing

fasten

using

with

the

Label

Gulde(C

seen

guide,

screw

the

screw

the

fixing

small

sized

reversal

in

the

attach

(D.

fixing

0,

screw

label,

devices.

fig.

19.

the

accessory

adjust

the

screw

0.

adjust

the

0.

use

sponge

position

position

the

label

guide

to

of

label

of

label

the

(C)

lower

guide

(A)

guide

(B)

since

the

C^^nSta^

part

of

up-feed

to

fit

to fit

iabel

plate.

with

with

guide

the

the

(A)

upper

can

be

7.

Removing

1)

Remove

preciously.

2)

Remove

3)

After

the

Inverting

the

inverting

the

inverting

unfastening

the

Clamp

clamp

air

fixing

devices

tubes ® and

screw,

Devices

when

(D,

take

off

Label

Guide(B)

using

the

and

one-tough

the

inverting

Label

Guide(A)

pper

standard

specification

juncture

clamp

Feed

Plate

from

the

devices

Ye

ow

(unit).

or

adjusting

straight

[

X-Y

union.

Fig.

20

Straight

Union

B

ack

[

Fig.

21

Page 14

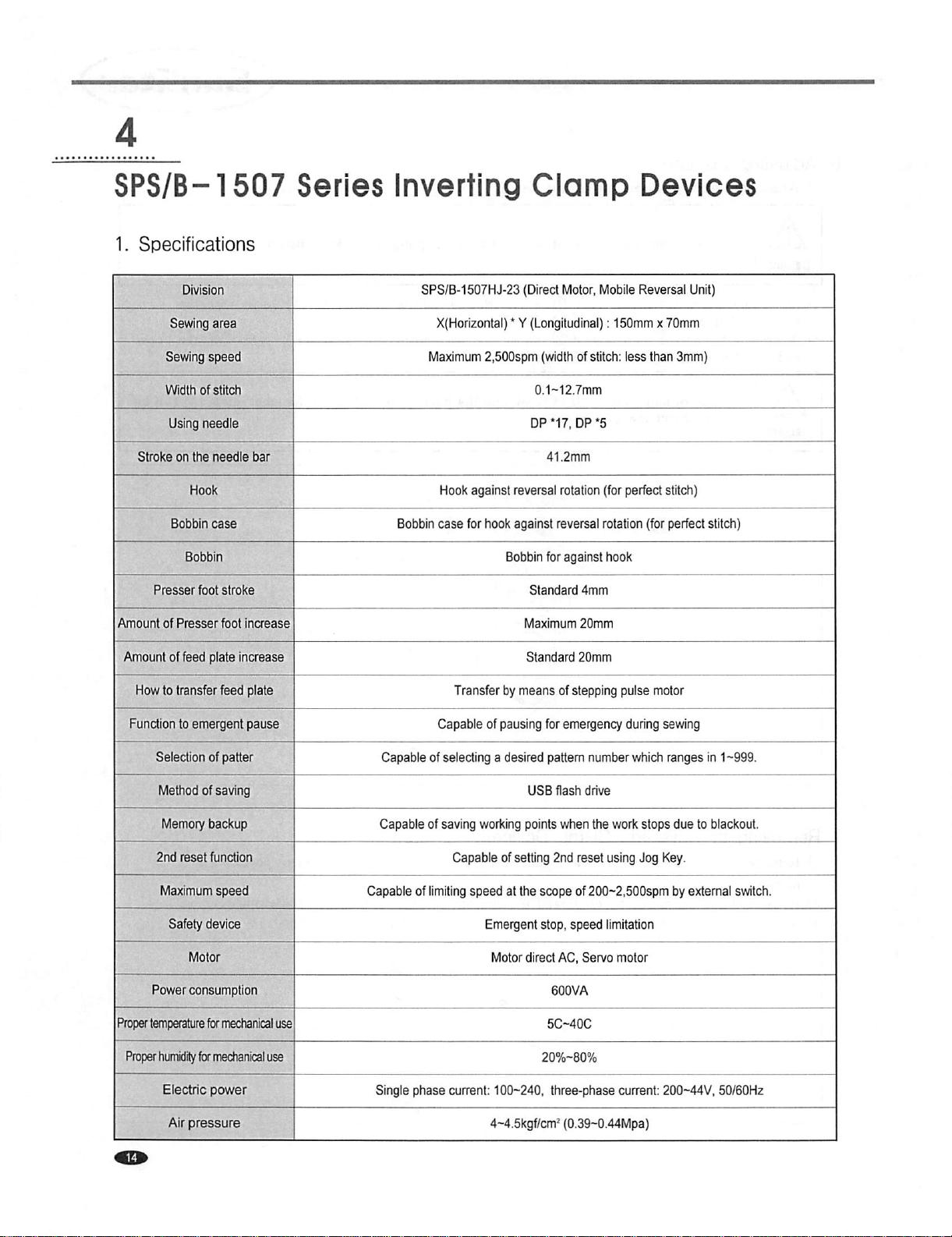

SPS/B-1507

1.

Specifications

Series

Inverting

Clamp

Devices

Sewing

Stroke

Presser

Amount

of

Amount

How

to

Function

Sewing

area

speed

Width

of

stitch

Using

needle

on

the

needle

Bobbin

case

foot

Presser

of

feed

plate

transfer

to

emergent

stroke

foot

increase

increase

feed

piate

pause

bar

SPS/B-1507HJ-23

X(Horizontal) * Y

Maximum

Bobbin

Hook

case

2,500spm

against

for

hook

Transfer

Capable

of

(Direct

Motor,

(Longitudinal):

(width

of

DP

*17,

DP

reversal

rotation

against

reversal

Bobbin

for

against

Standard

Maximum

Standard

by

means

pausing

4mm

20mm

20mm

of

stepping

for

emergency

Mobile

Reversal

150mm x 70mm

stitch:

less

*5

(for

perfect

rotation

hook

puise

during

than

stitch)

(for

perfect

motor

sewing

Unit)

3mm)

stitch)

Selection

Method

Memory

2nd

Maximum

Safety

Power

Proper

temperature

Proper

humidity

Electric

of

patter

of

saving

backup

reset

function

speed

device

consumption

for

mechanical

for

mechanicai

power

use

use

Capable

Capable

Capable

of

Single

phase

of

selecting a desired

of

saving

working

Capable

limiting

of

speed

setting

at

the

Emergent

Motor

current:

100-240,

4-4.5kgf/cm^

pattern

number

USB

flash

drive

points

when

2nd

reset

scope

of

200-2,500spm

stop,

speed

direct

AC,

Servo

5C-40C

20%-80%

three-phase

(0.39-0.44Mpa)

which

the

work

stops

using

Jog

limitation

motor

current:

ranges

in 1 ~999.

due

to

blackout.

Key.

by

external

200-44V,

50/60H2

switch.

Page 15

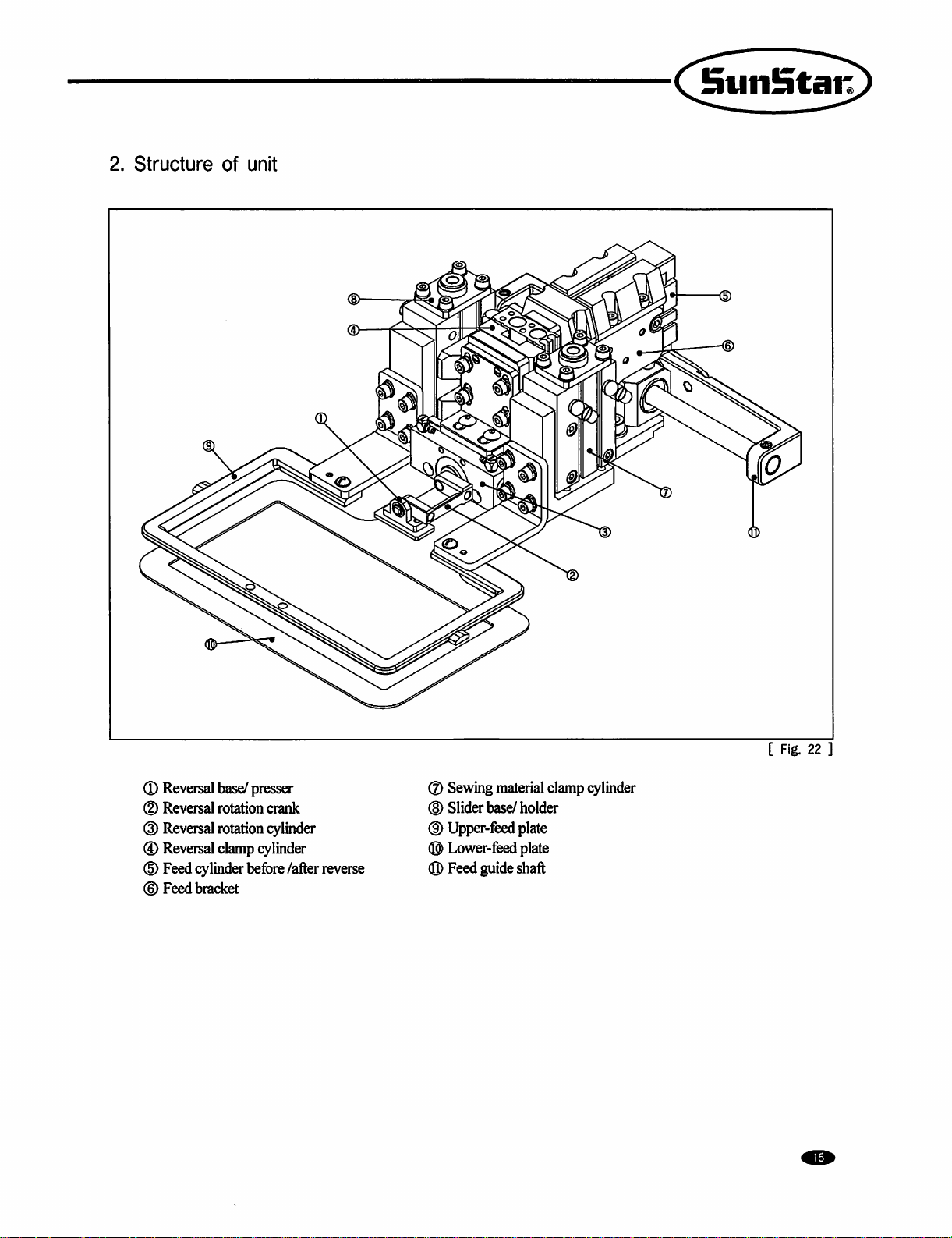

2.

Structure

of

unit

®

Reversal

(D

Reversal

(D

Reversal

®

Reversal

(D

Feed

(©

Feed

base/

presser

rotation

rotation

clamp

cylinder

bracket

before

crank

cylinder

Under

/after

reverse

®

Sewing

(H)

Slider

base/

(D

Upper-feed

®

Lower-feed

(Q)

Feed

guide

material

clamp

holder

plate

plate

shaft

cylinder

[

Fig.

22

Page 16

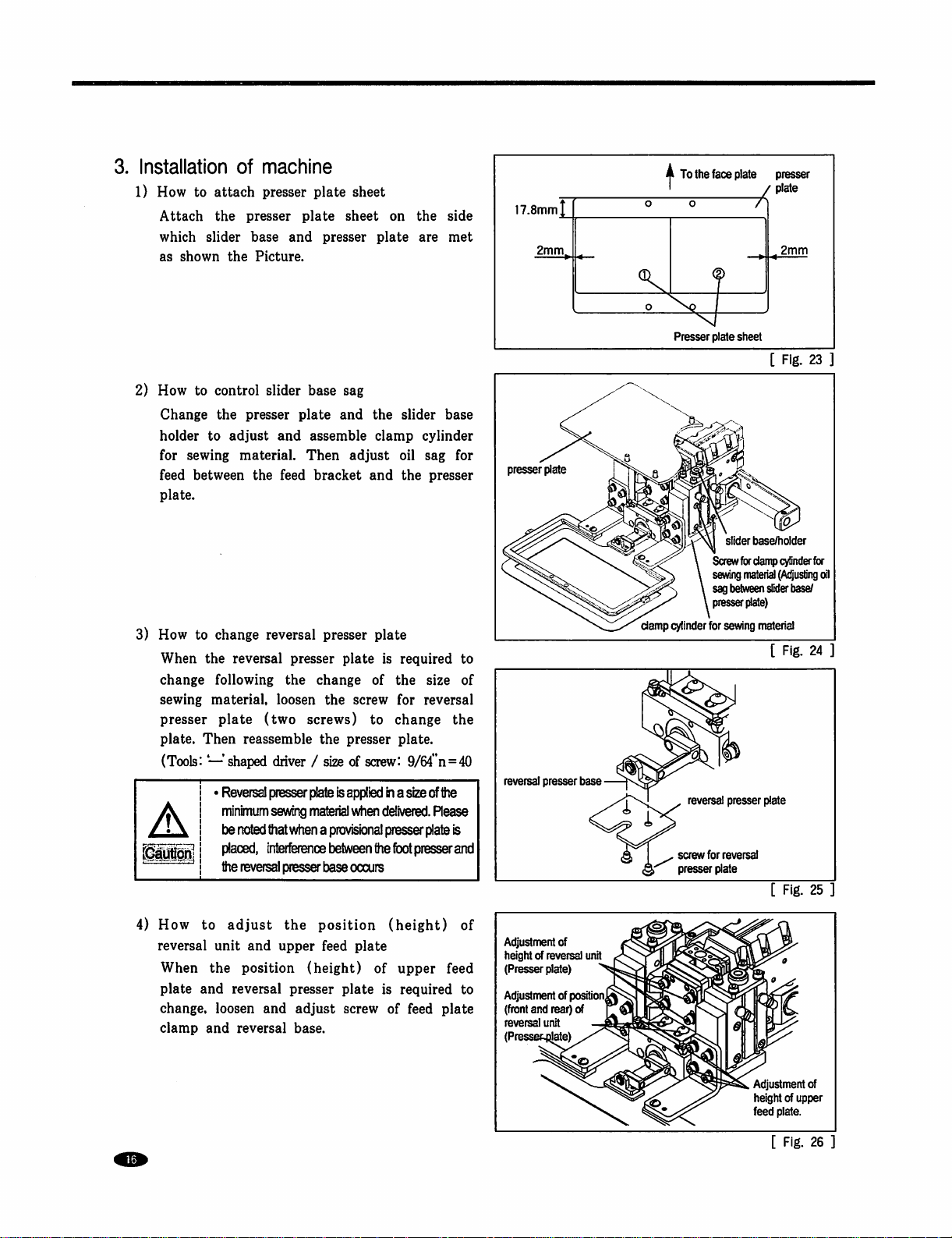

3.

Installation

1)

How

to

Attach

which

as

shown

2)

How

to

Change

holder

for

sewing

feed

between

plate.

of

attach

the

presser

slider

base

the

Picture.

control

the

presser

to

adjust

material.

the

machine

presser

slider

plate

and

plate

and

feed

plate

base

assemble

Then

bracket

sheet

sheet

presser

sag

and

the

adjust

and

on

plate

slider

clamp

oil

the

the

side

are

met

base

cylinder

sag

for

presser

17.8mm|_

2mm^

presser

plate

o

A

To

the

'

o

Presser

face

plate

plate

sheet

slider

Screw

for

presser

/ plate

2mm

[

Fig.

base/holder

damp

cylinder

23

for

3)

How

to

change

When

the

reversal

change

sewing

presser

plate.

following

material,

plate

Then

(Tools: — shaped

Reversal

minimum

be

placed,

the

4)

How

to

adjust

reversal

When

plate

change,

clamp

unit

the

and

loosen

and

reversal

reversal

presser

the

loosen

(two

screws)

reassemble

driver / size

presser

plate

sevwng

material

noted

that

when a provisional

'(nterference

reversal

presser

the

and

upper

position

reversal

presser

and

(height)

adjust

base.

presser

change

the

plate

plate

of

screw

is

to

the

presser

of

screw:

Is

appl'ed

when

delivered.

presser

between

the

base

occurs

position

feed

(height)

plate

of

plate

is

screw

required

the

size

for

reversal

change

plate.

9/64"n=40

in a size

of

Rease

plate

toot

presser

upper

required

of

feed

to

of

the

the

is

and

of

feed

to

plate

reversal

presser

base

Adjustment

height

(Presser

Adjustment

(front

reversal

(Presse

of

of

reversal

plate)

of

and

rear)

unit

position^

of

unit

damp

cylinder

for

sewing

matenal

[

Fig.

24

—

J

1 ,

screw

presser

reversal

presser

for

reversal

plate

plate

[

Fig.

25

Adjustment

height

feed

plate.

[

Fig.

of

of

upper

26

Page 17

5)

How

Turn

table

accelerate

A.

Control

B.

Control

C.

Control

6)

How

®

Check

If

(E)

Stroke

stroked)

©

How

®

®

®

to

control

clockwise

as

shown

the

speed.

the

the

operating

the

in

rotation

speed

pressure

to

use

the

stroke

out

that

not.

set

the

switch

for

is

for

to

use

Lower

the

upper

When

the

sewing

plate

and

then

middle

When

stroke

upper

speed

knob(D

the

Adjust

feed

of

parameter

parameter

three

operating

of

below

the

speed

cylinder

reversal

switch

(Function

at

strokes

reversal

feed

plate

material

fix

sewing

or

right

stroke

feed

plate

goes

of

reversal

speed

controller®

picture

in

proper

of

reversal

after/before

unit's

presser

no:

'4'

(Refer

is

provided:

press

by

pressing

is

properly

material.

to

the

down

to

unit

order

to

speed

and

cylinder

reversal

60)

related

to'

Change

Right

plate,

and

right

stroke®

positioned,

(In

order

full

once

the

bottom,

of

Solenoid

lower

the

then

fix

unit

to

general

of

Parameter

stroke®

left

stroke®

press

to

change

again.

Then

press

valve

speed.

with

is

for

is

to

fix

middle

the

it

left

stroke®

attached

Turning

the

screw®.

sewing

the

goes

is

for

General

operating

for

starting

position

stroke®

position

up

to

to

to

the

lower

counterclockwise

set

at

'4'

Sewing'of

upper

manual)

feed

plate,

sewing.

of

sewing

to

lower

of

sewing

the

start

material.

reversal

material,

initial

position.

sewing.

[

Fig.

part

of

is

to

27

middle

presser

press

CD

®

(D

©

(D

(D

©

[

Fig.

28

Page 18

The

They

attention

interfered

inverting

other

1.

Use

are

used

to

with

devices),

is

to

program

Pattern

(D

Insert a USB

d)

Press a BBIB

d)

By

using

menu,

upper

of

Inverting

when

inverting

that

inverting

needle

one

bar.

is

to

newly.

Program

input

clamp

There

Programming

flash

drive

Keys

then

press

feed

plate

descends

clamp

are

call

the

Starting

the

inverting

by

into

.

and

devices

is

interfered

two

ways

already

Ponit

AV.

\

Jump

Code

Using

the

USB

move

to

key.

At

move

to

Functions

are

available.

with

needle

for

inputting

programmed

Sewing

.

\

as

the

Starting

PI

P6

Sewing

'1'

Inverting

terminal,

"2.

Program"

this

time,

the

origin.

During

bar.

inverting

pattern

Point

Finishing

Code

the

programming

or

inverting

codes

to

add

<<

B•

3.

4.

the

cylinder

(the

the

inverting

Main

Program

Bobbin

Machine

patterns,

drive

orders

to

codes

pay

part

drive

and

Menu>>

Wind

Test

is

the

®

After

pressing

pressing

If

you

date,

then

operated

|^BB

j^BH^eys.

press

BbbI

key.

upper

feed

data.

key.

move

Then

the

plate

to

the A point

press

machine

moves

according

key.

operates

pattern

the

by

ORIGIN

X:OOOOOA

Y:

0 0 0 0 OA

Function

004:JUMP

X : ? ? ? ? ?

Y . 9 9 9 9 9

N:

OOlB

JUMP

X:?????A

Y:?????A

Function

NiOOOOO

Code?B

NONE

N:000??

Code?B

Page 19

<3)

After

pressing

pressing

ktMBftW

09

key.

set

up

[0][0][l].

the

2nd

origin

by

<Function

Stiiiiatai'

Code>

(Z)

Press

After

point

010

d)

If

data,

operated

pressing

PI.

by

you

press

then

upper

data.

^^^0

pressing

^^0

key.

feed

key,

BHH

plate

move

the

machine

moves

to

the

sewing

Then

press

operates

according

start

09

pattern

the

CODE

SEC

X:?????A

Y:

?????A

No

-ORG

Function

004:JUMP

X : ? ? ? ? ?

Y : ? ? ? ? ?

N : 0 0 1 ■

JUMP

X:?????A

:

ilO

N:000??

Code?|

N:000??

1

NO]

NONE

®

After

using

(For

width,

<0)

Move

then

coordinates

®

If

you

data,

operated

pressing

^9

example,

to

press

then

|H0

keys,

input

[0][3][0].)

the

P2.

of

press

vaama

upper

data.

if

each

key.

then

press

you

want

PS.

and

key

corner.

key.

feed

plate

input

the

^O^Bl^O

to

set

P4

by

each

time

the

machine

moves

stitch

key.

up

3mm

using

to

input

operates

according

width

by

as

stitch

keys,

the

pattern

the

007;LINE

WIDTH:l3

007;LINE

X : ? ? ? ? ?

Y : ?

? ? ? ?

N;

003

LINE

X:?????A

0

[0.Imm]

N:00???

NONE

Page 20

After

pressing

pressing

HIB

keys

[0][4]and

input

the

[9].

inverting

code

by

<Function

Code>

(g)

Press

pressing

(©

After

Program

S

confirming,

key.

P5

j

key.

key.

and

1.

input

P6

Operate

by

the

the

inverting

using

inverting

code

cylinder

by

by

pressing

CODE

049:REV

PCS

REV

X:?????A

Y:?????A

No

:

SET

Function

007:LINE

X : ?

? ? ?

Y • 9 9

A ♦ • • • • •

N:

0021

:

SET

CO/1]

NONE

N:00???

Code?!

?

9

©

Press

"000 I TRIM"

screen

using

If

data,

operated

After

you

on

pressing

press

then

key

the

keys.

upper

data.

to

input

appears

right

appears

key.

Then,

key.

feed

trimming

on

the

again.

move

press

the

machine

plate

moves

code.

screen,

then

to

the B point

operates

according

key.

the

pattern

the

by

TRIM

X:?????A

Y:?????A

Function

004:JUMP

X : ? ? ? ? ?

Y : ? ? ? ? ?

N:OOll

JUMP

X:?????A

NONE

N:00???

Code?|

NONE

N:00???

Page 21

BuiiHtai'

2.

Adding

1)

Perform

After

want

a

(For

input

For

key.

ascends.

test

pressing

to

save

USB

flash

example,

[5][5]and

completing

The

To

the

Reading

codes.

0

(D

d)

the

Insert a USB

added

Press

After

key.

upper

sewing.

KBytlii«a

by

using

key.

Save

drive

as

to

save

[l].)

pattern

upper

feed

back

to

Codes

pattern

flash

the

inverting

key.

moving

feed

to

praco

plate

key,

input

the

keys,

and

the

generated

the

relevant

the

pattern

data

plate

moves

the

initial

for

Reversal

that

does

drive

code.

"2^Progr^"

descends

number.

number

generation,

to

the

screen,

not

have

that

has a pattern

menu

L-ay

At

and

moves

number

press

pattern

as

press

origin,

press

to

the

data

inverting

by

using

this

time,

to

the

you

into

551,

_____

then

key.

Patterns

to

be

the

origin.

015

NO:

<<Main

E•Program

3.Bobbin

4.Machine

Already

Programmed

<<<Main

B.P

3.Bobbin

4.Machine

ORIGIN

iPTRN

151

rogram

WRITE

Menu>>

Wind

Test

Menu>>

Wind

Test

(D

After

pressing

number

change

to

(For

2)

Inserting

(D

Add

keys,

the

After

by

by

read

example,

[5][0][0].)

the

the

and

inverting

pressing

pressing

key,

that

contains a sewing

using

the

pattern.

to

inverting

inverting

move

code.

B

read

code

code

to

the

keys.

keys,

key.

input

speed

then

pattern

P4

[0][4]

by

number

using

that

input

and

the

pattern

you

press

MWIfcililri

500.

you

want

the

inverting

[9].

want

input

to

add

to

key

code

X:GOOOGA

Y:GGGGOA

Function

G14:PTRN

LINE

X:?????A

Y:?????A

Function

<Function

N:OOGOO

Code?E

READ

N:000??

Code?|

Code>

CODE

No

Page 22

Q)

Press

Operate

™waa

the

key.

inverting

cylinder

by

pressing

049:REV

3)

(©

Test

®

After

confirming,

inverting

code.

press

sewing

Press

upper

and

ascends

adjusting

once,

the

press

^SI^^B^^^Bswitch

sewing

sewing,

point

then

By

repressing

After

the

the

origin,

feed

proper

key,

upper

comes

the

upper

key.

plate

moves

to

turn

speed

if

you

feed

to

start.

up-feed

ascends.

BDD

feed

the

SBOBIRSS

After

moving

to

on

the

for

press

plate

After

plate

plate

key

to

to

the

the

sewing

test

sewing

descends,

once

completing

moves

complete

descends

and

more,

to

the

the

and

turns

off.

input

origin,

start

by

point

After

pressing

switch

if

you

the

test

the

test

sewing

test

sewing.

moves

the

the

start

to

POS

REV

X:?????A

y: ? ? ? ?

?A

Function

<Test

ORIGIN

XrOOOOOA

[0/1]

SET

N:00???

Code?|

Sewing>

SP : 12

N:00000

4)

Saving

(0)

©

iWi^BwwM

as

After

pressing

number

press

@!lS^Hikey.

data

into a USB

(For

example,

input

[5].[5]and

the

plate

moves

To

complete

feed

plate

press

£|gB|

new

pattern

you

want

to

the

key.

After

ascends.

key.

number

key,

to

save

Save

flash

drive

to

save

the

[2].)

During

flickers.

the

After

turns

origin.

pattern

moving

To

back

input

the

by

using

the

generated

as a relevant

pattern

number

saving

completing

off,

and

the

data

generation,

to

the

origin,

to

he

initial

pattern

key.

pattern

number.

as

the

pattern,

the

saving,

upper

feed

press

the

screen,

and

552,

upper

Y : 0 0 0 0

OA

Function

015:PTRN

NO

:i!52

ORIGIN

X:OOOOOA

y:OOOOOA

Function

<<Main

B.Program

3.Bobbin

4.Machine

Code?!

WRITE

N:00000

Code?l

Menu>>

Wind

Test

Page 23

Parts

book

WARNING

1.

soil

3114

4^'Hl

2.

-&

^4^

3.

4^

<^131

1.

The

parts

when

they

purchased

2.

This

is a parts

3.

Parts

are

Part

^0]

classified

are

as

Subject

71]

It]4

Book^^

44'^1

as

separtately

ass'y

items

book.

It

to

change

A)

4^1^

^

1

ass'y

items

assembled.

only.

cannot

be

used

in

Design

4^9^

^-£

may

4^

Sl^M4.

cause

Hence,

as a manual.

Without

^4^1

damage

when

Prior

to

they

Notice.

;^1|-|-

^^o]

7V-^tM4.

4^

•|-7]-tM4.

the

machine

are

ordered,

or

bad

they

can

^

^o]

sewing

be

Note

oI-eH

http:

//www.sunstarcs.com

7]-®]^

Slit

7l^£l

4i4-i-

4i44

You

can

make

an

http I //www.sunstarcs.com

You

can

request

In

parts

Management - Order

you

can

place

an

If

you

don't

know

In a download

This

parts

book

list,

is

it

4^4

i2lt

4444

order

for

parts

order

the

parts

you

can

classified

4o]i'Hl

4^

for

the

you

Management - Order

by

entering

number,

read

by

44-i

parts

want

after

the

click

parts

the

mechanism,

;a44>^]ol

s.at^

ti

of

Sunstar

login

part

the

book

-tl^t

4-S-4-b

44

machine

if

you

Registration

number

parts

book

by

searching

therefore

4^

ttt

4^

7)^4

?l:7]7i-

-§-<.1^44

to

connect

are a registered

and

quantity.

menu

model

you

bar.

can

Internet

entry,

you

use.

find

member.

part

address,

easily.

Page 24

R

Inverting

Clamp

Devices

Mechanism ( SPS/A-1306

Series

)

i

Page 25

Parts

No.

GP-036450-00

GP-048392-00

52A002S-306H

DSC-BJ0D4800

SW-0103-9011

52A005S-306H

SC-0524-4122

52A007S-306H

52A008S-306H

GP-036449-00

52A010S-306H

52A011S-306H

SC-0543-4525

22S021S-306H

52A014S-306H

52A015S-306H

SC-0502-4125

52A017S-306H

SC-0548-4122

PPP-CA005900

09A029S-811H

09A030S-811H

49A029S-811H

05A039S-8nH

01-017W-1600

GP-017759-02

09A021S-811H

09A023S-811H

52A022S-306H

Inverting

Base

Inverting

Crank

Inverting

Crank

Screw

{1/8"n=40)

Inverting

Crank

Screw

(0.33mm

Inverting

Inverting

Presser

Feeding

Feeding

Screw

Guide

Guide

Screw

Inverting

Screw

Inverting

Inverting

Inverting

Air

A"r

Inverting

Inverting

Plate

Frame

Frame

(0.46mm

Presser

Presser

(0.36mm

(0.13mm

Cylinder

Elbow

Hose

(M)

Lifting

Lever

Rack

Support

Cylinder

Cylinder

Rack

Presser

Presser

Base

n=44)

Base

Base

(A)

(B)

n=40)

(A)

(B)

n=40)

Bracket

n=28)

Ass'y

Knuckle

Hinge

Plate(A)

Plate(B)

Tension

Sprra

(CQ2B16-7.5D)

Screw

(Invert

Ctarm^

eta

Bfloi±

afs

3ga

eta

383

SUM(1/8"n=40)

"2W

m

383

mQ\±

eta

m

0!^

0!^

SUM

__

¥Se

mioi^:

iH[oi±

$BJI@J(A)

$BiSj(B)

7fOIE

(A)

7fOIE

(B)

"sum

m

SUAf

eia

m

ya ^ §!XIUM

OIIOI

0IICH2±

SIM

eia

m

SSeiBi

sBta

SJiia © (cq2bi6-7.5d)

ui

gjS¥

¥ie

(a)

¥ss

(b)

o|S

!ntiiiHtar

Notc)Part

A-28

marked

with a sign

if

is

exclusively

used

for

electronic

equipment.

Page 26

B

Inverting

Clamp

Devices

Mechanism ( SPS/A-1811

Series

)

Page 27

Ref.

B-1

B-8

B-9

B-10

B-11

No.

GP-048393-00

09-A017S-811H

09A026S-811H

09A021S-811H

09A011S-811H

09A010S-811H

SC-0183-4122

22A043S-811H

06-022W-2350

SC-0508-4515

SN-0120-4000

09A025S-811H

SC-0156-4118

SC-000458-00

09A013S-811H

09A015S-811H

09A016S-811H

09A018S-811H

09A019S-811H

SW-0120-1011

SC-0200-4123

09A020S-811H

09A021S-811H

09A022S-811H

SC-0120-4120

09A023S-811H

09A029S-811H

09A030S-811H

09A027S-811H

SC-0151-3118

09A028S-811H

49A003S-811H

05A039S-811H

09A-031S-811H

22A043S-811H

GP-013524-02

09A037S-811H

09A032S-811H

09A033S-811H

09A034S-811H

09A035S-811H

SC-0543-4525

01-017W-1600

Inverting

Inverting

Inverting

inverting

Inverting

Inverting

Screw

Screw

Washer

Screw

Nut

Inverting

Screw

Screw(B)

Washer

Invering

Invering

Washer

Screw

Inverting

Inverting

Inverting

Screw

Screw

Crank

Crank

Rack

Clamo

Clamp

Clamp

(0.61mm

For

(0.61mm

Rack

(0.36mm

For

Needle

Bearing(A)

Needle

Bearing(B)

Support

Support

(0.46mm

Presser

Presser

Presser

For

Inverting

For

Inverting

Cylinder

Inverting

Rack

Inverting

Cylinder

Screw

(0.61mm

Air

Cylinder

Air

Elbow

Air

Hose

(M)

Feed

Plate

Screw

Lower

Feed

Upper

Feed

Label

Guide

Label

Guide

Label

Guide

Seet

for

Label

Screw

(0.46mm

Washer

Shaft

Spacer

n=28)

Feed

Plate

n=28)

Cover

n=40)

Inverting

Base

Base

n=40)

Plate

Plate

Plate

Presser

Inverting

Presser

Knuckle

HIinge

Bracket

n=28)

Ass'

y

Clamp

(R)

Plate

Plate

(A)

(6)

(C)

Guide

(B)

n=40)

Base

Clamp

Clamp

"A"

"B"

"A"

"B"

"D"

Plate

Screw

B

"A.B"

Plate

"D"

yaasiE

e!|

SUAf

moiEa

m

asuM

am.

sia

as

iUM

m

ggs

UOIS

mm

UOIl

bilOig

m

^

m

iUAf

ya

¥S&"A"

ya

¥SS"B"

m

¥13

m

¥B®(A.B)

m

¥sa(D)

m

&E

Sij

iUAf

oilol

ma

oioi

OUCH

QIOIE

§UAf

81III0IE

^nioiE

Bfai

7I0IE

Biai

PfOlE

Biai

7fOIE

Bia

:'IOIE

SUAI

m

las

m

UM

(A)

(B)

8!I0I±"B-

"D"

lUM

u

SXILfM

(S

&

a

(A)

(B)

(C)

(B)

asm

(B)

[KT7108N]

[KT

71010]

SUAJ

A|e

fiiiiiHtai'

Page 28

c

Wiper & Presser

Foot

Mechanism

i

I

Page 29

Ref.

C-1

No.

Parts

No.

11S036S-306H

09A004S-811H

SC-0543-4525

09A005S-8

SC-0525-4122

09A001S-811H

09A006S-811H

SC-0330-4422

06-034W-7400

09A007S-811H

05A045S-811H

09A008S-811H

09A009S-811H

01-071W-1600

SC-0502-4125

09A002S-811H

09A036S-811H

06-040R-106L

Wiper

On/Off

Switch

Ass

y

Wiper

Cover

Screw

(0.46mm

Wiper

H

Base

Screw

(0,46mm

Wiper

Solenoid

Nut

{M4XP0.7)

Wiper

Crank

Screw

(0.61mm

Washer

Wiper

Connecting

Hinge

Screw

Wiper

installing

Wiper

Washer

Screw

(0.36mm

Emergency

Presser

Washer

Stud

for

Rubber

Foot

Wiper

for

Ass'

For

Plate

Switch

Stopper

\Woer

n=40)

n=40)

y

n=28)

Rod

B-11

n=28)

Stopper

etOIIH

Zfi

mm

lUAf

mm

§UAf

SIOIHI

ui

SfOlIB

33H

iuXi

m

suoiia

sa

SfOIQj

2foiia

m

m

^5^

m

SfOia

±£IB

2fOI3Il

±91*1®

m

diioi±

dEllkOIE(£)

SE

SUAf

BUM

±SIB

H

Page 30

D

Pneumatic

(

SPS/A-1306

Control

Mechanism

Pneumatic

Machine

Seires

)

Page 31

Ref.

D-1

No.

Parts

No.

49A001S-811H

05A052S-811H

49A006S-811H

49A009S-811H

49A014S-811H

02031SC-2113

10-010W-7507

SN-0115-2000

49A017S-811H

49A018S-811H

22A060S-306H

49A013S-811H

49A1005-811H

49A015S-811H

49A020S-811H

Urethane

Urethane

Regulator

Tee

Elbow

Union

Screw

(M5xp0.8)

Washer

Nut

M5XP0.8)

Solenoid

Valve

Taoping

Screw

Solenoid

Valve

Straight

Union

Check

Va

Hose

Nipple

Silencer

Hose

Hose

ve

(M)

(f

Bracket

6)

■m

■m

8/^

sa^j

a

auw

m

ue

^BilkOjE

aa

m

ft

BlhiOiE

±^Hom

m

Ufi

±s5i

^±(*6)

{i»4)

iM

IM

^us

StiiiHtan

Mau

Page 32

€

Pneumatic

(SPS/A-1306

Control

Electronic

Mectianism

Machine

Series)

1

Page 33

49A004S-811H

49A005S-811H

49A006S-8

49A008S-811H

10-010W-7507

49A009S-811H

49A007S-811H

49A011S-811H

49A013S-811H

05A052S-811H

22A060S-306H

49A014S-811H

49A020S-811H

52A0

4S-306H

52A015S-306H

49A015S-811H

49A018S-811H

49A001S-811GH

49A

00S-811H

49A013S-811H

fStiiiHtar:

Quick

Joint

Plug

Ass

y

Finger

Valve

1H

Filter

Regulator

Screw

Nut

(M5XP0.8)

Air

Pressure

MSxpO.S)

Switch

Plug(A)

Air

Hose

{^

6)

Manifold

Block

Elbow

Union

Plug

(B)

Solenoid

Tapping

Check

Straight

Hose

Air

Nipple

Hose

Va

Valve

Screw

(^4)

ve

Union

m

saE

sstn

5S7I

HSUA

IBia

(A)

OllOj

(^6)

OHUgE

sa7l

(B)

^atoiE"aa

i±~us

EMS

UAt

OIIOI

(#4)

(1@)

Page 34

F

Pneumatic

Control

Mechanism ( SPS/A-1811

Series

)

Page 35

Ref.

No.

Parts

No.

49A001S-811H

49A017S-811H

51A048S-81H2

49A013S-811H

49A100S-811H

49A015S-811H

Urethane

Solenoid

Manifold

Straight

Union

Check

Valve

Hose

Nipple

Hose

valve

Block

(#4)

(^4)

^eilhiOlE

DUUgE

gq

±iaioiESul

nB.

Ufi

HuliStai'

Page 36

G

Inverting

Clamp

Devices

Mechanism ( SPS/A-2516

Series)

Page 37

Ref.

No.

GP-048393-01

GP-048393-00

09A017S-811H

09A026S-811H

09A021S-811H

09A011S-811H

GP-027965-00

SC-0183-4

SC-0508-4515

SC-0156-4118

SC-000458-00

09A013S-811H

09A015S-811H

09A016S-811H

09A018S-811H

09A019S-811H

SW-0120-1011

SG-0200-4123

GP-027935-00

09A029S-811H

09A030S-811H

09A027S-811H

SC-0151-3118

09A028S-811H

49A003S-811H

05A039S-811H

GP-027964-00

GP-027967-00

GP-027959-00

GP-027936-00

GP-027958-00

09A034S-811H

GP-027957-00

SC-0543-4525

50-006A-2516

22A039S-811H

50-003W-2516

06-002W-2350

22S014S-306H

22S026S-306H

SN-0121-7400

SC-0508-1230

StiiiHtai'

Inverting

Inverting

inverting

Inverting

Inverting

inverting

Inverting

22

Screw

Screw

Inverting

Screw

Screw(B)

Washer

Invering

Invering

Washer

Screw

Saew

Screw

Crank

Crank

Crank

Rack

Clamp

Clamp

Clamp

(0.61mm

{0.61mm

Nut

Rack

{0.36mm

For

Needle

Bearing(A)

Needle

Bearing(B)

Support

Support

{0.46mm

Inverting

Presser

For

Inverting

For

Inverting

Inverting

Cylinder

Inverting

Rack

Inverting

Cylinder

Screw

(0.61mm

Air

Cylinder

Air

Eltxjw

Air

Hose

(0

Feed

Plate

Lower

Feed

Upper

Feed

Label

Guide

Label

Guide

Label

Guide

Seet

for

Label

Screw

(0.46mm

Washer

Air

Slide

Table

Screw

Spring

Washer

Washer

Giude

Pin

Scrw

Nut

Screw

Shaft

Spacer

n=28)

n=28)

Cover

n=40)

Inverting

Base

Base

n=40}

Plate

Presser

Presser

Knuckle

Hlinge

Bracket

n=28)

Ass'y

4)

Clamp

(R)

Plate

Plate

(A)

(B)

(C)

Guide

n=40)

holder

Base

Clamp

"A"

"B"

'A"

Screw

(B)

Plate

"A,8'

Rate

"D"

HIS

eij

m

muE ^ mioi±

iUAf

m

s?

SUM

m

gas

UOIl

bilOlil

UOIl

tHI0(S

2IM

&E

SIS

¥S

m

SUM

m

^S5f"A"

m

¥SSf(A,B)

&E

iFl5}(D)

&E

m

SS

SUM

oaoi

oaoTiH?

OUCH

niOlE

9SS(¥)

SflllGIE

^inoiE

sia

:'foiE

aa

7I0IE

aa

7I0IE

aa

:'(oiE

SUM

m

OllOj

^aOlE

SUM

S(M

"sTm

y\o\s

E

as

UA(

"ui

as

UAf

m

uAi

(A)

(B)

ti

llOI±"A"

HIIOI:i-B"

SUAf

US

§!X|UAf

(S

E

e

(A)

(B)

(c)

(B)

^st

EIIOIB

(B)

[KT7108NJ

(KT

71010]

SUAf

Km

SDI

Mar.08.12

Jan.25.09

Page 38

H

Inverting

Clamp

Devices

H-32

H-27

Mechanism

H-34

H-33

Jf"

(SPS/B-1507HJ)

Page 39

H-1

H-2

H-3

H-4

H-5

H-6

H-7

H-8

H-9

H-10

H-11

H-12

H-13

H-14

H-15

H-16

H-17

H-18

H-19

H-20

H-21

H-22

H-23

H-24

H-25

H-26

H-27

H-28

H-29

H-30

H-31

H-32

H-33

H-34

H-35

H-36

H-37

H-3a

H-39

H-40

H-41

H-42

H-43

H-44

H-45

H-46

H-47

CCP-BB039600

DSC-BB008100

DSC-AA003100

CPR-LF000200

DGR-AF002600

CCP-BJ014600

CCP-BB039203

DSC-CB000300

CCP-BB048801

CCP-BB039104

PBR-AA014400

DPN-AD014502

CCP-BB039002

DSC-BB008300

PPP-CA009600

PPP-AA002500

PPP-AD000100

PPP-AD001000

CCP-BB038901

PSC-AC003900

CCP-BB038802

PSC-AG000800

'

PSC-CB005700

PSC-AC004900

PWS-CA000900

PWS-AA000200

CCP-BB038702

PSC-AC025100

PPP-CA010100

PPP-AA000100

PSC-AC025000

PWS-AA002100

CCP-BB038603

PSC-AC007100

PPP-CA010200

PPP-AA000200

CCP-BB044101

PSC-AC007100

PSC-AC013400

CCP-BB045102

PSC-AC002800

CCP-BB045002

PSC-AC013000

CCP-BB039503

PSC-AC013200

PWS-CA000800

CCP-BB044001

Name

of

Presser

Plate

Screw{3/16"

Bolt{3/16"

Presser

Rack

Inverting

Inverting

Set

Screw

Inverting

Inverting

Ball

Pin

Inverting

Screw(9/64"

Air

Cylinder

Fitting

Air

Hose(TU-0425)

Air

Hose(TU-0425-Y}

inverting

n=32.

Plate

Gear

Crank

Crank

(11/64"

Base

Presser

Bearing

(NSK

Presser

(CRJB1-180)

(M-3ALU-4)

Cylinder

n=32)

L=10)

Coating

Washer

n=40,

Spacer

Plate

MF74)

Plate

n=40,

L=5)

Base(CRJB1-180)

Bolt(M5xP0.8,L=15)

Inverting

Bolt

Set

Bolt

Spring

Washer

Cylinder

Bo!t(M3xP0.5.

Air

Fitting

Bolt

Washer

Cylinder

Bolt

Air

Fitting

Guide

Bolt

Bolt

Cylinder

Bolt

Cylinder

Bolt

Feed

Bolt

Spring

Guide

Base

(M5*P0.8,L=10)

Screw

(M5xP0.8,L=4)

(M4xP0.7,L=12)

Washer

Bracket

(MXS8-20)

L=12)

Cylinder

MXS8-20

(M-5HL-4)

(M3xP0.5.

Base

(MXH10-40)

L=20)

(M4xP0.7,L=10}

Cylinder

{MXH10-40)

{M-5H-4)

Block

B

(M4xP0.7,L=10)

(M3xP0.5,L=10)

Guide

(M3xP0.5,L=8)

Guide

Rail

(M4xP0.7.L=8)

Bracket

B

(M5xP0.8,L=15)

Washer

Block

A

Parts

Film

Base

L=5)

S!|

y\oi

ya

e>a

aa

gAl

OljOl

as

o||cH

o||cH

ya

as

Oijot

as

•ygq

0\\0\

SIS

•ygq

£.

aisa fifAi

Hijoi^A.

>;i[HoiAH

a

Ysa

-ygici

s.±

s.±

HiiO|±;

saw

Saf-M

uijol^.

^aq

^

B

MB

7^0|H

aii^

B

Jan.17.13

2 Oct.19.12

Oct.19.12

Page 40

H

Inverting

Clamp

Devices

Mechanism

(SPS/B-1507HJ)

Page 41

Ref.

H-48

H^50

H^si

hIs

H-54

hIs

H-56

H-57

H^58

h19

H^60

H^ei

fTii

H-63

H-64

H-65

H-66

H-67

H-68

H-69

H-70

H^TI

H^72

No.

PSC-AC013000

CCP-BB044201

PPP-CA009800

PPP-AA001100

PSC-AC009800

CCP-BB039300

CCP-BF000700

PSC-AC004900

PWS-AA000200

ACP-PS004401

CCP-BB038301

DPN-BB000500

ACP-PS004301

CCP-BB038201

PSC-AC004900

PWS-CA000900

PWS-AA000200

CCP-BJ014300

DSC-BF003600

PWS-AAD00200

CGA-GJ001601

PSG-AA002600

PWS-AA000600

CCP-BB039402

DPN-AA026400

PSC-AC001700

PSC-AC003200

PWS-AA000600

PBR-FA000400

CGA-GC026901

CMB-LD028100

Bolt

M4xP0.7.L=8)

Air

Cylinder

Fitting

(KJL04-M5)

Bolt

(M4xP0.7,L=30)

S

ider

Base

Clamp

Shaft

Bolt

(M4xP0.7.L=12)

Washer

Feed

Plate

Feed

Plate

Locating

Pin

Feed

Plate

Feed

Plate

Bolt

(M4xP0.7.L=12)

Spring

Washer

Washer

upper

Feed

Screw

11/64*

Washer

Lower

Feed

Bolt

(M6xP1.

Washer

Feed

Bracket

Pin

Bolt

(M5xP0.8,L=10)

"ioit

Washer

Linear

Bushing

Presser

Fool

Model

Mark

Holder

Clamp

Assembly(L)

Clamp(L)

Clamp

AssembMU

Clamp(R)

Plate

Bracket

n=40.

Plate

L=12)

A

(SDM

L=8

10UU)

m

MME ^ £01

m

mm

moiE E iiMKJo

moiE E iiasm)

mmsE

GIOIE

E

niOlE

E

y

mo

ES

saa

gis

mm

51

ffl

OIEe!

SE

§iS

SStfAt

moiE

aa?i

a

moiE

EU

SJUOI

sai

gtsEj

mm

¥AI

QB

StinStai'

8

1

1

2

Page 42

I

Pneumatic

Control

Mechanism

(SPS/B-1507HJ)

m

Page 43

Ref.

1-1

1-2

1-3

[-4

[-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-14

1-15

1-16

1-17

1-18

1-19

1-20

1-21

1-22

1-23

1-24

1-25

No.

Parts

AAR-PS000200

PPP-AG000100

PPP-BD000100

1 PPP-BG000100

PPP-AA000400

PPP-AAOOOSOO

DSC-HB000700

PSC-AG002300

PWS-AA001000

PPP-AF000200

PSC-AC001700

DWS-AA002100

PSN-AA000700

AAR-PS009500

PPP-BF000100

PPP-AB000200

PPP-BA000400

PPP-BB000400

PPP-BCOOOlOO

PPP-AAOOOSOO

PPP-AA001100

PPP-AF000100

CAR-BB000100

PSC-DD000100

PSC-BA000200

No.

Filter

Finger

Filter

Air

Pressure

Fitting

Fitting

Stud

Screw

Bolt

Washer

"Phjg

Nut

Solenoid

Pressure

Speed

Solenoid

Manifold

Silencer

Fitting

Fitting

Tiug

Manifold

Tapping

Screw

Name

Regulator

Valve

Regulator

Switch

Valve

Assembly

Reducing

Controller

Valve

Bracket

Screw

of

Parts

Assembly

Valve

lEiaiSaiOiEKS)

S7i

ieaiioii

nig

Qjg

m

:^xiuM

m

mm

Isa

^2t?glgOI

UM

seihiOiE

S21

iM(E)

ZiiEsisBi

SMEOEiM

lUSE

iiTi

m

li

iiia

lUgESBm

aauM

aui

zfguM

SuiiStar

^

Page 44

Attachments

1.

Pneumatic

1)

SPS/A-1306-HS-10

circuit

diagram

for

SPS/A-1306

series

turnover

device

Inverting

Cyl'd

I

I

AIR

IN

—

ity

L J

Page 45

2)

SPS/A-1306-HS-20

Inverting

Cyl'd

<y

Feed

Frame

Cyrd(R)

€]►

E

Feed

Frame

Cyrd(L)

AIR

IN

s

m

S78

m

,

I

I

EA

L.

L J

0

S34F

{m

EA

CZl

I

—,

I

<CD-

in

in

o

I

in

L

I

I

I

I

I

Page 46

Cyrd(L)

m

d

d

4

Device

Stroke

2-Step

Cyl'dfR)

Device

Stnke

2-Slep

Cyl'dfL)

Prame

Peed

€

<E]i

S56S

S34F

3

SB

tB

u

IZ12

CZK-

1

<nni

1.

J

I

^

I

-T-'

L

Cyl'dlR)

Prame

Peed

Cyl'd

Inverting

SPS/A-1306-HS-21

3)

S76I

3

[ZS

CD-

I

I

<CD-

Mi

1.

IN

AIR

J

L

Page 47

4)

SPS/A-1306-HS-23(SPS/A-1306-HS-22)

Inverting

Cyl'd

Feed

Frame

CyI*d(R)

<E

Feed

Frame

Cyl'd(L)

AIR

IN

S78

m

<cz>

czy

0

S34R

|3

EB

BA

—

1

BA

S34L

EeE

3

SB

BA

<CZH

c:z^

L

I

I

£

in

in

o

■T

in

.

9

L

I

L

J

Page 48

(|yi'd

Device

a

1

BB

Inverting

device

Cj^'d(L)

Frame

Feed

turnover

series

Cyrd(R)

Frame

Peed

SPS/A-1811

S78I

}_

ca-r

<nn

J

S34F

3

SB

P

[Z12

_■

11

L

0

V

w

for

2

Cyl'd

diagram

Foot

Presser

S12P

132

circuit

SPS/A-1811-HS-20

Pneumatic

1)

2.

B8

P

IN

AIR

i_

<cii

CZh

Page 49

CylM

Device

L

Inverting

Gjl'd

Deiice

Stnke

2-Step

Cyl'diL)

Frame

Feed

S7BI

EE

CJ

L

3

S56S

EE

EB

P

u

J--

J

5J

1.

4-

3

V

w

ZB

P

:

J1

L

w

Cjrd(R)

S34F

IZE

Ffame

Feed

SB

Cyl'd

P

€

Foot

Presser

€'

SPS/A-1811-HS-21

2)

S12F

[as

CZh

IN

AIR

i.

<cz]

Page 50

Cyl'd

Device

-\

3

EB

InvertiDg

l^'d

Sefice

^ke

2-Step

Cyrd(L)

Frame

Feed

Cyrd(R)

Frame

Feed

L

S7BI

[32

h

'

I

'

4

IB

P

J

5J

S56S

132

£

IB

S34L