SunStar SC 8200J Series, SC 8200J/01-B/PF, SC 8200J/02-B/MF, SC 8200L/01-R/PF, SC 8200L/02-R/MF User Manual

Page 1

1) FOR AT MOST USE WITH EASINESS,

PLEASE CERTAINLY READ THIS MANUAL

BEFORE STARTING USE.

2) KEEP THIS MANUAL IN SAFE PLACE

FOR REFERENCE WHEN THE MACHINE

BREAKS DOWN.

MMMMEE--110000440077

USER

’’

S MANUAL

R

SSuunnSSttaarr CCOO..,, LLTTDD..

SC 8200J Series

Direct Drive,

Feed-off-the-Arm

3 Needle 6 Thread Double

Chain Stitch M/C

Page 2

Best Quality

Best Price

Best Service

SSUUNNSSTTAARR CCOO..,, LLTTDD..

R

1.

Thank you for purchasing our product. Based on the rich expertise and

experience accumulated in industrial sewing machine production, SUNSTAR

will manufacture industrial sewing machines, which deliver more diverse

functions, high performance, powerful operation, enhanced durability, and

more sophisticated design to meet a number of user’s needs.

2. Please read this user’s manual thoroughly before using the machine. Make

sure to properly use the machine to enjoy its full performance.

3. The specifications of the machine are subject to change, aimed to enhance

product performance, without prior notice.

4.

This product is designed, manufactured, and sold as an industrial sewing

machine. It should not be used for other than industrial purpose.

Page 3

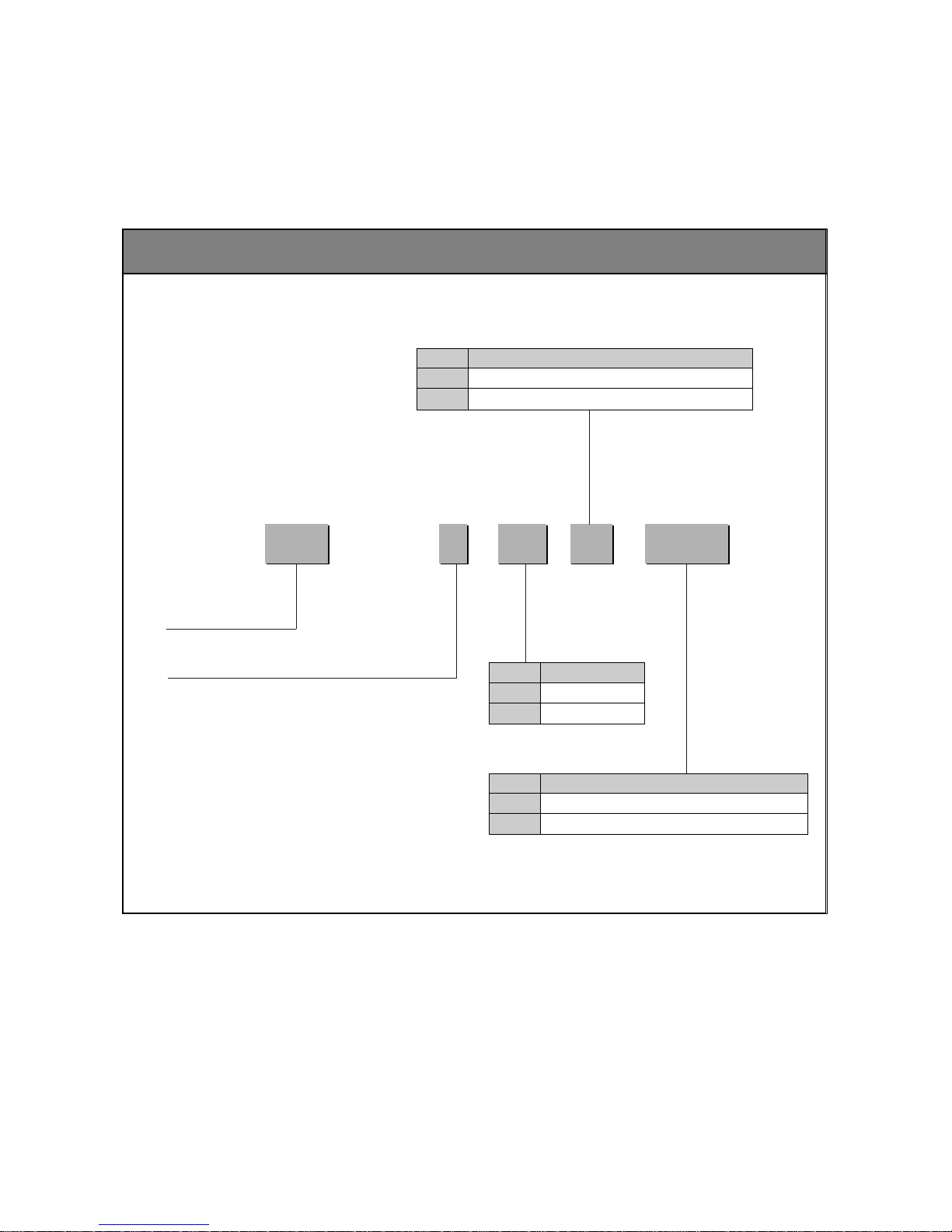

Machine Type

SC 8200 J / 01-

/

Sunstar Chain Stitch

J : Jean

L : Light Materials

01

Code

Direct Motor

02

Clutch Motor

Motor

B

R

Code

Roller Type Puller(For Heavy weight Materials)

Belt Type Puller(For Light Materials)

Puller type

PF

MF

Code

Structure of pneumatic presser foot(Direct)

Structure of Mechanism presser foot(Clutch)

Presser foot type

*Machine Type

SC 8200J/01-B/PF

SC 8200J/02-B/MF

SC 8200L/01-R/PF

SC 8200L/02-R/MF

Page 4

4

Contents

1 Machine Safety Regulations ------------------------------------------------------------------ 6

1) Transporting machine ------------------------------------------------------------------------------ 6

2) Installing machine ----------------------------------------------------------------------------------- 6

3) Repairing machine ---------------------------------------------------------------------------------- 6

4) Operating machine ---------------------------------------------------------------------------------- 7

5) Safety devices ---------------------------------------------------------------------------------------- 7

6) Caution mark position ------------------------------------------------------------------------------ 8

7) Contents of marks ----------------------------------------------------------------------------------- 8

2. Machine Parts ----------------------------------------------------------------------------------------- 9

3. Specifications

--------------------------------------------------------------------------------------- 10

4. Installation

--------------------------------------------------------------------------------------------- 11

1) Table Installation ----------------------------------------------------------------------------------- 11

2) Machine Head Installation ----------------------------------------------------------------------- 12

3) Ground Wire Connection ------------------------------------------------------------------------ 13

4) Attaching the pulley cover(clutch type) ------------------------------------------------------- 13

5) Connection to clutch-type pedal --------------------------------------------------------------- 14

6) LRP Puller Attachment --------------------------------------------------------------------------- 15

7) SRP Puller Attachment --------------------------------------------------------------------------- 17

8) Sewing of several clothes as one (FEED-OFF-ARM)

Attaching & Setting Puller to Sewing Machine---------------------------------------------- 19

5. Machine Preparation ----------------------------------------------------------------------------- 23

1) Oil Supply -------------------------------------------------------------------------------------------- 23

6. Sewing Preparation ------------------------------------------------------------------------------- 25

1) Needle Installation --------------------------------------------------------------------------------- 25

2) Lower Thread Placement ------------------------------------------------------------------------ 25

3) Upper Thread Placement ------------------------------------------------------------------------ 26

4) Handling of Waste Oil ----------------------------------------------------------------------------- 26

7. Sewing ---------------------------------------------------------------------------------------------------27

1) Sewing ------------------------------------------------------------------------------------------------ 27

Page 5

5

2) Trial Operation (pedal operation method) --------------------------------------------------- 28

3) Trial sewing (How to operate a clutch-type pedal) ---------------------------------------- 28

8. Thread T ension ------------------------------------------------------------------------------------- 29

1) Thread Tension Adjustment --------------------------------------------------------------------- 29

2) Adjustment of Presser Bar Pressure --------------------------------------------------------- 29

3) Adjusting the pneumatic presser bar --------------------------------------------------------- 30

9. Cleaning ------------------------------------------------------------------------------------------------ 31

1) Daily Cleaning -------------------------------------------------------------------------------------- 31

10. Adjustment ------------------------------------------------------------------------------------------ 32

1) Adjustment of Needle Bar Height -------------------------------------------------------------- 32

2) Adjustment of Needle and Looper Timing --------------------------------------------------- 33

3) Needle Avoiding Looper Timing --------------------------------------------------------------- 33

4) Adjustment of Needle Bar Guide -------------------------------------------------------------- 34

5) Adjustment of Feed Dog Height --------------------------------------------------------------- 34

6) Adjustment of Thread Release Lever -------------------------------------------------------- 35

7) Adjustment of Thread Take-up Guide -------------------------------------------------------- 35

8) Adjustment of Upper Thread Adjusting Cam ----------------------------------------------- 36

9) Adjustment of Thread Release Shaft --------------------------------------------------------- 36

10) Adjustment of Lower Thread Take-up Timing -------------------------------------------- 36

11) Lapper Installation ------------------------------------------------------------------------------- 36

12) Adjusting position of the belt puller ---------------------------------------------------------- 37

13) Fixing without puller ----------------------------------------------------------------------------- 38

14) Decelerator Timing Adjustment -------------------------------------------------------------- 39

15) Adjustment of Puller Feeding Amount -------------------------------------------------------40

16) Speed Lever Stitch Length Adjustment ---------------------------------------------------- 40

17) P.S.W-I Stitch Length Adjustment ---------------------------------------------------------- 40

18) Ascending Momentum of the Ruller --------------------------------------------------------- 41

19) Bearing Replacement---------------------------------------------------------------------------- 41

20) Breakdown of TENSION DISK & E-RING --------------------------------------------------41

Page 6

6

11

Machine Safety Regulations

Safety instructions on this manual are defined as Danger, Warning and Caution.

If you do not follow the instructoins, physical injuries and machine damages might be occurred.

: This indication should be observed definitely. If not, there will be a danger during the installation, conveyance and

maintenance of the machine.

: When you follow this indication, injuries from the machine can be prevented.

: When you follow this indication, error on the machine can be prevented.

Caution

Warning

Danger

1) Transporting

machine

Danger

2) Installing

machine

Warning

3) Repairing

machine

Caution

Those in charge of transporting the machine should have a full understanding of the machine.

The following indications should be followed when the machine is being transported.

ⓐ More than 2 people must transport the machine.

ⓑ To prevent accidents from occurring during transportation, wipe off the oil on the

machine compeletely .

When the machine needs to be repaired, only the assigned troubleshooting engineer educated

at the company should take charge.

ⓐ Before cleaning or repairing the machine, turn off the main power and wait 4 minutes till

the machine is completely out of power.

ⓑ Not any of the machine specifications or parts should be changed without consulting the

company. Such changes may make the operation dangerous.

ⓒ Spare parts produced by the company should only be used for replacements.

ⓓ Put all the safety covers back on the machine after the machine has been repaired.

The machine may not work properly or breakdown, if installed in certain places, Install the

machine where the following qualifications agree.

ⓐ Remove the package and wrappings from the top. Take special notice on the nails on the

wooden boxes.

ⓑ Dust and moisture stains and rusts the machine. Install an airconditioner and clean the

machine regularly .

ⓒ Keep the machine out of the sun.

ⓓ Leave sufficient space of more than 50cm behind, and on the right and left

side of the machine for repairing.

ⓔ EXPLOSION HAZARDS

Do not operate in explosive atmospheres. To avoid explosion, do not operate this

machine in an explosive atomsphere including a place where large quantities of

aerosol spray product are being used or where oxygen is being administered unless

it has been specifically certified for such operation.

ⓕ The machine is not provided with a local lighting due to the feature of machine.

Therefore the illumination of the working area must be fulfilled by end user .

[Refer] Details for machine installation are described in 4. Installation.

Page 7

7

SC8200 Series are designed as industrial sewing machines performing sewing on denim and

other similar materials. Please observe the following instructions during the machine operation.

ⓐ Read through this manual carefully and completely before operating the machine.

ⓑ Wear proper clothes for work.

ⓒ When the machine is in operation, do not bring your hands or body near the moving parts

of the machine, such as needle, looper, spreader, thread take-up lever and pulley, etc.

ⓓ Keep the covers and safety plates in place during operation.

ⓔ Be sure to connect the earthing conductor .

ⓕ Turn off the main power and check if the switch is turned “off”before opening electric

boxes such as the control box.

ⓖ Stop the machine before threading the needle or checking after work.

ⓗ Do not step on the pedal when turning the power on.

ⓘ Do not operate the machine with any cooling fan blocked.

The air-filter on control box must be cleaned once a week.

ⓙ If possible, install the machine away from source of strong electrical noise such as high

frequency welding machines

4) Operating

machine

Warning

Caution

[ Warning ]

Keep cover in place before operating, turn off power before inspecting or adjusting in order

to prevent physical injury from belt.

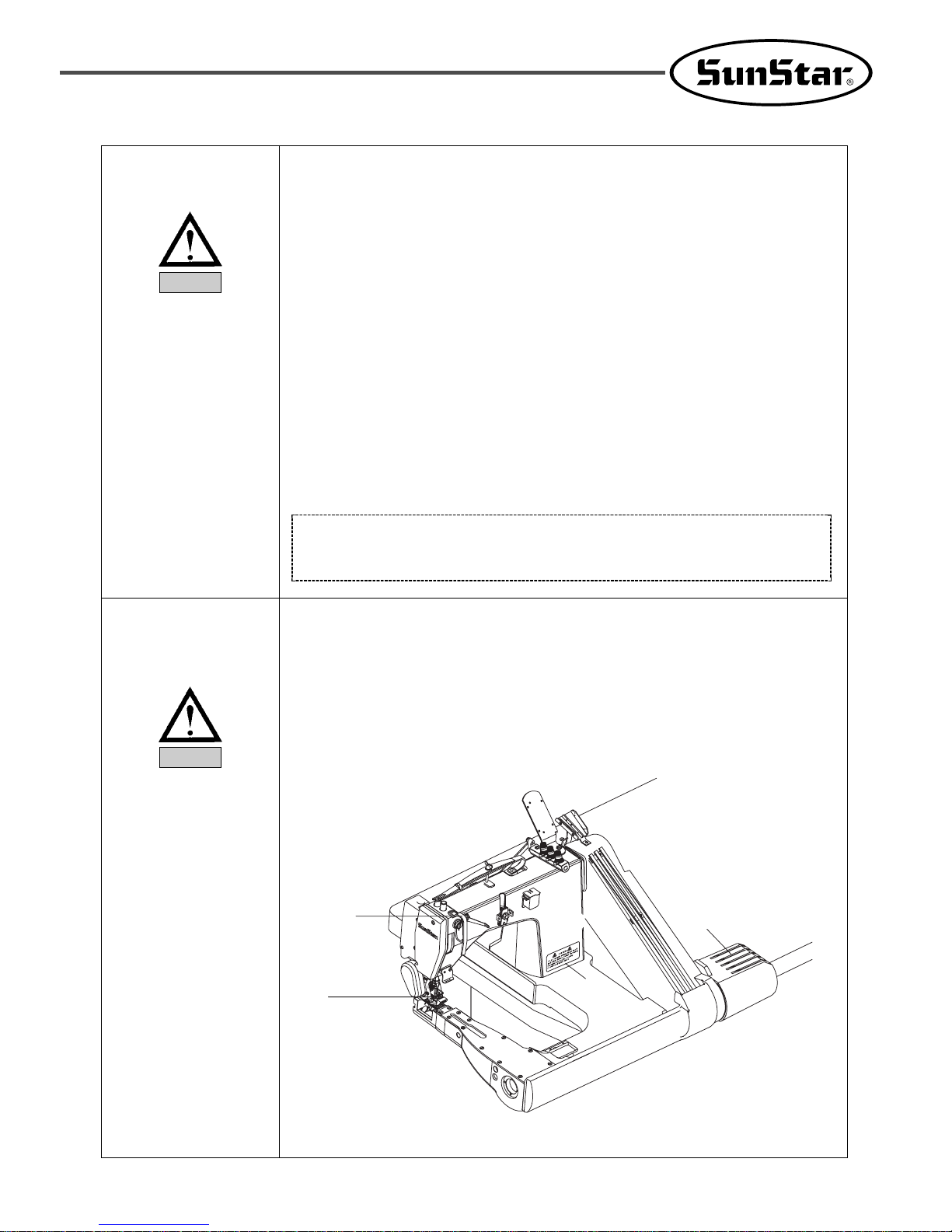

5) Safety devices

ⓐ

Safety label : Things to be kept in mind during operation are described.

ⓑ

Thread take-up lever cover : Prevents the contact between a body part and the thread take-

up lever

ⓒ

Safety plate : Prevents the contact between needles and fingers.

ⓓ

Motor cover : Prevents any potential accidents from occurring while a motor is in

operation.

ⓒ

ⓑ

ⓐ

ⓓ

Page 8

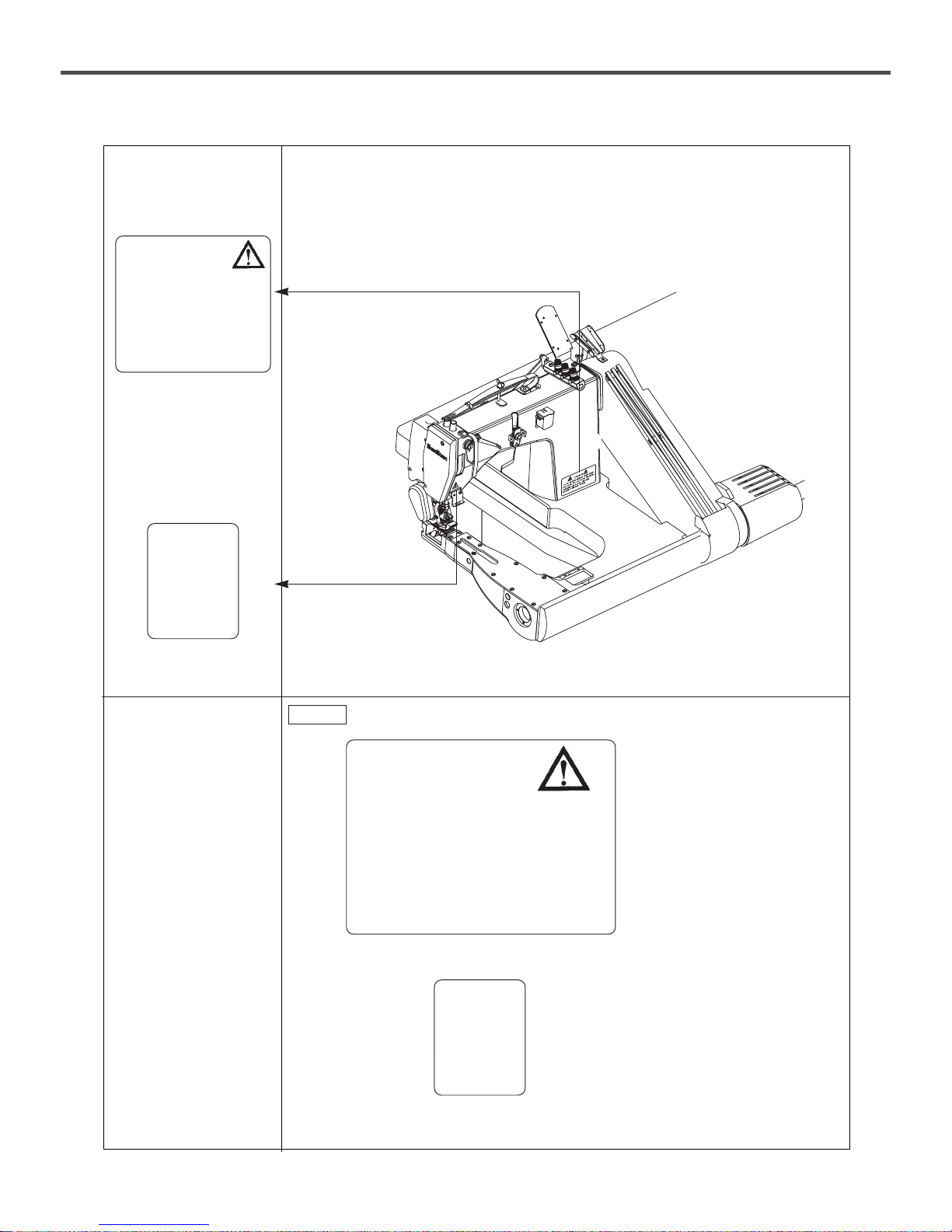

8

Caution

(1)

(2)

7) Contents of

marks

Caution mark is attached on the machine for safety .

When you operate the machine, follow the directions on the mark.

6) Caution mark

position

CAUTION

주의

Do not operate without finger guard and

safety devices. Before threading, changing

and needle, cleaning etc. switch off

main switch.

손가락 보호대와 안전장치 없이 작동하지

마십시오.

실, 바늘교환시나 청소전에는 반드시 주전원의

스위치를 꺼 주십시오.

CAUTION

주의

Do not operate without finger guard

and safety devices. Before threading,

changing and needle, cleaning

etc. switch off main switch.

손가락 보호대와 안전장치 없이 작동하지 마

십시오.

실, 바늘교환시나 청소전에는 반드시

주전원의 스위치를 꺼 주십시오.

CAUTION

경고

CAUTION

경고

Page 9

9

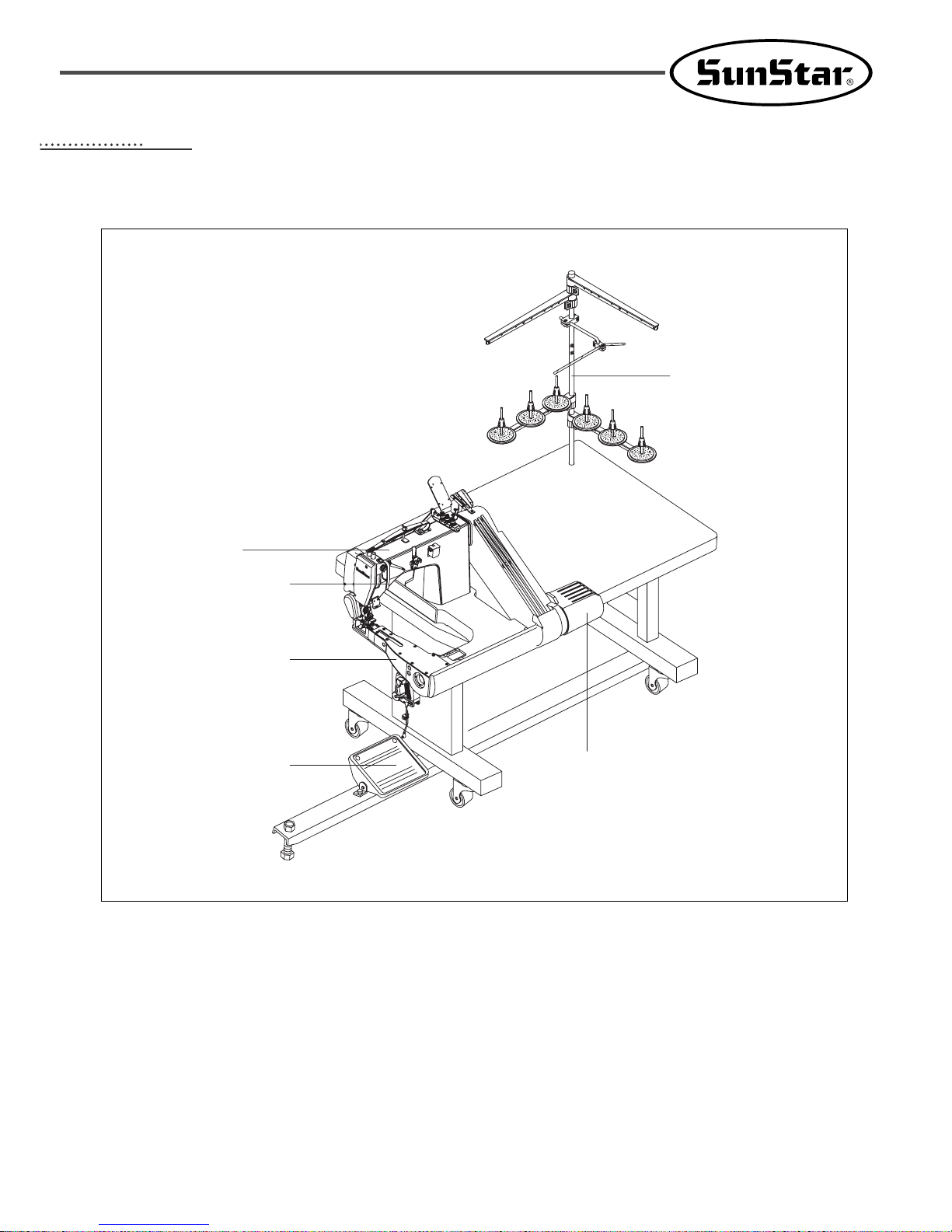

22

Machine Parts

① Arm

② Bed

③ Main Shaft Motor Cover

④ Pedal

⑤ Thread Stand

⑥ Thread Take-up Lever Cover

⑤

③

④

②

⑥

①

Page 10

10

33

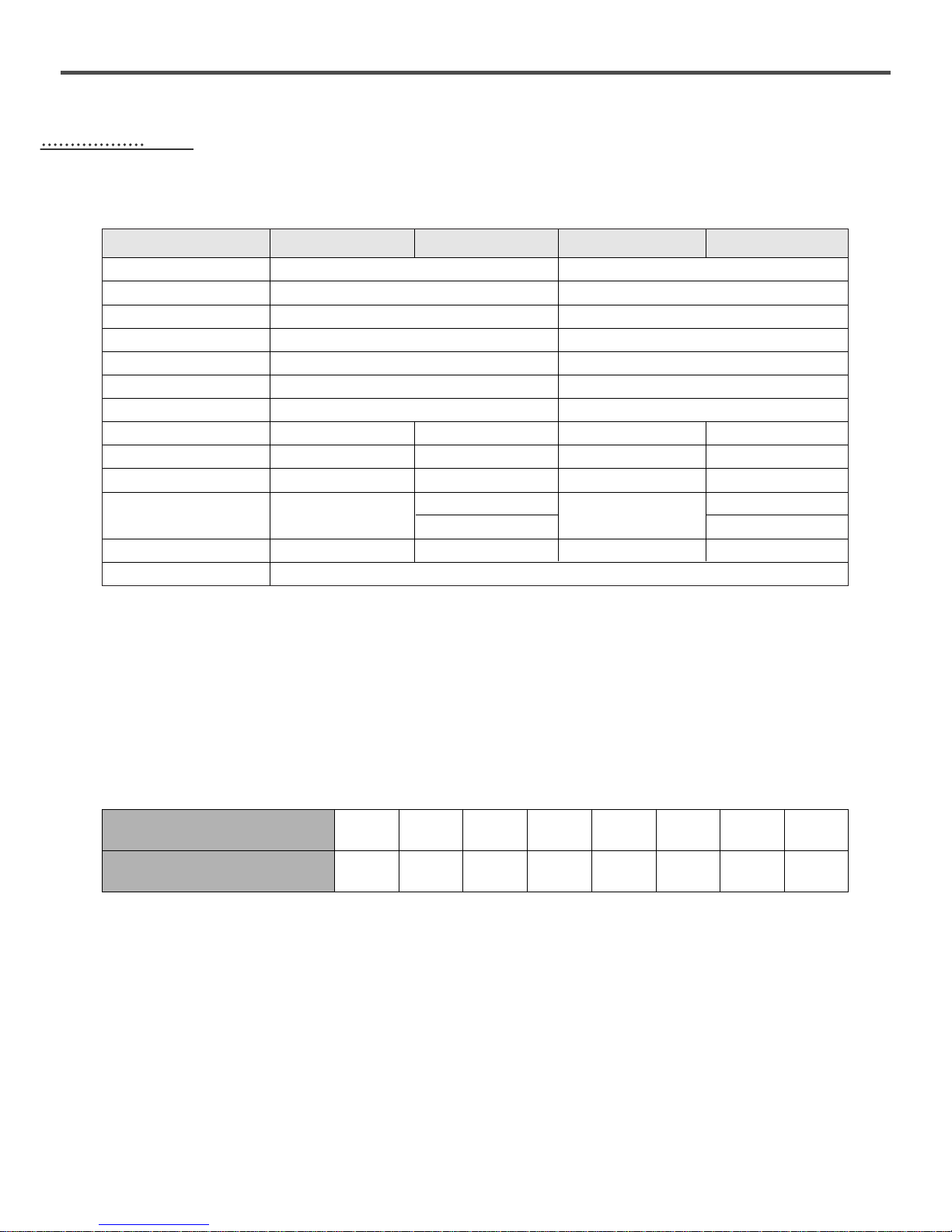

Specifications

Table for Clutch Motor S/M Spin Number

Table for sewing machine rotation number in the event of a clutch motor (external diameter of hand pulley: 80mm)

Computation is according to anumber of regularity rotation.

External diameter of the

sewing machine pulley (mm)

60 65 70 75 80 85 90 95

Number of sewing machine rotation

(rpm)

2583 2799 3014 3229 3445 3665 3875 4091

Usage Heavy weight Materials(Jeans) Light Materials

Stitch Length (mm) 2-4.2 1.1-3.1

Needle Bar Stroke (mm) 35 27

Feed Dog Height (mm) 1.2 0.9

Needle TVX5#Nm22 TVX64NY#11PSU

Attachment 1/4XH, 1/4X 1/4M

Puller Belt-type , Roller Type Puller Roller Type Puller

Presser Foot Climb Sensor O X X X

Presser Bar Pneumatic Type O X O X

Pulley Size X 60Hz : 80, 50Hz : 100 X 60Hz : 80, 50Hz : 100

Main Motor AC Servo (FORTUNA4)

Clutch 2P 60Hz 400W

AC Servo (FORTUNA4)

Clutch 2P 60Hz 400W

Clutch 2P 50Hz 400W Clutch 2P 50Hz 400W

Max. Sewing Speed (spm) 4000 4000 (default setting: 3500) 4000 4000 (default setting: 3500)

Lubrication Oil tank type

Model SC 8200J/01 SC 8200J/02 SC 8200L/01 SC 8200L/02

Power : Main Shaft Motor for Clutch (SMC-1701D), Hand Pulley 80

In case of 3500 RPM : 2P 60HZ(1-phase high-speed) → Motor pulley 80, V belt M Type 43 inch

2P 50HZ(1-phase high-speed) → Motor pulley 100, V belt M Type 44 inch

Page 11

11

44

Installation

1) Table Installation

(1) Table Type

Page 12

12

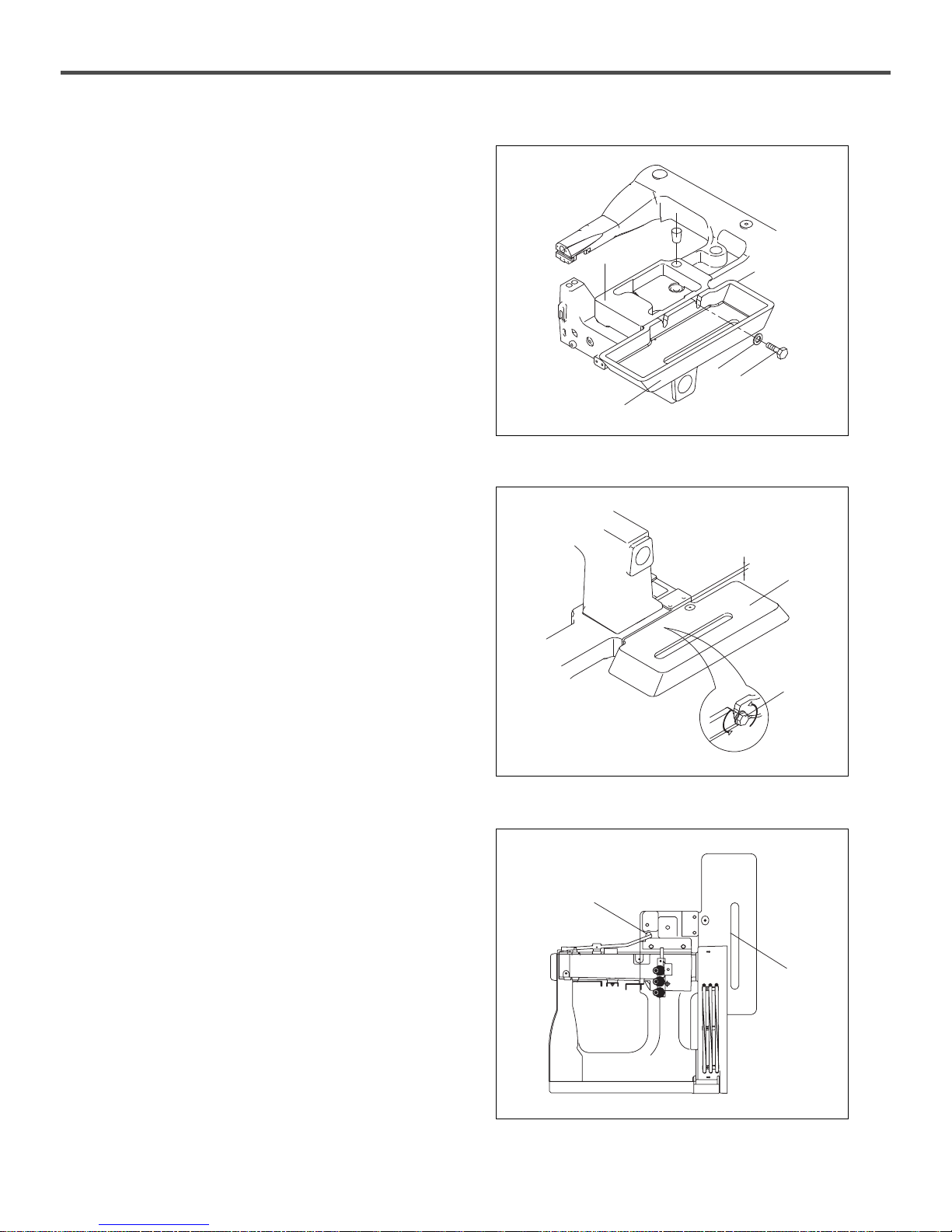

2) Machine Head Installation

A. Assemble the pulley cover base ② to the machine

bed ① using two hexagonal bolts ③ and two

washers ④.

Insert two bar cushions ⑤ into the holes under the

bed.

B. When placing the two hexagonal bolts ③, make sure

that they are deeply inserted into the notches on the

pulley cover base ②. And make sure that the pulley

cover base ② is in parallel with the bed (if not, the

pulley cover might contact the machine pulley).

Parallel

②

③

⑥

⑩

①

⑤

④

③

②

C. Place the machine head on the table and properly

place the hole of the presser bar lifter chain ⑥. Then

locate the belt hole ⑩ in the slant direction from the

presser bar lifter chain. Make the front and back

adjustments.

Page 13

13

D. Assemble the cushion ⑦ to the machine bed and the

pulley cover base using the fixed screw ⑧, and use

the screw ⑨ to fix it to the table.

※ Place the machine head on the table and make

sure it is well balanced. If the balance of the

machine head is not right, lubrication may not

properly take place.

⑧

⑦

⑨

3) Ground Wire Connection

Connect the ground wire to the base and the control box.

A. Connect the ground wire ① to the base using a screw

② and a washer ③.

B. Pass the ground wire ① through the hole on the

table.

C. Connect the ground wire ① to the control box.

4) Attaching the pulley cover(clutch type)

A. Place the belt① on the pulley② and lift the belt.

②

①

Page 14

14

B. With the belt pulled upward, ④ the belt cover (Dn)

③ to the base⑥ using the screws④ and the washers

⑤ (5EA).

C. Insert the belt① into the belt cover (Dn)③ and fix

the belt cover⑦ using the screws⑧ (3EA).

5) Connection to clutch-type pedal

Connect the lap lift lever① and the pneumatic pressure

switch② to Chain ③.

And then connect the pneumatic switch② to Chain ⑤

on the foot pedal④.

④

⑤

③

⑥

⑦

①

⑧

③

①

②

③

⑤

④

Page 15

15

①

②

6m/m TAP

64/9

INCH

TAP

③Parellel

④

⑥

⑤

6) LRP Puller Attachment

A. Replace the no. ①presser foot bolt with the

decelerator bolt.

B. Attach the no.

②

lower roller to the machine.

* Refer to clause H.

C. Attach the no.

③

decelerator to the machine.

※ Adjust the no.

③

È upper/ lower roller horizontally.

D. Replace the pulley of the no.

④

machine with the

decelerator pulley.

E. Connect the no.

⑤

shaft lever with the no.⑥pulley

lever.

Page 16

16

⑦

⑧

64/9 INCH TAP

① ② ③Parellel

F. No. ⑦: Stitch Lever

(The stitch is getting wider by lowering from

1 to 4 one by one)

G. A belt cover should be installed.

※

The belt cover should be cut out like no.⑧for a

brand new machine.

G. H. Lower roller installation

Attach the bracket to the no.①fixed tap hole like no. ②and keep parallel like no.

③

Page 17

17

B. Open the pulley cover of 8200 and fix the pulley of

the puller to the shaft.

C. The position of the timing is the place to adjust the

pulling of the roller.

After operate no. 6 of the manuals, adjust the wheel

movement identically.

6m/m TAP

TIMING

M6×60m/m

M8×25m/m

64/9 inch TAP

7) SRP Puller Attachment

A. Replace the presser foot bolt with the puller bolt.

D. Attach the puller to the body of 8200.

(Use the M8X25m/m, M6X60m/m bolt.)

Page 18

18

Parellel

E. In case fixing the puller, adjust a needle plate base

and a urethane roller base of the puller in parallel.

F. Fix a pulley lever of the puller and a pulley.

G. Install the cover of the puller.

Page 19

19

C. Fix the Puller with the fixation bolt (M10 * 20m/m-3EA)

during attachment.

D. Locate the red-marked thread take-up lever position on the

top.

8) MODEL : BP(Belt Puller Type)

Sewing of several clothes as one (FEED-OFFARM)

Attaching & Setting Puller to Sewing Machine

A. Insert Timing Belt Pulley A into the upper shaft of M/C.

B. Attach the Belt Puller to the M/C.

Timing Belt Pulley A

upper shaft

fixation bolt

thread take-up lever

Page 20

20

F. Adjust the belt tension using idler on the red-marked part to

keep the position unchanged when the puller timing belt is

connected to the timing belt pulley A.

G. Put the belt cover.

E. Fix it to conform to the red-marked part. (The machine and

the time of the puller accord well)

punched mark

idler

belt cover

Saw teeth movement of the machine and the timing of puller need to be united.

Caution

Fix the belt with proper tension not too loosely or tightly.

Caution

Fix the belt cover not to interfere in the machine.

Caution

Page 21

21

I. Connect the fixation screw (M6x40m/m-2EA,M8x20m/m-

1EA) of the red-marked part to the joint before the puller

body is fixed.

J. Fix the puller body to make the needle plate of the machine

and the contact part horizontally.

H. Locate the body of the puller on the red-marked part.

B(exclusive bolt)

joint

Please use the exclusive bolt for belt puller when fixing the part B.

Caution

Surface of the

needle plate

The contact

part on the belt

Page 22

22

L. Stitch width adjustment

Adjust the stitch width of the puller.

(1-1m/m,2-2m/m,3-3m/m, 4-4m/m,5-5m/m)

M. Check

Please change the belt or detach the puller body by pulling

it when checking the machine.

K. Adjust the stopper not to interfere with the puller when the

needle is moving up and down.

stoper

The punched mark should be matched to adjust the stitch width exactly. (Refer to the No.5 item)

Caution

Page 23

23

55

Machine Preparation

1) Oil Supply

A. Make the oil supply slot screw ① pointed upward

and turn the hand pulley. Then remove the screw ①

and supply oil to the oil tank ② until it reaches

above the central line ③.

B. Open the front cover ① and remove the rubber plug

②. Supply lubricant until it reaches the central line

on the oil window ③.

C. Place back the rubber plug ② and close the front

cover ①.

D. Supply one or two drops of oil to the needle bar

lubrication hole ④ once a week.

E. Replace the waste oil tank ⑤ on a regular basis after

long-term use.

①

②

③

④

③

⑤

②

①

If oil is supplied below the central line, oil cannot be sucked into the upper shaft, and sufficiently supplied

to the upper shaft.

Caution

Page 24

24

F. Loosen the oil tank lid screw ① and supply lubricant

until the mark reaches the middle on the oil window

②.

G. Place back and fasten the screw ①.

When the oil level drops below the central line, additional oil must be supplied.

Caution

②

①

Page 25

25

66

Sewing Preparation

1) Needle Installation

2) Lower Thread Placement

Place the lower thread as in the figure below.

A. Turn the hand pulley to make the needle holder ①

reaches the highest position.

B. Loosen the needle fixing screw ②. Make the long

groove of the needle ③ headed forward and then

fasten the fixing screw again ②.

①

③

②

Make sure to turn off the power before needle installation.

Otherwise, injury might occur due to the mistaken operation of the pedal.

Caution

Make sure to turn off the power before lower thread placement.

Otherwise, injury might occur due to the mistaken operation of the pedal.

Caution

Page 26

26

3) Upper Thread Placement

Place the upper thread as in the figure below.

4) Handling of Waste Oil

When the waste oil can beneath the table is filled with

waste oil, remove it to empty the can.

Make sure to turn off the power before lower thread placement.

Otherwise, injury might occur due to the mistaken operation of the pedal.

Caution

When removing or assembling the waste oil can, oil might drop to the floor. Place a cloth, paper, or oil

dish during the oil can removal and assembly.

Caution

Page 27

27

77

Sewing

1) Sewing

A. Turn on the power.

B. Press Pedal A and place the fabric below the presser

bar.

C. Remove a foot from Pedal A.

D. When stepping Pedal B, the machine starts

operating.

E. When the sewing is complete, conduct pseudo

sewing until the cutter ① and trim the thread at the

cutter ①.

①

Properly install all safety devices before using the machine. Otherwise, injury might occur.

Caution

Do not touch the operating sections or the input device during sewing. It may negatively affect the

machine or become the cause of injury.

Caution

In the following situations, please turn off the power. Otherwise, injury might occur due to the mistaken

operation of the pedal.

① Thread placement on the needle

② Needle replacement

③ When the machine is not used or user should be away from the machine for a long time

Caution

Page 28

28

2) Trial Operation (pedal operation method)

A. Lightly step the pedal until B to check if slow sewing

is possible.

B. Press the pedal until C to check if fast sewing is

possible.

C. Press the pedal forward (B or C) and place it at the

neutral A position. Then the needle stops below the

needle plate face (when the lower stop function is

set).

D. When the pedal is pressed until D (or press the pedal

until D and place it to neutral A position), the needle

stops above the needle plate face after trimming.

Do not touch or press with other object the revolving or moving parts while the machine is in operation.

Injury or mechanical damage might occur.

Caution

3) Trial sewing (How to operate a clutchtype pedal)

A. When the pedal① is pressed, the presser foot starts

vertical movement. With the pedal① being pressed,

set the sewing position for trial sewing.

B. Remove a foot from the pedal①, and then the

presser foot starts descending and fixes the sewing

materials.

C. Pressing the pedal② starts operating the trial sewing.

②

①

Page 29

29

88

Thread Tension

1) Thread Tension Adjustment

A. Turn the upper thread adjusting nut ① to properly

adjust the upper thread tension.

B. Turn the lower thread adjusting nut ② to properly

adjust the lower thread tension.

2) Adjustment of Presser Bar Pressure

Use the pressure adjusting nut ① to adjust the pressure

of the presser bar.

①

②

②

Page 30

30

3) Adjusting the pneumatic presser bar

The presser bar① can be adjusted for its pressure in two

steps depending on height.

When the first part② is detected by the second part③,

the pressure is changed. The initial pressure is

2.5~3.5kg, and it changes to 6.5~7.5kg.

A. Loosen the screw④.

B. Lift the presser foot① to the extent of placing it at a

desired position. (Max. lift: 11mm, the default height

of presser foot is 5mm)

C. With the presser foot lifted to the desired position,

move the center of the sensor③ to the most top of

the sensor plate②.

D. Fasten the screw④.

※

The first gauge① is the scale showing the maximum

adjustable pressure of the presser foot (default value:

0.4MPa), and the second gauge② is the scale

showing the minimum adjustable pressure of the

presser foot(default value: 0.1MPa).

②

③

④

①

①

④

③

②

②

Page 31

31

99

Cleaning

1) Daily Cleaning

A. Dust removal

- Open the looper cover and remove thread scraps

and dusts.

- When all dusts are removed, put back the looper

cover.

B. Oil Supply

- See the oil supply section of the manual.

C. Check

- Ensure that thread is properly placed.

- If the tip of the needle is broken, immediately

replace the needle.

- Conduct trial sewing.

①

Page 32

32

1100

Adjustment

⑨

⑩

①

⑧

②

⑦

⑥

①

⑧

①

⑤

③

1) Adjustment of Needle Bar Height

Adjust the height of the needle bar ①.

Make sure that each needle ① is at the center of the needle hole ⑧ on the needle plate ②.

A. Remove the screw ⑨ and then remove the presser foot ⑩.

B. Turn the pulley until the needle bar is located at the lowest position.

C. Loosen the needle bar clamp screw ⑤ and adjust the distance between the bottom of the needle clamp ③ and the

needle plate ② at 14.8mm(For light materials:11.5mm).

※ With the needle clamp adjustment as set forth above, when the needle clamp ③ reaches the highest position,

the distance between the needles ① and the needle plate ② becomes 14mm(For light materials:9mm).

(applicable to heavy and super heavy materials).

D. Remove three screws ⑦ and then remove the needle plate ②.

E. Turn the pulley to place the needles ① and the needle guard ⑥ in parallel. Then adjust the slant of the needle

clamp ③ to remove the space between left, right needles ① and the needle guard ⑥.

Use the three screws ⑦ to assemble the needle ②. Check that the needles ① are at the center of the needle holes

⑧, and then fasten the needle bar clamp screw ⑤.

F. Use the screw ⑨ to assemble the presser foot ⑩.

Page 33

33

2) Adjustment of Needle and Looper Timing

When the needle ① descends, and the lowest looper ②’s backward movement is complete, the distance between the

center of the needle and the looper becomes 2.7~2.9mm.

A. Remove the presser foot, the needle plate, and the feed dog.

B. Turn the pulley until the looper ②’s backward movement is complete.

C. Loosen the two adjusting screws ⑦ on the lower shaft pulley ⑥.

D. Turn the pulley toward the user side until the needle ① reaches the lowest position.

E. Tightly fasten the two adjusting screws ⑦.

F. Loosen the adjusting screw ⑧ and move the looper holder ⑨ in the arrow direction until the distance between the

needle center and the tip of the looper becomes 2.7~2.9mm. The tightly fasten the adjusting screw ⑧ again.

G. Check if the looper thread eyes match needle eyes while the loopers are moving back and forth.

H. Assemble the presser foot, the needle plate, and the feed dog.

3) Needle Avoiding Looper Timing

When the looper moves forward, it moves behind the needle. When the looper moves backward, it moves in front of

the needle. For the forward movement, adjust the distance between the needle and the looper at around 0.05~0.1m.

A. Remove the forward feed arm cover ①.

B. Adjust the timing of the looper heading forward and backward. The adjusting screws on the back which move in

the same direction of the cam moving back and forth should match the screw adjusting hole ③. Then, the

adjusting screws on the back which move in the same direction of the cam moving up/down should match the

looper connecting road adjustment hole ②. For adjustment, loosen the adjusting screw on the front which moves

in the same direction of the cam moving back and forth. Then loosen the adjustment screw on the back to adjust

the cam moving back and forth. When adjustment is completed, tightly fasten the two adjusting screws.

C. Loosen the looper holder screw ④. When the tip of the next looper and the needle center are in a straight line,

move the looper holder ⑤ in the arrow direction to adjust the distance between them at 0.05~0.1mm. Do not

move the looper holder ⑤ in any other direction than the instructed direction. If you did, see “10-2. Adjustment

of Needle and Looper Timing” in page 16 for making adjustment.

D. Assemble the forward feed arm cover ①.

⑦

⑥

①

②

⑧

⑨

(Looper moving forward) (Looper moving backward)

①

②

③

④

⑤

Page 34

34

4) Adjustment of Needle Bar Guide

When the stitch length is the minimum and the looper moves toward the needle, the distance between the needle

guard and the needle should be 0.2mm.

The height should remain as low as possible to the extent that the looper does not break.

A. Adjust the stitch length to be minimal (see page 12).

B. Spin the pulley toward the user side to make the needle center and the looper in the straight line.

C. Loosen the adjusting screw ③. Then move the needle bar guide to set the distance between the needle bar guide

bottom ① and the needle to be 1~2mm.

D. Tightly fasten the adjusting screw ③.

E. Loosen the adjusting screw ④. To set the distance between the needle bar guide and the needle at 0.2mm, move

the needle bar guide left and right.

F. Tightly fasten the adjusting screw ④.

5) Adjustment of Feed Dog Height

Adjust the highest part of the feed dog to be 1.2mm(For

light materials:0.9mm) above the needle plate surface

when the feed dog ① is at the highest position.

Adjust the height of the feed dog ① by spinning the

feed bar eccentric shaft ②.

A. Spacer Installation (for denim sewing)

If irregular stitches occur during the sewing of super

heavy materials, adjust the sub feed dog to the

accurate height using the spacer.

- Remove the adjusting screw ① and the sub-feed

dog ②.

- Locate the spacer ③ below the sub-feed dog ②

and fasten the adjusting screw ①.

※ Spacer is included in the parts box.

④

③

①

①

②

When setting the stitch length depending on fabrics and thread used, the closer the needle bar guide and

the needle becomes, the better the sewing result is.

Caution

Page 35

35

6-1) Adjustment of Thread Release Lever

Adjust the thread release lever's thread hole center to be

7~9mm above the thread hole center on the upper thread

tension adjusting device when the needle bar is at the

lowest position.

A. Turn the pulley until the needle bar descends to the

lowest position.

B. Loosen the screw ① and move the thread release

lever ② up and down to adjust the thread release

lever thread hole center to be 7~9mm above the

thread hole center on the upper thread tension

adjusting device.

C. Fasten the adjusting screw ① again.

※ As the thread release lever moves higher, the

stitches become firmer.

6-2) Adjustment of Thread Release Lever

When the needle bar is at the lowest position, adjust to

place the center of the thread release lever thread hole at

2 to 3mm below from the center of the thread hole of the

thread take-up lever thread guide.

A. Turn the pulley until the needle bar is lifted to the

highest position.

B. Loosen the screw① and adjust the thread release

lever② up or down to place the center of the thread

release lever tread hole at 2~3mm below from the

tread guide’s thread hole.

C. Fasten the adjusting screw ① again.

①

7~9mm

①

2~3mm

6~7mm

②

7) Adjustment of Thread Take-up Guide

Adjust the distance between the thread take-up's thread

guide hole and the thread take-up guide's upper part to

be 6~7mm(For light materials:3mm).

A. Turn the pulley toward the user's position when the

needle bar reaches the lowest position.

B. When the screw ① is loosened, move the thread

take-up guide ② up and down to set the distance

between the upper part of the thread take-up guide ②

and the thread guide hole to be 6~7mm.

C. Fasten the screw ①.

※ As the thread take-up guide ② moves higher, the

upper thread loops become larger.

①

②

Page 36

36

9) Adjustment of Thread Release Shaft

Adjust the thread release shaft to ensure when the

presser foot ascends, the thread tension discs are

released and to ensure when the presser foot descends,

the thread tension discs are tightened.

A. Loosen the adjusting screw ①.

B. Spin the thread release shaft ② to make the thread

tension discs start loosening when the presser foot is

4mm above the needle plate.

C. When the adjustment is complete, tightly fasten the

adjusting screw ①.

10)

Adjustment of Lower Thread T ake-up T iming

When the looper starts moving backward, make

adjustment to let the lower thread take-up ① contact the

thread ② and 7mm away from the lower thread take-up

base ③.

A. Insert the screwdriver into the adjustment hole on the

lower thread take-up base and loosen the two

adjusting screws④.

B. Lift the lower thread take-up ① from the lower

thread take-up base by 7mm.

C. Tightly fasten the two screws ④ after adjustment.

②

①

8)

Adjustment of Upper Thread Adjusting Cam

The maximum tolerance between the upper thread

tension adjuster ② and the upper thread tension plate ③

is 0.5~0.7mm (2-needle) or 0.8~1.0mm (3-needle).

Loosen the adjusting screw ① and move the upper

tension adjuster ② in and out to set the maximum

tolerance between the adjuster ② and the upper thread

tension plate ③ to be 0.5~0.7mm (2-needle) or

0.8~1.0mm (3-needle).

※ If tolerance between the upper thread adjuster ② and

the upper thread tension plate ③ is reduced, the

tension gets higher.

①

②

③

Page 37

37

12) Adjusting position of the belt puller

The belt puller is adjustable in four directions including

up, down, left, and right.

When the needle is located below, the belt should

closely contact the needle plate. Otherwise, smooth

seaming is difficult to get.

11) Lapper Installation

Insert the lapper guide pin into the overall hole on the

upper bed cap. Check if the end of the lapper is not too

close to the presser foot.

Page 38

38

A. Unfasten the screws①, ②.

B. Turn the screws③, ④ with a driver to adjust the

position of the belt puller. The belt should closely

contact the sunken part of the needle plate without

space, and it should not be contacted by the needle

bar when the needle bar is at its lowest position.

C. After adjustment is completed, tightly fasten the

screws①, ②.

13) Fixing without puller

The puller can be fixed while being pushed backward

and it can be fixed either at the angle of 50°or 100°.

A. Loosen the screw ①.

B. Lift the belt puller while the screw ① is pulled up.

C. Fasten the screw ①.

①

②

③

④

①

Page 39

39

Roller Timing Adjustment Spot

⑩

⑫

⑪

※ Checkpoints

14) Decelerator Timing Adjustment

When a saw teeth of the machine starts to move up and

pushes the stuff out, adjust the roller of decelerator to go

around.

A. The decelerator is bearing type so if the angle is

turning, part of the bearing can be damaged or be

generated heat. After installation, therefore, check as

follows

B. Unfasten the no.

⑩

bolt, shake no.⑪stitch length

lever back and forth more than 3 times leading to

place no.

⑩

shaft lever its position.

After that, match no.

⑫

arrow to the other arrow and

fix the no.

⑩

bolt.

Page 40

40

Stitch Adjustment Method

Descending from no.1

toward no.5, the stitch is

getting longer.

15) Adjustment of Puller Feeding Amount

- Shaft lever(PART NO.12) function can choose the

feeding of roller(quantity of motion/the stitch role of

sawing machine).

A(quantity of motion) : Large=5.2m/m, Small=2.3m/m

B(quantity of motion) : Large=4m/m, Small=2m/m

C(quantity of motion) : Large=3.3m/m, Small=1.3m/m

16) Speed Lever Stitch Length Adjustment

- The shaft lever(PART NO.25) stitch is adjusted as the

scale is widened and it can be adjusted by changing the

setting position.

- Timing adjustment

Unfasten part no.13, shake no.25 back and forth more

than 5 times.

After the position of bearing is settled, adjust to the place

which the arrow direction is matched and fix the part no.13.

(See Decelerator Timing Adjustment of the manuals)

17) P.S.W-I Stitch Length Adjustment

* LRP Type(PART NO.66), SRP Type(PART NO.55)

Generally use by fixing to the standard position (A) part

but in case of using the stitch longer, position (B) can be used.

In case of moving the position of shaft lever(PART NO.12),

be sure that the power switch of M/C is in the OFF position and the power cord is unplugged.

Caution

Page 41

41

18) Ascending Momentum of the Ruller

* LRP Type(PART NO.77), SRP Type(PART NO.71)

-> the quantity of motion in case of working with a

machine (13m/m).

* The quantity of motion when part no.29(manual lever) is

lifted by hand (15m/m~25m/m)

19) Bearing Replacement

- Parts Life [LRP Type (PART NO.54, NO.57), SRP Type

(PART NO.91, NO.95) 5R BEARING]

Parts can be used for 2.5 to 3.5 years although there are

some gaps according to the workload.

-Replacement Time

Replace them when the machine stitch mismatches to the

stitch of the puller due to the pulling malfunction with

long use.

20) Breakdown of TENSION DISK & E-RING

LRP Type(PART NO.62~NO.76), SRP Type(PART NO.51~NO.65)

- Engine structure has the pulling function of piller and built-in

grease, does not need oil.

13m/m

15m/m~25m/m

Need not use oil due to the oilless bearing. In case of refueling unnecessary oil, the stuff can be tainted so

the use of oil is prohibited.

Caution

If the thread winds around the engine structure or the parts are damaged by mistakes, the function of puller

can be out of order so do work with care.

(The damage caused by a careless worker cannot be repaired for free.)

Caution

Loading...

Loading...