Page 1

USER S MANUAL

SC 7900-Series

R

1) Read all instructions before using the

machine to prevent trouble.

2) Keep the instructions and refer to it during

machine failures.

Page 2

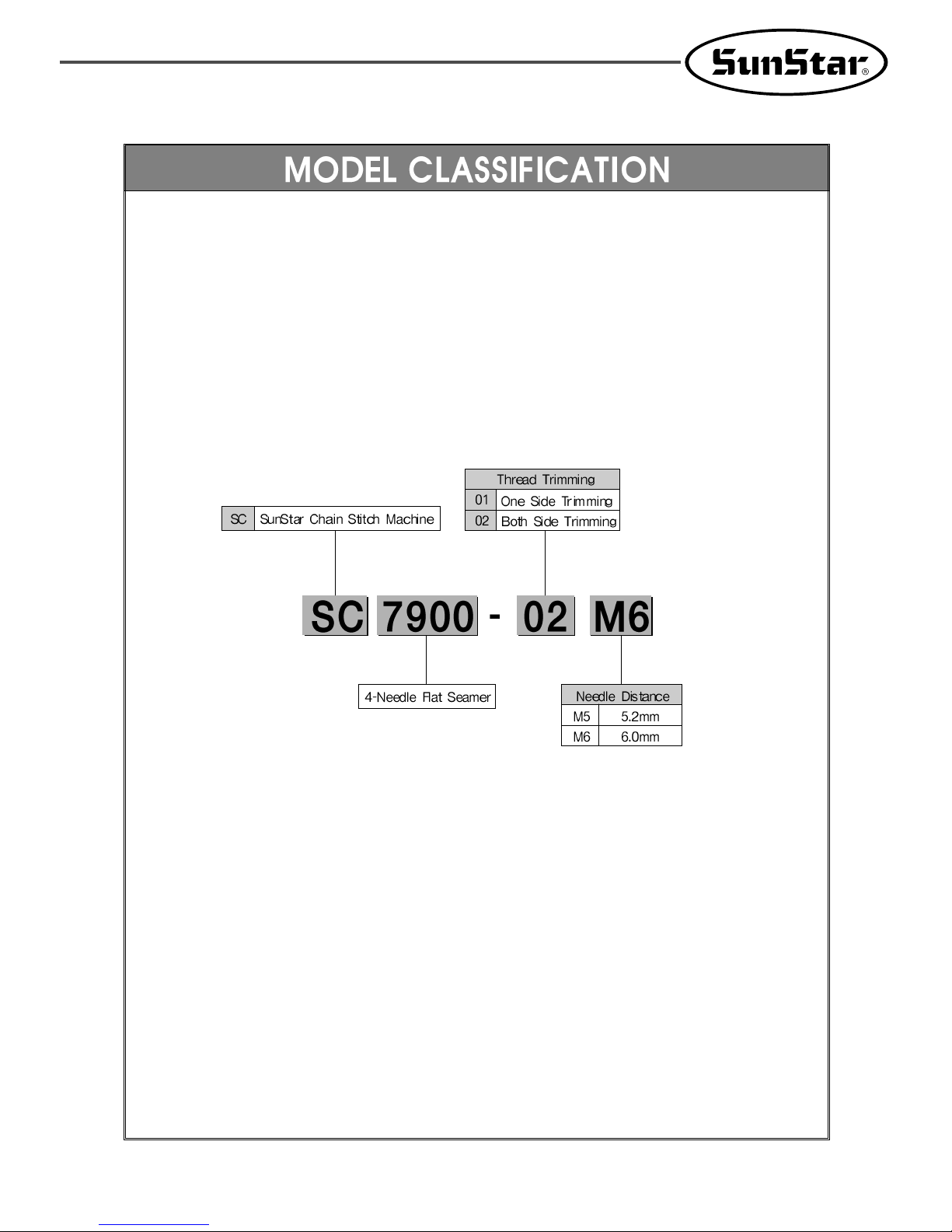

Best Quality

Best Price

Best Service

R

1. Thank you very much for buying a HIGH-SPEED OVERLOCK sewing

machine.

SUNSTAR will satisfy you by manufacturing the industrial sewing machine

with refined design, improved durability, great power, perfect performance,

variable functions based on skills and experience.

2. Please read this manual thoroughly before use.

3. This manual can be changed the contents without prior notice to improve

the functions.

4. This is designed and manufactured as an industrial machine. Do not use this

machine for other than its intended use.

Page 3

Page 4

4

Table of Contents

1. SAFETY RULES ------------------------------------------------------------------------------------- 6

1) MACHINE DELIVERY ------------------------------------------------------------------------------------------- 6

2) MACHINE INST ALLATION------------------------------------------------------------------------------------- 6

3) MACHINE REPAIR ------------------------------------------------------------------------------------------------ 6

4) MACHINE OPERATION ----------------------------------------------------------------------------------------- 7

5) SAFETY DEVICE -------------------------------------------------------------------------------------------------- 7

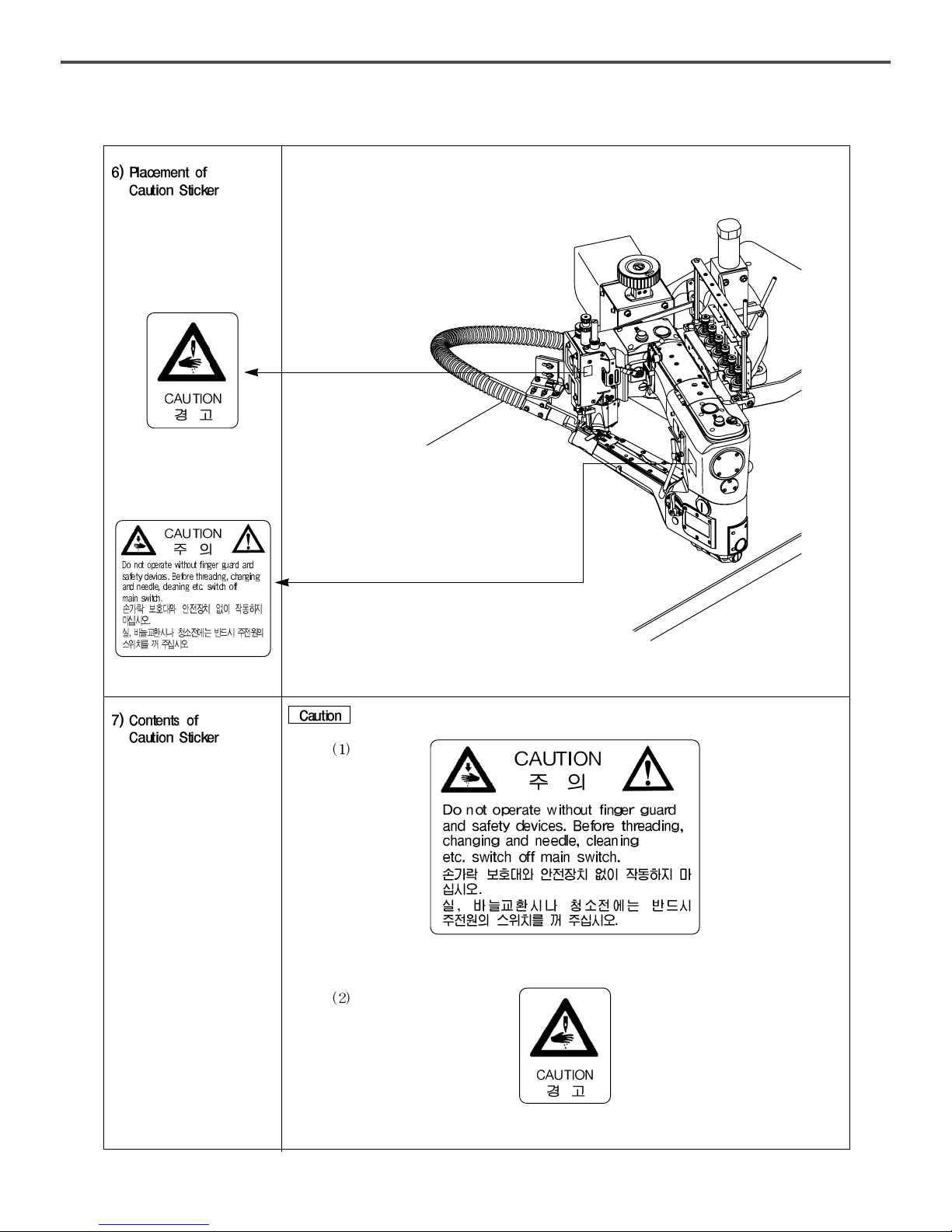

6) PLACEMENT OF CAUTION STICKERS -------------------------------------------------------------------- 8

7) CONTENTS OF CAUTION STICKERS----------------------------------------------------------------------- 8

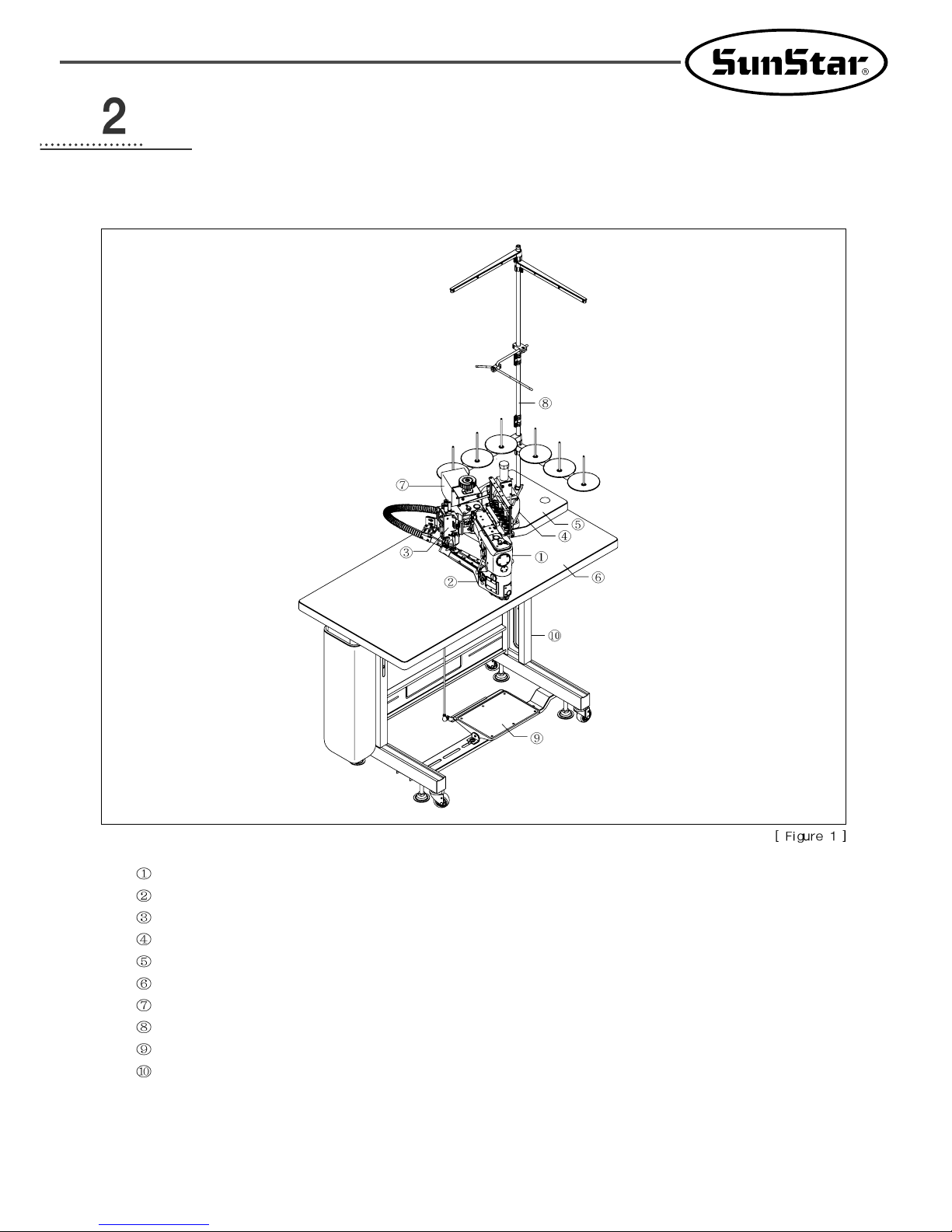

2. ENTIRE STRUCTURE ----------------------------------------------------------------------------- 9

3. SPECIFICATIONS ----------------------------------------------------------------------------------- 10

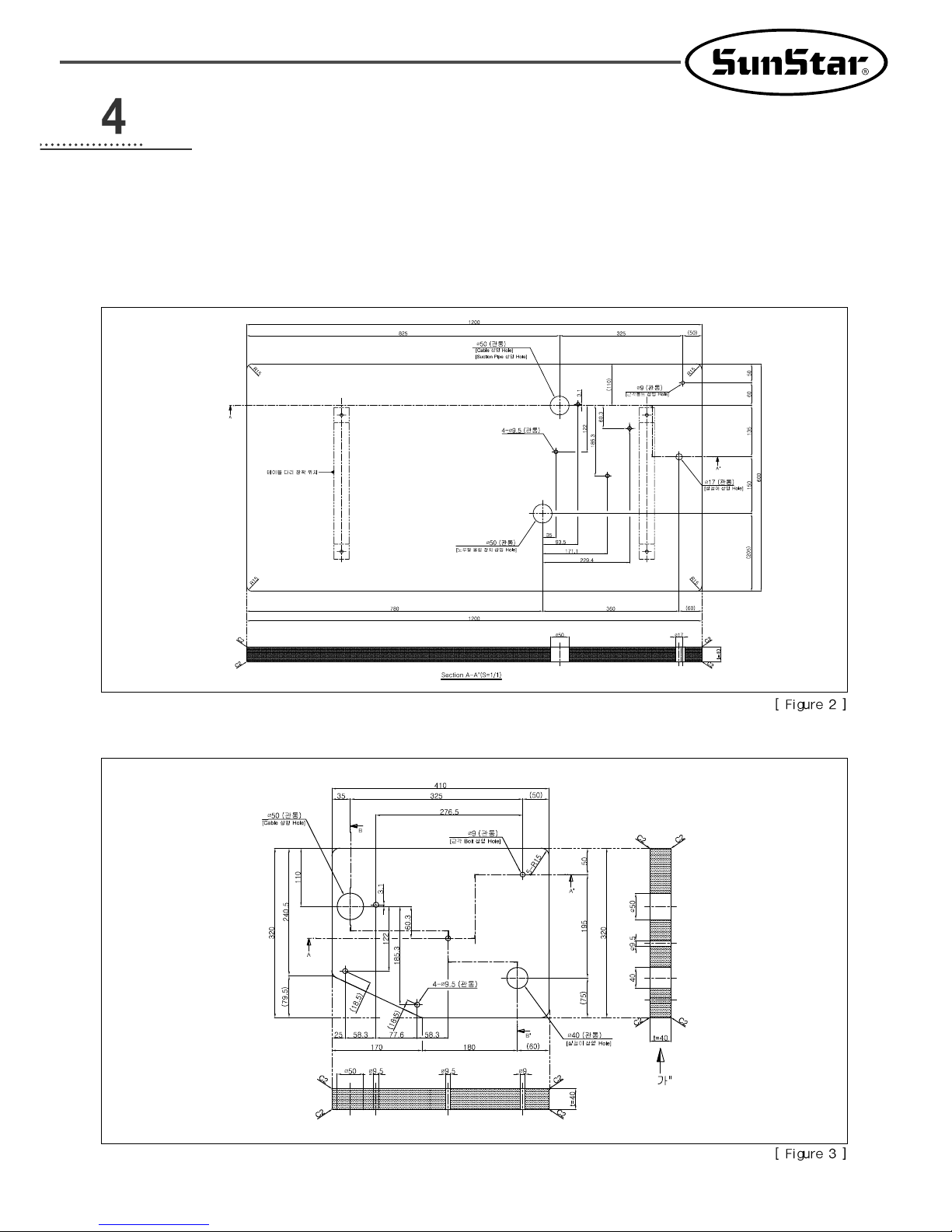

4. INSTALLATION -------------------------------------------------------------------------------------- 11

1) T ABLE INSTALLATION------------------------------------------------------------------------------------------ 11

2) M/C INST ALLATION---------------------------------------------------------------------------------------------- 13

3) THREAD GUIDE FOR ST AND SUPPORT INST ALLATION -------------------------------------------- 14

4) GROUND WIRE CONNECTION------------------------------------------------------------------------------- 14

5) AIR-COMPRESSED PRESSURE BAR LIFTER INSTALLA TION-------------------------------------- 15

6) DIRECT MOTOR INSTALLA TION---------------------------------------------------------------------------- 16

7) AIR-COMPRESSED TREAD TRIMMING DEVICE (Optional) INSTALLA TION------------------- 17

8) AIR-COMPRESSED DEVICE INST ALLATION ------------------------------------------------------------ 18

5. LUBRICATION---------------------------------------------------------------------------------------- 20

1) OIL--------------------------------------------------------------------------------------------------------------------- 20

2) LUBRICATING OIL ----------------------------------------------------------------------------------------------- 20

3) OIL GAUGE/OIL WINDOW------------------------------------------------------------------------------------- 20

4) LUBRICATING OIL EXCHANGE------------------------------------------------------------------------------ 21

5) OIL PRIMING------------------------------------------------------------------------------------------------------- 21

6) LUBRICATING OIL REPLENISHMENT --------------------------------------------------------------------- 21

7) OIL FILTER CLEANING ----------------------------------------------------------------------------------------- 22

6. STANDARD ADJUSTMENTS ------------------------------------------------------------------- 23

1) NEEDLE-------------------------------------------------------------------------------------------------------------- 23

2) NEEDLE INST ALLATION--------------------------------------------------------------------------------------- 23

3) THREADING-------------------------------------------------------------------------------------------------------- 24

4) THREAD TENSION ADJUSTMENT -------------------------------------------------------------------------- 25

5) PRESSER FOOT ADJUSTMENT------------------------------------------------------------------------------- 25

6) PRESSER FOOT PRESSURE ADJUSTMENT--------------------------------------------------------------- 26

7) VERTICAL ADJUSTMENT OF PRESSER FOOT---------------------------------------------------------- 27

8) MAIN FEED ADJUSTMENT------------------------------------------------------------------------------------ 27

9) DIFFERENTIAL FEED ADJUSTMENT ---------------------------------------------------------------------- 28

10) THREAD LUBRICATING DEVICE -------------------------------------------------------------------------- 29

11) OVERLAP WIDTH ADJUSTMENT OF UPPER SEWING MACHINE------------------------------- 29

12) USING A LAP FORMER---------------------------------------------------------------------------------------- 30

Page 5

5

7. DETAILED ADJUSTMENTS --------------------------------------------------------------------- 31

1) THREAD TENSION ADJUSTMENT -------------------------------------------------------------------------- 31

2) LOOPER THREAD TENSION ADJUSTMENT ------------------------------------------------------------- 32

3) UPPER THREAD TENSION ADJUSTMENT---------------------------------------------------------------- 33

4) NEEDLE HEIGHT SETTING------------------------------------------------------------------------------------ 33

5) UPPER THREAD RET AINER----------------------------------------------------------------------------------- 34

6) ADJUSTMENT OF NEEDLE AND LOOPER TIMING---------------------------------------------------- 35

7) ST ANDARD POSITION OF NEEDLE GUARD------------------------------------------------------------- 36

8) FEED DOG HEIGHT SETTING--------------------------------------------------------------------------------- 37

9) EXCHANGE OF PRESSER FOOT ----------------------------------------------------------------------------- 38

10) EXCHANGE OF PRESSER FOOT SPRING PLATE A--------------------------------------------------- 40

11) BLADE EXCHANGE AND ADJUSTMENT---------------------------------------------------------------- 41

8. AIR-COMPRESSED THREAD TRIMMER (OPTIONAL) MANUAL ----------------- 43

1) CONSIDERATIONS BEFORE USING------------------------------------------------------------------------- 43

2) MODEL NUMBER SETTING ----------------------------------------------------------------------------------- 43

3) SENSOR SETTING METHOD ---------------------------------------------------------------------------------- 43

4) RELATED P ARAMETER----------------------------------------------------------------------------------------- 45

5) THREAD TRIMMING MODE SETTING--------------------------------------------------------------------- 45

6) THREAD TRIMMING RANGE SETTING ------------------------------------------------------------------- 47

Page 6

6

SAFETY RULES

The following set of safety rules categorized as Danger, Warning and Caution indicates possibilities of physical or property

damages if not fully observed.

DANGER : These safety instructions must be observed to be safe from danger when installing, delivering, or

maintaining the machine.

WARNING : These safety instructions must be observed to be safe from machine injuries.

CAUTION : These safety instructions must be observed to prevent machine errors.

1) Machine Delivery

2) Machine Installation

3) Machine Repair

Only qualified technicians who are familiar with the safety instructions should carry the

machine. Make sure to fully observe the following instructions when carrying the machine.

The machine should be carried out by two or more people.

Clean oil spots to prevent accidents when delivering.

Installation environment may incur machine malfunction or breakdown. Make sure to meet

the following conditions.

Undo a package from the top in order. Beware nails in wooden box.

Dust and humidity can cause pollution and corrosion of the machine. Air conditioner

should be equipped and cleaned regularly.

Do not expose the machine directly to the sun.

Allow at least 50cm of space on each side of the machine for convenient maintenance.

Explosion hazard

Do not operate machine in explosive atmospheres, where aerosol spray is used in large

quantity or oxygen is controlled.

The lighting is not offered because of the nature of the machine, the lighting should be

install in the workspace by users.

[Reference] details of the machine installation are illustrated in 4. INSTALLAION.

Only SUNSTAR MACHINERY Co.,Ltd-trained and selected repair engineers should go

repair work.

Turn off the power before cleaning or repairing the machine. Wait for 4 minutes so the

machine electricity is completely discharged.

Do not change the specifications or any parts on the machine without confirmation from

SUNSTAR MACHINERY Co.,Ltd. Such change may cause safety accidents.

Use only SUNSTAR MACHINERY Co.,Ltd parts when repairing machine.

Put all safety cover on after repairing.

Page 7

7

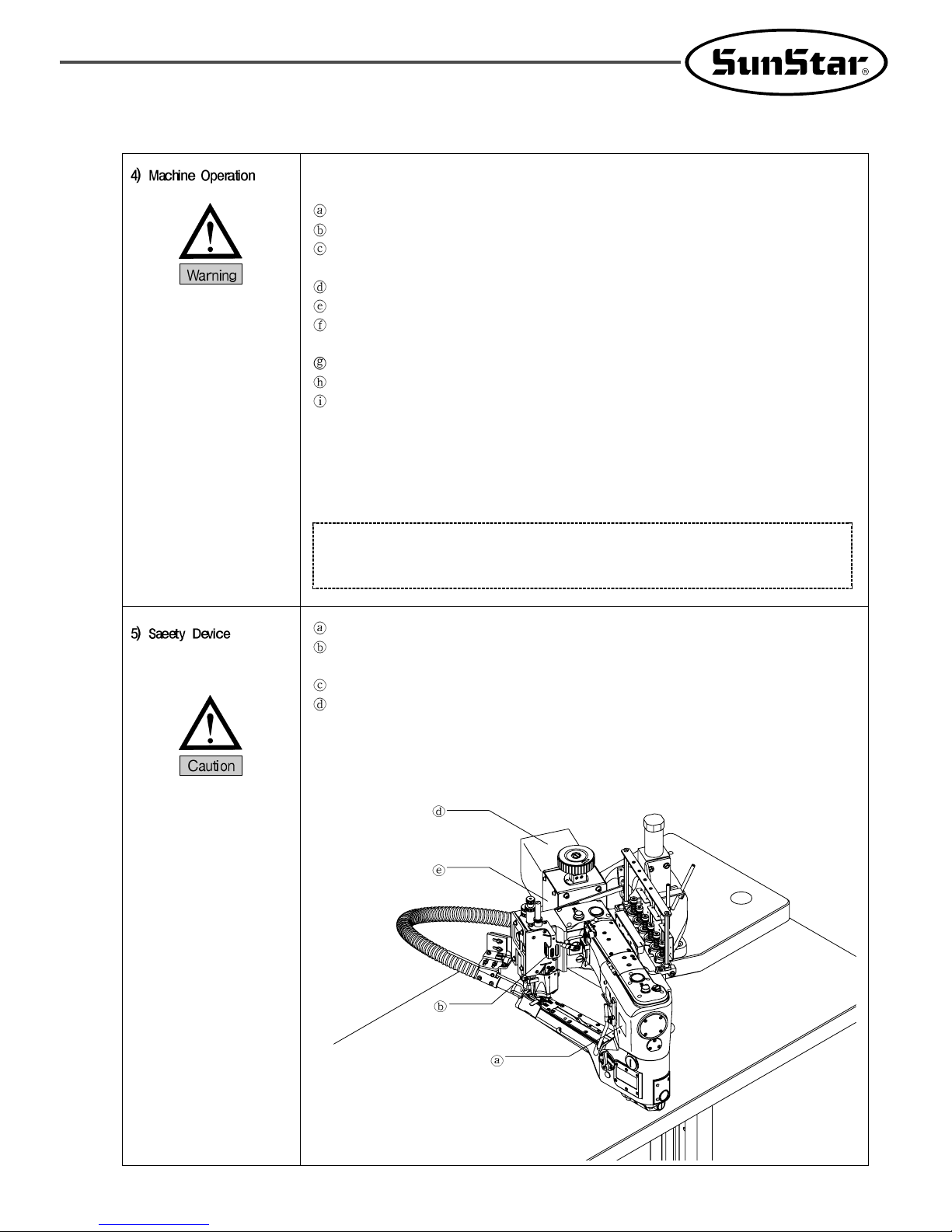

SC 7900 Series is designed for applying sewing to knitwear and other similar materials.

Read thoroughly the following instructions.

Read thoroughly and fully understand the manual before operating the machine.

Dress for safety.

Keep your hands or head away from the moving parts of the machine such as needle,

looper, spreader, take-up lever, and pulley when the machine is in operation.

Do not remove the safety valve and all kinds of covers when the machine is in operation.

Be sure to connect the ground wire

Be sure the main power is turned off and the power switch is set to OFF before opening

the cover of any electrical component or control box.

Turn the machine off when threading needles or inspecting the finished sewing.

Do not press the pedals when you turn on the power.

Install the machine away from strong electromagnetic wave such as high frequency

welder as far as possible.

[WARNING]

When you operate machine, you should put the cover on to prevent physical injury by the

gear or other parts. Turn off the power before inspecting or adjusting.

Safety Label: Note directions for sewing machine use

Thread take-up Cover: Device to prevent finger to come in contact with the thread takeup.

Base cover: Device to prevent accidents during rotation of motor.

Motor cover: Device to prevent accidents during rotation of motor.

Page 8

8

CAUTION STICKERS is attached on the machine for the safety.

Read thoroughly the manual before operating the machine.

Page 9

9

ENTIRE STRUCTURES

Arm

Bed

Head

Arm support

Arm support table

Table

Motor cover

Spool thread stand

Pedal

Table legs

Page 10

10

SPECIFICATIONS

Explanation

Stitch form

Use

Sewing speed

Stitch width

Needle

Needle distance

Needle bar stroke

Presser foot lift

Feeding volume adjustment system

Differential feed ratio

Differential feed ratio adjustment system

Lubrication system

Used oil

Oil pan capacity

High-speed Cylinder bed 4-needle interlock sewing machine (the Arm type)

ISO 406, 605, 608

General sewing (knitwear)

4,200 s.p.m (in case of intermittent operations)

1.6mm~2.5mm

Stitches per 25.4mm: 10~16, stitches per 30mm: 12~19

Sewing machine needles: Groz-Beckert UY118GKS

Retainer needles: Groz-Beckert UY36211

M5 : 5.2mm

M6 : 6.0mm

30mm

Type 01: 8mm, type 02: 6mm at the highest point

Adjustment link

Max. Forward differential feed ratio=1.0:1.5

Max. Reverse differential feed ratio=1.0:0.7

Adjustment lever

Automatic lubrication by gear pump

General sewing machine oil ISO VG 22

The lower part of bed: 100cc

The inner part of arm: 100cc

Page 11

11

INSTALLATIONS

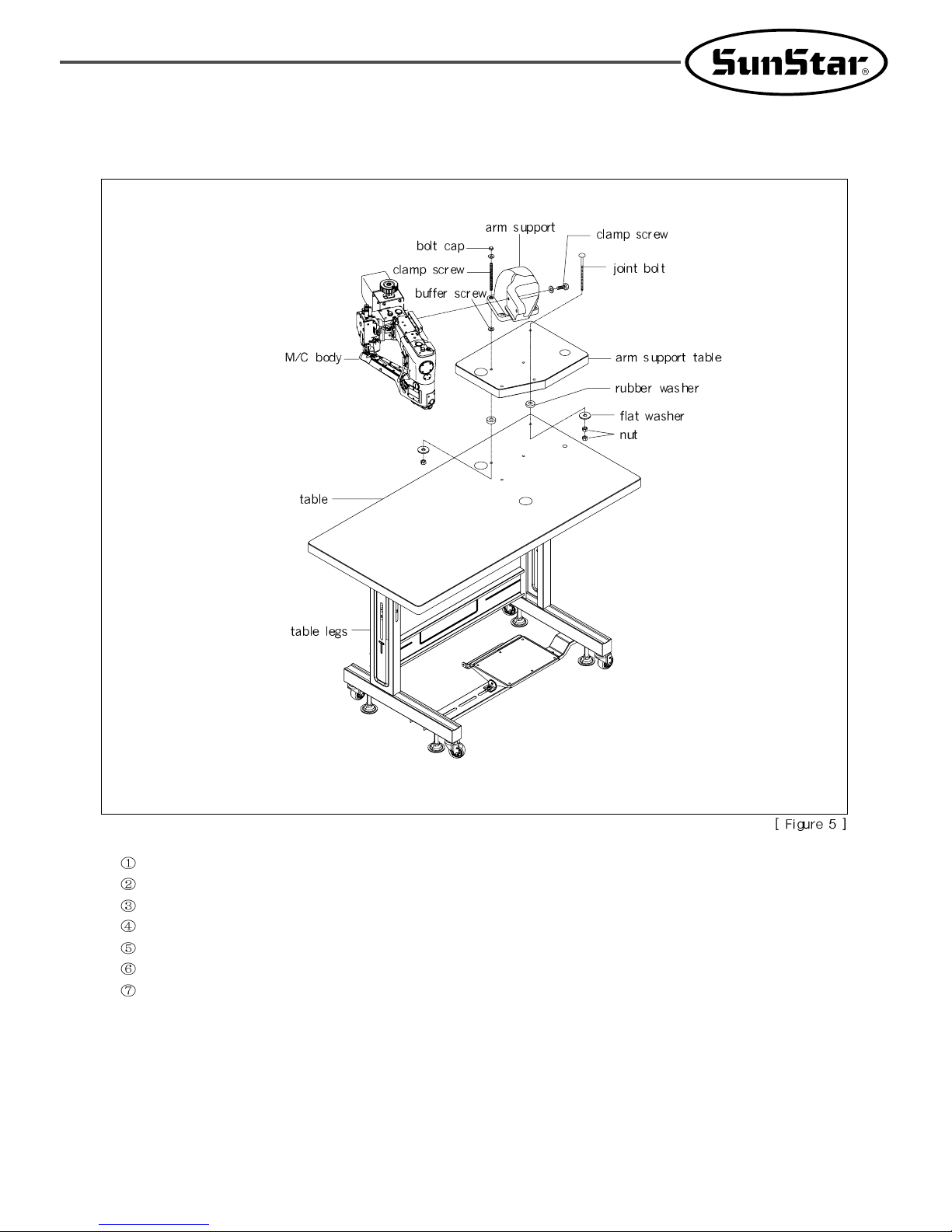

1) TABLE INSTALLATION

(1) T able type

A. T able

B. Arm support table

Page 12

12

(2) T able installation

Fix a dust bag with the screw like the figure 4.

Assemble a control box like the figure 4.

Page 13

13

2) M/C INSTALLATION

Assemble table legs.

Put the assembled legs and a table together.

Place a rubber washer on the linking part of the table and put a arm support table on it.

Set a buffer rubber onto the arm support connection then lift a arm support up.

Combine a clamp screw for the arm support putting cap nut and a nut with the arm support.

Combine the arm support table with the table using joint bots and nuts.

Combine the M/C body with the arm support using the clamp screw.

Page 14

14

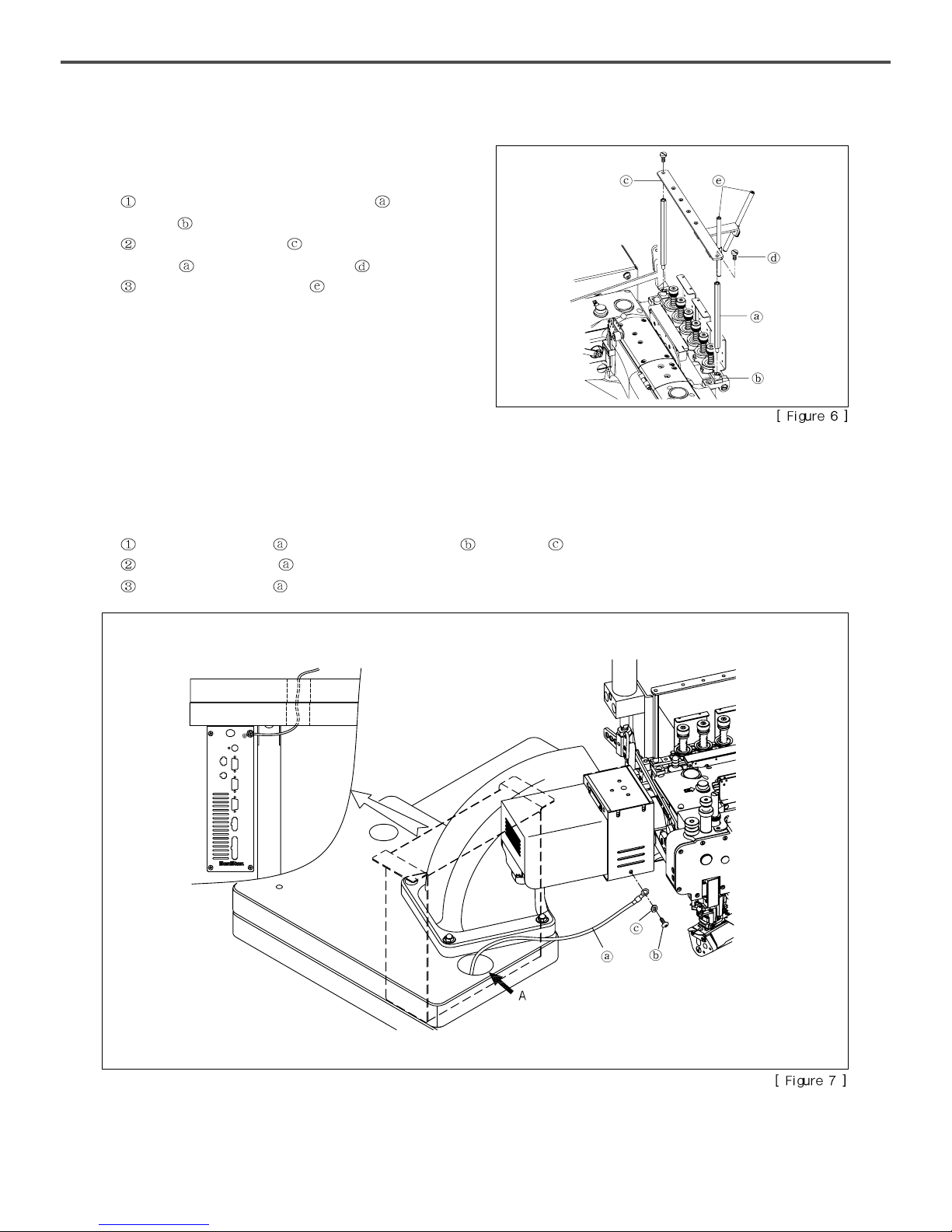

3) THREAD GUIDE FOR STAND SUPPORT

INSTALLATION

Assemble a thread guide for stand support onto a support

bracket

.

Put the thread guide plate on the thread guide for stand

support

and then fix it with the screw .

Assemble the thread guide pipe .

4) GROUND WIRE CONNECTION

Connect a ground wire to the base cover and the control box.

Connect the ground wire to the base cover using a screw and a washer .

Penetrate the ground wire the hole A on the table.

Connect the ground wire to the control box.

Page 15

15

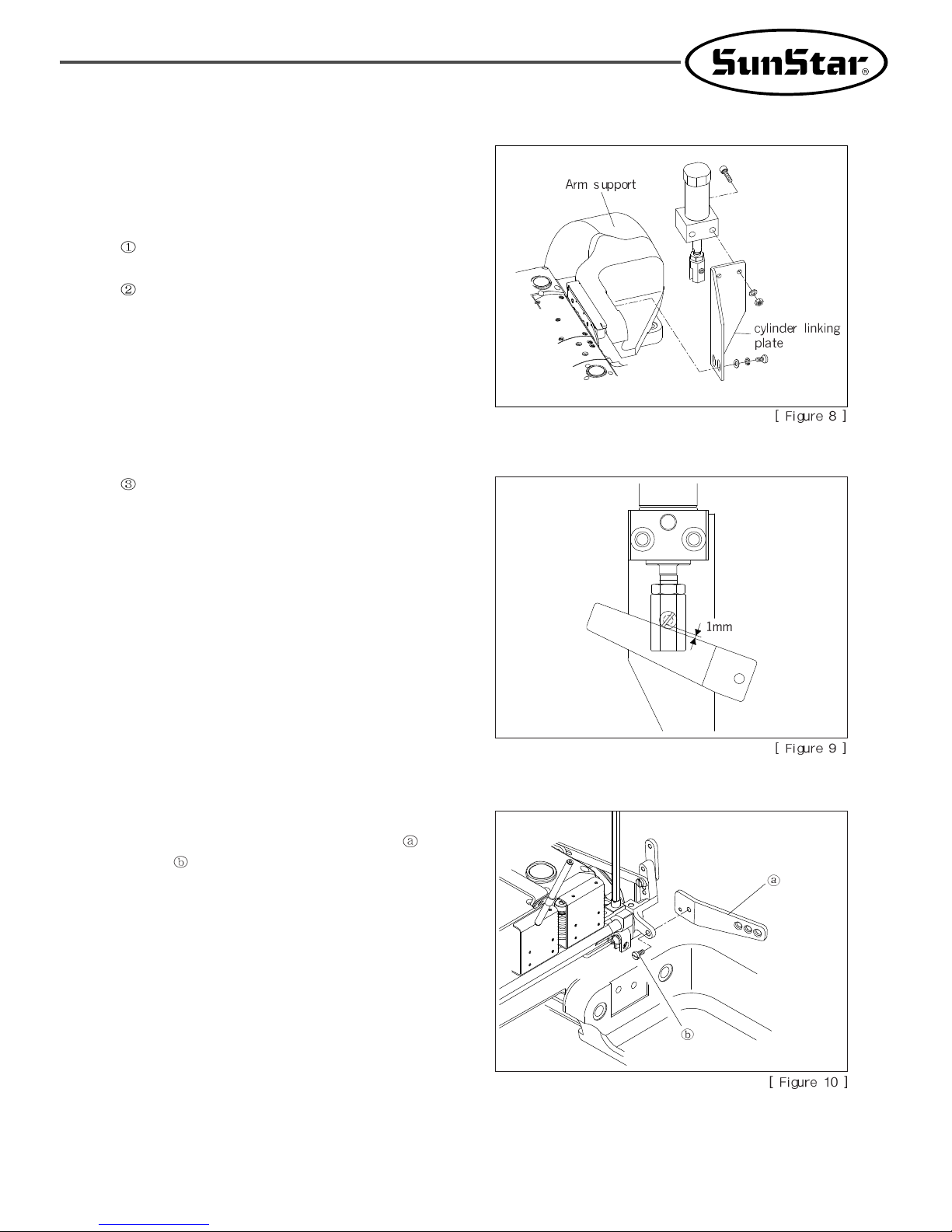

5) AIR-COMPRESSED PRESSURE BAR LIFTER

INSTALLATION

An air-compressed pressure bar lifter is composed of several

parts.

Assemble an air-compressed cylinder and an assembled

device with cylinder knuckles to the cylinder linking plate.

Assemble the cylinder linking plate with the arm support.

Adjust the cylinder knuckle to make the distance of 1mm

between the cylinder knuckle short screw and the knee lifter

connection lever. (Refer to the figure 9)

(1) Knee lifter connection leve

Assemble the knee lifter connection lever

with the

screw

.

Page 16

16

Assemble the coupling A to be 11.2mm in the arm-fix bracket.

(Refer to the figure 12)

Fix the coupling A( ) to the main crank shaft. (Refer to the figure 13)

Assemble the motor parts( ) and the motor cover. (Refer to the figure 11)

6) DIRECT MOTOR INSTALLATION

Assemble the arm-fix bracket and the assembled part with the arm. (Refer to the figure 11)

Page 17

17

7) AIR-COMPRESSED THREAD TRIMMING DEVICE (OPTIONAL) INSTALLATION

An air-compressed thread trimming device is composed of several parts. (G-CT-0002)

Assemble the thread cutting block and the thread cutting base at

the center of the front and the side. (Refer to the figure 15)

Y ou should be careful no to intrude into the sensor part when setting the suction pipe.

Page 18

18

8) AIR-COMPRESSED DEVICE INSTALLATION

(1) Specification

Connect the air hose to the manifolder block of the filter regulator and solenoid valve.

Connect the air hose to the upper fitting of the air-compressed cylinder and the left side of the upper solenoid valve.

Connect the air hose to the lower fitting of the air-compressed cylinder and the right side of the upper solenoid valve.

Connect the air hose to the suction pipe and the lower solenoid valve.

Connect the cable which is written in PF linking to the control box to the upper solenoid valve.

Connect the cable which is written in CL linking to the control box to the lower solenoid valve.

After installing to the table, open the air-compressed regulator of the filter regulator and set the compressed air at the

0.4~0.5 bar.

Page 19

19

(2) Air-compressed device (optional) installation

Connect the air hose to the manifolder block of the filter regulator and solenoid valve.

Connect the air hose to the upper fitting of the air-compressed cylinder and the left side of the solenoid valve A.

Connect the air hose to the lower fitting of the air-compressed cylinder and the right side of the solenoid valve A.

Connect the air hose to the suction pipe and the solenoid valve B.

Connect the air hose to the cutter cylinder and the solenoid valve C.

Connect the cable which is written in PF linking to the control box to the solenoid valve A.

Connect the cable which is written in CL linking to the control box to the solenoid valve B.

Connect the cable which is written in TT linking to the control box to the solenoid valve C.

After installing to the table, open the air-compressed regulator of the filter regulator and set the compressed air at the

0.4~0.5 bar.

Page 20

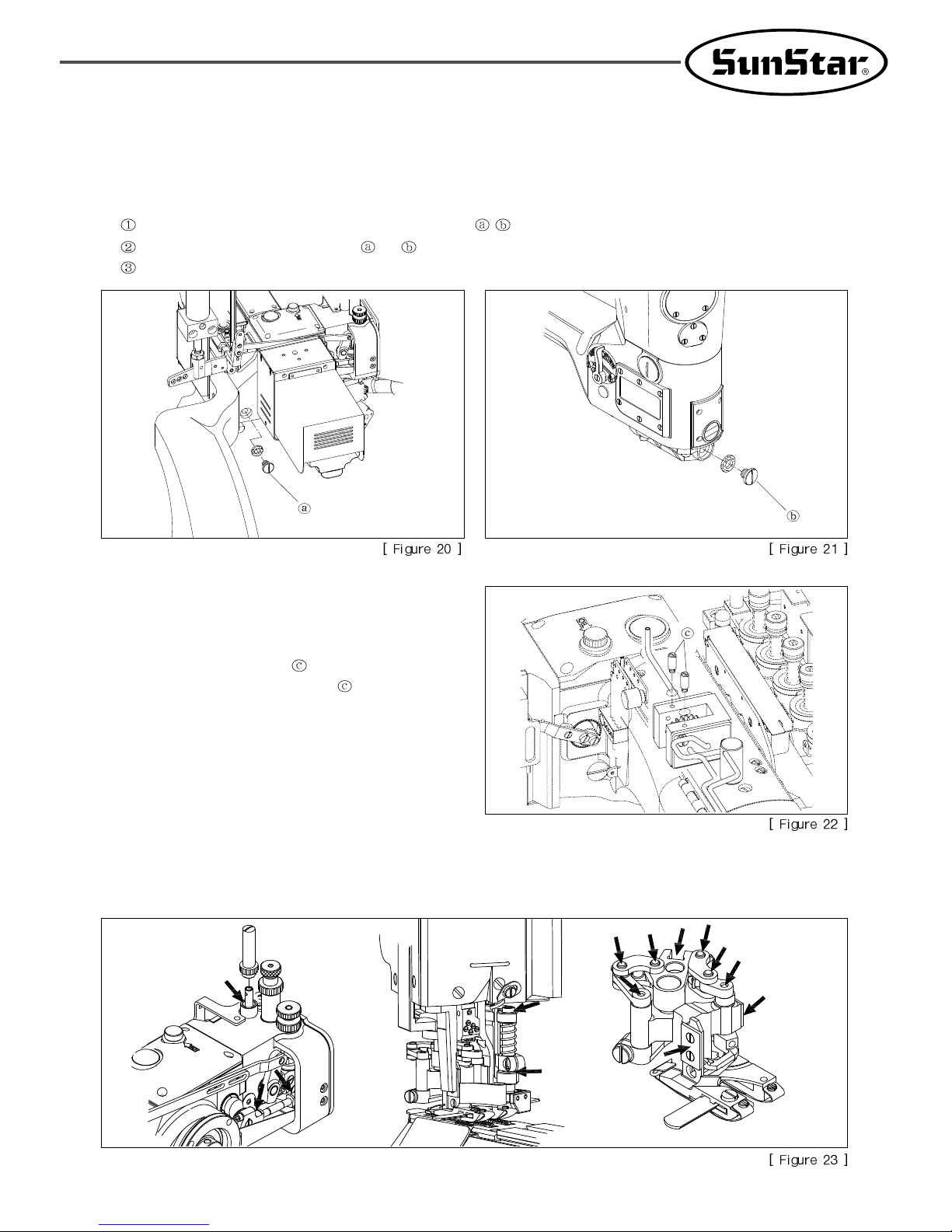

20

LUBRICATION

1) OIL

Use the industrial sewing machine oil which is provided by SUNSTAR or SF oil from YANASE.

2) LUBICATING OIL

This sewing machine is shipped without oil. To use the machine without breakdown, remove the oil cap screw , and then

lubricate oil to the top limit of the oil gauge

, .

3) OIL GAUGE/OIL WINDOW

Check the oil gauge , before operating the sewing machine. Lubricate oil when the oil indicator or the oil surface (refer to the

figure 18, 19) is under the 2 lines. Check the spattering of the oil through the oil window

, when operating the sewing machine.

Page 21

21

4) LUBRICATING OIL EXCHANGE

Change the oil during the first month every 200 hours and then change it two times per year. If not, the life of the sewing machine is

going down.

Discharge the lubricating oil by loosening the oil outlet screw , .

After discharging, fix the oil outlet screw and firmly.

Refer to the 2) LUBICATING OIL for lubricating.

5) OIL PRIMING

Prime the oil before operating new machine or the machine not

to use for a long time.

After remove the upper screw

of oil pump housing and oil

priming, then fix it again with the screw

.

(Refer to the figure 22)

6) LUBRICATING OIL REPLENISHMENT

Lubricate about 3~4 drops of oil into the oil hole[Figure 23] every one time a month. If the oil leaks out, the oil spots could be

occurred on the parts. Therefore wipe out after replenishing oil.

Page 22

22

7) OIL FILTER CLEANING

Clean the suction filter and the oil filter 2~3 times a year. Clean as followings.

- Oil filter cleaning

Discharge the lubricating oil by loosening the oil outlet

screw

After discharging, fix the oil outlet screw firmly.

Separate the oil pan from the bed by loosening the oil pan

clamp screw

.

Remove the foreign substances by pulling out a oil filter .

Assemble it again in reverse order.

Refuel referring to the 2) LUBICATING OIL.

- Suction filter cleaning

Separate the oil pump by loosening the oil pump fixation

screw

.

Remove the foreign substances of the suction filter .

Assemble it again in reverse order

Page 23

23

STANDARD ADJUSTMENTS

1) NEEDLE

(1) Sewing needle

This sewing machine uses the UY118GKS sized needles made by from Groz-Beckert.

Select the proper needle according to the thickness and type of the sewing materials because of the various size of needle.

(2) Retainer needle

This sewing machine uses the UY36211 sized needles made by from Groz-Beckert.

Select the proper needle according to the thickness and type of the sewing materials because of the various size of needle.

2) NEEDLE INSTALLATION

Loosen the clamp screw .

Remove the old needle using the tweezers.

Lift the needle to the end of needle hole and then fix it

firmly by tightening the clamp screw

.

Page 24

24

3) THREADING

Thread a needle referring to the [Figure 27].

If not, the problems can be happened such as stitch skip, thread cutting, irregular tension etc. A, B, C and D are the needle thread, E is the

fancy thread, F is the looper thread.

After threading, cut the scrap of thread before stitching. Do the same for the looper thread and the fancy thread.

Page 25

25

4) THREAD TENSION ADJUSTMENT

Adjust differently the thread tension by the thread, fabric, stitch

width and other sewing conditions.

The thread tension is adjusted by rotating nuts(

~ ). When

rotating clockwise, the tension is stronger. When rotating

counterclockwise, the tension is weaker. (Refer to the Figure 28)

~ : needle thread

: upper thread

: looper thread

(1) Presser foot lifting adjustment

Set the distance between the presser bar lifting lever

and the presser bar linking bracket to 1mm when the

presser foot is near the needle plate(Refer to the 6, 7

VERTICAL ADJUSTMENT OF PRESSER FOOT).

This is the standard.

Adjustment order

a. Remove the rubber cap

, ,

b. Undo the screw

in the presser bar lifting lever link(large

size)

.

c. Adjust the distance by moving the presser bar lifting lever

link(small size)

to left or right, then fix it by tightening

the screw

.

5) PRESSER FOOT ADJUSTMENT

Page 26

26

Set the distance between the needle holder at the lowest of the needle bar and the upper thread holder to 0.3mm. This is

the standard. The presser foot is lifted when pressing the pedal backward.

Adjustment order

a. Loosen the fixing nut

.

b. Adjust the distance by moving the presser bar lifting fixed plunger

back and forth.

(2) Thread release shaft adjustment

Without pressing the presser bar pedal, set the distance between the thread release pin

and the thread release shaft to 0.5mm

when six thread release pins

are separated a little and the upper and lower plate of the thread adjusting device plate are

attached together.

Adjustment order

a. Loosen the clamp screw in the presser bar lifting lever(large size).

b. Adjust the thread release shaft

by rotating with a driver.

6) PRESSER FOOT PRESSURE ADJUSTMENT

To make the presser foot pressure lower is better as far as the

sewing material is moved well and the stitch is formed.

Loosen the presser bar adjustment screw nut

and regulate the

presser bar pressure with rotating the presser bar adjustment

screw

then fix it by tightening the nut .

When rotating the presser bar adjustment screw

clockwise,

the pressure is stronger. When rotating counterclockwise, the

tension is weaker. (Refer to the Figure 34)

Page 27

27

7) VERTICAL ADJUSTMENT OF PRESSER FOOT

Set the needle bar to the lowest point.

Loosen the pressure adjustment fixation nut and adjust it by rotating the pressure adjustment nut .

(When rotating the pressure adjustment nut counterclockwise, the presser foot is lifting.)

Adjust the distance between the presser foot base and the presser foot spring plate A to 0.3~0.5mm.

(It is better for the presser foot to float a little bit to make adjustment of sewing material overlapping width easily, reduce the noise

and vibration, improve the durability of the presser foot spring plate, prevent the feed dog damage.

Fix it by tightening the pressure adjustment fixation nut firmly.

8) MAIN FEED ADJUSTMENT

The stitch length can be regulated from 1.6mm to 2.5mm basically and it is able to be regulated more or less than the value. The

following table indicates the stitches per 25.4mm and the stitches per 30mm.

Loosen the needle guard(back) clamp screw and move the needle guard to the very end then tighten the screw lightly.

(Refer to the Figure 37)

(This process is not necessary when narrowing the stitch length.)

Remove the left screw of the bed. (Refer to the Figure 38)

Loosen the feed rocker link shaft screw and adjust the stitch length.

(Move the screw

upward for increasing the stitch length and move the screw downward for decreasing the stitch length.)

Page 28

28

After adjusting the stitch length, fix it firmly by tightening the feed rocker link shaft screw then fill the left screw of the bed.

(The left screw

of the bed is to prevent oil leakage so tighten it firmly.)

After adjusting the needle guard(back) to the proper position and tighten the needle guard(back) clamp screw firmly.

9) DIFFERENTIAL FEED ADJUSTMENT

To adjust the differential feed dog, rotate the differential feed

operating lever

to the left or the right.

If the differential feed operating lever

is on the 4 or 5, the

momentums of the main feed dog and the differential feed dog

will be the same.

For the forward differential, turn the differential feed operating

lever

to the scale of 9. For the reverse differential, turn the

differential feed operating lever

to the scale of 1.

Page 29

29

10) THREAD LUBRICATING DEVICE

When sewing at a high speed or using synthetic fiber thread and

sewing material, it causes the skipped stitches and thread

breakage.

This sewing machine basically has the thread lubricating device

to handle this problem.

Fix the silicone oil felt bracket

to the silicone oil tank .

Ethane silicone oil should be used and check the amount of oil on occasion opening the silicone oil cap.

11) OVERLAP WIDTH ADJUSTMENT OF UPPER SEWING MACHINE

(1) Standard position of the lower knife

Set the distance between the lower knife

and the lower knife holder to 0~0.5mm. (Refer to the Figure 41)

(2) Standard position of the upper blade

Set the distance between the upper knife

and the lower knife to 0.5mm when the upper knife is on the most left.

(3) Sewing material overlap position adjustment

T o move the end of the sewing material to the left or the right, move the lower knife

to the left or the right.

Page 30

30

12) USING A LAP FORMER

(1) Left / Right standard position

Make an array of the lap former A point at the center of the 4

sewing needles.

Loosen the clamp screw

and adjust the position of the lap

former

according to the edge of the overlapping sewing

materials or the feed direction of the fabric.

(2) Front / Rear standard position

Set the lap former

at the position which the lap former

slide block

and the needle plate are attached.

Adjust the lap former

front and rear depends on the

thickness of the cloth.

Page 31

31

DETAILED ADJUSTMENTS

1) THREAD TENSION ADJUSTMENT

(1) Thread pin adjustment

4 sewing needles have the thread pins that adjust each thread

tension.

Put the thread take-up lever to the lowest point.

Loosen the thread pin clamp screw and set the height

of the thread pin

to the first on the left of the take-up

lever

, then fix it by tightening the thread pin clamp

screw

.

Loosen the thread pin clamp screw . Set the height of

the thread pin

and the thread pin equally or 0.8mm

above. Then fix it by tightening thread pin clamp

screw

.

Loosen the thread pin clamp screw . Set the height of

the thread pin

and the thread pin 1.6mm above. Then

fix it by tightening thread pin clamp screw

.

Loosen the thread pin clamp screw . Set the height of

the thread pin

and the thread pin 3.2mm above. Then

fix it by tightening thread pin clamp screw

.

(2) Thread guide adjustment

Make the thread guide hole height of the needle thread

guide

and the thread guide hole height of the fixation

block holder

equally.

Set the needle thread guide 5mm below the needle thread

guide

.

Set the needle thread guide 9mm below the needle thread

guide

.

Set the needle thread guide 15mm below the needle

thread guide

.

Page 32

32

2) LOOPER THREAD TENSION ADJUSTMENT

(1) Looper threads take-up lever guide standard position

Align the right end of the looper thread take-up guide with

the right end of the guide support plate

. (Refer to the

Figure 46)

(2) Looper threads take-up lever timing adjustment

The timing setting standard of the looper thread take-up is to

set the looper thread

through the point A when the needle

bar goes down 2.8mm from the highest point.

Loosen the looper thread take-up clamp screw

and adjust

like above then fix it by tightening the clamp screw.

(Refer to the Figure 47)

(3) Looper threads take-up lever eyelet standard position

Set the looper thread take-up lever eyelet

, at the very right position. This is the standard.

Page 33

33

3) UPPER THREAD TENSION ADJUSTMENT

4) NEEDLE HEIGHT SETTING

(1) Thread take-up lever thread guide hole standard position

Set the distance between the thread take-up holder base

and the thread guide hole of the thread take-up lever to 4.4mm. (Refer

to the Figure 48)

Loosen the thread take-up lever fixation screw and adjust the the thread take-up lever .

The tighten the thread take-up lever fixation screw and set it in order.

(2) Upper thread take-up lever timing adjustment

When the upper thread is seized by the upper thread holder, set the upper thread to 0~1mm position from the highest point of the

thread take-up lever, which is point A in the Figure 46.

Loosen the upper thread take-up lever clamp screw

and tighten the clamp screw.

When the needle bar is at the highest point, the height of the 4th end of the needle on the left is set as followings like Figure 47.

M5 (5.2mm type) = 13.49mm

M6 (6mm type) = 12.7mm

Lift the needle bar to the highest point.

Remove the rubber cap and loosen the needle bar clamp screw .

Page 34

34

Adjust the needle bar like the above.

Tighten the needle bar clamp screw firmly and close the rubber cap .

5) UPPER THREAD RETAINER

(1) Upper thread retainer standard position

Set the upper thread retainer to the first and second needle behind on the left when the upper thread retainer

is at the closest to

the needle. (Refer to the Figure 50)

Set the upper thread retainer like above by loosening the upper thread retainer clamp screw

. Then set according to the fixation

by tightening the upper thread retainer clamp screw

.

(2) Upper thread holder standard position

When the upper thread holder

is at the closest to the upper thread retainer , set the distance between them to 0.4~0.7mm.

When the upper thread holder

is at the end of the right direction, set the distance between the upper thread holder and the

retainer needle

to 0.5mm.

Set the upper thread retainer like above by loosening the upper thread retainer clamp screw

. Then set according to the fixation

by tightening the upper thread retainer clamp screw

.

Page 35

35

6) ADJUSTMENT OF NEEDLE AND LOOPER TIMING

(1) Standard height of the looper

Insert the looper

into the end of the looper holder .

Loosen the looper clamp screw

and fix it by tightening the

clamp screw firmly. (Refer to the Figure 54)

(2) Distance between the looper and the needle

When the looper

goes to the farthest part from the needle,

make the distance between the looper

and the very left

center of the needle to 4.2~4.8mm. Loosen the looper holder

clamp screw

and fix it by tightening the clamp screw

firmly. (Refer to the Figure 54)

(3) Front / back position of the looper and the needle

When the looper

moves from the left to the right, the looper

should pass through behind the needle. (Refer to the

Figure 55)

Set the distance the looper

and the needle to 0~0.05mm to

make the looper

is at the closest to the needle. Set the looper

not to attach to the needle. (Refer to the Figure 55)

When rotating the looper adjusting screw

clockwise by

loosening the looper holder clamp screw

, it moves to the F

direction. When rotating the looper adjusting screw

counterclockwise, it moves to the B direction. Therefore fix

by tightening the clamp screw after setting it. (Refer to the

Figure 56)

Page 36

36

7) STANDARD POSITION OF NEEDLE GUARD

(1) Standard position of the needle guard (front)

Loosen the needle guard (front) fixation screw

. Adjust the needle guard (front) for the distance between the looper and

the needle to 0mm when the end of the looper

meets the center of the first needle on the left. Then fix it by tightening the

needle guard (front) fixation screw

.

(2) Standard position of the needle guard (rear)

Open the looper cover and loosen the needle guard (rear)

fixation screw

. When the needle guard (rear) is at the

closest to the needle, adjust the distance to 0.05~0.1mm and

then fix it by tightening the needle guard (rear) fixation

screw

. (Refer to the Figure 59)

Page 37

37

8) FEED DOG HEIGHT SETTING

Differential feed dog and the main feed dog is set to be adjusted independently.

(1) Standard height of the feed dog

Loosen the main feed dog clamp screw

. When the feed

dog height is on the top, adjust the part A of the main feed

dog

at the needle plate to the 1.2~1.5mm. Then fix it by

tightening the main feed dog clamp screw

. Fix the

differential feed dog

by tightening the differential feed

dog clamp screw

after loosening the differential feed dog

clamp screw

and adjusting the height of the main feed dog

and feed dog horizontally. (Refer to the Figure 60, 61)

(2) Fine tuning of the feed dog

After fine tuning the feed dog height with the feed bar

eccentric pin

by loosening the feed bar eccentric pin

clamp screw

which is at the center of the bed, fix it by

tightening the feed bar eccentric pin clamp screw

.

(Refer to the Figure 62)

Page 38

38

9) EXCHANGE OF PRESSER FOOT

Remove the needle in the needle holder.

Remove the rubber cap . (Refer to the Figure 63)

Loosen the presser bar adjusting screw and the presser bar

connection bracket clamp screw

(Refer to the Figure 63)

Loosen the knife holder guide clamp screw . (Refer to the

Figure 64)

Loosen the knife holder shaft support bar clamp screw and

remove the knife holder shaft support bar A.

(Refer to the Figure 65)

Page 39

39

Loosen the presser foot clamp screw .

(Refer to the Figure 66)

Put to the highest point of the needle bar by rotating the hand

pulley.

Remove the presser adjusting screw and lift the presser bar

by using the presser bar pressure adjusting spring

. (Refer

to the Figure 67)

Remove the thread holder crank from the hook drive

sleeve

. (Refer to the Figure 68)

Remove the presser foot among the presser foot guide (left),

(right) by turning the presser foot to the left.

(Refer to the Figure 68)

Insert the replacement presser foot in the presser foot guide

(left), (right) by turning to the right. (Refer to the Figure 68)

Insert the thread holder crank into the hook drive

sleeve

. (Refer to the Figure 68)

Page 40

40

Insert the presser bar into the presser foot by pushing to the

end and fix it by tightening the presser foot clamp screw

.

(Refer to the Figure 69)

Check that the presser foot does move smoothly up and

down not to move left and right. If not, loosen the presser

foot guide clamp screw

and fix it after resetting the presser

foot guide

.

Attach the knife holder shaft support bar to the knife holder

bracket

with attention to the direction. Fix it by tightening

the knife holder shaft support bar clamp screw

. (Refer to

the Figure 65)

Adjust the knife holder guide and the knife (upper) position

when the needle bar is at the lowest point. (Refer to the “7-

11) BLADE EXCHANGE AND ADJUSTMENT”)

When the needle bar is at the lowest point and the presser

foot is closest to the needle plate, insert the presser bar

pressure adjusting spring

and adjust the presser bar

pressure with the presser bar adjusting screw

by referring

to the “6-6) PRESSER FOOT PRESSURE ADJUSTMENT”.

Then tighten the presser bar connection bracket clamp screw

by pressing the presser bar connection bracket slightly and

fix it.

Close the rubber cap .

Insert the needle into the needle holder.

Loosen the presser foot spring plate A clamp screw .

Remove the presser foot spring plate A from the presser

foot.

Remove the presser foot spring plate A from the spring

plate holder

.

Insert the each replacement presser foot spring plate A into

the spring plate holder

.

Insert the presser foot spring plate A into the presser foot

in parallel.

Fix by tightening the presser foot spring plate A clamp

screw

.

10) EXCHANGE OF PRESSER FOOT SPRING PLATE A

Page 41

41

11) BLADE EXCHANGE AND ADJUSTMENT

(1) Knife (upper) pressure

When the needle bar is at the lowest point and the

knife(upper)

is the very left, the presser foot is attached to

the needle plate and the knife(upper)

is near the lower

blade

.

The standard clearance between the knife holder guide

and the knife holder shaft support bar is 1mm.

Tighten the knife holder guide clamp screw

after adjusting

the knife holder guide

by loosening the knife holder guide

clamp screw

.

(2) Knife removal

Remove the knife(upper) by loosening the knife holder

guide clamp screw

and the knife clamp screw .

Remove the lower blade by loosening the lower blade

holder clamp screw

.

(3) Knife reinstallation

Fix the replacement lower blade with the lower blade

holder clamp screw

and fix the knife(upper) with

the knife holder screw

. (Refer to the “6-11)

OVERLAP WIDTH ADJUSTMENT OF UPPER

SEWING MACHINE”)

Adjust the knife holder guide referring to the above

knife(upper) pressure.

Page 42

42

(4) Adjustment of the knife (upper) and lower blade

meshing angle

Disassemble

~ parts in order then adjust them by

turning the setting screw B

. (Refer to the Figure 74)

Page 43

43

AIR-COMPRESSED THREAD TRIMMER (OPTIONAL) MANUAL

1) CONSIDERTIONS BEFORE USING

Check the OFF-status condition of a power switch before adjusting the machine.

When setting the related sensor detection, refer to the following “8-3) SENSOR SETTING METHOD”.

Put the end part of the sewing material at the front before sewing.

2) MODEL NUMBER SETTING

3) SENSOR SETTING METHOD

(1) Sensor setting

Sensor position: Make a sensor lamp and a needle bar in

a straight line.

Check the normal operation of a sensor: Turn the power on without sewing materials. When the sensor lamp comes on, it

means that the sensor operates normally.

needle

bar

sensor

lamp

straight

Page 44

44

Sensor detection adjustment

a. Turn the detection switch to the MAX.

b. Turn the detection switch 180 degree to the MIN in

reverse like the Figure 76.

c. Adjust the sensor detection to make sensor lamp comes

on when there is not sewing material and goes out when

there is sewing material like

Check the normal

operation of a sensor”.

(2) Clearance between the sensor and the thread trimming

device

The clearance between the sensor and the thread trimming

device is about 36mm and the cutting stitch number should

be decided by considering this clearance and the stitch length.

The basic setting value is the 2mm pitch.

(Related parameter: Group A No.41, No.48)

Page 45

45

4) RELATED PARAMETER

5) THREAD TRIMMING MODE SETTING

(1) Manual thread trimming mode by the knee switch

Pedals in the neutral position before sewing

Pedals in the neutral position during sewing

Pedals in the neutral position after sewing

“

”

“

”

Page 46

46

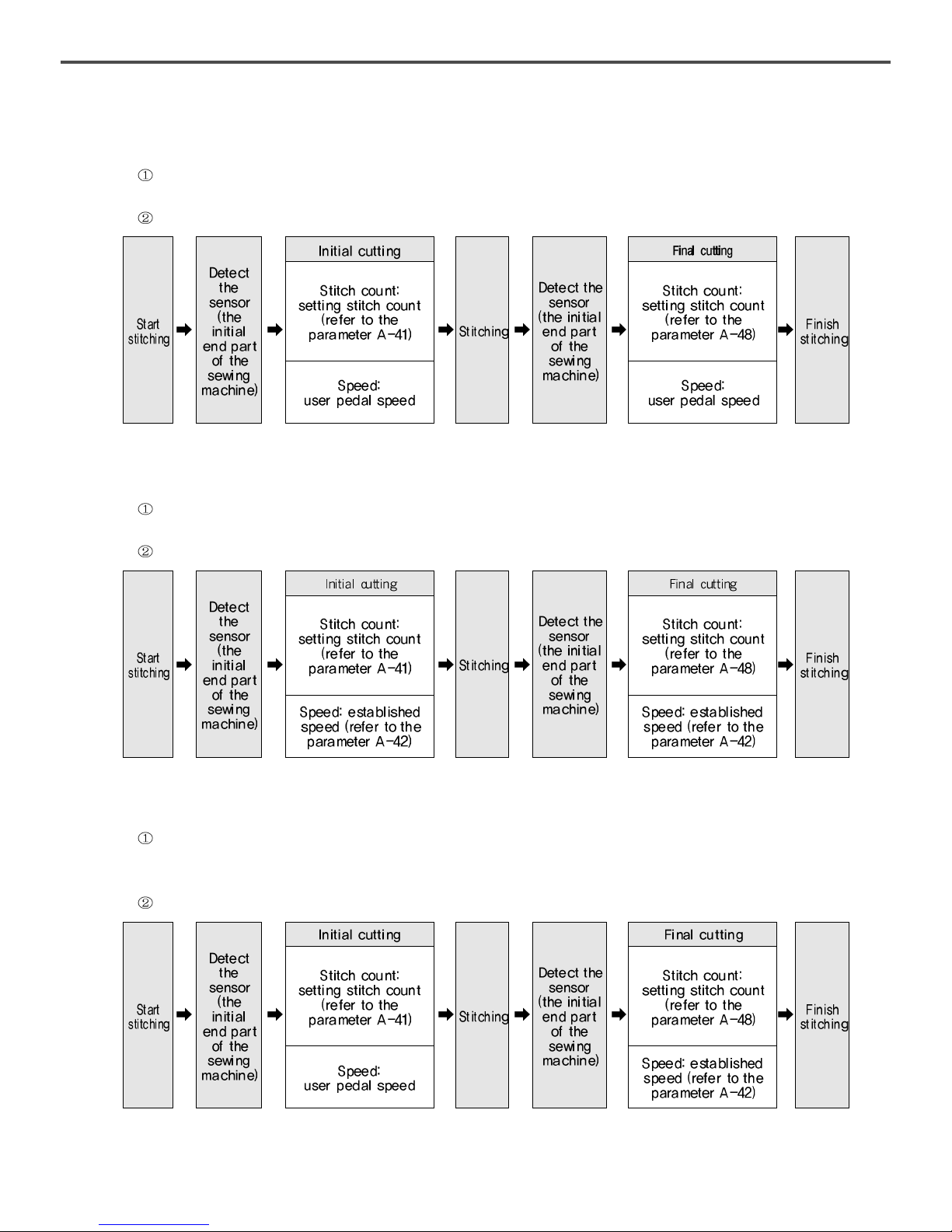

(2) Operation process of “Auto thread trimming mode 1”

feature: During pressing the pedals, the initial cutting and the final cutting is performed counting as much as the setting values

after sensor detecting.

thread trimming process

(3) Operation process of “Auto thread trimming mode 2”

feature: The sewing material is feeding as much as the stitches after detecting the sensor. When the movement stops, the initial

cutting and the final cutting start operating.

thread trimming process

(4) Operation process of “Auto thread trimming mode 3”

feature: During pressing the pedals, the value is sent to the setting value by counting the stitches after detecting the sensor.

Then the initial cutting starts working when taking your foot off the pedal. After that, the sewing material is automatically

feeding as fast as the counted values. When the feed is over, the final cutting starts operating.

thread trimming process

Page 47

47

6) THREAD TRIMMING RANGE SETTING

Loading...

Loading...