Page 1

SSUUNNSSTTAARR MMAACCHHIINNEERRYY CCOO..,, LLTTDD..

R

User’s

Manual

SC 7200 Series

SC 7300 Series

SC 7310 Series

Super High-Speed

Cylinder Bed Interlock

Machine

1) For proper use of the machine,

thoroughly read this manual before use.

2) Keep this manual in a safe place for

future reference in case the machine

breaks down.

MMMMEE--005500882222

Page 2

Page 3

Best Quality

Best Price

Best Service

SSUUNNSSTTAARR MMAACCHHIINNEERRYY CCOO..,, LLTTDD..

R

1.

Thank you for purchasing our product. Based on the rich expertise and

experience accumulated in industrial sewing machine production, SUNSTAR

will manufacture industrial sewing machines, which deliver more diverse

functions, high performance, powerful operation, enhanced durability, and

more sophisticated design to meet a number of user’s needs.

2. Please read this user’s manual thoroughly before using the machine. Make

sure to properly use the machine to enjoy its full performance.

3. The specifications of the machine are subject to change, aimed to enhance

product performance, without prior notice.

4.

This product is designed, manufactured, and sold as an industrial sewing

machine. It should not be used for other than industrial purpose.

Page 4

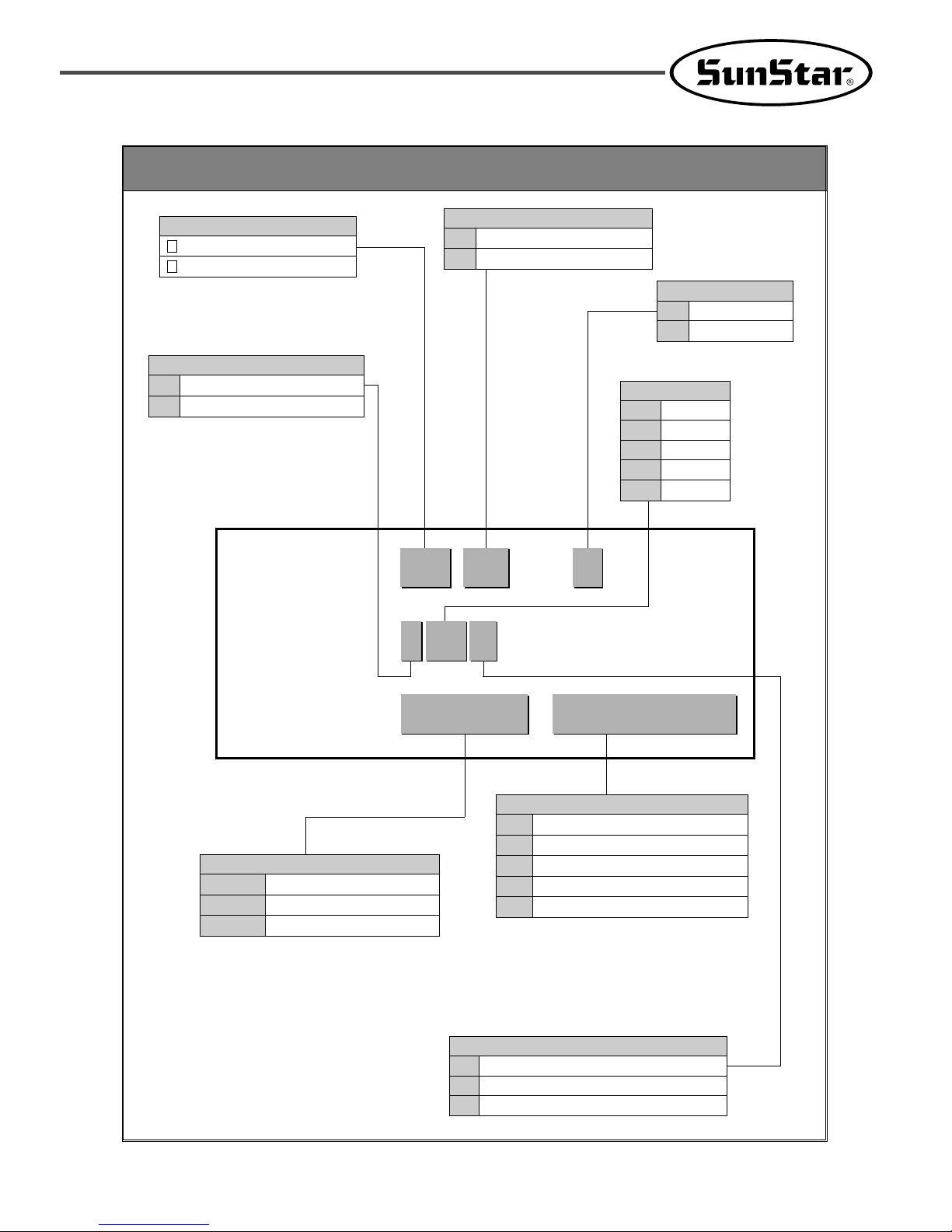

Classification of Pattern Types

MODEL SC 7300 /C

SPEC. 1 56 G

DEVICE UT-A /

/

...

SUNSTAR

Chain Stitch M/C

Symbol of Series

7372Cylinder Bed-3Needle

Cylinder Bed-2Needle

Bed Type & No. of Needle

C

N

M

Fortuna Ⅳ

Fortuna Ⅲ

Clutch Motor

Main Motor

01Without Top Cover Thread

With Top Cover Thread

Top Cover Thread

G

L

S

Standard

For long stitch (longer than 2.5mm)

For short stitch (shorter than 1.8mm)

Shape of Stitch Plate

32

40

48

56

64

Needle Distance

3.2mm

4.0mm

4.8mm

5.6mm

6.4mm

UT-A

UT-B

Under Thread Trimmer [2-Solenoid Valve Type]

Under Thread Trimmer [3-Solenoid Valve Type]

Device

ST-C

CO

HE

WF

ATF

TL

SL

TC

Top Cover Thread Trimmer(Cylinder Bed)

Covering Guide

Hemming Guide

Walking Foot

Auto Tape Feeder

See through light for Hemming

Compact Spot light

Needle thread Clamp

Attachment (Option)

Page 5

UT-A+S

UT-B+S

ST-C

2-Solenoid Valve Type

3-Solenoid Valve Type

Upper Thread Trimmer

Thread Trimmer Device

Classification of Pattern Types

MODEL SC 73 10 /C

SPEC. 1 56 G

DEVICE UT-B+S /

/

...

SUNSTAR

Cylinder Bed Chain Stitch M/C

Symbol of Series

7372Cylinder Bed-3Needle

Cylinder Bed-2Needle

Bed Type & No. of Needle

CNFortuna Ⅳ

Fortuna Ⅲ

Main Motor

01Without Top Cover Thread

With Top Cover Thread

Top Cover Thread

G

L

S

Standard

For long stitch (longer than 2.5mm)

For short stitch (shorter than 1.8mm)

Shape of Stitch Plate

32

40

48

56

64

Needle Distance

3.2mm

4.0mm

4.8mm

5.6mm

6.4mm

Attachment

WK1

AL

EL

TL

PK

Walking Presser foot (Hemming)

Attaching guide for elastic lace

See through light for hemming

Compact spot light

Needle thread clamp

Page 6

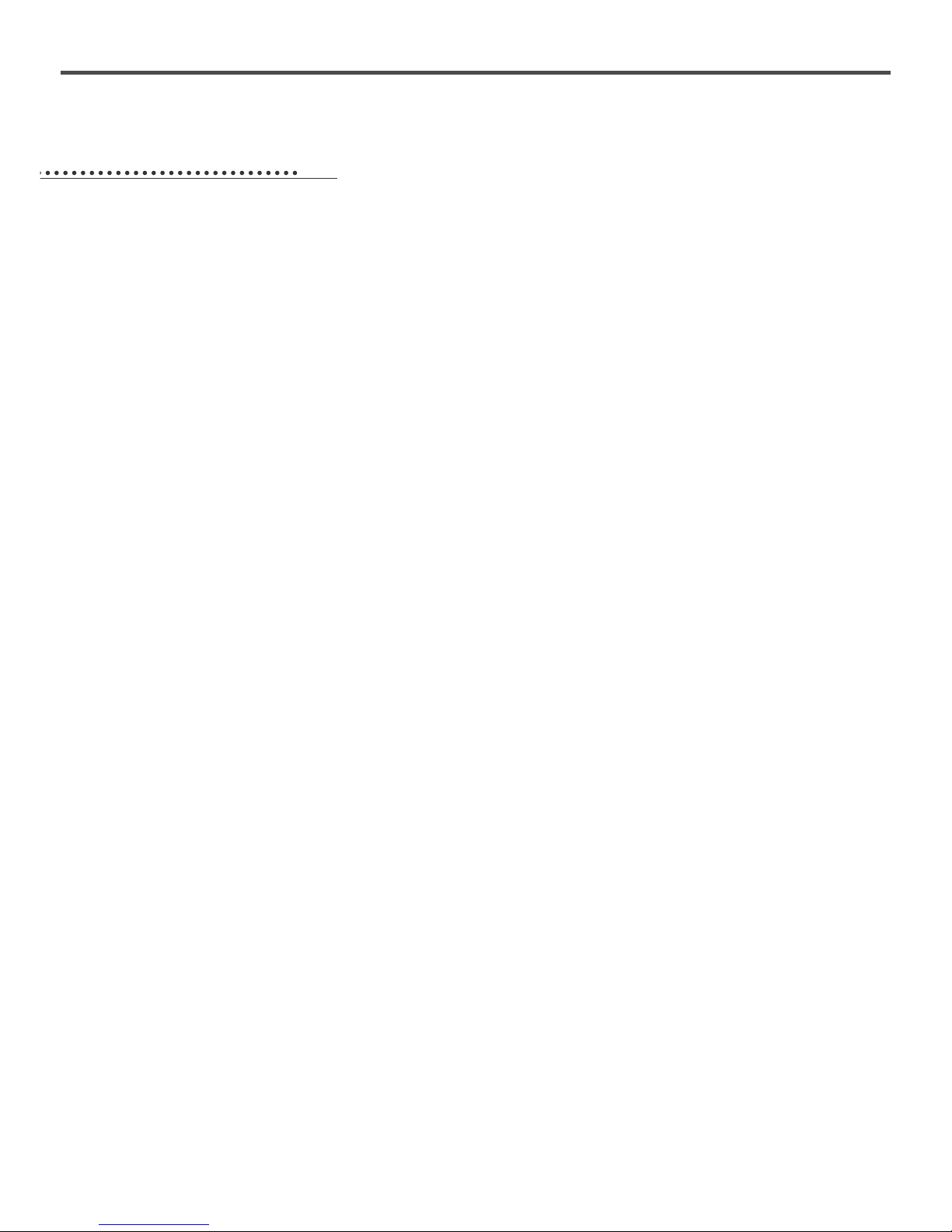

6

CONTENTS

1. Machine Safety Regulations .................................................................................... 8

1) Transporting machine ........................................................................................................... 8

2) Installing machine ................................................................................................................ 8

3) Repairing machine ............................................................................................................... 8

4) Operating machine ............................................................................................................... 9

5) Safety devices ....................................................................................................................... 9

6) Caution mark position ........................................................................................................ 10

7) Contents of marks .............................................................................................................. 10

2. Names of machine parts ......................................................................................... 11

3. Specifications ................................................................................................................ 12

4. Installation ....................................................................................................................... 13

1) Installation of table ............................................................................................................. 13

2) Installation of motor and belt ............................................................................................ 17

3) Adjustment of belt tension ................................................................................................ 18

4) Installation of belt cover .................................................................................................... 18

5) Installing cover for needle bar thread guide ...................................................................... 19

6) Installation of thread guide plate ....................................................................................... 19

5. Sewing speed and rotating direction of pulley .......................................... 20

6. Lubrication ...................................................................................................................... 20

1) Lubricating oil .................................................................................................................... 20

2) Supplying oil ...................................................................................................................... 21

3) Oil Gauge and Oil Window ............................................................................................... 21

4) Oil change ........................................................................................................................... 21

5) Cleaning the oil filter ........................................................................................................ 22

6) Cleaning the machine ......................................................................................................... 22

7. Standard adjustments of the sewing machine .......................................... 23

1) Needle used ........................................................................................................................ 23

2) Installation of needle .......................................................................................................... 23

3) Threading ............................................................................................................................ 24

Page 7

7

4) Adjustment of thread tension ............................................................................................. 24

5) Adjustment of presser foot tension .................................................................................... 25

6) Adjustment of presser foot position .................................................................................. 25

7) Adjustment of stitch length ............................................................................................... 25

8) Adjustment of differential feed .......................................................................................... 27

9) Lubricating device of needle thread and needle cooling device ....................................... 28

8. Fine-tuning of the sewing machine ................................................................... 29

1) Adjustment of needle thread tension ................................................................................. 29

2) Adjustment of looper thread tension ................................................................................. 30

3) Adjustment of needle and spreader ................................................................................... 30

4) Adjustment of needle and looper timing ........................................................................... 32

9. Automatic Thread Trimmer................................................................................... 35

1) Operation ............................................................................................................................. 35

2) Wiring.................................................................................................................................. 37

3) Air pressure wiring map .................................................................................................... 42

4) Installation of synchronizer sensor..................................................................................... 45

5) Adjustment of automatic thread trimmer ........................................................................... 46

6) Adjustment of thread tension release mechanism ............................................................. 53

7) Adjustment of air wiper .....................................................................................................56

8) Presser foot lifter mechanism ............................................................................................ 57

9) ST-C device ......................................................................................................................... 58

10. SC 7310 (Left Fabric Trimmer) .......................................................................... 61

1) Installation of accessories .................................................................................................. 61

2) Adjustment of the suction pipe (A) ................................................................................... 62

3) Adjustment of the suction pipe cover plate ....................................................................... 62

4) Cutting length (Location of fabric cutting) ....................................................................... 62

5) Removal and installation of the fixed mes (left) ............................................................... 63

6) Installation of the moving mes(left) .................................................................................. 64

7) Adjustment of the moving mes(left) stroke ...................................................................... 65

8) Mes (Knife) adjustmeent ................................................................................................... 66

9) Adjustment of fabric guide ................................................................................................ 66

10) Separation of the left mes driving ................................................................................... 67

Page 8

8

11

Machine Safety Regulations

Safety instructions on this manual are defined as Danger, Warning and Caution.

If you do not follow the instructoins, physical injuries and machine damages might be occurred.

: This indication should be observed definitely. If not, there will be a danger during the installation, conveyance and

maintenance of the machine.

: When you follow this indication, injuries from the machine can be prevented.

: When you follow this indication, error on the machine can be prevented.

Caution

Warning

Danger

1) Transporting

machine

Danger

2) Installing

machine

Warning

3) Repairing

machine

Caution

Those in charge of transporting the machine should have a full understanding of the machine.

The following indications should be followed when the machine is being transported.

ⓐ More than 2 people must transport the machine.

ⓑ To prevent accidents from occurring during transportation, wipe off the oil on the

machine compeletely.

When the machine needs to be repaired, only the assigned troubleshooting engineer educated

at the company should take charge.

ⓐ Before cleaning or repairing the machine, turn off the main power and wait 4 minutes till

the machine is completely out of power.

ⓑ Not any of the machine specifications or parts should be changed without consulting the

company. Such changes may make the operation dangerous.

ⓒ Spare parts produced by the company should only be used for replacements.

ⓓ Put all the safety covers back on the machine after the machine has been repaired.

The machine may not work properly or breakdown, if installed in certain places, Install the

machine where the following qualifications agree.

ⓐ Remove the package and wrappings from the top. Take special notice on the nails on the

wooden boxes.

ⓑ Dust and moisture stains and rusts the machine. Install an airconditioner and clean the

machine regularly.

ⓒ Keep the machine out of the sun.

ⓓ Leave sufficient space of more than 50cm behind, and on the right and left

side of the machine for repairing.

ⓔ EXPLOSION HAZARDS

Do not operate in explosive atmospheres. To avoid explosion, do not operate this

machine in an explosive atomsphere including a place where large quantities of

aerosol spray product are being used or where oxygen is being administered unless

it has been specifically certified for such operation.

ⓕ The machine is not provided with a local lighting due to the feature of machine.

Therefore the illumination of the working area must be fulfilled by end user.

[Refer] Details for machine installation are described in 4. Installation.

Page 9

9

SC 7300 Series is made to sew patterns on fabrics and other similar materials for industrial use.

Follow the following indications when operating the machine.

ⓐ Read through this manual carefully and completely before operating the machine.

ⓑ Wear proper clothes for work.

ⓒ When the machine is in operation, do not bring your hands or body near the moving parts

of the machine, such as needle, looper, spreader, thread take-up lever and pulley, etc.

ⓓ Keep the covers and safety plates on the machine during operation.

ⓔ Be sure to connect the earthing conductor.

ⓕ Turn off the main power and check if the switch is turned “off”before opening electric

boxes such as the control box.

ⓖ Stop the machine before threading the needle or checking after work.

ⓗ Do not step on the pedal when turning the power on.

ⓘ Do not operate the machine with any cooling fan blocked.

The air-filter on control box must be cleaned once a week.

ⓙ If possible, install the machine away from source of strong electrical noise such as high

frequency welding machines

4) Operating

machine

Warning

Caution

[ Warning ]

Keep cover in place before operating, turn off power before inspecting or adjusting in order

to prevent physical injury from belt.

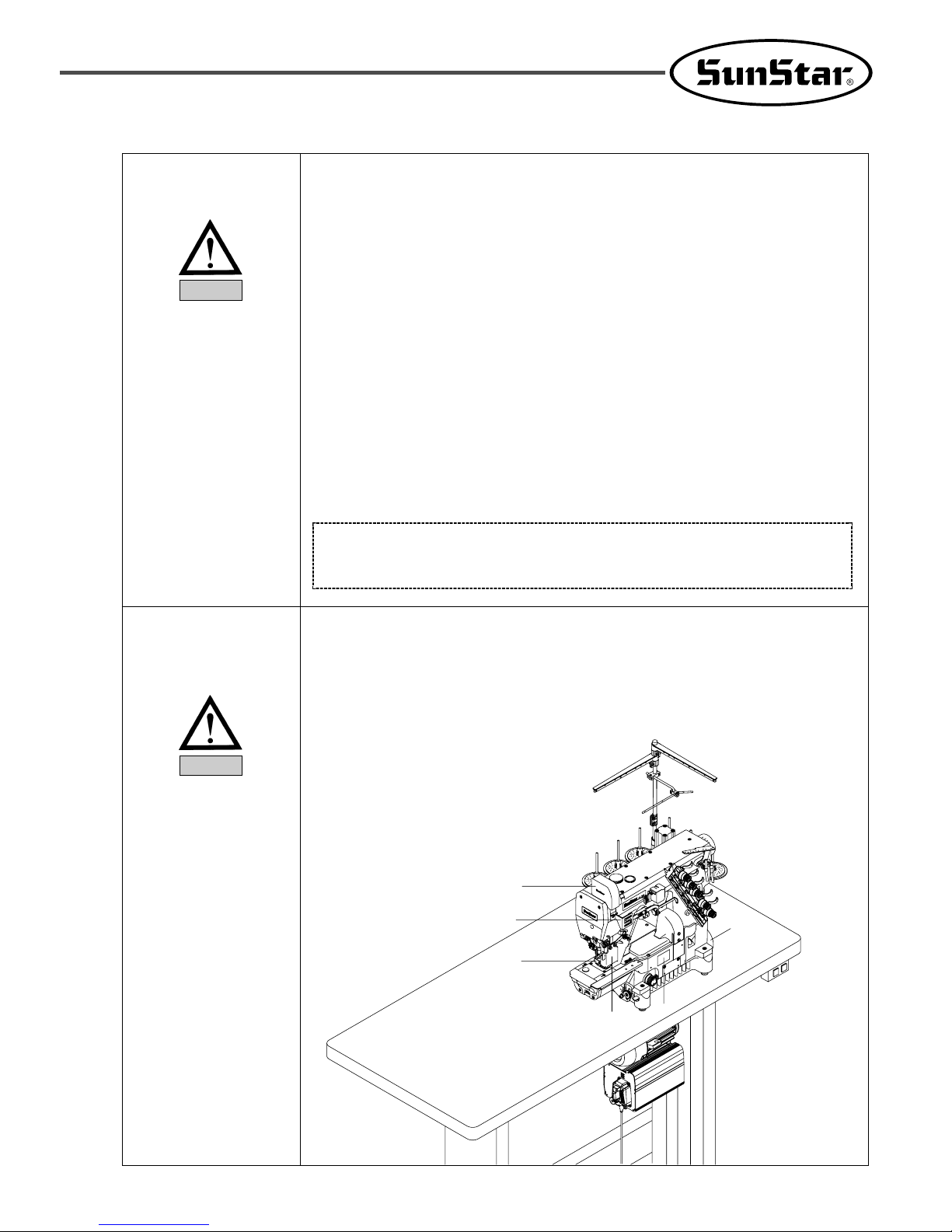

5) Safety devices

ⓐ Safety label : Cautions during machine operation

ⓑ, ⓒ Thread take-up lever cover : A device designed to prevent any physical contact with

thread take-up lever

ⓓ Belt cover: A device designed to prevent the body and clothes from getting jammed by

the moto

ⓔ Finger guard : A device to prevent contact between fingers and needles

ⓕ Safety plate: Eye-protecting device

ⓔ

ⓒ

ⓑ

ⓕ

ⓐ

ⓓ

Page 10

10

Caution

(1)

(2)

7) Contents of

marks

Caution mark is attached on the machine for safety.

When you operate the machine, follow the directions on the mark.

6) Caution mark

position

CAUTION

주의

Do not operate without finger guard and

safety devices. Before threading, changing

and needle, cleaning etc. switch off

main switch.

손가락 보호대와 안전장치 없이 작동하지

마십시오.

실, 바늘교환시나 청소전에는 반드시 주전원의

스위치를 꺼 주십시오.

CAUTION

주의

Do not operate without finger guard

and safety devices. Before threading,

changing and needle, cleaning

etc. switch off main switch.

손가락 보호대와 안전장치 없이 작동하지 마

십시오.

실, 바늘교환시나 청소전에는 반드시

주전원의 스위치를 꺼 주십시오.

CAUTION

경고

CAUTION

경고

Page 11

11

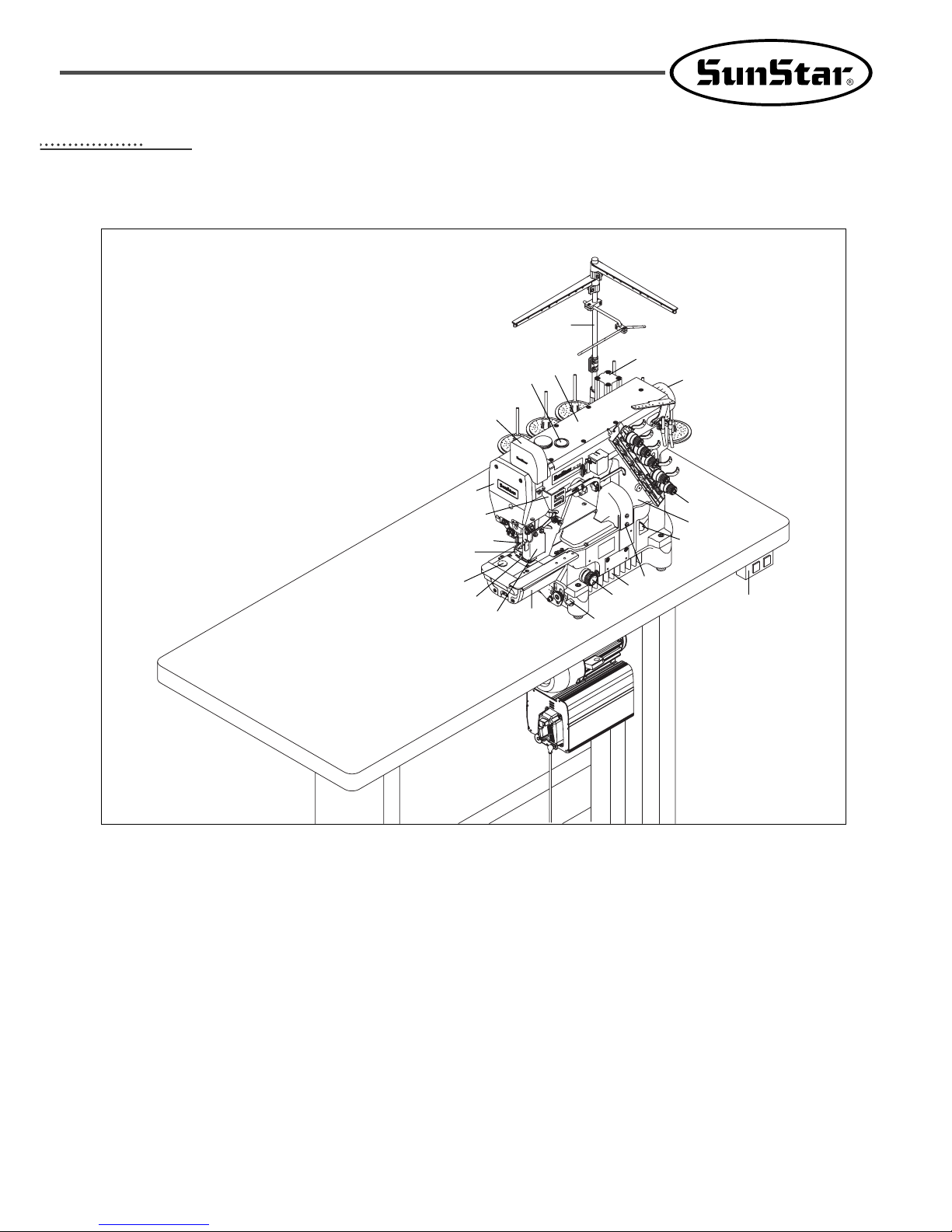

22

Names of machine parts

① Arm

② Bed

③ Oil pan

④ Face plate

⑤ Upper cap

⑥ Oil window

⑦ Knee-lifting cylinder

⑧ Upper shaft pulley

⑨ Thread-adjusting device

⑩ Oil gauge

⑪ Looper cam cover

⑫ Differential feed regulating screw

⑬ Differential feed regulating lever

⑭ Presser foot

⑮ Main feed regulating button

⒃ Air wiper

⒔ Power switch

⒕ Bobbin stand

Safety devices

⒖ Thread guide cover for needle thread

⒗ Thread take-up lever cover for needle thread

Finger guard

Safety plate

⒔

⑪

③

⑫

⑬

②

⑭

⑮

⒃

⒗

④

⒖

⑥

⑤

⒕

⑦

⑧

⑨

①

⑩

Page 12

12

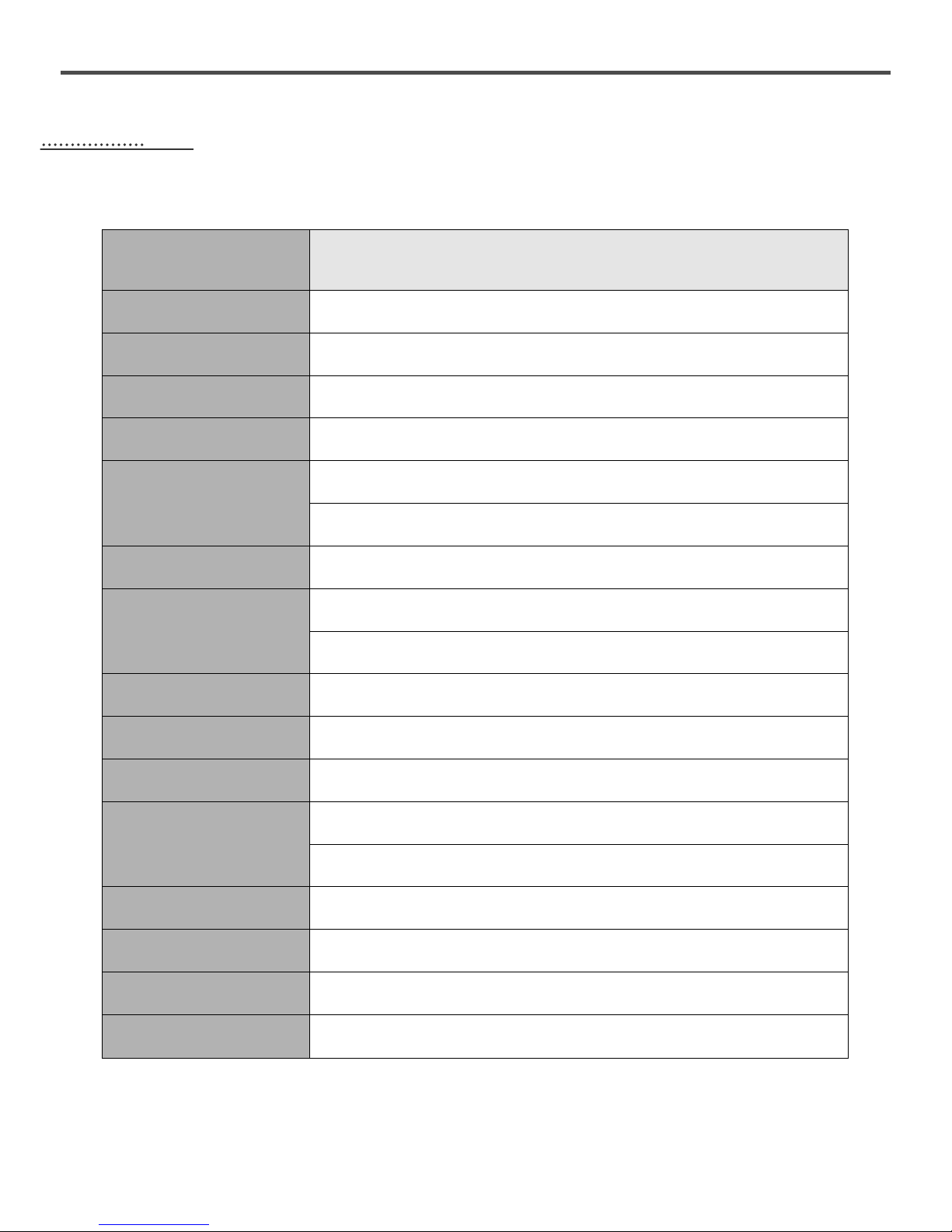

33

Specifications

Description

Stitch Type

For use

Sewing speed

Stitch length

Needle

Needle clearance

Needle bar stroke

Lifting of presser foot

Feed Regulation

Differential ratio

Differential Feed Regulation

Lubrication

Oil used

Oil fan capacity

Super high-speed cylinder bed, 3-needle, interlock stitch machine

ISO 406,407,602,605

General seaming of knitted materials

Max. 6000 s.p.m (In the case of on-and-off operation)

1.4~3.6mm

Stitches per inch: 7-18; The number of stitches per 30mm: 8-21

UY

×

128GAS No. 65 - No. 90(Standard : No. 70)

2-needle: 3.2, 4.0, 4.8, 5.6, 6.4 mm

3-needle: 5.6, 6.4 mm

31mm

Max. 7 mm (5 mm if equipped with a spreader)

Push-Button type

Max. Normal Differential Ratio → 1 : 2.9

Max. Reverse Differential Ratio → 1: 0.3

Adjusting screw and adjusting lever

Automatic lubrication by oil pump

All-purpose machine oil

800CC

Model SC 7300 Series

Page 13

13

44

Installation

[ Figure 1 ]

다리 장착 위치

Stand Mounting Position

다리 장착 위치

120

75

40

Stand Mounting Position

(275)

(255)

4-R20

360

100

805

3-ф9(Hole thru)

ф50(Hole thru)

ф17(Hole thru)

66±0.3

33±0.3

159±0.5

57±0.3

K

ф25

225

360

ф40

4-ф7(Hole thru)

140

180±0.5

20570

80

1,200

(685)

235±0.5

47.5±0.3

K"

280

Section K-K"

[Scale=1:2]

72.5

75

540

25

10

C1

C1

C1

C1

80

(60)

40

1) Installation of table

⑴ Types of table

A. Table Top Type (trimming)

[ Figure 2 ]

(275)

다리 장착 위치

Stand Mounting Position

805

다리 장착 위치

Stand Mounting Position

75

120

75

ф17(Hole thru)

ф25

K

57±0.3

159±0.5

180±0.5

80

(60)

40

360

(255)

4-R20

100

(685)

3-ф9(Hole thru)

66±0.3

33±0.3

140

1,200

70

235±0.5

47.5±0.3

K"

280

4-ф7(Hole thru)

ф40

72.5

225

360

540

40

C1

C1

25

10

C1

C1

Section K-K"

[Scale=1:2]

B.

Table Top Type (Non-trimming)

Page 14

14

[ Figure 3 ]

다리 장착 위치

Stand Mounting Position 805

159±0.5

K

6

6

4-ф50

235±0.5

(255)

4-R20

280±0.5

180

3-R10

8-R5

R10

50

41

3-R10

91

25

80

40

(60)

100 360

70

280

4-ф13

4-ф25.5

60

331

70 265

540

3

47.5

K″

37

16

4-ф13(Hole thru.)

4-ф25.5C'B Depth3

25

100

3-ф9(Hole thru)

ф50(Hole thru)

66±0.3

33±0.3

35

V-벨트중심

Center of V-Belt

ф17(Hole thru)

57±0.3

(275)

다리 장착 위치

120

75

40

75

Stand Mounting Position

Section K-K″

[Scale=1:2]

C1

C1

C1

C1

75

1,200

C. Semi-Submerged Type (Trimming type)

[ Figure 4 ]

다리 장착 위치

Stand Mounting Position

다리 장착 위치

Stand Mounting Position

120

C1

C1

159±0.5

805

(275)

80360100

4-R20

1,200

280

75

235±0.5

Section K-K″

[Scale=1:2]

3

60

4-ф13

265

4-ф25.5

280±0.5

6

4-ф50

8-R5

3-R10

ф17(Hole thru)

4-ф13(Hole thru.)

3-ф9(Hole thru)

66±0.3

33±0.3

4-ф25.5'B Depth3

6

18050

25

91

41

3-R10

R10

331

70

47.5

K″

37

16

40

(255)

(60)

K

57±0.3

35

V-벨트중심

Center of V-Belt

75

540

70

75

40

C1

C1

D. Semi-Submerged Type (Non-trimming type)

Page 15

15

[ Figure 5 ]

E. Options for small-sized motor type

Page 16

16

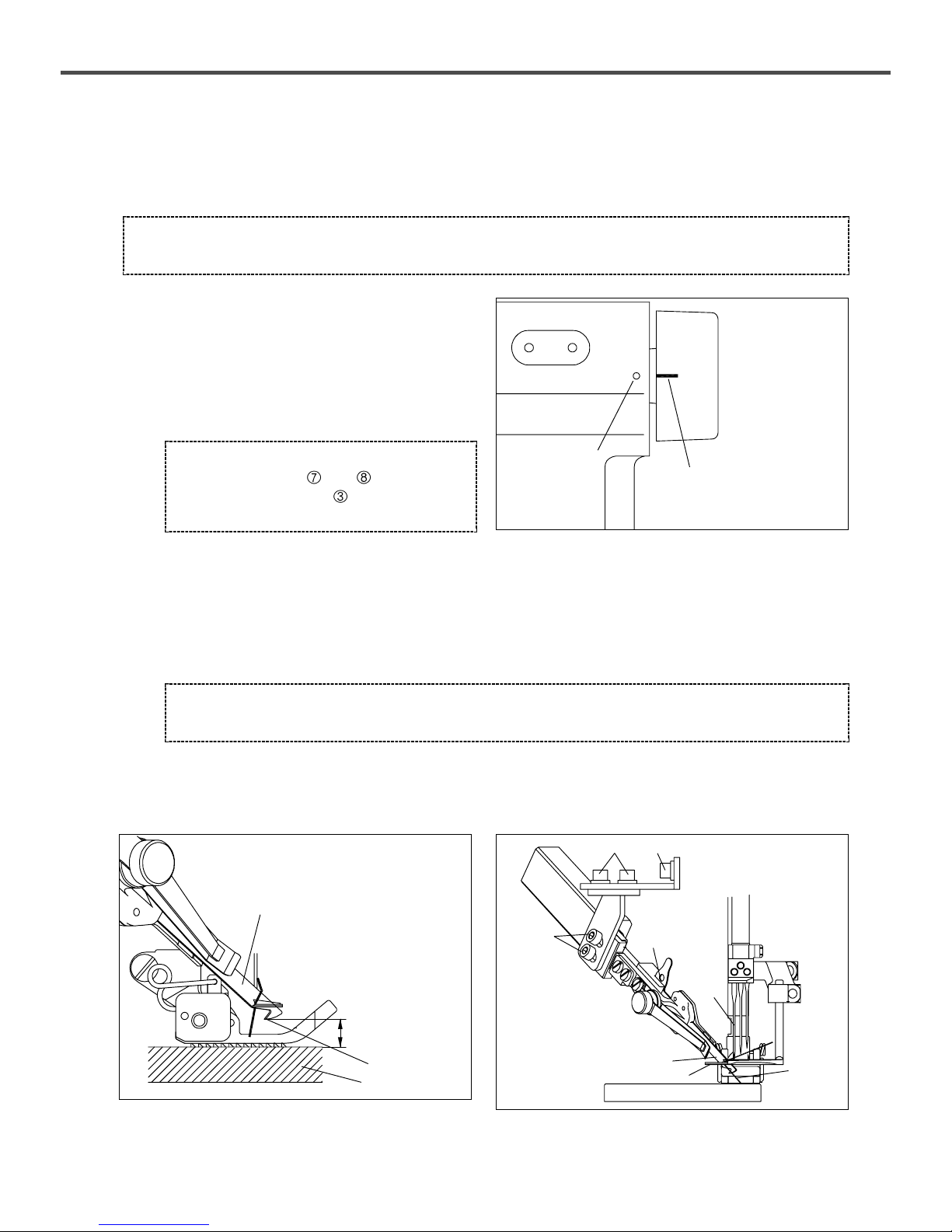

⑵ Installation of table-top type table

Mount the sewing machine as shown in Figure 6 and 7.

Fix the table with screws and nuts. Place the rubber cushion on the bolt and then fix the oilpan onto the cushion securely.

Mount the sewing machine as illustrated in Figure 8 and 9.

First, insert the screw into the bed support bar ⑩ and fix it onto the table. Then fit the rubber cushion onto the screw and

place the oilpan securely.

[ Figure 7 ][ Figure 6 ]

⑶ Installation of semi-submerged type table

[ Figure 9 ][ Figure 8 ]

①

①

⑤

⑤

⑤

Machine

Machine

Oilpan

⑥

⑧

⑨

⑦

②

⑩

⑪

⑤

Oilpan

Table

Table

Table

4mm

Table

⑤

②

②

⑧

⑩

⑪

⑤

⑥

⑥

⑥

②

⑨

⑦

②

②

③

③

④

④

②

Page 17

17

⑷ Installation of small-sized motor type table (option)

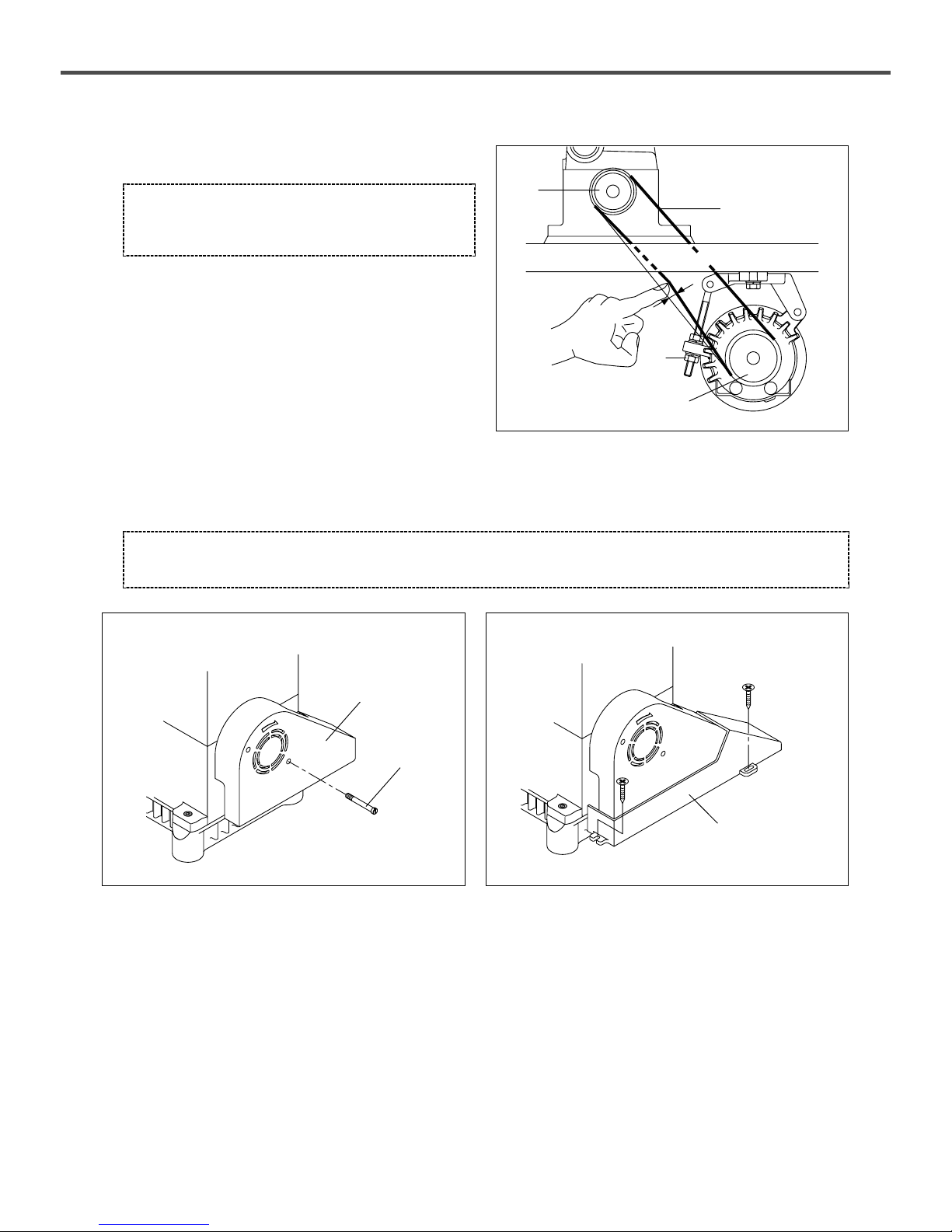

2) Installation of motor and belt

Use a 3-Phase, 2-Pole, 400W(1/2 HP) clutch motor and M-type V-belt for the machine.

Start the pedal. When the motor pulley begins to move to the left, adjust the position of the motor so that the centers of the

motor pulley and the M/C pulley meet with each other.

Mount the sewing machine as shown in Figure 10 and 11.

Insert the screw and nut into the table, and place the rubber cushion on the bolt. Securely place the oilpan on the cushion

afterwards.

※ The diameter of pulleys in the market is generally set with a 5 mm clearance.

75

80

85

90

100

110

120

130

s.p.m of machine

50Hz 60Hz

3,200 3,900

3,400 4,100

3,600 4,400

3,900 4,700

4,300 5,200

4,700 5,700

5,100 6,200

5,500 6,700

[ Figure 11 ]

[ Figure 10 ]

[ Figure 12 ]

①

⑤

Oilpan

Table

5.5mm

61mm

10mm

40。

④

②

③②

①

⑤

⑤

Machine

Table

⑤

②

③

④

②

Diameter. of Motor

Pulley(mm)

Page 18

18

3) Adjustment of belt tension

4) Installation of belt cover

[ Warning ]

Be sure to turn the power switch off before adjusting belt

tension.

[ Warning ]

Always install the belt cover for safety.

Turn the screw④ of the motor③ around. Adjust the belt ①

to go in approximately 10~20mm when its center portion is

pushed with a finger. (Refer to figure 13)

[ Figure 13 ]

Fasten the belt cover (upper)① with a screw② as shown in figure 14. For A-Type table, mount the belt cover (lower)③ as

shown in figure 15.

①

④

③

②

10~20mm

[ Figure 15 ][ Figure 14 ]

①

②

③

Page 19

19

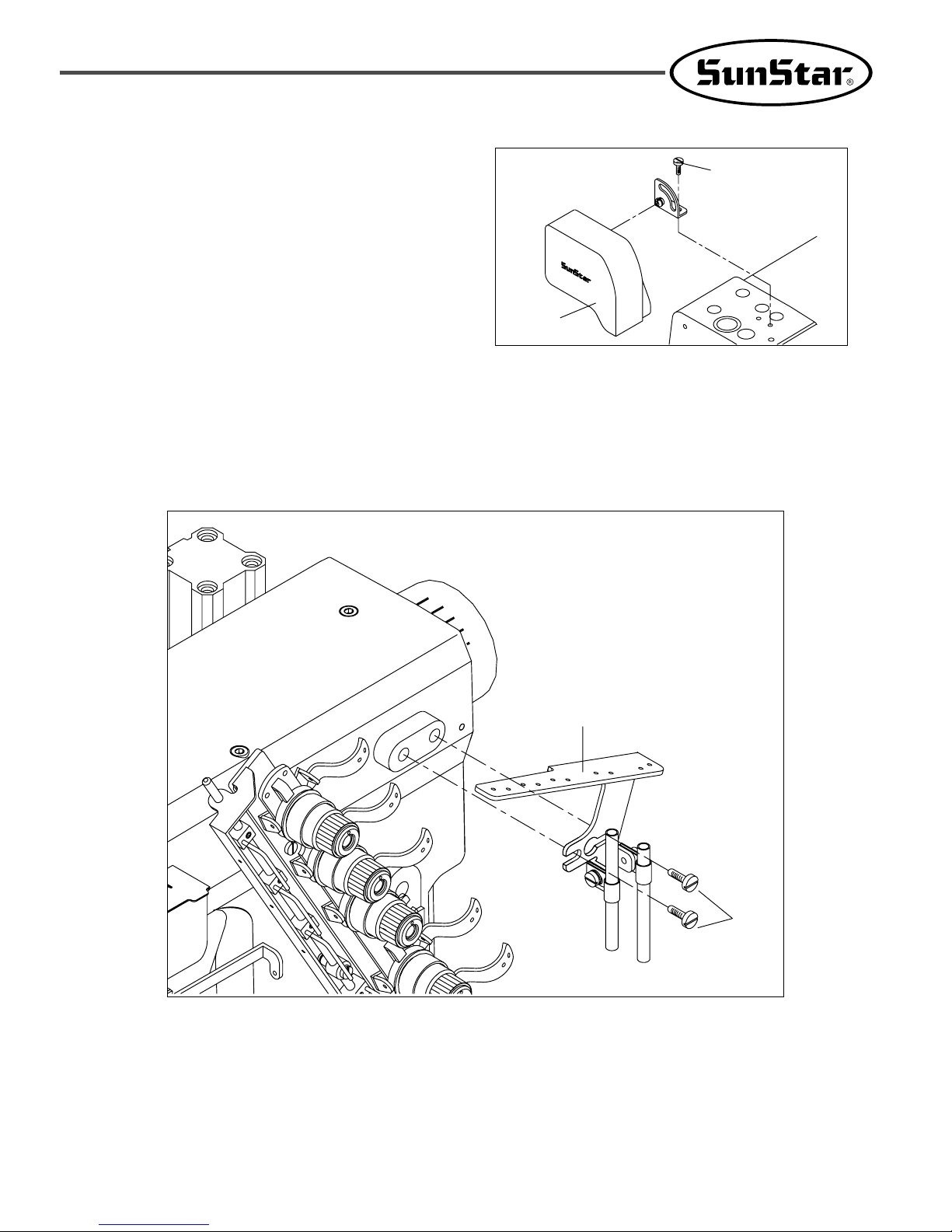

5) Installing cover for needle bar thread

guide

As illustrated in the figure, fix the cover② for needle bar

thread guide onto the arm with two screws①.

6) Installation of thread guide plate

Use screws ① (2 each) to mount the thread guide plate ② onto the arm as described below in the figure.

[ Figure 17 ]

②

①

[ Figure 16 ]

①

②

Page 20

20

[ Warning ]

Be sure to turn the power switch off before oiling

[ Caution ]

Do not put foreign materials into the lubricating oil. It will degrade the lubricating oil and cause mechanical breakdowns.

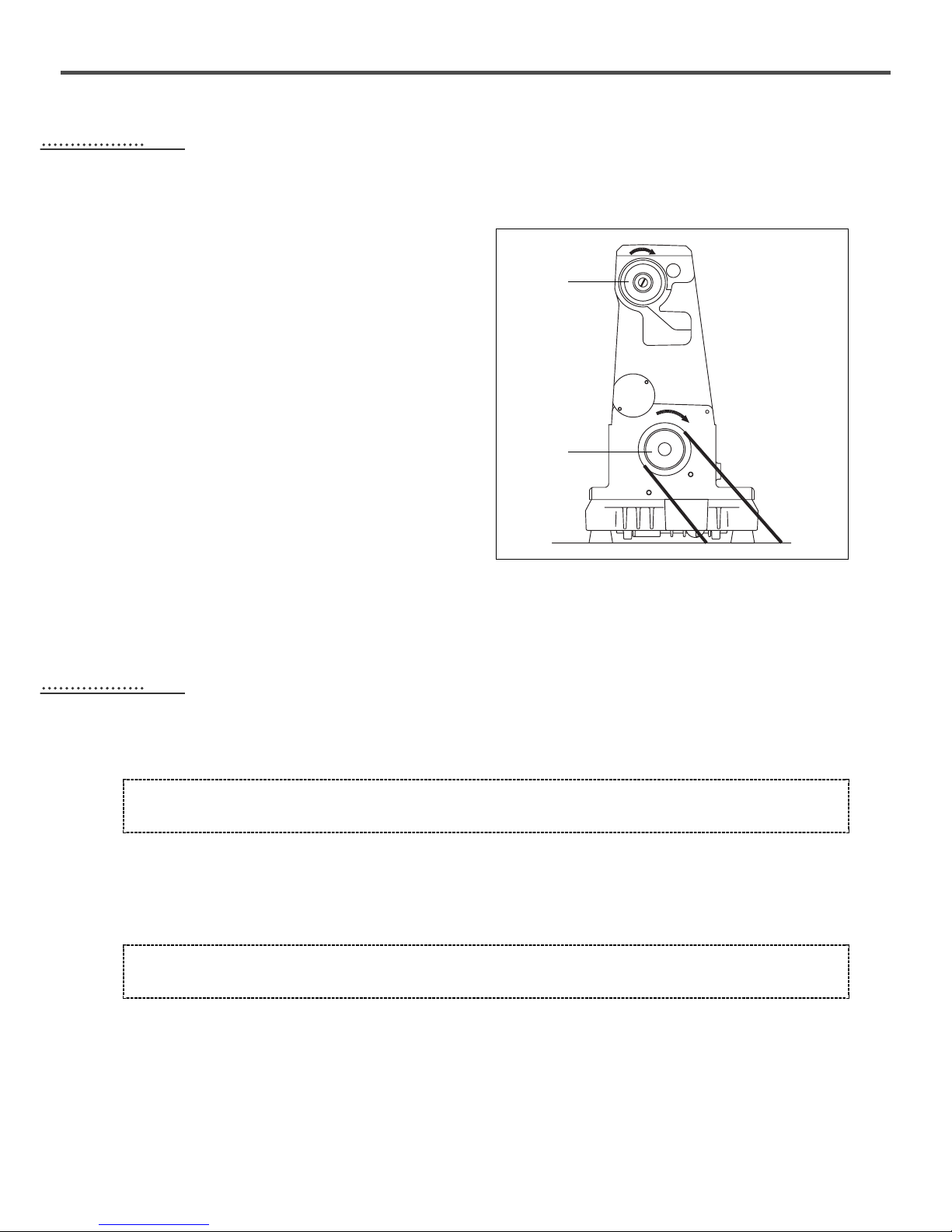

The maximum speed of the sewing machine is 6,000 s.p.m,

and 4,000 s.p.m for commercial use. (If a puller is installed,

maximum sewing speed is 4,500 s.p.m, and 4,000 s.p.m for

commercial use.)

To ensure durability, run the sewing machine at 5,000 s.p.m

for 200 hours of operation (or 1 month) when using the

machine for the first time.

As shown in figure 18, the rotating direction of the lower

shaft pulley① and upper shaft pulley② is clockwise.

[ Figure 18 ]

1) Lubricating oil

Use industrial-purpose lubricating oil supplied by SunStar or SF oil by YANASE for this particular type of sewing machine.

Sewing speed and rotating direction of pulley

①

②

55

66

Lubrication

Page 21

21

[ Caution ]

Too little oil may cause mechanical breakdowns and too much may degrade the quality of sewing materials. Be sure to

adjust the amount of oil appropriately.

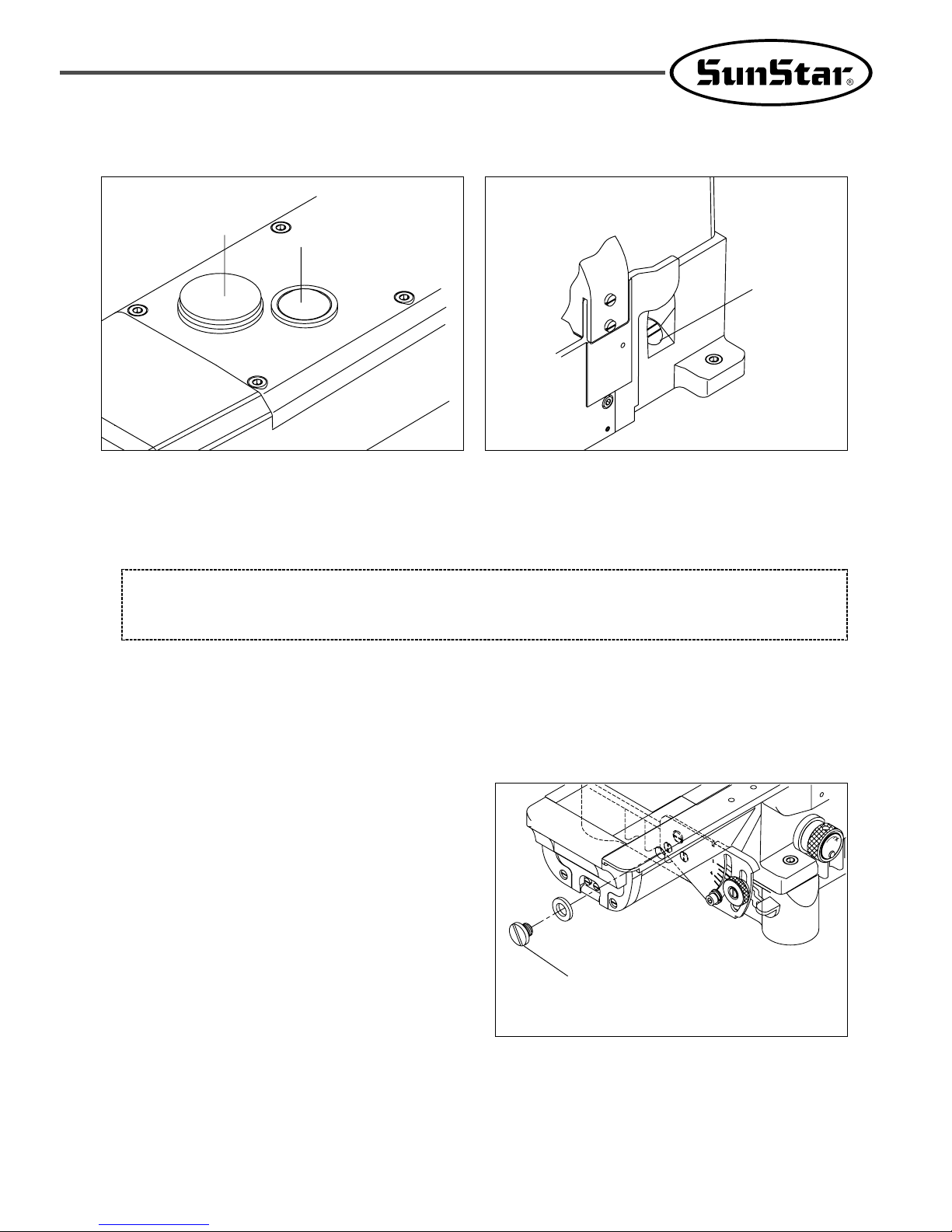

3) Oil Gauge and Oil Window

Always check the oil gauge ③ before starting the machine. Supply oil if the remaining oil comes short of the lower line of

the gauge.

When operating the machine, check the flow of the oil through oil window ②.

4) Oil change

To ensure durability of the sewing machine, be sure to

change oil after 250 hours of initial operation.

Change oil according to the following.

⑴ Unfasten oil discharge screw ① to let out the lubricating

oil.

⑵ Fasten oil discharge screw① securely afterwards.

⑶ Refer to 2) Supplying oil for lubrication.

[ Figure 21 ]

The sewing machine is not oiled when shipped out from the factory. To ensure trouble-free use of the sewing machine, open

the upper rubber lid ① and supply oil to the upper line of the oil gauge ③.

2) Supplying oil

①

[ Figure 20 ][ Figure 19 ]

①

②

③

Page 22

22

[ Caution ]

When removing the oil filter cover, be sure to prevent the remaining oil in the oil filter from leaking.

6) Cleaning the machine

After each daily operation, clean the sewing machine to

remove any dust or thread pieces left.

Open bed cover (left), bed front cover or other covers for

cleaning. You may also use air guns.

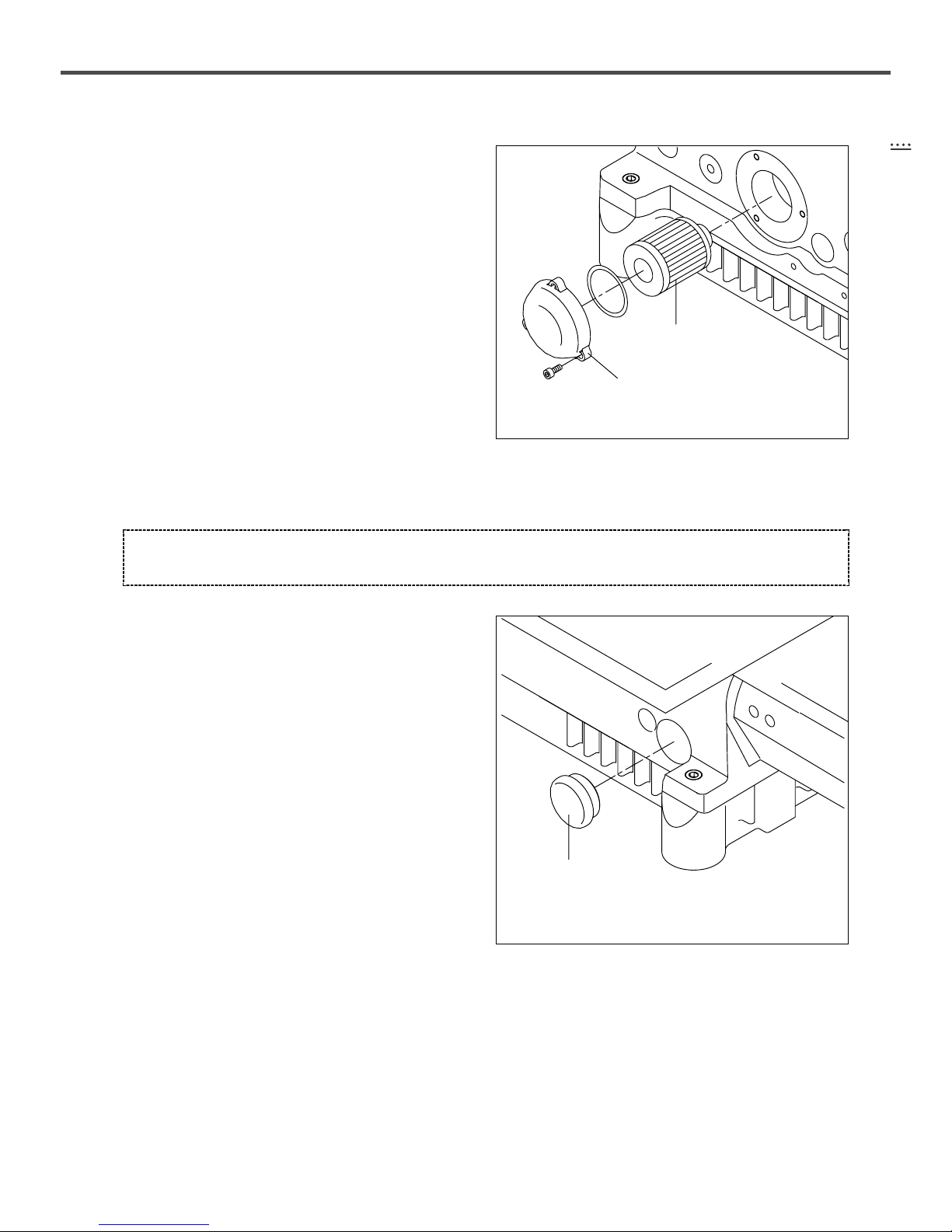

Take out the backside rubber cap of the bed ① at the back of

the sewing machine. Clean out dust or any residues in the oil

net with a tweezer or an air gun once a week.

[ Figure 23 ]

5) Cleaning the oil filter

Oil will not supply smoothly if dust gets built up in oil filter

①. Check the oil filter once every six months.

Check the oil filter through the oil window if there is no or

only little amount of oil being supplied.

Before checking the oil filter, remove the oil filter cover ②.

Clean dust build-ups inside the oil filter.

[ Figure 22 ]

①

①

②

Page 23

23

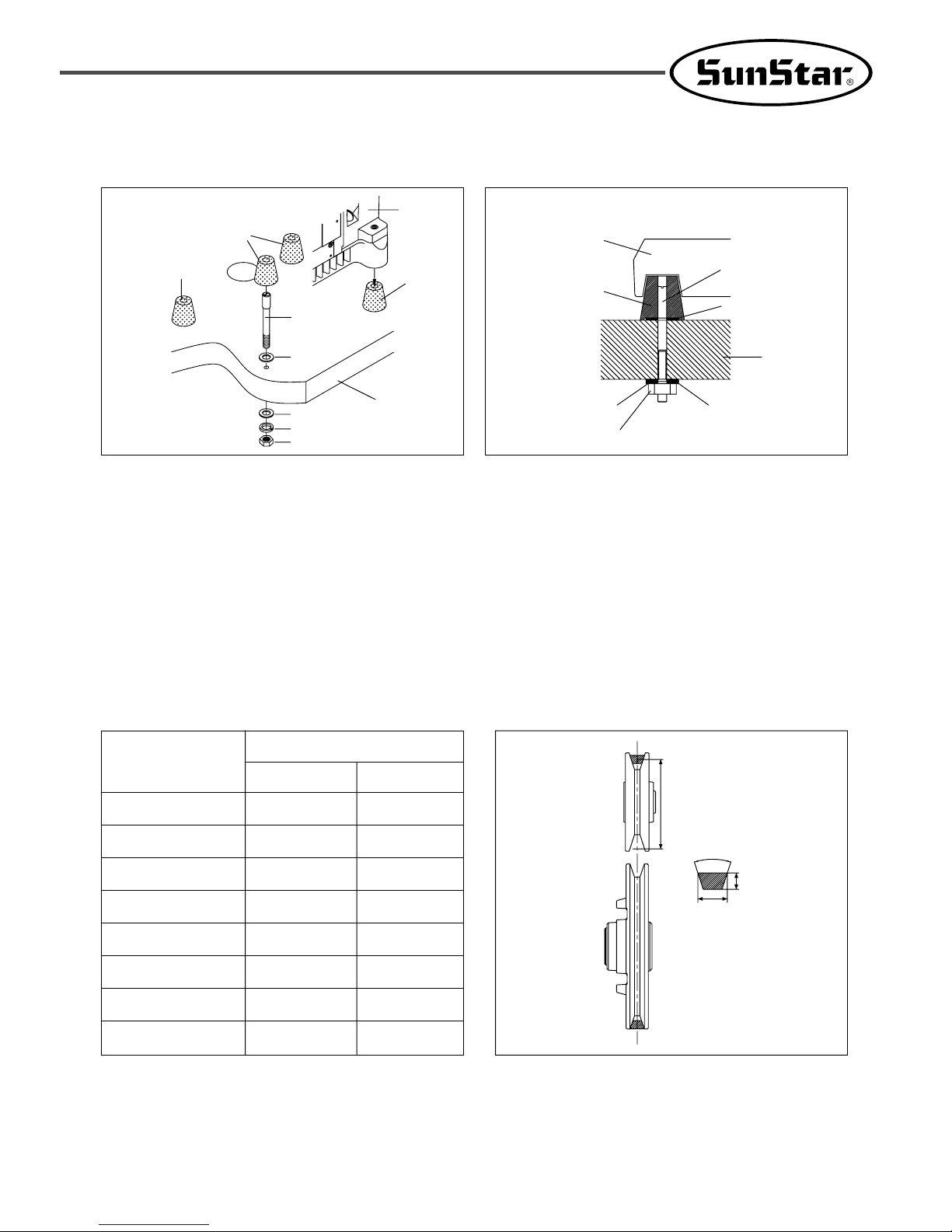

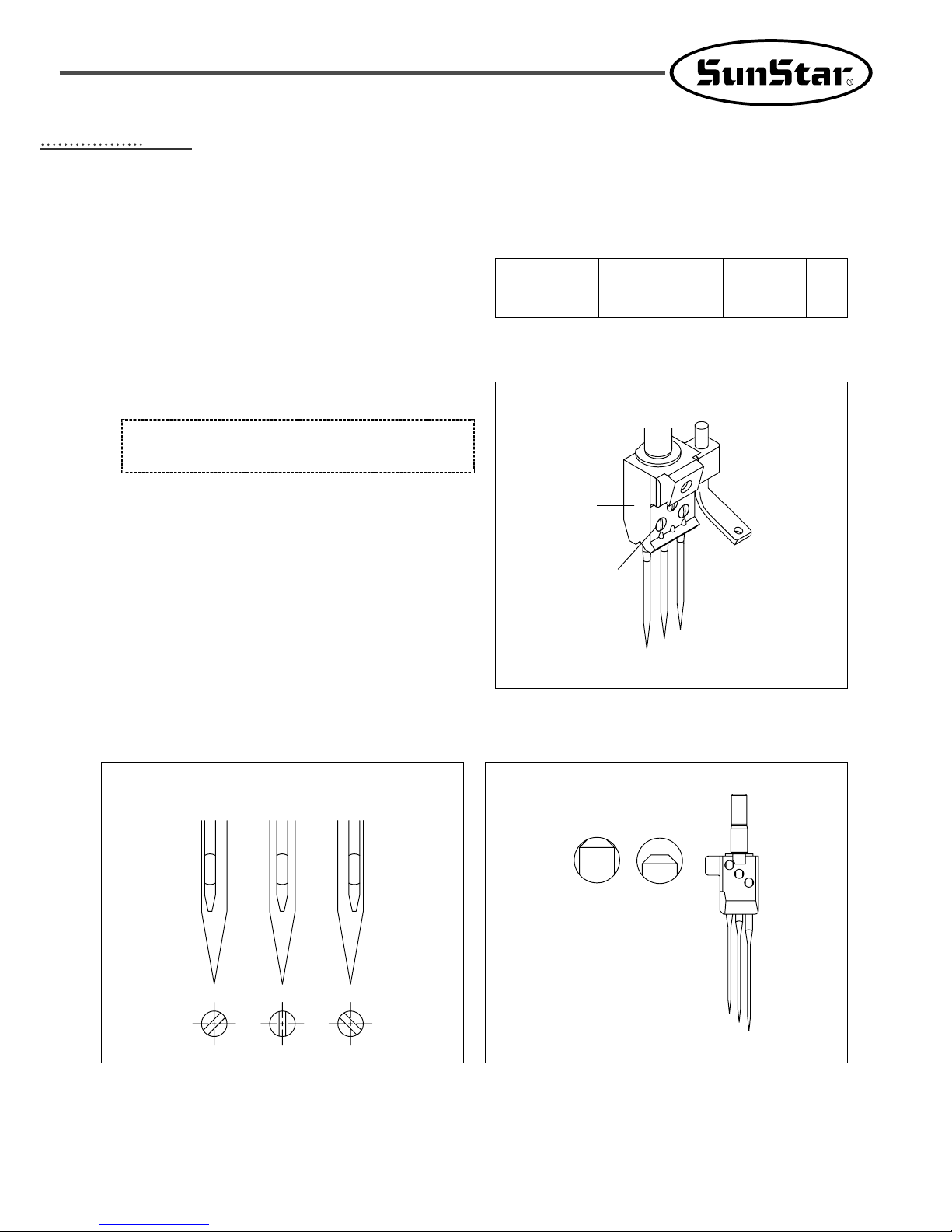

2) Installation of needle

Use a needle driver to loosen the screw ①, and remove the

old needle with tweezers. (Figure 24)

Set the needle groove to completely face back, and raise the

needle to the groove tip of the needle holder ②. Then fasten

the screw ① firmly. (Figure 25, 26)

[ Warning ]

Turn the power switch off before installing a needle.

[ Figure 24 ]

1) Needle used

This sewing machine uses UY128GAS needles.

Needles come in various size. Select the most appropriate

needle depending on the thickness or the type of sewing

materials.

Japanese size 9 10 11 12 13 14

Metric size 65 70 75 80 85 90

[ Figure 26 ][ Figure 25 ]

77

Standard adjustments of the sewing machine

②

①

××○

○×

Page 24

24

3) Threading

Insert the thread as shown in figure 27 for 3-needle sewing machine.

If treading is not done correctly, stitches may skip, threads may break or tension may be uneven. A, B and C stand for each

needle thread, D for top cover thread and E for looper thread.

Except for the second needle thread in the case of 2-needle sewing machine, refer to the above instructions for threading.

You can thread easily by lifting the lever② of the looper thread guiding bracket①.

For general types of threads, pull the thread into the looper⑤ through looper shaft bushing eyelet④, but for threads made of

cotton or polyester, remember not to insert the thread into looper shaft bushing eyelet④.

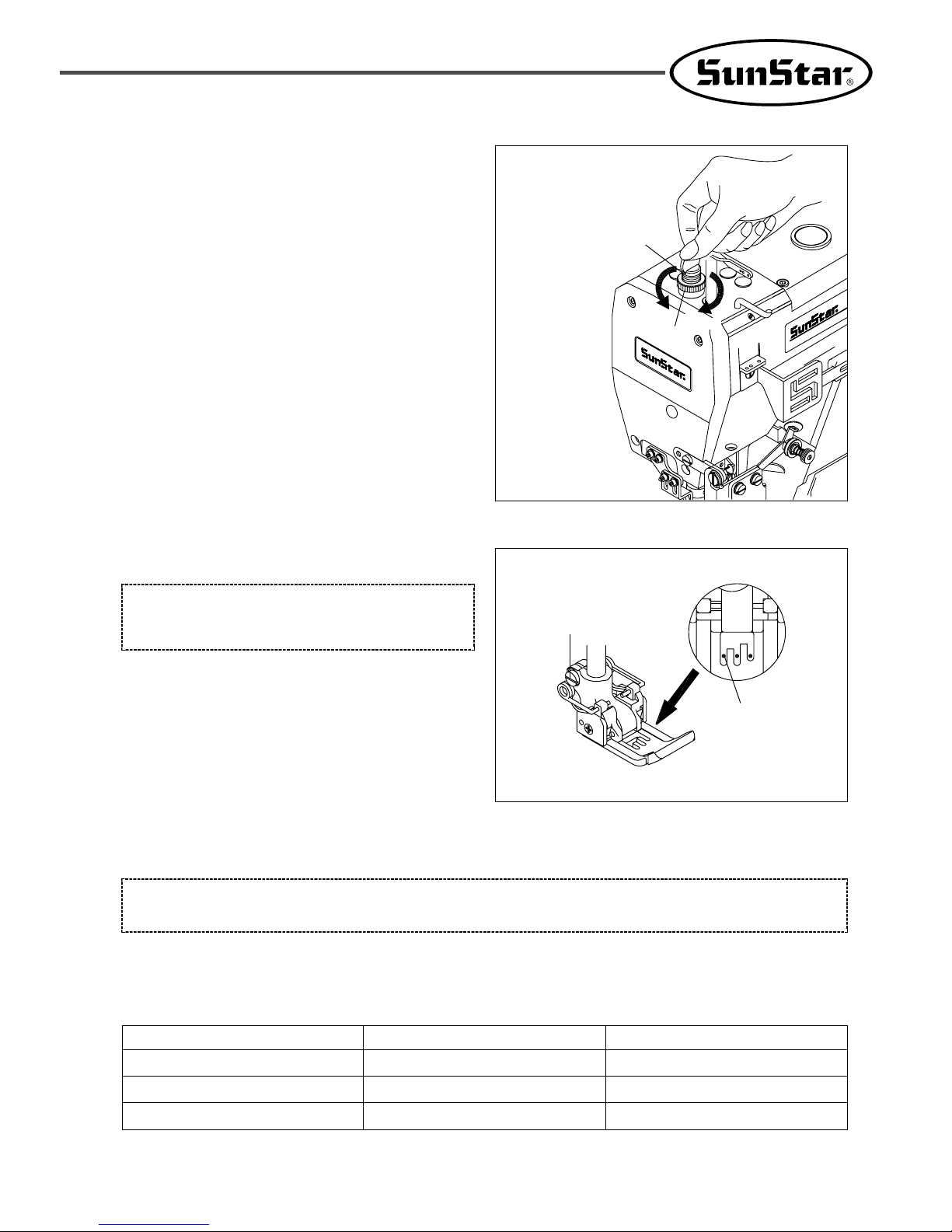

4) Adjustment of thread tension

Thread tension must be adjusted according to the type of

threads and fabrics, stitch length and other sewing

conditions.

Thread tension can be adjusted by rotating the thread

adjusting device cap①. Turn clockwise to strengthen and

counterclockwise to weaken the tension.

[ Figure 28 ]

①

Strong

Weak

[ Figure 27 ]

①

A

B

C

D

E

②

③

④

⑤

The path of trimming sewing machine

When using wool thread

Do not insert thread

when using wool thread

Page 25

25

5) Adjustment of presser foot tension

If the sewing material is in good condition, it is better to

have as little tension as possible on the presser foot.

Loosen the presser bar nut① and turn the presser bar screw

② with a coin to adjust the tension of the presser bar. Re-

tighten it afterwards.

Tension will become stronger if the screw② is turned

clockwise, and weaker if turned counterclockwise.

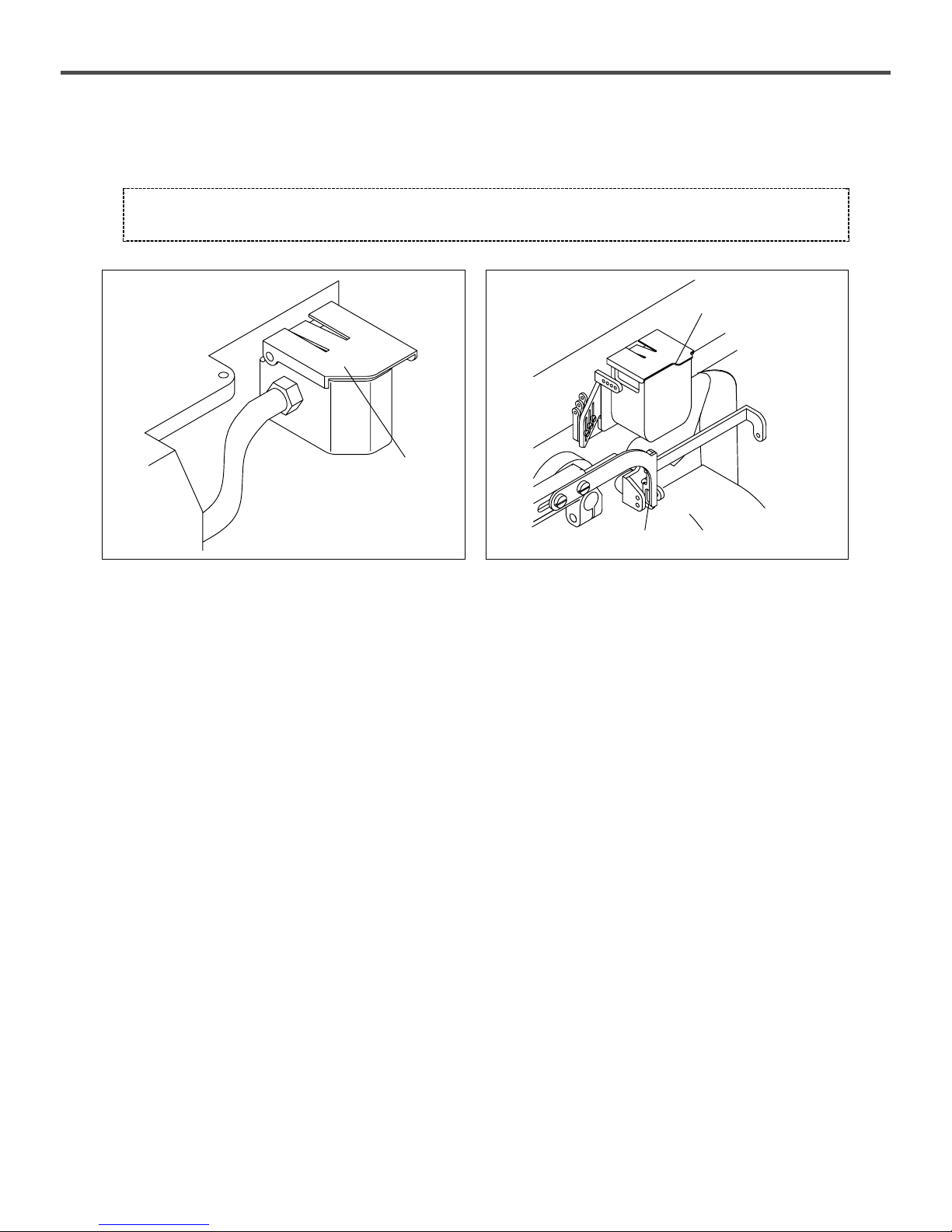

6) Adjustment of presser foot position

7) Adjustment of stitch length

⑴ Stitch length

Stitch length can be adjusted straight from 1.4mm to 3.6 mm

The table below shows stitch length, number of stitches per inch(25.4mm) and per 30 mm.

After unfastening the screw ①, move the front part of the

presser foot left and right to bring the needle to pass the

center of the needle passage of the presser foot.

[ Warning ]

Be sure to turn the power switch off before adjusting the

position of the presser foot.

[ Warning ]

Be sure to turn the power switch off before adjusting stitch length.

Stitch length (mm) No. of stitches (per inch) No. of stitches (per 30mm)

3.6 7 8

2.4 10.5 12.5

1.4 18 21

[ Figure 30 ]

①

Needle

[ Figure 29 ]

②

①

Weak

Strong

Page 26

26

⑵ Change of stitch length

Press lightly stitch length-adjusting button① with your left hand so that the end comes in contact with inner parts.

With the button① pushed in, turn the upper shaft pulley② with your right hand so that the button① goes in deeper.

At this point, rotate the upper shaft pulley with the button① strongly pushed in.

Stitch length is a value you get when the mark around the upper pulley meets the mark ③.

[ Figure 32 ][ Figure 31 ]

①

③

②

When the stitch width adjustment is completed, make sure that the adjusting button①①returns

to the original position before operating the machine. Otherwise, damage to the machine might

occur.

Caution

Page 27

27

8) Adjustment of differential feed

[ Caution ]

Be sure to turn the power switch off before adjusting differential feed.

[ Figure 34 ][ Figure 33 ]

①

②

③

④

⑴ Differential feed

Set normal differential feed or reverse differential feed by rotating differential feed regulating handle①. As differential

feed is driven independently from main feed, changes in main feed (stitch length) will result in differential ratio. Be sure

to re-adjust main feed to maintain a consistent level of differential ratio.

Scales in figure 34 show the level of differential feed. For example, if the desired feed or stitch length is 2, turn the

differential feed regulating handle ① to bring the scale at 2 to obtain the differential ratio of 1:1.

Normal differential is when the scale is set larger than 2, and reverse differential is when set less than 2.

⑵ Change of differential feed

Select the lever position from the scale pointed by the differential feed regulating lever④ when (differential feed)

regulating handle① is turned, to regulating lever stopper ②. Then tighten with the regulating lever nut ③ afterwards.

For maximum differential feed, turn the handle ① to set the lever at the scale ‘1’.

※ The range of differential feed changes in accordance with stitch length. Refer to the table below.

Stitch length (mm) Maximum normal differential feed Maximum reverse differential feed

3.6 1 : 1.1 1 : 0.3

2.5 1 : 1.6 1 : 0.4

2.0 1 : 2 1 : 0.5

1.4 1 : 2.9 1 : 0.7

Page 28

28

9) Lubricating device of needle thread and needle cooling device

High-speed sewing generates heat as a result of frictions between the needle and sewing materials. Heat may result in thread

breaks, skipped stitches, or enlarged stitch holes when used with polyester threads or fabrics.

To prevent such troubles, this sewing machine comes attached with the needle cooling device and needle thread lubricating

device as a standard option.

※ Open cover ① of the silicon oiling tank and cover ② of the needle thread oiling tank to check the level of silicon oil. Oil

if necessary.

※ If there is no need for silicon due to specific sewing conditions, remove the felt to prevent the needle and the thread from

passing the dry felt.

[ Warning ]

Be sure to turn the power switch off before work.

[ Figure 36 ][ Figure 35 ]

①

②

Page 29

29

1) Adjustment of needle thread tension

[ Warning ]

Turn the power switch off before adjusting tension.

For some types of threads, looping is not an easy thing to

do. Wrong loops may make it difficult for the looper to pass

needle thread loop and cause skipped stitches.

In such case, pull the needle thread through the auxiliary

tension-adjusting device of the needle thread ① as shown in

figure 37.

[ Figure 37 ]

Use the needle thread guide ③ when using stretchable

threads such as synthetic thread and the loop of needle

thread is unstable.

It is a standard setting to bring the center of the needle hole

of the needle bar take up ② against the upper side of the

needle thread guide when the needle bar is at its lowest

position.

The height of the needle bar guide can be adjusted by

loosening the screw ④.

88

Fine-tuning of the sewing machine

①

[ Figure 38 ]

③

②

④

Page 30

30

2) Adjustment of looper thread tension

[ Warning ]

Be sure to turn the power switch off before adjusting tension.

As a standard, the center of the thread hole of the looper

thread guide ② and ③ is generally positioned along the line

of the looper thread guide bracket①.

Loosen the screw to lower the looper thread guide down to

decrease the looper thread tension, and raise it up to increase

the tension.

※ When using the woolly thread, bring the looper thread

guide(②, ③) down as much as possible, and do not

insert thread into disc ④.

[ Figure 39 ]

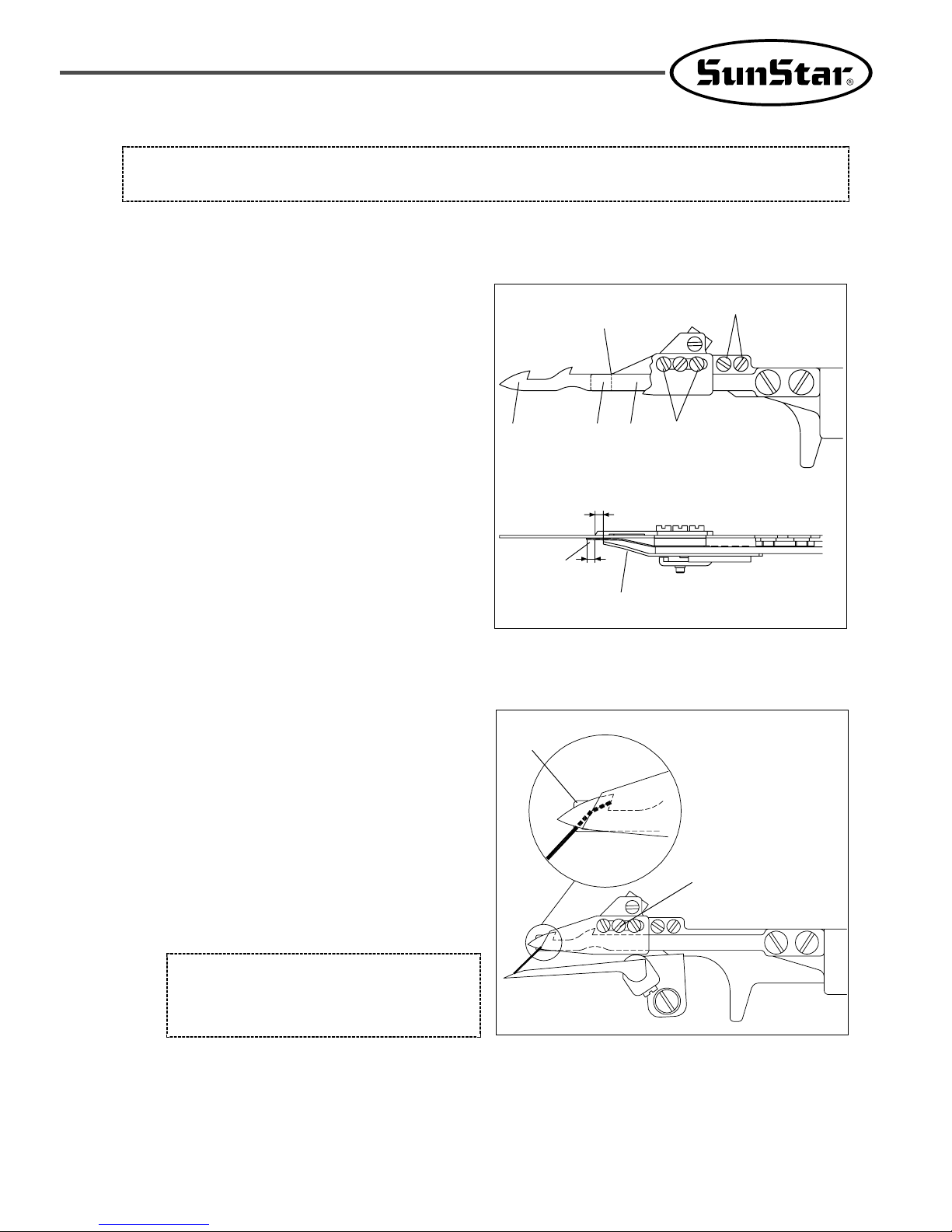

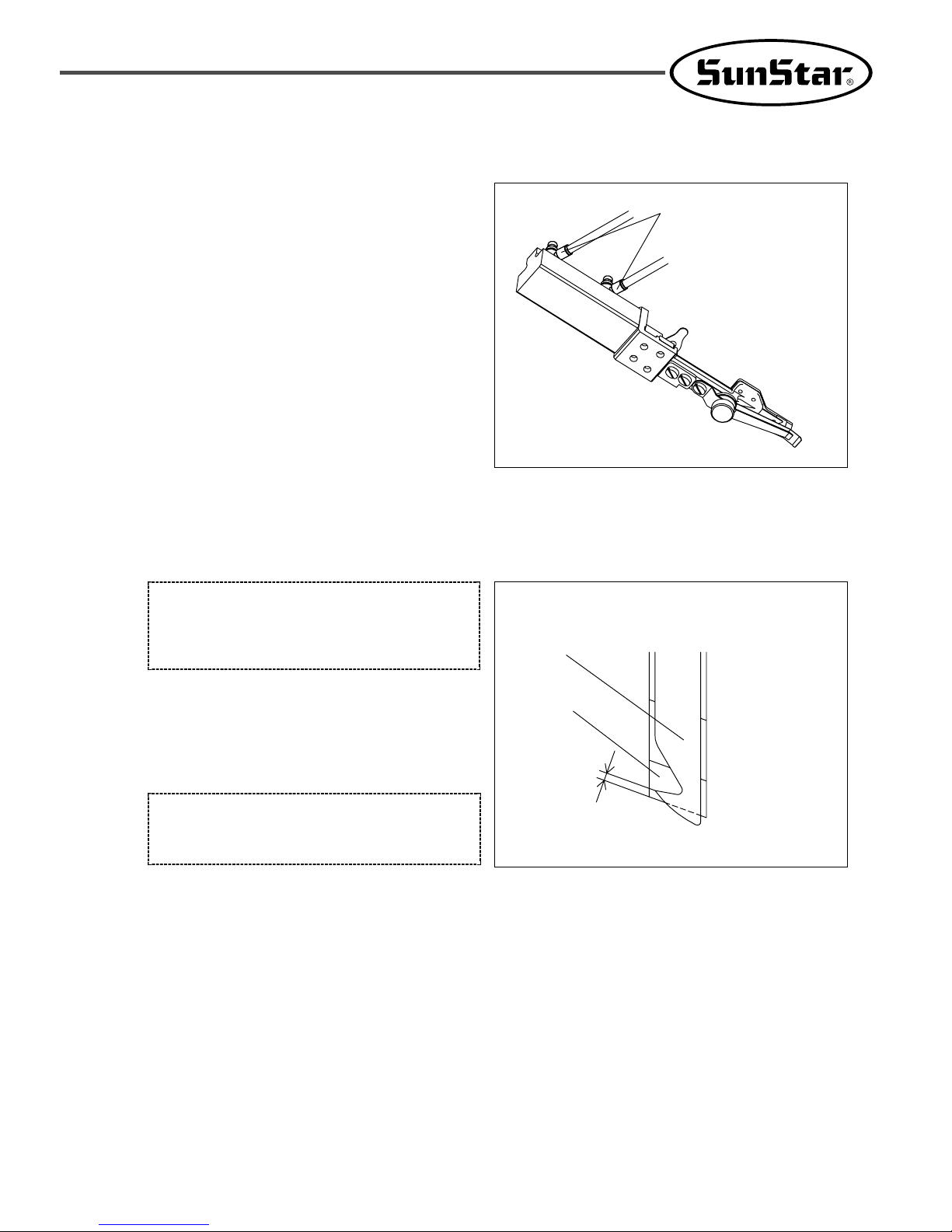

3) Adjustment of needle and spreader

[ Warning ]

Turn the power switch off before adjustments

⑴ Installation of spreader

When the spreader① moves to the left, the clearance between the left needle and the hook tip of the spreader (a) is

0.5mm ~ 0.8mm. (Figure 40)

When the spreader sits at the far left, the distance from the left needle center to the hook tip of the spreader (a) is 4.5mm ~

5.5mm.

The height between the stitch plate and the lower side of the spreader① is 8.5mm ~ 9.5mm. (Figure 41)

The spreader can be adjusted by untightening the spreader fixing screw② and the spreader handle fixing screw③.

(Figure 42)

[ Figure 40 ] [ Figure 41 ] [ Figure 42 ]

③

④

②

①

①

a

0.5~0.8mm

4.5~5.5mm

8.5~9.5mm

①

③

②

Page 31

31

⑵ Installation of top cover thread guide

The clearance between the lower side of the top cover

thread guide④ to the upper side of the spreader① is

0.5mm.

Fix the screw⑤ when the spreader is at its far right, in

order to hook the thread well onto the thread hooking

part.

[ Figure 43 ]

⑶ Installing the top cover thread eyelet

When the needle bar is at its lowest, the clearance between

the upper side of the top cover thread guide ④ and the

lower side of the top cover thread eyelet ⑥ is 1.0mm.

Bring the needle groove of top cover thread eyelet ⑥ to

the centerline of the slots of the top cover thread guide ④.

Tighten the screw ⑦ afterwards.

※ Adjust (1), (2) and (3), depending on the type of

thread used.

[ Figure 44 ]

④

④

⑦

⑥

⑥

⑥

④

①

①

0.5mm

1.0mm

⑤

Page 32

32

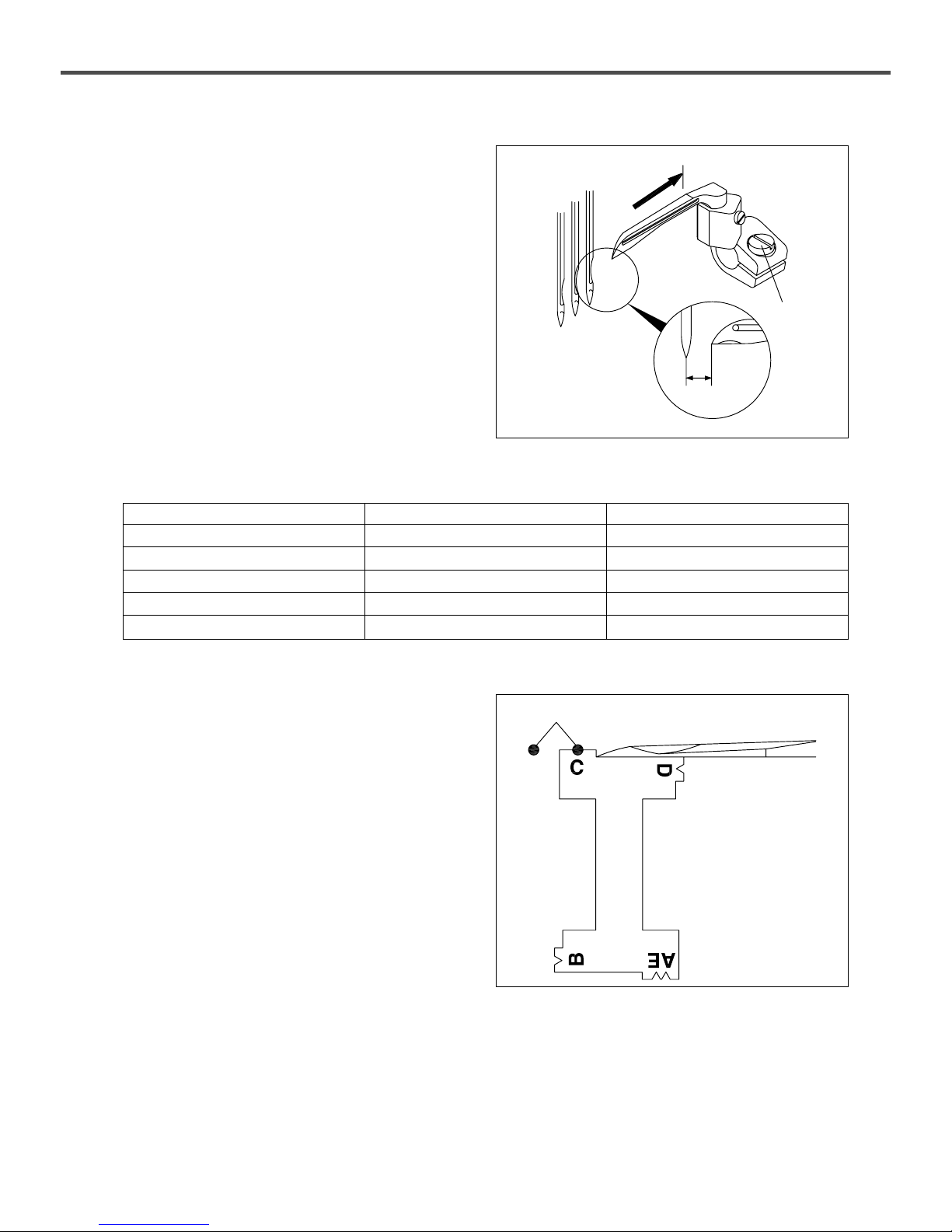

4) Adjustment of needle and looper timing

⑴ Left/right position of looper

The clearance between the end tip of the looper and the

center of the right needle changes in accordance with

needle distance, when the needle is at its lowest, and the

looper is at its far right. Be sure to adjust the distance as

shown in the table below.

Adjustment can be done by loosening the screw① of the

looper holder.

※ In all cases, the distance from the center of the needle

bar to the end tip of the looper is 6.0 mm.

[ Figure 45 ]

①

Using the Looper Timing Gauge makes it easy to adjust

the left and right position of the loopers. Timing Gauge

is an optional part. If needed, you may ask for the

purchase to where the product was bought or SunStar

directly.

※ Use Timing Gauge

Timing Gauge is marked with such scales as A, B, C, D and E depending on needle distance. When the looper is in

the most right-end position and the right needle settles on the “V groove”according to needle distance, keep the

Timing Gauge and the loopers in sync, and fasten the “looper holding nut.”

[ Figure 46 ]

Needle

Distance between needles Gauge scales

Distance from the left of the needle bar to the end tip of the looper

3.2mm (32) A 4.4 mm

4.0mm (40) B 4.0 mm

4.8mm (48) C 3.6 mm

5.6mm (56) D 3.2 mm

6.4mm (64) E 2.8 mm

Page 33

33

⑶ Front/rear position of needle and looper

The recommended clearance when the end tip of the

looper① meets the left needle is 0.2 ~0.3 mm. For

adjustments, unfasten the screw④ of the looper holder.

[ Figure 49 ]

⑷ Needle and needle guard(rear)

※ When needle guard (R) is at the lowest point of the

needle bar, align the center of the needles along the

line② of the needle guard (R) ①.

①

①

①

③

④

②

②

0.2~0.3mm

For 3-needle type

For 2-needle type

0.2~0.3mm

[ Figure 50 ]

⑵ Needle height

When the end tip of the looper passes the left needle center, it must pass the needle groove at 0.5~1.0 mm off from the

upper part. In other words, the height of the needle is set by the looper.

Using a driver, unfasten the screw① of the needle bar holder through a hole in the face plate and adjust the needle bar up

and down to get the right needle height.

[ Figure 48 ][ Figure 47 ]

①

0.5~1.0mm

Page 34

34

⑸ Needle and needle guard(front)

When the end point of the looper comes to the center of

the left needle, adjust the end point of the looper to rise

1.5~2 mm higher than the needle. At this point, set the

clearance between the needle and the needle guard (F) at

0~0.3 mm.

[ Figure 53 ]

①

①

And, when the end point of the looper returns to the right needle, set the clearance with the needle guard (F) at 0~0.3 mm.

Adjustments can be done by untightening th screws (②, ③).

[ Figure 55 ]

[ Figure 54 ]

0~0.3mm

①

③

②

0~0.05mm

0~0.05mm

※ Front/rear position of needle guard(R)

When the end tip of the looper comes to the center of the right needle, press the needle guard (R) to adjust the

clearance between the needle and the looper at 0~0.05 mm. At this point, be sure to set the distance between the left

needle and the needle guard (R) at 0~0.05 mm. Adjustments can be done by loosening the screws (②, ③).

[ Figure 52 ]

[ Figure 51 ]

②

③

1.5~2.0mm

0~0.3mm

Page 35

35

99

Automatic Thread Trimmer

(1) Operation procedures for UT-B and UT-A device.

Motor is selected either from ① or ②. Operation

procedures for ① or ② are as follows.

A. Put sewing materials under the presser foot and step

on the pedal towards ① position.

B. Leave pedal at ② neutral

→ The needle will stop at the highest point.

C. Step the pedal backward towards ③ position.

→ The trimming device will begin to move under the

needle plate to cut the needle thread and looper

thread. The looper thread will be caught by clamp

spring, and air wiper will run for two seconds, and

then presser foot will go up.

→ (For UT-A device, lifting of the presser foot and

wiper operation will begin at the same time.)

D. Leave the pedal at ② neutral

→ The presser foot will go down.

1) Operation

[ Figure 56 ]

① Start

② Neutral

③ Trimming,

Presser foot

lifting

[ Caution ]

If the pedal is not in ① position, move the pedal towards ② or ③ to bring the presser foot up/down.

[ Note ]

Be sure to lay sewing materials under the presser foot before operation.

Page 36

36

Motor is selected either from ① or ②. Operation

procedures for ① or ② are as follows.

A. Put sewing materials under the presser foot and step

on the pedal towards ① position

→ Sewing will begin.

B. Leave pedal at ② neutral

→ The needle will stop at the highest point.

C. Step the pedal backward towards ③ position.

→ The trimming device will begin to move under the

needle plate to cut the needle thread and looper

thread. The clamp spring will catch the looper

thread, after trimming top cover thread, and the

presser foot will go up.

D. Leave the pedal at ② neutral.

→ The presser foot will go down.

(2) Operation procedures for ST-C device.

[ Note ]

Be sure to place sewing materials under the presser foot before operation.

[ Figure 57 ]

① Start

② Neutral

③ Trimming,

Presser foot

lifting

[ Caution ]

If the pedal is not in ① position, move the pedal towards ② or ③ to bring the presser foot up/down.

Page 37

37

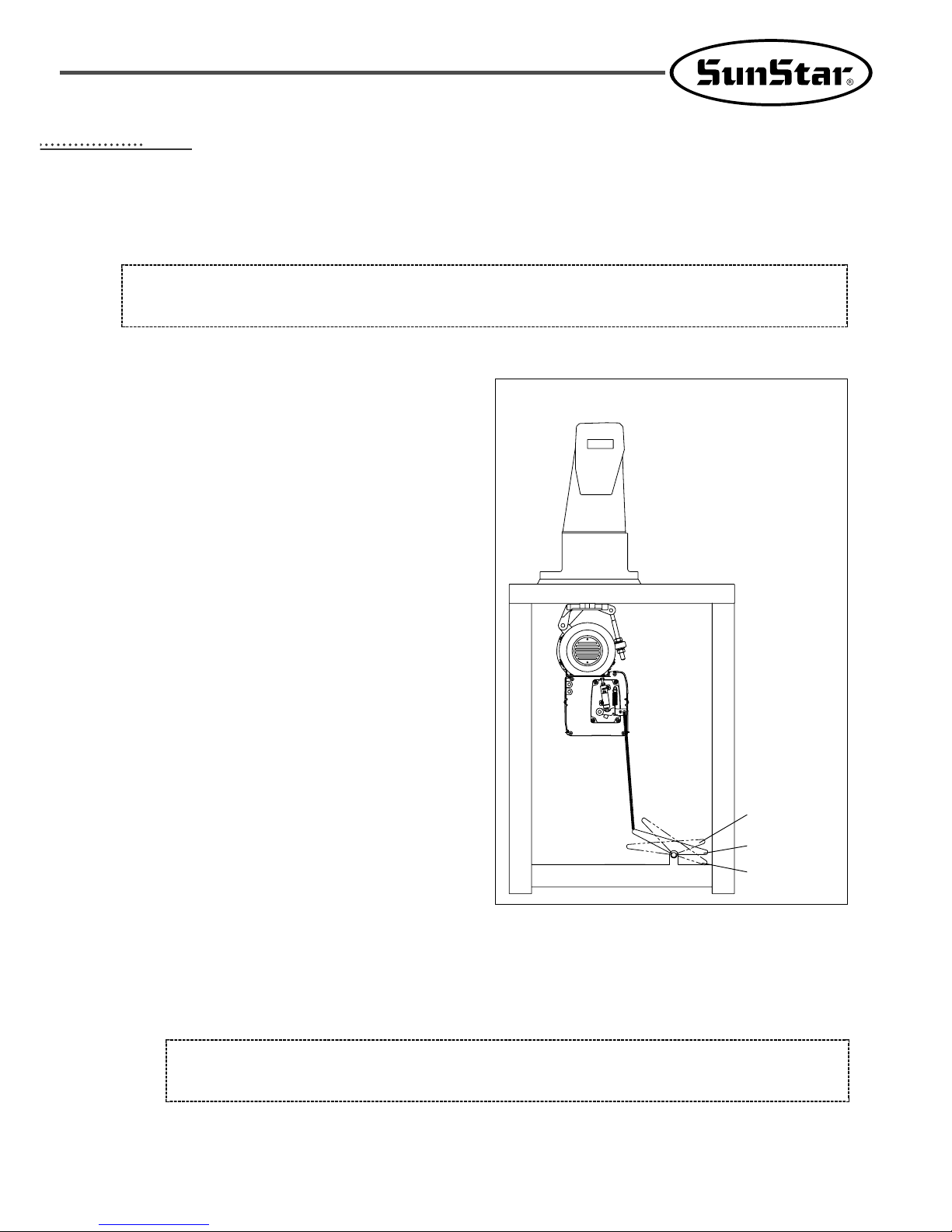

A. Adjusting limit switch

a. Loosen screws ① and ②.

b. When trimming blade returns to its original

position, adjust so that the switch is turned on.

c. Fix screws ① and ②.

2) Wiring

(1) Limit switch

[ Figure 58 ]

①

②

B. Connecting limit switch

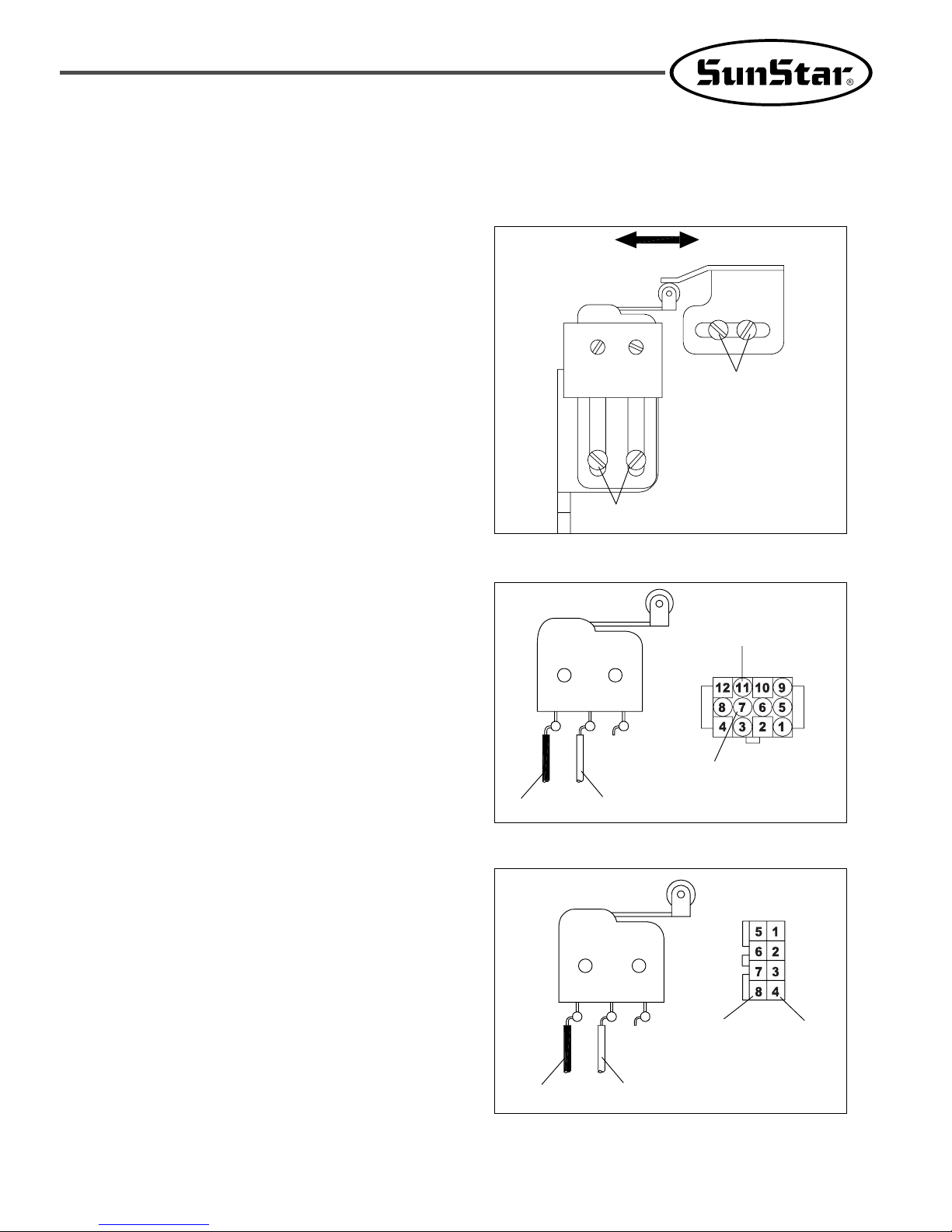

a. General Servo motor A (Fortuna Ⅲ)

Link the limit switch cord to the 12P-connector as

follows.

[ Figure 59 ]

White

WhiteBlack

Black

Switch and lamp connector

WhiteBlack

Switch and lamp connector

b. Small motor A (Fortuna Ⅳ)

Link the limit switch cord to 8P-connector as

follows.

[ Figure 60 ]

White Black

Page 38

38

a. For UT-B device

·Press solenoid valve buttons to check how each

device moves.

·If the device does not work, check the cords.

·For the pneumatic solenoid valve carries polarity,

check the connection between the cable and the

connector.

·The device will not work if the cords are plugged

in incorrectly to opposite power.

b. For UT-A device.

·Press solenoid valve buttons to check how each

device moves.

·If the device does not work, check the cords.

·For the pneumatic solenoid valve carries polarity,

check the connection between the cable and the

connector.

·The device will not work if the cords are plugged

in incorrectly to opposite power.

(2) Connecting solenoid valve

A. Fortuna Ⅲ servo motor

[ Figure 61 ]

Standard solenoid connector

Knee-lifting solenoid connector (Green)

[ Figure 62 ]

Standard solenoid connector

Knee-lifting solenoid connector (Green)

Solenoid valve number Solenoid valve application Connector type Pin number

1 Presser foot lifting Knee-lifting solenoid connector 3 [+], 4 [signal]

2 Lower trimming Standard solenoid connector 2 [signal], 6 [+]

3 Air wiper operation Standard solenoid connector 3 [signal], 7 [+]

Solenoid valve number Solenoid valve application Connector type Pin number

1

Presser foot lifting and air wiper operation

Knee-lifting solenoid connector 3 [+], 4 [signal]

2 Lower trimming Standard solenoid connector 2 [signal], 6 [+]

Page 39

39

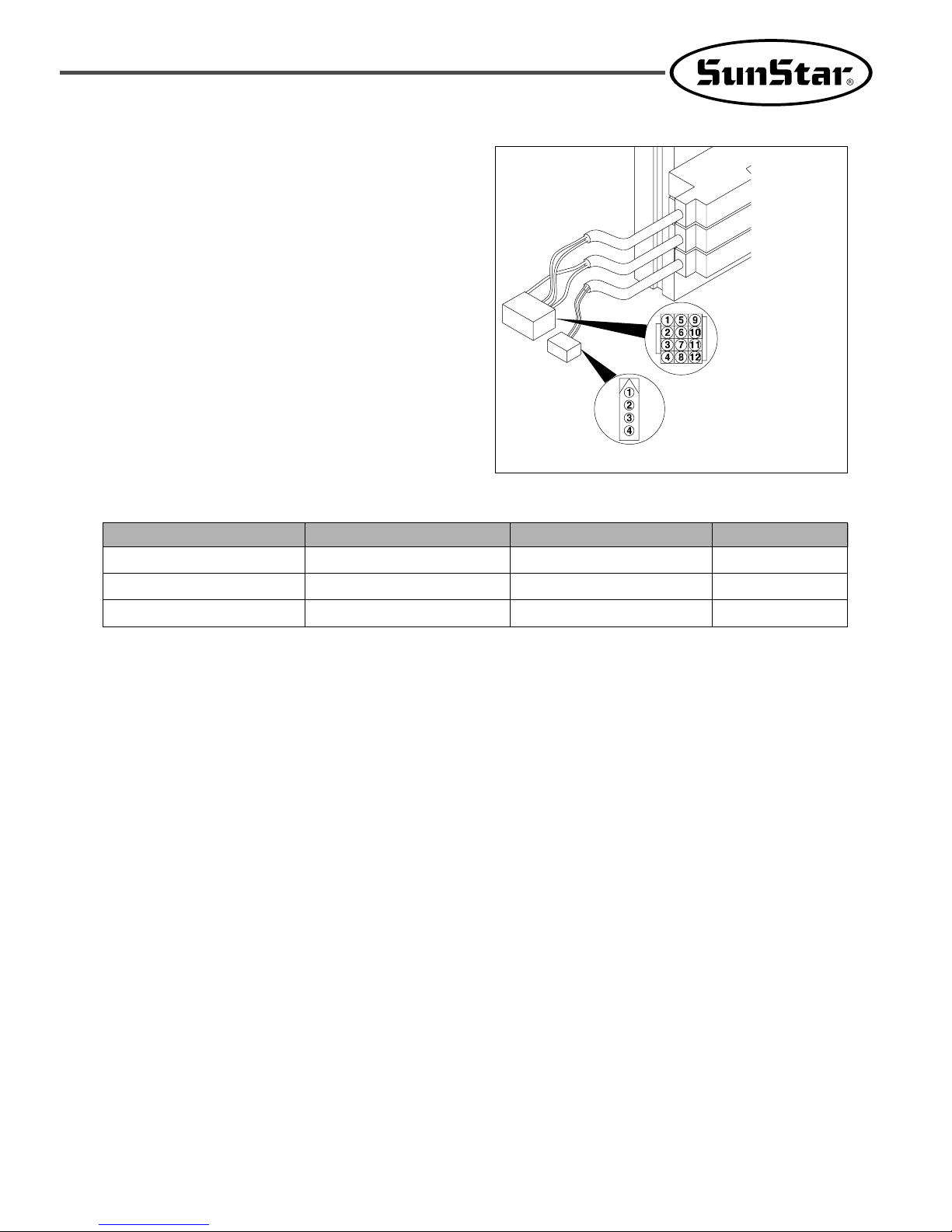

[ Figure 63 ]

Standard solenoid connector

Knee-lifting solenoid connector (Green)

c. For ST-C device.

·Press solenoid valve buttons to check how each

device moves.

·If the device does not work, check the cords.

·For the pneumatic solenoid valve carries

polarity, check the connection between the cable

and the connector.

·The device will not work if the cords are

plugged in incorrectly to opposite power.

Solenoid valve number Solenoid valve application Connector type Pin number

1 Presser foot lifting Knee-lifting solenoid connector 3 [+], 4 [signal]

2 Lower trimming Standard solenoid connector 2 [signal], 6 [+]

3 Top cover thread trimming Standard solenoid connector 3 [signal], 7 [+]

Page 40

40

a. For UT-B device.

·Press solenoid valve buttons to check how each

device moves.

·If the device does not work, check the cords.

·For the pneumatic solenoid valve carries

polarity, check the connection between the cable

and the connector.

·The device will not work if the cords are

plugged in incorrectly to opposite power.

b. For UT-A device.

·Press solenoid valve buttons to check how each

device moves.

·If the device does not work, check the cords.

·For the pneumatic solenoid valve carries polarity,

check the connection between the cable and the

connector.

·The device will not work if the cords are plugged

in incorrectly to opposite power.

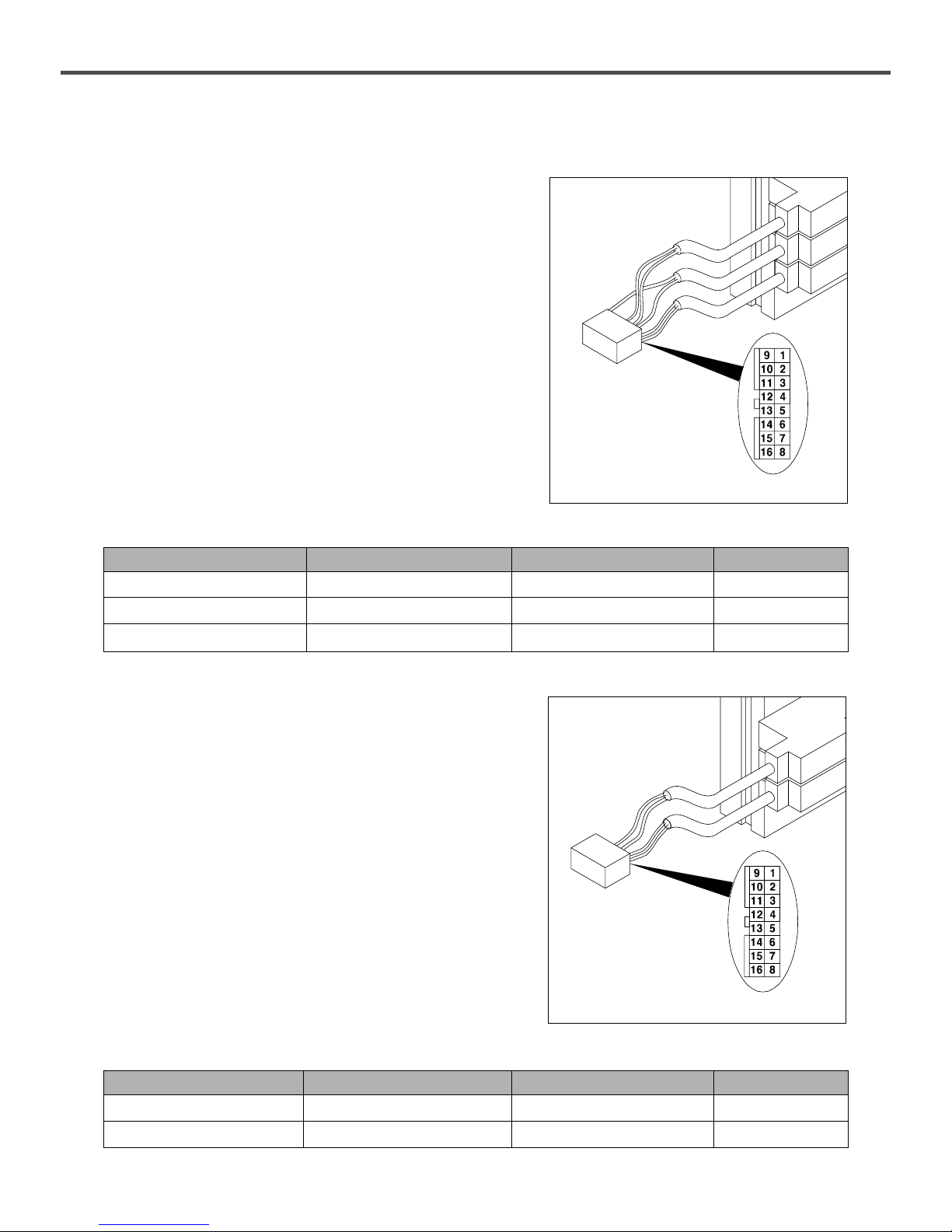

B. Fortuna Ⅳ Compact Servo Motor

[ Figure 64 ]

Standard solenoid connector

[ Figure 65 ]

Standard solenoid connector

Solenoid valve number Solenoid valve application Connector type Pin number

1 Presser foot lifting Standard solenoid connector 2 [+], 10 [signal]

2 Lower trimming Standard solenoid connector 11 [signal], 3 [+]

3 Air wiper operation Standard solenoid connector 12 [signal], 4 [+]

Solenoid valve number Solenoid valve application Connector type Pin number

1

Presser foot lifting and air wiper operation

Standard solenoid connector 2 [+], 10 [signal]

2 Lower trimming Standard solenoid connector 11 [signal], 3 [+]

Page 41

41

[ Figure 66 ]

Standard solenoid connector

c. For ST-C device.

·Press solenoid valve buttons to check how each

device moves.

·If the device does not work, check the cords.

·For the pneumatic solenoid valve carries

polarity, check the connection between the cable

and the connector.

·The device will not work if the cords are

plugged in incorrectly to opposite power.

Solenoid valve number Solenoid valve application Connector type Pin number

1 Presser foot lifting Standard solenoid connector 2 [+], 10 [signal]

2 Lower trimming Standard solenoid connector 11 [signal], 3 [+]

3 Top cover thread trimming Standard solenoid connector 12 [signal], 4 [+]

Page 42

42

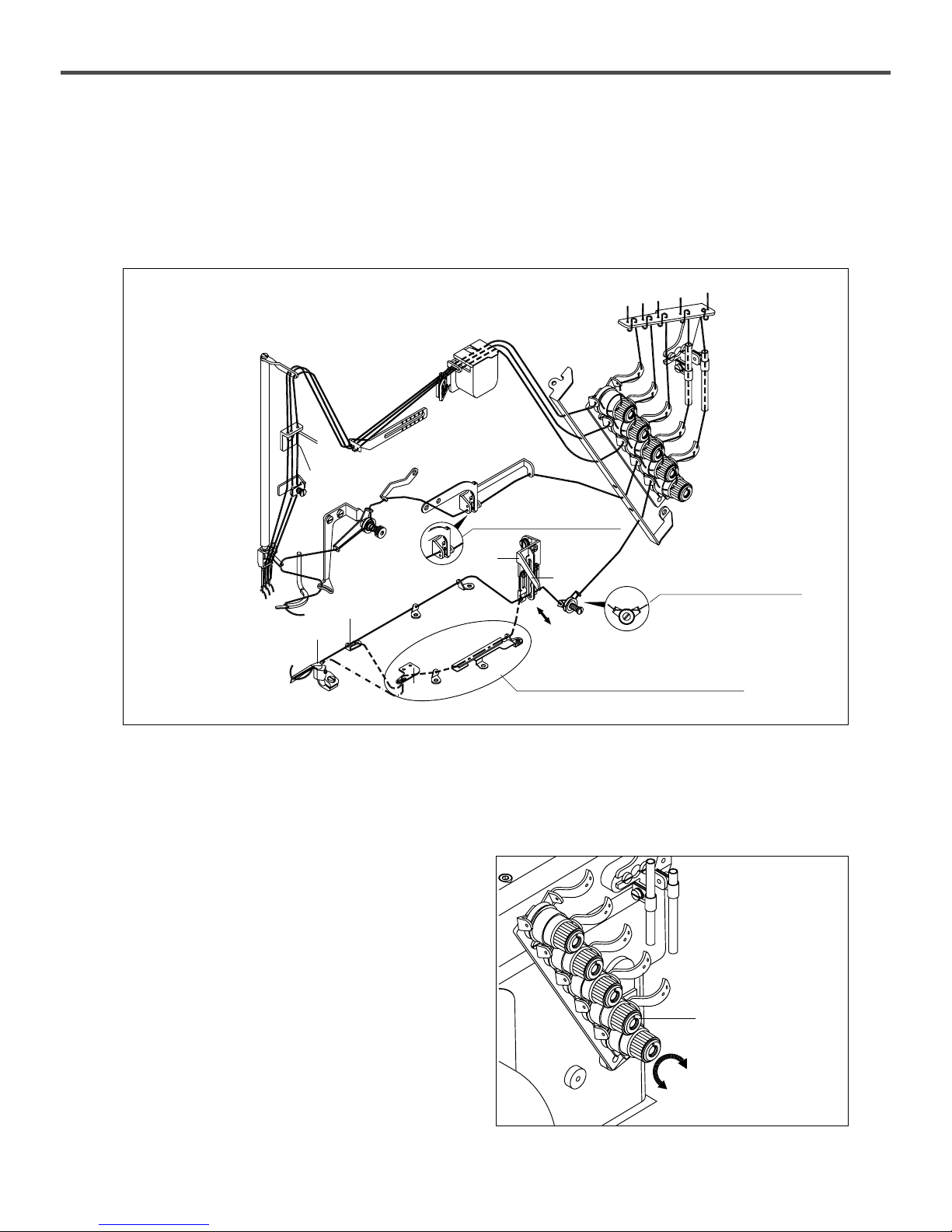

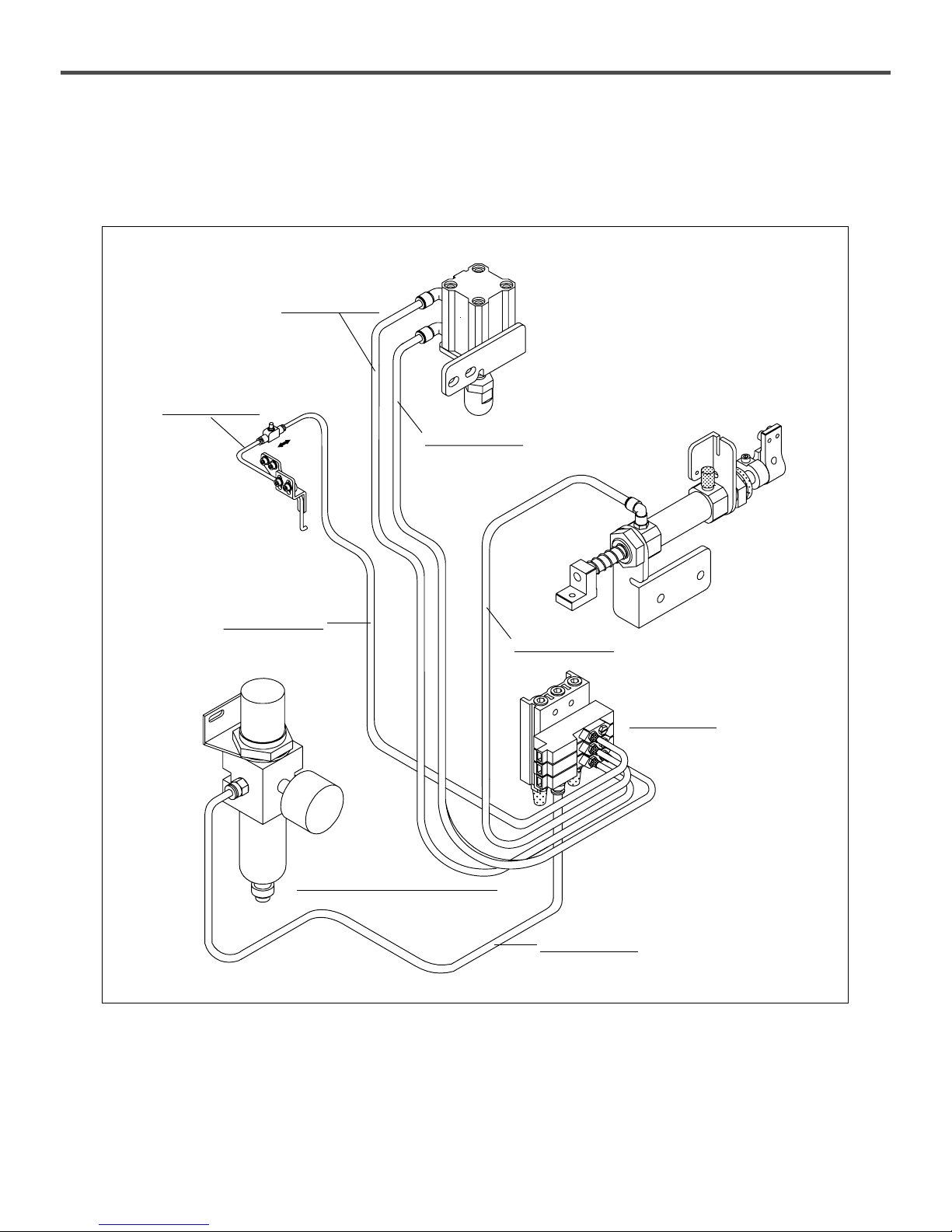

3) Air pressure wiring map

(1) UT-B device

[ Figure 67 ]

2.5×4×350mm

2.5×4×400mm

2.5×4×150mm

2.5×4×300mm

2.5×4×300mm

4×6×1,500mm

solenoid valve

air pressure : 0.4MPa~0.5MPa

(4Kgf/cm2~5Kgf/cm2)

IN

OUT

Page 43

43

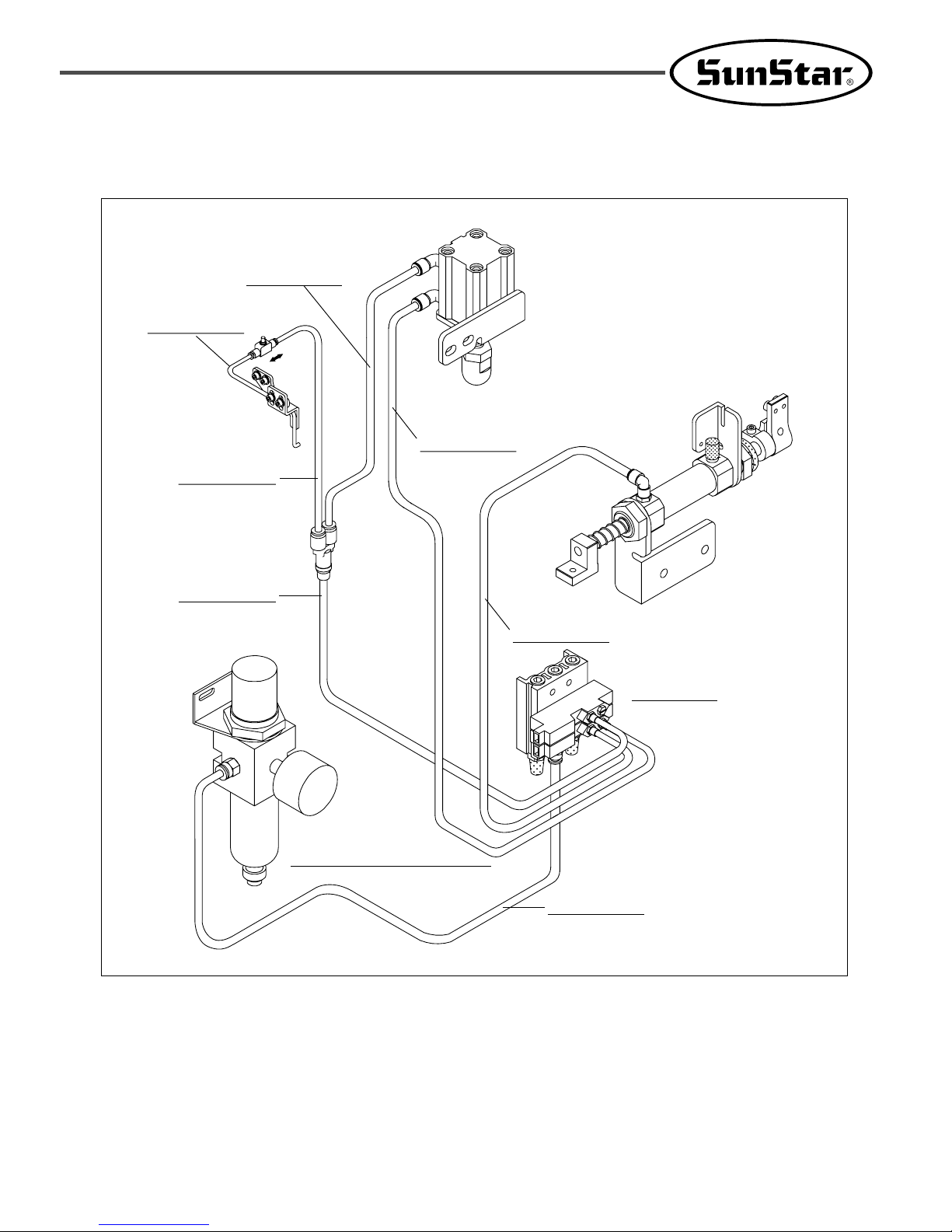

(2) UT-A device

[ Figure 68 ]

2.5×4×150mm

IN

OUT

2.5×4×200mm

2.5×4×200mm

2.5×4×150mm

2.5×4×300mm

2.5×4×300mm

4×6×1,500mm

solenoid valve

air pressure : 0.4MPa~0.5MPa

(4Kgf/cm2~5Kgf/cm2)

Page 44

44

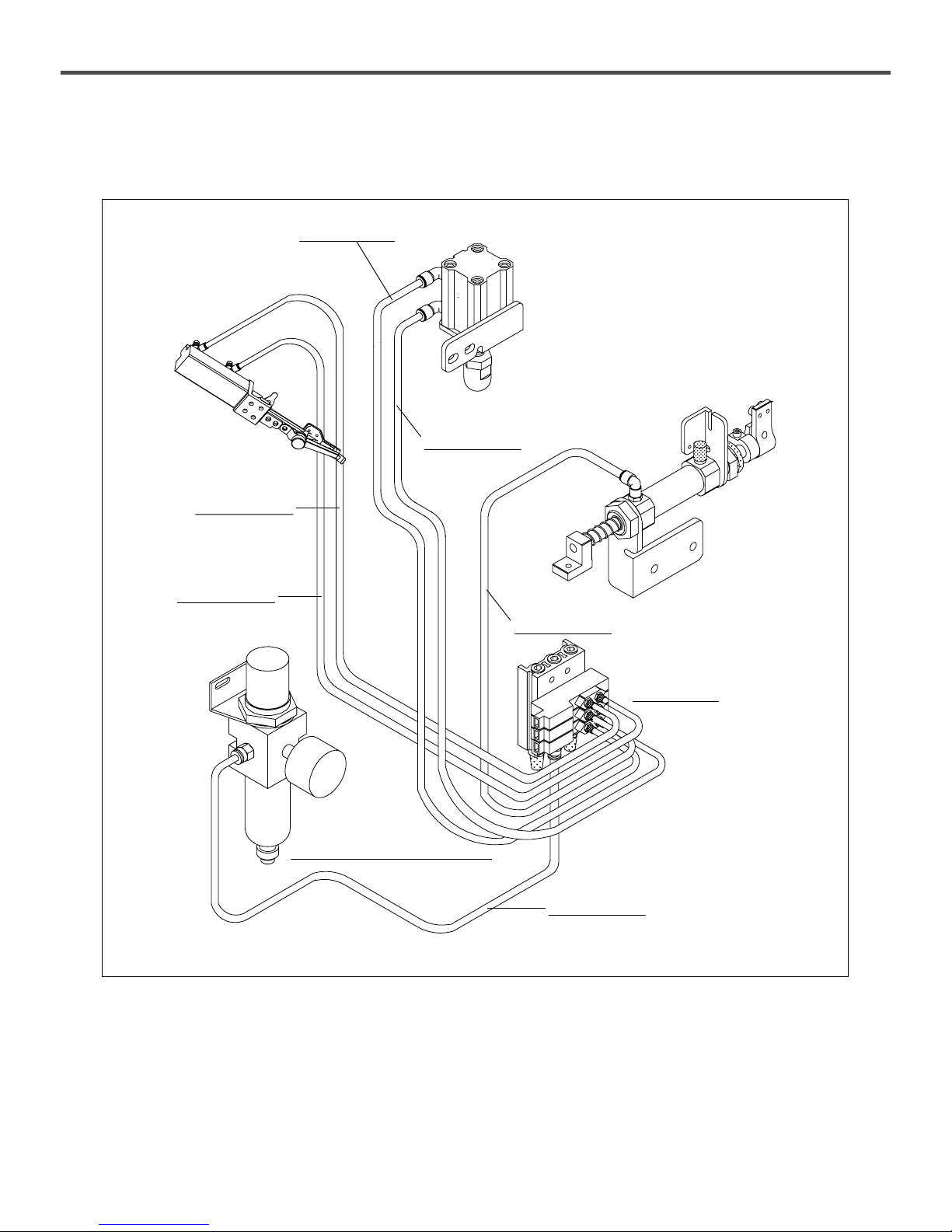

(3) ST-C device

[ Figure 69 ]

2.5×4×350mm

2.5×4×600mm

2.5×4×580mm

2.5×4×300mm

2.5×4×300mm

4×6×1,500mm

solenoid valve

air pressure : 0.4MPa~0.5MPa

(4Kgf/cm2~5Kgf/cm2)

Page 45

45

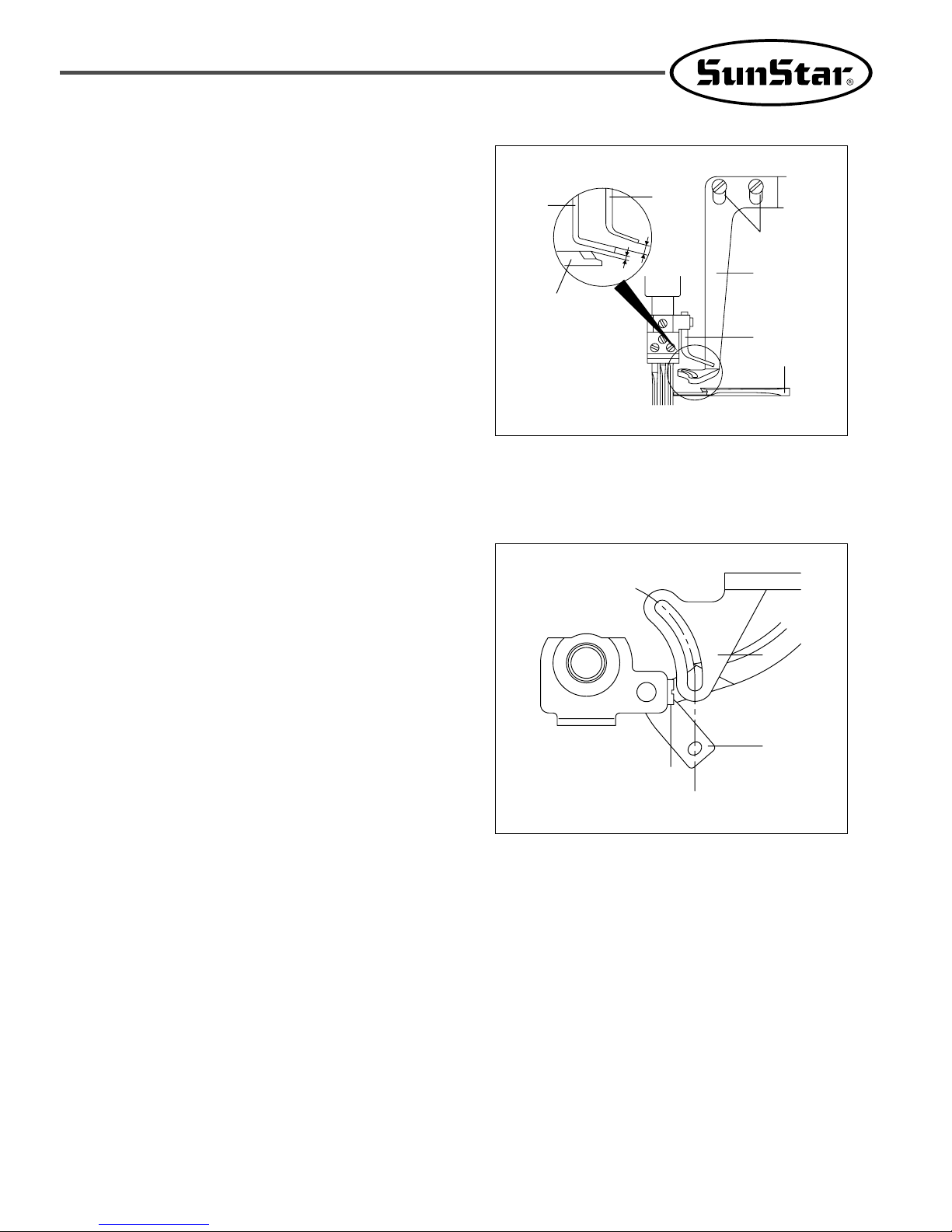

(1) Install the synchronizer ① on the machine and fasten

screw ② lightly.

(2) Turn on the motor switch

(3) Press the pedal and form a few stitches

(4) Press the pedal backward to stop the needle

(5) Loosen the screw ② and turn the line ⑤ on the upper

shaft pulley to align with the hole ④ in the arm. Be sure

to keep the position of the screw ② unchanged.

4) Installation of synchronizer sensor

[ Figure 70 ]

[ Warning ]

Leave the trimming cylinder plug pulled off from the control box in the motor. Otherwise, parts can be damaged.

③

①

②

(6) To see whether the needle bar is located at 0.5mm below

the highest point, press the pedal and run the machine.

[ Figure 71 ]

⑤

④

[ Caution ]

(1) At this point, the needle bar should be positioned at the highest point.

(2) The optimal condition for the synchronizer sensor is when the needle bar is 0.5mm below the highest point by

turning the upper shaft pulley a bit more.

Page 46

46

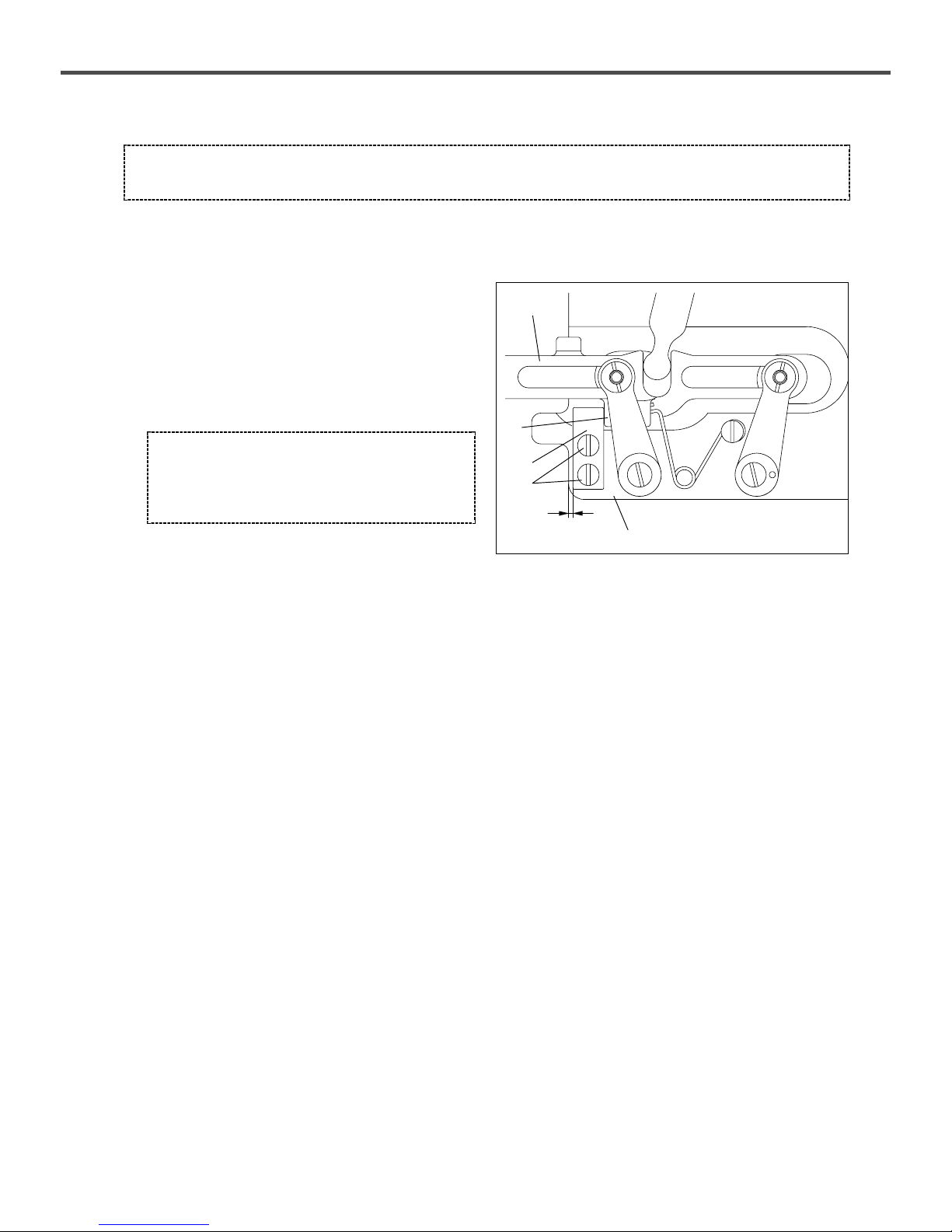

A. The desirable stroke is 15mm.

B. Loosen the screw ② of the collar ① to adjust the

stroke.

(1) Adjusting thread trimming air cylinder

5) Adjustment of automatic thread trimmer

[ Figure 72 ]

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

②

①

15mm

[ Figure 73 ]

②

⑤

①

④

③

A. Bring in parallel side ② of the moving blade ① and

side ④ of the moving blade body ③.

B. Adjust the screw ⑤.

(2) Position of moving blade

A. Unfasten the screw ⑩.

B. Bring in parallel the needle thread hook ⑥ of the

moving blade and the corner ⑧ of the fixed blade ⑦.

C. When the moving blade is at the far right, move the

fixed blade ⑦ left and right to set the clearance

between the fixed blade ⑦ and the looper thread hook

at 0.5mm.

D. Tighten the screw ⑩.

(3) Adjustment between moving blade and fixed blade

[ Figure 74 ]

⑨

⑥

⑧

⑦

⑩

0.5mm

[ Caution ]

The operation status of the automatic thread trimmer

should be re-adjusted when air cylinder stroke

changes. Check the status of the limit switch.

(Refer to 9-2 Wiring)

[ Warning ]

The trimming device can be moved manually only

when the needle is at the highest point. Otherwise,

parts can be damaged.

Page 47

47

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

A. Loosen the screw ⑩.

B. Adjust so that the side of the clamp spring ⑪ and the

side ⑫ of the moving blade ① are aligned with each

other.

C. Tighten the screw ⑩.

D. Loosen the screw ⑭.

E. Adjust so that the side of the clamp spring pressure ⑬

is parallel to the side of the clamp spring ⑪ and the

moving blade①.

F. Set a clearance of 2.0mm between the end tip of the

clamp spring pressure ⑬ and the end tip of the fixed

blade.

G. Fix the screw ⑭ tightly.

(4) Position of clamp spring and clamp spring pressure

[ Figure 75 ]

① ⑪

⑪

⑬

⑬

⑮

⑪

⑩

⑭

⑫

2mm

2mm

[ Figure 76 ]

A. The looper thread is caught by the clamp spring after

trimming

B. To increase pressure, turn the screw ⑮ clockwise and

to decrease pressure, turn it counter-clockwise.

(5) Pressure adjustment of clamp spring

[ Caution ]

If the looper thread is caught securely after

trimming, keep the pressure to the minimum.

Page 48

48

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

The fixed blade body ⒃ simultaneously moves to the

left with the moving fixed body ③ and stops after

contacting the stopper for fixed blade body ⒔. At this

point, the fixed blade will slide under the needle plate

and begin to move.

(6) Position of fixed blade body

A. Unfasten the screw ⒕.

B. Set a clearance of 1mm between the left end tip of the

thread trimming base ⒖ and the left end tip of the

stopper for fixed blade body ⒔.

C. Adjust the screw ⒕ afterwards.

[ Figure 77 ]

⒃

⒔

⒕

⒖

③

1mm

[ Warning ]

Do not force the fixed blade body ⒃ to the left for the

clamp spring pressure can touch the looper.

Page 49

49

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

A. Unfasten the nut ⒗.

B. Bring the moveable blade ① to the far left.

C. Move the bracket (L) for moving knife driving lever

left and right to set a clearance of 3.5mm~4.5mm

between the needle thread hook ⑥ and the left

needle.

D. Fasten the nut ⒗ afterwards.

(7) Relation between moving blade and needle

[ Figure 78 ]

⒗ ⒗

[ Figure 79 ]

①

⑥

3.5mm~4.5mm

Needle

Page 50

50

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

A. Position the moving blade ① to the left.

B. When the distance between the endpoint of the

moving blade ① and the right endpoint of the looper

is 12mm, adjust to bring the endpoint towards the

center of the looper.

C. To move the endpoint back, loosen the screw to

turn the hinge (R) for blade guide lever clockwise.

To move the endpoint front, turn the hinge

counter-clockwise.

D. Fasten the screw afterwards.

(8) Position of moving blade point

[ Figure 80 ]

①

12mm

[ Figure 81 ]

Page 51

51

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

(9) Adjusting moving blade carrier guide (lower)

The optimal clearance between the moving blade ① and the upper portion of the looper is 0.05~0.1mm.

A. Loosen the screw and move the moving blade carrier guide (lower) up and down for adjustments.

B. Fix the screw tightly.

C. Check if the fixed blade body and the moving blade body move smoothly.

[ Figure 82 ]

①

[ Figure 83 ]

The fixed blade body simultaneously moves to the left

with the moving blade body and stops as it touches the

stopper for the fixed blade carrier.

A. Loosen the screws (2 each).

B. When the moving blade body stops as described

above, adjust the clearance between the moving blade

body ③ and the moving blade carrier guide (upper)

between 0.05 and 0.1mm.

C. Tighten the screws .

(10) Adjusting moving blade carrier guide (upper)

0.05mm~

0.1mm

[ Figure 84 ]

③

③

0.05mm~

0.1mm

Page 52

52

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

Check the following.

A. Does the moving blade ① pass through the loops of

needle threads and ?

B. Does the hook of the looper thread ⑨ move in front of

the looper thread?

C. Does the needle thread get pulled by the hook ⑥ to

ensure trimming by the fixed blade?

D. Does the looper thread get pulled by the hook ⑨ to

ensure trimming by the fixed blade?

(11) Relation between needle thread, looper thread and moving blade

[ Figure 85 ]

⑨

①

[ Figure 86 ]

⑥

⑨

Page 53

53

A. Loosen the screw ③.

B. When the rod of the trimming cylinder is at the far

left (when the trimming device is not working),

adjust the block for trimming switch guide ① to

parallel with the rod end ② of the trimming cylinder.

C. Tighten the screw ③.

(1) Block for trimming switch guide.

6) Adjustment of thread tension release mechanism

[ Figure 87 ]

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

⑦

①

②

③

⑧

[ Figure 88 ]

④

⑤

⑤

④

⑥

A. Loosen the nut ⑦ of the thread trimming air cylinder.

B. Adjust the holder for limit switch bracket ⑧ to bring

the thread tension release connecting plate ④ to

come between the screw head ⑤ and the tension

release lever ⑥.

C. Tighten the nut ⑦.

(2) Thread tension release connecting plate.

[ Figure 89 ]

⑩

⑨

A. Loosen the screw ⑩ of the tension release lever

located on the backside of the machine.

B. Lift the thread pull-off lever ⑨ to the top.

C. Tighten the screw ⑩ afterwards.

(3) Thread pull-off lever

Page 54

54

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

A. Loosen the screw ⑬ of the thread pull-off eccentric cam ⑫.

B. Turn ⑫ to position the tension disc separator ⑭ so that the tension disc separator opens as fast as possible.

C. Loosen the screw ⒕ to set a clearance of 35mm between the top of the thread pull-off bar ⑮ and the top of the

guide for thread pull-off bar ⒃.

D. With the screw ⒕, fix the thread pull-off bar ⑮ onto the thread pull-off bar holder ⒔.

E. Loosen the screw ⒗.

F. Set a clearance of 4.0mm between the collar for thread pull-off bar ⒖ and the guide for thread pull-off bar ⒃.

G. Fasten the screw ⒗.

(4) Tension disc separator

[ Figure 90 ]

⑮

⒃

⑭

⑬

⑫

⒖

⒗

⒔

⒕

35mm

4mm

Page 55

55

⒖

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

The thread pull-off hook unit “A” is designed to control the needle thread in the sewing material to the

minimum when sewing starts.

A. Loosen the screw .

B. To reduce the amount of remaining thread, lift the thread pull-off hook unit “A” . To increase, bring the

unit down.

(5) Thread pull-off hook unit

[ Figure 91 ]

⑮

⒃

⑭

⑬

⑫

35mm

4mm

⒗

⒔

⒕

[ Caution ]

A. Use the thread pull-off hook “B”unit only when you are using wool thread for the looper thread. When

the thread pull-off hook “B”unit is not in use, bring it up so that thread does not get caught.

B. Do not force the thread pull-off hook “A”unit up. Stitches may not be formed when the sewing starts.

Page 56

56

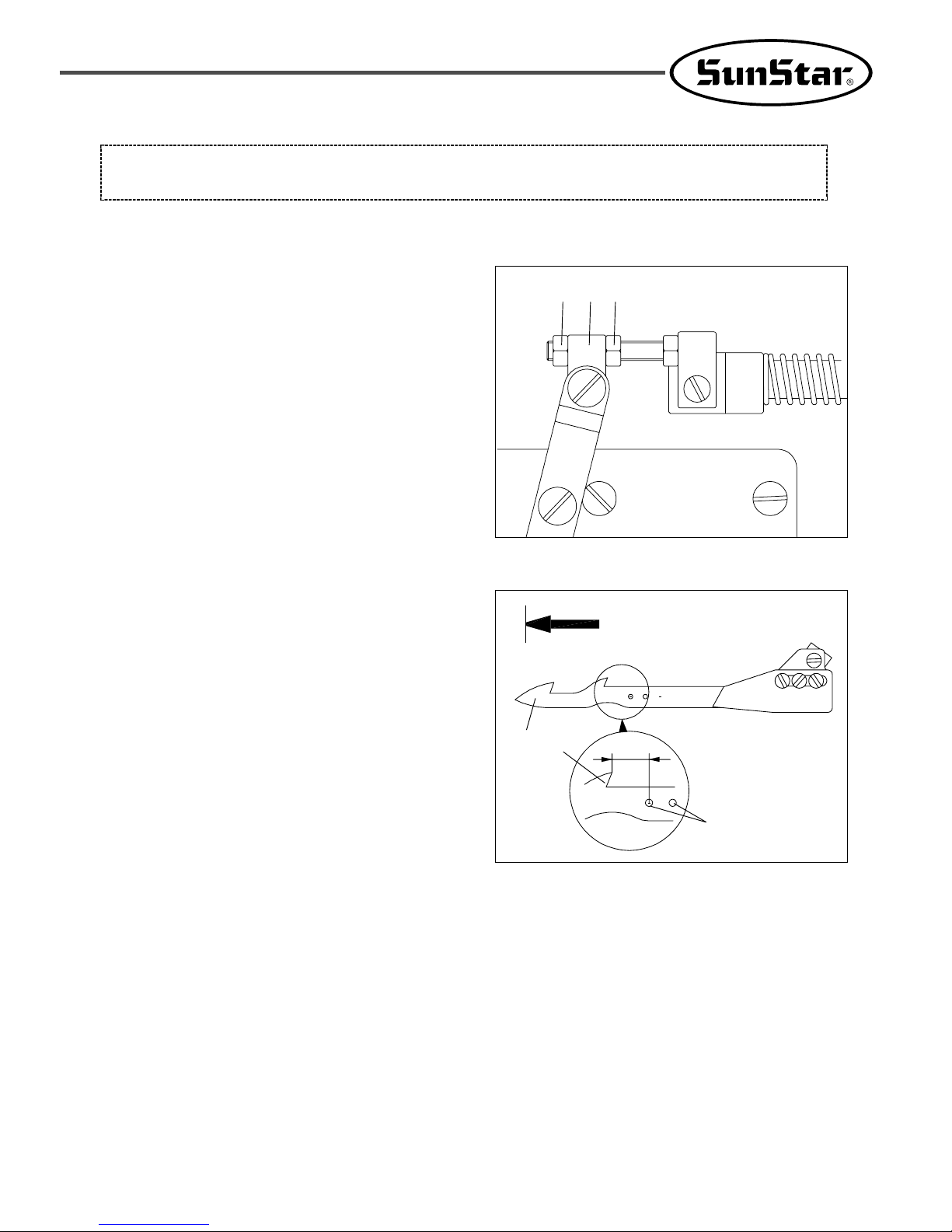

(1) Loosen the screw ③.

(2) Move the air wiper ① front and back so that the air wiper

① operates behind the needle.

(3) Fasten the screw ③.

(4) Loosen the screw ④.

(5) When the needle is at the highest point, adjust the air

wiper ① so that the center of the air blowing hole ② is

1.0~2.0 mm lower than the needle groove of the left

needle.

(6) Fasten the screw ④.

(7) Control the amount of air with the speed controller ⑤.

To reduce the air, turn the screw clockwise and to

increase, turn it counter-clockwise.

7) Adjustment of air wiper

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

[ Figure 92 ]

③

④

①

②

1mm~

2mm

[ Figure 93 ]

IN

OUT

④

③

⑤

[ Caution ]

A. Keep the air level to the minimum as long as the machine functions well.

B. If air gets out from the needle front, the needle thread may slip off of the needle hole. Make sure that the wiper

operates to the backside of the needle.

Page 57

57

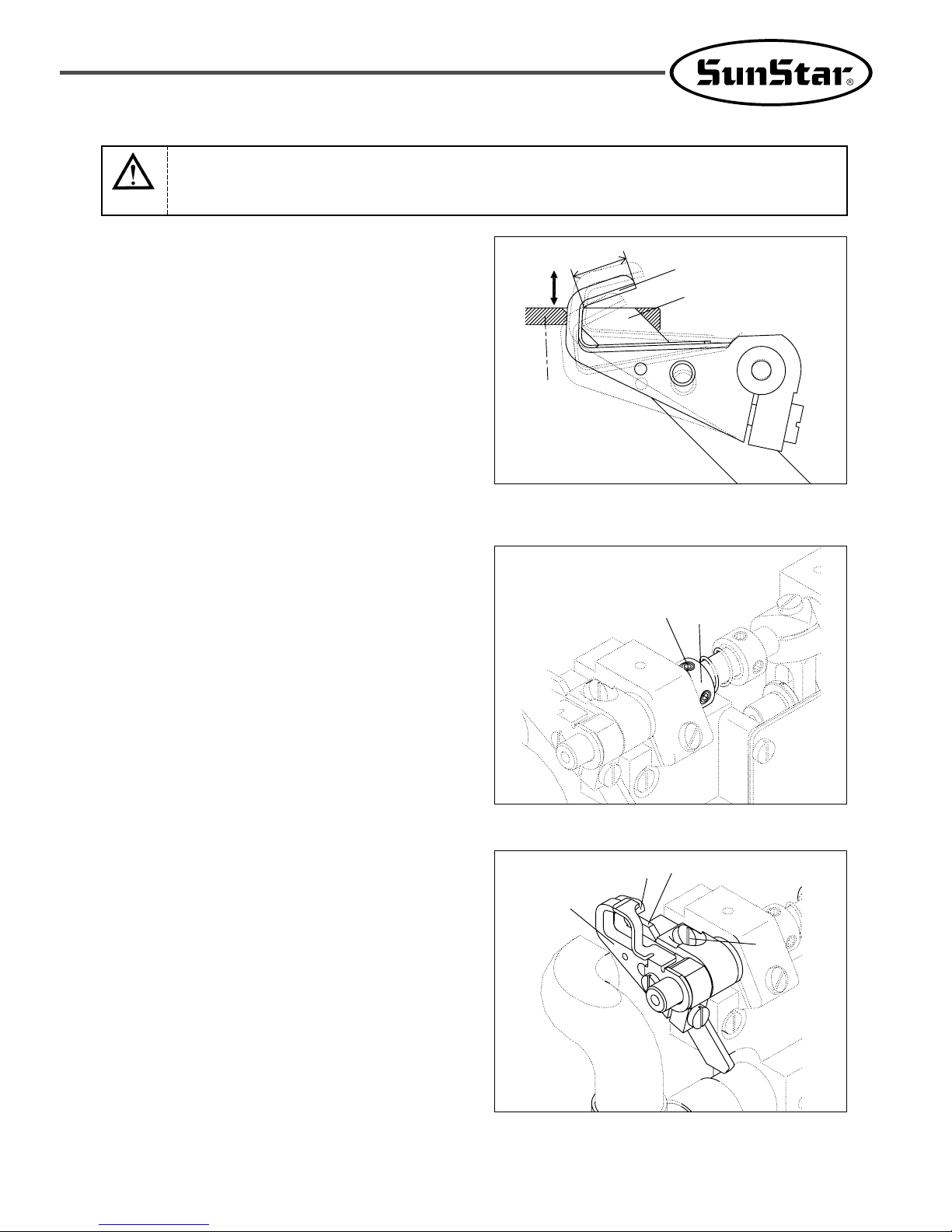

(1) Unfasten the nut ②.

(2) When the knee-lifting air cylinder rod ① is at the lowest

point, turn the knuckle for knee-lifting air cylinder ③ to

bring up the presser foot by 5mm (7mm).

(3) Fasten the nut ② afterwards.

8) Presser foot lifter mechanism

[ Figure 94 ]

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

①

②

③

Page 58

58

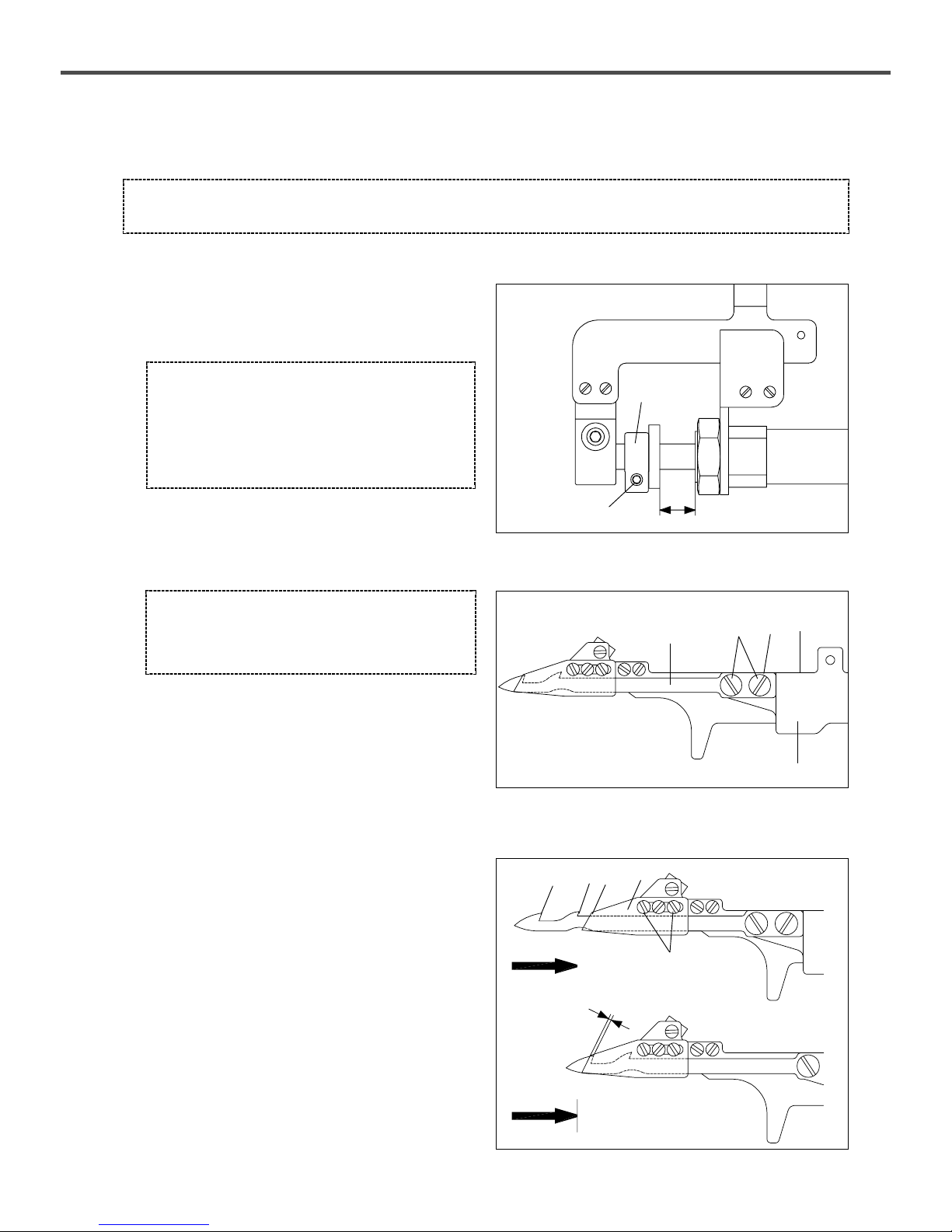

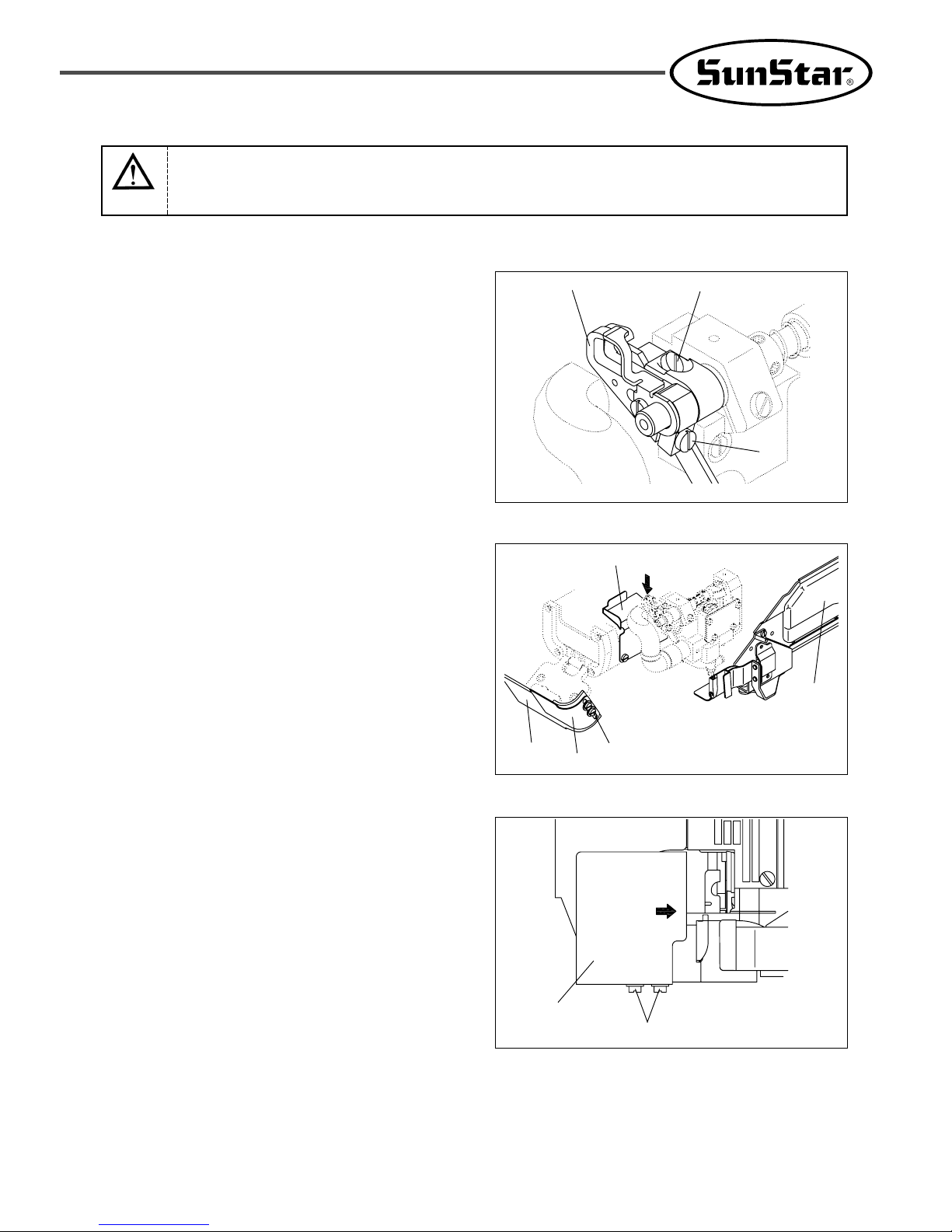

(1) Position of movable trimming blade

A. Align the line ① of the upper shaft pulley with the

carving ② of the sewing machine body (The needle

bar will go up to the highest point).

B. Insert into the hole ④ of the movable trimming knife ③ with tweezers to bring down the knife ③ to the lowest point.

C. When the movable trimming knife ③ is at the lowest point, unfasten the screw ⑩ to set a clearance of 5.5~6.0mm

between the needle plate (stitch plate) and the blade tip ⑨ of the movable trimming knife ③.

D. After adjustments, fix the screws ⑦, ⑧ and ⑩.

E. Move the movable trimming knife ③ up and down to see whether it crosses top cover thread.

9) ST-C device

[ Figure 95 ]

②

①

[ Figure 96 ]

③

⑨

Needle plate

5.5mm~

6mm

[ Figure 97 ]

⑥

⑦⑩

④

⑤

Top

cover

thread

③

⑥

⑧

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

[ Caution ]

Loosen the screws and to prevent the

movable trimming knife from touching the

presser foot, the left needle and the spreader.

[ Caution ]

After adjustments, the movable trimming knife ③ should cross the top cover thread.

Page 59

59

(2) Speed adjustment of trimming thread-moving blade

A. The speed of the trimming thread-moving blade can be

adjusted with a speed controller of the cylinder.

B. To reduce speed, loosen the nut of the speed controller

and turn the screw clockwise and vice versa.

[ Figure 98 ]

Speed controller

[ Warning ]

Before adjustments, always turn off the motor switch

and check to make sure that the motor is in stop

mode.

(3) Clearance between movable trimming knife and fixed trimming knife

The clearance between the movable trimming knife ③

and the fixed trimming knife ⑪ before the blades move is

0~0.5mm.

[ Figure 99 ]

⑪

0~0.5mm

③

[ Caution ]

The stroke of the movable trimming knife is

equivalent to the cylinder stroke.

Page 60

60

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

The pressure of the thread clamp spring should be kept to

a minimum as long as the thread can be caught

comfortably after trimming.

A. Loosen the nut ⑬.

B. After trimming, use the screw ⑭ to adjust the pressure

so that the thread clamp spring ⑫ and the movable

trimming knife ③ can catch the thread.

To shorten the thread after trimming, lift the thread pulloff hook ⑮ up and vice versa.

(5) Adjusting thread pull-off hook unit

(4) Pressure of thread clamp spring

[ Figure 100 ]

⑭

⑬

⑫

③

[ Figure 101 ]

⒃

⑮

[ Caution ]

A. Use as much thread stroke as possible. If there is not

enough stroke, trimming thread may not be caught

after trimming.

B. When using flexible thread such as wool thread, insert

it into the eyelet ⒃.

Page 61

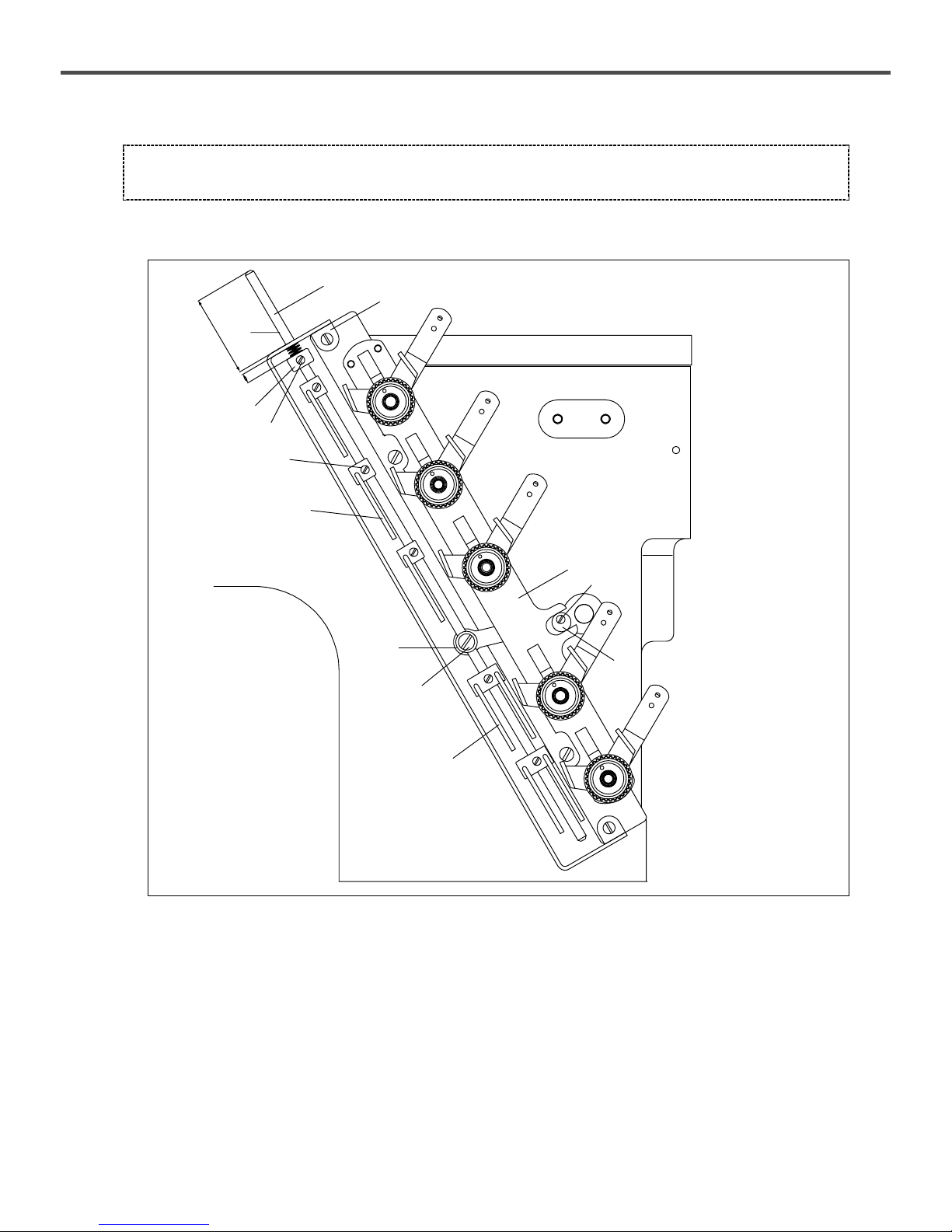

61

1100

SC 7310 (Left Fabric Trimmer)

⑦

⑥

②

⑧

③

※ Adjusting the mes system

1) Installation of accessories

The suction pipe(B)①, the suction pipe(B) holder⑤, the curved hose⑦, and the speed controller should be installed in the

following order:

(1) Install the speed controller⑧ on the floor of the left mes driving base② as shown in the figure.

(2) Insert the suction pipe(B) ① into the hole on the surface of the left mes driving base② and fix it with the screw③.

(3) Use the screw④ fixed on the rear side of the sewing machine and install the suction pipe(B) holder⑤.

(4) Install the suction pipe(B) ① at the holder⑤.

(5) Use the hose band⑥ and fix the curved hose⑦ to the suction pipe.

[ Figure 102 ]

④

⑤

①

Turn off the motor switch before making any adjustments. Make sure that the motor is completely

turned off.

Warning

Page 62

62

Loosen the screw⑩ to adjust the location of or remove the

suction pipe(A) ⑨.

Install the suction pipe(A) ⑨ 5mm away on the left side of

the moving mes(left) holder cover plate⑦.

※ Compressed air-based extraction

Set the extraction power at the lowest possible pressure

for chip extraction. Adjust the chip extraction power,

using the speed controller⑧.

※ Vacuum system-based extraction

Connect the curved hose to the vacuum dust collector.

Set the extraction power at the lowest possible pressure

for chip extraction. Adjust the vacuum system to change

the extraction power.

2) Adjustment of suction pipe(A)

[ Figure 103 ]

⑦

⑨

⑩

⑧

5mm

The length of fabric to be cut should be adjusted in the

following order:

(1) Loosen the screws for the fixed mes (left mes) holder

and the collar.

(2)

Move the fixed mes(left) holder⑬ to the desired position.

(3) Tighten the screws⑭ of the fixed mes(left) holder⑬.

The tightening torque is 1.5~2N

•

m (15~20kgf•cm).

(When shipped out from the factory, the distance between

the left collar⑮ and the right collar⒔ is set at 9mm.)

(4) Loosen the screw⒕ of the collar(right)⒔.

(5) Place a strand of thread between the fixed mes(left)②

and the moving mes(left)①, and check whether the

pressure applied to the moving mes(left) is proper. Turn

the pulley manually [Fig. 106].

4) Cutting length (Location of fabric cutting)

[ Figure 105 ]

⑬

⒃

⑮

⒕

⒔

ⓐ

⑭

When adjustment is completed, loosen the screw⑫ on the

suction pipe cover plate⑪, and align the right side of the

cover plate with the pipe entrance.

3) Adjustment of the suction pipe cover plate

[ Figure 104 ]

⑪

⑫

Regularly supply oil through the oil hole ⓐⓐ.

Note

Turn off the motor switch before making any adjustments. Make sure that the motor is completely

turned off.

Warning

Page 63

63

(6) Adjust the moving mes(left)① and the fixed mes(left)

② to set the position of 7mm away from the end of the

moving mes (around the root area of the moving

mes(left)) to be at the same height of the front face of the

fixed mes(left).

Afterwards, tighten the screw⒃ of the collar(left)⑮.

(7) Check whether the meses (knives) are operating

properly.

[ Figure 106 ]

②

Needle

Plate

7mm

①

※ How to remove the fixed mes(left)

(1) Loosen the screw⒃ of the collar(left)⑮.

(2) Move the moving mes(left) holder③ to the left side and

make space between the moving mes(left)① and the

fixed mes(left)②.

(3) Tighten the screw⒃ of the collar(left)⑮.

(4) Loosen the screw④, which fixes the moving mes(left)

②, and lower the fixed mes(left)②.

5) Removal and installation of the fixed mes (left)

[ Figure 107 ]

⒃

⑮

※ How to install the fixed mes (left)

(1) Set the height of the fixed mes(left)② and the height of

the needle plate front face to be same and tighten the

screw④.

(2) Loosen the screw⒃ of the collar(left)⑮, and use the

spring pressure to make the moving mes(left)① and the

fixed mes(left)② contact each other.

(3) Place a strand of thread between the moving mes(left)①

and the fixed mes(left)② to check whether the pressure

applied to the moving mes(left) is appropriate. Turn the

pulley manually.

(4)

Adjust the moving mes(left)① and the fixed mes(left) ②

to set the position of 7mm away from the end of the

moving mes (around the root area of the moving mes(left))

to be at the same height of the front face of the fixed

mes(left). Tighten the screw

⒃

of the collar(left)⑮.

(5) Check whether the meses (knives) are properly operating

once again.

[ Figure 108 ]

③

①

②

④

Turn off the motor switch before making any adjustments. Make sure that the motor is completely

turned off.

Warning

Page 64

64

▶ How to install the moving mes(left)

(1) Assemble the moving mes and the moving mes holder

using the moving mes holder pin.

(2) Loosely assemble the moving mes shaft⑤ and the

moving mes holder using the screw③.

Make sure that the distance between the moving mes

holder cover plate and the end of the shaft is 6.5mm.

(3)

Manually turn the pulley to lower the moving mes(left)①.

When the mes (knife)① is located at the dead point,

move the moving mes(left) holder④ to place the end of

the moving mes(left) blade 0.5mm above the front face

of the fixed mes(left).

Then tighten the screw③ of the moving mes(left) holder

④.

(4) Loosen the screw⒃ of the collar(left)⑮, and use the

spring pressure to make the moving mes(left) and the

fixed mes(left) contact. [Fig. 107]

(5) Place a strand of thread between the moving mes(left)①

and the fixed mes(left)② to check whether the pressure

applied to the moving mes(left) is appropriate. And turn

the pulley manually.

(6) Adjust the moving mes(left) and the fixed mes(left) to

set the position of 7mm away from the end of the

moving mes(left)① (around the root area of the moving

mes(left)) and the front face of the fixed mes(left)② to

be at the same height. Then tighten the screw⒃ of the

collar(left)⑮. [Fig. 107]

(7) Check whether the mes(knife) is properly operating once

again.

6) Installation of the moving mes(left)

②

①

[ Figure 109 ]

④

⑤

③

[ Figure 110 ]

[ Figure 111 ]

⑤

④

7mm

Needle

Plate

6.5mm

Turn off the motor switch before making any adjustments. Make sure that the motor is completely

turned off.

Warning

Page 65

65

7) Adjustment of the moving mes(left) stroke

①

⑨

⑧

⑦

⑥

⑤

The stroke of the moving mes(left) can be adjusted at the range of 3.0mm to 4.0mm. When shipped out from the factory, the

stroke default value is set at 4.0mm. In order to change the stroke of the moving mes(left), follow the instructions below in order.

(1) Loosen the screwⓐ and remove the bracket cover⑤ and the gasket⑥.

(2) Loosen the nut⑦ of the moving mes(left) adjusting lever pin⑨.

(3) Move the lever pin⑨ in the Y direction to reduce the stroke. Move the lever pin in the X direction to increase the stroke.

(4) Adjust the nut⑦ of the moving mes(left) adjusting lever pin⑨.

(5) Slightly loosen the screw④ of the moving mes(left) holder②.

(6) Turn the pulley manually to lower the moving mes(left)①.

When the moving mes(left)① is located at the dead point, move the moving mes(left) holder② to place the end of the

moving mes(left) blade 0.5mm above the front face of the fixed mes(left).

Then tighten the screw④ of the moving mes(left) holder②.

(7) Loosen the screw⒃ of the collar(left)⑮. Use the spring pressure to make the moving mes(left) and the fixed mes(left)

contact each other.

(8) Place a strand of thread between the moving mes(left)① and the fixed mes(left)③, and check whether the pressure

applied to the moving mes(left) is appropriate. Then turn the pulley manually.

(9) Adjust the moving mes(left)① and the fixed mes, and set the position of 7mm away from the end of the moving mes

(around the root area of the moving mes(left)) and the front face of the fixed mes(left)③ to be at the same position. Then

loosen the screw⒃ of the collar(left)⑮.

(10) Check whether the mes(knife) is operating properly.

(11) Use the screwⓐ to install the bracket cover⑤ and the bracket cover gasket⑥.

[ Figure 112 ]

③

②

④

⒃

⑮

ⓐ

⑨

⑩

⑧

⑦

Turn off the motor switch before making any adjustments. Make sure that the motor is completely

turned off.

Warning

The stroke of the moving mes(left) becomes maximal, when the punched mark⑧⑧and the

punched mark⑩⑩are aligned. Do not place the moving mes(left) adjusting lever pin⑨⑨above

the maximal position by moving it to the X direction.

Note

Page 66

66

8) Mes (knife) adjustment

When the meses (knives) become dull, prepare cold water to sharpen the fixed mes (left mes)①. Keep the fixed mes (left

mes) cold, while it is being sharpened as in the figure below.

[ Figure 114 ]

[ Figure 113 ]

①

10。

45。

Use the fabric guide (left)① to make adjustments on the

edges of fabric.

Use the fabric guide② to adjust the width of folded part.

Loosen the screw③ to make adjustments.

9) Adjustment of fabric guide

[ Figure 115 ]

②

③

①

Turn off the motor switch before making any adjustments. Make sure that the motor is completely

turned off.

Warning

The moving mes is made of cemented carbide, so that a regular grinder cannot be used to

sharpen it. Therefore, it is recommended to keep a spare moving mes all the time. To

purchase a moving mes, contact a distributor or SunStar Head Office.

Note

Page 67

67

The left mes driving should be divided in the following

order :

(1) Loosen the screws④ for the fixed mes (left mes).

(2) Move the fixed mes (left mes) 5mm downward from the