Page 1

Version

1.0

USSR'S

MRNURL

PARTS

ISO

9001

Certification

of

ROOK

es

Quality

System

5

1)

2)

FOR

PLEASE

BEFORE

KEEP

FOR

BREAKS

AT

MOST

OBTTAINLY

STARTtNG

THIS

MANUAL

RffB)BICE

DOVm.

USE

WHSI

VmH

READ

IN

SAFE

THE

EASINESS,

THIS

MANUAL

PLACE

MACHINE

Page 2

1.

Thank

experience

wili

functions,

more

2.

Please

sure

3.

The

product

4.

This

machine.

you

manufacture

sophisticated

read

to

properly

specifications

product

for

purchasing

accumulated

industrial

high

performance,

design

this

user's

use

performance,

is

designed,

It

should

manual

the

of

the

without

not

be

our

product.

in

industrial

sewing

powerful

to

meet a number

machine

machine

prior

sewing

machines,

operation,

thoroughly

to

enjoy

are

subject

notice.

manufactured,

used

for

other

Based

machine

which

of

user's

before

its

full

to

and

sold

than

industrial

on

the

rich

expertise

production,

deliver

enhanced

needs.

using

performance.

change,

as

an

purpose.

more

durability,

the

machine.

aimed

industrial

SUNSTAR

diverse

Make

to

enhance

sewing

and

and

SUNSTAR

CO.,

LTD.

Page 3

DAS

Certification

Scope

The

following

The

Company

Manufacture,

Scope ofapproval:

Date

of

Certificate

Certificate

Certificate

Company

SUNSTAR

has

been

for

Sewing

Issue:

Valid

Number:

until:

of

Quality

ELECTRIC

approvedfor

Sale

and

Machines

NACE

19,

the

Servicing

and

Electrical

26"^

26**^

KOl-1714

Approval

CO.,

following

of

Embroidery

and

November

November

scope ofoperation:

Motors

optical

2003

2006

LTD.

and

Controllers

Machines

equipment

03^^

Date

DAS

CERTIFICATION

Company

6

Amber

Beiper,

Derbyshire

Telephone & Fax:

Number:

Court,

Crich

DE56 1 HG

3384526

+44

December

Lane,

(0)

1773

Ltd.

828586

2003

DAS

Certification

ISO

9001:

Approval

2000

Page 4

iJiiMj.H-:

"«we?yi»-a-F-WTr"

s^Wa

US€R'

MRNURL

S

Page 5

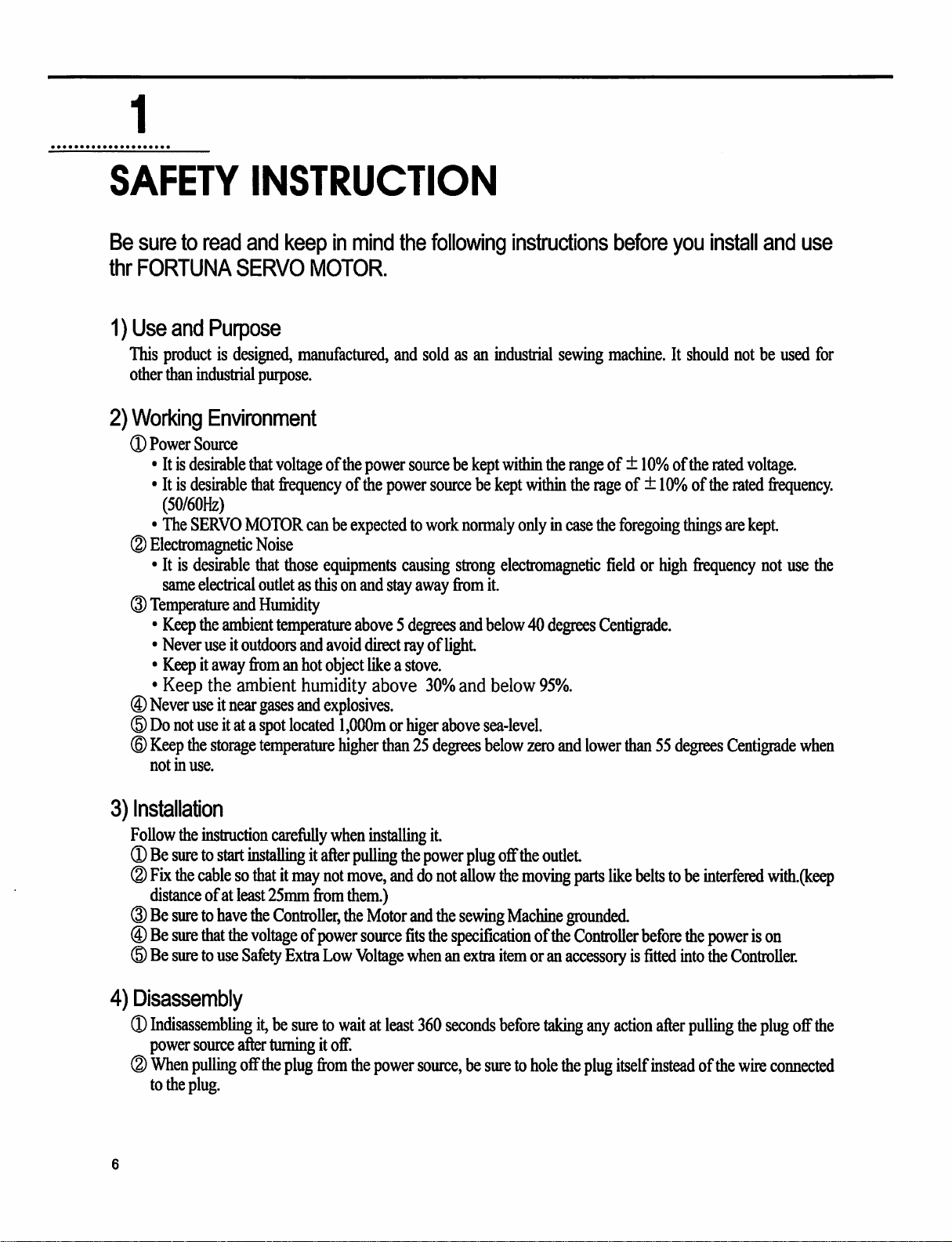

CONTENTS

1.

Safety

instruction

2.

Precautions

3.

Locating

4.

Installation

1)

2)

3)

4)

5)

6)

7)

5.

Wiring

1)

2)

3)

4)

and

Mounting

Assembling

Mounting

Mounting

How

to

equip

Mounting

An

example

and

Specification

Specification

Name

and

How

to

change

before

use

using

parts

your

Servo

Motor

the

belt

cover

and

adjusting

the

position

and

the

Program

of

installing

the

sensor

adjust a built-in

Unit(P/U)

the

grounding

of

the

power

of

electric

current

description

on

the

electric

of

the

controller

on

the

table

and

adjusting

fbot-lift

(Synchronizer)

SunStar

plug

in

the

outside

voltage

the

belt

solenoid

and

location

detector(synchronizer)

sewing

machine

wiring

of

power

connector

supplied

for

box

tension

setting

the

film

plug

of

control

box

solenoidfThe

factory

installed

setting

is;J2) • •

6

8

10

11

11

12

13

14

16

18

19

20

20

20

21

21

6.

Connection

7.

Things

8.

Program

2)

3)

4)

5)

6)

7)

8)

9.

Simple

10.

3)

4)

11.

12.

13.

^

to

be

unit

1)

Program

Program

Start

Method

How

Motor

Advanced

Automatic

unit

Unit

and

End

of

to

Use

Controller

Change

operation

1)

Names

of

2)

Simple

Program

Fortune

1)

2)

Thread

series 5 full

Basic

Functions

Fortune

Series 5 Full

Method

of

Trimming

Breakdown

How

to

place

Block

diagram

Parts

Book

the

earth

wire

of

checked

part

part

Method

Backtack

Use:

Edge

Pattem

Each

Use

and

after

installation

names

and

names

of

Use

Stitch

Conection

Inertia

Tuning

Function

Sensor

Setting

Sewing

Functions

Function

ofTwin

unit

part

names

Part

in

the

Simple

Unit

Method

of

function

of

the

Fortune

Function

and

Explanations

Sequence

Software

Function

troubleshooting

for

controller

the

sewing

method

Needles

Operation

Use

software

Series 5 Full

for

Specific

machine

of

Method

(applicable

and

method

Unit

method

Function

Specific

Items

Method

and

use

to

the

models

of

use

of

use

Software

Parameters

of

the

Parameter

of

Use

(Items

motor

supporting

no.

54,55,56

twin

needles) • -48

of

Group

B)

23

23

24

50

55

• •

84

85

86

87

24

24

35

38

39

42

46

50

50

55

56

71

75

Page 6

SAFETY

Be

sure

to

read

thr

FORTUN A SERVO

1)

Use

and

Purpose

This

product

other

than

2)

Working

®

Power

•

It

•

It

(50/60HZ)

•

The

©

Electromagnetic

•

It

same

@

Temperature

•

Keep

•

Never

•

Keep

•

Keep

®

Never

®

Do

®

Keep

not

is

designed,

industrial

Environment

Source

is

desirable

is

desirable

SERVO

is

desirable

electrical

and

the

ambient

use

it

it

away from

the

ambient

use

it

near

not

use

it

at a spot

the

storage

in

use.

INSTRUCTION

and

keep

in

mind

the

following

MOTOR.

manufactured,

purpose.

that

voltage

that frequency

MOTOR

of

can

be

the

of

Noise

that

those

equipments

outlet

as

this

on

Humidity

temperature

outdoors

and

avoid

an

hot

object

humidity

gases

and

explosives.

located

temperature

1,000m

higher

and

sold

power

source

die

power

source

expected

and

above 5 degrees

to

work

causing

stay

away from

direct

ray

of

like a stove.

above

30%

or

higer

than

25

degrees

as

an

industrial

be

kept

within

be

kept

normaly

strong

electromagnetic

it.

and

below

light

and

below

above

sea-level.

below

instructions

sewing

the

within

only

in

40

degrees

95%.

zero

and

before

machine.

range

of ± 10%

the

rage

of ± 10%

case

the

foregoing

fi

eld

Centigrade.

lower

than

you

It

of

or

high fi^quency

55

degrees

install

should

things

not

the

rated

voltage.

of

the

rated frequency.

are

kept.

Centigrade

and

be

used

not

use

use

for

the

when

3)

installation

Follow

®

®

®

@

®

4)

®

®

the

instmction

Be

sure

to

start

Fbc

the

cable

distance

Be

Be

Be

of

sure

to

have

sure

that

sure

to

use

at

carefully

installing

so

that

it

may

least

25mm from

the

Controller,

the

voltage

Safety

of

Extra

Disassembly

Indisassembling

power

source

When

pulling

to

the

plug.

it,

be

after

turning

off

the

plug from

sure

when

it

after

pulling

not

move,

them.)

the

power

Low

Voltage

to

wait

it

off.

the

installing

Motor

source

at

power

it.

the

power

and

do

not

and

the

fi

ts

the

when

an

least

360

seconds

source,

specification

plug

off

the

allow

the

moving

sewing

Machine

extra

item

before

be

sure

to

outlet

parts

grounded.

of

the

Controller

or

an

accessory

taking

any

hole

the

plug

like

belts

to

before

is fitted

action

after

itself

instead

be

interfered

the

power

into

the

pulling

of

the

with.(keep

is

on

Controller.

the

plug

wire

connected

off

the

Page 7

5)

Service

®

Make

d)

Never

®

When

platform.

®

Be

sure

6)

Other

®

Tack

@

In

case

go

ahead

®

Do

not

®

Take

®

Never

and

Maintenance

sure

that

service

try

to

operate

inserting

to

use

Safety

care

not

of

remodellhig

based

try

to

operate

care

not

drop

the

with

a

thread

standard

Instructions

to

let

your fingers

on

your

to

let

water

Controller

and

maintenance

the

Motor

into

or

touching

products

or fitting

own

with

specified

touch

of

additional

judgments.

the

safely

or

coffee

or

or

the

Motor

are

carried

out

and

the

Controller

the

machine,

for

replacement

any

moving

device

something

to

the

parts

device,

removed.

like

ground.

by a skilled

technician,

open.

be

sure

to

turn

of

parts.

including

be

sure

those

belts.

to

follow

admitted

into

the

power

off

safety

standards

the

Controller

and

step

and

or

the

down from

do

not

ever

Motor.

the

try

to

^The

Inslrijc^ons

Motor.

Ignoring

FteasetbflowaB

piBsented

such

the

Instructions

above

instnictions

vvhen

are ft)r

oould

the

cause

operating

sal^

and

damage

the

to

rnachine.

more

proper

the

machine

operation

or

of

the

physical

injury

Fcxtura

of

the

user.

Page 8

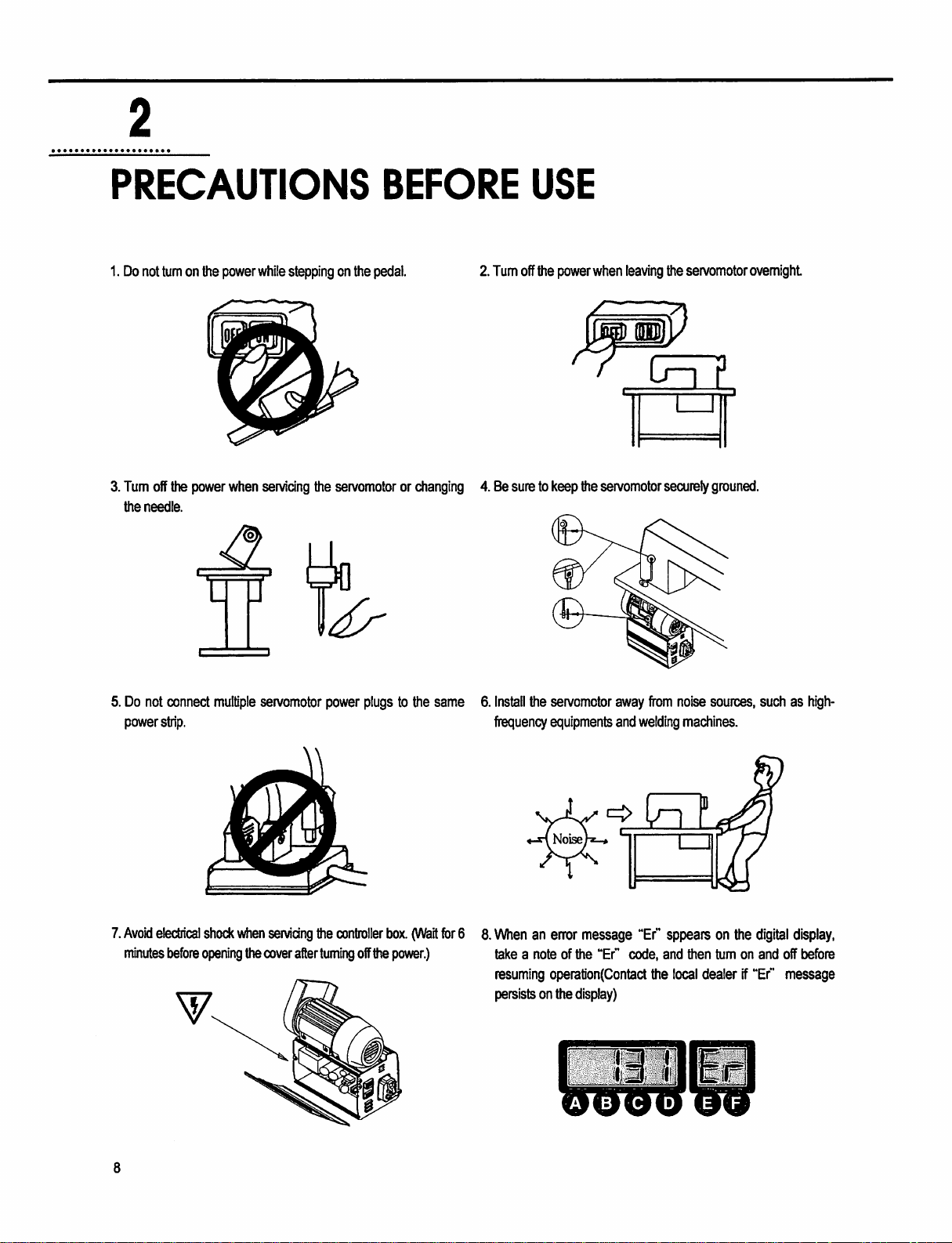

2

PRECAUTIONS

1.

Do

not

turn

on

the

power

while

stepping

3.

Tum

off

the

power

when

the

servicing

needle.

E

the

BEFORE

on

the

pedal.

servomotor

or

changing

2.

Turn

4.

Be

USE

off

the

sure

to

power

keep

the

when

leaving

the

S[i

servomotor

securely

servomotor

overnight

grouned.

5.

Do

power

7.

Avoid

minutes

not

connect

strip.

electrical

before

multiple

shock

when

opening

the

servomotor

servicing

cover

after

power

the

controller

turning

plugs

box.

off

the

to

the

(Wait

power.)

same

for 6 8.

6.

Install

the

frequency

♦-rf

When

an

take a note

resuming

persists

on

servomotor

equipments

Noise}^-*

error

of

operation(Contact

the

away

and

message

the

"Er"

display)

from

welding

"Er"

code,

the

noise

sources,

machines.

appears

and

then

local

dealer

on

tum

the

on

if

such

digital

and

off

"Er"

as

high-

display,

before

message

Page 9

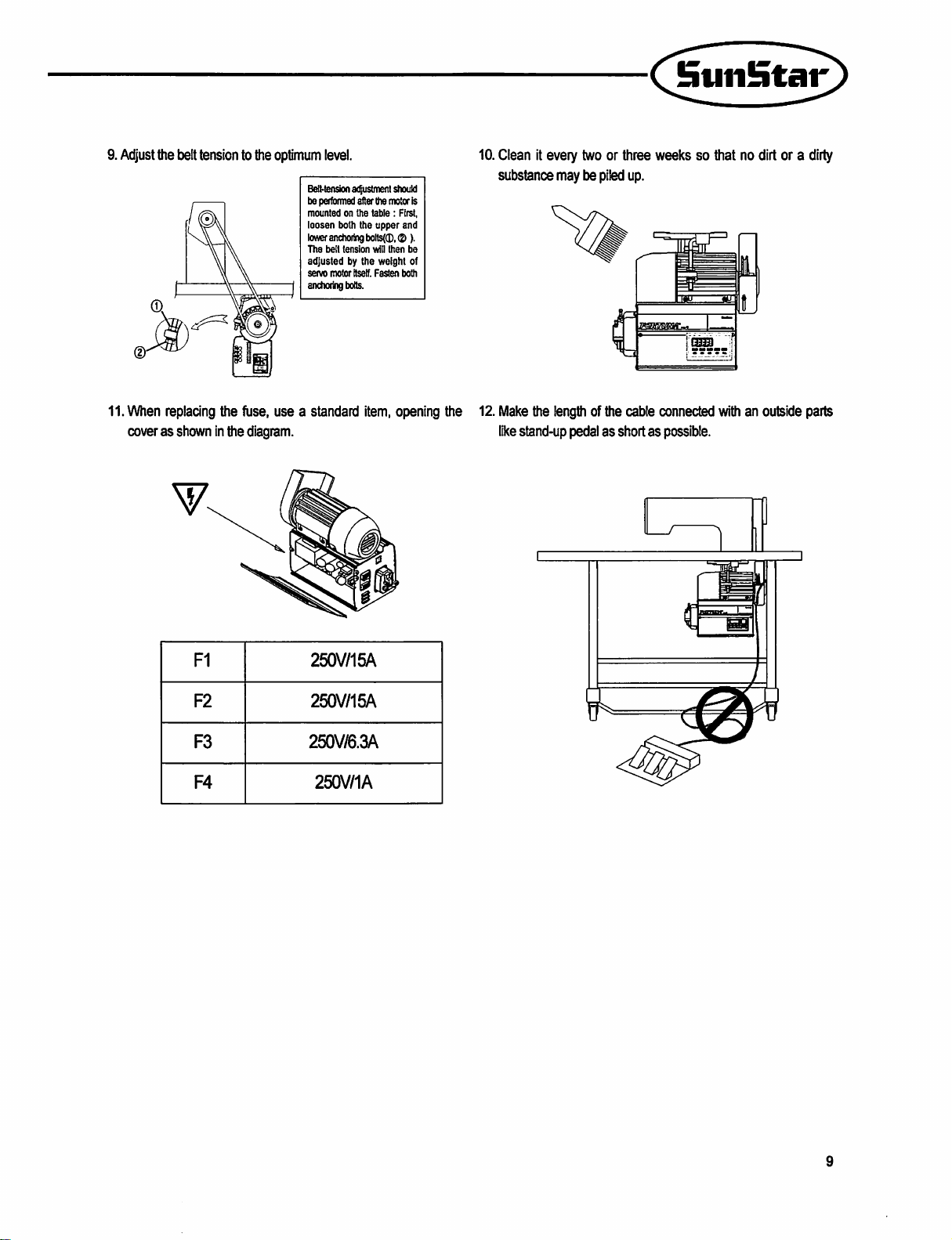

9.

Adjust

11.

When

cover

the

t)elt

tension

repladng

as

shown

to

the

fuse,

in

the

diagram.

the

optimum

level.

Beit-tension

t)e

peribrmed

mounted

loosen

loMer

anchoring

The

belt

adjusted

servo

motor

anchoring

use a standard

acfustment

after

ttw

on

ttie

table:

botti

the

upper

bolt^0,®).

tension

will

by

the

weight

Itself.

Fasten

bolts.

item,

stiould

motor

is

First,

and

then

be

of

both

opening

the

10.

Clean

substance

12.

Make

the

like

stand-up

it

every

may

length

two

or

be

piled

of

the

pedal

as

(Sun^a^

three

weeks

so

that

no

dirt

or a dirty

up.

cable

short

as

connected

possible.

with

an

outside

parts

F1

F2

F3

F4

250V/15A

250V/15A

250V/6.3A

250V/1A

Page 10

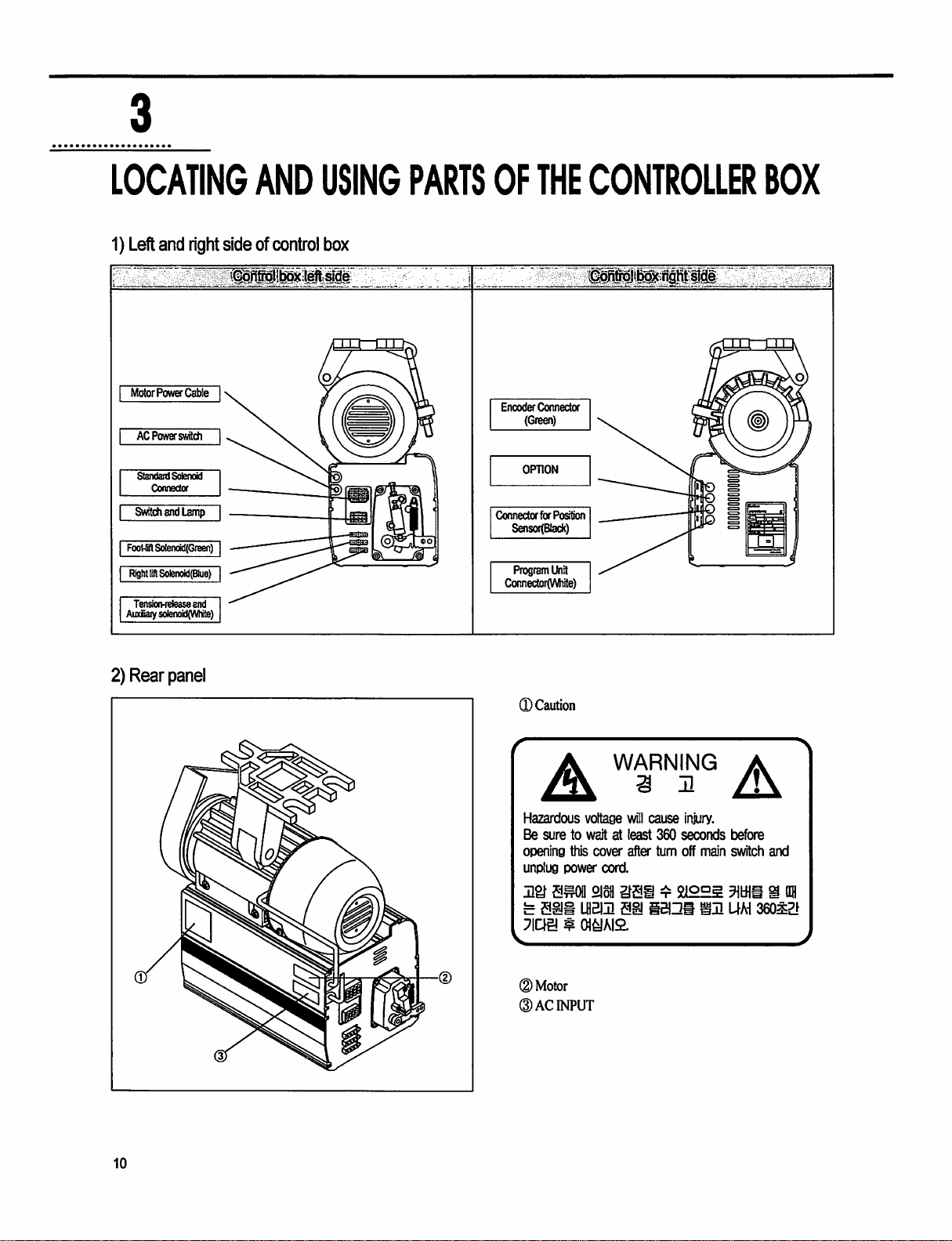

3

LOCATING

1)

Left

and right

Motor

Power

Cable

AG

Power

switch

Standard

Solenoid

Connector

Switch

and

Lamp

Foot^

SoIenokltGreen]

Right

InlSolenotdTBlue)

Tenson-reteaseand

AuxSaiy

sdenoidrwhite)

AND

side

of

control

USING

PARTS

box

OF

THE

Encoder

Connector

(Green)

OPTION

Connector

for

Position

Sensor(BIack)

Program

Unit

Connector(VVhite)

CONTROLIS

BOX

2)

Rear

panel

©Caution

Hazardous

Be

sure

to

opening

Hgf

^

©Motor

©ACINPUT

unplug

Em

Em

^

this

power

WARNING

voltage

wait

at

cover

cord.

2lofl

lhbiji

e^

o\mQ.

a

will

cause

least

360

after

turn

^

iBini

n

in^ry.

seconds

off

main

212E5

A

Isefore

switcfi

and

mm

%

UM

saoszf

aa

10

Page 11

4

INSTALLATION

1)

Mounting

(D

Make

figure.

®

Insert

flat

your

Servo

sure

that

the

holes

three

motor-fbcing

and

spring

washers

Motor

are

bored

bolts

through

over

the

on

on

bolt

the

table

the

table

as

the

thiee

stems,

and

shown

holes

on

then

fasten

in

the

the

table.

the

bolts

3-0 9 Hole

Attach

the

with

nuts.

MlCabte^tde

motor

base

Table

L

padded

with

BeHHcle

vibration-ptoof

rubber,

\

and

slide

®

Make

Motor-Fixing

sure

that

Bo!ts(3ea)

the

center

a

of

motor

Vibn^Ptoofnifaber

SpringWaser

pulley

is

matched

Flatvy^

to

Motv-FDdng

=}=

NutofD

diat ofdie

sewing

Bolts

machine

Table

before

tightening

Motor-Fodng

Bo(ts(3ea)

mp

the

motor-fixing

Controller

Box

bolts

and

nuts.

11

Page 12

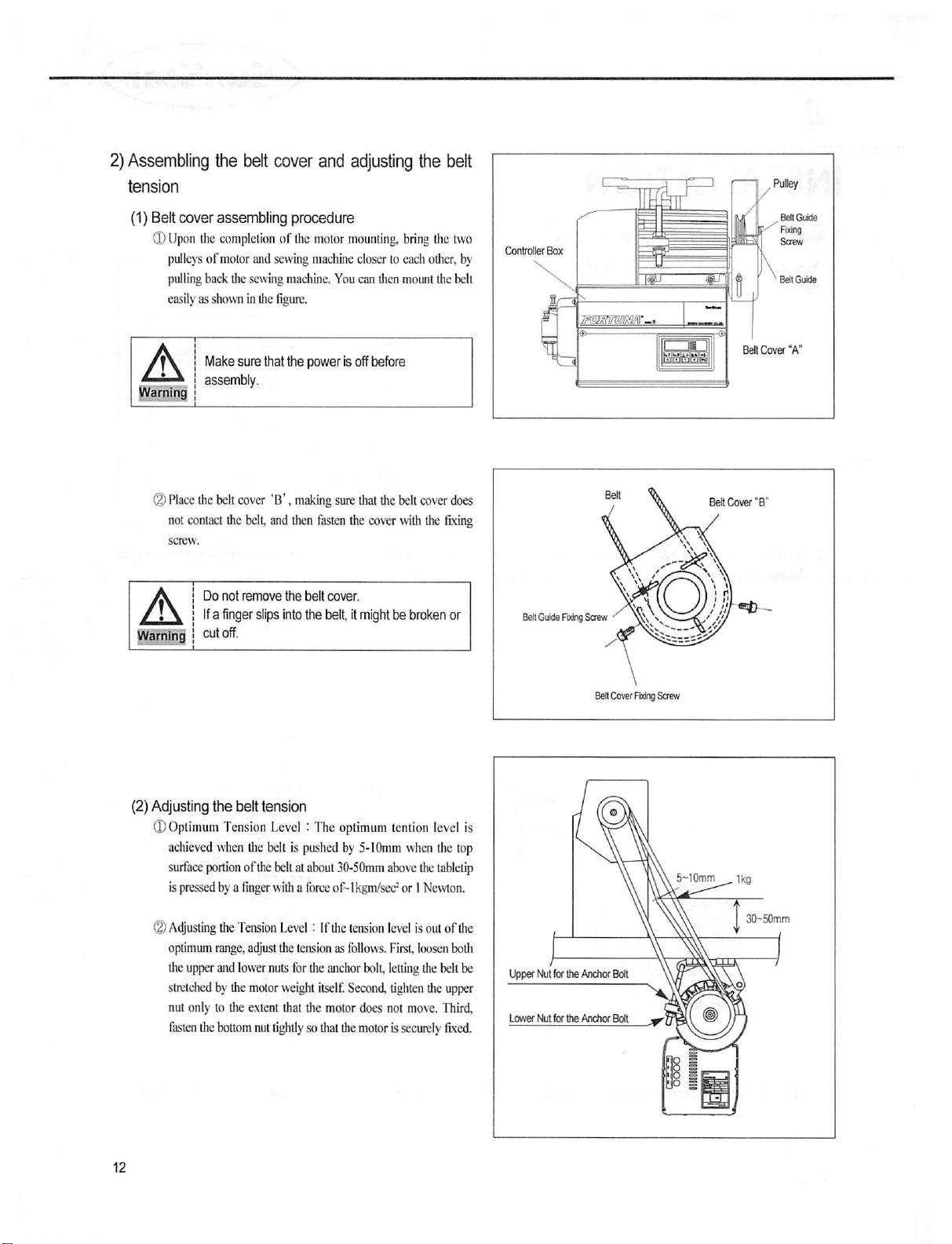

2)

Assembling

tension

(1)

Belt

cover

®

Upon

the

pulleys

pulling

easily

as

A

Wamlhd

(2)

Place

the

not

contact

A

Warning

the

belt

cover

assembling

completion

of

motor

and

sewing

back

the

sewing

shown

in

the

Make

sure

that

assembly.

belt

cover

'B',

the

bell,

and

Do

not

remove

If a finger

cutoff.

slips

and

procedure

of

the

motor

machine

machine.

figure.

the

power

making

Ihen

fasten

the

belt

cover.

into

the

belt

adjusting

mounting,

closer

You

can

is

off

before

sure

that

the

cover

it

might

bring

to

each

then

mount

the

bell

with

be

the

cover

broken

belt

the

two

other,

by

the

belt

does

the

fixing

or

BeK

Guide

FDdng

Screw

(2)

Adjusting

iD

Optimum

achieved

surface

Ispressedby

©

Adjusting

optimum

the

stretched

nut

fasten

the

belt

tension

Tension

when

portion ofthe

the

range,

upper

and

by

only

to

the

bottom

Level : The

the

bell

is

belt

afingerwilhaforceof-Ikgm/sec^or

Tension

Level: If

adjust

the

lower

nuts

the

motor

weight

the

extent

that

nut

tightly

optimum

pushed

at

about

30-50mm

the

tension

as

for

the

anchor

itself.

the

motor

so

that

the

by

5-lOmm

tension

follows.

boll,

Second,

does

motor

lention

level

when

the

above

the

tabletip

1

Newton.

level

is

out

First,

loosen

letting

the

belt

tighten

the

not

move.

Third,

is

securely

is

top

of

the

both

be

upper

fixed.

Upper

lower

Nut

for

Nut for

Ihe

Anchor

the

Anchor

Belt

Cover

RoigSoew

5-10mm ^ 1kg

Bolt

Bolt

Page 13

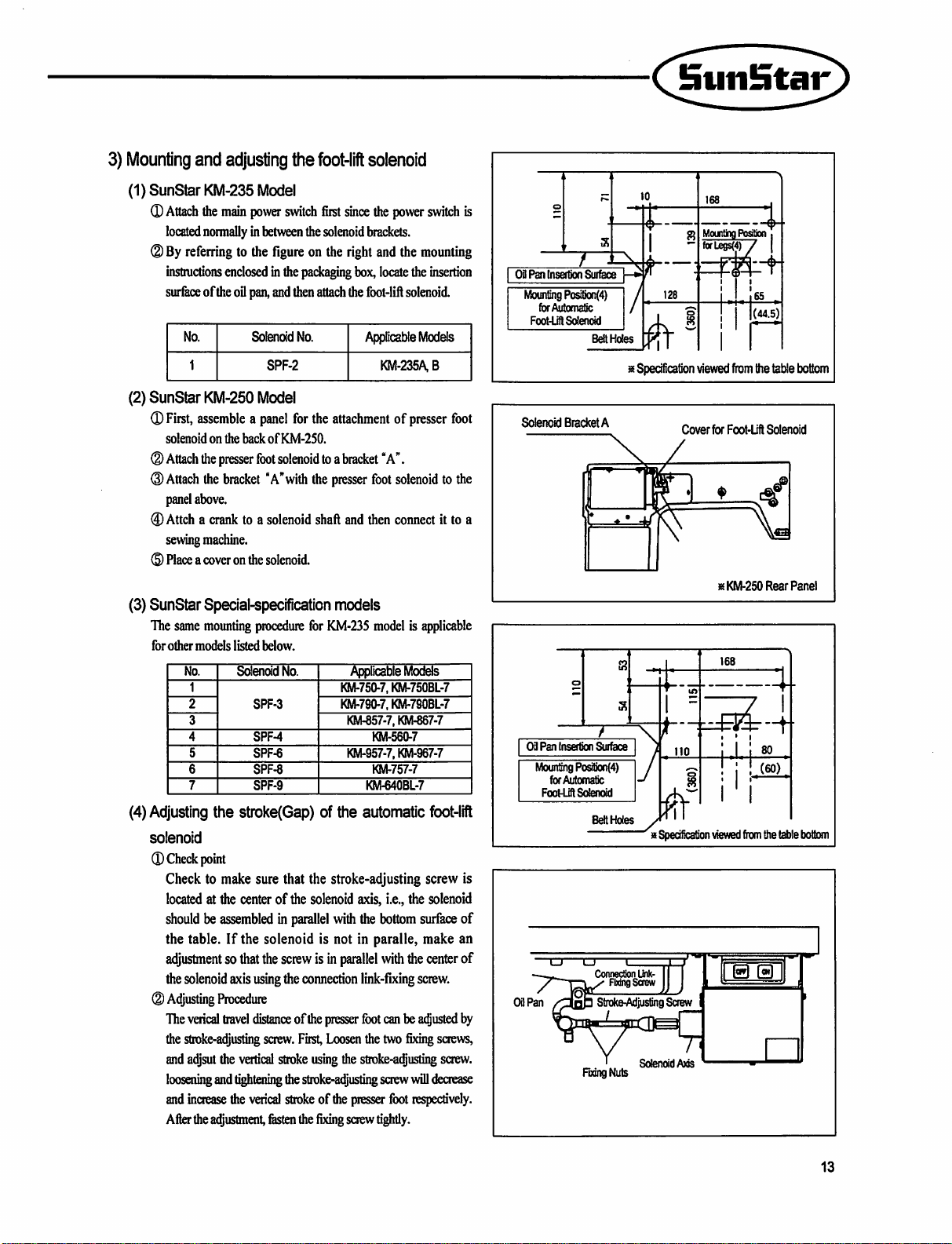

3)

Mounting

and

adjusting

the

foot-lift

solenoid

(1)SunStarKM-235

0

Attach

the

located

normally

(2)

By

referring

instmctions

surface

of

No.

1

Model

main

power

in

between

to

the

figure

enclosed

in

the

oil

pan,

and

Solenoid

SPF-2

switch first

the

on

the

padcaging

then

No.

(2)SunStarKM-250Model

(D

First,

solenoid

(D

Attach

©Attach

panel

0

Attch a crank

sewing

(5)

Place a cover

(3)

SunStar

The

same

for

other

(4)

Adjusting

solenoid

0

Check

Check

located

should

the

adjustment

the

solenoid

(2)

Adjusting

The

the

stroke-adjusting

and

loosening

and

After

assemble a panel

on

the

backof

the

presser

the

bracket

above.

to a solenoid

machine.

on

Special-specification

mounting

models

listed

No.

2

3

4

5

6

7

1

Sdenotd

the

stroke(Gap)

point

to

make

at

the

center

be

assembled

table.

If

the

so

that

axis

Procedure

verical

travel

adjsut

the

vertical

and

tightening

increase

the

the

adjustment,

for

ICM-2S0.

foot

solenoid

"A"with

the

solenoid.

procedure fiir

below.

No.

SPF-3

SPF-4

SPF-6

SPF-8

SPF-9

sure

that

the

of

the

solenoid

in

parallel

solenoid

the

screw

using

the

connection

distance

of

the

saew.

First,

stroke

the

stroke-adjusting

verical

stroke

fasten

the

since

the

power

solenoid

brackets.

the

right

and

the

mounting

box,

locate

the

attach

the

foot-lift

solenoid.

Applicable

the

attachment

to a bracket

the

presser

foot

shaft

and

then

Models

KM-235A

of

presser

"A".

solenoid

connect

models

KM-235

of

is

is

in

presser

Loosen

using

of

fixing

model

is

q)plicable

Applicable

KM-750-7.

KM-790-7.

KM-857-7.KM-867-7

KM-957-7.KM-967-7

the

stroke-adjusting

with

not

in

parallel

the

die

presser

screw

Models

KM-750BL-7

KM-790BL-7

KM-560-7

KM-757-7

KM-640BL-7

automatic

screw

axis,

i.e.,

the

the

bottom

surface

paralle,

link-fixing

foot

the

stroke-adjusting

tighdy.

make

with

the

screw.

can

be

adjusted

two fixing

screw

will

foot

respectively.

switch

is

insertion

B

foot

to

the

it

to

a

foot-lift

is

solenoid

of

an

center

of

by

screws,

screw,

decrease

03

Pan

tnseftion

Mounting

Positjcn(4)

for

Automatic

Foot-UflSoIenotd

Solenoid

Bracket

03

Par

Insertion

Mount'ng

for

Automatic

Foot4JftSoteno(d

Oil

Pan

Sur^

Belt

Holes

h'-

«

Specification

A

r

Position(4)

FodngNuts

■■

T

Surface

Beft

Holes

Connection

Unk-

Fixing

Screw

Stroke^justing

Solenoid

168

Mounting

fofl£BS(4)

128

■ o

viewed

Cover

for

[fer-

*

«KM-250

168

110

i

»

SpecHication

Screw

viewed

Axis

PosiBon

65

(44.5)

from

the

table

Foot-Lift

Solenoid

Rear

"h'

.l.

i

! (60)

from

the

@

0

bottom

Panel

table

bottom

13

Page 14

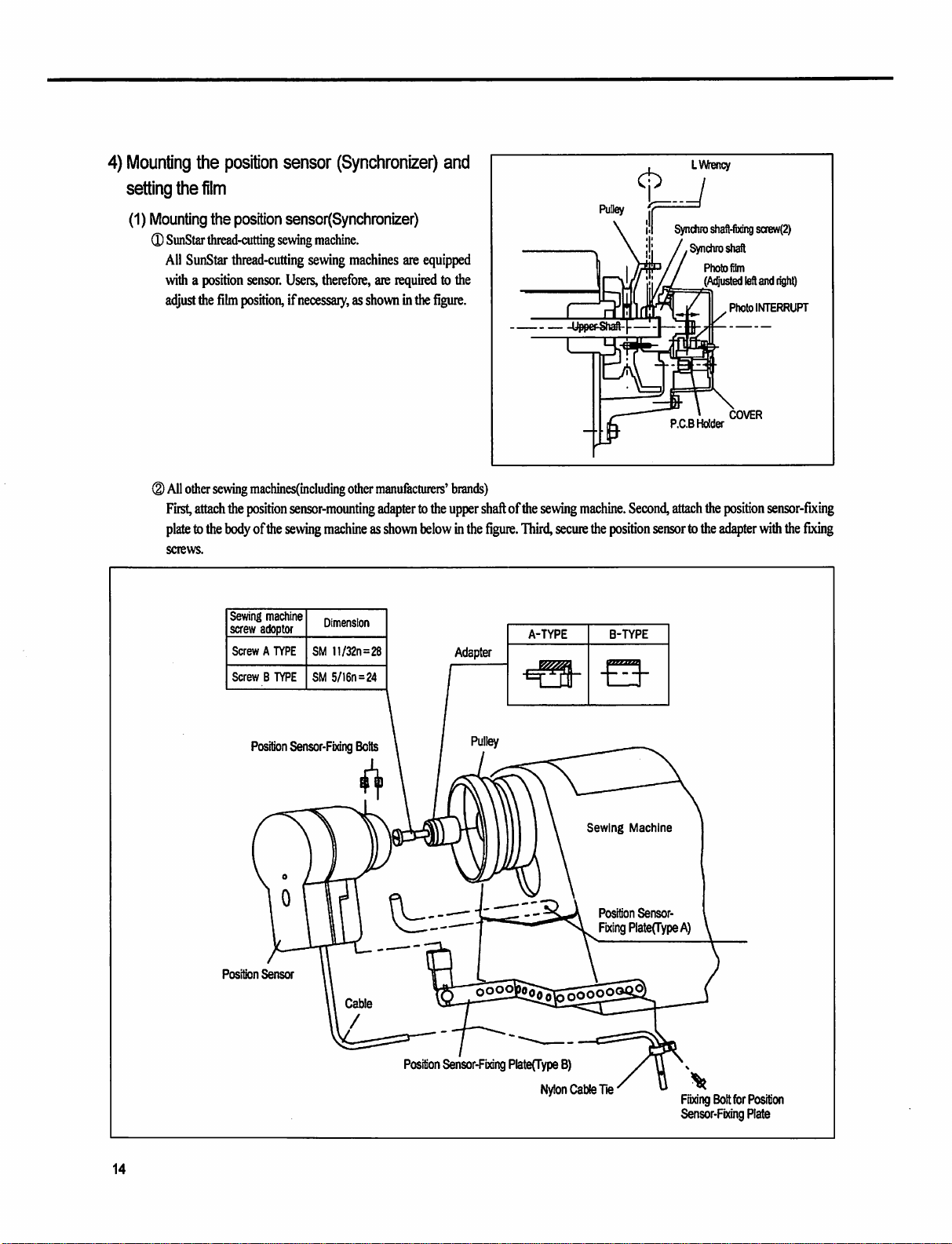

4)

Mounting the

setting

(1)

the

Mounting

(D

SunStar

All

with a position

adjust

position

sensor

film

the

position

thread-cutting

SunStar

thread-cutting

the film

sensor(Synchronizer)

sewing

sensor.

Users,

position,

(Synchronizer)

machine.

sewing

machines

therefore,

if

necessary,

as

are

are

required

shown

in

and

equipped

to

the

the figure.

,

LWency

^

Puliey

1?

\ ill

. \

1 Iw^//

_

"n

_upp^

fSh^i

jlj

J'ji^

ni

irlri

*-]—

/

Synchro

shafl-fbdng

screw(2)

/.Synchroshaft

Pbotofilm

(Adjusted

left

and

right)

,U y P'"'®

INTERRUPT

I

®

All

other

First,

plate to

screws.

sewing

attach tiie

the

bocfy ofti

Sewing

screw

Screw A TYPE

Screw B TYPE

position

machines(including

sensor-mounting

te

sewing

machine

adopter

Position

Sensor-Fixing

other

machine

Dimension

SM

11/32n=28

SM

5/16n=24

Bolts

manufacturers'

adapter

as

shown

brands)

to

the

upper

below

in

Adapter

shaft

of

the

the figure.

Third,

A-TYPE

sewing

machine.

secure

the

Sewing

/

position

B-TYPE

^

P.C.B

Second,

attach

sensor to

Machine

\

COVER

Holder

the

position

the

ad^ter

sensor-fixing

witii

the fixing

t:--

Position

Sensor

Position

Sensor-Fixing

14

Plate(Type

8)

Nylon

Cable

Position

Sensor-

Fixing

PiateCTypeA)

Tie'

Fixing

Bolt

tor

Sensor-Fixing

Position

Plate

Page 15

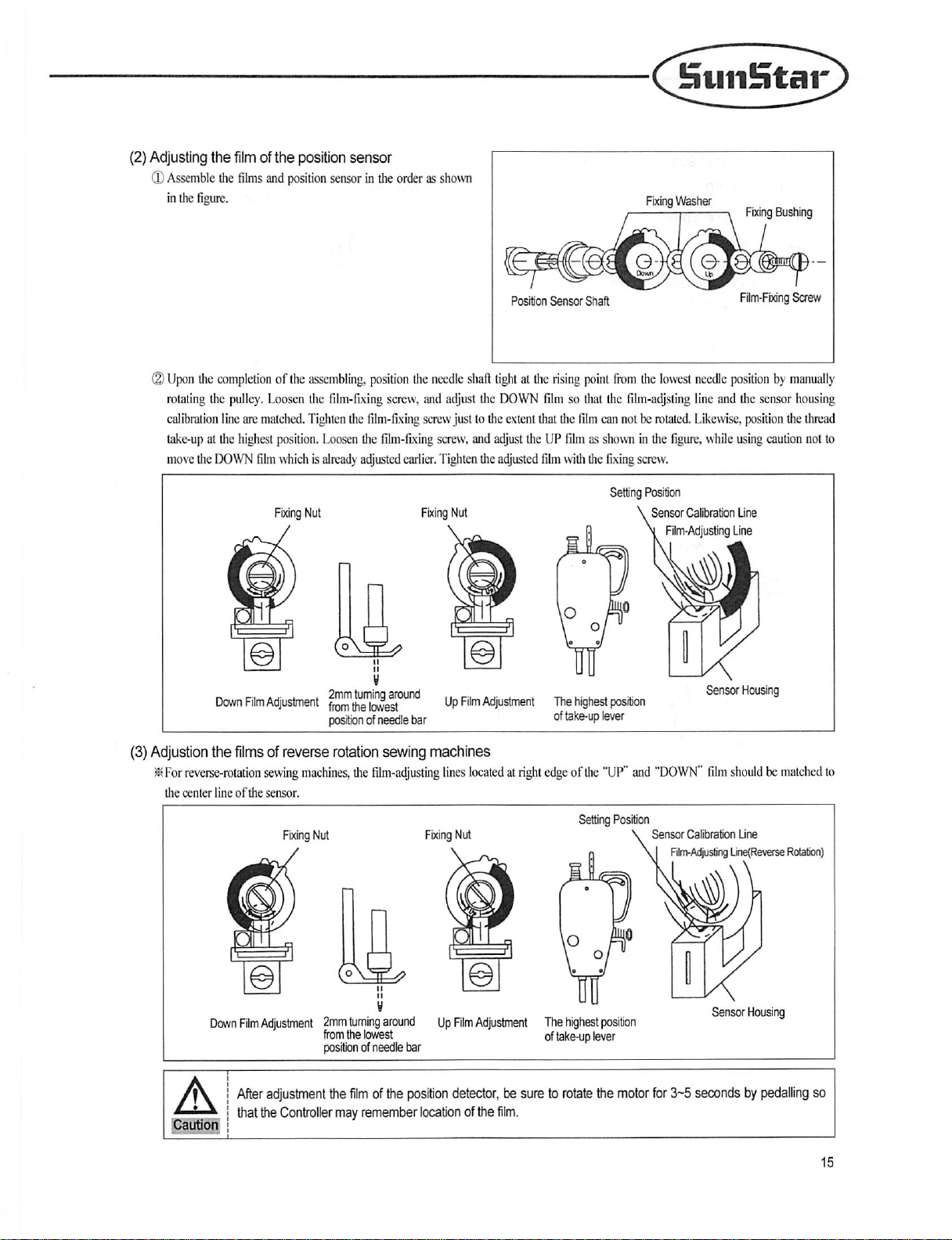

(2)

Adjusting

(D

Assemble

in

the

the

film

the

films

figure.

of

the

and

position

position

sensor

sensor

in

the

order

as

shown

Sviiilntar

FExingVl^sher

Fixing

Bushing

©

Upon

the

completion

rotating

the

calibration

take-up

at

the

move

die

DOWN film

Down

pulley.

line

are

matched.

highest

Rim

of

the

assembling,

Loosen

the

film-fixing

Tighten

position.

Loosen

\^ich

is

already

Fixing

Nut

Adjustment

position

position

the

needle

screw,

and

the

film-fixing

the film-fixing

adjusted

of

screw

earlier.

Fixing

needle

bar

shaft

adjust

the

just

to

screw,

and

Tighten

the

Nut

Up

Rim

Adjustment

Position

tight

at

the

DOWN

the

extent

adjust

the

adjusted film

Sensor

rising

film

so

that

the film

UP film

with

The

highest

take-up

Shaft

point

from

the

that

the

film-adjsting

can

not

be rotated.

as

shown

in

the

fixing

screw.

Setting

\Sensor

positlcffi

lever

Film-Fixing

lowest

needle

position

by

line

and

the

sensor

Likewise,

the figure,

Position

Calibration

t Film-Adjusting

while

using

Une

Une

Sensor

Housing

position

the

caution

Screw

manually

housing

thread

not

to

(3)

Adjustlon

For

reverse-rotation

the

center

A

Cautioif

the

films

line ofdie

Down

Film

After

that

of

reverse

sewing

sensor.

Fixing

Adjustment

adjustment

the

Controller

rotation

machines,

Nut

2mm

from

position

the

may

sewing

the

film-adjusting

tuming

the lowest

of

needle

film

of

rememtier

machines

Fixing

around

bar

the

position

location

lines

Up

located

at

right

Nut

Film

Adjustment

detector,

of

the

be

sure

film.

e<^e

of

the

Setting

The

highest

of

take-up

to

rotate

"UP"

and

Position

position

lever

the

motor for

"DOWN"

Sensor

vj

film

Calibration

Rim-Adjusting

Sensor

S-^S

seconds

should

be

matched

Une

Une(Reverse

Rotation)

Housing

by

pedalling

to

so

Page 16

5)

How

to

equip

and

adjust a built-in

detector(synchronizer)

(1)

How

to

equip

the

built-in

location

(synchronizer)

^

In

case

ofaSunStar

When a built-in

sewing

machine

equipped,

location

Sewing

pulley

of

Positon

machine

all

magnetic

thread

location

with

that

the

users

magnetic

for

detection

up

trimmer

detector(synchronizer)

the

SunStar

need

Locate

(synchronize^

location

detector

thread

to

do

is

to

according to

detector

for

trimmer

simply

adjust

their

needs.

the

is

the

Locate

detector

(synchronizer)

Position

magnetic

Position

up

magneto

■£

)

d

Sewing

machine

Position

magnetic

down

16

Page 17

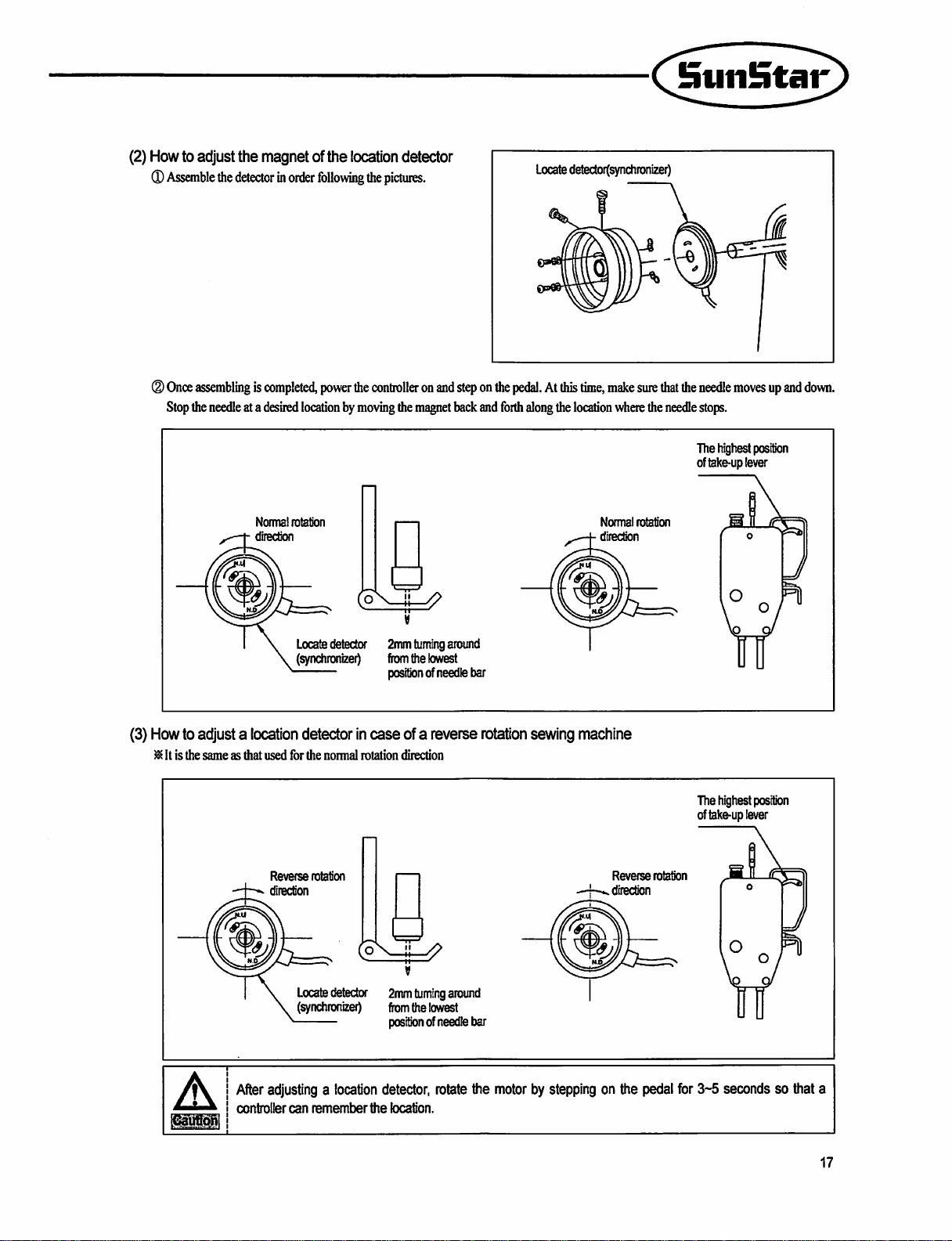

(2)

How

0

(2)

to

adjust

Assemble

Once

Stop

the

detector

assembling

the

needle

the

magnet

in

order

is

completed,

at a desired

Normal

rotation

direction

location

of

the

location

following

power

the

by

moving

the

pictures.

controller

detector

on

and

the

magnet

step

on

back

and

the

pedal.

forth

along

Locate

d6tector(synchronizer)

At

this

time,

make

sure

the

location

where

the

Nonnal

rotation

direction

that

the

needle

needle

stops.

The

of

moves

highest

position

take-up

lever

o

up

\J

and

down.

(3)

How

^

to

adjust a location

It

is

the

same

as

diat

Locate

detector

(synchronizer) ftom

detector

used

for

the

normal

Reverse

rotation

direction

Locate

detector

(synchronizeO

2mm

in

case

rotation

2mm

(ix}m

turning

around

the

lowest

of a reverse

direction

tuming

the

lowest

rotation

around

sewing

machine

Reverse

rotation

direction

\

r

The

highest

of

take-up

\v

V

position

lever

J

A

adjusting a location

controller

can

remember

detector,

the

rotate

location.

the

motor

After

by

stepping

on

the

pedal

for

3~5

seconds

so

that

a

17

Page 18

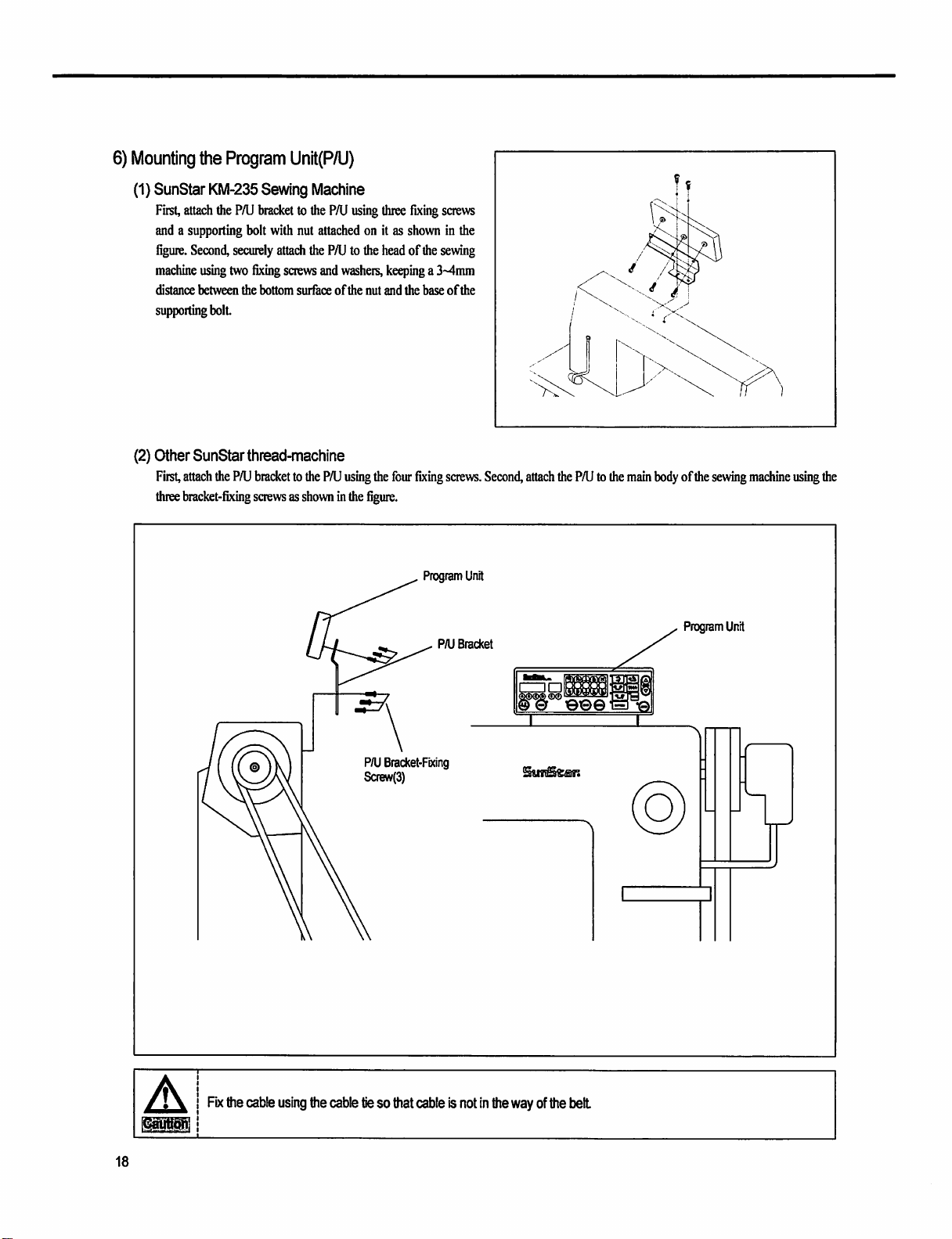

6)

Mounting the

(1)

SunStar

First,

attach

and a supporting

fi

gure.

machine

distance

supporting

(2)

Other

First,

attach

three

bracket-fixing

Program

KM-235

the

P/U

bolt

Second,

securely

using

two fixing

between

the

bolL

SunStar

thread-machine

the

PAJ

Unit(P/U)

Sewing

bracket

to

with

nut

attach

screws

bottom

surface

bracket

to

the

screws

as

shown

Machine

the

P/U

using

attached

the

PAJ

to

and

washers,

of

the

PAJ

using

in

the figure.

three fixing

on

it

as

shown

the

head

of

the

keeping a 3~4nun

nut

and

the

base

the

four fixing

Program

screws

in

the

sewing

of

the

screws.

Second,

Unit

attach

the

PAJ

to

the

main

body ofthe

If

sewing

machine

using

the

PAJ

Bracket-Fixing

Screw(3)

P/U

Bracket

©©©

Program

Unit

Fix

die

cable

using

the

cable

tie

so

that

cable

is

not

in

the

A

18

way

of

the

belt

Page 19

7)

An

example

of

installing

the

SunStar

sewing

machine

19

Page 20

5

WIRING

1)

Specification

(1)

Single

(2)

Single

of

phase

Control

phase

Control

the

100V~120V

200V~240V

AND

power

Box

Box

plug

Switch

Switch

GROUNDING

Box

o

o

&■

dte"

Box

fi

o

-o

r

o

r

n

a

PH

>'(Prat*<tivt

EARTHV

EARTHV

E«

o o 110

Eatttv

D D

o

10

AC

AC

110V

220V

(3)

Three

phase

200V~240V

Control

Switch

Box

-o

o-x—o-

Box

o-

u

[fe"

^Be

sure

to

connect

2)

Specification

Be

sure

to

use

20

of

wiring

Protective

electric

materials

Eaitii

current

which

can

in

wiring

stand

electric

of

power

current

plug

of

higher

than

15A.

PE

(Pfottctlw

EARTHV

EiittO

30

AC

220V

Page 21

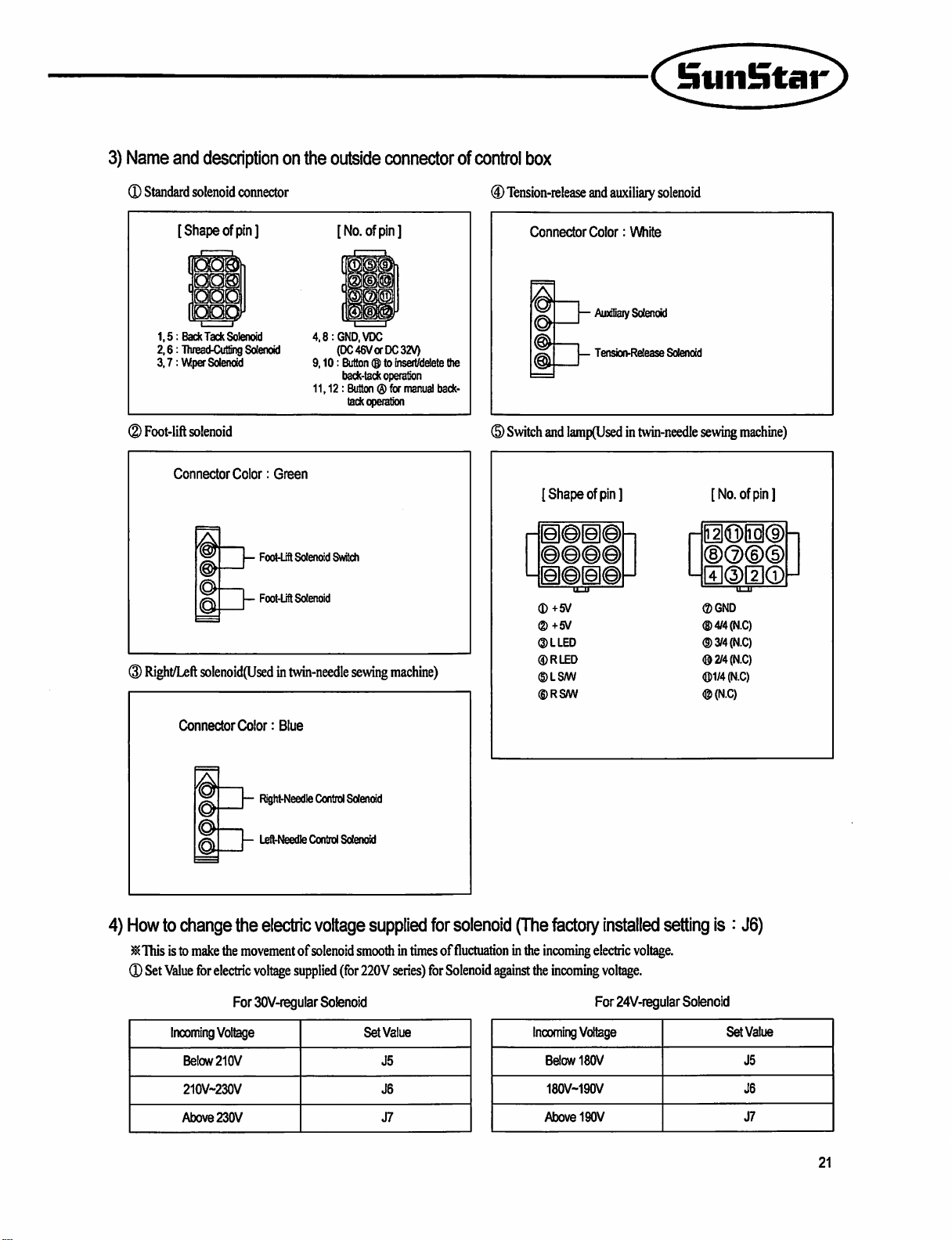

3)

Name

0

and

description

Standard

solenoid

on

connector

the

outside

connector

of

control

box

®

Tension-release

and

auxiliaiy

solenoid

[Shape

1,5:

Back

2,6:

Thread^^otting

3,7

:Wper

(D

Foot-lift

solenoid

Connector

(3)

Right/Left

of

pin]

Tack

Solenoid

Solenoid

Solenoid

Color:

—

Foot-Lifl

1

Foot-Lift

solenoid(Used

4,8:GND.VDC

9,10:

11,12:

Green

Solenoid

Solenoid

in

twin-needle

[No.

ofpm]

(DC

46V

or

Button ® to

tiack-tack

operation

Button ® for

tack

operation

Switch

sewing

DC

SZV)

inseit/delete

manual

ttie

back-

machine)

©

Switch

Connector

—

—

and

lamp(Used

[Shape

®

®+5V

®LLED

®RLED

©ISM

©RSW

of

+5V

Color:

White

Auxiliaiy

Solenoid

Tension-Release

in

twin-needle

pin]

Solenoid

sewing

machine)

[No.

of

pin]

©GND

©4/4(N.C)

®3/4(N.C)

©2/4(N.C)

®1/4(N.C)

®(N.C)

4)

How

(D

^

This

Set

Connector

^

©.—T

to

change

is

to

make

Value

for

electric

Incoming

Below

210V~230V

Above

Color:

—

Right-Needle

1

Left-Needle

the

electric

the

movement

voltage

For

30V-regular

Voltage

210V

230V

Blue

Control

Control

voltage

of

solenoid

supplied

(for

Solenoid

Solenoid

Solenoid

supplied

smooth

in

220V

series)

Set

Value

J5

J6

J7

for

solenoid

times

of fluctuation

for

Solenoid

(The

factory

in

the

incoming

against

the

incoming

Incoming

Below

180V-190V

Above

installed

electric

voltage.

voltage.

For

24V-regular

Voltage

180V

190V

setting

is : J6)

Solenoid

Set

Value

J5

J6

J7

21

Page 22

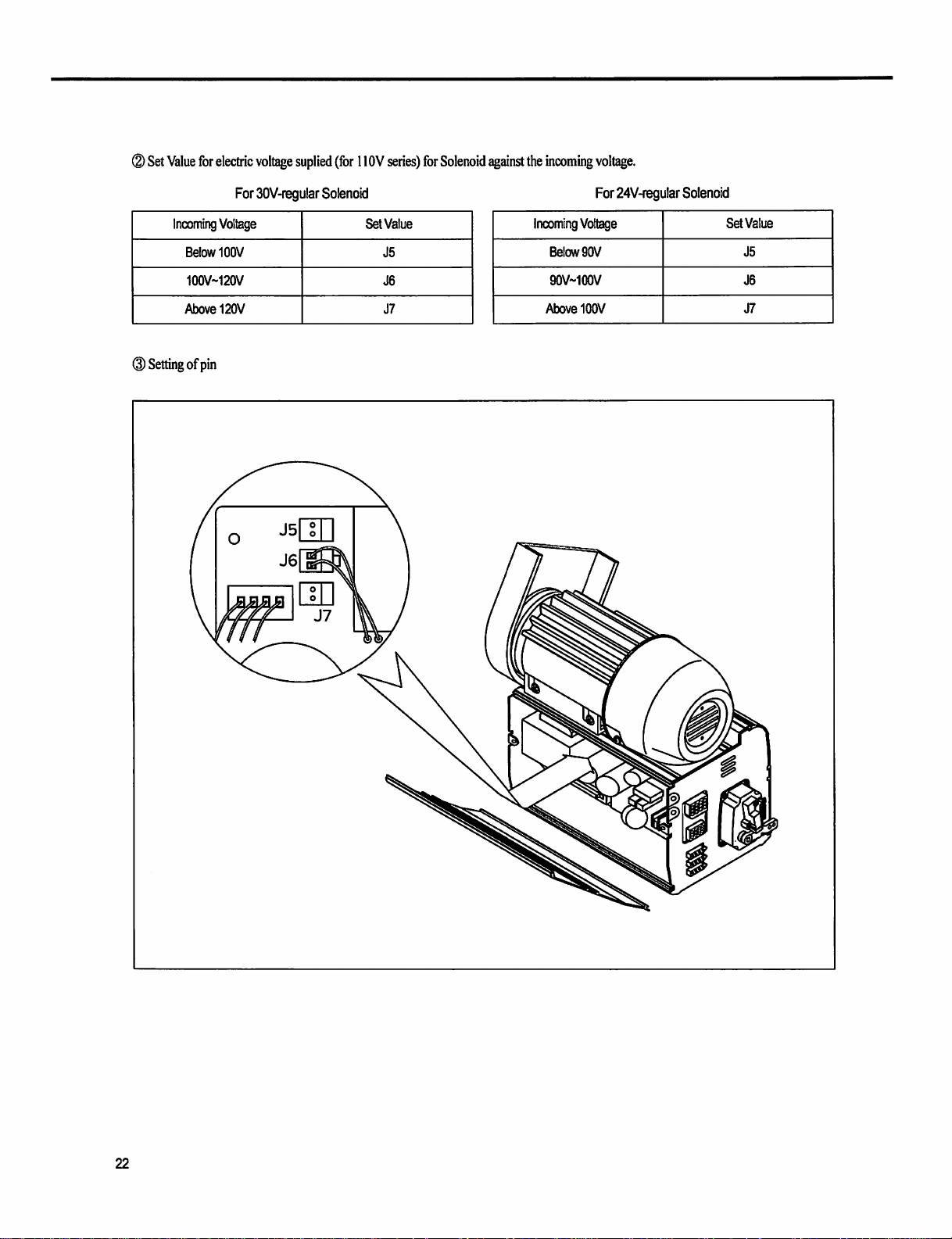

(D

Set

Value

Incoming

for

electric

For

Voltage

voltage

suplied

(for 1 lOV

30V-regular

Solenoid

series)

Set

Value

for

Solenoid

against

the

incoming

Incoming

voltage.

For

24V-regular

Voltage

Solenoid

Set

Value

@

Setting

Below

100V

100V~120V

Above

120V

of

pin

J5

J6

J7

Below

90V

90V~100V

Above

100V

J5

J6

J7

22

Page 23

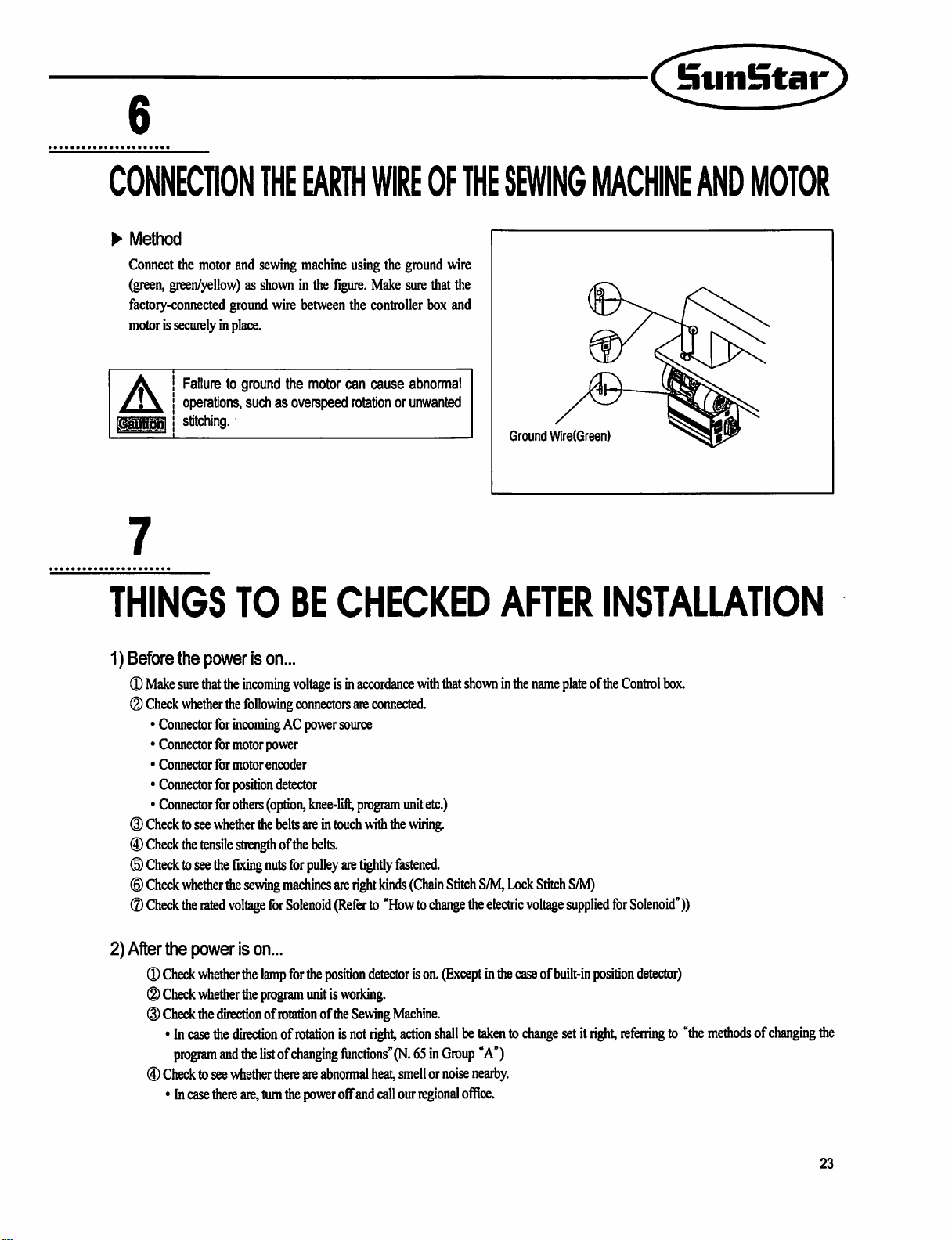

6

CONNECnON

►

Method

Connect

(green,

factoiy-connected

motor

A

the

motor

green/yellow)

is

securely

Failure

operations,

stitching.

and

as

ground

in

place.

to

ground

such

THE

sewing

shown

wire

the

as

overspeed

7

THINGS

TO

BE

EARTH

machine

in

the

between

motor

WIRE

using

figure.

Make

the

controller

can

cause

rotation

the

or

ground

sure

abnormal

unwanted

CHECKED

OF

THE

wire

that

the

box

and

SEWING

Ground

AFTER

MACHINE

Wlre(Green)

INSTALLATION

AND

MOTOR

1)

Before

0

(D

0

®

(B)

®

®

2)

After

the

power

Make

sure

that

Check

whetiier

•

Connector

•

Connector

•

Connector

•

Connector

•

Connector

Check

to

see

Check

the

tensile

Check to

Check

Check

0

(D

0

see

whether tiie sewing

the

rated

the

power

Check

whether

Check

whether

Check

the

•

In

case

program

Check to

*

In

case

is

the

incoming

the

following

for

incoming

for

motor

for

motor

for

position

for

others

whether

strength

the

fixing

voltage

is

on...

the

die

direction

the

direction

and

the

see

whether

there

are,

on...

voltage

connectors

AC

power

power

encoder

detector

(option,

the

belts

are

of

die

nuts

for

machines

for

Solenoid

lamp

for

program

of

rotation

of

rotation

list

of

changing

there

are

turn

the

power

is

in

source

knee-lift,

in

touch

belts.

pulley

are

are

(Refer to

the

position

unit

is

woiking.

of

the

is

functions"

abnormal

off

accordance

are

program

wifti

tightly festened.

right

detector

Sewing

not

right,

and

with

connected.

unit

etc.)

the

wiring.

kinds

(Chain

"How to

is

on.

Machine.

action

(N.

65

heat,

smell

call

our regional

that

shown

Stitch

change

the

(Except

shall

be

in

Group

or

noise

office.

in

S/M,

Lock

electric

in

the

taken to

"A")

nearby.

the

name

Stitch

voltage

case

of

change

plate

of

S/M)

supplied

built-in

position

set

it

right, referring to

the

Control

for

Solenoid"))

detector)

box.

"the

methods

of

changing

the

23

Page 24

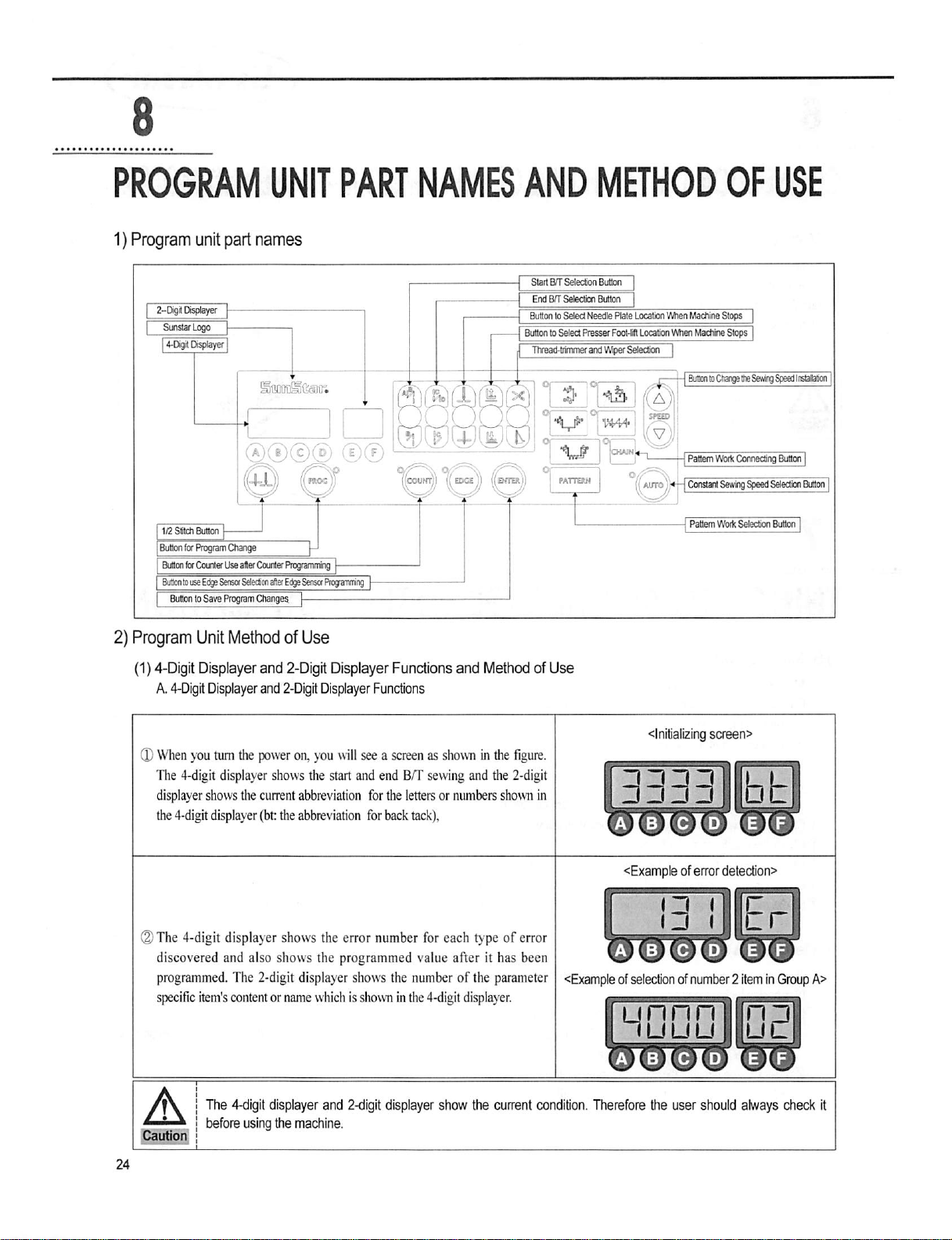

PROGRAM

1)

Program

unit

2-Digt

Di^iiayer

SunstarLogo

4-Digit

Diailayer

part

UNIT

names

PART

NAMES

AND

Stan

B/T

End

BH'

Button

Button

to

Ttvead-trinvner

METHOD

Selection

Button

Selection

Button

to

Select

Needle

Plate

Select

Presser

Foot-lift

and

Wtper

Location

Wtien

Location

Wtien

Selection

|

OF

UacMne

Stops

Uacfiine

Stops

USE

1/2

Button ferCcuter

Butem

2)

Program

(1)

4-Digit

A.

(D

When

The

displayer

the

SHcti

Button

Use

to

use

Edge

Se/Bor

Button

to

Save

Program

Unit

Method

Displayer

4-Digit

Displayer

you

turn

4-digit

displayer

shows

4-digit

displayer

alter

Couler

Selection

after

Ctianges

and

and

the

power

shows

the

current

(bt:

the

Progranvniig

Ei^

Sensor

Piogramming

of

Use

2-Digit

Displayer

2-Digrt

Displayer

on,

you

will

see a screen

the

start

and

abbreviation

abbreviation

for

for

Functions

Functions

as

shown

end

B/T

sewing

the

letters

or

back

tack),

and

Method

in

the figure.

and

the

numbers

shown

of

Use

2-digit

in

PATTERN

BiM toOiange

Pattern

Aino

Constant

Pattern

<lnjtiallzing

ItR

mtt

CcnnectinQ

SaniQ

Woili

Setectnn

screen>

Sewing

Speed Irstalalion

Button

Speed

Selection

Button

Button

(2)

The

4-digit

discovered

and

programmed.

specific

item's

A

The

before

displayer

The

content

4-digit

shows

also

shows

2-digit

or

name

displayer

using

the

the

error

the

programmed

displayer

machine.

shows

whicii

is

and

2-diglt

shown

number

for

value

the

number

in

the

4-digit

displayer

show

each

t>-pe

after

it

of

the

displayer.

the

of

error

has

been

parameter

current

riTiB

VVIWSTV

<Example

lunnniin^i

condition.

Therefore

<Example

of

selection

of

of

uuu

the

user

error

detection>

number 2 item

should

in

always

Group

A>

check

it

Page 25

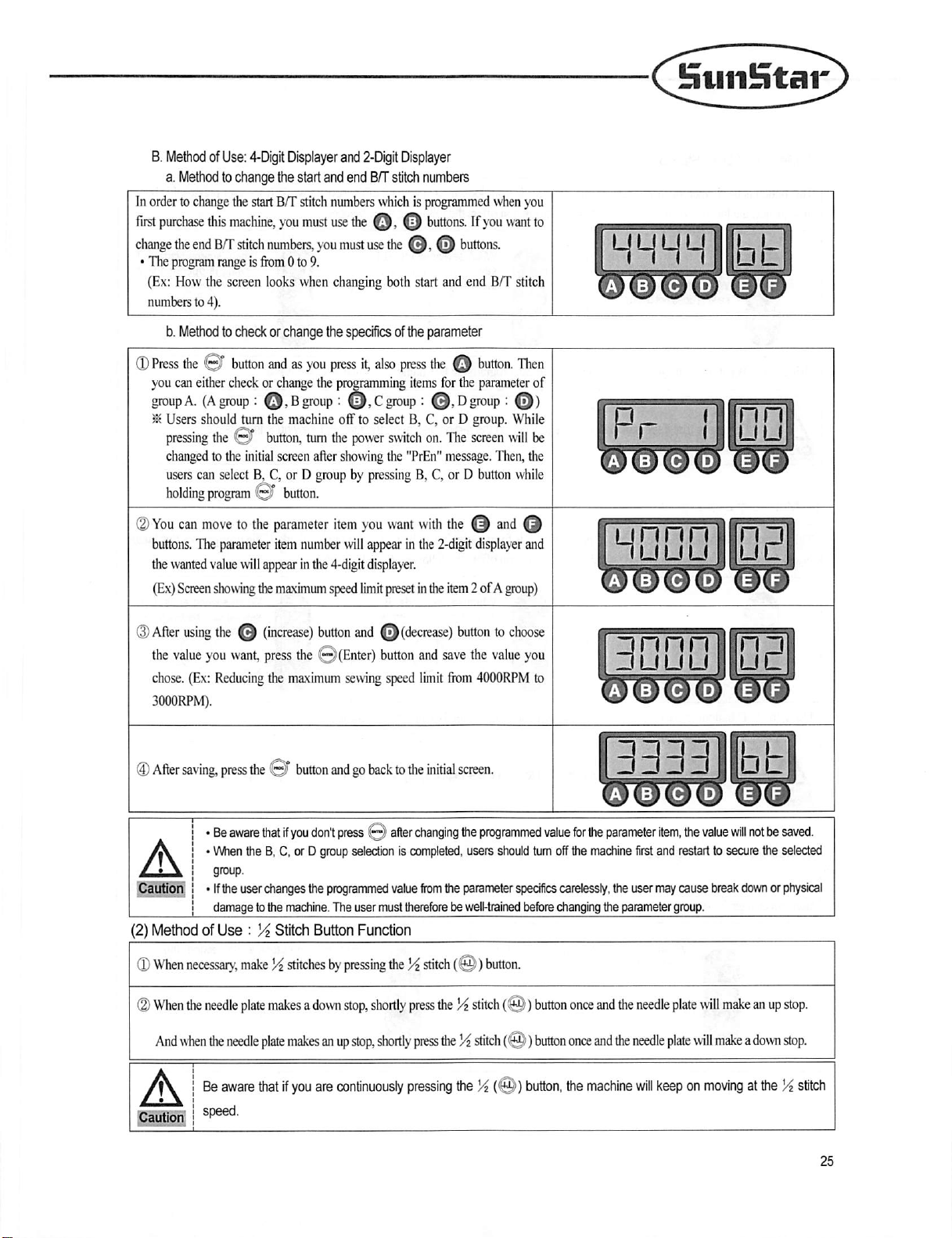

B.

Method

a.

Method

In

order

to

change

first

purchase

change

the

end

•

The

program

(Ex:

How

numbers

to

b.

Method

0

Press

the

you

can

either

^upA.

^

Users

pressing

changed

users

holding

0

You

can

buttons.

The

the

wanted

(Ex)

Screen

of

Use;

4-Digit

to

change

the

start

this

machine,

B/T

stitch

range

is

fiom 0 to

the

screen

4).

to

check

0r

button

check

or

Displayer

the

B/T

you

numbers,

looks

or

change

and

as

change

and

2-Digit

start

and

end

QfT

stitch

numbers

must

use

the

o o

you

must

use

9.

when

changing

the

specifics

you

press

it,

the

programming

Displayer

stitch

numbers

which

is

the

o o

both

start

of

the

also

press

items

programmed

buttons.

If

you

when

want

buttons.

and

end

B/T

stitch

parameter

the o button.

for

^e

Then

parameter

(Agroup ; 0,Bgroup : Q,Cgroup ; Q,Dgroup : Q)

should

turn

the

machine

the ^ button,

to

the

initial

screen

can

select

B,

C,

or D group

program

move

to

parameter

value

showing

button.

the

parameter

item

will

appear

the

maximum

olf

turn

the

after

showing

item

number

will

in

the

4-digit

speed

to

select

B,

power

switch

the

"PrEn"

by

pressing

you

want

appear

in

displayer.

limit

preset

C,

or D group.

on.

The

screen

message.

B,

C,

or D button

with

the ^ and

the

2-digit

displayer

in

the

kern 2 ofA group)

While

will

Then,

while

you

to

of

be

the

Q

and

!nuiiBtai'

HHHH

nnn

bt

®

After

the

value

chose.

3000RPM).

®

After

A

^autiorf

^Cautiorf

(2)

Method

0

When

0

When

And

using

the o (increase)

you

want,

press

the

(Ex:

Reducing

saving,

'

Be

'

When

! • If toe

I damage

of

Use ; %

necessary,

the

needle

when

the

the

press

the

©T

aware

that

the

B,

user

changes toe

to toe

Stitch

make

Yz

plate

makes a down

needle

plate

maximum

button

if

you

C,

or D group

machine.

stitches

makes

button

and

©(decrease)

i@i(Enter)

and

don't

programmed

Button

by

an

button

sewing

speed

go

back to

the

press © after

selection

is

completed,

vaiue

The

user

must

therefore

Function

pressing

the

Yz

stop,

shortly

press

up

stop,

shortly

changing

press

button

and

save

the

value

limit fiom

initial

from toe

stitch

4000RPM

screen.

the

programmed

users

parameter

be

well-trained

(@))

button.

the

Yz

stitch

the

Yz

stitch

to

choose

you

should

specifics

before

(0))

(0)

to

value

tum

off

carelessly,

changing toe

button

once

button

once

for

the

parameter

the

machine

and

and toe

□

nnn

□

uuu

item,

first

and

the

user

may

parameter

the

needle

needle

the

restart

cause

group.

plate

plate

will

vaiue

to

secure

break

will

make

make

will

not

down

an up

adown

be

saved.

the

selected

or

physical

stop.

stop.

Be

aware

that

If

you

are

A

continuously

speed.

pressing

the

Yz

(©)

button,

the

machine

will

keep

on

moving

at

the

Yz

stitch

Page 26

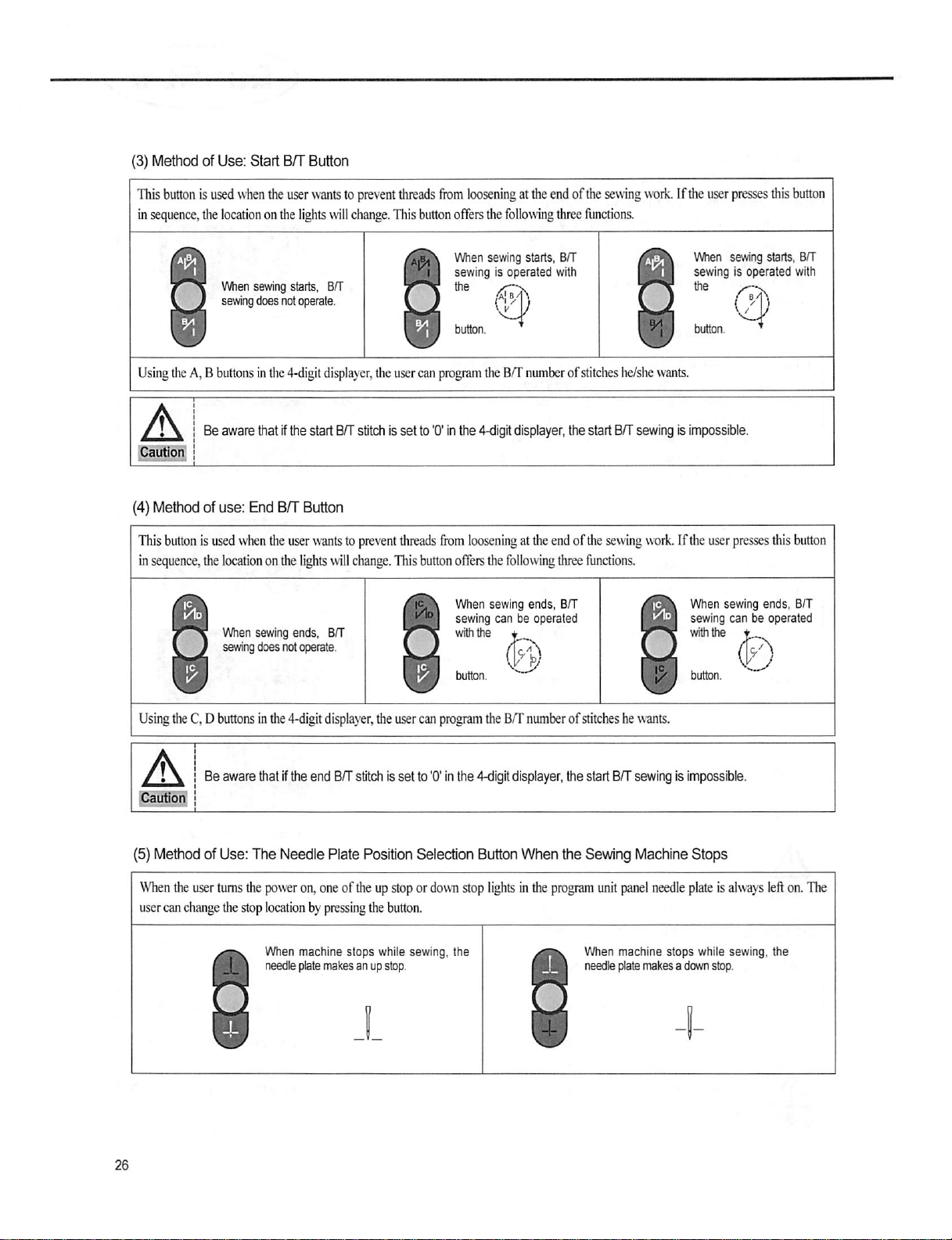

(3)

Method

This

button

in

sequence,

Using

the

A

(4)

Method

This

button

in

sequence,

of

Use:

Start

is

used

when

the

the

location

on

When

sewing

sewing

does

A, B buttons

Be

of

is

the

in

aware

that

use:

End

used

when

location

on

When

sewing

sewing

does

the

the

B/T

Button

user

wants

the

lights

starts,

not

operate.

4-digit

displayer,

if

the

start

B/T

Button

user

wants

the

lights

ends.

not

cerate.

to

prevent

will

ch^ge.

Brt

B/T

stitch

to

prevent

will

change.

B/T

threads

This

the

user

is

set

threads fiom

This

from

button

offers

When

sewing

can

program

to

'0'

in

the

button

offers

When

sewing

withthe

loosening

loosening

at

the

the

following

sewing

starts,

is

operated

the

B/T

number

4-digit

displayer,

at

the

the

following

sewing

ends,

can

be

operated

«

end ofthe

three

with

end

three

sewing

functions.

B/T

of

stitches

the

start

of

the

sewing

functions.

B/T

work.

he/she

Bff

sewing

work.

If

the

user

When

sewing

the

wants.

is

impossible.

If

the

When

sewing

wrthtoe

presses

sewing

is

y—V

user

presses

sewing

can

t

this

button

starts,

this

ends,

be

operated

B/T

with

button

B/T

operated

Using

A

(5)

Method

When

user

the

C, D buttons

Be

aware

of

Use:

the

user

turns

can

change

the

in

the

that

The

Needle

the

power

stop

location

When

needle

4-digit

displayer,

if

the

end

B/T

Plate

on,

one

by

pressing

machine

plate

makes

die

stitch

is

Position

of

the

up

the

button.

stops

while

an

up

stop.

user

can

program

set

to

'0'

Selection

stop

or

down

sewing,

in

the

the

stop

the

B/T

number ofstitches

4<ligit

displayer,

Button

When

lights

in

the

the

the

program

he

start

B/T

sewing

Sewing

unit

panel

When

machine

needle

plate

wants.

is

impossible.

Machine

makes a down

Stops

needle

plate

stops

is

always

while

stop.

left

sewing,

the

on.

The

Page 27

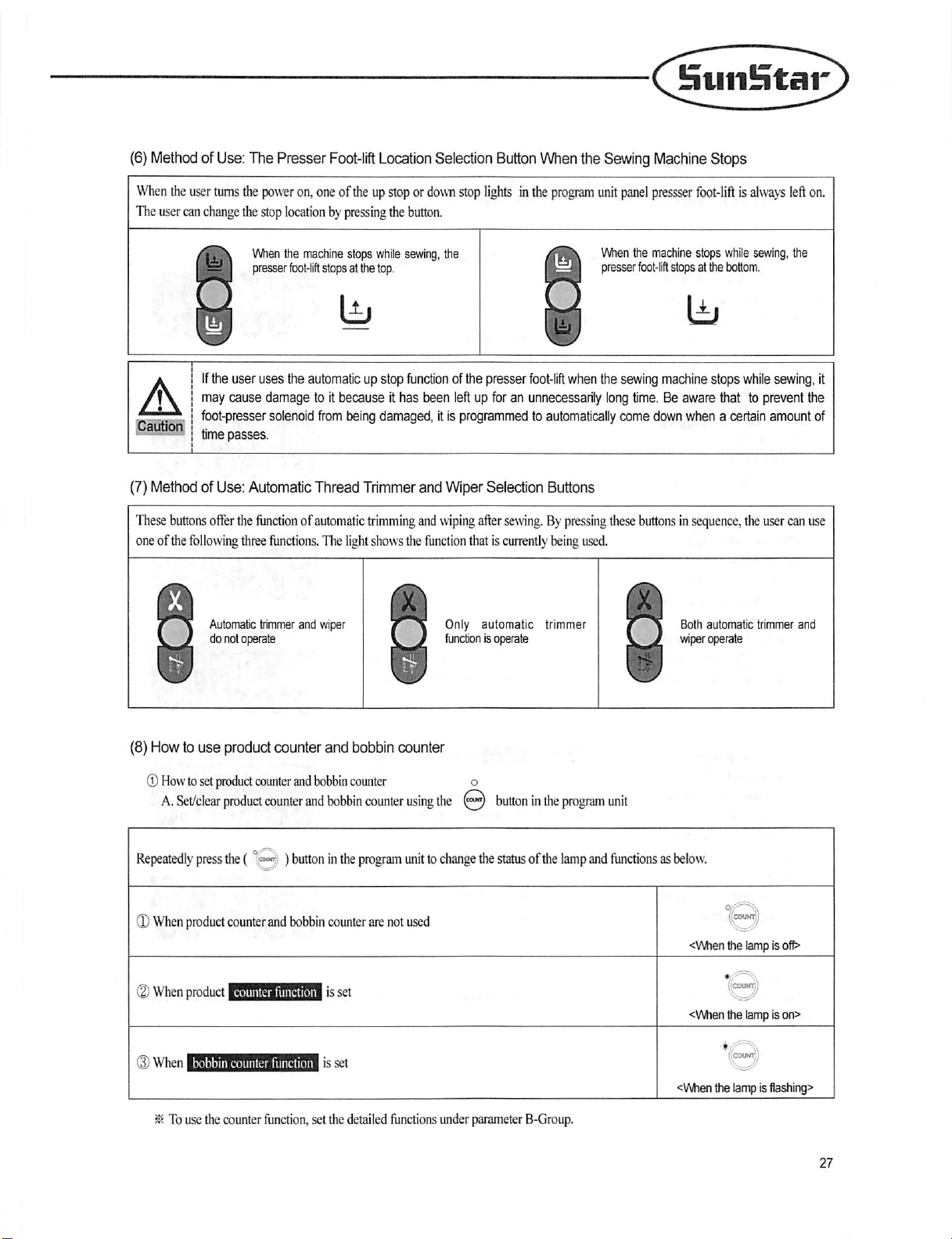

(6)

Method

When

the

The

user

A

;Cautiort

(7)

Method

These

buttons

one ofthe

of

Use:

The

user

turns

the

power

can

change

the

stop

When

presser

If

the

user

uses

may

cause

foot-presser

time

passes.

of

Use:

Automatic

offer

the

function

following

three

Presser

damage

solenoid

Foot-lift

on,

one

of tiie

location

by

pressing

the

machine

fbot-lifl

stops

the

automayo

to

it

because

from

Thread

of

automatic

functions.

The

light

Location

up

stop

the

stops

while

at

the

top.

up

stop

it

being

damaged,

Trimmer

trimming

shows

Selection

or

down

button.

sewing,

the

function

of

has

been

left

it

Is

and

Wiper

and

wiping

the

function

Button

stop

lights

in

the

the

presser

foot-lift

up

for

an

unnecessarily

programmed

Selection

after

that

to

sewing.

is

currently

When

the

Sewing

program

automatically

when

unit

panel

When

the

presser

foot-iifl

the

sewing

long

time.

come

Buttons

By

pressing

these

buttons

being

used.

Suiilntar

Machine

pressser

machine

machine

Be

down

Stops

foot-lift

is

always

stops

while

the

bottom.

stops

while

that

the

sewing,

to

stops

at

aware

when a certain

in

sequence,

left

on.

the

sewing,

prevent

the

amount

of

user

can

use

it

(8)

How

to

use

®

How

to

set

A.

Set/clear

Repeatedly

(D

(2)

When

product

When

product

press

Automatic

do

not

operate

trimmer

product

product

counter

product

counter

the

( )

counter

and

and

wiper

counter

and

and

bobbin

and

bobbin

button

in

bobbin

counter

bobbin

counter

counter

the

program

are

counter

using

unit

not

used

Only

function

the

to

change

automatic

is

operate

o

button

the

status ofthe

trimmer

in

the

lamp

program

unit

and

functions

Both

wiper

as

below.

automatic

operate

((coUNTyj

<\Mien

the

I'coutn,;

■■

<When

the

(icouffT;^

trimmer

lamp

lamp

is

off>

is

on>

and

^

To

use

the

counter

function,

set

the

detailed

functions

under

parameter

B-Group.

<\Mien

the

lamp

is

flashing>

Page 28

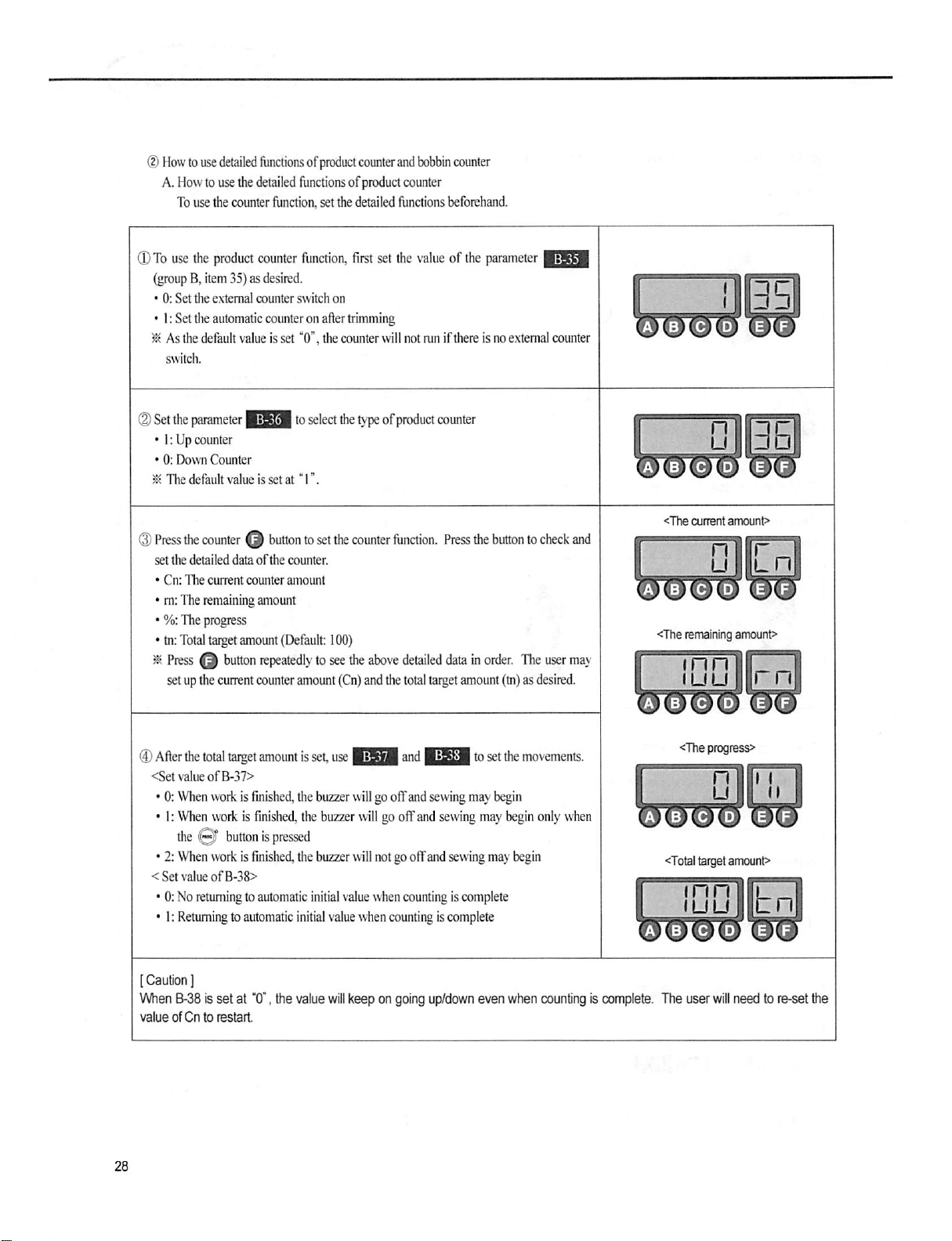

(D

How

to

use

detailed

A.

How

to

use

To

use

the

Q

To

use

the

product

(group

B,

item

•

0:

Set

the

external

•

1:

Set

the

automatic

^

As

the

default

switch.

(2)

Set

the

parameter

•

I;

Up

counter

•

0:

Down

Counter

^

The

default

(E)

Press

the

counter Q button

set

the

detailed

•

Cn:

The

current

•

m:

The

remaining

•

%:

The

progress

•

tn:

Total

target

^

Press ^ button

set

up

the

current

flinctioiis

the

detailed

counter

function,

counter

35)

as

desired.

counter

counter

value

is

set

value

is

set

at

data ofthe

amount

counter.

counter

amount

amount

(Default:

repeatedly

counter

of

product

counter

and

functions ofproduct

set

the

detailed

function,

switch

"0",

to

to

T.

to

amount

on

on

after

trimming

the

counter

sel

select

the

set

the

100)

to

see

the

(Cn)

first

counter

counter

functions

set

the

will

not

type

of

product

function.

above

detailed

and

the

total

bobbin

counter

beforehand.

value

of

the

run

If

there

counter

Press

data

in

target

amount

parameter

Is

the

order.

||^g[

no

external

counter

button

to

check

The

user

(tn)

as

desired.

and

may

<The

<The

oiirent

□1^

remaining

inn

luu

amount>

amount>

u^„\

llrn

®

Affer

the

total

<Set

value ofB-37>

•

0:

When

work

•

1:

When

work

the

Ql"

•

2:

When

work

<

Set

value ofB-38>

•

0:

No

returning

•

I:

Retuming

[

Caution

]

When

B-38

is

valueofCntoiestarl

target

is

is

button

is

to

to

automatic

set

at

amount

fmished,

the

finished,

is

pressed

finished,

the

automatic

initial

"0',

the

value

is

set,

buzzer

the

buzzer

buzzer

initial

use

will

will

value

value

will

keep

go

will

go

not

when

when

on

and

off

and

sewing

off

and

go

off

and

counting

counting

is

going

up/down

to

may

sewing

may

sewing

is

complete

complete

even

set

the

begin

may

begin

begin

when

movements.

only

when

counting

is

complete.

<The

progress>

"Qiri

<Total

taipet

inn

lUU

The

user

amount>

will

need

iir

lit

to

re-set

tfte

Page 29

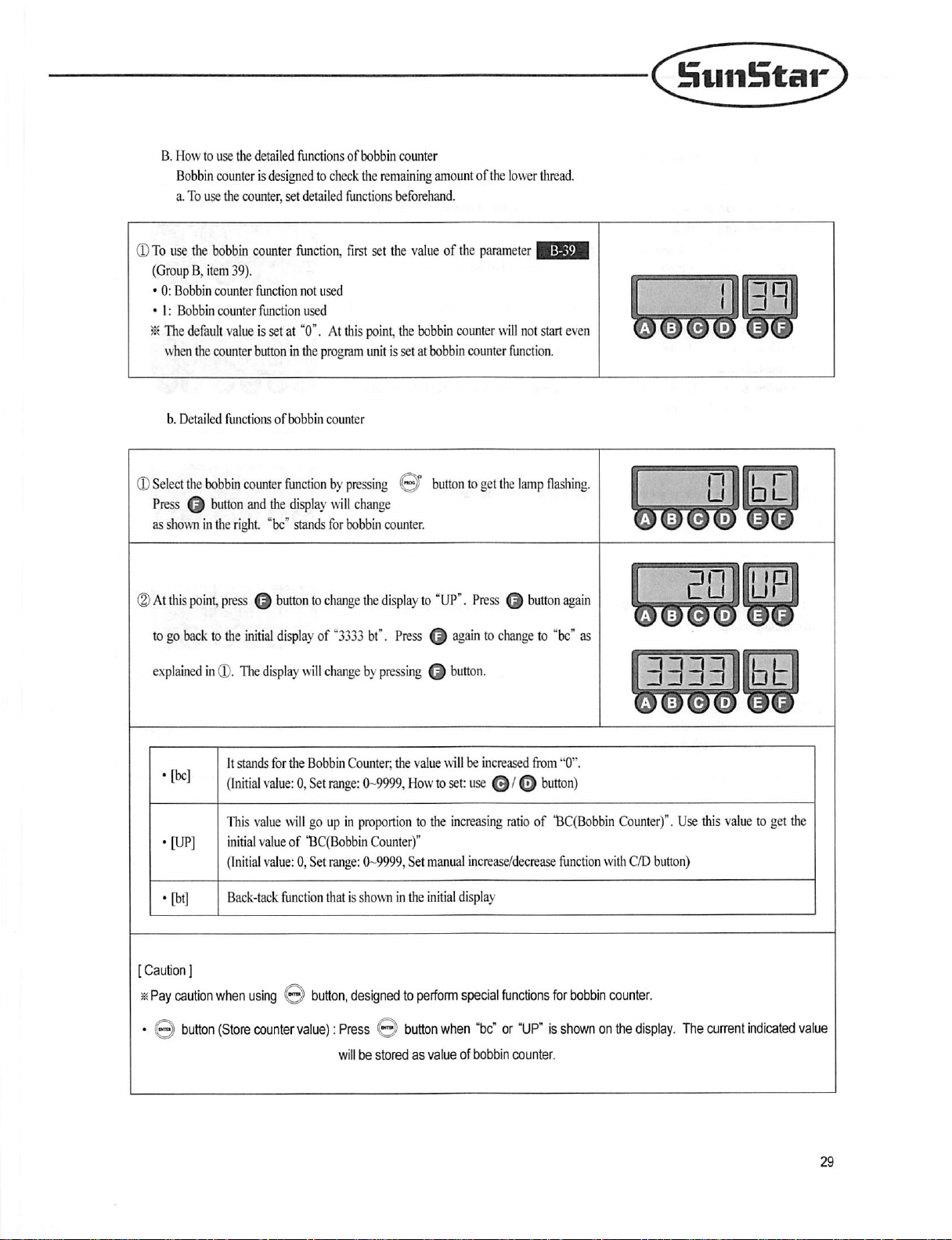

B.

How

to

use

Bobbin

counter

a.

To

use

the

0

To

use

the

bobbin

(Group

B,

item

•

0:

Bobbin

counter

•

1:

Bobbin

counter

^

The

default

value

when

the

counter

b.

Detailed

functions

©

Select

the

bobbin

Press ^ button

as

shown

in

the

the

detailed

functions

is

designed

counter,

set

counter

function,

39).

function

not

function

is

set

at

"0".

button

in

of

bobbin

counter

function

and

the

display

right

"be"

stands

of

to

check

detailed

functions

first

used

used

At

this

the

program

counter

by

pressing

will

change

for

bobbin

bobbin

counter

the

remaining

beforehand.

set

the

value

point,

the

bobbin

unit

is

set

at

@5"

counter.

amount ofthe

of

the

parameter

counter

will

bobbin

counter

but^n

to

get

the

lower

thread,

1^31

not

start

even

function.

lamp

flashing.

HuiiStar

(2)

At

this

point,

press ^ button

to go

back

to

the

initial

explained

in

©.

The

It

stands

(Initial

This

initial

(Initial

Back-tack

[

Caution

]

is

Pay

caution

when

• © button

(Store

to

change

the

display

display

of

'3333

bt".

Press Q again

display

will

change

by

pressing Q button.

for

the

Bobbin

Counter,

the

value:

0,

Set

range:

0-9999,

value

will

go

up

in

proportion

value

of

"BCfBobbin

value:

0,

Set

function

using © button,

counter

value):

Counter)"

range:

0-9999,

that

is

shown

in

designed

Press © button

will

be

stored

to

"UP".

Press

value

will

be

How

to

set:

use

to

the

increasing

Set

manual

increase/decrease

the

initial

display

to

perform

special

when

as

value

of

^button

to

change to

increased

GO

functions

"be"

or

bobbin

from

button)

ratio

of

"UP"

Is

counter.

"be"

'BC(Bobbin

for

again

as

"0".

Counter)".

function

with

bobbin

counter.

shown

on

the

3333

Use

this

value

C/D

button)

display.

The

current

I

bb

to

get

the

Indicated

value

Page 30

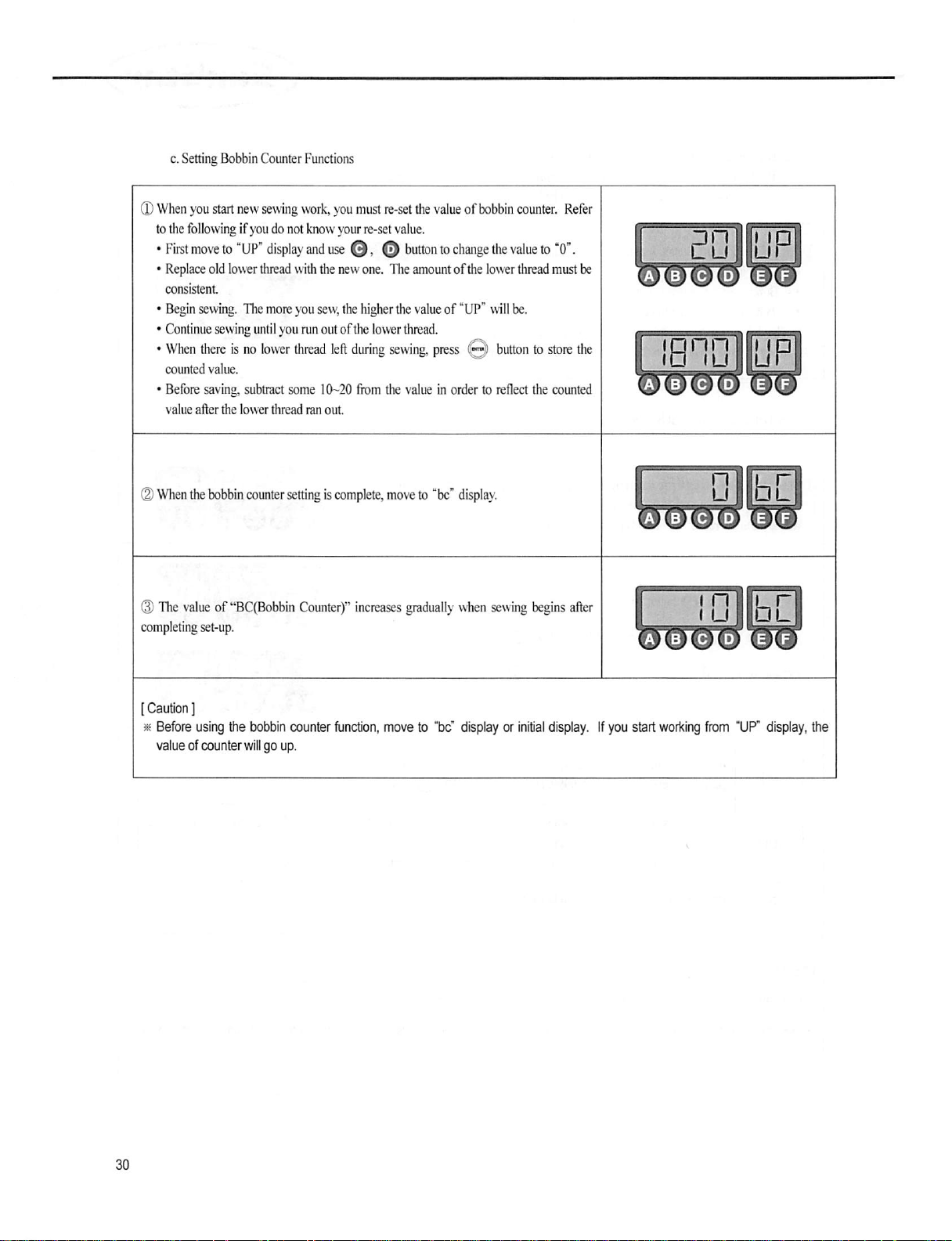

c.

Setting

0

When

you

start

to

the

following ifyou

•

First

move

•

Replace

old

consistent

•

Begin

sewing.

•

Continue

•

When

there

counted

value.

•

Before

saving,

value

after

(2)

When

the

bobbin

0

The

value

completing

set-up.

Bobbin

Counter

new

sewing

do

to

"UP"

display

lower

thread

The

more

sewing

until

you

is

no

lower

subtract

die

lower

thread

counter

of

"BC(Bobbin

Functions

work,

you

not

know

your

and

use

o o

with

the

new

you

sew,

the

run

out ofthe

thread

left

some

10-20 fiom

ran

out

setting

is

complete,

Counter)"

must

re-set

the

re-set

value.

button

one.

The

amount ofthe

higher

the

value

lower

thread.

during

sewing,

the

value

move

to

increases

gradually

value

of

bobbin

to

change

lower

of

"UP"

press

Q)

in

order

to

"be"

display.

when

counter.

the

value

to

"0".

thread

must

will

be.

button

to

store

reflect

the

counted

sewing

begins

Refer

be

the

after

innnirTp

- (ullu

OlET

UIK

[

Caution

^

Before

value

]

using

the

of

counter

bobbin

counter

will

go

up.

function,

move

to

"be"

display

or

initial

display.

If

you

start

working

from

"UP"

display,

the

Page 31

d.

When

(D

Replace

the

"BC(Bobbin

(2)

Take

note

value

and

thread

left.

®

The

value

and

the

buzzer

(D

When

sewing

•

Press

the

(AUTO

bobbin

counter

is

old

lower

thread

Counter)"

that

setting

of

Bobbin

stops

CLEAR/PRESET)

the

buzzer

value

Counter

will

go

after

button

will

go

will

narrows

off

and

counting

to

change

complete

with

the

up

gradually.

go

off

when

under

is

reached

the

monitor

is

complete,

the

value of"BC"

new

one

and

the

value

20.

This

at

setting

will

start

use

start

sewing,

goes

up,

and

is

to

warn

that tiiere

value,

the

stitching

blinking.

the

following

to

the

"0"

then

the

value

of

the

g^

between

that

is

little

lower

will

be

stopped

method

to

return.

automatically.

SuiiStar

[

Caution

]

«

To

use

the

bobbin

%

Use ^ button

iK

Wind

the

lower

differently

depending

counter

function,

to

change

the

thread

with

on

lower

first

set

B-Group

display

to

set/clear

consistency

thread

to

and

sewing

ensure ftie

39

to

"1."

the

value

of

bobbin

proper

use

conditions.

counter

during

of

bobbin

counter

sewing.

functions.

Counter

functions

may

work

Page 32

(9)

Method

A

Method

This

function

light

goes

on

8.

Method

®

Cautionary

•

Before

• Ifthe

able

off.

•

The

•

The

again,

be

erased

of

Use:

Pattern

to

Set

is

used

when

after

pressing

of

Use

words

when

using

the

user

presses

to

go

back

pattem

function

value

set

in

press

the

and

the

Up

the

Pattern

you

the

of

Pattem

using

pattem

the

pattem

to

normal

sewing

each

pattem

same

mode

user

Work

Selection

Woik

need

to

continuously

button,

you

can

Sewing

Specific

the

pattem

function,

must

finish

switch

sewing.

However,

speed

will

mode

again

to

reset

the

Button

FuncUon

work

on a sewing

use

the

pattem

sewing

Functions

function

the

trimming

twice

when

be

the

is

not

erased

use

it.

However,

information

work

he/she

if

the

pattem

programmed

when

if

again.

function.

and

is

not

using

mode

speed.

the

power

the

program

material.

If

turn

on

the

pattem

the

pattem

has

not

been

is

turned

is

initialized,

the

switch

light.

function,

completely

off

the

finished,

Therefore,

all

the

formerly

light

will

the

if

you

want

programmed

go

off

and

pattem

to

use

PATTERN

he/she

will

be

light

will

not

go

the