Page 1

OWNER / INSTALLER: For your safety this manual must be carefully and thoroughly read and

understood before installing, operating or servicing this heater.

!INSTALLER: This manual is the property of the owner. Please present this manual to the

owner when you leave the job site.

▲WARNING: Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury or death. Read the installation, operation and maintenance

instructions thoroughly before installing or servicing this equipment.

IF YOU SMELL GAS:

FOR YOUR SAFETY

! DO NOT try to light any appliance.

! DO NOT touch any electrical switch; DO NOT use any

telephone in your building.

! IMMEDIATELY call your gas supplier from a neighbor's

telephone. Follow the gas supplier's instructions. If you

cannot reach your gas supplier, call the fire department.

DO NOT store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

INSTALLATION AND OPERATION INSTRUCTIONS

SUNSTAR ECLIPSE

INFRARED RADIANT TUBE HEATER

Single and Two Stage Pull Through System (Negative Pressure)

Models: SIR25, SIR35, SIR45 – (N5/L5)

SIR35, SIR45 – (N7/L7)

!IMPORTANT: SAVE THIS MANUAL FOR FUTURE REFERENCE.

Post Office Box 36271 (28236) • 306 West Tremont Avenue (28203) • Charlotte, North Carolina

Phone (704) 372-3486 • Fax (704) 332-5843 • www.sunstarheaters.com • email: info@sunstarheaters.com

SUNSTAR HEATING PRODUCTS, INC.

Form 43471010

Dec 2017

Page 2

TABLE OF CONTENTS

For installations with mounting heights less than 10 feet, install the

heater at the highest possible height for the best radiant energy

distribution.

This product can expose you to chemicals including ceramic fibers, which

are known to the State of California to cause cancer, and carbon monoxide,

which is known to the State of California to cause birth defects or other

reproductive harm. For more information go to www.p65warnings.ca.gov.

SECTION DESCRIPTION PAGE

1.0) Safety ................................................................................................................................................... 2

2.0) Installer Responsibility ...................................................................................................................... 2

3.0) General Information ........................................................................................................................... 2

4.0) Minimum Clearances to Combustibles ........................................................................................... 4

5.0) Specifications...................................................................................................................................... 5

6.0) Packing List ......................................................................................................................................... 5

6.1) Accessory Packages .......................................................................................................................... 6

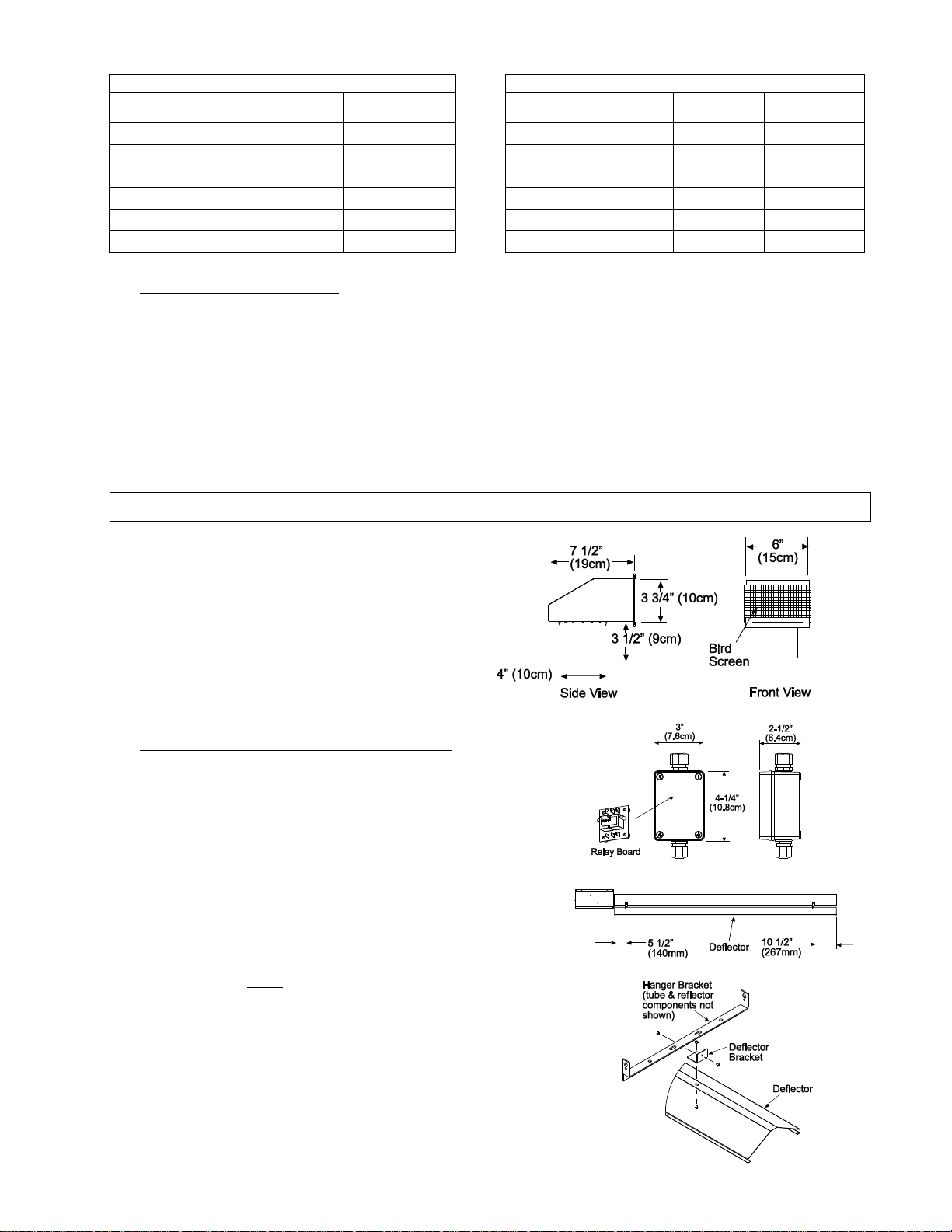

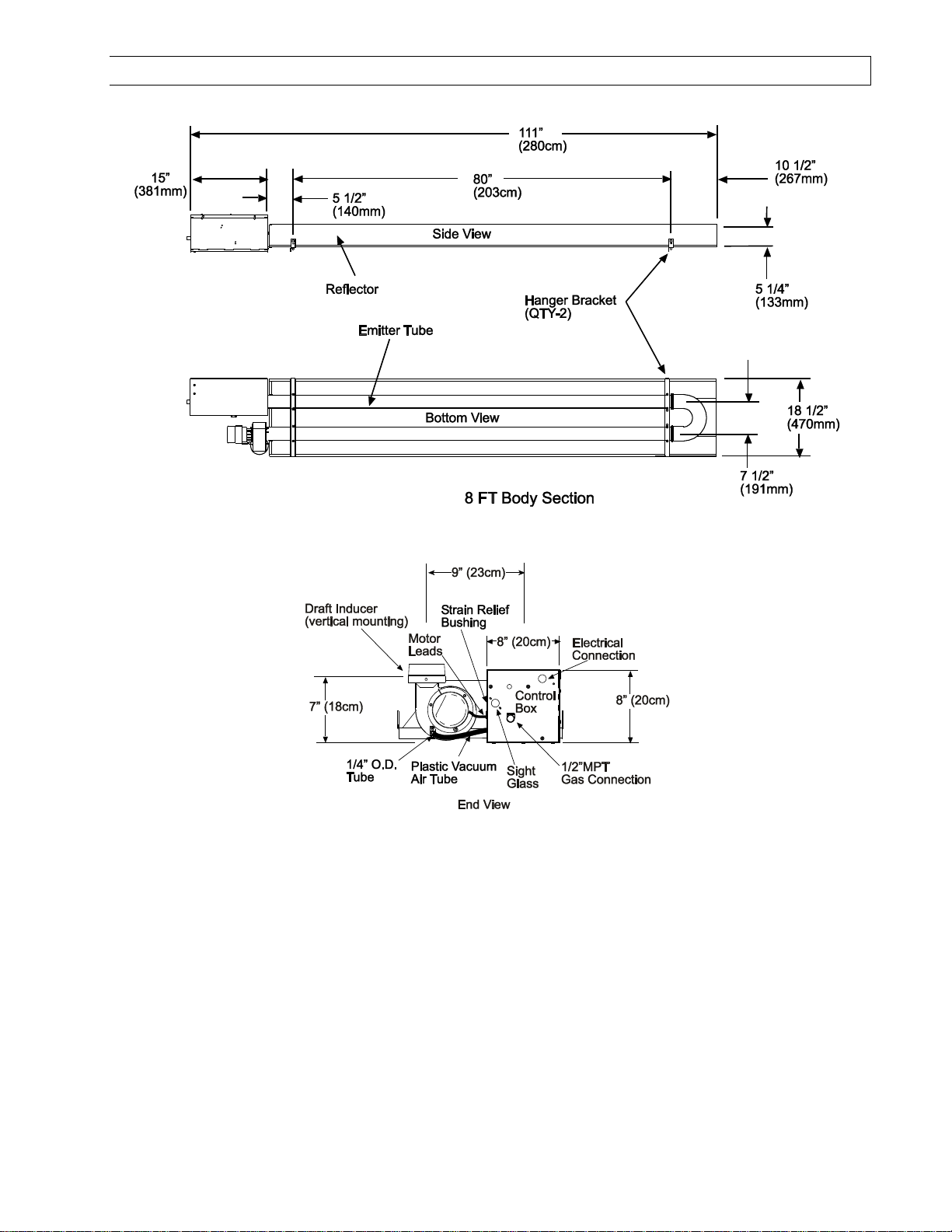

7.0) Dimensions – SIR Series ................................................................................................................... 7

8.0) Heater Assembly Overview ............................................................................................................... 8

9.0) Typical Suspension Methods ............................................................................................................ 9

10.0) Heater Assembly .............................................................................................................................. 10

11.0) Gas Connections and Regulations ................................................................................................. 13

12.0) Instructions for Pressure Test Gauge Connection ....................................................................... 15

13.0) Electrical Connections ..................................................................................................................... 17

13.1) Single Stage (N5/L5) – Internal and Thermostat Connections ................................................ 17

13.2) Two Stage (N7/L7) – Internal and Thermostat Connections .................................................... 20

14.0) Venting ............................................................................................................................................... 24

15.0) Air for Combustion ........................................................................................................................... 29

15.1) Direct Outside Air for Combustion ................................................................................................. 29

16.0) Lighting and Shutdown Instructions .............................................................................................. 31

17.0) Sequence of Operation – Single Stage (N5/L5) .......................................................................... 31

17.1) Sequence of Operation – Two Stage (N7/L7) .............................................................................. 31

18.0) Control Component Location .......................................................................................................... 33

19.0) Cleaning and Annual Maintenance ............................................................................................... 34

20.0) Troubleshooting Guide – Single Stage (N5/L5) .......................................................................... 35

20.1) Troubleshooting Guide – Two Stage (N7/L7) .............................................................................. 38

21.0) Replacing Parts ................................................................................................................................ 42

21.1) Removal of Spark Electrode ........................................................................................................... 42

21.2) Removing Main Burner and Gas Valve ......................................................................................... 43

21.3) Air Switch Pressure Check .............................................................................................................. 43

21.4) Ignition System Checks ................................................................................................................... 44

21.5) Motor and Blower Wheel Check ..................................................................................................... 45

22.0) Installation Data ............................................................................................................................... 45

23.0) Replacement Parts Guide ............................................................................................................... 46

24.0) Warnings Card .................................................................................................................................. 50

This heater complies with ANSI Z83.20 (current standard) and CSA 2.34. Copies of the National Fuel Gas Code (ANSI

Z223.1-latest edition) are available from the CSA at 8501 East Pleasant Valley Road, Cleveland, Ohio 44131 or 55 Scarsdale

Road, Don Mills, Ontario M3B 2R3. All NFPA codes are available from the National Fire Protection Association, Batterymarch

Park, Quincy, Massachusetts 02269.

Form 43471010

Dec 2017 -1-

Page 3

Warning instructions must be followed to prevent or avoid hazards which

may cause serious injury, property damage or death.

Caution instructions must be followed to prevent incorrect operation or

installation of the heater which may cause minor injury or property

damage.

1.0) SAFETY

This heater is a self-contained infrared radiant tube heater. Safety information required during installation and

operation of this heater is provided in this manual and the labels on the product . The installation, service and

maintenance of this heater must be performed by a contractor qualified in the installation and service of gas

fired heating equipment.

All personnel in contact with the heater must read and understand all safety information, instructions and labels

before operation. The following symbols will be used in this manual to indicate important safety information.

SAFETY REQUIREMENTS

The heater area must be kept clear and free from combustible materials, gasoline and other flammable

vapors and liquids.

This heater is designed for use with one type of gas (LPG or Natural). Make sure that the type of gas to be

supplied to this heater matches that shown on the heater rating plate.

DO NOT install this heater directly onto an LPG container or propane cylinder without directions from your

propane company. LPG containers (propane cylinders) must not be stored indoors or in the vicinity of any

gas-burning appliance.

Children and adults should be alerted to the hazards of high surface temperatures and should stay away to

avoid burns or clothing ignition.

Clothing or other flammable materials should not be hung from the heater or placed on or near the heater.

Young children should be carefully supervised when they are in the same space as the heater.

NEVER attempt to service the heater while it is plugged in, operating or hot. Any guard or other protective

device removed for servicing a heater must be replaced prior to operating the heater.

2.0) INSTALLER RESPONSIBILITY

The installer is responsible for the following:

The heater and venting, as well as electrical and gas supplies must be installed in accordance with these

installation instructions and any applicable codes and regulations.

Every heater shall be located with respect to building construction and other equipment so as to permit

access to the heater.

Each installer must follow the clearances to combustible materials for the heaters.

Install the heater so that the supports and hangers are correctly spaced in accordance with these

instructions. The heater must be supported by materials having a working load limit of at least 115lbs.

Supply the owner with a copy of these Installation and Operation Instructions.

Where unvented heaters are used, gravity or mechanical means shall be provided to supply and exhaust at

least 4 CFM per 1,000 Btu/hr input of installed heaters.

Never use the heater as a support for a ladder or other access equipment. Do not hang anything from the

heater.

Supply all installation materials necessary that are not included with the heater.

Check the nameplate to make sure that the burner is correct for the gas type in the building and the

installation altitude.

3.0) GENERAL INFORMATION

This heater is a self-contained infrared radiant tube heater for use in locations where flammable gases or vapors

are not generally present (as defined by OSHA acceptable limits) and is intended for space heating of garages,

vestibules and entry ways, workshops, enclosed patios, golf practice ranges and most industrial and com mercial

applications. DO NOT install this heater in residential bedrooms or bathrooms, mobile homes or recreational

vehicles.

-2- Dec 2017

Form 43471010

Page 4

INSTALLATION REQUIREMENTS

(FOR CANADA ONLY)

a. Installation of this appliance is to be in accordance with latest edition of CSA B149.1 (Natural Gas and

Propane Installation Code).

b. For installation in public garages or aircraft hangars, the minimum clearances from the bottom of the

infrared heater to the upper surface of the highest aircraft or vehicle shall be 50 percent greater than the

certified minimum clearance, but the clearance shall not be less than 8 feet.

The installation must conform to local building codes or in the absence of local codes, with the National Fuel Gas

Code ANSI Z223.1/NFPA54 or the Natural Gas and Propane Installation Code CSA B149.1. Heaters shall be

installed by a licensed contractor or licensed installer. Clearances to combustibles as outlined in this manual

should always be observed. In areas used for storage of combustible materials where they may be stacked

below the heater, NFPA54 requires that the installer must post signs that will “specify the maximum permissible

stacking height to maintain the required clearances from the heater to combustibles.”

Every heater shall be located with respect to building construction and other equipment so as to permit access

to the heater. Each installer shall use quality installation practices when locating the heater and must give

consideration to clearances to combustible materials, vehicles parked below, lights, overhead doors, storage

areas with stacked materials, sprinkler heads, gas and electrical lines and any other possible obstructions or

hazards. Consideration also must be given to service accessibility.

The heater, when installed in aircraft hangars and public garages, must be installed in accordance with

ANSI/NFPA 409-latest edition (Standard for Aircraft Hangars), ANSI/NFPA 88a-latest edition (Standard for

Parking Structures), and ANSI/NFPA 88b-latest edition (Standard for Repair Garages) with the following

clearances:

a. At least 10 feet above the upper surfaces of wings or engine enclosures of the highest aircraft that may be

housed in the hangar and at least 8 feet above the floor in shops, offices, and other sections of hangars

communicating with aircraft storage or service areas.

b. At least 8 feet above the floor in public garages. ▲WARNING: Minimum clearances marked on the heater

must be maintained from vehicles parked below the heater.

Although these heaters may be used in many applications other than space heating (e.g., process heating),

Sunstar will not recognize the warranty for any use other than space heating.

This heater is for Indoor Installation and Covered Patio Installation only and can be used in either Vented or

Unvented mode. The term Unvented actually means Indirect Vented. While the products of combustion are

expelled into the building, national codes require ventilation in the building to dilute these products of

combustion. This ventilation may be provided by gravity or mechanical means.

This heater is not an explosion proof heater. Where the possibility of exposure to volatile and low flash point

materials exists, it could result in property damage or death. This heater must not be installed in a spray booth

where the heater can operate during the spraying process. Consult your local fire marshal or insurance company.

High Altitude:

Appliances are supplied as standard for altitudes of O to 2,000 feet (0-610 m). High-altitude ratings are obtained

by a change in the orifice size. When ordered for high altitude installations, burners are supplied by the factory

ready for high altitude installation. Check the nameplate for altitude before proceeding with the installation. In

Canada the adjustment for altitude is made in accordance with Standard CGA 2.17, Gas-Fired Appliances for Use

at High Altitudes.

Form 43471010

Dec 2017 -3-

Page 5

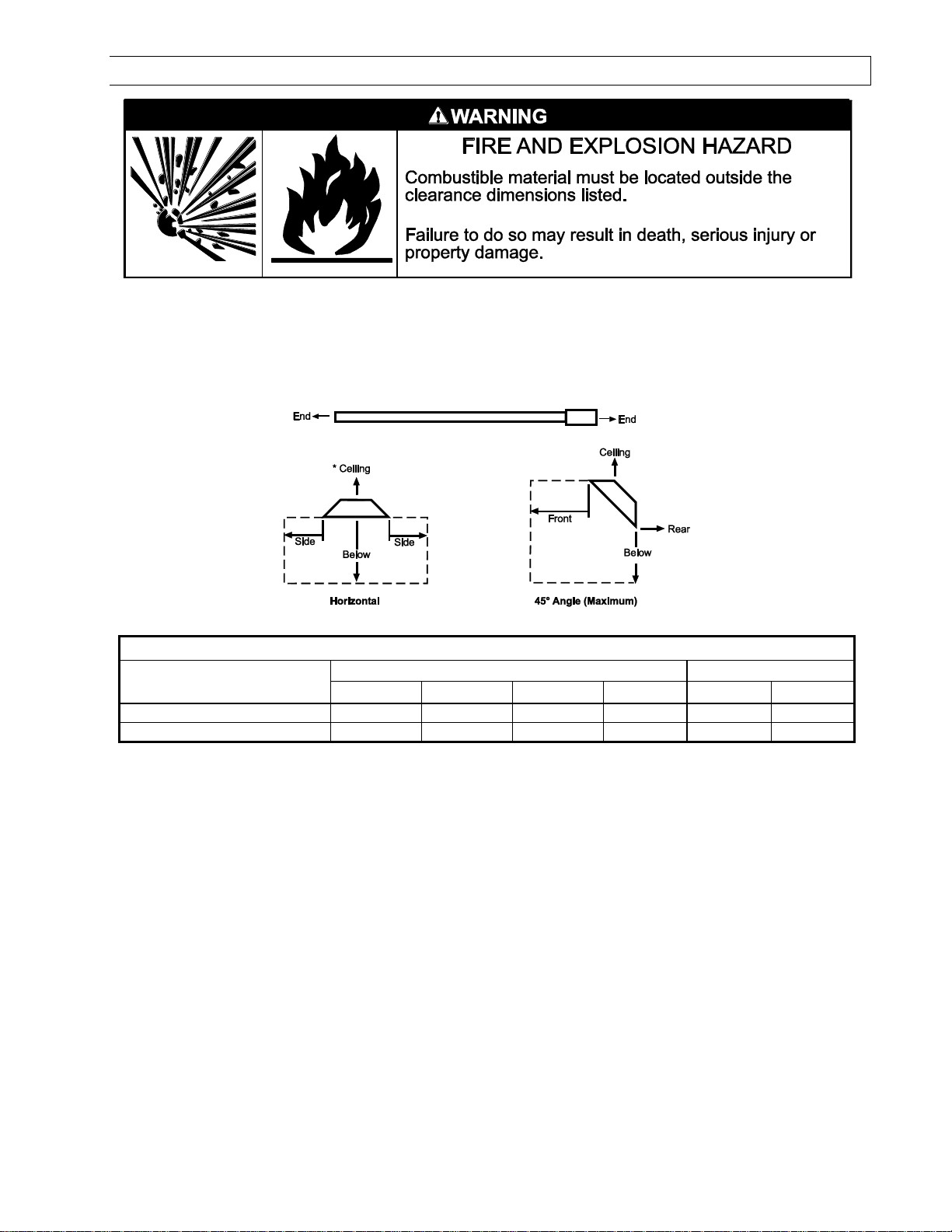

MINIMUM CLEARANCES TO COMBUSTIBLES

Model No.

Mounted Horizontally

Angle Mounted at 45º

Sides

Ceiling1

Below2

Ends

45º Front

45º Rear

SIR 25

8”

4”

41” *

8”

30”

4”

SIR 35, 45

12”

4”

57” **

8”

40”

4”

4.0) MINIMUM CLEARANCES TO COMBUSTIBLES

Minimum clearances to combustibles shall be measured from the outer surfaces as shown in the following

diagram. For reduced clearances below the heater, use the Deflector Kit (Part No. 43504010), described in

Section 6.1), and maintain the minimum clearances specified in the notes below. Follow the instructions

packaged with the kit for installation. Install the warnings card (ordered separately) and complete the blank

spaces using the clearances from combustibles table below. See Section 24 for a printed copy of the warnings

card.

* The clearance is 33” with deflector. ** The clearance is 42” with deflector / 30” side clearance with deflector.

1

The clearance is 12” when installed in an UNVENTED configuration in industrial and commercial installations.

2

IN CANADA, clearances below the heater are:

SIR25: 36” (27” with deflector);

SIR35/45: 48” (36” with deflector)

▲WARNING: Certain materials or objects, when stored under the heater, will be subjected to radiant heat and

could be seriously damaged. Observe the Minimum Clearances to Combustibles listed in the manual and on the

heater at all times.

NOTE:

1. The clearances specified above must be maintained to combustibles and other materials that may be

damaged by temperatures 90ºF above ambient temperature. Clearances to combustibles are posted on the

control box. In areas used for storage of combustible materials where they may be stacked below the heater,

NFPA54 requires that the installer must post signs that will “specify the maximum permissible stacking height

to maintain the required clearances from the heater to combustibles.” Space-Ray recommends posting these

signs adjacent to the heater thermostat or other suitable location that will provide enhanced visibility.

2. The stated clearance to combustibles represents a surface temperature of 90 ºF (32 ºC) above room

temperature. Building materials with a low heat tolerance (such as plastics, vinyle siding, canvas, tri-ply, etc.)

may be subject to degradation at lower temperatures. It is the installer’s responsibility to assure that adjacent

materials are protected from degradation.

-4- Dec 2017

Form 43471010

Page 6

5.0) SPECIFICATIONS

Model

No.

Btu/hr

High

Input

(2-stage)

Btu/hr

Low

Input

Heat

Exchanger

Length

Total

Heater

Length

Flue Restrictor

Plate

I.D. & Part #

Orifice Size

Minimum *

Mounting Height

Natural Gas

Propane Gas

@

Horizontal

@

45º Angle

16’

9’-3”

SIR25

25,000

n/a

7/8”

42741120

#42

(0.094)

#52

(0.064)

8’

8’

SIR35

35,000

25,000

1”

42741041

#35

(0.110)

1.75mm

(0.069)

8’

8’

SIR45

45,000

31,500

1-1/8”

42741031

1/8”

(0.125)

5/64”

(0.078)

8’

8’

Control Option

Suffix

Gas Type

Description

N5

Natural

Single Stage Gas Valve – Single Stage Input

L5

Propane

Single Stage Gas Valve – Single Stage Input

N7

Natural

Two Stage Gas Valve – Modulating Input – High/Low Fire

L7

Propane

Two Stage Gas Valve – Modulating Input – High/Low Fire

Type

Gas

Gas Pipe

Connection

Tube

Diameter

Flue

Connection

Fresh Air

Connection

Electrical

Supply

Current

Rating

Natural

or Propane

½” MPT

(Male)

3”

4” Round

4” Round

120 Volt, 60Hz,

1 Phase

2.6 Amp

Module Electrical Rating:

Ignition System (direct spark):

Fuse : 2 Amp 250V (for 24V Circuit) Input Power

Input-Control: 18-30VAC 60 Hz (class 2 transformer)

Flame Sensitivity: 0.7 uA (microamps) minimum

30 second pre-purge period

21 second trial for ignition period

Single trial for ignition (local sense)

Part Description QTY

Control Box Assembly .............................................................................................................................. 1

Draft Inducer Assembly (with 4” Starting Collar #40504020) .......................................................... 1

Flue Restrictor Plate (refer to 5.0) for I.D. & part number) ................................................................. 1

15” Plastic Vacuum Air Tube (#03988150) .......................................................................................... 1

Control Fastener Kit (#42787000) ........................................................................................................ 1

Containing: ¼ - 20 Locknuts (#02167010) ............................................................. 6

Tube Flange Gaskets (#4292150) ........................................................ 2

Gas Connector 5/8” OD x 36” (#30302360) US only ......................................................................... 1

Installation & Operation Instructions (#43471010) ........................................................................... 1

* MOUNT HEATERS AS HIGH AS POSSIBLE. Minimums are shown as a guideline for human comfort and uniform

energy distribution for complete building heating applications. Consult your SunStar representative for the

particulars of your installation requirements.

Model Identification:

6.0) PACKING LIST

A. Control/Draft Inducer Package

Form 43471010

Dec 2017 -5-

Page 7

1-STAGE CONTROLS

2-STAGE CONTROLS

MODEL NO.

PART NO.

GAS TYPE

MODEL NO.

PART NO.

GAS TYPE

SIR25-N5

43501030

NATURAL

SIR35-N7

43501090

NATURAL

SIR25-L5

43501040

PROPANE

SIR35-L7

43501100

PROPANE

SIR35-N5

43501050

NATURAL

SIR45-N7

43501110

NATURAL

SIR35-L5

43501060

PROPANE

SIR45-L7

43501120

PROPANE

SIR45-N5

43501070

NATURAL

SIR45-L5

43501080

PROPANE

C. Exhaust Hood Package, Part #42924000

Contains:

Exhaust Hood Assembly, #42925550……QTY–1

#8-18 x ½ Self-Drilling Screws, #02189030……QTY–2

D. Kit, 2-Stage Relay Board, Part #44195000

Contains:

Relay Board , #30709058……QTY–1

Enclosure, #30709059……QTY–1

Cord Connector – ½” , #30635040……QTY–2

E. Deflector Kit, Part #43504010

The Deflector Kit is available for use to reduce the

clearances to combustibles below the heater. Refer

to the Minimum Clearances to Combustibles Table in

Section 4.0) when using this Deflector Kit. Heater

must be mounted ONLY in the horizontal position

when using this kit.

Part Description QTY

#43468000, 8Ft. Body Package ........................................................................................................... 1

Containing: #43469000, Pre-assembled 8’ ALC steel tube assembly with reflectors .......... 1

#42762010, Control End Reflector ........................................................................... 1

#42761010, Foot End Reflector ................................................................................ 1

#02125130, #10-24x1/2 Screws .............................................................................. 4

#02189020, #10-16x1/2 Screws .............................................................................. 2

#02266010, Speed Clips ........................................................................................... 14

#42769010, Sliding Clamps ...................................................................................... 4

CONTROL/DRAFT INDUCER PACKAGE NUMBERS

B. Body Package Descriptions

6.1) ACCESSORY PACKAGES

-6- Dec 2017

Form 43471010

Page 8

7.0) DIMENSIONS – SIR SERIES

Form 43471010

Dec 2017 -7-

Page 9

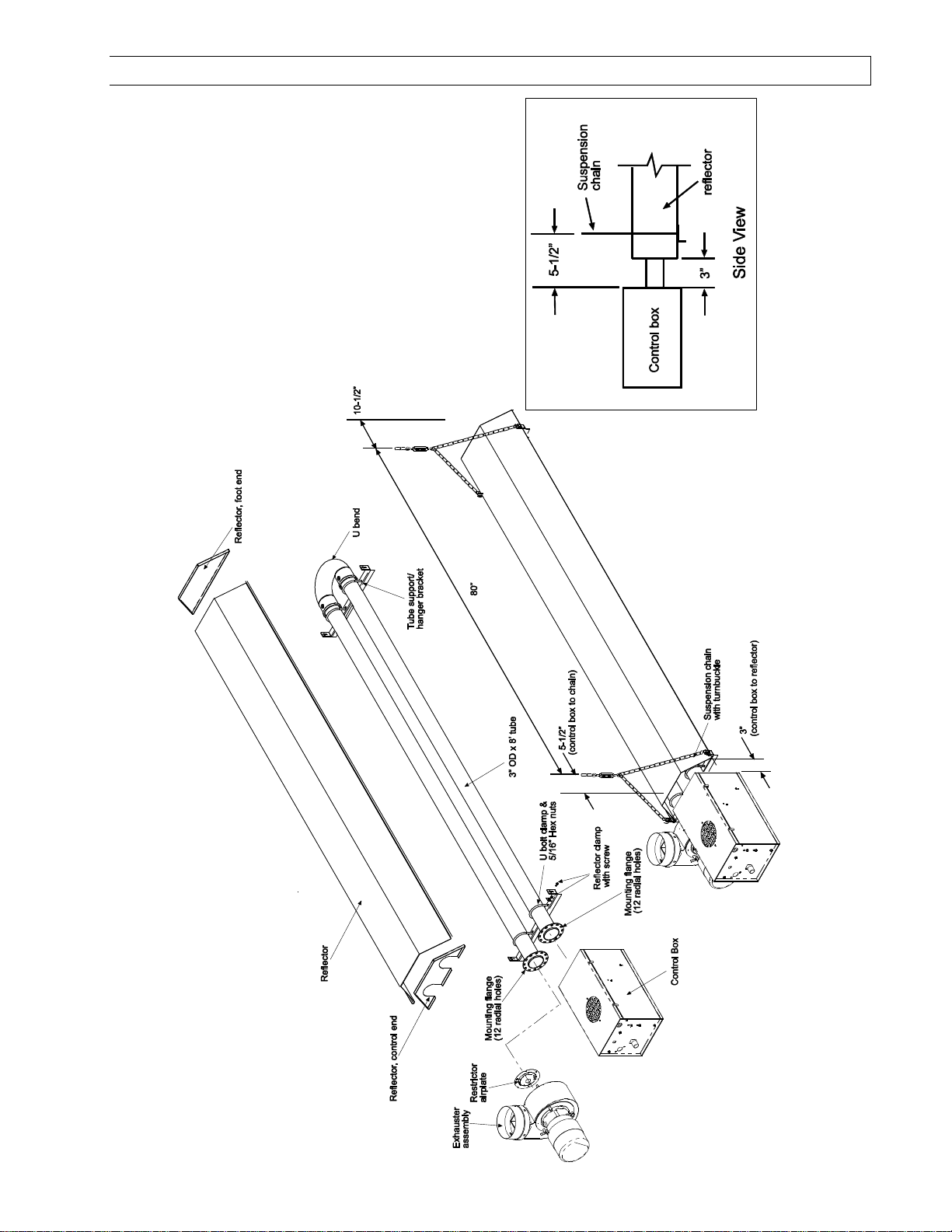

8.0) HEATER ASSEMBLY OVERVIEW

-8- Dec 2017

Form 43471010

Page 10

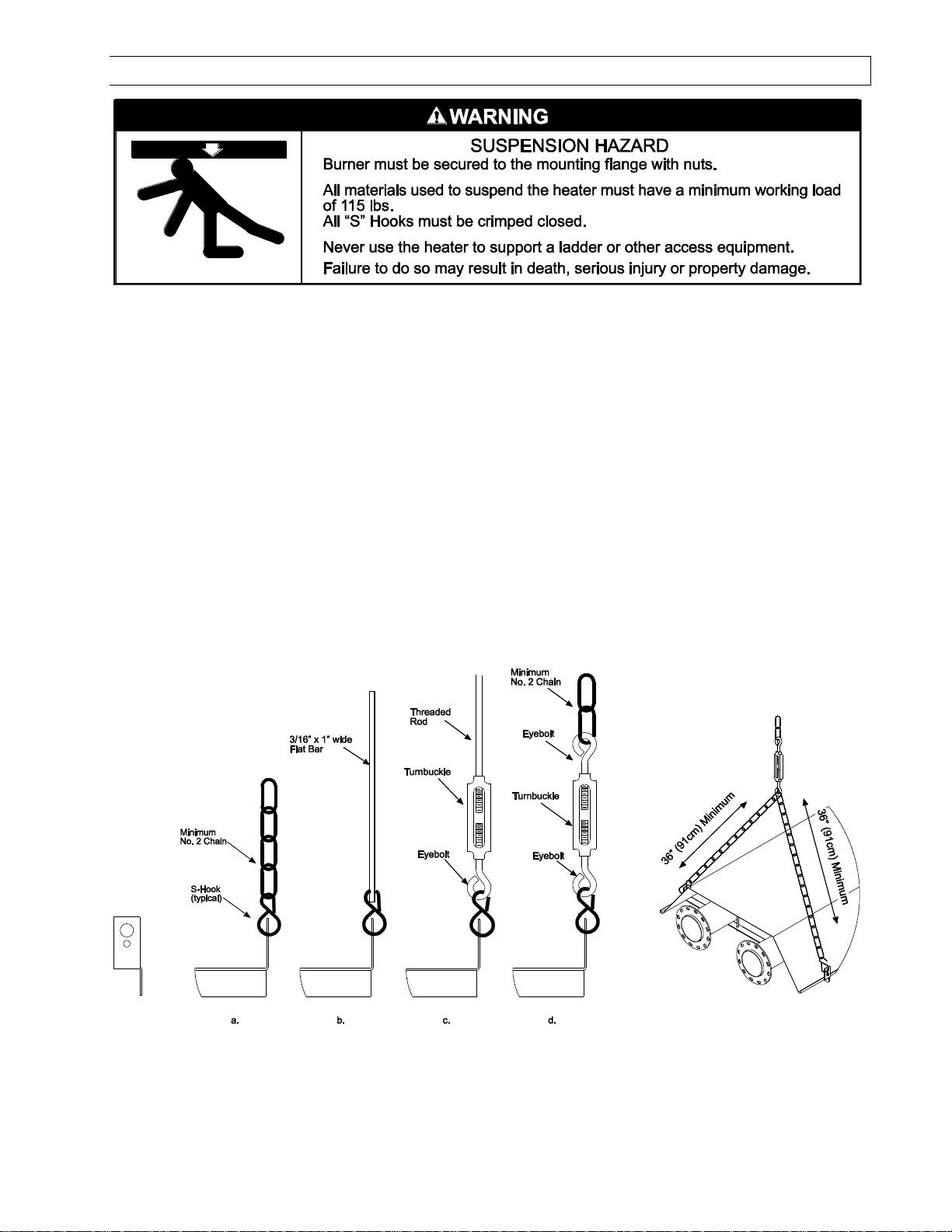

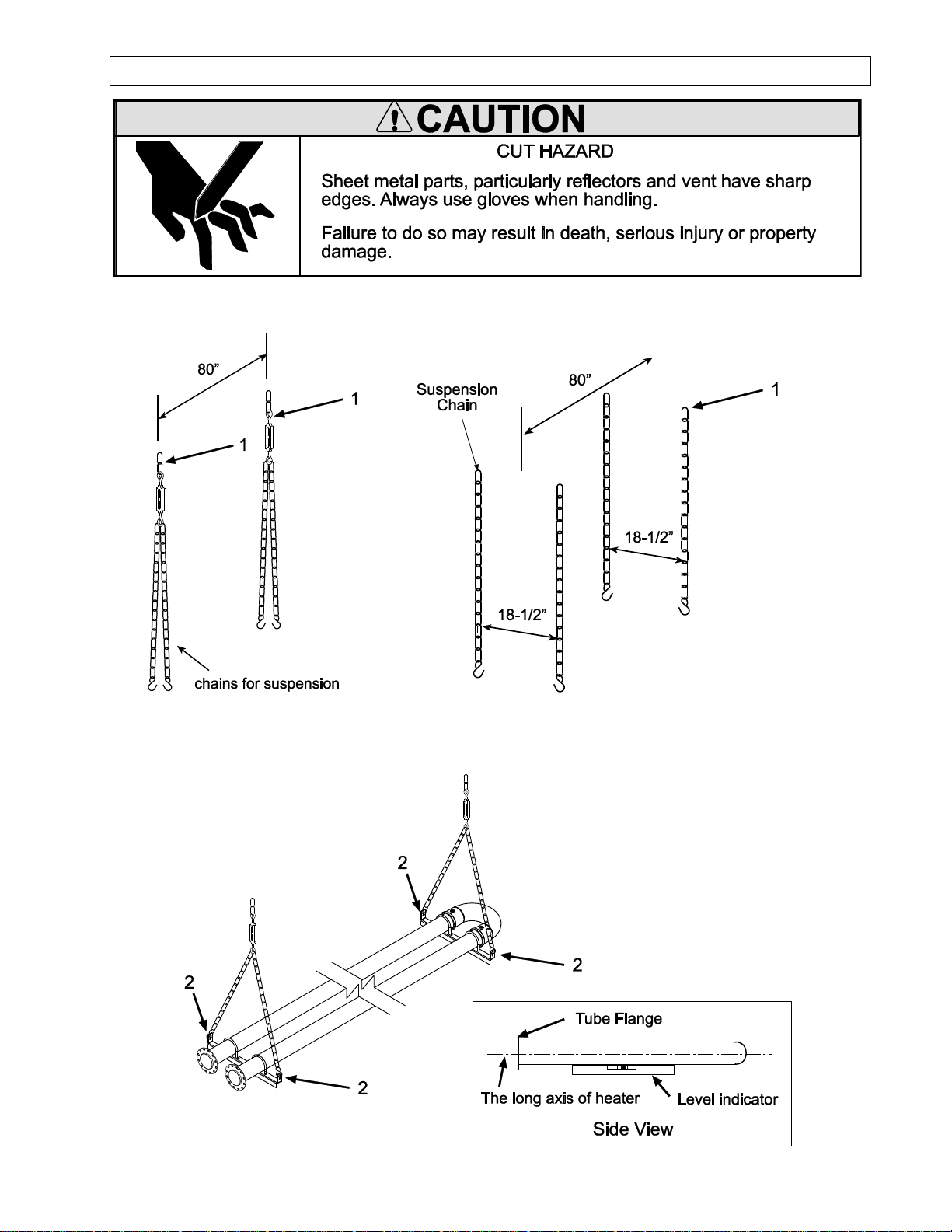

9.0) TYPICAL SUSPENSION METHODS

Various means of suspending the heater can be used. See the following drawings for typical examples.

1. Use only noncombustible materials for suspending hangers and brackets.

2. A minimum No. 2 chain with a working load limit of 115 lbs. is required.

3. Turnbuckles can be used with chains to allow leveling of the heater. All “S” hooks and eye bolts must be

manually crimped closed by the installer.

4. When using rigid means for heater suspension (rod, flat bar, etc.) provide sufficient lengths or swing join ts to

compensate for expansion. See Figures b and c.

5. Heaters subject to vibration must be provided with vibration isolating hangers.

6. Heaters must not be supported by gas or electric supply lines and must be suspended from a permanent

structure with adequate load capacity.

SunStar recommends that the tube sections be suspended using chains with turnbuckles. This will allow slight

adjustments after assembly and heater expansion/ contraction during operation.

If a “trapeze” method is used for tube support/hanger brackets (shown below), the minimum chain length for the

two connecting chains is 36” to minimize any vibration that might be generated by the draft inducer assembly. If

these chains must be less than 36”, then do not use the trapeze method and, instead, use individual chains on

each tube support/hanger bracket.

Form 43471010

Dec 2017 -9-

Page 11

Trapeze Method

Individual Suspension Method

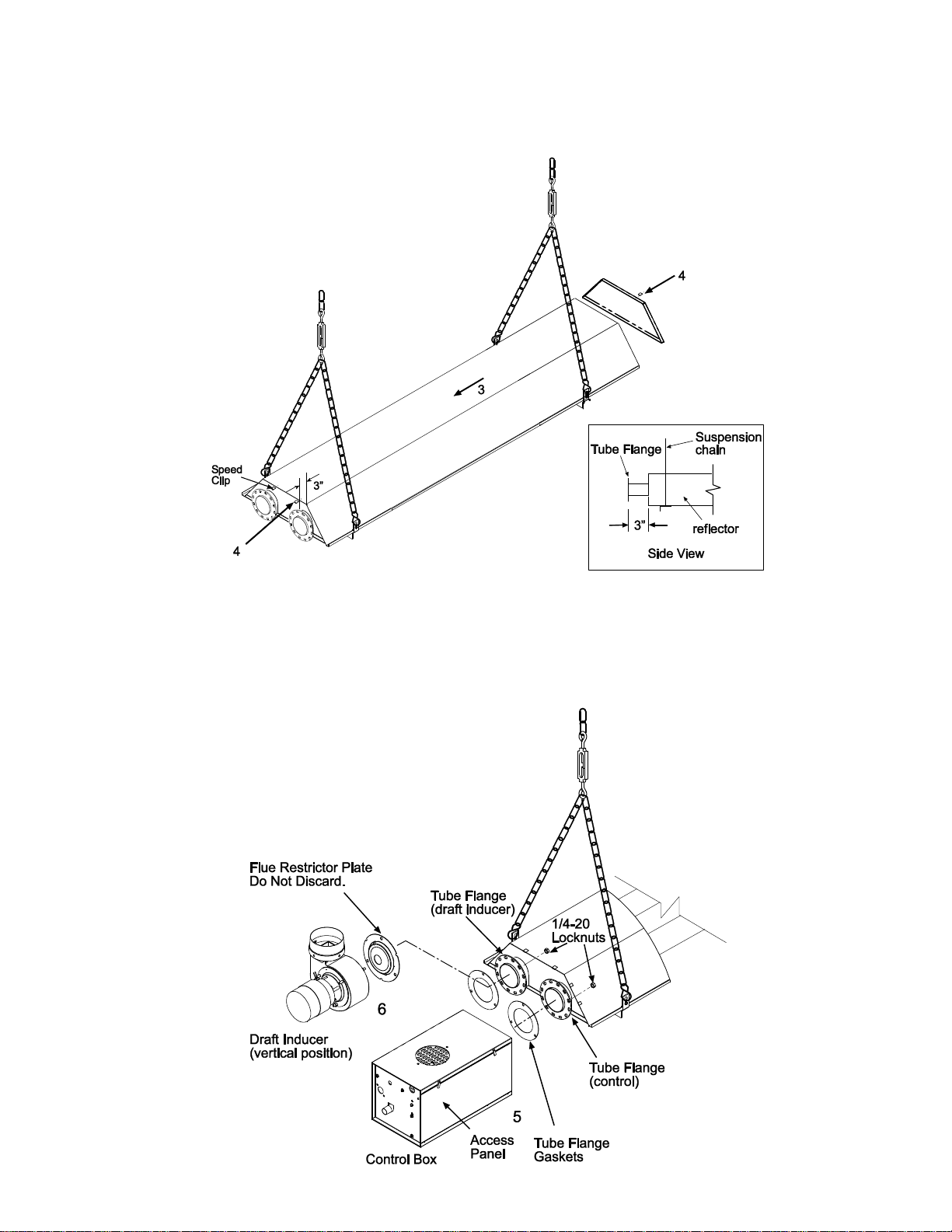

10.0) HEATER ASSEMBLY

During field assembly of the heater, the recommended procedure is as follows:

1. Install suspension (according to Section 7.0) using proper suspension method (see Section 9.0).

2. Lift the tube section and suspend it into place. When lifting, caution should be used to avoid damaging the

assembly. Make sure that the long axis of heater is level.

-10- Dec 2017

Form 43471010

Page 12

3. Assembly the reflector onto the tube section. Leave 3” space between the tube flange and the reflector for

later mounting of control box and draft inducer.

4. Place the flanges of the control end reflector flush with the end of the first reflector. Secure by sliding speed

clips onto reflector edges. Evenly space 6 speed clips on sides and top of reflectors to provide a snug fit.

Place foot end reflector on the opposite end of the reflector and secure as above.

5. Attach the control box and gaskets to the right-hand control tube flange and secure with (3) 1/4-20 locknuts.

The control box must be mounted with the perforated fresh air plate on top, facing the ceiling.

6. Attach the draft inducer assembly and gaskets to the left-hand draft inducer tube flange and secure with (3)

1/4-20 locknuts. A flue restrictor plate is attached to the draft inducer weld studs. DO NOT DISCARD

RESTRICTOR PLATE and make sure this remains in place while the draft inducer is being attached to the

heater body.

Form 43471010

Dec 2017 -11-

Page 13

The reflector clamps MUST be installed per reflector clamp

installation detail which allows the reflector to slide under the

clamp during heater operation.

Do not relocate the tube support/hanger bracket at the control box end of

the heater. This will increase the weight on the emitter tube and can result

in premature tube failure.

7. Slip the plastic vacuum air tube over the 1/4” O.D. aluminum tube end of the draft inducer and the air

switch probe in the control box. The air tube should be shortened to prevent a downward sag which could

allow condensation build-up in the tube.

8. Insert motor lead wires through the strain relief bushing of the control box and connect to L1 and L2 of

terminal block. Refer also to the wiring diagram in Section 13.0).

9. Mount the sliding reflector clamps (#42769010) per Reflector Clamp Installation (Detail “A”) on both tube

support/hanger brackets. Make sure the reflector can slide under the clamp during heater operation.

-12- Dec 2017

Form 43471010

Page 14

ANGLE MOUNTED HEATERS ONLY

10. The heater can be mounted horizontally or up to an angle of 45º maximum from horizontal. When the heater

is to be angle mounted adjacent to a sidewall, make sure the draft inducer assembly is on the lower side of

the heater so that the control box access panel is easily accessible. Make sure the long axis of heater is level.

11. Multiple draft inducer positions can also be used as shown in the diagrams. This allows for the desired

configuration of flue venting.

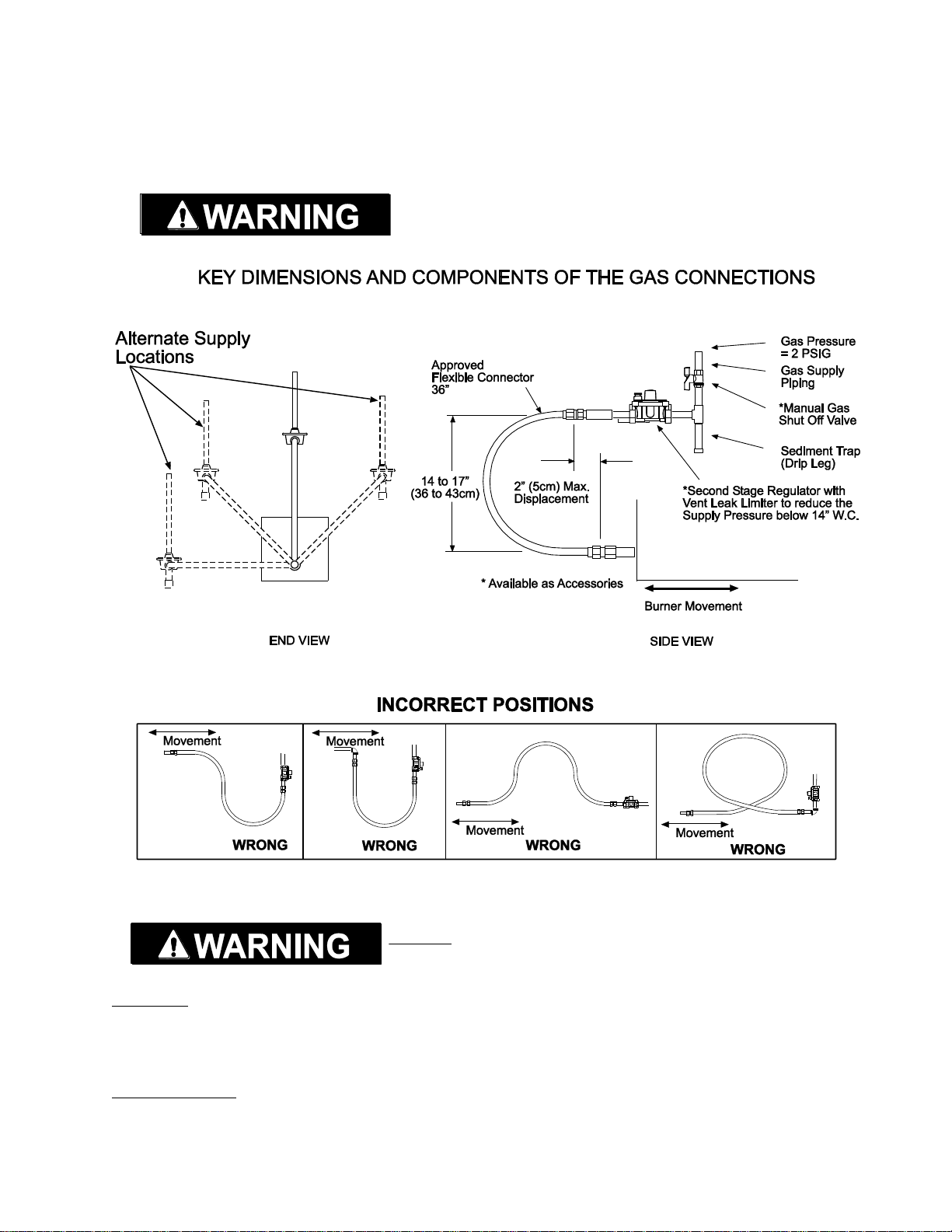

11.0) GAS CONNECTIONS AND REGULATIONS

IMPORTANT BEFORE CONNECTING THE GAS TO THE HEATER

1. Connect to the supply tank or manifold in accordance with the latest edition of National Fuel Gas Code (ANSI

Z223.1), and local building codes. Authorities having jurisdiction should be consulted before the installation

is made. (In Canada, refer to the latest edition of CSA Standard B149.1, Natural Gas and Propane

Installation Code.)

2. Check that the gas fuel on the burner rating plate matches the fuel for the application.

3. Check that the gas supply piping has the capacity for the total gas consumption of the heaters and any other

equipment connected to the line.

4. Check that the calculated supply pressure with all gas appliances and heaters operating will not drop below

the minimum supply pressure required for these heaters. Check inlet supply pressures on Section 12.0).

5. All gas supply lines must be located in accordance with the required clearances to combustibles from the

heater as listed on the clearances label of the heater and Section 4.0) of this manual.

6. Pipe joint compounds must be resistant to the action of liquefied petroleum gases.

7. Tube heaters will expand/contract during operation. Where local codes do not prohibit, a CSA or U.L.

approved flexible connector supplied with this heater is required for connections between the rigid piping

and the heater. A union should be installed before the control box inlet. An approved shut off valve should be

installed within 6 feet of the union.

8. The gas pipe, flexible hose and connections must be self supporting. The gas pipe work must not bear any of

the weight of the heater or any other suspended assembly.

9. This appliance is equipped with a step-opening, combination gas valve. The maximum supply pressure to the

appliance is 14” W.C. or 1/2 P.S.I. If the line pressure is more than the maximum supply pressure, then a

second stage regulator which corresponds to the supply pressure must be used.

Form 43471010

Dec 2017 -13-

Page 15

DO not use an open flame of any kind to test for leaks.

US ONLY: Connector MUST be installed in “” configuration. Use only

the 36” long connector that was furnished with this heater.

10. After all gas connections have been made, make sure the heater and all gas outlets are turned off before

the main gas supply is turned on slowly. Turn the gas supply pressure on and check for leaks. To check for

leaks, check by one of the methods listed in Appendix D of the National Fuel Gas Code.

11. If a 2nd stage regulator is used, the ball valve down stream in the supply line must be closed when purging

the gas lines to prevent gas seeping through it. If initial gas pressure is higher than 14” w.c. the redundant

combination gas valve is designed to lock out. Pressure build-up in the supply lines prior to the heater must

be released before proper heater operation.

US ONLY: A gas connector certified for use on a tubular type infrared heater per the standard for Connectors

for Gas Appliances, ANSI Z21.24/CSA 6.10 is supplied for installation in US only. The gas connector is 36” long

and 1/2” nominal ID, and must be installed as shown above, in one plane, and without sharp bends, kinks or

twists.

CANADA ONLY: A Type I hose connector should be used that is certified as being in compliance with the

Standard for Elastomeric Composite Hose and Hose Couplings for Conducting Propane and Natural Gas

(CAN/CGA 8.1) and is of length of 36+/- 6 in (90+/- 15 cm). The gas connector must be installed as shown

above, in one plane, and without sharp bends, kinks or twists.

-14- Dec 2017

Form 43471010

Page 16

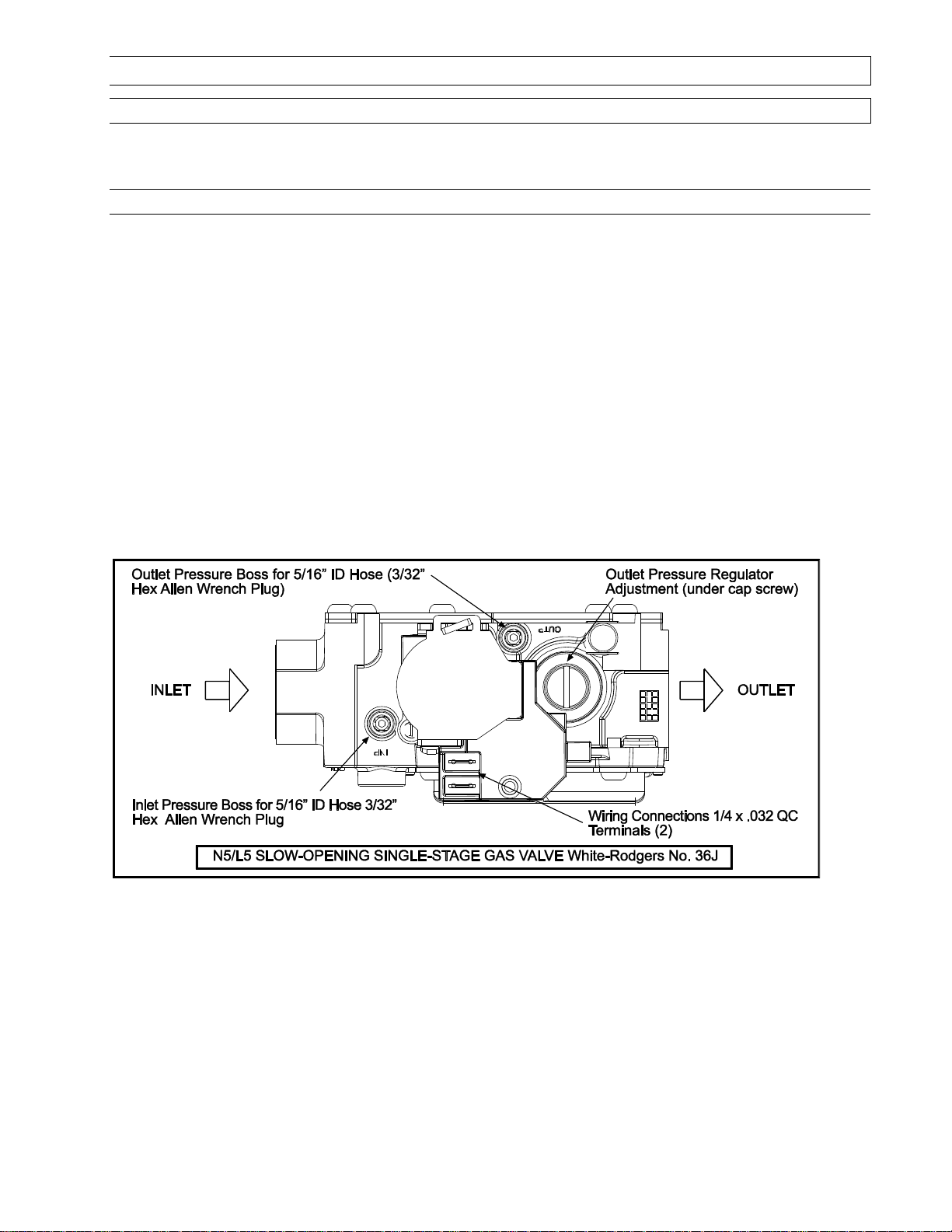

12.0) INSTRUCTIONS FOR PRESSURE TEST GAUGE CONNECTION

OUTLET GAS PRESSURE CHECK AND ADJUSTMENTS WHITE-RODGERS GAS VALVES

Gauges that measure pressure in pounds per square inch are not accurate enough to measure or set the

manifold pressure. All measurements MUST BE made when the heater and all other gas burning equipment that

are connectied to the gas supply system are operating at maximum capacity. The combination gas valve is

factory set and should not need adjustment. If gas pressure adjustment is required, follow the instructions:

1. Turn off all electrical power to the system to connect manometer hoses.

2. Turn the pressure test screw (3/32” Hex) in the center of the boss not more than one turn counterclockwise.

Attach a 5/16” hose and manometer over the tapered outlet pressure boss on the valve (see Figures 1 and

2 below). If regulator needs to be adjusted, see instructions below.

TO ADJUST REGULATOR (single stage gas valves):

1. Turn on power and energize the main gas valve. Remove regulator cover screw (see Figure 1 below). Turn

regulator adjustment screw clockwise to increase presure, or counterclockwise to decrease

pressure. Replace regulator cover screw and tighten securely.

DO NOT EXCEED THE PRESSURES SHOWN IN THE GAS PRESSURE TABLE.

2. After testing pressure and adjusting the regulator, turn off all electrical power to the system, remove

manometer hoses, turn outlet test screw (3/32” Hex) clockwise to seal pressure port. Tighten to 7 in lb

minimum. Turn on system power.

TO ADJUST REGULATOR (two stage gas valves):

1. Turn on power and energize main gas valve solenoid. Do not energize the HI solenoid.

2. Remove regulator cover screw from the low outlet pressure regulator (see Figure 2 below) and turn screw

clockwise to increase pressure, or counterclockwise to decrease pressure. Replace regulator

cover screw and tighten securely.

3. Energize main gas valve solenoid as well as the HI terminal.

4. Remove regulator cover screw from the high outlet pressure regulator (see Figure 2 below) and turn screw

clockwise to increase pressure, or counterclockwise to decrease pressure. Replace regulator

cover screw and tighten securely.

DO NOT EXCEED THE PRESSURES SHOWN IN THE GAS PRESSURE TABLE.

5. After testing pressure and adjusting the regulator, turn off all electrical power to the system, remove

manometer hoses, turn outlet test screw (3/32” Hex) clockwise to seal pressure port. Tighten to 7 in-lb

minimum. Turn on system power.

SUPPLY PRESSURE

1. The installer will provide a 1/8” N.P.T. tapped plug, accessible for test gauge connection immediately

upstream of the gas supply connection to the heater.

Form 43471010

Dec 2017 -15-

Page 17

*Minimum permissible gas supply pressure for purpose of input adjustment.

GAS PRESSURE TABLE

GAS TYPE

MANIFOLD PRESSURE

High Low (2-stage only)

SUPPLY PRESSURE

Minimum*

Maximum

Natural Gas

3.5” W.C.

1.4” W.C.

5” W.C.

14” W.C.

Propane Gas

10.0” W.C.

4.0” W.C.

11” W.C.

14” W.C.

-16- Dec 2017

Form 43471010

Page 18

13.0) ELECTRICAL CONNECTIONS

1. All electric wiring shall conform to the latest edition of the National Electrical Code (ANSI/NFPA No. 70), or

the code legally authorized in the locality where the installation is made.

2. The unit must be electrically grounded in accordance with the National Electrical Code (ANSI/NFPA No.

70-latest edition). In Canada, refer to current standard C22.1 Canadian Electrical Code Part 1.

3. The wiring providing power to the heater shall be connected to a permanently live electrical circuit, one that

is not controlled by a light switch.

4. The power supply to the unit should be protected with a fused disconnect switch or circuit breaker. A service

switch, as required by local codes, shall be located in the vicinity of the heater (check local codes for

allowable distances) and should be identified as Heater Service Switch. All electrical wiring must be located

in accordance with the required Clearances to Combustibles from the heater as listed on the nameplate on

the heater.

5. When connecting the supply circuit to the heater, wiring material having a minimum size of 14 AWG and a

temperature rating of at least 90C shall be used.

6. If any of the original wire as supplied with the appliance must be replaced, it must be replaced with wiring

material having a temperature rating of at least 105ºC. (18 Ga. CSA 600V Type TEW)

7. A replaceable 2-amp fuse (1-1/4” long) is located inside the control box.

13.1) SINGLE STAGE (N5/L5) – INTERNAL AND THERMOSTAT CONNECTIONS

Form 43471010

Dec 2017 -17-

Page 19

SINGLE STAGE CONTROLS - INTERNAL CONNECTION WIRING DIAGRAM

SINGLE STAGE CONTROLS - SCHEMATIC WIRING DIAGRAM

SINGLE STAGE CONTROLS - THERMOSTAT WIRING DIAGRAMS

A. LINE VOLTAGE (120V) THERMOSTAT CONNECTIONS – SINGLE HEATER PER THERMOSTAT

-18- Dec 2017

Form 43471010

Page 20

B. LINE VOLTAGE (120V) THERMOSTAT CONNECTIONS – MULTIPLE HEATERS PER THERMOSTAT

C. LOW VOLTAGE (24V) THERMOSTAT CONNECTIONS – SINGLE HEATER PER THERMOSTAT

Order 24V Relay Kit (Part No. 43274000) for Low Voltage (24V) thermostat connection.

D. LOW VOLTAGE (24V) THERMOSTAT CONNECTIONS – MULTIPLE HEATERS PER THERMOSTAT

Form 43471010

Dec 2017 -19-

Page 21

13.2) TWO STAGE (N7/L7) – INTERNAL AND THERMOSTAT CONNECTIONS

TWO STAGE CONTROLS - INTERNAL CONNECTION WIRING DIAGRAM

-20- Dec 2017

Form 43471010

Page 22

TWO STAGE CONTROLS - SCHEMATIC WIRING DIAGRAM

TWO STAGE CONTROLS - THERMOSTAT WIRING DIAGRAMS

A. LOW VOLTAGE (24V) THERMOSTAT CONNECTIONS – SINGLE HEATER PER THERMOSTAT

Form 43471010

Dec 2017 -21-

Page 23

B. LOW VOLTAGE (24V) THERMOSTAT CONNECTIONS – MULTIPLE HEATERS PER THERMOSTAT

C. MANUAL SWITCH CONNECTIONS – SINGLE HEATER OPERATION PER DUAL MANUAL SWITCH

-22- Dec 2017

Form 43471010

Page 24

D. MANUAL SWITCH CONNECTIONS – MULTIPLE HEATERS OPERATION PER DUAL MANUAL SWITCH

Form 43471010

Dec 2017 -23-

Page 25

Model

Heat

exchanger

length ft

Maximum vent length ft. (4” diameter)

Maximum Fresh air

intake length ft

(4” diameter)

Vertical Venting

Sidewall Venting

SIR 25

15

100

75

50

SIR 35

15

100

75

50

SIR 45

15

100

75

50

14.0) VENTING

This is a category lll appliance.

A. BASIC FLUE VENTING — Venting must comply with the latest edition of the National Fuel Gas Code (ANSI

Z223.1-latest edition) or the authority having jurisdiction. Other venting references are in the equipment

volume of the ASHRAE Handbook.

SINGLE HEATER VENTING (VERTICAL THROUGH THE ROOF)

Note: For residential applications, the heater must not be connected to a separate chimney, but must be

installed using the venting system specified below.

1. When venting the heater to outside of building through a roof, use single-wall metal pipe. This is to be

constructed of galvanized sheet metal or other approved noncombustible corrosion-resistant material as

allowed by state or local codes.

2. A vent passing through a combustible roof shall extend through an approved clearance roof thimble. Double-

wall, Type B vent must be used for the portion of the vent system which passes through the combustible roof.

An approved vent cap must be attached to end of the flue.

3. The maximum equivalent length of vent pipe should be carefully observed. A safety switch in the heater is

designed to shut the heater off before excessive flue restriction causes bad combustion. Refer to the Vent

Sizing Table for maximum vent lengths and vent pipe diameter.

Minimum Equivalent Length = 5 ft. of pipe

Maximum Equivalent Length = 75 ft. of pipe

Use the following correction factors to obtain the equivalent length:

Subtract 15 ft. if the run is horizontal.

Subtract 10 ft. for an approved vent cap.

Subtract 10 ft. for each elbow beyond 15 ft. from the heater.

Subtract 15 ft. for each elbow within 15 ft. of the heater.

4. Joints between sections of piping shall be fastened by sheet metal screws or other approved means and

should be sealed to prevent leakage of flue gas into building. For Residential Installations: The seams along

the length of the piping and the joints between sections of piping should be sealed to prevent a potential

leakage of flue gas into building. Use 100% RTV Silicone Rubber Adhesive sealant suitable for 500 ºF. For

Commercial and Industrial Installations: Use aluminum or Teflon tape suitable for 550ºF (3M Company

tapes 433 or 363) or RTV silicone sealant.

5. Avoid locating elbows in the first 5’ of vent pipe whenever possible. Limit to (2) 90 elbows. When vent pipe

is in a horizontal run, it must have 1/4 inch per foot rise.

6. All portions of the vent pipe shall be supported to prevent from sagging (6’ spacing is recommended).

7. When the vent pipe passes through areas where the ambient temperature is likely to induce condensation

of the flue gases, the vent pipe should be insulated and a condensation drain should be provided.

8. Minimum clearance for single-wall flue pipe to combustible material shall be 6 inches. This may be reduced

when the combustible material is protected as specified in the National Fuel Gas Code or the authority

having jurisdiction.

-24- Dec 2017

Form 43471010

Page 26

9. Single-wall metal pipe shall not originate in any unoccupied attic or concealed space and shall not pass

MINIMUM HEIGHT

FROM ROOF TO LOWEST DISCHARGE OPENING

Roof Pitch

H (min)

Flat to 6/12

1.0 Feet

Over 6/12 to 8/12

1.5 Feet

Over 8/12 to 10/12

2.5 Feet

Over 10/12 to 12/12

4.0 Feet

Over 12/12 to 16/12

6.0 Feet

Over 16/12 to 20/12

7.5 Feet

Over 20/12 to 21/12

8.0 Feet

through any attic, inside wall or concealed space, or through any floor. For the installation of a single -wall

metal pipe through an exterior combustible wall, refer to latest edition of the National Fuel Gas Code or the

authority having jurisdiction.

10. A venting system shall terminate at least 3 ft. above any forced air inlet located within 10 ft.

VENT TERMINATION (RESIDENTIAL INSTALLATIONS)

1. The vent terminal shall terminate above the roof line so that no discharge opening is less than 2 feet (0.6m)

horizontally from the roof surface. The lowest discharge opening will be no closer than the minimum height

specified in the following table. These minimum heights may be used provided the vent is not less than 8

feet (2.4m) from any vertical wall or similar obstruction.

2. All other gas vents shall terminate not less than 2 feet (0.6m) above the highest point where they pass

through the roof and at least 2 feet (0.6m) higher than any portion of a building located within 10 feet (3.1m)

as shown in the illustration below.

Form 43471010

Dec 2017 -25-

Page 27

SINGLE HEATER VENTING (HORIZONTAL THROUGH SIDEWALL)

This heater, when horizontally vented, must be installed with the approved venting system. When venting the

heater horizontally through a combustible outside sidewall, the same requirements listed previously for venting

Vertical Through The Roof apply except as follows:

1. For horizontal venting, the vent lengths may be as follows:

Minimum Equivalent Length = 5 ft. of pipe

Maximum Equivalent Length = 75 ft. of pipe

Use the following correction factors to obtain the equivalent length:

Subtract 15 ft. if the run is horizontal.

Subtract 10 ft. for an approved vent cap.

Subtract 10 ft. for each elbow beyond 15 ft. from the heater.

Subtract 15 ft. for each elbow within 15 ft. of the heater.

NOTE: To minimize problems associated with condensation in long horizontal runs, vent pipe can be insulated.

2. The horizontal venting system approved with this heater consists of the following components: one 4” Vent

Cap (Part #30297040), one 4” x 36” ‘B’ Vent Section (Part #30496360), and one 4” Wall Thimble (Part

#30500040). Please specify the appropriate number of 24-inch sections of single-wall vent pipe and elbows

when ordering: Vent Pipe (Part #30497240), 90º Elbows (Part #30498040), and 45º Elbows (Part

#30499040).

3. Avoid locating elbows in the first 5 feet of vent pipe whenever possible. Limit the quantity of 90º elbows to

two (2). When vent pipe is in a horizontal run, it must fall 1/4 inch per 10 foot down towards the vent

terminal. The heater must be installed level.

4. A minimum clearance of 18 inches must be maintained between the outside wall and vent cap (18”

clearance will provide stability under high wind conditions).

5. The horizontal venting system shall not terminate:

Less than 4 ft. (1.2m) below, 4 ft. (1.2m) horizontally from or 1 ft. (30cm) above any door, operable

window or gravity air inlet into any building. The bottom of the vent terminal shall be located at least 7 ft.

(2.1m) above grade or above snow accumulation level as determined by local codes.

Less than 3 ft. (0.9m) from a combustion air inlet.

Less than 3 ft. (0.9m) from any other building opening or any gas service regulator.

Less than 7 ft. (2.1m) above public walkways.

Directly over areas where condensate or vapor could create a nuisance or hazard or be harmful to the

operation of gas utility meters, regulators, relief valves, or other equipment. Building materials should

be protected from flue gases and condensate.

Less than 12” (0.30m) when directly below a combustible overhang.

6. In regions of the country where prevailing winds are consistently higher than 40 mph, it may be necessary to

terminate the vent system above the roof level.

MULTIPLE HEATER VENTING (CONNECTIONS INTO A COMMON VENT OR MANIFOLD)

Requirements for venting of multiple heaters are the same as described for SINGLE HEATER VENTING except as

follows:

1. The common vent size and total vent height is normally determined by the number of heaters per common

vent, length of horizontal connector runs, and connector rise. Connector lengths should be as short as

possible and have a minimum 1/4 inch per foot rise. Without regard to connector rise and total vent height

due to many possible venting configurations, the following should be observed:

Common vent pipe & vent connector diameter should be no less than that shown in the following Vent

Sizing Table.

-26- Dec 2017

Form 43471010

Page 28

A Y-connector must be used to the common vent.

If any heater connected to a common vent system for multiple

heaters is found inoperative, the heater should be disconnected from

the vent system and its entrance into the vent system capped.

2. Material for connectors and Y-connectors should be constructed of galvanized sheet metal or other approved

noncombustible corrosion resistant material as allowed by state or local codes. All common vent pipe

should be insulated flue pipe or double-wall, Type B vent.

3. Avoid unnecessary bends. Limit to two (2) 90º elbows.

4. The entire length of vent connector shall be readily accessible for inspection, cleaning and replacement.

5. Groups of heaters with a common vent must be controlled by a common thermostat.

Multiple Heater Vertical Venting Arrangement

Multiple Heater Horizontal Venting Arrangement

Form 43471010

Dec 2017 -27-

Page 29

VENT SIZING TABLE — Multiple Heater Venting

Number of Heaters

1 2 3 4 5

SIR 25

4”

4”

4”

5”

5”

SIR 35

4”

4”

5”

5”

6”

SIR 45

4”

4”

5”

5”

6”

COMMON VENT DIAMETER

(If a size is not available use the next larger size.)

Multiple Heater Venting (Connections into a Manifold)

THE ABOVE ILLUSTRATIONS AND TABLE OF VENT SIZES FOR COMMON VENTING OF MULTIPLE HEATERS ARE IN

ACCORDANCE WITH THE NATIONAL FUEL GAS CODE ANSI Z223.1-LATEST EDITION, NFPA 54-LATEST EDITION, EQUIPMENT

VOLUME OF 1988 ASHRAE HANDBOOK, CURRENT CAN/CGA-B149.1/2-M86 INSTALLATION CODE, AND AGA PUBLICATION

NO. 10M5.85 2.5-2 ON FUNDAMENTALS OF GAS APPLIANCE VENTING AND VENTILATION-REVISED BUT ARE NOT A PART OF

THE CSA CERTIFICATION.

B. INDIRECT VENTING (UNVENTED HEATERS) — COMMERCIAL AND INDUSTRIAL INSTALLATIONS ONLY — This

heater requires ventilation in the building to dilute the products of combustion and provide fresh air for

efficient combustion. Where unvented heaters are used, gravity or mechanical means shall be provided to

supply and exhaust at least 4 CFM per 1,000 Btu/hr input of installed heaters. Exhaust vents must be

located at the highest point above and in the vicinity of the heaters, and the inlet vents must be located

below the level of the heaters. An exhaust hood (Part #42924000) must be placed on the outlet collar of the

draft inducer or on the existing 4” starting collar when used unvented and must be mounted only in an

upright position and directed towards the reflector body as shown.

-28- Dec 2017

Form 43471010

Page 30

15.0) AIR FOR COMBUSTION

All vent terminations and Combustion Air Intake Terminations must

be at least 6” higher than anticipated snow depth.

If indoor combustion air is to be supplied for a tightly enclosed area, one square inch of free area opening shall

be provided below the heater for each 1,000 Btu/hr per hour of heater input. When outside air is used, the

opening below the heater shall be one square inch of free area for each 4,000 Btu/hr of heater input. In

contaminated atmospheres or high humidity areas, optional outside air for combustion is recommended.

Adequate clearances around the perforated fresh air plate must be maintained at all times. In larger open areas

of buildings, infiltration normally is adequate to provide air for combustion.

15.1) DIRECT OUTSIDE AIR FOR COMBUSTION

Outside combustion air should be supplied directly to the heater when the building is subject to negative

pressure, or when contaminants or high humidity are present in the building air. These contaminants include

paints, solvents, corrosive vapors or any other foreign particles that may cause damage to the heater or result in

poor combustion.

Outside combustion air can be brought directly to the heater by a 4” diameter duct less than 50 ft. long or

equivalent (see table in Section 14.0) based on selected model and heat exchanger lengths). This is attached to

the 4” diameter starting collar. The starting collar is fitted to the top of the control box cabinet after first

removing and discarding the perforated cover. An approved vent cap must be placed directly on the end of the

outside combustion air inlet pipe. The combustion air inlet should be not less than 3 ft. (0.9m), either vertically

or horizontally, from the flue vent termination. The air intake terminal must be located not less than 1 ft. (30cm)

above grade. It is good installation practice to supply combustion air from the same pressure zone as the vent

outlet. Avoid bringing combustion air to the heater from an attic space. There is no guarantee that adequate

combustion air will be supplied.

In colder climates, where necessary, insulate the outside combustion air duct. Avoid locating the outside

combustion air duct directly above the control box. Provide a capped cleanout T as necessary. In high humidity

applications, the control box should be sealed with silicone sealer.

In multiple heater applications, the combustion air intake may be ducted individually or common ducted in the

same configuration as shown for venting in Section 14.0). For combustion air intake duct sizing, please refer to

the Vent Sizing Table and use the diameter indicated, based on the number of heaters per duct.

Form 43471010

Dec 2017 -29-

Page 31

-30- Dec 2017

Form 43471010

Page 32

16.0) LIGHTING AND SHUTDOWN INSTRUCTIONS

1. Turn on the gas and electrical supply.

2. Set the thermostat to call for heat. The blower motor will energize.

3. Ignition should occur after the 30-second air pre-purge.

4. If ignition fails, the unit will spark for approximately 21 seconds and go into safety lockout. Turn the

thermostat (power) off for 60 seconds to take the system out of lockout.

5. If the heater does not light, manually reset the thermostat or shut off power completely for 5 minutes before

attempting to relight.

6. To permanently shut down the heater, turn off the gas and electrical supply.

NOTE: The lighting and shutdown instructions are also shown on the permanent nameplate label attached to the

heater control box.

17.0) SEQUENCE OF OPERATION – SINGLE STAGE (N5/L5)

The chart below shows the sequence of operation for the normal operating cycle.

If the flame is not sensed during sequence T3 then the burner will automatically begin ignition sequence T2. If

the flame is not re-established the heater will go to lockout.

Form 43471010

Dec 2017 -31-

Page 33

17.1) SEQUENCE OF OPERATION – TWO STAGE (N7/L7)

The chart below shows the sequence of operation for the normal operating cycle for a two stage heater (N7/L7).

.If the flame is not sensed during sequence T3 or T4, then the burner will automatically begin ignition as in

sequence T2. If the flame is not re-established the heater will go to lockout.

-32- Dec 2017

Form 43471010

Page 34

18.0) CONTROL COMPONENT LOCATION

NOTE: Access panel only opens to 90.

Form 43471010

Dec 2017 -33-

Page 35

19.0) CLEANING AND ANNUAL MAINTENANCE

This heater must be cleaned and serviced annually by a qualified contractor before the start of each heating

season and at any time excessive accumulation of dust and dirt is observed. Maximum heating efficiency and

clean combustion will be maintained by keeping the heater clean. To clean the heater, turn off all electrical and

gas supply to the heater.

The contractor shall check the following during periodic maintenance.

Clearances to combustibles: Check that clearances are being maintained. Make sure there are no

flammable objects, liquids or vapors near the heater. See also Section 4.0).

Reflectors: Reflectors should be kept clean, at a minimum blow off the reflectors. (Dirty reflectors may

reduce heat output).

Heat exchanger tubes: Inspect the heat exchanger tubes to make sure they are not cracked, sagging or

showing signs of fatigue.

Combustion air intake: Disconnect combustion air intake from the control box and inspect internally using a

flashlight to make sure no foreign material has collected in the tubes and that there is no obstruction

around the air intake openings. Clean any foreign materials. Inspect any joints to make sure they are

completely sealed. See also Section 15.0).

Venting System: Disconnect vent pipe and inspect internally using a flashlight to make sure no foreign

material has collected in the pipes. Check the external vent cap and make sure that there is no obstruction

around the exhaust openings. Clean any foreign materials. Inspect any joints to make sure they are

completely sealed. See also Section 14.0).

Gas lines: Make sure that the gas lines are not leaking. Check the gas connection to the heater for any signs

of damage, fatigue or corrosion. If there are any signs of damage to the gas connection or leaks found in the

gas piping, immediately stop using the heater until the gas pipe and connections have been repaired or

replaced. Check that the gas lines are not bearing the weight of the heater. See also Section 11.0).

Control Box: In order to extend the longevity of the heater, the heat exchanger tube and the burner must be

level. Check that the control box is level. Clean the access panel, and the inside of the control box.

Blower wheel and housing: Check that the blower wheel spins freely, blow out any dust or dirt with

compressed air. A dirty wheel can reduce the volume of air pulled and can result in premature tube failure.

Electrode condition: Visually check that the electrode gap is maintained at 3/16” and that the tips of the

flame sensor and spark electrode are free from deposits. Clean off any deposits. Check that the electrode

ceramic is free from cracks. CAUTION: The ceramic portion of the electrode is very fragile so any cleaning or

adjustments must be done with care. See Section 21.1).

Suspension system: Check that the suspension system is holding the heater level. Make sure that the heater

is hanging securely, look for any evidence where the heater may have been hit accidentally and tighten any

loose hanging points. Check that S hooks are closed. Check that there is no evidence of wear on the chain at

the connection to the heater and at the ceiling.

Main Burner and Orifice: Check the Main burner and orifice; remove any dirt or debris including spider webs.

See Section 21.1).

-34- Dec 2017

Form 43471010

Page 36

20.0) TROUBLESHOOTING GUIDE – SINGLE STAGE (N5/L5)

Form 43471010

Dec 2017 -35-

Page 37

TROUBLESHOOTING GUIDE – SINGLE STAGE (CONTINUED)

-36- Dec 2017

Form 43471010

Page 38

TROUBLESHOOTING GUIDE – SINGLE STAGE (CONTINUED)

Form 43471010

Dec 2017 -37-

Page 39

20.1) TROUBLESHOOTING GUIDE – TWO STAGE (N7/L7)

-38- Dec 2017

Form 43471010

Page 40

TROUBLESHOOTING GUIDE – TWO STAGE (CONTINUED)

Form 43471010

Dec 2017 -39-

Page 41

TROUBLESHOOTING GUIDE – TWO STAGE (CONTINUED)

-40- Dec 2017

Form 43471010

Page 42

TROUBLESHOOTING GUIDE – TWO STAGE (CONTINUED)

Form 43471010

Dec 2017 -41-

Page 43

21.0) REPLACING PARTS

Only use genuine Space-Ray replacement parts. Parts are available from the factory for replacement by a

licensed person. Refer to the Replacement Parts Guide in Section 23.0) for all replacement parts.

21.1) REMOVAL OF SPARK ELECTRODE

1. Disconnect electrical supply and open access panel.

2. Pull out the ignition cable hooked to spark electrode.

3. Remove two mounting screws.

4. Take out the spark electrode. Check that the spark gap is 3/16”.

5. Check spark electrode. Spark electrode should be clean and free from debris.

6. Check ceramic on the spark electrode. It should be free from cracks.

-42- Dec 2017

Form 43471010

Page 44

21.2) REMOVING MAIN BURNER AND GAS VALVE

The main burner can be inspected without removing the burner housing from the heat exchanger tube.

1. Disconnect electrical supply and gas connection at the restrainer nipple.

2. Open the access panel and disconnect the wires from gas valve.

3. Remove the burner clamp and screws.

4. Remove the burner and gas valve assembly from the cabinet.

5. Unscrew the burner from the manifold.

6. Check the orifice. If the gas valve is to be replaced, the pipe joint compounds must be resistant to the action

of liquefied petroleum gases.

21.3) AIR SWITCH PRESSURE CHECK

1. Open hinged access panel.

2. Add tubing to connect the air switch with the connector tee and the existing tubing.

3. Connect plastic tubing of a digital or inclined water manometer with a 0-2” scale onto the connector tees.

4. Turn heater on and wait until blower motor is activated.

5. Observe air pressure from manometer. This should be higher than the set point 0.16” w.c. for correct

operation.

All pressures are with the heater in operation for at least 15 minutes.

Form 43471010

Dec 2017 -43-

Page 45

LED Indication

Error Mode

Steady On

Internal Control Fault

2 Flashes

Flame Sense Fault

3 Flashes

Ignition Lockout

21.4) IGNITION SYSTEM CHECKS

TO CHECK IGNITION CABLE.

a. Make sure that the ignition cable does not touch any metal surface.

b. Make sure that connections to the stud terminal and the igniter/sensor are clean and tight.

c. Make sure that the ignition cable provides good electrical continuity.

TO CHECK IGNITION SYSTEM GROUNDING.

(Nuisance shutdowns are often caused by a poor or erratic ground.) A common ground is required for the module,

igniter, flame sensor and main burner.

a. Check for good metal-to-metal contact between the igniter bracket and the main burner.

b. Check the ground lead from the GND (BURNER) terminal on the module to the igniter bracket. Make sure

connections are clean and tight. If the wire is damaged or deteriorated, replace it.

c. Replace igniter/sensor with factory replacement part if insulator is cracked.

TO CHECK SPARK IGNITION CIRCUIT.

▲WARNING: The ignition circuit generates a 20,000 Volt open circuit and electrical shock can result.

a. Check ignition cable.

b. Check external fuse located inside the control box.

c. Verify power (24V) at module input terminals and output terminal to gas valve.

d. Replace spark module if fuse and power are OK.

IGNITION MODULE DIAGNOSTICS (Fenwal #35-6087J1-034 module only)

The LED located on the ignition module will flash ON for ¼ second, then OFF for ¼ second during a fault

condition. The pause between fault codes is 3 seconds.

TO CHECK FLAME SENSOR CIRCUIT (Fenwal #35-6087J1-034 module only)

The flame current is the current that passes through the flame from the sensor to the ground. The

minimum flame current necessary to keep the system from lockout is 0.7 micro-amps.

a. To measure the flame current, connect an analog DC micro-ammeter to the FC- and FC+ terminals per

diagram. The meter should read 0.7 micro-amps or higher when the burner is running full on.

b. If the meter reads below zero, the meter leads are reversed. Disconnect power and reconnect the meter

leads for proper polarity.

c. Remove micro-ammeter. Return system to normal operation.

-44- Dec 2017

Form 43471010

Page 46

21.5) MOTOR AND BLOWER WHEEL CHECK

Date of

Installation:

# of Heaters in

System:

Serial

No.

Model:

SIR

N = Natural Gas

L = Propane Gas

If draft inducer motor fails to run:

a. Check power supply to junction box.

b. Check for loose or broken motor lead wire.

c. Check to see that blower wheel turns freely and is not rubbing housing. Blower wheel may have worked

loose from shaft and jammed against housing.

d. Check for blower wheel damage; replace if necessary. If no damage, readjust blower wheel on shaft &

retighten set screw.

e. If all above does not correct, replace motor.

22.0) INSTALLATION DATA

Form 43471010

Dec 2017 -45-

Page 47

DRAFT INDUCER COMPONENTS

Item No.

Part No.

Description

Qty.

1

42737990

Kit. Draft Inducer Replacement

1

1a

42928000

Kit, Motor Replacement

1

2

03721000

Motor

1

3

30347000

Motor Spacer (4 per motor)

4

4

42740000

Motor Plate

1

5

03723000

Blower Wheel

1

6

43221000

Draft Inducer Gasket

1 7 42744000

Sensing Tube, Draft Inducer

1 8 42742000

Sensing Tube Bracket

1

9

42739000

Blower Housing Sub-Assembly

1

10

40504020

4” O.D. Flue Pipe Starting Collar

1

11

42741120

Restrictor Plate, 7/8” I.D. (25,000 Btu/hr)

1

12

42741041

Restrictor Plate, 1” I.D. (35,000 Btu/hr)

1

13

42741031

Restrictor Plate, 1-1/8” I.D. (45,000 Btu/hr)

1

14

n/a

23.0) REPLACEMENT PARTS GUIDE

-46- Dec 2017

Form 43471010

Page 48

CONTROL COMPONENTS

Item No.

Part No.

Description

Qty.

15

03988150

Plastic Vacuum Air Tube, 15” long

1

16

42750000

Cabinet Assembly

1

17

42751000

Access Panel

1

18

42752000

Air Inlet Plate (Perforated)

1

19

42447000

Sight Glass

1

20

42837040

Kit, Air Switch, set @ 0.11” W.C., #NS2-0307-00

1

21

30383000

Relay, 24V SPST-NO (2-stage controls)

1

22

30279980

Transformer, AT120B1051

1

23

42709000

Terminal Block Shield

1

24

30281000

Terminal Block, EK-204

1

24a

30743000

Terminal Block, EL-3008 (2-stage controls)

1

24b

30738030

Thermostat Connection Block – 3 Pole (2-stage controls)

1

25

42759000

Electrode Bracket

1

26

30295000

Electrode PSE-GF1 (Igniter/Sensor)

1

27

30314070

Ignition Cable, 7” long

1

28

44010010

Kit, Spark Module – Fenwal #35-608711-034

1

29

42398040

Monitoring Light, Green

1

30

42398060

Monitoring Light, Red

1

31

42398050

Monitoring Light, Amber (2 each for 2-stage controls)

1

32

42757000

Restrainer Nipple, 5” long

1

33

44010250

Kit, Gas Valve – WR #36J23-203B1 Single Stage (natural gas)

1

33a

44010260

Kit, Gas Valve – WR #36J23-204B1 Single Stage (propane gas)

1

34

44010310

Kit, Gas Valve – WR #36J58-201B1 Two Stage (natural gas)

1

34a

44010320

Kit, Gas Valve – WR #36J58-202B1 Two Stage (propane gas)

1

35

42701000

Orifice Fitting – ½” NPT x 7/16-27

1

37

03259xxx

Orifice for SIR25,35,45 (State Model & Gas Type for Size)

1

38

42700000

Main Burner

1

39

30148000

Universal Bushing, 7/8”

1

40

42755000

Burner Bracket Sub-Assembly

1

41

42753000

Burner Clamp

1

Labels / Manual

Item No.

Part No.

Description

Qty.

42

42785000

Label, Wire Diagram – Ladder (1-stage controls)

1

42a

42785030

Label, Wire Diagram – Ladder (2-stage controls)

1

43

42706000

Label, Wire Diagram – Connections (1-stage controls)

1

43a

42706020

Label, Wire Diagram – Connections (2-stage controls)

1

44

43471010

Installation and Operation Instructions (not shown)

1

45

43344050

Label, Gas Connector Warning

1

46

43470000

Label, Clearance to Combustibles

1

47

42848040

Label, Nameplate (1-stage controls)

1

47a

42848049

Label, Nameplate (2-stage controls)

1

48

42013010

Label, “SunStar” Logo

1

49

43470030

Label, Warning (residential)

1

50

42834000

Label, 120V Caution

1

51

42875000

Label, Warning

1

52

43470040

Label, Operating Instructions

1

53

43470050

Label, Caution/Attention

1

54

43470060

Label, Horizontal Venting

1

55

43269060

Label, 24V Thermostat Connection – (2-stage controls)

1

56

43269070

Label, Low/High Fire (2-stage controls)

1

Form 43471010

Dec 2017 -47-

Page 49

-48- Dec 2017

Form 43471010

Page 50

BODY COMPONENTS

Item

No.

Part No.

Description

1

02266010

Reflector Speed Clip

2

42769011

Reflector Clamp with screw (4 per heater)

3

42770000

“U” Bolt Clamp, 3” OD Tube (6 per heater)

3a

02127110

“U” Bolt Hex Nut, 5/16-18 (2 per “U” Bolt)

4

42773000

Tube Support/Hanger Bracket, 18-1/2” (2 per heater)

5

42763080

Reflector, 8’ long (1 per heater)

6

42762010

Reflector, control end

7

42761010

Reflector, foot end

8

44028132

7-1/2’ Tube Replacement Kit, 3” OD, ALC w/one 12-radial hole flange

9

42764000

U Bend, 3” OD x 3-3/4” centerline radius

10

02254010

Set Screw, 5/16-24 x 1/2” (2 per heater)

Note:

1) Screws, Nuts and Washers are standard hardware items and can be purchased at any local hardware store.

2) Please order by PART NUMBER – not by Item Number.

3) Replacement Part Prices are available when ordering.

4) Please refer to complete Model Number when ordering.

ALL ILLUSTRATIONS ARE INTENDED TO GIVE THE GENERAL IMPRESSION OF UNITS ONLY. WE RESERVE THE RIGHT TO ALTER

ANY SPECIFICATION WITHOUT NOTICE.

Form 43471010

Dec 2017 -49-

Page 51

24.0) WARNINGS CARD

Copies of this card may be ordered at no charge under part no. 43344980 for installation near the heater.

C

-50- Dec 2017

Form 43471010

Loading...

Loading...