Page 1

SunRotor® Solar Pump

Installation and Resource Manual

Page 2

CONTENTS

1 Introduction .................................................................................................................................................. 3

2 Warranty Registration Form ...................................................................................................................... 4

3 Warnings ....................................................................................................................................................... 5

4 Solar Water Pumping System .................................................................................................................... 6

4.1 SunRotor® Submersible Pump ............................................................................................................. 7

4.2 SunRotor® Controller ............................................................................................................................ 7

5 Solar Array Installation .............................................................................................................................. 8

5.1 Sizing the Solar Array ........................................................................................................................... 8

5.2 Location of the Solar Array .................................................................................................................. 8

5.3 Solar Orientation ................................................................................................................................... 8

5.4 Solar Array Mounting Rack ................................................................................................................. 8

5.5 Mounting Pole Guide for Top-Of-Pole Mounts ................................................................................ 9

5.6 Seasonal Tilt of the Solar Array ......................................................................................................... 10

5.7 Solar Array Wiring .............................................................................................................................. 10

5.8 Grounding and Lightning Protection ............................................................................................... 12

6 Pump Controller Installation .................................................................................................................. 15

6.1 Pump Controllers & Accessories....................................................................................................... 15

6.2 Locating and Mounting the Controller ............................................................................................ 16

6.3 Indicator Lights .................................................................................................................................... 16

6.4 Remote Float Switch ........................................................................................................................... 17

7 Pump Preparation ...................................................................................................................................... 17

7.1 Wire Sizing ........................................................................................................................................... 17

7.2 Installing the Check Valve ................................................................................................................. 18

7.3 Splicing the Wires ................................................................................................................................ 19

7.4 Safety Rope ........................................................................................................................................... 19

7.5 Low Water Sensor ............................................................................................................................... 19

7.6 Freeze Protection ................................................................................................................................. 20

7.7 Binding Pipe, Cables, & Rope ............................................................................................................ 20

7.8 Wellhead Components ....................................................................................................................... 21

Page 1 www.sunrotor.com

Page 3

7.9 Allowance for Pipe Stretch ................................................................................................................. 21

7.10 Coping with Dirty Water Conditions ........................................................................................... 21

7.11 Water Sanitization ........................................................................................................................... 22

8 Pump Installation ...................................................................................................................................... 22

8.1 Assembling the Drop Pipe, Cables, and Safety Rope .................................................................... 22

8.2 Machine Installation ............................................................................................................................ 22

8.3 Hand Installation ................................................................................................................................. 23

8.4 Running the Cables ............................................................................................................................. 23

9 Wiring the System ..................................................................................................................................... 24

9.1 Electrical Warnings ............................................................................................................................. 24

9.2 Wiring the Controller .......................................................................................................................... 24

9.3 Wiring Power to the Controller ......................................................................................................... 26

9.4 Post-Installation Testing ..................................................................................................................... 26

10 Troubleshooting......................................................................................................................................... 26

10.1 If the Pump Doesn’t Run ................................................................................................................ 26

10.2 Inspect the System ........................................................................................................................... 27

10.3 Electrical Testing .............................................................................................................................. 28

10.4 Troubleshooting Checklist ............................................................................................................. 30

11 Maintenance ............................................................................................................................................... 30

11.1 Helical Rotor Pump End Maintenance ......................................................................................... 31

11.2 Centrifugal Pump End Maintenance ............................................................................................ 31

11.3 Pump Motor Repair ......................................................................................................................... 31

11.4 Solar Panel Maintenance................................................................................................................. 31

11.5 Miscellaneous ................................................................................................................................... 32

11.6 Repairs and Replacements ............................................................................................................. 32

12 About Solar Power & Pump Company.................................................................................................. 33

13 Additional Information ............................................................................................................................ 34

www.sunrotor.com Page 2

Page 4

1 INTRODUCTION

To gain the maximum level of service and satisfaction from your pumping system, please carefully

read the contents of this guide before installation. Should any questions arise after reading through

this installation guide, please contact your local Authorized SunRotor® Dealer, or call the SunRotor®

Technical Service Team at 1-580-303-4015. Follow all appropriate state and federal electrical codes.

Please read through the warranty information carefully before installation. Check the depth limits for

your custom panel/pump configuration. Depth limits can be found on the pump data sheets. If at

any time, additional copies of this installation guide, warranty information, or data sheets are

needed, they may be obtained on the SunRotor® website under the Downloads section or directly by

visiting www.sunrotor.com/downloads.

© 2014 Copyright by Solar Power & Pump Company, LLC. All Rights Reserved.

REGISTRATION FORMS

Please look through the following form and fill out before, during, and after as needed. This form is

necessary to REGISTER YOUR WARRANTY. The information provided will assist in fixing or

troubleshooting any future technical issues, as well as provide the proper background information

should any repairs or replacements be needed. Please make a copy of this form to keep with the

pump records. Listed below is the mailing address where the registration form can be sent.

Alternatively, the form can be filled out electronically by visiting the link provided below.

Mailing Address:

Solar Power & Pump Company

301 W 12th St.

Elk City, OK 73644

Online Registration:

www.sunrotor.com/warranty-registration

Thank you for your assistance and participation. If we can be of any further assistance, please call us

at 1(866) 246-7652, e-mail one of the following e-mail addresses, or use the contact form provided on

the website:

Technical Service: service@sunrotor.com

General Information: info@sunrotor.com

Contact Form: www.sunrotor.com/contact

The SunRotor® Solar Products Team

Page 3 www.sunrotor.com

Page 5

2 WARRANTY REGISTRATION FORM

Name

Address

Phone Number

Purchased From

Date of Purchase

Pump Model

Pump Serial Number

Controller Model

Controller Serial Number

System Power

PV-Direct

Battery System

If PV:

Number of Panels

Solar Panel Brand

Solar Panel Wattage

Watts

Operating Voltage

V

Well Depth

ft

Casing Diameter

inches

Static Water Level

ft

Pump Set Depth

ft

Lift above ground level

ft

Discharge Pressure, In Any

PSI

www.sunrotor.com Page 4

Page 6

3 WARNINGS

CAUTION: disregarding may

result in damage to equipment

and VOIDING OF WARRANTY

WARNING: disregarding may

result in SERIOUS INJURY OR

DEATH

Please review the following warnings. These are listed for both personal safety and the safety of the

products. Disregarding or ignoring these warnings can result in SERIOUS INJURY and/or VOID YOUR

WARRANTY. All SunRotor

system is being installed without a licensed pump installer, an electrician or knowledge of electrical

circuits is HIGHLY recommended. If any questions or concerns regarding these warnings should arise,

please contact your Authorized SunRotor® Dealer or the SunRotor® Technical Services Team at 1-580303-4015. Solar Power & Pump Company, LLC is NOT LIABLE for any DAMAGE or INJURY.

®

Solar Pumps should be installed by a licensed pump installer. If this

All SunRotor

controller and void the warranty. Do NOT exceed the following open circuit voltages: SRC-M50T:

50VDC; SRC-M100T: 100VDC; SRC-M200T; 200VDC. For all other controllers, please contact the

SunRotor® Technical Services Team. See Section 9.2 Wiring the Controller.

The system should be installed and serviced by qualified personnel only. All electrical codes should be

observed. Make ABSOLUTELY CERTAIN all power sources are disconnected prior to wiring.

Extreme heat can damage the pump. Protect the pump from sunlight or other heat sources.

SunRotor

fill the pipe with debris. Running it under these conditions may damage the pump and VOID YOUR

WARRANTY. Do NOT use the pump to develop a new well or purge a dirty well.

Install proper system grounding for safety and lightning protection. Although the warranty does NOT

cover damage caused by ACTS OF GOD, proper grounding can significantly reduce the chance of

extreme damage. See Section 5.8 Grounding and Lightning Protection.

Follow all wire sizing recommendations on pump data sheets. Under-sizing the wires can cause the

pump to experience low power failure.

Do not touch controller input or pump wires together to test for a spark.

Do not run the pump dry.

The cable splice must make a water-tight seal to the OUTER JACKET of the pump cable. See Section 7.3

Splicing the Wires.

There are potential hazards in handling any heavy mechanical assembly. If you have any doubts about

your ability to perform the Hand Installation SAFELY, please hire a professional pump installer. Do not

use a winch or a vehicle. See Section 8.3 Hand Installation.

Do not run the pump against a blocked or restricted outlet.

Please pay close attention to the following symbols throughout this guide:

®

controllers have a maximum voltage rating. Exceeding these ratings will destroy the

®

solar pumps are CLEAN WATER PUMPS. Extreme sand or silt may cause the pump to stop or

Page 5 www.sunrotor.com

Page 7

4 SOLAR WATER PUMPING SYSTEM

1. PV Panel Array

2. Solar Module Mounting Rack

3. Water Pipe

4. Well Seal Assembly

5. Low Water Sensor

6. Submersible Pump

7. Conduit and Wiring from Controller to Well Seal

8. Wiring Harness from Controller to Solar Modules

9. DC Input Controller

10. Tank Full Tethered Float Switch with Weight

11. Anti-freeze Bleeder Valve

FIGURE 4-1 SOLAR PUMP DIAGRAM

www.sunrotor.com Page 6

Page 8

4.1 SUNROTOR

®

SUBMERSIBLE PUMP

The SunRotor® submersible pump line offers a varied selection depending on the requirements.

From low cost to high yield, the SunRotor® Sales Team can find a solar pump system to fit nearly any

request. Both helical rotor and centrifugal pumps are offered, in a range of 12V to 110V brushless DC

motors. The conventional brushed DC motor maintenance and replacement is not necessary with

brushless DC motors.

The helical rotor series offers something that many pumps cannot: the ability to easily repair it in the

field. If the well has any abrasive substances such as sand, the rotor and stator can begin to show

wear and tear over time; however, with the SunRotor® Helical Rotor Repair Kit, it’s as easy as

removing the casing on your pump end, screwing in the new rotor, and placing the new stator in its

place in the pump end. After bolting everything back into place, the pump will run like it was new.

If for any reason the motor goes out (no matter the warranty status), the SunRotor® Technical Services

Team can most likely rebuild it, which is much more cost effective than purchasing a new pump.

For more information on the SunRotor® solar pump line and accessories for water pumping systems,

contact the SunRotor® Sales Team at 1(866) 246-7652.

4.2 SUNROTOR

®

CONTROLLER

The SunRotor® controller offers state of the art controller electronics, housed within a highly durable

metal weather resistant connection box with cooling fins cast on the back. It has a clear cover which

allows visible inspection of all of the connections and LED status lights. It offers a wide operational

range with max input tolerances of 50/100/200 volts DC, and it converts excess voltage into amperage

with its linear current boosting feature.

The controller also offers a timer function that is used to adjust the delay time for the low water

switch. The standard setting for the delay timer is 20 minutes, but can be increased by turning the

knob clockwise and reduced by turning it counterclockwise. This setting can be adjusted between 0

and 30 minutes while the controller is either on or off. The delay is designed to allow well recovery

before the pump is restarted. This significantly reduces the number of times the pump cycles on and

off throughout the day, and likewise, reduces the chance of damage to the pump from unnecessary

wear and tear.

Another option is the speed control. The speed knob adjusts the RPMs of the pump and has the

default position set to the maximum. Like the Timer Control Knob, clockwise movement increases

and counterclockwise movement decreases this value. Speed control can be useful in maintaining the

water level in a low producing well or water source, as it can be set to match the pumping speed with

the production level specific to the water source. Additionally, properly regulating the speed of the

pump can produce a more consistent water flow and prolong the life of the pump, as there will be

less startups each day. The speed control can be adjusted with the system on or off.

Page 7 www.sunrotor.com

Page 9

5 SOLAR ARRAY INSTALLATION

5.1 SIZING THE SOLAR ARRAY

Be sure that the PV array has been properly sized to meet the pump's power requirement. A PV

array will only produce its rated power when properly aligned with the sun and no dust or debris

accumulation. Solar panels offer peak performance in cooler temperatures. An undersized array can

cause poor starting and reduced flow in low light conditions. An oversized array is recommended (at

least +20%); the pump will start earlier and run later, as well as have higher performance on cloudy

or hazy days.

5.2 LOCATION OF THE SOLAR ARRAY

Install the solar array in a location that will maximize sun exposure. If necessary, it may be placed a

substantial distance from the wellhead to gain sun exposure, reduce visibility, etc. The greater the

distance, the larger the electrical wire must be, so cost rises with distance.

ATTENTION: Shading a portion of a PV array will stop the pump. Each PV module

(panel) contains a series of small solar cells. Any cell that is shaded acts like a resistor

and will reduce the output of the entire module. So, shading just one corner of the solar

array will reduce the power substantially, slowing or possibly stopping the pump.

5.3 SOLAR ORIENTATION

For optimal performance, the solar array must be oriented within 10° of true (solar) south.

Depending on location, a compass reading may show an error of as much as 20°. To correct this

discrepancy, apply the magnetic declination for the region. Many regional maps indicate the

magnetic declination. Additionally, this information can be found on the National Geophysical Data

Center website (http://www.ngdc.noaa.gov/geomag-web/#declination).

5.4 SOLAR ARRAY MOUNTING RACK

CAUTION: Use a mounting structure engineered for wind resistance, ease of adjustment,

and most importantly, safety. Follow any and all instructions and cautions provided

with the mounting rack.

For the best quality and economy, factory-built mounting racks are recommended. Pole-top racks are

especially popular for solar water pumps. Factory-built racks are available from your Authorized

SunRotor® Dealer.

Place the bottom of the array at least 2 feet (.6 m) above ground to clear rain spatter, growing

vegetation and snow. Keep in mind that trees and perennial plants will grow taller over the years.

A pole-top mounted rack is advised. It allows the array to be placed high enough to clear the reach of

livestock, people and growing vegetation—potentially eliminating the need for fencing. If the rack is

www.sunrotor.com Page 8

Page 10

to be placed higher than approximately 6 feet (2m), it is advisable to weld its mounting pipe to

Module

Area

Pole Size

(Steel Pipe)

Depth

in Ground

Height*

Above Ground

Hole

Diameter

15 SQ. FT.

2" SCH40 (2-3/8" OD)

30"-36"

48"-72"

8"-12"

20 SQ. FT.

2.5" SCH40 (2-7/8" OD)

34"-40"

48"-72"

10"-14"

28 SQ. FT

3" SCH40 (3-1/2" OD)

36"-42"

48"-72"

12"-16"

35 SQ. FT.

3" SCH40 (3-1/2" OD)

38"-44"

60"-72"

12"-16"

60 SQ. FT.

4" SCH40 (4-1/2" OD)

42"-48"

60"-72"

16"-24"

90 SQ. FT.

6" SCH40 (6-5/8" OD)

48"-60"

60"-84"

24"-30"

120 SQ. FT.

6" SCH40 (6-5/8" OD)

48"-72"

72"-84"

24"-30"

160 SQ. FT.

8" SCH40 (8-5/8" OD)

60"-78"

84"-102"

30"-36"

180 SQ. FT.

8" SCH40 (8-5/8" OD)

60"-78"

84"-102"

30"-36"

`225 SQ. FT.

8" SCH80 (8-5/8" OD)

72"-84"

96"-120"

36"

260 SQ. FT.

8" SCH80 (8-5/8" OD)

72"-84"

96"-120"

36"

another pipe one size larger, to tolerate wind loads. Refer to your rack manufacturer’s instructions.

PLEASE NOTE: adding additional panels and using a fixed position mount is normally more economical

than solar tracking systems. The increased production from extra panels compensates for the lack of

tracking, and eliminates the extra costs of having to repair and maintain the tracking system. Please

consult your Authorized SunRotor® Dealer for more information.

5.5 MOUNTING POLE GUIDE FOR TOP-OF-POLE MOUNTS

The following table provides guidelines for an average installation. Soil type varies widely from one

region to another. The actual depth and diameter of the hole and the amount of concrete used is very

dependent on soil type. Installations in loose, sandy soil will require a larger, deeper hole with more

concrete than an installation in hard, rocky soil. The height of the above ground section of the pole

and the wind speeds in the area also play an important role in determining the depth and diameter of

the hole. If in doubt, it is recommended that a civil engineer familiar with the area and local soil

conditions is consulted.

FIGURE 5-1 MOUNTING POLE GUIDE

* If a taller pole is needed for snow clearance or to clear nearby obstructions, the hole should be deeper to allow

more of the pole to be placed in the ground. For each extra foot added above the ground, an increase of

approximately 6” (with concrete) will be needed in the ground.

General Procedure: When the hole is ready, place the pole inside until it is resting on the bottom of

the hole. It is a good idea to fill the bottom 2 to 4 inches of the hole with rocks. Brace the pole plumb

and pour concrete around it until it is filled up to ground level. Next, pour a little extra concrete on

top, and using a trowel, start forming a mound around the pole so that the concrete slopes away from

the pole. Allow the concrete to set up for at least 24 hours before installing the mounting rack.

Page 9 www.sunrotor.com

Page 11

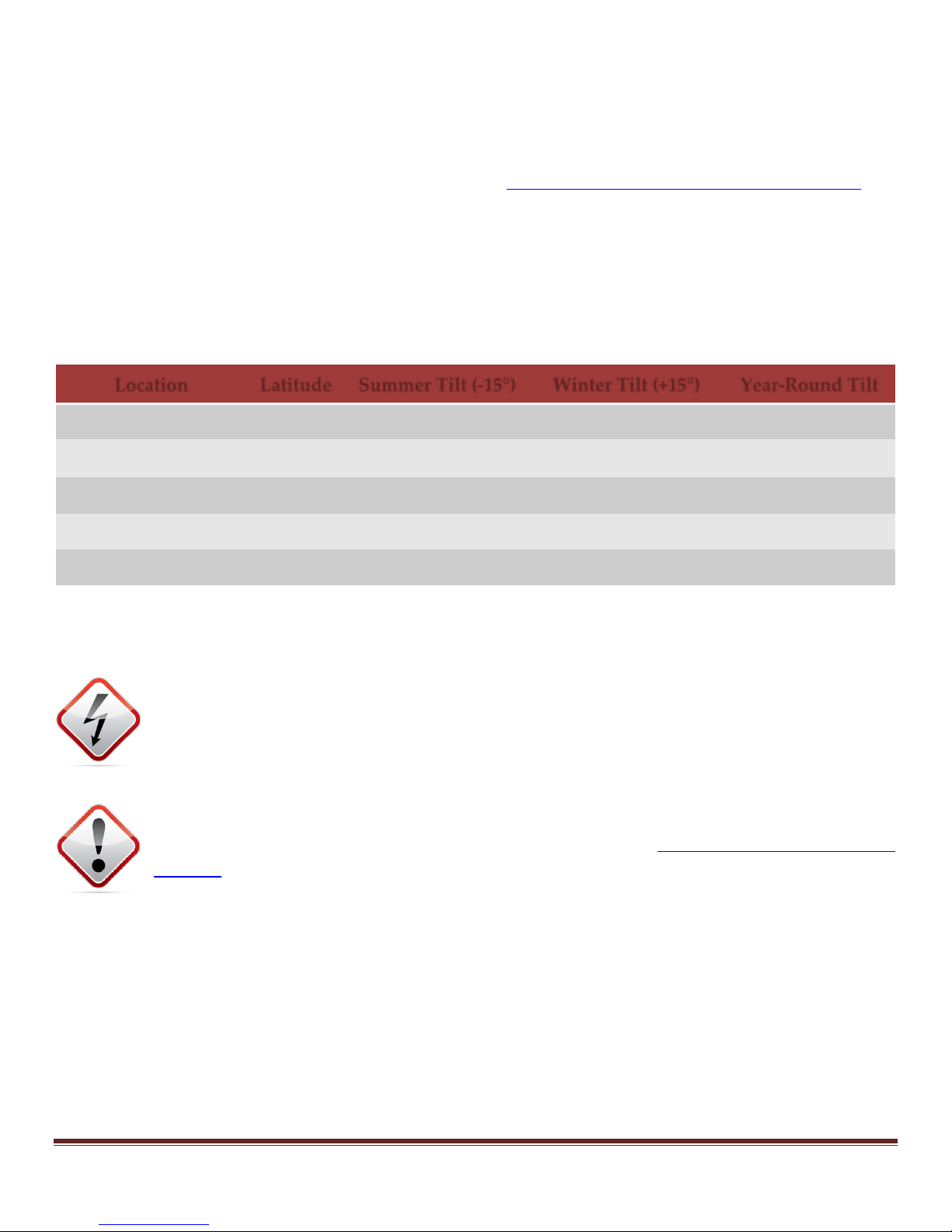

5.6 SEASONAL TILT OF THE SOLAR ARRAY

Location

Latitude

Summer Tilt (-15°)

Winter Tilt (+15°)

Year-Round Tilt

Southern Canada

50°

35°

65°

50°

Upper Third of US

45°

30°

60°

45°

Middle Third of US

40°

25°

55°

40°

Lower Third of US

35°

20°

50°

35°

Central Mexico

20°

5°

35°

20°

The sun is highest in the sky during the summer and lowest in winter. To maximize pumping during

both seasons, adjust the tilt angle periodically. Nearly all currently manufactured mounting racks

can be adjusted. It is sufficient to perform the adjustment only twice per year, at the spring and

autumn equinoxes, to the angles indicated below. See Figure 5-2 Solar Array Tilt Angles by Latitude.

If season adjustments are unwanted or unnecessary, set the tilt angle to the latitude of the pump

location, as a compromise. Do not set the array absolutely horizontal, or dust and debris will

accumulate.

Ideal angles are: Summer optimum = latitude -15° Winter optimum = latitude +15°

FIGURE 5-2 SOLAR ARRAY TILT ANGLES BY LATITUDE

For additional tilt angles not listed, please consult the Mounting Rack Manual or Authorized SunRotor® Dealer

5.7 SOLAR ARRAY WIRING

WARNING: Photovoltaic arrays generate hazardous voltages. A 48 Volt (nominal) array

can generate nearly 100 volts when disconnected from load. All wiring MUST be done

by qualified personnel, in compliance with local, state, and national electrical codes.

To prevent shock hazard while working on array wiring, leave one wire disconnected

between two modules to break the circuit, or cover array to shade it.

ATTENTION: Wiring the panels in the wrong configuration (series or parallel) can damage

the controller. Be certain of the wiring configuration (See Figure 5-3 Solar Panel Wiring

Diagram for examples) prior to connecting the array to the controller. Additionally, it is

recommended to cover or shade the panels when connecting them to the controller. This

prevents electrical discharge from damaging the equipment. Any damage caused by disregarding

these warnings will NOT be covered under the warranty.

If the system uses a single panel, simply plug the MC4 connectors on the solar panel to the male and

female connectors on the controller; however, if more power or voltage is needed to meet the pump

requirements, multiple panels will have to be wired in either series, parallel, or a combined

series/parallel configuration. Examples are provided below to better explain the differences between

parallel and series.

www.sunrotor.com Page 10

Page 12

For these examples, ratings from one of the most common panels will be used. See Figure 5-3 Solar

Panel Wiring Diagram.

195W (24V) Panel Rating – VMP: 38.16 VDC; Voc: 45.36 VDC; I: 5.10 amps

Parallel: Solar panels that are wired in parallel combine their wattage and their amperage, and the

voltage remains the same. In the first example (2 Panels – Parallel) on Figure 5-3 Solar Panel Wiring

Diagram, the positive (+) ends of each panel are connected via a branch connector. The same is done

for the negative (-) ends of each panel. The end of the branch connectors then connect directly to the

MC4 cables that come pre-installed with the controller. Because this is wired in a parallel

configuration, the voltage remains constant at 38 VDC (VMP or average up to 45.36 VDC open

circuit), the watts are doubled to 390W (195W x 2), and a current of 10.20 amps (5.10 amps x 2) is

present. Primarily, this configuration is used to supply more current when the pump requires more

than a single panel can offer. Additionally, adding extra panels in parallel can increase the depth

limit and/or earlier start and later stop times when compared to a single panel system.

Series: Solar panels that are wired in series combine their wattage and voltage, and the amperage

remains constant. This is displayed in the second example (2 Panels – Series) on Figure 5-3 Solar Panel

Wiring Diagram. The positive (+) end of the first panel connects to the controller, while the negative

(-) connects to the positive (+) of the second panel. The second panel’s negative (-) connects to the

controller, completing the circuit. Since this array is wired in series, the voltage doubles to 76 VDC

(VMP or average up to 90.72 VDC open circuit), the watts double to 390W (195W x 2), and the current

remains the same at 5.10 amps. The most common need for this configuration is to power a high

voltage motor.

Series/Parallel: The third example (4 Panels – Series/Parallel) on Figure 5-3 Solar Panel Wiring Diagram

shows TWO PARALLEL STRINGS of TWO PANELS IN SERIES. Each string of two panels in series puts out

76 VDC (VMP or average up to 90.72 VDC open circuit), 390W, and 5.10 amps. The parallel-wired

calculations are 76 VDC (VMP or average up to 90.72 VDC open circuit), 780W, and 10.20 amps. This

configuration is reserved for higher voltage pumps that require more current than a single string of

solar panels wired in series can provide.

Warning: Before connecting any of the cables from the solar array to the controller, be

sure to verify the open circuit voltage does not exceed the voltage limits of the controller

(50/100/200 VDC). Voltages in excess of this maximum will damage the controller. If the

pre-installed MC4 connectors on the controller are removed, be certain that the positive

and negative wires are not crossed when connecting them to the controller. If unsure of the polarity

or voltage, confirm with a voltmeter. Standard SunRotor® controllers have reverse polarity

protection, and will not power up if the polarity is incorrect.

Solar Panels can be wired into the controller in a number of variations to produce the desired

Watt/Voltage/Amperage configuration. Below are examples of the most common 2-4 panel wiring

configurations, including panel arrays configured in series, parallel, and a combination of the two.

Page 11 www.sunrotor.com

Page 13

FIGURE 5-3 SOLAR PANEL WIRING DIAGRAM

5.8 GROUNDING AND LIGHTNING PROTECTION

Lightning can damage solar pump systems if the following precautions are not taken. A proper

connection to ground (earth) is important as it allows static electricity to discharge to earth—helping

to prevent the attraction of lightning. In case of a nearby lightning strike, a well-grounded solar array

support structure provides a path to conduct an induced surge of current around the electrical

circuitry, preventing damage in most cases.

www.sunrotor.com Page 12

Page 14

SunRotor® pump controllers have built-in surge protectors that help to protect them if the controller’s

ground terminal is connected to an effective ground path. Bond the structural components and

electrical enclosures. Interconnect the PV array frames, the mounting rack, and the ground terminals

of all electrical devices, and run the wire to an earth connection. See Figure 5-4 Grounding Diagram.

FIGURE 5-4 GROUNDING DIAGRAM

Page 13 www.sunrotor.com

Page 15

Earth connection: Install a conductive ground path. Use a minimum of one 8-foot copper-plated

ground rod or equivalent, preferably in moist earth. In an area where the earth is very dry (poorly

conductive), it is recommended to bury at least #6 or double #8 (or 10 mm2) bare copper grounding

wire in a trench (perhaps the pipe trench) at least 100 feet (30m) long, with one end connected to the

array structure. Or, cut the ground wire in half and spread it in two directions. A steel well casing

may be used as a ground rod. Drill and tap a hole to make a strong bolted connection to the casing.

The cemented footers of a ground mounted solar array WILL NOT provide adequate electrical

grounding!

Grounding the power circuit?—DO NOT ground either the positive or the negative electrical wires.

The best lightning protection results from grounding the metallic structure only, and letting the

power system “float” ungrounded.

Exception: Connecting the pump to a battery-based home power system that has a negative

ground. If the wiring distance to the pump exceeds 100 feet (particularly in a high lightning

area), or a charge controller that requires negative grounding, DC-rated surge protection devices

are recommended.

Exception: If system grounding is required by the electrical authority in the region, ground the

PV ARRAY’S NEGATIVE wire on the controller, and switch only the positive in the array

disconnect switch (if used). This may increase the risk of lightning damage.

Additional Lightning Protection: Additional grounding measures or protection devices are

recommended in the following instances:

1. Isolated location on high ground in a severe lightning area

2. Very poor grounding potential due to dry, rocky, or otherwise poorly conductive soil

3. Long wire run (more than 100 ft / 30 m) between array and wellhead, or between controller

and remote float switch

DC-rated surge protection devices are available from your Authorized SunRotor® Dealer.

A long run of cable to a float switch can be a source of damaging surges. Shielded, twisted-pair cable

adds considerable protection. Shielded cable has a metallic foil or braid surrounding the two wires.

Ground the shield at the controller end only, not the float switch.

www.sunrotor.com Page 14

Page 16

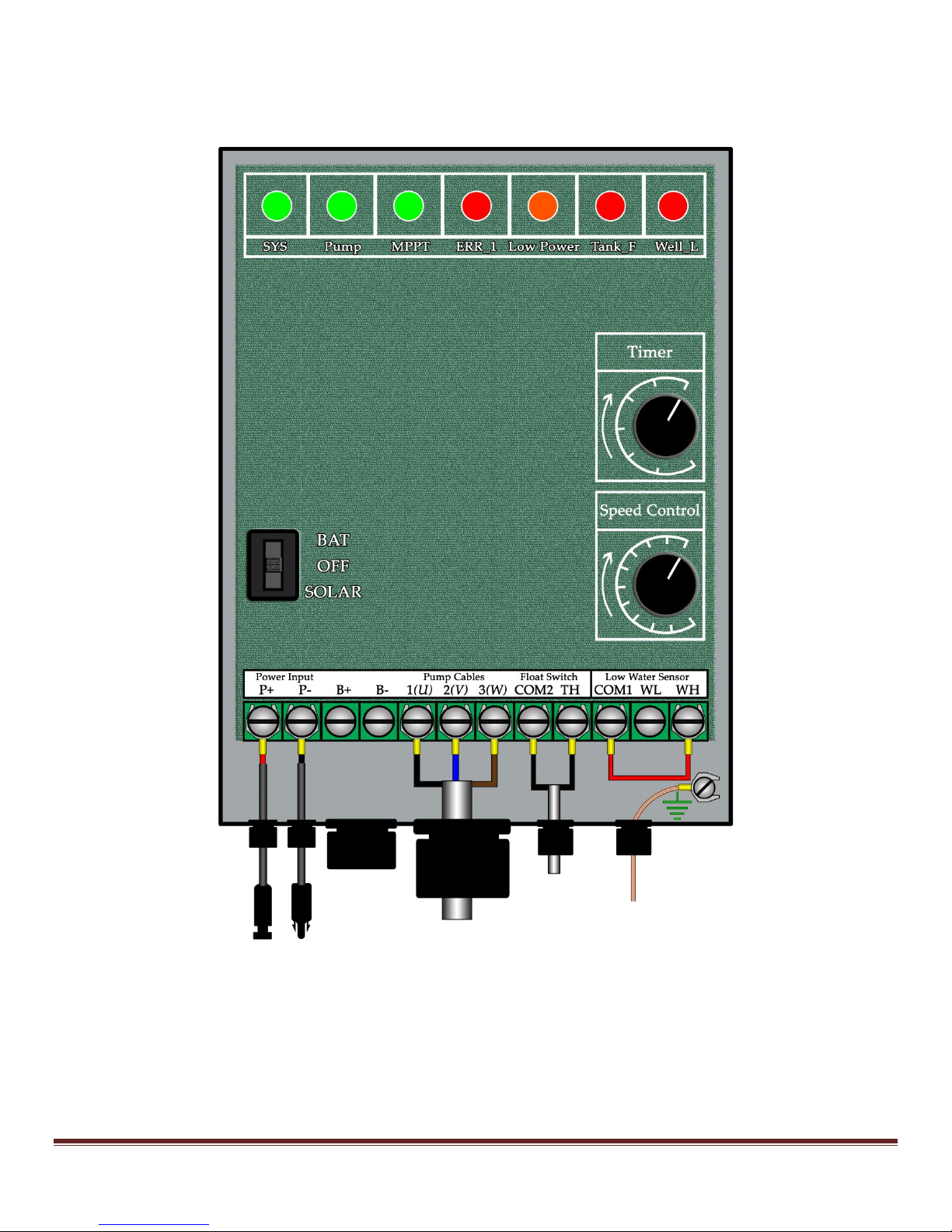

6 PUMP CONTROLLER INSTALLATION

FIGURE 6-1 SUNROTOR

®

CONTROLLER DESIGN

6.1 PUMP CONTROLLERS & ACCESSORIES

All SunRotor® solar pumps require a SunRotor® controller. The standard SunRotor® controller

features adjustable speed control, low water and tank full sensor connections, linear current boosting

technology, and an adjustable timer that allows well recovery (up to 30 min) after the low water

sensor has been tripped. This feature allows the well to recover properly before beginning to pump

again, saving unnecessary wear and tear on the pump. This model also comes with a hinged, clear

Page 15 www.sunrotor.com

Page 17

door providing easy access to adjust the settings, and the ability to see the indicator lights at a glance.

The controller comes in three sizes: 50V, 100V, and 200V DC input tolerance limits. The size will be

determined by the solar array and pump configuration.

There are other models available that offer fewer features than the standard controller. The overall

function is the same, and the wiring is similar. If any controller other than the SRC-M50T, SRCM100T, or SRC-M200T is purchased, please contact your Authorized SunRotor® Dealer or the

SunRotor® Technical Services Team for any information not provided within this installation guide.

The ability to use both AC (generator, power lines, etc.) and DC (solar array, batteries) is available

with additional equipment. A Power Pack is necessary if both AC and DC input are desired. If a

battery back-up is required for times of need, such as when it is hazy or dark, a charge controller is

needed. No information is provided within this installation guide on configuring and installing these

accessories; however, they may be available on the SunRotor® Solar Products website under the

product information or the Downloads page. If it cannot be found there, please contact the

SunRotor® Technical Services Team at 1(866) 246-7652.

6.2 LOCATING AND MOUNTING THE CONTROLLER

CAUTION: Direct sunlight can reduce the life of the controller.

Mount the controller so it is shaded from the mid-day sun. The easiest location is under the PV array.

If necessary, mount the controller inside a shelter or make a sheet-metal shade for it. If the solar array

is a substantial distance from the wellhead, it is preferable to place the controller closer to the pump.

If the solar array is nearby, it is recommended to mount the controller box to the pipe below the solar

array. Securely fasten the controller to the opposing side of the solar panels. The solar panels will

keep the controller out of the direct sunlight, increasing its efficiency and life. Controller mounting

hardware may be purchased from your Authorized SunRotor® Dealer, or built using materials

commonly available from electrical supply stores.

6.3 INDICATOR LIGHTS

The indicator lights located on the upper half of the controller display the status of the pumping

system (See Figure 6-1 SunRotor® Controller Design). Below is an explanation of each indicator light

and its function.

SYS (Solid Green): This indicator light will illuminate whenever the switch is in the on position and

the power is available to the controller.

Pump (Solid Green): This indicates that power is being applied to the pump. This indicator will

illuminate 20-30 seconds after the system has been switched on as long as there is adequate power

available and all water level sensors are reading normal.

www.sunrotor.com Page 16

Page 18

MPPT (Flashing Green): The MPPT (Maximum Power Point Tracking) monitors the power input from

the solar panels and adjusts the voltage and current to gain the highest performance of the pump.

This indicator light will flash green when the MPPT is working properly.

ERR_1 (Solid Red): This light will usually illuminate when there is an overcurrent issue. If the pump

is drawing too high of an amperage, the overcurrent protection will engage to protect the pump,

motor, and controller. The pump will be shut down until the system is reset. It should automatically

start after 20 minutes. If not, cycle the power switch and verify the ERR-1 light has turned off. If it

repeats, call Technical Support. Overcurrent can be caused by pump or motor problems, shorts in the

wiring, or even a blockage in the piping. Please consult your Authorized SunRotor® Dealer for

technical support, or contact SunRotor® Technical Services Team directly at 1(866) 246-7652.

LOW POWER (Solid Orange): This indicator light will illuminate when there is not enough power to

operate the pump or when the pump motor cannot start because of blockage, torn stator, or other

factors. Low sunlight or hazy conditions are usually the cause.

Tank_F (Solid Red): This light indicates the storage tank is full. When water in the tank reaches its

desired level, the float switch rises and closes the circuit. The pump will shut down until the water

level decreases and the remote switch returns back to the open position.

Well_L (Solid or flashing Red): This indicator light is illuminated when the water level in the water

source has dropped below the sensor. When the low water sensor is tripped, the pump is shut down,

and the timer will start as long if it has been set above zero (red light flashes when timing). The

pump will restart when this time expires. The time is adjustable between 0 and 30 minutes.

6.4 REMOTE FLOAT SWITCH

The purpose of a float switch is to turn the pump off when the storage tank fills, and to turn it back

on after the level drops again. The use of a float switch is highly recommended to reduce the running

time and to prevent waste of ground water. It can control the pump from a long distance away as

long as the proper wire is used. Ask your Authorized SunRotor® Dealer about pricing and

applications for float switches.

7 PUMP PREPARATION

7.1 WIRE SIZING

All SunRotor® solar pump systems require a minimum of 10 gauge pump cable, except when the

TDH is greater than 300 ft., in which 8 gauge pump cable is required. It is also recommended that

any and all additional instrument cable not provided with purchased sensors and float switches be a

minimum of 18 gauge shield twisted-pair cable. This will help prevent damage from ambient or

transient lightning strikes. If unsure of the proper wire sizing, contact your Authorized SunRotor®

Dealer or the SunRotor® Technical Services Team at 1(866) 246-7652.

Page 17 www.sunrotor.com

Page 19

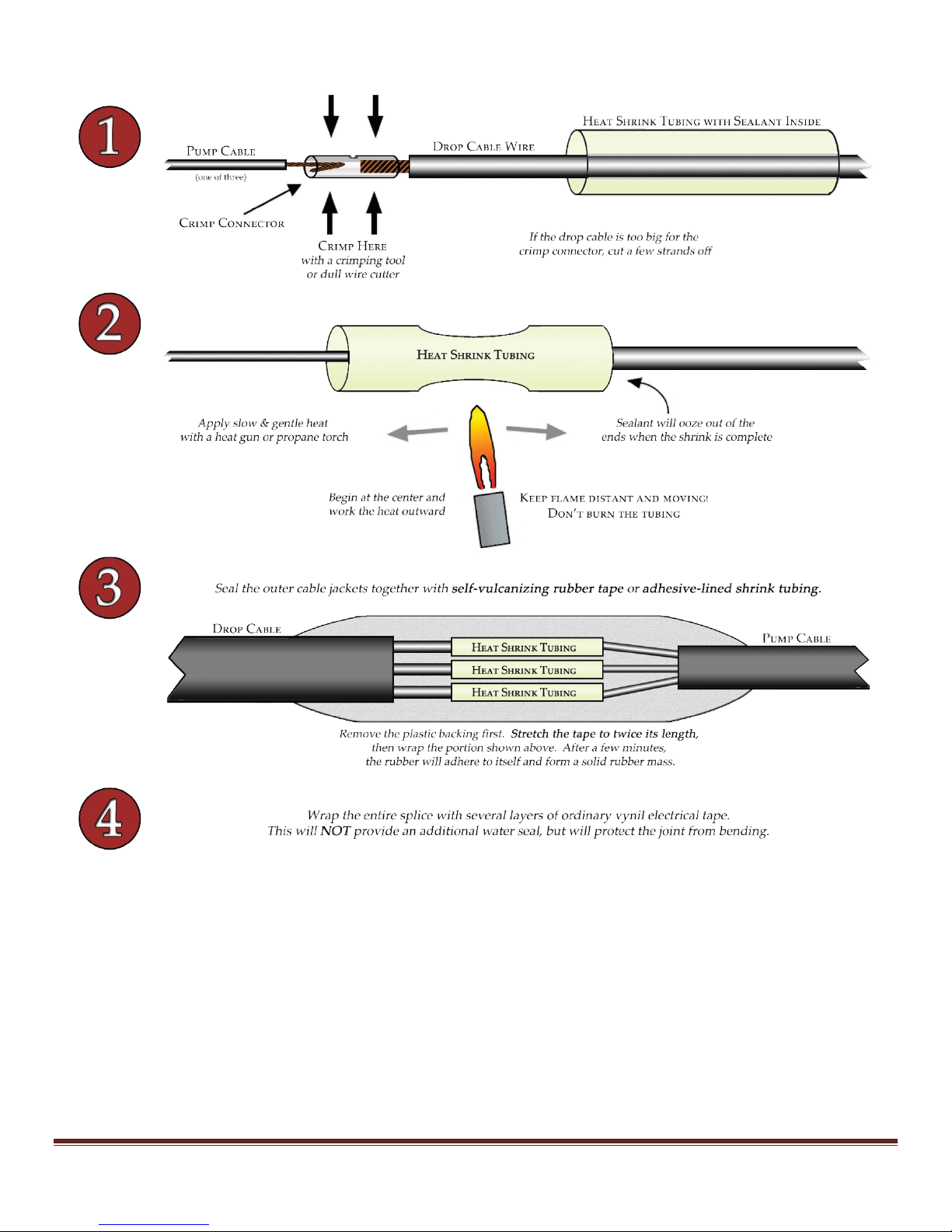

FIGURE 7-1 WIRE SPLICE DIAGRAM

7.2 INSTALLING THE CHECK VALVE

All SunRotor® solar pumps are shipped with a check valve that must be installed prior to setting the

pump. These are used to protect the pump from water pressure driving it in the reverse direction,

which could generate potentially harmful voltage to the controller. Most check valves have an arrow

indicator displaying the direction of flow; make sure the arrow is facing opposite the pump. To

reduce the chances of this valve being installed improperly, it will ship with an all-thread adapter

already mounted. The all-thread will be connected to the pump outlet, whereas the drop pipe fittings

will attach to the other.

www.sunrotor.com Page 18

Page 20

7.3 SPLICING THE WIRES

Properly splicing the pump and sensor wires is a key step during the solar pump installation process.

The recommended process includes the use adhesive-filled heat shrink tubing. After stripping the

ends of the wires, use the provided crimp connectors to merge the two ends. Place both ends into the

heat shrink tubing—and with a standard hot hair heat gun or flame torch—work from the middle

outward to the edges. Adhesive should be oozing from each end of the shrink tubing, ensuring a

proper seal has been made. Be sure to mark or write down the matching cables connections (Black >>

Green; Brown >> Red; etc.). Pull lightly on each corresponding cable after crimping them together to

verify that they are both secure and making a good connection.

ATTENTION: Use caution while heating the shrink tubing. If care is not used, injury may

be sustained by the flame or heated adhesive leaking from the ends. Remember to keep

the heat source moving to avoid burning the tubing or wire insulation. A double

watertight seal must be provided using properly engineered materials to prevent water

from seeping into the pump cable—and possible into the motor. Failure to do so will VOID THE

WARRANTY. See Figure 7-1Wire Splice Diagram.

7.4 SAFETY ROPE

It is recommended that the safety rope be polypropylene or polyethylene water well safety rope. It

can be purchased from your Authorized SunRotor® Dealer or local pump supply store. If

unavailable, use polypropylene marine rope rated for at least 1000 pounds (450 kg). Stainless steel

cable may be used, if preferred.

ATTENTION: DO NOT use nylon rope in water. Nylon absorbs water and softens after 5 to

10 years. Failure may cause damage or loss of equipment. Polypropylene is the accepted

material for water well rope.

7.5 LOW WATER SENSOR

Low water sensors are placed above the pump inside the well. The sensor sends a signal to the

controller that stops the pump when the well’s water level drops below the sensor. This ensures the

pump motor isn’t damaged if the well’s recovery rate is less than the flow rate of the pump.

ATTENTION: It is HIGHLY recommended that all SunRotor® solar pumps are installed with

this sensor. It is an extremely economical and effective method of protecting equipment.

Damage to the equipment from pumping dry is NOT covered under your warranty.

Install the low water sensor 6-18 inches above the pump. Secure it to the drop pipe by using cable

ties around the body of the device. Wrap both the low water sensor body and cable ties with high

quality, waterproof electrical tape. PLEASE NOTE: there are holes at or on the top of the low water

sensor; do NOT cover these holes when securing the device to the drop pipe.

Page 19 www.sunrotor.com

Page 21

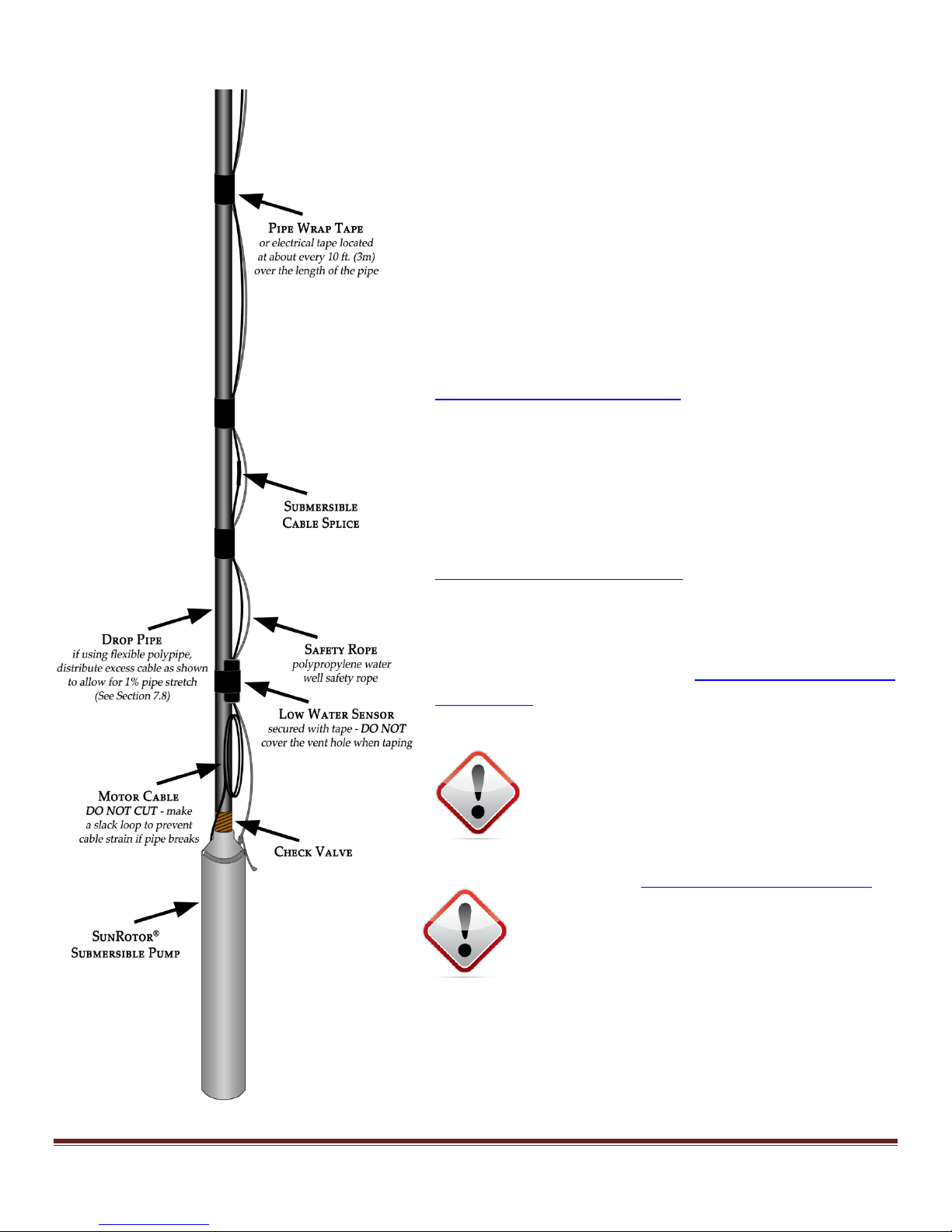

FIGURE 7-2 BINDING DIAGRAM

7.6 FREEZE PROTECTION

In a cold climate, water can freeze in the pipe and block

water flow. This can cause the pipe to burst, or worse,

pump or controller damage. This type of damage is

NOT covered under your warranty.

The use of an anti-freeze bleeder valve is recommended

if installing in climates prone to freezing conditions. In

normal operation, the pressure of the moving water

keeps this valve closed, yet allows for the draining of

water in the lines after your pump stops pumping (See

Figure 4-1 Solar Pump Diagram). Alternatively, the use of

a pitless adapter may be used.

7.7 BINDING PIPE, CABLES, & ROPE

The cables (both the pump and low water sensor) and

the safety rope must be bound to the drop pipe with

tape of an industry-approved (UL-listed) variety. See

Figure 7-2 Binding Diagram. Pipe wrap tape is

recommended. First, wind tape around the pipe, more

than one turn, so that it sticks to itself. Second, wind it

around the cable and rope. This prevents it from

slipping down the pipe. See Section 7.9 Allowance for

Pipe Stretch to determine the amount of additional

lengths of cable and rope needed prior to wrapping.

CAUTION: DO NOT use nylon cable ties in

water. Nylon absorbs water and softens

after 5 to 10 years. Failure may cause

damage or loss of your equipment.

ATTENTION: Figure 7-2 Binding Diagram is

used for illustration purposes ONLY. Be sure

to carefully read through the provided

instructions first, as the illustration may not

be 100% accurate in scale or positioning.

Disregarding this notice may result in damage or loss

of equipment, and is NOT covered under your

warranty.

www.sunrotor.com Page 20

Page 22

7.8 WELLHEAD COMPONENTS

There are a few recommended methods to support the drop pipe. The first is a well seal. This is a

plate that fits on the top of the well casing. It provides a seal against contamination of the well, and it

supports the weight of the in-well assembly. In freezing climates, the wellhead must be located in a

heated building or in a covered well pit if no anti-freeze bleeder valve is used with the well seal.

The other method is the use of a pitless adapter. This is a fitting that allows your buried pipe to pass

through the well casing underground, without the need to build a covered pit. This system is used in

many conventional well systems and is available from local well pump suppliers. A well cap is

needed with this method.

The pitless adapter is ideal for freezing climates. It also provides protection against animals,

children, and vehicles that can damage exposed piping.

CAUTION: The pump must be supported primarily by the drop pipe. The rope serves as a

safety measure in case of pipe breakage. The electrical cable must NEVER support any

weight.

The use of flexible conduit running from the top of the well seal or cap to the controller is

recommended. This will help against contamination and damage from animals. Please inform your

Authorized SunRotor® Dealer if the use of flexible conduit is planned, as additional parts are needed.

7.9 ALLOWANCE FOR PIPE STRETCH

Polyethylene (PE) drop pipe will stretch by about 1% of its original length. Rope will also stretch. To

keep it from bearing much weight, cut your rope 1% longer than the drop pipe.

The pump cable should NEVER BEAR ANY WEIGHT. Prevent this by making the length of your cable (the

portion below the wellhead) 1.5% longer than your drop pipe. DO NOT CUT IT YET—extra length is

needed to make a slack loop at the bottom, and to make connections at the surface. If the pump may

need to be lowered in the future, leave some extra cable rolled up at the wellhead, so no splicing will

be needed later.

WARNING: Never lift the pump by the electrical cable.

7.10 COPING WITH DIRTY WATER CONDITIONS

CAUTION: SunRotor® solar pumps are clean water pumps, and are not meant to tolerate

water with extremely high sand or silt, or a high salinity, without increased wear and

tear. DO NOT use this pump to develop or purge your well. Damage caused by pumping

in such conditions is NOT covered under the warranty.

Page 21 www.sunrotor.com

Page 23

The pump has a good resistance to occasional bits of sand and fine silt that normally occur in a water

well. However, as with any pump, extreme abrasive substances will cause accelerated wear and tear

on the rotor and stator, particularly if the water appears turbid.

To avoid pumping dirty water:

1. Have the water well developed, purged, or otherwise improved by a drilling contractor.

2. Temporarily install a larger AC pump (with a generator if necessary) to pump at a high flow

rate until silt is purged from the well.

If dirty water cannot be avoided:

1. Use a smaller drop pipe (recommended no larger than ¾”) if or when possible. This will

maximize the velocity of water flow to allow particles to rise and leave the drop pipe.

2. In case of a drilled well, place the pump as high as possible in the well. If the pump can be

placed higher than the perforations in the well casing, then all but the finest silt will probably

be avoided.

3. Inspect and replace parts periodically (See Section 11 Maintenance).

4. Monitor the situation by observing the accumulation of sediment in the storage tank.

7.11 WATER SANITIZATION

If the well water will be used for household consumption, sanitize the well prior to pump

installation. This can be done with chlorine bleach or a dry chlorine compound poured down the

well just before (or just after) a pump is installed. Consult a local supplier or environmental health

authority for a recommended procedure.

8 PUMP INSTALLATION

8.1 ASSEMBLING THE DROP PIPE, CABLES, AND SAFETY ROPE

Tie the rope underneath the well seal or well cap. If the well cap does not have a place for a rope,

drill a hole in the casing and install an eye bolt. Prepare this detail BEFORE installation of the pump!

Do not leave the rope exposed to sunlight, as it can damage the outside of the casing.

When tying the rope to the pump, it’s important to make a knot that will not slip under tension (a

double half-hitch knot is recommended). If unsure of how to properly secure the pump to the rope,

please use the following method: before passing the rope through the eyelets, make a simple loop

knot 3 or 4 feet from the end of the rope, leaving it loose. Now pass the rope through the eyelets and

bring the end back up. Feed it up through the loop knot so that it doubles the loop and pull the knot

tight—it should feel secure with no tendency to slip.

8.2 MACHINE INSTALLATION

If professionally equipped to install conventional AC submersible pumps, the same equipment can be

used for SunRotor® solar pumps. This method is used primarily for pumps with a set depth of 150 ft

www.sunrotor.com Page 22

Page 24

or more. If setting the pump less than 150 ft, consider using the Hand Installation (See Section 8.3

Hand Installation). It may take less time to drop or pull the pump by hand than it does to use a pump

service truck, especially in a difficult location.

8.3 HAND INSTALLATION

WARNING: Hand Installation can be hazardous. There are potential hazards in handling

any heavy mechanical assembly. If there are any doubts about the ability to SAFELY install

by hand, please hire a professional pump installer. Any injury or damage sustained by

using this method will be the sole responsibility of the installer.

CAUTION: DO NOT use a winch to install or remove the pump. To remove the pump, pull

up the rope, cable, and pipe simultaneously; otherwise, there is a risk of having the

flexible pipe and cables sag down and jam between the pump and casing. This can cause

damage or loss of equipment, and potentially, even the loss of the well itself.

CAUTION: DO NOT use a vehicle to pull the pump. To remove a pump installed by hand,

use HAND POWER only! During removal, the pump can catch on joints or edges in the

casing. Any problems along the way will be felt as you pull by hand. Any damage for

neglecting these warnings will void the warranty.

Lay a barrel (metal oil drum or similar rounded object) next to the wellhead. Run the pipe, cable, and

rope over the round surface, to ease the downward bend and to prevent scraping against the edge of

the casing. Wear leather gloves.

Lower the pump slowly and carefully. To verify the static water level, assign a helper to listen

carefully for a splash as the pump hits the water. You can then determine the static level by

measuring the length of remaining pipe above ground.

The in-well assembly should hang with the weight on the pipe. Tie the rope securely, inside the

casing. Do not attach the rope to the removable cap of the casing, or it will prevent easy removal.

CAUTION: Do not support or pull the pump by the safety rope alone.

Pulling only the rope can cause the cable and pipe to sag and to jam in the casing. It must

be grabbed by the pipe and cable along with the rope. Wear tough leather work gloves.

8.4 RUNNING THE CABLES

Run the pump and low water sensor cables through well seal assembly to the specified grommets on

the bottom of the controller (See Figure 6-1 SunRotor® Controller Design).

If using flexible conduit, attach one end to the top of the well seal assembly and run the wires though

it. Place the connector on the controller side of the flexible conduit and run the cable trough and into

the controller and attach the connector to the controller.

Page 23 www.sunrotor.com

Page 25

9 WIRING THE SYSTEM

9.1 ELECTRICAL WARNINGS

ATTENTION: Wiring the panels in the wrong configuration (series or parallel) can send

excessive voltage and damage the controller. Be confident in understanding the system’s

wiring configuration and voltage limitations (See Figure 5-3 Solar Panel Wiring Diagram for

examples) prior to connecting the solar array to the controller. Additionally, it is

recommended that the panels are covered or shaded when connecting them to the

controller to prevent damaging the equipment. Any damage caused by ignoring these

warnings will not be covered under the warranty.

WARNING: There are live electrical currents with high voltages present that can cause

SERIOUS INJURY OR DEATH. Please use extra precautions and thoroughly read through this

section prior to wiring the system. Follow all appropriate electrical codes. If unsure, hire

a professional. Solar Power & Pump Company is not liable for personal injury or damage

to the equipment.

Please read through this entire section prior to wiring the system. If any questions or concerns on

safety or correct wiring are present this process, please contact your Authorized SunRotor® Dealer or

the SunRotor® Technical Services Team at 1(866) 246-7652.

9.2 WIRING THE CONTROLLER

Run the pump and sensor cables through the bottom of the controller. The use of spade connectors at

the end of your wires is recommended for easy maintenance and repairs in the future.

ATTENTION: Installing a low water sensor is HIGHLY recommended. This device sends a

signal to the controller—which in turn shuts the pump off—if water in the well drops

below the sensor set depth. This protects the pump from running dry.

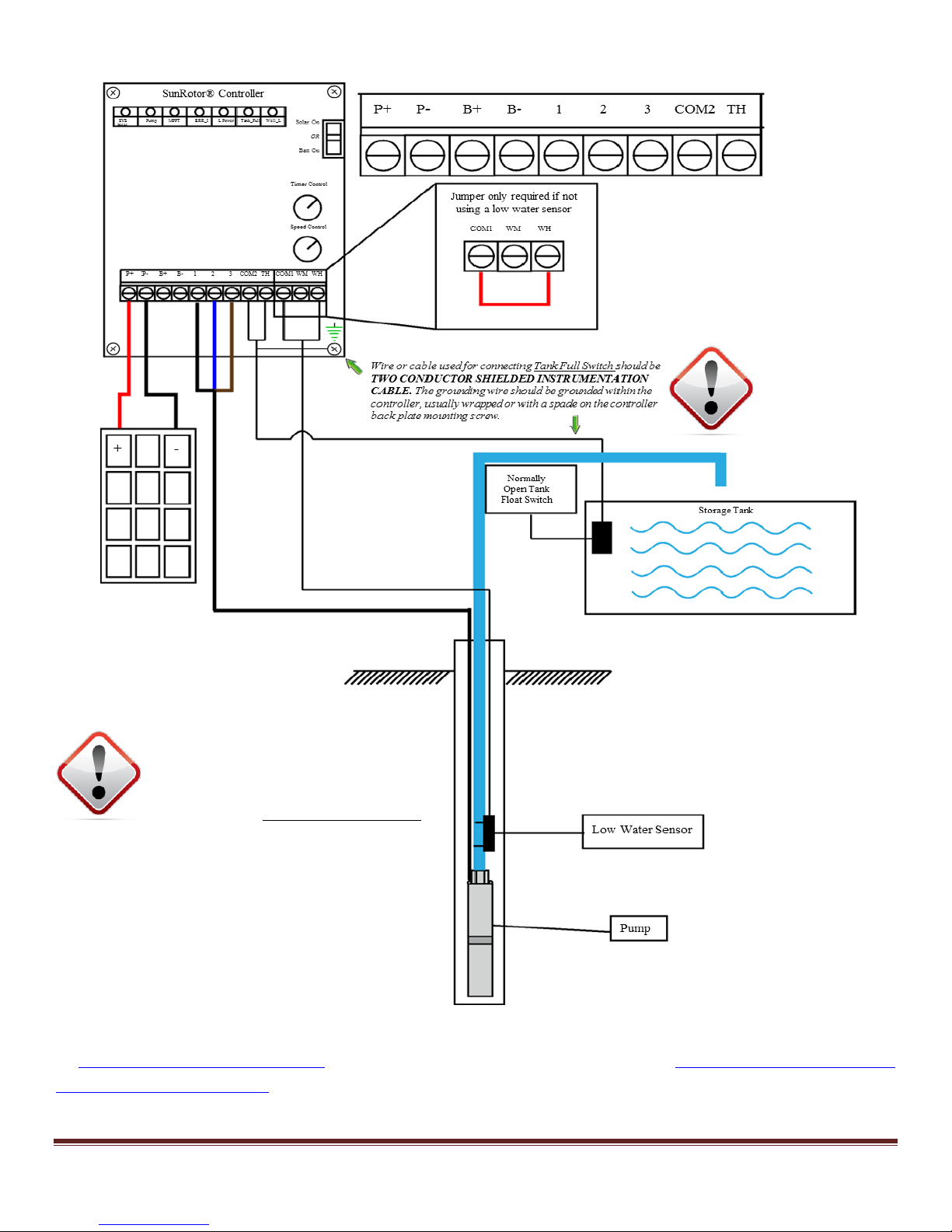

As shown in Figure 9-1 SunRotor® Pump Controller Wiring Diagram, attach the two wires to

the COM1 and WH terminals. If no low water sensor is used, a jumper is required for the pump to

run.

Wire or cable used for connecting the Tank Full Switch should be two-conductor shielded

instrumentation cable. The use of this cable helps prevent potential lightning damage normally

associated with a lengthy string of cable. Additionally, a ground wire is included in this type of

cable. Similar to the low water sensor, the wires need to be attached to COM2 and TH terminals.

The ground wire should be attached to the nearest back plate mounting screw (See Figure 9-1

SunRotor® Pump Controller Wiring Diagram).

www.sunrotor.com Page 24

Page 26

FIGURE 9-1 SUNROTOR

SunRotor® Submersible pumps have a

strict submergence limit of 100 FT.

Exceeding this depth could damage the

pump and will VOID THE WARRANTY.

®

PUMP CONTROLLER WIRING DIAGRAM

Wire the pump cable into the controller. If the corresponding wires were written down as suggested

in Section 7.2 Splicing Your Wires, attach them accordingly; otherwise, use Figure 9-1 SunRotor® Pump

Controller Wiring Diagram to wire the pump properly (typically terminal 1: black; terminal 2: blue;

terminal 3: brown on most SunRotor® model solar pumps). If unsure, attach the pump wires to any

Page 25 www.sunrotor.com

Page 27

of the numbered terminals, and power up the controller to test the pump direction. If no water is

pumped, or if there is suction on the outlet pipe (this only applies to helical rotor pumps—centrifugal

pumps will produce about ¼th flow rate), turn off the power and switch any two of the three pump

cable wires. This will reverse the pump rotation. Turn the pump back on, and confirm water flows

at the proper rate from the pipe. If no water flows after switching two wires, turn the power off and

contact either your Authorized SunRotor® Dealer or the SunRotor® Technical Services Team at 1(866)

246-7652.

9.3 WIRING POWER TO THE CONTROLLER

The SunRotor® controller comes equipped with MC-4 cable connectors already attached to the proper

controller terminals. Ensure the solar array wiring configuration and voltage before attaching the

connectors (See Figure 5-3 Solar Panel Wiring Diagram). Make sure the controller is set to the OFF

position and plug the corresponding female and male ends together.

9.4 POST-INSTALLATION TESTING

The following tests are recommended after completing the installation.

To test the low water sensor, disconnect one wire to open the circuit. Since it is a normally closed

switch, removing one end of the sensor cable or jumper will trigger the circuit logic to turn off the

pump. To test the timer function, set the timer to a low setting: somewhere between 0 and 5 (around

2 ½ minutes). Disconnect the cable and wait for the pump to turn off. After the pump stops,

reconnect the cable. The pump should automatically turn back on after the specified time has passed.

Most tank full float switches are normally open. To test it, jumper between the two tank full

terminals. This will create a closed circuit, and the pump should turn off. Once the jumper is

removed, the pump will restart.

If these tests do not produce the same results, see Section 10 Troubleshooting. Please contact your

Authorized SunRotor® Dealer or the SunRotor® Technical Service Team directly at 1(866) 246-7652 if

any further information is needed.

10 TROUBLESHOOTING

10.1 IF THE PUMP DOESN’T RUN

Most problems are caused by incorrect connections (in a new installation) or bad splices on the pump

cable or low water sensor. The SYSTEM light will indicate that the system is switched on. It

indicates that VOLTAGE is present, but there may not be sufficient power to start the pump.

System appears dead, no lights showing on the controller:

1. Is there a disconnect switch or circuit breaker installed on the solar array circuit? Is it off?

2. Look for disconnected or damaged wires.

3. Is there any dust or debris on your solar array?

www.sunrotor.com Page 26

Page 28

Pump attempts to start every 60-90 seconds but doesn’t run:

1. There may be insufficient power reaching the controller. A solar-direct system should start if

there is enough sun to cast a slight shadow.

2. If the pump was recently connected (or reconnected) to the controller, it may be running in the

opposite direction due to a wiring error. See Section 9.2 Wiring the Controller.

3. The pump or pipe may be packed with mud, sediment, or debris.

4. Helical rotor models: The rubber stator may be expanded from heat, due to sun exposure or

pump water that is warmer than 100°F (38°C). This may stop the pump temporarily, but will

not cause damage.

10.2 INSPECT THE SYSTEM

Many problems can be located by a simple inspection. No electrical experience is required for this.

Inspect the Solar Array

1. Is it facing the sun? (See Section 5.3 Solar Orientation).

2. Is there a partial shadow on the array? If only 10% of the array is shadowed, it can potentially

stop the pump.

Inspect All Wires and Connections

1. Look carefully for improper wiring (especially in a new installation).

2. Make a visual inspection of the condition of the wires and connections. Wires are often

chewed by animals if they are not enclosed in conduit or buried.

Inspect the Controller

1. Open the clear hinged door to have an unobstructed view of the terminal strip and circuit

board.

2. First, check for a burnt smell. This will indicate a failure of the electronics. Look for burnt

wires, bits of black debris, and any other signs of lightning or other electrical damage.

3. Inspect the grounding wires and connections. Most controller failures are caused by an

induced surge from nearby lightning where the system is NOT effectively grounded.

Grounded connections must be properly made, tight, and free of corrosion (See Section 5.8

Grounding and Lightning Protection).

Check the Low Water Sensor (See Section 7.5 Low Water Sensor)

If the controller indicates LOW WATER (Well_L indicator light is solid red) when the pump is in the

water, inspect the low-water sensor. The sensor should have been mounted on the drop pipe above

the pump. If inspection is not feasible, bypass the sensor or test it electronically.

1. If the sensor is NOT being used, there must be a wire used to jumper the COM1 and WH

terminals.

2. The sensor must be mounted vertically (within about 10°).

Page 27 www.sunrotor.com

Page 29

3. The sensor or its wires may be broken. Inspect the wires for damage.

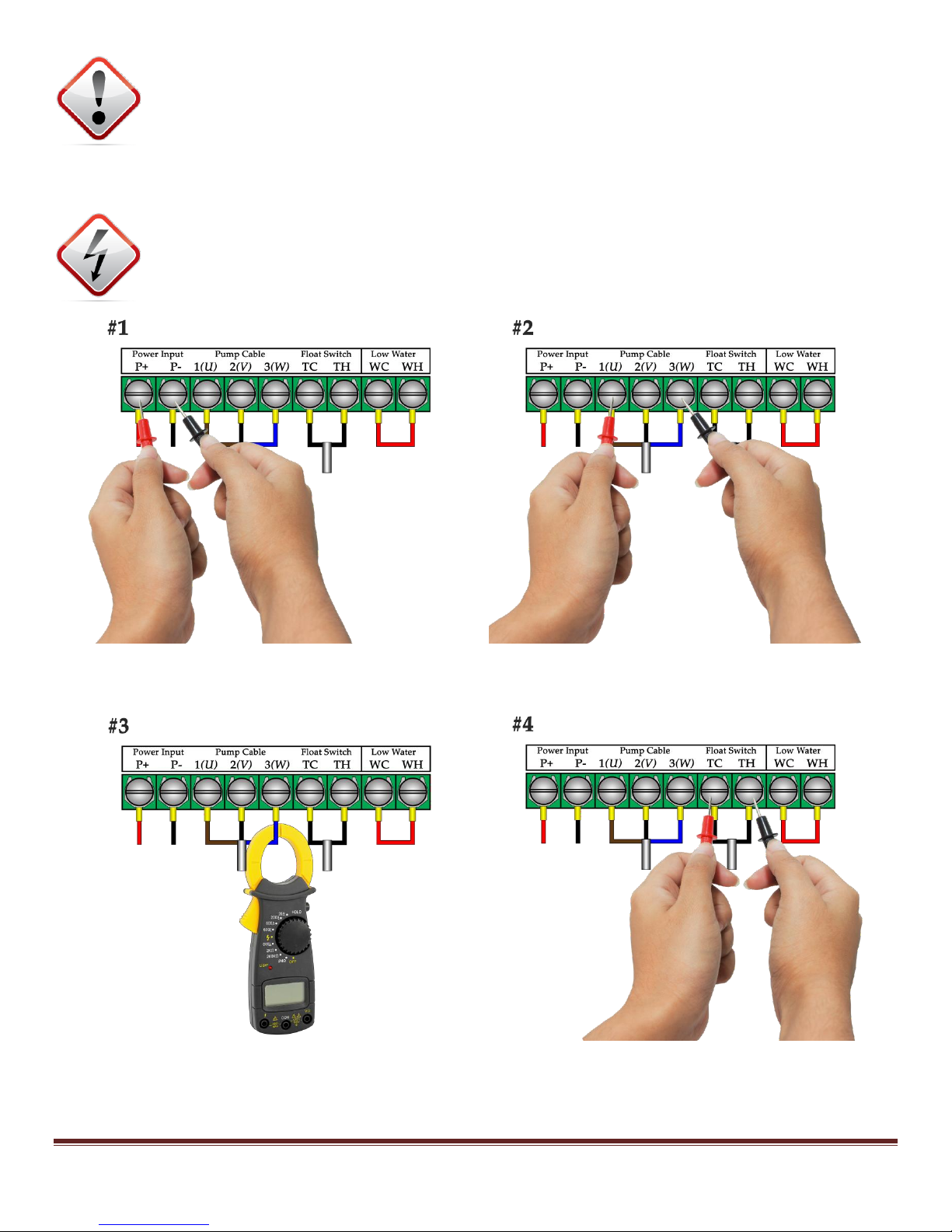

Test/Photo

Number

Test

Description

Notes

Meter

Setting

Probe

Input +

Interpretation

1A

PV (solar) array

open-circuit voltage

Switch the controller to

the OFF position

DC volts

V …

Reading should reflect the VOC

value on the panel label

1B

DC input voltage

during pumping

Switch the controller to

The ON position

DC volts

V …

Indicates proper

controller input function

2A

Pump AC voltage

during pumping

Read any two of the pump cable

wires (1, 2, 3)

AC volts

V …

Voltage determines speed, and

assures that the motor

is spinning

2B

Pump circuit

resistance

Power OFF

Measure ALL 3 pump wires

(1-2 / 1-3 / 2-3)

Ohms

Ω

Ω ...

Normal (0.6 – 1.4) and equal means

the motor, cable, and

splices are all good

3

Motor AC current

draw

Measure any one of the three pump

cable wires

AC amps

AMPS 1A

or higher

Current is proportional

to the torque

load on the motor

4

Resistance between

float switch wires

Check both open and closed circuit

resistances

Ohms

Ω

Ω ...

If there is any resistance other than

0 or ∞, your Tank Full may trip,

causing unwanted stopping of

pump

4. If the pump can run when the sensor is OUT of the water, the float in the sensor is stuck. In

surface water, this can happen from algae, small insects or snails, or other debris.

Check the Tank-Full Float

If the Tank_F indicator light is red when the storage tank is not full, the float switch may be

damaged. Inspect the tank full float switch. It should be mounted to the side of the storage tank

unless a tethered float switch is used, in which case you can find it by following the float switch cable

down to the weight. If inspection is not feasible, bypass the switch or test it electronically.

10.3 ELECTRICAL TESTING

There are several tests that can be performed with a mutlimeter to determine why the solar water

pumping system has failed. Figure 10-1 Electrical Testing will provide you with what settings and

terminals to check. Reference the corresponding images for clarification.

Probe input: Some meters give a choice of probe sockets. The black negative (-) probe ALWAYS goes

in the “COM” (common) socket. The red positive (+) probe varies, and is specified below on each of

the tests.

FIGURE 10-1 ELECTRICAL TESTING

www.sunrotor.com Page 28

Page 30

ATTENTION: To measure voltage, the red positive (+) probe needs to be placed in the

VOLTS socket on the meter. If it is in the AMPS socket, attempting a voltage reading will

cause a short circuit and can damage the equipment.

Access: Open the controller cover to access the terminals. The appearance of the terminals and/or

wiring may vary.

WARNING: These tests pose potential shock and burn hazards to both equipment and

person. Follow appropriate safety precautions. If unsure, hire a professional. Solar

Power & Pump Company is not liable for personal injury or damage to equipment.

Page 29 www.sunrotor.com

Page 31

10.4 TROUBLESHOOTING CHECKLIST

The following items may be causing the solar water pumping system to have less than expected flow

rate or pump failure. Be sure to go through the list before contacting your Authorized SunRotor®

Dealer or calling the SunRotor® Technical Services Team.

1. Is the solar array receiving shadow-free light? It only takes a small shadow to reduce

efficiency. Is the solar array oriented properly toward the south, and tilted at the proper

angle? See Section 5 Solar Array Installation.

2. Has any additional lift or pressure requirements been added or changed? The system was

sized based on specific information provided; if this is changed, there may be a reduction in

flow rate.

3. Are the wires and pipes undersized? If the pump wires and pipe were not adequately sized

for the distances used, the flow rate may not be consistent due to loss in current and/or friction

loss.

4. Inspect and test the solar array input and controller output. Are the values lower than what

the system is rated for? This may be caused by a short in the wire, bad connection or

improperly configured wiring.

5. Are there any leaks in the pipe from the pump? There should be little or no leakage over a

period of hours.

6. Has the pump’s speed control setting been moved lower than the maximum? The speed

control can slow the pump down to 30% of maximum power, and may be causing lower than

expected flow rates if moved.

7. Look in the water tank or pipes:

a. Is the AC motor current lower than normal? The rotor and/or stator may have been

worn from too much abrasive materials or particles (sand or clay) in the water. See

Section 11 Maintenance for more details on how to change the rotor/stator.

b. Is the AC motor current higher than normal? Does it have trouble starting in low light?

This is likely related to a blockage in the pump and/or pipe.

c. Is there sediment accumulating in the pipes or tank? Additional accessories may be

needed to keep from damaging the system (See Section 7.10 Coping with Dirty Water

Conditions).

Additionally, age may be a factor. After many years of use, it may be necessary to have the motor

rebuilt or replace the pump end. For more information and services provided, please contact the

SunRotor® Technical Services Team.

11 MAINTENANCE

One of the defining features of the SunRotor® solar pump product line is its ability to be repaired at a

fraction of the cost of buying a new replacement. A little care and attention can extend the life of the

system drastically and save money in the long run.

www.sunrotor.com Page 30

Page 32

WARNING: The power should be turned OFF, as well as the pump wires removed, prior

to performing any maintenance on the pump or other equipment. Disregarding this

warning may lead to DEATH or SERIOUS INJURY. Follow any and all local, state, and

federal electrical standards and procedures and use caution.

11.1 HELICAL ROTOR PUMP END MAINTENANCE

The helical rotor pump line offers one of the easiest procedures for maintaining water demands. In

locations where abrasive minerals or sediments reside in the water source, both the rotor and stator

can eventually wear down, which in turn decreases the flow rate of the system. To replace these

parts, the pump will first need to be pulled from the well. Before starting any service, please turn off

the controller and disconnect the pump wires to prevent any high voltage current from causing

injury or death.

After the pump has been pulled from the well, begin dismantling the pump end. First, take off the

filter screen by removing the screws holding it secure to the pump. Next, remove the three (four on

some models) bolts holding the cast pump end in place. Once removed, access to the stator will be

available. Pull the worn stator from the rotor. Inspect the rotor for damage. If the rotor is

undamaged push a new stator on and replace the pumps end.

If the rotor is damaged, remove the three (four) bolts from the motor and remove the pump housing.

Remove the setscrews in the motor coupler (rubber piece) and unscrew the rotor from the motor shaft

(counter threaded, turn clockwise to remove). Install the new rotor and replace the setscrews in both

ends of the rubber coupling. Re-attach the pump housing, install the stator and then the pump end.

Finish with reinstalling the filter screen. In most circumstances, this will be all that is necessary to

regain the original flow rates. Set the pump back as it was in the initial installation. Once everything

is back in place, turn the pump on and observe the flow rate. There should be an observable increase

if the worn rotor/stator was the only underlying fault in the system.

11.2 CENTRIFUGAL PUMP END MAINTENANCE

Centrifugal pump ends currently do not offer the same convenience of field repair as the helical rotor

pump ends. Contact your Authorized SunRotor® Dealer or the SunRotor® Technical Services Team

for more information.

11.3 PUMP MOTOR REPAIR

All of the SunRotor® solar pumps—with the exception of the SR-26—have repairable pump motors.

Winding damage on the motor is currently unrepairable. If the pump motor is found to be the cause

of the system failure, contact the SunRotor® Technical Services Team for available rebuild options.

11.4 SOLAR PANEL MAINTENANCE

Depending on the region the system is installed, a few key procedures will help in maintaining the

required water demand. Many solar pump installations will be located in fields and other rural

areas, prone to the elements and dirt blown by the wind. If accessible, wipe or hose down the solar

Page 31 www.sunrotor.com

Page 33

panel array occasionally to prevent dust and debris build-up on the solar array. This will ensure the

system is being provided with all of the available power produced by the panels.

11.5 MISCELLANEOUS

Debris, livestock, insects, and other creatures can cause the system to run at less than optimal speeds.

When available, check wires, cables, pipes, and hose for damage caused by any number of

environmental circumstances. A few minutes to give the system a once-over can extend the life of the

solar water pumping system.

11.6 REPAIRS AND REPLACEMENTS

In the event that the pump needs to be repaired and/or replaced, contact the SunRotor® Technical

Services Team at 1(866) 246-7652 or 1(580) 303-4015. You will be provided with an RMA number.

ATTENTION: DO NOT send any equipment back to SunRotor® Solar Products without an

RMA. Your equipment may be lost or mishandled without the proper identification.

Detailed instructions will be provided upon contact. If required to send the pump back for repair or

replacement, please cut the pump cable above the splice (on the controller side). Including the splice

helps to determine the cause of the pump failure.

In the case of controller failure, return only the circuit board, not the enclosure. Remove the four (4)

screws holding the aluminum backplate to the enclosure. Return only the circuit board and

backplate.

For all other parts and accessories, contact the SunRotor® Technical Services Team.

www.sunrotor.com Page 32

Page 34

12 ABOUT SOLAR POWER & PUMP COMPANY

Solar Power & Pump Company, located in Elk City, OK, was founded in 1998 by CEO/Owner Dennis

Austin. Dennis graduated from SWOSU in Weatherford, OK with a B.S. in Industrial Technology.

He spent many years working all over the United States building advanced systems including, but

not limited to, remediation equipment, pumps and controllers, emergency power systems, as well as

programming automated systems and controls. Eventually, he moved back to western Oklahoma

and his family roots, and began selling and installing solar water pumping systems. Noticing some

trends and possible positive changes within the machinery and design of the current systems out

there, he decided to branch out and have his own solar submersible pump designs manufactured.

In 2008, SunRotor® Solar Products was born. Using knowledge gained from throughout his career,

paired with the knowledge passed along from family in the water business, the first highly efficient

and affordable SunRotor® solar pump was introduced to the market. Since then, more models have

been added, as well as new features, with new and innovative designs and functions planned for the

future.

In late 2013, Solar Power & Pump Company expanded once again, this time purchasing a well-known

and established solar surface pump line, Dankoff Solar out of Santa Fe, NM. Dankoff Solar has been

offering solutions for solar surface water pumping applications for 36 years, and perfectly

complements the SunRotor® solar submersible pump product line. Pairing the two products, many

of our customers are finding new and inventive ways to meet any number of water demand

applications.

It is the goal of Solar Power & Pump Company to not only bring the most efficient and cost effective

products to the market, but to continue to grow the industry. Currently, there is new technology

being developed, with hopes of changing how the world meets their water delivery needs.

One of the biggest factors in Solar Power & Pump Company’s success has been its growing dealer

base. Their eager willingness to provide the highest level of customer service has been without a

doubt pivotal to the company’s continued growth and success. These values and work ethic, which

are well known in the South or any small farming community, have expanded well beyond the

region, and are now experienced throughout the global market in a manner that makes us all proud.

Last, but certainly not least, thanks need to be given to the loyal Solar Power & Pump Company

customers. Through their patience and understanding, a wonderful partnership has been formed,

and their word of mouth has been some of the best advertising ever experienced. For that, thanks

alone could never be enough. It is the hopes and dreams of Solar Power & Pump Company that all

the work put into new product development, as well as continuing to make the current products both

more efficient and cost effective, will show our vast gratitude. Please never hesitate to contact us by

any form, be it phone, e-mail, or website submission for any number of reasons—product inquiry,

suggestions, etc. Thank you again.

SunRotor® Solar Products Team

Page 33 www.sunrotor.com

Page 35

13 ADDITIONAL INFORMATION

Solar Power & Pump Company prides itself on offering each and every customer with easy access to

as much information as needed—no matter the reason or motivation. Below are some additional

links that may be of use.

SunRotor

®

Downloads and Resources—all of the products’ spec sheets, warranty, and other

educational documents are available here

https://www.sunrotor.com/downloads

SunRotor

®

Warranty Registration—visit this page to register your solar pumping system

https://www.sunrotor.com/warranty-registration

SunRotor

®

Renewable Energy Incentives—find all of the important tax deductions available

when using a solar powered water pumping system