Page 1

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

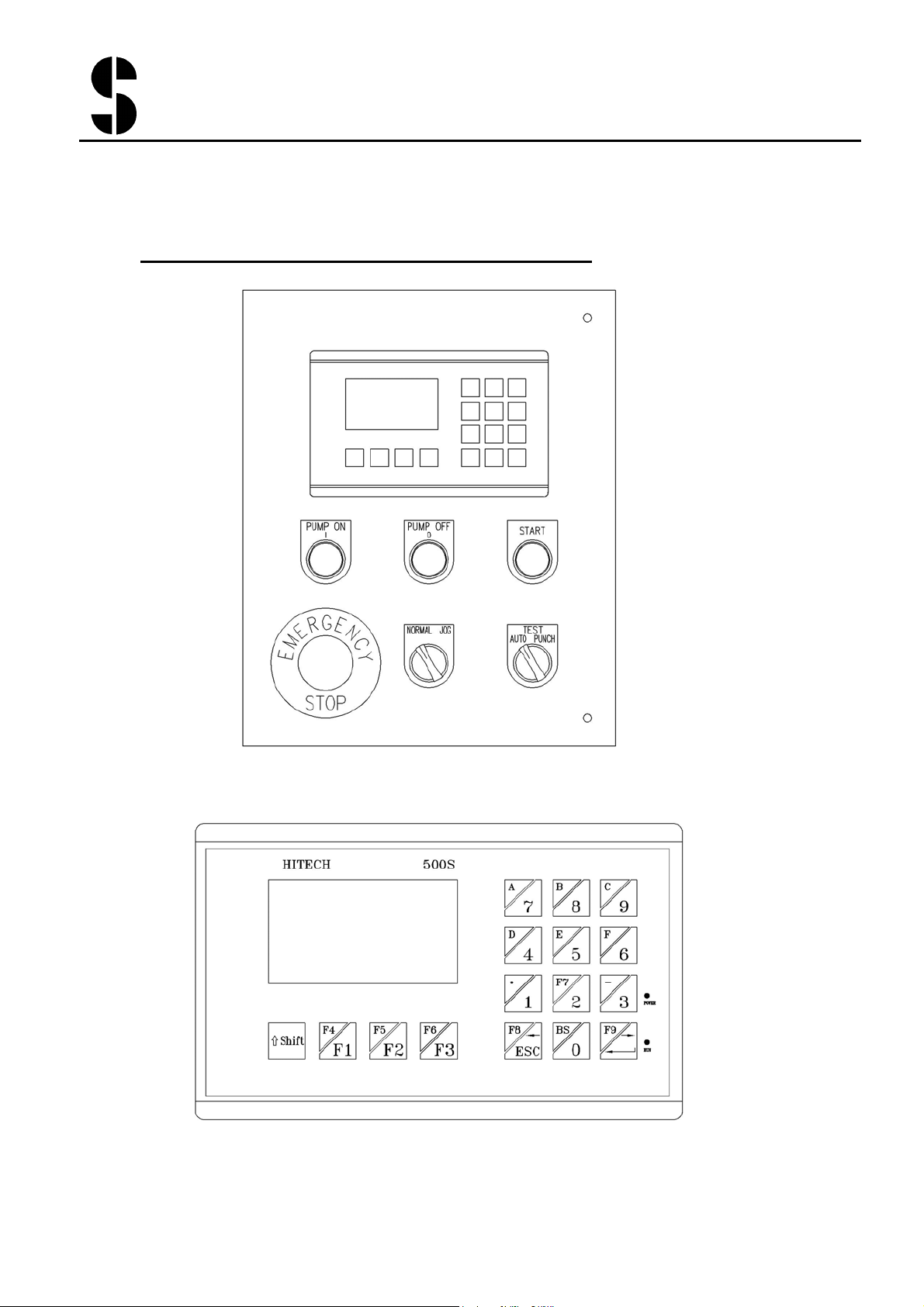

1. Buttons and Switches on the Controller Panel:

Page 2

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

Page 3

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

z Emergency Stop: Stop the machine in emergency.

z PUMP ON: start the motor

z PUMP OFF: stop the motor

z NORMAL/JOG switch: switch between cylinder normal movement

and jog movement (refer also to Operation Modes)

z AUTO/TEST/PUNCH switch (refer to section below on Operation

Modes)

z START: Run programs. Light flashes during program execution. If

any of the select switches is turned before the end of program, the

program stops.

2. Opertion Modes:

AUTO: Run the program and execute punch. The Stoppers moves

automatically to next position after each hole is punched.

TEST: Run the program without punching. The stoppers moves

automatically to next position each time the foot paddle is pressed, but the

cylinder does not punch the hole. Use this mode to test the correctness of

the program.

PUNCH+NORMAL: Execute punch without using the NC stoppers.

This is like using the normal PM machine to punch holes. Use this mode

to check the correct setting of the stroke limit switches. In the mode, the

stoppers can be moved by the cursor keys, but cannot run programs.

PUNCH+JOG: The cylinder moves down when the foot paddle is pressed,

but does not move back up when the paddle is released. Use this mode for

checking the punch alignment each time the tool is changed. The NC

stopper does not function in this mode.

Note: in AUTO and TEST modes, the NORMAL+JOG is non-functional.

The cylinder moves only as Normal mode and not Jog mode.

Page 4

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

3. Operation Sequence

1) Turn on power. Be sure the emergency button is released. Screen

will be on after a brief self-check.

2) Be sure the stripper is closed.

3) Press Pump ON to start the motor

4) Turn to PUNCH+NORMAL mode and check the limit switch for

cylinder stroke adjustment is set correctly.

5) Turn to AUTO mode. The screen will prompt you for calibration

6) Press F6 (shift+F3) to calibrate the stoppers

7) After calibration, the screen switches to the function mode.

8) Press one of three type of programs (F1, F2, or F3)

9) In the Array or Cust program screen, press the program number to

call out the previously stored program, or use F8/F9 to move up/down

the program numbers.

10) In the desired program, enter the values for each of the parameter

fields. Use ESC and Enter keys to move up/down the parameter

fields.

11) Press F5 to store the parameter fields.

12) You may switch to TEST m ode to test run the program, or in AUTO

mode press START to run the program and execute punching. The

stoppers move to the first hole of the program.

13) If in TEST mode, press the foot paddle to move to next hole. If in

AUTO mode, press the foot paddle to execute the punch. After the

hole punching is completed, the stopper automatically moves to the

next hole (if any).

4. Calibration of NC stopper

Each time the power of the machine is turn on, you will need to first

calibrate the NC stopper. Press F6 (shift+F3) and the NC stopper will

calibrate itself. When the NC stoppers stops and screen switch to

Function screen, calibration is completed. If problem occurs, Err. 23

appears (refer also to section “Error Messages”). Press F7 (Shift+2) at

anytime to enter the calibration screen again.

Page 5

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

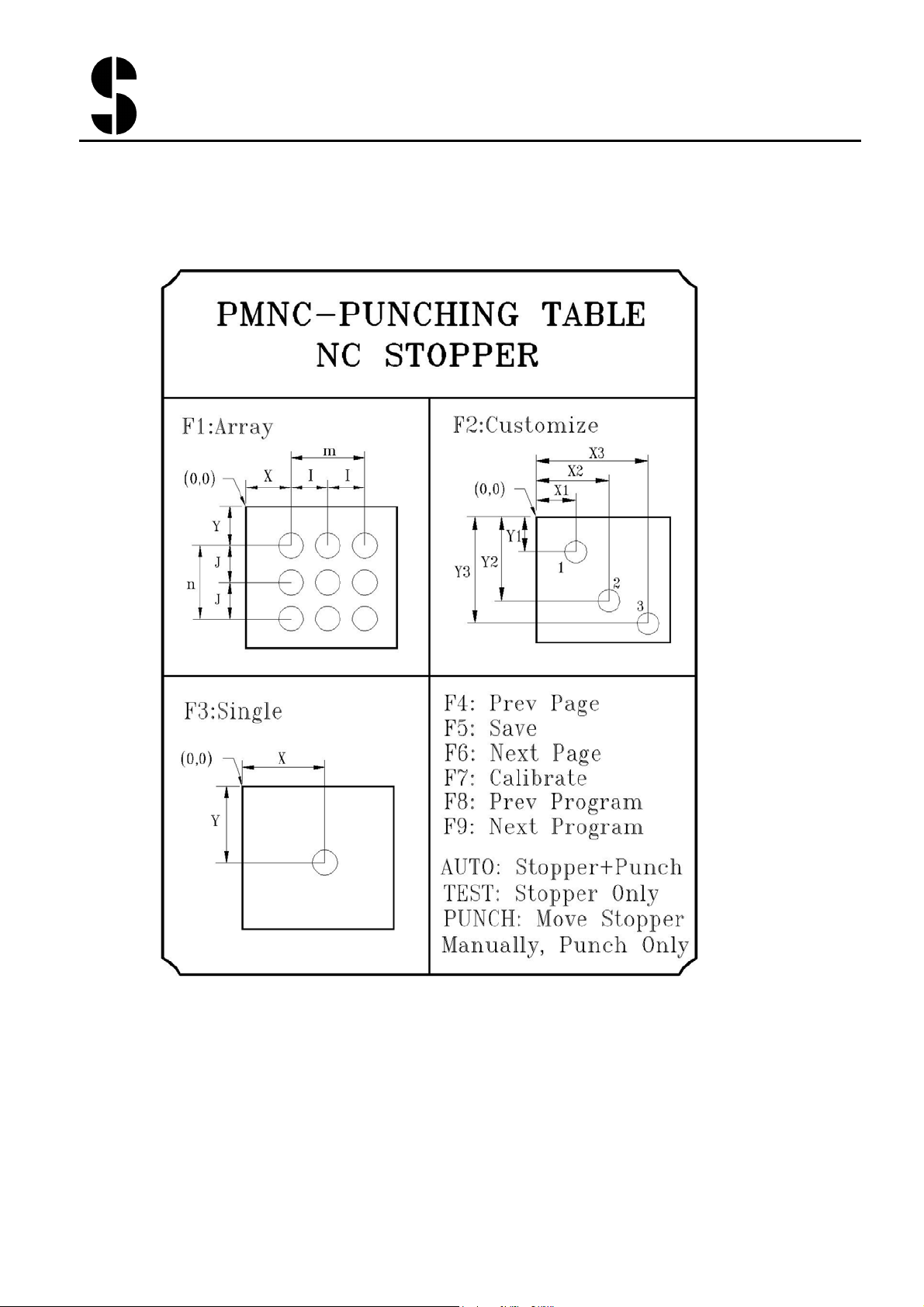

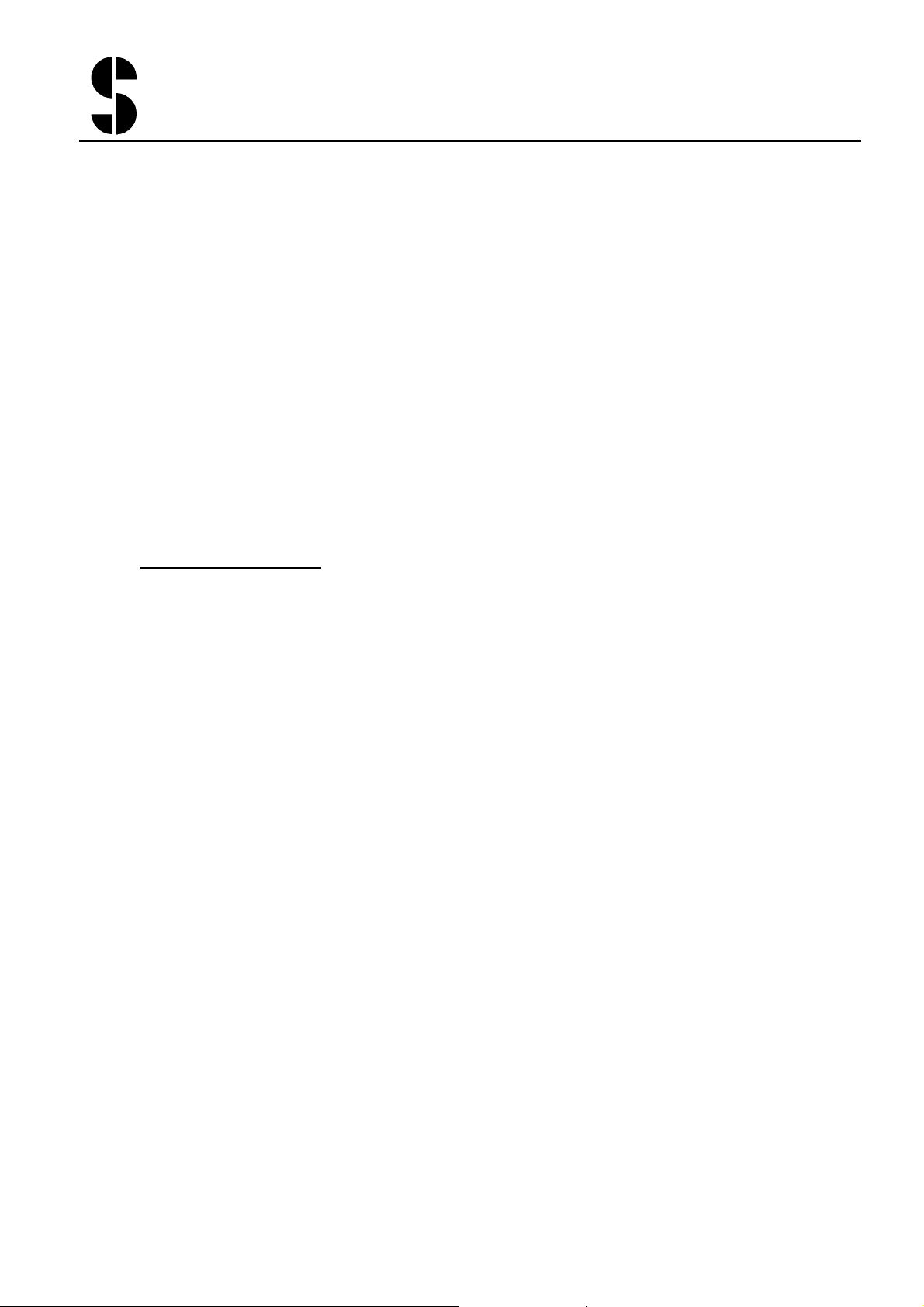

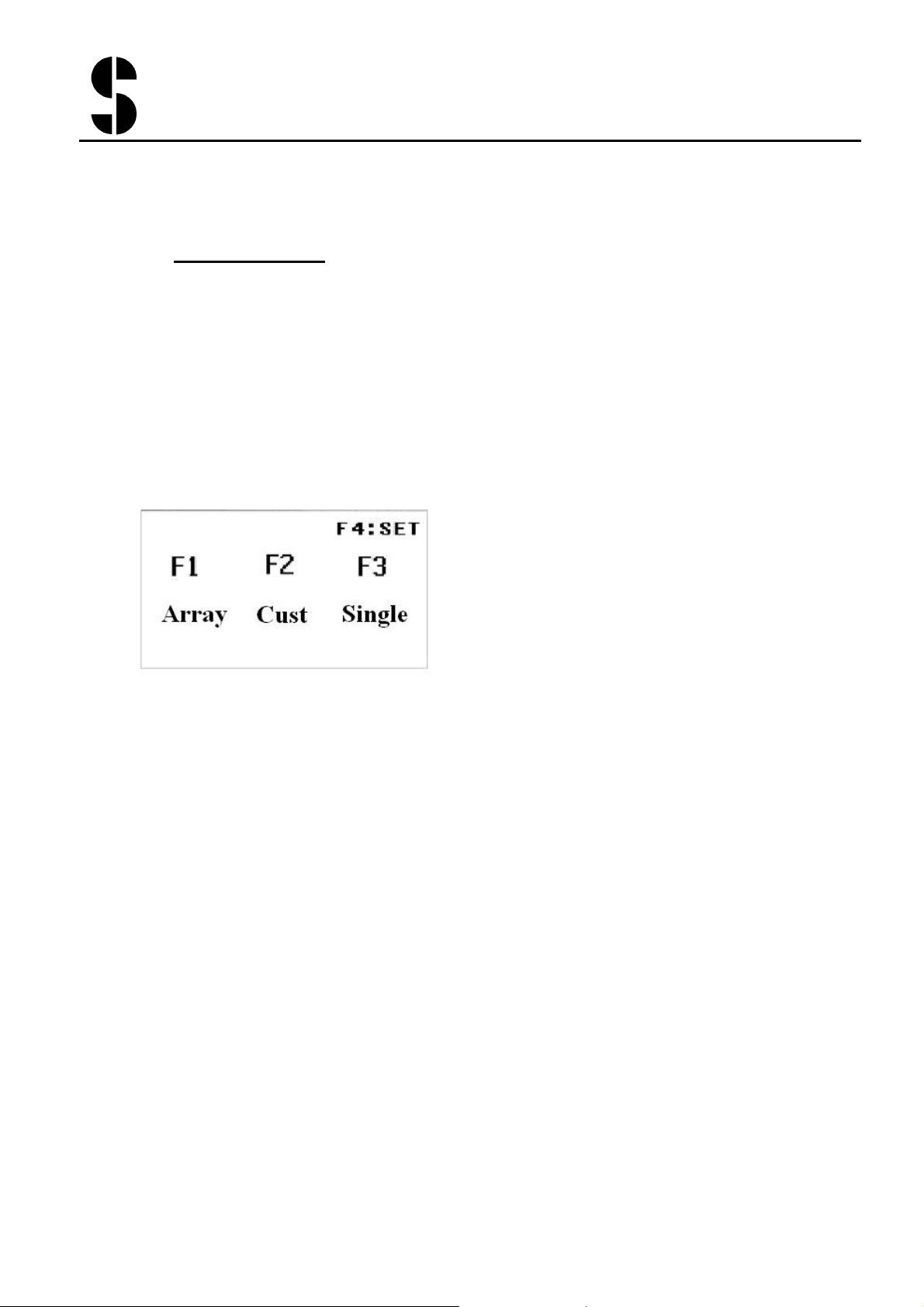

1. Function Screen

There are 3 types of programs available in the controller. Array program

is array program of holes. Up to 99 Array programs can be stored in the

controller. Cust program is a series of customized holes (up to 20 holes in

one program). Up to 25 Cust programs can be stored in the controller.

Single program is single hole punching. It is useful to move the stoppers

to a precise desired position. Single program cannot be stored.

Press F1 to enter the Array Program Screen

Press F2 to enter the Cust Program Screen

Press F3 to enter the Single Program Screen

Press F4 (Shift+F1) to enter the Setting Screen (password required)

You can press F1, F2, F3 at anytime to enter the program screens.

Page 6

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

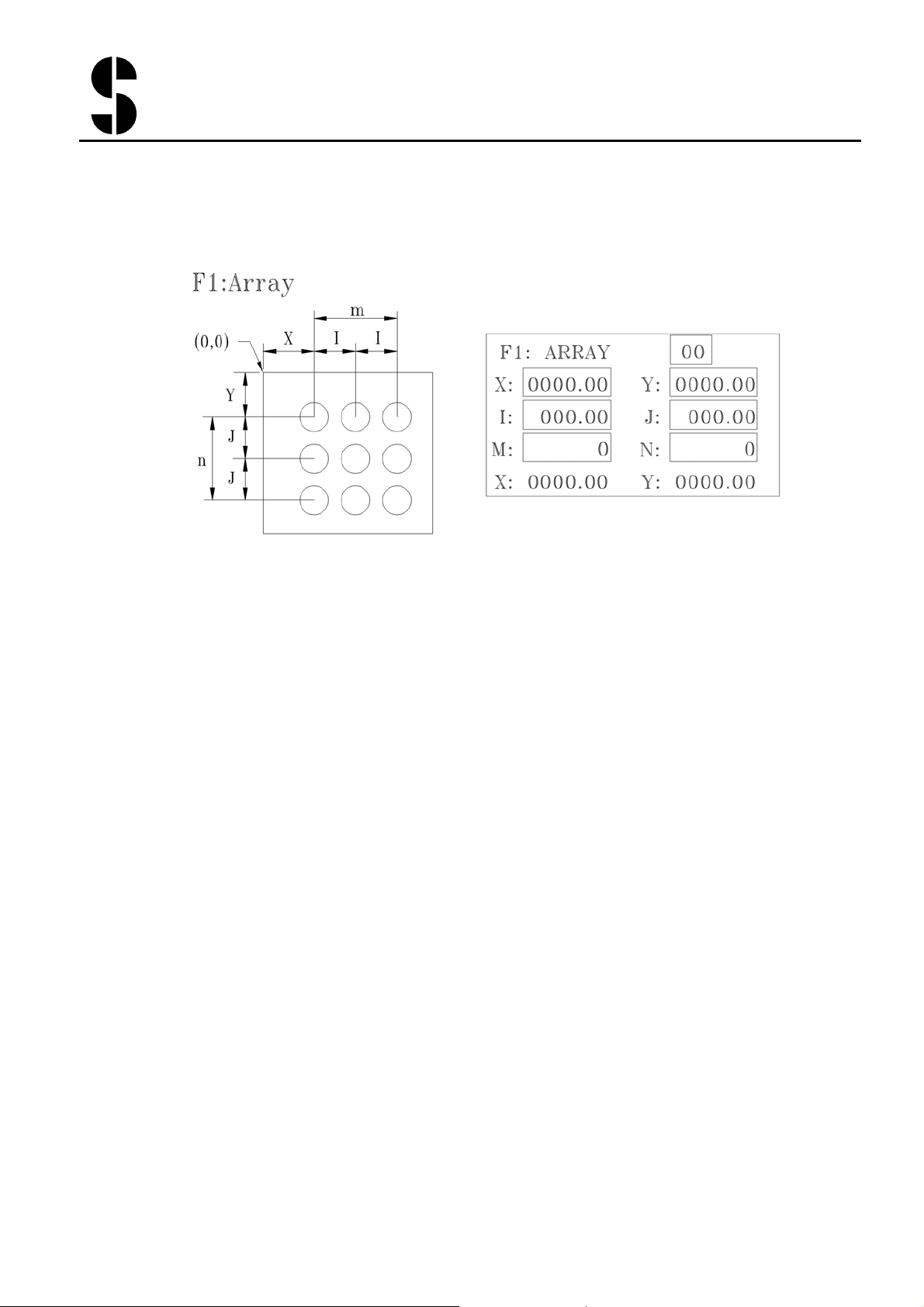

Use the ESC and Enter key to move to previous and next parameter field

and enter the value with the number pad. The allowed number range is

shown while entering the value.

Array Number (1 to 99) up to 99 sets of array program can be stored. Call

out any previously stored program by enter the array number.

F8 (Shift+ESC):Previous Array program number

F9 (Shift+enter):Next Array program number.

X:X-coordinates of the first hole

Y:Y-coordinates of the first hole

I:distance to the next hole in X direction

J:distance to the next hole in Y direction

M:number of holes in X direction

N:number of holes in X direction

X and Y in last line shows the current position of the NC stoppers

F5:Save the entry. If switch to other screen without press F5 first, then

the entered values are not saved.

Press START to execute the program, NC stopper moves to first hole.

Page 7

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

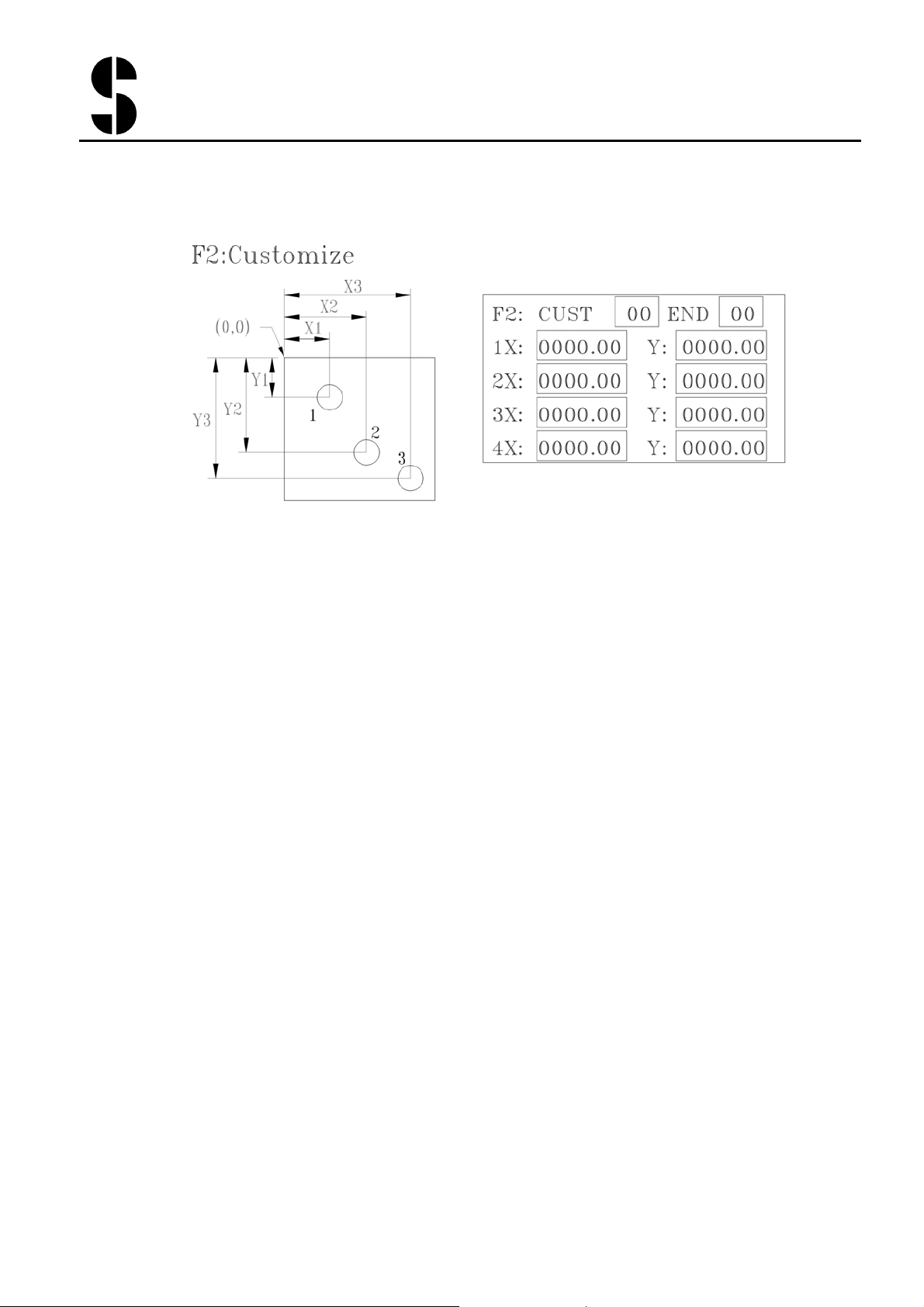

Use the ESC and Enter key to move to previous and next parameter field

and enter the value with the number pad. The allowed number range is

shown while entering the value.

CUST Number (1 to 25) up to 25 sets of array program can be stored.

Call out any previously stored program by enter the array number.

F8 (Shift+ESC):Previsous CUST program number

F9 (Shift+enter):Next CUST program number.

1 X,Y:Coordinate of the first hole

2 X,Y:Coordinate of the 2nd hole

….

20 X,Y:Coordinate of the first hole

Up to 20 holes can be stored in one Cust program, but only coordinates of

4 holes are shown on the screen at one time.

F6 (Shift+F3) : Next Page (next 4 holes)

F4 (Shift+F1) : Previous Page (previous 4 holes)

END: enter the value indicate the number of holes in this Cust program.

Example: END=3, then only the first 3 holes (1X,1Y), (2X,2Y), (3X,3Y)

will be punched when running this program.

F5:Save the entry. If switch to other screen without press F5 first, then

the entered values are not saved.

Press START to execute the program, NC stopper moves to first hole.

Page 8

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

Use the ESC and Enter key to move to previous and next parameter field

and enter the value with the number pad. The allowed number range is

shown while entering the value.

X,Y:Coordinate of the hole

Note: X and Y in last line shows the current position of the NC stoppers

Press START to execute the program, NC stopper moves to hole.

Page 9

SUNRISE

Fluid Power Inc.

6.

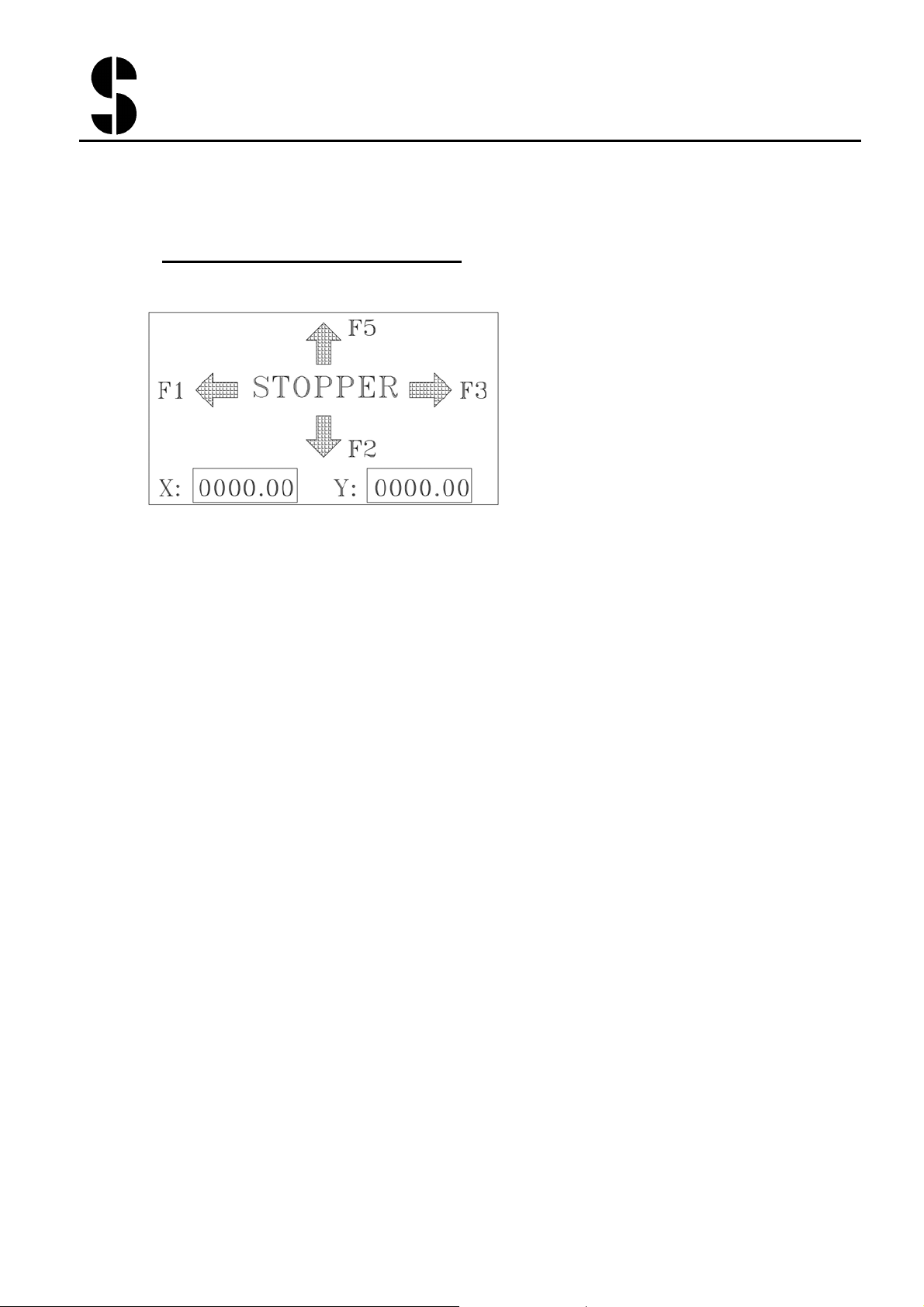

Manually move the NC stoppers

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

Turn to PUNCH mode and the screen switches to the manual mode. Use

the cursor to move the stoppers. Current position of the stopper is shown

on screen.

F1:Move the X-stopper to left(X-Axis value increase)

F2:Move the Y-stopper toward you(Y-Axis value decrease)

F3:Move the X-stopper to right(X-Axis value decrease)

F5 (Shift+F2):Move the Y-stopper away from you(Y-Axis value

increase)

X,Y:Current position of the NC stoppers

Page 10

SUNRISE

Fluid Power Inc.

7.

Setting Screen

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

WARNING:

incorrect entry of these setting parameters may result to

malfunctioning of the table or even damage of the table. The setting are

preset in factory before shipment, and should be changed only by

qualified maintenance/service personnel.

I)

If the origin point is off, or you need to adjust the software

protection of X and Y travel range (min and max of X and Y table

travel), you will need to change the parameters in the travel setting

screen.

To enter the setting screen (Password Protected), press F4 and you

will be prompted for password. Enter

and following setting

7777

screen appears:

F8: previous setting page

F9: next setting page

X-s:Set the value of the X stopper after calibration.

Y-s:Set the value of the Y stopper after calibration.

Mi(X)/Mi(Y):Set the minimum value of X and Y stopper travel range.

Ma(X)/Ma(Y):Set the maximum value of X and Y stopper travel range

These Min/Max values are also call the software travel range.

Page 11

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

To enter the motor parameter setting screen

II)

prompted for password. Enter

and following setting screen appears:

6666

press F4

and you will be

Tolerance level: this is the tolerance level allowed for the difference

between the programmed value compared to the actual value. If the

difference is greater than the tolerance level, then the set value, the

program stops and the Error screen is shown.

Motor Frequency: Set the motor frequency. (unit: pps)

Acceleration/Deceleration Time: Set the motor acceleration/deceleration

time. (unit: ms)

Press F4 to exit the setting screen.

Page 12

SUNRISE

Fluid Power Inc.

8.

EURROR MESSAGE

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

Error 11: When the movement of the cylinder is required but the pump is

not turned on.

Solution: Press “pump on” to turn on pump.

Error 12: Before execute a program, the cylinder needs to be at the top

position. If the cylinder is not in top position (e.g. cylinder moved down

in JOG mode) and the “Start” is pressed, Err 12 is shown.

Solution: Turn the switch to “punch” to move the cylinder to top position.

Error 13: The Stripper is open. For safety reason, the machine will not

move when the stripper is open.

Solution: close the stripper.

Page 13

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

Error 14: In Array mode, the value of M and N cannot be 0.

Solution: Press F1 to Array screen, enter values greater than 1 for M and

N parameter.

Error 15: In Custom mode, the value of the END cannot be 0.

Solution: Press F2 to CUST screen, enter values greater than 1 for END

parameter.

Error 21: The Stopper has reached the Hardware Min or Max travel range

allowed (set by proximity switches).

Solution: Select PUNCH mode. Use cusor key (F1, F3, F2, F5) to move

the NC stopper away from the Min or Max position.

Page 14

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

Error 22: The Stopper has reached the software Min or Max travel range

allowed (set by Mi/Ma parameters in SET screen).

Solution: Select PUNCH mode. Use cusor key (F1, F3, F2, F5) to move

the NC stopper away from the Min or Max position.

Error 23: In Calibration, the NC stopper is not able to find the origin

position after certain time.

Solution: check the origin proximity switch to see if the contact piece is

positioned too far or if the switch is broken. Turn power off then turn on

power again to reset the controller and try to calibrate again. If problem

persists, contract Sunrise agent for repair.

Error 24: During running an ARRAY program, the difference between the

actual position and programmed position is greater then the tolerance level

(set in Setting screen).

Solution: Check if there is any obstruction on the NC stopper to prevent it

from moving smoothly (e.g. stopper need to push too heavy a plate).

Press F1 to leave the error. Note: if the tolerance level is set too small,

this error may happen more frequently.

Page 15

SUNRISE

Fluid Power Inc.

No. 7, Road 12, Industrial Zone,

Taichung City 407, Taiwan, R.O.C.

Tel: 886-4-2359-1190 Fax: 886-4-2359-3409

E-mail: awtkao@ms1.hinet.net

Error 25: During running an CUST program, the difference between the

actual position and programmed position is greater then the tolerance level

(set in Setting screen).

Solution: Check if there is any obstruction on the NC stopper to prevent it

from moving smoothly (e.g. stopper need to push too heavy a plate).

Press F2 to leave the error. Note: if the tolerance level is set too small,

this error may happen more frequently.

Error 26: During running a SINGLE program, the difference between the

actual position and programmed position is greater then the tolerance level

(set in Setting screen).

Solution: Check if there is any obstruction on the NC stopper to prevent it

from moving smoothly (e.g. stopper need to push too heavy a plate).

Press F3 to leave the error. Note: if the tolerance level is set too small,

this error may happen more frequently.

Loading...

Loading...