User Guide

Air source heat pump water heater

Air Source Heat Pump

Domestic water

circulation series

Key Locking and Unlock

7.8 Other Functions

5. 4

Installation Scheme

0

0

0

1

Temperature ranges

A

m

The heat pumps are d esigned

Lasting

All units have high efficiency compressors with durable features which can withstand high temperatures

and high pressure. The tubes are placed in a shell heat exchanger which is durable against anticorrosion, hard water, high pressure and unexpected freeze caused by power cut-offs.

s

e

. A

a

ing the

temperatu re of the cir culating water. Voltag e protection, water coil and free ze protection.

at all times.

ensure

meets local safety reg ulations.

ensure that

to heat

not exposed

Anti-free zing measures must be impleme nted correctly to avoid damage to the water syst em and the

heat pump ex changer.

Please take i nto accou nt the heat pump size and we ight when transporti ng.

Ensure that the main source of power is off when installing.

material

Simple maintena nce and servicing

allation sp ace.

Strong Cabinet

s

monitorin g the

Produc t serial nu mbe r:Ⅰmeans th e first gen era tion , Ⅱ mea ns the seco nd genera tio n.

Identi ficatio n cod e of manufa cture: T me ans S unra in, T means Sun rain

X means wa ter circu lat ion air sou rce heat pu mp wa ter he ate r, refrig erant cir cul ation or

static h eating mo del o mitted

Heatin g capalit y, un it:L/h

C means fo reign tra de se ries air so urce heat p ump w ater h eat er, domes tic serie s omi tted

Auxili ary energ y cod e: D means av ilabel el ect ric er erg y, not code m eans no ele ctr ic energy .

F mean spl it and with out w ater tank t ype

K means ai r source he at pu mp, S mean wa ter sourc e hea t pump .

D means no rthern an d low t emperat ure type ai r sou rce he at pu mp, sourt hern and

common t upe omitt ed

KFC- 75 XTⅠ

KFC- 110XTⅠ

KFC- 15 0XTⅠ

3.51

0.93

4.23

1.35

6.14

5.35

1.37

6.23

2.0

9.0

75

0.75

110

m³/h

<54

936*385*550

936*385*550

1011*420*615

1100*520*740

1100*520*740

1180*560*815

Panasonic

1.99

9.0

2.7

12.3

150

7.4

2

GMCC

GMCC

Sunrain

Sunrain

220~ 2 40/1/50

R410a

R410a R410a

<54

<55

Rotary

Rotary

Rotary

55

60

1

55

60

1

55

60

1

1.1

1.5

Tube in shell

50

60

Dn20

Dn20

Dn20

Tube in shell

Tube in shell

60

40/48 55/65

65/79

IPX4

IPX4

IPX4

220~ 2 40/1/50

220~ 2 40/1/50

Water Outlet

Water Inlet

Power Cable Hole

Controller Cable Hole

Length (mm)

Wide (mm)

650

650

A (mm)Height (mm)Model

4. 2 Dimension

L

H

W

A

High Pressure Gauge

385

385

B (mm)

B

645

420

3

KFC-75XTⅠ

KFC-110X TⅠ

KFC-150XTⅠ

936

936

1011

385

385

420

550

550

615

Model:KFC -75XTⅠ

4

Model:KFC -110XTⅠ

5

Model:KFC -150XTⅠ

6

7

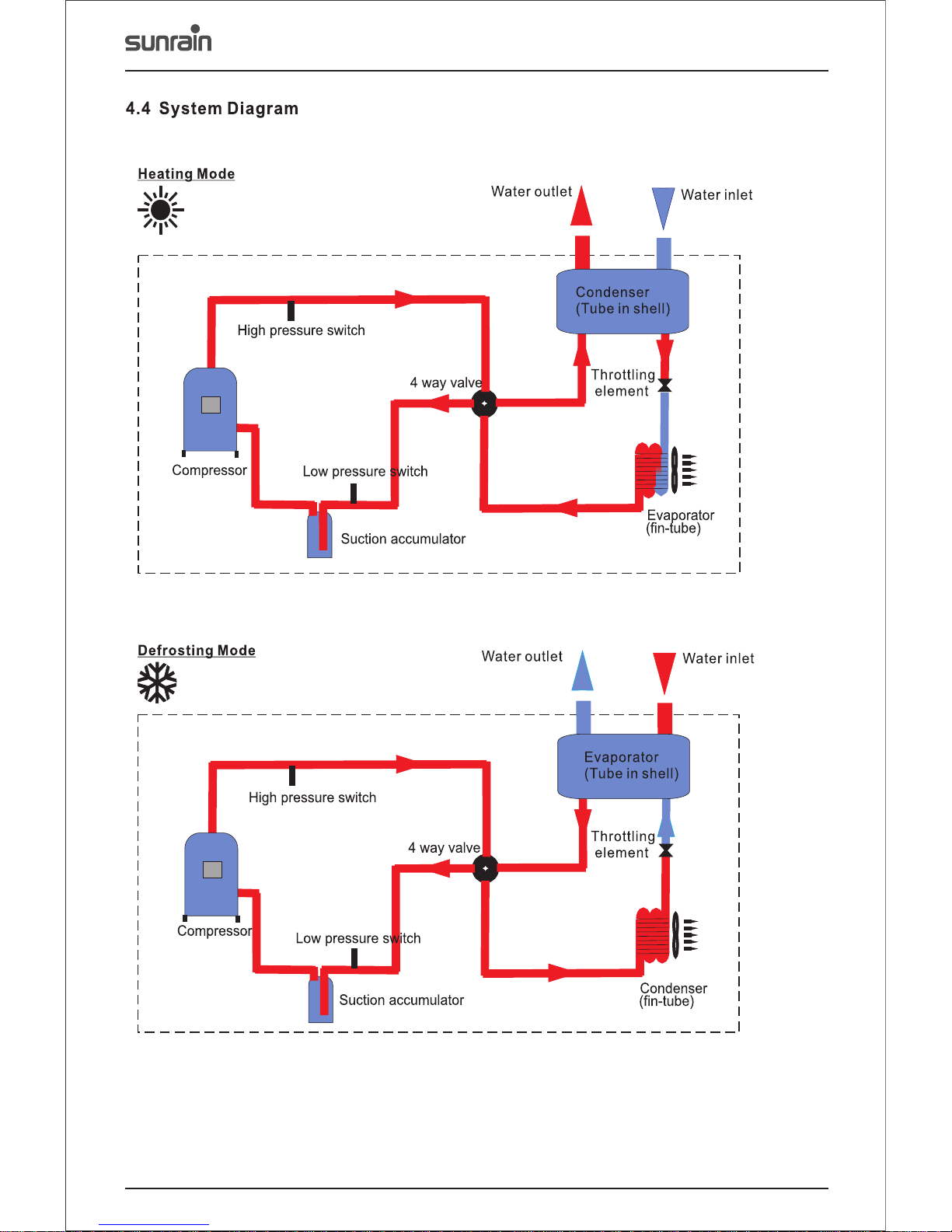

4.5 Components

Compressor

4-Way Valve

The reliable 4 way valve can

avoid gas mixing, and ensure

stable defrosting.

Condenser

Evaporator

ABS Plastic Fan

Photos Features/AdvantagesComponents

Circulation Pump

Famous brand water circulation

pump, e.g. .Grundfos

Refrigerant

LCD Controller

Intelligent controller with LCD readout

and automatical defrosting;

4-timer function available;

12 meter controller wire.

8

The dependable high efficiency compressor,

with optimized R410A system, can achieve

up to 60 degree temperatures, while

ensuring long life of the compressor.

R410A gas, environmental ly friendly

and of high per formanc e.

The tube-in-shell heat exchanger acts as a

condenser, with a bigger heat exchanging

area and greater efficiency for hot water

solutions.

The hydrophilic fin-tube heat exchanger

has a big heat exchanging area and

workable fin distance, thus significantly

improving the efficiency of heating and

defrosting.

The exterior motor fan, with multiple fan

blades. The fan is fixed firmly and its

blades run slower, making sure of high air

volumes while lowering the noise.

Accessories going together with the heat pump:

There are four casing options:

1. General casing: hot galvanised steel or cold steel casing with a powder coated.

2. hot galvanised steel casing with Electrophoresis treated in advance and powder coated. (This

is used for Sunrain domestic heat pumps. With thicker casing and special treated means, this casing

is much better on anti-rust performance.)

Special:

9

1 x SABS Approved Cobra Strainer 1 x Rubber Feet for Installation 1 x User Manual

1 x LCD controller 1 x Water-Proof Controller Box 1 x Wall-Mounted Controller Box

12m x Controller Wire

12m x Sensor Wire

10

uncomplic ated and al low for future access.

If the unit is to be install ed on the floor, the suppor ting fram ework should be mounte d to avoid

intake of water during r ainy seasons. In snowy a reas, it is i mportant to prevent ac cumulated snow

from blocki ng up the esc aping air. The recomm ended height is 20 – 30 cm.

A drain ditch or o ther faci lities should be arran ged under the outdoor un it to collect the water loss.

If installing the unit o n the balcony or roof, the i nstalla tion site must meet the al lowable bearing

capacity of the buildi ng structure, withou t comprom ising the structural s afety of th e unit.

Ensur e the unit is well ventilated, and th e direction of the air exhaust is kept away from windows

of neighboring buildings, and the exha ust air cannot flow back. Furthermore, adequate space sho uld

be available around the unit.

The unit mu st be install ed on a reliable base or framework. The framework should be 3 t imes the

weight of the u nit and safet y measures should be taken to avoid the m alfunctio ning of the fasteners.

Above ground i nstalla tions should be avoide d as much as possible as the u nit may fall and cause

injury

Do not install the heat pu mp close to a road or path to avoid the uni t getting splashed on. K eep

children aw ay from the h eat pump.

5.2 Water System Installation

5.2.1 Water Tank Installation

5.2.2 Water Piping Installation

1. The water tank should be put in place where suggested to install the heat pump, the water tank and

ambient temperature is higher. the circulation pump at the same level.

2. It can be installed either outdoors or on the

roof-top (some elements such as the size of

water tank and the bearing capability of the

building should be considered). Installation on

roof-top should be based on support such as a 4. Do not install the water tank in a pollutive or

crossbeam or pillar. corrosive area.

3.The water tank should not beplaced installed

lower than the base of the heat pump; It is

1. A

drainpipe and overflow pipe should be installed near

the gutter or the sinkhole for draining water more

efficiently. Discharge valve is necessary on the

drainpipe.

discharge valve is necessary on the drainpipe,

stop valve of the system (depending on the

ambient temperature) for avoiding icing of the

water supply pipe and the valves.

6. Keep the water pipes straight and the pipeline

2. Service valve needs to be installed before the

allocation reasonable; Reduce pipe turnings as

magnet-valves on the system pipeline for further

many as possible to reduce water resistance.

inspection.

7.Prevent the pipeline and the connectors from

3. The pressure of the water outlet should be

water leakage.

between 0.3MPa and 0.6MPa.

8.The water pressure bearing capability of each

4.It is recommended to use metal pipeline such

part of the piping system should be tested after

as stainless steel pipes, internal-plastic pipes,

the installation is finished; Drainage should be

internal stainless steel pipes or copper pipes etc;

done to create a clean interior system.

Telescopic issue of the pipeline between heat

9. Measures of heat preservation for the hot

pump unit and water tank should be considered if

water pipeline need to be conducted after

plastic pipeline such as PPR pipe and ABS pipe

assuring no water leakage.

etc. is used.

5. In winter, heat preservation may need to be

carried out on the water supply valve and the

Water

Tank

Water

Tank

11

In addition, the height difference between the heat

pump and the water tank should be no more than

2 meters, when the water tank position is higher

than that of the heat pump.

KFC-75XTⅠ

KFC-110X TⅠ

KFC-150XTⅠ

12

5.3

M

SET

M

SET

5.4. Wire Controller Installation

The wired controller is originally fixed on the maintenance door of the machine; please refer to the

to the steps below you want to install it on the wall:

?1.Take down the controller from the machine. The communication wire is connected with the circuit

board, separate them where they meet.

?2.Use a screwdriver to open the clip as picture 1, separate the controller as 2 parts, as picture 2.

?3.On the wall that you are going to install the controller, drill 2 holes at a level parallel to the sight line as

picture 3. The hole distance is 60mm, diameter is 8mm.

?4.Place the plastic screws of the enclosure into the hole, and use the tapping screw (ST4*16 D-1)

enclosed to fix the back cover of controller on the wall, as picture 4.

?5.Match the front and back covers perfectly, as picture 5, make sure that it is fixed firmly on the wall.

?6.Connect the communication wire firmly.

1 2

5

6

The front cover

60mm

Φ8

3 4

Outlet of the communication wire

ATTENTION:

When the controller is fitted on the wall, don't pull the communication wire, or it may become loose.

The back cover

13

14

release

the

a professio nal

Comprehensive inspection of the entire

system should be a requirement, and ensure

that the water level inside the tank is higher

than the cycling heating outlet and the water

outlet, before the commissioning.

After turning on the electricity, turn on the

heat pump by pressing the on/off key on the

wire control panel.

es

making any ab normal

sounds.

the

Check the cir culatio n pump and all other parts

meet the requirement s. The whole system can

be put into use a fter the pr e-operation.

Menu button

Clock button

C

Timing button

Temperature s ≥

15

.

.

You can start or shut d own the con troller on the main inte rface.

to the main interface by p ressing the

When shutting down, pr ess the button for 5 secon ds

The menu button has both “ ”a nd “ ” , which ca n be used to see all options .

You can push the “M bu tton, S ET” button with “ button to set differ ent funct ions. When

starting, set the wate r temperature using th ese butto ns within a range of 28 – 55℃, the i nitial

value being 5 0℃.

” “ ”

On the main interface, press this button to set the clock and systematic parameters.

-

to the set temperature , will change the system .

1

1

compressor

16

ti mi ng stages

Timing button

Starting up electric heating in line with flashing

Starting up water pump, flashing

Starting up fan flashing.

2

3

4

5

17

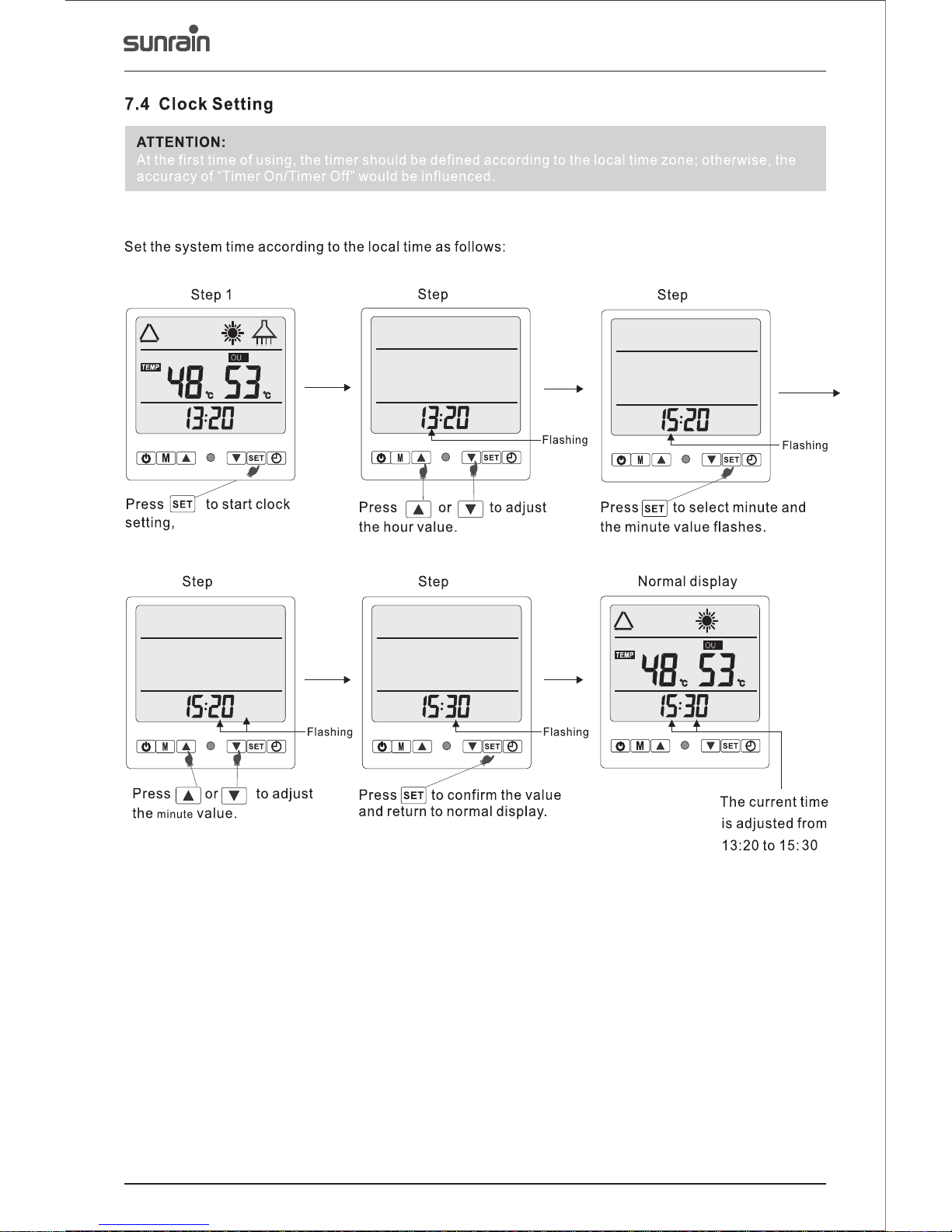

“13:20"(the hour

ralue flashes)

Press the button or

button to set the Hour of the

timing time of turn on.

Press the button, it will

enter the setting interface

of the current timing phase.

Step1

Press the button, it will

enter the turn on/off timing

time checking interface.

Press the button, the

numbers which indicates

the Minute will twinkle.

Step2 Step3

Step4 Step5 Step6

Press the button or

button to set the Hour of the

timing time of turn off.

Press the button, it will

enter the setting interface

of the current timing phase.

7.5 ON/OFF Time Setting

7.5.1

7.5.2

7.5.3

7.5.4

7.5.5

7.5.6

7.5.7

7.5.8

18

On

screen

The time checking sc reen will display the st atus of the t iming phase1 and 2.

On

screen

After

After

h

m

the minutes of the time.

After setting the minu tes, re-press the ‘SET ’ but ton, it wil l show the screen to turn off the tim er.

After setting the turn off timer, r e-press the “SET” butt on to confi rm the current timing ph ase and

return back t o checkin g the turn off and on time r.

In the turn on/off tim er screen , press the button to confirm the cur rent set times and return

back to the on/off tim er.

turn on time.

SET

SET

SET

SET

Step1

Step1

Step1

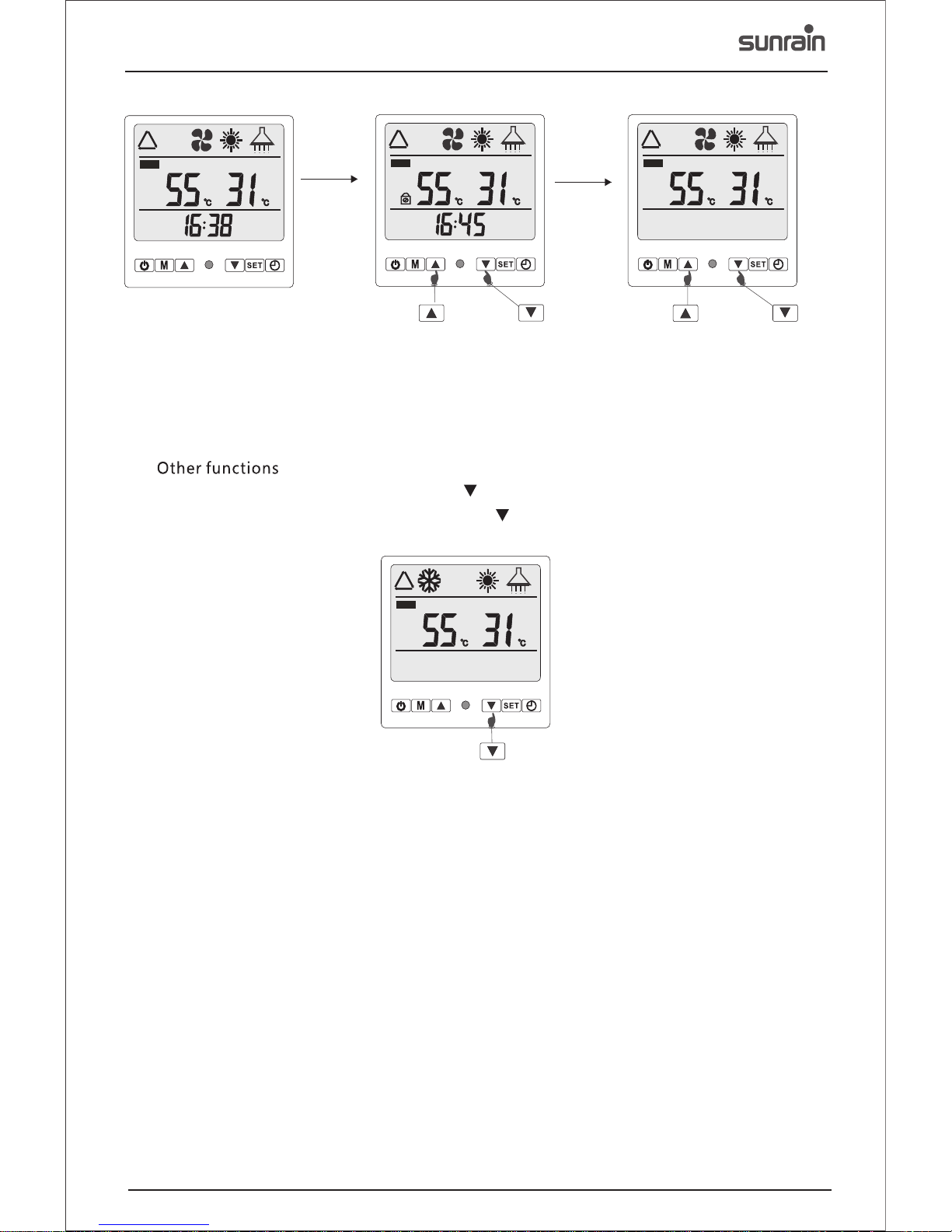

Press button and

button for 5 seconds at the

same time, it will lock the

buttons.

Press button and

button for 5 seconds at the

same time, it will unlock the

buttons.

Long press th e button,

it will enter t he Compulso ry

deforstin g starus.

7.8

20

7.8.1 To check the defrosti ng status , press the“ ” button for a lon ger time.

7.8.2 To start the electric h eating, p ress the ‘M’ and “ ” button for a lon ger time. R epeat this or

turn off the machine t o cancel the electric he ating,

SET

SET

SET

SET

Step1

Step1

Step1

Press button and

button for 5 seconds at the

same time, it will lock the

buttons.

Press button and

button for 5 seconds at the

same time, it will unlock the

buttons.

Long press th e button,

it will enter t he Compulso ry

deforstin g starus.

7.8

20

7.8.1 To check the defrosti ng status , press the“ ” button for a lon ger time.

7.8.2 To start the electric h eating, p ress the ‘M’ and “ ” button for a lon ger time. R epeat this or

turn off the machine t o cancel the electric he ating,

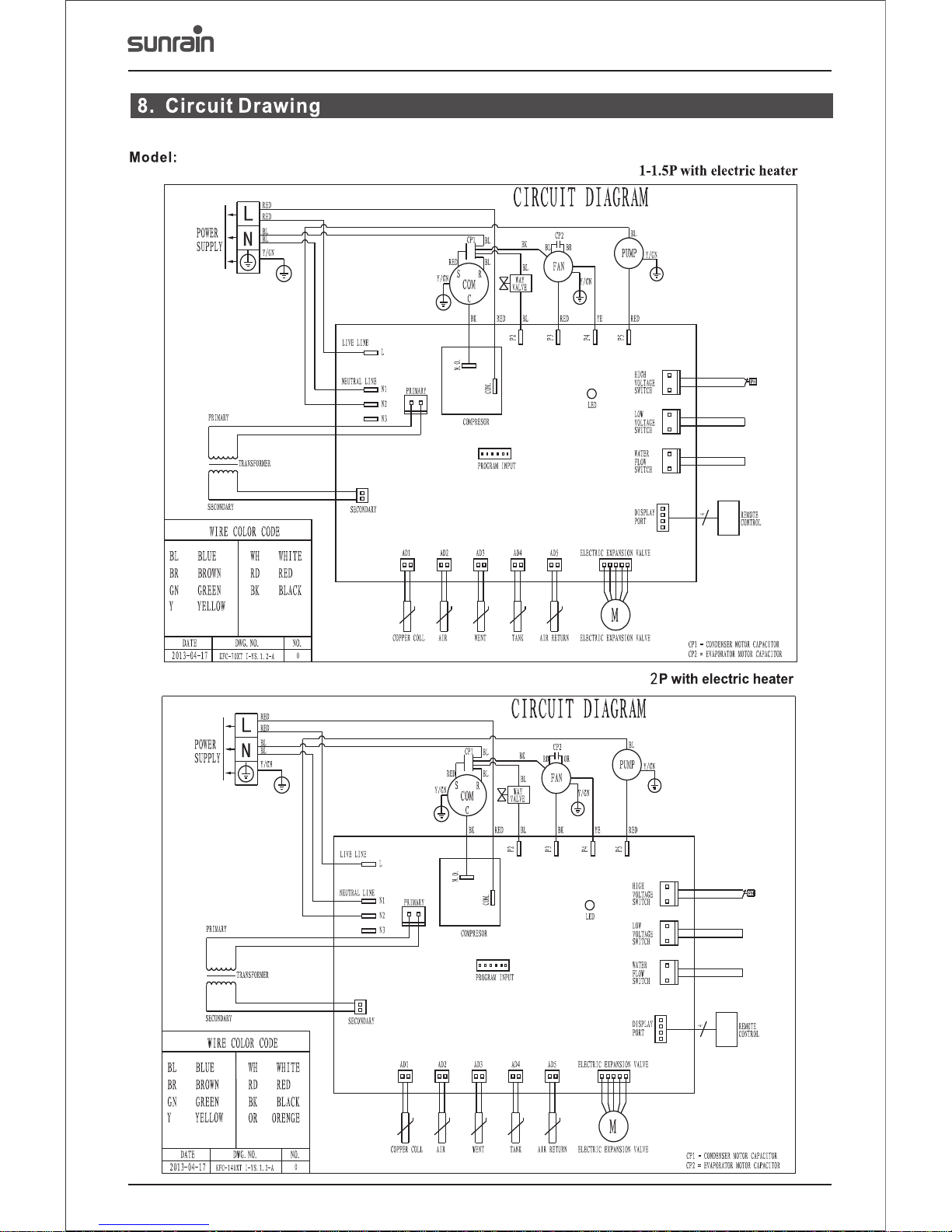

KF C-75XTⅠ/ KF C- 110XTⅠ/ KF C- 150XTⅠ

21

9.1 Maintenance

Keep the surroundings of the heat pump dry, clean

and ventilated. Regularly clean the evaporator to keep

high heat exchanging efficiency.

Check the inside pipe connectors and refrigerant

service port are not dirty with oil. Make sure there is no

The external water filter should be cleaned regularly

refrigerant leakage.

to ensure the cleanness of the water in the system

and avoid damage caused by blockage in the filter.

and shut off thepower supply, and put it into a shield. Full

All protective settings in the unit have been set before inspection of the system is required before next

. Users must not adjust it when

heat pump

exiting the factory the operation.

unit is in use.

Users should call the installer or the seller when there

Regular inspection is required for the power source is an error on the heat pump controller.

and the wiring connection of the electric system. Loose

wiring connection and electric components should be

Clean the condenser with phosphoric acid of 15%

repaired in time.

consistence under temperature of 50C-60C. Run the

circulation pump for 3 hours, and then flush with fresh

water for 3 times. When installing the pipe, add a 3 way

valve on the pipes and add a cover for cleaning use.

Cleaning the condenser with a corrosive washing liquid

is prohibited.

Check the water pump and the valves on the pipes

, and make sure there is no work properly leakage

from connectors.

22

9. Maintenance and Trouble Shooting

The water supply system, relief valve of the water

tank, water level control device and air discharge

davice. Need to be checked regularly in case of low

circulation and low water volume, which is caused

by air entering the system. This is to ensure the

capacity and reliability of the heat pump.

Clean the inside of the water tank after it has been

used for a period of roughly two months (depending

on the quality of water).

Before turning off the heat pump for an extended

period of time, drain out all the water in the pipes,

The heat pump water heater is an advanced

equipment with high automization. The

reliability and operating life of the heat pump can

be and even increased by regular

inspection and effective maintenance.

guaranteed

E

23

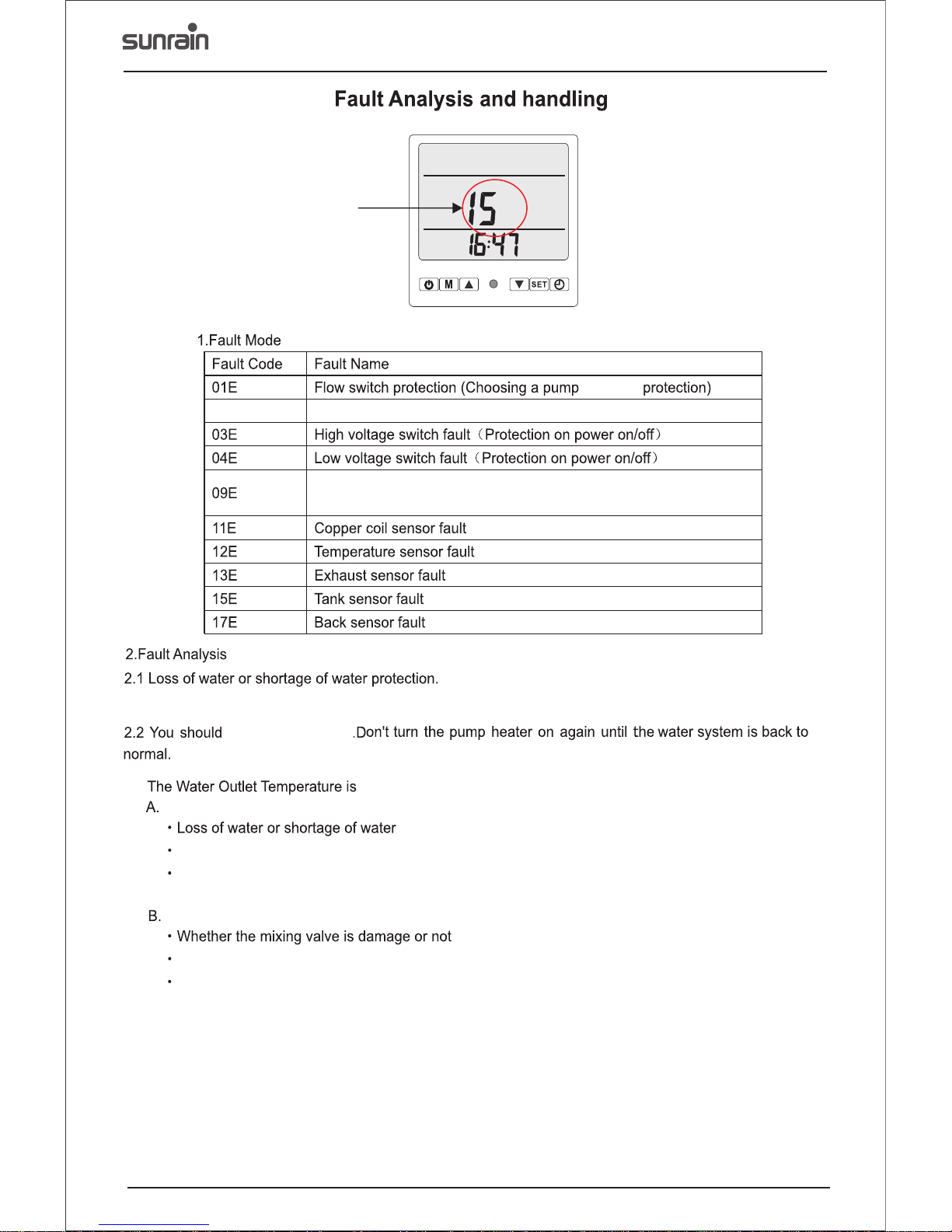

Fault Mode

that has

Protectio n from high e xhaust temperature s

Communica tion faul t (Operation plate did n ot receiv e data from

the main boar d)

The pump heat er will sto p high pressure protec tion when there is a loss of w ater or sho rtage of water.

turn off the power.

2.3

If the water temperatu re is too high – you can inspe ct the pump heater as follows:

Whether the mixing val ve is damaged

Whether the line contr oller works abnormal ly. If it is a bnormally, please replace th e controller

immediate ly.

If the water outlet temp erature is too low – you can i nspect th e pump heater as follows

Whether the line contr oller works abnormal ly.

.

.

.

.

If the controller work s abnormally, pleas e refer to fa ult code or contact a prof essiona l.

2.4 When insp ecting th e fault protection, en sure the pu mp heater has stopped wo rking.

2.5 Af ter removing the fault , the compr essor will not work for an other 3 min utes. The pump heate r will

start to work again. It th ere appears to be low or hig h pressure protectio n or exhaus t temperature

protectio n for 3 minut es, the pump heater will s top worki ng. Af ter the problem has been r esolved the

pump heater w ill work af ter the power has been swi tched back on. If there is somethin g wrong with he

hot water sensor or defr osting sensor, the pump h eater wil l stop working. After rem oving the fault, the

compresso r does not wo rk for about 3 minutes. If t here is a fault with the temperatur e sensor the

pump heater w ill conti nue working.

irregular

24

9.7 Trouble Shooting

0

5

10

15

20

25

30

35

40

45

50

10

15

9.6 Manometer Instruction

Malfunction Possible Reasons Solutions Recommended

Heat pump unit is out of

operation.

1. Power source fault.

2. Loose connection of power wire.

3. Power fuse burnt out.

4. Low water level switch is not on.

1. Cut off the power source and check.

2. Check the power wire connection.

3. Check the fuse.

4. Supply water until the water level switch is on.

Water pump is running

but no water circulation

or much noise made by

water pump.

1. little water in the system

2. Air exists in the water system.

3. Some valves are not opened.

4. The water filters is blocked up.

1. Fill water into the water supply system.

2. Discharge air from the water system.

3. Open all the valves in the system.

4. Clean the water filter.

Low heating capacity.

1. Lack of refrigerant.

2. Faulty water system heat preservation

3. Low evaporator heat transferring.

4. Low water flow volume.

1. Leakage hunting and fix it,discharge all the

refrigerant and inject the right amount.

2. Improve the heat preservation.

3. Wash the evaporator.

4. Clean the water filter.

Heavy frosting, low

heating capacity.

1. The evaporator is too dirty.

2. Defrost sensor fault.

3. The 4 way valve can not change

direction.

4. Long defrosting duration

1. Wash the evaporator.

2. Change to a new defrost sensor

3. Check the solenoid if it is energized.

4. Change the temperature for entering defrost

and the duration.

High noise of

compressor.

1. Liquid refrigerant into the compressor.

2. Interior component of the compressor is

faulty.

1. Check if the thermostatic expansion valve is

faulty.

2. Change the compressor.

0

5

2

0

2

5

30

35

40

45

50

The Manomet er is high pr essure device that a hea t pump uses. When it is on, the Manomet er pointer

should poin t to the maxi mum pressur e value of th e refrigerant. The m aximum pr essure should be

42Kgs to allo w for safe us e. When the heat pump is off, the poi nter will show the ambie nt temper ature

(e.g. 28℃) and related air p ressure (e.g.18 k.g/ Cm)²

When restar ting the he at pump after not using it f or a while, p lease check the manome ter ambie nt

temperature is not sma ller than 2℃, If it is below 2℃, the n the refri gerant has leaked and yo u will

need to confirm with a pro fessional engineer a s soon as possible.

Users shoul d contact t he professional main tenance staff when there is a pro blem with the heat pump.

The maintenance tabl e below may be helpful whe n doing the troublesho oting.

25

Compressor is out

of operation.

1. Power source fault.

2. Compressor AC contactor

damaged.

3. Loose wire connection.

4. Over-heat protection.

5. Over-high water temperature

6. Low water flow volume.

1. Check the power source, change faulty components.

2. Change the contactor.

3. Check every wire connection of compressor.

4. Check gas leakage.

5. Bring down the water temperature value.

6. Clean the filter, check if there is air inside the water

system.

Fan is out of

operation.

1. Loose fan motor wire.

2. Burnt out fan motor.

3. Fan AC contactor fault.

1. Check every wire of the fan connection.

2. Change the motor.

3. Change the AC contactor.

Low water flow

volume protection.

1. Circulation pump fault.

2. Circulation pump is too small.

3. Water filter blockage.

4. Flow volume control device restore.

1. Check the operation of the circulation pump and fix it.

2. Change a bigger pump.

3. Wash the water filter.

4. Adjust or change the flow volume control device.

Over-high

compressor

discharge pressure.

1. Low water flow volume.

2. Thermostatic expansion valve

opening is broken /blocked.

1. Check the circulation pump,and the water filter.

2. Check and adjust the openings, or directly change the

expansion valve.

Over-low

compressor suction

pressure.

1. Not enough gas.

2. Large pressure drops through the

heat exchanger.

1. Check gas leakage.

2. Check and adjust the expansion valve openings.

Shortage of oil in

compressor.

Shortage of lubricant oil.

Find out the su itable ki nd of oil for the compress or and

Inject suitable type o il into the compressor.

Thermostatic

throttle valve can

not start.

1. The switch for it is not open.

2. Low water pressure, water pipe

diameter too small, pipe is too long.

1. Inspect the power source of the solenoid valve.

2. Check if there is blockage in the pipes, and add

boosting pump when necessary.

Malfunction Possible Reasons Solutions Recommended

Our company have the right of amending products and

specifications,and do not give any special notice.

If any fault or omission exiting in the proce ss of printing,

our company have the right of modificatio n momentarily.

Jiangsu Sunrain Solar Energy Group Co.,Ltd

Ma nu facturer : Gu an gd on g Solareast Air Source Energ y Co.,Ltd

Address: XinYue Road No:5-6, Shunde Zone. Foshan City, Guangdong Province.

Zip Code:528300 TEL:4008-603366 Website:www.sunrain.com

Loading...

Loading...