SUNPRO FZ88R, SST802R Installation Instructions Manual

®

STEERING COLUMN MOUNTING INSTRUMENT PANEL MOUNTING PANEL LAYOUT

2-1/4”

9

8

3

5

4

7

1

2

6

TACH

ITEM NO . DESC RIP TION

QTY.

1 1

2 1

3 1

4 1

5 1

6 2

7 2

8 1

9 1

CUP

FEMALE NUT

MALE NUT

M O U N T I N G BRACKET

COLUMN B R A C K E T

#8 LOCK W ASHER

#8-32 ACORN NUT

ADJUSTABLE CLAMP

RUBBER S TRIP

SUNPRO

3-3/8" TACHOMETERS

SST802R, FZ88R

INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

These tachometers are designed for 12-volt negative

(-) ground 4-cycle engines. As sold they are compatible

with most distributor and distributorless ignition systems.

The CP7560 Tach Signal adapter is required to connect

the tachometer to Coil On Plug ignition systems and to

diesel engines with electronic injection.

HARDWARE KIT CONTENTS

Dash Mount Bracket...................................................1 ea

Column Mount Bracket...............................................1 ea

Chrome Cup................................................................1 ea

Adjustable Clamp........................................................1 ea

Installation Kit .............................................................1 ea

CAUTION

Please read this instruction manual and review the

installation procedures carefully before attempting the

installation of your tachometer.

SAFETY GUIDELINES

To prevent accidents that could result in serious injury and/

or damage to your vehicle or tachometer, carefully follow

these safety rules and test procedures.

Wear safety goggles when working on your vehicle.

•

A l w a y s o p e r a t e v e h i c l e i n a

•

well-ventilated area. If vehicle is in an enclosed area,

exhaust should be routed directly to the outside via

leakproof exhaust hose.

Make sure that your vehicle is in Park or Neutral, and

•

that the parking brake is rmly set.

Avoid contact with hot surfaces such as exhaust

•

manifolds and pipes, mufers (catalytic converters),

radiator and hoses.

FUNCTIONAL QUICK CHECK

It is suggested that the tachometer be electrically

connected to the vehicle, (using alligator clip leads or

other suitable means) following the steps below, and an

electrical functional check of the tachometer be made,

prior to making a permanent installation.

Start the vehicle’s engine. Conrm the operation of the

tachometer. Disconnect the tachometer.

INSTALLING MOUNT BR ACKET

Your tachometer is designed to be mounted on any

at or curved surface, or on the steering column

using the clamp kit.

Steering Column Mounting

1. Assemble steering column bracket (5) and cup (1)

using male nut (3) and female nut (2). Tighten male

nut only enough to still allow cup to be positioned to

proper angle.

2. Wrap rubber strip (9) around steering column.

3. Place assembled cup and column bracket on rubber

strip and secure to steering column with adjustable

clamp (8).

Instrument Panel Mounting

1. Select best possible mounting location for good visibility from a normal driving position.

2. Mounting bracket (4) can be used for a marking or

drill template.

3. Drill two 3/16” holes for #8 screws, lock washer and

nuts or two 5/32” holes for #8 self-tapping screws.

This picture is not to scale!

FULL ON E (1) YE AR WARRAN TY

Sunpro, 15825 Ind ustrial Parkway, Clevel and, Ohio 44135, warrants to the

user that this unit will be f ree f rom d efects in m aterials and workmanship for

a period of one (1) year fro m the date of origin al purchase.

Any unit that fails wit hin this period will be repaired or replaced at Sunpro’s

option and wi thout charge when returned to the Factory. Sunpro re quests

that a co py of the origina l, dated sales re ceipt be return ed with the unit t o

determine if the warrant y period is still in effec t.

This warranty does not a pply to damages caused by acciden t, alter ations, or

improp er or unreasona ble use. Expendable items, such as bat teries, fuses,

lamp bulb s, ash tubes are al so excluded from t his warranty.

Sunpro DISCLAIMS ANY LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAG ES FOR BRE ACH O F AN Y WRI TTEN WARRANT Y ON THE

UNIT. Some s tates do not allow the disc laimer of liabil ity for incidental or

consequentia l d amages, so the above disclai mer may or may not apply to

you. T his warrant y gives speci c le gal ri ghts, a nd you may also have rights ,

which vary from state to st ate.

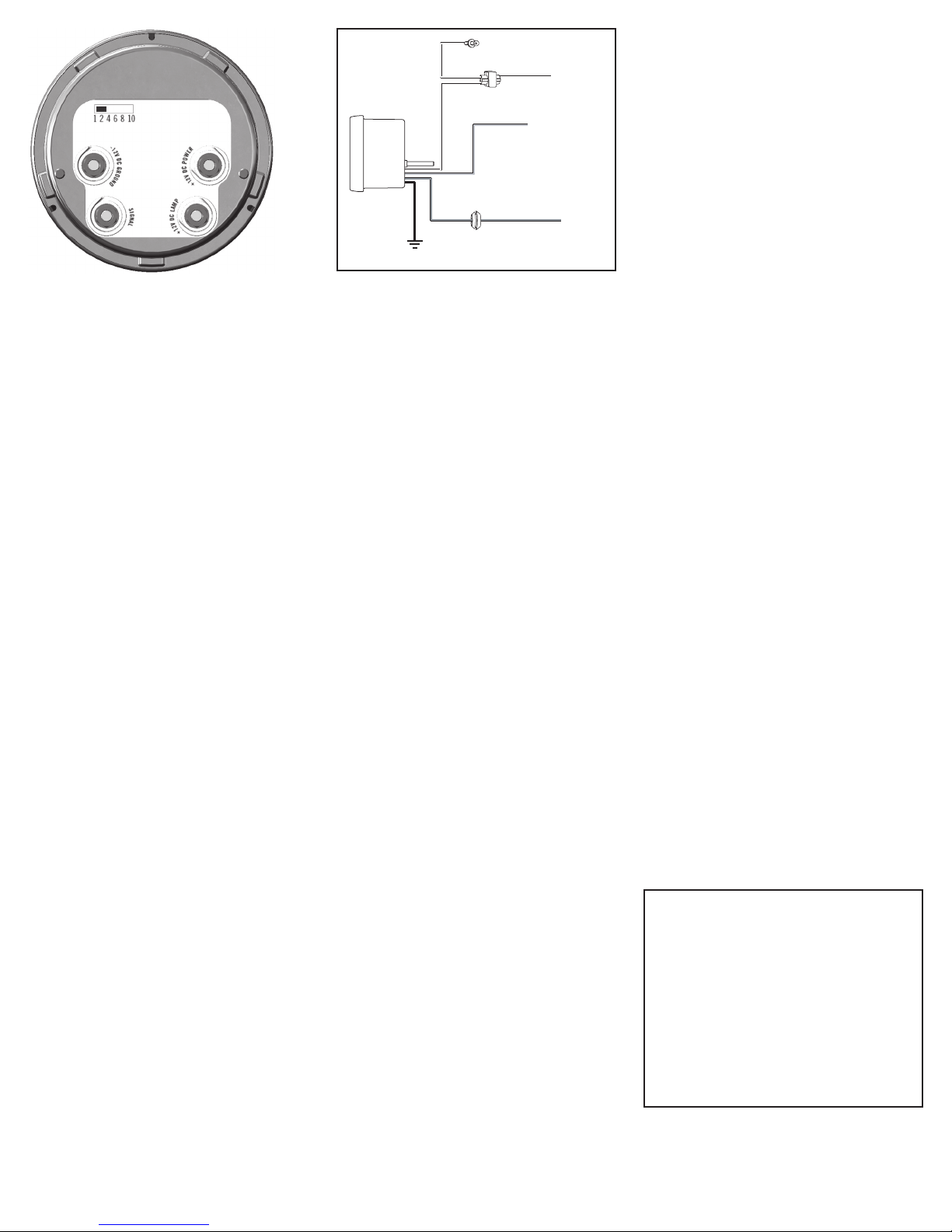

SWITCHED

+12V

SEE SIGNAL

POST CONNECTION

WIRE

SPLICE

TO DIMMER

SWITCH

LIGHT

WIRE

LAMP INSTRUMENT

GROMMET

WIRE

TO GND

GND

WIRE

SIGNAL

WIRE

+12V

ELECTRICAL CONNECTIONS

CAUTION

For your own personal safety, and to prevent possible

damage to the electrical system of your vehicle during

the installation, disconnect the negative (-) battery cable.

Reconnect this cable after installation is complete. Do

not route wires along or against sharp edges, hot engine

surfaces, or near spark plug wires. If needed, drill a 3/8”

hole in the rewall for the grommet (included).

1. Attach wires to tachometer as required.

NOTE: Use # 18 or # 20 AWG stranded automotive

primary wire.

2. Thread wires through female nut (2), cup (1), bracket

(4 or 5) and male nut (3). Note: At this point, items 1,

2, 3 and 4 or 5 should have been preassembled.

3. Leave tachometer out of the cup for now.

SIGNAL POST CONNECTION AND CYLINDER

SELECTION

The Cylinder Selector Switch is located on the back of the

tachometer. The factory setting is 8-cylinders. Change

the setting if necessary.

DISTRIBUTOR EQUIPPED ENGINES

Connect the SIGNAL tachometer post to the negative

(-) side of the ignition coil. This terminal may be referred

to as the TACH, TACH TEST, DEC, or ECU terminal.

Set the Cylinder Selection switch on the back of the

tachometer to match the number of cylinders in the

engine.

DISTRIBUTORLESS IGNITION SYSTEM EQUIPPED

ENGINES WITH A TACHOMETER OUTPUT LEAD

Connect the SIGNAL tachometer post to the vehicle‘s

tachometer output lead.

Set the Cylinder Selection switch on the back of the

tachometer to match the number of cylinders in the

engine.

DISTRIBUTORLESS IGNITION SYSTEM EQUIPPED

ENGINES WITHOUT A TACHOMETER OUTPUT

LEAD

If your vehicle’s DIS ignition system does not have a

tachometer output lead but allows access to the driver

wires from the vehicle computer to the ignition module,

connect the SIGNAL tachometer post to one of the

driver wires.

Set the Cylinder Selection switch on the back of the

tachometer to the 2-cylinder position regardless of

the number of cylinders in the engine.

-12V DC GROUND, +12V DC POWER, AND 12V

DC LAMP POST CONNECTIONS

ALL VEHICLE SYSTEMS

1. Connect the post labeled -12V DC GROUND to the

negative (-) battery terminal, or a clean unpainted

chassis ground using a ring terminal or other suitable means.

2. Connect the post labeled

+12V DC POWER to any

vehicle harness wire which is energized with battery

voltage, ONLY when the ignition key is in the ON

(RUN) position, NOT OFF OR ACCESSORIES.

3. Connect the post labeled

12V DC LAMP to the

instrument panel lighting circuit that is controlled by

the instrument panel dimmer control.

Some vehicles (typically imported) wire the dimmer

control into the ground side of the instrument panel

lighting circuit, as opposed to the more conventional

“hot” or 12-volt side. In vehicles which use this circuit,

connect the 12V DC LAMP post to a circuit which is

energized by the headlamp switch.

INSTALLING TACHOMETER IN CUP

1. Place tachometer in cup. Gently pull wires out, so

they would not be jammed between the cup and

tachometer.

2. Secure tachometer in cup using #8 lock washers

(6) and #8-32 acorn nuts (7). Turn acorn nuts down

nger-tight and, with a wrench or nut driver, tighten an

additional 1/2 turn. DO NOT OVER TIGHTEN.

3. Position cup as desired and tighten male nut (3).

The 4, 6, 8, and 10-cylinder settings are most common

for all distributor equipped engines and Distributorless

Ignition Systems (DIS) with a tachometer output lead.

The 2-cylinder setting is designed for 2-cylinder engines and

DIS systems without a tachometer output lead that allow

access to the driver wires from the vehicle computer

to the ignition module.

The 1-cylinder setting is used with single cylinder engine

vehicles and in conjunction with the CP7560 Tach Signal

adapter.

The CP7560 Tach Signal Adapter (sold separately)

senses current pulses in the wire that supplies +12 volts

to the ignition coil primary windings or fuel injector and

converts the pulses to a signal that is understood by the

tachometer. The CP7560 Tach Signal Adapter is required

to connect the tachometer to Coil On Plug ignition systems

and to diesel engines with electronic injection.

MULTIPLE SPARK DISCHARGE IGNITION SYSTEM

EQUIPPED ENGINES

For Multiple Spark Discharge ignition systems, connect

the SIGNAL tachometer post only to the tachometer

output terminal on the ignition module. Do NOT connect

to the ignition coil.

Set the Cylinder Selection switch on the back of

the tachometer to match the number of cylinders

in the engine.

COIL ON PLUG IGNITION SYSTEM EQUIPPED

ENGINES

To connect the tachometer to these engines you need

to purchase the CP7560 Tach Signal adapter. Follow

instructions included with the adapter to hook up wires

and to set the Cylinder Selection switch.

DIESEL ENGINES WITH ELECTRONIC INJECTION

To connect the tachometer to these engines you need to

purchase the CP7560 Tach Signal adapter. Follow instructions included with the adapter to hook up wires and to set the

Cylinder Selection switch.

Sunpro is a registered trademark of Snap-on Corporation

used under license by SPX Corporation.

1-800-228 -7667

0002 -00 0- 3113

Loading...

Loading...