Sun Power XP SERIES Owner's Manual

Save

Time, Fuel

& Power with

Sun-Power

Auto Gates

Australian made XP SERIES Automatic Gate Operators

Energy saving

Solar & Electric - Auto Gate Operators

Installation Guide & D I Y Owner’s Manual

Please DO NOT attempt installation

without reading & then following this manual

Technical support is available if, after having read these instructions, you require assistance

This Instruction Booklet/Owner’s Manual, should be retained by Gate owner for future reference.

Further copies are available on the web site

Take your time - Read the Manual - Get it right

Call us if you need help - Enjoy the benefits

----------------------------------------------------------

129 Gladstone St Fyshwick ACT 2609 Ph: 02 6280 4655 Fax: 02 6280 7592

e.sungate@bigpond.net.au www.sungateaustralia.net V 13511-1 ©

Contents:

Dear Installer/Owner 1 - 2

Introduction 1 - 2

Installation

Standard Installation 2 - 3

Installation Procedure 2 - 8

Side Mount Installation 7 - 8

Restricted side room 7 - 9

Out-swing Installation 7 - 9

Pre-wiring plus Control Board & Settings:

Important Note 2

Auto Close, Multi-user 10

Settings - Overloads 10

Trimpots –Locations/Functions 11

Circuit board diagram 240V 12

Circuit board diagram Solar 13

L.E.D Sequence 14

Anti-clash leaf delay 15

SOLAR wiring detail 16

Options:

Push Buttons [PB] 15

Electric Lock [EL] 17

Photoelectric Safety [PE], Antenna 17

Troubleshooting/Radio Receiver/Transmitters

Trouble Shooting 18

Radio Receiver [Rx] 19

Radio Transmitters [Tx] 19

Antenna [Ant] 19

Specifications/Dimensions 19

Sun -Power Auto Gates reserves the right to make upgrades & alterations without notice

Dear Installer/Owner

Your Australian Made SUN-POWER XP Series Auto Gate Operator has been designed and built to make

installation simple and maintenance almost Non - existent.

To save you time, and make installation easier, The Circuit Board is pre-wired & placed under the powder

coated, steel weatherproof cover together with the Motor/Gears/Battery/Radio receiver etc, this means

that you do not have to spend extra time wiring up to a separate control box. Likewise the radio receiver is

also connected and the 3 remote controls are pre-programmed.

Circuitry for most options is already included. You simply have to connect up the external devices such as

Solar Panel, Antenna, Push buttons etc.

The design features, in the SUN-POWER XP Series Gate Operators, will save you time on site, and the

installation will be neat & tidy.

Apart from its physical attributes the control circuit has some powerful operating features. These can be

adjusted on site, without modification to suit a range of situations.

This Manual should answer most of your questions regarding the installation and operation of the SUNPOWER XP Gate Operator. If further information is required, please email, fax, phone or write to us.

Note:

Primary [Master] Operator has a Circuit Board [Primary Operator can be installed on LH or RH]

Secondary [Slave] Operator does NOT have circuit board

Introduction:

The SUN-POWER XP Series INTELLIGENT Automatic Gate Operator is an electronically controlled Automatic

Gate Operator for swing gates. An excellent range of quality features are built in to the XP Series Operators

and a selection of options is also available.

The Sun-Power XP Series Operators can be used in a variety of situations.

240V AC • SOLAR Power • 12V AC/DC

Single Gate or Pair of Gates • Normal or Restricted side-room applications

Where a Gate is require to swing beyond 90° and up to 130° [Or less than 90º]

The powerful control system gives the flexibility to change some important characteristics of the operation.

Including …………..

Signal to close • Automatic close • Sensitivity to obstacles • Multi-user function

The control system also allows for the addition of the following options.

Push Buttons • Photoelectric cells • Digital Keypads • Electric Locks etc

For all its sophistication the Sun-Power XP Series Auto Gate Operator is extremely reliable and its’ rugged

construction ensures a long trouble free life.

1.

This SUN-POWER XP Auto gate Operator has undergone rigorous factory load testing and has been

passed as ready for site installation.

Please ensure that you read ALL of these instructions, plus any other instructions supplied, then

simply follow Instructions step by step.

Take your time - Read the Manual – Get it right – Enjoy the benefits

IMORTANT NOTE [Warning]: Do NOT alter any pre-wiring of circuit board [except motor polarity* when

necessary]. Altering Pre-wiring [except motor polarity*] will compromise your warranty

* ALL power [240v/Solar/battery] must be disconnected before attempting to change motor polarity

XP Series Swing Gate Operators are suitable for and guaranteed, when they are correctly hinged and

operate smoothly and evenly*.

* XP Series Gate operators will drive a variety of Gate Styles, Sizes & Weights. Suitability is dependent on

the quality of hinging and the force required, at One Metre from the hinge center-point, to open and close

the gate. 15 Kg is the maximum for gates opening IN [PULL] and 7.5 Kg for gates opening OUT [PUSH]

240V Power, Solar Panel or Battery must not be connected until appropriate [see item 6 page 6] or if you do

not understand any of the instructions, or have any doubts, then please Fax 02 6280 7592 or Email your

queries sungate@bigpond.net.au or ring us on 02 6280 4655 re your concerns before you apply power to

the unit or you may void your warranty

DO NOT connect the RED Spade Terminal to the Battery until you are ready to set the Limit Switches. The

RED Spade Terminal is supplied, disabled* from the Battery. [* i.e. Not connected to the Battery]

The last item to be connected is the SOLAR PANEL, do this after ALL other settings and adjustments have

been made.

Important: [Battery change - Circuit board posts - Motor polarity change ]

Before moving the circuit board for any reason [or changing motor polarity], including when changing the

Battery, you must ensure that ALL Power from any 240v/ Battery/ Solar Panel is disconnected to avoid

damage to the circuit board. The Circuit board is supplied mounted on top of 4 nylon ‘posts’ please ensure

these ‘posts’ remain in place and circuit board is correctly located on top of these posts.

Ensure that there are NO loose wire strands when disconnecting and connecting any wires.

Do not expose control board or any electronic circuitry to Rain/Moisture etc .

Surface insecticide spray/ant sand/moth balls must not be applied onto any electronic circuitry.

All cabling must not be run in conjunction with any high voltage cables or electric fencing – if in doubt, seek advice

from a qualified Electrician in Your State or Territory.

Installation:

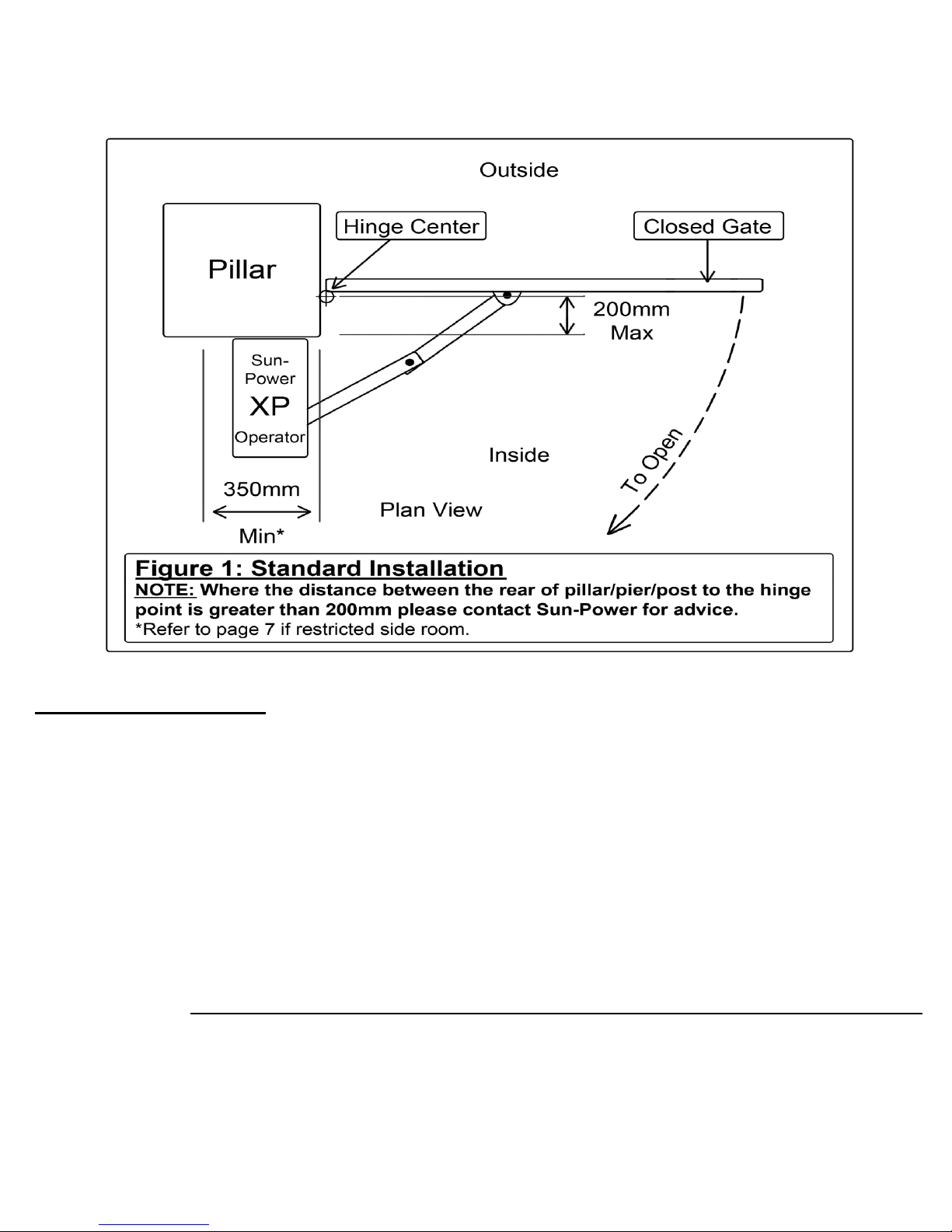

Standard Installation. [PULL]

A “Standard Installation” is one where gate[s] open in - ie; swinging INWARD toward the Motor Housing.

Generally the gate hinge should be no more than 200mm* from the rear of the Pier/Post/Pillar, ask us for

advice if this distance is greater.

Side room of 350mm is normally required to accommodate the swing of the arms. Refer to Pages 7/8/9 if

there is restricted side room [See fig 1] some pictures of restricted side-room installation are in the

“image gallery at “www.sungateaustralia.net

2.

Installation procedure:

1.

Ensure that the gates swing freely and that all existing latches/padbolts/Chains etc are disabled or removed

from the gate & Gate posts

2.

When using a 240v Unit [XP 100 or XP 100/300] the Master operator [the one containing the Circuit Board]

should be fitted to the Gate Post nearest the Power Supply.

Remove the cover, from the XP Operator [taking care that you DO NOT expose circuit board to

moisture] to access the slotted fixing holes cut in the rear of the Chassis. Bend the tabs out and

bend them back against the rear of the chassis, in this position they act a spacers allowing clearance

for the cover[s] NOTE: [Do not remove these tabs – just bend them out and fold them to the back]

[Unless you are using the optional XP-MP Mounting Plate]

3.

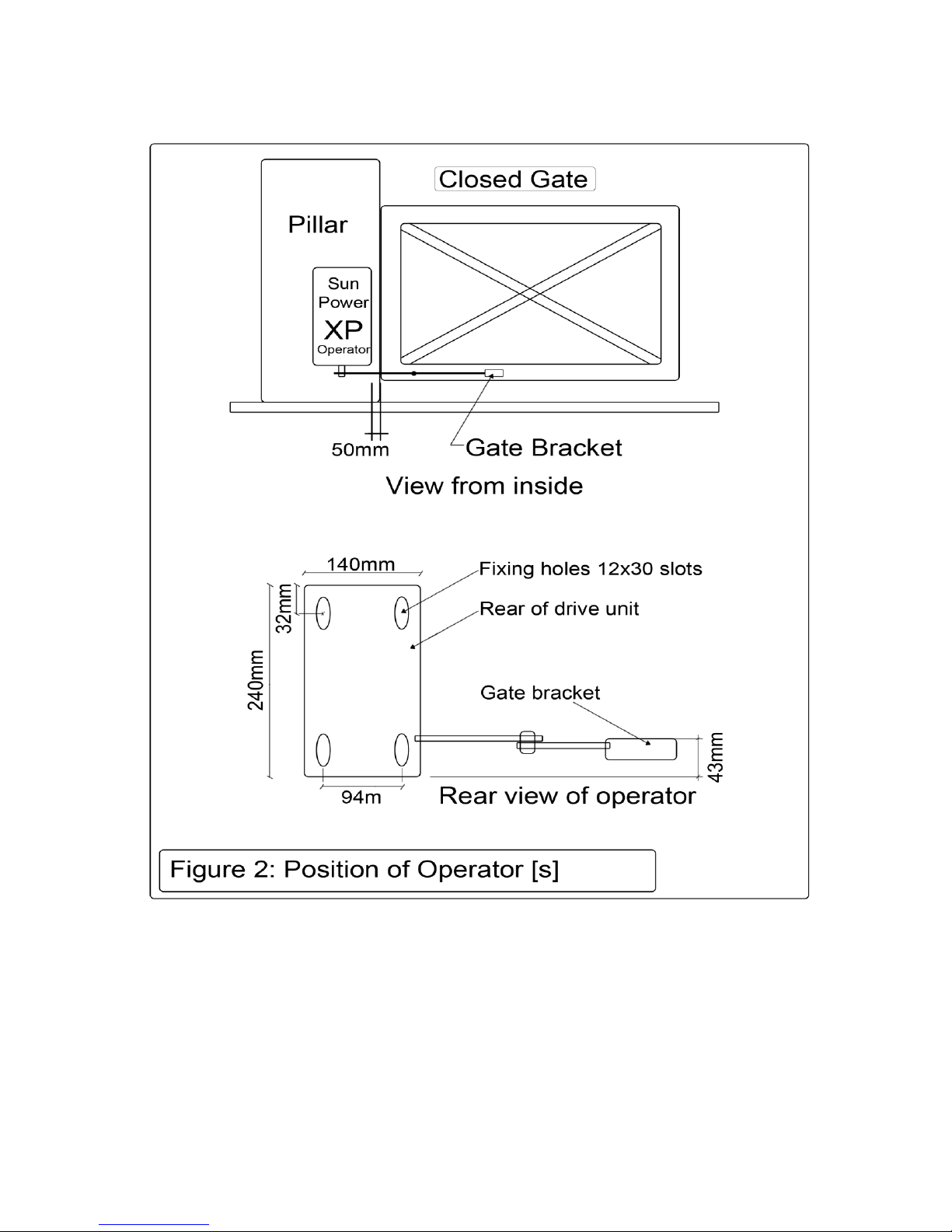

Position each unit on the gate post/pier/pillar[s]

The Vertical position is found by locating the gate bracket. The Gate bracket is best placed where there is

adequate fixing on the gate and movement of the arms is unrestricted [See Fig. 2]

The XP Auto Gate Operator[s] may now be bolted in place.

3.

4. If you have a Pair of Gates then……….

Connect the Slave to the Master Unit with 2 Core Flex-Cable [Max load draw 8

Amp at 12 Volts] [Fig.8 cable - .75mm sq – 24/.020 minimum] See Fig. 3

All cabling must not be run in conjunction with any high voltage cables or electric

fencing – if in doubt, seek advice from a qualified Electrician in Your State or

Territory. 4.

The XP Operators are set in the factory for a “Standard PULL Installation” When the Master is placed

on the LEFT HAND SIDE [from the inside [motor side] – looking out] the wiring is Brown above Blue

[refer also to pages 12 & 13]

When the Master is located on the RIGHT HAND SIDE [from the inside [motor side] – looking out] then the

motor wires need to be reversed. ie; BLUE above BROWN.

To accomplish this, locate the connection blocks for each motor on the Circuit board. Swap* the

BROWN & BLUE wires for Motor 1 [& Motor 2 if a pair of gates] [See Figure 3 above].

* ALL power [240v/Solar/battery] must be disconnected before attempting to change motor polarity

5. Location of Gate Bracket on Gate:

The Gate bracket should be positioned on the gate so that the arms are ALMOST in a straight line

when the gates are closed [See Figure 4] To check the location of the gate brackets, first disengage

the Main arm from the drive shaft [Using the spanner provided, unscrew the bolt until the arm

swings freely] Then clamp the gate bracket in position. Open and close the gate to ensure the gate

bracket is appropriately located.

5.

Loading...

Loading...