SunPower Equinox SPR-X20-327-BLK-C-AC, Equinox SPR-X21-335-C-AC, Equinox SPR-X21-335-BLK-C-AC, Equinox SPR-X20-327-C-AC, Equinox SPR-X22-360-C-AC Installation Manual

...

INSTALLATION GUIDE

©SunPower Corporation

All Rights Reserved

February 2018

1.0 Overview and Scope ...................................................................................................................................................... 7

1.1 Safety and Warnings for Type C and Type D AC Modules .................................................................................... 8

1.1.1 Site Safety ............................................................................................................................................................ 8

1.1.2 General Warnings ............................................................................................................................................... 9

1.2 Installer Responsibilities ........................................................................................................................................... 9

1.3 Tools, Equipment, Components, and Torque Values .......................................................................................... 10

1.3.1 Tools ................................................................................................................................................................... 10

1.3.2 Equipment ......................................................................................................................................................... 10

1.3.3 Components ...................................................................................................................................................... 11

1.3.4 EnergyLink Monitoring Components ............................................................................................................. 15

1.3.5 Torque Values ................................................................................................................................................... 16

1.4 Listings, Classification, and FCC and IC Compliance ............................................................................................... 16

1.4.1 Fire Classification.................................................................................................................................................. 17

1.4.2 FCC and IC Compliance ....................................................................................................................................... 17

1.5 Rapid Shutdown, System Grounding, NEC Compliance, Ground Path, and Disconnects .................................. 17

1.5.1 Rapid Shutdown ................................................................................................................................................... 18

1.5.2 System Grounding ............................................................................................................................................... 18

1.5.3 NEC Compliance ................................................................................................................................................... 19

1.5.4 Ground Path .......................................................................................................................................................... 21

1.5.5 Disconnects ........................................................................................................................................................... 23

1.6 Pre-Installation Checklist ............................................................................................................................................ 26

1.7 Installation Outline ...................................................................................................................................................... 27

1.8 Install InvisiMount and AC Modules .......................................................................................................................... 27

1.8.1 Attachment Span and Rail Cantilever ................................................................................................................ 27

1.8.2 Module Spacing .................................................................................................................................................... 27

1.8.3 Join Rails ................................................................................................................................................................ 28

1.8.4 Install Flashings, Roof Attachments, and Rails ................................................................................................. 29

1.9 Prepare AC Modules and Transition Cable .............................................................................................................. 32

1.9.1 AC Module Clips Overview .................................................................................................................................. 32

Document #518101 RevD 2 SunPower Proprietary

1.9.2 Prepare All Modules ............................................................................................................................................. 33

1.9.2.1 Prepare and Wire the Transition Cable ..................................................................................................... 34

1.9.3 Install Modules ..................................................................................................................................................... 35

1.9.4 Verify Voltage ........................................................................................................................................................ 41

2.0 Install and Commission EnergyLink with PVS5x .................................................................................................... 42

2.1 Safety, Compliance, and Certification ................................................................................................................... 42

2.1.1 Safety Instructions ............................................................................................................................................ 42

2.1.2 FCC Compliance ................................................................................................................................................ 43

2.1.3 Safety Certification ........................................................................................................................................... 43

2.2 Install PVS5x .............................................................................................................................................................. 44

2.2.1 Overview ............................................................................................................................................................ 44

2.2.2 Kit Contents ....................................................................................................................................................... 45

2.2.3 System Connection .......................................................................................................................................... 45

2.2.4 Mount PVS5x ..................................................................................................................................................... 46

2.2.5 Wire PVS5x Power ............................................................................................................................................ 46

2.2.6 Install and Wire Consumption CTs ................................................................................................................. 47

2.2.7 Verify CT Voltage Phases ................................................................................................................................. 48

2.2.8 Connect System Communication ................................................................................................................... 49

2.2.9 Connect PVS5x to the Internet........................................................................................................................ 50

2.3 Commission with PVS Management App ........................................................................................................... 50

2.3.1 Connect to PVS Management App ............................................................................................................... 51

2.3.2 Set Up Communication .................................................................................................................................... 51

2.3.3 Check Firmware ................................................................................................................................................ 52

2.3.4 Discover Devices ............................................................................................................................................... 52

2.3.5 Configure Devices ............................................................................................................................................. 53

2.3.6 Verify Device Operation ................................................................................................................................... 54

2.3.7 Commission Devices ........................................................................................................................................ 55

2.4 Create EnergyLink Home Account for Customer Monitoring ............................................................................ 56

2.5 Replace PVS5x Enclosure Cover ............................................................................................................................. 57

Appendix A: System and Site Checklist and Array Layout Diagram ................................................................................. 58

Document #518101 RevD 3 SunPower Proprietary

A.1 Complete SunPower System and Site Checklist and Create Array Layout Diagram ..................................... 58

Appendix B: Module Removal ............................................................................................................................................... 62

Appendix C: Conductor Selection ......................................................................................................................................... 66

Appendix D: Certificates ......................................................................................................................................................... 69

D.1 Microinverter Revision E: Rapid Shutdown ..................................................................................................... 70

D.2 Microinverter Revision D: Rapid Shutdown .................................................................................................... 77

D.3 Microinverter Revision C: Rapid Shutdown .................................................................................................... 79

D.4 Microinverter First Revision: Rapid Shutdown ............................................................................................... 81

D.5 Type D AC Module .............................................................................................................................................. 83

D.6 Type C AC Module .............................................................................................................................................. 85

D.7 AC Extension Cable ............................................................................................................................................. 86

D.8 InvisiMount System ............................................................................................................................................ 87

D.9 InvisiMount End Clamp ..................................................................................................................................... 88

D.10 PVS5x ................................................................................................................................................................... 89

Appendix E: Quick Start Guide – AC Module Cable Selection ........................................................................................... 90

Appendix F: Technical Specifications .................................................................................................................................... 98

F.1 Type C AC Module Ratings ........................................................................................................................................... 98

F.1.1 X22-360-C-AC..................................................................................................................................................... 98

F.1.2 X21-345-C-AC and X21-335-C-AC .................................................................................................................... 99

F.1.3 X21-335-BLK-C-AC and X20-327-BLK-C-AC .................................................................................................. 100

F.1.4 X20-327-C-AC................................................................................................................................................... 101

F.1.5 E20-327-C-AC and E19-320-BLK-C-AC .......................................................................................................... 102

F.2 Type D AC Module Ratings ........................................................................................................................................ 103

F.2.1 X22-370-D-AC and X22-360-D-AC ................................................................................................................. 103

F.2.2 X21-345-D-AC, X21-335-D-AC, and X20-327-D-AC ...................................................................................... 104

F.2.3 X21-350-D-AC, X21-335-BLK-D-AC, and X20-327-BLK-D-AC ...................................................................... 105

F.2.4 E20-327-D-AC and E19-320-D-AC ................................................................................................................. 106

F.3 PVS5x ........................................................................................................................................................................... 107

F.4 InvisiMount™ ............................................................................................................................................................... 108

F.5 Grid Support, Utility Interactive Inverters, and Regulatory Certification for Type C AC Modules ................... 109

Document #518101 RevD 4 SunPower Proprietary

F.5.1 Grid Profile: IEEE 1547 (2003) ............................................................................................................................ 109

F.5.2 Microinverter Ratings ......................................................................................................................................... 110

F.6 Grid Support, Utility Interactive Inverters, and Regulatory Certification for Type D AC Modules ................... 111

F.6.1 Default Factory Settings for Type D AC Modules: IEEE 1547a-2014 Grid Profile ........................................ 111

F.6.2 Legacy Support Settings: IEEE 1547-2003 Grid Profile ................................................................................... 112

F.6.3 CA Rule 21 Phase 1 Settings for Type D AC Modules ..................................................................................... 114

F.6.4 Reactive Power Capability for Type D AC Modules ......................................................................................... 115

F.6.5 Reactive Power Control Accuracy for Type D AC Modules ............................................................................ 116

F.6.6 Active or Reactive Power Priority for Type D AC Modules ............................................................................. 116

F.6.7 Fixed Power Factor for Type D AC Modules .................................................................................................... 119

F.6.8 Volt/VAr Operation for Type D AC Modules ..................................................................................................... 119

F.6.9 Microinverter Ratings for Type D AC Modules ................................................................................................ 120

Appendix G: AC Module 3-Line Drawing Example ............................................................................................................ 122

Appendix H: Install Rail-Mounted Junction Box ................................................................................................................ 124

Appendix J: Install Rooftop Transition Flashing ................................................................................................................ 126

Appendix K: Attach AC Rail Clips ......................................................................................................................................... 132

Appendix L: Technical Notifications .................................................................................................................................... 133

L.1 PVS5x Site Wiring Check Procedure, T16008 ...................................................................................................... 133

L.2 Installing SunPower AC Modules in High-Noise Environments, T16009......................................................... 136

L.3 Grounding SunPower Equinox Systems, T16013 ............................................................................................... 139

L.4 Rapid Shutdown Compliance for SunPower Equinox Type C AC Modules, T17002 ...................................... 151

L.5 Field Verification of Type C AC Module IEEE 1547 Utility Interactive Trip and Reconnect Functions, T16012

.......................................................................................................................................................................................... 156

L.6 InvisiMount™ and Equinox™ Rail-Mounted J-Box and Rooftop Transition Flashing Specifications, T17003

.......................................................................................................................................................................................... 159

L.7 Update Chrome Version for PVS Management App Commissioning, T16010 ............................................... 161

L.8 Field Verification of Type D AC Module Trip and Reconnect Functions, T17006 ........................................... 163

L.9 Using the PVS5 Management App to Set and Verify the California CPUC Rule 21 Grid Profile on Type D AC

Modules, T17006 ........................................................................................................................................................... 166

L.10 Using the PVS5 Management App to Set and Verify the Xcel Energy of Colorado Grid Profile on Type D

AC Modules, T17008 ...................................................................................................................................................... 173

Document #518101 RevD 5 SunPower Proprietary

L.11 Using the PVS5 Management App to Set and Verify United Illuminating of Connecticut Grid Profiles on

Type D AC Modules, T17010......................................................................................................................................... 179

L.12 Using the PVS5 Management App to Set and Verify New York Utility (NYSEG, RG&E) Grid Profiles on Type

D AC Modules, T17009 .................................................................................................................................................. 185

L.13 PVS Management App Enhanced Functionality for Residential Commissioning, T17013 .......................... 191

L.14 PVS Management App Q2 2017 Updates for Residential Commissioning, T17005 .................................... 196

L.15 Equinox Commissioning Best Practices, T17016 ............................................................................................. 199

Appendix M: PVS5x Installation Instructions and Quick Start Guide ............................................................................. 201

Appendix N: Consumption Meter CT Installation Instructions and Alternate CT Installation Configurations ......... 204

Appendix P: Production Meter CT Installation Instructions ............................................................................................ 207

Appendix Q: EnergyLink PVS5x Knockout Template ........................................................................................................ 208

Document #518101 RevD 6 SunPower Proprietary

1.0 Overview and Scope

This guide describes how to install SunPower Equinox (“the system”). Do not attempt any aspect of the installation

until you have thoroughly read this entire guide. Failure to follow these instructions can result in personal injury or

equipment damage or failure, and may void the system warranty.

The system ships with the following components:

• SunPower AC modules and accessories (including extension cables)

• SunPower InvisiMount™ mounting system

• SunPower EnergyLink™ monitoring system

Document #518101 RevD 7 SunPower Proprietary

1.1 Safety and Warnings for Type C and Type D AC Modules

IMPORTANT SAFETY INSTRUCTIONS – SAVE THESE INSTRUCTIONS!

All personnel must adhere to the following safety procedures when working with the system, including inspection,

installation, operation, service work, repair, and testing. Failure to comply with these precautions or with specific

warnings elsewhere in this guide may violate safety standards of design, warranty, manufacture, and intended use

of the equipment. SunPower assumes no liability for failure to comply with these requirements.

Warning! The installation, adjustment, or repair of a solar system involves the risk of contact

with potentially lethal voltages and currents.

SunPower Type C and Type D AC modules meet all current requirements for rapid shutdown as defined in NEC

690.12 Rapid Shutdown of PV Systems on Buildings. As part of the UL 1741 SA / UL 1741 Listing of the SunPower AC

module product being grid support utility interactive, upon turning off the AC disconnect to de-energize the circuit

to the AC modules on the roof, each AC module output will shut off within 2.0 seconds to comply with IEEE 1547. In

this manner, all wiring leaving each AC module complies with the controlled conductor limits in 690.12.

Follow all applicable laws, including state and federal Occupational Safety and Health Administration (OSHA)

standards when working on any construction project. Always reference the National Fire Protection Agency (NFPA)

70E, Standard for Electrical Safety in the Workplace when performing electrical work.

Perform the installation in accordance with all applicable codes. In addition, reference NEC Articles 250 and 690—as

well as applicable IEC standards—for proper compliance when wiring and grounding the system. All state and

federal guidelines and regulations must be followed as well.

1.1.1 Site Safety

• These installation instructions are for use by qualified personnel only.

• System access is intended for authorized personnel only.

• Only authorized persons may shut down the system or open any system enclosure.

• To reduce the risk of fire, connect only to a dedicated circuit that has overcurrent protection not exceeding the

maximum value stated in the product’s Listing (20 A) in accordance with the NEC, ANSI/NFPA 70. Maximum

dedicated branch circuit overcurrent protection: 20 A.

• The metal components of the module can reach temperatures of approximately 176°F (80°C). Use appropriate

safety procedures when handling modules.

Document #518101 RevD 8 SunPower Proprietary

1.1.2 General Warnings

• Do not attempt to service any portion of the system.

• Do not attempt installation during conditions involving rain, snow, ice, or high winds.

• Do not attempt to install or service the system if you are not a qualified, trained electrician or technician familiar

with power electronic equipment.

• Always wear rubber insulating gloves rated for the appropriate voltage level, and suitable eye and head

protection when working near live electrical equipment.

• Always have a cell phone available for calling emergency personnel.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

Note: Perform all electrical installations in accordance with any local codes and the National Electrical Code (NEC).

1.2 Installer Responsibilities

Warning! If installing the Equinox system on a metal roof, you must verify with the AHJ whether additional bonding

to the roof is required. Follow the instructions provided by the AHJ and by the roofing manufacturer.

SunPower Equinox is for residential 240 V split single-phase and 208 V three-phase wye double-pole

applications only.

Installers are solely responsible for specific aspects of the system they are installing:

• Selection and verification of design parameters, including wind and snow load and all related aspects.

• Validation of third-party roof attachment design and interoperability, including any stipulations for rail overhang

(cantilever) beyond the last roof attachment (standoff) at the end of a row. Use the SunPower Design Tool

(https://invisimountdesign.us.sunpower.com/login.html

verify spans between roof attachments and maximum cantilever. (Access the Tool by logging into the Portal and

then clicking the Design Tool link.)

• Code compliance and permitting.

• Vetting system compatibility with the installation site and structures.

• Verifying the roof integrity prior to installation.

• Selecting the correct attachment and flashing type for the particular roof.

• Care of the roof during the installation.

) OR the InvisiMount Span Tables document (#524734) to

Document #518101 RevD 9 SunPower Proprietary

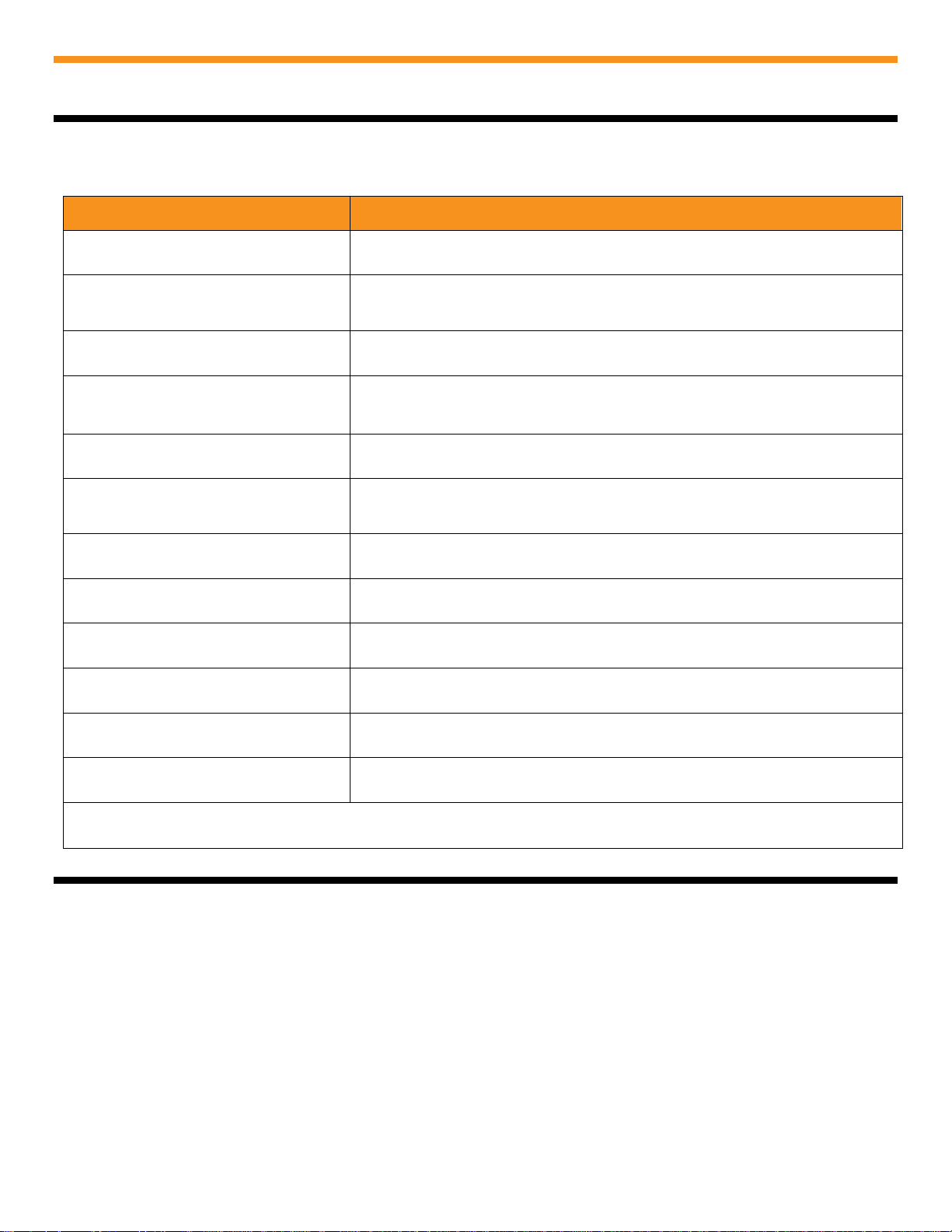

1.3 Tools, Equipment, Components, and Torque Values

1.3.1 Tools

The following tools are required to install the system:

Tool Task

10 mm and 15 mm deep sockets Attaching L-foot nuts, mid clamps, end clamps, splices, and splice screws

Assorted screwdrivers and wire

strippers

Caulk gun Installing rooftop transition flashing

CHANNELLOCK® pliers

(or equivalent)

Claw hammer Installing rooftop transition flashing

Cordless drill with electrical

conduit knockout tool or hole saw

Flathead screwdriver Removing and installing rail-mounted J-box cover

Metal saw Cutting rails

Roofing bar Installing rooftop transition flashing

Rubber mallet Removing end clamp

Torque wrench Verifying fastener torque

General electrical wiring

Tightening fittings on rail-mounted J-box and rooftop transition flashing

Drilling holes in rooftop transition flashing and rail-mounted J-box

Utility knife Installing rooftop transition flashing

In addition, ensure that you have all necessary tools to install your chosen roof attachments!

1.3.2 Equipment

All applicable personal protective equipment (PPE) is always required, including:

• Fall protection

• Gloves

• Safety glasses

Document #518101 RevD 10 SunPower Proprietary

• Hard hat

• Appropriate footwear

• All appropriate electrical PPE

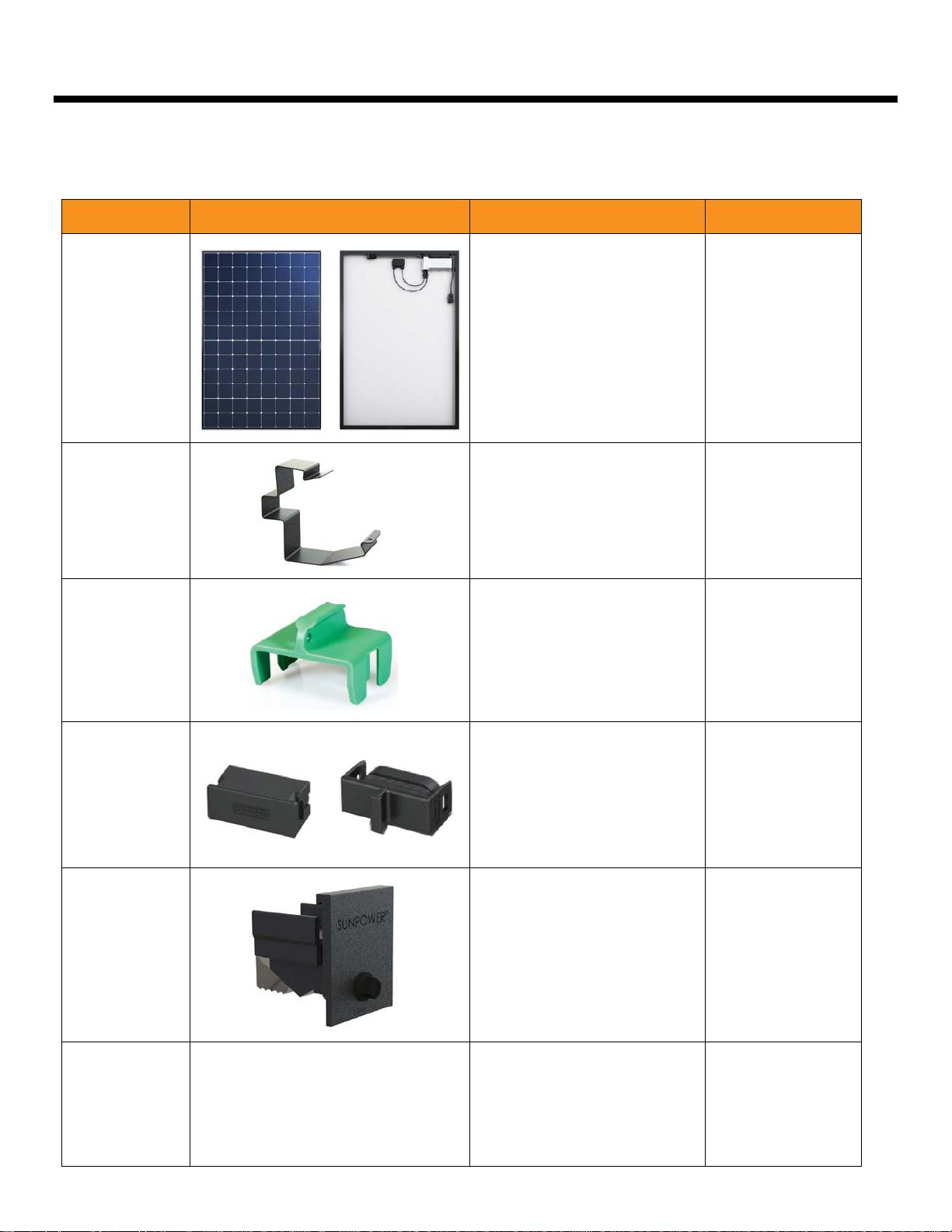

1.3.3 Components

Important! SunPower requires that you use a torque wrench—not an impact driver—to enforce consistent fastener

tightness and thereby ensure safe, high-quality installations.

Component Definition Tool and Torque

AC module

AC rail clip

(optional)

Disconnect

tool

An assembly that includes a

photovoltaic glass panel, a

microinverter, a robust frame,

and two electrical leads.

Attaches to rails and helps to

support a single AC cable

above the lower edge of the

rails.

Unlocks AC cable plug–

receptacle pairs after they

have been connected.

See Mid clamp

and

End clamp

n/a

n/a

End cap

End clamp

Extension

cable

Fits into the plug or the

receptacle of the last module

in a circuit.

Note: The caps are different

for plugs and receptacles.

Module-to-rail fastener that

fits into the end of a rail,

clamps to secure each of the

endmost modules in a given

row, and provides equipment

bonding from modules to the

rail.

Premanufactured AC cables

that enable connecting of

non-adjacent AC modules.

n/a

• 10 mm deep

socket

• 85 +5/−0 in-lb

(9.6 N-m)

n/a

(See Disconnect

tool)

Component Definition Tool and Torque

Extension cables contain

identical conductor

composition as the built-in AC

module cables (threeconductor, 12 AWG, type TCER), and are available in

several lengths, with plug–

plug, receptacle–receptacle,

or plug–receptacle connector

pairs. Cables are UL

Recognized and conform to

UL 6703 and UL 9703.

The cable outside diameter is

11.2 mm (0.44 in).

Flashing

L-foot

Thin sections of material that

n/a

are installed between the roof

substrate and any rooftop

penetration in order to

prevent water from

penetrating the roof.

Note: Shown with with

SunModo’s roof attachment

and L-foot for composition

shingle roofs; and with their

tile hook mount—separate

components all available

from SunPower.

L-shaped bracket that

provides interface between

the roof attachment and the

rail; typically made of

stainless steel or aluminum.

Refer to the roof

attachment

manufacturer

guidance. If using a

roof attachment

other than L-feet,

refer to that

attachment

manufacturer

guidance.

Document #518101 RevD 12 SunPower Proprietary

Component Definition Tool and Torque

L-foot bolt

and nut

Mid clamp

Plug

Hardware that secures the

rail to the L-foot (or to the

chosen roof attachement):

Bolt: M10-1.5 × 25 mm

• 10 mm deep

socket

• 375 +20/−0 in-lb

(42 +2/−0 N-m)

DIN 933 SS304

Nut: M10-1.5 DIN 6923

SS304

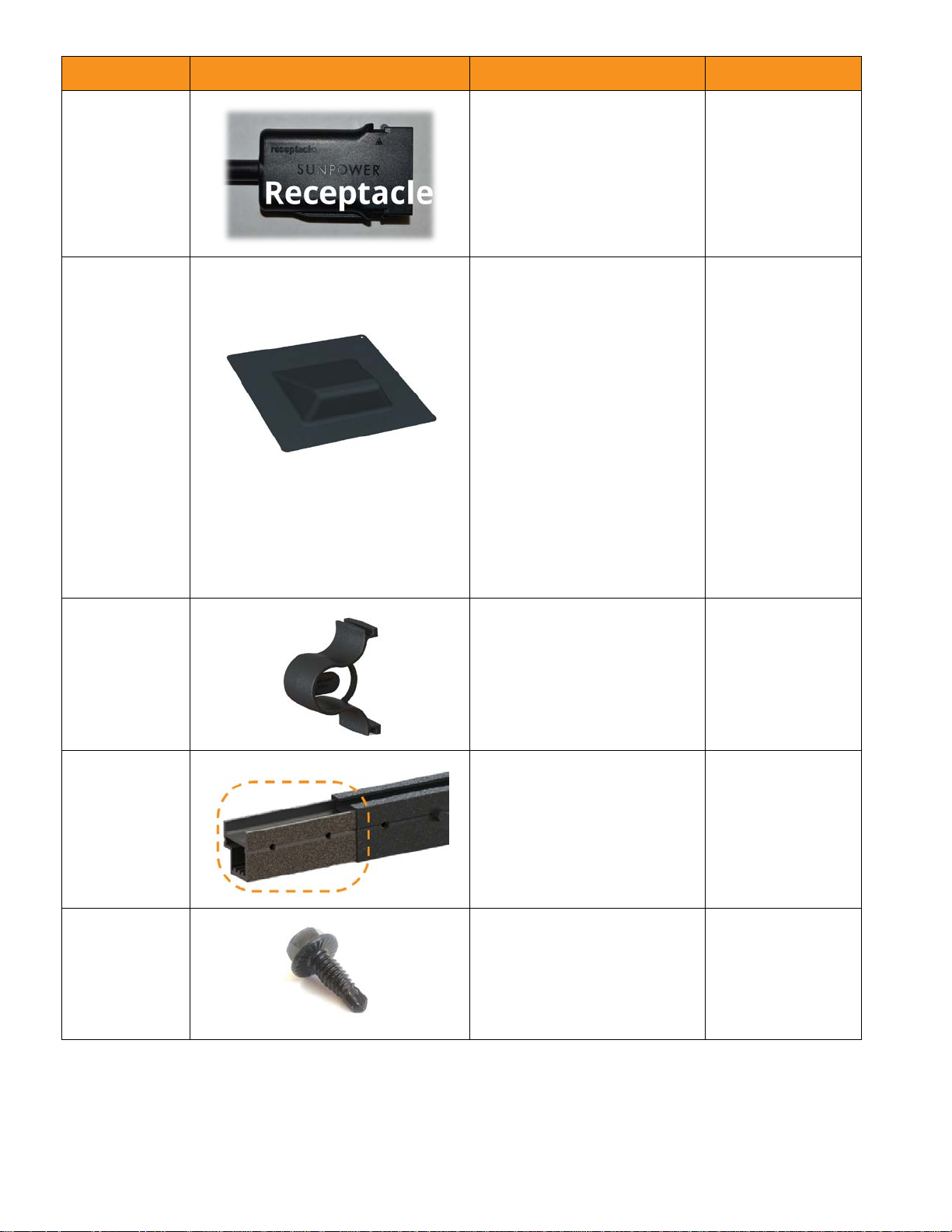

Module-to-rail fastener that

attaches in the top rail

channel; secures module

frames; and provides

equipment bonding between

modules and the rail.

The AC cable connector end

• 10 mm deep

socket

• 85 +5/−0 in-lb

(9.6 N-m)

n/a

that has tabs on either side.

Note: SunPower AC cable

connectors are an approved

means of disconnect.

Rail

Rail-mounted

J-box

(optional)

Extruded aluminum

component that attaches to

the L-feet and supports

clamped modules. Each rail

section is 10′ 9″ (3.28 m) long.

For the nuts that fit

onto the bolts

which slide into

the side channel:

• 15 mm deep

socket

• 375 +20/−0 in-lb

(42 +2/−0 N-m)

Junctions array circuits on the

roof; attaches to a rail with no

tools.

For cover screws:

• flathead

screwdriver

• 16 in-lb

(1.8 N-m)

Document #518101 RevD 13 SunPower Proprietary

Component Definition Tool and Torque

Receptacle

Rooftop

transition

flashing

(optional)

The AC cable connector end

n/a

that does not have tabs.

Note: SunPower AC cable

connectors are an approved

means of disconnect.

Installs on the rooftop and

enables wiring to transition

• Utility knife

• Roofing bar

between the rooftop and the

building interior.

Note: If you are not using a

transition box such as a

SolaDeck™ enclosure, use the

rooftop transition flashing

along with the rail-mounted Jbox (or attic-mounted J-box)

to transition between building

wiring and array wiring.

• Caulk gun

• Claw hammer

• Drill with

conduit

knockout tool

or hole saw

• Two

CHANNELLOCK

tongue &

groove pliers

(or equivalent)

Row-to-row

(R2R) spacer

Splice

Splice screw

Plastic spacer that snaps into

n/a

the exterior module frame

and uniformly enforces the

distance between rows of

adjacent modules.

Extruded aluminum

See Splice screw

connector that, along with

splice screws, joins two rails.

Black oxide coated stainless

steel fastener that, in

conjunction with a splice,

attaches two sections of rail

together.

• 10 mm deep

socket

• 40 +5/−0 in-lb

(4.5 N-m)

Document #518101 RevD 14 SunPower Proprietary

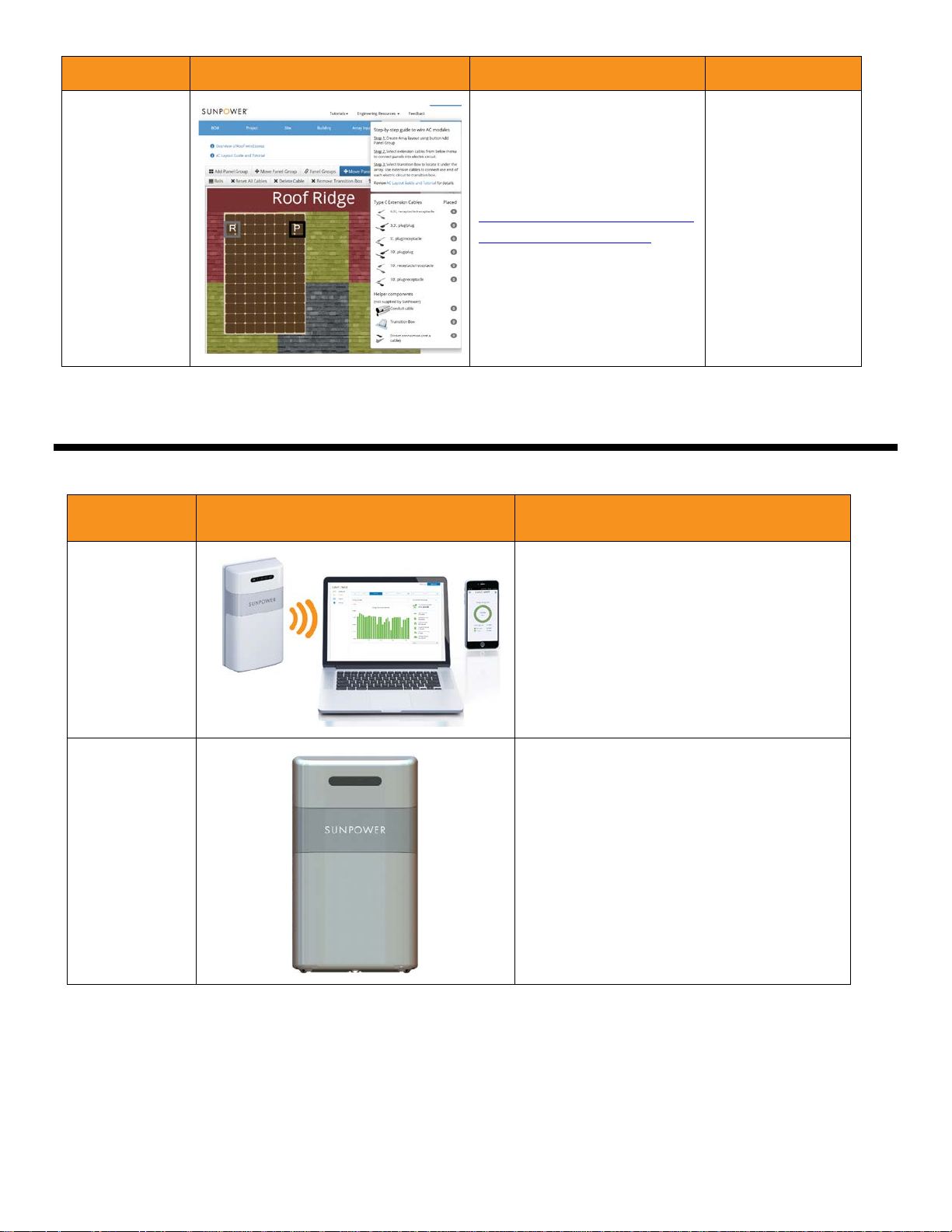

Component Definition Tool and Torque

Enables complete array

design online as well as

providing the bill of materials

for the array.

SunPower

Design Tool

invisimountdesign.us.sunpow

er.com/bom/index.html

Access the Tool from the

Portal.

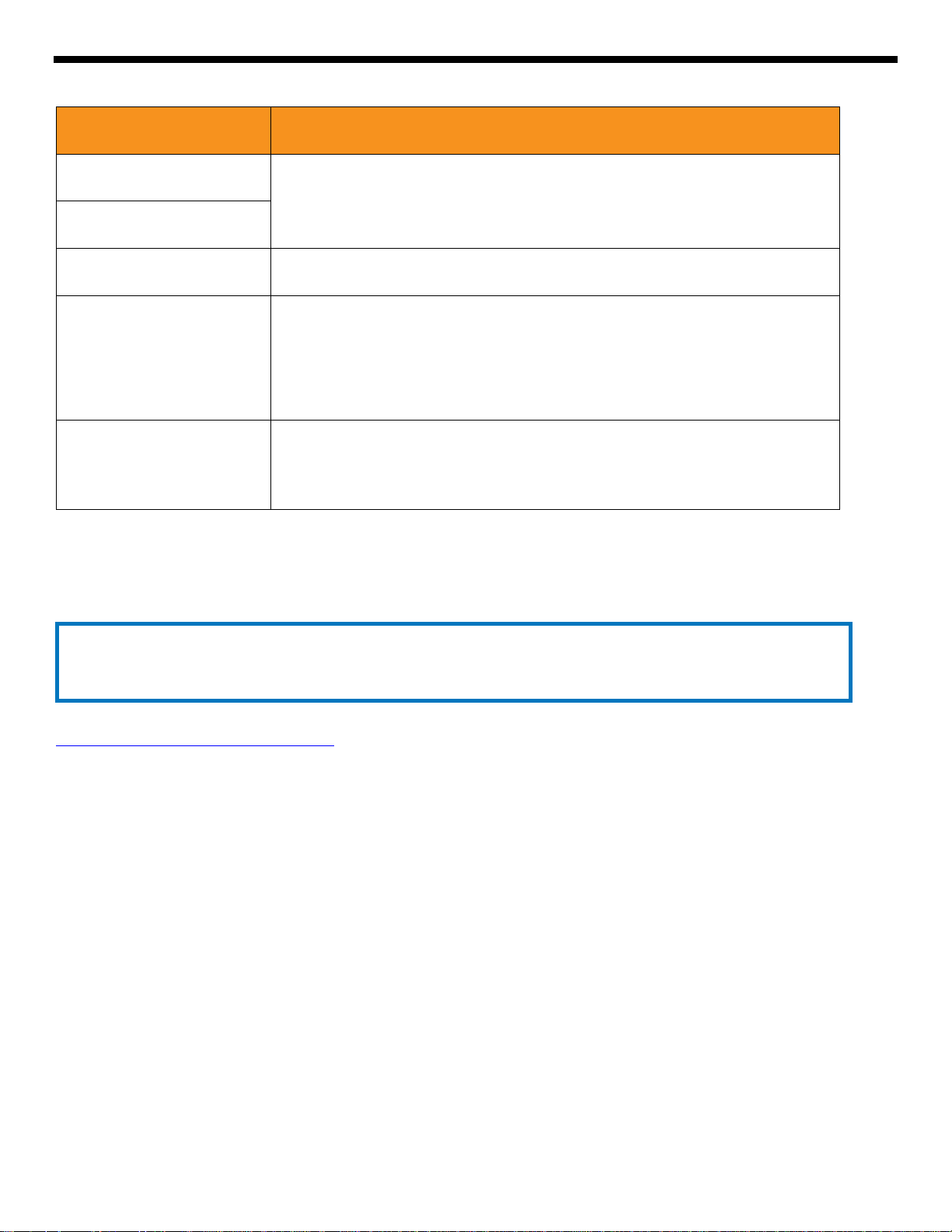

1.3.4 EnergyLink Monitoring Components

Term Definition

n/a

EnergyLink™

Monitoring

PVS5x

SunPower’s proprietary monitoring solution

that enables partners and customers to

easily understand and view both system

production and home energy consumption.

PV Supervisor 5x; commnicates with the AC

modules to monitor system performance

and transmit data to SunPower servers.

Document #518101 RevD 15 SunPower Proprietary

1.3.5 Torque Values

Fastener Final Torque

End clamp

85 +5/−0 in-lb (9.6 N-m)

Mid clamp

L-foot to rail nuts 375 +20/−0 in-lb (42 +2/−0 N-m)

Rail splice screws 40 in-lb (4.5 N-m)

(This torque value is achieved by 1/3 turn of the screw after the screw face

has contacted the rail face. After tightening in this manner, verify the

applied torque with a torque wrench.)

L-foot to roof

attachment

Refer to the roof attachment manufacturer’s documentation (included in

the roof attachment box). If using a roof attachment other than L-feet, refer

to that attachment manufacturer’s included documentation.

1.4 Listings, Classification, and FCC and IC Compliance

Important! This guide assumes you are installing AC modules on InvisiMount as part of a SunPower Equinox

system; if you are installing DC modules on InvisiMount, do not use this guide—instead use the InvisiMount

Residential Mounting System Installation Guide.

The InvisiMount system is UL 2703 Listed. For the most recent information, refer to the UL database

http://database.ul.com/QHYZ.E478330

the following SunPower Type C and Type D AC modules:

• SPR-X22-360-C-AC

• SPR-X21-345-C-AC

• SPR-X21-335-C-AC

• SPR-X21-335-BLK-C-AC

. At the time of publication of this guide (#518101 RevD), the Listing includes

• SPR-X20-327-BLK-C-AC

• SPR-X20-327-C-AC

• SPR-E20-327-C-AC

• SPR-E19-320-C-AC

• SPR-X22-370-D-AC

• SPR-X22-360-D-AC

• SPR-X21-350-BLK-D-AC

• SPR-X21-345-D-AC

• SPR-X21-335-BLK-D-AC

Document #518101 RevD 16 SunPower Proprietary

• SPR-X21-335-D-AC

• SPR-X20-327-BLK-D-AC

• SPR-X20-327-D-AC

• SPR-E20-327-D-AC

• SPR-E19-320-D-AC

Grounding from the module to the rail is accomplished through both the mid clamp and the end clamp. The

InvisiMount Listing also includes the following components, which have been evaluated for both mounting and

bonding in accordance with UL 2703:

• end clamp

• mid clamp (UL 2703 Listing is also valid if a mid clamp is used as an alternative to an end clamp)

• rail

• splice and splice screw

• L-foot

1.4.1 Fire Classification

• The maximum distance between the roof deck and the bottom of the module frame is 3” (7.6 cm).

• In order to maintain the system classification, this assembly must be mounted over a fire resistant roof covering

for the application.

• The system achieves a Class A fire rating when installed with modules having a Type 2 fire classification.

• The system achieves a Class A fire rating when installed in the manner specified in these instructions.

• The system was evaluated for use on roofs having a pitch ≥ 2″/foot (greater than or equal to 2:12).

1.4.2 FCC and IC Compliance

Note: For PVS5x FCC and compliance information, refer to Section 2.1.2.

The microinverter built into each AC module has been tested and fully complies with Federal Communication

Commission (FCC) Part 15 Class B for digital devices; as well as Industry Canada (IC) Interference-Causing Equipment

Standard ICES-003 Class B. The regulations in FCC Part 15 are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy, and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications.

1.5 Rapid Shutdown, System Grounding, NEC

Compliance, Ground Path, and Disconnects

Warning! If installing the Equinox system on a metal roof, you must verify with the AHJ whether additional bonding

to the roof is required. Follow the instructions provided by the AHJ and by the roofing manufacturer.

This section is intended to provide a well-rounded understanding of all aspects of rapid shutdown, grounding,

disconnect requirements, and NEC compliance for SunPower Equinox.

Document #518101 RevD

17 SunPower Proprietary

1.5.1 Rapid Shutdown

SunPower Type C and Type D AC modules meet all 2014 and 2017 NEC requirements for rapid shutdown as defined

in NEC 690.12 Rapid Shutdown of PV Systems on Buildings. As part of the UL 1741 SA / UL 1741 Listing of the

SunPower AC module product being grid support utility interactive, upon turning off the AC disconnect to deenergize the circuit to the AC modules on the roof, each AC module output will shut off within 2.0 seconds to

comply with IEEE 1547. In this manner, all wiring leaving each AC module complies with the controlled conductor

limits in 690.12.

Refer to Section D.1, D.2, and D.3 for the Rapid Shutdown Certificates of Compliance.

1.5.2 System Grounding

The InvisiMount system is Listed to UL 2703 for integrated grounding; SunPower AC modules are an

electrical bonding component and are Listed to UL 1741 SA / UL 1741; thus no additional grounding

hardware, lugs, or copper wire are required on the roof.

• The SunPower AC module is one of the components that electrically bonds all of the metallic non-current

carrying components in the system, and is Listed to UL 1741 SA (Type D AC modules) / UL 1741 (Type C AC

modules).

• Only AC equipment grounding requirements apply when installing Listed AC modules to racking that is Listed to

UL 2703—neither DC system grounding requirements (GEC) nor DC equipment grounding requirements (EGC) apply.

• The equipment grounding conductor (EGC) that is built into and Listed with the AC module cable system is sized

appropriately and meets all of the AC equipment grounding requirements for the system.

• The AC dedicated branch circuit wiring from the distribution panel to the array must include an equipment

grounding conductor (EGC) in the same raceway or cable as the AC circuit conductors. This EGC must be

connected to the green conductor of the transition cable, which is part of the AC module cable system.

• The AC module connectors (plugs and receptacles) are rated for disconnect, both under load and not under load.

• A grounding electrode conductor (GEC) for the module or array is not required because the DC power is internal

to the AC module. The existing AC GEC at the premises or structure utility service serves as the NEC-required

GEC for the AC module system.

• The AC cable grounding path has been tested by UL, and its electrical continuity from the AC cable ground pin to

the module frame has been evaluated as part of the AC module Listing.

• The AC module interconnecting cable system provides an internal EGC for grounding the AC modules.

• Neither the AC modules nor the array require a GEC. The AC module must be connected to a dedicated AC

branch circuit with an appropriately sized equipment grounding conductor (EGC). The EGC must be connected to

a grounding electrode using the existing premises wiring system, typically originating at the building service

entrance or service panel.

• The AC interconnecting cable system attached to each module’s microinverter is fully insulated and includes an

internal EGC. The grounding pin is longer than the others in the plug, providing a “first-make, last-break”

connection sequence.

• The green conductor in the AC cable is connected to the EGC from the utility dedicated branch circuit (“the

building ground”).

Document #518101 RevD

18 SunPower Proprietary

• The AC ground wire inside the microinverter terminates on the microinverter chassis with a bolted connection,

and is environmentally sealed; and the microinverter chassis is bonded to the module frame with stainless steel

hardware to provide ground continuity to the module frame.

• If a module is removed from a circuit (for service or replacement, for example), remember that the AC

module cable system is daisy-chained and that therefore you must first disconnect all power and then

install a temporary EGC to bridge the gap by inserting an AC extension cable or other means, in order to

maintain effective ground continuity to subsequent modules. Disconnecting a module from the circuit

removes voltage and might also remove ground from the other downstream modules in the circuit.

Extreme care should be taken to ensure that no other energized sources are adjacent to these

ungrounded modules. Refer to Appendix B.

Each SunPower AC module includes a factory-integrated microinverter (MI) that does not require a neutral

wire to be connected to it for operation or for compliance with IEEE 1547. Power produced is conducted on the

L1–L2 240 VAC or 208 wye VAC grid connection. Utility interactive functions in the MI circuitry have been evaluated

to IEEE 1547, and use the ground wire instead of the neutral to determine grid values. This functionality is part of its

UL Listing.

This product must only be connected to a single-phase system (L–L) of a premises with the neutral (N)

bonded to ground at the service entrance per code. (The MI does not reference the N to ground internally,

therefore this reference must be accomplished only at the service entrance.) Ensure that the installation site has a

high-quality N-to-ground reference at the service. The MI determines L–N voltages based on measuring internally

from L to the MI chassis, which is connected to the EGC.

1.5.3 NEC Compliance

The following are the grounding-related NEC Articles and their applicability to SunPower Equinox:

The following are the grounding-related NEC Articles and their applicability to SunPower Equinox:

• 690.11 pertains to DC arc fault circuit protection and is not applicable to SunPower Equinox.

• 690.12 requires rapid shutdown; SunPower AC modules (the heart of Equinox) meet all requirements for rapid

shutdown as defined in NEC 690.12 Rapid Shutdown of PV Systems on Buildings. As part of the UL 1741 SA / UL

1741 Listing of the SunPower AC module product being utility interactive, upon turning off the AC disconnect to

de-energize the circuit to the AC modules on the roof, each AC module output will shut off within 2.0 seconds to

comply with IEEE 1547. In this manner, all wiring leaving each AC module complies with the controlled conductor

limits in 690.12.

• 690.31(D) requires that the equipment be grounded using an equipment grounding conductor (EGC) inside the

AC module cable. Equinox AC cables are compliant because they do include this EGC.

• 690.41 does not apply to AC modules. This section applies to the grounding of DC circuits (e.g., positively

grounded PV systems). As such, it applies to photovoltaic source circuits or photovoltaic output circuits. Per

690.6, the output of an AC module is an inverter output circuit and therefore the requirements of 690 that

pertain to photovoltaic source circuits or output circuits do not apply to AC modules.

• 690.42 does not apply to AC modules for the same reasons 690.41 does not.

• 690.43 covers equipment grounding, which is the only required type of grounding for an AC module. SunPower

Equinox fully complies with the relevant portions of 690.43:

Document #518101 RevD

19 SunPower Proprietary

o 690.43(A) – SunPower Equinox is grounded when installed according to the instructions and connected to

an equipment grounding conductor bonded to the premises grounding electrode system.

o 690.43(B) – SunPower Equinox requires the installation of an equipment grounding conductor between the

array and other equipment (typically originating at the rooftop junction box and terminating at the

grounding busbar or terminal in the main service panel).

o 690.43(C) – InvisiMount end clamps and mid clamps are Listed and identified for bonding module frames to

rails.

o 690.43(D) – InvisiMount end clamps and mid clamps are Listed and identified for bonding module frames to

rails.

o 690.43(E) – InvisiMount mid clamps are identified for the purpose of grounding modules.

o 690.43(F) – The integrated AC module cable and AC module extension cables do include an equipment

grounding conductor.

• 690.45 specifies that EGCs should be sized based on 250.122. Equinox meets this requirement by including a 12

AWG equipment grounding conductor. The EGC in every AC module cable is 12 AWG. The maximum overcurrent

protection for an AC module circuit is 20 A. The minimum EGC size based on the table at 250.122 is 12 AWG. If

multiple circuits are routed with a single EGC for the array, 250.122(C) permits the installer to use 12 AWG for the

combined EGC.

• 690.46 modifies 690.45 when the EGC is not protected within a raceway, and does not apply to SunPower

Equinox. It modifies 690.45 by requiring a larger conductor when the EGC is not routed with circuit conductors

and installed outside of a raceway. But SunPower Equinox does comply with 690.31(D) which requires that the

EGC be contained within the cable assembly. 690.46 was inserted into the Code to prevent installers from using

small conductors such as 14, 12, or 10 AWG to ground rails in systems having no integrated grounding.

• 690.47 does not apply to AC modules:

o 690.47(A) does not apply to Equinox because the AC “system” was already existing on the premises (already

installed per Article 250 of the code) and the AC module system connects to the load side of this service.

Installing AC modules constitutes the installation of new “equipment” on an existing AC system. As such, the

existing system already has a grounding electrode system, and the only requirement is to connect the new

equipment to that system.

o 690.47(B) applies to DC systems; it does not apply to AC modules, and does not apply to SunPower Equinox.

This section pertains only to DC systems in which a photovoltaic source circuit would be either grounded or

ungrounded; but 690.6 exempts AC modules from requirements pertaining to photovoltaic source circuits.

Code language states that the intention of an auxiliary grounding electrode can be achieved through a

properly installed EGC back to the premises grounding electrode. SunPower Equinox meets this intention

for rooftop arrays by using the integrated grounding system along with a properly sized and installed EGC.

o 690.47(C) does not apply to SunPower Equinox for the same reasons that 690.47(A) and 690.47(B) do not

apply.

o 690.47(D) only provides guidance for a “dc grounding electrode conductor” and does not apply to SunPower

Equinox on residential rooftops where there is an existing adequate premises grounding electrode system.

In most cases (99%), the premises wiring electrode eliminates the need for an additional array grounding

electrode (Exception No. 2) and the equipment grounding conductor connected to the grounding busbar or

terminal in the main service panel is sufficient for connecting the metallic surfaces of the array to ground.

• 690.48 addresses module removal. When an AC module is removed from a SunPower Equinox system, it

interrupts the circuit and equipment grounding connection between modules. This can leave the equipment

Document #518101 RevD

20 SunPower Proprietary

ungrounded if it is not returned to service. Upon a module’s removal, the modules downstream of the removed

module are reconnected using an AC module extension cable to bridge the gap, which re-establishes the

equipment grounding connection.

• 690.49 does not apply to Equinox because it refers to photovoltaic source and output circuit grounded

conductors.

• 690.50 does not apply to Equinox because equipment bonding jumpers are not used.

• 690.52 requires that the AC module be marked with identification of its leads and that it provide five specific

ratings. SunPower AC modules are so marked and are thus fully compliant.

• 705.12(D)(6) previously required AC arc fault protection on the output of AC modules if the modules use rooftop

cables that are not in a raceway; however, 705.12(D)(6) has been deleted by a tentative interim amendment (TIA)

to the 2014 NEC, and has been deleted in the 2017 NEC:

www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-andstandards?mode=code&code=70&tab=editions

www.nfpa.org/assets/files/AboutTheCodes/70/TIA_70_14_11.pdf

AFCI on the AC side is not required and is not included with SunPower AC modules.

Section 4.1 of the SunPower AC Module Safety and Installation Instructions (#514744) states:

As a Listed product, “SunPower AC modules shall be installed and used in accordance with any instructions included in

the listing or labeling” (NEC 110.3(B)). In addition, SunPower AC modules “shall be grounded using the integrated

equipment grounding conductor...no additional grounding conductor attachment to the AC module is required.”

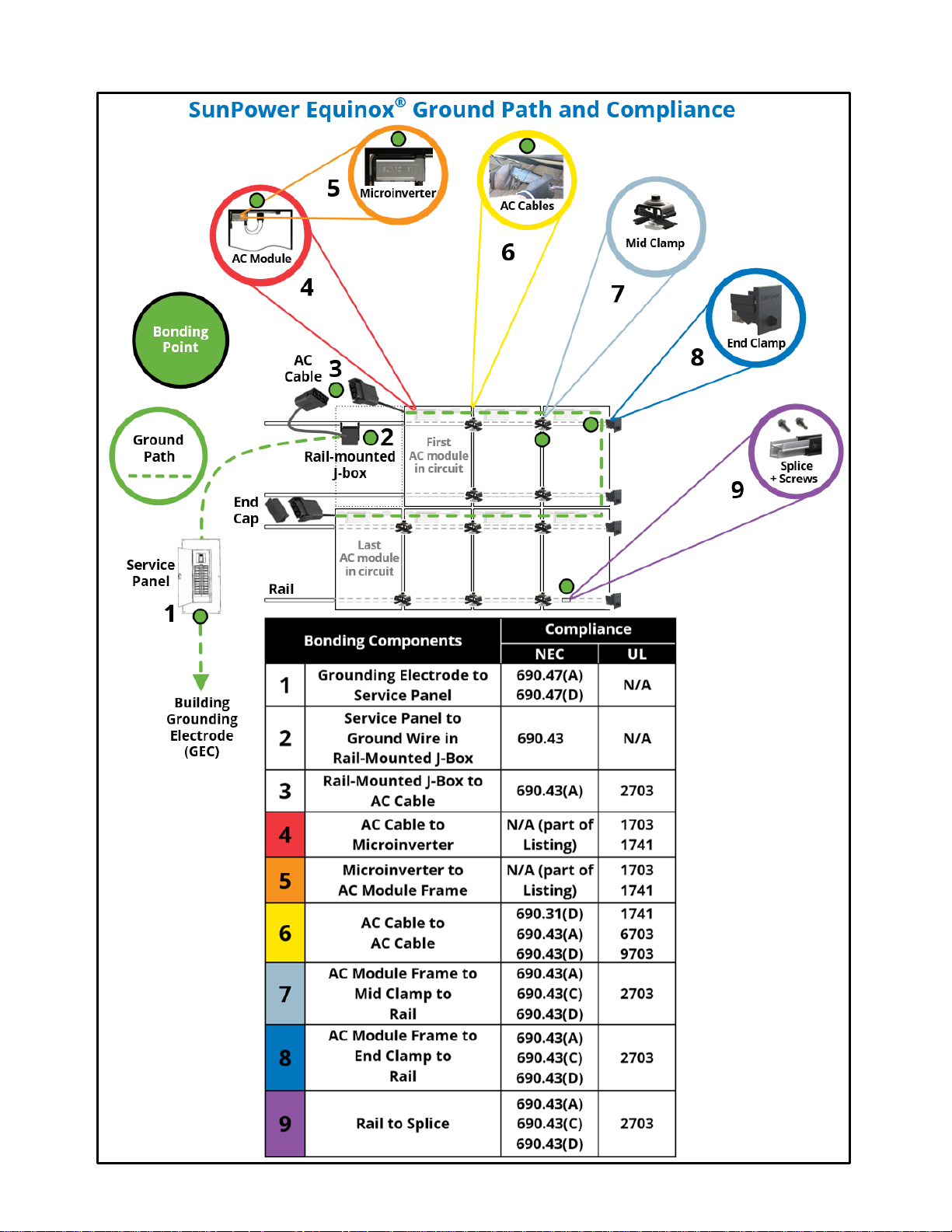

1.5.4 Ground Path

The system features:

• integrated module-to-rail as well as module-to-module bonding (achieved through the mid clamp and end

clamp).

• integrated rail-to-rail bonding (achieved through the self-drilling splice screws and the splice).

• system bonding achieved through the equipment ground conductor (EGC).

The following diagram illustrates the key grounding and bonding aspects of the system:

• the system ground path

• each component

• each bonding point

• the applicable NEC and UL references

Document #518101 RevD

21 SunPower Proprietary

Document #518101 RevD

22 SunPower Proprietary

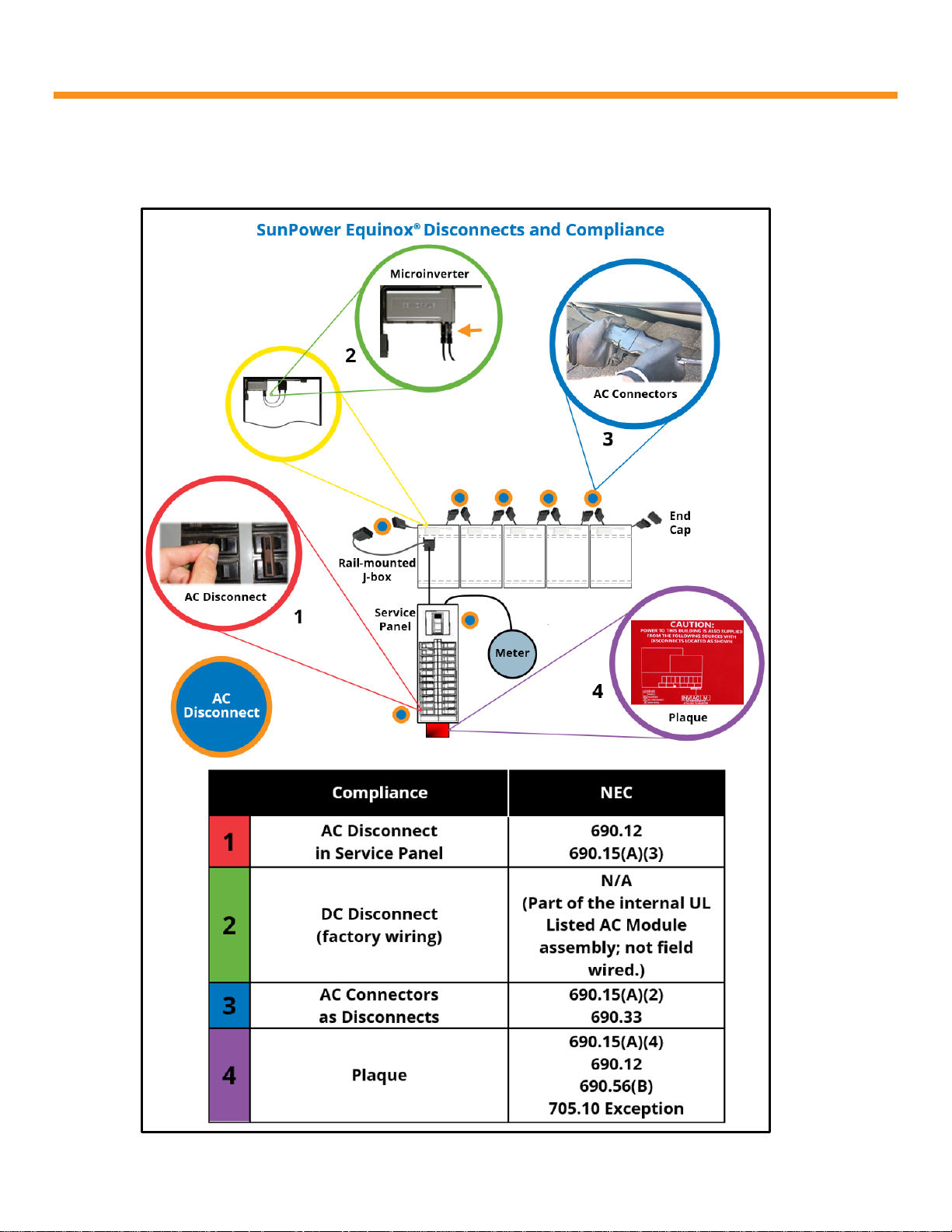

1.5.5 Disconnects

The following diagram and text illustrate NEC conformance to each of the relevant disconnect aspects of the

system, including the use of SunPower AC module connectors as disconnects.

Document #518101 RevD

23 SunPower Proprietary

SunPower AC modules require the use of cables and connectors that are UL Recognized and that conform to UL

6703 and UL 9703; the provided SunPower AC extension cables and their built-in connectors meet these

requirements, contain an EGC, and are rated at 20 A and 600 V. In addition, the AC module connectors are rated

for disconnect under load.

Applicable NEC context for AHJs evaluating a roof-mounted AC module array

AC modules must be installed per 690.6:

• 690.6(A): DC photovoltaic source circuits don’t apply to AC modules.

• 690.6(B): The output of an AC module shall be considered an inverter output circuit.

• 690.15(A): With respect to the AC output, an AC module installed on a roof is the equivalent of an inverter in a

not readily accessible location.

• 690.15(A)(2): An AC disconnecting means must be within sight of (or in) an inverter; the AC cable connectors can

function as this disconnecting means as per 690.17 Exception; if and only if the connectors are rated for

disconnect as per 690.33; the connectors on the SunPower AC cables (module and extension) are fully compliant

in all these respects.

SunPower Equinox fully complies with NEC disconnect requirements

690.15(A) requires utility interactive inverters in not readily accessible locations to comply with certain

provisions. Because the output of an AC module is to be “considered an inverter output circuit,” it’s reasonable to

apply as much of 690.15 as applies to inverter output circuits, but not photovoltaic source circuits:

• 690.15(A)(1) does not apply because it only applies to photovoltaic source or photovoltaic output circuits.

• 690.15(A)(2) does apply and mandates that an AC disconnecting means shall be mounted within sight of or

within the inverter.

• 690.15(A)(3) does apply and mandates that an additional, readily accessible disconnecting means is required.

How does SunPower Equinox comply with 690.15(A)(2)?

The module-integrated AC module cable connectors (plugs and receptacles) are the AC disconnecting means,

because 690.17(E) Exception states that:

A connector shall be permitted to be used as an ac or dc disconnecting means, provided that it complies with the

requirements of 690.33 and is listed and identified for use with specific equipment.

How do the Equinox AC module connectors comply with 690.17(E) Exception?

Our connectors are UL Recognized for use with all of the module models listed in Section 1.4.

• 690.33(A): Equinox connectors are polarized and noninterchangable with other receptacles on the premises.

• 690.33(B): Equinox connectors are guarded (are touch-safe).

• 690.33(C): Equinox connectors are of the locking type.

• 690.33(D): Equinox connectors are first-make, last-break for the internal equipment grounding conductor (EGC).

• 690.33(E): Equinox connectors are rated for interrupting current (load break) and are suitable as disconnects.

How do Equinox AC modules comply with 690.15(A)(3)?

The breaker in the readily accessible main service panel—or any other AC disconnect in the system—can be

considered the readily accessible disconnecting means. But if the circuit runs through the house (as it will in many

installations), it would seem then that SunPower AC modules must also comply with 690.31(E).

Document #518101 RevD

24 SunPower Proprietary

But while 690.31(E) does have special provisions for photovoltaic source and output circuits inside a building, a

SunPower AC module is an inverter output circuit, and the provisions applying to photovoltaic source and output

circuits thus do not apply to AC modules. (The clear intent of the code is to provide special protections for DC

circuits, but there are no special provisions for AC circuits.)

Summary

In a SunPower Equinox system the required AC disconnect on the roof is the AC connector pair (a plug and a

receptacle); the AC disconnect on the ground is the AC breaker in the service panel (or the external switch, if used).

The integrated grounding solution incorporated into SunPower Equinox is 100% end-of-line tested and Listed by UL.

Document #518101 RevD

25 SunPower Proprietary

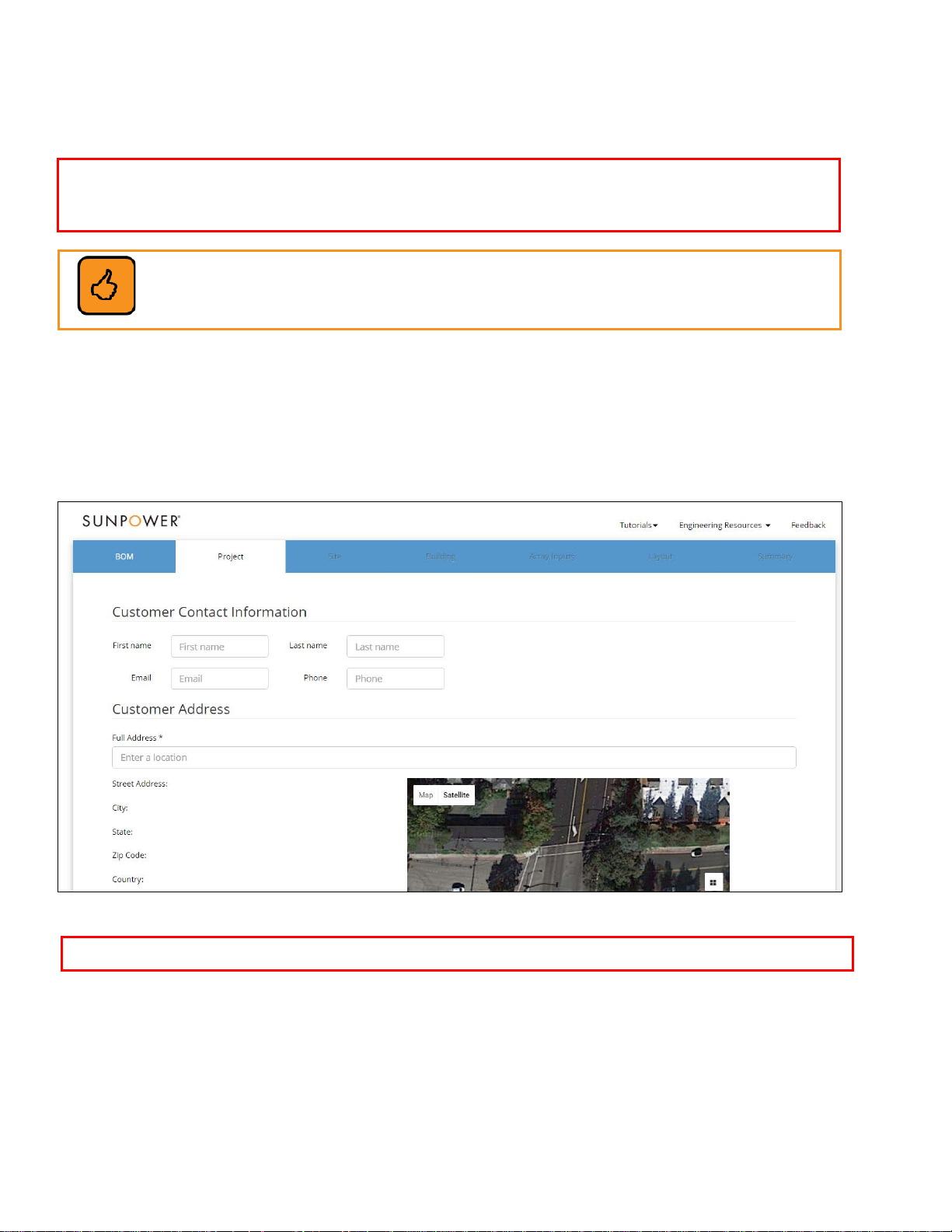

1.6 Pre-Installation Checklist

Important! SunPower strongly recommends using the online SunPower Design Tool (accessed

from the Portal) to design your arrays and determine the accompanying bill of materials (BOM).

In addition, always refer to the InvisiMount Span Tables document (#524734).

Best Practice: To help save time, ensure a safe and high-quality installation, and avoid any

confusion about the system details, fill out the SunPower System and Site Checklist

(located in Appendix A of this guide) as you build the array and install the system.

Your array should be fully designed and all required permitting obtained before you begin installing the system.

Use the SunPower Design Tool OR the InvisiMount Span Tables document (#524734) to determine the actual span

between attachments for a given system.

Designers can access the Tool by logging into the Portal and then clicking the Design Tool link. The Tool yields all

the racking–specific structural calculations that can then be provided to the AHJ and that are typically part

of the permitting process.

SunPower Design Tool

Ensure that you bring the resulting PDF file to the site—its cabling diagram offers you significant time savings!

Document #518101 RevD

26 SunPower Proprietary

1.7 Installation Outline

1. Mark the rooftop for penetrations.

2. Install the flashings (if part of the attachment solution for your roof type) and the roof attachments.

3. Install the InvisiMount system and the AC modules.

4. Install the EnergyLink™ hardware (PV Supervisor 5x) monitoring system and set up EnergyLink.

5. Commission the system.

1.8 Install InvisiMount and AC Modules

Important! The maximum number of modules for a single 20 A circuit in a 240 V single-phase system is 12.

These instructions describe attaching the rails parallel to the roof peak (“E–W”). The rail section length is 10′ 9″ (3.28

m) and is optimized to accommodate three modules in portrait position; or two modules in landscape.

For composition shingle roofs, it is acceptable to attach InvisiMount to either the rafters or the roof deck. SunPower

recommends the following attachments which have been integrated into the SunPower Design Tool for easy design

and permitting:

• For rafter attachment: SunModo K10068-BK8 (SunPower #508329)

• For deck attachment SunModo K10068-BK7 (SunPower #508330)

Instructions for installing the above attachments can be found here:

sunmodo.com/wp-content/uploads/2015/04/D10011-V002-Guide-EZ-Roof-Mount.pdf

For curved and flat tile roofs, SunPower recommends Quick Mount PV QMHSS Quick Hook (SunPower #510083),

which is also integrated into the SunPower Design Tool. Installation instructions can be found here:

www.quickmountpv.com/support/videos/qhk-quick-install.html

Important! Hook attachments may be attached to the rafters only—not to the roof deck.

1.8.1 Attachment Span and Rail Cantilever

The maximum span (distance between roof attachments) is 8′ (2.4 m). The maximum rail overhang length

(cantilever) beyond a rail’s endmost attachment is 24″ (61 cm). This distance may be less—but never more—based on

site-specific conditions. Use the SunPower Design Tool (https://invisimountdesign.us.sunpower.com/login.html

the InvisiMount Span Tables document (#524734) to verify spans between roof attachments and maximum cantilever

for your particular site.

Access the Tool by logging into the Portal and then clicking the Design Tool link.

) OR

Note: A spliced rail does not require any special allowance for span or cantilever.

1.8.2 Module Spacing

• Adjacent modules that share a mid clamp (side to side; L–R in a typical row): 0.8” (20 mm), governed and

enforced when the mid clamps are installed.

• Adjacent rows (an upper and a lower row in a typical array): 13/16” (20 mm), governed and enforced by the row-

to-row (R2R) spacers when used (refer to Fig. 23); minimum is 1/4” (6.5 mm).

Document #518101 RevD

27 SunPower Proprietary

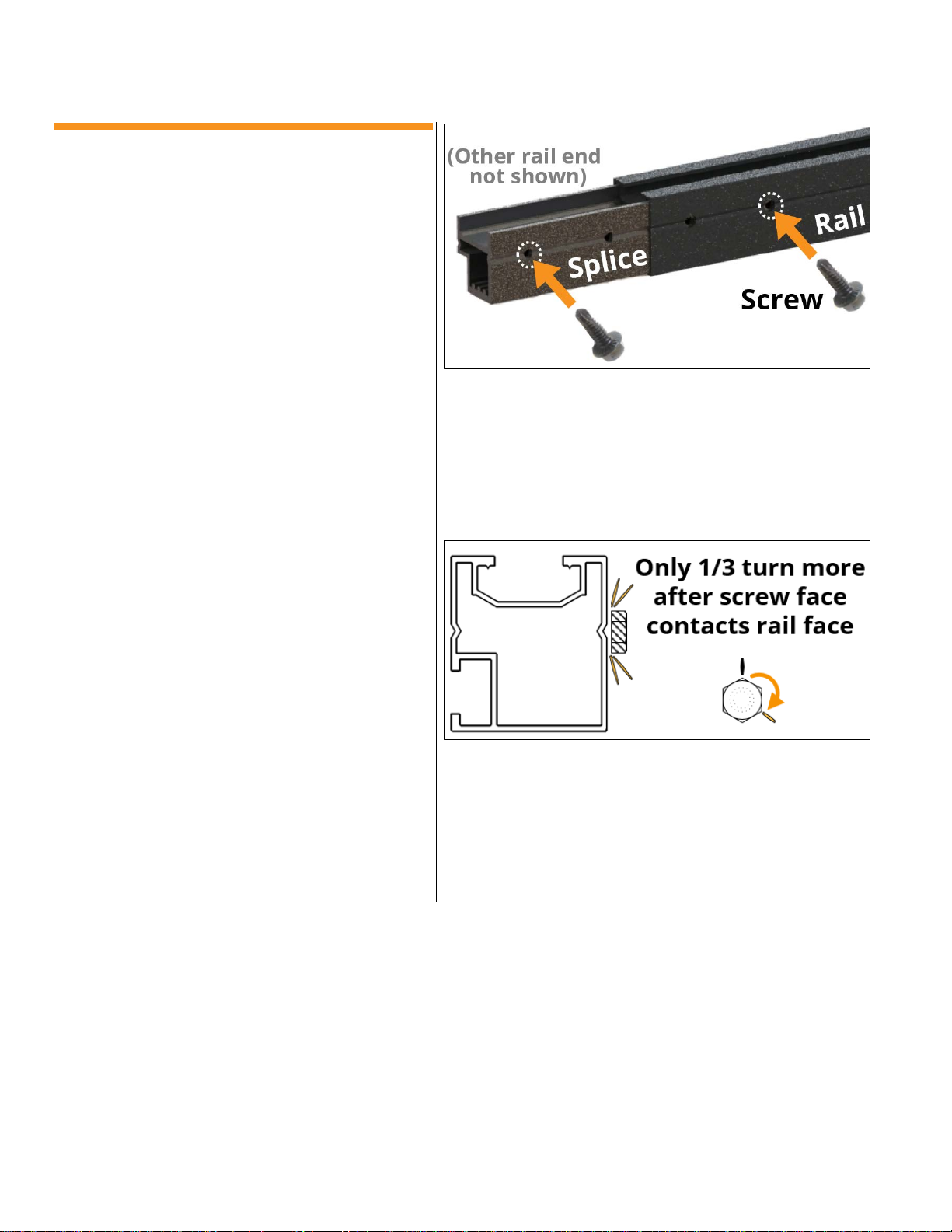

1.8.3 Join Rails

The rails and the splices have pre-drilled holes for

the splice screws: four in the splice and two in each

rail end. You install one screw per rail section, in the

hole furthest from the rail end (Fig. 1).

Important! The splice is an integral part of the

ground path. There must be no interference

between the splice screws and the L-feet.

1. Fit a splice halfway into a rail end, align the

splice holes with the rail holes, secure the

components so that they will not move, and

then drive a splice screw through the aligned

hole that is furthest from the rail end, stopping

1/3 turn after the screw face has contacted the

rail face (Fig. 2). This method provides 40 +5/−0

in-lb (4.5 N-m) of torque. Use a torque wrench to

verify and (if necessary) apply final torque to

each screw.

2. Splice screws are single use. If a screw becomes

dull or prevents smooth, consistent penetration

of the splice, use a new screw in the original

hole. If a screw breaks, use the other existing

hole—do not reuse the original hole, and do not

drill additional holes.

3. Fit the second rail all the way onto the splice

protruding from the first rail, align the

respective holes, and install the second screw.

The rail holes and splice holes must be aligned;

the rail ends are not required to be in contact

with each other. The maximum distance

between a spliced rail pair is 1/4″ (6.4 mm).

Fig. 1

Fig. 2

Document #518101 RevD

28 SunPower Proprietary

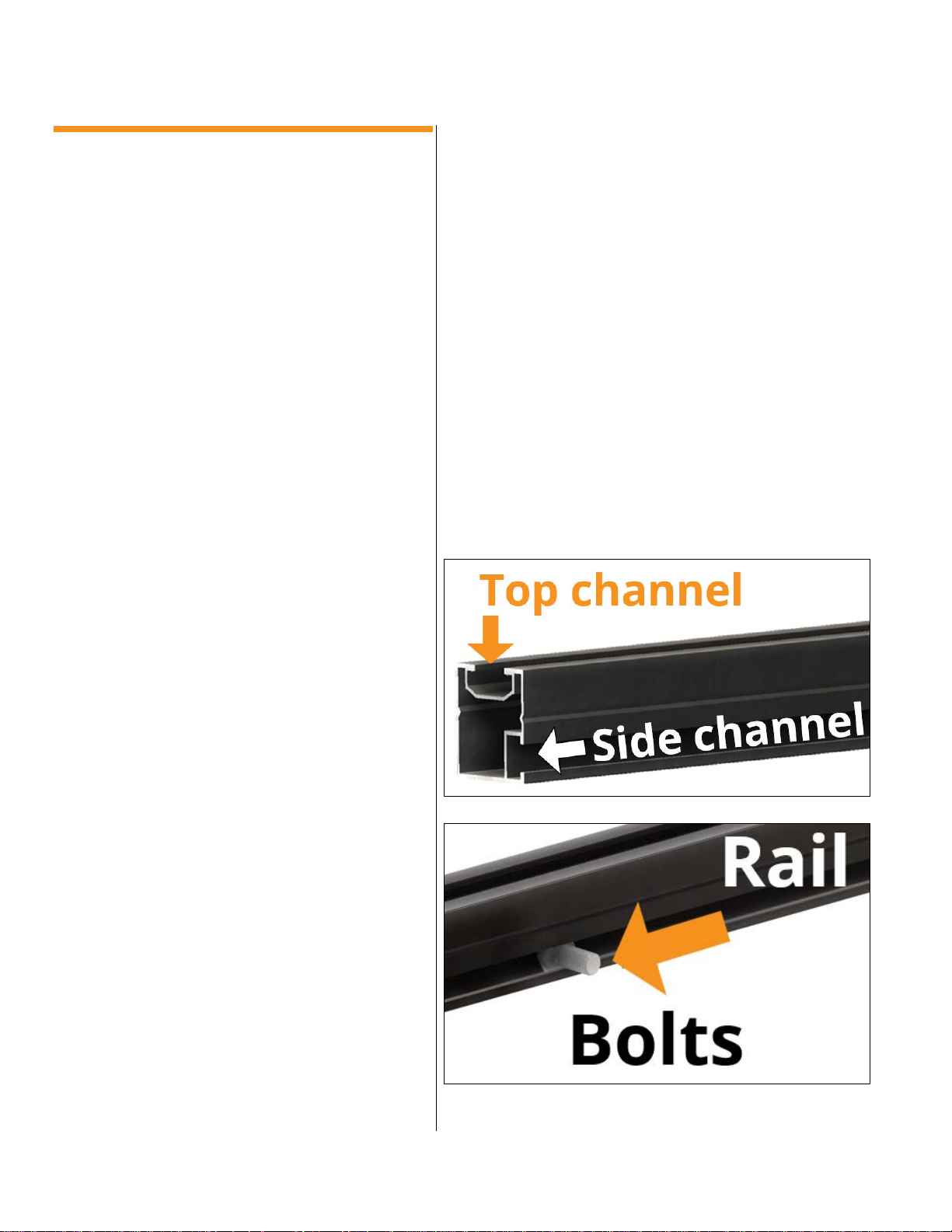

1.8.4 Install Flashings,

Roof Attachments,

and Rails

1. Define the installation zone and array layout on

the rooftop and mark it for penetrations as

necessary.

2. Referring to the manufacturer guidance for both

the flashing (if appropriate for the roof type) and

for your chosen roof attachment:

a. Install the flashings and the roof

attachments.

b. According to the roof attachment

manufacturer guidance, attach an L-foot to

each of the roof attachments. Leave the

hardware finger-tight for the moment.

3. Position the rails on the roof, adjacent to the L-

feet and such that the side channel of each rail

is facing the roof peak (Fig. 3 and Fig. 5).

4. For each rail, determine the number of L-feet to

which it will attach, and then slide that number

of bolts into the rail’s side channel (bolt heads fit

into channel; Fig. 4). For bolt specification see

Section 1.33.

Important! For your roof attachment strategy,

remember that a spliced rail is the same as a

solid rail in that a spliced rail does not require

any special allowance in terms of overhang

or attachments.

Document #518101 RevD

Fig. 3

Fig. 4

29 SunPower Proprietary

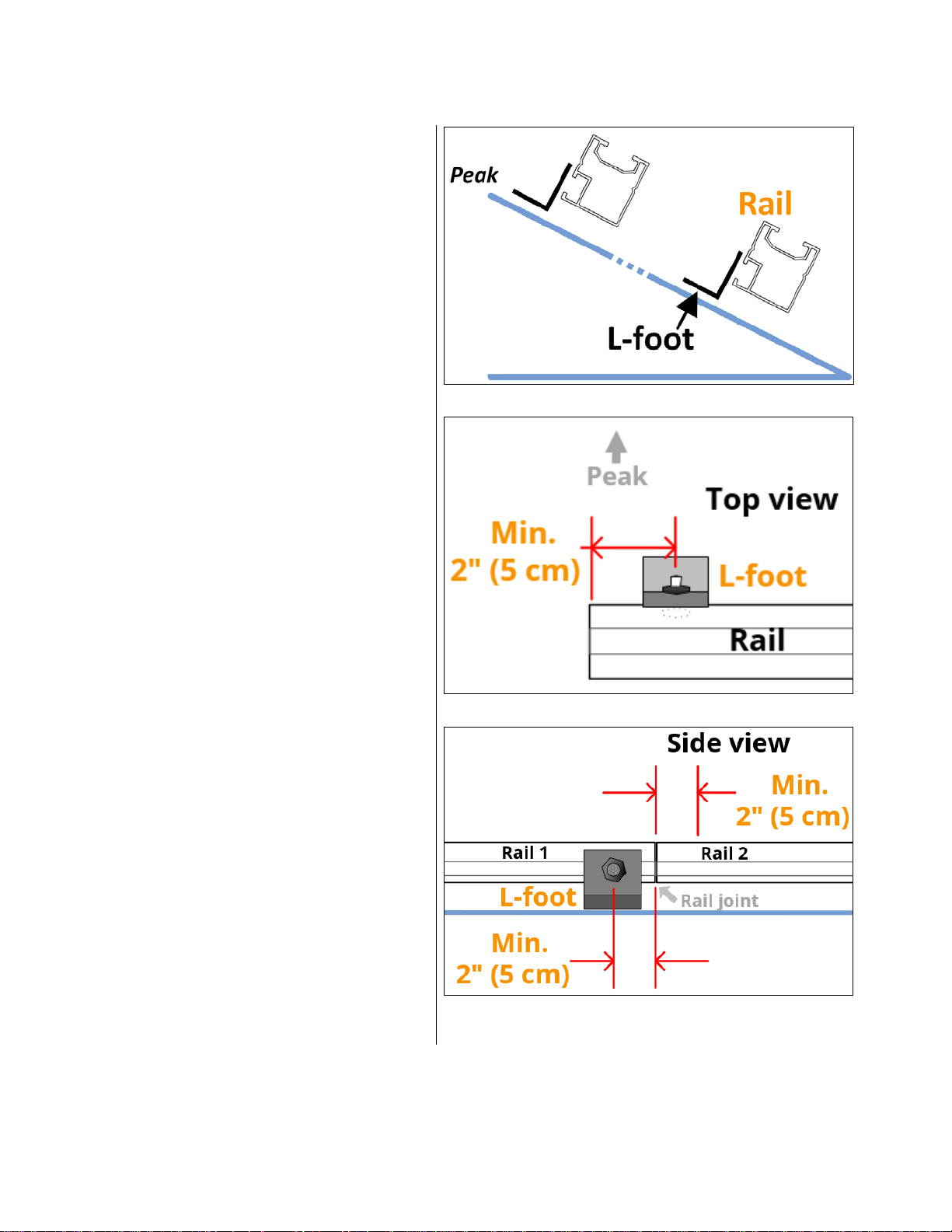

5. Position the rail—with its side channel facing the

peak—adjacent to and “below” (relative to the

peak) the L-feet for the given row (Fig. 5).

Note: L-feet must only “face” the peak (Fig. 5

and Fig. 6).

6. Position the rail bolts a minimum of 2″ (5 cm)

from the end of a rail (Fig. 6); and a minimum of

2″ (5 cm) from any rail joint (Fig. 7).

Fig. 5

Fig. 6

Document #518101 RevD

Fig. 7

30 SunPower Proprietary

Loading...

Loading...