Page 1

Sun Server X2-4

(formerly Sun Fire X4470 M2)

Service Manual

Part No.: E20784-06

April 2013

Page 2

Copyright ©2011, 2012, 2013 , Oracle and/or its affiliates. Allrights reserved.

This softwareand related documentationare provided under a license agreement containingrestrictions onuse anddisclosure and are protected by

intellectual propertylaws. Exceptas expressly permittedin yourlicense agreement or allowed by law, you may not use, copy,reproduce, translate,

broadcast, modify, license,transmit, distribute,exhibit, perform,publish, ordisplay anypart, inany form,or byany means.Reverse engineering,

disassembly, or decompilation of this software, unlessrequired by law for interoperability, is prohibited.

The informationcontained hereinis subjectto changewithout noticeand isnot warrantedto beerror-free.If youfind anyerrors, please report them to us

in writing.

If thisis softwareor related software documentation that is delivered tothe U.S.Government oranyone licensingit onbehalf ofthe U.S.Government, the

following noticeis applicable:

U.S. GOVERNMENTEND USERS.Oracle programs,including anyoperating system,integrated software, anyprograms installed on the hardware,

and/or documentation,delivered toU.S. Governmentend usersare "commercial computer software" pursuantto theapplicable FederalAcquisition

Regulation andagency-specific supplementalregulations. Assuch, use,duplication, disclosure, modification,and adaptationof theprograms, including

any operatingsystem, integratedsoftware, anyprograms installed on the hardware,and/or documentation,shall besubject tolicense termsand license

restrictions applicableto theprograms. No other rights are granted to the U.S. Government.

This software orhardware is developed for generaluse ina varietyof information management applications. It is not developed orintended foruse in any

inherently dangerous applications,including applicationsthat maycreate a risk of personal injury.If youuse thissoftware or hardwarein dangerous

applications, thenyou shallbe responsibleto takeall appropriate fail-safe,backup, redundancy, and other measures to ensure itssafe use.Oracle

Corporation andits affiliatesdisclaim anyliability forany damagescaused byuse ofthis software orhardware in dangerousapplications.

Oracle andJava areregistered trademarks of Oracle and/or its affiliates.Other namesmay betrademarks oftheir respective owners.

Intel andIntel Xeonare trademarksor registered trademarks of Intel Corporation. All SPARC trademarks areused underlicense andare trademarks or

registered trademarks of SPARCInternational, Inc. AMD, Opteron, theAMD logo,and theAMD Opteron logo are trademarksor registered trademarksof

Advanced MicroDevices. UNIXis aregistered trademark of The Open Group.

This software or hardware and documentation may provide access to or information on content, products, and services from third parties. Oracle

Corporation and its affiliates are not responsible for and expressly disclaim all warranties of any kind with respect to third-party content, products, and

services. Oracle Corporation and its affiliates will not be responsible for any loss, costs, or damages incurred due to your access to or use of third-party

content, products, or services.

Copyright ©2011, 2012, 2013, Oracle et/ou ses affiliés.Tous droits réservés.

Ce logicielet ladocumentation quil’accompagne sontprotégés parles loissur lapropriété intellectuelle. Ils sont concédés sous licence et soumis à des

restrictions d’utilisationet dedivulgation. Saufdisposition devotre contrat de licence ou de la loi, vous ne pouvez pas copier, reproduire, traduire,

diffuser, modifier, breveter, transmettre, distribuer, exposer,exécuter, publierou afficherle logiciel,même partiellement,sous quelqueforme etpar

quelque procédéque cesoit. Parailleurs, ilest interdit deprocéder à toute ingénierie inverse du logiciel, de le désassembler ou de le décompiler, excepté à

des finsd’interopérabilité avecdes logicielstiers outel queprescrit par la loi.

Les informationsfournies dansce documentsont susceptiblesde modificationsans préavis.Par ailleurs,Oracle Corporationne garantitpas qu’elles

soient exemptesd’erreurs etvous invite,le caséchéant, àlui enfaire part par écrit.

Si celogiciel, oula documentationqui l’accompagne,est concédésous licenceau Gouvernementdes Etats-Unis,ou àtoute entitéqui délivrela licencede

ce logicielou l’utilisepour lecompte duGouvernement desEtats-Unis, lanotice suivantes’applique :

U.S. GOVERNMENTEND USERS.Oracle programs,including anyoperating system,integrated software, anyprograms installed on the hardware,

and/or documentation,delivered toU.S. Governmentend usersare "commercial computer software" pursuantto theapplicable FederalAcquisition

Regulation andagency-specific supplementalregulations. Assuch, use,duplication, disclosure, modification,and adaptationof theprograms, including

any operatingsystem, integratedsoftware, anyprograms installed on the hardware,and/or documentation,shall besubject tolicense termsand license

restrictions applicableto theprograms. No other rights are granted to the U.S. Government.

Ce logicielou matériela étédéveloppé pourun usagegénéral dansle cadred’applications degestion desinformations. Celogiciel oumatériel n’estpas

conçu nin’est destinéà êtreutilisé dansdes applicationsà risque,notamment dansdes applicationspouvant causerdes dommagescorporels. Si vous

utilisez celogiciel oumatériel dansle cadred’applications dangereuses, ilest devotre responsabilité de prendre toutesles mesures desecours, de

sauvegarde, deredondance et autres mesures nécessaires àson utilisation dans desconditions optimalesde sécurité.Oracle Corporationet sesaffiliés

déclinent touteresponsabilité quantaux dommagescausés parl’utilisation dece logicielou matérielpour cetype d’applications.

Oracle etJava sontdes marquesdéposées d’OracleCorporation et/oude sesaffiliés.Tout autre nommentionné peutcorrespondre à des marques

appartenant àd’autres propriétaires qu’Oracle.

Intel etIntel Xeonsont desmarques oudes marques déposéesd’Intel Corporation.Toutes lesmarques SPARC sont utilisées sous licence et sont des

marques oudes marques déposéesde SPARC International, Inc. AMD, Opteron, le logo AMD et le logo AMD Opteron sontdes marques ou des marques

déposées d’AdvancedMicro Devices.UNIX estune marque déposéed’The OpenGroup.

Ce logicielou matérielet ladocumentation quil’accompagne peuventfournir desinformations oudes liensdonnant accèsà descontenus, desproduits et

des servicesémanant detiers. OracleCorporation etses affiliésdéclinent touteresponsabilité ou garantie expresse quant aux contenus, produits ou

services émanantde tiers.En aucuncas, OracleCorporation etses affiliésne sauraientêtre tenus pour responsables des pertes subies, des coûts

occasionnés oudes dommagescausés parl’accès àdes contenus,produits ouservices tiers,ou àleur utilisation.

Please

Recycle

Page 3

Contents

Using This Documentation xi

1. Sun Server X2-4 Service Manual Overview 1–1

1.1 System Overview 1–1

1.1.1 Intel Xeon E7 Platform 1–1

1.1.2 Block Diagrams 1–2

1.1.3 Processors (CPUs) 1–3

1.1.4 Memory 1–4

1.1.5 Cooling 1–5

1.1.6 Input/Output (I/O) 1–6

1.1.7 Summary of Supported Components and Capabilities 1–7

1.2 Server Front Panel Features 1–9

1.3 Server Back Panel Features 1–10

1.4 Performing Service Related Tasks 1–11

2. Preparing to Service the Sun Server X2-4 2–1

2.1 Location of Replaceable Components 2–1

2.2 Tools and Equipment Needed 2–3

2.3 Performing Electrostatic Discharge and Static Prevention Measures 2–3

2.3.1 Using an Antistatic Wrist Strap 2–3

iii

Page 4

2.3.2 Using an Antistatic Mat 2–4

2.4 Positioning the Server for Maintenance 2–4

▼ Extend the Server to the Maintenance Position 2–4

2.5 Releasing the Cable Management Arm 2–5

▼ Release the CMA 2–5

2.6 Powering Off the Server 2–6

▼ Power Off the Server Using the Service Processor Command-Line

Interface 2–7

2.7 Removing the Server Top Cover 2–8

▼ Remove the Server Top Cover 2–8

2.8 Removing or Installing Filler Panels 2–9

2.9 Attaching Devices to the Server 2–10

2.9.1 Connector Locations 2–10

2.9.2 Cabling the Server 2–11

▼ Cable the Server 2–11

3. Servicing CRU Components That Do Not Require Server Power Off 3–1

3.1 Servicing Disk Drives (CRU) 3–1

3.1.1 Disk Drive Status LED Reference 3–1

3.1.2 Removing and Installing Disk Drives and Disk Drive Filler Panels

3–2

▼ Remove a Disk Drive Filler Panel 3–2

▼ Remove a Disk Drive 3–3

▼ Install a Disk Drive 3–4

▼ Install a Disk Drive Filler Panel 3–5

3.2 Servicing Fan Modules (CRU) 3–5

3.2.1 About Server Fans 3–6

3.2.2 Fan Module LED Reference 3–6

3.2.3 Detecting Fan Module Failure 3–7

3.2.4 Removing and Installing Fan Modules 3–7

iv Sun Server X2-4 Service Manual • April 2013

Page 5

▼ Remove a Fan Module 3–8

▼ Install a Fan Module 3–9

3.3 Servicing Power Supplies (CRU) 3–11

3.3.1 Power Supply LED Reference 3–11

3.3.2 Detecting a Power Supply Failure 3–12

3.3.3 Removing and Installing Power Supplies 3–12

▼ Remove a Power Supply 3–13

▼ Install a Power Supply 3–14

4. Servicing CRU Components That Require Server Power Off 4–1

4.1 Servicing Memory Risers and DIMMs (CRU) 4–1

4.1.1 CPUs, Memory Risers, and DIMMs Physical Layout 4–2

4.1.2 Memory Riser Population Rules 4–3

4.1.3 Memory Riser DIMM Population Rules 4–4

4.1.4 Memory Performance Guidelines 4–5

4.1.4.1 Recommended Memory Placement 4–6

4.1.5 DIMM Fault Isolation 4–7

4.1.6 Supported DIMMs 4–7

4.1.7 Unsupported DIMMs 4–7

4.1.8 Removing and Installing Memory Risers, DIMMs, and Filler

Panels 4–8

▼ Remove a Memory Riser Filler Panel 4–8

▼ Remove a DIMM Filler Panel 4–8

▼ Remove a Memory Riser and DIMM 4–9

▼ Install Memory Risers and DIMMs 4–13

▼ Install a Memory Riser Filler Panel 4–16

▼ Install a DIMM Filler Panel 4–16

4.2 Servicing PCIe Cards (CRU) 4–17

4.2.1 PCIe Card Configuration Rules 4–17

Contents v

Page 6

4.2.2 PCIe Cards With Bootable Devices 4–18

4.2.3 Avoiding PCI Resource Exhaustion Errors 4–18

4.2.4 Removing and Installing PCIe Cards and PCIe Card Filler Panels

4–19

▼ Remove a PCIe Card Filler Panel 4–19

▼ Remove a PCIe Card 4–20

▼ Install a PCIe Card 4–22

▼ Install a PCIe Card Filler Panel 4–23

4.3 Servicing the DVD Drive and DVD Driver Filler Panel (CRU) 4–24

▼ Remove the DVD Drive or DVD Drive Filler Panel 4–24

▼ Install the DVD Drive or DVD Drive Filler Panel 4–25

4.4 Servicing the System Lithium Battery (CRU) 4–27

▼ Remove the System Battery 4–27

▼ Install the System Battery 4–28

5. Servicing FRU Components 5–1

5.1 Servicing the CPU and Heatsink (FRU) 5–1

5.1.1 CPU Placement 5–2

5.1.2 Removing and Installing a Heatsink Filler Panel, CPU Cover Plate,

Heatsink, and CPU 5–2

▼ Remove a Heatsink Filler Panel and CPU Cover Plate 5–2

▼ Remove a Heatsink and CPU 5–3

▼ Install a Heatsink and CPU 5–5

▼ Install a Heatsink Filler Panel 5–8

5.2 Servicing the Fan Board (FRU) 5–8

▼ Remove the Fan Board 5–8

▼ Install the Fan Board 5–10

5.3 Servicing the Power Supply Backplane (FRU) 5–12

▼ Remove the Power Supply Backplane 5–12

▼ Install the Power Supply Backplane 5–14

vi Sun Server X2-4 Service Manual • April 2013

Page 7

5.4 Servicing the Disk Drive Backplane (FRU) 5–15

▼ Remove the Disk Drive Backplane 5–16

▼ Install the Disk Drive Backplane 5–17

5.5 Servicing the Motherboard (FRU) 5–19

▼ Remove the Motherboard 5–19

▼ Install the Motherboard 5–20

6. Returning the Server to Operation 6–1

6.1 Replacing the Server Top Cover 6–1

▼ Replace the Server Top Cover 6–1

6.2 Returning the Server to the Normal Rack Position 6–2

▼ Return the Server to the Normal Rack Position 6–2

6.3 Powering On the Server 6–3

▼ Power On the Server 6–3

7. Servicing the Server at Boot Time 7–1

7.1 Powering On the Server 7–1

7.2 About the BIOS 7–2

7.3 Default BIOS Power-On Self-Test (POST) Events 7–2

7.4 BIOS POST F1 and F2 Errors 7–4

7.5 How BIOS POST Memory Testing Works 7–7

7.6 Ethernet Port Device and Driver Naming 7–8

7.6.1 Ethernet Port Booting Priority 7–9

7.7 BIOS Setup Utility Menus 7–9

7.8 Performing Common BIOS Procedures 7–11

▼ Access the BIOS Setup Utility 7–12

▼ Reset the BIOS Password 7–13

▼ Configure Support for TPM 7–15

▼ Configure SP LAN Settings 7–18

Contents vii

Page 8

▼ Configure Option ROM Settings 7–21

7.8.1 Configuring Serial Port Sharing 7–22

▼ Assign Serial Port Output Using the CLI 7–23

▼ Assign Serial Port Output Using the Web Interface 7–23

7.9 BIOS and SP Updates 7–24

7.10 BIOS Configuration Tool 7–24

8. Troubleshooting the Server and ILOM Defaults 8–1

8.1 Troubleshooting the Server 8–1

8.2 Diagnostic Tools 8–2

8.2.1 Diagnostic Tool Documentation 8–3

8.3 Using the Preboot Menu Utility 8–4

8.3.1 Accessing the Preboot Menu 8–5

8.3.1.1 Prerequisites for Accessing the Preboot Menu 8–5

▼ Access the Preboot Menu 8–6

▼ Edit Preboot Menu for Remote Serial Access 8–7

8.3.1.2 Edit Mode Settings in Preboot Menu 8–9

8.3.2 Restoring Oracle ILOM to Default Settings 8–9

▼ Reset Oracle ILOM Configuration Using the Preboot Menu 8–

10

8.3.3 Restoring Oracle ILOM Access to the Serial Console 8–10

▼ Restore Access to the Serial Console Using the Preboot Menu

8–10

8.3.4 Restoring the SP Firmware Image 8–11

8.3.4.1 Prerequisites for Restoring SP Firmware Using the

Preboot Menu 8–12

▼ Restore the SP Firmware Image Using the Preboot Menu 8–12

8.3.5 Preboot Menu Command Summary 8–13

8.4 Contacting Support 8–15

8.5 Locating the Chassis Serial Number 8–16

viii Sun Server X2-4 Service Manual • April 2013

Page 9

A. Server Specifications A–1

A.1 Physical Specifications A–1

A.2 Electrical Specifications A–1

A.3 Environmental Requirements A–2

B. BIOS Setup Utility Menus B–1

B.1 BIOS Main Menu Selections B–2

B.2 BIOS Advanced Menu Selections B–3

B.3 BIOS PCIPnP Menu Selections B–12

B.4 BIOS Boot Menu Selections B–14

B.5 BIOS Security Menu Selections B–16

B.6 BIOS IO/MMIO Menu Selections B–17

B.7 BIOS Chipset Menu Selections B–19

B.8 BIOS Exit Menu Selections B–21

C. Connector Pinouts C–1

C.1 USB Connectors C–1

C.2 Serial Connector C–2

C.3 Gigabit-Ethernet Connectors C–2

C.4 Network Management Port Connector C–3

C.5 Video Connectors C–4

C.6 Serial Attached SCSI (SAS) Connector C–4

D. Getting Server Firmware and Software D–1

D.1 Firmware and Software Updates D–1

D.2 Firmware and Software Access Options D–2

D.3 Available Software Release Packages D–2

D.4 Accessing Firmware and Software D–3

▼ Download Firmware and Software Using My Oracle Support D–3

D.4.1 Requesting Physical Media D–4

Contents ix

Page 10

D.4.2 Gathering Information for the Physical Media Request D–5

▼ Request Physical Media (Online) D–5

▼ Request Physical Media (By Phone) D–6

D.5 Installing Updates D–7

D.5.1 Installing Firmware D–7

D.5.2 Installing Hardware Drivers and OS Tools D–8

Index Index–1

x Sun Server X2-4 Service Manual • April 2013

Page 11

Using This Documentation

This service manual explains how to replace parts in Oracle’s Sun Server X2-4 and

how to use and maintain the system.

Note – The Sun Server X2-4 was formerly named the Sun Fire X4470 M2 server. This

former name might still appear in the software. The new product name does not

indicate any change in system features or functionality.

This document is intended for system administrators, network administrators, and

service technicians who have an understanding of server systems.

Note – This service manual describes how to replace both customer-replaceable

units (CRUs) and field-replaceable units (FRUs). FRUs should only be serviced by

authorized service providers.

■ “Before You Read This Document” on page xi

■ “Getting the Latest Software and Firmware” on page xii

■ “Related Documentation” on page xii

■ “Support and Accessibility” on page xiii

Before You Read This Document

It is important that you review the safety guidelines in the Sun Server X2-4 Safety and

Compliance Guide and in the Important Safety Information for Sun Hardware Systems.

xi

Page 12

Getting the Latest Software and

Firmware

Firmware, drivers, and other hardware-related software for each Oracle x86 server,

server module (blade), and blade chassis are updated periodically.

For information and download instructions, see Appendix D.

Related Documentation

Documentation Link

All Oracle documentation http://www.oracle.com/documentation

Sun Server X2-4 http://www.oracle.com/pls/topic/lookup?ctx=

SunServerX2-4

Oracle Integrated Lights

Out Manager (ILOM) 3.0

Oracle Integrated Lights

Out Manager (ILOM) 3.1

(for Sun Server X2-4

Software Release 1.3 and

above)

Oracle Hardware

Installation Assistant

http://www.oracle.com/pls/topic/lookup?ctx=

ilom30

http://www.oracle.com/pls/topic/lookup?ctx=

ilom31

http://www.oracle.com/pls/topic/lookup?ctx=

hia

xii Sun Server X2-4 Service Manual • April 2013

Page 13

Support and Accessibility

Description Links

Access electronic support

through My Oracle Support

Learn about Oracle’s

commitment to accessibility

http://support.oracle.com

For hearing impaired:

http://www.oracle.com/accessibility/support.

html

http://www.oracle.com/us/corporate/accessibi

lity/index.html

Using This Documentation xiii

Page 14

xiv Sun Server X2-4 Service Manual • April 2013

Page 15

CHAPTER

1

Sun Server X2-4 Service Manual

Overview

This chapter provides an overview of the Sun Server X2-4.

It contains the following topics:

■ Section 1.1 “System Overview” on page 1-1

■ Section 1.2 “Server Front Panel Features” on page 1-9

■ Section 1.3 “Server Back Panel Features” on page 1-10

■ Section 1.4 “Performing Service Related Tasks” on page 1-11

1.1 System Overview

Oracle’s Sun Server X2-4 is a 3 rack unit (RU) rackmount server that uses the Intel

Xeon E7 platform. This section describes the major features, components, and

capabilities of the server.

1.1.1 Intel Xeon E7 Platform

The Intel Xeon E7 platform is based on the Intel Xeon Processor E7-4800 Series and

uses the Intel 7500 Chipset I/O hub (IOH) as its primary chipset. The platform uses

the Intel QuickPath Interface (QPI), a high-speed, differentially signaled,

point-to-point interface that forms a communication fabric among the processors

(CPUs) and IOHs in the system.

The Sun Server X2-4 uses two Intel 7500 Chipset I/O hubs, each connected to two of

the four CPUs. One of these I/O hubs is designated the legacy I/O hub and has a

connection to the Intel I/O Controller Hub 10 (ICH10) southbridge component.

1-1

Page 16

1.1.2 Block Diagrams

FIGURE 1-1 shows a block diagram for a Sun Server X2-4 with four CPUs.

FIGURE 1-2 shows a block diagram for a Sun Server X2-4 with two CPUs.

Note – In the diagrams, the PCIe SAS/RAID Controller is shown as installed in Slot

2. If a particular SAS/RAID Controller has specific cooling requirements, it might

have to be installed in Slot 4. For information about cooling requirements, refer to the

Sun Server X2-4 Product Notes.

FIGURE 1-1 Four CPU Block Diagram

1-2 Sun Server X2-4 Service Manual • April 2013

Page 17

FIGURE 1-2 Two CPU Block Diagram

1.1.3 Processors (CPUs)

The Sun Server X2-4 supports two or four processors (CPUs), as shown in FIGURE 1-1

and FIGURE 1-2. The two-CPU configuration must have CPUs (with heatsinks) in

sockets 0 and 2 and heatsink filler panels installed in sockets 1 and 3.

In a two-CPU configuration, all three QPI interconnects and both CPUs must be

operational. The four-CPU configuration offers a greater level of resiliency with

redundant QPI interconnects that allow working CPUs to route around a disabled

CPU as the system starts.

Chapter 1 Sun Server X2-4 Service Manual Overview 1-3

Page 18

Features of each Intel Xeon Processor E7-4800 Series include:

■ Up to ten cores with Hyper-Threading (two threads/core)

■ Up to 30MB shared last level cache

■ 32nm process technology

■ Two integrated memory controllers with four Intel Scalable Memory Interconnects

(SMI channels)

■ Supports speeds of DDR3-1067 MT/s via an Intel 7510 Scalable Memory Buffer

■ Four full-width, bidirectional Intel QuickPath interconnects (QPI links)

■ 6.4 GT/s (12.8 GB/s per direction)

■ Automatic self-healing by degrading to half-width or quarter-width link

operation

■ CPU Thermal Design Power (TDP) of 105W or 130W

Note – For more information about Intel QuickPath Interconnects, refer to Weaving

High Performance Multiprocessor Fabric from Intel Press at

http://www.intel.com/intelpress/sum_qpi.htm.

1.1.4 Memory

Each CPU in the Sun Server X2-4 has four SMI channels leading to Intel 7510 Scalable

Memory Buffers (located on two memory risers). Each memory buffer has an SMI

link to the CPU and two DDR3 interfaces. Each SMI interface can operate at speeds

of 6.4 GT/s, which correspond to DDR3 operation at 1067 MT/s. From the CPU to

the Intel 7510 Scalable Memory Buffer, the SMI interface supports 11 lanes (9 data + 1

CRC + 1 spare). From the Intel 7510 Scalable Memory Buffer to the CPU, the SMI

interface supports 14 lanes (12 data + 1 CRC + 1 spare). The CPU retries memory

transactions that incur a CRC error. For persistent errors, the SMI link has spare lanes

for automatic self-healing.

The system supports a maximum of eight memory risers (4 CPU configuration) or

four memory risers (2 CPU configuration). Each riser houses 8 DIMM slots for the

four DDR3 channels. The system can operate with 0, 2, 4, 6 or 8 DIMMs on a given

riser. For maximum performance, install at least two ranks of DIMMs on every

available DDR3 channel (for example, 4 DIMMs per riser with two risers per CPU).

Each of two memory controllers in a CPU operates its two SMI channels as a

lock-step pair. The memory controller treats each pair of DDR3 channels behind the

two memory buffers as a 144-bit-wide DRAM interface. As a result, the DIMMs must

be installed in pairs, with identical DIMMs in each pair.

The DDR3 interfaces include the following features:

1-4 Sun Server X2-4 Service Manual • April 2013

Page 19

■ Accommodates x4 and x8 Single-Rank, Dual-Rank, Quad-Rank RDIMMs

■ Supports up to 2 RDIMMs per DDR3 channel (8 DIMM slots per memory riser)

■ DDR3 speed: 1067 MT/s or 978 MT/s (dictated by SMI speeds of CPUs)

■ DRAM Technology: 2 or 4 Gb die, 1.35-volt or 1.5-volt operation

■ DIMM Capacity: 4, 8, 16 GB (16 GB with Quad-Rank DIMMs only)

■ Currently supported DIMMs are PC3L RDIMMs, dual-rank in 4-, 8-, and

quad-rank 16-GB sizes

For more information about CPUs, memory risers, and memory layout, including

guidelines for populating memory risers and DIMMs, see Section 4.1 “Servicing

Memory Risers and DIMMs (CRU)” on page 4-1.

FIGURE 1-3 shows the architecture of the server memory.

FIGURE 1-3 Memory Architecture

1.1.5 Cooling

The Sun Server X2-4 is cooled from front to back. Cooling occurs in two areas of the

chassis, separated by a plastic dividing wall. In the power supply cooling zone, fans

at the back of the power supplies cool the drive bays as well as the power supplies,

Chapter 1 Sun Server X2-4 Service Manual Overview 1-5

Page 20

by drawing air into the depressurized zone at the right of the chassis. In the main

cooling zones, six 92-mm high-performance fans, arranged in two rows for

redundancy, cool the motherboard, memory risers, and I/O cards. The motherboard

is divided into three zones and each pair of fans is separately regulated to cool that

zone. Since the main cooling zones are pressurized, it is important to maintain the

seal of the dividing wall so that the power supply units can draw air through the

drive bay.

The unrestricted airflow over the motherboard minimizes system noise. Dividing the

cooling into zones allows for greater use of system resources, since each zone can

operate independently at its highest efficiency.

FIGURE 1-4 shows the cooling zones.

FIGURE 1-4 Server Cooling Zones

Figure Legend

1 Power supply cooling zone

2 Chassis cooling zone 2

3 Chassis cooling zone 1

4 Chassis cooling zone 0

1.1.6 Input/Output (I/O)

For internal storage, the server chassis provides:

1-6 Sun Server X2-4 Service Manual • April 2013

Page 21

■ Six 2.5-inch drive bays, accessible through the front panel. The supported drive

interfaces for each bay depend on the host bus adapter (HBA) chosen.

■ An optional slot-loading DVD+/-RW drive on front of the server, below the drive

bays. This SATA DVD connects to a USB-SATA bridge, so that is appears to the

system software as a USB storage device.

■ One internal high-speed USB port on the motherboard. This port can hold a USB

flash device for system booting.

In addition, the service processor can present virtual USB storage devices to the

system.

The ICH10 southbridge on the motherboard provides six built-in SATA2 (3-Gbit/s)

ports, accessible through two SAS4I connectors (Port 0-3 and Port 4-5). When

configured with any 2.5-inch SAS drives, the system must be equipped with one PCI

Express (PCIe) Gen-2 internal HBA card to support the front 2.5-inch drive bays.

Each offered PCIe Gen-2 HBA has 8 SAS2/SATA2 internal ports accessible through

two SAS4I connectors (Port 0-3 and Port 4-7). Since the drive cage has only six bays,

Port 6-7 of an internal HBA are not used in this system.

With an internal SAS-2 HBA card installed in a PCIe slot, the six bays can handle any

combination of supported SAS and SATA hard disk drives (HDDs) and solid-state

drives (SSDs). If the disk backplane is connected to the built-in ICH10 SATA-2

controller rather than an HBA card, only SATA storage devices will operate. (When a

RAID volume is configured on the HBA card, the drive bays for the RAID members

must hold the same type of storage device.)

1.1.7 Summary of Supported Components and

Capabilities

The following table summarizes the components and capabilities of the Sun Server

X2-4.

Chapter 1 Sun Server X2-4 Service Manual Overview 1-7

Page 22

TABLE 1-1 Sun Server X2-4 Components and Capabilities

Component Sun Server X2-4

Processor (CPU) Supported configurations:

• Two processors installed in socket 0 and socket 2

• Four processors installed in sockets 0 through 3

For the latest information on CPU specifications, go to the Sun x86 Servers web

site and navigate to the Sun Server X2-4 page:

http://www.oracle.com/technetwork/server-storage/sun-x8

6/overview/index.html

Memory Up to eight memory riser modules are supported (two risers per CPU) in the

server chassis. Each riser module supports eight PC3L RDIMMs, allowing up to

sixteen RDIMMs per processor.

• A 2-socket system using four riser modules populated with 16-GB RDIMMs

supports a maximum of 512 GB of system memory.

• A 4-socket system using eight riser modules populated with 16-GB RDIMMs

supports a maximum of 1024 GB of system memory.

Storage devices For internal storage, the server chassis provides:

• Six 2.5-inch drive bays, accessible through the front panel. The supported drive

interfaces for each bay depend on the HBA chosen.

• An optional slot-loading DVD+/-RW drive on front of the server, below the

drive bays. This SATA DVD connects to a USB-SATA bridge, so that is appears

to the system software as a USB storage device.

• One internal high-speed USB port on the motherboard. This port can hold a

USB flash device for system booting.

USB 2.0 ports Two front, two rear, and one internal.

VGA ports One front and one rear high-density DB-15 video ports.

Note - The rear VGA port supports VESA Device Data Channel for monitor

identification.

PCI Express 2.0 I/O slots Ten PCI Express 2.0 slots that accommodate low-profile PCIe cards. All slots

support x8 PCIe connectors. Two slots are also capable of supporting x16 PCIe

connectors.

• Slots 0 and 9: x4 electrical interface

• Slots 1, 2, 4, 6, 7, and 8: x8 electrical interface

• Slots 3 and 5: x8 or x16 electrical interface (x16 connector)

Note - PCI Express slots 3 and 5 will operate as x16 interfaces only when an x16

capable card is installed and the adjacent slot (4 or 6) is unpopulated.

Cluster card slot One specialized slot dedicated for use in storage appliances. The Sun Server X2-4

does not support populating this slot with standard PCIe cards.

1-8 Sun Server X2-4 Service Manual • April 2013

Page 23

TABLE 1-1 Sun Server X2-4 Components and Capabilities (Continued)

Component Sun Server X2-4

PCI Express I/O cards For a list of I/O cards that are customer-orderable options, go to the Sun x86

Servers web site and navigate to the Sun Server X2-4 page:

http://www.oracle.com/technetwork/server-storage/sun-x8

6/overview/index.html

Ethernet ports Four 10/100/1000 RJ-45 GbE ports on rear panel.

Each Network Interface Controller (NIC) supports Intel QuickData Technology,

Intel I/OAT, VMDq, PCI-SIG SR-IOV, IPSec offload, and LinkSec.

Service processor Integrated Baseboard Management Controller (BMC), which supports the

industry-standard IPMI feature set.

Supports remote KVMs, DVD, and floppy over IP (optional license required).

Includes serial port.

Supports Ethernet access to SP through a dedicated 10/100BaseT management

port and optionally through one of the host GbE ports (sideband management).

Power supplies Two hot-swappable power supplies, each with 2000 Watts capacity (from 200 Volts

to 240 Volts), auto-ranging, light load efficiency mode and redundant

over-subscription.

Cooling fans Six hot-swappable, redundant fans at chassis front (top-loading); redundant fans

at each power supply.

Management software Oracle Integrated Lights Out Manager (ILOM)

1.2 Server Front Panel Features

FIGURE 1-5 shows the Sun Server X2-4 front panel and describes its components.

Chapter 1 Sun Server X2-4 Service Manual Overview 1-9

Page 24

FIGURE 1-5 Server Front Panel Features

Figure Legend

1 Locate LED/Locate button: white 10 DB-15 video connector

2 Service Action Required LED: amber 11 SATA DVD drive (optional)

3 Power/OK LED: green 12 Hard disk drive 0 (optional)

4 Power button 13 Hard disk drive 1 (optional)

5 SP OK/Fault LED: green/amber 14 Hard disk drive 2 (optional)

6 Service Action Required LEDs (3) for Fan

Module (FAN), Processor (CPU) and Memory:

amber

7 Power Supply (PS) Fault (Service Action

Required) LED: amber

8 Over Temperature Warning LED: amber 17 Hard disk drive 5 (optional)

9 USB 2.0 connectors (2)

15 Hard disk drive 3 (optional)

16 Hard disk drive 4 (optional)

1.3 Server Back Panel Features

FIGURE 1-6 shows the Sun Server X2-4 back panel and describes its components.

1-10 Sun Server X2-4 Service Manual • April 2013

Page 25

FIGURE 1-6 Server Back Panel Features

Figure Legend

1 Power supply unit 0 status indicator LEDs:

Service action required: amber

DC OK: green

AC OK: green or amber

2 Power supply unit 0 AC inlet 9 USB 2.0 connectors (2)

3 Power supply unit 1 status indicator LEDs:

Service action required: amber

DC OK: green

AC OK: green or amber

4 Power supply unit 1 AC inlet 11 Service processor (SP) network management

5 System status LEDs:

Power/OK: green

Service action required: amber

Locate: white

6 PCIe card slots 0–4 13 DB-15 video connector

7 Cluster card slot

8 Network (NET) 10/100/1000 ports:

NET0–NET3

10 PCIe card slots 5–9

(NET MGT) port

12 Serial management (SER MGT)/RJ-45 serial

port

1.4 Performing Service Related Tasks

This guide contains information and procedures for maintaining and servicing your

server.

TABLE 1-2 identifies the sections in this guide that describe the task you want

to perform.

Chapter 1 Sun Server X2-4 Service Manual Overview 1-11

Page 26

TABLE 1-2 Service Tasks

Service Task See:

Understand server features and processes Section 1.1 “System Overview” on page 1-1

Identify server LEDs and buttons Section 1.2 “Server Front Panel Features” on

page 1-9

Section 1.3 “Server Back Panel Features” on

page 1-10

Prepare to service the server Chapter 2

Replace or upgrade a FRU or CRU Chapter 3

Chapter 4

Chapter 5

Return the server to operation after servicing Chapter 6

Service the server at boot time Chapter 7

Troubleshoot the server Chapter 8

Review server hardware specifications Appendix A

Review BIOS Setup Utility menus Appendix B

Review connector pinouts Appendix C

Download software and firmware for the

server

Appendix D

1-12 Sun Server X2-4 Service Manual • April 2013

Page 27

CHAPTER

2

Preparing to Service the Sun Server

X2-4

This chapter includes the information you might need before servicing the Sun

Server X2-4.

It contains the following topics:

■ Section 2.1 “Location of Replaceable Components” on page 2-1

■ Section 2.2 “Tools and Equipment Needed” on page 2-3

■ Section 2.3 “Performing Electrostatic Discharge and Static Prevention Measures”

on page 2-3

■ Section 2.4 “Positioning the Server for Maintenance” on page 2-4

■ Section 2.5 “Releasing the Cable Management Arm” on page 2-5

■ Section 2.6 “Powering Off the Server” on page 2-6

■ Section 2.7 “Removing the Server Top Cover” on page 2-8

■ Section 2.8 “Removing or Installing Filler Panels” on page 2-9

■ Section 2.9 “Attaching Devices to the Server” on page 2-10

2.1 Location of Replaceable Components

FIGURE 2-1 identifies the replaceable component locations on the Sun Server X2-4,

with the top cover removed.

2-1

Page 28

FIGURE 2-1 Replaceable Component Locations

Figure Legend

1 Motherboard

2 Low-profile PCIe cards

3 Power supplies

4 Power supply backplane

5 Disk backplane

6 System lithium battery

7 CPUs and heatsinks

8 Memory risers

9 Fan board

10 Fan modules

11 DVD dri ve

12 Hard disk drives (HDD)

2-2 Sun Server X2-4 Service Manual • April 2013

Page 29

2.2 Tools and Equipment Needed

To service the system, you need the following tools:

■ No. 2 Phillips screwdriver

■ ESD mat and grounding strap

You might also need a system console device, such as one of the following:

■ PC or workstation with RS-232 serial port

■ ASCII terminal

■ Terminal server

■ Patch panel connected to a terminal server

2.3 Performing Electrostatic Discharge and

Static Prevention Measures

Electrostatic discharge (ESD) sensitive devices, such as the PCIe cards, hard drives,

CPUs, and memory cards, require special handling.

Caution – Circuit boards and hard drives contain electronic components that are

extremely sensitive to static electricity. Ordinary amounts of static electricity from

clothing or the work environment can destroy the components located on these

boards. Do not touch the components along their connector edges.

Caution – You must disconnect AC power cords to both power supplies before

servicing some of the components documented in this guide.

2.3.1 Using an Antistatic Wrist Strap

Wear an antistatic wrist strap when handling components such as disk drive

assemblies, circuit boards, or PCIe cards. When servicing or removing server

components, attach an antistatic strap to your wrist and then to a metal area on the

chassis. Following this practice equalizes the electrical potentials between you and

the server.

Chapter 2 Preparing to Service the Sun Server X2-4 2-3

Page 30

Note – An antistatic wrist strap is not shipped with the servers. However, antistatic

wrist straps are included with customer-replaceable units (CRUs), field-replaceable

units (FRUs), and optional components.

2.3.2 Using an Antistatic Mat

Place ESD-sensitive components such as printed circuit boards on an antistatic mat.

You can use the following items as antistatic mats:

■ Antistatic bag used to wrap a replacement part

■ ESD mat (orderable from Oracle)

■ A disposable ESD mat (shipped with some optional system components)

2.4 Positioning the Server for Maintenance

To remove and replace components in the Sun Server X2-4, you must extend the

server to the maintenance position.

▼ Extend the Server to the Maintenance Position

1. Verify that no cables will be damaged or will interfere when the server is

extended.

Although the cable management arm (CMA) that is supplied with the server is

hinged to accommodate extending the server, you should ensure that all cables

and cords are capable of extending.

2. From the front of the server, release the two slide release latches (

Squeeze the green slide release latches to release the slide rails.

2-4 Sun Server X2-4 Service Manual • April 2013

FIGURE 2-2).

Page 31

FIGURE 2-2 Slide Release Latch

3. While squeezing the slide release latches, slowly pull the server forward until

the slide rails latch.

2.5 Releasing the Cable Management Arm

For some service procedures, if you are using a cable management arm (CMA), you

might have to release the CMA to gain access to the back of the chassis.

▼ Release the CMA

Refer to FIGURE 2-3 for the following procedure.

1. Press and hold the tab [1].

2. Swing the CMA out of the way [2].

When you have finished with the service procedure, swing the CMA closed and

latch it to the left rack rail.

Chapter 2 Preparing to Service the Sun Server X2-4 2-5

Page 32

FIGURE 2-3 Releasing the Cable Management Arm

2.6 Powering Off the Server

Many service procedures require you to remove main power from the server. To

remove main power from the server, use one of the methods described in the

following table.

2-6 Sun Server X2-4 Service Manual • April 2013

Page 33

TABLE 2-1 Shutdown Procedures

Shutdown Method

Graceful shutdown Press and release the Power button on the front panel. Pressing the Power button

causes Advanced Configuration and Power Interface (ACPI)-enabled operating

systems to perform an orderly shutdown of the operating system. Servers not

running ACPI-enabled operating systems will shut down to standby power mode

immediately. When the main power is off, the Power/OK LED on the front panel

flashes slowly, indicating that the server is in standby power mode.

Note - The Power/OK LED might flash several times at 1 Hz to indicate that

power-off is going to occur soon. Main power is still on during this 1-Hz flashing.

Emergency shutdown Press and hold the Power button for at least five seconds until the main power is

off and the server enters standby power mode. When the main power is off, the

Power/OK LED on the front panel flashes slowly, indicating that the server is in

standby power mode.

Caution - All applications and the operating system will be closed abruptly

without saving changes. Data loss or corruption might occur.

Oracle Integrated Lights

Out Manager (ILOM) SP

CLI shutdown

Caution – To completely power off the server, you must disconnect the AC power

cords from the AC inlets on the power supplies on the back panel of the server.

▼ Power Off the Server Using the Service Processor

Command-Line Interface

You can use the Oracle ILOM service processor (SP) to perform a graceful shutdown

of the server and ensure that all of your data is saved and the server is ready for

restart. For additional information, refer to the Oracle Integrated Lights Out Manager

(ILOM) 3.1 Documentation Library at

http://www.oracle.com/pls/topic/lookup?ctx=ilom31.

1. Log in as root. Type:

ssh root@service_processor_ip_address

See “Power Off the Server Using the Service Processor Command-Line Interface”

on page 2-7.

Password: root_password (The default password is changeme.)

The ILOM command-line interface (CLI) prompt appears (->).

Depending on the type of problem, you might want to view server status or log

files, or run diagnostics before you shut down the server.

Chapter 2 Preparing to Service the Sun Server X2-4 2-7

Page 34

2. Power down the server. Type:

-> stop /SYS (for a Graceful shutdown as defined in

-> stop -f /SYS (for an Emergency Shut as defined in

TABLE 2-1)

TABLE 2-1)

2.7 Removing the Server Top Cover

Servicing some components requires you to remove the top cover from the server.

Caution – Removing the top cover without properly powering down the server and

disconnecting the AC power cords from the power supplies will result in a chassis

intrusion switch failure. This failure causes the server to be immediately powered off.

Any changes you make to the memory riser or DIMM configurations will not be

properly reflected in the service processor’s inventory until you replace the top cover.

▼ Remove the Server Top Cover

1. Ensure that the AC power cords are disconnected from the server power

supplies.

2. To unlatch the server top cover, insert your fingers under the two cover latches

and simultaneously lift both latches in an upward motion (

2-8 Sun Server X2-4 Service Manual • April 2013

FIGURE 2-4)[1].

Page 35

FIGURE 2-4 Removing the Server Top Cover

3. Lift the cover slightly and slide it toward the front of the server chassis about

0.5 inch (12 mm).

4. Lift up and remove the top cover [2].

2.8 Removing or Installing Filler Panels

Each server is shipped with module-replacement filler panels for CPUs, disk drives

(HDD or SSD), memory modules (DIMMs), the DVD drive, and the PCIe cards. A

filler panel is an empty metal or plastic enclosure that does not contain any

functioning system hardware or cable connectors.

The filler panels are installed at the factory and must remain in the server until you

replace them with a purchased module to ensure proper airflow through the system.

If you remove a filler panel and continue to operate your system with an empty

Chapter 2 Preparing to Service the Sun Server X2-4 2-9

Page 36

module slot, the server might overheat due to improper airflow. For instructions on

removing or installing a filler panel for a server component, refer to the section in

this guide about servicing that component.

2.9 Attaching Devices to the Server

As part of servicing the Sun Server X2-4, you might have to connect devices to the

server. The following sections describe the locations of connectors on the server and

the order in which you should attach cables and devices to the server.

2.9.1 Connector Locations

FIGURE 2-5 shows and describes the locations of the Sun Server X2-4 back panel

connectors.

FIGURE 2-5 Server Back Panel Connectors

Figure Legend

1 Power supply unit 0 AC inlet 5 Service processor (SP) network management

2 Power supply unit 1 AC inlet 6 Serial management (SER MGT)/RJ-45 serial

3 Gigabit Ethernet ports NET-0, 1, 2, 3 7 DB-15 video connector

4 USB 2.0 ports

2-10 Sun Server X2-4 Service Manual • April 2013

(NET MGT) Ethernet port

port

Page 37

2.9.2 Cabling the Server

When connecting cables to the server, connect them in the order described in the

following procedure.

▼ Cable the Server

Connect external cables to the server in the following order. Refer to FIGURE 2-5 for

the location of connectors on the back of the server.

1. Connect an Ethernet cable to the Gigabit Ethernet (NET) connectors as needed

for OS support.

2. (Optional) If you plan to interact with the system console directly, connect any

additional external devices, such as a mouse and keyboard, to the server’s USB

connectors and/or a monitor to the DB-15 video connector.

3. If you plan to connect to the Oracle ILOM software over the network, connect

an Ethernet cable to the Ethernet port labeled NET MGT.

Note – The service processor (SP) uses the NET MGT (out-of-band) port by default.

You can configure the SP to share one of the sever ’s four 10/100/1000 Ethernet ports

instead. The SP uses only the configured Ethernet port.

4. If you plan to access the Oracle ILOM command-line interface (CLI) using the

management port, connect a serial null modem cable to the RJ-45 serial port

labeled SER MGT.

Chapter 2 Preparing to Service the Sun Server X2-4 2-11

Page 38

2-12 Sun Server X2-4 Service Manual • April 2013

Page 39

CHAPTER

3

Servicing CRU Components That Do

Not Require Server Power Off

This chapter describes how to service customer-replaceable units (CRUs) that do not

require you to power off the server.

It contains the following topics:

■ Section 3.1 “Servicing Disk Drives (CRU)” on page 3-1

■ Section 3.2 “Servicing Fan Modules (CRU)” on page 3-5

■ Section 3.3 “Servicing Power Supplies (CRU)” on page 3-11

Note – Depending on your configuration, in some cases you might have to power off

the server when removing or replacing the disk drive.

3.1 Servicing Disk Drives (CRU)

This section describes how to remove and install disk drives.

Note – The server provides six 2.5-inch drive bays, accessible through the front

panel. The supported drive interfaces for each bay depend on the installed HBA.

3.1.1 Disk Drive Status LED Reference

FIGURE 3-1 shows the disk drive status LEDs. TABLE 3-1 describes the LEDs and their

functions.

3-1

Page 40

FIGURE 3-1 Disk Drive Status LEDs

TABLE 3-1 Disk Drive Status LED Descriptions

Legend LED Symbol Color Lights When...

1 OK to Remove Blue A disk drive can be removed safely

during a hot-plug operation.

2 Service Action Required Amber The system is running and the disk

drive is faulty. The front and rear

panel Service Action Required LEDs

are also lit if the system detects a

disk drive fault.

3 OK/Activity Green Drive is properly inserted into the

system. LED will flash off and on

when the drive is being accessed.

3.1.2 Removing and Installing Disk Drives and Disk

Drive Filler Panels

Use the following procedures to remove and install disk drives and disk filler panels

from the server.

▼ Remove a Disk Drive Filler Panel

1. Attach an antistatic wrist strap.

See Section 2.3 “Performing Electrostatic Discharge and Static Prevention

Measures” on page 2-3.

2. Identify the disk drive filler panel you want to remove.

3-2 Sun Server X2-4 Service Manual • April 2013

Page 41

3. On the disk drive filler panel you want to remove, push the release button to

open the latch.

4. Grasp the latch and pull the filler panel out of the drive slot.

Caution – The latch is not an ejector. Do not bend it too far to the right. Doing so can

damage the latch.

Caution – Whenever you remove a disk drive filler panel, you should replace it with

another filler panel or a disk drive; otherwise, the server might overheat due to

improper airflow.

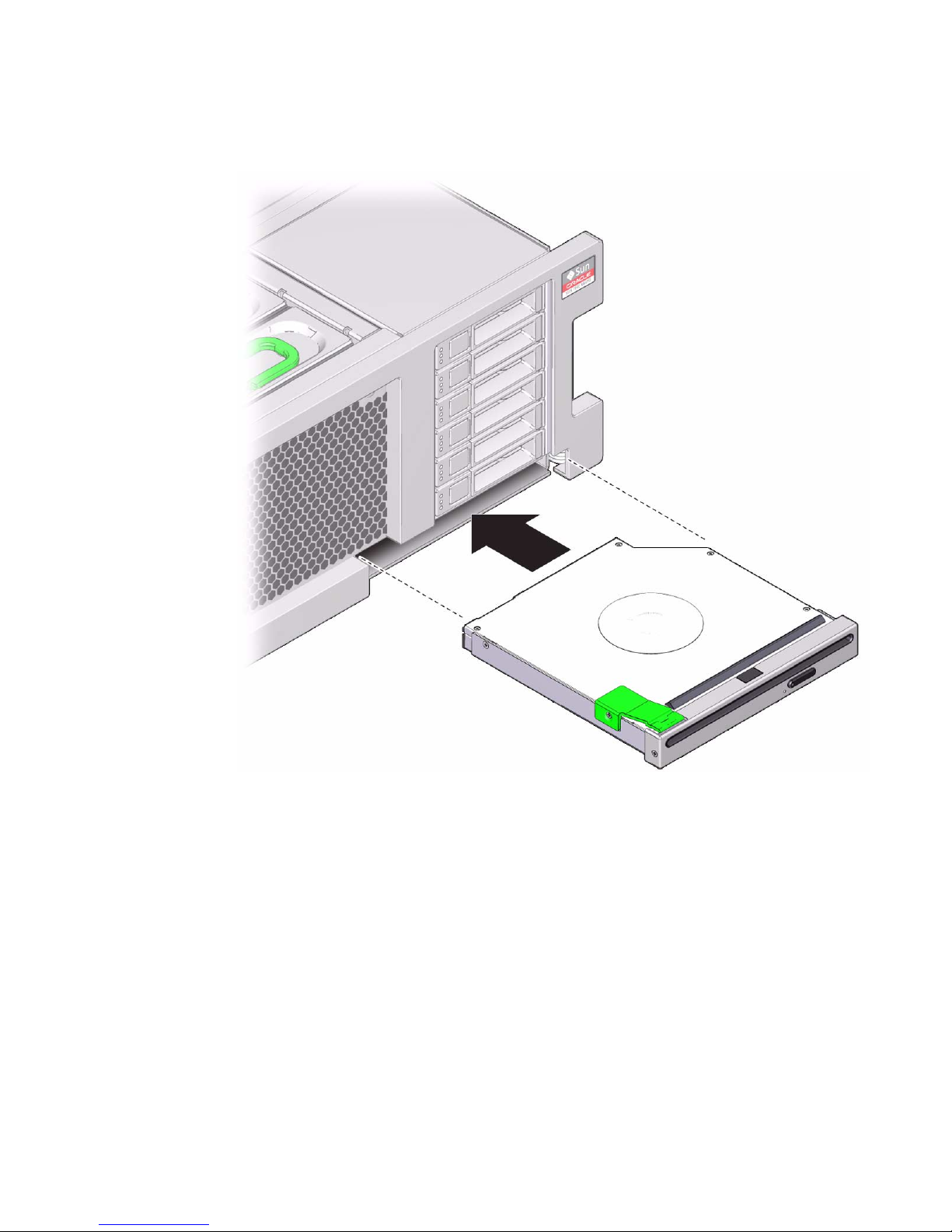

▼ Remove a Disk Drive

Refer to FIGURE 3-2 when completing the following procedure.

1. Attach an antistatic wrist strap.

See Section 2.3 “Performing Electrostatic Discharge and Static Prevention

Measures” on page 2-3.

2. Identify the disk drive you want to remove.

The amber Service Action Required LED on the drive might be lit.

See Section 3.1.1 “Disk Drive Status LED Reference” on page 3-1.

3. Determine whether you can replace the disk drive using the hot-plug procedure

or whether you need to power off the server and use the cold-swap procedure.

A cold-swap is required if the disk drive:

■ Contains the operating system, and the operating system is not mirrored on

another drive

■ Cannot be logically isolated from the online operations of the server

4. Do one of the following:

■ To cold-swap the drive, power off the server. Complete one of the procedures

described in Section 2.6 “Powering Off the Server” on page 2-6.

■ To hot-plug the drive, take the drive offline. This removes the logical software

links to the drive and prevents any applications from accessing it. For

information on how to take a disk drive offline, refer to the Sun Disk

Management Overview at

docs.oracle.com/cd/E19591-01/820-6350/index.html.

Chapter 3 Servicing CRU Components That Do Not Require Server Power Off 3-3

Page 42

5. On the drive you plan to remove, push the disk drive release button to open the

latch.

6. Grasp the latch and pull the drive out of the drive slot.

Caution – The latch is not an ejector. Do not bend it too far to the right. Doing so can

damage the latch.

Caution – Whenever you remove a disk drive, you should replace it with another

disk drive or a filler panel; otherwise, the server might overheat due to improper

airflow.

FIGURE 3-2 Removing a Disk Drive

▼ Install a Disk Drive

Installing a disk drive into a server is a two-step process. You must first install the

disk drive into the drive slot, and then configure that drive to the server. Refer to

FIGURE 3-3 when completing the following procedure.

Note – If you removed an existing disk drive from a slot in the server, you must

install the replacement drive in the same slot as the drive that was removed. Disk

drives are physically addressed according to the slot in which they are installed.

1. Unpack the disk drive and place it on an antistatic mat.

2. Verify that the release lever on the disk drive is fully opened.

3-4 Sun Server X2-4 Service Manual • April 2013

Page 43

3. Slide the drive into the drive slot until it is fully seated.

FIGURE 3-3 Installing a Disk Drive

4. Close the latch to lock the drive in place.

5. Do one of the following:

■ If you have cold-swapped the drive, restore power to the server. Complete the

procedure described in Section 6.3 “Powering On the Server” on page 6-3.

■ If you have hot-plugged the drive, configure the disk drive. Refer to the Sun

Disk Management Overview for information.

▼ Install a Disk Drive Filler Panel

1. Verify that the release lever on the disk drive filler panel is fully opened.

2. Slide the disk drive filler panel into the drive slot until it is fully seated.

3. Close the latch to lock the filler panel in place.

3.2 Servicing Fan Modules (CRU)

This section describes how to remove and install fan modules.

Chapter 3 Servicing CRU Components That Do Not Require Server Power Off 3-5

Page 44

3.2.1 About Server Fans

The six fan modules are located at the front of the chassis; you can access them

without removing the server cover.

Caution – While the fan modules do provide some cooling redundancy, if a fan

module fails, replace it as soon as possible to maintain server availability. When you

remove one of the fans in the back row, you must replace it within 30 seconds to

prevent overheating of the server.

3.2.2 Fan Module LED Reference

Each fan module contains LEDs that are visible from the top of the server. TABLE 3-2

describes fan module LEDs and their functions.

TABLE 3-2 Fan Module Status LEDs

LED Symbol Color Lights When...

Power/OK Green The system is powered on and the fan module

is functioning correctly.

Service Action

Required

FIGURE 3-4 shows the fan module LED status locations.

3-6 Sun Server X2-4 Service Manual • April 2013

Amber The fan module is faulty.

The front and rear panel Service Action

Required LEDs are also lit if the system

detects a fan module fault.

Page 45

FIGURE 3-4 Fan Module Status LEDs

3.2.3 Detecting Fan Module Failure

The following LEDs are lit when a fan module fault is detected:

■ Front and rear Service Action Required LEDs

■ Fan Module Service Action Required (TOP) LED on the front of the server

■ Fan Module Service Action Required LED on or adjacent to the faulty fan module

The system Overtemp LED might light if a fan fault causes an increase in system

operating temperature.

See Section 1.2 “Server Front Panel Features” on page 1-9 and Section 1.3 “Server

Back Panel Features” on page 1-10 for locations of system LEDs.

3.2.4 Removing and Installing Fan Modules

Use the following procedures to remove and install fan modules from the server.

Chapter 3 Servicing CRU Components That Do Not Require Server Power Off 3-7

Page 46

▼ Remove a Fan Module

Refer to FIGURE 3-5 when completing the following procedure.

Caution – If you remove one of the fans in the back row, replace it within 30 seconds

to prevent overheating of the server.

Caution – Hazardous moving parts. Unless the power to the server is completely

shut down, the only service permitted in the fan compartment is the replacement of

the fan modules.

1. Prepare for servicing:

a. Attach an antistatic wrist strap.

See Section 2.3 “Performing Electrostatic Discharge and Static Prevention

Measures” on page 2-3.

b. Extend the server to the maintenance position.

See Section 2.4 “Positioning the Server for Maintenance” on page 2-4.

2. Identify the faulty fan module with a corresponding Service Action Required

LED.

The Service Action Required LEDs are located on the fan module as shown in

FIGURE 3-4.

3. Using your thumb and forefinger, grasp the handle on the fan module and lift it

out of the server.

Caution – When removing a fan module, do not rock it back and forth. Rocking the

fans modules can cause damage to the fan board connectors.

Caution – When changing the fan modules, note that only the fan modules can be

removed or replaced. Do not service any other components in the fan compartment

unless the system is shut down and the power cords are removed.

3-8 Sun Server X2-4 Service Manual • April 2013

Page 47

FIGURE 3-5 Removing a Fan Module

▼ Install a Fan Module

Refer to FIGURE 3-6 when completing the following procedure.

1. Unpack the replacement fan module and place it on an antistatic mat.

2. Install the replacement fan module into the server.

The fan modules are keyed to ensure that they are installed in the correct

orientation.

Chapter 3 Servicing CRU Components That Do Not Require Server Power Off 3-9

Page 48

FIGURE 3-6 Installing a Fan Module

3. Apply firm pressure to the “Press here to latch” artwork on the top of the fan

module to ensure that the fan module is fully seated.

4. Verify that the Service Action Required LED on the replaced fan module is not

lit.

5. Verify that the Top Fan LED and the Service Action Required LED on the front

of the server are not lit.

See Section 1.2 “Server Front Panel Features” on page 1-9 and Section 1.3 “Server

Back Panel Features” on page 1-10 for locations of system LEDs.

Note – If you are replacing a fan module when the server is powered down, the

LEDs might stay lit until power is restored to the server and the server can determine

that the fan module is functioning properly.

6. Return the server to the normal rack position.

See Section 6.2 “Returning the Server to the Normal Rack Position” on page 6-2.

3-10 Sun Server X2-4 Service Manual • April 2013

Page 49

3.3 Servicing Power Supplies (CRU)

The power supplies on the Sun Server X2-4 are redundant. That is, the server needs

only one power supply to operate. Redundant power supplies enable you to remove

and replace a power supply without shutting down the server, provided that the

other power supply is online and working.

Caution – If a power supply fails and you do not have a replacement available, to

ensure proper airflow, leave the failed power supply installed in the server until you

replace it with a new power supply.

This section describes how to remove and install power supplies.

3.3.1 Power Supply LED Reference

Each power supply contains a series of LEDs on the back panel of the system as

shown in

FIGURE 3-7 Power Supply Status LEDs

FIGURE 3-7.

TABLE 3-3 describes the functions of the LEDs.

Chapter 3 Servicing CRU Components That Do Not Require Server Power Off 3-11

Page 50

TABLE 3-3 Power Supply Status LED Descriptions

Legend LED Symbol Color Lights When...

1 Service Action Required Amber The power supply is faulty. Service

action is required.

2 DC OK Green Both DC outputs (3.3V standby and

12V main) are active and within

regulation.

3 AC OK Green or

Amber

• Green: AC voltage within

operating range is applied to the

power supply.

• Amber: AC range below operating

range is applied to the power

supply.

3.3.2 Detecting a Power Supply Failure

The following LEDs are lit when a power supply fault is detected:

■ Front and rear Service Action Required LEDs

■ Rear PS Fault LED on the front bezel of the server

■ Service Action Required LED on the faulty power supply

See Section 1.2 “Server Front Panel Features” on page 1-9 and Section 1.3 “Server

Back Panel Features” on page 1-10 for locations of system LEDs.

3.3.3 Removing and Installing Power Supplies

Use the following procedures to remove and install power supplies.

Caution – Hazardous voltages are present. To reduce the risk of electric shock and

danger to personal health, follow the instructions.

3-12 Sun Server X2-4 Service Manual • April 2013

Page 51

▼ Remove a Power Supply

Refer to FIGURE 3-8 when completing the following procedure.

1. Prepare for servicing:

a. Attach an antistatic wrist strap.

See Section 2.3 “Performing Electrostatic Discharge and Static Prevention

Measures” on page 2-3.

b. If necessary, release the cable management arm to access the power supplies.

See Section 2.5 “Releasing the Cable Management Arm” on page 2-5.

2. Identify which power supply (0 or 1) requires replacement.

A lit Service Action Required LED on a power supply indicates that a failure was

detected.

3. Disconnect the power cord from the faulty power supply.

4. Press down on the release latch.

5. Slide the power supply out of the chassis.

Caution – Whenever you remove a power supply, you should replace it with

another power supply; otherwise, the server might overheat due to improper airflow.

If a new power supply is not available, leave the failed power supply installed until

it can be replaced.

Chapter 3 Servicing CRU Components That Do Not Require Server Power Off 3-13

Page 52

FIGURE 3-8 Removing a Power Supply

▼ Install a Power Supply

Refer to FIGURE 3-9 when completing this procedure.

Caution – Install an A239A or A239C power supply, labeled for upright installation,

in the Sun Server X2-4. The A239A/A239C power supply correctly exhausts air from

the rear of the server. Do not install an A239 or A239B power supply, which might

cause the system to overheat and shut down.

1. Align the power supply with the empty power supply chassis bay.

2. Slide the power supply into the bay until it is fully seated.

3. Move the release latch up to secure the power supply in place.

3-14 Sun Server X2-4 Service Manual • April 2013

Page 53

FIGURE 3-9 Installing a Power Supply

4. Reconnect the power cord to the power supply.

5. Verify that the AC Present LED is lit.

See Section 3.3.1 “Power Supply LED Reference” on page 3-11.

6. Verify that the following LEDs are not lit:

■ Service Action Required LED on the power supply

■ Front and rear Service Action Required LEDs

■ Rear PS Failure LED on the bezel of the server

See Section 1.2 “Server Front Panel Features” on page 1-9 and Section 1.3

“Server Back Panel Features” on page 1-10 for locations of system LEDs.

Chapter 3 Servicing CRU Components That Do Not Require Server Power Off 3-15

Page 54

3-16 Sun Server X2-4 Service Manual • April 2013

Page 55

CHAPTER

4

Servicing CRU Components That

Require Server Power Off

This chapter describes how to service customer-replaceable units (CRUs) that require

you to power down the system before servicing.

It contains the following topics:

■ Section 4.1 “Servicing Memory Risers and DIMMs (CRU)” on page 4-1

■ Section 4.2 “Servicing PCIe Cards (CRU)” on page 4-17

■ Section 4.3 “Servicing the DVD Drive and DVD Driver Filler Panel (CRU)” on

page 4-24

■ Section 4.4 “Servicing the System Lithium Battery (CRU)” on page 4-27

4.1 Servicing Memory Risers and DIMMs

(CRU)

Caution – These procedures require that you handle components that are sensitive

to static discharge. This sensitivity can cause the component to fail. To avoid damage,

ensure that you follow antistatic practices as described in Section 2.3 “Performing

Electrostatic Discharge and Static Prevention Measures” on page 2-3.

When replacing or upgrading a DIMM on the server you should consider the

following:

■ Physical layout of the CPUs, memory risers, and DIMMs

See Section 4.1.1 “CPUs, Memory Risers, and DIMMs Physical Layout” on

page 4-2.

4-1

Page 56

■ Memory riser population rules

See Section 4.1.2 “Memory Riser Population Rules” on page 4-3.

■ Memory riser DIMM population rules

See Section 4.1.3 “Memory Riser DIMM Population Rules” on page 4-4.

■ Rules for installing DIMMs across memory risers

See Section 4.1.4 “Memory Performance Guidelines” on page 4-5.

■ DIMM rank classifications labels

See Section 4.1.6 “Supported DIMMs” on page 4-7.

■ Instructions for installing a DIMM

See “Install Memory Risers and DIMMs” on page 4-13.

4.1.1 CPUs, Memory Risers, and DIMMs Physical

Layout

The physical layout of the CPUs, memory risers, and DIMMs is shown in FIGURE 4-1

and FIGURE 4-2.

4-2 Sun Server X2-4 Service Manual • April 2013

Page 57

FIGURE 4-1 CPU and Memory Riser Layout

4.1.2 Memory Riser Population Rules

Note – Only memory risers that are labeled “V2 Memory Riser” are supported in the

Sun Server X2-4. Before installing memory risers in the server, ensure that the

memory riser contains this label.

The system firmware checks if the installed CPUs are for the Sun Server X2-4. The

system firmware raises a fault for memory risers whose model belongs with the other

family of CPUs.

The memory riser population rules for the Sun Server X2-4 are as follows:

1. A maximum of two memory risers (numbered MR0 and MR1) are supported per

CPU, thus allowing up to eight memory risers in a 4-CPU system, or up to four

memory risers in a 2-CPU system.

Chapter 4 Servicing CRU Components That Require Server Power Off 4-3

Page 58

2. Each memory riser slot in the server chassis must be filled with either a memory

riser or filler panel, and each memory riser must be filled with DIMMs and/or

DIMM filler panels. For example, in 2-CPU systems, empty CPU sockets (P1 and

P3) must have associated memory riser slots populated with two riser filler panels

per CPU.

3. Performance-oriented configurations should be configured with two memory

risers per CPU. In configurations that do not require two memory risers per CPU,

the following guidelines should be followed:

■ First populate riser slot MR0 for each CPU, starting with the lowest numbered

CPU (P0).

■ The populate riser slot MR1 for each CPU, starting with the lowest numbered CPU

(P0).

FIGURE 4-2 Memory Riser DIMMs Physical Layout and Population Order

4.1.3 Memory Riser DIMM Population Rules

The memory riser DIMM population rules for the Sun Server X2-4 are as follows:

1. Maximum memory operating speed is 1066 MHz. This also applies to supported

DIMMs rated for higher speeds.

2. Supported DIMMs include single-, dual-, or quad-rank 4 GB, 8 GB, 16 GB and 32

GB JEDEC˘2013standard, DDR3 low voltage ECC RDIMMs.

3. All DIMMs on a CMOD must be the same density and organization.

4-4 Sun Server X2-4 Service Manual • April 2013

Page 59

Note – Do not mix dual-rank 16 GB DIMMs with quad-rank 16 GB DIMMs on a

CMOD. Mixing DIMMs of different rank or density degrades performance.

■ Single-rank DIMMs (marked 1Rx8) and dual-rank DIMMs (marked 2Rx4) do

not include heat spreaders.

■ Quad-rank DIMMs are marked 4Rx4 and include heat spreaders. DIMMs with

heat spreaders have two U-shaped metal clips on the top of the DIMM.

4. Each memory riser supports up to 8 DIMMs, with a maximum 64 DIMMs for a

4-socket Sun Server X2-4.

5. DIMM slots are color coded with the following population order:

■ Blue

■ White

■ Black

■ Green

6. DIMM slots must be populated in matching pairs of identical DIMMs (from the

same memory kit) within a processor.

The recommended DIMM population order, as depicted in

■ D0/D4

■ D2/D6

■ D1/D5

■ D3/D7

7. Install quad-rank DIMMs before dual-rank DIMMs on the same riser. Specifically,

a DRAM channel with both rank types must have the quad-rank DIMM in the

D0/D4 or D2/D6 slot.

Note – When a mixed quad-rank DIMM and dual or single rank DIMM are on the

same memory riser, the quad-rank DIMM should be installed in slot0 of each

channel.

4.1.4 Memory Performance Guidelines

Meeting these guidelines will provide the best system performance. Guidelines are

listed in decreasing importance.

FIGURE 4-2 is:

1. Provide some DIMMs on every memory riser.

Chapter 4 Servicing CRU Components That Require Server Power Off 4-5

Page 60

2. Provide DIMMs on every DRAM channel (at least 4 DIMMs per memory riser).

3. For each CPU, have equal total gigabytes on the MR0 and MR1 risers. Memory

bandwidth is 5% higher when all pairs of risers have balanced capacity.

4. Spread the memory capacity evenly across the CPUs so the operating system can

distribute large memory tasks better.

5. Avoid mixing dual-rank and quad-rank DIMMs in the same memory riser.

4.1.4.1 Recommended Memory Placement

For the Sun Server X2-4, the operating speed of the DIMMs does not decrease as

more DIMMs are installed. For best memory performance, follow these simple

guidelines to add or replace DIMMs in the server. Use one or more sizes of DIMMs,

with an even number of DIMMs of each size.

1. Using the largest-capacity DIMMs, add two DIMMs per riser, starting at P0/MR0,

continuing through P3/MR1, and then beginning again at P0/MR0 if necessary,

until all of the largest-capacity DIMMs are placed.

For installations with one DIMM size, all DIMMs will be placed in this step. For

installations with additional DIMMs of different sizes, continue to the next

guideline step.

If you are adding or replacing quad-rank (16GB) DIMMs, they can be installed

only in D0/D4 slots or D2/D6 slots, or else in DRAM channels where those slots

already contain 16GB DIMMs.

2. Using DIMMs of the next largest capacity, add two DIMMs per riser, starting with

risers with the fewest DIMMs and proceeding from P0/MR0, continuing through

P3/MR1, and then beginning again at P0/MR0 if necessary, until there are no

more DIMMs of this size, or all risers have four DIMMs.

As long as any riser has fewer than four DIMMs, keep repeating this step with the

DIMMs of decreasing capacity. When all risers have four DIMMs, continue to the

next guideline step.

3. Using DIMMs of the next largest capacity, add two DIMMs per riser to risers with

the least total gigabytes. Start from P0/MR0, continuing through P3/MR1, and

then begin again at P0/MR0 is necessary.

Repeat guideline step 3 with all remaining DIMMs, in decreasing order of DIMM

capacity, until all DIMMs are placed.

4-6 Sun Server X2-4 Service Manual • April 2013

Page 61

4.1.5 DIMM Fault Isolation

The eight DIMMs supported on each memory riser card in the Sun Server X2-4 are

divided into two logical DDR3 channels. The first logical channel contains DIMMs

installed in slots D0, D1, D4 and D5. The second logical channel contains DIMMs

installed in slots D2, D4, D6 and D7.

When one or more DIMMs within a logical DDR3 channel are faulted, all four

DIMMs within that logical channel will be disabled by BIOS on subsequent boots.

This isolates the faulty component from the system to ensure that proper operation is

not compromised by the presence of the faulty component.

4.1.6 Supported DIMMs

Initially supported DIMMs for the Sun Server X2-4 are PC3L-type RDIMMs, which

are DDR3 low-voltage DIMMs.

TABLE 4-1 Supported DIMM Size and Organization

DIMM Size Organization

TABLE 4-1 identifies supported DIMM sizes.

• 4GB Dual-rank by-8 (2Rx8)

• 8GB Dual-rank by-4 (2Rx4)

• 16GB Quad-rank by-4 (4Rx4)

• 16GB Dual-rank by-4 (4Rx4)

4.1.7 Unsupported DIMMs

The Sun Server X2-4 does not support the following DIMMs:

■ MetaRAMs

■ LR-DIMMs or UDIMM

■ DIMMs using 256 Mb or 512 Mb DRAM technologies

■ DDR3-800 MHz RDIMMs

■ DDR3-978 MHz RDIMMs

Chapter 4 Servicing CRU Components That Require Server Power Off 4-7

Page 62

4.1.8 Removing and Installing Memory Risers, DIMMs,

and Filler Panels

Use the following procedures to remove and install memory risers, DIMMs, and filler

panels.

▼ Remove a Memory Riser Filler Panel

1. Prepare for servicing:

a. Attach an antistatic wrist strap.

See Section 2.3 “Performing Electrostatic Discharge and Static Prevention

Measures” on page 2-3.

b. Power off the server.

See Section 2.6 “Powering Off the Server” on page 2-6.

c. Extend the server to the maintenance position.

See Section 2.4 “Positioning the Server for Maintenance” on page 2-4.

d. Remove the top cover.

See Section 2.7 “Removing the Server Top Cover” on page 2-8.

2. Locate the memory riser filler panel you want to remove.

3. Lift the memory riser filler panel straight up to remove it from the memory

module socket.

Caution – Whenever you remove a memory riser filler panel, replace it with another

filler panel or a memory riser; otherwise, the server might overheat due to improper

airflow.

▼ Remove a DIMM Filler Panel

1. Prepare for servicing:

a. Attach an antistatic wrist strap.

See Section 2.3 “Performing Electrostatic Discharge and Static Prevention

Measures” on page 2-3.

4-8 Sun Server X2-4 Service Manual • April 2013

Page 63

b. Power off the server.

See Section 2.6 “Powering Off the Server” on page 2-6.

c. Extend the server to the maintenance position.

See Section 2.4 “Positioning the Server for Maintenance” on page 2-4.

d. Remove the top cover.

See Section 2.7 “Removing the Server Top Cover” on page 2-8.

2. Locate the memory riser containing the DIMM filler panel you want to remove.

3. Lift the memory riser straight up to remove it from the memory module socket.

4. Locate the DIMM filler panel you want to remove.

5. To remove the DIMM filler panel, do the following:

a. Rotate both DIMM slot ejectors outward as far as they will go.

The filler panel is partially ejected from the socket.

b. Carefully lift the DIMM filler panel straight up to remove it from the socket

(

FIGURE 4-6).

Caution – Whenever you remove a DIMM filler panel, replace it with another filler

panel or a DIMM; otherwise, the server might overheat due to improper airflow.

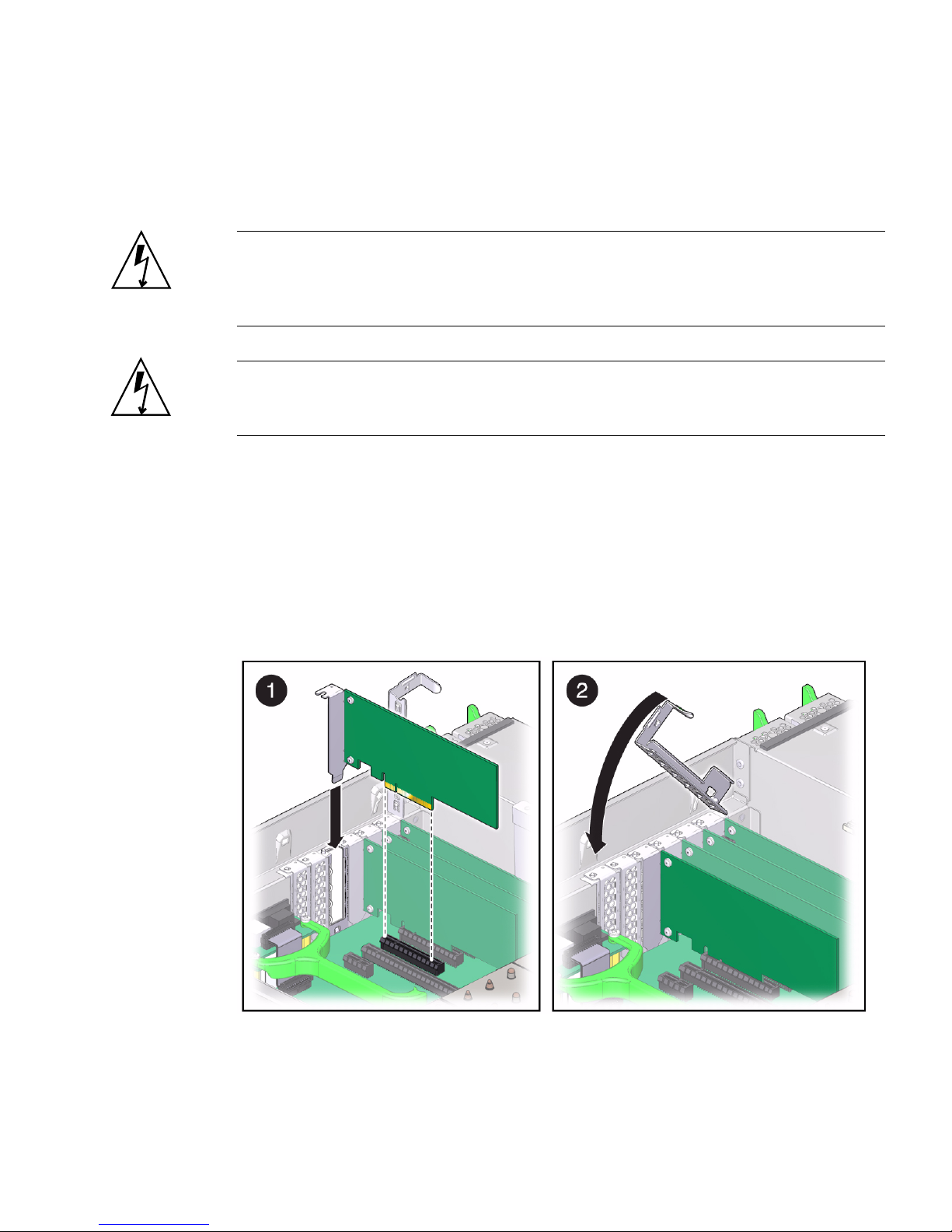

▼ Remove a Memory Riser and DIMM

1. Prepare for servicing:

a. Attach an antistatic wrist strap.

See Section 2.3 “Performing Electrostatic Discharge and Static Prevention

Measures” on page 2-3.

b. Power off the server.

See Section 2.6 “Powering Off the Server” on page 2-6.

c. Extend the server to the maintenance position.

See Section 2.4 “Positioning the Server for Maintenance” on page 2-4.

d. Remove the top cover.

See Section 2.7 “Removing the Server Top Cover” on page 2-8.

2. Identify the memory riser with the faulty DIMM by pressing the Fault Remind

button on the air divider (

FIGURE 4-3).

Chapter 4 Servicing CRU Components That Require Server Power Off 4-9

Page 64

■ If the memory riser Service Action Required LED is off: all DIMMs on this riser

are operating properly.

■ If the memory riser Service Action Required LED is on (amber): one or more of

the DIMMs installed on this riser is faulty or misconfigured.

Note – Located above the Fault Remind button is the Fault Remind button Power

LED. When the Fault Remind button is pressed, the Power LED illuminates (green)

to indicate that the remind circuitry is working correctly.

FIGURE 4-3 Fault Remind Button on the Air Divider

3. Lift the memory riser that has its Service Action Required LED lit straight up to

remove the memory riser from the memory module socket (

4-10 Sun Server X2-4 Service Manual • April 2013

FIGURE 4-4).

Page 65

FIGURE 4-4 Removing the Memory Riser

4. Identify the faulty or misconfigured DIMM(s) by pressing the Fault Remind

button on the memory riser (

■ If the DIMM Service Action Required LED is off: DIMM is operating properly.

■ If the DIMM Service Action Required LED is on (amber): DIMM is faulty or

FIGURE 4-5).

misconfigured and corrective action is required.

Chapter 4 Servicing CRU Components That Require Server Power Off 4-11

Page 66

FIGURE 4-5 Fault Remind Button on Memory Riser

5. To remove the DIMM do the following (FIGURE 4-6):

a. Rotate both DIMM slot ejectors outward as far as they will go.

The DIMM is partially ejected from the socket.

b. Carefully lift the DIMM straight up to remove it from the socket.

4-12 Sun Server X2-4 Service Manual • April 2013

Page 67

FIGURE 4-6 DIMM Socket Release and Alignment

Figure Legend

1 DIMM connector slot

2 DIMM connector key

3 DIMM ejector lever

Caution – Whenever you remove a memory riser or DIMM, you should replace it

with another memory riser or a DIMM or a filler panel; otherwise, the server might

overheat due to improper airflow.

Caution – Be sure to install DIMMs in matched pairs of identical DIMM types (same

part number).

▼ Install Memory Risers and DIMMs

Refer to FIGURE 4-7 and FIGURE 4-8 when completing the following procedure.

Chapter 4 Servicing CRU Components That Require Server Power Off 4-13

Page 68

1. Unpack the DIMMs and place them on an antistatic mat.

2. Ensure that the ejector levers at both ends of the memory module slot are in a