StorageTek SL3000

Modular Library System

Systems Assurance Guide

Part Number: 316194102

May 2010

Revision: B

Submit comments about this document by clicking the Feedback [+] link at: http://docs.sun.com

StorageTek SL3000 Modular Library System: Systems Assurance Guide

316194102 Revision: B

Copyright © 2008, 2010, Oracle and/or its affiliates. All rights reserved.

This software and related documentation are provided under a license agreement containing restrictions on use and disclosure

and are protected by intellectual property laws. Except as expressly permitted in your license agreement or allowed by law, you

may not use, copy, reproduce, translate, broadcast, modify, license, transmit, distribute, exhibit, perform, publish, or display any

part, in any form, or by any means. Reverse engineering, disassembly, or decompilation of this software, unless required by law

for interoperability, is prohibited.

The information contained herein is subject to change without notice and is not warranted to be error-free. If you find any errors,

please report them to us in writing.

If this is software or related software documentation that is delivered to the U.S. Government or anyone licensing it on behalf of

the U.S. Government, the following notice is applicable:

U.S. GOVERNMENT RIGHTS Programs, software, databases, and related documentation and technical data delivered to U.S.

Government customers are “commercial computer software” or “commercial technical data” pursuant to the applicable Federal

Acquisition Regulation and agency-specific supplemental regulations. As such, the use, duplication, disclosure, modification,

and adaptation shall be subject to the restrictions and license terms set forth in the applicable Government contract, and, to the

extent applicable by the terms of the Government contract, the additional rights set forth in FAR 52.227-19, Commercial Computer

Software License (December 2007). Oracle USA, Inc., 500 Oracle Parkway, Redwood City, CA 94065.

This software or hardware is developed for general use in a variety of information management applications. It is not developed

or intended for use in any inherently dangerous applications, including applications which may create a risk of personal injury. If

you use this software or hardware in dangerous applications, then you shall be responsible to take all appropriate fail-safe,

backup, redundancy, and other measures to ensure the safe use. Oracle Corporation and its affiliates disclaim any liability for any

damages caused by use of this software or hardware in dangerous applications.

Oracle is a registered trademark of Oracle Corporation and/or its affiliates. Oracle and Java are registered trademarks of Oracle

and/or its affiliates. Other names may be trademarks of their respective owners.

AMD, Opteron, the AMD logo, and the AMD Opteron logo are trademarks or registered trademarks of Advanced Micro Devices.

Intel and Intel Xeon are trademarks or registered trademarks of Intel Corporation. All SPARC trademarks are used under license

and are trademarks or registered trademarks of SPARC International, Inc. UNIX is a registered trademark licensed through

X/Open Company, Ltd.

This software or hardware and documentation may provide access to or information on content, products, and services from third

parties. Oracle Corporation and its affiliates are not responsible for and expressly disclaim all warranties of any kind with respect

to third-party content, products, and services. Oracle Corporation and its affiliates will not be responsible for any loss, costs, or

da mag es i ncu rre d du e to you r ac ces s to or u se of third-party content, products, or services.

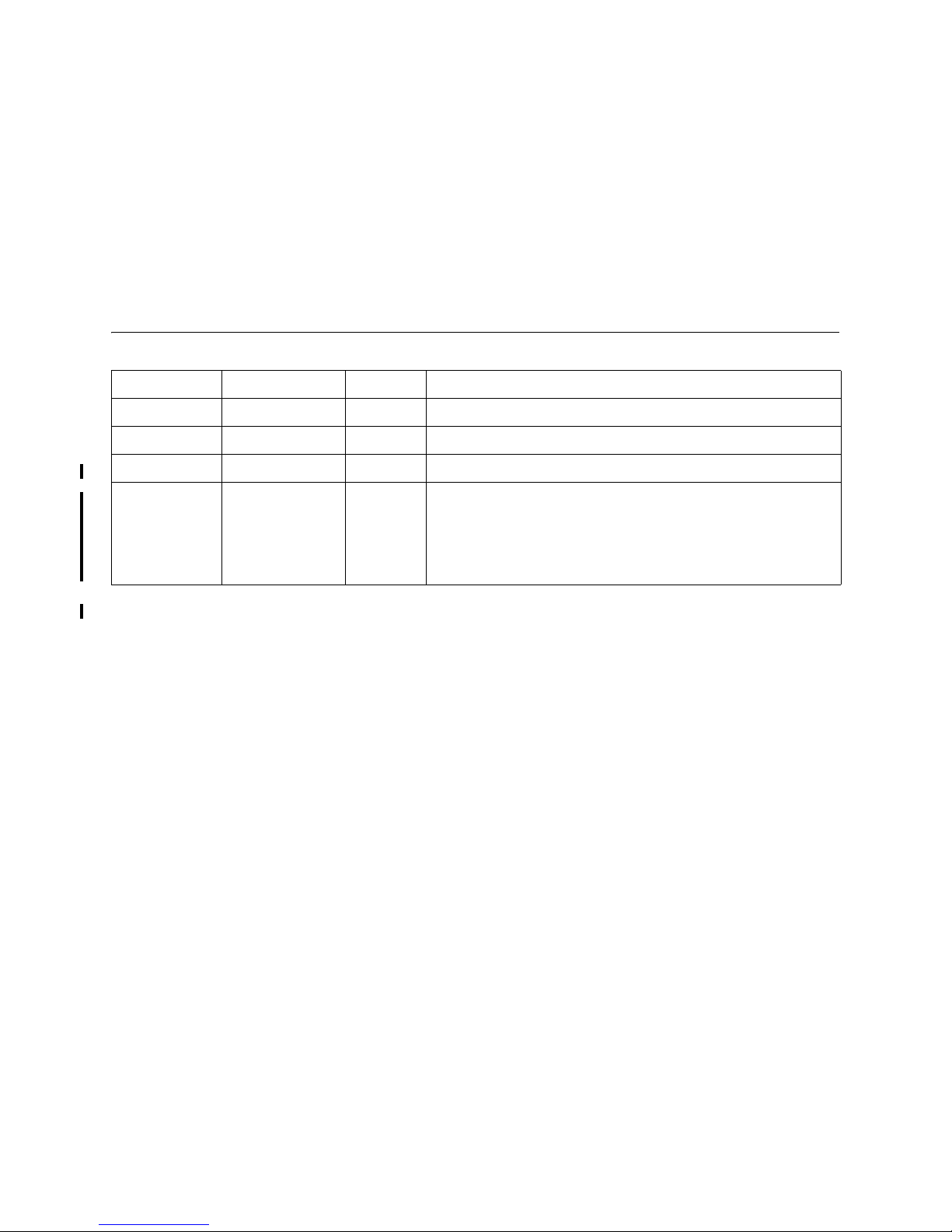

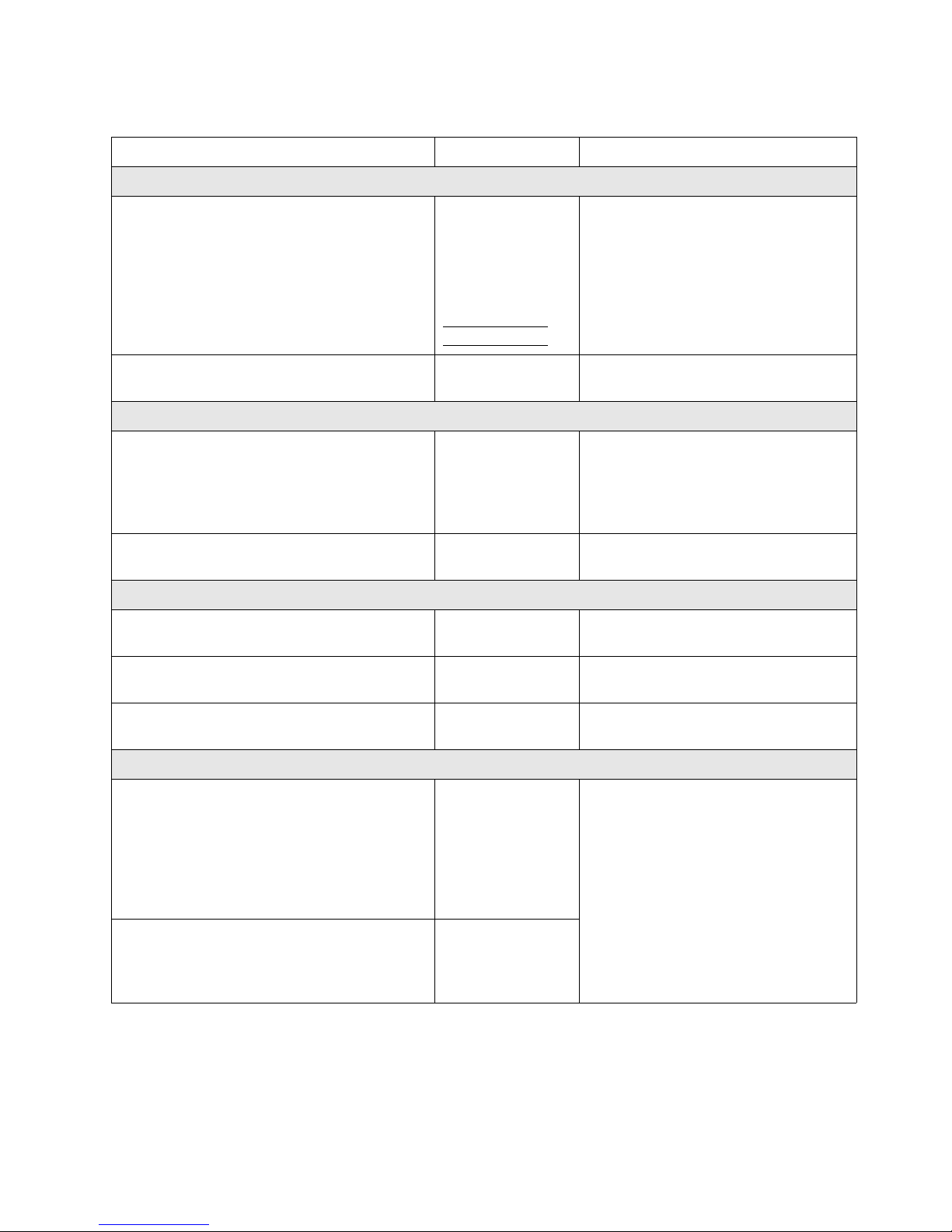

Summary of Changes

EC Number Date Revision Description

EC000348 April 2008 A Initial release.

EC000628 July 2008 AB Refer to this version for a list of updates.

EC001137 April 2009 AC Refer to this version for a list of updates.

May 2010 B Updates to this revision include:

■ Oracle branding.

■ LTO5 support.

■ PUA Fibre Channel card.

■ Engineering updates

Note – Change bars ar

e included in this revision.

316194102 • Revision: B iii

iv SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Contents

Preface xix

1. Introduction 1

Modular Design 2

Base Module 3

Drive Expansion Module 5

Cartridge Expansion Module 7

Parking Expansion Module 8

Access Expansion Module 9

Addressing 10

Physical Capacities 11

Power Options 13

AC Power Configurations 13

Power Redundancy 13

N+1 Power Configuration—Standard 13

2N Power Configuration—Optional 13

AC Power Cables 14

Robotic DC Power Configurations 14

Electronic Control Module DC Power Configurations 14

Single Drive Type DC Power Configurations 15

Mixed Drive Type DC Power Configurations 16

Electronics Control Module 18

Robotic Units 19

Cartridge Access Ports 20

Bulk Load Cartridge Access Ports 21

CAP Labels 22

316194102 • Revision: B v

Cooling 23

Library Electronics Control Module 23

Tape Driv es 23

DC Power Supplies 23

Tape Drives 24

Drive Tray 25

Interfaces 26

Host Connectivity 26

SCSI 26

TCP/IP 27

Connections 27

Network 28

Service 28

Monitoring 28

StorageTek Library Console 29

Web-launched Library Console 30

Security Considerations 30

Client Requirements 30

Web-launched SLConsole Updates 30

Simple Network Management Protocol 31

Library Management Software 32

Nearline Control Solution 33

Storage Management Component 33

Host Software Component 33

Virtual Storage Manager 34

LibraryStation 34

Extended High Performance Data Mover 34

Expert Library Manager 35

Expert Performance Reporter 35

Enterprise Library Software 35

Automated Cartridge System Library Software 36

Independent Software Vendors 37

Standards of Conformance 38

vi SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

2. Systems Assurance 39

System Assurance Planning Meetings 39

Customer Contact Sheet 41

StorageTek Member Contact Sheet 42

3. Site Planning 43

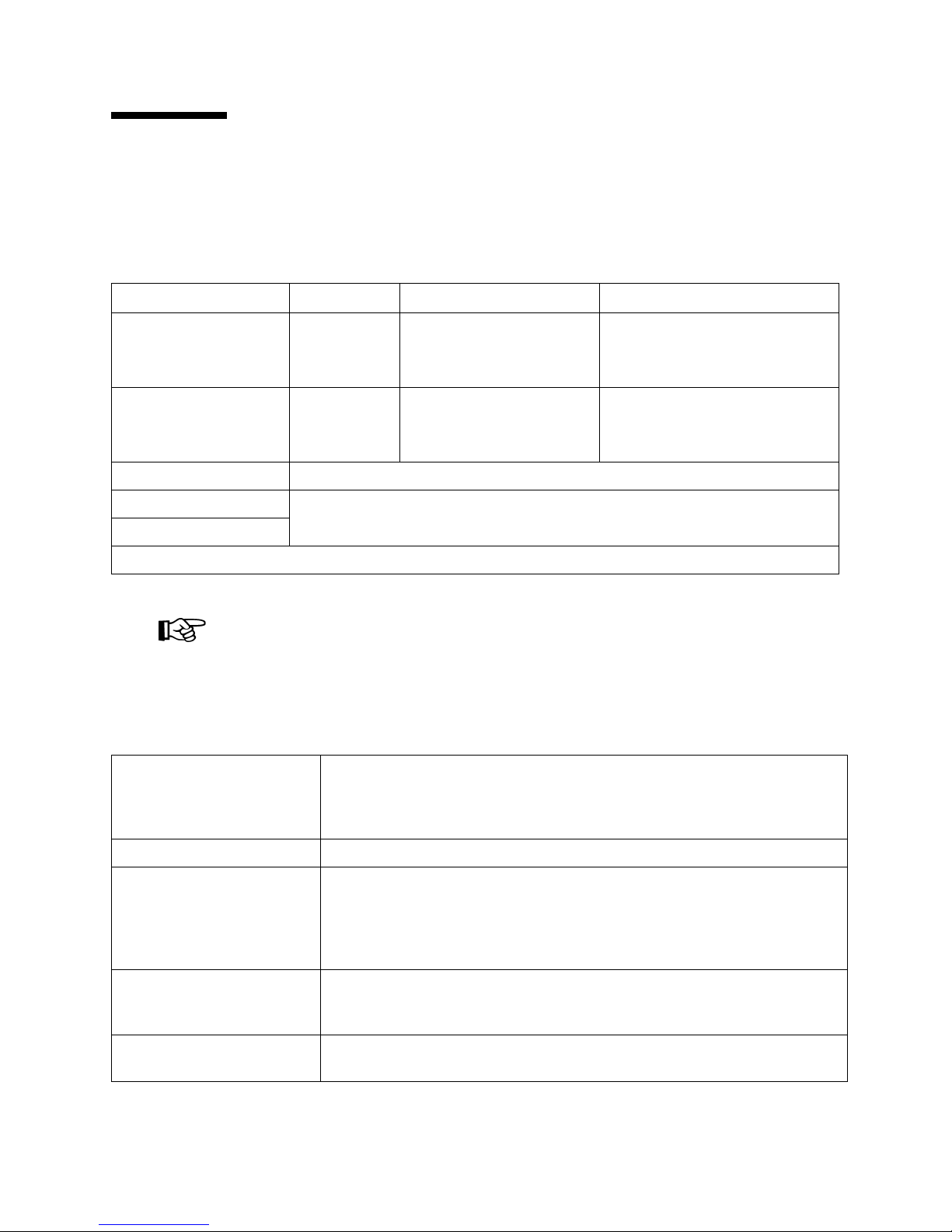

Specifications 44

Base Module 46

Drive Expansion Module 46

Cartridge and Parking Expansion Modules 47

Access Expansion Module 47

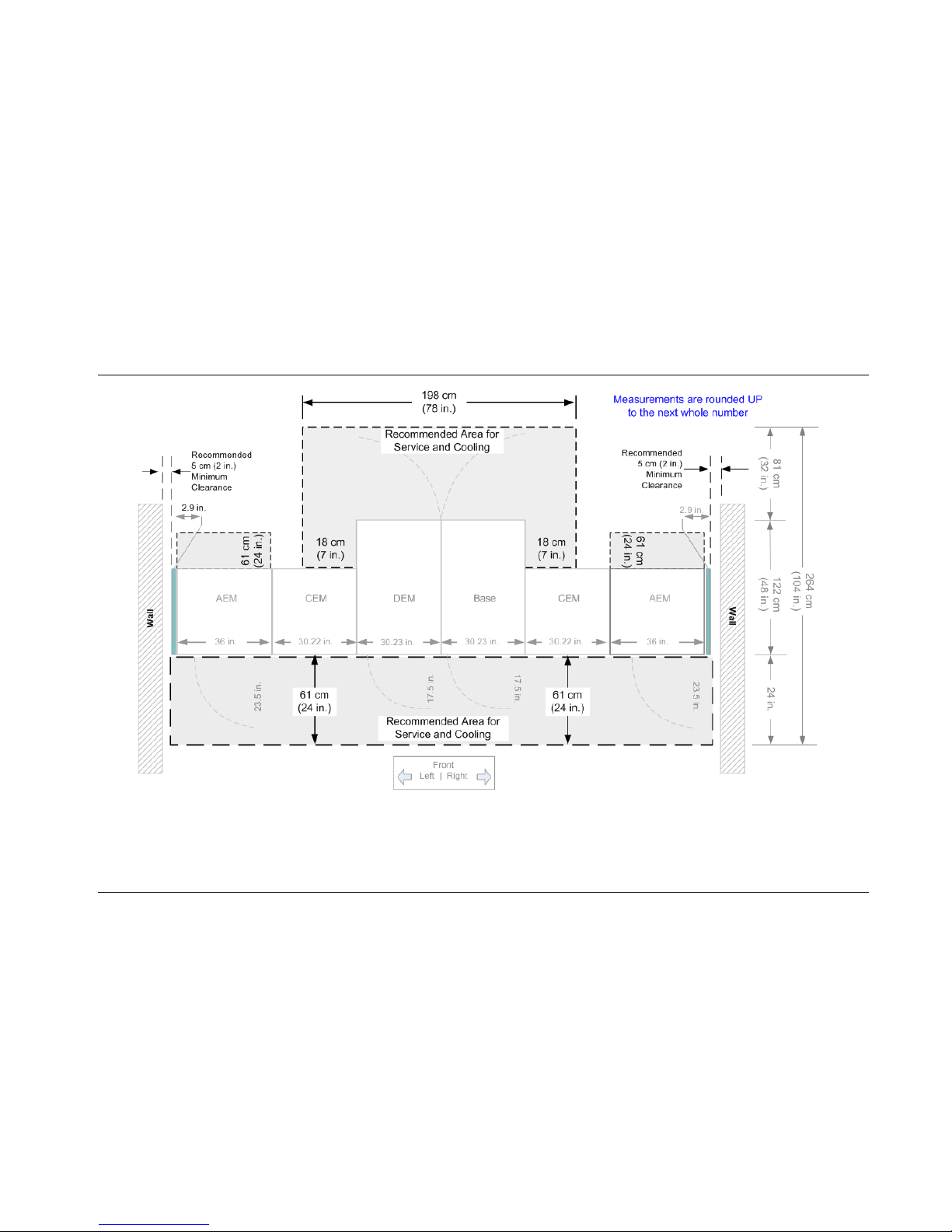

Covers, Doors, and Service Clearances 47

Service Clearances 48

Side Clearance During Installation 49

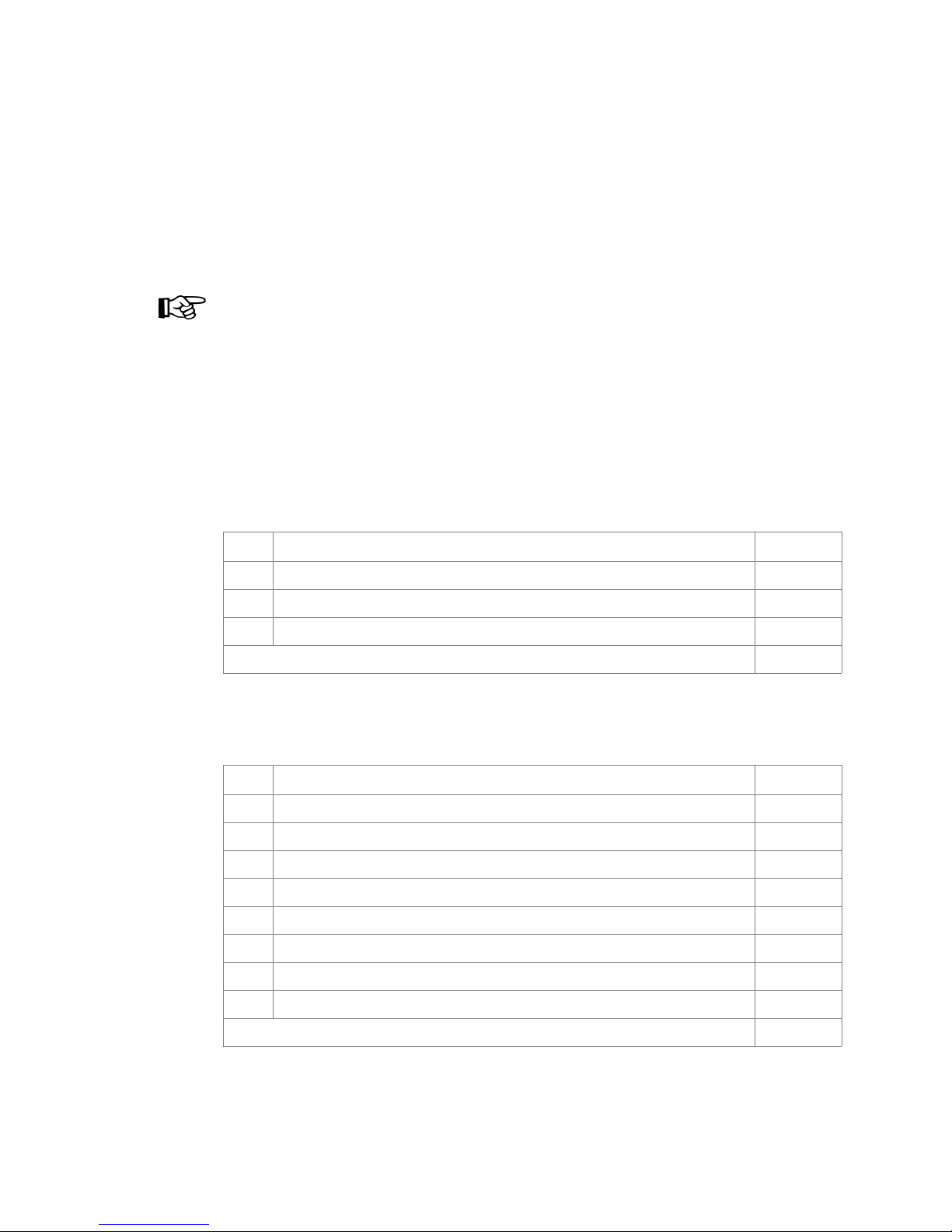

Floor Loading 50

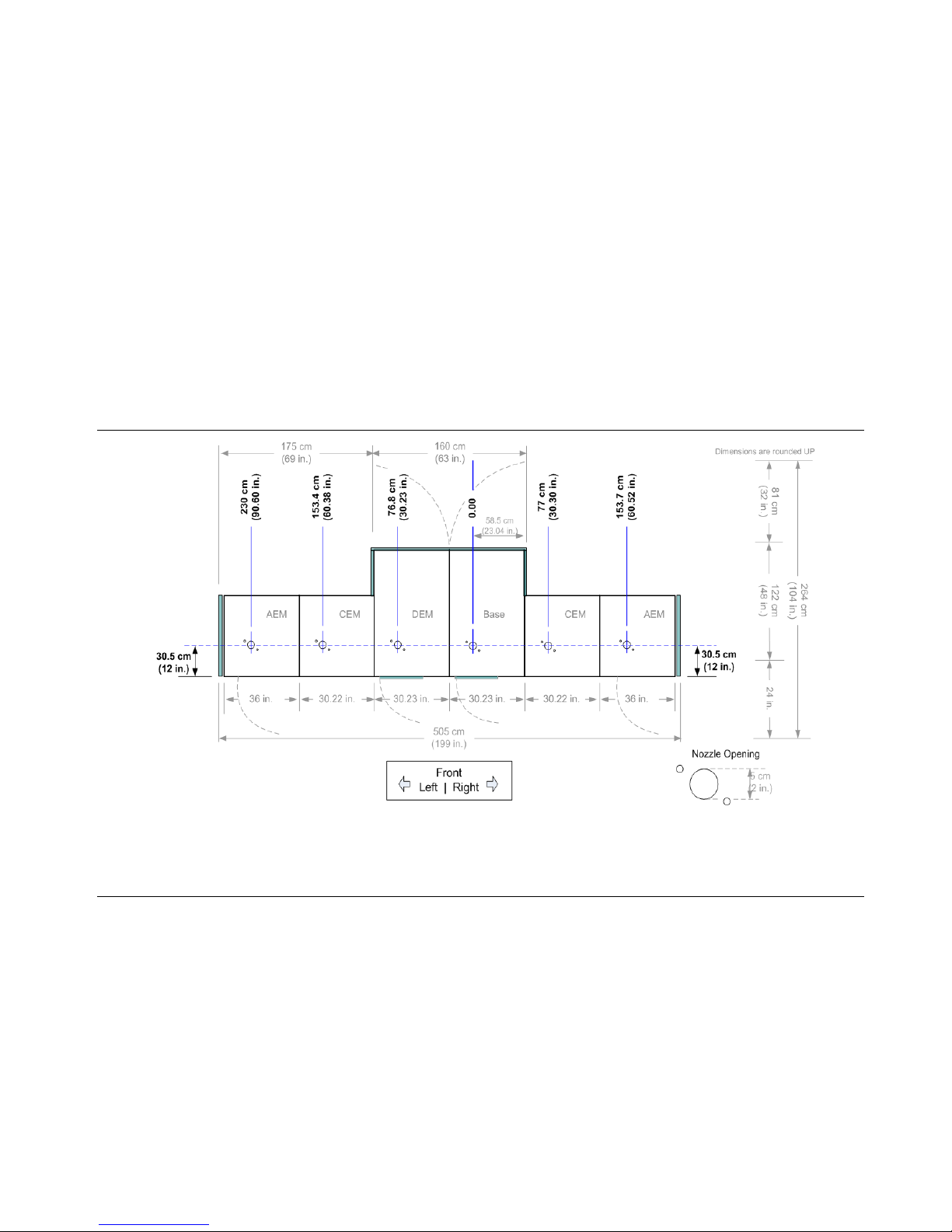

Fire Suppression Planning 51

Environmental Requirements 52

Airborne Contaminants 53

Power Consumption 54

Calculating Power Consumption 55

Installation Considerations 56

Available Space 56

Installation Time and Personnel 56

Pallets 57

Pallet Double Stacking 58

Customer’s Floor 59

Cable Routing 60

Seismic or Earthquake Ratings 61

Installation Tools—Required 64

Drive Tray Power-on Tool 65

Optional Power Drill 65

Array Extraction Tool 65

Installation Kits 65

AC Power Configurations and Cables 66

316194102 • Revision: B Contents vii

Obtaining a Password 67

Installing the Library Console Software 68

Hardware Activation Keys 68

Hardware Activation Key Files 68

SL3000 Configuration Work Sheet 69

4. Customer Site Survey 73

Interoperability 73

Site Preparation Checklist 74

System Configuration 79

Applications 81

SCSI Media Changer Applications 83

Databases 84

Hardware Configurations 85

Library 85

Tape Driv es 86

Data Cartridges 87

Network and Components 88

ESCON Directors 90

FICON Directors 91

Cables 92

Library Network Cables 92

Tape Drive Cables 92

Using World Wide Names 93

Tape Drive Dynamic World Wide Name 93

Using Persistent Binding 94

Using Zoning to Isolate Devices and Enhance Security 94

5. Ordering 95

Ordering Flowchart—Just the Facts 95

Hardware Activation Key Files 105

Activation Files for New Libraries 105

Upgrades to Existing Libraries 105

Library Part Number Details 106

viii SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

X-Option Details 107

Modules 107

Power 107

Partitioning 108

Additional Capacity 108

Ethernet Switch/Harnesses 108

Library X-options and Conversion Bills 110

Log SnapShot Feature 111

Tape Drive Selection 112

T9840 Tape Drive Marketing Numbers 113

T10000 Tape Drive Marketing Numbers 114

LTO Tape Drive Marketing Numbers 115

Tape Drive X-options and Conversion Bills 116

Cables 118

Fibre Channel, ESCON, and Ethernet Cables 118

Fibre Channel Cables 118

Plenum-rated Cables 118

ESCON Cables 120

Ethernet Cables 120

A. Addressing 121

CenterLine Technology 121

Addressing 123

Columns 124

Wal ls 125

Module Identification Block 125

HLI–PRC Addressing 127

Drive Numbering 130

Out-of-the Box Slot Numbering 131

Default SCSI Element Ordering 133

Slot Maps Illustrated 135

Reserved and System Slots 153

B. Optimization 155

316194102 • Revision: B Contents ix

Planning for Content 155

Robotic Rails and TallBots 156

Cartridge Access Ports 156

Managing Cartridges 157

Planning for Tape Drives 157

Library Addressing 158

Numbering Diagram Example 158

Partitioning 159

Capacity on Demand 160

Rectangular Boundaries 161

Guidelines 163

Planning the Data Path 164

Host Software Precautions 164

Performance Zone 165

Planning the Partitions 166

C. Tape Drives and Media 169

Environmental - Tape Drive 170

Tape Driv es 171

Tape Drive Comparisons 172

Encryption Capable Tape Drives 173

Tape Drive and Media Comparisons 173

T-Series Tape Drives 173

LTO Tap e D ri v e s 174

Encryption Capable Drive Trays 175

Media 176

Vol um e I D L ab el 177

Cleaning and Diagnostic Labels 178

Media Comparisons 179

Ordering Cartridges and Labels 180

Tape Media Policies 181

Environmental - Media 181

Tape Media W5C Help Sheet 182

x SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Figures

FIGURE 1-1 SL3000 Modular Library System—Configuration Example 1

FIGURE 1-2 Base Module—Front View 3

FIGURE 1-3 Base Module—Rear View Drawing 4

FIGURE 1-4 Drive Expansion Module with a Base Module 5

FIGURE 1-5 Rear View of the Drive Expansion Module 6

FIGURE 1-6 Cartridge Expansion Module with Base Module 7

FIGURE 1-7 Parking Expansion Module with Base Module 8

FIGURE 1-8 Access Expansion Module—Front View 9

FIGURE 1-9 Electronics Control Module 18

FIGURE 1-10 TallBot 19

FIGURE 1-11 Cartridge Access Port and Key Pad 20

FIGURE 1-12 Bulk Load CAPs—Access Expansion Modules 21

FIGURE 1-13 Cartridge Access Port Labels 22

FIGURE 1-14 SL3000 Tape Drive Trays 25

FIGURE 1-15 Library Console—Example Screen 29

FIGURE 1-16 SNMP Example 31

FIGURE 1-17 ACSLS Example 36

FIGURE 3-1 SL3000 Library—Front Door Open 43

FIGURE 3-2 Metric Dimensions (frame measurements) 44

FIGURE 3-3 Standard Dimensions (frame measurements) 45

FIGURE 3-4 Service Clearances—Minimum and Recommended 48

FIGURE 3-5 End Cover Clearance 49

FIGURE 3-6 Floor Loading—Load Pads 50

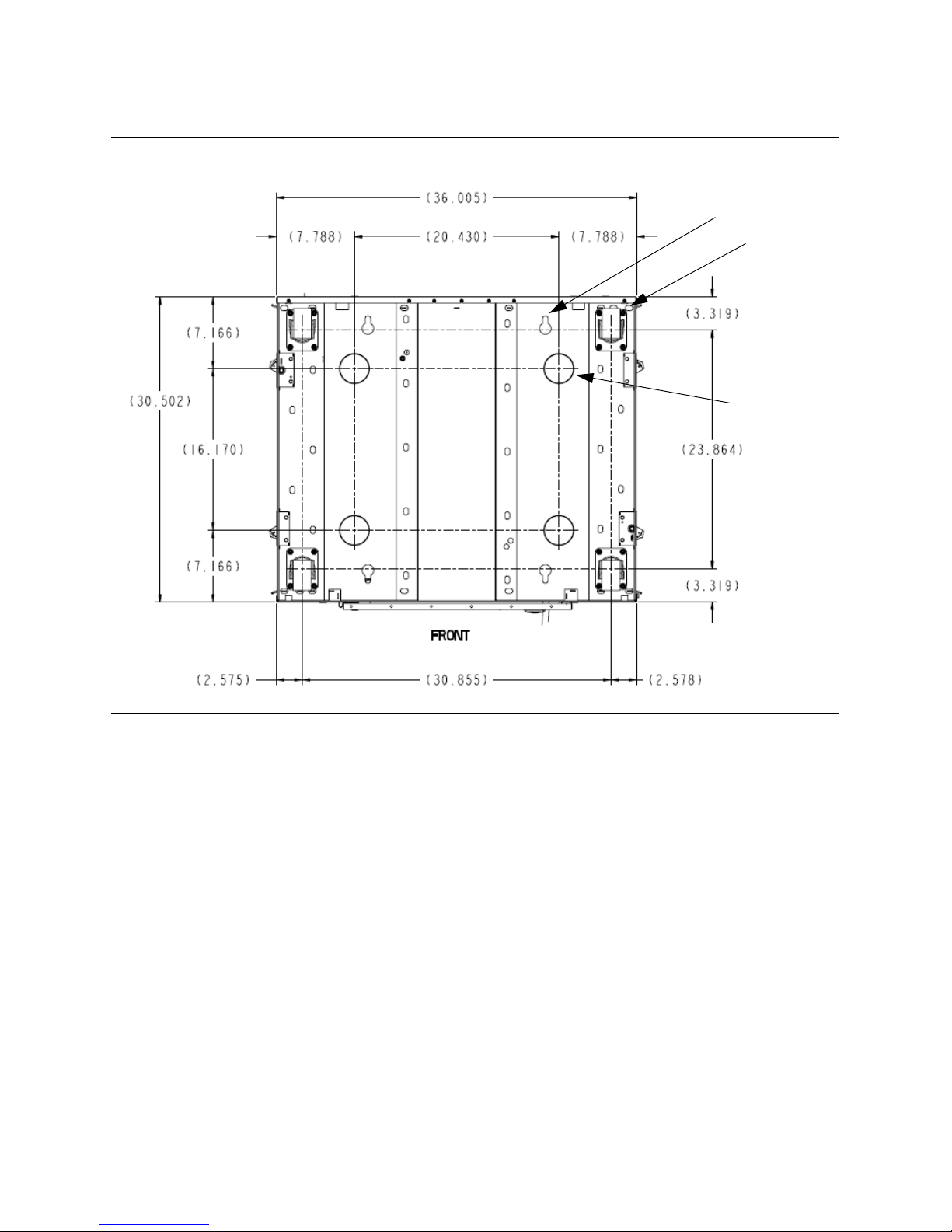

FIGURE 3-7 Fire Suppression Ceiling Access (Viewed from the top of the library) 51

316194102 • Revision: B xi

FIGURE 3-8 Pallet and Module Shipping Information 57

FIGURE 3-9 Do Not Stack on Second Pallet 58

FIGURE 3-10 Floor Slope 59

FIGURE 3-11 Cable Routing 60

FIGURE 3-12 Seismic Mounting Locations 61

FIGURE 5-1 Ordering Flowchart 96

FIGURE 5-2 SL3000 Controller Cards and Log SnapShot Feature 111

FIGURE A-1 CenterLine Technology 122

FIGURE A-2 Centerline and Column Addressing 124

FIGURE A-3 Module Identification Block 125

FIGURE A-4 Panel Numbering for HLI-PRC Addressing 128

FIGURE A-5 Panel Numbering for HLI–PRC Addressing—Example 1 128

FIGURE A-6 Panel Numbering for HLI–PRC Addressing—Example 2 128

FIGURE A-7 Panel Numbering for HLI–PRC Addressing—Example 3, With two PEMs 129

FIGURE A-8 Panel Numbering for HLI–PRC Addressing—Example 4, With two AEMs 129

FIGURE A-9 Slot Numbering—Out-of-the-Box 131

FIGURE A-10 Out-of-the-Box Numbering 132

FIGURE A-11 SCSI Element Numbering 134

FIGURE A-12 SL3000 Slot Map—Base Module (1 of 3) 136

FIGURE A-13 SL3000 Slot Map—Base Module (2 of 3) 137

FIGURE A-14 SL3000 Slot Map—Base Module (3 of 3) 138

FIGURE A-15 SL3000 Slot Map—Drive Expansion Module (1 of 5) 139

FIGURE A-16 SL3000 Slot Map—Drive Expansion Module (2 of 5) 140

FIGURE A-17 SL3000 Slot Map—Drive Expansion Module (3 of 5) 141

FIGURE A-18 SL3000 Slot Map—Drive Expansion Module (4 of 5) 142

FIGURE A-19 SL3000 Slot Map—Drive Expansion Module (5 of 5) 143

FIGURE A-20 SL3000 Slot Map—Cartridge Expansion Module, Back Wall 144

FIGURE A-21 SL3000 Slot Map—Cartridge Expansion Module, Front Wall, Installed on the

Right 145

FIGURE A-22 SL3000 Slot Map—Cartridge Expansion Module, Installed on the Left 146

FIGURE A-23 SL3000 Slot Map—Parking Expansion Module, Installed on the Right 147

FIGURE A-24 SL3000 Slot Map—Parking Expansion Module, Installed on the Left 148

FIGURE A-25 SL3000 Slot Map—Access Expansion Module, Installed on the Left (Rear Wall) 149

FIGURE A-26 SL3000 Slot Map—Access Expansion Module, Installed on the Left (Front Wall) 150

xii SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

FIGURE A-27 SL3000 Slot Map—Access Expansion Module, Installed on the Right (Rear Wall) 151

FIGURE A-28 SL3000 Slot Map—Access Expansion Module, Installed on the Right (Front Wall) 152

FIGURE A-29 Reserved/System Slot Locations—Base Module Only 154

FIGURE B-1 Out-of-the-Box Numbering 158

FIGURE B-2 Adding Capacity to Partitions 162

FIGURE B-3 Performance Zone 165

FIGURE B-4 Planning for Partitions 167

FIGURE C-1 Encryption-capable Drive LEDs 175

FIGURE C-2 Encryption Capable Tape Drive and Library Configuration 175

FIGURE C-3 Tape Cartridge Elements 176

FIGURE C-4 Data Cartridge Label Examples 177

FIGURE C-5 Cleaning and Diagnostic Cartridge Labels 178

316194102 • Revision: B Figures xiii

xiv SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Tables

TABLE 1-1 Accessible Physical Slot Count Per Module 12

TABLE 1-2 Power Cable Part Numbers and Descriptions 14

TABLE 1-3 Tape Drive DC Power Supply Requirements 15

TABLE 1-4 Watts Per Drive 16

TABLE 1-5 Available Watts Per Module 16

TABLE 1-6 DC Power Supplies Per Module 16

TABLE 1-7 Mixed Drive Type Power Configuration—Calculation Example 17

TABLE 1-8 Supported Tape Drives 24

TABLE 1-9 Library Software Compatibility Matrix 32

TABLE 1-10 ACSLS 7.3 Qualification Summary 37

TABLE 1-11 Standard of Compliance 38

TABLE 2-1 System Assurance Checklist 40

TABLE 3-1 Base Module Specifications 46

TABLE 3-2 Drive Expansion Module Specifications 46

TABLE 3-3 Cartridge and Parking Expansion Module Specifications 47

TABLE 3-4 Access Expansion Module Specifications 47

TABLE 3-5 Covers, Doors, and Service Clearance Specifications 47

TABLE 3-6 Environmental Specifications 52

TABLE 3-7 Environmental Definitions 52

TABLE 3-8 Gas Limit Recommendations 53

TABLE 3-9 Power Consumption Quick Reference 54

TABLE 3-10 Installation Time Estimates 56

TABLE 3-11 Installation Tools 64

TABLE 3-12 Power Cable Part Numbers and Descriptions 66

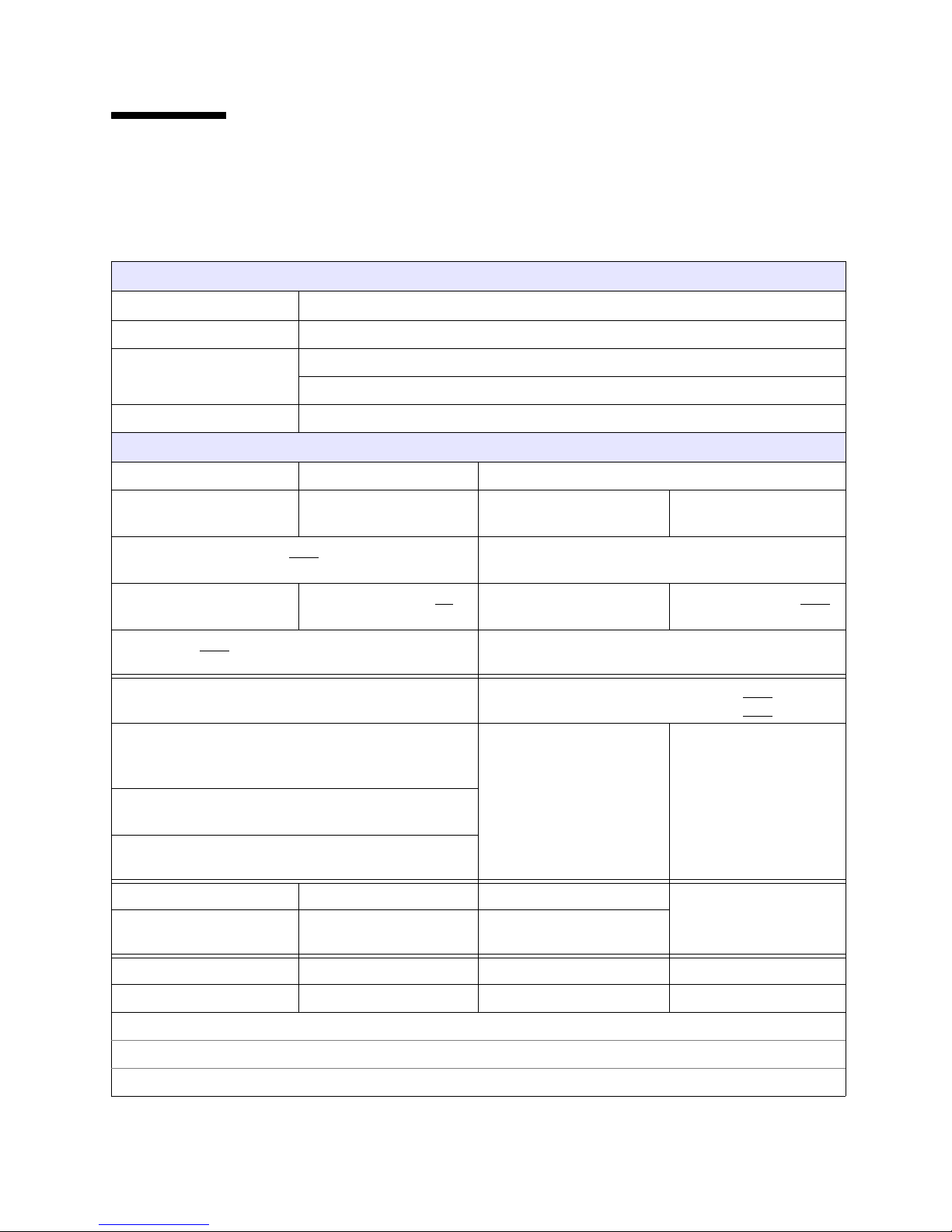

TABLE 3-13 SL3000 Library Configuration 69

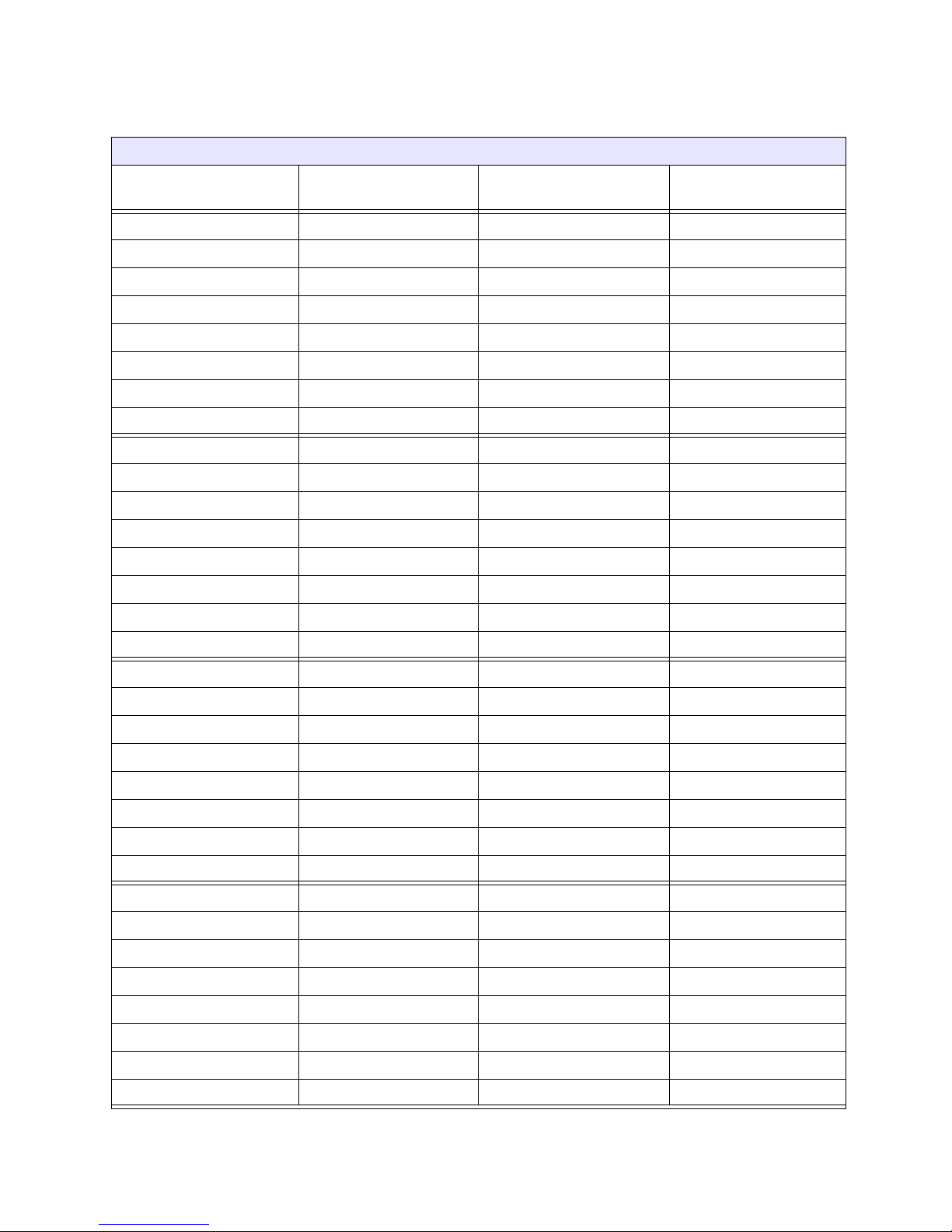

TABLE 4-1 Site Preparation Checklist 74

316194102 • Revision: B xv

TABLE 4-2 Operating System Survey 79

TABLE 4-3 System Configuration 80

TABLE 4-4 Customer Applications 81

TABLE 4-5 Backup and Archive Software 82

TABLE 4-6 SCSI Media Changer (SMC) Qualification Summary 83

TABLE 4-7 Customer Databases 84

TABLE 4-8 Existing Libraries 85

TABLE 4-9 Tape Drive Types 86

TABLE 4-10 Existing Tape Drives 86

TABLE 4-11 Existing Tape Cartridges 87

TABLE 4-12 Fibre Channel Switches 88

TABLE 4-13 Ethernet Hubs and Switches 88

TABLE 4-14 Fibre Channel Switch Connections 89

TABLE 4-15 ESCON Directors 90

TABLE 4-16 FICON Director Worksheet 91

TABLE 5-1 Ordering Flowchart 97

TABLE 5-2 Library X-Options 110

TABLE 5-3 Tape Drive Selection 112

TABLE 5-4 T9840 Marketing Numbers and Descriptions 113

TABLE 5-5 T10000 Models A and B Marketing Part Numbers and Descriptions 114

TABLE 5-6 LTO3 and LTO4 Marketing Part Numbers and Descriptions 115

TABLE 5-7 Drive Tray Conversion Kits 116

TABLE 5-8 T-Series Port Conversion Marketing Part Numbers and Descriptions 116

TABLE 5-9 LTO Dual Port Conversion Marketing Part Numbers and Descriptions 117

TABLE 5-10 LC-to-SC Adapter Kit 118

TABLE 5-11 Fiber Optic Cables: LC-to-LC, 50/125 Micron, Multimode Cables 118

TABLE 5-12 Fiber Optic Cables: LC-to-SC, 50/125 Micron, Single Mode Cables 119

TABLE 5-13 Fiber Optic Cables: LC-to-LC, 9/125 Micron, Single Mode Cables 119

TABLE 5-14 LC-to-SC, 9/125 Micron Cables 119

TABLE 5-15 ESCON Cables 120

TABLE 5-16 Ethernet Cables 120

TABLE A-1 Addressing Scheme 123

TABLE A-2 Special Labels 126

TABLE A-3 Module Identification Block Examples 126

xvi SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

TABLE A-4 Base and Drive Module Tape Drive Numbering Scheme—Software and Hardware 130

TABLE A-5 Reserved/System Slots 153

TABLE B-1 Partition Planning 166

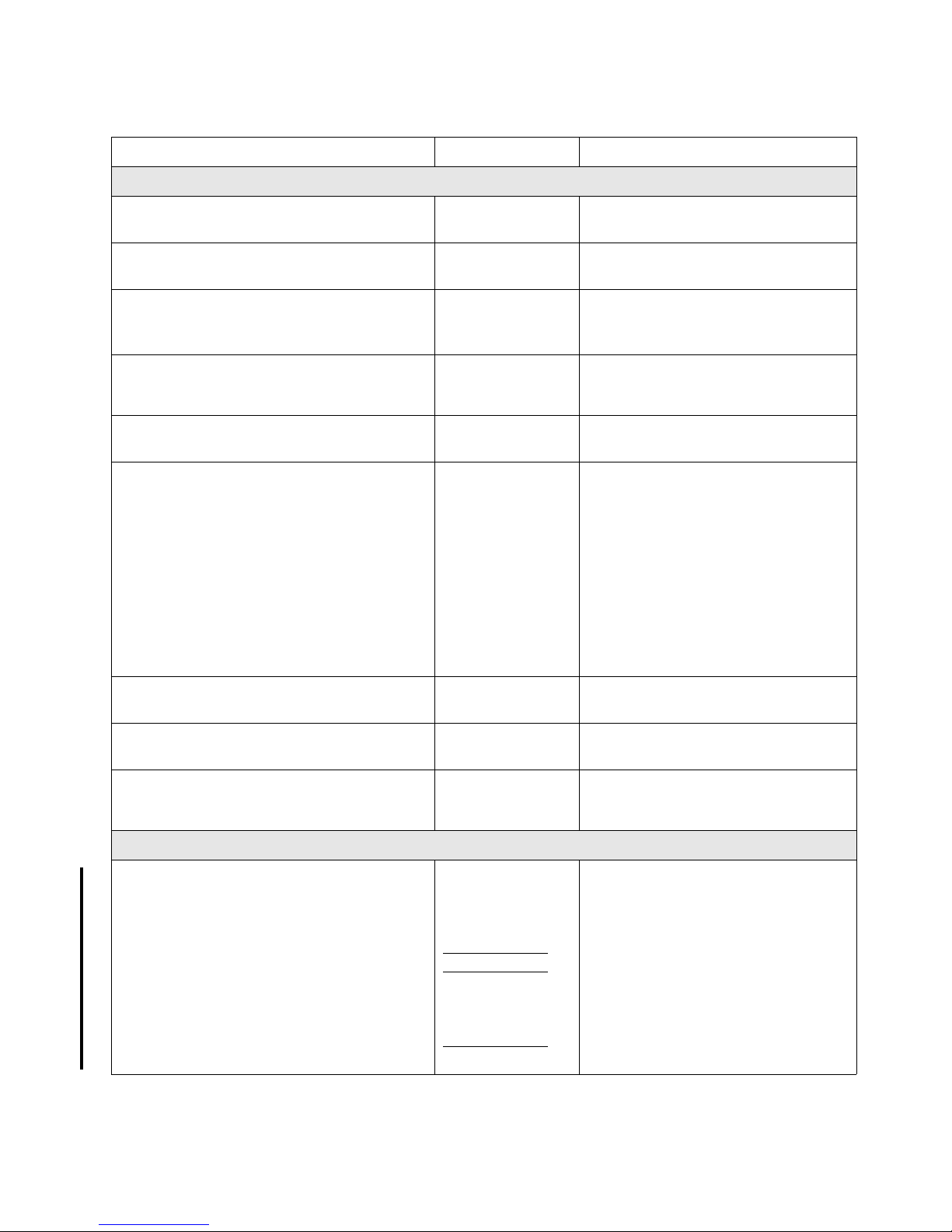

TABLE C-1 Supported Tape Drives 169

TABLE C-2 Environmental Specifications for Tape Drives 170

TABLE C-3 Tape Drive Comparison 172

TABLE C-4 T-Series Tape Drive Media Compatibilities 173

TABLE C-5 Tape Drive and Media Support 173

TABLE C-6 LTO5 Media Compatibility 174

TABLE C-7 Environmental Specifications for Media 181

316194102 • Revision: B Tables xvii

xviii SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Preface

This guide is intended for StorageTek representatives, partners, customers, and anyone

responsible for planning the installation of Oracle’s StorageTek SL3000 Modular

Library System.

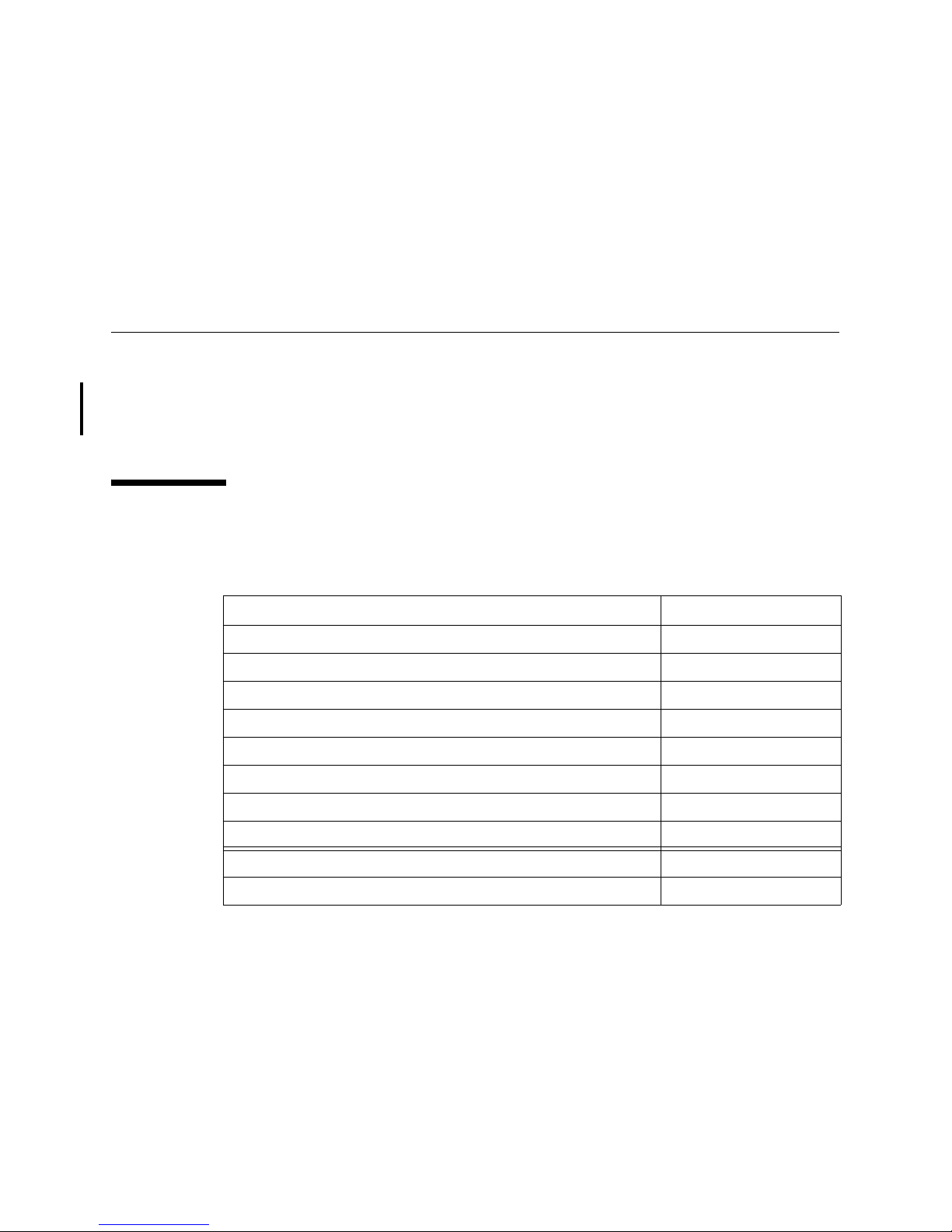

Related Information

These publications contain additional information:

Publication Description Part Number

Principles of Operation 31619400x

Installation Manual 31619420x

Service Manual 31619430x

Troubleshooting Guide 41860910x

User’s Guide 31619440x

SNMP Guide for SL3000 Libraries 31619450x

Interface Reference Manual (SCSI Specification) 31619520x

Regulatory and Safety Compliance Manual 820-5506-xx

T9x40 Tape Drive Systems Assurance Guide MT5003

T10000 Tape Drive Systems Assurance Guide TM0002

316194102 • Revision: B Preface xix

Documentation, Support, and Training

Function URL Description

Web S i te http://www.oracle.com/index.html General information and links.

Documentation

■ Customer:

■ Employee:

■ Partner:

http://docs.sun.com/

http://docs.sfbay.sun.com/

https://spe.sun.com/spx/control/Login

Search for technical documentation.

Download PDF/HTML documents.

Order printed documents.

Downloads

■ Customer:

■ Employee:

Support http://www.oracle.com/us/support/index.htm Obtain and escalate support.

Tr ai ni ng http://www.oracle.com/education/training_

Online Account https://reg.sun.com/register Register for an Online Account.

http://www.sun.com/download/index.jsp

http://dlrequest.sfbay.sun.com:88/usr/login

formats.html

This table is in transition and subject to change to links within Oracle.

Download firmware and graphical

user interfaces, patches, and features.

Access training resources.

Learn about Oracle courses.

Oracle Welcomes Your Comments

Oracle is interested in improving its documentation and welcomes your comments and

suggestions. Submit your comments by clicking the Feedback [+] link at:

http://docs.sun.com

Please include the title and part number o

SL3000 Modular Library System: Systems Assurance

f your document with your feedback:

Guide PN: 31619410x, Revision B

xx SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

CHAPTER

123 34 43

1

Introduction

The SL3000 is the latest addition to Oracle’s StorageTek modular library family, which

includes the SL500 and SL8500 modular library systems.

This chapter introduces you to the SL3000 library

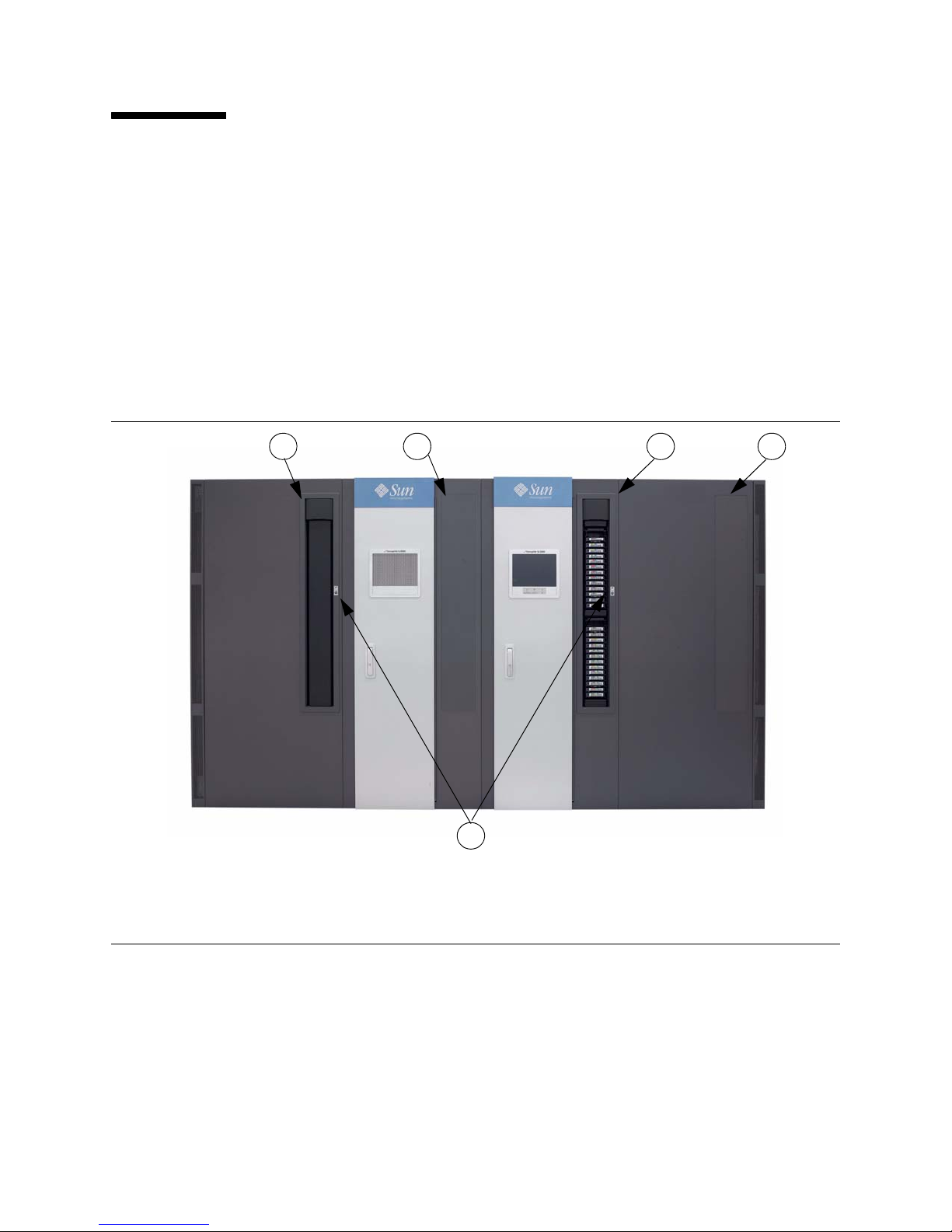

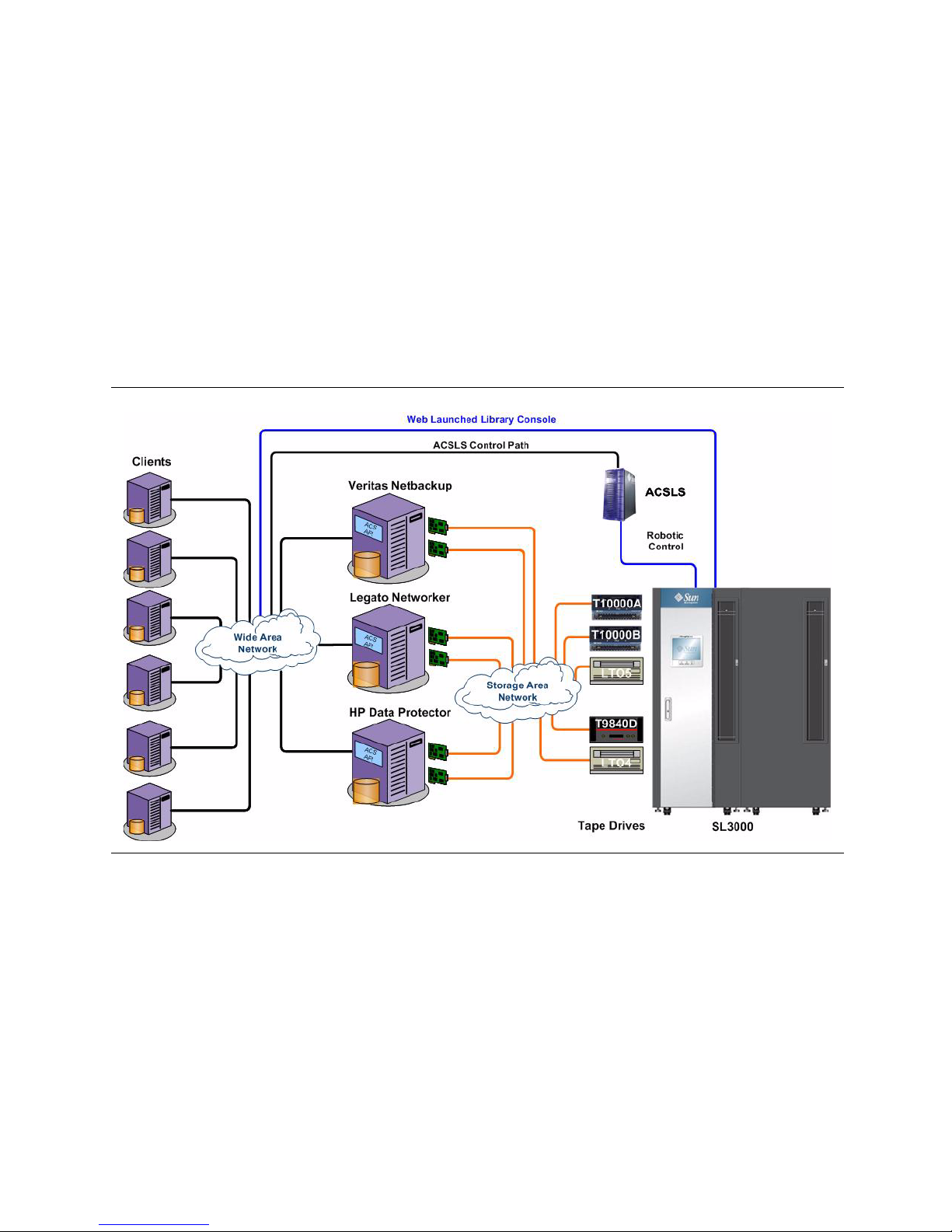

FIGURE 1-1 SL3000 Modular Library System—Configu

1. Base Module—Base

3. Cartr

(required—one per library)

2. Drive Expansion Module—DEM

ptional, must be installed to the left of the

(o

4. Access Exp

base module—one per library)

, components, and configurations.

ration Example

idge Expansion Module—CEM

(maximum of eight per library)

ansion Module—AEM

(maximum of two per library—required for the

Dual T

allBot feature)

This library offers customers the benefits of:

■ Storage capacity from 200 to 5,925 slots

■ Performance from 1 to 56 tape drives

■ Bulk cartridge loading capabilities from 234 to 468 cartridges (one or two AEMs)

■ Heterogeneous attachments using standard interfaces

■ Multiple library management software options and programs

316194102 • Revision: B 1

Modular Design

Modular Design

The SL3000 library maintains the fundamentals of a modular design that allows

customers the ability to meet the demands of rapidly growing and constantly

changing environments.

The SL3000 library was designed to:

■ Address medium to large open systems and entry-level mainframe markets.

■ Occupy a standard data center footprint with measurements of approximately:

Height

Depth

Length

198 cm (78 in.)

124 cm (49 in.)

From: 91.5 cm (36 in.) a single Bas

To: 782.4 cm (308 in.) Base, DEM, 8 CEMs, and covers; [7.8 m

e module; [0.9 m (3 ft)]

(25.7 ft)]

To: 965.2 cm (380 in.) Base, DEM, 8 CEMs, 2 AEMs, covers; [9.65

m (31.7 ft)]

A maximum configuration consists of 12 modules.

■ 1 Base module

■ 1 Drive expansion module

■ 8 Cartridge expansion modules

■ 2 Access expansion modules

See Chapter 3, “Site Planning” for specific details.

Modules

There are currently five types of modules in an SL3000 library:

■ Base module (Base) one, required

■ Drive expansion module (DEM)—maximum of one—on the left side of a base

module only

■ Cartridge expansion module (CEM)—maximum of eight (without conversion to

parking expansion modules)—

■ Parking expansion module (PEM)

robotics feature—

■ Access expansion module (AEM)

■ Single AEM provides bulk loading capabilities only.

■ Two AEMs provide bulk loading and a parking zone for the dual robotics feature.

■ Two AEMs are required for the dual robotics feature.

left and right ends of the library

left or right side

1

—must order two, one on each end for the dual

1

—one or two, on the ends of the library

1. You need either two parking expansion or two access expansion modules to support the

dual robotics feature. You can not mix and match PEMs with AEMs.

2 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

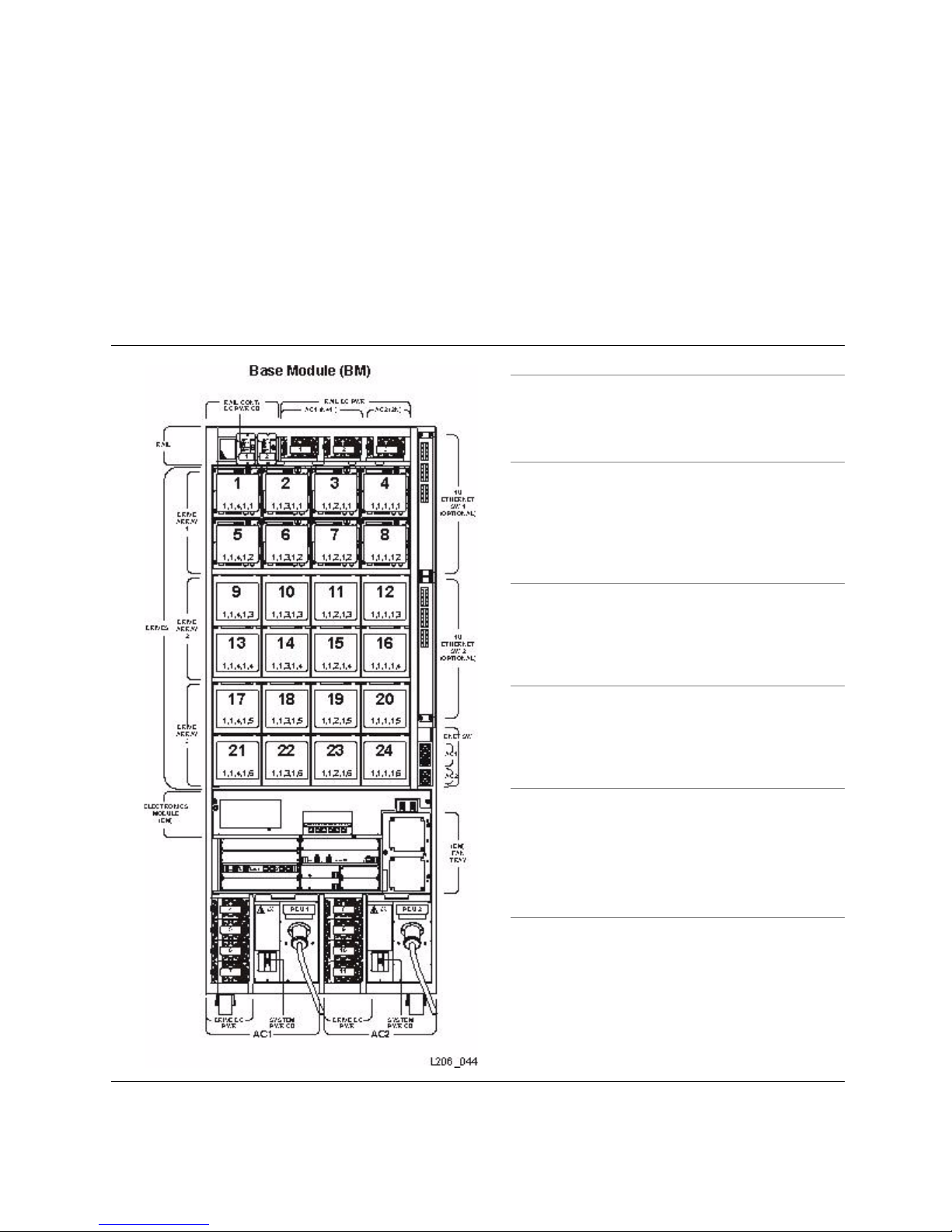

FIGURE 1-2 Bas

Modular Design

Base Module

FIGURE 1-2 shows an example of the Base Module. This module provides the entry

level offering, which consists of a single frame and

other modules in the library. This module includes the power supplies, robotic units,

electronics control module, cartridge access port, storage slots, tape drives, and

operator controls.

One base module—

and only one—is required for every library installation.

On the front of this module is:

■ A single, 26 cartridge–dual magazine–cartridge access port (CAP).

■ A service door for library access.

■ A front panel with three LEDs: Library Active, Service Required, and Wait.

■ Plus an optional feature for a touch screen operator panel or perforated window.

e Module—Front View

Configurations

8 drive slots, CAP, perforated window (standard configuration)

Optional Configurations

16 drive slots, CAP, perforated window

24 drive slots, CAP, perforated window

8 drive slots, CAP, and Op

16 drive slots, CAP, and Operator panel or window

24 drive slots, CAP, and Operator panel or window

centralizes the infrastructure for all

erator panel or window

1.

Dimensions Measurement

Height 197 cm (77.625 in.) to

200 cm (78.63 in.) fully adjusted

Width 76.78 cm (30.23 in.) without covers

91.5 cm (36 in.) with cover

s

Depth 124 cm (49 in.)

Wei gh t Frame only: 361 kg (790 lb)

Service clearance

Front: 46 cm (18 in.) [allow 56 cm (22 in.)]

Rear: 81 cm (32 in.)

Both doors open

Side covers Width: 7.4 cm (2.9 in

Total: 262 cm (103 inches)

.) per side cover

Cooling clearance: 5 cm (2 in.)

Install: 91 cm (36 in.)

1.

Perforated windows are the standard offering. Arrays may displace an operator panel or window.

2.

Recommended cooling clearance.

3.

Required to install or remove the sides covers; they swing out and lift off of brackets.

3.

The Base module can contain up to 24 tape drives in any combination that the library

supports—see “Tape Drives” on page 24 for a list and description of these drives.

Physical capacity varies depend

ing on the configuration—see TABLE 1-1 on page 12.

2.

316194102 • Revision: B Chapter 1 Introduction 3

Modular Design

FIGURE 1-3 Bas

The minimum configuration includes one drive bay that can contain from 1 to 8 tape

drives. Two additional drive bays can be added to accommodate either 8 or 16 more

drives for a total of 24 drives.

Note – A

dding a second drive bay will displace from 55 to 66 cartridge slots; adding

a third drive bay will displace from 60 to 72 slots.

The rear door of the Base module allows access to the:

■ Electronics control module (ECM)

■ Power distribution units (PDUs) and DC power supplies (DCPS)

■ Tape d riv e s

■ Two 1-unit rack spaces (1 unit = 44.5 mm [1.75 in.]) not for customer use

e Module—Rear View Drawing

Description

Robotic rail power and HBS cards

■ DCPS 1 and 2 or 3

First drive array (top)

The first drive bay is standard.

Note:

Drive arrays are adde

d from the top ➪

down.

Second drive array (center)

Adding a second drive array displaces

55/66 data cartridge slots

Third drive array (bottom)

Adding a third drive array displaces

60/72 data cartridge slots

Electronics control module:

■ HBCR and HBT cards

■ MPU2 Fibre Channel card (not shown)

■ Two cPCI power supplies

■ Two cooling fans

■ Two p o wer s w itch e s (N+ 1 and 2 N )

Power distribution units (up to 2)

■ PDU 1 and PDU 2

4 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Drive DC power supplies (up to 8)

■ DCPS 4 through 11

Drive Expansion Module

FIGURE 1-4 shows an example of the Drive Expansion Module (DEM). This module is

attached adjacent to the Base module on the left sid

expansion of tape drives and provides additional data cartridge capacity.

One drive expansion module—an

Its position is immediately to the left of the

On the front of this module is space for:

■ A service door for library access (standard)

■ A front panel with three LEDs: Library Active, Service Required, and Wait

■ A single, 26 cartridge-dual magazine, cartridge access port optional feature

■ Touch screen operator panel optional feature if not in the base (or window)

FIGURE 1-4 Drive E

Modular Design

e only. The DEM allows further

d only one—can be included in an installation.

centerline (left edge of the base module).

xpansion Module with a Base Module

Configurations

8 drive slots, perforated window

16 drive slots, perforated window

24 drive slots, perforated window

32 drive slots, perforated window

8 drive slots, CAP, perforated window

16 drive slots, CAP, perforated window

24 drive slots, CAP, perforated window

32 drive slots, CAP, perforated window

8 drive slots, CAP, and Ope

rator panel/Window/Arrays

1.

16 drive slots, CAP, and Operator panel/Window/Arrays

24 drive slots, CAP, and Oper

32 drive slots, CAP, and Oper

Dimensions

2

Measurement

ator panel/Window/Arrays

ator panel/Window/Arrays

Height 197 cm (77.625 in.) to

200 cm (78.63 in.)

Width

Module-only:

Base and DEM:

76.78 cm (30.23 in.)

168.3 cm (66.26 in.) with covers

Depth 124 cm (49 in.)

Wei gh t Frame only: 265 kg (584 lb)

Service clearance

Front: 46 cm (18 in.)

Rear: 81 cm (32 in.)

Both doors open

Side covers

3, 4, 5

262 cm (103 inches)

Cooling clearance: 5 cm (2 in.)

Install: 91 cm (36 in.)

1. Perforated windows are the standard offering. Arrays may displace an operator panel or window.

2. The dimensions of the DEM are the same as the Base module.

3. When installing additional modules, the covers are removed from the Base and replaced on the ends of

the last module in the string.

4. Required to install or remove the sides covers; they swing out and lift off of brackets.

5. This is the r

316194102 • Revision: B Chapter 1 Introduction 5

ecommended cooling clearance.

Modular Design

The DEM comes with slots to support up to 8 tape drives (standard).

Optional features allow the DEM to increase drive capacity from 16, to 24, and 32

additional tape drive slots. These features allow expansion up to a total of 56 tape

drives per library.

There is an additional power system integral to the DEM to support the additional tape

drives and two 1-unit rack spaces for vertically mounting auxiliary equipment, such as

Ethernet switches (not for customer use).

FIGURE 1-5 Rear View of the Drive Expansion Module

Description

First drive array (top)

The first drive bay is standard.

Note: Drive arrays are added from

the top ➪ down.

Second drive array

Adding a second drive array

displaces 55/66 slots

Third drive array

Adding a third drive array

displaces 60/72 slots

Fourth drive array

Adding a fourth drive array displaces

65/78 slots or all the slots on the rear wall

Power distribution units (up to 2)

■ PDU 3 and PDU 4

Drive DC power supplies (up to 8)

■ DCPS 15 through 22

Note: Physical capacity varies depending on the configuration—see TABLE 1-1 on page 12.

6 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Modular Design

Cartridge Expansion Module

FIGURE 1-6 is the Cartridge Expansion Module (CEM) and provides additional

cartridge slot capacity and growth—no tape d

rives are present within this module.

A maximum of eight (8) CEMs are supported on a single library

module (required) and optional drive expansion module if installed.

Important:

■ As a best practice, the initial CEM should be installed to the right of a base module,

■ A balance of CEMs—to the left and to the right—provides for the most efficient

■ When using redundant robotic units, the addition of parking expansion modules in

Each CEM adds approximately 438 to 620 data cartridge slots to the library depending

on

FIGURE 1-6 Cartr

in addition to the base

then a second to the left of the drive expansion module. Then again to the right, and

the last one to the left. This method provides the best usage of the cartridge slots.

The exception is if an extra CAP is installed and physical capacity i

s less important

than having redundant CAPs. If redundant CAPs are required, install the CEM with

a CAP on the left. This assumes no DEM is installed. If one is installed, then place

the CEM on the right and install a CAP on the DEM.

operation. Cartridge expansion modules can be installed with up to 4 to the right

and up to 4 to the left. However, this increase in the amount of robotic travel results

in a decrease of overall library performance.

place of the CEMs or the use of access expansion modules is required at both ends of

the library.

the direction of growth (left or right) and options (CAP or no CAP).

idge Expansion Module with Base Module

Configuration (next to Base with 24 drive slots)

CEM (expanded left)

CEM with optional CAP (left)

CEM (expanded right)

CEM with optional CAP (right)

Dimensions Measurement

Height 197 cm (77.625 in.) to

200 cm (78.63 in.) fully adjusted

Width 76.76 cm (30.22 in.)

84.12 cm (33.12 in.) with cover

Depth 77.47 cm (30.5 in.)

Weight Frame only: 175 kg (385 lb)

Side covers

Side clearance

Service clearance

1

Cooling clearance: 5 cm (2 in.)

2

Install: 91 cm (36 in.)

None required

(Front and Rear)

Base Module | CEM

1. When installing additional modules, the covers are removed from existing modules and replaced on the ends

of the last module in the string.

2. Required to install or remove the sides covers; they swing out and lift off of brackets.

316194102 • Revision: B Chapter 1 Introduction 7

Modular Design

Parking Expansion Module

FIGURE 1-7 is the Parking Expansion Module (PEM). This module is the same as a

cartridge expansion module except with 6 columns of arrays (3 on the front wall and

3

on the rear wall) that are inaccessible. This allows the library to park a defective

robot without blocking access to cartridges for the other operational robot.

Notes:

1. Parking expansion modules must be installed as the last module in the string; on

both right- and left-sides. This allows a defective robot to be parked out of the way

of the operational robot, allowing operations to continue.

2. A PEM is a converted CEM. Conversion is done by changing an internal module ID

label that is shipped with the redundant TallBot feature.

3. The arrays do not need to be removed; this allows the customer to restore this

module to a CEM; however, any data cartridges in those arrays will be

4. Customers can order an optional CAP with a left expansion module; however, a

CAP on the right PEM is inaccessible.

FIGURE 1-7 Parking Expansion Module with Base Module

inaccessible.

PEM Next module (CEM/DEM/Base)

Parking Cartridge

Area Slots

Configuration

PEM (expanded left) 308 slots

PEM (expanded right) 312 slots

620 slots total

Always installed in pairs for redundant robotics.

Dimensions

1

Measurement

Height: 197 cm (77.625 in.) to

200 cm (78.63 in.) fully adjusted

Width: 76.76 cm (30.22 in.)

84.12 cm (33.12 in.) with cover

Depth: 77.47 cm (30.5 in.)

Weight: Frame only: 103.4 kg (277 lb)

Side covers:

Side clearance:

2

Cooling clearance: 5 cm (2 in.)

3

Install: 91 cm (36 in.)

Service clearance: None

Notes:

1. The dimensions of the PEM are the same as the cartridge expansion module.

2. When installing additional modules, the covers are removed from existing modules and replaced on the ends of

the last module in the string. PEMs must be the last modules in the string.

3. Required to install or remove the sides covers; they swing out and lift off of brackets.

8 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

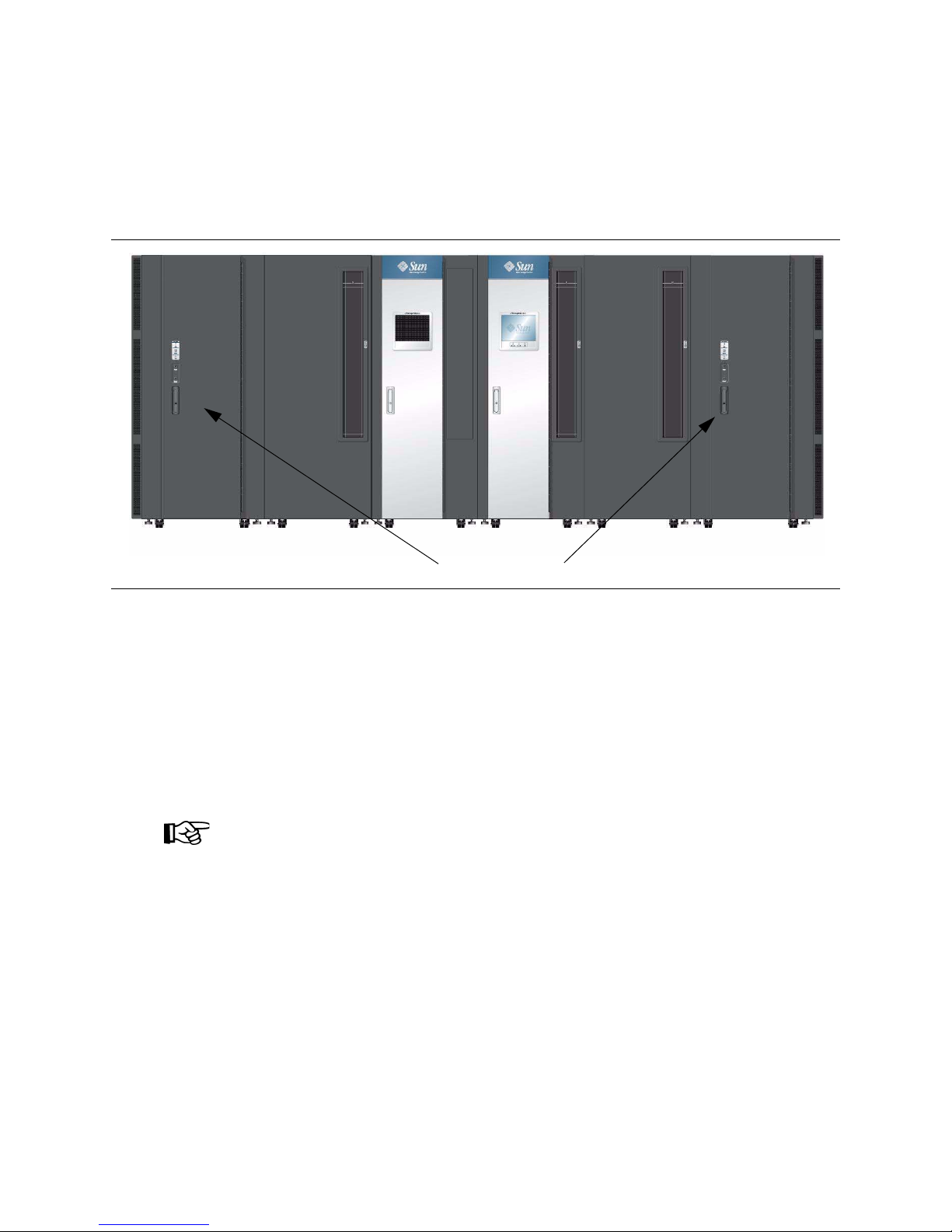

Access Expansion Module

FIGURE 1-8 shows the optional Access Expansion Module (AEM), which provides:

■ Bulk loading and unloading of up to 234 cartridges at a time per module.

■ Non-disruptive robot maintenance through the use of a safety door (or “garage”

door), which sections off a defective robot from the other library modules.

A service representative can safely access the disabled robot through the AEM access

door while the library remains online. If redundant robots are installed, the library

can continue normal operations through the remaining functional robot.

The library can have either one or two AEMs.

1. With one AEM, installed on either end of the string (recommend the left side*), the

library supports bulk load and unload features only.

* Note: Installing the AEM on the left side gains an additional 104 cartridge slots

from the previous module.

2. With two AEMs, one installed on each end of the library string, the library supports

both bulk load/unload, and the non-disruptive, redundant, robotic features.

Note – AEMs and PEMs cannot be installed in the same library.

FIGURE 1-8 Access Expansion Module—Front View

Modular Design

Configurations

Expanded left 234 slots

Plus 104 slots from the

previous module

Expanded right 234 slots

Single AEM = Bulk load capabilities only

Dual AEMs = Bulk load and redundant robotics feature.

Dimensions Measurement

Height: 197 cm (77.625 in.) to

200 cm (78.63 in.) fully adjusted

Width: 91.5 cm (36.0 in.) without covers

99 cm (39 in.) with covers

Depth: 77.47 cm (30.5 in.)

Weight: Frame only: 204.2 kg (450 lb)

Side covers

Side clearance

Notes:

1. When installing additional modules, the covers are removed from

existing modules and replaced on the ends of the last module in

the string.

2. Required to install or remove the sides covers; they swing out and

lift off of brackets.

1

Cooling clearance: 5 cm (2 in.)

2

Install: 91 cm (36 in.)

316194102 • Revision: B Chapter 1 Introduction 9

Addressing

Addressing

The modules of the library consist of walls, columns, and rows that house cartridges,

tape drives, cartridge access ports, and robotic units.

The SL3000 uses five parameters separated by comma's to indicate locations or

esses in the library. These parameters are < L, R, C, S, W >, which is:

addr

■ Library (L) = Library number

■ Rail (R) = Rail

■ Column (C) = Horizontal location in the library

■ Side (S) = Walls

■ Row (W) = Vertical location in the library

Library and Rail

The library and rail parameters do not apply to this library and are constants.

These parameters will always be 1 (one).

Columns

There are two types of columns that provide the

horizontal locations for components;

such as data cartridges, tape drives, and cartridge access ports:

■ Positive numbered are to the right of the centerline*

■ Negative numbered are to the left of the centerline*

Note – Ce

nterline* is the left-edge of the Base module.

Columns are numbered from left to right; tape drive arrays have 4 columns per

dule; media or data cartridge arrays have 6 columns per module.

mo

Side

There are two types of walls in the SL3000 library:

■ Front wall parameter is 1

■ Rear wall parameter is 2

Rows

Rows provide the

down from 1 (top) to 52 (bottom).

See Appendix A, “Addressing” for specifics about the various addressing schemes

used with the SL3000 Library.

vertical locations for components and are numbered from the top

10 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

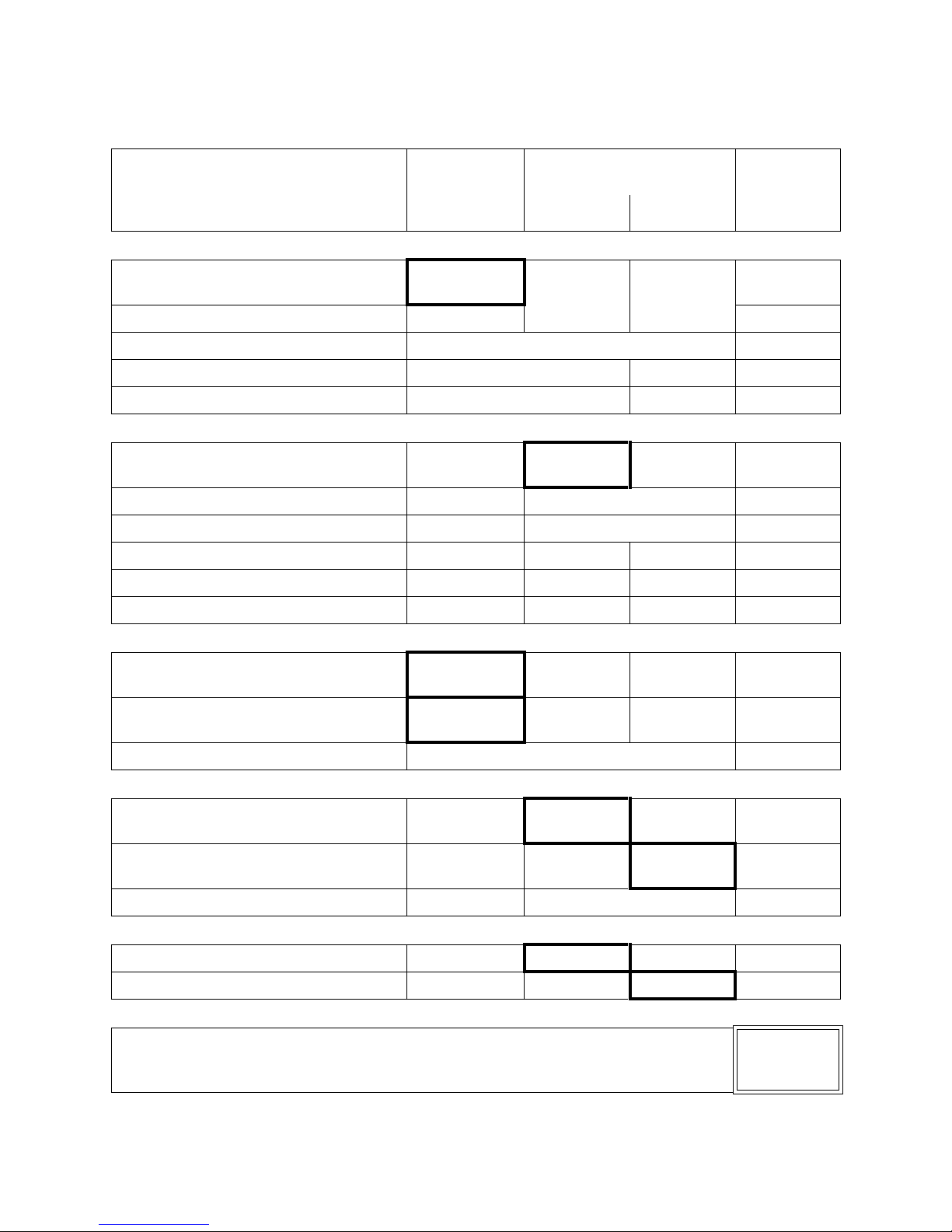

Physical Capacities

Physical Capacities

The SL3000 is scalable, with physical storage capacities from 200 to 5,925 storage slots.

TABLE 1-1 on page 12 provides detailed physical capacities for each module type.

To calculate the total accessible physical storage slots for a configuration, start with the

standard configuration slot count, outlined with a heavy border, and then make the

appropriate adjustments for options and positioning.

Following are some examples:

■ Base Module with operator’s panel, a module installed on the right, and three total

drive arrays:

320 + 0 + 13 – 55 – 60 = 218

■ DEM, a module installed on the left, window arrays, a CAP, and four drive arrays:

410 + 88 + 23 – 77 – 66 – 72 – 78 = 228

■ CEM installed to the left of CenterLine, a module installed on the left, and a CAP:

516 + 104 – 78 = 542

■ PEMs (always installed in pairs), one with a CAP, one without:

308 + 312 – 78 = 542

■ AEMs are considered CAPs and do not include any capacity for the library.

To calculate the final accessible storage capacity, select the slot counts for each module,

then add them together to reach the total slot count for the library with the

configuration selected.

In addition, the SL3000 features Capacity on Demand. This feature allows you to:

■ Pay for only the capacity you actually use, then

■ Expand capacity—with minimal disruption—when you need it.

See “Capacity on Demand” on page 160 for details about installing and managing

library storage capacity.

316194102 • Revision: B Chapter 1 Introduction 11

Physical Capacities

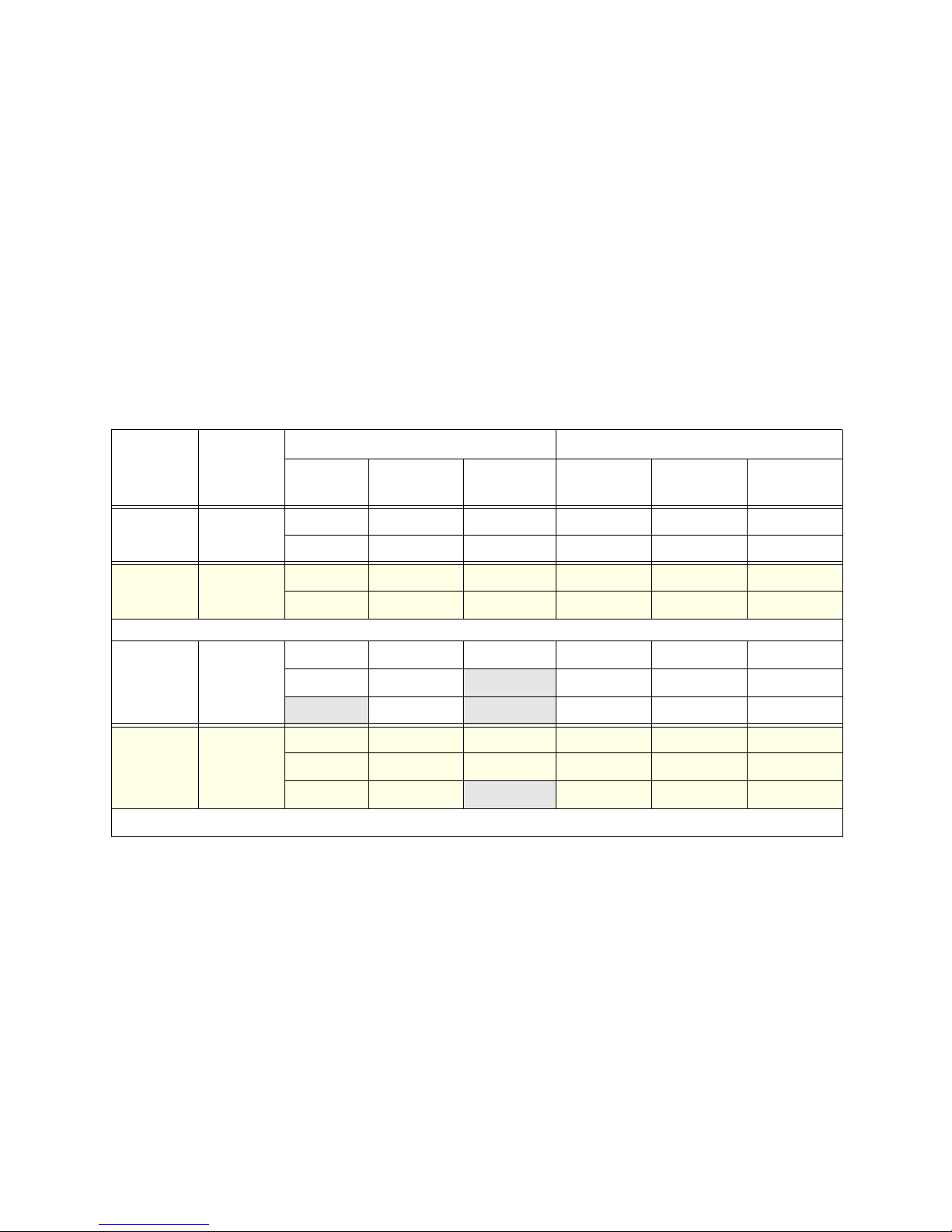

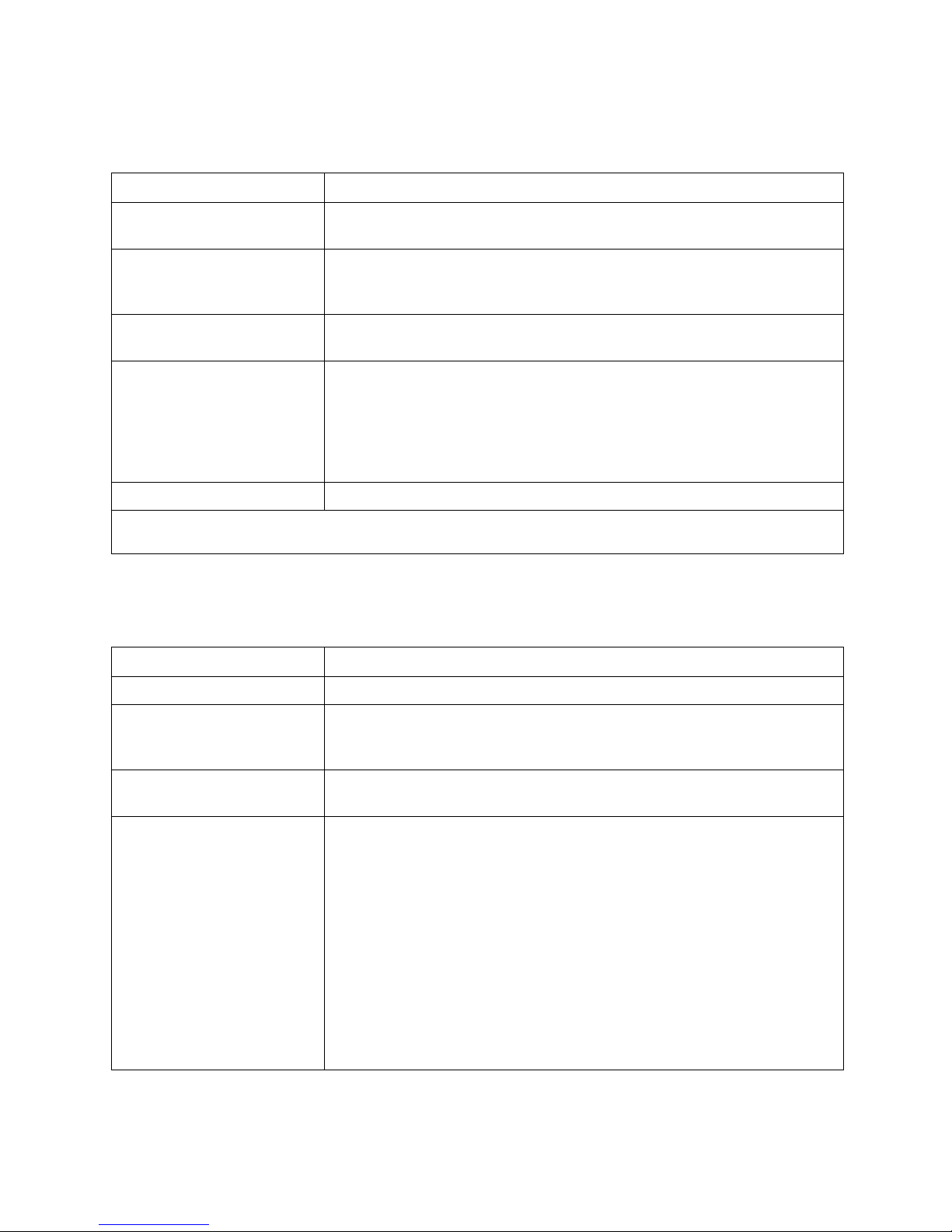

TABLE 1-1 Accessible Physical Slot Count Per Module

Standalone

or

Adjacent Module

Installed on the:

Position-

Module Options Right Left Total Count

Independent

Base Module

Standard (with viewing window),

standal

one

320

+13 +88

With operator’s panel +0

With window storage arrays +23

With second drive array -55 -66

With third drive array -60 -72

Drive Expansion Module (DEM)

Standard (with viewing window

— 410 +88

and no CAP)

With window storage arrays — +23

With CAP — -77

With second drive array — -55 -66

With third drive array — -60 -72

With fourth drive array — -65 -78

Cartridge Expansion Module (CEM)

Standard (no CAP), to the left of

C

enterLine

Standard (no CAP), to the right of

C

enterLine

516 +0 +104

620 +0 +0

With CAP -78

Parking Expansion Module (PEM)

Standard (no CAP), to the left of

C

enterLine

Standard (no CAP), to the right of

enterLine

C

— 308

— 312

With CAP — -78

Access Expansion Modu

le (AEM)

Standard to the left of CenterLine — 0 +104

Standard to the right of CenterLine — 0

Total accessible storage slot count

12 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Power Options

Power Options

SL3000 libraries require that the customer select one of the following, single phase,

AC

power options for the Base and Drive Expansion modules, these are:

■ 120 VAC, 50/60 Hz, at 20 Amps

(range: 100–127 VAC, 47–63 Hz, 16 Amps)

limited support for T9840 and T10000 drives; no redundant TallBot support

■ 240 VAC, 50/60 Hz, at 30 Amps

(range: 200–240 VAC, 47–63 Hz, 24 Amps)—full featured

AC Power Configurations

SL3000 libraries have two power configurations:

■ N+1, offering DC power redundancy only.

■ 2N, offering both AC and DC power redundancy.

Power Redundancy

The SL3000 provides full redundancy for tape drives, robotics units, and electronics.

The following redundancy options are available:

■ N+1—One AC PDU, with one extra DC power supply for DC power redundancy.

This is the standard power configuration for the SL3000. This configuration requires

at least a 20

■ 2N—Two PDUs for AC redundancy; each PDU has a set of DC power supplies

(N

DC power supplies). This configuration requires a second, separate customer

Amp circuit breaker at the customer’s branch service panel.

power source.

■ 2N+1—Two PDUs for AC redundancy; each PDU has extra DC power supplies for

N+1 redundancy for each PDU. The second PDU does not have N+1 for the TallBot.

N+1 Power Configuration—Standard

N+1 is the standard power configuration for the libraries and contains one system

power distribution unit (PDU).

Note – The N+1 power configuration offers DC power redundancy only.

The N+1 system PDU connects to the customer’s branch circuit and requires at least a

20 Amp circuit breaker at the customer’s branch service panel.

2N Power Configuration—Optional

The optional 2N power configuration contains two system power distribution units

(PDU_1 and PDU_2) and requires a second—separate—customer power source.

Note – The 2N power configuration offers both AC and DC power redundancy.

316194102 • Revision: B Chapter 1 Introduction 13

Power Options

AC Power Cables

TABLE 1-2 lists the cables available from StorageTek or qualified electricians, which

must be or

Keep in mind that you must order:

■ N+1: One power cord for each, the Base module and DEM if installed.

■ 2N: Two power cords for each, the Base module and DEM if installed.

dered for the appropriate power configuration.

TABLE 1-2 P

Power Source Description

120 VAC/ 20A US / Japan 20 A L5-20P L5-20R

240 VAC / 30A US 30 A L6-30P L6-30R

240 VAC / 30A International 30 A 330P6W L6-30R

ower Cable Part Numbers and Descriptions

Circuit

Breaker

Connector Type

Wall Library Item X-Option

Robotic DC Power Configurations

Each Base module ships with two 1200 Watt—load sharing—DC power supplies for the

robotic units; the location of these supplies determines if it is an N+1 or 2N

configuration.

See FIGURE 1-3 on page 4 for the location of these power supp

Base Module).

Electronic Control Module DC Power Configurations

Power Cord

Length/Type

3.7 m (12 ft)

12 AWG

3.7 m (12 ft)

12

AWG

4 m (13 ft)

HAR

Part Numbers

419813801

419813701

419813601

XSL3000-

PC20110-Z

XSL3000-

PC30220-Z

XSL3000-

0220Z

IPC3

lies (on the top of the

Dual 200 Watt cPCI power supplies distribute power to the electronics control module,

which are located below the HBT card, supporting either an N+1 or 2N configuration.

■ For an N+1 configuration, two cPCI power supplies are installed on the left.

■ For a 2N configuration, one cPCI power supply is installed on each side.

■ For a 2N+1 configuration, two cPCI power supplies are installed on each side.

14 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Power Options

Single Drive Type DC Power Configurations

This library uses 1200 Watt—load sharing—DC power supplies (DCPS) for distribution

of +48 VDC power for the tape drives acr

oss a power grid.

Each Base module and DEM ship with two (2

number of tape drives ordered, additional power supplies may be required.

To determine the number of supplies required, you must determine:

■ Power configuration (120 VAC or 240 VAC)

■ Tape drive type (T10000, T9840, or LTO)

■ Number of drives

See TA BLE 1-3 on page 15 to help determine the number of supplies

■ This table shows only the installation of a single drive type.

■ See Mixed Drive Types on page 16 when mixing tape drives in the same module.

TABLE 1-3 T

Module

Ty

pe

ape Drive DC Power Supply Requirements

PDU

Typ e

Base 120 VAC

DEM 120 VAC

) DC power supplies. Depending on the

required.

Maximum Number of Drive Types Power Configuration

N+1 & 2N

T10000 T9840 LTO N+1 2N

Total

1 – 8 1 – 7 1 – 16 1 + 1 = 2 1 + 1 = 2 2 + 2 = 4

9 – 13 8 – 12 17 – 24 2 + 1 = 3 2 + 2 = 4

3 + 3 = 6

1 – 8 1 – 7 1 – 16 1 + 1 = 2 1 + 1 = 2 2 + 2 = 4

9 – 16 8 – 14 17 – 32 2 + 1 = 3 2 + 2 = 4 3 + 3 = 6

Base 240 VAC

DEM 240 VAC

Note: The bas

e and drive expansion modules each come with 2 DC power supplies as standard.

1 – 12 1 – 1 1 – 24 1 + 1 = 2 1 + 1 = 2 2 + 2 = 4

13 – 24

12 – 22 N/A 2 + 1 = 3 2 + 2 = 4 3 + 3 = 6

N/A 23 – 24 N/A 3 + 1 = 4 3 + 3 = 6 4 + 4 = 8

1 – 12 1 – 11 1 – 25 1 + 1 = 2 1 + 1 = 2 2 + 2 = 4

13 – 24 12 – 22 26 – 32 2 + 1 = 3 2 + 2 = 4 3 + 3 = 6

25 – 32 23 – 32 N/A 3 + 1 = 4 3 + 3 = 6 4 + 4 = 8

316194102 • Revision: B Chapter 1 Introduction 15

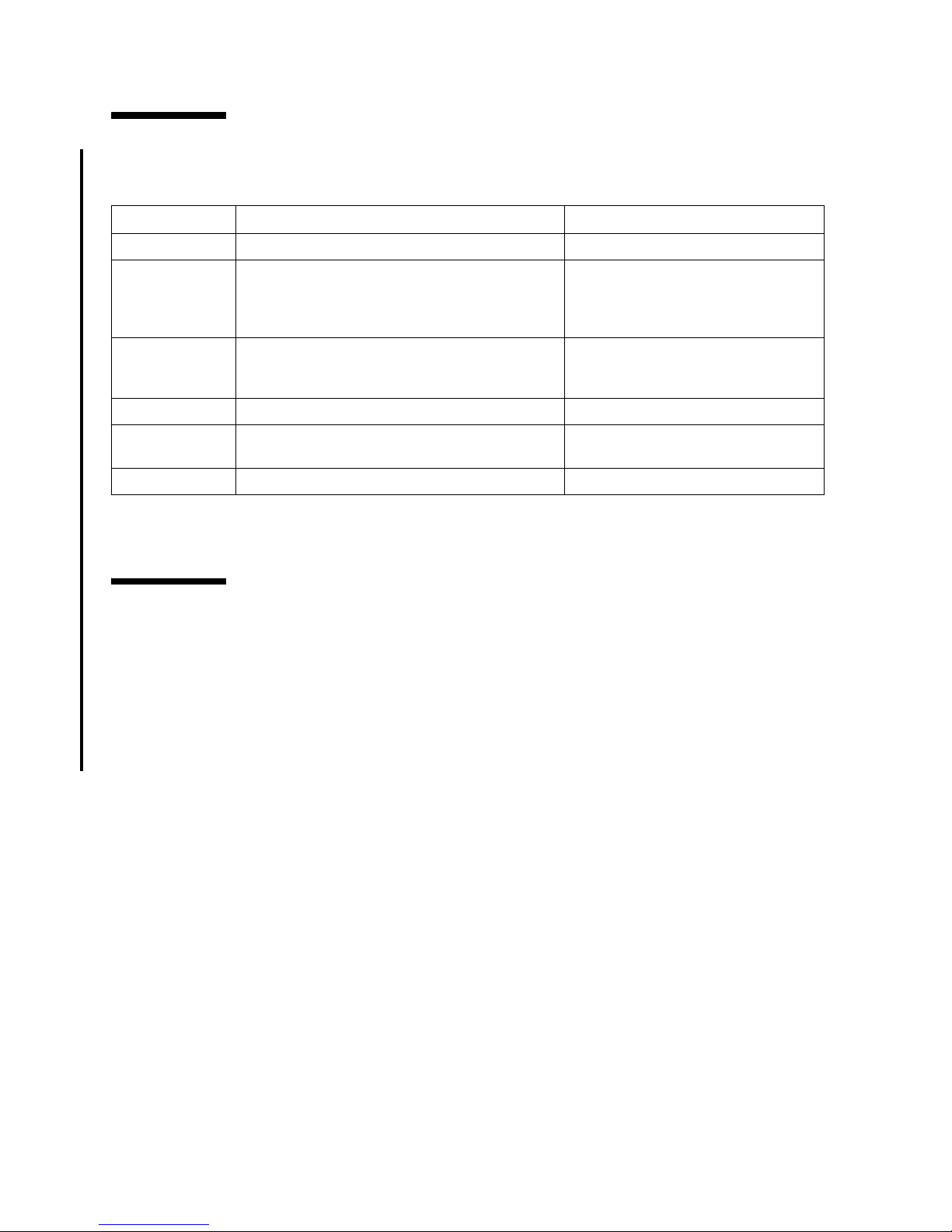

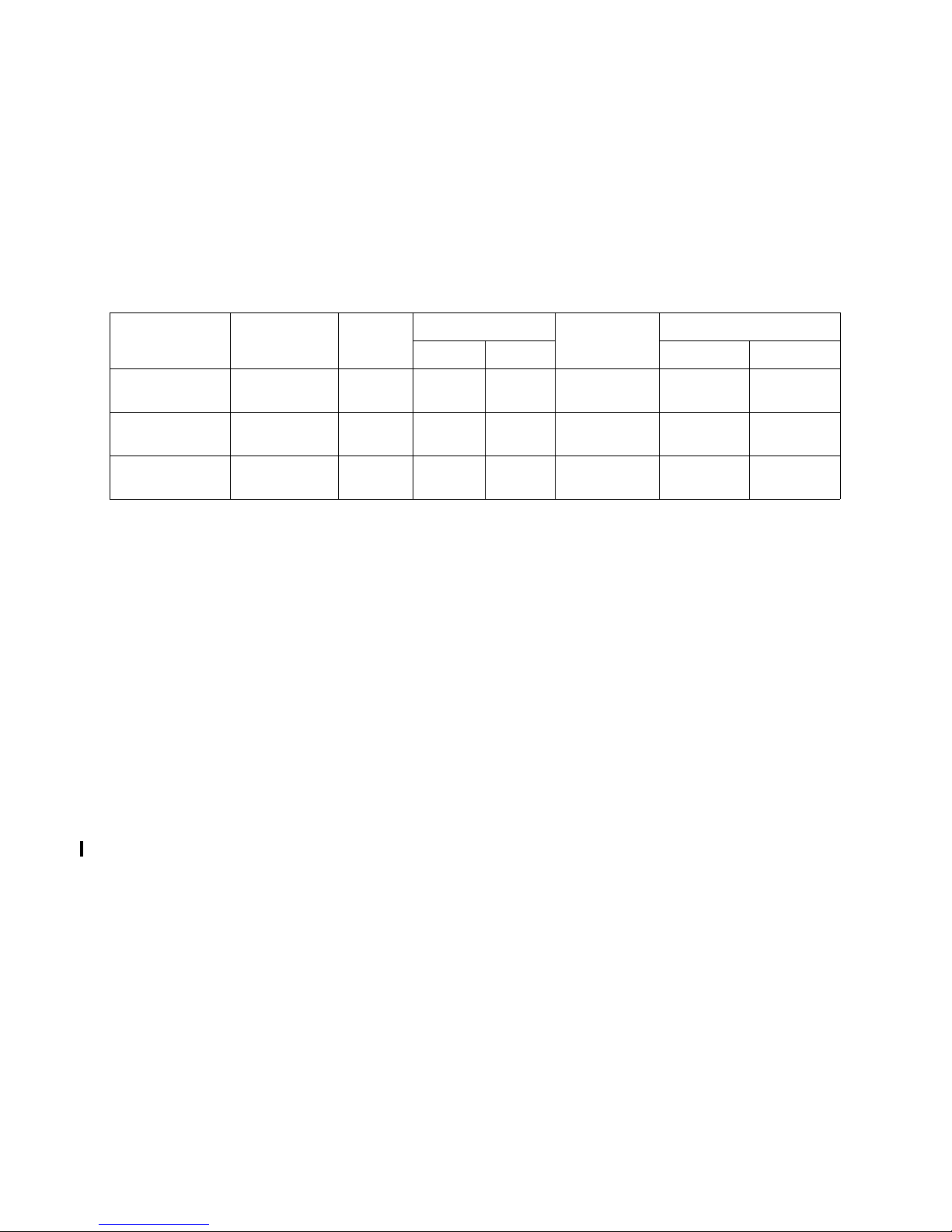

Power Options

Mixed Drive Type DC Power Configurations

When mixing tape drive types in a library, you need to calculate the total

Wat t consumption for the selected

1. Determine the number of tape drives for each drive type.

drives. To do this:

2. Multiply that by the Watts per

drive for each drive type TABLE 1-4.

3. Add the total Watts for all drive types.

4. Use TA BLE 1-5 to compare Watts to PDU type.

5. Use TA BLE 1-6 to determine the number of DC power supplies needed.

TABLE 1-4 Wa tts P er Dr i ve

Watts Used by

Drive Type

Each Drive

T9840 123.9 7 11

T10000 115.2 8 12

LTO 56.9 16 25

Drives supported by a Power Supply

120 VAC 240 VAC

TABLE 1-5 Available Watts Per Module

Watt Limitation per Supply

120 VAC 240 VAC

Module Type PDU Type

120 VAC 1553 951 W 1426 W

Base

240 VAC 3234

120 VAC 1868

DEM

240 VAC 4313

Watts Available for

Tape Drives

TABLE 1-6 DC Power Supplies Per Module

Power Configuration

PDU Type Total Watts

1 - 951 1 + 1 = 2 1 + 1 = 2 2 + 2 = 4

120 VAC

952 - 1,868 2 + 1 = 3 2 + 2 = 4 3 + 3 = 6

1 - 1,426 1 + 1 = 2 1 + 1 = 2 2 + 2 = 4

240 VAC

1,427 - 2,852 2 + 1 = 3 2 + 2 = 4 3 + 3 = 6

2,853 - 4,278 3 + 1 = 4 3 + 3 = 6 4 + 4 = 8

Add for

T

otal Watts

Per Type

Drive

Typ e

# of

Drives

Multiplied By

Watts

TABLE 1-4)

(

16 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

N+1 2N N+1 & 2N Total

Power Configuration

Total Wa t t s

TABLE 1-6)

(

Option

(N

+1 or 2N)

PDU Type

TABLE 1-5)

(

DCPS

(TABLE 1-6)

TABLE 1-7 provides an example about how to calculate mixed drive types in both the

Base module and drive e

TABLE 1-7 Mixed

Power Options

xpansion module:

Drive Type Power Configuration—Calculation Example

Add for

# of

Drive Type

T10000 6 115.2 691.2 N+1 120 VAC not

T9840 6 123.9 743.4

Base

LTO 8 56.9 455.2 1889.8 N+1 240 VAC 2 + 1 = 3

T10000 4 115.2 460.8 N+1 120 VAC 2 + 1 = 3

T9840 4 123.9 495.6 1184 2N 120 VAC 2 + 2 = 4

DEM

LTO 4 56.9 227.6 N+1 240 VAC 2 + 1 = 3

Driv

Multiplied By

TABLE 1-4)

es

(

To

tal Watts

Per Type

Tot a l W a t t s

TABLE 1-6)

(

Option

Power Configuration

PDU Type

(TABLE 1-5)

2N 120 VAC supported

2N 240 VAC 2 + 2 = 4

2N 240 VAC 2 + 2 = 4

(TABLE 1-6)

Notice in the above example, the:

■ Base module requires a 240 VAC PDU with either an N+1 or 2N power option.

■ DEM requires either a 120 VAC or 240 VAC PDU with either an N+1 or 2N option.

■ Remember, you cannot mix 120 VAC with 240 VAC PDUs within the library.

What you need to order:

Minus 2 (-2)Additional

Module PDU Type Option DC Redundancy

DCPS

DC

PS

120 VAC

Base

240 VAC

120 VAC

DEM

240 VAC

N+1

2N

N+1 2 + 1 = 3 1 1

2N 2 + 2 = 4 2 2

N+1 2 + 1 = 3 1 1

2N 2 + 2 = 4 2 2

N+1 2 + 1 = 3 1 1

2N 2 + 2 = 4 2 2

Remember, two DC power supplies are shipped standard for the tape drives, robotics,

and electronics control module in the Base module.

Two DC power supplies are shipped standar

d for the tape drives in the drive

expansion module.

You only need to order additio

nal DC power supplies to support the type and number

of tape drives for the selected configuration.

316194102 • Revision: B Chapter 1 Introduction 17

Electronics Control Module

Electronics Control Module

All of the electronics, control, and host connectivity is located in the electronics control

module (ECM). The ECM is located in the rear of the Base module.

FIGURE 1-9 Electr

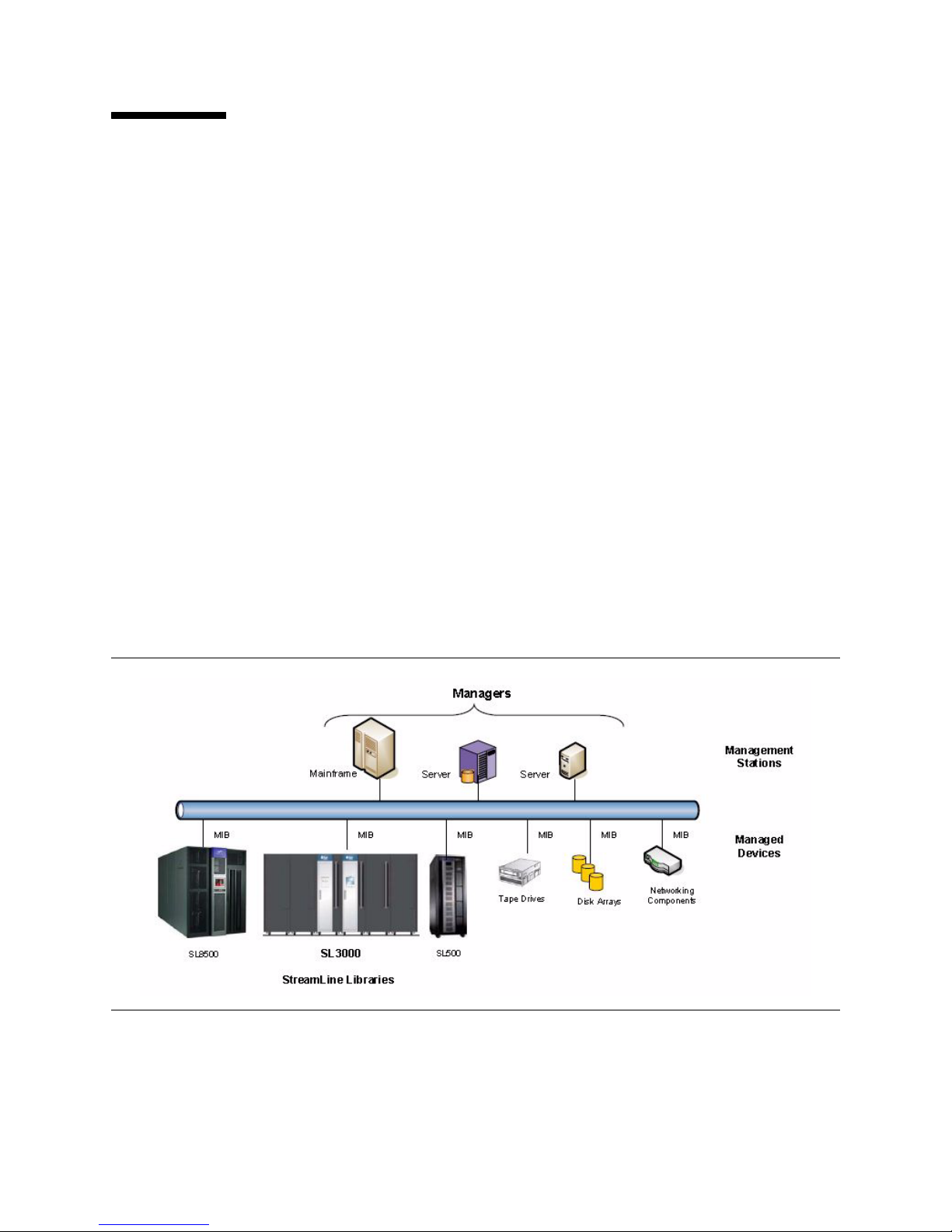

onics Control Module

HBCR Card

1. RS-232 serial port (reserved)

2. RS-232 serial port, CSE connection

(Command Line Interface—not customer accessible)

3. Port 2B—Primary Port—Ethernet 10/100 Base-T

HBT Card

7. RS-232 serial port (reserved)

8. RS-232 serial port, CSE connection

(Command Line Interface—not customer accessible)

9. RSVD port—Ethernet 10/100 Base-T (reserved)

4. Port 2A—Dual TCP/IP—Ethernet 10/100 Base-T

5. Port 1B—Ethernet 10/100 Base-T (reserved)

6. Port 1A—Ethernet 10/100 Base-T (reserved)

HBCR LEDs HBT LEDs

■ Active = Always lit during operation

■ Standby = Inactive

■ Fault = Indicates the controller detected a fault

■ Eject OK = Inactive

Notes:

■ The ECM also ships with an optional MPU2 or PUA card for Fibre Channel interface connections.

■ This card is not shown, but is installed below the HBCR card.

■ An HBCR library controller is included with the SL3000.

■ Active = Always lit during operation

■ Standby = Inactive

■ Fault = Indicates the controller detected a fault

■ Eject OK = Inactive

18 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Robotic Units

Robotic Units

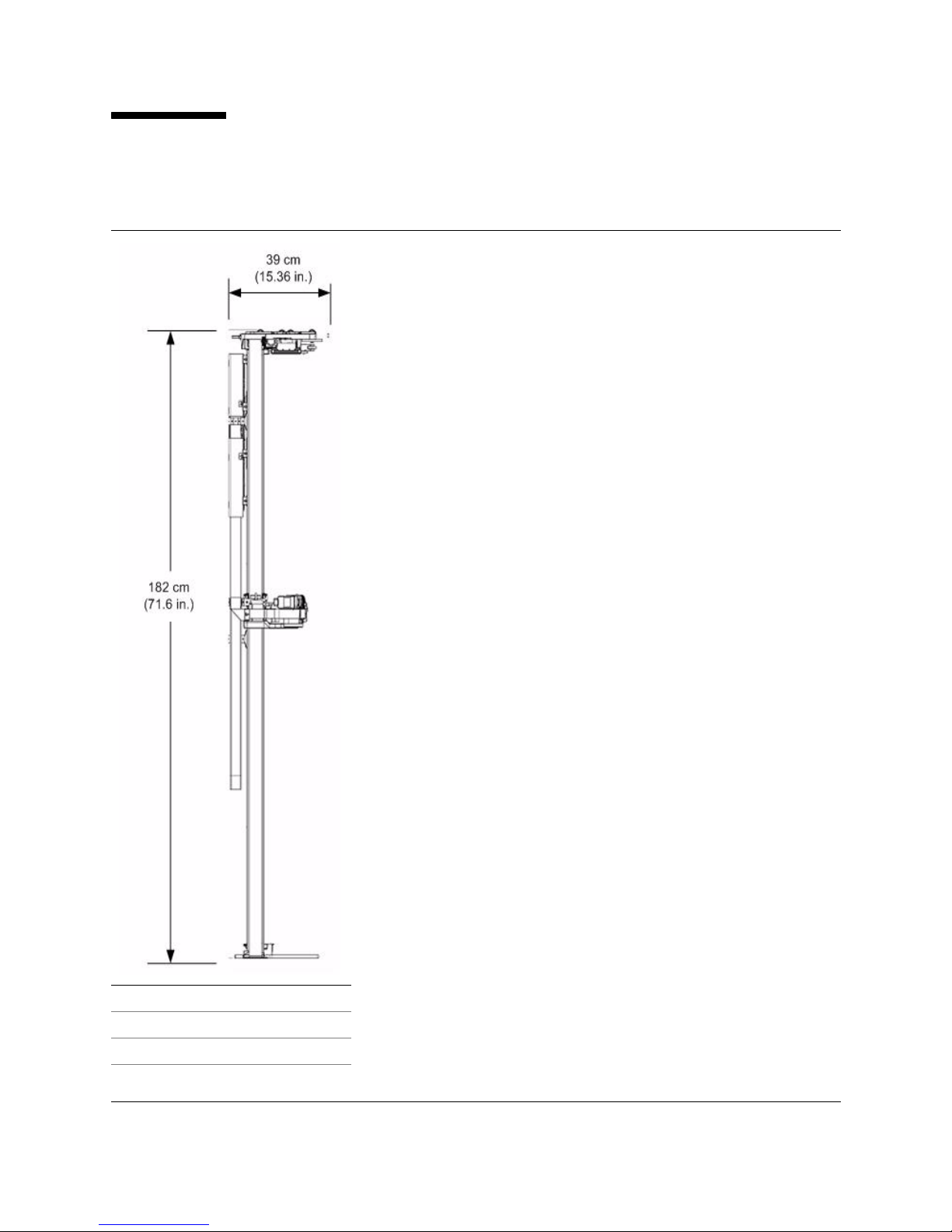

FIGURE 1-10 TallBot

Height 182 cm (71.6 in.)

Width 30 cm (11.84 in.)

Depth 39 cm (15.36 in.)

Wei gh t 8.6 kg (19 lb)

The robotic unit in an SL3000 library is called a TallBot. Each

library can have either one (standard) or two (redundant)

TallBots called “Dual Bots” or Dual Robotics.”

TallBots are responsible for the movement and cataloging—or

auditing—of cartridges throughout the library.

TallBots are driven along two extrusions

rear wall of the library; one rail at the top and one rail attached

to the floor. Each module contains pre-installed, segmented

extrusions.

Two copper strips are inserted into the top extr

provide both a power and a signal path for TallBot operation.

■ Power comes from +48 VDC, 1200 Watt, load sharing supplies.

■ Signals are received and transmitted between the TallBots and the

library controller (HBCR card).

■ A Rail Power Enable module is installed as a safety circuit for rail

power.

Gears on the TallBot motors mesh with molded plastic tracks

that are installed within the extrusions.

Handling of the cartridges by the TallBots include:

■ Retrieving cartridges—GET operation—from the CAP or slot

■ Inserting cartridge—PUT operation—into a CAP or slot

■ GETs and PUTs of cartridges to and from wall slots

■ Mounts and dismounts of cartridges to and from tape drives

TallBots contain a bar-code scanner that:

■ Reads the configuration blocks in each module during library

initialization

■ Targets on cartridge storage/CAP slots and tape drives

Targets are shaped |\| similar to an “N”.

■ Identifies volume serial numbers (VOLSERs) of cartridges

during CAP entries and Audits.

VOLSERs are read during audits and CAP entries only. After

that, cartridges are assigned locations within the library—slots.

During GET operations, the library uses the slot locations of the

rtridges to complete the required task.

ca

Redundant TallBot—Dual Bot operation of

■ Increases the speed for robotic operations

■ Backs up robotic operation in case one should fail

This option requires 200—240 V

AC, 2N power and parking

expansion modules or the access expansion modules at each end

of the library. A defective TallBot will take itself offline and

moves or is pushed into one of these modules, allowing the

library to continue operations with one TallBot until time can be

scheduled to replace the defective TallBot.

—called rails—on the

usion that

fers an option that:

316194102 • Revision: B Chapter 1 Introduction 19

Cartridge Access Ports

1 2 1 2

3

Cartridge Access Ports

The cartridge access port—CAP—is a vertically-mounted, rotating cylinder with two

removable 13-slot magazines (26 slots total).

■ The Base module comes with a CAP as a standard feature.

■ Drive and Cartridge expansion modules have an optional feature to contain a CAP

for a maximum of up to 10 standard (rotational) CAPs per SL3000 library.

Note – A

CAP in the right-side Parking Expansion Module is not accessible and

should be unplugged.

Each CAP comes with a small keypad including indicators and a us

operate that specific CAP.

FIGURE 1-11 Car

er interface to

tridge Access Port and Key Pad

1. Cartridge access ports (rotational CAPs)

2. Blank covers. When a CAP is not ins

This can always be upgraded in the future to include a CAP.

3. Keypad and indicator us

er interface.

Best Practices:

■ If partitioning, the recommendation is to install enough CAPs to provide at least one

CAP for each partition. This allows each partition to contain its own, dedicated CAP.

■ CAP control is split down the centerline. Make sure there is a left- and right-side

CAP to support the library. If a CAP encounters a failure, all CAPs following that

one will be unusable until the defective CAP is serviced. For this reason, the

recommendation is to install CAPs in a balanced fashion around the centerline.

20 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

talled, a blank cover is installed.

Cartridge Access Ports

Bulk Load CAPs

Bulk Load Cartridge Access Ports

The Access Expansion Modules have the ability for the customer to add cartridges in

bulk, up to 234 cartridges on each side,

without disrupting library operations.

FIGURE 1-12 Bul

Best Practices:

When entering and ejecting cartridges in smaller quantities, use the smaller rotational

CAPs to complete the job. These CAPs are easier to use and take less time to audit than

the larger AEM bulk load CAPs.

k Load CAPs—Access Expansion Modules

Although, operation of the cartridge acces

s port does not directly affect the

performance of the library, here are some guidelines that can help with the operation:

■ Whenever possible, enter cartridges through the cartridge access ports.

■ When planning the workloads, place applications that require significant enters and

ejects adjacent to the CAP magazines.

Tip:

Place labels outside on the library wall indicating

which CAP and which magazine gets

what type of cartridge. See “CAP Labels” on page 22.

■ Insert cartridges with the correct orientation:

■ Fully seated and laying flat within the slots

■ Parallel to the floor

■ Hub-side down

■ Barcode label pointing out and below the readable characters.

316194102 • Revision: B Chapter 1 Introduction 21

Cartridge Access Ports

CAP Labels

FIGURE 1-13 Cartridge Access Port Labels

Labels are provided for the customer to identify the

cartridge access ports. These labels include:

■ Left (L) and Right (R) SCSI labels

■ Sequential numbered labels for HLI

■ Create your own labels, which allows the customer to

write on the label to identify the CAPs as they want

22 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Cooling

Cooling

Cooling within the SL3000 is divided into three areas:

■ Library (Electronics control module)

■ Tape d riv e s

■ DC power supplies

Library Electronics Control Module

There are two (2) fans located to the right of the electronics control module that

provide cooling for the electronics in the library. Air is drawn from the sides of the

library and flows through the fans to the rear of the library.

■ These fans are monitored by the HBCR card for proper operation.

■ An amber Fault indicator is on the fan assembly to indicate a failure.

While there are two (2) dedicated fans, one (1) fan is sufficient to provide adequate

cooling for the library and the electronics. Nevertheless, since the fans can be replaced

without interfering with library operations, it is best to replace a defective fan when it

is detected.

Tape D rives

Each tape drive tray contains a fan for drive cooling. Power for the fans is supplied

through the tape drive’s power converter card. Air is drawn from the front of the drive

and flows through the fan to the rear of the drive/library.

DC Power Supplies

Each 1200 Watt DC power supply contains a fan that pulls air from the library, through

the rear of the supply, and out the rear of the library.

316194102 • Revision: B Chapter 1 Introduction 23

Tape Drives

Tape Drives

TABLE 1-8 lists the supported tape drives, interfaces, and media types for the

SL3000 library.

TABLE 1-8 Suppo

Vendor Drive Type

StorageTek T9840C

HP

rted Tape Drives

T9840D*

*Encryption feature

T10000A*

T10000B*

*Encryption feature

LTO 3

LTO 4*

LTO 5*

2

Interface Type3 Media

Fibre Channel

FICON

9840

Vol Sa fe ca pa bl e

ESCON

2 Gb/4 Gb

Fibre Channel

T10000 Standard,

Sport, and VolSafe

FICON

LTO 3 , LTO4, an d LTO 5

Fibre Channel

WORM (L

LTO 2 ( read-on l y )

T)

*Encryption feature

IBM

LTO 3

LTO 4*

LTO 5*

Fibre Channel

LTO 3 , LTO4, an d LTO 5

WORM (LT)

LTO 2 ( read-on l y )

*Encryption feature

Notes:

1. StorageTek T9940 tape drives are not suppor

ted.

2. The Quantum SDLT 600 and DLT-S4 tape drives are not supported.

3. The parallel version of the small computer system i

nterface (SCSI) is not a supported connection.

4. LTO 2 media is supported for backward compatibility of LTO products (data migration).

4

4

Plus future releases of the above tape dri

See Appendix C, “Tape Drives and Media” for more information.

24 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

ve technologies, media, and interfaces

Tape Drives

Drive Tray

A single universal drive tray accommodates the different tape drives and interfaces.

The targeting system is the same as the other StorageTek SL-series libraries

(SL500 and SL8500); therefore, the tape drive automation bezels ar

e identical.

The drive trays, however

Instead of a single layer tray, the S

■ Power supply and connections are on the top, and the

■ Tape drive is under the power supply.

FIGURE 1-14 SL3000

Tape Drive Trays

Measurements:

■ Height: 16.5 cm (6.5 in.)

■ Width: 16.5 cm (6.5 in.)

■ Depth: 49.5 cm (19.5 in.)

, are different.

L3000 drive trays have two layers:

Each tray slides into a drive bay located w

A drive array can be removed to expand the cartridge capacity, or installed to increase

drive capacity.

tape

Internal power supply cards and cabling are unique depending on the drive-type and

interface within the

Cabling to the drive itself is at the rear of th

through the strain relief system. Cabling access is allowed for both under-floor and

ceiling routed cables.

316194102 • Revision: B Chapter 1 Introduction 25

ithin an 8-drive array.

drive tray.

e drive tray and library, then routed

Interfaces

Interfaces

SL3000 libraries support several types of interfaces for a variety of uses and platforms:

■ Host connectivity and library management

■ Service

■ Monitoring

Host Connectivity

There are two types of host connections to the library:

■ Small computer system interface (SCSI)

■ Ethernet (TCP/IP) using 10/100 Base-T and CAT-5 cables.

Important:

When implementing a new library into a network

customer, system and network administrators, and StorageTek representatives work

closely together to define the configuration and connection.

2

over a physical Fibre Channel interface, or

, it is strongly recommended that the

The design of the SL3000 library allows connection to either

Fibre Channel or Ethernet

environments. This design allows for several combinations of a host interface in both

partitioned and non-partitioned configurations.

■ In a non-partitioned configuration, the library can use only one (1) interface

type—either Fibre Channel or Ethernet (a second Ethernet connection can be used to

access StorageTek Library Console)

■ In a partitioned configuration, the library can use both interface types.

The library may have only SCSI partitions, only Ethernet partitions, or a

combination of both—u

Addressing between these two h

■ Ethernet hosts use a host library interface -panel, row, column (HLI-PRC)

p to a total of

ost connections varies:

eight (8) partitions.

numbering scheme.

■ SCSI hosts expect a sequential element numbering scheme with each element type

(slots, tape drives, and CAPs) given its own sequential range.

SCSI Media Changer-3 (SMC-3) is su

pported.

SCSI

The SL3000 library uses the small computer system interface (SCSI) protocol and

command set over a physical Fibre Channel (FC-SCSI) connection.

There are two optional Fibre Channel cards that provide connection to the library:

■ MPU2 = Single port connection (older availability)

■ PUA = Dual port connection (newer model containing two ports)

2. SCSI protocol and command set over a physical Fibre Channel interface.

26 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

Interfaces

Note – The StorageTek implementation of Fibre Channel conforms to:

■ American National Standards Institute (ANSI), and

■ National Committee for Information Technology Standards (NCITS)

Supported topologies include:

Switched Fabric: This topology is recommended for the library.

A switched fabric provides dynamic inter-connections between nodes and multiple,

simultaneous Fibre Channel connections for the network. If the library is connected

to a Fibre Channel switch or fabric-capable host, it configures itself as a switched

topology and can support up to 16 million ports logged into the fabric.

Arbitrated Loop: While the library supports the arbitrated loop topology, this connection

scheme is not recommended for new or future implementations. StorageTek does not

recommend the arbitrated loop connection by setting Hard ALPAs (Arbitrated Loop Physical

Addresses).

Arbitrated Loops provide multiple connections for devices that share a single loop

and allows only point-to-point connections between an initiator and target during

communications. An arbitrated loop can connect only up to 126 ports.

Refer to the SL3000 Interface Reference Manual PN 31619520x for more information. This

manual contains information about the small computer system interface command set

plus information about Fibre Channel operations, command implementations,

topologies, cables, and connectors.

TCP/IP

The library can also use TCP/IP protocol over an Ethernet physical interface,

(CAT-5, Ethernet, 10/100 BaseT cable) to manage and communicate with the host and

library management applications. To connect to and communicate with the library, this

interface enables both:

■ Open system platforms with ACSLS

■ Enterprise-level mainframes with HSC /VSM

The library controller (HBCR card) is responsible for coordinating all component

operations within the library and providing the interface connection with the host.

Connections

There are two separate Ethernet connections on the HBCR card for host to library

communications—Ports 2A and 2B.

■ Port 2A provides the Dual TCP/IP connection—this is an optional feature for SL3000

libraries. If not used for Dual TCP/IP, it can be used for connection to StorageTek

Library Console.

■ Port 2B provides the primary host connection—this is the standard connection for

SL3000 libraries.

316194102 • Revision: B Chapter 1 Introduction 27

Interfaces

Both ports comply with the Institute of Electrical and Electronics Engineers standard–

IEEE 802.3–for Ethernet networks. Both ports are capable of auto-negotiating the:

■ Method of transmission

■ Half-duplex: Transmits data in just one direction at a time

■ Full-duplex: Transmits data in two directions simultaneously

■ Speed of the transmission

■ 10Base-T: 10 megabits per second (Mbps)

■ 100Base-T: 100 megabits per second (Mbps)

Network

■ Whenever possible, use a dedicated, private network for communication between

the library and host management software.

A private network connection using an Ethernet hub or switch is recommended for

m

aximum throughput and minimum resource contention.

■ If a shared network is required, these actions can help with the communication

between the host and the library:

■ Directly connect the library to a switch.

■ Place the library on its own subnet.

■ Use a managed switch that can:

– Set priorities on ports to give the host and library higher priori

– Provide dedicated bandwidth between the host and the library.

– Create a VLAN between the host and the library.

■ Use a virtual private network (VPN) to insulate host to library traffic.

ty.

Service

The command line interface (CLI) is a library interface for service representatives only.

This interface allows these representatives to configure and diagnose the library.

Note – Customers are not allowed to access the CLI interface. Only trained and

qualified representatives or partne

rs can access the CLI.

There are two ways to access and use the CLI:

■ Serial Port Connection on the HBCR card (RS-232) and a HyperTerminal connection

to enter the commands.

■ Ethernet Port Connection (ports 1A, 2A, or 2B) on the HBCR card and use a secure

shell (PuTTY) to enter the commands.

Monitoring

There are several ways to monitor this library, using:

■ StorageTek Library Console (local and remote)

■ Web-launched Library Console

■ Simple Network Management Protocol (SNMP)

28 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

StorageTek Library Console

1

2

3 4 5

7

89

10

6

The StorageTek Library Console (SLConsole or Library Console) is a graphical user

interface that allows management of the library either locally from an operator panel

attached to the library or remotely running on a computer (PC) or Solaris workstation.

FIGURE 1-15 Library Console—Example Screen

Interfaces

1. Tools Menu

2. Help Menu

3. Title Bar

4. Function Tabs

5. Options Bar

6. Display Area

7. Library Health Indicator

8. UserID

9. Communications Health Indicator

10.Device Tree

316194102 • Revision: B Chapter 1 Introduction 29

Interfaces

Web-launched Library Console

The Web-launched library console—also called the SLConsole—is a standard feature of

the SL3000 library and is included on a CD shipped with each library. Installing the

software on this CD enables the SLConsole to be installed on a centralized Web server.

Individual clients can then use a supported Web browser to download the console.

Using the SLConsole allows customers to connect to any SL3000 library for which they

have a valid user ID.

The Web-launched SLConsole is delivered to clie

nts as a Java Web Start process, which

executes outside the browser.

Security Considerations

The Web-launched SLConsole software is digitally signed, which guarantees that it has

been issued by Sun Microsystem, Inc. and has not been altered or corrupted since it

was created. As a Java Web Start process, the SLConsole includes the security features

provided by the Java 2 platform.

The customer is responsible for implementing all appropriate additional security

ms, including firewalls and user access.

syste

Client Requirements

Customers can download the SLConsole to clients meeting the following requirements:

Platform

■ Solaris 9—SPARC

■ Solaris 10—SPARC

■ Windows 2003 Server—32-bit

■ Windows XP Client—32-bit

■ Windows Vista—32-bit

Browser

■ Mozilla Firefox, version 1.5 or higher

■ Microsoft Internet Explorer, version 5.5 or higher

■ Java 1.5 Plug-in (the browser will install this automatically if it is

not present already)

Other

■ Ethernet connection to the SL3000 library

■ Ethernet connection to the SLConsole server

Web-launched SLConsole Updates

Updates to the SLConsole only need to be installed on the centralized Web server.

Once the updates are installed on the server,

clients whenever the application is started on the client.

30 SL3000: Systems Assurance Guide • May 2010 Revision: B • 316194102

they are downloaded automatically to all

Simple Network Management Protocol

Simple Network Management Protocol

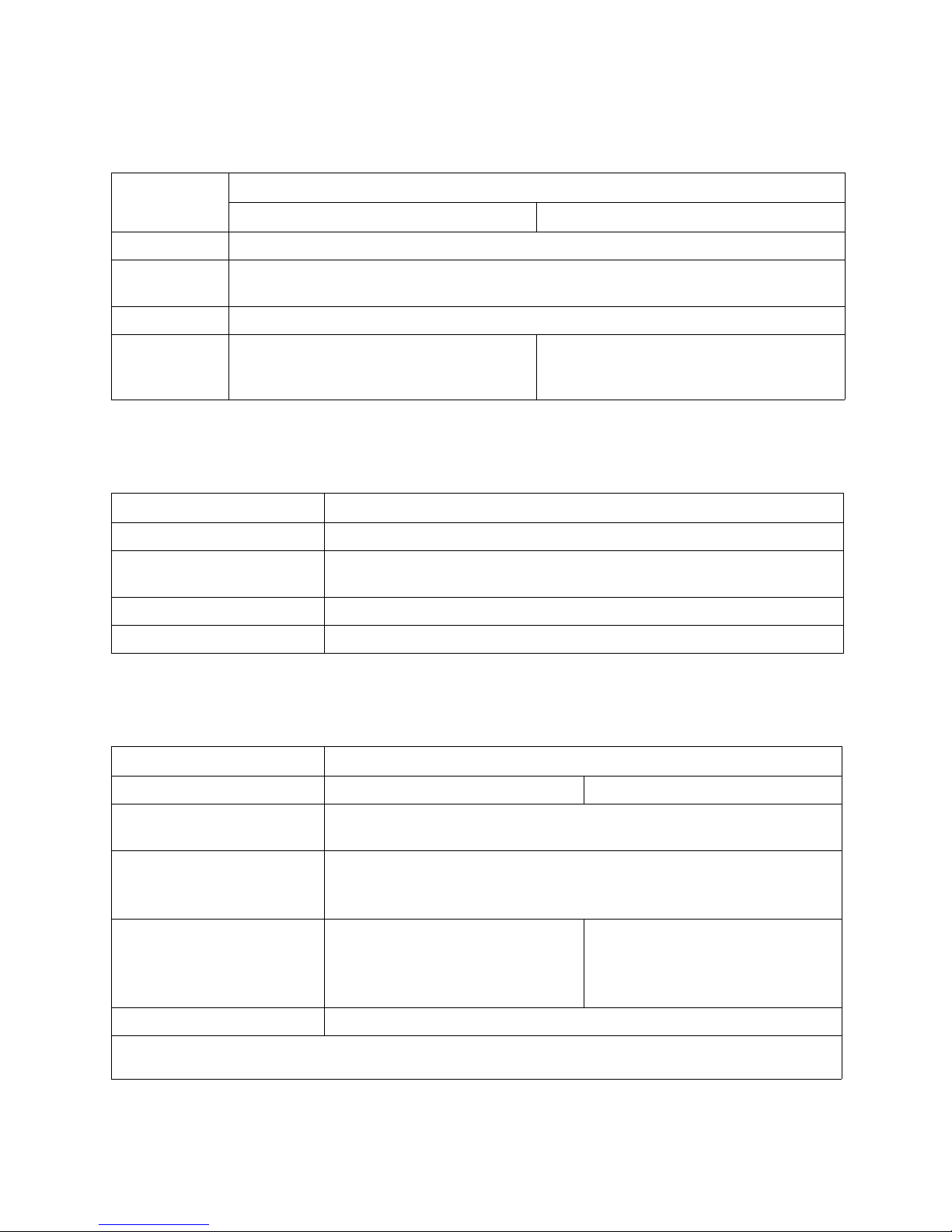

Simple Network Management Protocol (SNMP) is an application layer protocol that

performs network management operations over an Ethernet connection using a User

Datagram Protocol (UDP/IP).

Occasionally, the library may encounter a condition that an administrator or operator

would want to know about, such as an open door that causes the library to stop. These

conditions—or alerts—are called SNMP traps.

The Simple Network Management Protocol allows:

■ Libraries to inform the systems administrator of potential problems.

■ Systems administrators to query the library for configuration, operation, and

statistical information.

The SL3000 library supports:

■ SNMPv2c of the simple network management protocol for machine status queries.

Note: with this version, any information transmitted is not secure.

■ SNMPv3 of the simple network management protocol is reserved for proprietary

information. Because this version supports encryption and stronger user

identification it is the preferred protocol for proprietary data.

This functionality requires the use of a Management Information Base (MIB) on the

controller card. The MIB contains information that specifically describe the library,

components, and configuration.

SNMP in a library setting.

FIGURE 1-16 SNMP Example

FIGURE 1-16 on page 31 illustrates one example of

Refer to the SL3000 SNMP Reference Guide PN 31619450x for more information.

This reference guide provides information about SNMP and the implementation on

StorageTek SL3000 modular libraries.

316194102 • Revision: B Chapter 1 Introduction 31

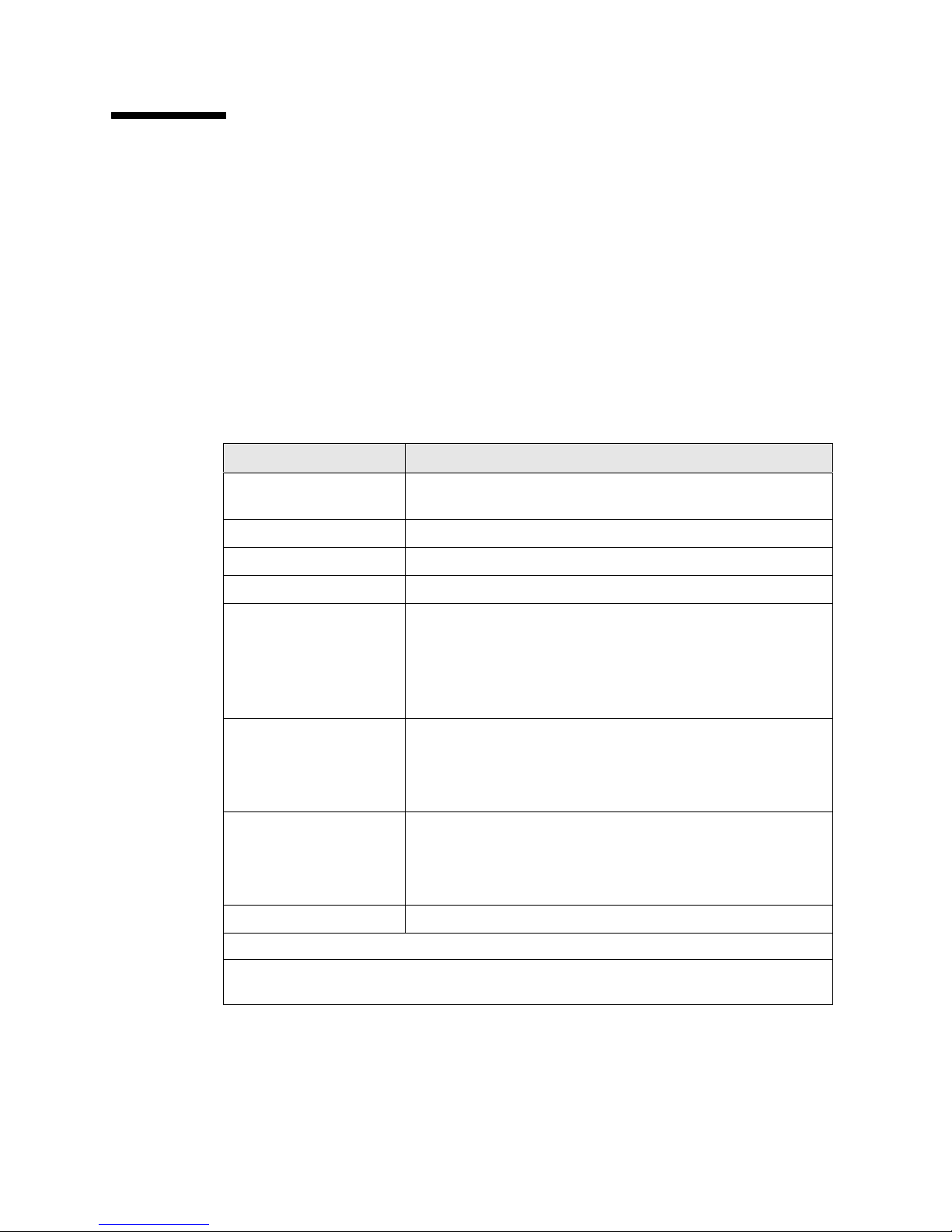

Library Management Software

Library Management Software

Library management software applications control the library, manage the volume

database—location and attribute information—plus command activities such as

mounts, dismounts, enters, and ejects.

There are several software components depending on the platform, connection type,