SPARC T4-1 Server

Installation Guide

Part No.: E22988-09

August 2013

Copyright ©2011, 2013, Oracle and/or its affiliates. Allrights reserved.

This softwareand related documentation are provided undera license agreement containing restrictions on use and disclosureand are protected by

intellectual propertylaws. Exceptas expressly permitted inyour licenseagreement or allowed by law, you may not use, copy, reproduce, translate,

broadcast, modify, license, transmit, distribute, exhibit, perform, publish, or display any part, in any form, or by any means. Reverse engineering,

disassembly, or decompilation of this software, unless requiredby lawfor interoperability, is prohibited.

The informationcontained hereinis subjectto changewithout noticeand isnot warrantedto beerror-free.If youfind anyerrors, please report them to us

in writing.

If thisis softwareor related software documentation that is delivered to the U.S. Government or anyone licensing it on behalf of the U.S. Government, the

following noticeis applicable:

U.S. GOVERNMENTEND USERS.Oracle programs,including anyoperating system,integrated software, any programs installed onthe hardware,

and/or documentation,delivered toU.S. Governmentend usersare "commercial computer software" pursuantto theapplicable FederalAcquisition

Regulation andagency-specific supplementalregulations. Assuch, use,duplication, disclosure, modification, andadaptation ofthe programs, including

any operatingsystem, integratedsoftware, anyprograms installed on the hardware,and/or documentation,shall besubject tolicense termsand license

restrictions applicableto theprograms. No other rights are granted to the U.S. Government.

This software or hardware is developed for general use in a variety ofinformation managementapplications. It is not developed or intended for usein any

inherently dangerous applications, includingapplications thatmay create a riskof personalinjury. If you use this software or hardwarein dangerous

applications, thenyou shallbe responsibleto takeall appropriate fail-safe, backup,redundancy, and other measuresto ensure its safeuse. Oracle

Corporation andits affiliatesdisclaim anyliability forany damagescaused byuse ofthis software or hardware in dangerous applications.

Oracle andJava areregistered trademarks of Oracle and/or its affiliates.Other namesmay betrademarks oftheir respective owners.

Intel andIntel Xeonare trademarksor registered trademarks of Intel Corporation. All SPARC trademarks areused underlicense andare trademarks or

registered trademarks of SPARCInternational, Inc. AMD, Opteron, theAMD logo,and theAMD Opteron logo are trademarksor registered trademarksof

Advanced MicroDevices. UNIXis aregistered trademark of The Open Group.

This software or hardware and documentation may provide access to or information on content, products, and services from third parties. Oracle

Corporation and its affiliates are not responsible for and expressly disclaim all warranties of any kind with respect to third-party content, products, and

services. Oracle Corporation and its affiliates will not be responsible for any loss, costs, or damages incurred due to your access to or use of third-party

content, products, or services.

Copyright ©2011, 2013, Oracle et/ou ses affiliés. Tous droits réservés.

Ce logicielet ladocumentation quil’accompagne sontprotégés parles loissur lapropriété intellectuelle. Ils sont concédés sous licence et soumis à des

restrictions d’utilisationet dedivulgation. Saufdisposition devotre contrat de licence ou de la loi, vous ne pouvez pas copier, reproduire,traduire,

diffuser, modifier,breveter, transmettre, distribuer, exposer,exécuter,publier ouafficher le logiciel, même partiellement, sous quelque forme et par

quelque procédéque cesoit. Parailleurs, ilest interdit de procéder à touteingénierie inversedu logiciel,de ledésassembler oude ledécompiler,excepté à

des finsd’interopérabilité avecdes logicielstiers outel queprescrit par la loi.

Les informationsfournies dansce documentsont susceptiblesde modificationsans préavis.Par ailleurs,Oracle Corporationne garantitpas qu’elles

soient exemptesd’erreurs etvous invite,le caséchéant, àlui enfaire part par écrit.

Si celogiciel, oula documentationqui l’accompagne,est concédésous licenceau Gouvernementdes Etats-Unis,ou àtoute entitéqui délivrela licencede

ce logicielou l’utilisepour lecompte duGouvernement desEtats-Unis, lanotice suivantes’applique :

U.S. GOVERNMENTEND USERS.Oracle programs,including anyoperating system,integrated software, any programs installed onthe hardware,

and/or documentation,delivered toU.S. Governmentend usersare "commercial computer software" pursuantto theapplicable FederalAcquisition

Regulation andagency-specific supplementalregulations. Assuch, use,duplication, disclosure, modification, andadaptation ofthe programs, including

any operatingsystem, integratedsoftware, anyprograms installed on the hardware,and/or documentation,shall besubject tolicense termsand license

restrictions applicableto theprograms. No other rights are granted to the U.S. Government.

Ce logicielou matériela étédéveloppé pourun usagegénéral dansle cadred’applications degestion desinformations. Celogiciel oumatériel n’estpas

conçu nin’est destinéà êtreutilisé dansdes applicationsà risque,notamment dansdes applicationspouvant causerdes dommagescorporels. Si vous

utilisez celogiciel oumatériel dansle cadred’applications dangereuses, il estde votre responsabilité de prendre toutes les mesures desecours, de

sauvegarde, deredondance et autres mesures nécessaires à sonutilisation dansdes conditionsoptimales desécurité. OracleCorporation etses affiliés

déclinent touteresponsabilité quantaux dommagescausés parl’utilisation dece logicielou matérielpour cetype d’applications.

Oracle etJava sontdes marquesdéposées d’OracleCorporation et/oude sesaffiliés.Tout autre nom mentionné peut correspondre à desmarques

appartenant àd’autres propriétaires qu’Oracle.

Intel etIntel Xeonsont desmarques oudes marques déposées d’IntelCorporation. Toutes lesmarques SPARCsont utiliséessous licenceet sontdes

marques oudes marques déposées deSPARC International, Inc.AMD, Opteron, le logoAMD etle logoAMD Opteron sont desmarques oudes marques

déposées d’AdvancedMicro Devices.UNIX estune marque déposée d’TheOpen Group.

Ce logicielou matérielet ladocumentation quil’accompagne peuventfournir desinformations oudes liensdonnant accèsà descontenus, desproduits et

des servicesémanant detiers. OracleCorporation etses affiliésdéclinent touteresponsabilité ou garantie expresse quant aux contenus, produits ou

services émanantde tiers.En aucuncas, OracleCorporation etses affiliésne sauraientêtre tenus pour responsables des pertes subies, des coûts

occasionnés oudes dommagescausés parl’accès àdes contenus,produits ouservices tiers,ou àleur utilisation.

Please

Recycle

Contents

Using This Documentation vii

Confirming Server and Site Specifications 1

Server Overview 1

Front Panel Components 3

Front Panel System LEDs and Buttons 4

Rear Panel Components 6

Rear Panel System LED and Button 7

Confirming Specifications 8

Physical Specifications 9

Minimum Clearance for Service Access 9

Electrical and Power Specifications 9

Environmental Specifications 11

Acoustic Noise Emissions 12

Airflow Considerations 12

Preparing for Installation 15

Shipping Kit Inventory List 15

Handling Precautions 17

ESD Precautions 17

Tools Needed for Installation 18

Installing the Server 19

iii

Rack Compatibility 19

▼ Stabilize the Rack 21

Installing Slide Rails 22

Slide Rail Assemblies 22

▼ Install the Slide Rail Assemblies 25

▼ Install the Server 29

(Optional) Installing the CMA 31

▼ Install the CMA 31

▼ Verify Correct Operation of the Slide Rails and the CMA 36

Connecting Cables 39

Cabling Requirements 39

Identifying Ports 40

USB Ports 41

SER MGT Port 41

NET MGT Port 42

Gigabit Ethernet Ports 43

Video Port 43

Connecting Data and Management Ports 44

▼ Connect the SER MGT Port Cable 44

▼ Connect the NET MGT Port Cable 45

▼ Connect the Ethernet Network Cables 46

▼ Connect Other Data Cables 47

▼ Secure Cables in the CMA 48

Powering On the Server for the First Time 51

Oracle ILOM System Console 51

▼ Connect a Terminal or Emulator to the SER MGT Port 52

▼ Power On the Server for the First Time 53

iv SPARC T4-1 Server Installation Guide • August 2013

▼ Verify Functionality 55

Assigning a Static IP Address to the SP 55

▼ Assign a Static IP Address to the SP 55

Oracle Solaris OS Configuration Parameters 57

Glossary 59

Index 65

Contents v

vi SPARC T4-1 Server Installation Guide • August 2013

Using This Documentation

This installation guide provides instructions, background information, and reference

material to help you install Oracle’s SPARC T4-1 Server.

■ “Related Documentation” on page vii

■ “Feedback” on page vii

■ “Support and Accessibility” on page viii

Related Documentation

Documentation Links

All Oracle products http://www.oracle.com/documentation

SPARC T4-1 Server http://www.oracle.com/pls/topic/lookup?ctx=SPARCT4-1

Oracle ILOM 3.0 http://www.oracle.com/pls/topic/lookup?ctx=ilom30

Oracle Solaris OS and

other systems software

Oracle VTS 7.0 http://www.oracle.com/pls/topic/lookup?ctx=OracleVTS7.0

http://www.oracle.com/technetwork/indexes/documentation/index.ht

ml#sys_sw

Feedback

Provide feedback on this documentation at:

vii

http://www.oracle.com/goto/docfeedback

Support and Accessibility

Description Links

Access electronic support

through My Oracle Support

Learn about Oracle’s

commitment to accessibility

http://support.oracle.com

For hearing impaired:

http://www.oracle.com/accessibility/support.html

http://www.oracle.com/us/corporate/accessibility/index.html

viii SPARC T4-1 Server Installation Guide • August 2013

Confirming Server and Site

Specifications

This chapter explains how to verify that the server and the installation site are ready

for the installation to take place. It contains these topics:

Step Description Links

1. Review the product notes for any late-breaking

news.

2. Review the server features, components, LEDs, and

external I/O ports.

3. Review the server specifications and site

requirements.

4. Prepare the information and tools needed to install

the server.

Server Overview

This topic provides a high-level introduction to the main components and

capabilities of the server.

SPARC T4-1 Server Product Notes

“Server Overview” on page 1

“Front Panel Components” on page 3

“Front Panel System LEDs and Buttons” on page 4

“Rear Panel Components” on page 6

“Rear Panel System LED and Button” on page 7

“Confirming Specifications” on page 8

“Preparing for Installation” on page 15

1

FIGURE: Oracle’s SPARC T4-1 Server

Component Description

Chassis Rack-mountable server with a 2RU form-factor.

CPU One T4 2.85 GHz multicore processor.

Memory Sixteen DDR3 DIMM memory slots supporting 4, 8, or 16 GB modules.

Storage devices For internal storage, the server provides:

• Eight 2.5-inch drive bays, accessible through the front panel.

• A slot-loading DVD+/-RW drive on front panel.

USB ports Four external USB 2.0 ports (two each on the front and rear panels).

Video ports One high-density DB-15 video port (rear panel).

PCI Express 2.0 I/O slots Six standard half-length, low-profile PCIe 2.0 slots. Two of the six slots are capable

of accepting either a PCIe card or a XAUI card.

Ethernet ports Four 10/100/1000 Mbps, RJ-45-based, autonegotiating Ethernet ports (rear panel).

SP Oracle Integrated Lights Out Manager (ILOM) with RJ-45 serial and Ethernet

interfaces.

Power supplies Two hot-swappable power supplies

Cooling fans Six sets (N+1) of hot-swappable counter-rotating fan modules.

2 SPARC T4-1 Server Installation Guide • August 2013

Related Information

■ SPARC T4-1 Server Service Manual

■ Oracle ILOM documentation

■ “Front Panel Components” on page 3

■ “Front Panel System LEDs and Buttons” on page 4

■ “Rear Panel Components” on page 6

■ “Rear Panel System LED and Button” on page 7

Front Panel Components

The following figure shows the components that are accessible on the server front

panel.

FIGURE: Components on the Server Front Panel

Figure Legend

1 System controls and indicators 8 Hard drive HDD5

2 RFID tag 9 Hard drive HDD6

3 Hard drive HDD0 10 Hard drive HDD7

4 Hard drive HDD1 11 SATA DVD module

5 Hard drive HDD2 12 USB port 2

6 Hard drive HDD3 13 USB port 3

7 Hard drive HDD4

Confirming Server and Site Specifications 3

Related Information

■ “Server Overview” on page 1

■ “Front Panel System LEDs and Buttons” on page 4

■ “Rear Panel Components” on page 6

■ “Rear Panel System LED and Button” on page 7

Front Panel System LEDs and Buttons

The following figure shows the layout of the system LEDs and the power control

button on the front panel.

FIGURE: Front Panel System LEDs and Power Buttons

Figure Legend

1 Locator LED and button 5 Power Supply Service Required LED

2 Fault - Service Required LED 6 System Overtemperature Fault - Service

3 Power OK LED 7 Top Fan Fault - Service Required LED

4 Power ON/Standby button

4 SPARC T4-1 Server Installation Guide • August 2013

Required LED

TABLE: Front Panel System LED Descriptions

LED or Button Icon or Label Description

Locator LED

and button

(white)

The Locator LED can be turned on to identify a particular system. When on, it

blinks rabidly. There are two methods for turning a Locator LED on:

• Issuing the Oracle ILOM command set /SYS/LOCATE value=Fast_Blink

• Pressing the Locator button.

Service

Required LED

Steady on light indicates that a fault has been detected in the system and that

service is required.

(amber)

Power OK

LED

(green)

Indicates the following conditions:

• Off – System is not running in its normal state. System power might be off.

The SP might be running.

• Steady on – System is powered on and is running in its normal operating

state. No service actions are required.

• Blink – System is running in standby mode and can be quickly returned to full

operation.

• Slow blink – A transitional activity is taking place.

• Fast blink – SP is booting.

Power button The recessed Power button toggles the system on or off.

• Press and release to turn the system on.

• Press and release to shut the system down in a normal manner.

• Press and hold for more than 5 seconds to perform an emergency shutdown.

Power Supply

Fault LED

(amber)

Overtemp LED

(amber)

Fan Fault LED

(amber)

REAR

PS

Indicates that a power supply fault has been detected and that service is

required.

Indicates that an overtemperature condition within the chassis has been detected

and that service is required.

TOP

Indicates that a fan module fault has been detected and that service is required.

FAN

Related Information

■ “Front Panel Components” on page 3

■ “Rear Panel Components” on page 6

■ “Rear Panel System LED and Button” on page 7

Confirming Server and Site Specifications 5

Rear Panel Components

The following figure shows the components that are accessible on the server rear

panel.

FIGURE: Components on the Server Rear Panel

Figure Legend

1 Power supply 0 12 Access to physical presence button

2 Power supply 1 13 USB port 0

3 Locator LED button 14 USB port 1

4 Service Required LED 15 VGA video port

5 PowerOKLED 16 PCIe slot 3 or XAUI slot 1

6 SP SER MGT port 17 PCIe slot 0 or XAUI slot 0

7 SP NET MGT port 18 PCIe slot 4

8 Gbit Ethernet port NET0 19 PCIe slot 1

9 Gbit Ethernet port NET1 20 PCIe slot 5

10 Gbit Ethernet port NET2 21 PCIe slot 2

11 Gbit Ethernet port NET2

Related Information

■ “Front Panel Components” on page 3

■ “Front Panel System LEDs and Buttons” on page 4

■ “Rear Panel System LED and Button” on page 7

6 SPARC T4-1 Server Installation Guide • August 2013

Rear Panel System LED and Button

The following figure shows location of the system LEDs and the locator button on the

rear panel.

FIGURE: Rear Panel System LEDs

Figure Legend

1 Locator LED and button 3 PowerOKLED

2 Fault - Service Required LED

Confirming Server and Site Specifications 7

TABLE: Rear Panel System LED Descriptions

LED or Button Icon or Label Description

Locator LED

and button

(white)

Service

Required LED

(amber)

Power OK

LED

(green)

The Locator LED can be turned on to identify a particular system. When on, it

blinks rabidly. There are two methods for turning a Locator LED on:

• Issuing the Oracle ILOM command set /SYS/LOCATE value=Fast_Blink

• Pressing the Locator button.

Steady on light indicates that a fault has been detected in the system and that

service is required.

Indicates the following conditions:

• Off – System is not running in its normal state. System power might be off.

The SP might be running.

• Steady on – System is powered on and is running in its normal operating

state. No service actions are required.

• Blink – System is running in standby mode and can be quickly returned to full

operation.

• Slow blink – A transitional activity is taking place.

• Fast blink – SP is booting.

Related Information

■ “Front Panel Components” on page 3

■ “Front Panel System LEDs and Buttons” on page 4

■ “Rear Panel Components” on page 6

Confirming Specifications

This section contains physical and environmental specifications for the server.

■ “Physical Specifications” on page 9

■ “Minimum Clearance for Service Access” on page 9

■ “Electrical and Power Specifications” on page 9

■ “Environmental Specifications” on page 11

■ “Acoustic Noise Emissions” on page 12

8 SPARC T4-1 Server Installation Guide • August 2013

■ “Airflow Considerations” on page 12

Physical Specifications

TABLE: System Specifications

Measure U.S. Metric

Width 16.75 in. 425.5 mm

Depth 28.13 in. 714.5 mm

Height (2 rack units) 3.49 in. 88.6 mm

Weight, approximate (with 2 power supplies and 8 HDDs, but

without PCI cards and rackmount hardware)

60 lb 27.2 kg

Related Information

■ “Server Overview” on page 1

■ “Minimum Clearance for Service Access” on page 9

Minimum Clearance for Service Access

TABLE: Minimum Clearances Needed

Parameter Value

Clearance, front of server 36 in. (91 cm)

Clearance, rear of server 36 in. (91 cm)

Related Information

■ “Server Overview” on page 1

■ “Physical Specifications” on page 9

Electrical and Power Specifications

Use these specifications only as a general planning guide. To determine power values

based on expected workloads, use the SPARC T4-1 power calculator located at this

online site:

Confirming Server and Site Specifications 9

http://www.oracle.com/goto/powercalculators/

Parameter

Operating input voltage ranges

(input voltage tolerance +/- 10%)

Value

(at 200 VAC)

200 to 240 VAC,

50-60 Hz

Value

(at 100 VAC)

100 to 120 VAC,

50/60 Hz

Maximum operating input current (see note) 3.9 A 7.87 A

Maximum operating input power (see note) 762 W 771 W

Maximum heat dissipation 2330 BTU/hr

2459 KJ/hr

2239.7 BTU/hr

2556.8 KJ/hr

Maximum standby power 20 W 22 W

Maximum server configuration specification under

nominal temperature and voltage conditions:

One T4 processor, sixteen 32-GByte DDR3 DIMMs,

eight HDDs, and six I/O cards.

Idle AC input power 469 W 485 W

Peak AC input power (running SpecJBB) 762 W 713 W

Minimum server configuration specification under

nominal temperature and voltage conditions:

One T4 processor, four 4-GByte DDR3 DIMMs, no

HDDs, and no I/O cards.

Idle AC input power 276 W 280 W

Peak AC input power (running SpecJBB) 335 W 358 W

Note – The maximum operating input current values are based on the formula

P / (V *0.90), where P = maximum operating input power and V=input voltage. For

example: 620W / (100V * 0.90) = 6.89A. You can use this formula to calculate the

maximum operating current at your input voltage.

Related Information

■ “Airflow Considerations” on page 12

10 SPARC T4-1 Server Installation Guide • August 2013

Environmental Specifications

Install and operate the server in a site with an ambient temperature range of 21˚C

(69.8˚F) to 23˚C (73.4˚F), which is an optimal range for server reliability. At 22˚C

(71.6˚F) it is easy to maintain safe relative humidity levels. Operating in this

temperature range provides a buffer if the environmental support systems fail.

Operating the server in a site with ambient relative humidity levels between 45% and

50% prevents corrosion, provides an operating time buffer in the event of

environmental control system failure, and helps avoid failures caused by static

discharges that occur when relative humidity is too low.

Note – Electrostatic discharge is easily generated and less easily dissipated in areas

where the relative humidity is below 35%, and becomes critical when levels drop

below 30%.

The server has been tested to meet all functional requirements when operating in the

operating environmental limits listed in the table below (all values are for a single,

non-rackmounted server).

Parameter Value

Operating temperature 5°Cto35°C (41°Fto95°F)

°

Non-operating temperature -40

Operating humidity 10% to 90% relative humidity, 27

Non-operating humidity Up to 93% relative humidity, 38

Operating altitude Up to 3000 m (10,000 ft)

Non-operating altitude Up to 12,000 m (40,000 ft); IEC 60068-2-13 Test M

Operating vibration 0.15 G (vertical), 0.10 G (horizontal), 5 – 500 Hz,

Non-operating vibration 0.5 G (vertical), 0.25 G (horizontal), 5 – 500 Hz,

Operating shock 3.0 G, 11 ms, half-sine

Non-operating shock • Roll-off: 1-inch roll-off free fall, front to back rolling

Cto65°C (-40°F to 149°F)

°

C (80.6°F) maximum

web bulb, noncondensing

°

C (100.4°F) maximum

web bulb, noncondensing

*

, maximum ambient temperature

is derated by 2 degrees C for every 1 km (3.6 degree F

per 3,280 ft); IEC 60068-2-13 Test M, and 60068-2-41 Test

Z/BM

swept-sine

swept-sine

directions

• Threshold: 25 mm threshold height at 0.75 m/s impact

velocity

Confirming Server and Site Specifications 11

* Except in China markets where regulations may limit installations to a maximum altitude of 2000 m.

Related Information

■ “Acoustic Noise Emissions” on page 12

■ “Airflow Considerations” on page 12

Acoustic Noise Emissions

Declared noise emissions for the SPARC T4-1 server are in accordance with ISO 9296

standards.

TABLE:

Description Parameter Value

LwAd Operating acoustic noise (max.)

LwAm (bystander positions) Operating acoustic noise (max.)

* 1 B = 10 dB

Acoustic Noise Emissions for the SPARC T4-1 Server

Idling acoustic noise

Idling acoustic noise

*

8.5 B

7.1 B

70.1 dB

59.3 dB

Related Information

■ SPARC T4-1 Server Safety and Compliance Guide

■ “Environmental Specifications” on page 11

Airflow Considerations

The servers have been tested to meet all functional requirements when operating in

the operating environmental limits presented in “Environmental Specifications” on

page 11. In addition to having proper environmental conditions, keeping the server ’s

internal temperatures within a safe operating range depends on having sufficient

airflow into and out of the chassis.

■ Ensure unobstructed airflow through the chassis.

■ Ensure that inlet air enters at the front of the server and exits from the back.

Ensure that the inlet air is within.

12 SPARC T4-1 Server Installation Guide • August 2013

■ Ensure that the server ventilation openings used for intake and outflow of air

provide an open area that is at least 60% of the open area perforations across the

front and rear of the server. This 60% minimum open area equates to the following

measurements:

Metric Units US Units

2

224.4 cm

■ Allow a minimum of 5 mm (0.2 in) clearance from the ventilation opening at the

(425 mm x 88 mm) 34.8 in2(16.7 in x 3.5 in)

front of the server and 80 mm (3.1 in) at the rear of the server when mounted.

These clearance values are based on the preceding inlet and exhaust impedance

(available open area) and assume a uniform distribution of the open area across

the inlet and exhaust areas. Clearance values greater than these are recommended

for improved cooling performance.

Note – The combination of inlet and exhaust restrictions such as cabinet doors and

the spacing of the server from the doors can affect the cooling performance of the

server and should be evaluated by the user.

■ Take care to prevent recirculation of exhaust air within a rack or cabinet.

■ Manage cables to minimize interfering with the server exhaust vent.

Related Information

■ “Minimum Clearance for Service Access” on page 9

■ “Environmental Specifications” on page 11

■ “Acoustic Noise Emissions” on page 12

Confirming Server and Site Specifications 13

14 SPARC T4-1 Server Installation Guide • August 2013

Preparing for Installation

This chapter identifies steps you must take to prepare for the installation. It contains

these topics:

■ “Server Overview” on page 1

■ “Front Panel Components” on page 3

■ “Front Panel System LEDs and Buttons” on page 4

■ “Rear Panel Components” on page 6

■ “Rear Panel System LED and Button” on page 7

■ “Confirming Specifications” on page 8

■ “Handling Precautions” on page 17

■ “ESD Precautions” on page 17

■ “Tools Needed for Installation” on page 18

Shipping Kit Inventory List

Note – When you receive your server, place it in the environment where you will

install it. Leave it in its shipping crate at its final destination for 24 hours. This resting

period prevents thermal shock and condensation.

Verify that you have received all of the components that ship with your server.

15

■ SPARC T4-1 server

■ 2 AC power cords

■ RJ-45 to DB-9 crossover adapter for the SER MGT port

■ Antistatic wrist strap

■ Rackmount kit

■ Cable management arm (if ordered)

■ SPARC T4-1 Server Getting Started Guide with license and safety documents

■ Optional components (for example, PCIe cards) that are packaged separately from

the other items

Related Information

■ “Server Overview” on page 1

■ “Preparing for Installation” on page 15

16 SPARC T4-1 Server Installation Guide • August 2013

Handling Precautions

Caution – Deploy the antitilt bar on the equipment rack before beginning an

installation.

Caution – The server weighs approximately 60 lb (25. kg). Two people are required

to lift and mount the server into a rack.

Caution – When completing a two-person procedure, always communicate your

intentions clearly before, during, and after each step to minimize confusion.

Related Information

■ “ESD Precautions” on page 17

ESD Precautions

Electronic equipment is susceptible to damage by static electricity. Use a grounded

antistatic wrist strap, foot strap, or equivalent safety equipment to prevent

electrostatic damage (ESD) when you install or service the servers.

Preparing for Installation 17

Caution – To protect electronic components from electrostatic damage, which can

permanently disable the server or require repair by service technicians, place

components on an antistatic surface, such as an antistatic discharge mat, an antistatic

bag, or a disposable antistatic mat. Wear an antistatic grounding strap connected to a

metal surface on the chassis when you work on server components.

Related Information

■ “Handling Precautions” on page 17

Tools Needed for Installation

To install the server, you must have the following tools:

■ No. 2 Phillips screwdriver

■ ESD mat and grounding strap

You must also provide a system console device, such as one of the following:

■ ASCII terminal

■ Workstation

■ Terminal server

■ Patch panel connected to a terminal server

Related Information

■ “ESD Precautions” on page 17

■ “Handling Precautions” on page 17

18 SPARC T4-1 Server Installation Guide • August 2013

Installing the Server

These topics describe how to install the server into a rack using the rail assembly in

the rackmount kit. Perform these procedures if you purchased the rail assembly.

Note – In this guide, the term rack means either an open rack or a closed cabinet.

Step Description Links

1. Verify that the rack is compatible with the server ’s

installation requirements.

2. Take antitilt precautions to ensure the rack does not

tip forward when the server is installed.

3. Attach the slide rails. “Install the Slide Rail Assemblies” on page 25

4. Install the server in the rack. “Install the Server” on page 29

5. (Optional) Install the CMA. “Install the CMA” on page 31

6. Verify that the slide rails and CMA (if used) operate

correctly.

“Rack Compatibility” on page 19

“Stabilize the Rack” on page 21

“Verify Correct Operation of the Slide Rails and the

CMA” on page 36

Rack Compatibility

Verify that your rack is compatible with the slide rail and cable management arm

options. The slide rails are compatible with a wide range of equipment racks that

meet the following standards.

Item Requirement

Structure Four-post rack (mounting at both front and rear).

Two-post racks are not compatible.

19

Item Requirement

Rack horizontal opening and unit

vertical pitch

Rack rail mounting hole sizes Only 9.5 mm square hole and M6 round mounting

Distance between front and rear

mounting planes

Clearance depth in front of front

mounting plane

Clearance depth behind front

mounting plane

Clearance width between front and

rear mounting planes

Conforms to ANSI/EIA 310-D-1992 or IEC 60927

standards.

holes are supported. All other sizes, including

7.2 mm, M5, or 10-32 mounting holes, are not

supported.

Minimum 622 mm and maximum 895 mm

(24.5 inches to 35.25 inches).

Distance to front cabinet door is at least 27 mm

(1.06 inch).

Distance to rear cabinet door is at least 900 mm (35.5

inches) with the cable management arm, or 770 mm

(30.4 inches) without the cable management arm.

Distance between structural supports and cable

troughs is at least 456 mm (18 inches).

Caution – Equipment Loading: Always load equipment into a rack from the bottom

up so that the rack will not become top-heavy and tip over. Deploy your rack’s

anti-tip bar to prevent the rack from tipping during equipment installation.

Caution – Elevated Operating Ambient Temperature: If the server is installed in a

closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment might be greater than room ambient temperature. Therefore, install the

equipment only in an environment compatible with the maximum ambient

temperature (Tma) specified for the server.

Caution – Reduced Air Flow: Install the equipment in a rack so that the amount of

air flow is adequate for the safe operation of the equipment.

Caution – Mechanical Loading: Mount the equipment in the rack so that the weight

is distributed evenly. A hazardous condition can exist with uneven mechanical

loading.

20 SPARC T4-1 Server Installation Guide • August 2013

Caution – Circuit Overloading: Do not overload the power supply circuits. Before

connecting the server to the supply circuit, review the equipment nameplate power

ratings and consider the effect that circuit overloading might have on overcurrent

protection and supply wiring.

Caution – Reliable Earthing: Maintain reliable earthing of rackmounted equipment.

Give particular attention to supply connections other than direct connections to the

branch circuit (for example, use of power strips).

Caution – Do not use slide rail mounted equipment as a shelf or a work space.

▼ Stabilize the Rack

Caution – To reduce the risk of personal injury, stabilize the expansion rack cabinet

and extend all anti-tilt devices before installing the server.

Refer to your rack documentation for detailed instructions for the following steps.

1. Open and remove the front and rear doors from the rack cabinet.

2. To prevent the rack cabinet from tipping during the installation, stabilize the

cabinet using all anti-tilt mechanisms provided.

3. If there are leveling feet beneath the rack cabinet to prevent it from rolling,

extend these leveling feet fully downward to the floor.

4. Fully extend the rack cabinet’s anti-tilt legs or anti-tilt bar, which are located at

the bottom front of the rack cabinet.

Related Information

■ The rack documentation

■ SPARC T4-1 Server Safety and Compliance Guide

■ “Rack Compatibility” on page 19

Installing the Server 21

Installing Slide Rails

■ “Slide Rail Assemblies” on page 22

■ “Install the Slide Rail Assemblies” on page 25

Slide Rail Assemblies

Each slide rail assembly consists of a three-section slide rail and a removable

mounting bracket. The slide rail attaches to the rack posts. The mounting bracket

attaches to the server chassis.

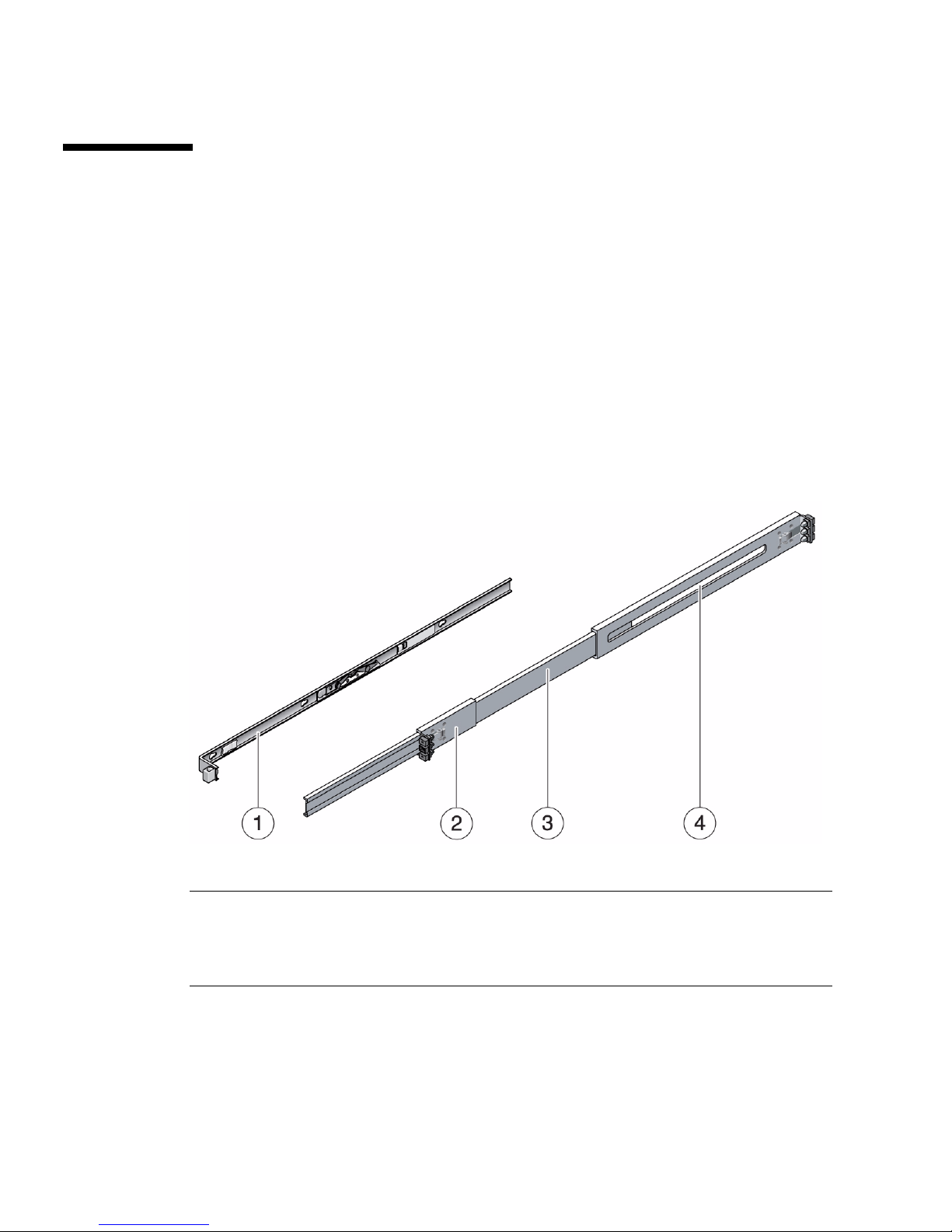

FIGURE: Sections of the Snap-In Slide Rail Assembly

Figure Legend

1 Mounting bracket

2 Front section

3 Middle section

4 Rear section

■ The slide rails adjust to fit rack depths from 24 in. (61 cm) to 36.5 in. (93 cm). The

middle and rear sections of the slide rails have holes for mounting the rail to the

rack posts.

22 SPARC T4-1 Server Installation Guide • August 2013

■ The front section extends out of the middle section, which allows the server to be

positioned far enough out of the rack for many service operations to be

performed.

■ The removable mounting bracket slides 14.5 in. (37 cm) out of the slide rail, then

locks in place. If you unlock the mounting bracket at this point, it slides an

additional 14.5 in. (37 cm) before separating from the slide rail.

There are six locks in a slide rail assembly. Four are on the mounting bracket. Two

locks are on the slide rail.

Installing the Server 23

FIGURE: Locating the Locks on the Slide Rail Assembly

Related Information

■ “Rack Compatibility” on page 19

■ “Install the Slide Rail Assemblies” on page 25

24 SPARC T4-1 Server Installation Guide • August 2013

▼ Install the Slide Rail Assemblies

1. Pull both mounting brackets completely out of their respective slide rails.

a. Simultaneously press and hold the upper and lower lock buttons of the slide

rail lock.

FIGURE: Unlocking the Express Rail Slide Rail Assembly

b. Pull the mounting bracket out until it stops.

c. Slide the mounting bracket release button to the left, then slide the mounting

bracket completely out of the slide rail.

Installing the Server 25

FIGURE: Express Rail Mounting Bracket Release Button

2. Attach a mounting bracket to the right side of the server chassis.

a. Position the mounting bracket against the chassis. Ensure that the slide rail

lock is at the front and the keyed openings on the mounting bracket are

aligned with the locating pins on the side of the chassis.

26 SPARC T4-1 Server Installation Guide • August 2013

FIGURE: Attaching an Express Rail Mounting Bracket to the Chassis

b. Ensure that the heads of the four locating pins protrude through the keyed

openings in the mounting bracket. Slide the mounting bracket toward the

front of the chassis until the bracket locks into place with an audible click.

c. Verify that all four locating pins are trapped in the keyed openings and that

the third locating pin from the front has engaged the mounting bracket lock.

3. Attach the second mounting bracket to the left side of the server chassis.

4. Orient the slide rails, ensuring that the ball bearing tracks (labeled FRONT) are

forward.

Installing the Server 27

FIGURE: Express Rail Slide Rails Orientation for Installation

5. Extend the slide rails (outer section) to fit the rack and attach the slide rails to

the rack.

You hear an audible click when the rails securely attach to the rack.

28 SPARC T4-1 Server Installation Guide • August 2013

FIGURE: Attaching Express Slide Rails to the Rack

Caution – Deploy the antitilt feature on the rack before continuing the installation.

Related Information

■ “Rack Compatibility” on page 19

■ “Slide Rail Assemblies” on page 22

▼ Install the Server

Caution – The weight of the servers on extended slide rails can be enough to

overturn an equipment rack.

Installing the Server 29

Caution – The server weighs approximately 60 lb (25 kg). Two people are required

to lift and mount the server into a rack enclosure.

1. If the rack is equipped with an antitilt bar, verify that it has been deployed and,

if not, deploy it.

2. Insert the ends of the mounting brackets into the sliding rails.

FIGURE: Mounting the Chassis on the Slide Rails

3. While pressing the two green slide rail release buttons, push the server into the

rack until the slide rail locks on the front of the mounting brackets engage the

slide rail assemblies. You will hear a click at that point.

Caution – Before continuing, verify that the server is securely mounted in the rack,

and that the slide rails are locked to the mounting brackets.

30 SPARC T4-1 Server Installation Guide • August 2013

Related Information

■ “Rack Compatibility” on page 19

■ “Slide Rail Assemblies” on page 22

■ “Install the Slide Rail Assemblies” on page 25

■ “Install the CMA” on page 31

■ “Verify Correct Operation of the Slide Rails and the CMA” on page 36

(Optional) Installing the CMA

■ “Install the CMA” on page 31

■ “Verify Correct Operation of the Slide Rails and the CMA” on page 36

▼ Install the CMA

Caution – Support the CMA during this installation. Do not allow the assembly to

hang by its own weight until it is secured by all three attachment points.

1. Remove the tape from the CMA rail extension (on the left of the CMA) and

remove the CMA rail extension.

2. Attach the CMA rail extension to rear left slide rail.

At the rear of the rack, plug the CMA rail extension into the end of the left sliding

rail assembly. The tab at the front of the rail extension clicks into place.

Installing the Server 31

FIGURE: Inserting the CMA Rail Extension Into the Rear of the Left Slide Rail

The right sides of the two CMA arms have hinged extensions. On the

manufacturer’s instruction sheet, the smaller extension is called the CMA

Connector for Inner Member. This extension attaches to the right mounting

bracket. The larger extension is called the CMA Connector for Outer Member, and

attaches to the right sliding rail.

3. Insert the smaller extension into the clip located at the end of the mounting

bracket.

Slide the smaller extension into the square hole on the middle-in-width of the clip

that is located at the end of the mounting bracket.

32 SPARC T4-1 Server Installation Guide • August 2013

FIGURE: Mounting the Inner CMA Connector

4. Insert the larger extension into the end of the right sliding rail.

Installing the Server 33

FIGURE: Attaching the Outer CMA Connector

5. Insert the hinged plastic connector at the left side of the CMA fully into the

CMA rail extension.

The plastic tab on the CMA rail extension locks the hinged plastic connector in

place.

34 SPARC T4-1 Server Installation Guide • August 2013

FIGURE: Mounting the Left Side of the Slide Rail

Related Information

■ “Rack Compatibility” on page 19

■ “Slide Rail Assemblies” on page 22

■ “Install the Slide Rail Assemblies” on page 25

■ “Install the Server” on page 29

■ “Verify Correct Operation of the Slide Rails and the CMA” on page 36

Installing the Server 35

▼ Verify Correct Operation of the Slide

Rails and the CMA

Perform this procedure both before and after you install the server cables in the

CMA. Performing the procedure before the CMA contains cables helps ensure that it

extends and contracts smoothly before the cables are added.

Note – The CMA includes velcro straps to secure the cables inside the CMA. Do not

install the velcro straps until you have installed the CMA, connected the cables, and

placed the cabling inside the CMA.

Tip – Two people are needed for this procedure, one to move the server in and out

of the rack, and one to observe the cables and CMA.

1. For a free-standing rack, deploy the antitilt bar.

2. Unlock the slide lock buttons at the right and left sides of the chassis.

36 SPARC T4-1 Server Installation Guide • August 2013

FIGURE: Unlocking the Slide Rail Assembly

3. If the server cables have been placed inside the CMA, inspect them for binding

or kinks.

4. Slowly pull the server out of the rack until the slide rails reach their stops.

5. Verify that the CMA extends fully and does not bind in the slide rails.

6. Verify that the server extends fully and locks in the maintenance position.

The server should stop after approximately 15 in. (40 cm) of travel.

7. Pull both slide rail release buttons toward you simultaneously and slide the

server back into the rack.

The server should slide smoothly into the rack without binding.

Installing the Server 37

FIGURE: Rail Mounting Bracket Release Button

8. Verify that the CMA retracted without binding.

9. Adjust the cable straps and CMA as required to secure the cables.

Related Information

■ “Rack Compatibility” on page 19

■ “Slide Rail Assemblies” on page 22

■ “Install the Slide Rail Assemblies” on page 25

■ “Install the Server” on page 29

■ “Install the CMA” on page 31

38 SPARC T4-1 Server Installation Guide • August 2013

Connecting Cables

These topics explain how to connect the data and power cables to the server:

Step Description Links

1. Review the cabling requirements. “Cabling Requirements” on page 39

2. Review I/O port connector details. “Identifying Ports” on page 40

3. Connect the management and data

cables.

4. Secure cables in the CMA. “Secure Cables in the CMA” on page 48

“Connecting Data and Management

Ports” on page 44

Cabling Requirements

Review these cabling notes before attaching cables to the server.

■ Minimum cable connections for the server:

■ At least one server on-board Ethernet network connection (NET port)

■ The SER MGT port

■ The NET MGT port

■ A power cable for each power supply

■ SP management ports: There are two management ports for use with the SP.

■ The SER MGT port uses an RJ-45 cable and is always available. This port is the

default connection to the SP.

■ The NET MGT port is the optional connection to the SP. This port becomes

available after you configure network settings for the SP (through the SER MGT

port).

The NET MGT port uses an RJ-45 cable for a 10/100 BASE-T connection. This

port does not support connections to Gigabit networks.

39

■ Ethernet ports are labeled NET0, NET1, NET2, and NET3. The Ethernet interfaces

operate at 10 Mbps, 100 Mbps, and 1000 Mbps.

TABLE: Ethernet Connection Transfer Rates

Connection Type IEEE Terminology Transfer Rate

Ethernet 10BASE-T 10 Mbit/sec

Fast Ethernet 100BASE-TX 100 Mbits/sec

Gigabit Ethernet 1000BASE-T 1000 Mbit/sec

■ VGA DB-15 video port: Use the video port to attach a color monitor to the server.

■ USB Ports: USB ports support hot-plugging. You can connect and disconnect USB

cables and peripheral devices without affecting system operations.

■ You can only perform USB hot-plug operations while the OS is running. USB

hot-plug operations are not supported when the system ok prompt is displayed

or before the system has completed booting.

■ You can connect up to 126 devices to each of the four USB controllers, for a total

of 504 USB devices per system.

■ Power cables: Do not attach power cables to the power supplies until you have

finished connecting the data cables, and have connected the server to a serial

terminal or a terminal emulator (PC or workstation).

Note – The server goes into Standby mode and the SP initializes as soon as a power

cable connects a power supply to an external power source. System messages might

be lost after 60 seconds if a terminal or terminal emulator is not connected to the SER

MGT port before power is applied.

Related Information

■ “Connecting Cables” on page 39

■ “Identifying Ports” on page 40

Identifying Ports

These topics provide reference information about the front and rear panel ports and

pin assignments.

■ “USB Ports” on page 41

40 SPARC T4-1 Server Installation Guide • August 2013

■ “SER MGT Port” on page 41

■ “NET MGT Port” on page 42

■ “Gigabit Ethernet Ports” on page 43

■ “Video Port” on page 43

USB Ports

Two USB ports can be accessed on the server’s front panel and two on the rear panel.

Each Each USB port supplies 5V output at 500 mA.

FIGURE: USB Connector

Figure Legend

1 +5V supply 3 Data +

2 Data - 4 Ground

Related Information

■ “Front Panel Components” on page 3

■ “Rear Panel Components” on page 6

SER MGT Port

The SER MGT RJ-45 port, located on the rear panel, provides the default connection

to the system console.

Connecting Cables 41

FIGURE: SER MGT Port

Figure Legend

1 Clear to Send 5 Ground

2 Data Carrier Detect 6 Receive Data

3 Transmit Data 7 Data Terminal Ready

4 Ground 8 Ready to Send

Related Information

■ “Front Panel Components” on page 3

■ “Rear Panel Components” on page 6

■ “Connect the SER MGT Port Cable” on page 44

■ “Connect a Terminal or Emulator to the SER MGT Port” on page 52

NET MGT Port

The NET MGT RJ-45 port, located on the rear panel, provides an optional Ethernet

connection to the service processor.

FIGURE: NET MGT Port

Figure Legend

1 Transmit Data + 5 No Connect

2 Transmit Data – 6 Receive Data –

3 Receive Data + 7 No Connect

4 No Connect 8 No Connect

42 SPARC T4-1 Server Installation Guide • August 2013

Related Information

■ “Front Panel Components” on page 3

■ “Rear Panel Components” on page 6

■ “Connect the NET MGT Port Cable” on page 45

■ “Assign a Static IP Address to the SP” on page 55

Gigabit Ethernet Ports

Four RJ-45 Gigabit-Ethernet connectors (NET0, NET1, NET2, NET3) are located on

the rear panel. The Ethernet interfaces operate at 10 Mbit/sec, 100 Mbit/sec, and

1000 Mbit/sec.

FIGURE: Gigabit Ethernet Port

Figure Legend

1 Transmit/Receive Data 0 + 5 Transmit/Receive Data 2 –

2 Transmit/Receive Data 0 – 6 Transmit/Receive Data 1 –

3 Transmit/Receive Data 1 + 7 Transmit/Receive Data 3 +

4 Transmit/Receive Data 2 + 8 Transmit/Receive Data 3 –

Related Information

■ “Front Panel Components” on page 3

■ “Rear Panel Components” on page 6

■ “Connect the NET MGT Port Cable” on page 45

Video Port

The server has one 15-pin VGA video port located on the server ’s rear panel.

Maximum supported resolution is 1024 x 768.

Connecting Cables 43

FIGURE: Video Connector

Figure Legend

1 Red Video 9 +5V

2 Green Video 10 Sync Ground

3 Blue Video 11 Monitor ID - Bit 0 (Ground)

4 Monitor ID - Bit 2 (Ground) 12 VGA 12C Serial Data

5 Ground 13 Horizontal Sync

6 Red Ground 14 Vertical Sync

7 Green Ground 15 VGA 12C Serial Clock

8 Blue Ground

Related Information

■ “Rear Panel Components” on page 6

Connecting Data and Management Ports

■ “Connect the SER MGT Port Cable” on page 44

■ “Connect the NET MGT Port Cable” on page 45

■ “Connect the Ethernet Network Cables” on page 46

■ “Connect Other Data Cables” on page 47

▼ Connect the SER MGT Port Cable

The SER MGT port is the farthest left RJ-45 port on the rear panel.

● Connect a Category 5 cable from the SER MGT port to the terminal device.

44 SPARC T4-1 Server Installation Guide • August 2013

FIGURE: SER MGT port – Rear Panel

This port is needed to set up the NET MGT port.

When connecting a DB-9 cable, use an RJ-45 to DB-9 adapter to perform the

crossovers given for each connector.

Note – Use the SER MGT port only for server management. This port is the default

connection between the SP and a terminal or a computer.

Caution – Do not attach a modem to this port.

Related Information

■ “Connect the NET MGT Port Cable” on page 45

■ “Connecting Cables” on page 39

▼ Connect the NET MGT Port Cable

The NET MGT port is located just to the right of the SER MGT port on the rear panel.

● Connect a Category 5 cable from the NET MGT port to your network switch or

hub.

Connecting Cables 45

FIGURE: NET MGT port – Rear Panel

Note – This port is not operational until you configure the network settings (through

the SER MGT port).

Note – The NET MGT port is configured by default to retrieve network settings with

Dynamic Host Configuration Protocol (DHCP) and allow connections using SSH.

You might need to modify these settings for your network. Instructions are given in

“Powering On the Server for the First Time” on page 51.

Related Information

■ “Connect the SER MGT Port Cable” on page 44

■ “Connecting Cables” on page 39

▼ Connect the Ethernet Network Cables

The server has four RJ-45 Gigabit Ethernet network connectors. They are marked

NET0, NET1, NET2, and NET3.

1. Connect a Category 5 cable from your network switch or hub to Ethernet Port 0

(NET0) on the rear of the chassis.

NET0 is the farthest left port in the 4-port network cluster.

46 SPARC T4-1 Server Installation Guide • August 2013

FIGURE: Ethernet Network Ports – Rear Panel

2. Connect Category 5 cables from your network switch or hub to the remaining

Ethernet ports (NET1, NET2, NET3), as needed.

Related Information

■ “Connecting Cables” on page 39

▼ Connect Other Data Cables

● If your server configuration includes PCIe expansion modules, connect the

appropriate I/O cables to their connectors.

Connecting Cables 47

FIGURE: PCIe and PCIe/XAUI Slot Configuration

Figure Legend

1 PCIe slot 0 or XAUI slot 0 4 PCIe slot 3 or XAUI slot 1

2 PCIe slot 1 5 PCIe slot 4

3 PCIe slot 2 6 PCIe slot 5

Related Information

■ “Connecting Cables” on page 39

▼ Secure Cables in the CMA

1. Once the server cables are connected and placed inside the CMA, open the

velcro cable straps and wrap the straps around the CMA securing the cables

inside the CMA.

48 SPARC T4-1 Server Installation Guide • August 2013

FIGURE: Securing the Server Cables With the CMA and Velcro Straps

2. Verify the operation of the slide rails and CMA, and cable service loops.

Repeat the steps described in the procedure: “Verify Correct Operation of the Slide

Rails and the CMA” on page 36.

Related Information

■ “Install the CMA” on page 31

■ “Verify Correct Operation of the Slide Rails and the CMA” on page 36

Connecting Cables 49

50 SPARC T4-1 Server Installation Guide • August 2013

Powering On the Server for the First

Time

These topics provide instructions for booting Oracle’s SPARC T4-1 server for the first

time and for enabling the NET MGT port. It consists of the following topics:

Step Description Links

1. Review the behavior of Oracle ILOM console output

when the system is powered on the first time.

2. Connect the server to a terminal display. “Connect a Terminal or Emulator to the SER MGT

3. Power on the server. “Power On the Server for the First Time” on page 53

4. Check that the server is operational. “Verify Functionality” on page 55

5. (Optional) Assign a static IP address to the SP. “Assigning a Static IP Address to the SP” on

6. Review the Oracle Solaris OS configuration

parameter descriptions.

“Oracle ILOM System Console” on page 51

Port” on page 52

page 55

“Oracle Solaris OS Configuration Parameters” on

page 57

Oracle ILOM System Console

When you power on the system, the boot process begins under the control of the

Oracle ILOM system console. The system console displays status and error messages

generated by firmware-based tests that are run during system startup.

Note – To see these status and error messages, connect a terminal or terminal

emulator to the SER MGT port before power is applied to the server.

51

After the system console finishes its low-level system diagnostics, the SP initializes

and runs a suite of higher level diagnostics. When you access the SP using a device

connected to the SER MGT port, you see the output of the Oracle ILOM diagnostics.

By default, the SP configures the NET MGT port automatically, retrieving network

configuration settings using the Dynamic Host Configuration Protocol (DHCP) and

allowing connections using SSH.

For a more detailed discussion on configuring the system console and connecting

terminals, refer to the system administration documentation for your server.

Related Information

■ “Connect a Terminal or Emulator to the SER MGT Port” on page 52

■ “Power On the Server for the First Time” on page 53

▼ Connect a Terminal or Emulator to the

SER MGT Port

A null modem configuration is needed for DTE to DTE communications. You can use

the supplied RJ-45 crossover adapter with a standard RJ-45 cable to achieve the null

modem configuration.

1. Connect a terminal or a terminal emulator (PC or workstation) to the SER MGT

port.

2. Configure the terminal or terminal emulator with these settings:

■ 9600 baud

■ 8 bits

■ No parity

■ 1 Stop bit

■ No handshake

3. (Optional) Connect an Ethernet cable between the server’s NET MGT port and

the network to which future connections to the SP and host will be made.

Related Information

■ “Oracle ILOM System Console” on page 51

■ “Power On the Server for the First Time” on page 53

52 SPARC T4-1 Server Installation Guide • August 2013

▼ Power On the Server for the First Time

1. Confirm that you have completed all of the preparations for installation.

See the instructions in “Confirming Server and Site Specifications” on page 1.

2. Confirm that you have completed the installation of the server in its rack.

See the instructions in “Installing the Server” on page 19.

3. (Recommended) Connect an Ethernet cable between one of the server’s NET

ports and the network to which the server will communicate.

Note – After the initial configuration of the system, communication with the SP and

host is usually performed through an Ethernet interface.

4. Plug the power cords into the power supplies and into separate power sources.

To provide redundancy, plug both power supplies into separate power sources.

The system can operate with only one power connection, but there is no

redundancy in this case.

The SP runs on the 3.3V standby voltage. As soon as AC power is connected to the

server, the SP powers on, runs diagnostics, and initializes the Oracle ILOM

firmware.

After a few minutes, the SP login prompt appears on the terminal device. The host

is not initialized or powered on yet.

5. At the terminal device, log in to the SP as root with a password of changeme.

hostname login: root

Password: changeme

. . .

->

6. Change the root password.

...

Warning: password is set to factory default.

-> set /SP/users/root password

Enter new password: ********

Enter new password again: ********

->

Powering On the Server for the First Time 53

7. Power on the server and redirect the host output to display on the serial

terminal device:

-> start /SYS

Are you sure you want to start /SYS (y/n)? y

-> start /HOST/console

Are you sure you want to start /HOST/CONSOLE (y/n)? y

Serial console started. To stop, type #.

. . .

After you start the HOST console, the server initialization takes approximately 20

minutes to complete.

8. Configure the OS by entering parameter values as prompted by a series of

onscreen instructions.

Tip – If you are not sure how to respond to a particular value, you can accept the

default and make changes at another time when the OS is running.

Note – You will be prompted to confirm the configuration multiple times. You will

be able to change parameter values if desired at each of these confirmation points.

9. (Optional) Deploy the server for its intended use.

Once the server has been configured and you have changed the default password,

the server is ready for normal use.

Related Information

■ “Connect a Terminal or Emulator to the SER MGT Port” on page 52

■ “Connecting Cables” on page 39

■ “Assign a Static IP Address to the SP” on page 55

54 SPARC T4-1 Server Installation Guide • August 2013

▼ Verify Functionality

● After powering on the system for the first time, use the Sun Validation Test

Suite (Sun VTS) software to verify the functionality and performance of the

system, including network connections.

Refer to the Sun VTS documentation for instructions on running these test

utilities, available at:

http://www.oracle.com/pls/topic/lookup?ctx=OracleVTS7.0

Assigning a Static IP Address to the SP

■ “Assign a Static IP Address to the SP” on page 55

■ “Oracle Solaris OS Configuration Parameters” on page 57

▼ Assign a Static IP Address to the SP

If the network your server is connected to does not support DHCP for IP addressing,

perform the following procedure to update the OS configuration to static IP

addressing and to assign a static IP address to the SP.

1. Set the SP to accept a Static IP Address.

-> set /SP/network pendingipdiscovery=static

Set 'pendingipdiscovery' to 'static'

2. Set the IP address for the SP.

-> set /SP/network pendingipaddress=service-processor-IPaddr

Set 'pendingipaddress' to 'service-processor-IPaddr'

3. Set the IP address for the SP gateway.

-> set /SP/network pendingipgateway=gateway-IPaddr

Set 'pendingipgateway' to 'gateway-IPaddr'

Powering On the Server for the First Time 55

4. Set the netmask for the SP.

-> set /SP/network pendingipnetmask=255.255.255.0

Set 'pendingipnetmask' to '255.255.255.0'

This example uses 255.255.255.0 to set the netmask. Your network

environment subnet might require a different netmask. Use a netmask number

most appropriate to your environment.

5. Use the show /SP/network command to verify that the parameters were set

correctly.

-> show /SP/network

/SP/network

Targets:

interconnect

ipv6

test

Properties:

commitpending = (Cannot show property)

dhcp_server_ip = none

ipaddress = xxx.xxx.xxx.xxx

ipdiscovery = static

ipgateway = xxx.xxx.xxx.xxx

ipnetmask = 255.255.252.0

macaddress = xx:xx:xx:xx:xx:xx

pendingipaddress = xxx.xxx.xxx.xxx

pendingipdiscovery = static

pendingipgateway = xxx.xxx.xxx.xxx

pendingipnetmask = 255.255.255.0

sidebandmacaddress = xx:xx:xx:xx:xx:xx

state = enabled

Commands:

cd

set

show

->

6. Commit the changes to the SP network parameters.

-> set /SP/network commitpending=true

Set 'commitpending' to 'true'

56 SPARC T4-1 Server Installation Guide • August 2013

Note – You can run the show /SP/network command again (after performing the

set /SP/network commitpending=true command) to verify that the

parameters have been updated.

Related Information

■ “Power On the Server for the First Time” on page 53

Oracle Solaris OS Configuration Parameters

When configuring the Oracle Solaris OS, you will be prompted for the following

configuration parameters. For more information about these settings, refer to the

Oracle Solaris documentation.

Parameter Description

Language Select a number from the displayed languages list.

Locale Select a number from the displayed locale list.

Terminal Type Select a terminal type that corresponds with your terminal device.

Network? Select Yes.

Multiple Network Interfaces Select the network interfaces that you plan to configure. If you are not sure,

select the first one in the list.

DHCP? Select Yes or No according to your network environment.

Host Name Type the host name for the server.

IP Address Type the IP address for this Ethernet interface.

Subnet? Select Yes or No according to your network environment.

Subnet Netmask If your answer to Subnet? was Yes, type the netmask for the subnet for your

network environment.

IPv6? Specify whether or not to use IPv6. If you are not sure, select No to

configure the Ethernet interface for IPv4.

Security Policy Select either standard UNIX security (no) or Kerberos Security (Yes). If you

are not sure, select No.

Confirm When prompted with this, review the onscreen information and change it if

needed. Otherwise, continue.

Name Service Select the name service according to your network environment.

Note – If you select a name service other than None, you will be prompted

for additional name service configuration information.

Powering On the Server for the First Time 57

Parameter Description

NFSv4 Domain Name Select the type of domain name configuration according to your

environment. If you are not sure, select Use the NFSv4 domain

derived by the system.

Time Zone (Continent) Select your continent.

Time Zone (Country or Region) Select your country or region.

Time Zone Select the time zone.

Date and Time Accept the default date and time, or change the values.

root Password Type the root password twice. This password is for the superuser account

for the Oracle Solaris OS on this server. This password is not the SP

password.

Related Information

■ “Oracle ILOM System Console” on page 51

■ “Connect a Terminal or Emulator to the SER MGT Port” on page 52

■ “Power On the Server for the First Time” on page 53

58 SPARC T4-1 Server Installation Guide • August 2013

Glossary

A

ANSI SIS American National Standards Institute Status Indicator Standard.

ASF Alert standard format (Netra products only).

ASR Automatic system recovery.

AWG American wire gauge.

B

blade Generic term for server modules and storage modules. See server module and

storage module.

blade server Server module. See server module.

BMC Baseboard management controller.

BOB Memory buffer on board.

C

chassis For servers, refers to the server enclosure. For server modules, refers to the

modular system enclosure.

CMA Cable management arm.

59

CMM Chassis monitoring module. The CMM is the service processor in the

modular system. Oracle ILOM runs on the CMM, providing lights out

management of the components in the modular system chassis. See Modular

system and Oracle ILOM.

CMM Oracle ILOM Oracle ILOM that runs on the CMM. See Oracle ILOM.

D

DHCP Dynamic Host Configuration Protocol.

disk module or

disk blade

DTE Data terminal equipment.

E

EIA Electronics Industries Alliance.

ESD Electrostatic discharge.

F

FEM Fabric expansion module. FEMs enable server modules to use the 10GbE

FRU Field-replaceable unit.

Interchangeable terms for storage module. See storage module.

connections provided by certain NEMs. See NEM.

H

HBA Host bus adapter.

host The part of the server or server module with the CPU and other hardware

that runs the Oracle Solaris OS and other applications. The term host is used

to distinguish the primary computer from the SP. See SP.

60 SPARC T4-1 Server Installation Guide • August 2013

I

ID PROM Chip that contains system information for the server or server module.

IP Internet Protocol.

K

KVM Keyboard, video, mouse. Refers to using a switch to enable sharing of one

keyboard, one display, and one mouse with more than one computer.

L

LwA Sound power level.

M

MAC Machine access code.

MAC address Media access controller address.

Modular system The rackmountable chassis that holds server modules, storage modules,

NEMs, and PCI EMs. The modular system provides Oracle ILOM through its

CMM.

MSGID Message identifier.

N

name space Top-level Oracle ILOM CMM target.

NEBS Network Equipment-Building System (Netra products only).

Glossary 61

NEM Network express module. NEMs provide 10/100/1000 Mbps Ethernet,

10GbE Ethernet ports, and SAS connectivity to storage modules.

NET MGT Network management port. An Ethernet port on the server SP, the server

module SP, and the CMM.

NIC Network interface card or controller.

NMI Nonmaskable interrupt.

O

OBP OpenBoot PROM.

Oracle ILOM Oracle Integrated Lights Out Manager. Oracle ILOM firmware is preinstalled

on a variety of Oracle systems. Oracle ILOM enables you to remotely

manage your Oracle servers regardless of the state of the host system.

Oracle Solaris OS Oracle Solaris operating system.

P

PCI Peripheral component interconnect.

PCI EM PCIe ExpressModule. Modular components that are based on the PCI

Express industry-standard form factor and offer I/O features such as Gigabit

Ethernet and Fibre Channel.

POST Power-on self-test.

PROM Programmable read-only memory.

PSH Predictive self healing.

Q

QSFP Quad small form-factor pluggable.

62 SPARC T4-1 Server Installation Guide • August 2013

R

REM RAID expansion module. Sometimes referred to as an HBA See HBA.

Supports the creation of RAID volumes on drives.

S

SAS Serial attached SCSI.

SCC System configuration chip.

SER MGT Serial management port. A serial port on the server SP, the server module SP,

and the CMM.

server module Modular component that provides the main compute resources (CPU and

memory) in a modular system. Server modules might also have onboard

storage and connectors that hold REMs and FEMs.

SP Service processor. In the server or server module, the SP is a card with its

own OS. The SP processes Oracle ILOM commands providing lights out

management control of the host. See host.

SSD Solid-state drive.

SSH Secure shell.

storage module Modular component that provides computing storage to the server modules.

T

TIA Telecommunications Industry Association (Netra products only).

Tma Maximum ambient temperature.

U

UCP Universal connector port.

Glossary 63

UI User interface.

UL Underwriters Laboratory Inc.

US. NEC United States National Electrical Code.

UTC Coordinated Universal Time.

UUID Universal unique identifier.

W

WWN World wide name. A unique number that identifies a SAS target.

64 SPARC T4-1 Server Installation Guide • August 2013

Index

A

acoustic noise emissions, 12

adapters for serial cables, 45

airflow requirements, 12

ambient temperature range, 11

anti-tilt legs or bar, 21

B

baud rate for serial terminal, 52

bits setting for serial terminal, 52

booting the system, 51

buttons, See "slide rail assembly locks"

C

cable management assembly, 38

cables

adapters for serial data cables, 45

clearance, 9

configuring

Oracle Solaris OS, 57

CPU description, 2

D

diagnostics, when run, 53

drives, 2

E

environmental requirements, 11

Ethernet ports

described, 2

pinouts, 43

H

handshaking for serial terminal, no, 52

hot-plugging USB ports, 40

humidity, ambient relative, 11

I

installing

mounting brackets, 25

server into rack, 19

L

levers, locking, See "slide rail assembly locks"

locating pins for mounting brackets, 25

locks, See "slide rail assembly locks"

M

memory description, 2

minimum cable connections, 39

modem not to be used with the SER MGT port, 45

mounting bracket

locating pins on chassis, 25

preparation for installation, 25

removing from slide rail, 25

unlocking, 25

N

network management (NET MGT) port

pinouts, 42

O

Oracle Solaris OS

configuration parameters, 57

P

parity for serial terminal, no, 52

PCIe cards

slots, 2

pinouts

Ethernet ports, 43

65

NET MGT port, 42

SER MGT port, 41

USB ports, 41

video port, 43, 44

pins, mounting bracket locating, 25

power supplies, 2

R

rack

compatibility, 19

mounting holes, supported, 20

specifications, 19

stabilizing, 21

rackmount

anti-tilt legs or bar, extending, 21

kit, 19

racks, supported, 19

safety warnings, 20

stabilizing the rack, 21

RJ-45 cable, 39

S

SER MGT port, 41

server overview, 1

service processor

powering on for the first time, 53

shipping kit contents, 15

SP (service processor), 2

specifications

acoustic, 12

environmental requirements, 11

physical, 9

server, 8

standby voltage, 3.3v, 53

stop bit, 52

V

video port

described, 2

pinouts, 43

resolution, 43

use of, 40

T

temperature requirements, 11

U

unlocking mounting bracket, 25

USB ports

described, 2

function, 40

output power, 41

pinouts, 41

66 SPARC T4-1 Server Installation Guide • August 2013

Loading...

Loading...