Page 1

Netra SPARC T3-1 Server

Installation Guide

Part No.: E20690-02

August 2013

Page 2

Copyright ©2011, 2013, Oracle and/or its affiliates. Allrights reserved.

This softwareand related documentation are provided undera licenseagreement containing restrictions on use and disclosureand are protected by

intellectual propertylaws. Exceptas expressly permitted inyour licenseagreement or allowed by law, you may not use, copy, reproduce, translate,

broadcast, modify, license, transmit, distribute, exhibit, perform, publish, or display any part, in any form, or by any means. Reverse engineering,

disassembly, or decompilationof thissoftware, unless requiredby lawfor interoperability, is prohibited.

The informationcontained hereinis subjectto changewithout noticeand isnot warrantedto beerror-free.If youfind anyerrors, please report them to us

in writing.

If thisis softwareor related software documentation that is delivered to the U.S. Government or anyone licensing it on behalf of the U.S. Government, the

following noticeis applicable:

U.S. GOVERNMENTEND USERS.Oracle programs,including anyoperating system,integrated software, any programs installed onthe hardware,

and/or documentation,delivered toU.S. Governmentend usersare "commercial computer software" pursuantto theapplicable FederalAcquisition

Regulation andagency-specific supplementalregulations. Assuch, use,duplication, disclosure, modification, andadaptation ofthe programs, including

any operatingsystem, integratedsoftware, anyprograms installed on the hardware,and/or documentation,shall besubject tolicense termsand license

restrictions applicableto theprograms. No other rights are granted to the U.S. Government.

This software or hardware is developed for general use in a variety ofinformation managementapplications. Itis not developed or intended for use in any

inherently dangerous applications, includingapplications thatmay create a riskof personalinjury. If you use this software or hardwarein dangerous

applications, thenyou shallbe responsibleto takeall appropriate fail-safe, backup,redundancy, and other measuresto ensure its safe use. Oracle

Corporation andits affiliatesdisclaim anyliability forany damagescaused byuse ofthis software or hardware in dangerous applications.

Oracle andJava areregistered trademarks of Oracle and/or its affiliates.Other namesmay betrademarks oftheir respective owners.

Intel andIntel Xeonare trademarksor registered trademarks of Intel Corporation. All SPARC trademarks areused underlicense andare trademarks or

registered trademarks of SPARCInternational, Inc. AMD, Opteron, theAMD logo,and theAMD Opteron logo are trademarksor registered trademarksof

Advanced MicroDevices. UNIXis aregistered trademark of The Open Group.

This software or hardware and documentation may provide access to or information on content, products, and services from third parties. Oracle

Corporation and its affiliates are not responsible for and expressly disclaim all warranties of any kind with respect to third-party content, products, and

services. Oracle Corporation and its affiliates will not be responsible for any loss, costs, or damages incurred due to your access to or use of third-party

content, products, or services.

Copyright ©2011, 2013, Oracle et/ou ses affiliés. Tous droits réservés.

Ce logicielet ladocumentation quil’accompagne sontprotégés parles loissur lapropriété intellectuelle. Ils sont concédés sous licence et soumis à des

restrictions d’utilisationet dedivulgation. Saufdisposition devotre contrat de licence ou de la loi, vous ne pouvez pas copier, reproduire,traduire,

diffuser, modifier,breveter, transmettre, distribuer, exposer, exécuter,publier ouafficher le logiciel, même partiellement, sous quelque forme et par

quelque procédéque cesoit. Parailleurs, ilest interdit de procéder à touteingénierie inversedu logiciel,de ledésassembler oude ledécompiler,excepté à

des finsd’interopérabilité avecdes logicielstiers outel queprescrit par la loi.

Les informationsfournies dansce documentsont susceptiblesde modificationsans préavis.Par ailleurs,Oracle Corporationne garantitpas qu’elles

soient exemptesd’erreurs etvous invite,le caséchéant, àlui enfaire part par écrit.

Si celogiciel, oula documentationqui l’accompagne,est concédésous licenceau Gouvernementdes Etats-Unis,ou àtoute entitéqui délivrela licencede

ce logicielou l’utilisepour lecompte duGouvernement desEtats-Unis, lanotice suivantes’applique :

U.S. GOVERNMENTEND USERS.Oracle programs,including anyoperating system,integrated software, any programs installed onthe hardware,

and/or documentation,delivered toU.S. Governmentend usersare "commercial computer software" pursuantto theapplicable FederalAcquisition

Regulation andagency-specific supplementalregulations. Assuch, use,duplication, disclosure, modification, andadaptation ofthe programs, including

any operatingsystem, integratedsoftware, anyprograms installed on the hardware,and/or documentation,shall besubject tolicense termsand license

restrictions applicableto theprograms. No other rights are granted to the U.S. Government.

Ce logicielou matériela étédéveloppé pourun usagegénéral dansle cadred’applications degestion desinformations. Celogiciel oumatériel n’estpas

conçu nin’est destinéà êtreutilisé dansdes applicationsà risque,notamment dansdes applicationspouvant causerdes dommagescorporels. Si vous

utilisez celogiciel oumatériel dansle cadred’applications dangereuses, il estde votre responsabilité deprendre toutes les mesures desecours, de

sauvegarde, deredondance et autres mesures nécessaires à sonutilisation dansdes conditionsoptimales desécurité. OracleCorporation etses affiliés

déclinent touteresponsabilité quantaux dommagescausés parl’utilisation dece logicielou matérielpour cetype d’applications.

Oracle etJava sontdes marquesdéposées d’OracleCorporation et/oude sesaffiliés.Tout autre nom mentionné peut correspondre à desmarques

appartenant àd’autres propriétaires qu’Oracle.

Intel etIntel Xeonsont desmarques oudes marques déposées d’IntelCorporation. Toutes lesmarques SPARCsont utiliséessous licenceet sontdes

marques oudes marques déposées deSPARC International, Inc.AMD, Opteron, le logoAMD etle logoAMD Opteron sont des marques oudes marques

déposées d’AdvancedMicro Devices.UNIX estune marque déposée d’TheOpen Group.

Ce logicielou matérielet ladocumentation quil’accompagne peuventfournir desinformations oudes liensdonnant accèsà descontenus, desproduits et

des servicesémanant detiers. OracleCorporation etses affiliésdéclinent touteresponsabilité ou garantie expresse quant aux contenus, produits ou

services émanantde tiers.En aucuncas, OracleCorporation etses affiliésne sauraientêtre tenus pour responsables des pertes subies, des coûts

occasionnés oudes dommagescausés parl’accès àdes contenus,produits ouservices tiers,ou àleur utilisation.

Please

Recycle

Page 3

Contents

Using This Documentation vii

Preparing for Installation 1

Installation Task Overview 1

Server Overview 2

Confirming Server Specifications 5

Physical Specifications 5

Minimum Clearance for Service Access 6

Electrical Specifications 6

Input Power Information 7

Overcurrent Protection Requirements 8

DC Power Source, Power Connection, and Grounding Requirements 8

AC and DC Server Environmental Requirements 10

Acoustic Noise Emissions 10

Cooling Zones and Airflow Clearance 11

Shipping Kit Inventory List 12

Front Panel Components 13

Back Panel Components 14

Server Handling Precautions 15

ESD Precautions 16

Tools Needed for Installation 16

Optional Component Installation 17

iii

Page 4

Installing the Server 19

Rack Compatibility 19

Rack Cautions 20

▼ Stabilize the Rack for Installation 21

Mounting the Server Into a 4-Post Rack 22

19-Inch, 4-Post Hardmount Rackmount Kit 23

▼ Install the Server (19-Inch, 4-Post Hardmount Rackmount Kit) 24

19-Inch, 4-Post Sliding Rail Rackmount Kit 27

▼ Install the Server (19-Inch, 4-Post Sliding Rail Rackmount Kit) 28

600-mm, 4-Post Hardmount Rackmount Kit 34

▼ Install the Server (600-mm, 4-Post Hardmount Rackmount Kit) 35

Mounting the Server Into a 2-Post Rack 42

23-Inch, 2-Post Hardmount Rackmount Kit 44

▼ Install the Server (23-Inch, 2-Post Hardmount Rackmount Kit) 45

19-Inch, 2-Post Hardmount Rackmount Kit 50

▼ Install the Server (19-Inch, 2-Post Hardmount Rackmount Kit) 51

19-Inch, 2-Post Rack Sliding Rail Rackmount Kit 56

▼ Install a Server (19-Inch, 2-Post Sliding Rail Rackmount Kit) 57

Connecting the Server Cables 65

Cabling Requirements 65

Back Panel Connectors and Ports 66

▼ Connect the SER MGT Cable 67

▼ Connect the NET MGT Cable 68

▼ Connect the Ethernet Network Cables 69

▼ Connect Other Data Cables 69

▼ Prepare the Power Cords 70

Assembling and Connecting DC Power Cords 71

iv Netra SPARC T3-1 Server Installation Guide • August 2013

Page 5

▼ Assemble the DC Input Power Cables 71

▼ Connect the DC Input Power Cords to the Server 74

Powering On the Server for the First Time 77

Power On Task Overview 77

Oracle ILOM System Console Overview 78

▼ Connect a Terminal or Emulator to the SER MGT Port 79

▼ Power On the Server for the First Time 79

Oracle Solaris OS Configuration Parameters 82

Assigning a Static IP Address to the Service Processor 83

▼ Log In to the Service Processor (SER MGT Port) 83

▼ Assign a Static IP to the NET MGT Port 85

Identifying the Server Ports 89

USB Ports 89

Alarm Port 90

SER MGT Port 91

NET MGT Port 91

Gigabit-Ethernet Ports 92

Video Port 93

Glossary 95

Index 101

Contents v

Page 6

vi Netra SPARC T3-1 Server Installation Guide • August 2013

Page 7

Using This Documentation

This installation guide provides instructions, background information, and reference

material to help you install Oracle’s Netra SPARC T3-1 server.

■ “Related Documentation” on page vii

■ “Documentation, Support, and Training” on page viii

Related Documentation

The Netra SPARC T3-1 server documents listed as online are available at:

http://www.oracle.com/pls/topic/lookup?ctx=E20689-01&id=homepage

Application Title Format Location

Installation,

administration,

service

Late-breaking

information

Getting started Netra Rack Server Getting Started Guide Printed Ships with

Installation and

planning

Administration Netra SPARC T3-1 Server Administration Guide PDF Online

Service Netra SPARC T3-1 Server Service Manual PDF Online

Safety and

compliance

Netra SPARC T3-1 Server Topic Set HTML Online

Netra SPARC T3-1 Server Product Notes PDF Online

Netra SPARC T3-1 Server Installation Guide PDF Online

Netra SPARC T3-1 Server Safety and Compliance Guide PDF Online

server

vii

Page 8

The Oracle Integrated Lights Out Manager (ILOM) 3.0 documentation is online at:

http://www.oracle.com/pls/topic/lookup?ctx=ilom30&id=homepage

Application Title Location

Late-breaking news

and issues

Installation and

configuration

Conceptual

information

Browser interface

procedures

CLI procedures Oracle Integrated Lights Out Manager (ILOM) 3.0 CLI Procedures Guide Online

SNMP and IPMI

procedures

Oracle Integrated Lights Out Manager (ILOM) 3.0 Features Updates and Release

Notes

Oracle Integrated Lights Out Manager (ILOM) 3.0 Getting Started Guide Online

Oracle Integrated Lights Out Manager (ILOM) 3.0 Concepts Guide Online

Oracle Integrated Lights Out Manager (ILOM) 3.0 Web Interface Procedures

Guide

Oracle Integrated Lights Out Manager (ILOM) 3.0 Management Protocols

Reference Guide: SNMP, IPMI, WS-Man, CIM

Online

Online

Online

Documentation, Support, and Training

These web sites provide additional resources:

■ Documentation (http://www.oracle.com/technetwork/indexes/

documentation/index.html)

■ Support (https://support.oracle.com)

■ Training (https://education.oracle.com)

viii Netra SPARC T3-1 Server Installation Guide • August 2013

Page 9

Preparing for Installation

These topics provide background information needed to install the Netra SPARC

T3-1 server.

■ “Installation Task Overview” on page 1

■ “Server Overview” on page 2

■ “Confirming Server Specifications” on page 5

■ “Shipping Kit Inventory List” on page 12

■ “Front Panel Components” on page 13

■ “Back Panel Components” on page 14

■ “Server Handling Precautions” on page 15

■ “ESD Precautions” on page 16

■ “Tools Needed for Installation” on page 16

■ “Optional Component Installation” on page 17

Related Information

■ “Installing the Server” on page 19

Installation Task Overview

Perform the following tasks to install and configure the server.

Step Description Links

1. Review the Server Product Notes for any

late-breaking news about the server.

2. Review the server features, specifications, and site

requirements.

3. Confirm you received all of the items you ordered. “Shipping Kit Inventory List” on page 12

Server Product Notes

“Server Overview” on page 2

“Confirming Server Specifications” on page 5

1

Page 10

Step Description Links

4. Familiarize yourself with the server features,

controls, and LEDs required for installation.

5. Review the input power information, assemble the

required tools, and take ESD and safety precautions.

6. Install any optional component into the server. “Optional Component Installation” on page 17

7. Install the server into either a 4-post or 2-post rack. “Stabilize the Rack for Installation” on page 21

8. Attach data and management cables to the server. “Connecting the Server Cables” on page 65

9. Connect the power cords to the server, configure the

ILOM service processor, power on the server for the

first time, and boot the operating system.

“Front Panel Components” on page 13

“Back Panel Components” on page 14

“Input Power Information” on page 7

“Tools Needed for Installation” on page 16

“ESD Precautions” on page 16

“Mounting the Server Into a 4-Post Rack” on

page 22

“Mounting the Server Into a 2-Post Rack” on

page 42

“Powering On the Server for the First Time” on

page 77

“Preparing for Installation” on page 1

Related Information

■ Netra SPARC T3-1 Server Product Notes

■ Netra SPARC T3-1 Server Safety and Compliance Guide

■ Netra SPARC T3-1 Server Service Manual

Server Overview

This topic describes the main components and capabilities of the server. The first

illustration shows the server with the air filter. The second illustration shows the

server without the air filter.

2 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 11

Preparing for Installation 3

Page 12

Component Description

CPU SPARC T3, single socket 16-core, 1.6 GHz

Memory DDR3 1066 MHz registered DIMMs with ECC

4 GB and 8 GB DIMM capacities supported

Total x16 DIMMs

Removable mass storage Four SFF (2.5 in.) SAS drives

One SATA DVD drive

Service processor ASPEED AST2200 BMC running Oracle ILOM 3.x. service processor firmware with

provision for:

• 2D graphics (HD-15 VGA Connector)

• 128 MB SDRAM

• Serial management (RJ-45)

• Network management (10/100Base-T Ethernet RJ-45)

• Complete host remote management including remote KVMS over Ethernet

TPM support TCG TPM v1.2 functionality support with an Infineon

SLB 9635

Front I/O ports Two USB 2.0 port (Type A)

Rear I/O ports From the motherboard:

• Four 10/100/1000Base-T Ethernet (RJ-45) with integrated link/speed LEDs

• SER MGT (TIA/EIA-232 serial via RJ-45: Sun/Cisco standard)

• NET MGT 10/100Base-T Ethernet (RJ-45)

• Two USB 2.0 ports (Type A)

• VGA video port (HD-15)

• Optional 10Gb dual ports with XAUI cards

From the PCI mezzanine board:

• DCA relay connection (DB-15)

Front panel indicators and

switches

Provision for the following indicator and switches:

• Power button switch

• Locate button switch with integrated white LED

• System OK LED (Green)

• System fault LED (Amber)

• Alarm LEDs - Critical (Red), Major (Red), Minor (Amber), User (Amber)

• Fan Module Fault LEDs

Expansion slots PCI-Express Generation 2:

• Two full-height / half-length PCI2 2.0 x8 electrical / x16 mechanical slots with

tool-less mechanical fillers

• Three PCIe 2.0 x8 electrical / x8 mechanical low-profile, or one PCIe 2.0 x8

electrical / x8 mechanical low-profile and two XAUI cards (fiber or copper

versions)

4 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 13

Related Information

■ “Confirming Server Specifications” on page 5

■ “Installation Task Overview” on page 1

Confirming Server Specifications

Prior to installing the server, review the server specifications and prepare the

installation site.

■ “Physical Specifications” on page 5

■ “Electrical Specifications” on page 6

■ “Input Power Information” on page 7

■ “Overcurrent Protection Requirements” on page 8

■ “DC Power Source, Power Connection, and Grounding Requirements” on page 8

■ “AC and DC Server Environmental Requirements” on page 10

■ “Acoustic Noise Emissions” on page 10

■ “Cooling Zones and Airflow Clearance” on page 11

Related Information

■ “Server Overview” on page 2

Physical Specifications

Note – To enable safe installation and servicing, provide 36 in. (91 cm) clearance in

the front and rear of the server.

Dimension Value

Height 3.43 in. (87.1 mm)

Width 17.52 in. (445 mm)

Depth 20.71 in. (526 mm) maximum (measured from bezel to PSU

handles.

Weight (server only) 41 lbs (18.6 kg) minimum

Preparing for Installation 5

Page 14

Related Information

■ “Minimum Clearance for Service Access” on page 6

■ “Electrical Specifications” on page 6

■ “Input Power Information” on page 7

■ “Overcurrent Protection Requirements” on page 8

■ “DC Power Source, Power Connection, and Grounding Requirements” on page 8

■ “AC and DC Server Environmental Requirements” on page 10

■ “Acoustic Noise Emissions” on page 10

■ “Cooling Zones and Airflow Clearance” on page 11

Minimum Clearance for Service Access

Description Specification

Clearance, front of server 36 inches (91 cm)

Clearance, rear of server 36 inches (91 cm)

Related Information

■ “Physical Specifications” on page 5

■ Netra SPARC T3-1 Server Service Manual

Electrical Specifications

Note – The values in this table are the power supply specifications.

Parameter AC DC

Voltage (nominal) 100 to 127 or 200 to 240 VAC

(90 to 140 or 180 to 264 VAC ranges)

Input current (maximum) 9.4 A @ 100 VAC or 4.7 A @ 200 VAC

(940 VA)

Frequency (nominal) 50/60 Hz (47 to 63 Hz range) N/A

DC input treatment N/A Isolated DC Return (DC-I)

-48 or -60 VDC (-40 to -75 VDC range)

19.58 A -48 VDC (940 VA)

6 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 15

Caution – The ports of this equipment or subassembly are suitable for connection to

intra-building or unexposed wiring or cabling only. The intra-building port(s) of the

equipment or subassembly must not be metallically connected to interfaces that

connect to the outside plant wiring. These interfaces are designed for use as

intra-building interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE,

Issue 4) and require isolation from the exposed outside plant cabling. The addition of

primary protectors is not sufficient protection in order to connect these interfaces

metallically to outside plant wiring.

Related Information

■ “Input Power Information” on page 7

■ “Overcurrent Protection Requirements” on page 8

■ “DC Power Source, Power Connection, and Grounding Requirements” on page 8

Input Power Information

The total input power for the server is divided equally among the power supplies in

operation. Reversing the positive and negative inputs to the power supplies of a DC

input server will not cause damage. However, the power supplies with reversed

input will not operate.

The inputs to a power supply are isolated from the server chassis and the other

power supply inputs. The AC or DC power inputs might be at different voltages

within the acceptable range and might have different offset voltages relative to the

server chassis.

Note – The server does not require an additional surge protector for the AC or DC

power configurations if the facility has a surge protector that limits voltage surges to

less than 2000 volts. You can, however, install a surge protector if your site requires

an additional protector.

Caution – Safety agency requirements prohibit Oracle Corporation from changing a

product from AC input to DC input or from DC input to AC input after the product

has been removed from the agency approved manufacturing site.

Related Information

■ “Electrical Specifications” on page 6

Preparing for Installation 7

Page 16

■ “Overcurrent Protection Requirements” on page 8

■ “DC Power Source, Power Connection, and Grounding Requirements” on page 8

Overcurrent Protection Requirements

This product does not provide branch circuit overcurrent protection as defined by the

U.S. NEC. To comply with the U.S. NEC, you must install this product on branch

circuits that have overcurrent protection as defined by Article 240 of the U.S. NEC.

■ Product power inputs with a current ratings of 16A or less must have a branch

circuit, or a supplementary overcurrent protection device, rated at no more than

20A.

■ Product power inputs with current ratings of more than 16A must have a branch

circuit, or a supplementary overcurrent protection device, rated at no more than

160% of the product input current rating.

■ Other national or local electrical codes might apply to the installation of this

product.

As a general guideline, overcurrent protection devices should be rated at a minimum

of 125% of the product input current rating in order to provide reliable power under

high temperature and transient voltage disturbance conditions. However, you must

consider the characteristics of the protection device and the applicable electrical

codes when selecting the rating of a protection device for the product installation.

Note – Overcurrent protection devices must meet applicable national and local

electrical safety codes, and be approved for the intended application.

Related Information

■ “Electrical Specifications” on page 6

■ “Input Power Information” on page 7

■ “DC Power Source, Power Connection, and Grounding Requirements” on page 8

DC Power Source, Power Connection, and

Grounding Requirements

The server power source and connections must meet the following requirements:

8 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 17

Caution – The DC power source must be reliably grounded. The server chassis must

be grounded with the power supply ground pins or with the chassis ground studs. It

is acceptable to have both grounds connected.

Note – The DC version of the server must be installed in a restricted-access location.

According to the intent of the U.S. NEC, National Electrical Code, a restricted-access

location is an area intended for qualified or trained personnel only and has access

controlled by a locking mechanism, such as a key lock or an access card system.

Caution – You must restrict the connection of the server to the DC power source to

minimize the possibility that transient energy will appear on the main input to the

equipment. The DC battery power source must be in the same premises as the server.

The server cannot be in one building with the power source in another building.

■ Suitable conductor material: Use copper conductors only.

■ Power supply connections through the input connector: 8 AWG (between the

server and the source). There are three conductors:

■ -48V or -60V (negative terminal, might be marked with a minus (-) symbol).

■ Chassis ground connection (optional if chassis ground wire is connected).

■ -48V or -60V return (positive terminal, might be marked with a plus (+)

symbol).

■ Server chassis ground 8 AWG conductor (optional if power supply grounds are

connected).

■ Cable insulation rating: Minimum of 75˚C (167˚F). (Low smoke fume (LSF), flame

retardant insulation might be required in some installations.)

■ Use mating connectors, Wago part number 51204745, for proper connection to the

product DC inputs. Connectors are included in the server’s shipping kit.

■ Branch circuit cable insulation color: According to applicable national electrical

codes.

■ Grounding cable insulation color: Green/yellow.

■ DC power source must meet TNV-2 requirements as defined by UL 60950-1 and

IEC 60950-1.

Related Information

■ “Electrical Specifications” on page 6

■ “Input Power Information” on page 7

■ “Overcurrent Protection Requirements” on page 8

Preparing for Installation 9

Page 18

■ “Assembling and Connecting DC Power Cords” on page 71

AC and DC Server Environmental Requirements

Caution – Netra rack mounted servers are certified to meet these worst-case

operating conditions only when using an approved rackmount kit. You must strictly

follow the rackmounting instructions in order to meet these environmental

specification.

Specification Operating Nonoperating

Ambient temperature

*

Maximum: 41˚F to 104˚F (5˚C to 40˚C) up to

6000 feet (1829 meters)

Optimal: 69.8˚F to 73.4˚F (21˚C to 23˚C)

Short term maximum: 23˚F to 131˚F (-5˚C to 55˚C)

†

–40˚F to 158˚F (–40˚C to 70˚C)

Relative humidity Operating: 5% to 85% noncondensing, 85˚ (27˚C)

maximum wet bulb

Elevation

(Company requirement)

Elevation

(NEBS requirement)

* Does not apply to removable media devices.

† Maximum ambient operating temperature is derated by 1 degree C per 500m elevation.

Maximum 9840 feet (3000 meters) at 104˚F (40˚C) Maximum 39370 feet (12000

-200 feet to 5900 feet (-60 meters to 1800 meters) at

104˚F (40˚C)

5900 feet to 13100 feet (1800 meters to 4000 meters)

at 86˚F (30˚C)

Related Information

■ “Acoustic Noise Emissions” on page 10

■ “Cooling Zones and Airflow Clearance” on page 11

Acoustic Noise Emissions

5% to 93% noncondensing

100.4˚ (37.7˚C) maximum wet

bulb

meters)

The declared noise emissions for the server are in accordance with ISO 9296

standards.

10 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 19

Parameter Operating Noise Emissions

Acoustic power LWA (dBA) 70.8 dBA (AC server)

70.8 dBA (DC server)

Related Information

■ Netra SPARC T3-1 Server Safety and Compliance Guide

Cooling Zones and Airflow Clearance

Note – Proper airflow into and out of the server is essential for keeping the server’s

internal temperatures within a safe operating range.

The server draws cool air from the front of the server and expels hot air out the rear.

To avoid overheating the server:

■ Ensure that inlet air enters at the front of the server and exits from the back.

■ Ensure unobstructed airflow through the server.

■ Do not direct warm air toward the front air intake of the server.

■ Prevent recirculation of exhaust air within a rack or cabinet.

■ Manage cables to minimize interfering with the server exhaust vent.

■ Ensure that the server ventilation openings used for intake and outflow of air

provide an open area that is at least 60% of the open area perforations across the

front and rear of the server.

■ Allow a minimum of 5 mm (0.2 in.) clearance at the front of the system and 80 mm

(3.1 in.) at the rear of the server when mounted. These clearance values are based

on the preceding inlet and exhaust impedance (available open area) and assume a

uniform distribution of the open area across the inlet and exhaust areas. Clearance

values greater than these are recommended for improved cooling performance.

Note – Be mindful that the combination of inlet and exhaust restrictions, such as

cabinet doors and the spacing of the server from the doors, can affect the cooling

performance of the server.

Related Information

■ “Physical Specifications” on page 5

Preparing for Installation 11

Page 20

■ “Minimum Clearance for Service Access” on page 6

Shipping Kit Inventory List

Note – When you receive your server, place it in the environment where you will

install it. Leave the server in its shipping crate at its final destination for 24 hours.

This resting period prevents thermal shock and condensation.

Verify that you have received all of the components that ship with your server.

■ Netra SPARC T3-1 server

■ 2 AC power cords (if ordered)

■ RJ-45 to DB-9 serial adapter

■ RJ-45 to DB-25 analog to digital video adapter

■ Antistatic wrist strap

■ 19-inch, 4-post rackmount kit

■ Netra Rack Server Getting Started Guide with license and safety documents

12 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 21

■ Optional components (for example, PCIe cards) that are packaged separately from

the other items unless they are installed at the factory as part of the system.

Related Information

■ “Server Handling Precautions” on page 15

■ “ESD Precautions” on page 16

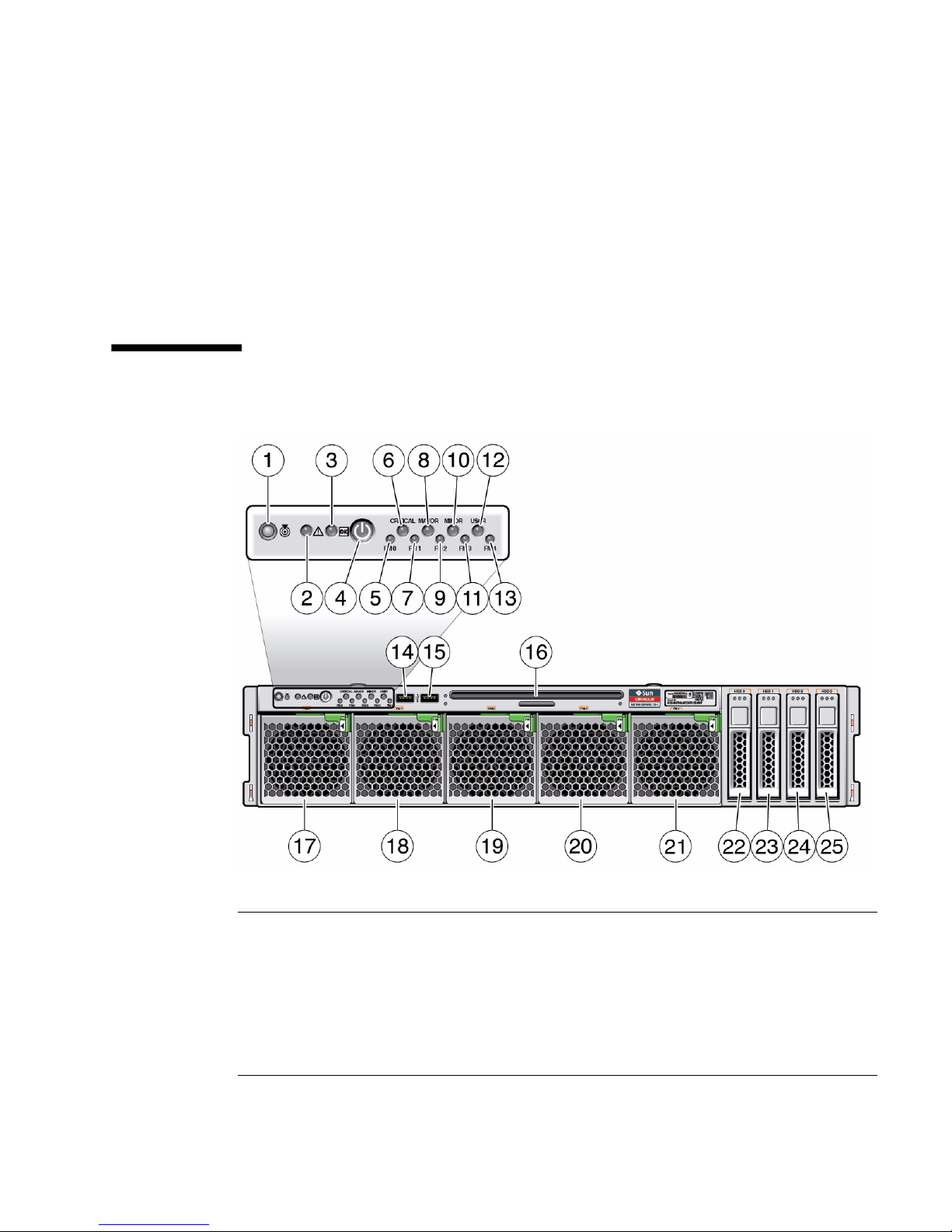

Front Panel Components

1 Locator LED/Locator button: white 14 USB 2.0 port (USB 3)

2 Service Action Required LED: amber 15 USB 2.0 port (USB 4)

3 Main Power/OK LED: green 16 DVD drive

4 Power button 17 Fan module (FM0)

5 Fan Fault (FM 0) LED: green (normal),

amber (fault)

18 Fan module (FM1)

Preparing for Installation 13

Page 22

6 Critical Alarm LED: red 19 Fan module (FM2)

7 Fan Fault LED (FM 1): green (normal),

amber (fault)

8 Major Alarm LED: red 21 Fan module (FM4)

9 Fan Fault LED (FM 2): green (normal),

amber (fault)

10 Minor Alarm LED: amber 23 Hard drive (HDD1)

11 Fan Fault LED (FM 3): green (normal),

amber (fault)

12 User Alarm LED: amber 25 Hard drive (HDD3)

13 Fan Fault LED (FM 4): green (normal),

amber (fault)

20 Fan module (FM3)

22 Hard drive (HDD0)

24 Hard drive (HDD2)

Fan module (FM 5) (internal - not

shown)

Related Information

■ “Back Panel Components” on page 14

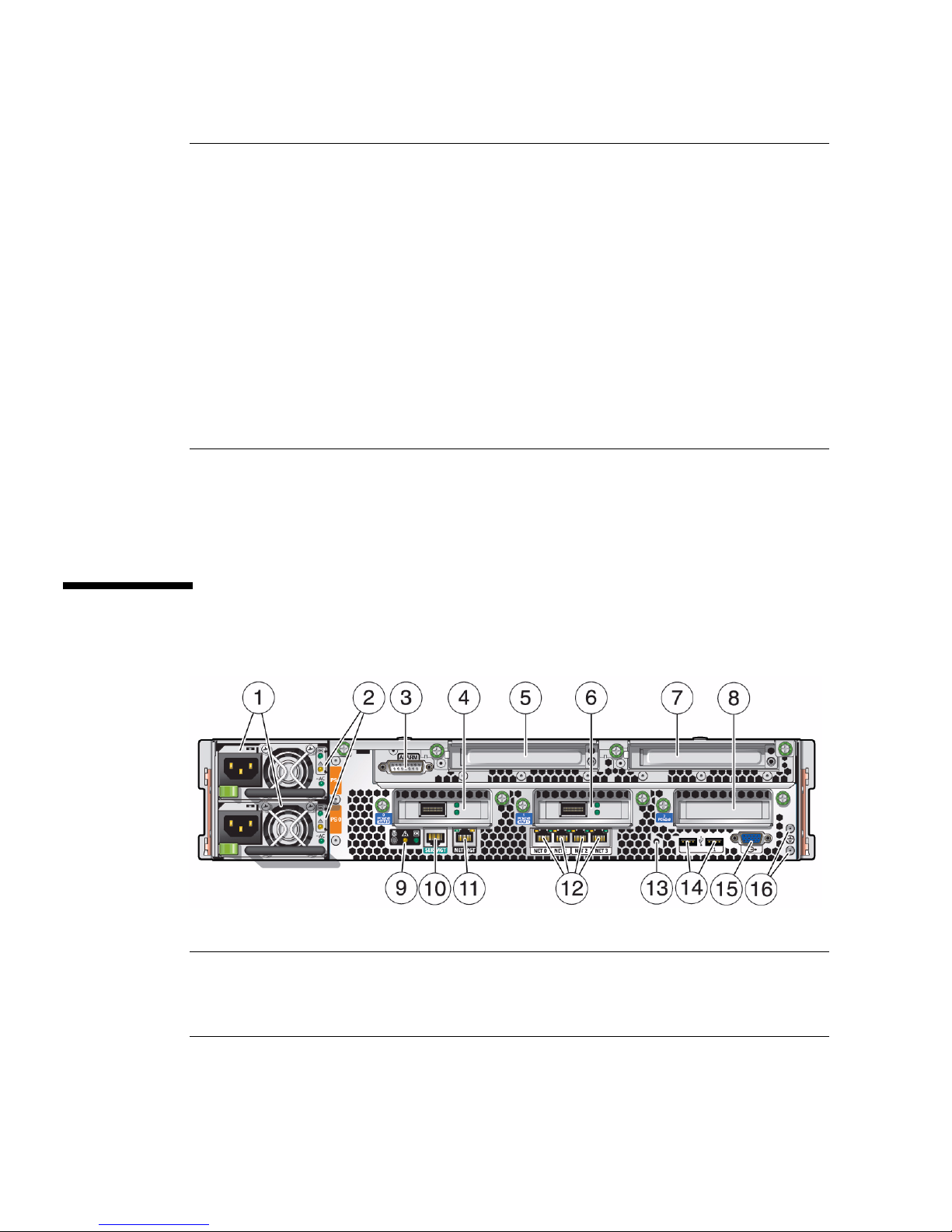

Back Panel Components

1 Power supplies (PS1 - PS0 top to

bottom) (AC supplies shown)

9 Service LEDs:- Locator LED/Locator

button (white)- Service Action

Required LED (amber)- Main

Power/OK LED (green)

14 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 23

2 Power supply status LEDs: - OK

(output): (green)

- Service Action Required: (amber)

- AC or DC (input power): (green)

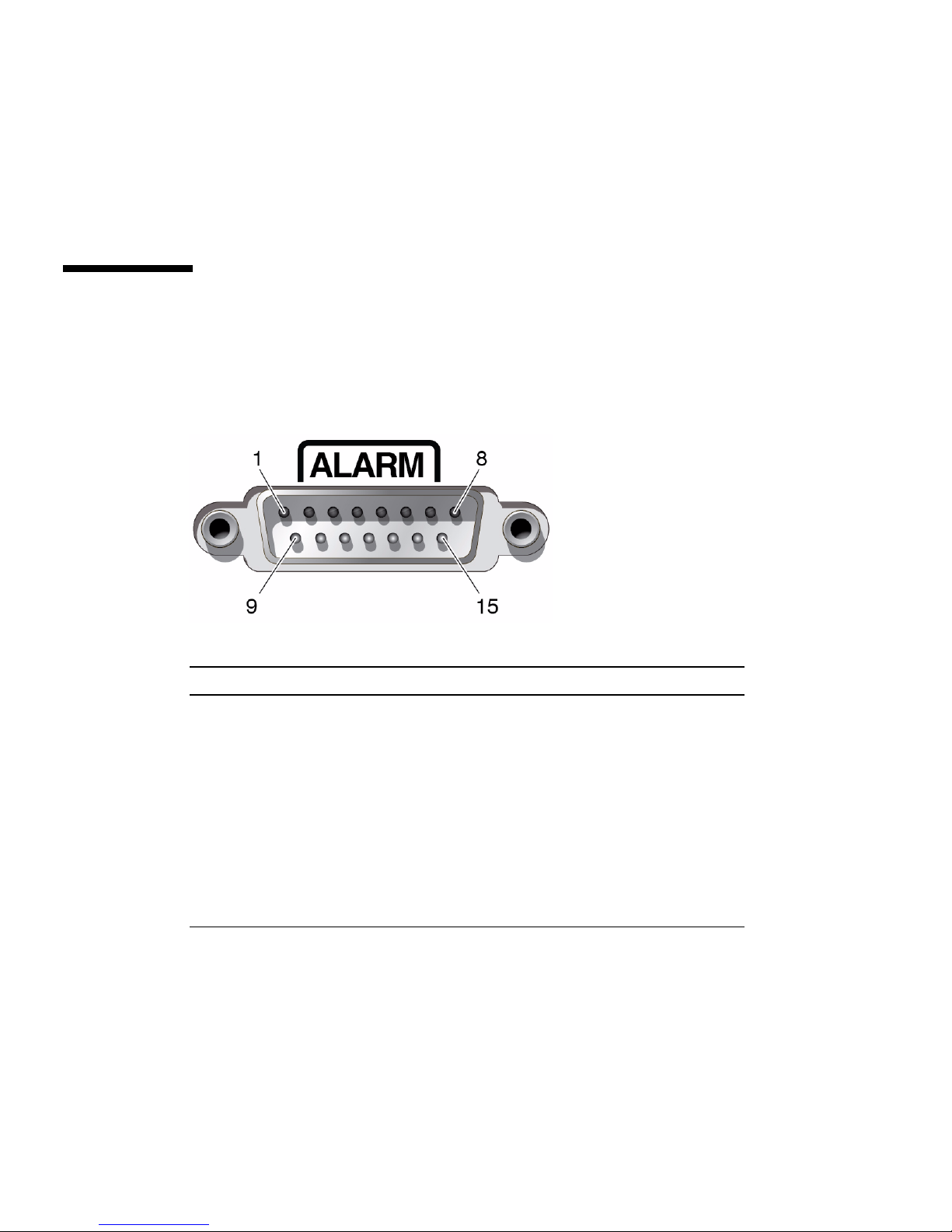

3 Alarm port 11 NET MGT RJ-45 network port

4 Expansion slot 0 (PCIe 2.0 x8 or XAUI) 12 Network 10/100/1000 ports (NET0 to

5 Expansion slot 3 (PCIe 2.0 x8) 13 Physical Presence button access hole

6 Expansion slot 1 (PCIe 2.0 x8 or XAUI) 14 USB 2.0 ports (USB 0, USB 1)

7 Expansion slot 4 (PCIe 2.0 x8) 15 Video connector (HD-15)

8 Expansion slot 2 (PCIe 2.0 x8) 16 Grounding studs

10 SER MGT RJ-45 serial port

NET3) for host

Related Information

■ “Front Panel Components” on page 13

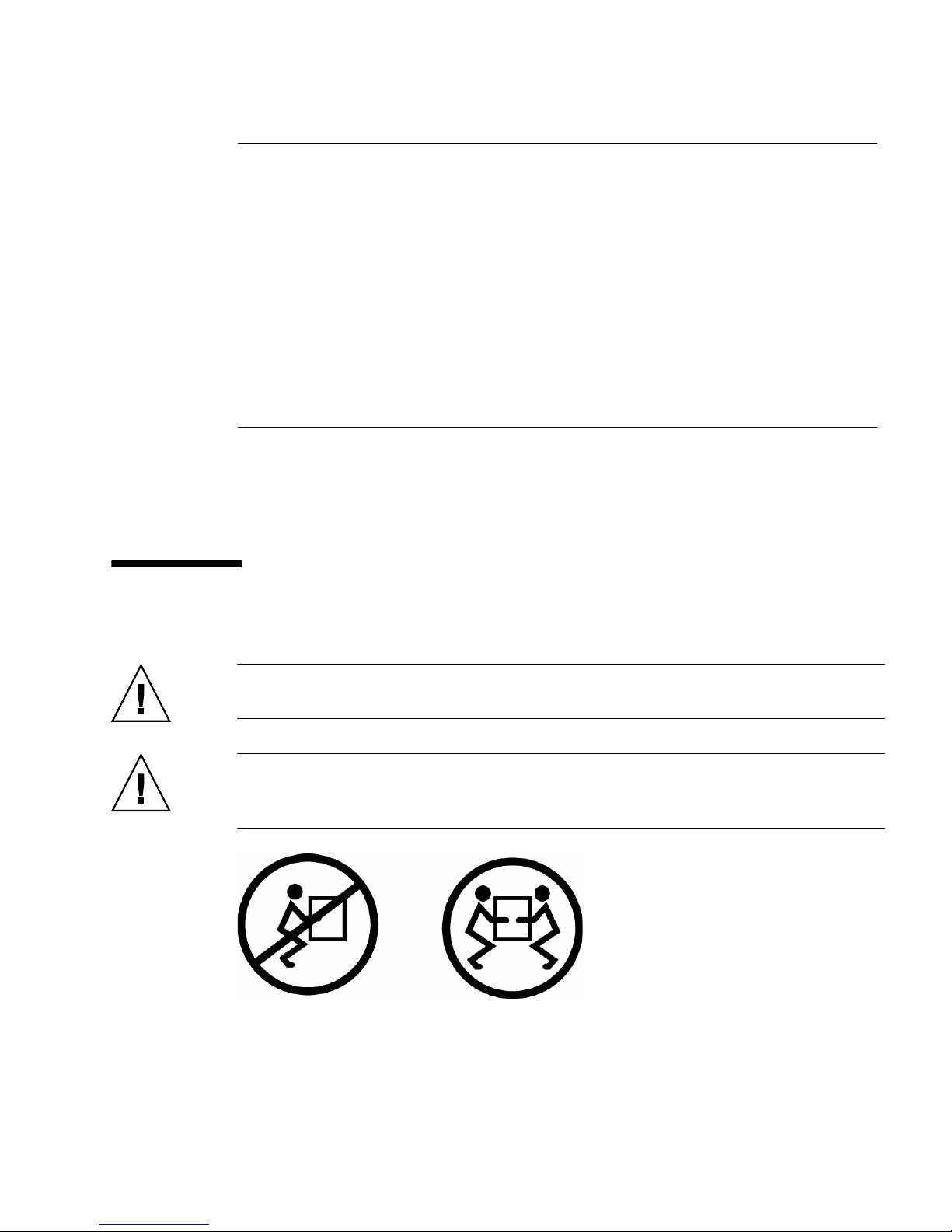

Server Handling Precautions

Caution – Deploy the antitilt bar on the equipment rack before beginning an

installation.

Caution – The server weighs approximately 55 lb (25 kg). Two people are required

to lift and mount this 2U server into a rack enclosure when using the procedures in

this document.

Preparing for Installation 15

Page 24

Caution – When completing a two-person procedure, always communicate your

intentions clearly before, during, and after each step to minimize confusion.

Related Information

■ “Physical Specifications” on page 5

■ “Minimum Clearance for Service Access” on page 6

■ “ESD Precautions” on page 16

ESD Precautions

Electronic equipment is susceptible to damage by static electricity. Use a grounded

antistatic wrist strap, foot strap, or equivalent safety equipment to prevent ESD when

you install or service the server.

Caution – To protect electronic components from electrostatic damage, which can

permanently disable the server or require repair by service technicians, place

components on an antistatic surface, such as an antistatic discharge mat, an antistatic

bag, or a disposable antistatic mat. Wear an antistatic grounding strap connected to a

metal surface on the chassis when you work on server components.

Related Information

■ “Installing the Server” on page 19

Tools Needed for Installation

To install the system, you must have the following tools:

■ No. 2 Phillips screwdriver

■ ESD mat and grounding strap

In addition, you must provide a system console device, such as one of the following:

■ ASCII terminal

16 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 25

■ Workstation

■ Terminal server

■ Patch panel connected to a terminal server

Related Information

■ “Optional Component Installation” on page 17

■ “ESD Precautions” on page 16

Optional Component Installation

The standard components of the server are installed at the factory. However, if you

ordered options such as additional memory or PCIe cards, these options will be

shipped separately. If possible, install these components prior to installing the server

in a rack. Optional components (for example, PCIe cards) ordered as part of the

system are installed in the server at the factory.

If you ordered any options that are not factory-installed, see Netra SPARC T3-1 Server

Service Manual and the component’s documentation for installation instructions.

Note – The list of optional components can be updated without notice. See the

product web pages for the most current list of components supported in the server.

Related Information

■ Optional component documentation

■ Netra SPARC T3-1 Server Service Manual

Preparing for Installation 17

Page 26

18 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 27

Installing the Server

These topics describe how to install the server into an equipment rack using a

rackmount kit.

Note – In this guide, the term rack means either an open rack or a closed cabinet.

■ “Rack Compatibility” on page 19

■ “Rack Cautions” on page 20

■ “Stabilize the Rack for Installation” on page 21

■ “Mounting the Server Into a 4-Post Rack” on page 22

■ “Mounting the Server Into a 2-Post Rack” on page 42

Related Information

■ “Preparing for Installation” on page 1

Rack Compatibility

Check that your rack is compatible with the slide rail options. The optional slide rails

are compatible with equipment racks that meet the following standards.

Item Requirement

Structure Four-post rack (mounting at both front and rear).

Rack horizontal opening and unit

vertical pitch

Distance between front and rear

mounting planes

Two-post racks are not compatible.

Conforms to ANSI/EIA 310-D-1992 or IEC 60927

standards. Only M6 tapped or 9.5 mm square are

supported.

Minimum 622 mm and maximum 895 mm

(24.5 in. to 35.25 in.).

19

Page 28

Item Requirement

Clearance depth in front of front

mounting plane

Clearance depth behind front

mounting plane

Clearance width between front and

rear mounting planes

Server dimensions Depth (not including PS handle): 732 mm (28.82 in.).

Distance to front cabinet door is at least 27 mm

(1.06 in.).

Distance to rear cabinet door is at least 900 mm (35.5

in.) with the CMA, or 770 mm (30.4 in.) without the

CMA.

Distance between structural supports and cable

troughs is at least 456 mm (18 in.).

Width (not including ears): 436.5 mm (17.19 in.).

Height: 129.85 mm (5.11 in.).

Related Information

■ “Rack Cautions” on page 20

Rack Cautions

Caution – Equipment Loading. Always load equipment into a rack from the bottom

up so that the rack will not become top-heavy and tip over. Deploy your rack’s

antitip bar to prevent the rack from tipping during equipment installation.

Caution – Elevated Operating Ambient Temperature. If the server is installed in a

closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment might be greater than room ambient temperature. Therefore, install the

equipment only in an environment compatible with the maximum ambient

temperature (Tma) specified for the server.

Caution – Reduced Air Flow. Install the equipment in a rack so that the amount of

air flow is adequate for the safe operation of the equipment.

Caution – Mechanical Loading. Mount the equipment in the rack so that the weight

is distributed evenly. A hazardous condition can exist with uneven mechanical

loading.

20 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 29

Caution – Circuit Overloading. Do not overload the power supply circuits. Before

connecting the server to the supply circuit, review the equipment nameplate power

ratings and consider the effect that circuit overloading might have on overcurrent

protection and supply wiring.

Caution – Reliable Grounding. Maintain reliable grounding of rackmounted

equipment. Give particular attention to supply connections other than direct

connections to the branch circuit (for example, use of power strips).

Caution – Do not use slide rail mounted equipment as a shelf or a work space.

Related Information

■ “Stabilize the Rack for Installation” on page 21

▼ Stabilize the Rack for Installation

Caution – To reduce the risk of personal injury, stabilize the expansion rack cabinet

and extend all antitilt devices before installing the server.

Refer to your rack documentation for detailed instructions for the following steps.

1. Open and remove the front and rear doors from the rack cabinet.

2. To prevent the rack cabinet from tipping during the installation, stabilize the

cabinet using all antitilt mechanisms provided.

3. If there are leveling feet beneath the rack cabinet to prevent it from rolling,

extend these leveling feet fully downward to the floor.

4. Fully extend the rack cabinet’s antitilt legs or antitilt bar, which are located at

the bottom front of the rack cabinet.

Related Information

■ “Rack Cautions” on page 20

■ Documentation for your rack cabinet

Installing the Server 21

Page 30

■ Netra SPARC T3-1 Server Safety and Compliance Guide

Mounting the Server Into a 4-Post Rack

These topics provide installation instructions for the 4-post rackmount kits. The

server ships with a 19-inch, 4-post hardmount rackmount kit. You can order two

optional rackmount kits for your specific 4-post rack.

Note – References to left and right are from your viewpoint as you face either the

front or rear of the equipment.

Caution – The server is heavy. Two people are required to lift and mount the server

into a rack enclosure when following these procedures.

Caution – Yo u must install the server into a rack following these instructions. If you

deviate from these instructions when installing the server, your installation will not

be supported.

Description Links

Mount the server using a 19-inch,

4-post hardmount rackmount kit

(included with the server).

Mount the server using an optional

19-inch, 4-post slide rackmount kit

for 600–800 mm cabinet depths.

Mount the server using an optional

600 mm x 600 mm rackmount kit.

“19-Inch, 4-Post Hardmount Rackmount Kit” on

page 23

“Install the Server (19-Inch, 4-Post Hardmount

Rackmount Kit)” on page 24

“19-Inch, 4-Post Sliding Rail Rackmount Kit” on

page 27

“Install the Server (19-Inch, 4-Post Sliding Rail

Rackmount Kit)” on page 28

“600-mm, 4-Post Hardmount Rackmount Kit” on

page 34

“Install the Server (600-mm, 4-Post Hardmount

Rackmount Kit)” on page 35

Related Information

■ “Preparing for Installation” on page 1

22 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 31

■ “Rack Cautions” on page 20

■ “Stabilize the Rack for Installation” on page 21

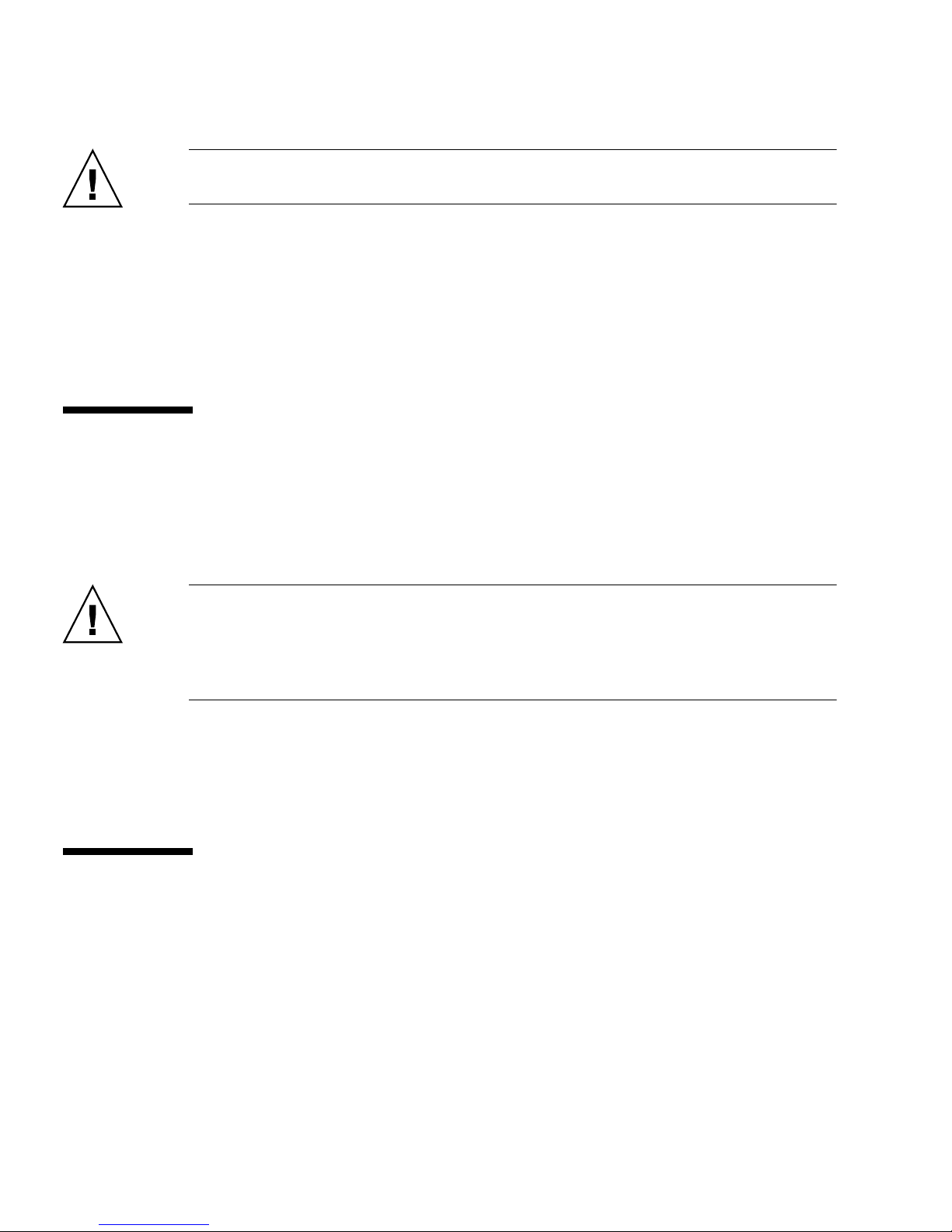

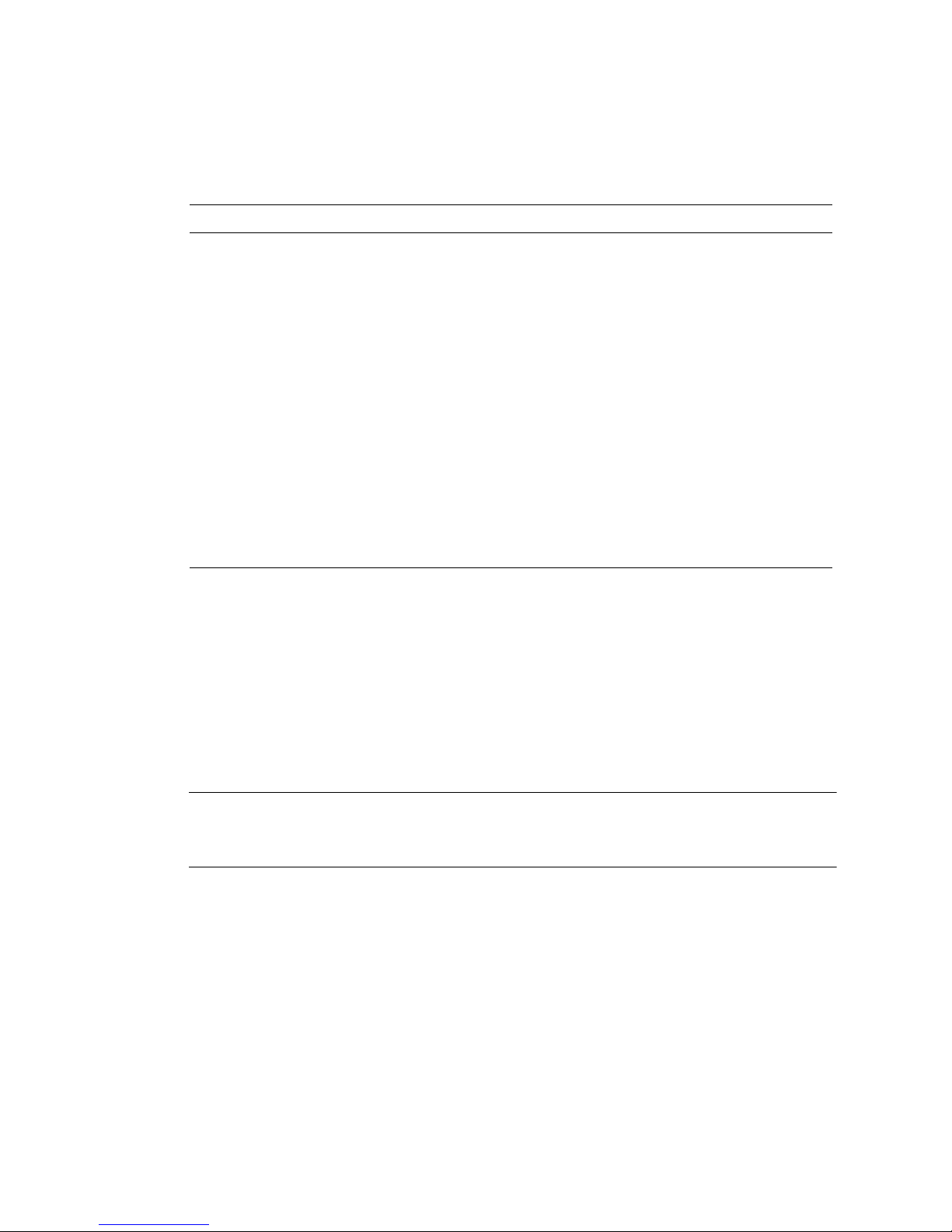

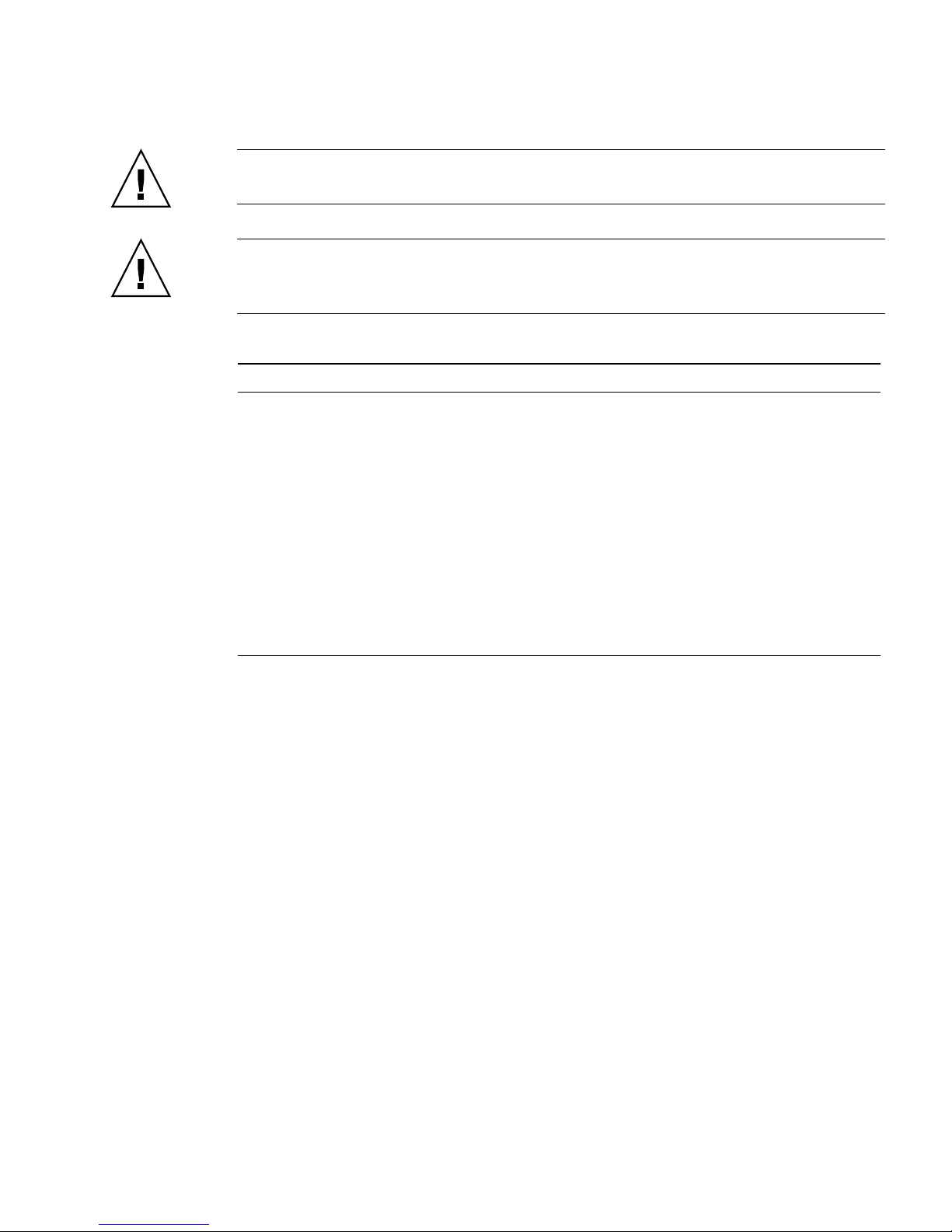

19-Inch, 4-Post Hardmount Rackmount Kit

1 Rear mount flanges (2) 3 Rear mount support brackets (2)

2 Screws (see following table) 4 Hardmount brackets (2)

Installing the Server 23

Page 32

TABLE: 19-inch, 4-Post Rackmount Screw Kit Contents

No. Description Where Used

10 M5 x 4.5 mm Phillips flathead screws 8 for hardmount brackets, 2 extra

10 M4 x 0.5 mm x 5 mm Phillips panhead

screws

10 M5 x 12.7 mm screws 10 for rack, if appropriate

10 M6 x 13 mm screws 10 for rack, if appropriate

9 M6 square clip nuts 9 for rack, if appropriate

12 10-32 x 0.5 in. combo head screws 12 for rack, if appropriate

12 12-24 x 0.5 in. combo head screws 12 for rack, if appropriate

4-6 for rear mount brackets, 6-4 extra

Related Information

■ “Install the Server (19-Inch, 4-Post Hardmount Rackmount Kit)” on page 24

▼ Install the Server (19-Inch, 4-Post Hardmount

Rackmount Kit)

Note – The front-to-back rail spacing must be at least 460 mm (18.11 in.) and not

more than 715 mm (28.15 in.) from the outside face of the front rail to the outside face

of the back rail.

1. Read the Cautions for racks.

See “Rack Cautions” on page 20.

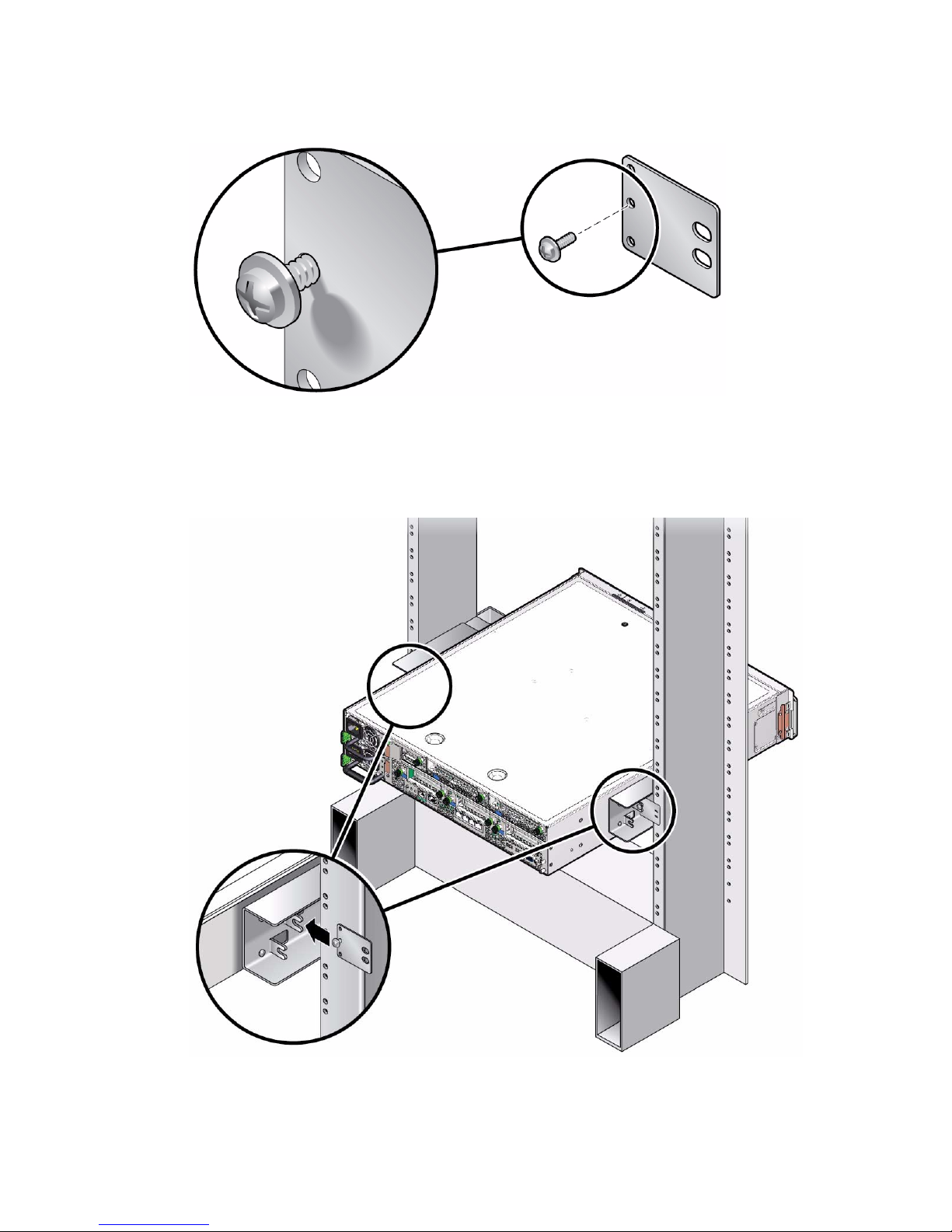

2. Use four of the supplied M5 x 4.5-mm flathead Phillips screws to secure each of

the hardmount brackets to the sides of the server.

24 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 33

3. Measure the depth of the rack.

4. Install the rear mount support brackets at the rear of the server, extending the

rear mount support brackets to the measured depth of the rack.

Use two to three of the supplied M4 x 0.5 x 5 mm panhead Phillips screws for each

bracket, depending on the rack depth.

5. Lift the server to the desired location in the rack.

Installing the Server 25

Page 34

6. Using two screws per side, secure the front of the hardmount brackets attached

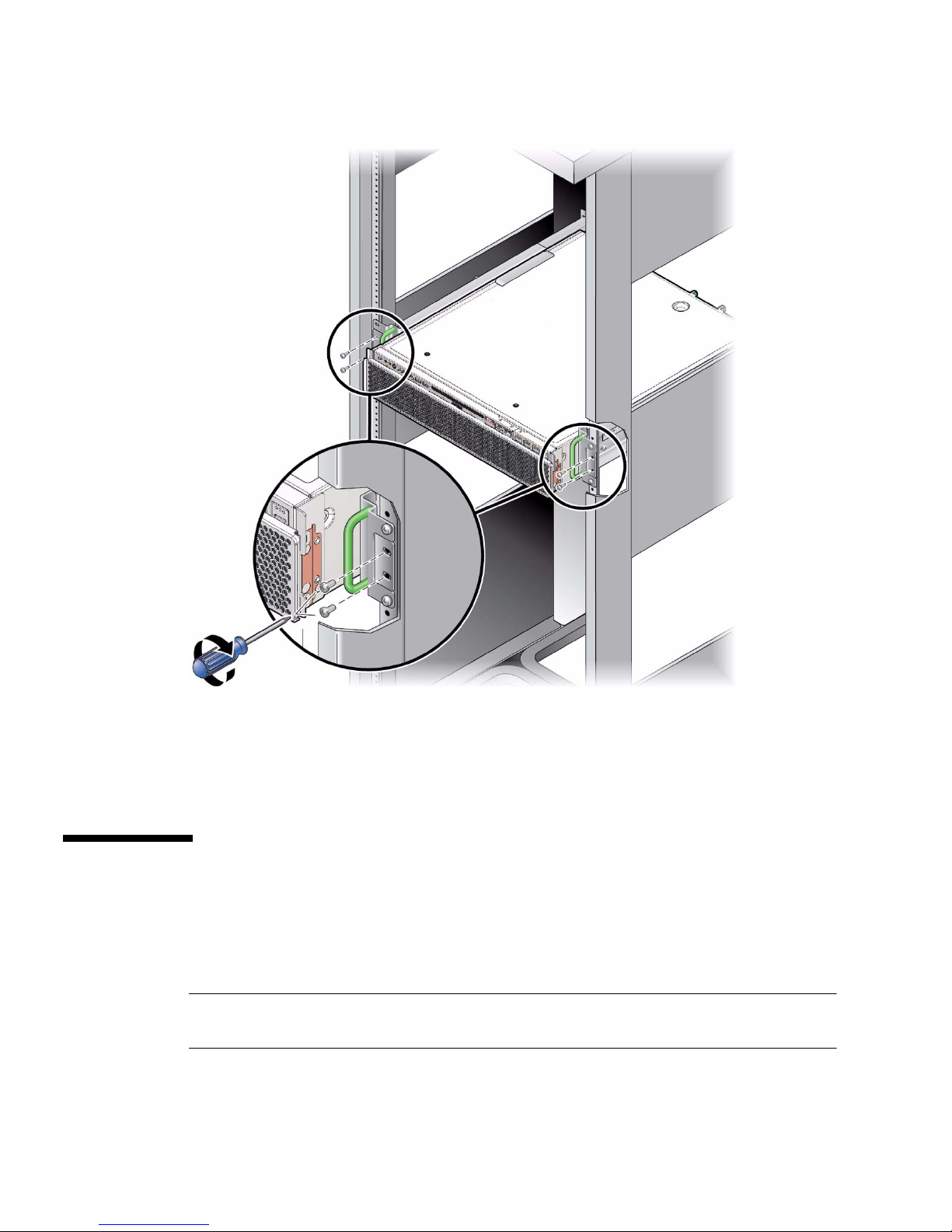

to the sides of the server to the front of the rack.

7. Get the two rear mount flanges from the rackmount kit.

8. Using two screws for each rear mount support bracket, secure the rear mount

support brackets to the rear of the rack.

Related Information

■ “Stabilize the Rack for Installation” on page 21

■ “19-Inch, 4-Post Hardmount Rackmount Kit” on page 23

26 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 35

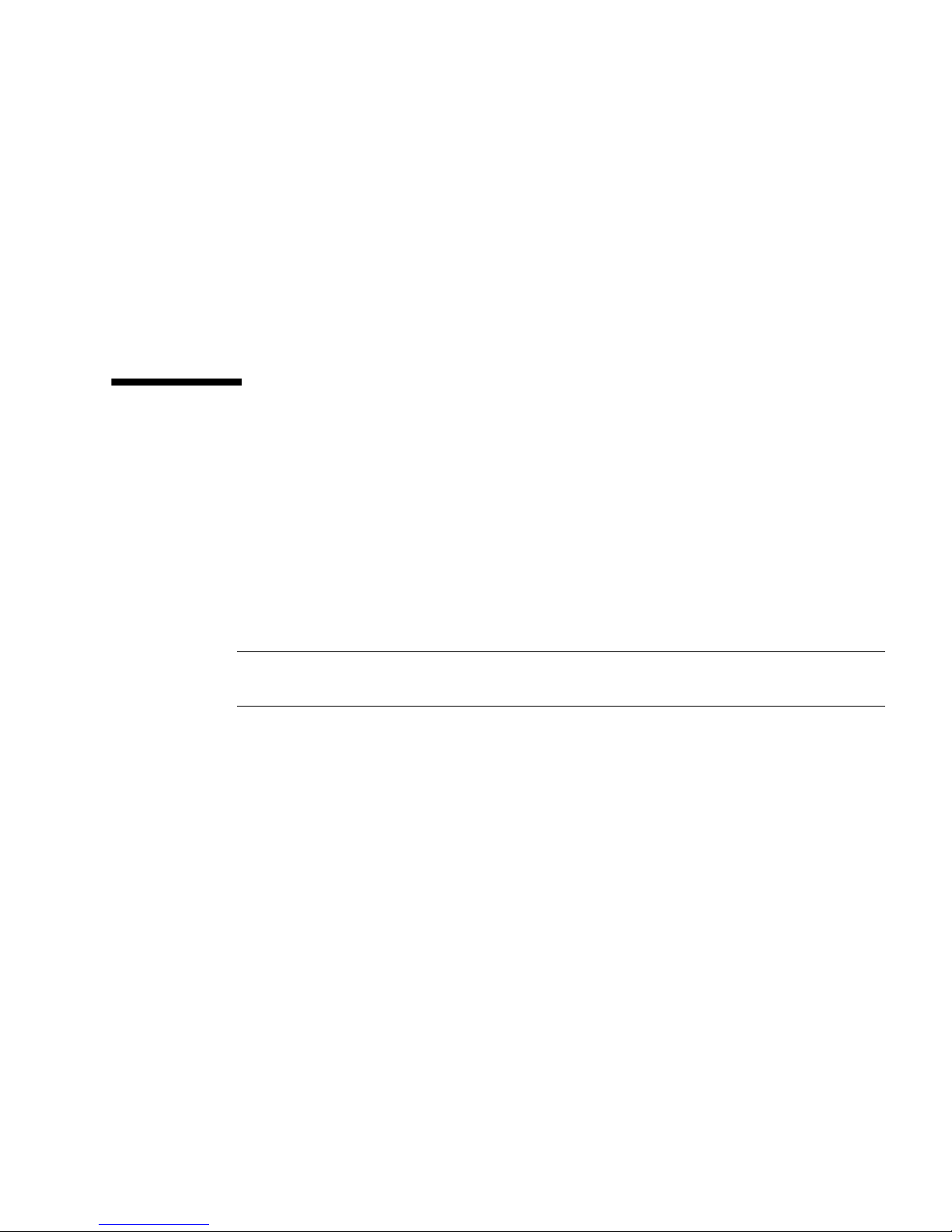

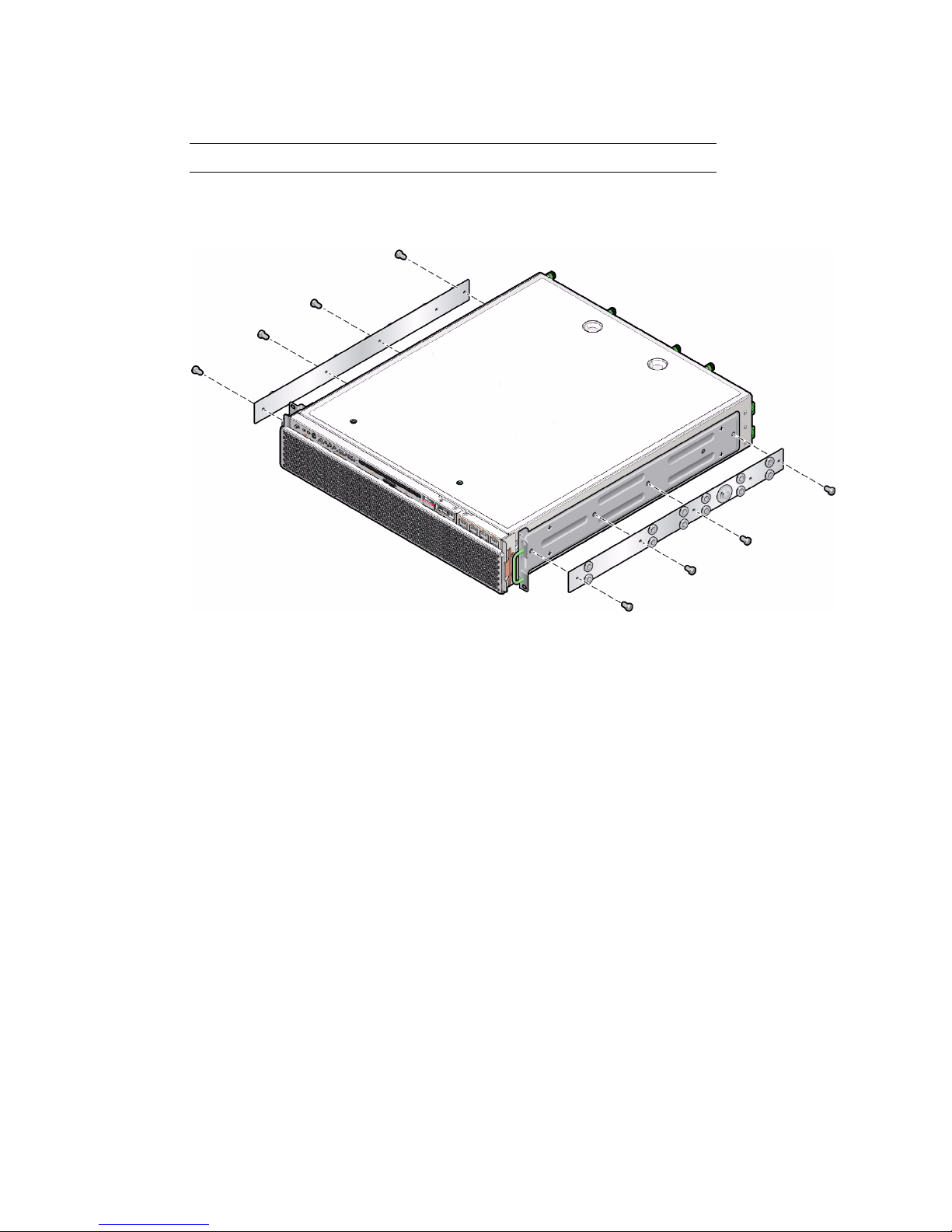

19-Inch, 4-Post Sliding Rail Rackmount Kit

After installing the server using this optional 19-inch, 4-post sliding rail rackmount

kit, you can extend the server out of the rack for servicing.

You also need the hardmount brackets from the standard rackmount kit that came

with the server.

1 Short brackets (2) 4 Screws (see following table)

2 Extension brackets (2) 5 Telco slide assemblies (2)

3 Threaded strips – M6 (4) 10-32 (4) 6 Long brackets (2)

Installing the Server 27

Page 36

TABLE: 19-Inch, 4-Post Sliding Rail Mount Screw Kit Contents

No. Description Where Used

10 M4 x 0.5 mm x 5 mm Phillips panhead

screws

10 M6 brass collar screws 4 for short brackets, 4 for long brackets, 2

8 M5 panhead screws, nuts, plain

washers and star washers

10 M5 x 12.7 mm screws 10 for rack, if appropriate

12 M6 x 13 mm screws 10 for rack, if appropriate

9 M6 square clip nuts 9 for rack, if appropriate

10 10–32 collar screws 4 short, 4 long, 2

extra

12 10-32 x 0.5 in. combo head screws 12 for rack, if appropriate

12 12-24 x 0.5 in. combo head screws 12 for rack, if appropriate

8 for glides, 2 extra

extra

8 for slides

8 for racks with 10 to 32 holes, if

appropriate

Related Information

■ “Install the Server (19-Inch, 4-Post Sliding Rail Rackmount Kit)” on page 28

▼ Install the Server (19-Inch, 4-Post Sliding Rail

Rackmount Kit)

Note – The front-to-back rail spacing must be at least 392 mm (15.43 in.) and not

more than 863.6 mm (34 in.) from the outside face of the front rail to the outside face

of the back rail.

1. Read the Cautions for racks.

See “Rack Cautions” on page 20.

2. Use four of the supplied M5 x 4.5 mm flathead Phillips screws to secure each of

the hardmount brackets to the sides of the server.

These hardmount brackets and screws are shipped with the standard server ship

kit, not as part of the sliding rail 19-inch, 4-post rackmount kit.

28 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 37

3. Press in the button on each slide assembly and pull the glide completely out of

the slide.

1 Glide 3 Slide (in two parts)

Installing the Server 29

Page 38

2 Button

4. Using eight of the M4 x 0.5 x 5 mm panhead Phillips screws from the rackmount

kit (four for each side), screw each glide to the side of the server chassis.

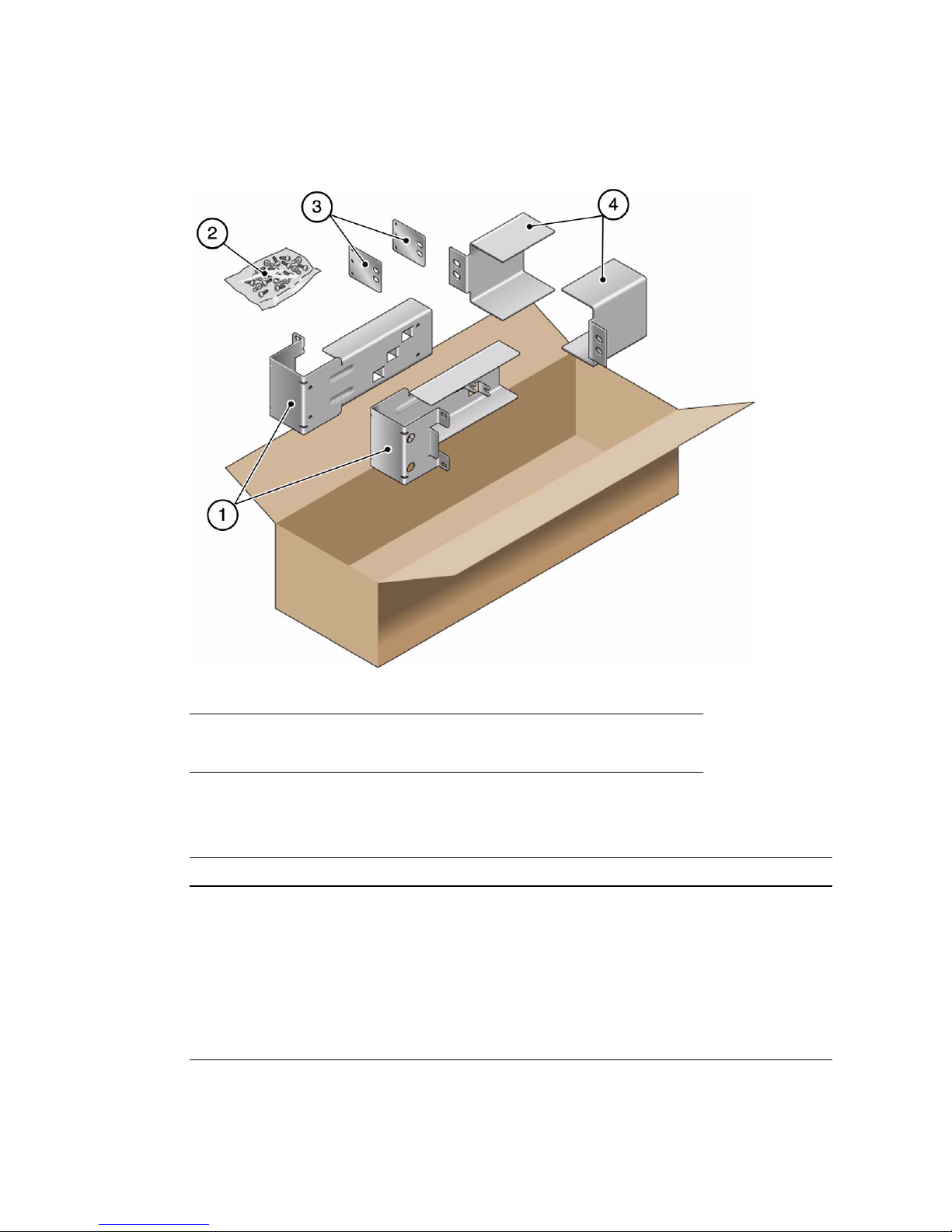

5. Lift each short bracket to the desired position at the front of the rack and attach

a short bracket to each of the front rack uprights.

Use two of the brass M6 collar screws and M6 cage nuts (if required), and one

threaded strip, to secure each bracket.

6. Lift each long bracket to the desired position at the rear of the rack and attach a

long bracket to each of the rear rack uprights.

To secure each bracket, use two of the brass M6 collar screws and M6 cage nuts (if

required) and one threaded strip, exactly as you did for the front rack uprights in

the previous step.

30 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 39

Note – If your rack has 10–32 holes, use the 10–32 collar screws and 10–32 threaded

strips.

7. Extend a slide to line up the access holes with the front screw holes.

8. Secure the slide onto the short and long brackets at the front and rear of the

rack.

Use the M5 panhead screws from the inside. Use the M5 nuts, plain washers, and

star washers from the outside. Use extension brackets instead of the long brackets

if the dimension is greater than 665 mm.

Installing the Server 31

Page 40

1 Short bracket

2 Slide

3 Long bracket

9. Mount the slide on the other side of the rack.

Repeat Step 7 and Step 8.

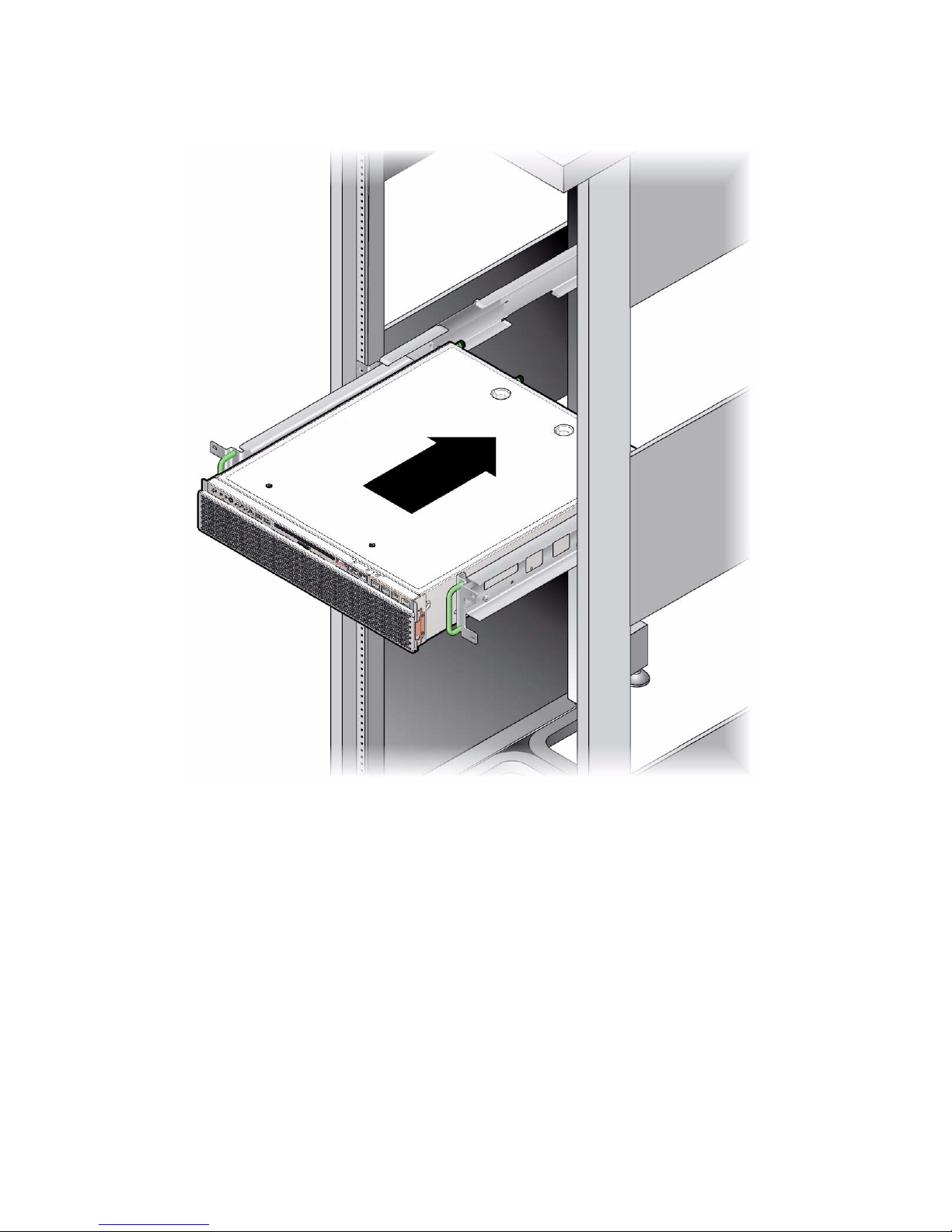

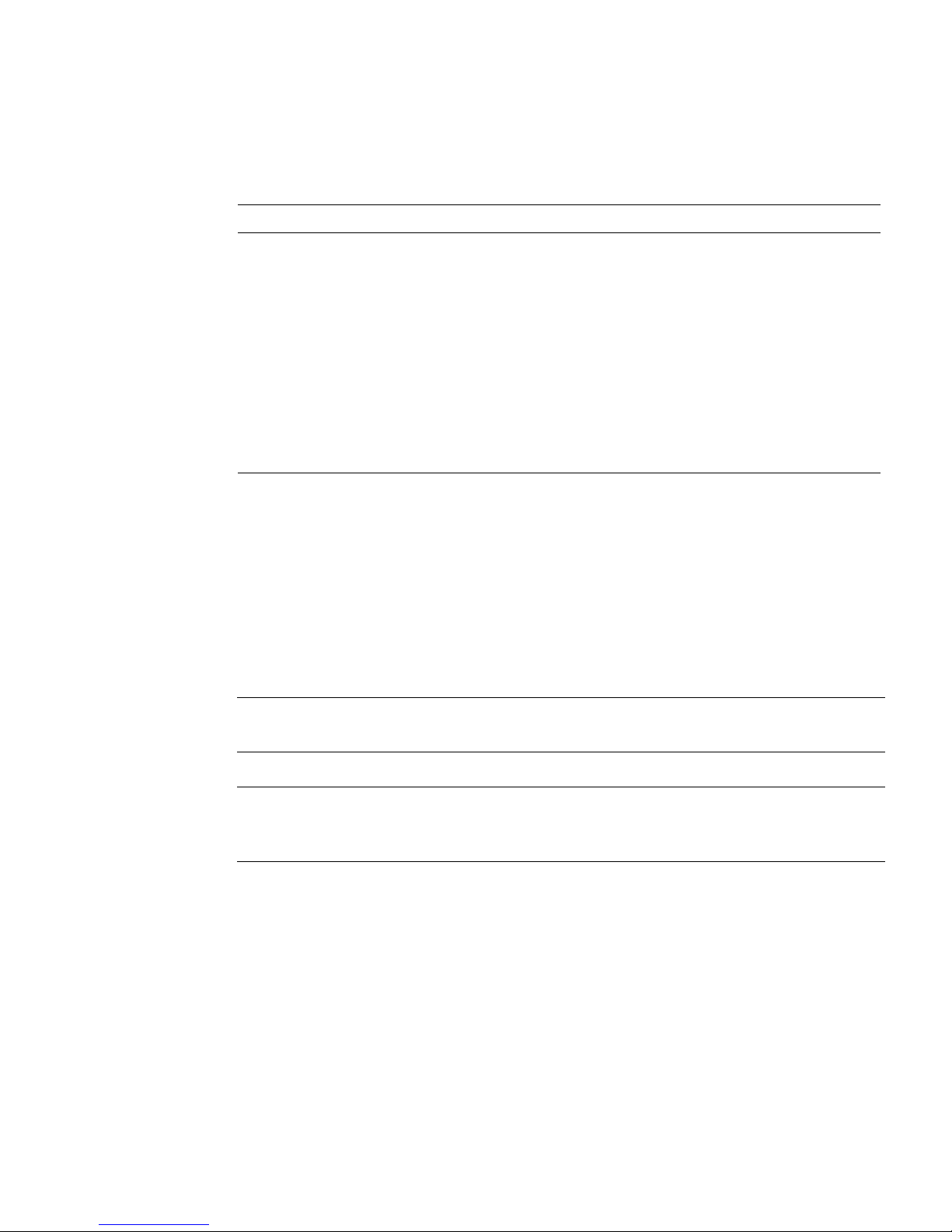

10. Push the slides completely into the assembly on each side of the rack and

release the stop catches.

11. Align the glides attached to the server with the slide assemblies in the rack.

You might find that there is too much or too little room between the two slides

mounted in the rack. Consequently, the glides attached to the server might not

align correctly with the slides in the rack. If either situation occurs, loosen the M6

collar screws and cage nuts on the long and short brackets (Step 5 and Step 6),

move the brackets inward or outward to the appropriate points, then tighten the

screws and cage nuts again.

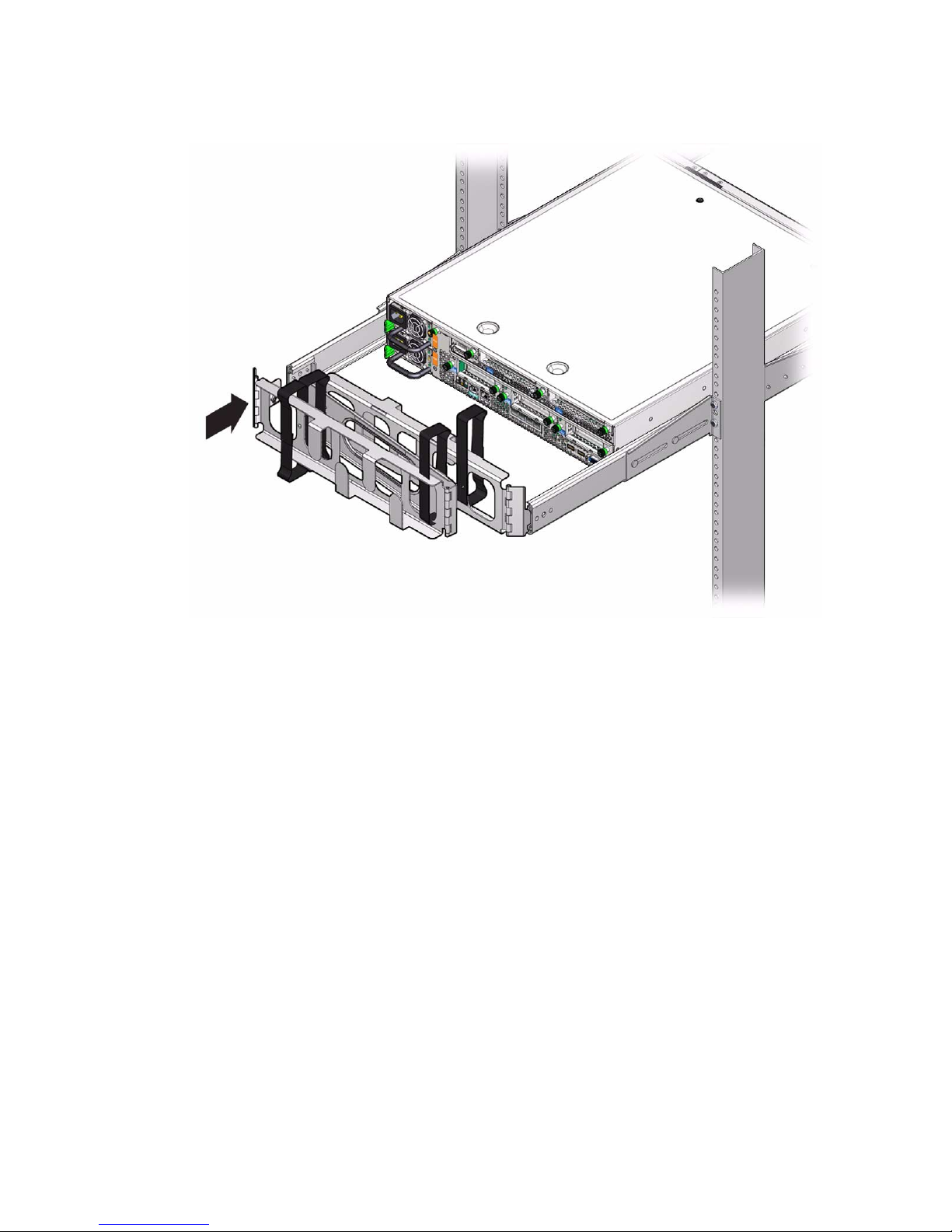

12. Push in the slide buttons and slide the server all the way into the rack

enclosure.

32 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 41

13. Using two screws per side, secure the front of the hardmount brackets that are

attached to the sides of the server to the front of the rack.

The size of the screws varies, depending on your particular rack.

Related Information

■ “Stabilize the Rack for Installation” on page 21

Installing the Server 33

Page 42

■ “19-Inch, 4-Post Sliding Rail Rackmount Kit” on page 27

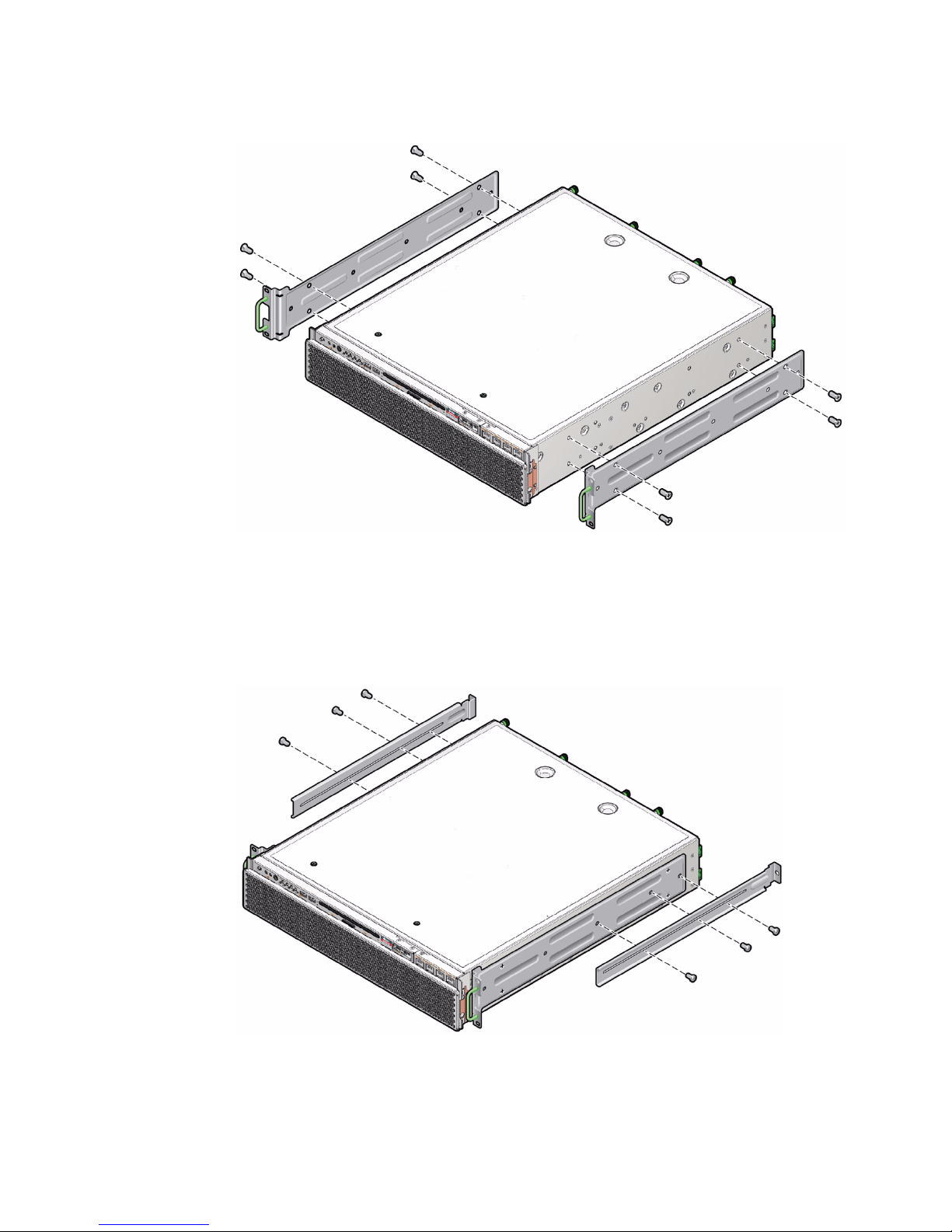

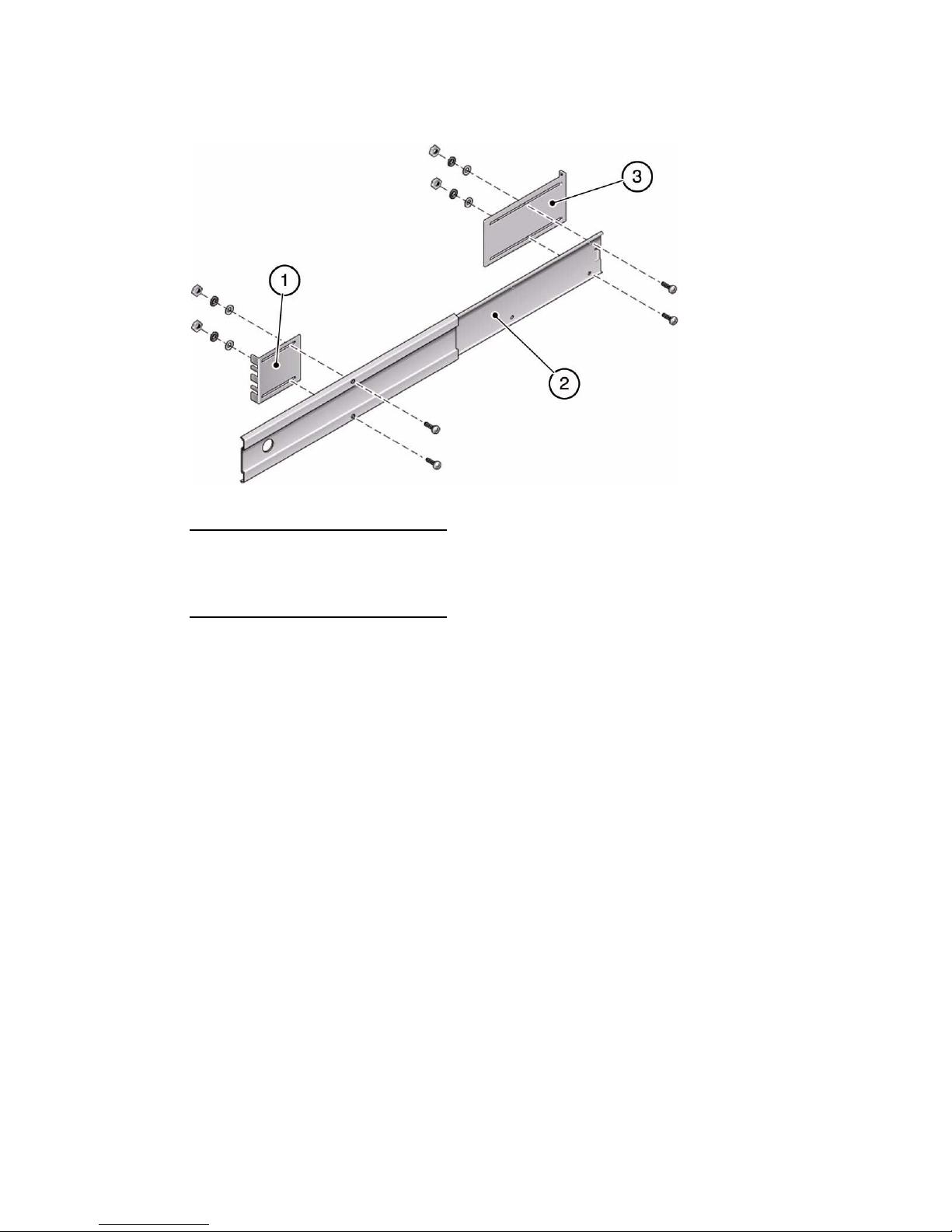

600-mm, 4-Post Hardmount Rackmount Kit

1 Adjustable rails (2) 3 Side rails (2)

2 Screws (see following table) 4 Rear flanges (2)

34 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 43

TABLE: 600-mm, 4-Post Hardmount Screw Kit Contents

No. Description Where Used

12 M5 x 7 SEM screws 8 for side rails, 4 for rear flanges

10 M5 x 12.7 mm screws 10 for rack, if appropriate

10 M6 x 13 mm screws 10 for rack, if appropriate

9 M6 square clip nuts 9 for rack, if appropriate

12 10-32 x 0.5 in. combo head screws 12 for rack, if appropriate

12 12-24 x 0.5 in. combo head screws 12 for rack, if appropriate

Related Information

■ “Install the Server (600-mm, 4-Post Hardmount Rackmount Kit)” on page 35

▼ Install the Server (600-mm, 4-Post Hardmount

Rackmount Kit)

Note – The front-to-back rail spacing must be at least 392 mm (15.43 in.) and not

more than 504 mm (19.84 in.) from the outside face of the front rail to the outside face

of the back rail.

1. Read the Cautions for racks.

See “Rack Cautions” on page 20.

2. Loosen the two screws at the middle of each adjustable rail so that you can

extend the adjustable rail.

Installing the Server 35

Page 44

3. Lift one of the adjustable rails to the desired location in the rack.

Using two screws, secure the front of the rail in the rack. The size of the screws

varies, depending on your particular rack.

36 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 45

4. At the rear of the rack, use two screws to secure the rear of the adjustable rails

to the rack.

The size of the screws varies, depending on your particular rack.

5. Tighten the two screws at the middle of each adjustable rail.

6. Mount the other adjustable rail into the rack.

Repeat Step 3 through Step 5.

7. Using one M5 x 7 SEM screw for each rear flange, loosely install the rear flange

onto the rear of each of the adjustable rails.

Do not completely secure the rear flanges to the adjustable rails. You will use these

flanges to set the rack depth for the server in a later step.

Installing the Server 37

Page 46

8. Using eight of the M5 x 7 SEM screws (four for each side rail), secure the side

rails to the sides of the server.

The side rails can accommodate rack rail setbacks (the distance from the front of

the rack to the rack rail) of 50 mm, 75 mm, or 100 mm, depending on the type of

rack you are installing the server into.

38 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 47

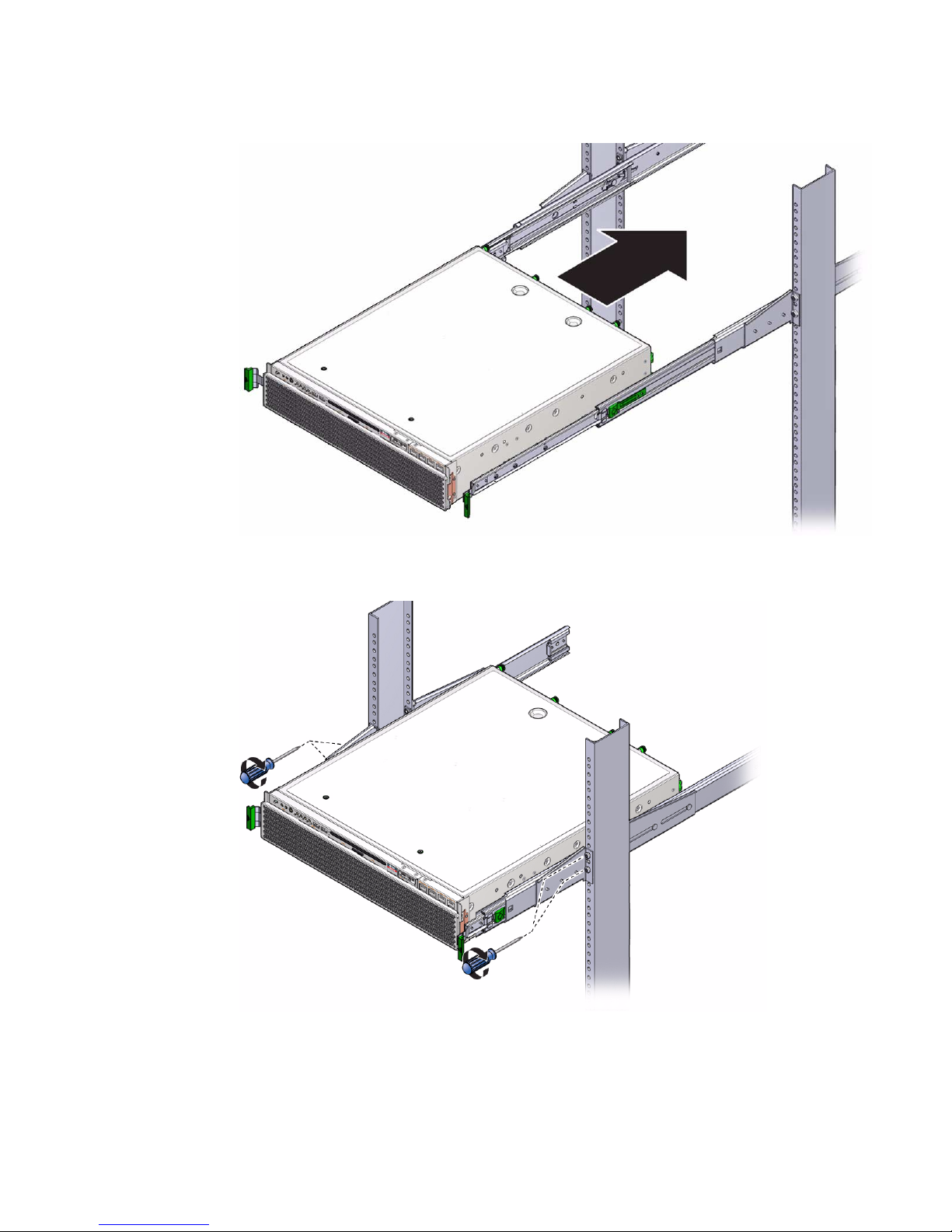

9. Lift the server into the rack and slide the server onto the adjustable rails.

Installing the Server 39

Page 48

10. Push the server to the desired depth in the rack, then go to the rear of the server

and push the rear flanges flush against the back of the server.

If the rack is especially shallow, you can flip the rear flanges around so that they

rest flush against the rear of the server.

11. Lift the server out of the rack.

12. Set the rear flanges to the desired depth in the rack, then tighten the single M5

x 7 SEM screw on each of the flanges to secure them to the adjustable rails.

13. Lift the server into the rack and slide it onto the adjustable rails.

14. Push the server backward until it rests flush against the rear flanges, then use

one M5 x 7 SEM screw for each rear flange to secure the rear of the server to the

rear flanges.

40 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 49

15. At the front of the rack, use two screws per side to secure the side rails that are

attached to the server to the front of the rack.

The size of the screws varies, depending on your particular rack.

Installing the Server 41

Page 50

Related Information

■ “Stabilize the Rack for Installation” on page 21

■ “600-mm, 4-Post Hardmount Rackmount Kit” on page 34

Mounting the Server Into a 2-Post Rack

The server ships with a 19-inch, 4-post hardmount rackmount kit, but you can order

optional rackmount kits for 2-post racks.

Note – References to left and right are from your viewpoint as you face either the

front or rear of the equipment.

42 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 51

Caution – The server is heavy. Two people are required to lift and mount the server

into a rack enclosure when following these procedures.

Caution – Yo u must install the server into a rack following these instructions. If you

deviate from these instructions when installing the server, your installation will not

be supported.

Description Links

Install the server using a 23-inch

2-post rackmount kit.

“23-Inch, 2-Post Hardmount Rackmount Kit” on

page 44

“Install the Server (23-Inch, 2-Post Hardmount

Rackmount Kit)” on page 45

Install the server using a 19-inch

2-post rackmount kit.

“19-Inch, 2-Post Hardmount Rackmount Kit” on

page 50

“Install the Server (19-Inch, 2-Post Hardmount

Rackmount Kit)” on page 51

Install the server using a 19-inch

2-post sliding rail rackmount kit.

“19-Inch, 2-Post Rack Sliding Rail Rackmount Kit”

on page 56

“Install a Server (19-Inch, 2-Post Sliding Rail

Rackmount Kit)” on page 57

Related Information

■ “Mounting the Server Into a 4-Post Rack” on page 22

■ “Preparing for Installation” on page 1

Installing the Server 43

Page 52

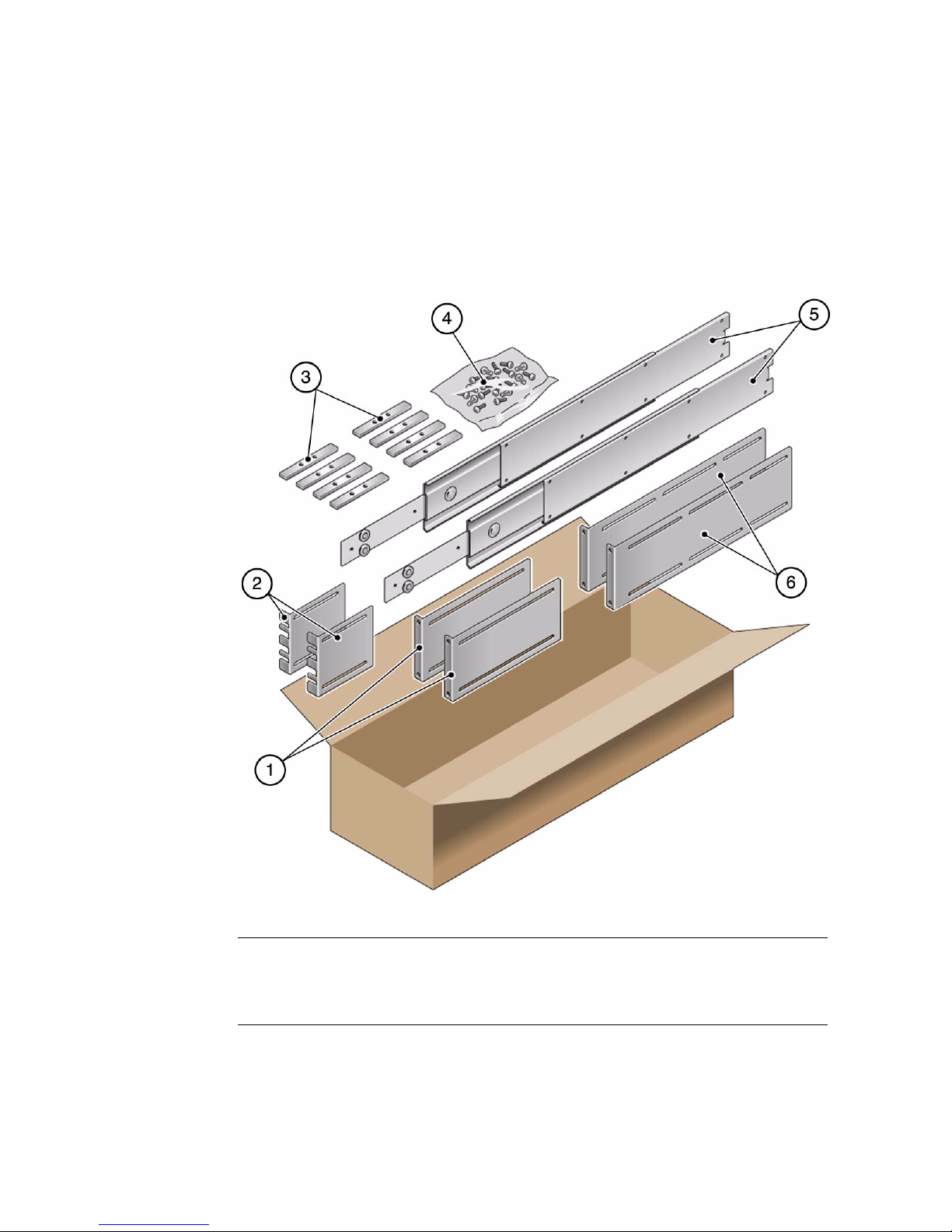

23-Inch, 2-Post Hardmount Rackmount Kit

1 Side brackets (2) 3 Rear plates (2)

2 Screws (see following table) 4 Rail guides (2)

TABLE: 23-Inch, 2-Post Rackmount Screw Kit Contents

No. Description Where Used

10 M5 x 7 SEM screws 8 for side brackets, 2 for rear plates

10 M5 x 12.7 mm screws 10 for rack, if appropriate

10 M6 x 13 mm screws 10 for rack, if appropriate

9 M6 square clip nuts 9 for rack, if appropriate

12 10-32 x 0.5 in. combo head screws 12 for rack, if appropriate

12 12-24 x 0.5 in. combo head screws 12 for rack, if appropriate

44 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 53

Related Information

■ “Install the Server (23-Inch, 2-Post Hardmount Rackmount Kit)” on page 45

▼ Install the Server (23-Inch, 2-Post Hardmount

Rackmount Kit)

Note – The 23-inch, 2-post rackmount kit supports rack web thicknesses (the width

of the rack post) of 76.20 mm (3 in.), 101.6 mm (4 in.), and 127 mm (5 in.).

1. Read the Cautions for racks.

See “Rack Cautions” on page 20.

2. Using eight of the M5 x 7 SEM screws (four for each side bracket), secure the

side brackets to the sides of the server.

3. Lift the rail guides to the desired height in the rack and, using two screws each,

secure both rail guides to the rack.

The size of the screws varies, depending on your particular rack.

Installing the Server 45

Page 54

4. Lift the server into the rack, and slide the server onto the rail guides.

46 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 55

5. Using two screws on each side, secure each side bracket on the server to the

front of the rack.

The size of the screws varies, depending on your particular rack.

6. (Optional) If your environment contains especially high vibrations, install the

rear plates to further secure the server to the rack.

The rear plates attach to the rear of the post and to one of the three eyelets on each

side bracket, depending on the thickness of the post.

a. Using one M5 x 7 SEM screw for each rear plate, loosely install the screw in

one of the three positions on the rear plate.

The position varies depending on the thickness of the rail in the rack. For

example, the following figure shows where you would install the screw for the

middle rack position on the rear plate.

Installing the Server 47

Page 56

b. Slide the rear plate in so that the screw slides into position into one of the

eyelets.

The screw head should be facing the rear of the server. The other side of the

rear plate should be in front of the rack post.

48 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 57

c. Tighten the screw to secure the rear plate to the eyelet on the side bracket.

d. Using two screws, secure the other side of the rear plate to the back of the

post.

The size of the screws varies, depending on your rack.

e. Secure the rear plate on the other post.

Repeat Step a through Step d.

Related Information

■ “Stabilize the Rack for Installation” on page 21

■ “23-Inch, 2-Post Hardmount Rackmount Kit” on page 44

Installing the Server 49

Page 58

19-Inch, 2-Post Hardmount Rackmount Kit

1 Rear plates (2)

2 Screws (see following table)

3 Side brackets (2)

50 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 59

TABLE: 19-Inch, 2-Post Hardmount Rack Screw Kit Contents

No. Description Where Used

10 M5 x 7 SEM screws 8 for side brackets, 2 extra

6 M3 x 8 SEM screws 4 for rear plates, 2 extra

10 M5 x 12.7 mm screws 10 for rack, if appropriate

10 M6 x 13 mm screws 10 for rack, if appropriate

9 M6 square clip nuts 9 for rack, if appropriate

12 10-32 x 0.5 in. combo head screws 12 for rack, if appropriate

12 12-24 x 0.5 in. combo head screws 12 for rack, if appropriate

Related Information

■ “Install the Server (19-Inch, 2-Post Hardmount Rackmount Kit)” on page 51

▼ Install the Server (19-Inch, 2-Post Hardmount

Rackmount Kit)

Note – The 19-inch, 2-post rackmount kit supports rack web thicknesses (the width

of the rack post) of 76.20 mm (3 in.), 101.6 mm (4 in.), and 127 mm (5 in.).

1. Read the Cautions for racks.

See “Rack Cautions” on page 20.

2. Using four of the M5 x 7 SEM screws for each side bracket, secure the side

brackets to the sides of the server.

Installing the Server 51

Page 60

3. Lift the server into the rack.

4. Using two screws for each bracket, secure the front of the server to the front of

the rack.

The size of the screws varies, depending on your rack.

52 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 61

5. (Optional) If your environment contains especially high vibrations, install the

rear plates to further secure the server to the rack.

The rear plates attach to the rear of the post and to one of the three sets of eyelets

on each side bracket, depending on the thickness of the post.

a. Using two of the M3 x 8 SEM screws for each rear plate, loosely install the

screws in one of the six positions on the rear plate.

The position varies depending on the thickness of the rail in the rack. For

example, the following figure shows where you would install the screws for the

optimum rack position on the rear plate.

Installing the Server 53

Page 62

b. Slide the rear plate in so that the screws slide into position into one set of the

eyelets.

The screw heads should be facing the rear of the server. The other side of the

rear plate should be in front of the rack post.

c. Tighten the screws to secure the rear plate to the set of eyelets on the side

bracket.

54 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 63

d. Using two screws, secure the other side of the rear plate to the back of the

post.

The size of the screws varies, depending on your rack.

e. Secure the rear plate on the other post.

Repeat Step a through Step d.

Related Information

■ “Stabilize the Rack for Installation” on page 21

■ “19-Inch, 2-Post Hardmount Rackmount Kit” on page 50

Installing the Server 55

Page 64

19-Inch, 2-Post Rack Sliding Rail Rackmount Kit

1 Slide assemblies (2) 4 Cable management arm

2 Inside glides (2) Threaded strips – M6 (4) 10-32 (4) (not pictured)

3 Screws (see following table)

56 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 65

TABLE: 19-Inch, 2-Post Sliding Rail Mount Screw Kit Contents

No. Description Where Used

10 M4 x 0.5 mm x 5 mm Phillips panhead

screws

10 M5 x 12.7 mm screws 10 for rack, if appropriate

12 M6 x 13 mm screws 10 for rack, 2 extra

9 M6 square clip nuts 9 for rack, if appropriate

10 10–32 collar screws, 4 short, 4 long, 2

extra

12 10–32 x 0.5 in. combo head screws 12 for rack, if appropriate

12 12–24 x 0.5 in. combo head screws 12 for rack, if appropriate

8 for glides, 2 extra

8 for racks with 10-32 holes, if appropriate

Related Information

■ “Install a Server (19-Inch, 2-Post Sliding Rail Rackmount Kit)” on page 57

▼ Install a Server (19-Inch, 2-Post Sliding Rail

Rackmount Kit)

Note – The 19-inch, 2-post sliding rail rackmount kit supports rack web thicknesses

(the width of the rack post) of 76.20 mm (3 in.), 101.6 mm (4 in.), and 127 mm (5 in.).

Note – The front-to-back rail spacing must be at least 392 mm (15.43 in.) and not

more than 863.6 mm (34 in.) from the outside face of the front rail to the outside face

of the back rail.

1. Read the Cautions for racks.

See “Rack Cautions” on page 20.

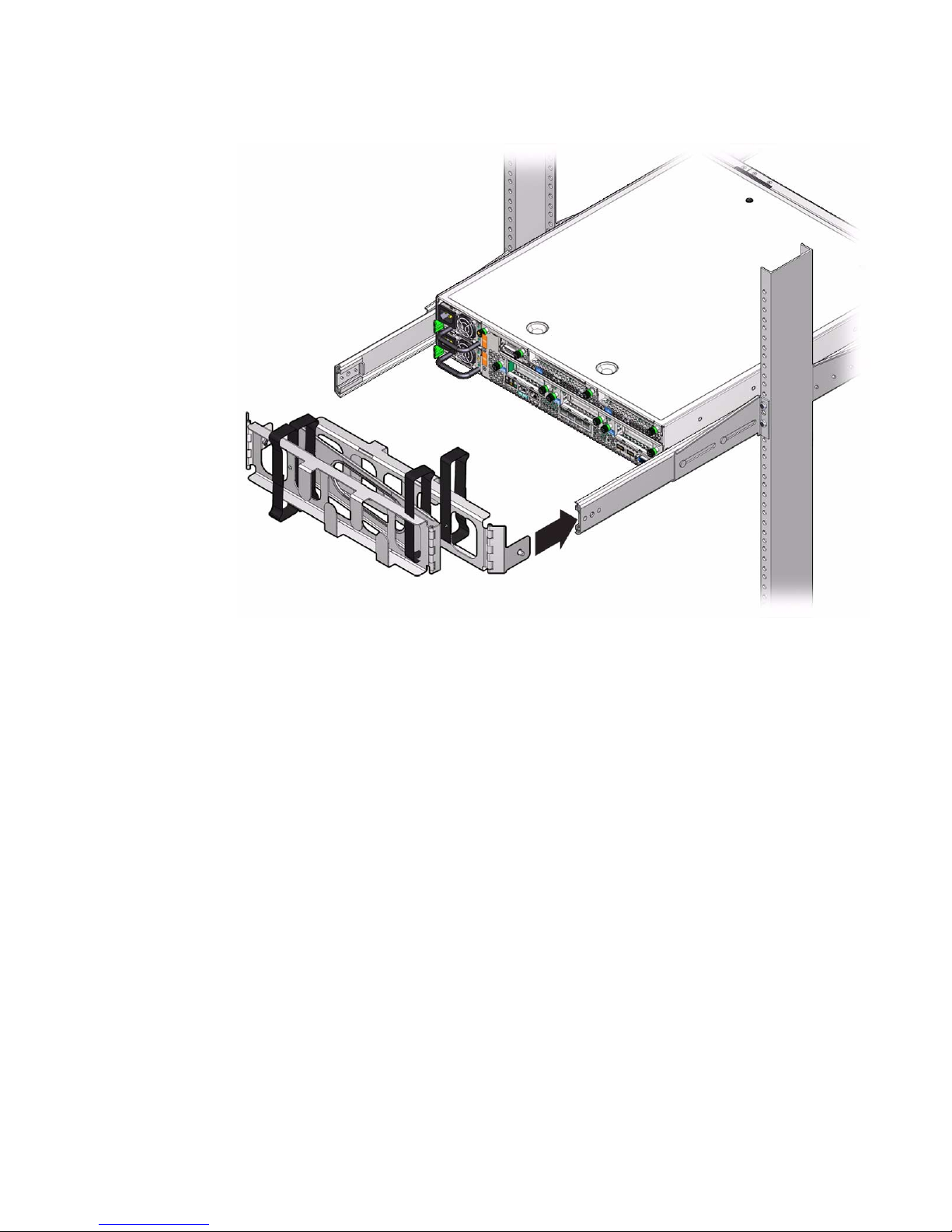

2. Press in the green button on each slide assembly, and pull the right side and left

side inner glides completely out of the slides.

Installing the Server 57

Page 66

1 Glide

2 Button

3 Slide (in two parts)

3. Using eight of the M4 x 0.5 x 5 mm Phillips panhead screws from the rackmount

kit (four for each side), attach each glide to the side of the server chassis.

58 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 67

4. Lift each front bracket to the desired position at the front of the rack and attach

a front bracket to each of the front rack posts.

To secure each bracket, use two of the M5 x 12.7 mm screws or two of the

M6 x 13 mm screws. Tighten the screws enough to secure the brackets, but leave

them loose enough for adjustment later.

5. Lift each rear bracket to the desired position at the rear of the rack and attach a

rear bracket to each of the rear rack posts.

To secure each bracket, use two of the M5 x 12.7 mm screws or two of the M6 x 13

mm screws, as you did in Step 4. Tighten the screws enough to secure the

brackets, but leave them loose enough for adjustment later.

Installing the Server 59

Page 68

Note – If your rack has 10–32 holes, use the 10–32 collar screws and 10–32 threaded

strips.

6. Align the glides attached to the server with the slide assemblies in the rack.

You might find that there is too much or too little room between the two slides

mounted in the rack. Consequently the glides attached to the server might not

align correctly with the slides in the rack. If either situation occurs, loosen the

screws on the front and back brackets (Step 4 and Step 5), move the brackets

inward or outward to the appropriate points, then tighten the brackets again.

7. Push in the slide buttons and slide the server all the way into the rack

enclosure.

60 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 69

8. Fully tighten the screws on the front brackets.

9. Fully tighten the screws on the rear brackets.

Installing the Server 61

Page 70

10. Attach the CMA to the right rail on the right side.

There are labels on both the rails and the CMA. The CMA side that has an arrow

attaches to the right inner glide. The other side of the CMA attaches to the outer

member.

62 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 71

11. Attach the CMA to the left rail.

There are labels on both the rails and the CMA. The CMA side that has an arrow

attaches to the left inner glide. The other side of the CMA attaches to the outer

member.

Installing the Server 63

Page 72

Related Information

■ “Stabilize the Rack for Installation” on page 21

■ “19-Inch, 2-Post Rack Sliding Rail Rackmount Kit” on page 56

64 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 73

Connecting the Server Cables

Connect and configure the network and serial ports before you attempt to boot the

server.

■ “Cabling Requirements” on page 65

■ “Back Panel Connectors and Ports” on page 66

■ “Connect the SER MGT Cable” on page 67

■ “Connect the NET MGT Cable” on page 68

■ “Connect the Ethernet Network Cables” on page 69

■ “Connect Other Data Cables” on page 69

■ “Prepare the Power Cords” on page 70

Related Information

■ “Back Panel Components” on page 14

Cabling Requirements

Prior to cabling and powering-on the server, gather the following network

information:

■ Netmask

■ IP address for the service processor

■ Gateway IP address

At a minimum, you must connect cables to these ports before powering on the server

for the first time:

■ SER MGT port

■ NET MGT port

■ At least one system on-board Ethernet network port

■ Power cables to the power supply inlet ports

65

Page 74

Back Panel Connectors and Ports

No. Connectors and Ports Description

1 Power supply 0 (AC version shown) Use the supplied or supported AC power cords... For DC

2 Power supply 1 (AC version shown) inlet

3 Alarm port This port provides a connection for a Telco Dry Alarm Relay

power cords see “Assembling and Connecting DC Power

Cords” on page 71.

Note - Before attaching power cords to the power supplies,

connect the data cables and connect the server to a serial

terminal or a terminal emulator (PC or workstation).

cable. The port accepts a DB-15 socket connector.

4 SER MGT port The serial management port uses an RJ-45 cable and is always

available. This port is the default connection to the ILOM

system controller.

5 NET MGT Ethernet port The network management port is the optional connection to

the ILOM SP. The service processor network management port

uses an RJ-45 cable for a 10/100BASE-T connection. If your

network does not use a DHCP server, this port will not be

available until you configure network settings through the

SER MGT port.

Note - This port does not support connections to Gigabit

networks.

6 Network 10/100/1000 ports (NET0, NET1,

NET2, and NET3)

66 Netra SPARC T3-1 Server Installation Guide • August 2013

The four Gigabit Ethernet ports enable you to connect the

server to the network.

Note - Using the ILOM sideband management feature, you

can access the SP using one of these ports. Refer to Netra

SPARC T3-1 Server Administration Guide for instructions.

Page 75

No. Connectors and Ports Description

7 USB ports (USB 0, USB 1) The two USB ports support hot-plugging. You can connect

and disconnect USB cables and peripheral devices while the

server is running, without affecting server operations.

Note - The maximum USB cable length for connecting to the

server’s USB ports is 5 mm.

Note - You can connect up to 126 devices to each of the four

USB controllers (two ports in front, two ports in back), for a

total of 504 USB devices per server.

8 HDB-15 video port Use a HDB-15 video cable to connect to a video device.

Note - The cable length used to connect between monitor and

the VGA port should not be over 6 meters.

Related Information

■ “Identifying the Server Ports” on page 89

■ “Back Panel Components” on page 14

▼ Connect the SER MGT Cable

The service processor serial management port is labeled SER MGT. Use the SER MGT

port only for server management.

Caution – Do not attach a modem to this port.

● Connect a Category 5 (or better) cable from the SER MGT to a terminal device.

When connecting a DB-9 cable, use an adapter to perform the crossovers given for

each connector.

Connecting the Server Cables 67

Page 76

Related Information

■ “Prepare the Power Cords” on page 70

■ “Connect the NET MGT Cable” on page 68

■ “Connect the Ethernet Network Cables” on page 69

■ “Connect Other Data Cables” on page 69

▼ Connect the NET MGT Cable

The service processor network management port is labeled NET MGT. After the

initial server configuration, you can connect to the service processor over an Ethernet

network using this NET MGT port.

If your network uses a DHCP server to assign IP addresses, the DHCP server will

assign an IP address to this NET MGT port. With this IP address, you can connect to

the service processor using an SSH connection. If your network does not use DHCP,

this NET MGT port will not be accessible until you configure the network settings

through the SER MGT port. For instructions, see “Assign a Static IP to the NET MGT

Port” on page 85

● Connect a Category 5 (or better) cable from the NET MGT port to your network

switch or hub.

Related Information

■ “Connect the Ethernet Network Cables” on page 69

■ “Connect the SER MGT Cable” on page 67

■ “Connect Other Data Cables” on page 69

68 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 77

▼ Connect the Ethernet Network Cables

The server has four Gigabit Ethernet network connectors, marked NET0, NET1,

NET2, and NET3. Use these ports to connect the server to the network. The Ethernet

interfaces operate at 10 Mbps, 100 Mbps, and 1000 Mbps.

Note – The ILOM sideband management feature enables you to access the SP using

one of these Ethernet ports. Refer to Netra SPARC T3-1 Server Administration Guide for

instructions.

1. Connect a Category 5 (or better) cable from your network switch or hub to

Ethernet Port 0 (NET0) on the rear of the chassis.

2. Connect Category 5 (or better) cables from your network switch or hub to the

remaining Ethernet ports (NET1, NET2, NET3), as needed.

Related Information

■ “Powering On the Server for the First Time” on page 77

▼ Connect Other Data Cables

If your server includes optional PCIe cards, connect the appropriate I/O cables to

their connectors.

● If your server configuration includes optional PCIe cards, connect the

appropriate I/O cables to their connectors.

Refer to the PCIe card documentation for specific instructions.

Connecting the Server Cables 69

Page 78

Related Information

■ PCIe card documentation

▼ Prepare the Power Cords

Prepare the power cords by routing them from the power source to the server.

Caution – Do not attach power cables to the power supplies until you have first

connect the server to a serial terminal or a terminal emulator (PC or workstation).

Note – The server goes into Standby mode and the ILOM service processor

initializes as soon as a power cable connects a power supply to an external power

source. System messages might be lost after 60 seconds if a terminal or terminal

emulator is not connected to the SER MGT port before power is applied.

Note – ILOM will signal a fault if both power supplies are not cabled at the same

time, since that situation will be a nonredundant condition.

1. Ensure that the +circuit breakers are off on the AC power source or that the DC

input cables are de-energized with no DC power present.

2. Route the power cords from the power source to the rear of the server and

secure the cables with nylon tie wraps.

Related Information

■ AC power source documentation

70 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 79

Assembling and Connecting DC

Power Cords

These topics provide the power requirements for the DC-powered version of the

server, as well as instructions on how to assemble and connect DC power cords to the

server.

Description Link

Review requirements for the DC power

source, chassis ground, the DC connectors,

and the overcurrent protection.

Assemble the DC input power cables. “Assemble the DC Input Power Cables” on

Connect the DC input power cables to the

server.

“Electrical Specifications” on page 6

“DC Power Source, Power Connection, and

Grounding Requirements” on page 8

“Input Power Information” on page 7

“Overcurrent Protection Requirements” on

page 8

page 71

“Connect the DC Input Power Cords to the

Server” on page 74

Related Information

■ “Electrical Specifications” on page 6

■ “Prepare the Power Cords” on page 70

▼ Assemble the DC Input Power Cables

The following procedure describes how to assemble the DC input power cables.

Assemble one cable for each DC power supply in your server.

Before you begin the installation procedure, verify that the required conditions

described in the following table have been satisfied.

71

Page 80

Prerequisite Condition Responsible Party

Install a DC power source that meets the server’s input power

Customer

specifications.

Secure DC power cables that meet the server’s power cabling

Customer

specifications.

Attach the DC input plug to the DC input power cables. The input plug

Customer

is provided in the server’s shipping kit.

1. Turn off power from the DC power source using the circuit breakers.

Caution – Before proceeding with these instructions, turn off the power from the DC

power source through the circuit breakers.

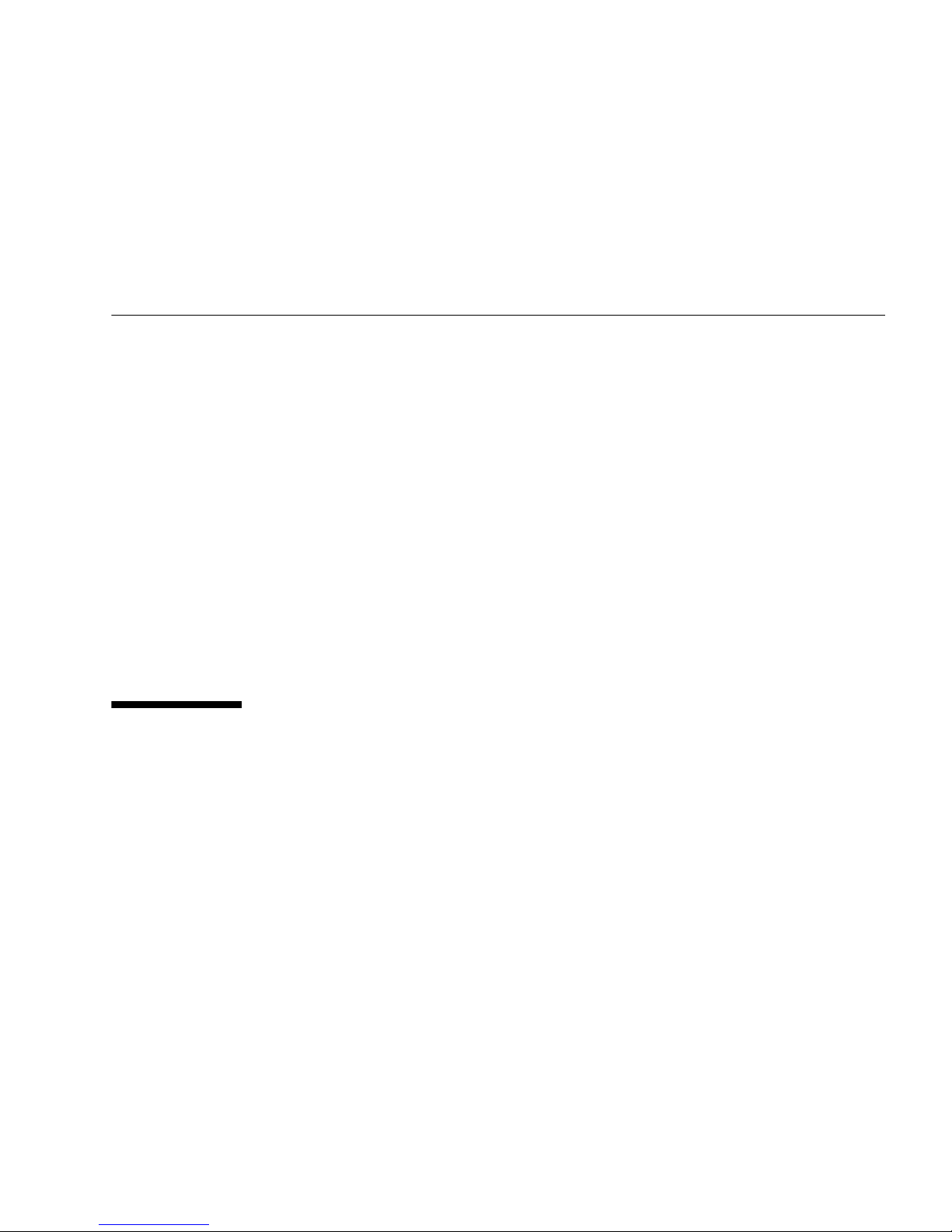

2. Identify the parts that you will use to assemble the DC input power cables.

For each cable, you need a DC input plug, cage clamp tool, or small screwdriver.

These items are provided in the shipping kit that came with your server (DC

models only).

3. Locate the three wires coming from your DC power source that will be used in

the connection to your unit:

■ -48V or -60V (negative terminal)

■ Chassis ground

■ -48V or -60V Return (positive terminal)

72 Netra SPARC T3-1 Server Installation Guide • August 2013

Page 81

Note – Depending on the DC power source, the -48V or -60V (negative terminal)

might be marked with a minus (-) symbol. The -48V or -60V Return (positive

terminal) might be marked with a positive (+) symbol.

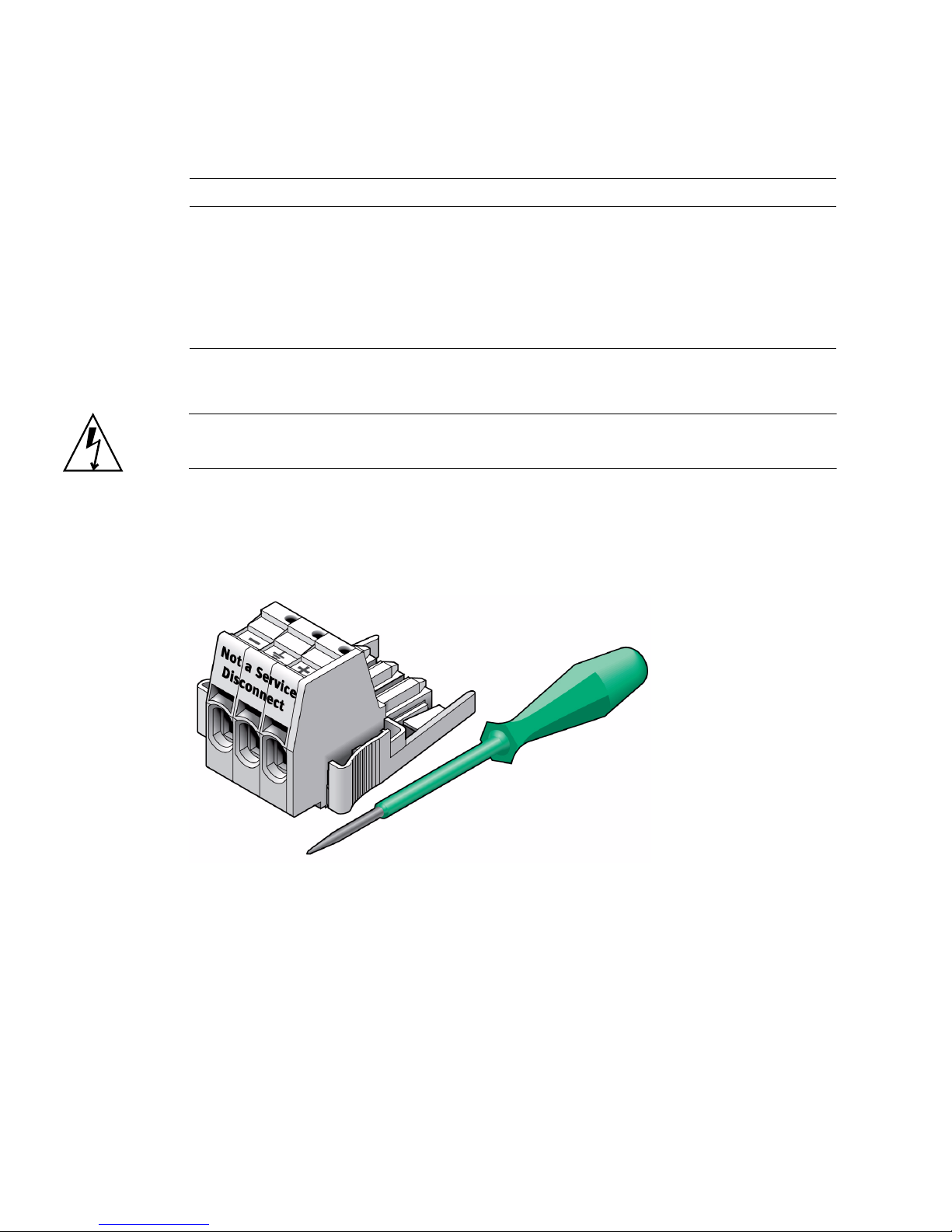

4. Strip 1/2 in. (13 mm) of insulation from each of the wires coming from the DC

power source.

Do not strip more than 1/2 in. (13 mm) from each wire. Doing so leaves

uninsulated wire exposed from the DC connector after the assembly is complete.

1 1/2 in. (13 mm)

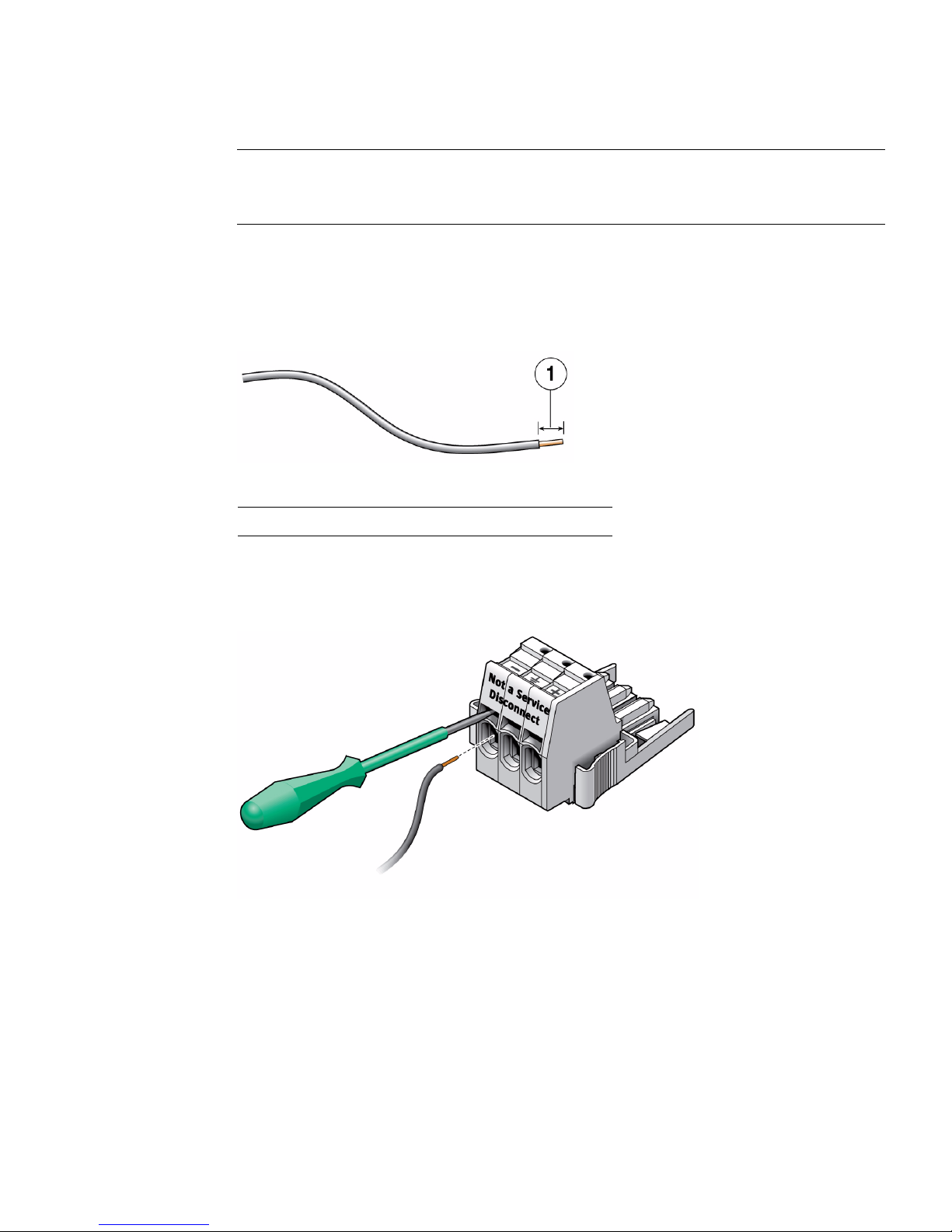

5. Open the cage clamp by inserting the cage clamp tool (or small screwdriver)

into the rectangular hole directly above the hole in the DC input plug where

you want to insert the first wire, and push in to open the cage clamp.

6. Feed the exposed section of the appropriate wire into the round plug hole in the

DC input plug.

Assembling and Connecting DC Power Cords 73

Page 82

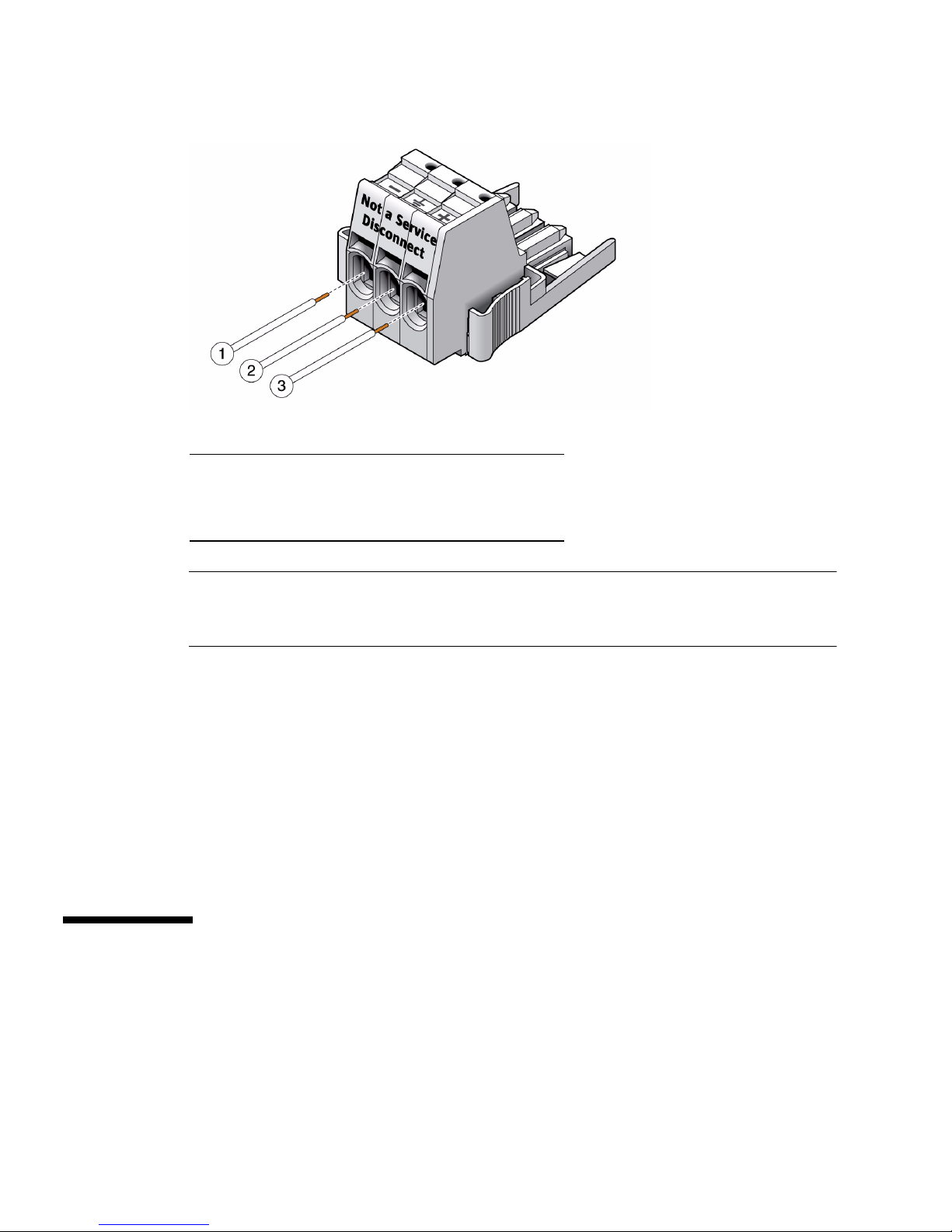

1 From -48V or -60V

2 From Chassis ground (green/yellow)

3 From -48V or -60V Return

Note – If you need to remove a wire from the DC input plug, insert the cage clamp

operating tool or a small screwdriver into the slot directly above the wire and push

in. Pull the wire from the DC input plug.