Page 1

CUSTOMER

:

DESCRIPTION

:

DC BRUSHLESS FAN

DIMENSIONS

:

40X40X10 mm

M O D E L

:

EF40101B2-1000U-A99

SUNON SPEC. NO.

:

D04111720G-01

CUSTOMER

APPROVAL NO.

:

APPROVED BY

CUSTOMER

:

(AUTHORIZED)

DRAWN

Ting

7/25

CHECKED

Kelly

Cindy

APPROVED

Gavinlee

SPEC.NO

D04111720G-01

ISSUE DATE

07.25.2017

EDITION

0

REVISION DATE

E.SPEC

E11400255

建準電機工業股份有限公司

SUNONWEALTH ELECTRIC MACHINE INDUSTRY CO., LTD.

NO. 30, LN. 296, XINYA RD., QIANZHEN DIST., TEL:886-7-8135888

KAOHSIUNG CITY 80673, TAIWAN (R.O.C)

FAX:886-7-8230505/8230606/8231010

URL:http://www.sunon.com E-mail: sunon@email.sunon.com.tw

SPECIFICATION FOR APPROVAL

2017.09.11

D.C.C.

SUNON

建 準 電 機

SUNONWEALTH

Page 1 of 14

Page 2

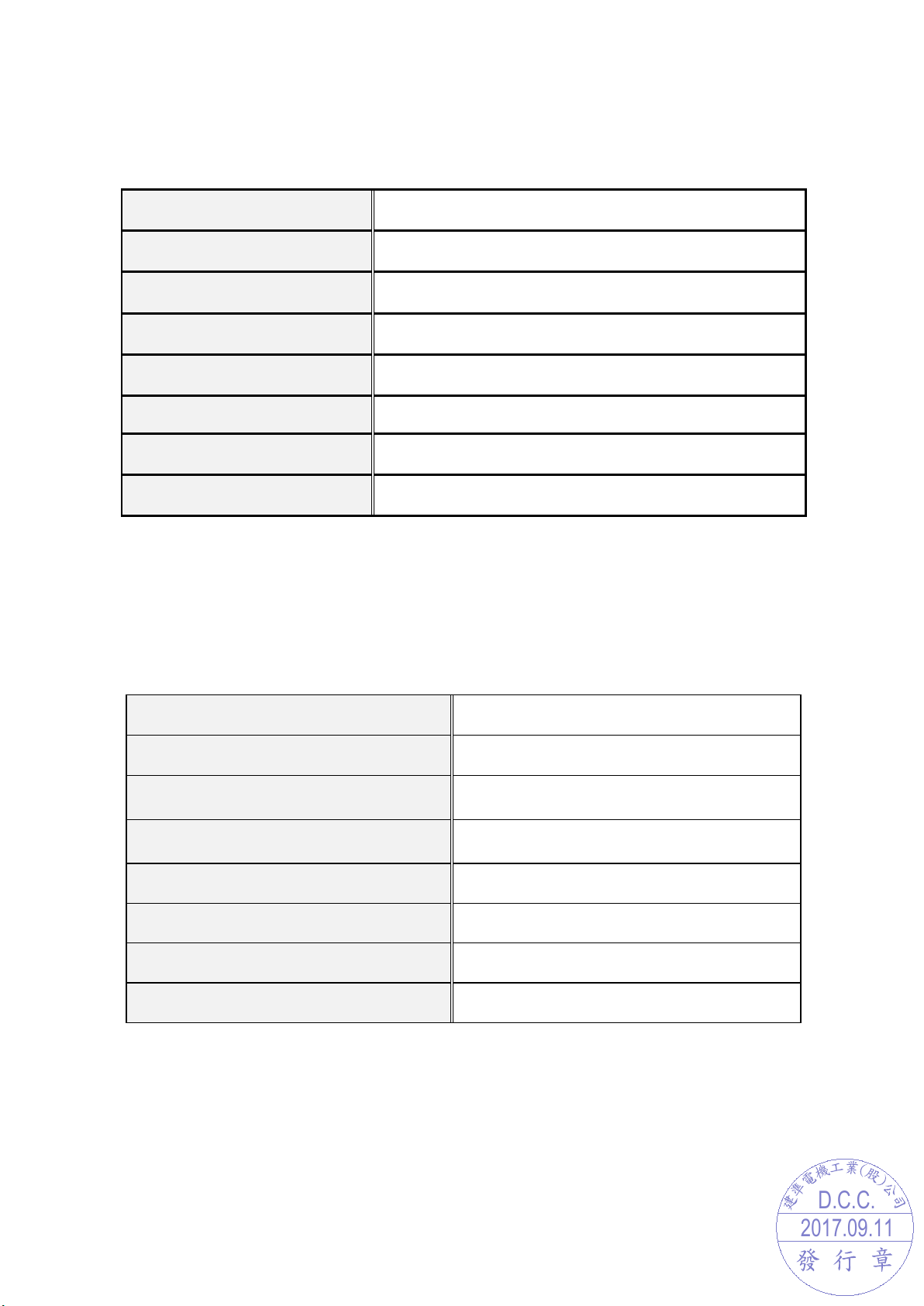

I. MODEL NUMBERING SYSTEM

編碼

尺寸(mm)

編碼

尺寸(mm)

編碼

尺寸(mm)

編碼

尺寸(mm)

01~09 01~09 A0~A9 100~109 K0~K9 200~209 V0~V9 300~309

10~19 10~19 B0~B9 110~119 L0~L9 210~219 W0~W9 310~319

20~29 20~29 C0~C9 120~129 M0~M9 220~229 X0~X9 320~329

30~39 30~39 D0~D9 130~139 N0~N9 230~239 Y0~Y9 330~339

40~49 40~49 E0~E9 140~149 P0~P9 240~249 Z0~Z9 340~349

50~59 50~59 F0~F9 150~159 Q0~Q9 250~259

60~69 60~69 G0~G9 160~169 R0~R9 260~269

70~79 70~79 H0~H9 170~179 S0~S9 270~279

80~89 80~89 I0~I9 180~189 T0~T9 280~289

90~99 90~99 J0~J9 190~199 U0~U9 290~299

Voltage

1

0: 5VDC

1: 12VDC

2: 24VDC

3: 36VDC

4: 48VDC

Function Code

A99

Customer Code

Thickness

Size

-

Series Code

B

Bearing

V: Vapo

B: 2 Ball

O: 1Ball

S: Sleeve

2

Speed

X:Super High

1: High

2: Medium

3: Low

4: Extra Low

1000U

40

10

-

EF

2017.09.11

D.C.C.

建 準 電 機

SUNONWEALTH

Page 2 of 14

Page 3

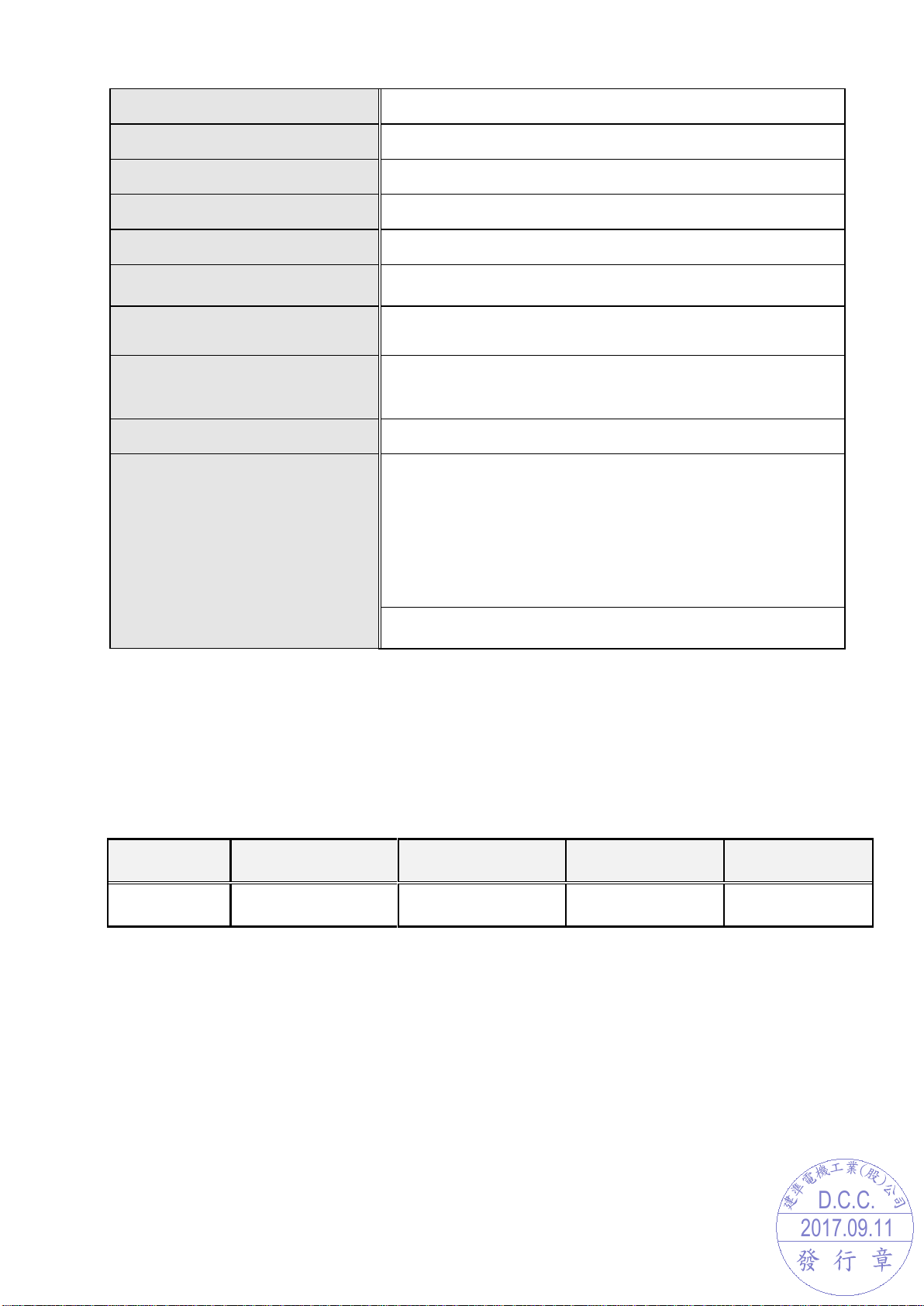

MOTOR DESIGN

Single phase, 4-poles Brushless DC motor.

BEARING SYSTEM

Precision ball bearing system

DIMENSIONS

See Page 6

MATERIALS OF FRAME

Thermoplastic PBT of UL 94V-0

MATERIALS OF FAN BLADE

Thermoplastic PBT of UL 94V-0

DIRECTION OF ROTATION

Counter-clockwise viewed from front of fan blade

MOUNTING HOLES

Diameter 4.3 mm in 4 holes

WEIGHT

15.8g

RATED VOLTAGE

12VDC

RATED CURRENT

37 mA / Max. 43 mA

RATED POWER CONSUMPTION

0.45 WATTS / Max. 0.52 WATTS

SAFETY POWER CONSUMPTION

0.48 WATTS

OPERATING VOLTAGE RANGE

6~13.8 VDC

STARTING VOLTAGE

6 VDC 25 deg. C POWER ON/OFF)

OPERATING TEMPERATURE RANGE

-10 to + 70 deg. C

STORAGE TEMPERATURE RANGE

-40 to + 80 deg. C

2017.09.11

D.C.C.

II. SPECIFICATION

1. MECHANICAL CHARACTERISTIC

2. ELECTRIC CHARACTERISTIC

建 準 電 機

SUNONWEALTH

Page 3 of 14

Page 4

3. PERFORMANCE CHARACTERISTIC

RATED SPEED

5000 RPM ± 15% at rated voltage

AIR FLOW

5.5 CFM

STATIC PRESSURE

0.10 Inch-H2O

ACOUSTIC NOISE

17.7 dB(A)

AIR FLOW V.S. PRESSURE

See Page 5

INSULATION CLASS

UL Class A

INSULATION RESISTANCE

PLASTIC HOUSING

DIELECTRIC STRENGTH

Applied AC 500 V for one minute or AC 600 V for 2

Seconds between housing and lead wire (+)

LIFE EXPECTANCY

70,000 Hours at 40 deg. C, 65% humidity, 90% CL .

PROTECTION

Automatic Restart

Note: In a situation where the fan is locked by an external

force while the electricity is on, an increase in coil

temperature will be prevented by temporarily turning off

the electrical power to the motor. The fan will

automatically restart when the locked rotor condition is

released.

Polarity Protection

SAFETY

UL

CUR

TUV

CE

NO.

E77551

E77551

2017.09.11

D.C.C.

4. SAFETY

SUNONWEALTH

建 準 電 機

Page 4 of 14

Page 5

MODEL :

EF40101B2-1000U-A99

PERFORMANCE CURVES

0

0.02

0.04

0.06

0.08

0.1

0 1 2 3 4 5 6

Air Flow-CFM

Static Pressure (Inch-H

2

O)

0

0.5

1

1.5

2

2.5

0 0.028 0.056 0.084 0.112 0.14 0.168

m3/min

mm-H

2

O

2017.09.11

D.C.C.

建 準 電 機

SUNONWEALTH

Page 5 of 14

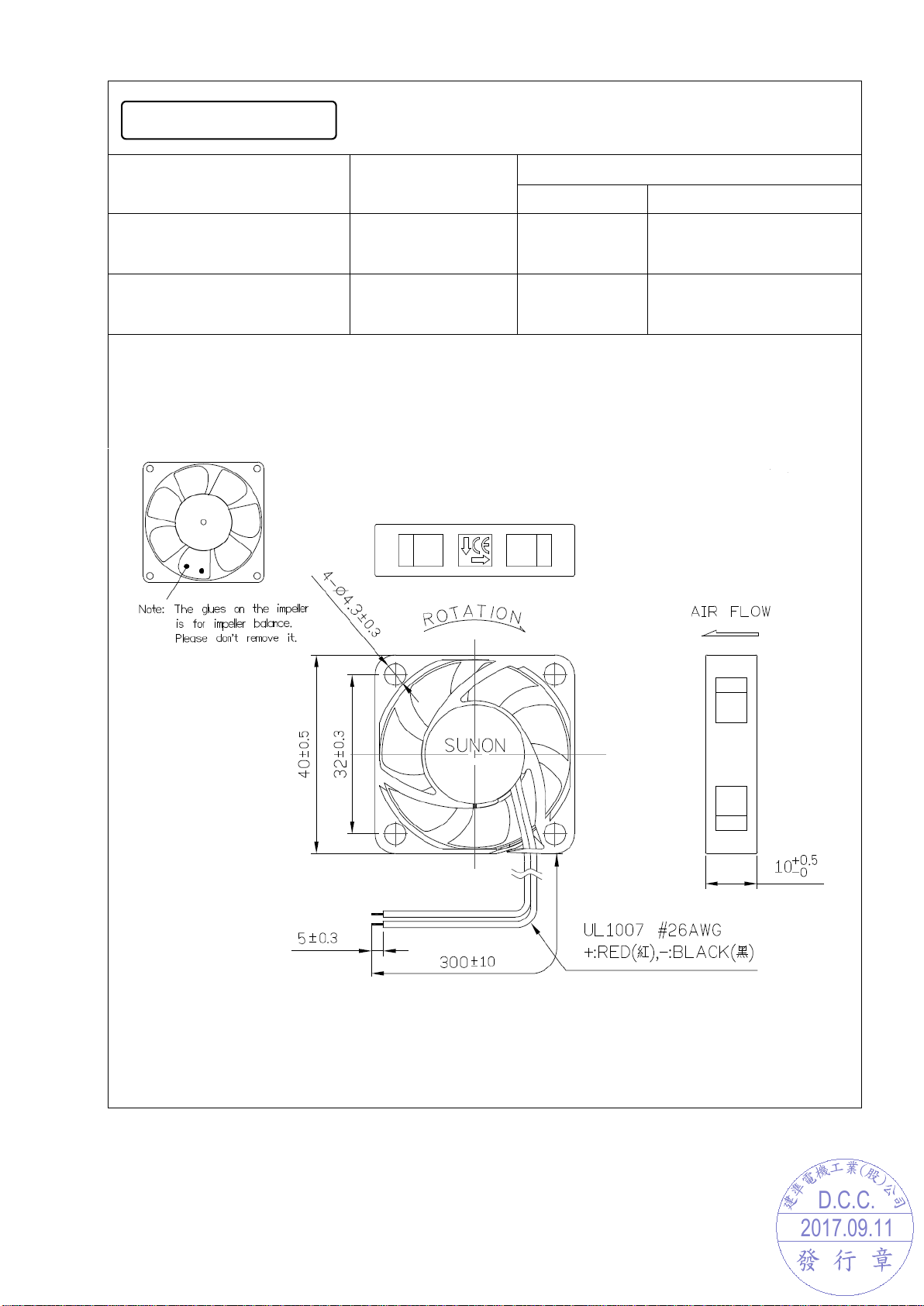

Page 6

DIMENSIONS

Screw Type

(Pan head)

Torque

Screw Spec

Size

Standard

Machine screw

3~4 Kgf-cm

M4.0

JIS B1111-1974

Self-tapping screw

6~8 Kgf-cm

∮5.0

JIS B1122 Type 2

Note: SUNON recommends the screw and torque as above. Please contact SUNON, if any

new requirement is requested.

UNIT:mm

2017.09.11

D.C.C.

建 準 電 機

SUNONWEALTH

Page 6 of 14

Page 7

LABEL

2017.09.11

D.C.C.

建 準 電 機

SUNONWEALTH

Page 7 of 14

Page 8

2017.09.11

D.C.C.

III. OTHER SPECIFIED TESTING

The following is a general description of certain tests that are performed on

representative SUNON fans. Nothing in this document is intended to suggest that

these tests are performed on every model of SUNON fan. Moreover, the descriptions

that follow each test are meant only to provide a general explanation of each test. If

you would like a more detailed explanation as to any test identified in this Section,

SUNON can provide such an explanation upon request.

1. DROP PROOF TEST

Fans are packaged in a standard size shipping box and are dropped to the ground from

certain heights and angles depending on the weight of the particular box.

2. HUMIDITY PROOF TEST

The fan is operated for 96 continuous hours in an environment with humidity of 90%

to 95% RH at 60°C 2°C.

3. VIBRATION PROOF TEST

Vibration with an amplitude 2mm and a frequency of 5-55-5hz is applied in all 3

directions (X,Y,Z), in cycles of 1 hour each, for a total vibration time of 3hours.

4. THERMAL CYCLING TEST

The fan is operated in a testing chamber for 50 cycles. In each cycle, the temperature is

gradually increased from -10°C to 70°C for 90 minutes, and subsequently operated at

70°C for 120 minutes. The temperature is then gradually decreased from 70°C to

-10°C for 90 minutes, and subsequently operated at -10°C for 120 minutes.

5. SHOCK PROOF TEST

100G of force is applied in the 3 directions (X,Y, and Z) for 2 milliseconds each.

6. LIFE EXPECTANCY

The “Life Expectancy” of SUNON fans is determined in SUNON’s reliability test

laboratory by using temperature chambers. The “Life Expectancy” of this fan has not

been evaluated for use in combination with any end application. Therefore, the Life

Expectancy Test Reports (L10 and MTTF Report) that relate to this fan are only for

reference.

建 準 電 機

SUNONWEALTH

Page 8 of 14

Page 9

IV. CHARACTERISTIC DEFINITION

2017.09.11

D.C.C.

The following is a general description of certain tests that are performed on

representative SUNON fans in order to determine the specifications of the fan.

Nothing in this document is intended to suggest that these tests are performed on

every model of SUNON fan. Moreover, the descriptions that follow each test are

meant only to provide a general explanation of each test. If you would like a more

detailed explanation as to any test identified in this Section, SUNON can provide

such an explanation upon request.

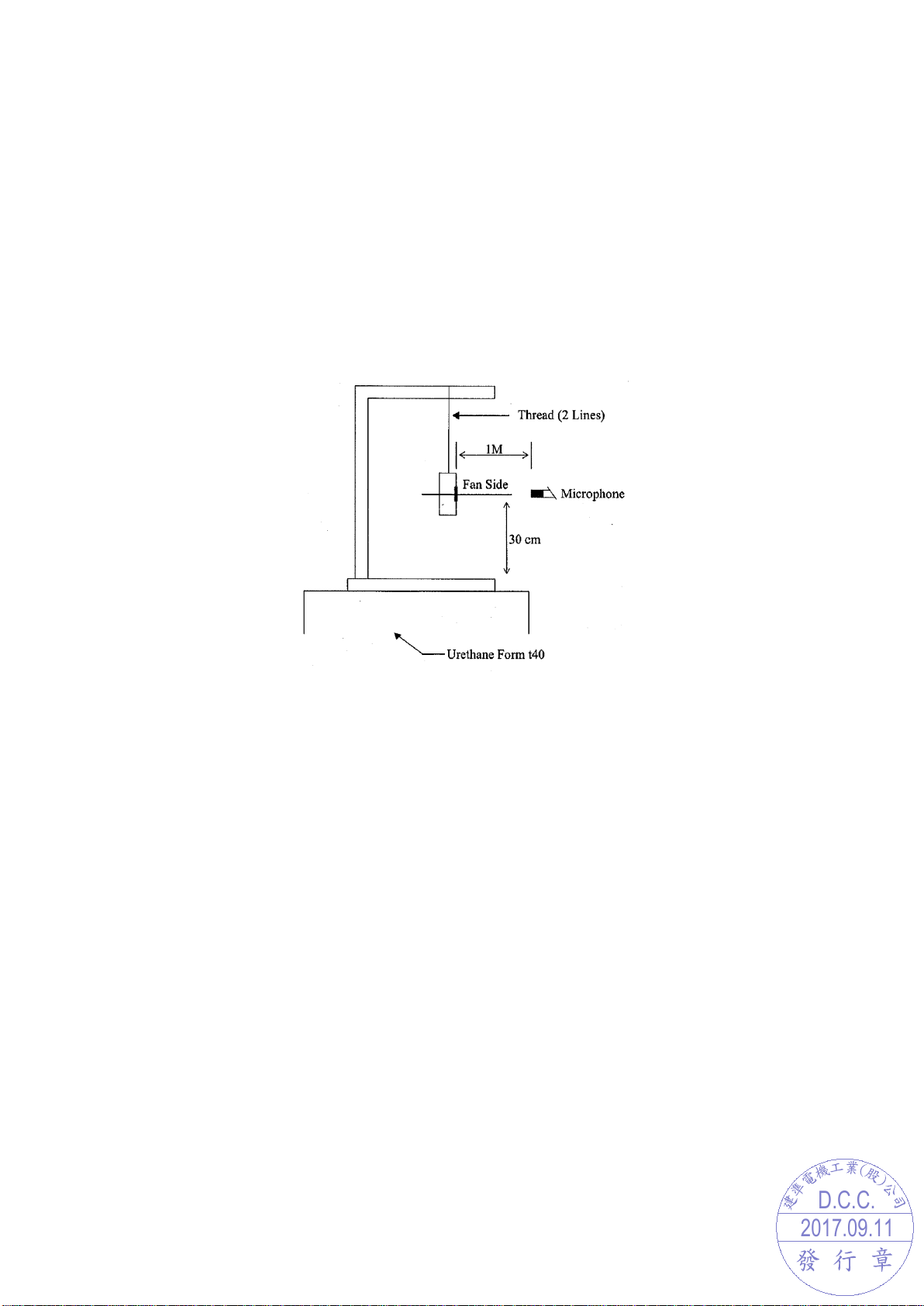

1. ACOUSTICAL NOISE

Measured in a semi-anechoic chamber with background noise level below 15dB(A).

1 METER FROM MICROPHONE TO FAN INTAKE

The fan is running in free air under shaft horizontal condition with the microphone at

distance of one meter from the fan intake.

2. INPUT POWER

Measured after continuous 10 minute operation at rated voltage in clean air

( STATIC PRESSURE=0), and at ambient temperature of 25 degrees C under shaft

horizontal condition.

3. RATED CURRENT

Measured after continuous 10 minute operation at rated voltage in clean air

( STATIC PRESSURE=0), and at ambient temperature of 25 degrees C under shaft

horizontal condition.

建 準 電 機

SUNONWEALTH

Page 9 of 14

Page 10

4. RATED SPEED

2017.09.11

D.C.C.

Measured after continuous 10 minute operation at rated voltage in clean air

( STATIC PRESSURE=0), and at ambient temperature of 25 degrees C under shaft

horizontal condition.

5. STARTING VOLTAGE

Measured the voltage which enables to start the fan in the clean air (static pressure = 0 )

by switching on at the voltage under shaft horizontal condition. It is not at continuously

increasing voltage adjustment.

6. LOCKED ROTOR CURRENT

Measured immediately after the fan blade is locked.

7. AIR FLOW AND STATIC PRESSURE

The performance specification of air flow and static pressure shown in this specification

for approval is measured using the exhaust method. A double chamber is used in

accordance with AMCA 210 standard or DIN 24163 specification . The values are

recorded when the fan speed has stabilized at rated voltage.

8. INSULATION RESISTANCE

1. PLASTIC HOUSING:

(1) Measured between internal stator and lead wire(+).

(2) Measured between housing and lead wire(+).

2. ALUMINIUM HOUSING:

Measured between internal stator and lead wire(+).

9. DIELECTRIC STRENGTH

Measure between housing and lead wire(+).

建 準 電 機

SUNONWEALTH

Page 10 of 14

Page 11

V. NOTE

2017.09.11

D.C.C.

Ⅰ

.SAFETY

1. DO NOT use or operate this fan in excess of the limitations set forth in this

specification. SUNON is not responsible for the non-performance of this fan

and/or any damages resulting from its use, if it is not used or operated in

accordance with the specifications.

2. SUNON recommends adding a protection circuit to the product or application in

which this fan is installed, such as a thermo-fuse, or current-fuse or

thermo-protector. The failure to use such a device may result in smoke, fire,

electric shock by insulation degradation in cases of motor lead short circuit,

overload, or over voltage, and/or other failure.

3. SUNON recommends installing a protection device to the product or application

in which this fan is installed if there is a possibility of reverse-connection between

VDC (+) and GND (-). The failure to install such a device may result in smoke,

fire, and/or destruction, although these conditions may not manifest immediately.

4. This fan must be installed and used in compliance with all applicable safety

standards and regulations.

5. Use proper care when handling and/or installing this fan. Improper handling or

installation of this fan may cause damage that could result in unsafe conditions.

6. Use proper care during installation and/or wiring. Failure to use proper care may

cause damage to certain components of the fan including, but not limited to, the

coil and lead wires, which could result in smoke and/or fire.

7. DO NOT use power or ground PWM to control the fan speed. If the fan speed

needs to be adjusted, please contact SUNON to customize the product design for

your application.

8. For critical or extreme environments, including non stop operation, please contact

SUNON and we will gladly provide assistance with your product selection to

ensure an appropriate cooling product for your application.

建 準 電 機

SUNONWEALTH

Page 11 of 14

Page 12

II. SPECIFICATION MODIFICATION

2017.09.11

D.C.C.

1. SUNON offers engineering assistance on fan installation and cooling system design.

2. All changes, modifications and/or revisions to the specifications, if any, are

incorporated in the attached specifications.

3. No changes, modifications and/or revisions to these specifications are effective

absent agreement, by both SUNON and the customer, in writing.

4. This fan will be shipped in accordance with the attached specification unless

SUNON and the customer have agreed otherwise, in writing, as specified in

Paragraph 3, above.

III. OTHER

1. When building your device, please examine thoroughly any variation of EMC,

temperature rise, life data, quality, etc. of this product by shock/drop/vibration

testing, etc. If there are any problems or accidents in connection with this product,

it should be mutually discussed and examined.

2. Use proper care when handling this fan. Components such as fan holders or

bearings may be damaged, if touched with fingers or other objects. Additionally,

static electricity (ESD) may damage the internal circuits of the fan.

3. DO NOT operate this fan in proximity to hazardous materials such as

silicon, cyanogens, formalin, phenol, or corrosive gas environments including, but

not limited to, H2S, SO2, NO2, or Cl2.

4. SUNON recommends that you protect this fan from exposure to outside elements

such as dust, condensation, humidity or insects. Exposure of this fan to outside

organic

elements such as dust, condensation, humidity or insects may affect its

performance and may cause safety hazards. SUNON does not warrant against

damage to the product caused by outside elements.

5. This fan must be installed properly and securely. Improper mounting may cause

harsh resonance, vibration, and noise.

6. Fan guards may prevent injury during handling or installation of the fan and are

available for sale with this fan.

建 準 電 機

SUNONWEALTH

Page 12 of 14

Page 13

2017.09.11

D.C.C.

7. Unless otherwise noted, all testing of this fan is conducted at 25°C ambient

temperature and sixty-five percent (65%) relative humidity.

8. DO NOT store this fan in an environment with high humidity. This fan must be

stored in accordance with the attached specifications regarding storage

temperature. If this fan is stored for more than 6 months, SUNON recommends

functional testing before using.

9. SUNON reserves the right to use components from multiple sources at its

discretion. The use of components from other sources will not affect the

specifications as described herein.

10. The “Life Expectancy” of this fan has not been evaluated for use in combination

with any end application. Therefore, the Life Expectancy Test Reports (L10 and

MTTF Report) that relate to this fan are only for reference.

VI. WARRANTY

This fan is warranted against all defects which are proved to be fault in our

workmanship and material for one year from the date of our delivery. The sole

responsibility under the warranty shall be limited to the repair of the fan or the

replacement thereof, at SUNON’s sole discretion. SUNON will not be responsible

for the failures of its fans due to improper handing, misuse or the failure to follow

specifications or instructions for use. In the event of warranty claim, the customer

shall immediately notify SUNON for verification. SUNON will not be responsible

for any consequential damage to the customer’s equipment as a result of any fans

proven to be defective.

建 準 電 機

SUNONWEALTH

Page 13 of 14

Page 14

Control declaration of environment-related substances/materials

1. In accordance with the Restriction of Hazardous Substances (RoHS) Directive

2011/65/EU, SUNON product have complied with law and discipline not to

employ the forbidden substances, and restrict the allowable concentration of

some limited substances deliberately in our components.

No

Substance

Criteria

1

CFCs & HCFCs (ozone depleting substances)

Forbidden

2

Chlorinated Organic Solvent

Forbidden

3

Lead and its compounds

Plastic (Frame, Impeller, wire harness, etc.)

<100ppm

Solder

<1000ppm

Steel alloy

<3500ppm

Aluminium alloy

<4000ppm

Copper alloy

<4wt%

4

Cadmium and its compounds

Solder

<20ppm

Parts composed of metals containing zinc

(e.g. brass, zinc for die casting)

<100ppm

Plastic

<5ppm

5

PBBs and PBDEs

Forbidden

6

PCB and PCT

Forbidden

7

CP, Short-chain Chlorinated paraffins C10-13, Cl ≥48 wt%

Forbidden

8

Mirex

Forbidden

9

PCN

Forbidden

10

Hexavalent Chromium compounds

<100ppm

11

Mercury and its compounds

Forbidden

12

Asbestos

Forbidden

13

Organic Tin compounds

Forbidden

14

Azo compounds

Forbidden

15

TBBP-A in external case plastic parts of products (PCB is exempted)

<1000ppm

16

Nickel in external case parts, which are likely to result in prolonged skin exposure

<1000ppm

17

Hexabromocyclododecane (HBCDD)

<1000ppm

18

Di-butyl Phthalate (DBP)

<1000ppm

19

Benzyl butyl Phthalate (BBP)

<1000ppm

20

Di-ethylhexyl Phthalate (DEHP)

<1000ppm

21

Di-isobutyl Phthalate (DIBP)

<1000ppm

Declaration of RoHS

2017.09.11

D.C.C.

建 準 電 機

SUNONWEALTH

Page 14 of 14

Loading...

Loading...