Sun Netra T5220 Server

Service Manual

Part No.: E21359-02

January 2012

Copyright ©2008, 2012,Oracle and/orits affiliates.All rightsreserved.

This softwareand related documentationare provided undera licenseagreement containingrestrictions on use and disclosure and areprotected by

intellectual propertylaws. Exceptas expressly permittedin yourlicense agreementor allowedby law,you maynot use,copy, reproduce, translate,

broadcast, modify, license,transmit, distribute,exhibit, perform,publish, ordisplay anypart, inany form,or byany means.Reverse engineering,

disassembly, or decompilation of this software, unlessrequired by law for interoperability, is prohibited.

The informationcontained hereinis subjectto changewithout noticeand isnot warrantedto beerror-free.If youfind anyerrors, please report them to us

in writing.

If thisis softwareor related softwaredocumentation thatis delivered tothe U.S.Government oranyone licensingit onbehalf ofthe U.S.Government, the

following noticeis applicable:

U.S. GOVERNMENTRIGHTS. Programs,software, databases, and related documentation and technical data deliveredto U.S.Government customers

are "commercial computersoftware" or"commercial technical data" pursuant to the applicable Federal Acquisition Regulation and agency-specific

supplemental regulations.As such,the use,duplication, disclosure, modification,and adaptationshall besubject tothe restrictionsand licenseterms set

forth inthe applicableGovernment contract,and, tothe extentapplicable bythe termsof theGovernment contract,the additionalrights setforth inFAR

52.227-19, CommercialComputer Software License(December 2007).Oracle America,Inc., 500Oracle Parkway, Redwood City, CA 94065.

This software or hardware is developed for general use ina varietyof informationmanagement applications. It is not developed orintended foruse inany

inherently dangerous applications,including applicationswhich maycreate arisk ofpersonal injury. Ifyou usethis softwareor hardware indangerous

applications, thenyou shallbe responsibleto takeall appropriate fail-safe,backup, redundancy, andother measuresto ensure itssafe use.Oracle

Corporation andits affiliatesdisclaim anyliability forany damagescaused byuse ofthis software orhardware in dangerous applications.

Oracle andJava areregistered trademarks of Oracle and/or its affiliates.Other namesmay betrademarks oftheir respective owners.

Intel andIntel Xeonare trademarksor registered trademarksof IntelCorporation. AllSPARC trademarks areused underlicense andare trademarksor

registered trademarks of SPARCInternational, Inc. AMD, Opteron, theAMD logo,and theAMD Opteron logo are trademarksor registered trademarksof

Advanced MicroDevices. UNIXis aregistered trademark of The Open Group.

This software or hardware and documentation may provide access to or information on content, products, and services from third parties. Oracle

Corporation and its affiliates are not responsible for and expressly disclaim all warranties of any kind with respect to third-party content, products, and

services. Oracle Corporation and its affiliates will not be responsible for any loss, costs, or damages incurred due to your access to or use of third-party

content, products, or services.

Copyright ©2008, 2012,Oracle et/ouses affiliés.Tous droits réservés.

Ce logicielet ladocumentation quil’accompagne sontprotégés parles loissur lapropriété intellectuelle. Ils sont concédés sous licence et soumis à des

restrictions d’utilisationet dedivulgation. Saufdisposition devotre contrat de licence ou de la loi, vous ne pouvez pas copier, reproduire, traduire,

diffuser, modifier, breveter, transmettre,distribuer, exposer, exécuter,publier ouafficher le logiciel, même partiellement, sous quelque forme et par

quelque procédéque cesoit. Parailleurs, ilest interdit deprocéder àtoute ingénierieinverse dulogiciel, dele désassemblerou dele décompiler, excepté à

des finsd’interopérabilité avecdes logicielstiers outel queprescrit par la loi.

Les informationsfournies dansce documentsont susceptiblesde modificationsans préavis.Par ailleurs,Oracle Corporationne garantitpas qu’elles

soient exemptesd’erreurs etvous invite,le caséchéant, àlui enfaire part par écrit.

Si celogiciel, oula documentationqui l’accompagne,est concédésous licenceau Gouvernementdes Etats-Unis,ou àtoute entitéqui délivrela licencede

ce logicielou l’utilisepour lecompte duGouvernement desEtats-Unis, lanotice suivantes’applique :

U.S. GOVERNMENTRIGHTS. Programs,software, databases, and related documentation and technical data deliveredto U.S.Government customers

are "commercial computersoftware" or"commercial technical data" pursuant to the applicable Federal Acquisition Regulation and agency-specific

supplemental regulations. As such, theuse, duplication,disclosure, modification, and adaptation shall be subject to the restrictions and license terms set

forth inthe applicableGovernment contract,and, tothe extentapplicable bythe termsof theGovernment contract,the additionalrights setforth inFAR

52.227-19, CommercialComputer Software License(December 2007). Oracle America, Inc.,500 OracleParkway, Redwood City, CA 94065.

Ce logicielou matériela étédéveloppé pourun usagegénéral dansle cadred’applications degestion desinformations. Celogiciel oumatériel n’estpas

conçu nin’est destinéà êtreutilisé dansdes applicationsà risque,notamment dansdes applicationspouvant causerdes dommagescorporels. Si vous

utilisez celogiciel oumatériel dansle cadred’applications dangereuses, ilest devotre responsabilité deprendre toutes les mesures de secours, de

sauvegarde, deredondance et autres mesures nécessaires à son utilisation dans des conditions optimales de sécurité. Oracle Corporation et ses affiliés

déclinent touteresponsabilité quantaux dommagescausés parl’utilisation dece logicielou matérielpour cetype d’applications.

Oracle etJava sontdes marquesdéposées d’OracleCorporation et/oude sesaffiliés.Tout autre nommentionné peutcorrespondre à des marques

appartenant àd’autres propriétaires qu’Oracle.

Intel etIntel Xeonsont desmarques oudes marques déposéesd’Intel Corporation.Toutes les marques SPARC sont utilisées sous licence et sont des

marques oudes marques déposéesde SPARC International, Inc. AMD, Opteron, le logo AMD et le logo AMD Opteron sontdes marquesou desmarques

déposées d’AdvancedMicro Devices.UNIX estune marque déposéed’The OpenGroup.

Ce logicielou matérielet ladocumentation quil’accompagne peuventfournir desinformations oudes liensdonnant accèsà descontenus, desproduits et

des servicesémanant detiers. OracleCorporation etses affiliésdéclinent touteresponsabilité ou garantie expresse quant aux contenus, produits ou

services émanantde tiers.En aucuncas, OracleCorporation etses affiliésne sauraientêtre tenus pour responsables des pertes subies, des coûts

occasionnés oudes dommagescausés parl’accès àdes contenus,produits ouservices tiers,ou àleur utilisation.

Please

Recycle

Contents

Preface ix

1. Server Diagnostics 1–1

1.1 Fault on Initial Power Up 1–1

1.2 Server Diagnostics Overview 1–2

1.2.1 Memory Configuration and Fault Handling 1–6

1.2.1.1 Memory Configuration 1–7

1.2.1.2 Memory Fault Handling 1–7

1.2.1.3 Troubleshooting Memory Faults 1–8

1.3 Using LEDs to Identify the State of Devices 1–8

1.3.1 Front and Rear Panel LEDs 1–8

1.3.2 Hard Drive LEDs 1–12

1.3.3 Power Supply LEDs 1–12

1.3.4 Ethernet Port LEDs 1–13

1.4 Using the Service Processor Firmware for Diagnosis and Repair

Verification 1–14

1.4.1 Using the ALOM CMT Compatibility CLI in ILOM 1–16

1.4.2 Creating an ALOM CMT CLI Shell 1–17

1.4.3 Running ALOM CMT CLI Service-Related Commands 1–18

1.4.3.1 Connecting to ALOM CMT CLI 1–18

iii

1.4.3.2 Switching Between the System Console and Service

Processor 1–19

1.4.3.3 Service-Related ALOM CMT CLI Commands 1–19

1.4.4 Displaying System Faults 1–21

1.4.5 Manually Cleaning PSH Diagnosed Faults 1–23

1.4.6 Displaying the Server’s Environmental Status 1–23

1.4.7 Displaying FRU Information 1–25

1.5 Running POST 1–27

1.5.1 Controlling How POST Runs 1–27

1.5.2 Changing POST Parameters 1–30

1.5.3 Reasons to Run POST 1–31

1.5.3.1 Verifying Hardware Functionality 1–31

1.5.3.2 Diagnosing the System Hardware 1–31

1.5.4 Running POST in Maximum Mode 1–31

1.5.5 Clearing POST Detected Faults 1–35

1.6 Using the Solaris Predictive Self-Healing Feature 1–37

1.6.1 Identifying PSH Detected Faults 1–38

1.6.1.1 Using the fmdump Command to Identify Faults 1–38

1.6.2 Clearing PSH Detected Faults 1–40

1.7 Collecting Information From Solaris OS Files and Commands 1–42

1.7.1 Checking the Message Buffer 1–42

1.7.2 Viewing System Message Log Files 1–42

1.8 Managing Components With Automatic System Recovery Commands 1–

43

1.8.1 Displaying System Components 1–44

1.8.2 Disabling Components 1–45

1.8.3 Enabling Disabled Components 1–46

1.9 Exercising the System With SunVTS Software 1–46

1.9.1 Checking Whether SunVTS Software Is Installed 1–46

iv Sun Netra T5220 Server Service Manual • January 2012

1.9.2 Exercising the System Using SunVTS Software 1–47

1.9.3 Exercising the System With SunVTS Software 1–48

1.10 Obtaining the Chassis Serial Number 1–51

1.11 Additional Service Related Information 1–52

2. Preparing for Service 2–1

2.1 Safety Information 2–1

2.1.1 Safety Symbols 2–1

2.1.2 Electrostatic Discharge Safety 2–2

2.1.2.1 Use an Antistatic Wrist Strap 2–2

2.1.2.2 Use an Antistatic Mat 2–2

2.2 Required Tools 2–3

2.3 Prerequisite Tasks for Component Replacement 2–3

2.3.1 Powering Off the Server 2–3

2.3.2 Disconnecting Cables From the Server 2–4

2.3.3 Removing the Server From the Rack 2–5

2.3.4 Performing Antistatic Measures 2–8

2.3.5 Removing the Top Cover 2–8

2.3.6 Removing the PCI Mezzanine 2–9

2.4 Field-Replaceable Units 2–11

3. Replacing Storage Components 3–1

3.1 Replacing a Hard Drive 3–1

3.1.1 Removing a Hard Drive 3–2

3.1.2 Installing a Hard Drive 3–5

3.2 Replacing the Optical Media Drive 3–6

3.2.1 Removing the Optical Media Drive 3–6

3.2.2 Installing the Optical Media Drive 3–7

3.3 Replacing the Media Bay Assembly 3–8

Contents v

3.3.1 Removing the Media Bay Assembly 3–8

3.3.2 Installing the Media Bay Assembly 3–11

4. Replacing Motherboard Assembly Components 4–1

4.1 Powering Off and Powering On the Server 4–1

4.2 Replacing PCI-X, PCIe/XAUI Cards 4–2

4.2.1 PCI Card Retainers 4–2

4.2.2 Replacing PCI-X 4 and PCIe 5 Cards 4–5

▼ To Remove the PCI-X 4 and PCIe 5 Cards 45

▼ To Install PCI-X 4 and PCIe 5 Cards 47

4.2.3 Replacing the PCI-X 3 Card 4–8

▼ To Remove the PCI-X 3 Card 49

▼ To Install the PCI-X 3 Card 49

4.2.4 Replacing the Lower PCIe/XAUI Cards 4–11

▼ To Remove the Lower PCIe/XAUI Cards 411

4.2.5 Installing the Lower PCIe/XAUI Cards 4–12

4.3 Cabling the Sun Storage 6 Gb SAS PCIe RAID HBA, Internal 4–15

▼ Cable the Sun Storage 6 Gb SAS PCIe RAID HBA, Internal 4-15

4.4 Replacing the Air Duct 4–17

4.4.1 Removing the Air Duct 4–17

4.4.2 Installing the Air Duct 4–18

4.5 FB-DIMM Layout 4–19

4.6 Replacing FB-DIMMs 4–23

4.6.1 Locating a Faulty FB-DIMM 4–24

4.6.2 Removing FB-DIMMs 4–24

4.6.3 Installing FB-DIMMs 4–26

4.6.4 Verifying Successful Replacement of a Faulty FB-DIMM 4–28

4.7 Replacing the Battery 4–30

4.7.1 Removing the Battery 4–30

vi Sun Netra T5220 Server Service Manual • January 2012

4.7.2 Installing the Battery 4–31

4.8 Replacing the NVRAM 4–32

4.8.1 Removing the NVRAM 4–32

4.8.2 Installing the NVRAM 4–33

4.9 Replacing the SCC Module 4–35

4.9.1 Removing the SCC Module 4–35

4.9.2 Installing the SCC Module 4–35

4.10 Replacing the Motherboard Assembly 4–36

4.10.1 Removing the Motherboard Assembly 4–36

4.10.2 Installing the Motherboard Assembly 4–39

5. Replacing Chassis Components 5–1

5.1 Replacing the Air Filter 5–1

5.1.1 Removing the Air Filter 5–1

5.1.2 Installing the Air Filter 5–2

5.2 Replacing a Power Supply 5–3

5.2.1 Removing a Power Supply 5–4

5.2.2 Installing a Power Supply 5–6

5.3 Replacing the System Fan Assembly (FT0) 5–6

5.3.1 Removing the System Fan Assembly 5–7

5.3.2 Installing the System Fan Assembly 5–8

5.4 Replacing the Hard Drive Fan Assembly (FT1) 5–9

5.4.1 Removing the Hard Drive Fan Assembly 5–10

5.4.2 Installing the Hard Drive Fan Assembly 5–12

5.5 Replacing the FB-DIMM Fan Assembly (FT2) 5–14

5.5.1 Removing the FB-DIMM Fan Assembly 5–14

5.5.2 Installing the FB-DIMM Fan Assembly 5–14

5.6 Replacing the Alarm Board 5–15

5.6.1 Removing the Alarm Board 5–15

Contents vii

5.6.2 Installing the Alarm Board 5–16

5.7 Replacing the LED Board 5–17

5.7.1 Removing the LED Board 5–17

5.7.2 Installing the LED Board 5–19

5.8 Replacing the Power Board 5–22

5.8.1 Removing the Power Board 5–22

5.8.2 Installing the Power Board 5–24

6. Finishing Up 6–1

6.1 Tasks for Finishing Up 6–1

6.1.1 Installing the PCI Mezzanine 6–1

6.1.2 Installing the Top Cover 6–3

6.1.3 Removing Antistatic Measures 6–4

6.1.4 Reinstalling the Server Chassis in the Rack 6–5

6.1.5 Reconnecting Cables to the Server 6–7

6.1.6 Powering On the Server 6–8

A. Signal Pinouts A–1

A.1 Gigabit Ethernet Ports A–1

A.2 Network Management Port A–2

A.3 Serial Ports A–3

A.3.1 Serial Management Port A–3

A.3.1.1 RJ-45 to DB-9 Adapter Crossovers A–4

A.3.1.2 RJ-45 to DB-25 Adapter Crossovers A–5

A.3.2 Serial Port TTYA A–5

A.4 Alarm Port A–6

A.5 USB Ports A–7

Index Index–1

viii Sun Netra T5220 Server Service Manual • January 2012

Preface

This manual describes how to troubleshoot the server and how to remove and install

replaceable components. This manual is written for technicians, system

administrators, authorized service providers, and users with advanced experience

troubleshooting and replacing hardware.

■ “Product Notes” on page ix

■ “Related Documentation” on page x

■ “Feedback” on page x

■ “Support and Accessibility” on page x

Product Notes

For late-breaking information and known issues about this product, refer to the

products notes at:

http://docs.oracle.com/cd/E19350-01/index.html

ix

Related Documentation

Documentation Link

All Oracle products http://www.oracle.com/documentation

Sun Netra T5220 Server http://docs.oracle.com/cd/E19350-01/index.html

Oracle Solaris OS and systems

software library

http://www.oracle.com/technetwork/indexes/documentation/

index.html#sys_sw

Feedback

Provide feedback about this documentation at:

http://www.oracle.com/goto/docfeedback

Support and Accessibility

Description Links

Access electronic support through

My Oracle Support

http://support.oracle.com

For hearing impaired:

http://www.oracle.com/accessibility/support.html

Learn about Oracle’s commitment to

accessibility

x Sun Netra T5220 Server Service Manual • January 2012

http://www.oracle.com/us/corporate/accessibility/

index.html

CHAPTER

1

Server Diagnostics

This chapter describes the diagnostics that are available for monitoring and

troubleshooting the server.

The following topics are covered:

■ Section 1.1, “Fault on Initial Power Up” on page 1-1

■ Section 1.2, “Server Diagnostics Overview” on page 1-2

■ Section 1.3, “Using LEDs to Identify the State of Devices” on page 1-8

■ Section 1.4, “Using the Service Processor Firmware for Diagnosis and Repair

Verification” on page 1-14

■ Section 1.5, “Running POST” on page 1-27

■ Section 1.6, “Using the Solaris Predictive Self-Healing Feature” on page 1-37

■ Section 1.7, “Collecting Information From Solaris OS Files and Commands” on

page 1-42

■ Section 1.8, “Managing Components With Automatic System Recovery

Commands” on page 1-43

■ Section 1.9, “Exercising the System With SunVTS Software” on page 1-46

■ Section 1.10, “Obtaining the Chassis Serial Number” on page 1-51

■ Section 1.11, “Additional Service Related Information” on page 1-52

1.1 Fault on Initial Power Up

If you have installed the server, and upon initial power up, you see errors indicating

faults with the Fully Buffered DIMMs (FB-DIMMs), PCI cards, or other components,

the suspect component might have become loosened or ajar during shipment.

1-1

Conduct a visual inspection of the server internals and its components. Remove the

top cover and physically reseat the cable connections, the PCI cards, and the

FB-DIMMs. See:

■ Section 2.3, “Prerequisite Tasks for Component Replacement” on page 2-3

■ Section 4.2, “Replacing PCI-X, PCIe/XAUI Cards” on page 4-2

■ Section 4.6, “Replacing FB-DIMMs” on page 4-23.

If performing these tasks is not successful, then continue to Section 1.2, “Server

Diagnostics Overview” on page 1-2.

1.2 Server Diagnostics Overview

There are a variety of diagnostic tools, commands, and indicators you can use to

monitor and troubleshoot a server:

■ LEDs – These indicators provide a quick visual notification of the status of the

server and of some of the FRUs.

■ Fault management architecture – FMA provides simplified fault diagnostics

through use of the /var/adm/messages file, the fmdump command, and a Sun

Microsystems web site.

■ ILOM firmware –This system firmware runs on the service processor. In addition

to providing the interface between the hardware and OS, ILOM also tracks and

reports the health of key server components. ILOM works closely with POST and

Solaris Predictive Self-Healing technology to keep the system up and running

even when there is a faulty component.

■ Power-on self-test (POST) – POST performs diagnostics on system components

upon system reset to ensure the integrity of those components. POST is

configurable and works with ILOM to take faulty components offline if needed.

■ Solaris OS Predictive Self-Healing (PSH) – This technology continuously

monitors the health of the CPU and memory, and works with ILOM to take a

faulty component offline if needed. The Predictive Self-Healing technology

enables Sun systems to accurately predict component failures and mitigate many

serious problems before they occur.

■ Log files and console messages – These provide the standard Solaris OS log files

and investigative commands that can be accessed and displayed on the device of

your choice.

■ SunVTS™ – An application that exercises the system, provides hardware

validation, and discloses possible faulty components with recommendations for

repair.

1-2 Sun Netra T5220 Server Service Manual • January 2012

The LEDs, ILOM, Solaris OS PSH, and many of the log files and console messages are

integrated. For example, a fault detected by the Solaris software will display the

fault, log it, pass information to ILOM where it is logged, and depending on the

fault, might light one or more LEDs.

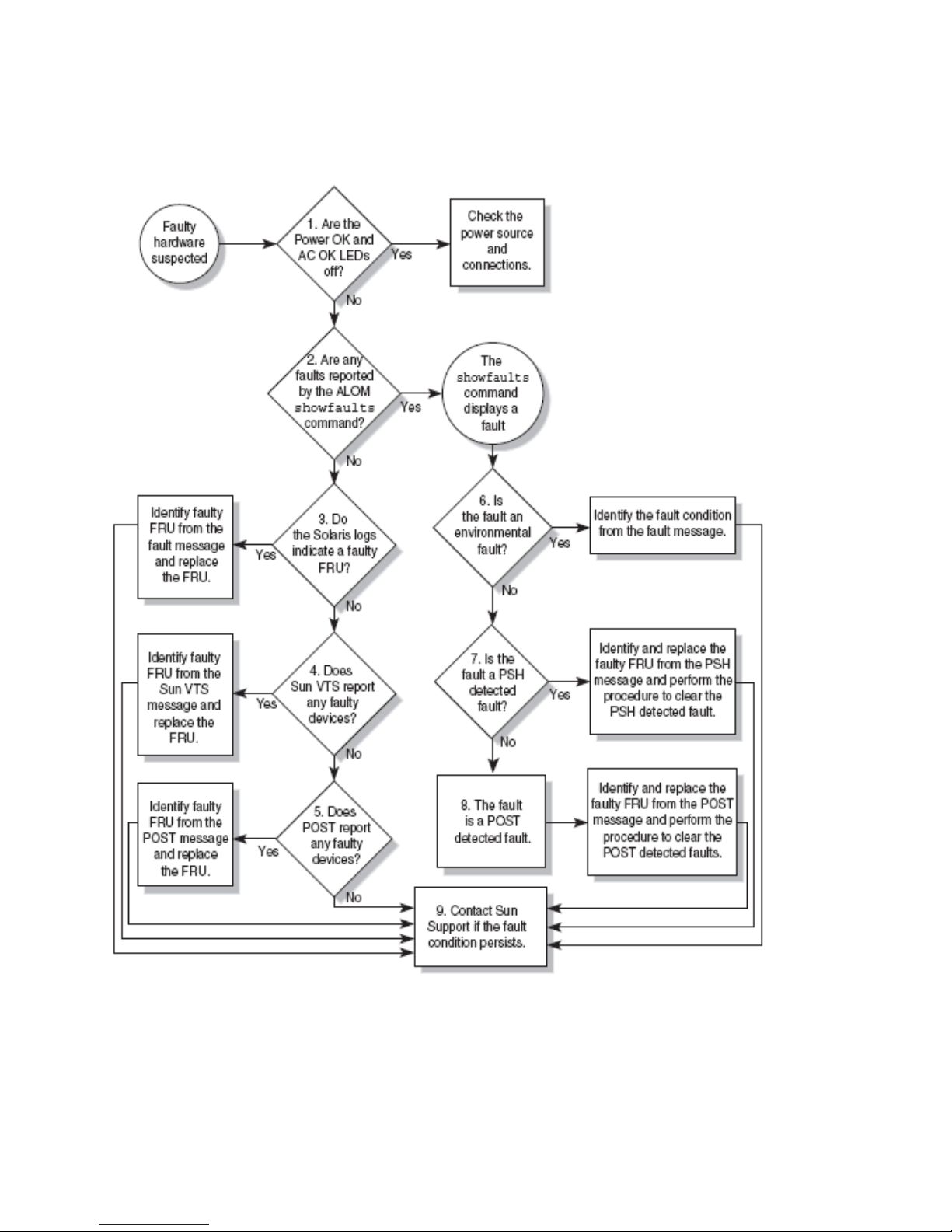

The diagnostic flowchart in

FIGURE 1-1 and TABLE 1-1 describes an approach for using

the server diagnostics to identify a faulty field-replaceable unit (FRU). The

diagnostics you use, and the order in which you use them, depend on the nature of

the problem you are troubleshooting. So you might perform some actions and not

others.

The flowchart assumes that you have already performed some rudimentary

troubleshooting such as verification of proper installation, visual inspection of cables

and power, and possibly performed a reset of the server (refer to the server

installation guide and server administration guide for details).

Use this flowchart to understand what diagnostics are available to troubleshoot

faulty hardware. Use

TABLE 1-1 to find more information about each diagnostic in this

chapter.

Chapter 1 Server Diagnostics 1-3

FIGURE 1-1 Diagnostic Flowchart

1-4 Sun Netra T5220 Server Service Manual • January 2012

TABLE 1-1 Diagnostic Flowchart Actions

Action

No. Diagnostic Action Resulting Action Additional Information

1.

2.

3.

4.

Check Power OK

and Input OK

LEDs on the server.

The Power OK LED is located on the front and rear

of the chassis.

The Input OK LED is located on the rear of the

server on each power supply.

If these LEDs are not on, check the power source and

power connections to the server.

Run the ALOM

CMT CLI

showfaults

command to check

for faults.

The showfaults command displays the following

kinds of faults:

• Environmental faults

• Solaris Predictive Self-Healing (PSH) detected

faults

• POST detected faults

Faulty FRUs are identified in fault messages using

the FRU name. For a list of FRU names, see

TABLE 2-1.

Check the Solaris

log files for fault

information.

The Solaris message buffer and log files record

system events and provide information about faults.

• If system messages indicate a faulty device,

replace the FRU.

• To obtain more diagnostic information, go to

Action

4.

Run SunVTS. SunVTS is an application you can run to exercise

and diagnose FRUs. To run SunVTS, the server must

be running the Solaris OS.

• If SunVTS reports a faulty device replace the FRU.

• If SunVTS does not report a faulty device, go to

Action

5.

Section 1.3, “Using LEDs to

Identify the State of

Devices” on page 1-8

Section 1.4.4, “Displaying

System Faults” on

page 1-21

Section 1.7, “Collecting

Information From Solaris

OS Files and Commands”

on page 1-42

Section 1.9, “Exercising the

System With SunVTS

Software” on page 1-46

5.

Run POST. POST performs basic tests of the server components

and reports faulty FRUs.

• If POST indicates a faulty FRU, replace the FRU.

• If POST does not indicate a faulty FRU, go to

Section 1.5, “Running

POST” on page 1-27

Action 9.

Chapter 1 Server Diagnostics 1-5

TABLE 1-1 Diagnostic Flowchart Actions (Continued)

Action

No. Diagnostic Action Resulting Action Additional Information

6.

7.

Determine if the

fault is an

environmental

fault.

Determine if the

fault was detected

by PSH.

If the fault listed by the showfaults command

displays a temperature or voltage fault, then the

fault is an environmental fault. Environmental faults

can be caused by faulty FRUs (power supply, fan, or

blower), or by environmental conditions such as

when computer room ambient temperature is too

high, or the server airflow is blocked. When the

environmental condition is corrected, the fault will

automatically clear.

If the fault indicates that a fan, blower, or power

supply is bad, you can perform a hot-swap of the

FRU. You can also use the fault LEDs on the server

to identify the faulty FRU (fans, blower, and power

supplies).

If the fault message displays the following text, the

fault was detected by the Solaris Predictive

Self-Healing software:

Host detected fault

If the fault is a PSH detected fault, identify the faulty

FRU from the fault message and replace the faulty

FRU.

After replacing the FRU, perform the procedure to

clear PSH detected faults.

Section 1.4.4, “Displaying

System Faults” on

page 1-21

Section 1.3, “Using LEDs to

Identify the State of

Devices” on page 1-8

Section 1.6, “Using the

Solaris Predictive

Self-Healing Feature” on

page 1-37

Section 1.6.2, “Clearing

PSH Detected Faults” on

page 1-40

8.

Determine if the

fault was detected

by POST.

POST performs basic tests of the server components

and reports faulty FRUs. When POST detects a

faulty FRU, it logs the fault and if possible, takes the

FRU offline. POST detected FRUs display the

following text in the fault message:

Section 1.5, “Running

POST” on page 1-27

FRU-name deemed faulty and disabled

In this case, replace the FRU and run the procedure

to clear POST detected faults.

Section 1.5.5, “Clearing

POST Detected Faults” on

page 1-35

1.2.1 Memory Configuration and Fault Handling

A variety of features play a role in how the memory subsystem is configured and

how memory faults are handled. Understanding the underlying features helps you

identify and repair memory problems. This section describes how the memory is

configured and how the server deals with memory faults.

1-6 Sun Netra T5220 Server Service Manual • January 2012

1.2.1.1 Memory Configuration

In the server memory there are 16 slots that hold DDR-2 memory FB-DIMMs in the

following FB-DIMM sizes:

■ 1 Gbyte (maximum of 16 Gbyte)

■ 2 Gbyte (maximum of 32 Gbyte)

■ 4 Gbyte (maximum of 64 Gbyte)

FB-DIMMs are installed in groups of 8, called ranks (ranks 0 and 1). At minimum,

rank 0 must be fully populated with eight FB-DIMMs of the same capacity. A second

rank of FB-DIMMs of the same capacity can be added to fill rank 1.

See Section 4.6, “Replacing FB-DIMMs” on page 4-23 for instructions about adding

memory to a server.

1.2.1.2 Memory Fault Handling

The server uses an advanced ECC technology, called chipkill, that corrects up to 4 bits

in error on nibble boundaries, as long as all of the bits are in the same DRAM. If a

DRAM fails, the FB-DIMM continues to function.

The following server features independently manage memory faults:

■ POST – Based on ILOM configuration variables, POST runs when the server is

powered on.

For correctable memory errors (CEs), POST forwards the error to the Solaris

Predictive Self-Healing (PSH) daemon for error handling. If an uncorrectable

memory fault is detected or if a “storm” of CEs is detected, POST displays the

fault with the device name of the faulty FB-DIMMs, logs the fault, and disables the

faulty FB-DIMMs by placing them in the ASR blacklist. Depending on the memory

configuration and the location of the faulty FB-DIMM, POST disables half of

physical memory in the system, or half the physical memory and half the

processor threads. When this offlining process occurs in normal operation, you

must replace the faulty FB-DIMMs based on the fault message. You then must

enable the disabled FB-DIMMs with the ALOM CMT CLI enablecomponent

command.

■ Solaris Predictive Self-Healing (PSH) technology – A feature of the Solaris OS,

uses the fault manager daemon (fmd) to watch for various kinds of faults. When a

fault occurs, the fault is assigned a unique fault ID (UUID), and logged. PSH

reports the fault and provides a recommended proactive replacement for the

FB-DIMMs associated with the fault.

Chapter 1 Server Diagnostics 1-7

1.2.1.3 Troubleshooting Memory Faults

If you suspect that the server has a memory problem, follow the flowchart

(

FIGURE 1-1). Run the ALOM CMT compatability CLI (in ILOM) showfaults

command, see Section 1.4.1, “Using the ALOM CMT Compatibility CLI in ILOM” on

page 1-16 and Section 1.4.4, “Displaying System Faults” on page 1-21. The

showfaults command lists memory faults and lists the specific FB-DIMMS that are

associated with the fault. Once you identify which FB-DIMMs to replace, see

Section 4.6, “Replacing FB-DIMMs” on page 4-23 for FB-DIMM replacement

instructions. You must perform the instructions in that chapter to clear the faults and

enable the replaced FB-DIMMs.

1.3 Using LEDs to Identify the State of

Devices

The server provides the following groups of LEDs:

■ Section 1.3.1, “Front and Rear Panel LEDs” on page 1-8

■ Section 1.3.2, “Hard Drive LEDs” on page 1-12

■ Section 1.3.3, “Power Supply LEDs” on page 1-12

■ Section 1.3.4, “Ethernet Port LEDs” on page 1-13

These LEDs provide a quick visual check of the state of the system.

1.3.1 Front and Rear Panel LEDs

The seven front panel LEDs (FIGURE 1-2) are located in the upper left corner of the

server chassis. Three of these LEDs are also provided on the rear panel (

FIGURE 1-3).

1-8 Sun Netra T5220 Server Service Manual • January 2012

FIGURE 1-2 Location of the Bezel Server Status and Alarm Status Indicators

5 6 7 8

4

3

2

1

Figure Legend

1 User (amber) Alarm Status Indicator 5 Locator LED and Button

2 Minor (amber) Alarm Status Indicator 6 Fault LED

3 Major (red) Alarm Status Indicator 7 Activity LED

4 Critical (red) Alarm Status Indicator 8 PowerOKLED

Chapter 1 Server Diagnostics 1-9

FIGURE 1-3 Rear Panel Connectors, LEDs, and Features on the Sun Netra T5220 Server

15 16 19

2 4 5

31 9

Figure Legend

1 Power Supply 0 LEDs top to bottom: Locator LED and

Button, Service Required LED, Power OK LED

2 Power Supply 0 12 USB ports left to right: USB0, USB1

3 Power Supply 1 LEDs top to bottom: Locator LED

Button, Service Required LED, Power OK LED

4 Power Supply 1 14 Captive screw for securing motherboard (2 of 2)

7 8

6

17 18

10

11 Alarm Port

13 TTYA Serial Port

11 14

12 13

20

5 Captive screw for securing motherboard (1 of 2) 15 PCI-X Slot 3

6 System LEDs left to right: Locator LED Button, Service

Required LED, Power OK LED

7 Service Processor Serial Management Port 17 PCI-X Slot 4

8 Service Processor Network Management Port 18 PCIe or XAUI Slot 1

9 Captive screws for securing the bottom PCI cards. Note

that there are two screws on either side of each bottom

PCI card (total 6).

10 Gigabit Ethernet Ports left to right: NET0, NET1, NET2,

NET3

16 PCIe or XAUI Slot 0

19 PCIe Slot 5

20 PCIe Slot 2

1-10 Sun Netra T5220 Server Service Manual • January 2012

TABLE 1-2 lists and describes the front and rear panel LEDs.

TABLE 1-2 Front and Rear Panel LEDs

LED Location Color Description

Locator LED

and Button

Front upper

left and rear

center

Fault LED Front upper

left and rear

center

Activity LED Front upper

left

Power Button Front upper

left

Alarm:Critical

Front left Red Indicates a critical alarm. Refer to the server administration guide

LED

Alarm:Major

Front left Red Indicates a major alarm.

LED

White Enables you to identify a particular server. The LED is activated

using one of the following methods:

• Issuing the setlocator on or off command.

• Pressing the button to toggle the indicator on or off.

This LED provides the following indications:

• Off – Normal operating state.

• Fast blink – The server received a signal as a result of one of the

preceding methods.

Amber If on, indicates that service is required. The ALOM CMT CLI

showfaults command provides details about any faults that cause

this indicator to be lit.

Green • On – Drives are receiving power. Solidly lit if drive is idle.

• Flashing – Drives are processing a command.

• Off – Power is off.

Turns the host system on and off. This button is recessed to prevent

accidental server power-off. Use the tip of a pen to operate this

button.

for a description of alarm states.

Alarm:Minor

Front left Amber Indicates a minor alarm.

LED

Alarm :User

Front left Amber Indicates a user alarm.

LED

Power OK LED Rear center Green The LED provides the following indications:

• Off – The system is unavailable. Either the system has no power

or ILOM is not running.

• Steady on – Indicates that the system is powered on and is

running it its normal operating state.

• Standby blink – Indicates that the service processor is running

while the system is running at a minimum level in Standby

mode, and is ready to be returned to its normal operating state.

• Slow blink – Indicates that a normal transitory activity is taking

place. The system diagnostics might be running, or that the

system might be booting.

Chapter 1 Server Diagnostics 1-11

1.3.2 Hard Drive LEDs

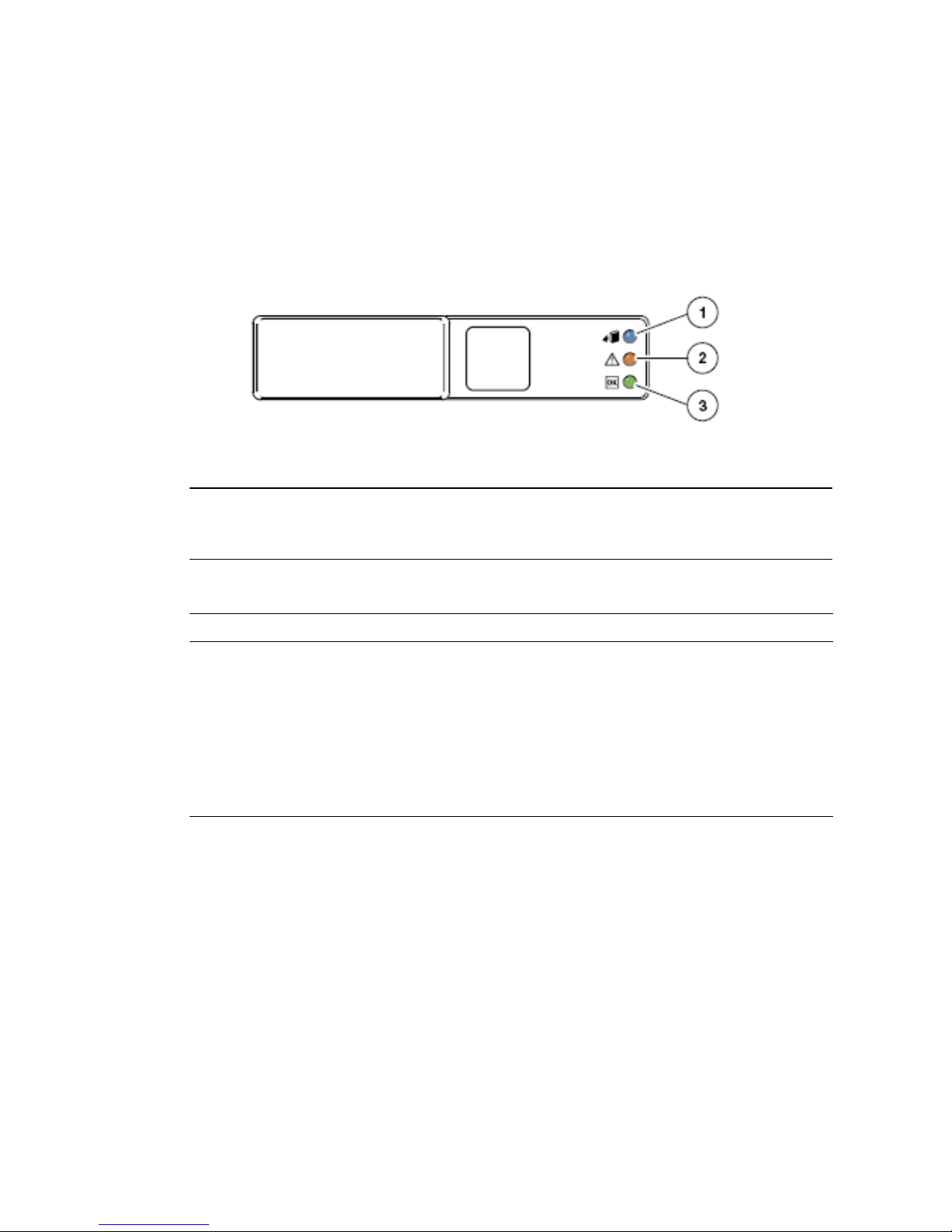

The hard drive LEDs (FIGURE 1-4 and TABLE 1-3) are located on the front of each hard

drive that is installed in the server chassis.

FIGURE 1-4 Hard Drive LEDs

Figure Legend

1 OK to Remove

2 Fault

3 Activity

TABLE 1-3 Hard Drive LEDs

LED Color Description

OK to

Remove

Fault Amber • On – The drive has a fault and requires attention.

Activity Green • On – The drive is receiving power. Solidly lit if drive is idle.

Blue • On – The drive is ready for hot-plug removal.

• Off – Normal operation.

• Off – Normal operation.

• Flashing – The drive is processing a command.

• Off – Power is off.

1.3.3 Power Supply LEDs

The power supply LEDs (FIGURE 1-5 and TABLE 1-4) are located on the rear of each

power supply.

1-12 Sun Netra T5220 Server Service Manual • January 2012

FIGURE 1-5 Power Supply LEDs

1

2

3

Figure Legend

1 Power OK power supply LED

2 Fault power supply LED

3 Input OK power supply LED

TABLE 1-4 Power Supply LEDs

LED Color Description

Power OK

Fault Amber • On – Power supply has detected a failure.

Input OK Green • On – Normal operation. Input power is within normal limits.

Green • On – Normal operation. DC output voltage is within normal

limits.

• Off – Power is off.

• Off – Normal operation.

• Off – No input voltage, or input voltage is below limits.

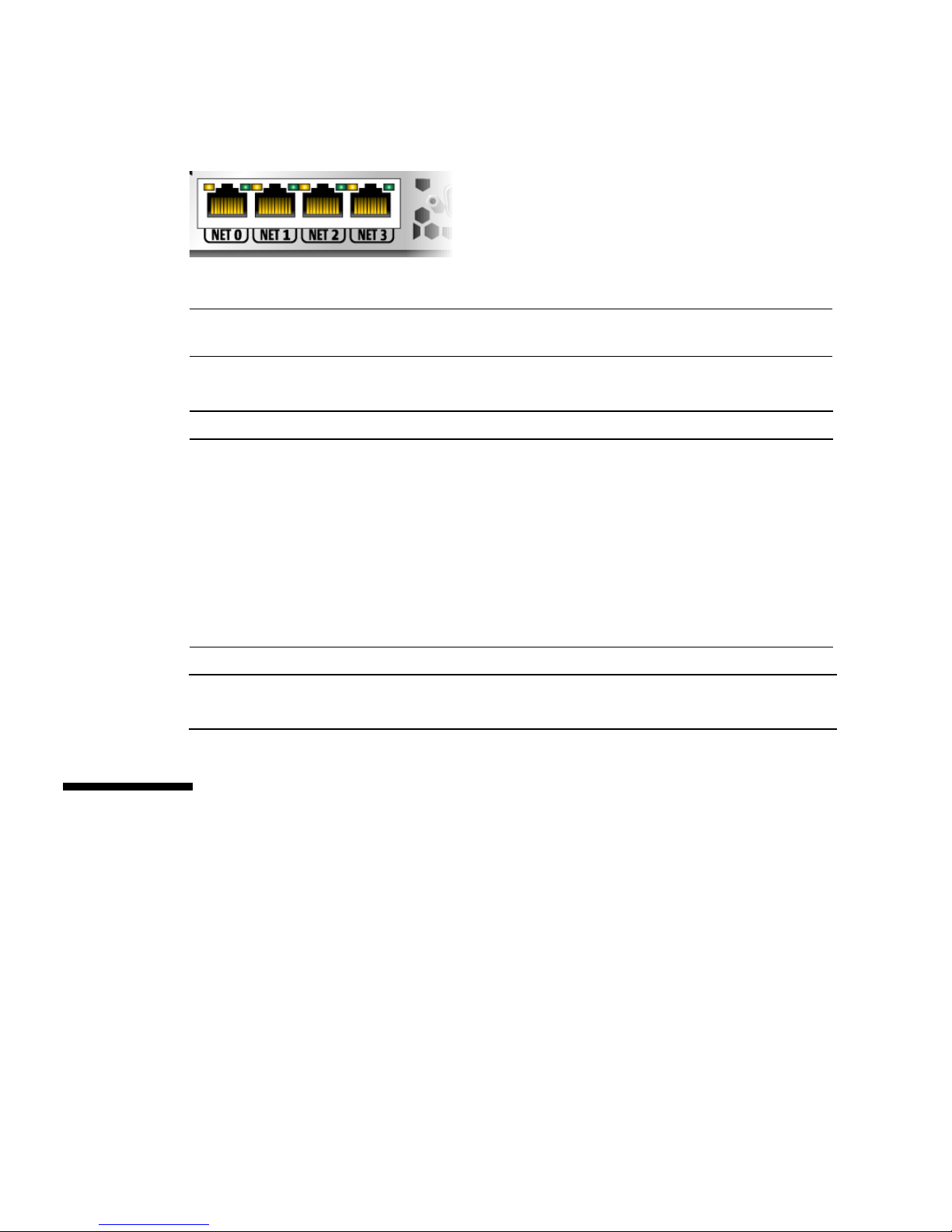

1.3.4 Ethernet Port LEDs

The ILOM management Ethernet port and the four 10/100/1000 Mbps Ethernet ports

each have two LEDs, as shown in

FIGURE 1-6 and described in TABLE 1-5.

Chapter 1 Server Diagnostics 1-13

FIGURE 1-6 Ethernet Port LEDs

Figure Legend

1 Link/Activity indicator LED (Same location for all Ethernet ports)

2 Speed indicator LED (Same location for all Ethernet ports)

TABLE 1-5 Ethernet Port LEDs

LED Color Description

Left LED Green Link/Activity indicator:

• Steady On – a link is established.

• Blinking – there is activity on this port.

• Off – No link is established.

Right LED Amber

or

Green

Speed indicator:

• Amber On – The link is operating as a Gigabit connection

(1000-Mbps)

• Green On – The link is operating as a 100-Mbps connection.

• Off – The link is operating as a 10/100-Mbps connection.

Note – The NET MGT port operates only in 100-Mbps or 10-Mbps so the speed

indicator LED can be green or off (never amber).

1.4 Using the Service Processor Firmware for

Diagnosis and Repair Verification

The Sun Integrated Lights Out Manager (ILOM) firmware is a service processor in

the server that enables you to remotely manage and administer your server.

ILOM enables you to remotely run diagnostics, such as power-on self-test (POST),

that would otherwise require physical proximity to the server’s serial port. You can

also configure ILOM to send email alerts of hardware failures, hardware warnings,

and other events related to the server or to ILOM.

1-14 Sun Netra T5220 Server Service Manual • January 2012

The service processor runs independently of the server, using the server’s standby

power. Therefore, ILOM firmware and software continue to function when the server

operating system goes offline or when the server is powered off.

Note – ILOM provides an ALOM CMT compatibility CLI. Refer to the Sun Integrated

Lights Out Management 2.0 Supplement for the Sun Netra T5220 Server for

comprehensive ILOM and ALOM CMT compatibility information.

Faults detected by ILOM, POST, and the Solaris Predictive Self-Healing (PSH)

technology are forwarded to ILOM for fault handling (

FIGURE 1-7).

In the event of a system fault, ILOM ensures that the fault LED is lit, FRU ID PROMs

are updated, the fault is logged, and alerts are displayed (faulty FRUs are identified

in fault messages using the FRU name). For a list of FRU names, see

FIGURE 1-7 ILOM Fault Management

TABLE 2-1.

The service processor detects when a fault is no longer present and clears the fault in

several ways:

■ Fault recovery – The system automatically detects that the fault condition is no

longer present. ILOM extinguishes the Service Required LED and updates the

FRU’s PROM, indicating that the fault is no longer present.

■ Fault repair – The fault has been repaired by human intervention. In most cases,

the service processor detects the repair and extinguishes the Service Required

LED. If the service processor does not perform these actions, you must perform

these tasks manually with the clearfault or enablecomponent commands.

The service processor also detects the removal of a FRU, in many cases even if the

FRU is removed while the service processor is powered off (that is, if the system

power cables are unplugged during service procedures). This situation enables ILOM

to know that a fault, diagnosed to a specific FRU, has been repaired.

Note – ILOM does not automatically detect hard drive replacement.

Chapter 1 Server Diagnostics 1-15

Many environmental faults can automatically recover. A temperature that is

exceeding a threshold might return to normal limits. An unplugged power supply

can be plugged in, and so on. Recovery of environmental faults is automatically

detected. Recovery events are reported using one of two forms:

■ fru at location is OK.

■ sensor at location is within normal range.

Environmental faults can be repaired through hot-removal of the faulty FRU. FRU

removal is automatically detected by the environmental monitoring, and all faults

associated with the removed FRU are cleared. The message for that case, and the alert

sent for all FRU removals is:

fru at location has been removed.

There is no ILOM command to manually repair an environmental fault.

The Solaris Predictive Self-Healing technology does not monitor the hard drive for

faults. As a result, the service processor does not recognize hard drive faults, and will

not light the fault LEDs on either the chassis or the hard drive itself. Use the Solaris

message files to view hard drive faults. See Section 1.7, “Collecting Information From

Solaris OS Files and Commands” on page 1-42.

1.4.1 Using the ALOM CMT Compatibility CLI in

ILOM

There are three methods of interacting with the service processor:

■ ILOM CLI (default)

■ ILOM browser interface (BI)

■ ALOM CMT compatibility CLI (ALOM CMT CLI in ILOM)

Note – The examples in this section use the ALOM CMT compatibility CLI.

The ALOM CMT CLI emulates the ALOM CMT interface supported on the previous

generation of CMT servers. Using the ALOM CMT CLI (with few exceptions) you

can use commands that resemble the ALOM CMT commands. The comparisons

between the ILOM CLI and The ALOM CMT compatibility CLI are described in the

Sun Integrated Lights Out Management 2.0 Supplement for the Sun Netra T5220 Server.

The service processor sends alerts to all ALOM CMT CLI users that are logged in,

sending the alert through email to a configured email address, and writing the event

to the ILOM event log.

1-16 Sun Netra T5220 Server Service Manual • January 2012

1.4.2 Creating an ALOM CMT CLI Shell

To create an ALOM CMT CLI, do the following:

1. Log in to the service processor with username: root.

When powered on, the service processor boots to the ILOM login prompt. The

factory default password is changeme.

SUNSPxxxxxxxxxxxx login: root

Password:

Waiting for daemons to initialize...

Daemons ready

Sun(TM) Integrated Lights Out Manager

Version 2.0.0.0

Copyright 2008 Sun Microsystems, Inc. All rights reserved.

Use is subject to license terms.

Warning: password is set to factory default.

2. Create a new user, set the account role to Administrator and the CLI mode to

alom.

-> create /SP/users/admin

Creating user...

Enter new password: ********

Enter new password again: ********

Created /SP/users/admin

-> set /SP/users/admin role=Administrator

Set 'role' to 'Administrator'

-> set /SP/users/admin cli_mode=alom

Set 'cli_mode' to 'alom'

Note – The asterisks in the example will not appear when you enter your password.

You can combine the create and set commands on a single line:

-> create /SP/users/admin role=Administrator cli_mode=alom

Creating user...

Enter new password: ********

Enter new password again: ********

Created /SP/users/admin

Chapter 1 Server Diagnostics 1-17

3. Log out of the root account after you have finished creating the new account.

-> exit

4. Log in to the ALOM CMT CLI (indicated by the sc> prompt) from the ILOM

login prompt.

SUNSPxxxxxxxxxxxx login: admin

Password:

Waiting for daemons to initialize...

Daemons ready

Sun(TM) Integrated Lights Out Manager

Version 2.0.0.0

Copyright 2008 Sun Microsystems, Inc. All rights reserved.

Use is subject to license terms.

sc>

Note – Multiple service processor accounts can be active concurrently. A user can be

logged in under one account using the ILOM CLI, and another account using the

ALOM CMT CLI.

1.4.3 Running ALOM CMT CLI Service-Related

Commands

This section describes commands commonly used for service-related activities.

1.4.3.1 Connecting to ALOM CMT CLI

Before you can run ALOM CMT CLI commands, you must connect to the service

processor in one of two ways:

■ Connect an ASCII terminal directly to the serial management port.

■ Use the ssh command to connect to the service processor through an Ethernet

connection on the network management port.

1-18 Sun Netra T5220 Server Service Manual • January 2012

Note – Refer to the Sun Integrated Lights Out Management 2.0 Supplement for the Sun

Netra T5220 Server for instructions on configuring and connecting to the service

processor.

1.4.3.2 Switching Between the System Console and Service Processor

■ To switch from the console output to the ALOM CMT CLI sc> prompt, type #.

(Hash-Period).

■ To switch from the sc> prompt to the console, type console.

1.4.3.3 Service-Related ALOM CMT CLI Commands

TABLE 1-6 describes the typical ALOM CMT CLI commands for servicing a server. For

descriptions of all ALOM CMT CLI commands, issue the help command or refer to

the Integrated Lights Out Management User’s Guide.

TABLE 1-6 Service-Related ALOM CMT CLI Commands

ALOM CMT Command Description

help [command] Displays a list of all ALOM CMT CLI commands with syntax and

descriptions. Specifying a command name as an option displays help for

that command.

break [-y][-c][-D] Takes the host server from the OS to either kmdb or OpenBoot PROM

(equivalent to a Stop-A), depending on the mode Solaris software was

booted.

• -y skips the confirmation question

• -c executes a console command after the break command completes

• -D forces a core dump of the Solaris OS

clearfault UUID Manually clears host-detected faults. The UUID is the unique fault ID of the

fault to be cleared.

console [-f] Connects you to the host system. The -f option forces the console to have

read and write capabilities.

consolehistory [-b lines|-e

lines|-v] [-g lines]

[boot|run]

Displays the contents of the system’s console buffer. The following options

enable you to specify how the output is displayed:

• -g lines specifies the number of lines to display before pausing.

• -e lines displays n lines from the end of the buffer.

• -b lines displays n lines from beginning of buffer.

• -v displays entire buffer.

• boot|run specifies the log to display (run is the default log).

Chapter 1 Server Diagnostics 1-19

TABLE 1-6 Service-Related ALOM CMT CLI Commands (Continued)

ALOM CMT Command Description

bootmode

[normal|reset_nvram|

bootscript=string]

Enables control of the firmware during system initialization with the

following options:

• normal is the default boot mode.

• reset_nvram resets OpenBoot PROM parameters to their default values.

• bootscript=string enables the passing of a string to the boot

command.

powercycle [-f] Performs a poweroff followed by poweron. The -f option forces an

immediate poweroff, otherwise the command attempts a graceful

shutdown.

poweroff [-y][-f] Powers off the host server. The -y option enables you to skip the

confirmation question. The -f option forces an immediate shutdown.

poweron [-c] Powers on the host server. Using the -c option executes a console

command after completion of the poweron command.

removefru PS0|PS1 Indicates if it is okay to perform a hot-swap of a power supply. This

command does not perform any action, but it provides a warning if the

power supply should not be removed because the other power supply is

not enabled.

reset [-y] [-c] Generates a hardware reset on the host server. The -y option enables you to

skip the confirmation question. The -c option executes a console

command after completion of the reset command.

resetsc [-y] Reboots the service processor. The -y option enables you to skip the

confirmation question.

setkeyswitch [-y] normal |

stby | diag | locked

Sets the virtual keyswitch. The -y option enables you to skip the

confirmation question when setting the keyswitch to stby.

setlocator [on | off] Turns the Locator LED on the server on or off.

showenvironment Displays the environmental status of the host server. This information

includes system temperatures, power supply, front panel LED, hard drive,

fan, voltage, and current sensor status. See Section 1.4.6, “Displaying the

Server’s Environmental Status” on page 1-23.

showfaults [

-v] Displays current system faults. See Section 1.4.4, “Displaying System

Faults” on page 1-21.

showfru [-g lines][-s | -d]

[FRU]

Displays information about the FRUs in the server.

• -g lines specifies the number of lines to display before pausing the output

to the screen.

• -s displays static information about system FRUs (defaults to all FRUs,

unless one is specified).

• -d displays dynamic information about system FRUs (defaults to all

FRUs, unless one is specified). See Section 1.4.7, “Displaying FRU

Information” on page 1-25.

1-20 Sun Netra T5220 Server Service Manual • January 2012

TABLE 1-6 Service-Related ALOM CMT CLI Commands (Continued)

ALOM CMT Command Description

showkeyswitch Displays the status of the virtual keyswitch.

showlocator Displays the current state of the Locator LED as either on or off.

showlogs [-b lines | -e lines |

-v] [-g lines][-p

logtype[r|p]]]

showplatform [-v] Displays information about the host system’s hardware configuration, the

Displays the history of all events logged in the ALOM CMT event buffers

(in RAM or the persistent buffers).

system serial number, and whether the hardware is providing service.

Note – See TABLE 1-10 for the ALOM CMT CLI automatic system recover (ASR)

commands.

1.4.4 Displaying System Faults

The ALOM CMT CLI showfaults command displays the following kinds of faults:

■ Environmental or configuration faults – System configuration faults, or

temperature or voltage problems that might be caused by faulty FRUs (power

supplies, fans, or blower), or by room temperature or blocked air flow to the

server.

■ POST detected faults – Faults on devices detected by the power-on self-test

diagnostics.

■ PSH detected faults – Faults detected by the Solaris Predictive Self-healing (PSH)

technology

Use the showfaults command for the following reasons:

■ To see if any faults have been diagnosed in the system.

■ To verify that the replacement of a FRU has cleared the fault and not generated

any additional faults.

● At the sc> prompt, type the showfaults command.

The following showfaults command examples show the different kinds of

output from the showfaults command:

Chapter 1 Server Diagnostics 1-21

■ Example of the showfaults command when no faults are present:

sc> showfaults

Last POST run: THU MAR 09 16:52:44 2006

POST status: Passed all devices

No failures found in System

■ Example of the showfaults command displaying an environmental fault:

sc> showfaults

Last POST Run: Wed Jul 18 11:44:47 2007

Post Status: Passed all devices

ID FRU Fault

0 /SYS/FANBD0/FM0 SP detected fault: TACH at /SYS/FANBD0/FM0/F1

has exceeded low non-recoverable threshold.

■ Example showing a fault that was detected by POST. These kinds of faults are

identified by the message Forced fail reason where reason is the name of the

power-on routine that detected the failure.

sc> showfaults

Last POST Run: Wed Jun 27 21:29:02 2007

Post Status: Passed all devices

ID FRU Fault

0 /SYS/MB/CMP0/BR3/CH1/D1 SP detected fault:

/SYS/MB/CMP0/BR3/CH1/D1 Forced fail (POST)

■ Example showing a fault that was detected by the PSH technology. These kinds

of faults are identified by the text

Host detected fault and by a UUID.

sc> showfaults -v

Last POST Run: Wed Jun 29 11:29:02 2007

Post Status: Passed all devices

ID Time FRU Fault

0 Jun 30 22:13:02 /SYS/MB Host detected fault, MSGID:

SUN4V-8000-N3 UUID: 7ee0e46b-ea64-6565-e684-e996963f7b86

1-22 Sun Netra T5220 Server Service Manual • January 2012

1.4.5 Manually Cleaning PSH Diagnosed Faults

The ALOM CMT CLI clearfault command enables you to manually clear PSH

diagnosed faults from the service processor without a FRU replacement or if the

service processor was unable to automatically detect the FRU replacement.

● At the sc> prompt, type the clearfault command.

■ Example showing a fault being cleared manually using the clearfault

command:

sc> clearfault 7ee0e46b-ea64-6565-e684-e996963f7b86

1.4.6 Displaying the Server’s Environmental Status

The showenvironment command displays a snapshot of the server ’s environmental

status. This command displays system temperatures, hard drive status, power supply

and fan status, front panel LED status, and voltage and current sensors. The output

uses a format similar to the Solaris OS command prtdiag (1m).

● At the sc> prompt, type the showenvironment command.

The output differs according to your system’s model and configuration.

Chapter 1 Server Diagnostics 1-23

EXAMPLE 1-1 shows abridged output of the showenvironment command.

EXAMPLE 1-1 showenvironment Command Output

sc> showenvironment

-----------------------------------------------------------------------------System Temperatures (Temperatures in Celsius):

-----------------------------------------------------------------------------Sensor Status Temp LowHard LowSoft LowWarn HighWarn

HighSoft HighHard

-----------------------------------------------------------------------------/SYS/MB/T_AMB OK 29 -10 -5 0 50 55 60

/SYS/MB/CMP0/T_TCORE OK 50 -14 -9 -4 86 96 106

/SYS/MB/CMP0/T_BCORE OK 51 -14 -9 -4 86 96 106

/SYS/MB/CMP0/BR0/CH0/D0/T_AMB OK 41 -10 -8 -5 95 100 105

...

-----------------------------------------------------------------------------System Indicator Status:

-----------------------------------------------------------------------------/SYS/LOCATE /SYS/SERVICE /SYS/ACT

OFF OFF ON

-----------------------------------------------------------------------------/SYS/PSU_FAULT /SYS/TEMP_FAULT /SYS/FAN_FAULT

OFF OFF OFF

-----------------------------------------------------------------------------System Disks:

-----------------------------------------------------------------------------Disk Status Service OK2RM

-----------------------------------------------------------------------------/SYS/HDD0 OK OFF OFF

/SYS/HDD1 NOT PRESENT OFF OFF

...

1-24 Sun Netra T5220 Server Service Manual • January 2012

EXAMPLE 1-1 showenvironment Command Output (Continued)

-----------------------------------------------------------------------------Fan Status:

-----------------------------------------------------------------------------Fans (Speeds Revolution Per Minute):

Sensor Status Speed Warn Low

-----------------------------------------------------------------------------/SYS/FANBD0/FM0/F0/TACH OK 7000 4000 2400

...

-----------------------------------------------------------------------------Voltage sensors (in Volts):

-----------------------------------------------------------------------------Sensor Status Voltage LowSoft LowWarn HighWarn HighSoft

-----------------------------------------------------------------------------/SYS/MB/V_+3V3_STBY OK 3.39 3.13 3.17 3.53 3.58

...

-----------------------------------------------------------------------------Power Supplies:

-----------------------------------------------------------------------------Supply Status Fan_Fault Temp_Fault Volt_Fault Cur_Fault

-----------------------------------------------------------------------------/SYS/PS0 OK OFF OFF OFF OFF

...

Note – Some environmental information might not be available when the server is in

standby mode.

1.4.7 Displaying FRU Information

The showfru command displays information about the FRUs in the server. Use this

command to see information about an individual FRU, or for all the FRUs.

Note – By default, the output of the showfru command for all FRUs is very long.

Chapter 1 Server Diagnostics 1-25

● At the sc> prompt, enter the showfru command.

In the following example, the showfru command is used to get information about

the motherboard (MB).

sc> showfru /SYS/MB

/SYS/MB (container)

SEGMENT: FL

/Configured_LevelR

/Configured_LevelR/UNIX_Timestamp32: Thu Jun 7 20:12:17 GMT

2007

/Configured_LevelR/Sun_Part_No: 5412153

/Configured_LevelR/Configured_Serial_No: BBX053

/Configured_LevelR/Initial_HW_Dash_Level: 02

SEGMENT: FD

/InstallationR (1 iterations)

/InstallationR[0]

/InstallationR[0]/UNIX_Timestamp32: Thu Jun 21 19:37:57 GMT

2007

/InstallationR[0]/Fru_Path: /SYS/MB

/InstallationR[0]/Parent_Part_Number: 5017813

/InstallationR[0]/Parent_Serial_Number: 110508

/InstallationR[0]/Parent_Dash_Level: 01

/InstallationR[0]/System_Id: 0721BBB050

/InstallationR[0]/System_Tz: 0

...

1-26 Sun Netra T5220 Server Service Manual • January 2012

1.5 Running POST

Power-on self-test (POST) is a group of PROM-based tests that run when the server is

powered on or reset. POST checks the basic integrity of the critical hardware

components in the server (CPU, memory, and I/O buses).

If POST detects a faulty component, the component is disabled automatically,

preventing faulty hardware from potentially harming any software. If the system is

capable of running without the disabled component, the system will boot when

POST is complete. For example, if one of the processor cores is deemed faulty by

POST, the core will be disabled, and the system will boot and run using the

remaining cores.

1.5.1 Controlling How POST Runs

The server can be configured for normal, extensive, or no POST execution. You can

also control the level of tests that run, the amount of POST output that is displayed,

and which reset events trigger POST by using ALOM CMT CLI variables.

TABLE 1-7 lists the ALOM CMT CLI variables used to configure POST. FIGURE 1-8

shows how the variables work together.

Note – Use the ALOM CMT CLI setsc command to set all the parameters in

TABLE 1-7 except setkeyswitch.

TABLE 1-7 ALOM CMT CLI Parameters Used for POST Configuration

Parameter Values Description

setkeyswitch normal The system can power on and run POST (based

on the other parameter settings). For details see

FIGURE 1-8. This parameter overrides all other

commands.

diag The system runs POST based on predetermined

settings.

stby The system cannot power on.

locked The system can power on and run POST, but no

flash updates can be made.

diag_mode off POST does not run.

normal Runs POST according to diag_level value.

Chapter 1 Server Diagnostics 1-27

TABLE 1-7 ALOM CMT CLI Parameters Used for POST Configuration (Continued)

Parameter Values Description

service Runs POST with preset values for diag_level

and diag_verbosity.

diag_level max If diag_mode = normal, runs all the minimum

tests plus extensive CPU and memory tests.

min If diag_mode = normal, runs minimum set of

tests.

diag_trigger none Does not run POST on reset.

user_reset Runs POST upon user-initiated resets.

power_on_reset Only runs POST for the first power on. This

option is the default.

error_reset Runs POST if fatal errors are detected.

all_resets Runs POST after any reset.

diag_verbosity none No POST output is displayed.

min POST output displays functional tests with a

banner and pinwheel.

normal POST output displays all test and informational

messages.

max POST displays all test, informational, and some

debugging messages.

1-28 Sun Netra T5220 Server Service Manual • January 2012

FIGURE 1-8 Flowchart of ALOM CMT CLI Variables for POST Configuration

Chapter 1 Server Diagnostics 1-29

TABLE 1-8 shows typical combinations of ALOM CMT CLI variables and associated

POST modes.

TABLE 1-8 ALOM CMT CLI Parameters and POST Modes

Parameter

Normal Diagnostic Mode

(Default Settings) No POST Execution

Diagnostic Service

Mode

Keyswitch Diagnostic

Preset Values

diag_mode normal off service normal

setkeyswitch

*

normal normal normal diag

diag_level max n/a max max

diag_trigger power-on-reset

none all-resets all-resets

error-reset

diag_verbosity normal n/a max max

Description of POST

execution

* The setkeyswitch parameter, when set to diag, overrides all the other ALOM CMT CLI POST variables.

This is the default POST

configuration. This

configuration tests the

system thoroughly, and

suppresses some of the

detailed POST output.

POST does not

run, resulting in

quick system

initialization. This

is not a suggested

configuration.

POST runs the full

spectrum of tests

with the maximum

output displayed.

POST runs the full

spectrum of tests

with the maximum

output displayed.

1.5.2 Changing POST Parameters

1. Access the ALOM CMT CLI sc> prompt:

At the console, issue the #. key sequence:

#.

2. Use the ALOM CMT CLI sc> prompt to change the POST parameters.

Refer to

TABLE 1-7 for a list of ALOM CMT CLI POST parameters and their values.

The setkeyswitch parameter sets the virtual keyswitch, so this parameter does

not use the setsc command. For example, to change the POST parameters using

the setkeyswitch command, enter the following:

sc> setkeyswitch diag

1-30 Sun Netra T5220 Server Service Manual • January 2012

To change the POST parameters using the setsc command, you must first set the

setkeyswitch parameter to normal. Then you can change the POST parameters

using the setsc command:

sc> setkeyswitch normal

sc> setsc value

For example:

sc> setkeyswitch normal

sc> setsc diag_mode service

1.5.3 Reasons to Run POST

You can use POST for basic hardware verification and diagnosis, and for

troubleshooting as described in the following sections.

1.5.3.1 Verifying Hardware Functionality

POST tests critical hardware components to verify functionality before the system

boots and accesses software. If POST detects an error, the faulty component is

disabled automatically, preventing faulty hardware from potentially harming

software.

1.5.3.2 Diagnosing the System Hardware

You can use POST as an initial diagnostic tool for the system hardware. In this case,

configure POST to run in maximum mode (diag_mode=service, setkeyswitch=

diag, diag_level=max) for thorough test coverage and verbose output.

1.5.4 Running POST in Maximum Mode

This procedure describes how to run POST when you want maximum testing, as in

the case when you are troubleshooting a server or verifying a hardware upgrade or

repair.

Chapter 1 Server Diagnostics 1-31

1. Switch from the system console prompt to the sc> prompt by issuing the #.

escape sequence.

ok #.

sc>

2. Set the virtual keyswitch to diag so that POST will run in service mode.

sc> setkeyswitch diag

3. Reset the system so that POST runs.

There are several ways to initiate a reset.

EXAMPLE 1-2 shows the powercycle

command. For other methods, refer to the Sun Netra T5220 Server Administration

Guide.

EXAMPLE 1-2 Initiating POST Using the powercycle Command

sc> powercycle

Are you sure you want to powercycle the system (y/n)? y

Powering host off at Fri Jul 27 08:11:52 2007

Waiting for host to Power Off; hit any key to abort.

Audit | minor: admin : Set : object = /SYS/power_state : value =

soft : success

Chassis | critical: Host has been powered off

Powering host on at Fri Jul 27 08:13:08 2007

Audit | minor: admin : Set : object = /SYS/power_state : value =

on : success

Chassis | major: Host has been powered on

1-32 Sun Netra T5220 Server Service Manual • January 2012

4. Switch to the system console to view the POST output:

sc> console

EXAMPLE 1-3 depicts abridged POST output.

EXAMPLE 1-3 POST Output (Abridged)

sc> console

Enter #. to return to ALOM.

2007-07-03 10:25:12.081 0:0:0>@(#)Sun Netra[TM] T5220 POST 4.x.build_119

2007/06/06 09:48

/export/delivery/delivery/4.x/4.x.build_119/post4.x/UltraSPARC/NetraT5220/inte

grated (root)

2007-07-03 10:25:12.386 0:0:0>Copyright 2007 Sun Microsystems, Inc. All rights

reserved

2007-07-03 10:25:12.550 0:0:0>VBSC cmp0 arg is: 00ff00ff.ffffffff

2007-07-03 10:25:12.653 0:0:0>POST enabling threads: 00ff00ff.ffffffff

2007-07-03 10:25:12.766 0:0:0>VBSC mode is: 00000000.00000001

2007-07-03 10:25:12.867 0:0:0>VBSC level is: 00000000.00000001

2007-07-03 10:25:12.966 0:0:0>VBSC selecting POST MAX Testing.

2007-07-03 10:25:13.066 0:0:0>VBSC setting verbosity level 3

2007-07-03 10:25:13.161 0:0:0>UltraSPARCT2, Version 2.1

2007-07-03 10:25:13.247 0:0:0>Serial Number: 0fac006b.0e654482

2007-07-03 10:25:13.353 0:0:0>Basic Memory Tests.....

2007-07-03 10:25:13.456 0:0:0>Begin: Branch Sanity Check

2007-07-03 10:25:13.569 0:0:0>End : Branch Sanity Check

2007-07-03 10:25:13.668 0:0:0>Begin: DRAM Memory BIST

2007-07-03 10:25:13.793

0:0:0>........................................................................

........................

2007-07-03 10:25:38.399 0:0:0>End : DRAM Memory BIST

2007-07-03 10:25:39.547 0:0:0>Sys 166 MHz, CPU 1166 MHz, Mem 332 MHz

2007-07-03 10:25:39.658 0:0:0>L2 Bank EFuse = 00000000.000000ff

2007-07-03 10:25:39.760 0:0:0>L2 Bank status = 00000000.00000f0f

2007-07-03 10:25:39.864 0:0:0>Core available Efuse = ffff00ff.ffffffff

2007-07-03 10:25:39.982 0:0:0>Test Memory.....

2007-07-03 10:25:40.070 0:0:0>Begin: Probe and Setup Memory

2007-07-03 10:25:40.181 0:0:0>INFO: 4096MB at Memory Branch 0

...

2007-07-03 10:29:21.683 0:0:0>INFO:

2007-07-03 10:29:21.686 0:0:0>POST Passed all devices.

2007-07-03 10:29:21.692 0:0:0>POST:Return to VBSC.

5. Perform further investigation if needed.

■ If no faults were detected, the system will boot.

Chapter 1 Server Diagnostics 1-33

■ If POST detects a faulty device, the fault is displayed and the fault information is

passed to ALOM CMT CLI for fault handling. Faulty FRUs are identified in fault

messages using the FRU name. For a list of FRU names, see

TABLE 2-1.

a. Interpret the POST messages:

POST error messages use the following syntax:

c:s > ERROR: TEST = failing-test

c:s > H/W under test = FRU

c:s > Repair Instructions: Replace items in order listed by

H/W under test above

c:s > MSG = test-error-message

c:s > END_ERROR

In this syntax, c = the core number, s = the strand number.

Warning and informational messages use the following syntax:

INFO or WARNING: message

In

EXAMPLE 1-4, POST reports a memory error at FB-DIMM location

/SYS/MB/CMP0/BR2/CH0/D0. The error was detected by POST running on core

7, strand 2.

EXAMPLE 1-4 POST Error Message

7:2>

7:2>ERROR: TEST = Data Bitwalk

7:2>H/W under test = /SYS/MB/CMP0/BR2/CH0/D0

7:2>Repair Instructions: Replace items in order listed by 'H/W

under test' above.

7:2>MSG = Pin 149 failed on /SYS/MB/CMP0/BR2/CH0/D0 (J2001)

7:2>END_ERROR

7:2>Decode of Dram Error Log Reg Channel 2 bits

60000000.0000108c

7:2> 1 MEC 62 R/W1C Multiple corrected

errors, one or more CE not logged

7:2> 1 DAC 61 R/W1C Set to 1 if the error

was a DRAM access CE

7:2> 108c SYND 15:0 RW ECC syndrome.

7:2>

7:2> Dram Error AFAR channel 2 = 00000000.00000000

7:2> L2 AFAR channel 2 = 00000000.00000000

1-34 Sun Netra T5220 Server Service Manual • January 2012

b. Run the showfaults command to obtain additional fault information.

The fault is captured by ALOM CMT CLI, where the fault is logged, the Service

Required LED is lit, and the faulty component is disabled.

Example:

EXAMPLE 1-5 showfaults Output

ok .#

sc> showfaults

Last POST Run: Wed Jun 27 21:29:02 2007

Post Status: Passed all devices

ID FRU Fault

0 /SYS/MB/CMP0/BR2/CH0/D0 SP detected fault: /SYS/MB/CMP0/BR2/CH0/D0

Forced fail (POST)

In this example, /SYS/MB/CMP0/BR2/CH0/D0 is disabled. The system can boot

using memory that was not disabled until the faulty component is replaced.

Note – You can use ASR commands to display and control disabled components. See

Section 1.8, “Managing Components With Automatic System Recovery Commands”

on page 1-43.

1.5.5 Clearing POST Detected Faults

In most cases, when POST detects a faulty component, POST logs the fault and

automatically takes the failed component out of operation by placing the component

in the ASR blacklist (see Section 1.8, “Managing Components With Automatic System

Recovery Commands” on page 1-43).

In most cases, the replacement of the faulty FRU is detected when the service

processor is reset or power cycled. In this case, the fault is automatically cleared from

the system. This procedure describes how to identify POST detected faults and, if

necessary, manually clear the fault.

Chapter 1 Server Diagnostics 1-35

1. After replacing a faulty FRU, at the ALOM CMT CLI prompt use the

showfaults command to identify POST detected faults.

POST detected faults are distinguished from other kinds of faults by the text:

Forced fail, and no UUID number is reported.

Example:

EXAMPLE 1-6 POST Detected Fault

sc> showfaults

Last POST Run: Wed Jun 27 21:29:02 2007

Post Status: Passed all devices

ID FRU Fault

0 /SYS/MB/CMP0/BR2/CH0/D0 SP detected fault: /SYS/MB/CMP0/BR2/CH0/D0 Forced

fail (POST)

If no fault is reported, you do not need to do anything else. Do not perform the

subsequent steps.

2. Use the enablecomponent command to clear the fault and remove the

component from the ASR blacklist.

Use the FRU name that was reported in the fault in Step 1.

EXAMPLE 1-7 Using the enablecomponent Command

sc> enablecomponent /SYS/MB/CMP0/BR2/CH0/D0

The fault is cleared and should not show up when you run the showfaults

command. Additionally, the Service Required LED is no longer on.

3. Power cycle the server.

You must reboot the server for the enablecomponent command to take effect.

4. At the ALOM CMT CLI prompt, use the showfaults command to verify that

no faults are reported.

TABLE 1-9 Verifying Cleared Faults Using the showfaults Command

sc> showfaults

Last POST run: THU MAR 09 16:52:44 2006

POST status: Passed all devices

No failures found in System

1-36 Sun Netra T5220 Server Service Manual • January 2012

1.6 Using the Solaris Predictive Self-Healing

Feature

The Solaris Predictive Self-Healing (PSH) technology enables the server to diagnose

problems while the Solaris OS is running, and mitigate many problems before they

negatively affect operations.

The Solaris OS uses the fault manager daemon, fmd(1M), which starts at boot time

and runs in the background to monitor the system. If a component generates an error,

the daemon handles the error by correlating the error with data from previous errors

and other related information to diagnose the problem. Once diagnosed, the fault

manager daemon assigns the problem a Universal Unique Identifier (UUID) that

distinguishes the problem across any set of systems. When possible, the fault

manager daemon initiates steps to self-heal the failed component and take the

component offline. The daemon also logs the fault to the syslogd daemon and

provides a fault notification with a message ID (MSGID). You can use the message ID

to get additional information about the problem from Sun’s knowledge article

database.

The Predictive Self-Healing technology covers the following server components:

■ UltraSPARC® T2 multicore processor

■ Memory

■ I/O bus

The PSH console message provides the following information:

■ Type

■ Severity

■ Description

■ Automated response

■ Impact

■ Suggested action for system administrator

If the Solaris PSH facility detects a faulty component, use the fmdump command to

identify the fault. Faulty FRUs are identified in fault messages using the FRU name.

For a list of FRU names, see

TABLE 2-1.

Chapter 1 Server Diagnostics 1-37

1.6.1 Identifying PSH Detected Faults

When a PSH fault is detected, a Solaris console message similar to EXAMPLE 1-8 is

displayed.

EXAMPLE 1-8 Console Message Showing Fault Detected by PSH

SUNW-MSG-ID: SUN4V-8000-DX, TYPE: Fault, VER: 1, SEVERITY: Minor

EVENT-TIME: Wed Sep 14 10:09:46 EDT 2005

PLATFORM: SUNW,Sun-Netra-T5220, CSN: -, HOSTNAME: hostname

SOURCE: cpumem-diagnosis, REV: 1.5

EVENT-ID: f92e9fbe-735e-c218-cf87-9e1720a28004

DESC: The number of errors associated with this memory module has exceeded

acceptable levels.

AUTO-RESPONSE: Pages of memory associated with this memory module are being

removed from service as errors are reported.

IMPACT: Total system memory capacity will be reduced as pages are retired.

REC-ACTION: Schedule a repair procedure to replace the affected memory module.

Use fmdump -v -u <EVENT_ID> to identify the module.

Faults detected by the Solaris PSH facility are also reported through service processor

alerts.

Solaris PSH in

EXAMPLE 1-9 depicts an ALOM CMT CLI alert of the same fault reported by

EXAMPLE 1-8.

EXAMPLE 1-9 ALOM CMT CLI Alert of PSH Diagnosed Fault

SC Alert: Host detected fault, MSGID: SUN4V-8000-DX

The ALOM CMT CLI showfaults command provides summary information about

the fault. See Section 1.4.4, “Displaying System Faults” on page 1-21 for more

information about the showfaults command.

Note – The Service Required LED is also turns on for PSH diagnosed faults.

1.6.1.1 Using the fmdump Command to Identify Faults

The fmdump command displays the list of faults detected by the Solaris PSH facility

and identifies the faulty FRU for a particular EVENT_ID (UUID).

Do not use fmdump to verify a FRU replacement has cleared a fault because the

output of fmdump is the same after the FRU has been replaced. Use the fmadm

faulty command to verify the fault has cleared.

1-38 Sun Netra T5220 Server Service Manual • January 2012

1. Check the event log using the fmdump command with -v for verbose output:

EXAMPLE 1-10 Output from the fmdump -v Command

# fmdump -v -u fd940ac2-d21e-c94a-f258-f8a9bb69d05b

TIME UUID SUNW-MSG-ID

Jul 31 12:47:42.2007 fd940ac2-d21e-c94a-f258-f8a9bb69d05b SUN4V-8000-JA

100% fault.cpu.ultraSPARC-T2.misc_regs

Problem in: cpu:///cpuid=16/serial=5D67334847

Affects: cpu:///cpuid=16/serial=5D67334847

FRU: hc://:serial=101083:part=541215101/motherboard=0

Location: MB

In

EXAMPLE 1-10, a fault is displayed, indicating the following details:

■ Date and time of the fault (Jul 31 12:47:42.2007)

■ Universal Unique Identifier (UUID). This is unique for every fault

(

fd940ac2-d21e-c94a-f258-f8a9bb69d05b)

■ Sun message identifier, which can be used to obtain additional fault information

(SUN4V-8000-JA)

■ Faulted FRU. The information provided in the example includes the part number

of the FRU (part=541215101) and the serial number of the FRU (serial=

101083). The Location field provides the name of the FRU. In

EXAMPLE 1-10 the

FRU name is MB, meaning the motherboard.

Note – fmdump displays the PSH event log. Entries remain in the log after the fault

has been repaired.

2. Use the Sun message ID to obtain more information about this type of fault.

a. Obtain the message ID from the console output or the ALOM CMT CLI

showfaults command.

Chapter 1 Server Diagnostics 1-39

b. Enter the message ID in the SUNW-MSG-ID field, and click Lookup.

EXAMPLE 1-11, the message ID SUN4V-8000-JA provides information for

In

corrective action:

EXAMPLE 1-11 PSH Message Output

CPU errors exceeded acceptable levels

Type

Fault

Severity

Major

Description

The number of errors associated with this CPU has exceeded

acceptable levels.

Automated Response

The fault manager will attempt to remove the affected CPU from

service.

Impact

System performance may be affected.

Suggested Action for System Administrator

Schedule a repair procedure to replace the affected CPU, the

identity of which can be determined using fmdump -v -u <EVENT_ID>.

Details

The Message ID: SUN4V-8000-JA indicates diagnosis has

determined that a CPU is faulty. The Solaris fault manager arranged

an automated attempt to disable this CPU. The recommended action

for the system administrator is to contact Sun support so a Sun

service technician can replace the affected component.

3. Follow the suggested actions to repair the fault.

1.6.2 Clearing PSH Detected Faults

When the Solaris PSH facility detects faults the faults are logged and displayed on

the console. In most cases, after the fault is repaired, the corrected state is detected

by the system and the fault condition is repaired automatically. However, this

must be verified and, in cases where the fault condition is not automatically

cleared, the fault must be cleared manually.

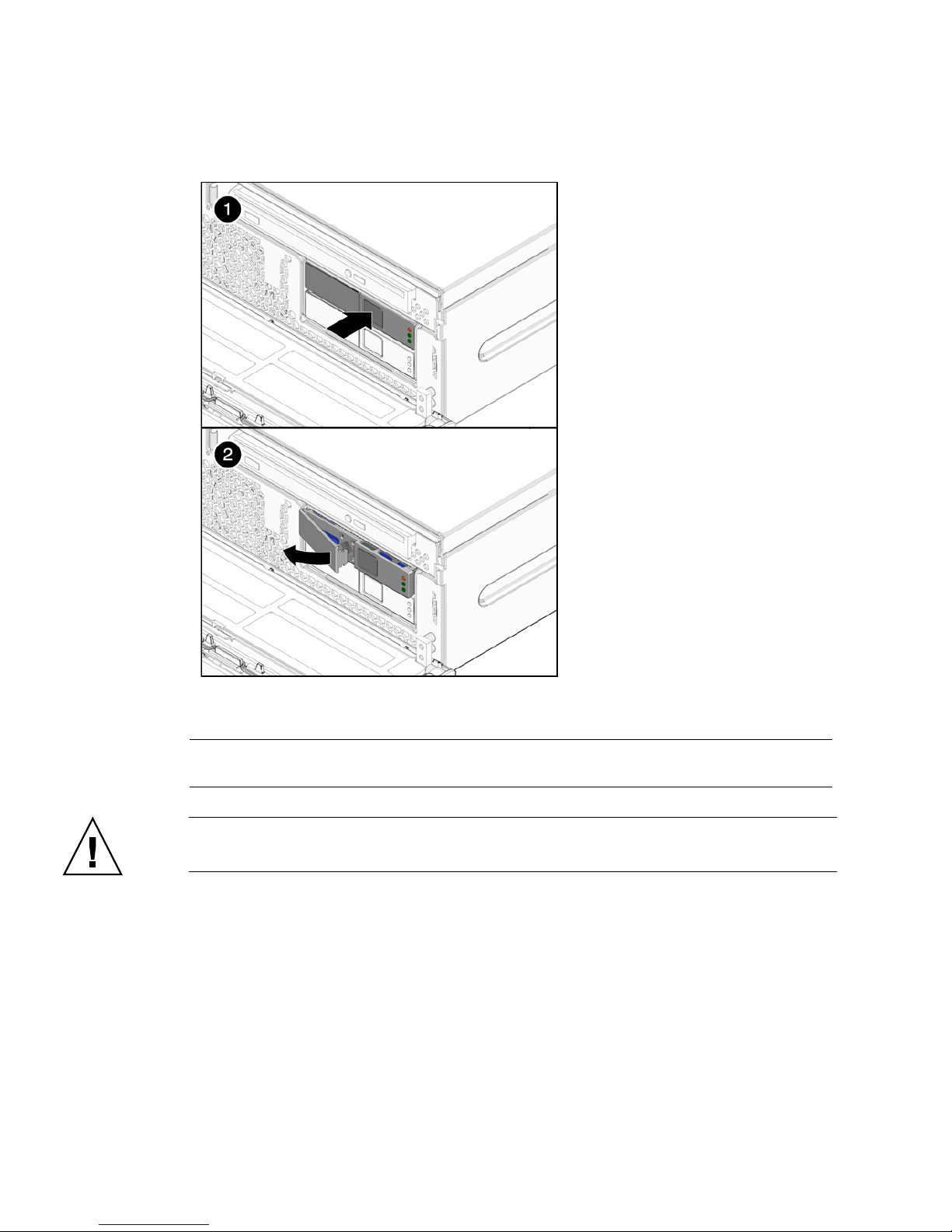

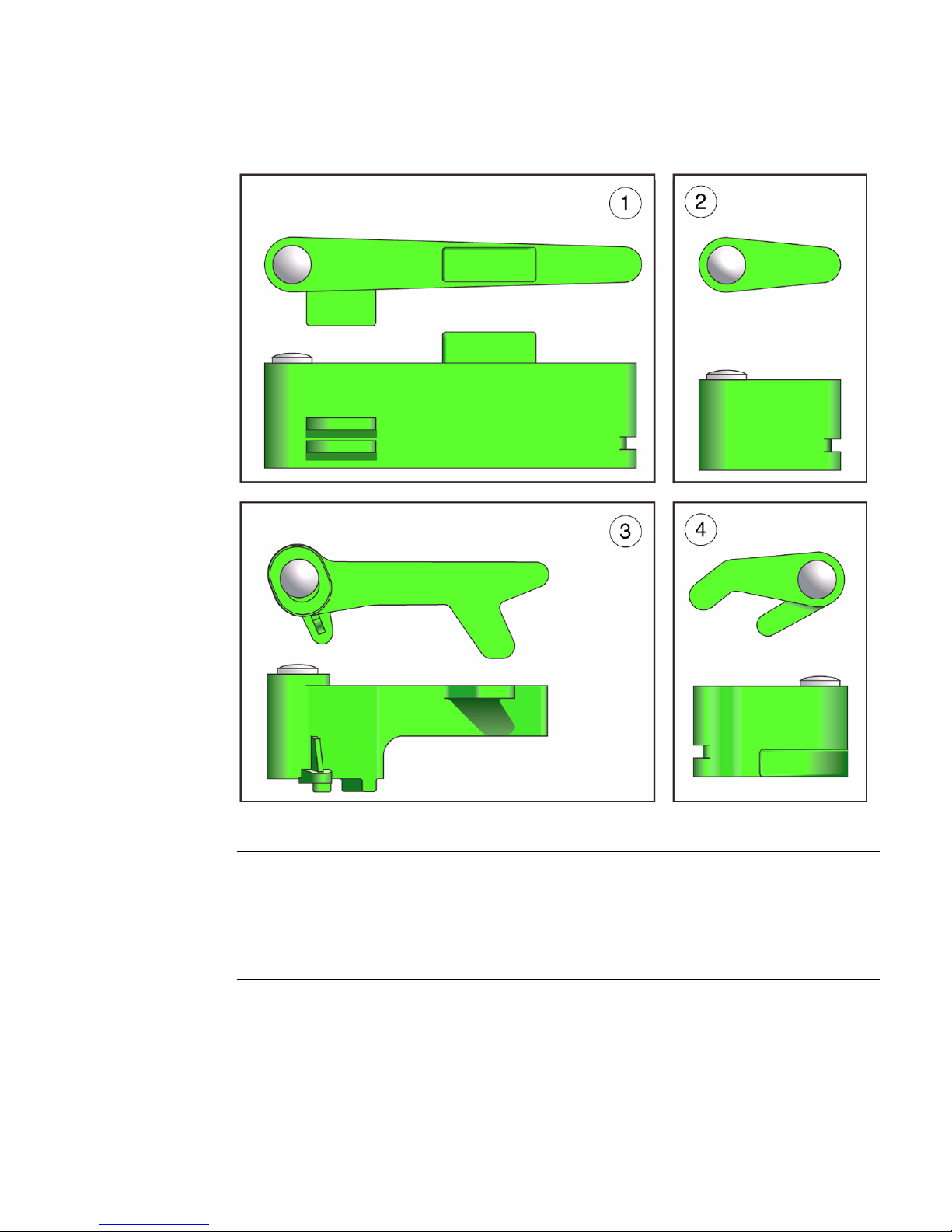

1. After replacing a faulty FRU, power on the server.