Netra™T4 AC100/DC100

Service and System

Reference Manual

Sun Microsystems, Inc.

901 San Antonio Road

Palo Alto, CA 94303-4900 U.S.A.

650-960-1300

Part No. 806-7336-11

August 2001, Revision A

Send comments about this document to: docfeedback@sun.com

Copyright 2001Sun Microsystems,Inc., 901San AntonioRoad, PaloAlto, CA 94303-4900U.S.A. Allrights reserved.

This product ordocument isdistributed underlicenses restrictingits use,copying, distribution, anddecompilation. Nopart ofthis productor

document maybe reproducedin anyform byany meanswithout priorwritten authorization ofSun andits licensors,if any.Third-party

software,including font technology,is copyrightedand licensedfrom Sunsuppliers.

Parts ofthe productmay bederived fromBerkeley BSDsystems, licensedfrom theUniversity of California.UNIX isa registeredtrademark in

the U.S.and othercountries, exclusivelylicensed throughX/Open Company,Ltd.

Sun, SunMicrosystems, theSun logo,AnswerBook2, docs.sun.com,Netra, Netraft, and Solarisare trademarks,registered trademarks, or

service marksof SunMicrosystems, Inc.in theU.S. andother countries. AllSPARCtrademarks areused underlicense andare trademarksor

registeredtrademarks ofSPARCInternational, Inc. inthe U.S.and othercountries. Productsbearing SPARCtrademarks are based upon an

architecturedeveloped bySun Microsystems,Inc.

The OPENLOOK andSun™ GraphicalUser Interfacewas developed bySun Microsystems,Inc. forits usersand licensees. Sun acknowledges

the pioneeringefforts ofXerox inresearchingand developing theconcept ofvisual orgraphical user interfaces for thecomputer industry.Sun

holds anon-exclusive licensefrom Xeroxto theXerox GraphicalUser Interface,which licensealso covers Sun’slicensees whoimplement OPEN

LOOK GUIsand otherwisecomply withSun’s writtenlicense agreements.

Federal Acquisitions:Commercial Software—GovernmentUsers Subjectto StandardLicense Termsand Conditions.

DOCUMENTATION IS PROVIDED “AS IS” AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANYIMPLIED WARRANTYOF MERCHANTABILITY,FITNESS FORA PARTICULARPURPOSE OR NON-INFRINGEMENT,

ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright 2001Sun Microsystems,Inc., 901San AntonioRoad, PaloAlto, CA 94303-4900Etats-Unis. Tousdroits réservés.

Ce produitou documentest distribuéavec deslicences quien restreignentl’utilisation, lacopie, la distribution,et ladécompilation. Aucune

partie dece produitou documentne peutêtre reproduitesous aucuneforme, parquelque moyenque ce soit,sans l’autorisationpréalable et

écrite deSun etde sesbailleurs delicence, s’il yen a.Le logicieldétenu par des tiers, etqui comprendla technologierelative auxpolices de

caractères,est protégépar un copyrightet licenciépar desfournisseurs deSun.

Des partiesde ceproduit pourrontêtre dérivéesdes systèmesBerkeley BSDlicenciés parl’Université de Californie.UNIX estune marque

déposée auxEtats-Unis etdans d’autrespays etlicenciée exclusivementpar X/Open Company,Ltd.

Sun, SunMicrosystems, lelogo Sun,AnswerBook2, docs.sun.com,Netra, Netraft, et Solarissont desmarques defabrique oudes marques

déposées, oumarques deservice, deSun Microsystems,Inc. auxEtats-Unis etdans d’autrespays. Toutesles marquesSPARCsont utiliséessous

licence etsont desmarques defabrique oudes marquesdéposées deSPARCInternational, Inc. auxEtats-Unis etdans d’autrespays. Les

produitsportant les marquesSPARCsont baséssur unearchitecture développéepar SunMicrosystems, Inc.

L’interfaced’utilisation graphiqueOPEN LOOKet Sun™a été développéepar SunMicrosystems, Inc.pour sesutilisateurs et licenciés. Sun

reconnaîtles effortsde pionniers deXerox pourla rechercheet ledéveloppement duconcept desinterfaces d’utilisation visuelle ou graphique

pour l’industriede l’informatique.Sun détientune licencenon exclusive deXerox surl’interface d’utilisationgraphique Xerox,cette licence

couvrant égalementles licenciésde Sunqui mettenten place l’interfaced’utilisation graphiqueOPEN LOOKet qui en outre seconforment aux

licences écritesde Sun.

LA DOCUMENTATIONEST FOURNIE “EN L’ETAT” ET TOUTES AUTRES CONDITIONS,DECLARATIONS ET GARANTIES EXPRESSES

OU TACITESSONT FORMELLEMENTEXCLUES, DANSLA MESURE AUTORISEE PAR LALOI APPLICABLE,Y COMPRISNOTAMMENT

TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE UTILISATION PARTICULIERE OU A

L’ABSENCE DE CONTREFAÇON.

Please

Recycle

Contents

Part I Service

1. System Description 1-1

1.1 System Features 1-1

1.2 System Unit Components 1-5

1.3 Environmental Performance 1-5

1.4 LEDs 1-6

1.4.1 System LEDs 1-6

1.4.2 LOMlite 2 LEDs 1-8

1.4.3 PSU LEDs 1-10

2. Power-On Self Test 2-1

2.1 POST Overview 2-1

2.1.1 How to Use POST 2-2

2.2 Pre-POST Preparation 2-3

2.3 Running POST 2-4

2.4 POST Diagnostic Levels 2-4

2.4.1 diag-level Variable Set to max 2-5

2.4.2 diag-level Variable Set to min 2-5

2.4.3 Error Messages 2-6

Contents iii

3. SunVTS 3-1

3.1 The Validation Test Suite 3-1

3.1.1 SunVTS Requirements 3-2

3.1.2 SunVTS References 3-2

3.1.3 Installation 3-3

3.1.4 New and Modified Features and Options 3-3

3.1.5 Starting SunVTS 3-5

3.2 SunVTS Tests 3-6

3.2.1 Guide to Using SunVTS 4.4 3-8

4. Troubleshooting 4-1

4.1 Power-On Failure 4-2

4.2 System LEDs 4-2

4.3 Drive Failure 4-2

4.4 Power Supply Unit Troubleshooting 4-4

4.5 OpenBoot PROM Diagnostics 4-7

4.5.1 New Features 4-8

4.5.2 New and Modified Commands and Tests 4-10

4.5.3 Device Tree 4-14

4.5.4 Running the Diagnostics 4-18

4.6 OpenBoot Emergency Procedures 4-30

4.6.1 Stop-A 4-30

4.6.2 Stop-N 4-31

4.6.3 Stop-F 4-31

4.6.4 Stop-D 4-31

5. Before Servicing the System 5-1

5.1 Accessibility 5-1

5.2 Tools 5-2

5.3 System ON/STBY Switch 5-2

5.3.1 Powering On the System 5-2

iv Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

5.3.2 Powering Off the System 5-4

5.4 Disconnection and Isolation 5-5

5.4.1 Netra T4 AC100 System 5-5

5.4.2 Netra T4 DC100 System 5-5

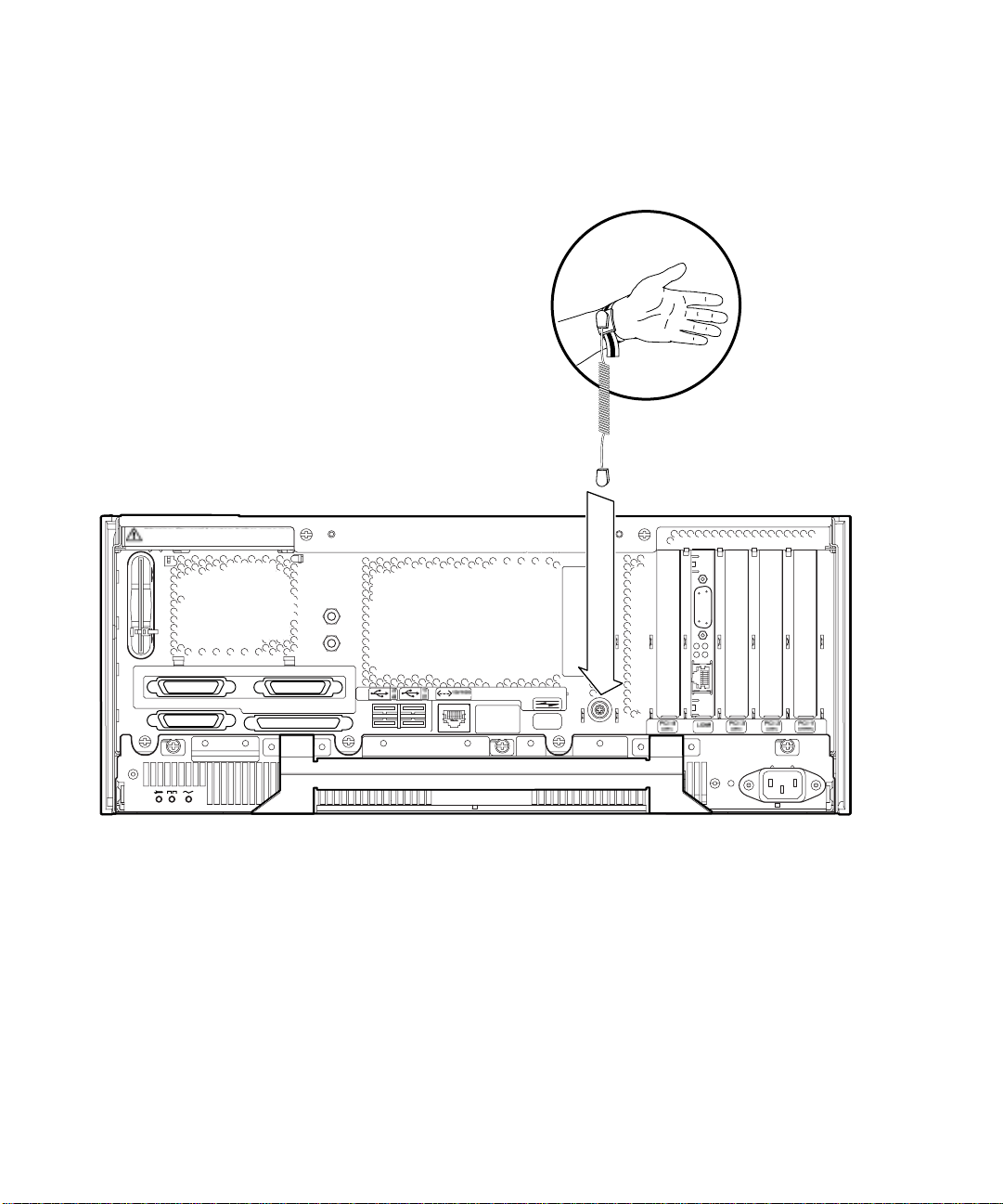

5.5 Antistatic Precautions 5-5

5.5.1 Attaching the Antistatic Wrist Strap 5-6

5.6 Top Access Cover 5-8

5.6.1 Preparation 5-9

5.6.2 Removing the Top Access Cover 5-9

5.6.3 Fitting the Top Access Cover 5-9

5.7 Front Fascia 5-10

5.7.1 Removing the Front Fascia 5-11

5.7.2 Fitting the Front Fascia 5-11

5.8 Air Filter 5-12

5.8.1 Removing and Fitting the Mesh Screen 5-12

5.8.2 Replacing the Filter 5-13

6. Power Subassemblies 6-1

6.1 Power Supply Unit 6-1

6.1.1 Preparation 6-1

6.1.2 Removing the PSU 6-2

6.1.3 Installing the PSU 6-3

6.2 Power Distribution Board 6-4

6.2.1 Preparation 6-4

6.2.2 Removing the PDB 6-5

6.2.3 Installing the PDB 6-6

6.3 System Switch and LED Assembly 6-8

6.3.1 Preparation 6-8

6.3.2 Removing the System Switch and LED Assembly 6-10

6.3.3 Installing the System Switch and LED Assembly 6-10

Contents v

7. Fan Subassemblies 7-1

7.1 PSU Fans 7-2

7.1.1 Preparation 7-3

7.1.2 Removing the PSU Fans Assembly 7-4

7.1.3 Installing the PSU Fans Assembly 7-4

7.2 CPU Fan Assembly 7-5

7.2.1 Preparation 7-5

7.2.2 Removing the CPU Fan Assembly 7-7

7.2.3 Installing the CPU Fan Assembly 7-7

8. Storage Devices 8-1

8.1 FC-AL Hard Disk Drive 8-1

8.1.1 Preparing to Remove a Disk Drive (Hot Swap) 8-2

8.1.2 Removing a Disk Drive (Hot Swap) 8-3

8.1.3 Hot Swapping a Disk Drive (Installation) 8-4

8.1.4 Preparing to Remove an Unmirrored Root Disk 8-5

8.1.5 Removing an Unmirrored Root Disk 8-5

8.1.6 Installing an Unmirrored Root Disk 8-6

8.2 Fiber Channel Backplane and Drive Bay 8-6

8.2.1 Preparation 8-8

8.2.2 Removing the FC-AL Backplane and Drive Bay 8-8

8.2.3 Installing the FC-AL Backplane and Drive Bay 8-9

8.3 Removable Media Module 8-10

8.3.1 Preparation 8-10

8.3.2 Removing a Removable Media Module 8-11

8.3.3 Installing a Removable Media Module 8-12

9. Motherboard and Component Replacement 9-1

9.1 PCI Cards 9-2

9.1.1 Preparation 9-3

9.1.2 Removing a PCI Card 9-3

vi Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

9.1.3 Installing a PCI Card 9-3

9.2 Processor Modules 9-4

9.2.1 Preparation 9-6

9.2.2 Removing a CPU Module 9-6

9.2.3 Installing a CPU Module 9-7

9.3 Memory Modules 9-9

9.3.1 Preparation 9-10

9.3.2 Removing a Memory Module 9-11

9.3.3 Installing a Memory Module 9-11

9.4 Replaceable Battery 9-12

9.4.1 Preparation 9-12

9.4.2 Removing the Battery 9-13

9.4.3 Installing the Battery 9-13

9.5 LOMLite2 Card 9-14

9.5.1 Preparation 9-15

9.5.2 Removing the LOMlite2 Card 9-15

9.5.3 Installing the LOMlite2 Card 9-15

9.6 System Configuration Card Reader 9-16

9.6.1 Preparation 9-16

9.6.2 Removing the SCCR 9-17

9.6.3 Installing the SCCR 9-17

9.7 Motherboard 9-18

9.7.1 Preparation 9-18

9.7.2 Removing the Motherboard 9-20

9.7.3 Installing the Motherboard 9-23

Part II System Reference

10. Functional Description 10-1

10.1 System 10-1

10.2 System Overview 10-2

Contents vii

10.2.1 UltraSPARC-III Processor 10-3

10.2.2 Main Memory 10-6

10.2.3 I/O Subsystem 10-11

10.2.4 Interrupts 10-16

10.2.5 BootBus 10-17

10.2.6 I2C Bus 10-20

10.2.7 PCI Bus 10-22

10.2.8 Peripherals 10-24

10.2.9 Other Peripheral Assembly Options 10-25

10.2.10 USB Ports 10-25

10.2.11 Parallel Port 10-26

10.2.12 Serial Port 10-27

10.2.13 Ethernet 10-31

10.2.14 FC-AL Subsystem 10-32

10.2.15 SCSI 10-33

10.2.16 SuperI/O 10-35

10.3 Power Supply 10-36

10.3.1 AC100 PSU 10-36

10.3.2 DC100 PSU 10-36

10.3.3 Control Signals 10-37

10.4 Motherboard 10-37

10.5 Jumper Descriptions 10-40

10.5.1 Flash PROM Jumpers 10-41

11. External I/O Connectors 11-1

11.1 Parallel Connector 11-2

11.2 Serial Connectors 11-3

11.3 SCSI Connector 11-4

11.3.1 SCSI Implementation 11-6

11.3.2 SCSI Cabling and Configuration 11-6

viii Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

11.4 Ethernet Connector 11-8

11.5 FC-AL Connector 11-9

11.6 USB Connectors 11-10

11.7 Alarms Ports 11-11

11.8 System Configuration Card Reader 11-12

12. Modem Setup 12-1

12.1 To Set Up the Modem 12-1

12.2 Serial Port Speed Change 12-2

12.3 Recommendations 12-2

A. Illustrated Parts List A-1

B. Product Specification B-1

B.1 Physical Specification B-1

B.1.1 Dimensions B-1

B.1.2 Mounting Flanges B-1

B.2 Electrical Specification B-2

B.2.1 Netra T4 AC100 System B-2

B.2.2 Netra T4 DC100 System B-3

B.3 Environmental Specification B-4

B.3.1 Operating and Storage B-4

B.3.2 Acoustic Noise B-5

B.3.3 Earthquake B-5

B.3.4 Electro-Magnetic Compatibility B-5

C. Tool Requirements C-1

D. Motherboard Connectors D-1

D.1 SCCR Connector D-1

D.2 Internal SCSI Connector D-3

D.3 Internal FC-AL Connector D-4

Contents ix

D.4 Power Connectors D-5

E. Example POST Diagnostic Output E-1

F. Updating LOMlite2 Firmware F-1

G. Connecting to the Netra T4 Server G-1

G.1 Connecting to the LOM Serial Port G-1

G.2 Connecting to the Serial Ports G-2

x Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

Figures

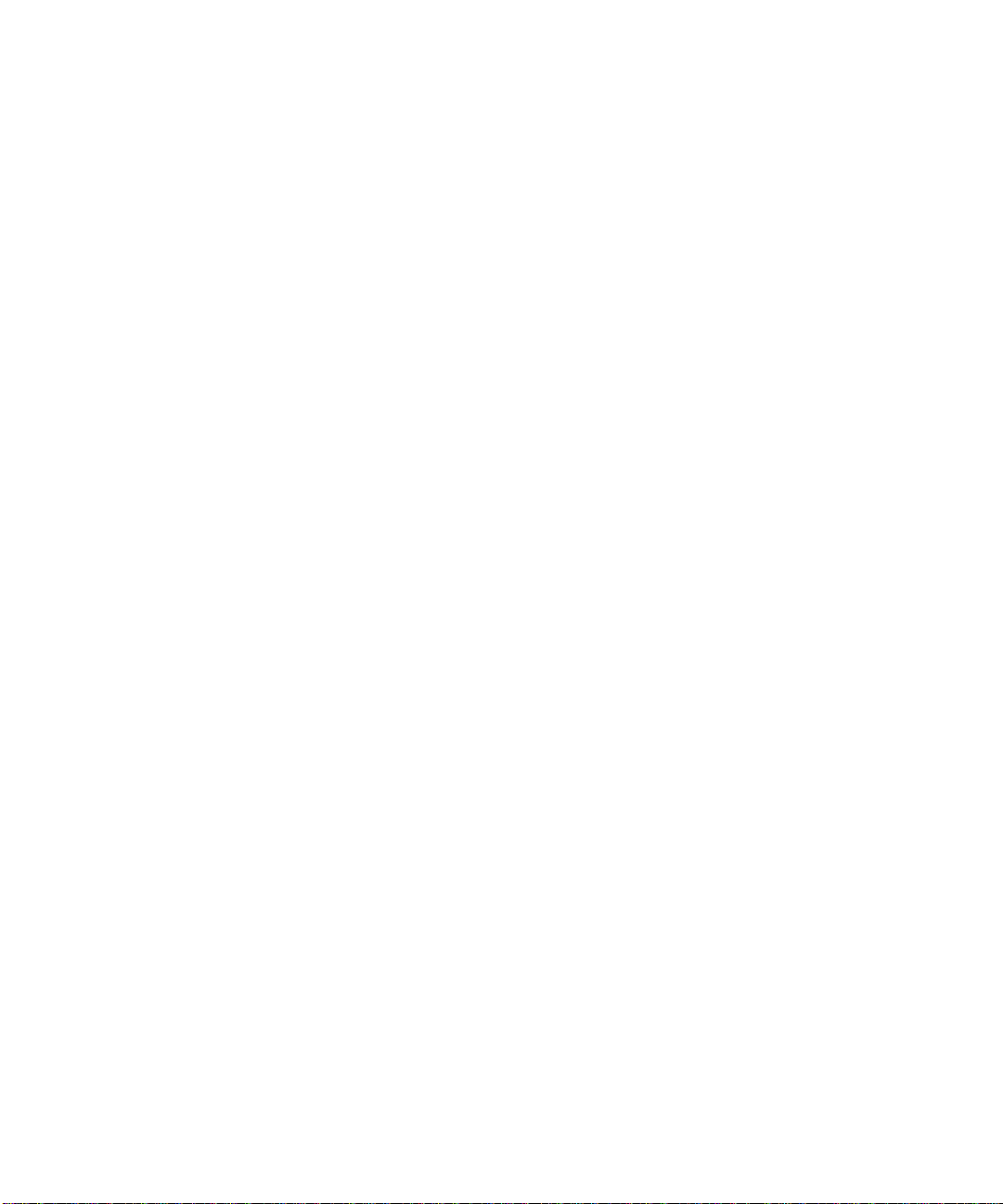

FIGURE 1-1 Netra T4 System Dimensions and Mounting Options (dimensions in mm) 1-2

FIGURE 1-2 Front Panel System LEDs 1-6

FIGURE 1-3 LOMLite2 Status LEDs 1-9

FIGURE 1-4 PSU Status LEDs (Netra T4 AC100 System) 1-10

FIGURE 1-5 PSU Status LEDs (Netra T4 DC100 System) 1-11

FIGURE 3-1 SunVTS Menu Bar 3-5

FIGURE 4-1 Power Supply Connector Jack Location 4-6

FIGURE 4-2 Netra T4 System Device Tree 4-14

FIGURE 5-1 System Power On/STBY (Front Panel) 5-3

FIGURE 5-2 Attaching the Antistatic Wrist Strap to the Rear of the Chassis 5-6

FIGURE 5-3 Attaching the Antistatic Wrist Strap to the Front of the Chassis 5-7

FIGURE 5-4 Top Access Cover 5-8

FIGURE 5-5 Front Fascia and Filters 5-10

FIGURE 6-1 Power Supply Unit 6-2

FIGURE 6-2 Power Distribution Board 6-4

FIGURE 6-3 System Switch and LED Assembly 6-9

FIGURE 7-1 Netra T4 System Fans 7-2

FIGURE 7-2 PSU Fans Assembly 7-3

FIGURE 7-3 CPU Fan 7-6

xi

FIGURE 7-4 Fan Connectors 7-8

FIGURE 8-1 FC-AL Disk Drive and Drive Bay Assembly 8-2

FIGURE 8-2 FC-AL Backplane and Drive Bay Assembly 8-7

FIGURE 8-3 Removable Media Modules 8-10

FIGURE 9-1 PCI Card Slots 9-2

FIGURE 9-2 CPU Modules 9-5

FIGURE 9-3 Using the Torque Tool 9-8

FIGURE 9-4 Memory Modules 9-10

FIGURE 9-5 Memory Banks 9-12

FIGURE 9-6 Battery Location 9-13

FIGURE 9-7 LOMlite2 Card 9-14

FIGURE 9-8 System Configuration Card Reader 9-16

FIGURE 9-9 Motherboard Layout 9-19

FIGURE 9-10 Motherboard Fixing Screws 9-21

FIGURE 9-11 Removing the Motherboard from the Chassis 9-22

FIGURE 10-1 Netra T4 Logical System Diagram 10-3

FIGURE 10-2 UltraSPARC-III Processor Functional Block Diagram 10-4

FIGURE 10-3 I/O Logical Diagram 10-5

FIGURE 10-4 Memory Subsystem 10-6

FIGURE 10-5 Main Memory Functional Block Diagram 10-8

FIGURE 10-6 DIMM Mapping 10-9

FIGURE 10-7 SBC Block Diagram 10-12

FIGURE 10-8 PCIO-2 Block Diagram 10-14

FIGURE 10-9 Ebus 10-16

FIGURE 10-10 System Interrupt Block Diagram 10-17

FIGURE 10-11 Netra T4 Boot Bus 10-18

FIGURE 10-12 I2C Bus 10-21

FIGURE 10-13 USB and Parallel Port Functional Block Diagram 10-26

xii Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

FIGURE 10-14 Serial Port Functional Block Diagram 10-28

FIGURE 10-15 LOMlite2 Serial Port Functionality 10-30

FIGURE 10-16 FC-AL Disk subsystem 10-33

FIGURE 10-17 Configuration for the SCSI Bus 10-34

FIGURE 10-18 System Motherboard Block Diagram 10-38

FIGURE 10-19 Selected Jumper Settings 10-41

FIGURE 10-20 Identifying Jumper Pins 10-41

FIGURE 10-21 Flash PROM Jumper Locations 10-42

FIGURE 11-1 Back Panel Connectors (AC100 Shown) 11-1

FIGURE 11-2 DB-25 Parallel Connector 11-2

FIGURE 11-3 DB-25 Serial Connectors 11-3

FIGURE 11-4 68-Pin SCSI Connector 11-4

FIGURE 11-5 Connecting External Mass Storage Devices 11-8

FIGURE 11-6 RJ45 TPE Socket 11-8

FIGURE 11-7 FC-AL Connector 11-9

FIGURE 11-8 Twin Series A USB Connector 11-10

FIGURE 11-9 DB-15 (Male) Alarms Service Port Connector 11-11

FIGURE 11-10 RJ45 Lights Out Management Serial Connector 11-12

FIGURE A-1 Exploded View of the Netra T4 System Unit A-2

FIGURE D-1 Smart Card Reader Connector, J3604, Pin Assignments D-1

FIGURE D-2 Internal FC-AL Connector, J2901 D-4

FIGURE D-3 Power Supply Connector J3603 D-6

FIGURE D-4 Power Supply Connector J3601 D-7

Figures xiii

xiv Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

Tables

TABLE 1-1 Front Panel System LED Functions 1-7

TABLE 1-2 LOMlite2 Status LED Functions 1-8

TABLE 1-3 PSU Status LED Functions 1-10

TABLE 1-4 PSU Status LED Functions (Netra T4 DC100) 1-11

TABLE 2-1 POST Completion Times 2-5

TABLE 3-1 New SunVTS Commands 3-4

TABLE 3-2 SunVTS Processor Tests 3-6

TABLE 3-3 SunVTS Memory Tests 3-7

TABLE 3-4 SunVTS Storage Device Tests 3-7

TABLE 3-5 SunVTS Network Tests 3-7

TABLE 3-6 SunVTS Communications Port Tests 3-7

TABLE 3-7 SunVTS Custom Test 3-8

TABLE 4-1 Internal Drives Identification 4-3

TABLE 4-2 J3601 Voltage-Pin Table 4-7

TABLE 4-3 J3603 Voltage-Pin Table 4-7

TABLE 4-4 probe and test Commands 4-10

TABLE 4-5 Selected OpenBoot PROM On-Board Diagnostic Tests 4-12

TABLE 4-6 Parent Node Names 4-15

TABLE 4-7 Child Node Names 4-17

xv

TABLE 4-8 OBDiag Configuration Variables 4-19

TABLE 4-9 Netra T4 System-Specific OBDiag Self Tests 4-20

TABLE 4-10 obdiag Help 4-24

TABLE 10-1 Valid Memory Configurations 10-9

TABLE 10-2 PCI Slot-to-PCI Bus Mapping 10-23

TABLE 10-3 Internal Hard Drive Features 10-24

TABLE 10-4 ISP2200A GPIO Bits 10-32

TABLE 10-5 AC Power Supply Output Values 10-36

TABLE 10-6 DC Power Supply Output Values 10-36

TABLE 10-7 Power Supply Control Signal Levels 10-37

TABLE 10-8 Motherboard Component Functions 10-39

TABLE 10-9 Flash PROM Jumper Settings 10-42

TABLE 11-1 Parallel Connector Pinout 11-2

TABLE 11-2 Serial Connector Pinout, RS423/RS232 11-3

TABLE 11-3 68-Pin SCSI Connector Pinout 11-4

TABLE 11-4 Determining SCSI Bus Length 11-7

TABLE 11-5 TPE Connector Pinout 11-8

TABLE 11-6 TPE STP-5 Cable Lengths 11-9

TABLE 11-7 FC-AL Connector Pinout 11-9

TABLE 11-8 USB Connector Pinout 11-10

TABLE 11-9 Alarms Service Port Connector Pinout 11-11

TABLE 11-10 Lights Out Management Serial Connector Pinout 11-12

TABLE A-1 Netra T4 Field Replaceable Units A-3

TABLE A-2 Netra T4 Optional Components A-4

TABLE B-1 AC Power Supply Input Requirements B-2

TABLE 12-1 DC Power Supply Input Requirements B-3

TABLE D-1 SCCR, J3604, Pin Assignments D-2

TABLE D-2 Internal SCSI Connector, J5002 D-3

TABLE D-3 Internal FC-AL Connector, J2901 D-4

xvi Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

TABLE D-4 Power Connectors D-5

TABLE D-5 Power Supply Connector J3603 Pin Description D-6

TABLE D-6 Power Supply Connector J3601 Pin Description D-7

TABLE G-1 LOM Serial Port Adaptor Pinouts G-1

TABLE G-2 Netra T4 Serial Port Crossover Adaptor Pinouts G-2

Tables xvii

xviii Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

Code Samples

CODE EXAMPLE 2-1 POST Test Menu 2-2

CODE EXAMPLE 2-2 POST Test Control Flags Menu 2-3

CODE EXAMPLE 2-3 Sample POST Console Error Message 2-6

CODE EXAMPLE 2-4 Sample POST Serial Port Error Message 2-6

CODE EXAMPLE 4-1 probe-scsi Diagnostic Output Message 4-10

CODE EXAMPLE 4-2 probe-scsi-all Output Message 4-11

CODE EXAMPLE 4-3 Test Output Message 4-11

CODE EXAMPLE 4-4 Watch-Clock Diagnostic Output Message 4-12

CODE EXAMPLE 4-5 watch-net Diagnostic Output Message 4-13

CODE EXAMPLE 4-6 watch-net-all Diagnostic Output Message 4-13

CODE EXAMPLE 4-7 66MHz PCI Bus Devices 4-15

CODE EXAMPLE 4-8 33MHz PCI Bus Devices 4-15

CODE EXAMPLE 4-9 Typical reset-all Screen Output 4-22

CODE EXAMPLE 4-10 obdiag Menu 4-23

CODE EXAMPLE 4-11 SUNW,lomv@0,0 Diagnostic Output Message 4-24

CODE EXAMPLE 4-12 SUNW,qlc@4 Diagnostic Output Message 4-25

CODE EXAMPLE 4-13 bbc@1,0 Diagnostic Output Message 4-25

CODE EXAMPLE 4-14 ebus@5 Diagnostic Output Message 4-25

CODE EXAMPLE 4-15 flashprom@0,0 Diagnostic Output Message 4-26

xix

CODE EXAMPLE 4-16 gpio@1,300600 Diagnostic Output Message 4-26

CODE EXAMPLE 4-17 i2c@1,2e Diagnostic Output Message with TIP Line Installed 4-26

CODE EXAMPLE 4-18 i2c@1,30 Diagnostic Output Message 4-27

CODE EXAMPLE 4-19 network@5,1 Diagnostic Output Message 4-27

CODE EXAMPLE 4-20 parallel@1,300278 Diagnostic Output Message 4-27

CODE EXAMPLE 4-21 pmc@1,300700 Diagnostic Output Message 4-28

CODE EXAMPLE 4-22 rtc@1,300070 Diagnostic Output Message 4-28

CODE EXAMPLE 4-23 scsi@6 Diagnostic Output Message 4-28

CODE EXAMPLE 4-24 scsi@6,1 Diagnostic Output Message 4-29

CODE EXAMPLE 4-25 serial@1,400000 Diagnostic Output Message 4-29

CODE EXAMPLE 4-26 usb@5,3 Diagnostic Output Message 4-29

CODE EXAMPLE 4-27 test-all Diagnostic Output Message 4-30

CODE EXAMPLE E-1 diag-level Variable Set to max E-1

CODE EXAMPLE E-2 diag-level Variable Set to min E-17

xx Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

Preface

This manual supports the Netra T4 AC100/DC100 server and comprises two parts:

■ Part I, Service, is written for technicians, advanced computer system end-users

with experience in replacing hardware and troubleshooting, system

administrators, and authorized service providers (ASPs). Only suitably qualified

service personnel may carry out tasks described in this manual that involve the

removal of the top cover.

■ Part II, System Reference, is written for OEM engineers, system designers and

application programmers who have to perform advanced tasks concerned with

the maintenance and configuration of the system.

How This Book Is Organized

Chapter 1 provides an overview of the key features of the Netra T4 server.

Chapter 2 describes the Power-On Self-Test (POST) diagnostics.

Chapter 3 contains an overview of the SunVTS Validation Test Suite.

Chapter 4 describes how to troubleshoot and correct hardware problems.

Chapter 5 discusses the precautions you should take before working on the system,

and explains how to gain access to the internal components.

Chapter 6 describes how to remove and fit the PSU and power subassemblies.

Chapter 7 describes how to remove and fit the system fans.

Chapter 8 describes how to remove and fit the system storage devices.

Chapter 9 describes how to remove and fit the motherboard and the components

that interface with it.

Chapter 10 provides a functional description of the system.

Chapter 11 provides information about the I/O connectors.

xxi

Chapter 12 describes how to connect and set up a modem.

Appendix A provides an illustrated list of replaceable parts and components.

Appendix B provides a product specification.

Appendix C contains a list of tools that are needed to service the system.

Appendix D provides details of the internal motherboard connectors.

Appendix E provides an example of a typical POST diagnostic output.

Appendix F describes how to update LOMlite2 firmware.

Appendix G describes how to connect to the Netra T4 serial ports.

Typographic Conventions

Typeface Meaning Examples

AaBbCc123 The names of commands, files,

and directories; on-screen

computer output

AaBbCc123

AaBbCc123 Book titles, new words or terms,

What you type, when

contrasted with on-screen

computer output

words to be emphasized

Command-line variable; replace

with a real name or value

Edit your.login file.

Use ls -a to list all files.

% You have mail.

% su

Password:

Read Chapter 6 in the User’s Guide.

These are called class options.

You must be superuser to do this.

To delete a file, type rm filename.

xxii Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

Shell and System Prompts

Shell Prompt

C shell machine_name%

C shell superuser machine_name#

Bourne shell and Korn shell $

Bourne shell and Korn shell superuser #

OpenBoot PROM ok

LOMlite2 lom>

1. In dual processor systems, the processor number, 0 or 1, is included; for example, {0} ok

1

Related Documentation

Application Title Part Number

Installation

User

Compliance Netra T4 AC100/DC100 Compliance and Safety Manual 806-7335-11

OpenBoot PROM OpenBoot 3.x Command Reference

Netra T4 AC100/DC100 Installation and User’s Guide 806-7334-11

806-1377-10

OpenBoot PROM Quick Reference

806-2908-10

Accessing Sun Documentation Online

A broad selection of Sun system documentation is located at:

http://www.sun.com/products-n-solutions/hardware/docs

A complete set of Solaris documentation and many other titles are located at:

http://docs.sun.com

Preface xxiii

Ordering Sun Documentation

Fatbrain.com, an Internet professional bookstore, stocks select product

documentation from Sun Microsystems, Inc.

For a list of documents and how to order them, visit the Sun Documentation Center

on Fatbrain.com at:

http://www.fatbrain.com/documentation/sun

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and

suggestions. You can email your comments to Sun at:

docfeedback@sun.com

Please include the part number (806-7336-11) of your document in the subject line of

your email.

xxiv Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

PART

I Service

CHAPTER

1

System Description

This chapter lists the main features of the Netra™ T4 AC100/DC100 server, and

describes the function of the LEDs located on the front and rear panels.

The chapter contains the following sections:

■ Section 1.1, “System Features” on page 1-1

■ Section 1.2, “System Unit Components” on page 1-5

■ Section 1.3, “Environmental Performance” on page 1-5

■ Section 1.4, “LEDs” on page 1-6

The Netra T4 server is a single or dual processor device that uses the

UltraSPARC™ III processor.

■ High performance processors

■ High performance disk, system, memory and I/O subsystems

■ High performance peripheral component interconnect (PCI) I/O

■ Rack mounting options

■ Front-to-back cooling

■ AC and DC power supply options

■ Alarms functionality for remote management

■ System configuration card

■ Hot swap disk drives

■ Visual diagnostics

■ Environmental monitoring

1.1 System Features

System unit components are housed in a 4RU rack-mounting enclosure designed to

NEBS Level 3 standards. Overall chassis dimension (width x depth x height) are

445.2mm x 508.1mm x 176.6mm (17.52in. x 20.00in. x 6.95in.). Flange mounting kits

are available for installing the system in 19-inch, 23-inch, 24-inch and 600-mm racks

(see

FIGURE 2-1). A slide adaptor kit is also available.

1-1

431.0

508.1

477.9

446.4

329.55

199.55

37.7 101.8

5.3

25.0

445.2

DIMENSION 'A'

19 in. FLANGES

23 in. FLANGES

24 in. FLANGES

600mm FLANGES

DIMENSION 'A'

470.4

470.4

561.3

595.8

518.2

361.05

231.05

56.5

176.6

5.3

FIGURE 1-1 Netra T4 System Dimensions and Mounting Options (dimensions in mm)

1-2 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

System unit electronics are contained on a single printed circuit board

(motherboard). The motherboard contains the CPU modules, memory, system

control application-specific integrated circuits (ASICs) and I/O ASICs.

A fully-configured system weighs approximately 27.3kg (60lb).

Operating Environment

■ Solaris 8 Update 4/01 and Update 7/01

Power

■ Rack mounting enclosure with one single-feed 100–240VAC power supply unit

(AC100) or one twin-feed –48VDC / –60VDC power supply unit (DC100)

Processors

■ Support for up to two 750MHz UltraSPARC III processor modules, each with

8MByte Ecache

Memory

■ Support for up to eight 128MByte-, 256Mbyte-, 512MByte- or 1GByte Next

Generation Dual Inline Memory Module (NG-DIMMS) installed in two groups of

four providing from 512MByte to 8GByte of memory

IO

■ Four PCI 2.1 compliant slots:

■ one long

■ two long

■ one short

■ One 10/100BaseT Ethernet connection

■ One Fast-Wide SCSI connection

■ Four USB connections (two twin Series A ports) @ 12Mb/s

■ One external FC-AL connection

■ Two internal FC-AL connections for hard disks

■ Two RS232/RS423 serial ports

■ One parallel port

1. Upto 312mm long

2. Upto 174.6mm long

1

64/32-bit, 66/33MHz

1

64/32-bit, 33MHz

2

64/32-bit, 33MHz

Chapter 1 System Description 1-3

■ One DB-15 LOMlite2 alarms relay port

■ One RJ45 LOMlite2 alarms serial port

System Configuration

■ I2C system configuration card reader (SCCR)

Storage

■ Up to two FC-AL 1-inch hot swap hard disks (36GByte)

■ External hardware RAID support through PCI

■ Software RAID support Sun Logical Volume Manager (SLVM)

■ Up to two removable media drives (DVD-ROM and DDS-4 DAT)

Reliability, Availability and Serviceability

■ LOMLite 2 automatic system recovery

■ Remote diagnosis via Solaris and LOMLite 2

■ Hot swap disks

■ Diagnostic LEDs

■ Environmental monitoring

■ Field Replaceable Unit (FRU) ID support

Documentation

■ Installation and User’s Guide

■ Service and System Reference Manual (this document)

■ Compliance and Safety Manual

■ Release Notes

Software Support

■ Lights Out Management 2.0 (LOMlite2)

■ SLVM (Sun Logical Volume Manager)

■ SunVTS™ 4.4 (Sun Validation Test Suite)

■ SunMC (Sun Management Center)

■ SNMP (Sun Netra SNMP Management Agent)

■ SunCluster

■ SRS/SunUP™ ready

1-4 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

PCI Card Support

■ SunSwift™

■ Fast Ethernet

■ Quad Fast Ethernet (QFE)

■ High Speed Serial Interface (HSI)

■ Serial Asynchronous Interface (SAI)

■ ATM-155

■ Dual Differential SCSI

■ Gigabit Ethernet

■ FC-AL

■ FC-AL and Gigabit Ethernet combination

■ SSL Crypto Accelerator

1.2 System Unit Components

The system unit components are listed by part number in Appendix A.

Note – The part numbers listed in Appendix A were correct when this manual was

published but they are subject to change without notice. Numerical references

illustrated in

Refer to your authorized Sun sales representative or service provider to confirm a

part number before you order a replacement part.

FIGURE A-1 correlate to the references listed in TABLE A-1 and TABLE A-2.

1.3 Environmental Performance

The principal environmental requirements are given in Section B.3, “Environmental

Specification” on page B-4.

Chapter 1 System Description 1-5

1.4 LEDs

The Netra T4 server has three sets of LEDs that show the status of the system.

1.4.1 System LEDs

The system LEDs are located behind the front fascia, immediately to the right of the

ON/STBY switch as you face the unit, as shown in

Light pipes transmit the Power, System, Alarm1, Alarm2 and Fault LEDs through

the fascia and are visible from the front of the system. To view the remaining LEDs,

you must lower the front fascia.

FIGURE 1-2.

DC SYSTEMS

ONLY

SYSTEM

ALARM 1

ALARM 2

DC-A

DC-B

HDD 0 HDD 1

SYSTEM

ALARM 1

ALARM 2

HDD 0 HDD 1

AC100 DC100

FIGURE 1-2 Front Panel System LEDs

1-6 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

The Alarm1, Alarm2, System and Fault LEDs are mirrored on the LOMlite2 card

visible from the rear of the system (see Section 1.4.2, “LOMlite 2 LEDs” on page 1-8).

TABLE1-1 Front Panel System LED Functions

LED Icon/Legend Color Function

Power Green Illuminated continuously while power is

supplied to the system.

System

1

SYSTEM Green Off (or reset) during power up procedures

and illuminated when UNIX is running and

the Alarms driver is installed. This LED is

reset by a hardware Watchdog timeout, or

whenever the user-defined Alarm3 is

asserted.

Alarm1

1

ALARM1 Amber Illuminated whenever the user-defined

Alarm1 is asserted

Alarm2

1

ALARM2 Amber Illuminated whenever the user-defined

Alarm2 is asserted

Input A OK DC-A Green Illuminated when the input voltage from

feeder A is above 37V

Off when Input A is below 35V

Not used by the AC100

Input B OK DC-B Green Illuminated when the input voltage from

feeder B is above 37V

Off when Input B is below 35V

Not used by the AC100

Fault

1

Amber Driven by the LOMlite2 module under

identified system fault conditions

Disk0 Active

Disk0 OK to

Remove

2

2

Green Illuminated when Disk0 is active

Blue Illuminated, in response to a user request,

when Disk0 can be removed safely without

affecting the system operation

Disk0 Fault

2

Amber Illuminated when the system has identified a

fault in Disk0

Chapter 1 System Description 1-7

TABLE1-1 Front Panel System LED Functions (Continued)

LED Icon/Legend Color Function

Disk1 Active

2

Green Illuminated when Disk1 is active

Disk1 OK to

Remove

Disk1 Fault

1. These LEDs are duplicated on the LOMlite2 card face plate (see Section 1.4.2, “LOMlite 2 LEDs” on page 1-8).

2. Lower the front fascia to view these LEDs.

2

2

1.4.2 LOMlite 2 LEDs

The LOMlite2 status LEDs, which mirror the alarm status and power LEDs on the

front panel, are located on the rear of the system, between the LOMlite2 DB-15

alarms relay port and RJ45 serial port as shown in

TABLE1-2

LED Icon/Legend Color Function

Alarm 1 1 Amber Illuminated when user-defined Alarm 1 is

Alarm 2 2 Amber Illuminated when user-defined Alarm 2 is

Fault Amber Driven by the LOMlite 2 card and

LOMlite2 Status LED Functions

Blue Illuminated, in response to a user request,

when disk1 can be removed safely without

affecting the system operation

Amber Illuminated when the system has identified a

fault in Disk1

FIGURE 1-3.

asserted

asserted

illuminated when a system fault condition

exists

System SYS Green Illuminated when Solaris is running and the

LOMlite2 driver is installed

Off while the system is powering up

Reset by watchdog timeout, assertion of userdefined Alarm 3

1-8 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

Alarms Service

Port

LEDs

ALARM

1

2

SYS

Warning: Power off system before removing

or replacing System Configuration Card

FIGURE 1-3 LOMLite2 Status LEDs

Serial Port

LOM SERIAL

Chapter 1 System Description 1-9

1.4.3 PSU LEDs

The PSU status LEDs are located at the left hand end of the PSU (see FIGURE 1-4).

1.4.3.1 Netra T4 AC100 System

TABLE1-3 PSU Status LED Functions

LED Icon Color Function

AC Input OK Green Illuminated when AC is present and above

PSOK Green Illuminated when output voltages are within

Fail Amber Illuminated when PSU is in a Fault condition

85VAC

operating range

Flashes when PSU is in Standby mode

Off when PSU is enabled (OK)

Flashes if unit is within 10˚C of thermal

shutdown or has shutdown

FIGURE 1-4 PSU Status LEDs (Netra T4 AC100 System)

1-10 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

1.4.3.2 Netra T4 DC100 System

TABLE1-4 PSU Status LED Functions (Netra T4 DC100)

LED Icon Color Function

Fail Amber Illuminated when PSU is in a Fault condition

PSOK Green Illuminated when output voltages are within

Input B OK B Green Illuminated when input voltage from feeder

Input A OK A Green Illuminated when input voltage from feeder

Off when PSU is not enabled (OK)

Flashes if unit is within 10˚C of thermal

shutdown or has shutdown

operating range

Flashes when PSU is in Standby mode

B is above 37V

Off when Input B is below 35V

A is above 37V

Off when Input A is below 35V

FIGURE 1-5 PSU Status LEDs (Netra T4 DC100 System)

Chapter 1 System Description 1-11

1-12 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

CHAPTER

2

Power-On Self Test

This chapter describes how to initiate power-on self test (POST) diagnostics.

The chapter contains the following topics:

■ Section 2.1, “POST Overview” on page 2-1

■ Section 2.2, “Pre-POST Preparation” on page 2-3

■ Section 2.3, “Running POST” on page 2-4

■ Section 2.4, “POST Diagnostic Levels” on page 2-4

2.1 POST Overview

POST is a firmware program that is useful in determining if a portion of the system

has failed. POST verifies the core functionality of the system, including the CPU

module(s), motherboard, memory, and some on-board I/O devices, and generates

messages that can be useful in determining the nature of a hardware failure. POST

can be run even if the system is unable to boot.

POST detects most system faults and is located in the motherboard OpenBoot™

PROM. POST can be set to run by the OpenBoot program at power up by setting two

environment variables, the diag-switch? and the diag-level flag, which are

stored on the System Configuration Card.

POST diagnostic and error message reports are displayed on a console.

2-1

2.1.1 How to Use POST

POST runs automatically when the system power is applied, and following an

automatic system reset if both of the following conditions apply:

■ diag-switch? is set to true (default is false)

■ diag-level is set to min, max or menus (default is min)

If diag-level is set to min or max, POST performs an abbreviated or extended test,

respectively (see Section 2.4, “POST Diagnostic Levels” on page 2-4).

If diag-level is set to menus, a menu of all the tests executed at power up is

displayed (

CODE EXAMPLE 2-1 POST Test Menu

{0}* Xcall Test

{0}Sending Cross Calls to CPU AID 1

{0} 0 Return

{0} 1 Run all Tests in this Menu

{0} 2 Change Test Control Flags

{0} 3 * Reset Menu

{0} 4 * CPU Tests

{0} 5 * Ecache Tests

{0} 6 * Memory Tests

{0} 7 * Schizo Tests

{0} 8 * RIO Tests

{0} 9 * Estar Test (UP only)

{0} a * ECC Tests

{0} b * MP Tests

{0} c * BIST

{0} d * System Frequency and CPU Ratio

{0} e * I2C/Fan/Temperature/Smart card

{0} f * Run POST

{0} 10 * Return to OBP

{0}Selection

CODE EXAMPLE 2-1):

2-2 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

Selection 2 enables you to change the test control flags (CODE EXAMPLE 2-2):

CODE EXAMPLE 2-2 POST Test Control Flags Menu

{0}Selection:2

{0} 0 Return

{0} 1 Run all Tests in this Menu

{0} 2 Change Test Control Flags

{0} 3 * Toggle Trace Flag - c

{0} 4 * Toggle Loop-a-test flag - l

{0} 5 * Toggle Loop-on-error flag - e

{0} 6 * Toggle Print-all-error flag - p

{0} 7 * Display current state of all flags

{0} 8 * Help on Test Flags

{0}Selection:

Note – If diag-switch = false, POST is disabled. If diag-switch = true and

diag-level = max, POST runs in max mode. If diag-switch = true and

diag-level = min, POST runs in min mode.

To run POST, power cycle the system.

2.2 Pre-POST Preparation

1. Connect a terminal to the LOM serial port on the Netra T4 server to view POST

progress and error messages. See Section G.1, “Connecting to the LOM Serial

Port” on page G-1.

Note – By default, the input and output device is the LOM serial port. To direct

POST output to ttya or ttyb, set both input-device and output-device to ttya

or ttyb:

2. Set the diag-switch? and diag-out-console configuration variables to true:

ok setver diag-switch? true

ok setver diag-out-console true

Chapter 2 Power-On Self Test 2-3

Alternatively, from the shell prompt:

# eeprom diag-switch?=true

# eeprom diag-out-console=true

3. Set the diag-level configuration variable to max or min (see Section 2.4, “POST

Diagnostic Levels” on page 2-4).

ok setenv diag-level

or

# eeprom diag-level=

Note – The default value is min.

value

value

2.3 Running POST

To run POST:

● Initiate POST using one of the following methods:

a. Briefly press the power ON/STBY switch to power cycle the system.

b. At the LOM prompt, type

poweroff followed by poweron.

2.4 POST Diagnostic Levels

Two levels of POST are available: maximum ( max) level and minimum (min) level.

The system initiates the selected level of POST based on the setting of diag-level,

a configuration variable.

2-4 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

The time required to complete POST depends on the CPU configuration and the

amount of installed memory. The following table lists the approximate time required

to complete the POST for single and dual processor systems with varying memory

installed, for diag-level variable settings of max and min.

TABLE2-1 POST Completion Times

CPU and Memory max setting min setting

2P, 4GByte 8 minutes 5 minutes

2P, 1GByte 4 minutes 6 minutes

1P, 2GByte 4 minutes 7 minutes

1P, 512MByte 3 minutes 5 minutes

The default value for diag-level is min.

2.4.1 diag-level Variable Set to max

When the diag-level variable is set to max, POST enables an extended set of

diagnostic-level tests. See

CODE EXAMPLE E-1 in Appendix E provides an example of the POST output from a

system with two 750MHz CPUs and 4Gbyte of memory, and with the diag-level

variable set to max.

TABLE 2-1 for approximate completion times.

2.4.2 diag-level Variable Set to min

When the diag-level variable is set to min, POST enables an abbreviated set of

diagnostic-level tests. See

CODE EXAMPLE E-2 in Appendix E provides an example of the POST output from a

system with two 750MHz CPUs and 4Gbyte of memory, and with the diag-level

variable set to min.

TABLE 2-1 for approximate completion times.

Chapter 2 Power-On Self Test 2-5

2.4.3 Error Messages

CODE EXAMPLE 2-3 shows a sample error message at the console:

CODE EXAMPLE 2-3 Sample POST Console Error Message

Power On Self Test Failed.

Cause: DIMM J0406 or System Board

ok

CODE EXAMPLE 2-4 shows a sample error message at the serial port.

CODE EXAMPLE 2-4 Sample POST Serial Port Error Message

{0} ERROR: TEST=*Memory Initial area TESTID=2

{0} H/W under test=*MAIN MEMORY

{0} Fault address 00000000.00000010

{0} Fault status 00000002.0000004f

{0} (CE) Correctable system data ECC error

{0} CPU data bit 6

{0} Memory data bit 146

{0} DIMM connector J0406

{0} Connector pin 124

{0} CPMS slice 124

2-6 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

CHAPTER

3

SunVTS

This chapter contains an overview of the Sun Validation Test Suite 4.4 (SunVTS™)

diagnostic tool. You can use SunVTS to validate a system when troubleshooting and

during periodic maintenance.

This chapter contains the following topics:

■ Section 3.1, “The Validation Test Suite” on page 3-1

■ Section 3.1.1, “SunVTS Requirements” on page 3-2

■ Section 3.1.2, “SunVTS References” on page 3-2

■ Section 3.1.3, “Installation” on page 3-3

■ Section 3.1.4, “New and Modified Features and Options” on page 3-3

■ Section 3.2, “SunVTS Tests” on page 3-6

3.1 The Validation Test Suite

SunVTS Version 4.4 is the Sun online Validation Test Suite supplied with the

Netra T4 system.

SunVTS is a comprehensive software diagnostic package that tests and validates

hardware by verifying the connectivity and functionality of most hardware

controllers, devices, and platforms.

SunVTS can be tailored to run on various types of systems ranging from desktops to

servers and has many features that you can customize to meet the varying

requirements of differing diagnostic situations.

3-1

SunVTS executes multiple diagnostic tests from a graphical user interface (GUI) or

TTY interface that provide test configuration and status monitoring.

The SunVTS interface can run on one system to display the SunVTS test session of

another system on the network.

SunVTS is distributed with each Solaris release. It is located on the Sun Computer

Systems Supplemental CD.

3.1.1 SunVTS Requirements

Your system must meet the following requirements to run SunVTS:

■ The SunVTS packages must be installed. The main package is SUNWvts. There

are additional supporting packages that differ with the revision of the Solaris

operating system that is installed. See also Section 3.1.3, “Installation” on

page 3-3 and the corresponding SunVTS documentation.

■ The system must be booted to the multiuser level (level 3).

■ To run SunVTS with a GUI (CDE or Open Look), that GUI must be installed.

Otherwise, run SunVTS with the TTY-mode interface.

3.1.2 SunVTS References

To find out more information about the using SunVTS, refer to the SunVTS

documentation for the Solaris release that you are running.

The SunVTS documents are part of the Solaris on Sun Hardware AnswerBook

collection. This AnswerBook collection is pre installed on the hard disk of new

systems. It is also distributed on the Software Supplemental CD that is part of each

Solaris Media Kit release and is also accessible at http://docs.sun.com.

TM

The following list describes the contents of each SunVTS document:

■ SunVTS User’s Guide describes how to install, configure, and run the SunVTS

diagnostic software.

■ SunVTS Test Reference Manual provides details about each individual SunVTS

test.

■ SunVTS Programmer’s Guide supports the development of custom tests.

3-2 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

3.1.3 Installation

The SunVTS 4.4 software comprises four installation packages:

■ SUNWvts—SunVTS kernel, user interface and tests

■ SUNWvtsx—SunVTS 64-bit package

■ SUNWvtsol—SunVTS user interface

■ SUNWvtsmn—SunVTS man pages

For details of the installation procedure, refer to the Netra T4 AC100/DC100

Installation and User’s Guide.

3.1.4 New and Modified Features and Options

The following additions have been made to support the Netra T4 system:

■ Tests have been included for the new components of the hardware platform.

■ Remote features enable you to interface to SunVTS from a remote system.

■ Multiple user interfaces can monitor and run tests concurrently.

■ A test scheduler enables you to specify groups of tests to be conducted in a

predefined order. Tests in a group are executed concurrently so that all tests in

one group complete before the tests in another group begin.

■ A new SunVTS message format displays the information re-ordered and labeled:

<timestamp> <hostname> “SunVTS:”[VTSID <vts msgid>]

<modulename> [.<submodulename>] [.<insttnum>].<vts_msgtype>]

[<device_pathname>:] <msg_txt>

08/05/01 17:19:47 vrij SunVTS: VTSID 34 disktest.VERBOSE c0t0d0:

“number of blocks 3629760”

Chapter 3 SunVTS 3-3

3.1.4.1 New and Modified Tests and Commands

The following commands have been added to this release of SunVTS.

TABLE3-1 New SunVTS Commands

Command Function

testadd Adds a test’s resource object files to the SunVTS shared object

library (contained in the SUNWvtstk package)

testrm Removes a test’s resource object file from the SunVTS shared object

library (contained in the SUNWvtstk package)

testinfo Lists all the resource object files from the SunVTS shared object

library (contained in the SUNWvtstk package)

vts_cmd Enables direct control of SunVTS from your program or scripts on a

remote machine

connect Enables a user interface to connect to a SunVTS kernel on any

system on a network

trace System call tracing that assists in tracing test flows through the

system interfaces

Record/Replay Enables test sequences and forks to be recorded and replayed to

improve failure reproducibility

Reprobe Searches and recompiles (reprobes) the system’s configuration on

demand

Note – To add a third party test executable binary, add the test to

/opt/SUNWvts/bin/sparcv9, then modify the

/opt/SUNWvts/bin/sparc9/.customtest file.

3-4 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

The commands are shown in the SunVTS GUI menus (FIGURE 3-1):

SunVTS Diagnostic

Commands View

Options

Reports DSched

Open System Map

Close System Map

Start Testing

Stop Testing

Reset

Start T est

Start Test with record

Replay

Suspend

Resume

Connect to host

Trace Test

Reprobe system

Performance meter

Exit SunVST

FIGURE 3-1 SunVTS Menu Bar

UI and kernel

UI only

kernel only

3.1.5 Starting SunVTS

You can start SunVTS in one of four modes, depending on whether you are

executing locally or remotely, on a CDE GUI, OpenLook GUI, or in TTY mode:

■ To run SunVTS kernel and default GUI on the local system, type:

System configuration

Log Files

Thresholds

Notify

Schedules

Test Execution

Advanced

Option Files

Start DS

Show DS

Quit Options

Quit DS UI only

Quit DS

# cd /opt/SUNWvts/bin

# ./sunvts

■ To run SunVTS kernel and OpenLook GUI on the local system, type:

# cd /opt/SUNWvts/bin

# ./sunvts -l

Chapter 3 SunVTS 3-5

■ To run SunVTS kernel in TTY mode on the local system, type:

# cd /opt/SUNWvts/bin

# ./sunvts -t

■ To connect and test a remote system, hostname, but display the GUI on the local

host, type:

# cd /opt/SUNWvts/bin

# ./sunvts -h

Note – The latest SunVTS features may not be supported by the SunVTS OpenLook

GUI.

3.2 SunVTS Tests

This section lists the tests available in SunVTS 4.4. Some tests have been modified

and new tests have been added to support the Netra T4 hardware platform.

TABLE3-2 SunVTS Processor Tests

Test Function

cputest This new test checks the specific functionality of the SPARC

processor data path, including:

■ g0 register functionality

■ Compress/Uncompress/Compare command

Legacy Tests These include:

■ systest—tests the I/O, memory and CPU channels

■ fputest—tests the floating point unit

■ mptest—tests two or more processors by having them access a

shared memory page

3-6 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

TABLE3-3 SunVTS Memory Tests

Test Function

Legacy Tests These include:

■ pmemtest—tests the physical memory by targeting parity, ECC,

memory read, and addressing problems

■ vmemtest—tests the virtual memory and the swap partitions of

the disks

TABLE3-4 SunVTS Storage Device Tests

Test Function

dvdtest This new test checks the DVD-R drive by reading the DVD.

qlctest This new test checks the ISP2200A FC-AL controller. The sub tests

include:

■ Revision checks

■ Internal loopback tests

■ External loopback tests (require external loopback cable)

Legacy Tests These include:

■ cdtest—tests the CD-ROM drive by reading the CD

■ tapetest—tests tape devices by writing, reading and verifying

synchronous and asynchronous data blocks

TABLE3-5 SunVTS Network Tests

Test Function

netlbtest This new test checks the ERI and GEM Ethernet controllers by

performing internal and external loopback tests (replaces gemtest).

nettest This system-to-system legacy test covers all networking devices

found in the system.

TABLE3-6 SunVTS Communications Port Tests

Test Function

usbkbtest This new test covers the keyboard and mouse.

Legacy Tests These include:

■ sptest—tests the serial sync. and async. ports

■ ecpptest—tests the parallel ports

Chapter 3 SunVTS 3-7

TABLE3-7 SunVTS Custom Test

Test Function

cpupmtest This new test checks the CPU power management functionality.

Note – Test failures occur if you run nettest and netlbtest simultaneously.

3.2.1 Guide to Using SunVTS 4.4

The following guidance notes points are included to help you use SunVTS 4.4.

■ The packages SUNWeswsa, SUNWsycfd, SUNWesnta and SUNWeswgn are no

longer required or supplied for physical mapping support.

■ The disktest probe does not premount any partitions by default. You can set the

environment variable BYPASS_FS_PROBE to zero to force all unmounted

partitions to premount.

■ Premounting will not take place, even if you have enabled it, if the disktest probe

detects the presence of Veritas or Solstice DiskSuite.

■ If you run a media subtest on a disk partition in WriteRead mode, data corruption

can occur if the partition is shared with other programs.

■ An option file created when BYPASS_FS_PROBE was set to 0 may not load when

BYPASS_FS_PROBE is set to 1. If required, create option files for both states of

BYPASS_FS_PROBE

■ SunVTS (Kerebos SEAM) security is now on by default. To turn security off, edit

the security file /opt/SUNvts/bin/.sunvts to include a “+” in the HOST

section. This will make all the listed hosts trusted hosts.

■ Physical mapping is supported only on systems that support configd.

■ Do not mix CDE and OpenLook environments.

■ The files .customtest and .customtest_OtherDevices are separate files in

the 64-bit version of SunVTS. They are installed in /opt/SUNWvts/bin/spacv9,

and not /opt/SUNWvts/bin as is the case for the 32-bit version.

■ The environment variable VTS_PM_PATH is used to locate the pix map files when

SunVTS is not installed in the default base directory (/opt).

■ The following tests have been renamed:

■ spif -> spiftest

■ pmem -> pmemtest

■ vmem -> vmemtest

■ The following tests are not supported in 64-bit mode:

■ cg14test

■ isdntest

■ tcxtest

■ The physical map view displays only one level of the hierarchy. To view the

complete hierarchy, use the logical view.

3-8 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

CHAPTER

4

Troubleshooting

This chapter describes how to troubleshoot possible hardware problems and

suggests corrective actions.

This chapter contains the following topics:

■ Section 4.1, “Power-On Failure” on page 4-2

■ Section 4.2, “System LEDs” on page 4-2

■ Section 4.3, “Drive Failure” on page 4-2

■ Section 4.4, “Power Supply Unit Troubleshooting” on page 4-4

■ Section 4.5, “OpenBoot PROM Diagnostics” on page 4-7

■ Section 4.6, “OpenBoot Emergency Procedures” on page 4-30

Caution – Regardless of the position of the ON/STBY switch, when an AC power

cord remains connected to the system, hazardous voltage is always present within

the power supply.

Caution – Wear an antistatic wrist strap and use an ESD-protected mat when

!

!

handling components. When servicing or removing system unit components, use an

antistatic wrist strap with a 10mm press stud connection and attach the antistatic

wrist strap to the press stud at the rear or front of the chassis before removing the

top access cover.

Caution – Owing to the weight of the unit, two persons are required to remove the

unit from and replace it in the rack.

4-1

4.1 Power-On Failure

This section provides examples of power-on failure symptoms and suggested

actions.

Symptom

The system does not power up when you press the ON/STBY switch.

Action

■ Ensure that a PSU is installed and properly seated. Check that the three PSU

fixing screws have been tightened.

■ Ensure that the AC power cord is properly connected to the system and to the

wall socket. Verify that the wall socket is supplying AC power to the system.

■ Press the ON/STBY switch. If the system does not power on, the CPU module(s)

may not be properly seated. Inspect the CPU module(s) for proper seating, and

press the ON/STBY switch again.

■ If the AC power wall socket is live and the CPU module(s) are properly seated,

but the system does not power on, the PSU may be defective. Check the status of

the PSU LEDs and see Section 4.4, “Power Supply Unit Troubleshooting” on

page 4-4.

4.2 System LEDs

The system LEDs located on the front and rear system panels provide information

about the status of the system and many of its subsystems. Refer to Section 1.4,

“LEDs” on page 1-6 for a description of their function.

4.3 Drive Failure

This section provides hard drive, DVD-ROM and DAT drive failure symptoms and

suggested actions.

4-2 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

Symptom

A hard drive read, write, or parity error is reported by the operating environment or

customer application.

A DVD-ROM or DAT drive read error or parity error is reported by the operating

environment or customer application.

Action

Replace the drive indicated by the failure message. The operating environment

identifies the internal drives, as listed in the following table.

TABLE4-1 Internal Drives Identification

Operating Environment Address Drive Physical Location and Target

c1t1d0s# Left hard drive, LiD/HA 1

c1t2d0s# Right hard drive, LiD/HA 2

c0t6d0s# DVD-ROM drive, target 6 (optional)

c0t5d0s# DAT drive, target 5 (optional)

Note – The # symbol in the operating environment address examples is a numeral

between 0 and 7 that describes the slice or partition on the drive.

Symptom

The DVD-ROM drive fails to respond to commands.

Action

Test the drive response to the probe-scsi command as follows.

Note – To bypass POST, type setenv diag-switch? false at the ok prompt.

Chapter 4 Troubleshooting 4-3

At the OBP ok prompt, type:

ok reset-all

ok probe-scsi-all

If the DVD-ROM drive responds correctly to probe-scsi-all, the message

identified in

successfully probed the device. This is an indication that the motherboard is

operating correctly. If the drive does not respond to the SCSI controller probe,

replace the unresponsive drive.

CODE EXAMPLE 4-2 is displayed; the system SCSI controller has

4.4 Power Supply Unit Troubleshooting

Caution – During the power supply voltage measurement checks, an operational

load must be on the power supply. Ensure that the power supply cables remain

connected to the motherboard.

The section describes how to use a digital volt meter (DVM) to test the power supply

under operational load. See the figures and tables in this section to identify the J3601

and J3603 power connectors.

1. Power off the system and remove the top access panel.

See Chapter 5 for details.

Caution – Use proper ESD grounding techniques when handling components. Wear

an antistatic wrist strap and use an ESD-protected mat. Store ESD-sensitive

components in antistatic bags before placing them on any surface. See Section 5.5,

“Antistatic Precautions” on page 5-5.

Caution – Hazardous voltages are present. To reduce the risk of electrical shock and

danger to personal health, follow the instructions.

2. Check the continuity of the power cables between the PDB and motherboard.

3. Ensure that the PSU is correctly located in the chassis and that the fixing screws

are fully tightened.

4-4 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

4. Check the PSU LEDs (see Section 1.4.3, “PSU LEDs” on page 1-10) to verify the

status of the PSU.

5. Check that the power cable connectors are properly seated at the PDB and motherboard.

6. Power on the system.

7. Using a DVM, check the power supply output voltages.

See

FIGURE 4-1 for the power supply connector location on the motherboard.

Note – All power supply connectors being tested must remain connected to the

motherboard and PDB.

a. With the negative probe of the DVM placed on a connector ground (GND) pin,

position the positive probe on each power pin.

b. Verify voltage and signal availability as listed in the voltage-pin tables.

8. If any power pin signal is not present with the power supply active, and the

power cables between the PDB and motherboard properly connected, replace the

power supply.

Chapter 4 Troubleshooting 4-5

J2001

SCSI port

J2202

J3001

SCSI ports

J3002

J5301

Enet

FC-AL

J2902

J3603

14

7

8

1

7

14

10

5

J3601

J3608

6

1

2

10

J3603J3604

9

1

1

8

J0407

J0406

J0405

J0404

J0403

J0402

J0401

J3608

J2104

J0407

J0406

J0405

J0404

J0403

J0402

J0401

J0400

J3603

A, B

1

0

1

0

1

0

1

0

CPU

slot 0

J0501

CPU

slot 1

J0701

J2103

33 MHz PCI 4 J2601

LOMLite 2J3501

33 MHz PCI 3 J2501

33 MHz PCI 2 J2401

33/66 MHz PCI 1 J2301

J0601

J0801

Battery

J5002

SEEPROMSEEPROM

J3603J3604

J3601J3601

J2901

J3602

FIGURE 4-1 Power Supply Connector Jack Location

4-6 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

TABLE4-2 J3601 Voltage-Pin Table

Pin Voltage Pin Voltage

10V8+5V

2 -12V 9 n/a

30V10+5V

4 0V 11 +3.3V

5 0V 12 +12V

6 0V 13 +12V

7 n/a 14 +5V

TABLE4-3 J3603 Voltage-Pin Table

Pin Voltage Pin Voltage

1 +3.3V 8 0V

2 +3.3V 9 0V

3 +3.3V 10 0 V

4 +3.3V 11 0 V

5+5V120V

6+5V130V

7+5V140V

4.5 OpenBoot PROM Diagnostics

The following sections describe the OpenBoot PROM diagnostics. To execute the

OpenBoot PROM on-board diagnostics, the system must be at the ok prompt.

■ Section 4.5.1, “New Features” on page 4-8

■ Section 4.5.2, “New and Modified Commands and Tests” on page 4-10

■ Section 4.5.3, “Device Tree” on page 4-14

■ Section 4.5.4, “Running the Diagnostics” on page 4-18

Chapter 4 Troubleshooting 4-7

4.5.1 New Features

This section summarizes the features supported in OpenBoot 4.2 that are not covered

in the OpenBoot 3.x Command Reference Manual (part no. 806-1377-10) and the

OpenBoot 3.x Quick Reference (part no. 806-2908-10).

■ Universal Serial Bus (USB)

■ FC-AL drive support

■ New device driver support for:

■ PCI prober

■ I2C

■ USB

■ NVRAM

■ FC-AL

■ ERI

■ Safari Giga Plane Two (gptwo) support

■ Autoconfiguration

■ Flash PROM (2MByte) divided into quadrants

■ Quadrant 0—Sun Blade™ 1000 OBP—Start address 0

■ Quadrant 1—Sun Fire™ E280R OBP/Netra T4 OBP—Start address 512k

■ Quadrant 2—POST (shared)—Start address 1.0M

■ Quadrant 3—OBDiag (shared)—Start address 1.5M

■ Flash updates replace two quadrants at a time

■ Quadrant 0 and 1

■ Quadrant 2 and 3

■ Support for:

■ Stop-A

■ Stop-A on ttya (#)

■ Stop-N (emulated by lom> bootmode reset_nvram))

■ Stop-F (emulated by lom> bootmode forth)

■ Stop-D (emulated by lom> bootmode diag)

PCI Buses

Two PCI buses are implemented that are fully independent in terms of address and

data paths, channel engines, gptwo memory physical address space, I/O physical

address space and configuration space. As the device space is not shared between

the two PCI buses, you must access the specific PCI node to view its properties.

4-8 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

Flash PROM

The flash PROM is divided into quadrants that are dedicated to Sun Blade 1000 OBP,

Sun Fire E280R OBP/Netra T4 OBP, POST and OBDiag, respectively. A flash update

involves two quadrants, either 0 and 1, or 2 and 3. You can download the quadrants

from a standalone utility, bootable DVD-ROM, or from the network. The updates are

available in binary or UNIX shell formats.

During a flash PROM update, the OBP firmware overwrites the upper half of PROM

(where POST resides), keeping the original OBP unchanged. After the new OBP is

tested successfully, the original OBP is overwritten with the new OBP. Finally, after

the OBP is tested again, POST is reloaded into the upper half of PROM.

OBP Prompt

On dual processor systems, the OBP prompt includes the CPU number:

{0} ok

Resets

When the system is first powered up, the configuration is determined using

information stored in the motherboard and CPU EEPROMS (CPU speed, memory

configuration, and so forth) and is saved in the BootBus Controller (BBC) SRAM.

This is termed a Configuration Reset. Subsequent system power cycles generate a

configuration reset.

A Soft Reset occurs on subsequent system resets, which uses the BBC’s SRAM

configuration information. To avoid booting with corrupted configuration

information, a checksum is performed on the data. If the data is found to be corrupt,

the subsequent reset reverts to a configuration reset.

Chapter 4 Troubleshooting 4-9

4.5.2 New and Modified Commands and Tests

The probe and test commands have been modified to include FC-AL and USB

keyboard and mouse, respectively:

TABLE4-4 probe and test Commands

Command New Features

probe-scsi Identifies the devices attached to the FC-AL buses

probe-scsi-all Identifies all devices attached to all SCSI and FC-AL buses

test-all Includes all tests

4.5.2.1 probe-scsi and probe-scsi-all

The probe-scsi diagnostic transmits an inquiry command to internal and external

FC-AL and SCSI devices connected to the system on-board SCSI or FC-AL interface.

If the SCSI device is connected and active, the target address, unit number, device

type, and manufacturer name are displayed.

The probe-scsi-all diagnostic transmits an inquiry command to all devices

connected to the system. The first identifier listed in the display is the SCSI host

adapter address in the system device tree followed by the SCSI device identification

data.

Initiate the probe-scsi diagnostic by typing the probe-scsi command at the ok

prompt and initiate the probe-scsi-all diagnostic by typing the probe-scsi-

all command at the ok prompt.

To perform a probe command, at the ok prompt, ensure that autoboot? is set to

false, then perform a reset-all.

The following code examples identify the probe-scsi and the probe-scsi-all

diagnostic output messages.

CODE EXAMPLE 4-1 probe-scsi Diagnostic Output Message

ok probe-scsi

LiD HA --- Port WWN --- ---- Disk description ---1 1 210000203700ca78 SEAGATE ST39103FCSUN9.0G01479916021084

3 3 210000203708ad4d SEAGATE ST39102FCSUN9.0G09299906F45038

ok

4-10 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

CODE EXAMPLE 4-2 probe-scsi-all Output Message

ok probe-scsi-all

/pci@8,600000/SUNW,glc@4

LiD HA --- Port WWN --- ---- Disk description ---3 3 210000203708ad4d SEAGATE ST39102FCSUN9.0G09299906F45038

1 1 210000203700ca78 SEAGATE ST39103FCSUN9.0G01479916021084

/pci@8,700000/scsi@6,1

Target 0

Unit 0 Disk SEAGATE ST39173W SUN9.0G2815

/pci@8,700000/scsi@6

Target 6

Unit 0 Removable Read Only device TOSHIBA DVD-ROM SD-M12011B08

ok

4.5.2.2 test alias name, device path, -all

The test diagnostic, combined with a device alias or device path, enables a device

self-test program. If a device has no self-test program, the message

No selftest method for device name is displayed. To enable the self-test

program for a device, type the test command, followed by the device alias or

device path name.

The following code example identifies the test output message.

TABLE 4-5 lists test

alias name selections, their descriptions, and their required preparation.

CODE EXAMPLE 4-3 Test Output Message

ok test net

Testing net

Chapter 4 Troubleshooting 4-11

TABLE4-5 Selected OpenBoot PROM On-Board Diagnostic Tests

Type of Test Description Preparation

test net Performs internal/external loopback

test of the system auto-selected

Ethernet interface.

test-all Sequentially tests system-configured

devices containing selftest.

4.5.2.3 watch-clock

The watch-clock diagnostic displays the result as a seconds counter. During

normal operation, the seconds counter repeatedly increments from 0 to 59. Initialize

the watch-clock diagnostic by typing the watch-clock command at the ok

prompt.

The following code example identifies the watch-clock diagnostic output message.

CODE EXAMPLE 4-4 Watch-Clock Diagnostic Output Message

An Ethernet cable must be

attached to the system and to an

Ethernet tap or hub. If the

Ethernet cable is not correctly

attached the external loopback

test will fail.

Tests are sequentially executed in

device-tree order(viewedwith the

show-devs command).

{0} ok watch-clock

Watching the ‘seconds’ register of the real time clock chip.

It should be ‘ticking’ once a second.

Type any key to stop.

4

4.5.2.4 watch-net and watch-net-all

The watch-net and watch-net-all diagnostics monitor Ethernet packets on the

Ethernet interfaces connected to the system. Good packets received by the system

are indicated by a period (.). Errors such as the framing error and the cyclic

redundancy check (CRC) error are indicated with an X and an associated error

description. Initiate the watch-net diagnostic is by typing the watch-net

command at the ok prompt and initiate the watch-net-all diagnostic by typing

the watch-net-all command at the ok prompt.

4-12 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

The following code examples identify the watch-net and the watch-net-all

output messages.

CODE EXAMPLE 4-5 watch-net Diagnostic Output Message

{0} ok watch-net

Internal loopback test -- succeeded.

Link is -- up

Looking for Ethernet Packets.

‘.’ is a Good Packet. ‘X’ is a Bad Packet.

Type any key to stop.................................

CODE EXAMPLE 4-6 watch-net-all Diagnostic Output Message

{0} ok watch-net-all

/pci@8,700000/network@5,1

Internal loopback test -- succeeded.

Link is -- up

Looking for Ethernet Packets.

‘.’ is a Good Packet. ‘X’ is a Bad Packet.

Type any key to stop.

4.5.2.5 Serial Port Protocol

The serial port protocol is now programmed as RS232 or RS423 using setenv rather

than by changing a jumper setting.

To change the serial ports to RS232, type:

ok setenv ttya-mode 9600,8,n,1,-,rs232

ok setenv ttyb-mode 9600,8,n,1,-,rs232

ok setenv auto-boot? false

ok reset-all

To change the serial ports to RS423, type:

ok setenv ttya-mode 9600,8,n,1,-,rs423

ok setenv ttyb-mode 9600,8,n,1,-,rs423

ok setenv auto-boot? false

ok reset-all

Chapter 4 Troubleshooting 4-13

4.5.3 Device Tree

The device tree for the Netra T4 system is shown in FIGURE 4-2.

33 MHz PCI 66 MHz EPCI

Internal External

876E SCSI Controller

scsi @ 6 scsi @ 6.1

sd @ 0,0

st @ 4,0

sd @ 6,0 DVD-ROM

ebus@ 5

rtc @ 1,300070

parallel @ 1,300278

serial @ 1,400000:a

serial @ 1,400000:b

LOM-console @ 1,3083f8

LOM-bus @ 1,3062f8

PMC @ 1,300700

gpio @ 1,300600

st @ 0,0

network @ 5,1

RIO

i2c @ 1,2e

dimm @ 0,a0

dimm @ 0,a8

Disks

Tapes

SBC

PCI slot #1

PCI slot #2

PCI slot #3

PCI slot #4

usb @ 5,3

USB external bus

BBC

i2c @ 1.30

nvram @ 0,e0

idprom@ 0,e0

ioexp @ 0,74

hardware-monitor @ 0,56

hardware-monitor @ 0,54

hardware-monitor @ 0,52

ioexp@ 0,4c

fan-control @ 0,4e

lomlite2 @ 0,ae

power-supply @ 0,ac

pci @ 8, 600000pci @ 8, 700000

ISP2200 FC/AL Controller

SUNW,qlc @ 4

HDMP0451 FC/AL HUB

fp @ 0,8 fp @ 0,0

ssd @ w2100002037653317,0

ssd @ w2100002037653328,0

FC/AL external bus

scc-reader ' 0,a6

fcal-backplane @ 0,a4

ioexp @ 0,7a

ioexp @ 0,72

motherboard-fru @ 0,a8

fan-control @ 0,48

temperature @ 0,98

cpu-fru @ 0,a2

temperature @ 0,30

cpu-fru @ 0,a0

FIGURE 4-2 Netra T4 System Device Tree

4-14 Netra T4 AC100/DC100 Service and System Reference Manual • August 2001

The device tree comprises the Parent Node (see TABLE 4-6), the Port ID, and the PCI

Bus Module (PBM) Control Space Offset within the System Bus Controller (SBC)

address space for the parent node.

TABLE4-6 Parent Node Names

Description Child New Name Parent Comments

SCSI Bus scsi pci@8,700000 Internal SCSI (scsi@6)

External SCSI (scsi@6,1)

USB Bus usb pci@8,700000

Ethernet Bus network pci@8,700000

EBus ebus pci@8,700000

FC-AL Bus qlc pci@8,600000

The following values apply to the Netra T4 system:

■ Port ID: 8

■ PBM Control Space Offset:

■ 600000 for 66MHz PCI bus (Bus A)

■ 700000 for 33MHz PCI bus (Bus B)

CODE EXAMPLE 4-7 shows the result of running the show-devs command on the

66MHz PCI bus and

CODE EXAMPLE 4-8 on the 33MHz PCI bus.

CODE EXAMPLE 4-7 66MHz PCI Bus Devices

ok show-devs /pci@8,600000

/pci@8,600000/SUNW,qlc@4

/pci@8,600000/SUNW,qlc@4/fp@0,0

/pci@8,600000/SUNW,qlc@4/fp@0,0/disk

ok

CODE EXAMPLE 4-8 33MHz PCI Bus Devices

ok show-devs /pci@8,700000

/pci@8,700000/scsi@6,1

/pci@8,700000/scsi@6

/pci@8,700000/usb@5,3

/pci@8,700000/network@5,1

/pci@8,700000/ebus@5

/pci@8,700000/scsi@6,1/tape

/pci@8,700000/scsi@6,1/disk

/pci@8,700000/scsi@6/tape

/pci@8,700000/scsi@6/disk

/pci@8,700000/ebus@5/serial@1,400000

Chapter 4 Troubleshooting 4-15

CODE EXAMPLE 4-8 33MHz PCI Bus Devices

ok show-devs /pci@8,700000

/pci@8,700000/ebus@5/lom-console@1,3083f8

/pci@8,700000/ebus@5/lombus@1,3062f8

/pci@8,700000/ebus@5/parallel@1,300278

/pci@8,700000/ebus@5/pmc@1,300700

/pci@8,700000/ebus@5/gpio@1,300600

/pci@8,700000/ebus@5/rtc@1,300070

/pci@8,700000/ebus@5/beep@1,32

/pci@8,700000/ebus@5/i2c@1,30

/pci@8,700000/ebus@5/i2c@1,2e

/pci@8,700000/ebus@5/power@1,30002e

/pci@8,700000/ebus@5/bbc@1,0

/pci@8,700000/ebus@5/flashprom@0,0

/pci@8,700000/ebus@5/lombus@1,3062f8/SUNW,lomv@0,0

/pci@8,700000/ebus@5/i2c@1,30/nvram@0,e0

/pci@8,700000/ebus@5/i2c@1,30/idprom@0,e0

/pci@8,700000/ebus@5/i2c@1,30/ioexp@0,74

/pci@8,700000/ebus@5/i2c@1,30/hardware-monitor@0,56

/pci@8,700000/ebus@5/i2c@1,30/hardware-monitor@0,54

/pci@8,700000/ebus@5/i2c@1,30/hardware-monitor@0,52

/pci@8,700000/ebus@5/i2c@1,30/ioexp@0,4c

/pci@8,700000/ebus@5/i2c@1,30/fan-control@0,4e

/pci@8,700000/ebus@5/i2c@1,30/lomlite2@0,ae

/pci@8,700000/ebus@5/i2c@1,30/power-supply@0,ac

/pci@8,700000/ebus@5/i2c@1,30/scc-reader@0,a6

/pci@8,700000/ebus@5/i2c@1,30/fcal-backplane@0,a4

/pci@8,700000/ebus@5/i2c@1,30/ioexp@0,7a

/pci@8,700000/ebus@5/i2c@1,30/ioexp@0,72

/pci@8,700000/ebus@5/i2c@1,30/motherboard-fru@0,a8

/pci@8,700000/ebus@5/i2c@1,30/fan-control@0,48

/pci@8,700000/ebus@5/i2c@1,30/temperature@0,98

/pci@8,700000/ebus@5/i2c@1,30/cpu-fru@0,a2

/pci@8,700000/ebus@5/i2c@1,30/temperature@0,30

/pci@8,700000/ebus@5/i2c@1,30/cpu-fru@0,a0

/pci@8,700000/ebus@5/i2c@1,2e/dimm-fru@1,ae

/pci@8,700000/ebus@5/i2c@1,2e/dimm-fru@1,ac

/pci@8,700000/ebus@5/i2c@1,2e/dimm-fru@1,aa

/pci@8,700000/ebus@5/i2c@1,2e/dimm-fru@1,a8

/pci@8,700000/ebus@5/i2c@1,2e/dimm-fru@1,a6

/pci@8,700000/ebus@5/i2c@1,2e/dimm-fru@1,a4