Netra™CT Server Service Manual

For the Netra CT 810 Server and Netra CT 410 Server

Sun Microsystems, Inc.

www.sun.com

Part No. 816-2482-11

January 2004, Revision A

Submit comments about this document at: http://www.sun.com/hwdocs/feedback

Copyright 2004Sun Microsystems,Inc., 4150 Network Circle, SantaClara, California95054, U.S.A. Allrights reserved.

Sun Microsystems, Inc.has intellectual property rights relating to technologythat isdescribed in thisdocument. Inparticular, and without

limitation, theseintellectual propertyrights may include one ormore ofthe U.S. patentslisted athttp://www.sun.com/patentsand one or

more additional patents orpending patent applications in theU.S. and in other countries.

This documentand the product to which it pertainsare distributedunder licenses restricting theiruse, copying,distribution, and

decompilation. Nopart of the product or of thisdocument may be reproduced in any formby any means without priorwritten authorizationof

Sun andits licensors, if any.

Third-party software, including fonttechnology, iscopyrighted andlicensed from Sun suppliers.

Parts ofthe productmay be derived from BerkeleyBSD systems,licensed from the University ofCalifornia. UNIX is a registered trademark in

the U.S.and in other countries, exclusivelylicensed throughX/Open Company,Ltd.

Sun, SunMicrosystems, theSun logo,AnswerBook2, docs.sun.com,Netra, ChorusOS,OpenBoot, Java, and Solaris are trademarks or registered

trademarks ofSun Microsystems,Inc. in the U.S. andin other countries.

All SPARCtrademarks areused under license and are trademarksor registeredtrademarks ofSPARCInternational, Inc. inthe U.S.and in other

countries. Products bearingSPARCtrademarks arebased upon an architecture developed by SunMicrosystems, Inc.

The OPENLOOK and Sun™ Graphical UserInterface was developed by SunMicrosystems, Inc.for its users and licensees. Sun acknowledges

the pioneeringefforts ofXerox inresearching anddeveloping the concept of visualor graphical user interfaces forthe computer industry.Sun

holds anon-exclusive license from Xeroxto the Xerox GraphicalUser Interface,which license also covers Sun’slicensees who implement OPEN

LOOK GUIsand otherwise comply with Sun’swritten license agreements.

U.S. GovernmentRights—Commercial use.Government users are subject tothe SunMicrosystems, Inc. standard license agreement and

applicable provisions ofthe FAR and its supplements.

DOCUMENTATION IS PROVIDED "AS IS" AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANYIMPLIED WARRANTY OFMERCHANTABILITY,FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT,

ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright 2004Sun Microsystems,Inc., 4150 Network Circle, SantaClara, California95054, Etats-Unis. Tous droits réservés.

Sun Microsystems, Inc.a les droits de propriété intellectuels relatants à latechnologie qui est décrit dansce document. En particulier,et sans la

limitation, cesdroits depropriété intellectuelspeuvent inclure un ou plusdes brevetsaméricains énumérés à http://www.sun.com/patents et

un oules brevetsplus supplémentairesou les applicationsde breveten attente dans les Etats-Uniset dans les autres pays.

Ce produit oudocument est protégé par un copyright etdistribué avec des licences quien restreignentl’utilisation, la copie, la distribution,et la

décompilation. Aucunepartie de ce produit ou document nepeut êtrereproduite sousaucune forme, par quelque moyenque ce soit, sans

l’autorisation préalableet écrite de Sun etde ses bailleurs de licence,s’il yena.

Le logicieldétenu par des tiers, etqui comprendla technologie relative aux policesde caractères,est protégépar un copyright et licenciépar des

fournisseurs deSun.

Des partiesde ce produit pourrontêtre dérivées des systèmes BerkeleyBSD licenciés par l’Université deCalifornie. UNIX est une marque

déposée auxEtats-Unis et dans d’autres pays et licenciéeexclusivement par X/Open Company, Ltd.

Sun, SunMicrosystems, lelogo Sun, AnswerBook2, docs.sun.com, Netra,ChorusOS, OpenBoot, Java, et Solarissont des marques de fabrique

ou desmarques déposéesde Sun Microsystems, Inc. auxEtats-Unis etdans d’autres pays.

Toutes les marquesSPARCsont utilisées sous licence etsont desmarques de fabrique ou desmarques déposéesde SPARC International, Inc.

aux Etats-Uniset dans d’autres pays. Les produits protant les marquesSPARCsont basés sur une architecture développée par Sun

Microsystems, Inc.

L’interfaced’utilisation graphiqueOPEN LOOK etSun™ aété développée par Sun Microsystems,Inc. pourses utilisateurs etlicenciés. Sun

reconnaît les efforts depionniers deXerox pour la recherche et le développementdu conceptdes interfaces d’utilisationvisuelle ougraphique

pour l’industriede l’informatique. Sun détient unelicense non exclusive de Xerox surl’interface d’utilisationgraphique Xerox, cette licence

couvrant égalementles licenciéesde Sunqui mettenten placel’interface d ’utilisation graphique OPEN LOOK et qui enoutre se conforment aux

licences écritesde Sun.

LA DOCUMENTATION EST FOURNIE "EN L’ÉTAT" ET TOUTES AUTRES CONDITIONS, DECLARATIONS ET GARANTIES EXPRESSES

OU TACITES SONT FORMELLEMENT EXCLUES, DANSLA MESUREAUTORISEE PAR LA LOI APPLICABLE, YCOMPRIS NOTAMMENT

TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE UTILISATION PARTICULIERE OU A

L’ABSENCE DE CONTREFAÇON.

Contents

Part I Preparing for Service

1. Preparing for FRU Installation and Replacement 1–1

1.1 Tools Required 1–1

1.2 Attaching the Antistatic Wrist Strap 1–2

1.3 Determining If You Have a Front-Access or Rear-Access Model 1–3

1.4 Determining If You Have AC- or DC-Powered Servers and Chassis 1–4

1.5 FRU Categories 1–7

1.5.1 Hot-Swappable FRUs 1–7

1.5.2 Cold-Swappable FRUs 1–8

1.6 Device Names 1–8

1.6.1 Device Names for I/O Card Slots in the Netra CT Servers 1–8

1.6.2 Device Names for Hard Disk Drives 1–9

2. Powering the Server Off and On 2–1

2.1 Powering On the Server 2–2

2.1.1 Verifying Full Power-Up 2–5

2.2 Powering Off the Server 2–6

2.2.1 To Perform a Hardware Power-Off 2–6

2.2.2 To Perform a Software Power Off 2–7

iii

3. Handling Cards and Assemblies 3–1

3.1 Handling CompactPCI Cards 3–1

3.2 Handling Assemblies 3–2

Part II Troubleshooting the System

4. Troubleshooting the System 5–1

4.1 Troubleshooting the System Using the System Status Panel 5–2

4.1.1 Locating and Understanding the System Status Panel 5–2

4.1.2 Using the System Status Panel LEDs to Troubleshoot the System

5–3

4.2 Troubleshooting the System Using prtdiag 5–8

4.3 Troubleshooting the System Using Diagnostic Software 5–13

4.4 Troubleshooting the System Using the Power-On Self Test (POST) 5–15

4.5 Troubleshooting the System Using the Alarm Card Software 5–17

4.6 Troubleshooting a Power Supply Using the Power Supply UnitLEDs 5–17

4.6.1 Troubleshooting the Power Supply Unit in the Netra CT 410

Server 5–17

4.6.2 Troubleshooting the Power Supply Units in the Netra CT 810

Server 5–18

4.7 Troubleshooting a CPU Card 5–19

4.7.1 General Troubleshooting Tips 5–19

4.7.2 General Troubleshooting Requirements 5–21

4.7.3 Mechanical Failures 5–22

4.7.4 Power-On Failures 5–22

4.7.5 Failures Subsequent to Power-On 5–22

4.7.6 Troubleshooting During POST/OBP and During Boot Process 5–

23

4.7.7 OpenBoot PROM On-Board Diagnostics 5–24

4.7.8 OpenBoot Diagnostics (OB Diag) 5–27

Part III Replacing Hot-Swappable FRUs

iv Netra CT Server Service Manual • January 2004

5. Hot Swap Software Commands 7–1

5.1 Understanding Hot Swap 7–1

5.1.1 How High Availability Hot Swap Works 7–2

5.1.2 Hot Swap with Boards That Don’t Support Full Hot Swap 7–2

5.1.3 System Status Panel LED States and Meanings 7–2

5.2 Using the cfgadm Utility 7–4

5.2.1 Logging In to the Netra CT Server 7–4

5.2.2 Running the cfgadm Utility 7–4

5.2.3 Basic and Full Hot Swap cfgadm Commands 7–5

6. Removing and Replacing Hot-Swappable Cards 8–1

6.1 Main Cards 8–2

6.1.1 Rules and Restrictions for Hot-Swapping Main Cards 8–6

6.1.2 Removing and Replacing Main Cards 8–8

6.2 Front-Transition Card 8–28

6.2.1 Removing a Host CPU Front Transition Card 8–29

6.2.2 Installing a Host CPU Front Transition Card 8–30

6.3 Rear-Transition Cards 8–31

6.3.1 Host CPU Rear Transition Card 8–32

6.3.2 Satellite CPU or I/O Rear Transition Card 8–38

6.3.3 Alarm Rear Transition Card 8–43

7. Removing and Replacing Hard Disk Drives and Removeable Media 9–1

7.1 Hard Disk Drive 9–2

7.1.1 Removing a Hard Disk Drive 9–3

7.1.2 Installing a Hard Disk Drive 9–8

7.2 DVD or DAT Drive (Netra CT 810 Server Only) 9–9

7.2.1 Removing a DVD or DAT Drive 9–10

7.2.2 Installing a DVD or DAT Drive 9–13

Contents v

8. Removing and Replacing Hot-Swappable Subassemblies 10–1

8.1 System Status Panel 10–2

8.1.1 Removing the System Status Panel 10–2

8.1.2 Replacing the System Status Panel 10–4

8.2 System Controller Board 10–6

8.2.1 Removing the System Controller Board 10–6

8.2.2 Replacing the System Controller Board 10–8

8.3 Air Filters 10–10

8.3.1 Removing the Air Filters 10–10

8.3.2 Replacing the Air Filters 10–12

8.4 Power Supply Unit (AC or DC) 10–13

8.4.1 Removing a Hot-Swappable Power Supply Unit 10–13

8.4.2 Replacing a Hot-Swappable Power Supply Unit 10–16

8.5 Fan Tray 10–17

8.5.1 Removing a Fan Tray 10–17

8.5.2 Replacing a Fan Tray 10–21

Part IV Replacing Cold-Swappable FRUs

9. Removing and Replacing the Servers 12–1

9.1 Servers 12–1

9.1.1 Removing a Server 12–2

9.1.2 Installing a Server 12–9

10. Removing and Replacing Cold-Swappable Subassemblies 13–1

10.1 Hard Disk Drive 13–1

10.1.1 Removing a Hard Disk Drive 13–2

10.1.2 Replacing a Hard Disk Drive 13–4

10.2 Power Distribution Unit (DC Models Only) 13–4

10.2.1 Removing the Power Distribution Unit 13–5

vi Netra CT Server Service Manual • January 2004

10.2.2 Replacing the Power Distribution Unit 13–10

10.3 AC Power Entry Unit (AC Models Only) 13–11

10.3.1 Removing the AC Power Entry Unit 13–11

10.3.2 Installing the AC Power Entry Unit 13–12

10.4 Front-Access DC Cable (Front-Access DC Models Only) 13–13

10.4.1 Removing the Front-Access DC Cable 13–13

10.4.2 Replacing a Front-Access DC Cable 13–15

10.5 Power Supply Unit 13–16

10.5.1 Removing a Cold-Swappable Power Supply Unit 13–16

10.5.2 Replacing a Cold-Swappable Power Supply Unit 13–19

Part V Illustrated Parts Breakdown

11. Illustrated Parts Breakdown 15–1

11.1 DC Chassis Components 15–2

11.2 AC Chassis Components 15–4

11.3 Netra CT 810 Server 15–6

11.4 Netra CT 410 Server, Diskfull 15–8

11.5 Netra CT 410 Server, Diskless 15–10

Part VI Appendixes, Glossary, and Index

A. Connector Pinouts A–1

A.1 CPU Card A–2

A.1.1 Ethernet A Port A–3

A.1.2 TTY A Port A–4

A.2 CPU Front Transition Card, Netra CT 410 Server A–5

A.2.1 SCSI (VHDC) A–6

A.2.2 Parallel Port A–7

A.2.3 Ethernet B Port A–8

A.2.4 TTY B A–9

Contents vii

A.3 CPU Rear Transition Card A–10

A.3.1 SCSI (VHDC) A–11

A.3.2 TTY A and B Ports A–12

A.3.3 Ethernet A and B Ports A–12

A.3.4 PIM Card Interface A–13

A.4 Alarm Card, 6U Single-Wide A–14

A.4.1 Alarm Port A–15

A.4.2 Ethernet Ports 1 and 2 A–16

A.4.3 COM Ports 1 and 2 A–17

A.5 Alarm Card, 3U Double-Wide A–18

A.5.1 Ethernet Ports 1 and 2 A–19

A.5.2 COM Ports 1 and 2 A–20

A.5.3 Alarm Port A–21

A.6 Alarm Rear Transition Card A–22

A.6.1 Ethernet Ports 1 and 2 A–23

A.6.2 COM Ports 1 and 2 A–24

A.6.3 Alarm Port A–25

B. Connecting a Terminal Console to the Server B–1

B.1 To Use an ASCII Terminal B–1

B.2 To Use a Solaris Workstation B–3

B.3 To Use a PC Laptop B–5

C. Error Messages C–1

C.1 Generic Error Messages C–2

C.2 scsb Error Messages C–3

C.3 Anticipated Hardware Failure C–9

C.3.1 Transient Interrupts C–9

C.3.2 Soft Hang C–10

viii Netra CT Server Service Manual • January 2004

C.4 I2C Complaints C–11

C.5 Bus Busy Complaints C–12

D. System Specifications D–1

D.1 Physical Specifications D–1

D.2 Electrical Specifications D–2

D.3 Environmental Specifications D–3

Contents ix

x Netra CT Server Service Manual • January 2004

Figures

FIGURE 1-1 Attaching the Antistatic Wrist Strap 1–2

FIGURE 1-3 Locating the Power Supply Units in the Netra CT Servers 1–4

FIGURE 1-4 AC Connectors on a Netra CT Chassis 1–5

FIGURE 1-5 DC Connectors on a Netra CT Chassis 1–6

FIGURE 2-1 Locating the Power Supply Locking Mechanism on the Netra CT 810 Server 2–2

FIGURE 2-2 System Status Panel Locations 2–3

FIGURE 2-3 System Power Button and System Power LED Locations (Netra CT 810 Server) 2–4

FIGURE 2-4 System Power Button and System Power LED Locations (Netra CT 410 Server) 2–4

FIGURE 4-1 System Status Panel Locations 5–2

FIGURE 4-2 System Status Panel (Netra CT 810 Server) 5–3

FIGURE 4-3 System Status Panel (Netra CT 410 Server) 5–3

FIGURE 4-4 Power and Okay to Remove LEDs 5–3

FIGURE 4-5 Power and Fault LEDs 5–4

FIGURE 4-6 Connectors on the CPU Front Transition Card (Netra CT 410 Server) 5–20

FIGURE 4-7 Connectors on the CPU Rear Transition Card 5–21

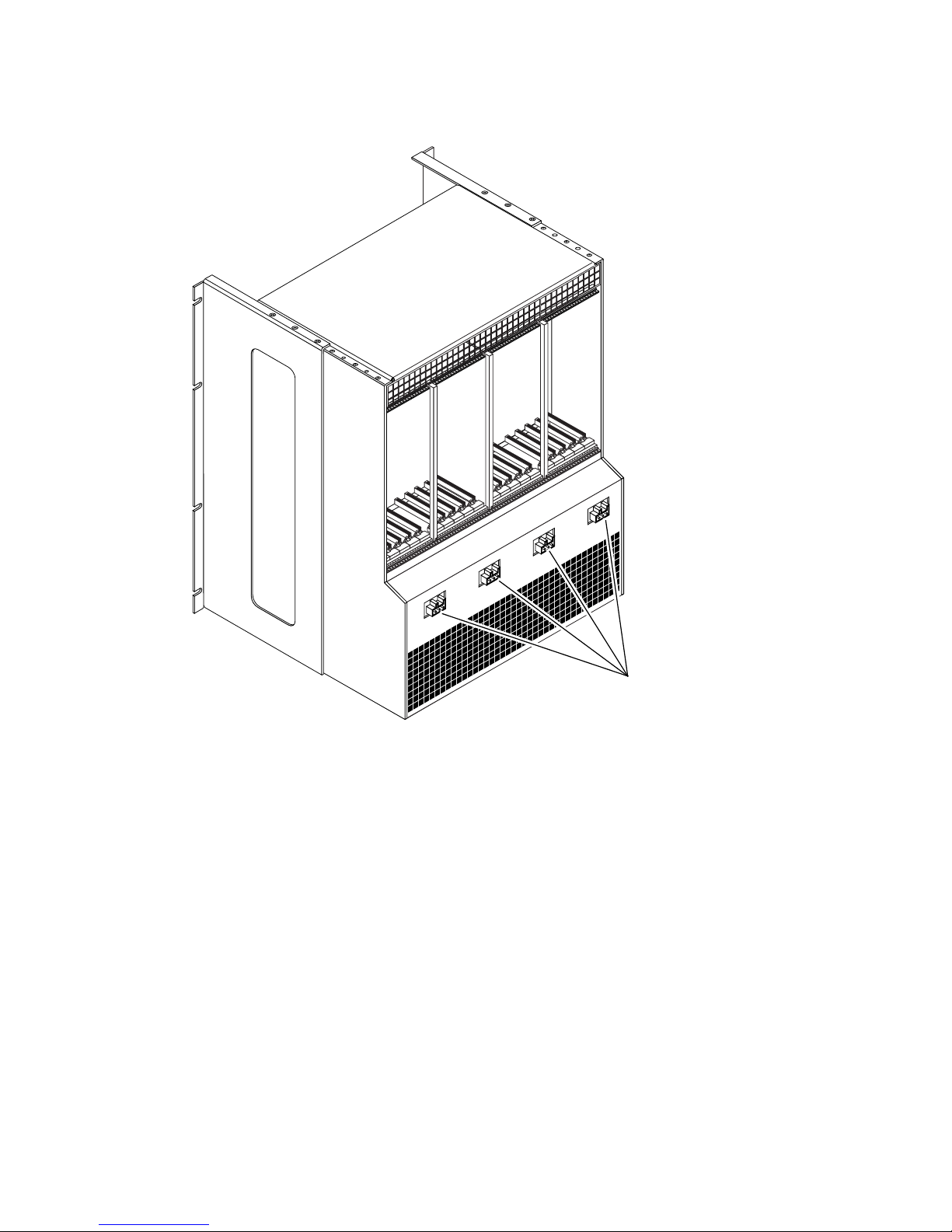

FIGURE 6-1 Cards Within a Netra CT 810 Server 8–3

FIGURE 6-2 Cards Within a Netra CT 410 Server, Diskfull Version 8–4

FIGURE 6-3 Cards Within a Netra CT 410 Server, Diskless Version 8–5

FIGURE 6-4 Loosening the Ejection Lever Captive Screws 8–12

FIGURE 6-5 Unlocking the Ejection Levers 8–13

xi

FIGURE 6-6 LEDs on the System Status Panel (Netra CT 810 Server) 8–14

FIGURE 6-7 LEDs on the System Status Panel (Netra CT 410 Server) 8–14

FIGURE 6-8 Aligning the Card with the Card Cage Cutouts 8–19

FIGURE 6-9 Tightening the Ejection Lever Captive Screws 8–20

FIGURE 6-10 Connectors for the Single-Wide 6U Alarm Card 8–26

FIGURE 6-11 Connectors for the Double-Wide 3U Alarm Card 8–27

FIGURE 6-12 Connectors on the Host CPU Card 8–28

FIGURE 6-13 Host CPU Front Transition Card Location in a Netra CT 410 Server 8–29

FIGURE 6-15 Connectors on the Host CPU Front Transition Card (Netra CT 410 Server) 8–31

FIGURE 6-16 Supported and Unsupported Host CPU Rear Transition Card for a Netra CT Server 8–33

FIGURE 6-17 Locating the Host CPU Rear Transition Card in the Rear-Access Model of a Netra CT 810

Server (Top View) 8–34

FIGURE 6-18 Locating the Host CPU Rear Transition Card in the Rear-Access Model of a Netra CT 410

Server (Top View) 8–35

FIGURE 6-19 Aligning the Card with the Rear Card Cage Cutouts 8–36

FIGURE 6-20 Connectors on the Host CPU Rear Transition Card 8–37

FIGURE 6-21 Supported Locations for Satellite CPU or I/O Rear Transition Card Sets in a Netra CT 810

Server (Top View) 8–39

FIGURE 6-22 Supported Locations for Satellite CPU or I/O Rear Transition Card Sets in a Netra CT 410

Server (Top View) 8–39

FIGURE 6-23 Supported Location for the Alarm Rear Transition Card in a Netra CT 810 Server (Top

View) 8–44

FIGURE 6-24 Supported Location for the Alarm Rear Transition Card in a Netra CT 410 Server (Top

View) 8–44

FIGURE 6-25 Connectors on the Alarm Rear Transition Card 8–46

FIGURE 7-1 Locating the Hard Disk Drive LEDs on the System Status Panel (Netra CT 810 Server) 9–6

FIGURE 7-2 Drive Bay Cover Locations 9–7

FIGURE 7-3 Removing the Removeable Media Module from a Netra CT 810 Server 9–12

FIGURE 8-1 System Status Panel Locations 10–2

FIGURE 8-2 Removing the System Status Panel (Netra CT 810 Server) 10–3

FIGURE 8-3 Removing the System Status Panel (Netra CT 410 Server) 10–4

FIGURE 8-4 Positioning the System Status Panel (Netra CT 810 Server) 10–5

xii Netra CT Server Service Manual • January 2004

FIGURE 8-5 Positioning the System Status Panel (Netra CT 410 Server) 10–5

FIGURE 8-6 Locating the System Controller Board LEDs on the System Status Panel (Netra CT 810

Server) 10–7

FIGURE 8-7 Locating the System Controller Board LEDs on the System Status Panel (Netra CT 410

Server) 10–7

FIGURE 8-8 Removing a System Controller Board 10–8

FIGURE 8-9 Inserting a System Controller Board 10–9

FIGURE 8-10 Locating the Air Filters (Netra CT 810 Server) 10–11

FIGURE 8-11 Locating the Air Filters (Netra CT 410 Server) 10–12

FIGURE 8-12 Locating the Power Supply Unit LEDs on the System Status Panel (Netra CT 810

Server) 10–14

FIGURE 8-13 Unlocking a Power Supply Unit 10–15

FIGURE 8-14 Removing a Power Supply Unit 10–16

FIGURE 8-15 Locating the Fan Tray LEDs on the System Status Panel (Netra CT 810 Server) 10–17

FIGURE 8-16 Locating the Fan Tray LEDs on the System Status Panel (Netra CT 410 Server) 10–18

FIGURE 8-17 Locating the Fan Trays in a Netra CT 810 Server 10–19

FIGURE 8-18 Locating the Fan Trays in a Netra CT 410 Server 10–19

FIGURE 8-19 Removing a Fan Tray from a Netra CT 810 Server 10–20

FIGURE 8-20 Removing a Fan Tray from a Netra CT 410 Server 10–20

FIGURE 9-1 Power Supply Units and Power Sources 12–3

FIGURE 9-2 Loosening the Screws at the Top and Bottom of a Netra CT 810 Server 12–5

FIGURE 9-3 Loosening the Screws at the Top and Bottom of a Netra CT 410 Server 12–6

FIGURE 9-4 Removing or Inserting a Netra CT 810 Server 12–7

FIGURE 9-5 Removing or Inserting a Netra CT 410 Server 12–8

FIGURE 10-1 Drive Bay Cover Locations 13–3

FIGURE 10-3 Locating the Power Distribution Unit LEDs on the System Status Panel (Netra CT 810

Server) 13–6

FIGURE 10-4 Locating the Power Distribution Unit LEDs on the System Status Panel (Netra CT 410

Server) 13–6

FIGURE 10-7 Locating the Power Distribution Units 13–9

FIGURE 10-9 AC Connectors on a Netra CT Chassis 13–12

FIGURE 10-11 Loosening the Front-Access DC Cable Screws 13–15

Figures xiii

FIGURE 10-12 Removing or Replacing a Power Supply Unit From a Netra CT 810 Server 13–17

FIGURE 10-13 Removing or Replacing a Power Supply Unit From a Netra CT 410 Server 13–18

FIGURE 10-14 Removing a Power Supply Unit From a Netra CT 410 Server 13–19

FIGURE 11-1 Illustrated Parts Breakdown, DC Chassis and Rear-Access Model Components 15–3

FIGURE 11-2 Illustrated Parts Breakdown, AC Chassis and Rear-Access Model Components 15–5

FIGURE 11-4 Illustrated Parts Breakdown, Diskfull Netra CT 410 Server 15–9

FIGURE 11-5 Illustrated Parts Breakdown, Diskless Netra CT 410 Server 15–11

FIGURE A-1 Connectors on the CPU Card A–2

FIGURE A-2 RJ-45 Ethernet Connector Diagram A–3

FIGURE A-3 TTY A Connector A–4

FIGURE A-4 Connectors on the CPU Front Transition Card (Netra CT 410 Server) A–5

FIGURE A-5 Parallel Connector A–7

FIGURE A-6 RJ-45 Ethernet Connector Diagram A–8

FIGURE A-7 TTY B Connector A–9

FIGURE A-8 Connectors on the CPU Rear Transition Card A–10

FIGURE A-9 RJ-45 Ethernet Connector Diagram A–12

FIGURE A-10 Connector Ports in the 6U Single-Wide Alarm Card A–14

FIGURE A-11 Alarm Port A–15

FIGURE A-12 RJ-45 Ethernet Connector Diagram A–16

FIGURE A-13 RJ-45 Ethernet Connector Diagram A–17

FIGURE A-14 Connectors on the Alarm Card (Netra CT 410 Server) A–18

FIGURE A-15 RJ-45 Ethernet Connector Diagram A–19

FIGURE A-16 RJ-45 Ethernet Connector Diagram A–20

FIGURE A-17 Alarm Port A–21

FIGURE A-18 Connectors on the Alarm Rear Transition Card A–22

FIGURE A-19 RJ-45 Ethernet Connector Diagram A–23

FIGURE A-20 COM Ports 1 and 2 A–24

FIGURE A-21 Alarm Port A–25

xiv Netra CT Server Service Manual • January 2004

Tables

TABLE 1-1 Device Names for I/O Card Slots in the Netra CT 810 Server 1–8

TABLE 1-2 Device Names for I/O Card Slots in the Netra CT 410 Server 1–9

TABLE 4-1 System Status Panel LEDs for the Netra CT 810 Server 5–4

TABLE 4-2 System Status Panel LEDs for the Netra CT 410 Server 5–5

TABLE 4-3 CompactPCI Board LED States and Meanings 5–6

TABLE 4-4 Meanings of Power and Okay to Remove LEDs 5–7

TABLE 4-5 Meanings of Power and Fault LEDs 5–7

TABLE 4-6 Apost Tests and Values through diagconf 5–14

TABLE 4-7 Selected OBP On-Board Diagnostic Tests 5–26

TABLE 5-1 Netra CT System Hot-Swap Modes 7–1

TABLE 5-2 CompactPCI Board LED States and Meanings on the System Status Panel 7–3

TABLE 6-1 CompactPCI Board LED States and Meaning 8–15

TABLE 6-2 CompactPCI Board Slot LED States and Meanings on the System Status Panel 8–24

TABLE 11-1 FRUs for the DC Chassis 15–2

TABLE 11-2 FRUs for the AC Chassis 15–4

TABLE 11-3 FRUs for the Netra CT 810 Server 15–6

TABLE 11-4 FRUs for the Netra CT 410 Server, Diskfull 15–8

TABLE 11-5 FRUs for the Netra CT 410 Server, Diskless 15–10

TABLE A-1 Ethernet Connector Pinouts, CPU Card (J2301) A–3

TABLE A-2 TTY A Connector Pinouts A–4

xv

TABLE A-4 Parallel Port Pinouts, CPU FTC for the Netra CT 410 Server A–7

TABLE A-5 Ethernet B Connector Pinouts, CPU FTC for the Netra CT 410 Server A–8

TABLE A-6 TTY B Port Pinouts, CPU FTC for the Netra CT 410 Server A–9

TABLE A-7 SCSI Port Pinouts, CPU RTC A–11

TABLE A-8 Ethernet A and B Connector Pinouts, CPU RTC A–13

TABLE A-9 Alarm Port Pinouts A–15

TABLE A-10 Ethernet Ports 1 and 2 Pinouts A–16

TABLE A-11 COM Port 1 Pinouts A–17

TABLE A-12 COM Port 2 Pinouts A–17

TABLE A-13 Ethernet Ports 1 and 2 Pinouts A–19

TABLE A-14 COM Port 1 Pinouts A–20

TABLE A-15 COM Port 2 Pinouts A–20

TABLE A-16 Alarm Port Pinouts A–21

TABLE A-17 Ethernet Ports 1 and 2 Pinouts A–23

TABLE A-18 COM Ports 1 and 2 Connector Pinouts, Alarm Rear Transition Card A–24

TABLE A-19 Alarm Port Pinouts A–25

TABLE D-1 Netra CT Server Chassis Physical Specifications D–1

TABLE D-2 Physical Specifications, Netra CT 810 Server D–2

TABLE D-3 Physical Specifications, Netra CT 410 Server D–2

TABLE D-4 DC Power Requirements D–2

TABLE D-5 Environmental Specifications D–3

xvi Netra CT Server Service Manual • January 2004

Preface

The Netra CT Server Service Manual contains procedures for the removal and

replacement of the field-replaceable units (FRUs) in a Netra™ CT server.

The intended reader of this manual is a service provider or experienced system

administrator who has experience installing hardware—systems and

components—and has used the Solaris™ operating environment. The reader should

be comfortable with LAN fundamentals and with networking in general.

Before performing the procedures described in this book, you should have

completed the installation and setup of the Netra CT server as described in the Netra

CT Server Installation Guide.

Safety and Compliance

All Netra CT servers are shipped with the Netra CT Server Safety and Compliance

Manual, which specifies the environmental and electrical safety requirements for the

product and contains compliance certification for various countries.

xvii

How This Book Is Organized

Part I “Preparing for Service”

Chapter 1 describes the procedures you need to perform before installing, removing,

or replacing field-replaceable units (FRUs) in a Netra CT server.

Chapter 2 gives the hardware and software procedures for powering the Netra CT

server on and off.

Chapter 3 provides instructions for handling the cPCI cards and assemblies correctly.

Part II “Troubleshooting the System”

Chapter 4 provides troubleshooting procedures for the Netra CT server.

Part III “Replacing Hot-Swappable FRUs”

Chapter 5 describes the hot-swap software commands.

Chapter 6 gives instructions for removing and replacing hot-swappable cards.

Chapter 7 contains instructions for removing and replacing hard disk drives and

removable media.

Chapter 8 gives instructions for removing and replacing hot-swappable

subassemblies.

Part IV “Replacing Cold-Swappable FRUs”

Chapter 9 provides instructions for removing and replacing the Netra CT 810 server

and Netra CT 410 server.

Chapter 10 gives instructions for removing and replacing cold-replaceable

subassemblies.

Part V “Illustrated Parts Breakdown”

Chapter 11 gives the illustrated parts breakdown for the Netra CT server.

Part VI “Appendixes, Glossary, and Index”

Appendix A lists the connector pinouts for the cards in the Netra CT server.

Appendix B provides instructions for connecting a terminal console to the server.

Appendix C gives the error messages for the Netra CT server.

Appendix D gives the system specifications for the Netra CT server.

xviii Netra CT Server Service Manual • January 2004

Using UNIX Commands

This document contains only limited information on basic UNIX® commands and

procedures such as shutting down the system, booting the system, and configuring

devices.

See one or more of the following for this information:

■ Solaris Handbook for Sun Peripherals (shipped in AnswerBook2™ form, available in

printed form as an at-cost option)

■ AnswerBook online documentation for the Solaris software environment

■ Other software documentation that you received with your system

Typographic Conventions

Typeface or

Symbol Meaning Examples

AaBbCc123 The names of commands, files,

and directories; on-screen

computer output

AaBbCc123 What you type, when

contrasted with on-screen

computer output

AaBbCc123 Book titles, new words or terms,

words to be emphasized

Command-line variable; replace

with a real name or value

Edit your .login file.

Use ls -a to list all files.

% You have mail.

su

%

Password:

Read Chapter 6 in the User’s Guide.

These are called class options.

You must be superuser to do this.

To delete a file, type rm filename.

Preface xix

Shell Prompts

Shell Prompt

C shell machine_name%

C shell superuser machine_name#

Bourne shell and Korn shell $

Bourne shell and Korn shell superuser #

Related Documentation

The Netra CT server documentation is listed in the following table:

Title Part Number

Netra CT Server Start Here 816-2479

Netra CT Server Product Overview 816-2480

Netra CT Server Installation Guide 816-2481

Netra CT Server Service Manual 816-2482

Netra CT Server System Administration Guide 816-2483

Netra CT Server Safety and Compliance Manual 816-2484

Netra CT Server Product Note 816-2488

You may want to refer to documentation on the following software for additional

information: the Solaris™ operating environment, the ChorusOS™ environment,

and the Netra High Availability (HA) Suite.

xx Netra CT Server Service Manual • January 2004

Accessing Sun Documentation

You can view, print, or purchase a broad selection of Sun documentation, including

localized versions, at:

http://www.sun.com/documentation

Contacting Sun Technical Support

If you have technical questions about this product that are not answered in this

document, go to:

http://www.sun.com/service/contacting

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and

suggestions. You can submit your comments by going to:

http://www.sun.com/hwdocs/feedback

Please include the title and part number of your document with your feedback:

Netra CT Server Service Manual, part number 816-2482-11

Preface xxi

xxii Netra CT Server Service Manual • January 2004

PA R T

I Preparing for Service

Preparing for FRU Installation and Replacement Chapter 1

Powering the Server Off and On Chapter 2

Handling Cards and Assemblies Chapter 3

CHAPTER

1

Preparing for FRU Installation and

Replacement

This chapter describes the steps you need to take before you install, remove, or

replace a field-replaceable unit (FRU) in your Netra CT server. This chapter is

divided into the following sections:

■ Section 1.1, “Tools Required” on page 1-1

■ Section 1.2, “Attaching the Antistatic Wrist Strap” on page 1-2

■ Section 1.3, “Determining If You Have a Front-Access or Rear-Access Model” on

page 1-3

■ Section 1.5, “FRU Categories” on page 1-7

■ Section 1.6, “Device Names” on page 1-8

1.1 Tools Required

You will need the following tools to install, remove, or replace most of the

components in a Netra CT server:

■ No. 1 Phillips screwdriver

■ No. 2 Phillips screwdriver

1-1

1.2 Attaching the Antistatic Wrist Strap

Most field-replaceable units have sensitive electronic components that require

antistatic precautions.

1. Get the antistatic wrist strap and electrostatic discharge mat from the ship kit.

2. Place the electrostatic discharge mat close to the system.

3. Unwrap the first two folds of the wrist strap and wrap the adhesive side firmly

against your wrist.

4. Peel the liner from the copper foil at the opposite end of the wrist strap and attach

the copper end of the strap to a bare metal area on the Netra CT server or on the

chassis.

A

BORT

RESET

ALARM

/

USER

RE

A

D

Y

ET

H

ERN

E

T

HDD1

m

ic

ro

sy

st

e

m

s

C

O

M

H

O

TS

W

A

P

H

D

D

0

ALARM

ABORT

H

D

D

0

RESET

ALARM/USER

READ

Y

E

T

H

E

R

N

E

T

COM 2

m

COM 1 ENET 1 ENET 2

i

cr

os

y

st

e

m

COM 2

s

H

OT

S

W

A

COM 1 ENET 1 ENET 2

P

C

O

M

ALARM

H

O

T

S

W

A

P

HO

TS

W

A

P

COM 2

COM 1 ENET 1 ENET 2

ALARM

H

O

T

S

W

A

P

FIGURE 1-1 Attaching the Antistatic Wrist Strap

1-2 Netra CT Server Service Manual • January 2004

1.3 Determining If You Have a Front-Access

or Rear-Access Model

If you are not sure whether you have a front-access or a rear-access model, go to the

front of the chassis and look at the top part of the chassis.

■ If you see the DC connectors at the front of the chassis, then you have a front-

access model (

■ If you do not see DC connectors at the front of the chassis, and metal filler plates

fill the gaps where the DC connectors would normally be, then you have a rearaccess model (

for the rear-access model.

FIGURE 1-2).

FIGURE 1-2). The DC or AC connectors are at the rear of the chassis

Front-access model

DC connectors

ABORT

RESET

ALARM/USER

READ

Y

ET

H

ERN

E

T

H

D

D

1

m

i

c

r

o

s

y

s

t

e

m

s

COM

H

O

T

S

W

A

P

H

D

D

0

ALARM

ABORT

H

D

D

0

R

ESET

A

L

ARM

/U

SE

R

R

E

A

D

Y

E

T

H

E

R

N

E

T

COM 2

COM 1 ENET 1 ENET 2

m

i

c

r

o

s

y

s

t

e

m

COM 2

s

H

O

T

S

W

A

P

COM 1 ENET 1 ENET 2

C

O

M

ALARM

H

O

T

SW

A

P

H

O

T

S

W

A

P

COM 1 ENET 1 ENET 2COM 2

H

O

T

S

W

AP

A

B

O

RT

R

E

S

ET

A

LA

R

M

/

U

S

E

R

RE

A

D

Y

E

T

H

E

R

N

E

T

H

D

D

1

m

i

c

r

o

s

y

s

t

e

m

s

C

O

M

H

O

T

S

W

A

P

Rear-access model

Filler panels

H

D

D

0

ALARM

A

B

O

R

T

H

D

D

0

R

ES

E

T

A

L

A

R

M/U

S

E

R

R

E

A

D

Y

E

T

H

E

R

N

E

T

COM 2

COM 1 ENET 1 ENET 2

m

i

c

r

o

s

y

s

t

e

m

COM 2

s

H

O

T

S

W

A

P

COM 1 ENET 1 ENET 2

C

O

M

ALARM

H

O

T

SW

A

P

H

O

T

S

W

A

P

COM 1 ENET 1 ENET 2COM 2

H

O

T

S

W

AP

FIGURE 1-2 Front-Access and Rear-Access Models

Chapter 1 Preparing for FRU Installation and Replacement 1-3

1.4 Determining If You Have AC- or DCPowered Servers and Chassis

All of the Netra CT servers installed in a chassis must be either AC or DC; do not

mix AC- and DC-powered servers in the same chassis. Even though there are no

differences in most of the components in the AC- and DC-powered servers (such as

fans, boards, and drives), the differences in the power supplies and the power

connectors restrict you from mixing AC- and DC-powered servers in the same

chassis.

The label located between the two silver screws at the base of the each power supply

unit tells you whether the servers in the chassis are all AC- or DC-powered

(

FIGURE 1-3).

Netra ct 810 server

ABORT

RESET

ALARM/USER

READY

ETHERNET

microsystems

COM

HOTSWAP

COM 1 ENET 1 ENET 2 ALARMCOM 2

HOT

SWAP

FIGURE 1-3 Locating the Power Supply Units in the Netra CT Servers

1-4 Netra CT Server Service Manual • January 2004

You can also determine if a chassis is powered by AC or DC by looking at the

connectors at the rear of the chassis.

AC-powered chassis and

FIGURE 1-5 shows the connectors at the rear of a DC-

FIGURE 1-4 shows the connectors at the rear of an

powered chassis.

FIGURE 1-4 AC Connectors on a Netra CT Chassis

AC connectors

Chapter 1 Preparing for FRU Installation and Replacement 1-5

FIGURE 1-5 DC Connectors on a Netra CT Chassis

s

1-6 Netra CT Server Service Manual • January 2004

DC connector

1.5 FRU Categories

In general, the FRUs in a Netra CT server can be divided into two categories:

■ Hot-installable/replaceable (referred to hereafter as hot-swappable), meaning that

you can install or remove and replace a FRU while the server is running, without

interrupting the operation of the server. This category of FRU sometimes requires

that you enter hot swap software commands before and after an installation or a

removal/replacement to incorporate the new FRU in the system correctly. For

more information on the hot swap commands, refer to Chapter 5.

■ Non-hot swappable, or cold-swappable, meaning that you must halt (and, in some

cases, also power off) the server before installing or removing and replacing a

FRU. Note that you must halt power only to the server where you would be

removing and replacing the FRUs; any other servers installed in the same chassis

can remain running.

Redundant power supplies and hard disk drives in a Netra CT 810 server are a

variation of the hot-swappable category. You can replace a single power supply in a

redundant configuration while the server is running, without having to enter any

software commands, or a single hard disk drive after you have unmounted the drive

or disengaged it if you are running a disk management software package.

1.5.1 Hot-Swappable FRUs

The FRUs listed below are hot-swappable:

■ I/O cards, both front-access and rear-access models

■ Satellite CPU cards

■ Alarm cards for both the Netra CT 810 server and the Netra CT 410 server

■ Alarm rear transition cards (rear-access model only)

■ Host CPU card

■ Host CPU front transition card (front-access model only)

■ Host CPU rear transition card (rear-access model only)

■ Either of the two hard disk drives in a Netra CT 810 server

■ DVD or DAT drives occupying the removeable media module

■ Fan trays

■ System status panels

■ System controller boards

■ Either of the two power supply units in a Netra CT 810 server

1. The alarm andalarm reartransition cardsare hot-swappableonly if the host CPUcard andsystem controller

board are also installedin the Netra CT server.

2. The host CPUcard andthe host CPU front and rear transition cards are hot-swappableonly ifthe alarm card

and systemcontroller boardare alsoinstalled in the Netra CTserver.

2

3

1

1

2

2

Chapter 1 Preparing for FRU Installation and Replacement 1-7

■ Power supply unit air filters

■ Main air filters

The instructions for removing and replacing these hot-swappable FRUs are covered

in Part III.

1.5.2 Cold-Swappable FRUs

The FRUs listed below are cold-swappable:

■ Single power supply in a Netra CT 410 server

■ Single or lone remaining power supply in a Netra CT 810 server

■ Single hard disk drive in a Netra CT 410 server

■ Single or lone remaining hard disk drive in a Netra CT 810 server

■ Power distribution units

■ Powered-off or empty servers

The instructions for removing and replacing these cold-swappable FRUs are covered

in Part IV.

1.6 Device Names

1.6.1 Device Names for I/O Card Slots in the Netra CT

Servers

TABLE 1-1 gives the device names for the I/O card slots in the Netra CT 810 server

and

TABLE 1-2 gives the device names for the I/O card slots in the Netra CT 410

server.

TABLE 1-1

Slot Number Device Name

2 /devices/pci@1f,0/pci@1/pci@1/pci@f

3 /devices/pci@1f,0/pci@1/pci@1/pci@e

4 /devices/pci@1f,0/pci@1/pci@1/pci@d

3. The system controller board ishot-swappable only if the alarmcard andhost CPUcard arealso installed in

the NetraCT server.

Device Names for I/O Card Slots in the Netra CT 810 Server

1-8 Netra CT Server Service Manual • January 2004

TABLE 1-1 Device Names for I/O Card Slots in the Netra CT 810 Server (Continued)

Slot Number Device Name

5 /devices/pci@1f,0/pci@1/pci@1/pci@c

6 /devices/pci@1f,0/pci@1/pci@1/pci@b

7 /devices/pci@1f,0/pci@1/pci@1/pci@a

8 /devices/pci@1f,0/pci@1/pci@1/pci@8

TABLE 1-2 Device Names for I/O Card Slots in the Netra CT 410 Server

Slot Number Device Name

1 /devices/pci@1f,0/pci@1/pci@1/pci@8

2 /devices/pci@1f,0/pci@1/pci@1/pci@f

4 /devices/pci@1f,0/pci@1/pci@1/pci@e

5 /devices/pci@1f,0/pci@1/pci@1/pci@d

1.6.2 Device Names for Hard Disk Drives

Following are the device names for the hard disk drives installed in the Netra CT

servers:

■ Netra CT 810 server:

■ HDD 0—c0t0d0

■ HDD 1—c1t1d0

■ Netra CT 410 server:

■ HDD 0—c0t0d0

Chapter 1 Preparing for FRU Installation and Replacement 1-9

1-10 Netra CT Server Service Manual • January 2004

CHAPTER

2

Powering the Server Off and On

This chapter gives instructions on powering the Netra CT server on and off.

■ Section 2.1, “Powering On the Server” on page 2-2

■ Section 2.2, “Powering Off the Server” on page 2-6

Note – Whenever you reboot or power your server on and off, the hot swap states

revert back to the default full hot swap state for all I/O slots. If you want basic hot

swap on an I/O slot, you must manually reset the I/O slot to basic hot swap after

rebooting or powering your server on and off.

Note – You can also power the Netra CT server on and off through the alarm card

using the poweroff and poweron commands. Refer to the Netra CT Server System

Administration Guide for more information.

2-1

2.1 Powering On the Server

Note – You must have the host CPU card, alarm card and system controller board

installed in the Netra CT server before you can power it on; the server will not

power on properly if all three of these components are not installed. Once the system

is powered on and running, then you can hot-swap any of the three components as

documented in this manual. Also, do not reboot the server if the alarm is in the

process of resetting.

1. Verify that the power supply locking mechanism(s) on the server you are about to

power on are in the locked (), or down, positions.

FIGURE 2-1 shows the location of the power supply locking mechanisms on the Netra

CT server. Make sure you lock both power supplies if you are powering on a Netra

CT 810 server.

COM

H

O

T

S

W

A

P

COM 1 ENET 1 ENET 2COM 2

H

O

T

S

W

A

P

FIGURE 2-1 Locating the Power Supply Locking Mechanism on the Netra CT 810 Server

2-2 Netra CT Server Service Manual • January 2004

When the power supply locking mechanism is locked, the green LED on the power

supplies flash, indicating that the power supplies are powered on, but the server has

not been powered on yet. Also, the PDU LEDs on the system status panel should be

in this state:

Green LED ( ) is ON

Amber LED ( ) is OFF

This tells you that the power supply locking mechanisms are in the locked (down)

position and the power distribution units are receiving power and functioning

properly.

2. Locate the system status panel.

The location of the system status panel in the Netra CT 810 server and Netra CT 410

server is illustrated in

FIGURE 2-2.

HDD0

ABORT

HDD0

RESET

ALARM/USER

READ

Y

ABORT

E

T

H

E

R

N

RESET

E

T

ALARM/USER

RE

A

D

Y

m

i

c

r

o

s

y

s

t

e

m

COM 2

s

COM 1 ENET 1 ENET 2

C

O

M

ALARM

H

O

T

S

W

A

P

H

O

T

S

W

A

P

COM 2

COM 1 ENET 1 ENET 2

H

O

T

S

W

A

P

A

B

O

R

E

T

H

ALARM

H

O

T

T

E

R

N

E

T

R

E

S

E

T

A

L

A

R

M

/U

S

E

m

C

O

S

W

R

R

i

c

r

E

o

s

y

A

s

t

e

m

D

s

Y

E

T

H

E

R

N

E

T

M

HDD

A

1

P

m

i

c

r

o

s

y

s

t

e

m

s

C

O

M

H

O

T

S

W

A

P

ALARM

COM 2

COM 1 ENET 1 ENET 2

H

O

T

S

W

A

P

System status panels,

Netra CT 410 servers

FIGURE 2-2 System Status Panel Locations

System status panel,

Netra CT 810 server

Chapter 2 Powering the Server Off and On 2-3

3. Locate the system power button on the system status panel and press the system

power button to power on the server.

FIGURE 2-3 shows the system power button location for the Netra CT 810 server, and

FIGURE 2-4 shows the system power button location for the Netra CT 410 server.

System power

LED

FIGURE 2-3 System Power Button and System Power LED Locations (Netra CT 810

System power

button

Server)

System power

LED

System power

button

FIGURE 2-4 System Power Button and System Power LED Locations (Netra CT 410

Server)

4. Verify that the system power LED on the system status panel is on, indicating that

the system is completely powered on.

FIGURE 2-3 shows the system power LED location for the Netra CT 810 server, and

FIGURE 2-4 shows the system power LED location for the Netra CT 410 server.

5. Verify that the green power ( ) LED on the power supplies are on, indicating

that they are powered on and functioning properly.

2-4 Netra CT Server Service Manual • January 2004

6. Connect to the console and boot up the server.

Refer to Appendix B for instructions on connecting a terminal to your server, if

necessary.

2.1.1 Verifying Full Power-Up

The Netra CT server may take several minutes to completely power up and finish

the configuration process, depending on the number of I/O cards you have installed

in the system. Do not remove or install any cards or components in the Netra CT

server until you have verified that the system is completely powered up.

To verify that the system has been completely powered up and is fully configured, as

root, enter:

# prtpicl -c fru -v | more

You should see output similar to the following:

chassis (fru, 3d00000008)

:ChassisType SUNW,NetraCT-810

:State configured

:_class fru

:name chassis

...

■ If the entry in the State field is configured, then the system is completely

powered up and configured. You can safely remove and install boards and

components at this point.

■ If the entry in the State field is not configured (for example, configuring or

unconfigured), then the system is still coming up. Do not remove or install any

cards or components in the Netra CT server in this state. You must wait several

more minutes until the state goes to configured.

Chapter 2 Powering the Server Off and On 2-5

2.2 Powering Off the Server

You can power off the Netra CT server in three ways:

■ Graceful hardware power-down

■ Ungraceful hardware power-down

■ Graceful software power-down

If you do not have a terminal hookup to your server and your CPU is functioning

normally, you should go through a graceful hardware power-down for your server.

For a graceful hardware power-down, you would press the system power button for

less than four seconds. This will start the orderly power-down sequence in a manner

that no persistent OS data structures are corrupted. In the orderly power-down,

applications in service may be abnormally terminated and no further services will be

invoked by the CPU.

If you do not have a terminal hookup to your server and your CPU is not

functioning normally, you will not be able to go through a graceful hardware powerdown; you will have to go through an ungraceful hardware power-down instead.

For an ungraceful hardware power-down, you would press the system power button

for more than four seconds. This will immediately shut the system down without

making any attempts to keep the persistent OS data structures from being corrupted.

A graceful software power-down is a normal power-down using a terminal

connected to your server, where you would log onto the server as root, then execute

a software command to bring the server down safely.

■ For hardware power-down instructions, go to Section 2.2.1, “To Perform a

Hardware Power-Off” on page 2-6.

■ For software power-down instructions, go to Section 2.2.2, “To Perform a

Software Power Off” on page 2-7.

2.2.1 To Perform a Hardware Power-Off

1. In preparation for bringing down the operating system and powering off the

server, ensure that all significant application activity is quiesced on the server.

2. Go to the front of the Netra CT server and locate the system status panel.

The location of the system status panels in the Netra CT 810 server and Netra CT 410

server is illustrated in

3. Locate the system power button on the system status panel.

FIGURE 2-3 shows the system power button location for the Netra CT 810 server, and

FIGURE 2-4 shows the system power button location for the Netra CT 410 server.

2-6 Netra CT Server Service Manual • January 2004

FIGURE 2-2.

4. Press the system power button and release it to go through a graceful hardware

power-down.

This will start the orderly power-down sequence in a manner that no persistent OS

data structures are corrupted. In the orderly power-down, applications in service

may be abnormally terminated and no further services will be invoked by the CPU.

The system power LED will blink for several seconds, then it will go off.

5. Verify that the green power ( ) LED on the power supplies are blinking,

indicating that the system is in the standby mode.

FIGURE 2-3 shows the system power LED location for the Netra CT 810 server, and

FIGURE 2-4 shows the system power LED location for the Netra CT 410 server.

6. If you want to completely power off the Netra CT server, push the purple power

supply unit locking mechanism(s) up into the unlocked ()position (

FIGURE 2-1).

Note – You must unlock the locking mechanism on both power supply unit(s) on the

Netra CT 810 server in order to completely power off that server.

The green power ( ) LED(s) on the power supply unit(s) should go off (unlit),

indicating that the system is now completely powered off.

2.2.2 To Perform a Software Power Off

1. In preparation for bringing down the operating system and powering down the

server, ensure that all significant application activity is quiesced on the server.

2. Log in as root at the system console and enter:

# cd /

# shutdown -i0 -g0 -y

When the server is finished shutting down, the ok prompt is displayed.

3. Connect to the console and boot up the server.

Refer to Appendix B for instructions on connecting a terminal to your server, if

necessary.

4. At the ok prompt, enter:

ok power-off

Chapter 2 Powering the Server Off and On 2-7

5. Go to the front of the Netra CT server and locate the system status panel (see

FIGURE 2-2).

The location of the system status panel in the Netra CT 810 server and Netra CT 410

server is illustrated in

FIGURE 2-2.

6. Verify that the green power ( ) LED on the power supplies are blinking,

indicating that the system is in the standby mode.

FIGURE 2-3 shows the system power LED location for the Netra CT 810 server, and

FIGURE 2-4 shows the system power LED location for the Netra CT 410 server.

7. If you want to completely power off the Netra CT server, push the purple power

supply unit locking mechanism(s) up into the unlocked ()position (

FIGURE 2-1).

Note – You must unlock the locking mechanism on both power supply unit(s) on the

Netra CT 810 server in order to completely power off that server.

The green power ( ) LED(s) on the power supply unit(s) should go off (unlit),

indicating that the system is now completely powered off.

2-8 Netra CT Server Service Manual • January 2004

CHAPTER

3

Handling Cards and Assemblies

This chapter gives instructions on how to safely handle the CompactPCI cards and

assemblies. This chapter is divided into the following sections:

■ Section 3.1, “Handling CompactPCI Cards” on page 3-1

■ Section 3.2, “Handling Assemblies” on page 3-2

Consult the Netra CT Server Safety and Compliance Manual for safety information prior

to performing the procedures in this chapter.

3.1 Handling CompactPCI Cards

Each Netra CT server in a chassis has a CompactPCI bus. All of the cards in a

server—the CPU card, alarm card, and I/O cards—are CompactPCI cards.

Caution – The system is sensitive to static electricity. To prevent damage to the

assembly, always connect an antistatic wrist strap between you and the system.

Caution – Do not flex the CompactPCI cards; the surface-mounted components can

break if the card is bent.

To minimize the amount of card flexing, observe the following precautions:

■ When removing a card from an electrostatic discharge bag, keep it vertical until

you lay the card on the electrostatic discharge mat.

■ Do not place a card on a hard surface. Use a cushioned antistatic mat. The card

connectors and components have very thin pins that bend easily.

■ Be careful of small parts located on the component side of a card.

3-1

■ Do not use an oscilloscope probe on the components. The soldered pins are easily

damaged or shorted by the probe point.

■ Transport a card in an antistatic bag.

Caution – The heat sinks on a card can be damaged by incorrect handling. Do not

touch the heat sinks while installing or removing a card. Hold a card only by the

edges. If a heat sink is loose or broken, obtain a replacement card.

Caution – The heat sinks on a card can be damaged by improper packaging. When

storing or shipping a card, ensure that the heat sinks have sufficient protection.

Caution – The system controller card and its modules have surface-mount

components that can be broken by flexing the card.

3.2 Handling Assemblies

Assemblies have their own set of handling requirements, similar to the requirements

for CompactPCI cards.

Caution – The system is sensitive to static electricity. To prevent damage to the

board, always connect an antistatic wrist strap between you and the system.

3-2 Netra CT Server Service Manual • January 2004

PA R T

II Troubleshooting the System

Troubleshooting the System Chapter 4

CHAPTER

4

Troubleshooting the System

This chapter gives instructions for troubleshooting the Netra CT server. You can

troubleshoot the system several ways.

■ Section 4.1, “Troubleshooting the System Using the System Status Panel” on

page 4-2

■ Section 4.2, “Troubleshooting the System Using prtdiag” on page 4-8

■ Section 4.3, “Troubleshooting the System Using Diagnostic Software” on

page 4-13

■ Section 4.4, “Troubleshooting the System Using the Power-On Self Test (POST)”

on page 4-15

■ Section 4.5, “Troubleshooting the System Using the Alarm Card Software” on

page 4-17

■ Section 4.6, “Troubleshooting a Power Supply Using the Power Supply Unit

LEDs” on page 4-17

■ Section 4.7, “Troubleshooting a CPU Card” on page 4-19

In addition, Appendix C lists the error messages that might appear when you are

operating or servicing your Netra CT server.

4-1

4.1 Troubleshooting the System Using the

System Status Panel

You can use the system status panel to troubleshoot the Netra CT server.

4.1.1 Locating and Understanding the System Status

Panel

The system status panel on the Netra CT server give the majority of troubleshooting

information that you will need for your server.

system status panels on the Netra CT servers.

panel for the Netra CT 810 server, and

FIGURE 4-3 shows the system status panel for

the Netra CT 410 server.

FIGURE 4-1 shows the locations of the

FIGURE 4-2 shows the system status

HDD0

ABORT

RESET

A

LARM/USER

READ

ET

COM 2

COM 1 ENET 1 ENET 2

ALARM

H

O

T

S

W

A

P

H

O

T

System status panels,

Netra CT 410 servers

System status panel,

Netra CT 810 server

FIGURE 4-1 System Status Panel Locations

HDD0

Y

ABORT

H

ERN

RE

E

T

S

ET

ALARM/

USER

RE

A

D

Y

m

i

c

r

o

s

y

s

t

e

m

s

C

O

M

S

W

A

P

COM 2

COM 1 ENET 1 ENET 2

H

O

T

S

W

A

P

A

B

O

R

E

ALARM

H

O

T

T

H

E

R

N

E

T

R

E

S

E

T

A

L

A

R

M

/

U

S

E

m

i

c

r

o

s

y

s

t

C

O

M

T

S

W

A

P

R

R

E

A

e

m

D

s

Y

E

T

H

E

R

N

E

T

HDD

1

m

i

c

r

o

s

y

s

t

e

m

C

O

M

H

O

T

S

W

A

P

ALARM

s

COM 2

COM 1 ENET 1 ENET 2

H

O

T

S

W

A

P

4-2 Netra CT Server Service Manual • January 2004

FIGURE 4-2 System Status Panel (Netra CT 810 Server)

FIGURE 4-3 System Status Panel (Netra CT 410 Server)

4.1.2 Using the System Status Panel LEDs to

Troubleshoot the System

When you first power-on the Netra CT server, some or all of the green Power LEDs

on the system status panel flash on and off for several seconds. Do not attempt to

troubleshoot the system until after the LEDs have gone through their initial poweron testing.

Each major component in the Netra CT 810 server or Netra CT 410 server has a set

of LEDs on the system status panel that gives the status on that particular

component. Each component will have either the green Power and the amber Okay

to Remove LEDs (

Green Power LED

FIGURE 4-4 Power and Okay to Remove LEDs

FIGURE 4-4) or the green Power and amber Fault LEDs (FIGURE 4-5).

Amber Okay to Remove LED

Chapter 4 Troubleshooting the System 4-3

Green Power LED

FIGURE 4-5 Power and Fault LEDs

TABLE 4-1 describes which combination of LEDs is used for each component in the

Netra CT 810 server, and

Amber Fault LED

TABLE 4-2 describes which combination of LEDs is used for

each component in the Netra CT 410 server. Note that the components in the Netra

CT servers all have the green Power LED, and they will have either the amber Okay

to Remove LED or the amber Fault LED, but not both.

TABLE 4-1 System Status Panel LEDs for the Netra CT 810 Server

LED LEDs Available Component

HDD 0 Power and Okay to

Upper hard disk drive

Remove

HDD 1 Power and Okay to

Lower hard disk drive

Remove

Slot 1 Power and Okay to

Host CPU card installed in slot 1

Remove

Slots 2 - 7 Power and Okay to

I/O card or satellite CPU card (

●) installed in slot 2 - 7

Remove

Slot 8 Power and Okay to

Alarm card (

■) installed in slot 8

Remove

SCB Power and Fault System controller board (behind the system status panel)

FAN 1 Power and Fault Upper fan tray (behind the system status panel)

FAN 2 Power and Fault Lower fan tray (behind the system status panel)

RMM Power and Okay to

Removeable media module

Remove

PDU 1 (DC only) Power and Fault Leftmost power distribution unit (behind the server)

PDU 2 (DC only) Power and Fault Rightmost power distribution unit (behind the server)

PSU 1 Power and Okay to

Leftmost power supply unit

Remove

PSU 2 Power and Okay to

Remove

4-4 Netra CT Server Service Manual • January 2004

Rightmost power supply unit

TABLE 4-2 System Status Panel LEDs for the Netra CT 410 Server

LED LEDs Available Component

Slot 1 Power and Okay to

Alarm card(■) installed in slot 1

Remove

Slot 2 Power and Okay to

I/O card or satellite CPU card (

●) installed in slot 2

Remove

Slot 3 Power and Okay to

Host CPU card installed in slot 3

Remove

Slot 4 and 5 Power and Okay to

I/O cards or satellite CPU cards (

●) installed in slot 4 and 5

Remove

HDD 0 Power and Okay to

Hard disk drive

Remove

SCB Power and Fault System controller board (behind the system status panel)

FAN 1 Power and Fault Upper fan tray (behind the system status panel)

FAN 2 Power and Fault Lower fan tray (behind the system status panel)

FTC Power and Fault Host CPU front transition card or host CPU front

termination board

PDU 1 (DC only) Power and Fault Power distribution unit (behind the server)

PSU 1 Power and Okay to

Power supply

Remove

■ TABLE 4-3 gives the LED states and meanings for any CompactPCI boards installed

in a slot in the Netra CT 810 server or Netra CT 410 server.

■ TABLE 4-4 gives the LED states and meanings for any component other than a

CompactPCI board that has the green Power and amber Okay to Remove LEDs.

■ TABLE 4-5 gives the LED states and meanings for any component other than a

CompactPCI board that has the green Power and amber Fault LEDs.

Note – Do not use the information in TABLE 4-4 to troubleshoot a power supply unit

in a server that has only one power supply unit (a Netra CT 410 server or a Netra CT

810 server with only one power supply). To troubleshoot the power supply in a

single power supply system, use the LEDs on the power supply itself. Refer to

Section 4.6, “Troubleshooting a Power Supply Using the Power Supply Unit LEDs”

on page 4-17 for more information. The information given in

TABLE 4-4 applies to all

other components in the Netra CT 810 server or Netra CT 410 server, including the

power supplies in a two power supply Netra CT 810 server.

Chapter 4 Troubleshooting the System 4-5

Green

Power

LED state

TABLE 4-3 CompactPCI Board LED States and Meanings

Amber

Okay to

Remove

LED state Meaning Action

Off Off The slot is empty or the system

thinks that the slot is empty

because the system didn’t detect

the card when it was inserted.

If there is a card installed in this slot, then one of

the following components is faulty:

• the card installed in the slot

• the alarm card

• the system controller board

Remove and replace the failed component to clear

this state.

Blinking Off The card is coming up or going

Do not remove the card in this state.

down.

On Off The card is up and running. Do not remove the card in this state.

Off On The card is powered off. You can remove the card in this state.

Blinking On The card is powered on, but it is

offline for some reason (for

example, a fault was detected on

the card).

Wait several seconds to see if the green Power LED

stops blinking. If it does not stop blinking after

several seconds, enter cfgadm and verify that the

card is in the unconfigured state, then perform

the necessary action, depending on the card:

• Alarm card—You can remove the alarm card in

this state.

• All other cards—Power off the slot through the

alarm card software, then remove the card.

On On The card is powered on and is in

use, but a fault has been

detected on the card.

Deactivate the card using one of the following

methods:

• Use the cfgadm -f -c unconfigure

command to deactivate the card. Note that in

some cases, this may cause the system to panic,

depending on the nature of the card hardware or

software.

• Halt the system and power off the slot through

the alarm card software, then remove the card.

The green Power LED will then give status

information:

• If the green Power LED goes off, then you can

remove the card.

• If the green Power LED remains on, then you

must halt the system and power off the slot

through the alarm card software.

4-6 Netra CT Server Service Manual • January 2004

TABLE 4-4 Meanings of Power and Okay to Remove LEDs

LED State Power LED Okay to Remove LED

On, Solid

Component is installed and

configured.

Component is Okay to Remove. You

can remove the component from the

system, if necessary.

On, Flashing

Component is installed but is

Not applicable.

unconfigured or is going through the

configuration process.

Off

TABLE 4-5 Meanings of Power and Fault LEDs

LED State Power LED Fault LED

On, Solid

On, Flashing

Component was not recognized by

the system or is not installed in the

slot.

Component is installed and

configured.

Component is installed but is

Component is not Okay to Remove.

Do not remove the component while

the system is running.

Component has failed. Replace the

component.

Not applicable.

unconfigured or is going through the

configuration process.

Off

Component was not recognized by

the system or is not installed in the

slot.

Chapter 4 Troubleshooting the System 4-7

Component is functioning properly.

4.2 Troubleshooting the System Using

prtdiag

You can troubleshoot the system using the prtdiag command. Log into the server

console and, as root, enter:

# /usr/platform/sun4u/sbin/prtdiag

If you have a Netra CT 810 server, you should get output on the console similar to

the following:

CODE EXAMPLE 4-1 prtdiag Output for a Netra CT 810 Server

System Configuration: Sun Microsystems sun4u SPARCengine CP2000 model 140

(UltraSPARC-IIi 648MHz)

Memory size: 512 Megabytes

platform is : SUNW,NetraCT-810

=============================== FRU Information ===============================

FRU FRU FRU Green Amber Miscellaneous

Type Unit# Present LED LED Information

---------- ----- ------- ----- ----- -------------------------Midplane 1 Yes Netra ct800

Properties:

Version=0

Maximum Slots=8

SCB 1 Yes on off System Controller Board

Properties:

Version=2

hotswap-mode=basic

SSB 1 Yes System Status Panel

CPU 1 Yes on off CPU board

temperature(celsius):38

I/O 2 Yes on off CompactPCI IO Slot

Properties:

auto-config=disabled

Board Type:Unknown

Devices:

pci

pci108e,1000

SUNW,hme

SUNW,isptwo

4-8 Netra CT Server Service Manual • January 2004

CODE EXAMPLE 4-1 prtdiag Output for a Netra CT 810 Server (Continued)

I/O 3 Yes on off CompactPCI IO Slot

Properties:

auto-config=disabled

Board Type:Unknown

Devices:

pci

pci108e,1000

SUNW,hme

SUNW,isptwo

I/O 4 Yes on off CompactPCI IO Slot

Properties:

auto-config=disabled

Board Type:Unknown

Devices:

pci

pci108e,1000

SUNW,hme

SUNW,isptwo

I/O 5 Yes on off CompactPCI IO Slot

Properties:

auto-config=disabled

Board Type:Unknown

Devices:

pci

pci108e,1000

SUNW,hme

SUNW,isptwo

I/O 6 Yes on off CompactPCI IO Slot

Properties:

auto-config=disabled

I/O 7 Yes on off CompactPCI IO Slot

Properties:

auto-config=disabled

Board Type:Unknown

Devices:

pci

pci108e,1000

SUNW,qfe

pci108e,1000

SUNW,qfe

pci108e,1000

SUNW,qfe

pci108e,1000

SUNW,qfe

pci1176,608

I/O 8 Yes on off CompactPCI IO Slot

Properties:

Chapter 4 Troubleshooting the System 4-9

CODE EXAMPLE 4-1 prtdiag Output for a Netra CT 810 Server (Continued)

auto-config=disabled

Board Type:Alarm Card

Devices:

pci

ebus

ethernet

PDU 1 Yes on off Power Distribution Unit

PDU 2 Yes on off Power Distribution Unit

PSU 1 Yes on on Power Supply Unit

condition:ok

temperature:ok

ps fan:ok

supply:on

PSU 2 Yes on on Power Supply Unit

condition:ok

temperature:ok

ps fan:ok

supply:on

FAN 1 Yes on off Fan Tray

condition:ok

fan speed:low

FAN 2 Yes on off Fan Tray

condition:ok

fan speed:low

HDD 0 Yes on off Hard Disk Drive

condition:ok

HDD 1 Yes on off Hard Disk Drive

condition:ok

RMM Yes on on Removable Media Module

condition:Unknown

System Board PROM revision:

--------------------------OBP 3.14.1 2000/04/28 12:56

4-10 Netra CT Server Service Manual • January 2004

If you have a Netra CT 410 server, you should get output on the console similar to

the following:

CODE EXAMPLE 4-2 prtdiag Output for a Netra CT 410 Server

System Configuration: Sun Microsystems sun4u SPARCengine CP2000 model 140

(UltraSPARC-IIi 648MHz)

Memory size: 512 Megabytes

platform is : SUNW,NetraCT-410

=============================== FRU Information ===============================

FRU FRU FRU Green Amber Miscellaneous

Type Unit# Present LED LED Information

---------- ----- ------- ----- ----- -------------------------Midplane 1 Yes Netra ct400

Properties:

Version=0

Maximum Slots=5

SCB 1 Yes on off System Controller Board

Properties:

Version=2

hotswap-mode=basic

SSB 1 Yes System Status Panel

I/O 1 Yes on off CompactPCI IO Slot

Properties:

auto-config=disabled

Board Type:Alarm Card

Devices:

pci

ebus

ethernet

I/O 2 Yes off off CompactPCI IO Slot

Properties:

auto-config=disabled

CPU 3 Yes on off CPU board

temperature(celsius):38

I/O 4 Yes on off CompactPCI IO Slot

Properties:

auto-config=disabled

Board Type:Unknown

Devices:

pci

pci108e,1000

SUNW,hme

SUNW,isptwo

I/O 5 Yes on off CompactPCI IO Slot

Properties:

auto-config=disabled

Board Type:Unknown

Chapter 4 Troubleshooting the System 4-11

CODE EXAMPLE 4-2 prtdiag Output for a Netra CT 410 Server (Continued)

Devices:

pci

pci108e,1000

SUNW,qfe

pci108e,1000

SUNW,qfe

pci108e,1000

SUNW,qfe

pci108e,1000

SUNW,qfe

PDU 1 Yes on off Power Distribution Unit

PSU 1 Yes on off Power Supply Unit

condition:ok

temperature:ok

ps fan:ok

supply:on

FAN 1 Yes on off Fan Tray

condition:ok

fan speed:low

FAN 2 Yes on off Fan Tray

condition:ok

fan speed:low

HDD 0 Yes on off Hard Disk Drive

condition:ok

System Board PROM revision:

--------------------------OBP 3.14.1 2000/04/28 12:56

4-12 Netra CT Server Service Manual • January 2004

4.3 Troubleshooting the System Using

Diagnostic Software

There are several software packages that allow you to run diagnostic tests on your

system, such as Sun VTS. SunVTS is a validation test suite that is provided as a

supplement to the Solaris operating environment. The individual tests can stress a

device, system or resource so as to detect and pinpoint specific hardware and

software failures and provide users with informational messages to resolve any

problems found. SunVTS runs at the operating system level.

There are several tests that are particularly useful when troubleshooting a Netra CT

server:

■ alarm2test—alarm2test is part of SunVTS, but it is used specifically to test

the alarm card installed in the Netra CT server by invoking the alarmdiag test

on the alarm card. alarm2test runs at the operating system level.

■ obdiag—obdiag is similar to the alarm2test, in that it invokes the

alarmdiag test on the alarm card; however, obdiag is run from the firmware

level, not the operating system level.

■ Apost—Apost is part of the Chorus operating system image on the alarm card. It

runs a basic test on the alarm card to verify that the alarm card is operating

properly before bringing up Chorus on the alarm card.

A new utility called diagconf, which is also part of the Chorus operating system

image on the alarm card, is now available. You can use diagconf to set or display

the configuration settings for Apost, allowing you to make the tests run on the

alarm card more or less thoroughly before the Chorus operating system is brought

up on the alarm card.

To display the values currently set for Apost, access the alarm card command line

interface (CLI), and, through the alarm card CLI, enter the following command:

hostname cli> diagconf -d

Chapter 4 Troubleshooting the System 4-13

You should see output similar to the following, giving you the values currently set

for the Apost test on the alarm card:

diag-switch False

verb-mode True

stop-on-error False

diag-level Max

mfg-mode Off

hdr-checksum 0xaa

time-stamp 0

record-format-ver 49

post-version 02

reset-status 0xd0000000

post-status ...

post-msg Watchdog Reset-------- POST Passed-------------------

Some values are hard-set and cannot be changed by a user, while others can be

changed to make that particular test more or less thorough. To change the value for

a particular test, enter the following command:

hostname cli> diagconf -s command value

where command is the name of the command that you want to change, and value is

the value you want to change.

The following table lists the Apost tests that can be changed by a user and the

allowable values for each. Any tests not listed in

TABLE 4-6 are either hard-set and

cannot be changed, or should not be changed by a user.

TABLE 4-6 Apost Tests and Values through diagconf

Command Value

diag-switch • True—Turns the diag-switch test on.

• False—Turns the diag-switch test off.

verb-mode • True—Turns the verb-mode test on.

• False—Turns the verb-mode test off.

stop-on-error • True—Stops the Apost testing when the first error is encountered.

• False—Continues Apost testing, regardless of the number of

errors encountered.

diag-level • Off—Turns the diag-level test off.

• Min—Sets the diag-level test to the minimum level of testing.

• Max—Sets the diag-level test to the maximum level of testing

4-14 Netra CT Server Service Manual • January 2004

For more information on these and other tests in the SunVTS test suite, refer to the

Computer Systems Release Notes Supplement for Sun Hardware document or the

SunVTS documentation on the Solaris on Sun Hardware Answerbook, both included

with your Solaris operating environment.

4.4 Troubleshooting the System Using the

Power-On Self Test (POST)

When you first power-up the Netra CT server, some or all of the green Power LEDs

on the system status panel will flash on and off for several seconds. The green Power

LED for the I/O slot holding the CPU card (slot 1 in the Netra CT 810 server and slot

3 in the Netra CT 410 server) will go to solid green while the green Power LEDs for

the remaining components are still flashing on and off; this is an indication that the

CPU card has passed the power-on self test (POST).

Before any processing can occur on a system, it must successfully complete the

POST. Messages are displayed for each step in the POST process. If there is a critical

failure, the system will not complete POST and will not boot. To monitor this

process, you must be connected to the TTY A port on the CPU card or CPU

transition card. See Section 5.2.1, “Logging In to the Netra CT Server” on page 5-4.