Sun Netra™CP3060 Blade Server

User’s Guide

Sun Microsystems, Inc.

www.sun.com

Part No. 819-4967-11

April 2009, Revision A

Submit comments about this document at: http://www.sun.com/hwdocs/feedback

Copyright ©2009 Sun Microsystems, Inc., 4150Network Circle,Santa Clara, California 95054, U.S.A.All rights reserved.

This distributionmay include materials developed bythird parties.

Parts ofthe product may be derivedfrom BerkeleyBSD systems, licensed from the University ofCalifornia. UNIX is a registered trademark in

the U.S.and in other countries, exclusivelylicensed through X/Open Company, Ltd.

Sun, SunMicrosystems, the Sun logo, Netra,Sun Ray, the Netra logoand the Solaris logo are trademarks or registered trademarks of Sun

Microsystems, Inc.,or its subsidiaries, in theU.S. and other countries.

All SPARC trademarks are usedunder license and are trademarks or registered trademarks of SPARC International, Inc. in the U.S. andother

countries. Productsbearing SPARC trademarksare basedupon architecturedeveloped by Sun Microsystems, Inc.

Use ofany spare or replacement CPUs is limitedto repair or one-for-one replacement of CPUs in products exported in compliance withU.S.

export laws.Use of CPUs as productupgrades unless authorized by theU.S. Government is strictly prohibited.

DOCUMENTATION IS PROVIDED "AS IS" AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESSFOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT,

ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright ©2009 Sun Microsystems, Inc., 4150Network Circle,Santa Clara, California 95054, Etats-Unis.Tousdroits réservés.

Cette distributionpeut comprendredes composants développés par destierces parties.

Des partiesde ce produit pourront être dérivées des systèmes BerkeleyBSD licenciés par l’Université deCalifornie. UNIX est une marque

déposée auxEtats-Unis et dans d’autres payset licenciée exclusivement par X/OpenCompany, Ltd.

Sun, SunMicrosystems, le logo Sun, Netra,Sun Ray, le logo Netraet le logo Solaris sontdes marquesde fabrique ou des marques déposées de

Sun Microsystems,Inc., ou ses filiales, auxEtats-Unis et dans d’autres pays.

Toutes les marques SPARC sont utilisées sous licence et sont des marques de fabrique oudes marquesdéposées de SPARC International, Inc.

aux Etats-Uniset dans d’autres pays. Lesproduits portantles marques SPARCsont basés sur une architecture développée par Sun

Microsystems, Inc.

L’utilisationde pieces detachees ou d’unitescentrales de remplacement est limitee aux reparationsou a l’echange standard d’unites centrales

pour lesproduits exportes, conformement a lalegislation americaine en matiere d’exportation. Sauf autorisationpar les autorites des EtatsUnis, l’utilisationd’unites centrales pour proceder ades mises a jour deproduits estrigoureusement interdite.

LA DOCUMENTATION EST FOURNIE "EN L’ETAT" ET TOUTES AUTRES CONDITIONS, DECLARATIONS ET GARANTIES EXPRESSES

OU TACITES SONTFORMELLEMENT EXCLUES, DANS LA MESURE AUTORISEE PAR LA LOI APPLICABLE, Y COMPRISNOTAMMENT

TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE UTILISATION PARTICULIERE OU A

L’ABSENCE DE CONTREFACON.

Please

Recycle

Contents

Preface xi

1. Introduction to the Sun Netra CP3060 Blade Server 1–1

1.1 Overview of the Sun Netra CP3060 Blade Server 1–1

1.2 Features of the Sun Netra CP3060 Blade Server 1–2

1.3 Sun Netra CP3060 Blade Server System Configurations 1–7

1.3.1 AMC Modules 1–8

1.3.2 Rear Transition Module 1–8

1.4 Hot-Swap Support 1–11

1.5 System Requirements 1–11

1.5.1 Hardware Requirements 1–12

1.5.2 Software Requirements 1–12

1.6 Technical Support and Warranty 1–13

1.6.1 Blade Server Part Number, Serial Number, and Revision Number

Identification 1–13

2. Hardware Installation 2–1

2.1 Equipment and Operator Safety 2–1

2.2 Materials and Tools Required 2–2

2.3 Preparing for the Installation 2–3

iii

2.3.1 Checking Power, Thermal, Environmental, and Space

Requirements 2–3

2.3.2 Determining Local Network IP Addresses and Host Names 2–4

2.3.3 Installation Procedure Summary 2–4

2.4 Configuring the Blade Server Hardware 2–5

2.4.1 Installation of DDR-2 DIMM Memory Modules 2–5

2.4.1.1 Installing a DDR-2 DIMM Memory Module 2–7

2.4.1.2 Removing a DDR-2 DIMM Memory Module 2–8

2.4.2 Installation of Optional Compact Flash Card 2–9

2.4.3 Configuring Rear Transition Module Hardware 2–11

2.5 Installing the Sun Netra CP3060 Blade Server 2–11

2.5.1 Installing the Sun Netra CP3060 Blade Server With a Rear

Transition Module 2–11

2.5.1.1 Installing a Rear Transition Module 2–12

2.5.2 Installing the Sun Netra CP3060 Blade Server 2–15

2.6 Connecting External I/O Cables 2–17

2.7 Installation of Optional AMC Modules 2–18

2.7.0.1 Installing an Optional AMC Module 2–19

3. Software Installation 3–1

3.1 Operating Systems and Patches 3–1

3.2 Firmware Updates 3–2

3.3 Mandatory /etc/system File Entry 3–2

▼ To Check and Create the Mandatory /etc/system File Entry 2

3.4 Installing Diskless Clients 3–3

3.4.1 Creating a Boot Server for Diskless Clients 3–3

3.4.2 Adding a Diskless Client 3–5

3.5 Downloading and Installing SunVTS Software 3–7

4. Firmware and Blade Server Management 4–1

iv Netra CP3060 Board User’s Guide • April 2009

4.1 System Firmware 4–1

4.2 Power-On Self-Test Diagnostics 4–2

4.2.1 POST Test Coverage 4–2

4.2.2 POST Diagnostic and Error Message Format 4–3

4.3 OpenBoot Firmware 4–3

4.3.1 Getting to the ok Prompt 4–4

4.3.2 Auto-Boot Options 4–5

4.3.3 OpenBoot Commands 4–5

4.3.3.1 probe-ide Command 4–6

4.3.3.2 show-devs Command 4–6

4.3.3.3 Checking Network Using watch-net and watch-net-

all Commands 4–8

4.3.4 OpenBoot Configuration Variables 4–9

4.3.4.1 Viewing and Setting OpenBoot Configuration

Variables 4–12

4.4 Error Handling Summary 4–12

4.5 Automatic System Recovery 4–13

4.5.1 Enabling and Disabling Automatic System Recovery 4–14

4.5.1.1 To Enable Automatic System Recovery 4–14

4.5.1.2 To Disable Automatic System Recovery 4–15

4.6 Hot-Swap Information 4–15

4.6.1 Hot-Swapping the Sun Netra CP3060 Blade Server 4–15

4.6.1.1 Hot-Swap LED 4–16

4.7 Network Device Aliases 4–17

4.8 Retrieving Device Information 4–17

4.9 Mandatory /etc/system File Entry 4–20

▼ To Check and Create the Mandatory /etc/system File Entry 20

5. Hardware and Functional Descriptions 5–1

5.1 Hardware Architecture 5–1

Contents v

5.1.1 UltraSPARC T1 Processor 5–4

5.1.1.1 Overview 5–4

5.1.1.2 Cores and Cache 5–5

5.1.1.3 Memory Controller 5–6

5.1.1.4 Instruction Set 5–6

5.1.1.5 Interrupts 5–6

5.1.1.6 UltraSPARC T1 RAS Features 5–6

5.1.1.7 UltraSPARC T1 Processor Speed 5–6

5.1.2 DDR-2 Memory Subsystem 5–7

5.1.2.1 DIMMs 5–7

5.1.2.2 Memory Subsystem RAS Features 5–8

5.1.2.3 Serial Presence Detect 5–9

5.1.3 System JBus 5–9

5.1.3.1 JBus RAS Features 5–9

5.1.4 I/O Subsystem 5–9

5.1.4.1 JBus-to-PCI-E Bridge 5–10

5.1.4.2 PCI-E Switch 5–11

5.1.4.3 PCI-E to Dual GbE Controller 5–11

5.1.4.4 Ethernet Switch 5–12

5.1.4.5 AMC Slot 5–12

5.1.4.6 Southbridge 5–16

5.1.5 Service Processor MPC885 5–17

5.1.5.1 MPC Bus External Devices 5–18

5.1.5.2 Field-Programmable Gate Array 5–18

5.1.5.3 XBus External devices 5–19

5.1.6 Intelligent Platform Management Controller 5–19

5.1.6.1 Intelligent Platform Management Bus 5–19

5.1.6.2 Interface to the MPC 5–19

vi Netra CP3060 Board User’s Guide • April 2009

5.1.6.3 IPMB-L Interface 5–20

5.1.6.4 ATCA Hot-Swap Latch 5–20

5.1.6.5 LEDs 5–20

5.1.6.6 Power Control 5–20

5.1.6.7 Extended Interface E-keying Control 5–21

5.1.6.8 I2C Architecture 5–21

5.1.6.9 I2C Device Address Map 5–22

5.1.6.10 System Monitor and Thresholds 5–24

5.2 Power-on Sequence 5–26

5.3 Power 5–27

5.3.1 Power Input 5–27

5.3.2 Fuses 5–27

5.3.3 ATCA Power Module (-48V to 12V) 5–28

5.3.4 On-Board DC/DC Regulators 5–28

5.3.5 TOD Clock Battery 5–28

A. Physical Characteristics A–1

A.1 Form Factor A–1

A.2 Layout A–1

A.3 Front Panel A–2

A.3.1 Visual Indicators A–3

A.3.2 Ports A–3

A.3.3 AMC Slot A–3

A.4 Connectors and Pinout A–3

A.4.1 Front Panel Connectors A–3

A.4.1.1 Ethernet Ports A–4

A.4.1.2 Serial Port A–4

A.4.2 AMC Connector A–5

A.4.3 Compact Flash Connector A–7

Contents vii

A.4.4 Midplane Power Connector (Zone 1) A–7

A.4.5 Data Transport Connector (Zone 2) A–9

A.4.6 RTM Connector (Zone 3) A–11

A.4.7 TOD Clock Battery Holder A–14

B. Sun OEM IPMI Commands B–1

B.1 Get Version Command B–2

B.2 Get RTM Status Command B–3

Index Index–1

viii Netra CP3060 Board User’s Guide • April 2009

Figures

FIGURE 1-1 Sun Netra CP3060 Blade Server Front Panel 1–4

FIGURE 1-2 Sun Netra CP3060 Blade Server (Top View) 1–4

FIGURE 1-3 Sun Netra CP3060 Blade Server in an ATCA Shelf Enclosure 1–8

FIGURE 1-4 Sun Netra CP3060 Rear Transition Module 1–9

FIGURE 1-5 Relationship of the Sun Netra CP3060 Blade Server, Midplane, and RTM 1–10

FIGURE 1-6 Sun Netra CP3060 Blade Server Barcode Labeling 1–14

FIGURE 2-1 DDR-2 DIMM Memory Locations 2–6

FIGURE 2-2 Installing a DDR-2 DIMM Memory Module 2–8

FIGURE 2-3 Removing a DDR-2 DIMM Memory Module 2–9

FIGURE 2-4 Compact Flash Card Connector 2–10

FIGURE 2-5 Installing the Sun Netra CP3060 Rear Transition Module 2–12

FIGURE 2-6 RTM Injector/Ejector Latch and Locking Screw 2–14

FIGURE 2-7 Installing Node Blade Server Into Chassis Slot 2–16

FIGURE 2-8 Sun Netra CP3060 Blade Server Latches and Locking Screws 2–17

FIGURE 2-9 Removing AMC Slot Filler Panel 2–19

FIGURE 2-10 Inserting AMC Module Into AMC Connector 2–20

FIGURE 4-1 Hot-Swap Latch and Hot-Swap LED 4–16

FIGURE 5-1 Block Diagram 5–3

FIGURE 5-2 UltraSPARC T1 Multicore Processor Block Diagram 5–5

FIGURE 5-3 DDR Memory Diagram 5–8

ix

FIGURE 5-4 AMC Power and Management Infrastructure 5–14

FIGURE 5-5 Clock Synchronization 5–16

2

FIGURE 5-6 I

C Block Diagram 5–22

FIGURE A-1 Sun Netra CP3060 Blade Server Layout A–2

FIGURE A-2 Ethernet RJ-45 Connector A–4

FIGURE A-3 Front Panel Serial Port Diagram A–5

FIGURE A-4 Power Distribution Connector (Zone 1) P10 A–8

FIGURE A-5 Zone 2 Connectors A–10

FIGURE A-6 Zone 3 Connectors A–12

x Netra CP3060 Board User’s Guide • April 2009

Preface

The Sun Netra CP3060 Blade Server User’s Guide provides information about features,

installation, configuration, functional hardware components, and physical properties

of this blade server. The Sun Netra CP3060 Blade Server User’s Guide is written for

system integration engineers, field applications and service engineers, and others

involved in the integration of these blade servers into systems.

How This Document Is Organized

Chapter 1 provides an overview of the Sun Netra CP3060 blade server.

Chapter 2 provides instructions on hardware installation.

Chapter 3 provides instructions on the software configuration.

Chapter 4 provides information about the Sun Netra CP3060 firmware.

Chapter 5 provides hardware and functional descriptions of the Sun Netra CP3060

blade server.

Appendix A provides information about the physical characteristics of the Sun Netra

CP3060 blade server.

Appendix B describes the Sun-specific OEM-defined Intelligent Platform

Management Interface (IPMI) commands.

xi

Using UNIX Commands

This document might not contain information on basic UNIX®commands and

procedures such as shutting down the system, booting the system, and configuring

devices. Refer to the following for this information:

■ Software documentation that you received with your system

■ Solaris™ Operating System documentation, which is at:

http://docs.sun.com

Shell Prompts

Shell Prompt

C shell machine-name%

C shell superuser machine-name#

Bourne shell and Korn shell $

Bourne shell and Korn shell superuser #

xii Netra CP3060 Board User’s Guide • April 2009

Typographic Conventions

*

Typeface

AaBbCc123 The names of commands, files,

AaBbCc123 What you type, when contrasted

AaBbCc123 Book titles, new words or terms,

* The settings on your browser might differ from these settings.

Meaning Examples

Edit your.login file.

and directories; on-screen

computer output

with on-screen computer output

words to be emphasized.

Replace command-line variables

with real names or values.

Use ls -a to list all files.

% You have mail.

su

%

Password:

Read Chapter 6 in the User’s Guide.

These are called class options.

Yo u must be superuser to do this.

To delete a file, type rm filename.

Related Documentation

For additional information about the Sun Netra CP3060 blade server and the Sun

Netra CP3060 rear transition module (RTM), refer to the following documents.

Title Part Number

Sun Netra CP3060 Blade Server Product Notes 819-4966

Sun Netra CP3060 Blade Server Getting Started Guide 819-4971

Sun Netra CP3060 Blade Server Programming Guide 819-4969

Sun Netra CP3060 Rear Transition Module Getting Started Guide 819-6692

Sun Netra CP3060 Rear Transition Module User’s Guide 819-6689

Important Safety Information for Sun Hardware Systems (printed version only) 816-7190-10

Except for Important Safety Information for Sun Hardware Systems, all the documents

listed are available online at:

http://www.sun.com/documentation

Preface xiii

Documentation, Support, and Training

Sun Function URL

Documentation http://www.sun.com/documentation/

Support http://www.sun.com/support/

Training http://www.sun.com/training/

Third-Party Web Sites

Sun is not responsible for the availability of third-party web sites mentioned in this

document. Sun does not endorse and is not responsible or liable for any content,

advertising, products, or other materials that are available on or through such sites

or resources. Sun will not be responsible or liable for any actual or alleged damage

or loss caused by or in connection with the use of or reliance on any such content,

goods, or services that are available on or through such sites or resources.

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and

suggestions. You can submit your comments by going to:

http://www.sun.com/hwdocs/feedback

Please include the title and part number of your document with your feedback:

Sun Netra CP3060 Blade Server User’s Guide, part number 819-4967-11

xiv Netra CP3060 Board User’s Guide • April 2009

CHAPTER

1

Introduction to the Sun Netra CP3060 Blade Server

This chapter contains the following sections:

■ Section 1.2, “Features of the Sun Netra CP3060 Blade Server” on page 1-2

■ Section 1.3, “Sun Netra CP3060 Blade Server System Configurations” on page 1-7

■ Section 1.4, “Hot-Swap Support” on page 1-11

■ Section 1.5, “System Requirements” on page 1-11

■ Section 1.6, “Technical Support and Warranty” on page 1-13

1.1 Overview of the Sun Netra CP3060 Blade Server

The Sun Netra CP3060 blade server is a high-performance single-blade server

computer based on one UltraSPARC

availability in a switched network computing environment. This blade server is

compliant with Advanced Telecom Computing Architecture

(PICMG

compactPCI (cPCI) standards-based products targeted for telco markets.

The PICMG (PCI Industrial Computer Manufacturers Group) standards committee

has developed the new ATCA (or PICMG 3.x) standard to address the issues posed

by previous standards based on cPCI and cPSB (PICMG 2.x). The PICMG 3.x

specification brought the following changes to the existing PICMG 2.x family of

products:

■ Larger board space (8U high compared to 6U for cPCI), which allows more

■ On-board power supplies deriving local power from redundant −48V power from

®

3.0 and PICMG 3.1) and can achieve greater performance levels than

features and processing power

the midplane (rather than separate power supplies)

®

T1 multicore processor and designed for high

®

(ATCA) specifications

1-1

■ 6-HP slot width, allowing greater component height

■ Advanced Mezzanine card (AMC) support and options

■ Elimination of PCI connectivity between the blade servers in the system and

reallocation of connectivity to serial interconnects, eliminating single points of

failure

■ Mandatory use of Intelligent Platform Management Interface (IPMI) management

interfaces

■ Flexible user I/O

■ Power and thermal management guidelines enforced by the management

infrastructure

■ Separation of control and data traffic by supporting the Base (PICMG 3.0) and

Extended (PICMG 3.1) interfaces

The ATCA standard consists of the PICMG 3.0, PICMG 3.1, PICMG 3.2, and PICMG

3.3 specifications. The Sun Netra CP3060 blade server complies with:

■ PICMG 3.0, the base specification that defines the mechanical, power distribution,

system management, data transport, and regulatory guidelines

■ PICMG 3.1, which builds upon the PICMG 3.0 base specification and the IEEE

802.3-2003 standard

1.2 Features of the Sun Netra CP3060 Blade Server

The Sun Netra CP3060 blade server provides two 1000BASE-T Ethernet interfaces for

the Base interface (a requirement of PICMG 3.0) and two serializer, deserializer

(SERDES) gigabit Ethernet interfaces (PICMG 3.1) for the Extended interface. The

Base interface is used as the control interface and the Extended interface can be used

for data traffic. Both Base and Extended interfaces are configured as Dual Star

topologies.

Sun Netra CP3060 blade server features include:

■ Single-wide ATCA module

■ Compliant with PCIMG3.0/3.1 specification

■ UltraSPARC T1 4-core, 6-core, or 8-core, 1.0-GHz processor

■ Service processor (MPC885) for CPU reset, boot, partition, and fault management

architecture (FMA)

■ Memory subsystem

■ Eight standard DDR-2 Very Low Profile (VLP) DIMM sockets

1-2 Netra CP3060 Board User’s Guide • April 2009

■ 200 MHz DIMMs, buffered and registered with error-correcting code (ECC)

■ Up to 16 Gbytes of DIMM memory with 2-Gbyte DIMMs

■ JBus-to-PCI-E application-specific integrated circuits (ASICs) to bridge processors

and the PCI-E I/O subsystem

■ Two on-board 1000BASE-T Ethernet interfaces used as ATCA Base Interface

■ Two on-board 1000 SERDES Ethernet interfaces used as ATCA Extended Interface

■ One AMC slot for x8 PCI-E I/O expansion or compatible disk drive

■ Compliant with PCIMG AMC.0/.1/.3 specifications

■ Two 3-Gbps Serial Advanced Technology Attachment (SATA) ports routed to

AMC connector

■ Two 10/100/1000 BASE-T Ethernet RJ-45 ports on front panel

■ One asynchronous serial port on front panel

■ Compact Flash socket to support an 8-Gbyte user flash type I/II memory card

■ System management support using Pigeon Point Systems Intelligent Platform

Management (IPM) controller, providing a redundant IPMI channel to

communicate with the ATCA shelf manager

■ Rear I/O access using a compatible Sun Netra CP3060 rear transition module

(RTM)

■ Maximum power consumption: 200 watts (including Sun Netra CP3060 RTM)

FIGURE 1-1 and FIGURE 1-2 show the Sun Netra CP3060 blade server.

Chapter 1 Introduction to the Sun Netra CP3060 Blade Server 1-3

FIGURE 1-1 Sun Netra CP3060 Blade Server Front Panel

1

2

3

4

5

6

7

8

1 - Top latch 6 - Out of Service LED (yellow)

2 - AMC Hard Disk Drive (optional) 7 - OK LED (green)

3 - Ethernet port A (RJ-45) 8 - Hot-Swap LED (blue)

4 - Ethernet port B (RJ-45) 9 - Hot-Swap switch and bottom latch

5 - Serial port (RJ-45, ttya)

1-4 Netra CP3060 Board User’s Guide • April 2009

9

FIGURE 1-2 Sun Netra CP3060 Blade Server (Top View)

AMC HDD

(optional)

Processor

(under heat

sinks)

AMC slot

enclosure

Compact

Flash connector

Zone 3

connectors

Zone 2

connectors

DIMMs

Zone 1

power

connector

DIMMs

Chapter 1 Introduction to the Sun Netra CP3060 Blade Server 1-5

TABLE 1-1 lists features of the blade server.

TABLE 1-1 Feature Summary for the Sun Netra CP3060 Blade Server

Feature Description

CPU • One UltraSPARC T1 processor (4, 6, or 8 core)

• CPU core speed: 1.0 GHz

Memory • Eight DDR-2 240-pin Very Low Profile (VLP) DIMMs, buffered,

registered

• 1-Gbyte or 2-Gbyte DIMMs, for a total memory of 16 Gbytes

• ECC supported

Power

ATCA 3.0 standard of 200 watts maximum

requirement

PICMG

compliance

Node board

• PICMG 3.0 R1.0

• PICMG 3.1 R1.0

Functions as a CPU node board with the Solaris software package

support

Operating

system

Internal I/O

(connections to

ATCA

midplane)

Solaris 10 6/06 OS and subsequent compatible versions with supported

Netra patches

• Dual gigabit Ethernet for Base interface

• Dual SERDES interface as Extended interface

• Dual IPMI channel connects to the midplane for communicating with

the Shelf Management card

External I/O • Two 10/100/1000 BASE-T Ethernet ports on front panel

• One asynchronous serial port for maintenance on front panel

• One AMC slot with front panel access for AMC I/O

• Rear access support using Sun Netra CP3060 RTM:

–One 10/100 Mbps Ethernet port

–One asynchronous serial port. Access is available in front and rear

when RTM is present. Note: Either serial port can be used; but only

one of the serial ports can be used at a time.

AMC I/O Provision for adding an independent hardware vendor (IHV)-supplied

AMC disk or PCI-E card on front panel

IPMI system

management

Uses IPMI communications with baseboard management controller

(BMC); performs advanced system monitoring (ASM) on local board

interface (for example, temperature sense, FRU ID, and control)

Hot-swap

support

• Basic, full, and high-availability (HA) hot-swap support for node board

• AMC disk/card hot-swap support

1-6 Netra CP3060 Board User’s Guide • April 2009

TABLE 1-1 Feature Summary for the Sun Netra CP3060 Blade Server (Continued)

Feature Description

Front panel

access

Building

compliance

Flash update Supported from downloaded file

• One serial port (RJ-45)

• Two 10/100/1000BASE-T Ethernet ports (RJ-45)

• Cutout for installing AMC without removing blade server from system

Network Equipment Building Systems (NEBS) Level 3

Note – For EMI compliance of front access ports, use shielded cables on all I/O

ports. The shields for all shielded cables must be terminated on both ends.

1.3 Sun Netra CP3060 Blade Server System Configurations

Sun Netra CP3060 blade servers can be installed in an ATCA shelf (or chassis),

shown in

configurations to suit each end-user requirement. For example, the blade server can

be configured to boot from a network as a diskless client with either a front panel or

RTM network connection, or from an optional Compact Flash card. Alternatively,

industry-standard Advanced Mezzanine Card (AMC) hardware from IHVs can be

installed to provide local disk I/O, which can be used optionally as a boot path. The

Sun Netra CP3060 blade server has fixed on-blade server memory and connectors for

additional memory.

FIGURE 1-3. The blade servers can be deployed in various electrical

Chapter 1 Introduction to the Sun Netra CP3060 Blade Server 1-7

FIGURE 1-3 Sun Netra CP3060 Blade Server in an ATCA Shelf Enclosure

Remote server

Ethernet

Ethernet

connection

Netra CP3060 blade server

Diskless client that boots through network from a remote server

1.3.1 AMC Modules

The Sun Netra CP3060 blade server has one AMC slot to provide additional I/O to

the front panel. The AMC slot supports AMC-compatible SATA disk drives and

PCI-E cards. See Section A.4.2, “AMC Connector ” on page A-5 for more

information.

Netra CP3060 RTM

Serial

connection

Terminal console

ATCA shelf

1.3.2 Rear Transition Module

The optional Sun Netra CP3060 RTM installs into the rear of the ATCA enclosure,

opposite the Sun Netra CP3060 blade server (see

the host node board’s Zone 3 rear I/O connectors and includes a serial port and

10/100BASE-T Ethernet port, both with RJ-45 connectors (see

FIGURE 1-4 Sun Netra CP3060 Rear Transition Module

1-8 Netra CP3060 Board User’s Guide • April 2009

FIGURE 1-5). The RTM connects with

FIGURE 1-4).

Zone 3 connectors

Serial portEthernet port

FIGURE 1-5 shows the physical relationship between the blade server, the rear

transition module, and the midplane in a typical ATCA system.

Chapter 1 Introduction to the Sun Netra CP3060 Blade Server 1-9

FIGURE 1-5 Relationship of the Sun Netra CP3060 Blade Server, Midplane, and RTM

Zone 3

connectors

Netra CP3060 blade server

(installed from front)

Netra CP3060 RTM

(installed from rear)

ATCA chassis midplane

Note – When the RTM is used with the Sun Netra CP3060 blade server, shielded

cables are required for serial I/O ports. Unshielded cables can be used on Ethernet

ports to satisfy EMI compliance standards. The shields for all shielded cables must

be terminated on both ends.

The customer can order the Sun Netra CP3060 RTM, build a custom card, or buy

from an IHV. A minimal set of I/O must provide a boot path for the host board and

a path for console I/O to deliver commands and to read board and system status.

1-10 Netra CP3060 Board User’s Guide • April 2009

Possible boot and console configurations are described in TABLE 1-2. Sun

Microsystems provides the Sun Netra CP3060 blade server and a compatible Sun

Netra CP3060 RTM. The other configurations require IHV hardware.

TABLE 1-2 I/O Configurations

I/O Hardware Required Description

Ethernet Sun Netra CP3060 blade server

Sun Netra CP3060 RTM

(RTM—supplied as an option

for rear access)

SATA Through the AMC connector SATA devices can be used for local booting.

Serial data Sun Netra CP3060 blade server

Sun Netra CP3060 RTM

Compact

Flash

Sun Compact Flash card The Compact Flash connector can be used to add an optional

Default boot path uses the Ethernet port; when the blade server

runs in diskless client configuration.

Serial port on front panel provides a path for a console I/O.

The serial port can be used on either the Sun Netra CP3060

blade server or Sun Netra CP3060 RTM, but both ports cannot

be used at the same time. If the serial port on Sun Netra CP3060

blade server is used, the serial port on the Sun Netra CP3060

RTM should not be used and vise versa.

8-Gbyte user flash type I/II memory card.

1.4 Hot-Swap Support

This section briefly discusses the hot-swap support on the Sun Netra CP3060 blade

server.

There are three hot-swap models described in the PICMG ATCA specification: basic

hot-swap, full hot-swap, and high-availability (HA) hot-swap. Refer to the PICMG

ATCA Specification, which provides a detailed description of this subject.

This process uses hardware connection control to connect the hardware in an orderly

sequence.

1.5 System Requirements

This section contains the system-level hardware and software requirements for the

Sun Netra CP3060 blade server.

Chapter 1 Introduction to the Sun Netra CP3060 Blade Server 1-11

1.5.1 Hardware Requirements

Sun provides the following items for customer order:

■ Sun Netra CP3060 node blade server

■ Sun Netra CP3060 RTM (optional)

The RTM enables rear system I/O access to the network, to a boot device, and to

a console terminal (shown in

Transition Module User’s Guide (819-6689) for more information.

The Sun Netra CP3060 RTM is optional and must be ordered separately.

■ Compact Flash card (optional)

An IDE Compact Flash card is optional and must be ordered separately.

Acquire the following components, if needed:

■ Serial terminal or terminal emulation for console output.

■ Cables for terminal and network connections.

■ The Sun Netra CP3060 RTM and the AMC disks and PCI-E cards are optional.

TABLE 1-3 lists ATCA and other minimum requirements met by the Sun Netra CP3060

blade server.

FIGURE 1-4). Refer to the Sun Netra CP3060 Rear

TABLE 1-3 ATCA and Other Minimum Requirements Met By the Sun Netra CP3060

Blade Server

Requirements

ATCA system enclosure for 8U boards (includes chassis,

midplane, power supply)

Console output device or serial terminal Yes

Boot device (such as hard drive, network, or Compact Flash card) Yes

Peripheral device for network access Yes

Intelligent Platform Management Controller (IPMC) Yes

1.5.2 Software Requirements

The Sun Netra CP3060 blade server supports the following versions of the Solaris

OS:

■ Solaris 10 OS and subsequent compatible versions

1-12 Netra CP3060 Board User’s Guide • April 2009

Sun Netra CP3060 Node

Blade Ser ver

Ye s

Refer to the Sun Netra CP3060 Blade Server Product Notes (819-4966) for more Solaris

OS information, including a list of the required Netra software patches. You can

view and download the latest version of this manual at the following web site:

http://www.sun.com/documentation

1.6 Technical Support and Warranty

Should you have any technical questions or support issues that are not addressed in

the Sun Netra CP3060 blade server documentation set or on the web site, contact

your local Sun Services representative. This hardware carries a one-year

return-to-depot warranty. For customers in the US or Canada, call 1-800-USA-4SUN

(1-800-872-4786). For customers in the rest of the world, find the World Wide

Solution Center nearest you by visiting our web site:

http://www.sun.com/service/contacting/solution.html

When you call Sun Services, be sure to indicate if the Sun Netra CP3060 blade server

was purchased separately and is not associated with a system. Have the proper

blade server identification information ready. Be prepared to give the representative

the blade server part number, serial number, and date code (see

FIGURE 1-6).

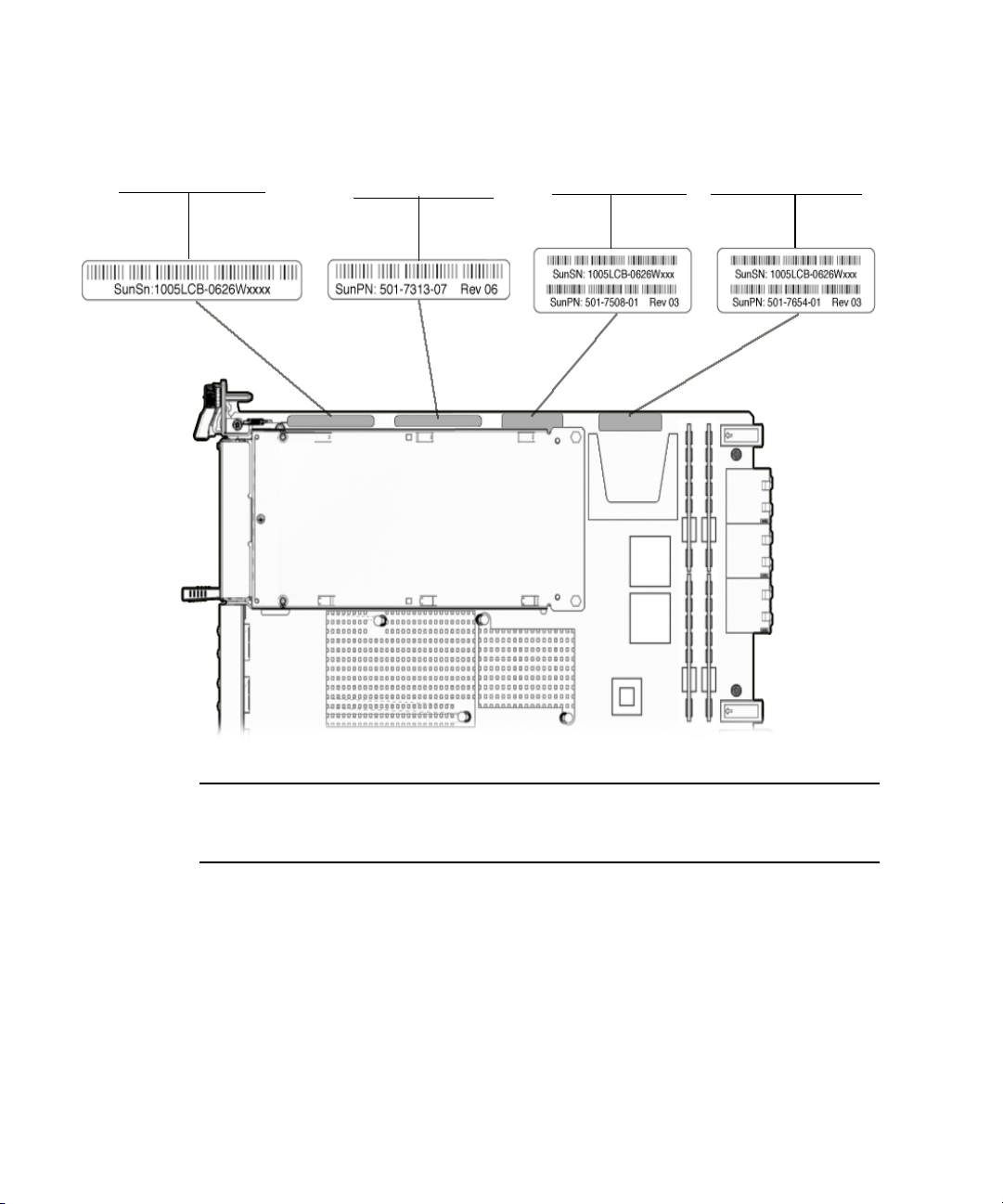

1.6.1 Blade Server Part Number, Serial Number, and Revision Number Identification

The Sun Netra CP3060 blade server part number, serial number, and revision can be

found on labels located on the card (see

the following information:

■ SunSN – Sun serial number (for example, 1005LCB-0626WM001M)

■ SunPN – Sun part number and dash number (for example, 501-7658-01), -01 is the

dash number

■ Rev – Revision number of the part (for example: Rev 06)

The Media Access Control (MAC) address label contains the MAC address for the

blade server in printed and barcode form.

Chapter 1 Introduction to the Sun Netra CP3060 Blade Server 1-13

FIGURE 1-6). The Sun barcode labels provide

FIGURE 1-6 Sun Netra CP3060 Blade Server Barcode Labeling

Blade Server serial number

Blade Server part number

CPU configuration Memory configuration

Note – You might find the labels shown in FIGURE 1-6 on other locations on your

blade server. Your particular blade server configuration might also appear different

from the illustration.

1-14 Netra CP3060 Board User’s Guide • April 2009

CHAPTER

2

Hardware Installation

This chapter describes the hardware installation procedures for the Sun Netra

CP3060 blade server, and contains the following sections:

■ Section 2.1, “Equipment and Operator Safety” on page 2-1

■ Section 2.2, “Materials and Tools Required” on page 2-2

■ Section 2.3, “Preparing for the Installation” on page 2-3

■ Section 2.4, “Configuring the Blade Server Hardware” on page 2-5

■ Section 2.5, “Installing the Sun Netra CP3060 Blade Server” on page 2-11

■ Section 2.6, “Connecting External I/O Cables” on page 2-17

2.1 Equipment and Operator Safety

Refer to Important Safety Information for Sun Hardware Systems (816-7190) for general

safety information.

Read the safety statements specific to the Sun Netra CP3060 blade server carefully

before you install or remove any part of the system.

Caution – Depending on the particular chassis design, operations with open

equipment enclosures can expose the installer to hazardous voltages with a

consequent danger of electric shock. Ensure that line power to the equipment is

disconnected during operations that make high voltage conductors accessible.

The installer must be familiar with commonly accepted procedures for integrating

electronic systems and with the general practice of Sun systems integration and

administration. Although parts of these systems are designed for hot-swap

2-1

operation, other components must not be subjected to such stresses. Work with

power connected to a chassis only when necessary, and follow these installation

procedures to avoid equipment damage.

This equipment is sensitive to damage from electrostatic discharge (ESD) from

clothing and other materials. Use the following antistatic measures during an

installation:

■ If possible, disconnect line power from the equipment chassis when servicing a

system or installing a hardware upgrade. If the chassis cannot be placed upon a

grounded antistatic mat, connect a grounding strap between the facility electrical

input ground (usually connected to the equipment chassis) and facility electrical

service ground.

■ Use an antistatic wrist strap when:

■ Removing a blade server from its antistatic bag

■ Connecting or disconnecting blade servers or peripherals

The other end of the strap lead should be connected to one of the following:

■ A ground mat

■ Grounded chassis metalwork

■ A facility electrical service ground

■ Keep blade servers in the antistatic bags until they are needed.

■ Place circuit blade servers that are out of their antistatic bags on an antistatic mat

if one is available. The mat must be grounded to a facility electrical service

ground. Do not place blade servers on top of an antistatic bag unless the outside

of the bag also has antistatic protective properties.

■ Remove a blade server from its antistatic bag only when wearing a properly

connected ground strap.

2.2 Materials and Tools Required

This section provides information on the materials and tools required to perform

installation. The minimum tools required to perform installation are:

■ Phillips screwdrivers, No. 1, No. 2 (optional)

■ Antistatic wrist strap

■ Terminal console

See Section 1.5.1, “Hardware Requirements” on page 1-12 for information on

hardware requirements.

2-2 Netra CP3060 Board User’s Guide • April 2009

2.3 Preparing for the Installation

Read the following subsections before starting to install these blade servers. In

addition, do the following:

1. Become familiar with the contents of the referenced documentation.

2. Verify that all listed hardware and software is available (see Section 1.5, “System

Requirements” on page 1-11).

3. Check power, thermal, environmental, and space requirements (see Section 2.3.1,

“Checking Power, Thermal, Environmental, and Space Requirements” on

page 2-3).

4. Verify that local area network (LAN) preparations are completed (see

Section 2.3.2, “Determining Local Network IP Addresses and Host Names” on

page 2-4).

5. Ensure that the host names and their network IP addresses are allocated and

registered at the site.

2.3.1 Checking Power, Thermal, Environmental, and Space Requirements

Verify that you meet the following requirements:

■ Your enclosure specifications support the sum of the specified maximum blade

server power loads. See Section 5.3, “Power” on page 5-27 for blade server power

specifications.

■ Facility power loading specifications can support the rack or enclosure

requirements.

■ Your enclosure specifications support the cooling airflow requirements. The Sun

Netra CP3060 blade server fits a standard ATCA shelf or chassis. If your

installation requirements are different, contact your field application engineer.

Chapter 2 Hardware Installation 2-3

2.3.2 Determining Local Network IP Addresses and Host Names

Collect the following information to connect hosts to the local area network (LAN).

Ask your network administrator for help, if necessary. You can use

record this information. This information is not needed for a standalone installation.

TABLE 2-1 Local Network Information

Information Needed Your Information

IP address*and host name for each Sun

Netra CP3060 client

Domain name

Type of name service and corresponding

name server names and IP addresses—for

example, DNS and NIS (or NIS+)

Subnet mask

Gateway router IP address

NFS server names and IP addresses

Web server URL

* Local IP addresses are not needed if they are assigned by a network DHCP server.

TABLE 2-1 to

You might need the MAC (Ethernet) addresses of the local hosts to make nameserver

database entries. The MAC address can be seen in the console output while booting

to the ok prompt. It can also be derived from the host ID seen on the barcode label

(see Section 1.6.1, “Blade Server Part Number, Serial Number, and Revision Number

Identification” on page 1-13).

2.3.3 Installation Procedure Summary

The steps in this section summarize the Sun Netra CP3060 blade server installation

at a high level. Be sure to read the details in Section 2.4, “Configuring the Blade

Server Hardware” on page 2-5 before installing the blade server.

The procedure to set up and configure a Sun Netra CP3060 blade server in a system

includes the following steps:

1. Configure the blade server’s physical hardware. For example, install memory or

Compact Flash, as necessary.

2. Configure the rear transition module (RTM), as necessary.

2-4 Netra CP3060 Board User’s Guide • April 2009

3. Optional - Physically install the Sun Netra CP3060 RTM into the chassis.

4. Physically install the Sun Netra CP3060 blade server into the chassis.

5. Connect the nodes to a local network. Alternatively, the blade server can be run as

a standalone system without a network connection.

6. Optional - Install an AMC module on the Sun Netra CP3060 blade server.

7. Install the operating system and patches, as necessary. See Section 3.1, “Operating

Systems and Patches” on page 3-1.

2.4 Configuring the Blade Server Hardware

This section lists hardware installation and settings that might apply to your blade

server configuration. Read and perform the procedures, as necessary, before

installing the Sun Netra CP3060 blade server into the chassis.

2.4.1 Installation of DDR-2 DIMM Memory Modules

The Sun Netra CP3060 blade server supports a total of 8 DIMMs and a maximum

memory capacity of 16 Gbytes (using eight 2-Gbyte DIMMs).

location of the DIMMs. In addition to the on-board memory, the Sun Netra CP3060

blade server accommodates the following:

■ Eight standard DDR-2 DIMMs, buffered, and registered

■ 1-Gbyte and 2-Gbyte DDR-2 modules supported

■ DIMMs are installed as shown in FIGURE 2-1

FIGURE 2-1 shows the

Note – You cannot mix 1-Gbyte and 2-Gbyte DIMMs.

The Sun Netra CP3060 blade server supports DDR-2 DIMM memory modules that

have the following characteristics:

■ Each DIMM has a 72-bit-wide data bus (64+8 ECC) and up to 14 address bits.

■ Maximum height of the DIMM module is 0.72 inches, Very Low Profile (VLP).

■ Supports single-bank or dual-bank SDRAM DIMMs.

■ Memory controller supports 128-bit data plus 9-bit error-correcting code (ECC).

■ Maximum of 16 Gbytes.

Chapter 2 Hardware Installation 2-5

For additional information, see Section 5.1.2, “DDR-2 Memory Subsystem” on

page 5-7.

FIGURE 2-1 DDR-2 DIMM Memory Locations

FIGURE 2-1 shows the location of the DIMMs.

DIMM0DIMM1

DIMM5 DIMM4 DIMM12 DIMM13 DIMM8 DIMM9

Note: Channels 1 and 2 are used in four DIMM configurations.

Channels 0 and 3 are only used in eight DIMM configurations.

2-6 Netra CP3060 Board User’s Guide • April 2009

(Channel 2)(Channel 1) (Channel 3)(Channel 0)

2.4.1.1 Installing a DDR-2 DIMM Memory Module

The following procedure provides a general guide for installing additional memory.

However, for directions on the installation process of the memory DDR-2 DIMMs on

the Sun Netra CP3060 blade server, refer to the documentation that shipped with the

memory module.

Caution – Do not remove the DDR-2 DIMM from its antistatic container until you

are ready to install it on the card. Handle the module only by its edges. Do not touch

module components or metal parts. Always wear a grounded antistatic wrist strap

when handling modules.

1. Locate the DDR-2 DIMM connectors on the Sun Netra CP3060 blade server.

Select the connectors where you will install the memory module (see

If you need to replace an existing memory module with a new module, see

Section 2.4.1.2, “Removing a DDR-2 DIMM Memory Module” on page 2-8 for

instructions on removing the DDR-2 DIMM module.

2. Remove the DDR-2 DIMM from its protective packaging, holding the module

only by the edges.

3. Insert the bottom edge of the DDR-2 DIMM into the bottom of the slot’s

hinge-style connector (see

The socket and module are both keyed, which means the module can be installed

one way only. With even pressure, push simultaneously on both upper corners of

the DDR-2 DIMM until its bottom edge (the edge with the gold fingers) is firmly

seated in the connector.

FIGURE 2-2).

FIGURE 2-1).

Chapter 2 Hardware Installation 2-7

FIGURE 2-2 Installing a DDR-2 DIMM Memory Module

Caution – Do not rock the DDR-2 DIMM into place. Ensure that all contacts engage

at the same time. You will feel or hear a click when the DDR-2 DIMM properly seats

in the connector.

4. Press the top edge of the DDR-2 DIMM toward the blade server until the

retainer clips click into place (see

FIGURE 2-2).

The small retainer clips on each side of the DDR-2 DIMM slot click into place in

the notches on the sides of the DDR-2 DIMM.

2.4.1.2 Removing a DDR-2 DIMM Memory Module

You might need to remove a DDR-2 DIMM module from the Sun Netra CP3060

blade server if you are returning the DDR-2 DIMM module or the blade server for

service, or if you are replacing a module with another DDR-2 DIMM module.

Note – Safely store the original factory-shipped DDR-2 DIMM and related DDR-2

DIMM packaging. You might wish to store any removed DDR-2 DIMM in the new

DDR-2 DIMM packaging, or use the packaging for service.

To remove a DDR-2 DIMM from the Sun Netra CP3060 blade server, perform the

following steps:

1. Take antistatic precautions: attach and electrically ground the wrist strap.

2-8 Netra CP3060 Board User’s Guide • April 2009

Caution – Always wear a grounded antistatic wrist strap when handling modules.

2. Place the Sun Netra CP3060 blade server on an antistatic mat, or on the blade

server’s antistatic bag if you do not have a mat available.

3. For the DDR-2 DIMM you wish to remove, simultaneously pull both DDR-2

DIMM retainer clips outward from the slot.

4. Grasp the DDR-2 DIMM by the edges, and carefully pull it out of its connector.

Place it in an antistatic bag.

FIGURE 2-3 Removing a DDR-2 DIMM Memory Module

5. If you are replacing the module you removed with a new DDR-2 DIMM, install

it as described in Section 2.4.1.1, “Installing a DDR-2 DIMM Memory Module” on

page 2-7.

2.4.2 Installation of Optional Compact Flash Card

An optional IDE Compact Flash card can be installed on the Sun Netra CP3060 blade

server. The Compact Flash card is not hot-swappable and there is no access to the

card once the blade server is installed in an ATCA chassis.

Chapter 2 Hardware Installation 2-9

To install the Compact Flash card, use the arrow on the card’s label as a guide and

insert the card into the Compact Flash connector (see

FIGURE 2-4 Compact Flash Card Connector

FIGURE 2-4).

Compact Flash connector

2.4.3 Configuring Rear Transition Module Hardware

If you are using the Sun Netra CP3060 RTM, refer to the Sun Netra CP3060 Rear

Transition Module User’s Guide (819-6689). You can also refer to the Sun Netra CP3060

RTM manual for detailed connector pin assignments.

2-10 Netra CP3060 Board User’s Guide • April 2009

2.5 Installing the Sun Netra CP3060 Blade Server

If you are installing the Sun Netra CP3060 blade server with the RTM, first install the

RTM at the rear of the server. Then install the node card in the front of the server.

Even though you will be installing the RTM first, look at the front of the server and

locate the slot number where you will be installing the Sun Netra CP3060 blade

server. Then go to the back of the server and install the RTM in that particular slot.

2.5.1 Installing the Sun Netra CP3060 Blade Server With a Rear Transition Module

A compatible RTM must be used with the Sun Netra CP3060 blade server for rear

I/O access. The RTM enables access to the network, to a boot device, and to a

console terminal. You can use the Sun Netra CP3060 RTM, or you might design your

own rear transition module.

Chapter 2 Hardware Installation 2-11

FIGURE 2-5 Installing the Sun Netra CP3060 Rear Transition Module

Zone 3

connectors

Netra CP3060 blade server

(installed from front)

Netra CP3060 RTM

(installed from rear)

ATCA chassis midplane

2.5.1.1 Installing a Rear Transition Module

1. Verify that you have taken the necessary antistatic precautions.

2. Go to the rear of the system and choose an appropriate slot for the RTM.

RTMs must be installed inline behind the accompanying node blade server. For

example, if the accompanying node blade server is installed in slot 3, its RTM

must be installed at the back of the system in slot 3. See

2-12 Netra CP3060 Board User’s Guide • April 2009

FIGURE 2-5.

3. Remove the slot filler panel from the selected node blade server slot, if

necessary.

4. Get the RTM from the shipping kit.

5. Perform any card-specific hardware procedures, if necessary.

Refer to the documentation that you received with the card for more information.

6. Prepare the card by opening the injector/ejector latches at the top and bottom of

the card (

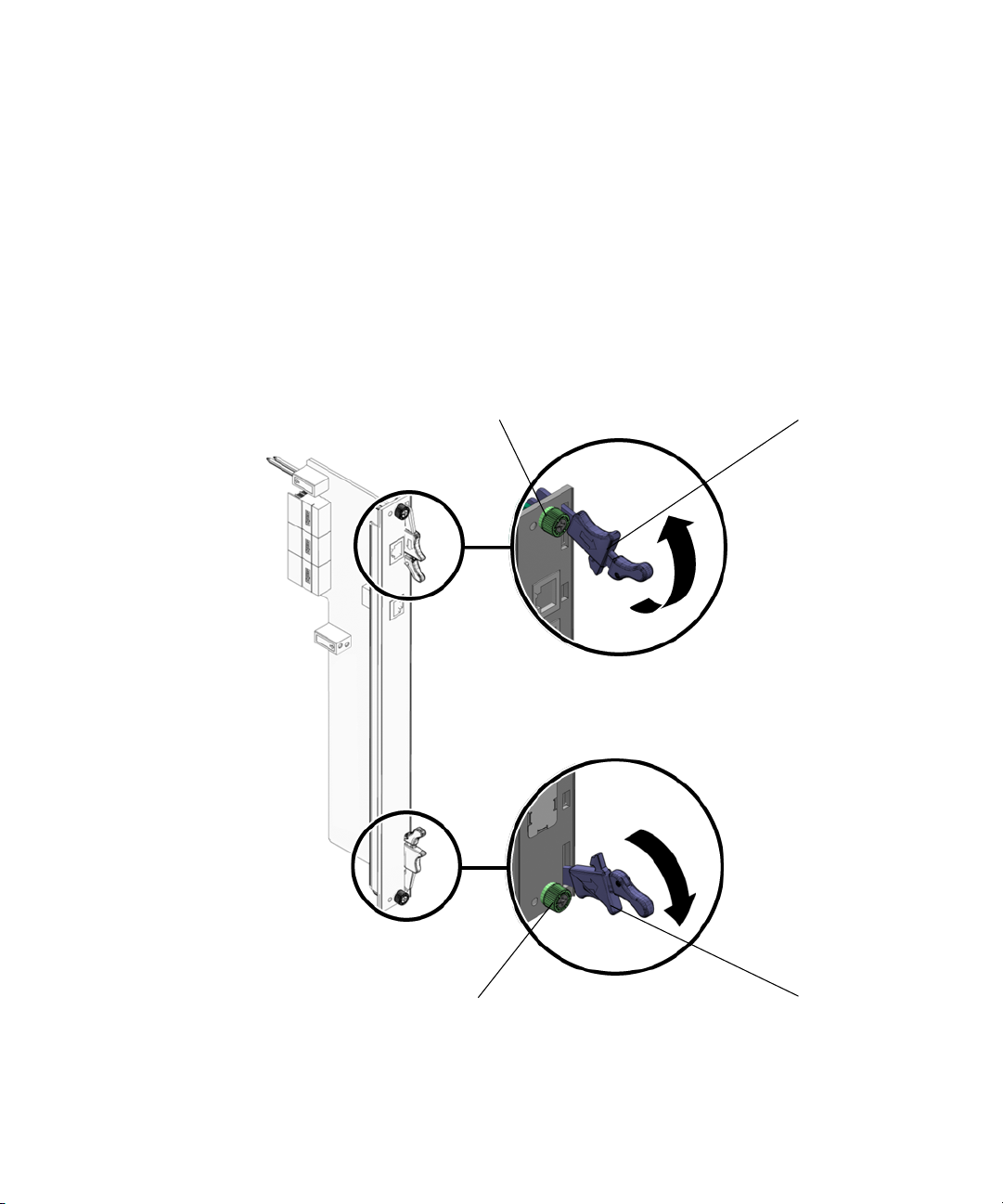

FIGURE 2-6 RTM Injector/Ejector Latch and Locking Screw

FIGURE 2-6).

Locking screw

Injector/ejector latch

Locking screw

Injector/ejector latch

Chapter 2 Hardware Installation 2-13

7. Carefully align the edges of the card with the card guides in the appropriate

slot.

It might be helpful to look into the enclosure to verify correct alignment of the

rails in the guides.

8. Taking care to keep the blade server aligned in the guides, slide the card in

until the injector/ejector latches engage the card cage.

9. Push the blade server into the midplane connectors and close the latches to seat

the blade server in the connectors.

10. Tighten the locking screws to ensure that the blade server is secured into the

shelf.

11. Install the Sun Netra CP3060 blade server into the shelf.

Go to Section 2.5.2, “Installing the Sun Netra CP3060 Blade Server” on page 2-15

for those instructions.

2.5.2 Installing the Sun Netra CP3060 Blade Server

1. If you have installed a Sun Netra CP3060 RTM, go to the front of the system

and locate the card slot where you installed the RTM at the rear of the system.

2. Remove the filler panel, if necessary.

The filler panel is secured to the card cage using two screws, one at the top of the

filler panel, the other at the bottom. Store the filler panel in a safe place; you

might need to use it again if you have to remove a card for an extended period of

time.

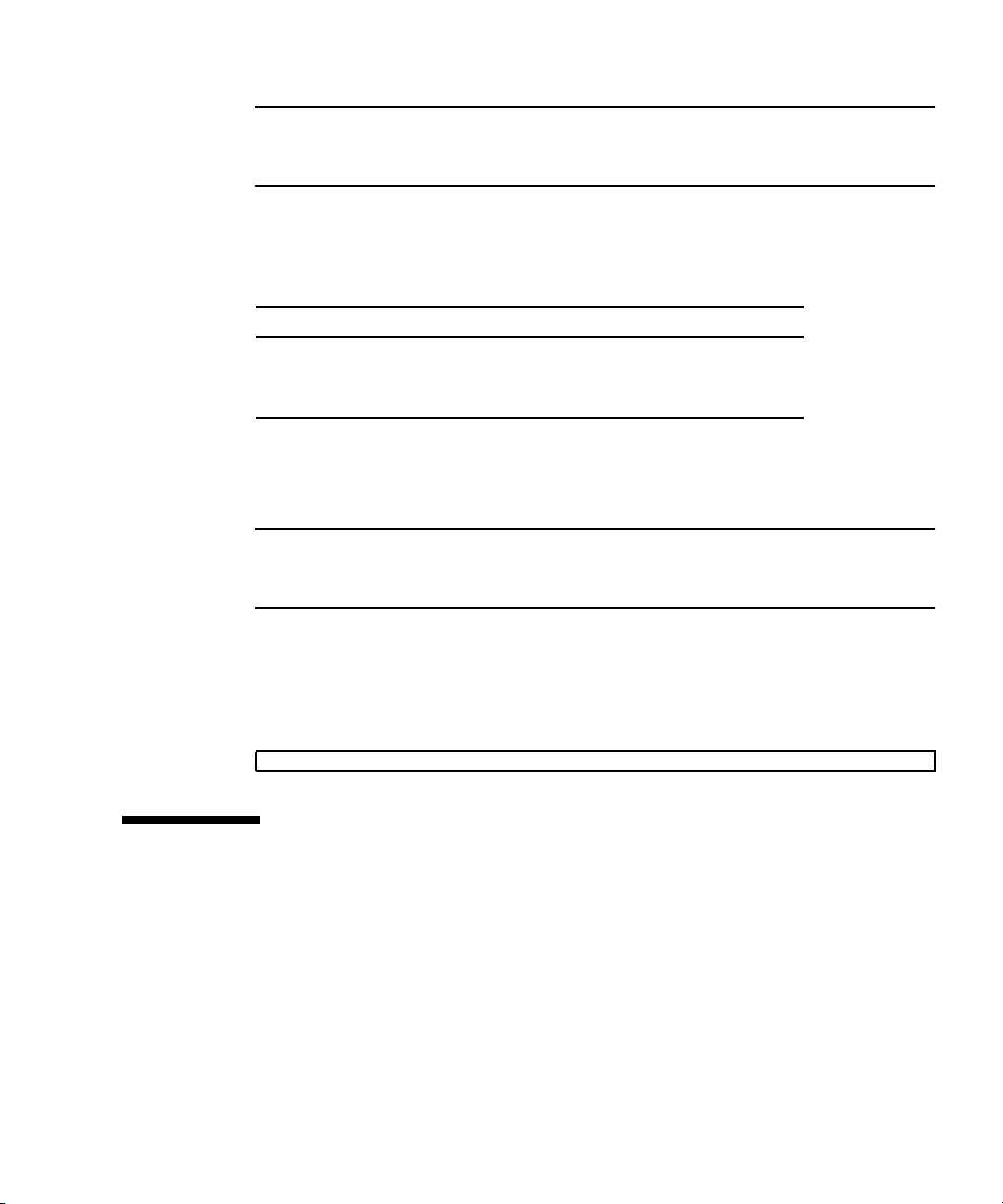

3. Prepare the blade server by opening the injector/ejector latches (

4. Carefully align the edges of the blade server with the card guides in the

appropriate slot (

It might be helpful to look into the enclosure to verify correct alignment of the

rails in the guides.

5. Taking care to keep the blade server aligned in the guides, slide the blade

server in until the injector/ejector latches engage the card cage.

2-14 Netra CP3060 Board User’s Guide • April 2009

FIGURE 2-7).

FIGURE 2-6).

FIGURE 2-7 Installing Node Blade Server Into Chassis Slot

6. Taking care to keep the blade server aligned in the guides, slide the blade

server in until the injector/ejector latches engage the card cage.

7. Push the blade server slightly into the midplane connectors, and then close the

latches to seat the blade server in the connectors (

FIGURE 2-8).

When the lower latch is closed, the blue Hot-Swap LED blinks while the blade

server is initializing. The blue LED turns off and the green OK LED lights when

the blade server is ready.

Chapter 2 Hardware Installation 2-15

FIGURE 2-8 Sun Netra CP3060 Blade Server Latches and Locking Screws

Locking screw

Bottom hot-swap

/

latch

Top latch

Locking screw

8. Tighten the locking screws to ensure the blade server is secured into the shelf

(see

FIGURE 2-6).

2.6 Connecting External I/O Cables

External I/O cables are connected to the Sun Netra CP3060 blade server, or to the

Sun Netra CP3060 RTM when a rear transition module is used. Information on

connecting each of these cables follows:

■ For Ethernet connections, category 5e or better network cable is required. One

end of the Ethernet cable is connected to a suitable 10/100/1000BASE-T switch

and the other end to one of the Ethernet ports on the Sun Netra CP3060 blade

server. Both Ethernet ports A and B are available on the Sun Netra CP3060 blade

server front panel.

2-16 Netra CP3060 Board User’s Guide • April 2009

Note – A single 10/100BASE-T Ethernet port is also available on the Sun Netra

CP3060 RTM when installed.) Refer to the Sun Netra CP3060 Rear Transition Module

User’s Guide (819-6689) for more information.

Use the bge device names shown in

TABLE 2-2 when configuring the Ethernet

ports.

TABLE 2-2 bge Device Names

Ethernet Ports Solaris 10 OS

Ethernet Port A (on front panel) and

Ethernet port on the RTM

Ethernet Port B (on front panel) e1000g1

■ An asynchronous serial I/O cable can be attached from serial communication

e1000g0

devices to the RJ-45 serial port on the Sun Netra CP3060 blade server’s front

panel.

Note – A serial port is also provided on the Sun Netra CP3060 RTM. Either the

serial port on the Sun Netra CP3060 blade server or the serial port on Sun Netra

CP3060 RTM can be used, but only one of the ports should be used at one time.

Once a serial cable is connected, use the tip utility on the host to establish a

full-duplex terminal connection with the Sun Netra CP3060 blade server. At the

UNIX prompt in a command tool or shell tool, type:

TABLE 2-3

# tip -9600 /dev/ttya (for serial port)

2.7 Installation of Optional AMC Modules

An Advanced Mezzanine card (AMC) is a card or module that provides additional

functionality to the Sun Netra CP3060 blade server. The blade server contains one

AMC slot in which you can install an optional AMC device (see

location of these slots). The AMC device can be installed and removed via a cutout

in the front panel while the Sun Netra CP3060 blade server is installed in the chassis.

Chapter 2 Hardware Installation 2-17

FIGURE 2-1 for the

2.7.0.1 Installing an Optional AMC Module

Note – The following procedure provides a general set of instructions for installing

AMC modules on the Sun Netra CP3060 blade server. Refer to the AMC module

manufacturer’s documentation for specific instructions on installing these devices.

1. Retrieve the wrist strap from the adapter’s shipping kit.

2. Attach the adhesive copper strip of the antistatic wrist strap to the metal

chassis. Wrap the other end twice around your wrist, with the adhesive side

against your skin.

3. Remove the AMC slot filler panel from the blade server’s front panel.

(

FIGURE 2-9).

FIGURE 2-9 Removing AMC Slot Filler Panel

AMC slot filler panel

4. Retrieve the AMC module from its shipping kit and place it on an antistatic

surface.

5. Insert the AMC module through the cutout and into the AMC slot (

2-18 Netra CP3060 Board User’s Guide • April 2009

FIGURE 2-10).

FIGURE 2-10 Inserting AMC Module Into AMC Connector

AMC module

(AMC disk drive shown)

6. Carefully plug the AMC module into the AMC connector (FIGURE 2-10).

Ensure that the AMC module is seated correctly in the connector.

Caution – Do not use excessive force when installing the AMC module into the slot.

You might damage the AMC connector on the Sun Netra CP3060 blade server,

causing permanent damage to the AMC module or the blade server. If the AMC

module does not seat properly when you apply even pressure, remove the AMC

module and carefully reinstall it.

7. Refer to the AMC module documentation for software and cabling installation

instructions.

Chapter 2 Hardware Installation 2-19

2-20 Netra CP3060 Board User’s Guide • April 2009

Chapter 2 Hardware Installation 2-21

CHAPTER

3

Software Installation

This chapter contains the following sections:

■ Section 3.1, “Operating Systems and Patches” on page 3-1

■ Section 3.2, “Firmware Updates” on page 3-2

■ Section 3.3, “Mandatory /etc/system File Entry” on page 3-2

■ Section 3.4, “Installing Diskless Clients” on page 3-3

■ Section 3.5, “Downloading and Installing SunVTS Software” on page 3-7

3.1 Operating Systems and Patches

The Sun Netra CP3060 blade server supports the Solaris 10 6/06 OS and subsequent

compatible versions, with supported Netra patches. The Solaris OS software can be

downloaded from the Sun download center at:

http://www.sun.com/download

Note – Refer to the Sun Netra CP3060 Blade Server Product Notes (819-4966) for

information on the Netra patches at http://www.sun.com/documentation.

For information on these versions of the Solaris OS, including installation, see the

appropriate Solaris Documentation Collection at the Sun Documentation web site at:

http://www.sun.com/documentation

3-1

3.2 Firmware Updates

The Sun Netra CP3060 firmware updates can be downloaded from the Sun

download center at:

http://www.sun.com/download

Note – For information on firmware updates, refer to the Sun Netra CP3060 Blade

Server Product Notes (819-4966) which are available online at

http://www.sun.com/documentation.

3.3 Mandatory /etc/system File Entry

A mandatory entry must be listed in the /etc/system file to ensure the optimal

functionality of the blade server.

The following entry must be in the /etc/system file:

set pcie:pcie_aer_ce_mask=0x1

Check that the entry is present before deploying the blade server.

▼ To Check and Create the Mandatory

/etc/system File Entry

1. Log in as superuser.

3-2 Netra CP3060 Board User’s Guide • April 2009

2. Check the /etc/system file to see if the mandatory line is present.

TABLE 3-1

# more /etc/system

*ident "@(#)system 1.18 05/06/27 SMI" /* SVR4 1.5 */

*

* SYSTEM SPECIFICATION FILE

.

.

.

set pcie:pcie_aer_ce_mask=0x1

.

3. If the entry is not there, add it.

Use an editor to edit the /etc/system file and add the entry.

4. Reboot the server.

3.4 Installing Diskless Clients

The following procedures describe how to create a boot server for diskless clients

and how to add new diskless clients to the patched boot server. For additional

instructions on installing diskless clients, refer to the appropriate Solaris

Documentation Collection at the Sun Documentation web site at:

http://www.sun.com/documentation

You must have a superuser password on your diskless server to perform the

following tasks.

3.4.1 Creating a Boot Server for Diskless Clients

Note – This procedure sets up a boot server by starting the operating environment

services required for diskless clients. Once you have set up the boot server, see

Section 3.4.2, “Adding a Diskless Client” on page 3-5 for instructions on adding

diskless clients to the boot server.

1. Verify that the IP addresses for all other network interfaces on the boot server

have corresponding hostnames in the hosts database.

Chapter 3 Software Installation 3-3

2. Log in to the network server as superuser and change to the /usr/sadm/bin

directory.

TABLE 1

# cd /usr/sadm/bin

3. Use the smosservice command to add boot services to the installation server.

Note – The following command is a single long entry. Do not press the Return key

until you have typed the entire text string shown in the following command.

TABLE 2

# ./smosservice add -u root -p root_password -- -x mediapath=image_directory

-x platform=sparc.sun4v.Solaris_n -x cluster=SUNWCXall -x locale=locale

Where:

■ root_password is the root password for the installation server

■ image_directory is the path to the directory where the Solaris install image is stored

■ N is the Solaris OS version you are using.

■ locale is the locale that you want to use

Refer to the smosservice(1M) man page for more information and options.

For example:

TABLE 3

# ./smosservice add -u root -p root_password -- -x mediapath=/export/install

-x platform=sparc.sun4v.Solaris_10 -x cluster=SUNWCXall -x locale=en_US

Where:

■ root_password = root_password

■ image_directory = /export/install

■ locale = en_US

■ n = 10 (for Solaris 10)

3-4 Netra CP3060 Board User’s Guide • April 2009

4. Download and install additional patches.

Refer to the Sun Netra CP3060 Blade Server Product Notes (819-4966) for the latest

information on the patches available for the Sun Netra CP3060 blade server. The

document can be downloaded from the following web site:

http://www.sun.com/documentation

Follow the instructions in the Sun Netra CP3060 Blade Server Product Notes

(819-4966) for downloading and applying patches to a diskless clients boot server.

5. After the patches are installed, follow the procedure in Section 3.4.2, “Adding a

Diskless Client” on page 3-5.

3.4.2 Adding a Diskless Client

1. Prepare a patched boot server for the diskless clients.

Follow the steps in Section 3.4.1, “Creating a Boot Server for Diskless Clients” on

page 3-3 to create a boot server for the diskless clients.

2. Log in to the patched boot server as superuser.

3. Collect the following information for the diskless client you are adding:

■ Client’s IP address

■ Client’s Ethernet address

■ Client’s host name

4. Change directories to the /usr/sadm/bin directory.

TABLE 4

# cd /usr/sadm/bin

5. Set up the diskless clients.

For each diskless client, type the following command as superuser:

TABLE 5

# ./smdiskless add -- -i ip_address -e ethernet_address -n host_name\

-x os=sparc.sun4v.Solaris_n -x root=/export/root/host_name \

-x swap=/export/swap/host_name -x swapsize=swap_size -x tz=time_zone \

-x locale=locale -x ns=name_service -x nameserver=name_server

Where:

■ ip_address is the client’s IP address

■ ethernet_address is the client’s Ethernet address

Chapter 3 Software Installation 3-5

■ host_name is the client’s host name

■ n is the Solaris OS version you are using, either 10 or 9.

■ swap_size is the size of the swap space that you will be using. The default is 24,

however your swap space should be the same amount as your memory

■ time_zone is the client’s time zone

■ locale is the client’s locale

■ name_service is the client’s nameservice

■ name_server is the nameserver’s hostname

Refer to the smdiskless(1M) man page for more information and options.

For example:

TABLE 6

# ./smdiskless add -- -i 129.144.214.999 -e 8:0:20:22:b3:aa -n client_host -x

os=sparc.sun4v.Solaris_10 -x root=/export/root/client_host -x swap=

/export/swap/client_host -x swapsize=999 -x tz=US/Pacific -x locale=en_US -x

ns=NIS -x nameserver=nameserver_host

Where:

■ ip_address = 129.144.214.999

■ ethernet_address = 8:0:20:22:b3:aa

■ host_name = client_host

■ n = 10 (for Solaris 10)

■ swap_size = 128

■ time_zone = US/Pacific

■ locale = en_US

■ name_service = NIS

■ name_server = nameserver_host

3-6 Netra CP3060 Board User’s Guide • April 2009

You must type your superuser password again after typing this command. The

installation process should take roughly 5 minutes per client and about 15-30

minutes for the operating environment service to install; however, no progress is

displayed on screen while the process is running. Do not cancel or kill the process

until the process has successfully completed.

You should see messages similar to the following after a few moments,

confirming that the command went through successfully the second time:

TABLE 7

Login to client_host as user root was successful.

Download of com.sun.admin.osservermgr.cli.OsServerMgrCli from client_host was

successful.

6. Boot the diskless client.

3.5 Downloading and Installing SunVTS Software

SunVTS™ software is a comprehensive suite that tests and validates the Sun Netra

CP3060 blade server by verifying the configuration and function of most hardware

controllers and devices on the blade server. SunVTS software is used to validate a

system during development, production, inspection, troubleshooting, periodic

maintenance, and system or subsystem stressing. SunVTS software can be tailored to

run on machines ranging from desktops to servers with modifiable test instances

and processor affinity features.

You can perform high-level system testing by using the appropriate version of

SunVTS software. For detailed information on SunVTS support and downloads,

refer to the following web site:

http://www.sun.com/oem/products/vts/

Ensure that the SunVTS software version is compatible with the Solaris OS version

being used. Information on the version of the SunVTS software installed can be

found in the file:

/opt/SUNWvts/bin/.version

For the latest version of SunVTS document, go to:

http://www.sun.com/documentation

Chapter 3 Software Installation 3-7

Note – For security reasons, only a superuser is permitted to run SunVTS software.

Installation and starting instructions are included with the software when it is

downloaded.

3-8 Netra CP3060 Board User’s Guide • April 2009

CHAPTER

4

Firmware and Blade Server Management

This chapter contains the following sections:

■ Section 4.1, “System Firmware” on page 4-1

■ Section 4.2, “Power-On Self-Test Diagnostics” on page 4-2

■ Section 4.3, “OpenBoot Firmware” on page 4-3

■ Section 4.4, “Error Handling Summary” on page 4-12

■ Section 4.5, “Automatic System Recovery” on page 4-13

■ Section 4.6, “Hot-Swap Information” on page 4-15

■ Section 4.7, “Network Device Aliases” on page 4-17

■ Section 4.8, “Retrieving Device Information” on page 4-17

4.1 System Firmware

The Sun Netra CP3060 blade server contains a modular firmware architecture that

gives you latitude in controlling boot initialization. You can customize the

initialization, test the firmware, and even enable the installation of a custom

operating system.

This platform also employs the Intelligent Platform Management controller

(IPMC)—described in Section 5.1.6, “Intelligent Platform Management Controller”

on page 5-19—which controls the system management, hot-swap control, and some

blade server hardware. The IPMC configuration is controlled by separate firmware.

The Sun Netra CP3060 blade server boots from the 4-Mbyte system flash PROM

device that includes the power-on self-test (POST) and OpenBoot™ firmware.

4-1

4.2 Power-On Self-Test Diagnostics

Power-on self-test (POST) is a firmware program that helps determine whether a

portion of the system has failed. POST verifies the core functionality of the system,

including the CPU modules, motherboard, memory, and some on-board I/O devices.

The software then generates messages that can be useful in determining the nature

of a hardware failure. POST can run even if the system is unable to boot.

If POST detects a faulty component, it is disabled automatically, preventing faulty

hardware from potentially harming any software. If the system is capable of running

without the disabled component, the system boots when POST is complete. For

example, if one of the processor cores is deemed faulty by POST, the core is disabled,

and the system boots and runs using the remaining cores.

POST diagnostic and error message reports are displayed on a console.

4.2.1 POST Test Coverage

The POST diagnostics include the following tests:

1. UltraSPARC T1 Processor Tests:

• MMU (Memory Management Unit), all cores

• DMMU TLBs: tags, data RAM tests

• IMMU TLBs: tags, data RAM tests

• Caches, all cores

• L2 Cache

• L1 Icache

• L1 Dcache

• FPU (Floating Point Unit

• Functional

• Register

• Interrupts

2. Memory Tests (up to 2-Gbyte/DIMM):

• SDRAM data line test

• SDRAM address line test

• SDARM cell integrity Test

• MOVing inversions memory test

3. POST Image Tests

• POST PROM checksum test

• POST memory checksum test

4. ECC Error Test

4-2 Netra CP3060 Board User’s Guide • April 2009

5. XBUS SRAM Test

6. JBus-to-PCIE Bridge Tests:

• Internal registers test JBus interrupts

• JBus interrupts

• PCI-E MSI Interrupts test

• PLX Interconnect test

• PCI DMA tests

• JBus-to-PCI-E loop-back test

7. PCIE Tests:

• Verify PCI-E Bus configuration

• Verify VID/DIC registers for all onboard PCI device

• Verify link status of all onboard PCI-E channel

4.2.2 POST Diagnostic and Error Message Format

POST diagnostic and error messages are displayed on a console. The format of the

these messages is the following:

Core-ID:Strand-ID ERROR: TEST = test-name

Core-ID:Strand-ID H/W under test = description

Core-ID:Strand-ID Repair Instruction

Core-ID:Strand-ID MSG = error-message-body

Core-ID:Strand-ID END_ERROR

The following is an example of a POST error message

TABLE 4-1

3:2>ERROR: TEST = L2-Cache Functional

3:2>H/W under test = Core l2 Cache

3:2>Repair Instructions: Replace items in order listed by ’H/W

under test’ above.

3:2>MSG = No way found to match tag address 00000000.00600000,

state 3

3:2>END_ERROR

4.3 OpenBoot Firmware

The Solaris OS installed operates at different run levels. For a full description of run

levels, refer to the Solaris system administration documentation.

Chapter 4 Firmware and Blade Server Management 4-3

Most of the time, the OS operates at run level 2 or run level 3, which are multiuser

states with access to full system and network resources. Occasionally, you might

operate the system at run level 1, which is a single-user administrative state.

However, the lowest operational state is run level 0.

When the OS is at run level 0, the ok prompt appears. This prompt indicates that the

OpenBoot™ firmware is in control of the system.

There are a number of scenarios under which OpenBoot firmware control can occur.

By default, before the operating system is installed the system comes up under

OpenBoot firmware control.

■ When the auto-boot? OpenBoot configuration variable is set to false, the system

boots to the ok prompt.

■ When the operating system is halted, the system transitions to run level 0 in an

orderly way.

■ When the operating system crashes, the system reverts to OpenBoot firmware

control.

■ During the boot process, when there is a serious hardware problem that prevents

the operating system from running, the system reverts to OpenBoot firmware

control.

■ When a serious hardware problem develops while the system is running, the

operating system transitions smoothly to run level 0.

■ When the OS is deliberately placed under the OpenBoot firmware control in order

to execute firmware-based commands.

4.3.1 Getting to the ok Prompt

There are different ways of reaching the ok prompt. The methods are not equally

desirable. See

TABLE 4-2 Ways of Accessing the ok Prompt

Access Method What to Do

Graceful shutdown of

the Solaris OS

Manual system reset Setting the OBP auto-boot variable to false causes the system

4-4 Netra CP3060 Board User’s Guide • April 2009

TABLE 4-2 for details.

From a shell or command tool window, issue an appropriate

command (for example, the shutdown or init command) as

described in Solaris system administration documentation.

to stop at the ok? prompt the next time the blade server is reset.

Caution – Obtaining the ok prompt suspends all application and operating system

software. After you issue firmware commands and run firmware-based tests from

the ok prompt, the system might not be able to resume where it left off.

If possible, back up system data before starting accessing the ok prompt. Also exit or

stop all applications, and warn users of the impending loss of service. For

information about the appropriate backup and shutdown procedures, see Solaris

system administration documentation.

4.3.2 Auto-Boot Options

The system firmware stores a configuration variable called auto-boot?, which

controls whether the firmware will automatically boot the operating system after

each reset. The default setting for Sun platforms is true.

Normally, if a system fails power-on diagnostics, auto-boot? is ignored and the

system does not boot unless an operator boots the system manually. An automatic

boot is generally not acceptable for booting a system in a degraded state. Therefore,

the Sun Netra CP3060 server OpenBoot firmware provides a second setting,

auto-boot-on-error?. This setting controls whether the system will attempt a

degraded boot when a subsystem failure is detected. Both the auto-boot? and

auto-boot-on-error? switches must be set to true to enable an automatic

degraded boot. To set the switches, type:

ok setenv auto-boot? true

ok setenv auto-boot-on-error? true

Note – The default setting for auto-boot-on-error? is false. The system will

not attempt a degraded boot unless you change this setting to true. In addition, the

system will not attempt a degraded boot in response to any fatal nonrecoverable

error, even if degraded booting is enabled. For examples of fatal nonrecoverable

errors, see “OpenBoot Configuration Variables” on page 9.

4.3.3 OpenBoot Commands

You type the OpenBoot commands at the ok prompt. Two of the OpenBoot

commands that can provide useful diagnostic information include:

■ probe-ide

Chapter 4 Firmware and Blade Server Management 4-5

■ show-devs

For a complete list of OpenBoot commands and more information about the

OpenBoot firmware, refer to the OpenBoot 4.x Command Reference Manual. An online

version of the manual is included with the OpenBoot Collection AnswerBook that

ships with Solaris software.

4.3.3.1 probe-ide Command

The probe-ide command communicates with all Integrated Drive Electronics (IDE)

devices connected to the IDE bus. This is the internal system bus for media devices

such as the DVD drive.

Caution – If you used the halt command or the Stop-A key sequence to reach the

ok prompt, issuing the probe-ide command can hang the system.

CODE EXAMPLE 4-2 shows sample output from the probe-ide command.

CODE EXAMPLE 4-1 probe-ide Command Output

{0} ok probe-ide

Device 0 ( Primary Master )

ATA Model: FUJITSU MHV2040BH

Device 1 ( Primary Slave )

ATA Model:

Device 2 ( Secondary Master )

Not Present

Device 3 ( Secondary Slave )

Not Present

4.3.3.2 show-devs Command

The show-devs command lists the hardware device paths for each device in the

firmware device tree.

CODE EXAMPLE 4-2 show-devs Command Output

{o} ok show-devs

/pci@7c0

/pci@780

/cpu@17

4-6 Netra CP3060 Board User’s Guide • April 2009

CODE EXAMPLE 4-2 shows some sample output.

CODE EXAMPLE 4-2 show-devs Command Output (Continued)

/cpu@16

/cpu@15

/cpu@14

/cpu@13

/cpu@12

/cpu@11

/cpu@10

/cpu@f

/cpu@e

/cpu@d

/cpu@c

/cpu@b

/cpu@a

/cpu@9

/cpu@8

/cpu@7

/cpu@6

/cpu@5

/cpu@4

/cpu@3

/cpu@2

/cpu@1

/cpu@0

/virtual-devices@100

/virtual-memory

/memory@m0,800000

/aliases

/options

/openprom

/chosen

/packages

/pci@7c0/network@0,1

/pci@7c0/network@0

/pci@780/pci@0

/pci@780/pci@0/pci@9

/pci@780/pci@0/pci@8

/pci@780/pci@0/pci@2

/pci@780/pci@0/pci@1

/pci@780/pci@0/pci@2/network@0,1

/pci@780/pci@0/pci@2/network@0

/pci@780/pci@0/pci@1/pci@0

/pci@780/pci@0/pci@1/pci@0/ide@1f,1

/pci@780/pci@0/pci@1/pci@0/ide@1f

Chapter 4 Firmware and Blade Server Management 4-7

CODE EXAMPLE 4-2 show-devs Command Output (Continued)

/pci@780/pci@0/pci@1/pci@0/ide@1f,1/cdrom

/pci@780/pci@0/pci@1/pci@0/ide@1f,1/disk

/pci@780/pci@0/pci@1/pci@0/ide@1f/cdrom

/pci@780/pci@0/pci@1/pci@0/ide@1f/disk

/virtual-devices@100/ipmi@f

/virtual-devices@100/flashupdate@e

/virtual-devices@100/led@d

/virtual-devices@100/explorer@c

/virtual-devices@100/sunmc@b

/virtual-devices@100/sunvts@a

/virtual-devices@100/fma@9

/virtual-devices@100/echo@8

/virtual-devices@100/loop@6

/virtual-devices@100/loop@7

/virtual-devices@100/rtc@5

/virtual-devices@100/ncp@4

/virtual-devices@100/console@1

/virtual-devices@100/flashprom@0

/virtual-devices@100/nvram@3

/openprom/client-services

/packages/SUNW,asr

/packages/obp-tftp

/packages/dropins

/packages/terminal-emulator

/packages/disk-label

/packages/deblocker

/packages/SUNW,builtin-drivers

{0} ok