Page 1

Sun Fire™E2900 Systems

Installation Guide

Sun Microsystems, Inc.

www.sun.com

Part No. 817-4053-15

May 2006, Revision A

Submit comments about this document at: http://www.sun.com/hwdocs/feedback

Page 2

Copyright 2006Sun Microsystems,Inc., 4150Network Circle, SantaClara, California95054, U.S.A.All rightsreserved.

Sun Microsystems,Inc. hasintellectual property rightsrelating totechnology thatis describedin thisdocument. Inparticular, andwithout

limitation, theseintellectual propertyrights mayinclude oneor more ofthe U.S.patents listedat http://www.sun.com/patentsand oneor

more additionalpatents orpending patentapplications inthe U.S.and inother countries.

This documentand theproduct towhich itpertains are distributedunder licensesrestricting theiruse, copying,distribution, and

decompilation. Nopart ofthe productor ofthis documentmay bereproducedin anyform byany meanswithout priorwritten authorizationof

Sun andits licensors,if any.

Third-party software, includingfont technology,is copyrightedand licensedfrom Sun suppliers.

Parts ofthe productmay bederived from BerkeleyBSD systems,licensed fromthe Universityof California.UNIX isa registered trademarkin

the U.S.and inother countries,exclusively licensedthrough X/OpenCompany, Ltd.

Sun, SunMicrosystems, theSun logo,AnswerBook2, docs.sun.com,Sun Fire, SunStorEdge, Netra,and Solarisare trademarksor registered

trademarks ofSun Microsystems,Inc. inthe U.S.and inother countries.

All SPARCtrademarks areused underlicense andare trademarks or registered trademarksof SPARCInternational, Inc.in theU.S. andin other

countries. Productsbearing SPARCtrademarks are basedupon anarchitecture developed by Sun Microsystems,Inc.

The OPENLOOK andSun™ GraphicalUser Interfacewas developedby SunMicrosystems, Inc.for itsusers andlicensees. Sun acknowledges

the pioneeringefforts ofXerox in researchingand developingthe conceptof visualor graphicaluser interfacesfor thecomputer industry.Sun

holds anon-exclusive licensefrom Xerox tothe XeroxGraphical UserInterface, whichlicense alsocovers Sun’slicensees whoimplement OPEN

LOOK GUIsand otherwisecomply withSun’s writtenlicense agreements.

U.S. GovernmentRights—Commercial use.Government usersare subject to the Sun Microsystems, Inc.standard licenseagreement and

applicable provisionsof theFAR andits supplements.

DOCUMENTATION IS PROVIDED "AS IS" AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANYIMPLIED WARRANTY OFMERCHANTABILITY, FITNESSFOR A PARTICULAR PURPOSEOR NON-INFRINGEMENT,

ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright 2006Sun Microsystems,Inc., 4150Network Circle, SantaClara, Californie95054, Etats-Unis.Tous droitsréservés.

Sun Microsystems,Inc. ales droits depropriété intellectuelsrelatants à la technologie qui est décritdans ce document. Enparticulier,et sansla

limitation, cesdroits depropriété intellectuels peuvent inclure unou plusdes brevetsaméricains énumérésà http://www.sun.com/patents et

un oules brevetsplus supplémentaires oules applicationsde breveten attentedans lesEtats-Unis etdans lesautrespays.

Ce produitou documentest protégé parun copyrightet distribuéavec deslicences quien restreignent l’utilisation,la copie,la distribution,et la

décompilation. Aucunepartie dece produitou documentne peutêtre reproduite sousaucune forme,par quelquemoyen quece soit,sans

l’autorisation préalableet écritede Sunet deses bailleursde licence,s’il yen a.

Le logicieldétenu pardes tiers,et quicomprend latechnologie relative auxpolices decaractères, estprotégépar uncopyright etlicencié pardes

fournisseurs deSun.

Des partiesde ceproduit pourront êtredérivées dessystèmes BerkeleyBSD licenciéspar l’Universitéde Californie.UNIX estune marque

déposée auxEtats-Unis etdans d’autrespays etlicenciée exclusivementpar X/OpenCompany, Ltd.

Sun, SunMicrosystems, le logoSun, AnswerBook2,docs.sun.com, SunFire, SunStorEdge, Netra, etSolaris sontdes marquesde fabriqueou des

marques déposéesde SunMicrosystems, Inc. aux Etats-Unis et dans d’autrespays.

Toutes lesmarques SPARC sont utilisées sous licence et sont des marques defabrique oudes marquesdéposées deSPARC International,Inc.

aux Etats-Uniset dansd’autres pays.Les produits portantles marquesSPARC sont baséssur unearchitecture développéepar Sun

Microsystems, Inc.

L’interfaced’utilisation graphiqueOPEN LOOKet Sun™a étédéveloppée parSun Microsystems, Inc.pour sesutilisateurs etlicenciés. Sun

reconnaît lesefforts de pionniers de Xeroxpour larecherche et le développement du concept des interfaces d’utilisation visuelle ou graphique

pour l’industriede l’informatique.Sun détientune licensenon exclusivede Xeroxsur l’interfaced’utilisation graphiqueXerox,cette licence

couvrant égalementles licenciéesde Sunqui mettenten placel’interface d’utilisation graphiqueOPEN LOOKet quien outrese conforment

aux licencesécrites deSun.

LA DOCUMENTATION EST FOURNIE "EN L’ÉTAT" ET TOUTES AUTRES CONDITIONS, DECLARATIONS ET GARANTIES EXPRESSES

OU TACITES SONT FORMELLEMENTEXCLUES, DANSLA MESUREAUTORISEE PARLA LOIAPPLICABLE, YCOMPRIS NOTAMMENT

TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE UTILISATION PARTICULIERE OU A

L’ABSENCE DE CONTREFAÇON.

Please

Recycle

Page 3

Contents

Regulatory Compliance Statements xi

Safety Agency Compliance Statements xv

Preface xxvii

1. Physical Installation 1–1

1.1 Installing Slides and Rails 1–2

1.1.1 Adjusting the Rail Assembly 1–3

1.1.2 Installing the Inner Slides on the System 1–4

1.1.3 Preparing the Rails for Two-Post Installations 1–6

1.1.4 Installing the Rail Assemblies in a Sun Fire/StorEdge Cabinet 1–7

1.1.4.1 Installing the Rail Assemblies in the Bottom Position

1–7

1.1.4.2 Installing the Rail Assemblies in the Top Position 1–8

1.1.5 Installing the Rail Assemblies in a Sun Rack 900 Cabinet 1–9

1.1.5.1 Installing the Rail Assemblies in the Bottom Position

1–9

1.1.5.2 Installing the Rail Assemblies in the Top Position 1–10

1.1.6 Installing the Rail Assemblies in a 19-Inch Four-Post Cabinet 1–11

1.1.7 Installing the Rail Assemblies in a 19-inch Two-Post Rack 1–12

1.2 Installing the System in a Cabinet 1–13

iii

Page 4

1.2.1 Preparing to Install the System in the Cabinet 1–13

1.2.2 Mounting the System in the Cabinet 1–15

1.3 Installing Slide Rail Locking Nuts 1–19

1.4 Installing the Cable Management Arm 1–21

1.4.1 Installing the CMA–Lite 1–22

1.4.2 Installing the CMA–800. 1–23

1.5 Connecting Sun Fire V1280/Netra 1280 Power Cables 1–30

1.6 Connecting Consoles to the System Controller 1–32

1.6.1 Connecting the Initial Administrative Console 1–33

1.6.2 Connecting the Administrative Console 1–35

1.7 Connecting the I/O Assemblies 1–35

1.8 Powering On the System 1–35

1.9 Powering Off the System 1–36

1.10 Installing Additional Hardware 1–36

1.11 Installing Additional Peripheral Devices 1–37

A. External Connections A–1

A.1 I/O Slots A–2

A.1.1 PCI IB_SSC Assemblies A–2

A.1.2 PCI+ IB_SSC Assemblies A–2

A.1.3 PCI-X IB_SSC Assemblies A–2

A.2 SCSI Connector A–3

A.2.1 SCSI Implementation A–4

A.3 Alarms Port A–5

A.4 LOM Serial Ports A–6

A.4.1 Using a DB-25 Adapter for Your Serial Link A–7

A.4.2 Using a DB-9 Adapter for Your Serial Link A–8

A.4.2.1 Connecting to a Male 9-Pin D-Type Serial Port A–8

A.5 10/100 LOM Ethernet Port A–9

iv Sun Fire E2900 Systems Installation Guide • May 2006

Page 5

A.5.1 Twisted-Pair Ethernet Cable-Type Connectivity A–9

A.6 Net0/Net1 Ethernet Ports A–10

Contents v

Page 6

vi Sun Fire E2900 Systems Installation Guide • May 2006

Page 7

Figures

FIGURE 1-1 Rail Assembly (Standard Configuration) 1–3

FIGURE 1-2 Spring Clips and Cutouts 1–5

FIGURE 1-3 Rail Assembly (Modified for Two-Post Installation) 1–6

FIGURE 1-4 Installing the Rails in a Sun Fire Cabinet 1–8

FIGURE 1-5 Installing the Rails in a Sun Rack 900 Cabinet or 19-Inch Four-Post Cabinet 1–10

FIGURE 1-6 Releasing the Door Hinge Mechanism 1–13

FIGURE 1-7 Removing the Shipping Cradle Bolts 1–14

FIGURE 1-8 Inserting the Lifting Device into the Shipping Cradle 1–15

FIGURE 1-9 Aligning the Slides 1–16

FIGURE 1-10 Removing the Shipping Cradle 1–17

FIGURE 1-11 Pushing the System into the System Cabinet 1–18

FIGURE 1-12 Tightening the Securing Screws 1–18

FIGURE 1-13 Inserting and Tightening the Slide Rail Spacers 1–20

FIGURE 1-14 Inserting and Tightening the Slide Rail Locking Nut 1–20

FIGURE 1-15 Bracket Mounting Holes 1–21

FIGURE 1-16 CMA–Lite Cable Management Arm 1–22

FIGURE 1-17 Upper/Lower CMA Arms and Left Hand/Right Hand T-Brackets 1–23

FIGURE 1-18 Upper/Lower Pivot Bracket Mounting Holes 1–24

FIGURE 1-19 Attachment of Upper CMA Arm and Pivot Bracket 1–25

FIGURE 1-20 Attachment of Lower CMA Arm and Pivot Bracket 1–26

vii

Page 8

FIGURE 1-21 Attaching Left Hand T-Bracket 1–27

FIGURE 1-22 Attachment of Right-Hand T-Bracket 1–28

FIGURE 1-23 Attachment of Upper/Lower CMA Arms to T-Bracket 1–29

FIGURE 1-24 System Controller and I/O Assembly Locations 1–34

FIGURE A-1 External I/O Connections—Sun Fire V1280/Netra 1280 Systems (Rear View) A–1

FIGURE A-2 68-Pin SCSI Connector A–3

FIGURE A-3 DB-15 (Male) Alarms Service Port Connector A–5

FIGURE A-4 RJ-45 Serial Connectors A–6

FIGURE A-5 RJ-45 TPE Socket A–9

FIGURE A-6 RJ-45 Gigabit Ethernet Connectors A–10

viii Sun Fire E2900 Systems Installation Guide • May 2006

Page 9

Tables

TABLE A-1 68-Pin SCSI Connector Pinout A–3

TABLE A-2 68-Pin SCSI Connector Pinout (continued) A–4

TABLE A-3 Alarms Service Port Connector Pinout A–5

TABLE A-4 RJ-45 Serial Connector Pinout A–6

TABLE A-5 Default Settings for Connecting to Serial A A–7

TABLE A-6 Pin Interconnections Performed by the Sun DB-25 Adapter A–7

TABLE A-7 Pin Interconnections Performed by a DB-9 (9-pin) Adapter A–8

TABLE A-8 Twisted-pair Ethernet Connector Pinout A–9

TABLE A-9 TPE STP-5 Cable Lengths A–9

TABLE A-10 RJ-45 Gigabit Ethernet Connector Pinout A–10

ix

Page 10

x Sun Fire E2900 Systems Installation Guide • May 2006

Page 11

Regulatory Compliance Statements

Your Sun product is marked to indicate its compliance class:

• Federal Communications Commission (FCC) — USA

• Industry Canada Equipment Standard for Digital Equipment (ICES-003) — Canada

• Voluntary Control Council for Interference (VCCI) — Japan

• Bureau of Standards Metrology and Inspection (BSMI) — Taiwan

Please read the appropriate section that corresponds to the marking on your Sun product before attempting to install the

product.

FCC Class A Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy, and if it is

not installed and used in accordance with the instruction manual, it may cause harmful interference to radio communications.

Operation of this equipment in a residential areais likely tocause harmful interference,in which casethe user willbe required

to correct the interference at his own expense.

Modifications: Any modifications made to this device that are notapproved bySun Microsystems,Inc. mayvoid theauthority

granted to the user by the FCC to operate this equipment.

FCC Class B Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception,which can bedetermined by turningthe equipment off and on, the user is encouraged to try to correctthe

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

Modifications: Any modifications made to this device that are notapproved bySun Microsystems,Inc. mayvoid theauthority

granted to the user by the FCC to operate this equipment.

xi

Page 12

ICES-003 Class A Notice - Avis NMB-003, Classe A

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

ICES-003 Class B Notice - Avis NMB-003, Classe B

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

xii Sun Fire E2900 Systems Installation Guide • May 2006

Page 13

BSMI Class A Notice

The following statement is applicable to products shipped to Taiwan and marked as Class A on the product compliance

label.

T33012

GOST-R Certification Mark

Regulatory Compliance Statements xiii

Page 14

xiv Sun Fire E2900 Systems Installation Guide • May 2006

Page 15

Safety Agency Compliance Statements

Read this section before beginning any procedure. The

following text provides safety precautions to follow when

installing a Sun Microsystems product.

Safety Precautions

For your protection, observe the following safety

precautions when setting up your equipment:

■ Follow all cautions and instructions marked on the

equipment.

■ Ensure that the voltage and frequency of your power

source match the voltage and frequency inscribed on

the equipment’s electrical rating label.

■ Never push objects of any kind through openings in

the equipment. Dangerous voltages may be present.

Conductive foreign objects could produce a short

circuit that could cause fire, electric shock, or damage

to your equipment.

Depending on the type of power switch your device has,

one of the following symbols may be used:

On – Applies AC power to the system.

Off – Removes AC power from the system.

Standby – The On/Standby switch is in the

standby position.

Modifications to Equipment

Do not make mechanical or electrical modifications to the

equipment. Sun Microsystems is not responsible for

regulatory compliance of a modified Sun product.

Placement of a Sun Product

Symbols

The following symbols may appear in this book:

Caution – There is a risk of personal injury

and equipment damage. Follow the

instructions.

Caution – Hot surface. Avoid contact.

Surfaces are hot and may cause personal

injury if touched.

Caution – Hazardous voltages are present. To

reduce the risk of electric shock and danger to

personal health, follow the instructions.

Caution – Do not block or cover the openings

of your Sun product. Never place a Sun

product near a radiator or heat register.

Failure to follow these guidelines can cause

overheating and affect the reliability of your

Sun product.

Noise Level

In compliance with the requirements defined in DIN 45635

Part 1000, the workplace-dependent noise level of this

product is less than 70 db(A).

xv

Page 16

SELV Compliance

Safety status of I/O connections comply to SELV

requirements.

Power Cord Connection

Caution – Sun products are designed to work

with power systems having a grounded

neutral (grounded return for DC-powered

products). To reduce the risk of electric shock,

do not plug Sun products into any other type

of power system. Contact your facilities

manager or a qualified electrician if you are

not sure what type of power is supplied to

your building.

Caution – Not all power cords have the same

current ratings. Household extension cords do

not have overload protection and are not

meant for use with computer systems. Do not

use household extension cords with your Sun

product.

The following caution applies only to devices with a

Standby power switch:

Caution – The power switch of this product

functions as a standby type device only. The

power cord serves as the primary disconnect

device for the system. Be sure to plug the

power cord into a grounded power outlet that

is nearby the system and is readily accessible.

Do not connect the power cord when the

power supply has been removed from the

system chassis.

The followingcaution applies only to deviceswith multiple

power cords:

Caution – For products with multiple power

cords, all power cords must be disconnected

to completely remove power from the system.

Battery Warning

Caution – There is danger of explosion if

batteries are mishandled or incorrectly

replaced. On systems with replaceable

batteries, replace only with the same

manufacturer and type or equivalent type

recommended by the manufacturer per the

instructions provided in the product service

manual. Do not disassemble batteries or

attempt to recharge them outside the system.

Do not dispose of batteries in fire. Dispose of

batteries properly in accordance with the

manufacturer’s instructions and local

regulations. Note that on Sun CPU boards,

there is a lithium battery molded into the realtime clock. These batteries are not customer

replaceable parts.

System Unit Cover

You must remove the cover of your Sun computer system

unit to add cards, memory, or internal storage devices. Be

sure toreplace the cover before powering on yourcomputer

system.

Caution – Do not operate Sun products

without the cover in place. Failure to take this

precaution may result in personal injury and

system damage.

Rack System Warning

The following warnings apply to Racks and Rack Mounted

systems.

Caution – For safety, equipment should

always be loaded from the bottom up. That is,

install the equipment that will be mounted in

the lowest part of the rack first, then the next

higher systems, etc.

Caution – To prevent the rack from tipping

during equipment installation, the anti-tilt bar

on the rack must be deployed.

xvi Sun Fire E2900 Systems Installation Guide • May 2006

Page 17

Caution – To prevent extreme operating

temperature within the rack insure that the

maximum temperature does not exceed the

product’s ambient rated temperatures.

Conformité aux normes de sécurité

Veuillez lire attentivement cette section avant de

commencer. Ce texte traite des mesures de sécurité qu’il

convient de prendre pour l’installation d’un produit Sun

Microsystems.

Caution – To prevent extreme operating

temperatures due to reduced airflow

consideration should be made to the amount

of air flow that is required for a safe operation

of the equipment.

Laser Compliance Notice

Sun products that use laser technology comply withClass 1

laser requirements.

Class 1 Laser Product

Luokan 1 Laserlaite

Klasse 1 Laser Apparat

Laser Klasse 1

CD and DVD Devices

The following caution applies to CD, DVD, and other

optical devices.

Caution – Use of controls, adjustments, or the

performance of procedures other than those

specified herein may result in hazardous

radiation exposure.

Mesures de sécurité

Pour votre sécurité, nous vous recommandons de suivre

scrupuleusement lesmesures de sécuritéci-dessous lorsque

vous installez votre matériel:

■ Suivez tous les avertissements et toutes les

instructions inscrites sur le matériel.

■ Assurez-vous que la tension et la fréquence de votre

source d'alimentation correspondent à la tension et à

la fréquence indiquées sur l'étiquette de la tension

électrique nominale du matériel

■ N'introduisez jamais d'objets quels qu'ils soient dans

les ouvertures de l'équipement. Vous pourriez vous

trouver en présence de hautes tensions dangereuses.

Tout objet étranger conducteur risque de produire un

court-circuit pouvant présenter un risque d'incendie

ou de décharge électrique, ou susceptible

d'endommager le matériel.

Symboles

Vous trouverez ci-dessous la signification des différents

symboles utilisés:

Attention – Vous risquez d'endommager le

matériel ou de vous blesser. Veuillez suivre les

instructions.

Attention – Surfaces brûlantes. Evitez tout

contact. Les surfaces sont brûlantes. Vous

risquez de vous blesser si vous les touchez.

Attention – Tensions dangereuses. Pour

réduire les risques de décharge électrique et

de danger physique, observez les consignes

indiquées.

Safety Agency Compliance Statements xvii

Page 18

Selon le type d'interrupteur marche/arrêt dont votre

appareil est équipé, l'un des symboles suivants sera utilisé:

Marche – Met le système sous tension

alternative.

Arret – Met le système hors tension

alternative.

Veilleuse – L'interrupteur Marche/Veille est

sur la position de veille.

Connexion du cordon d’alimentation

Attention – Les produits Sun sont conçus

pour fonctionner avec des systèmes

d'alimentation équipés d'un conducteur

neutre relié à la terre (conducteur neutre pour

produits alimentés en CC). Pour réduire les

risques de décharge électrique, ne branchez

jamais les produits Sun sur une source

d'alimentation d'un autre type. Contactez le

gérant de votre bâtiment ou un électricien

agréé si vous avez le moindre doute quant au

type d'alimentation fourni dans votre

bâtiment.

Modification du matériel

N'apportez aucune modification mécanique ou électrique

au matériel. Sun Microsystems décline toute responsabilité

quant à la non-conformité éventuelle d'un produit Sun

modifié.

Positionnement d’un produit Sun

Attention – Evitez d'obstruer ou de recouvrir

les orifices de votre produit Sun. N'installez

jamais un produit Sun près d'un radiateur ou

d'une source de chaleur. Si vous ne respectez

pas ces consignes, votre produit Sun risque de

surchauffer et son fonctionnement en sera

altéré.

Niveau de pression acoustique

Le niveau de pression acoustique du lieu de travail définie

par lanorme DIN 45 635 Part 1000 doitêtre au maximum de

70 db(A).

Conformité SELV

Le niveau de sécurité des connexions E/S est conforme aux

normes SELV.

Attention – Tous les cordons d'alimentation

ne présentent pas les mêmes caractéristiques

électriques. Les cordons d'alimentation à

usage domestique ne sont pas protégés contre

les surtensions et ne sont pas conçus pour être

utilisés avec des ordinateurs. N'utilisez jamais

de cordon d'alimentation à usage domestique

avec les produits Sun.

L'avertissement suivant s'applique uniquement aux

systèmes équipés d'un interrupteur Veille:

Attention – L'interrupteur d'alimentation de

ce produit fonctionne uniquement comme un

dispositif de mise en veille. Le cordon

d'alimentation constitue le moyen principal de

déconnexion de l'alimentation pour le

système. Assurez-vous de le brancher dans

une prise d'alimentation mise à la terre près

du système et facile d'accès. Ne le branchez

pas lorsque l'alimentation électrique ne se

trouve pas dans le châssis du système.

L'avertissement suivant s'applique uniquement aux

systèmes équipés de plusieurs cordons d'alimentation:

Attention – Pour mettre un système équipé de

plusieurs cordons d'alimentation hors tension,

il est nécessaire de débrancher tous les

cordons d'alimentation.

xviii Sun Fire E2900 Systems Installation Guide • May 2006

Page 19

Mise en garde relative aux batteries

Attention – Les batteries risquent d’exploser

en cas de manipulation maladroite ou de

remplacement incorrect. Pour les systèmes

dont les batteries sont remplaçables, effectuez

les remplacements uniquement selon le

modèle du fabricant ou un modèle équivalent

recommandé par le fabricant, conformément

aux instructions fournies dans le manuel de

service du système. N’essayez en aucun cas de

démonter les batteries, ni de les recharger hors

du système. Ne les jetez pas au feu. Mettez-les

au rebut selon les instructions du fabricant et

conformément à la législation locale en

vigueur. Notez que sur les cartes processeur

de Sun, une batterie au lithium a été moulée

dans l'horloge temps réel. Les batteries ne sont

pas des pièces remplaçables par le client.

Couvercle de l'unité

Pour ajouterdes cartes,de la mémoire ou des périphériques

de stockage internes, vous devez retirer le couvercle de

votre système Sun. Remettez le couvercle supérieur en

place avant de mettre votre système sous tension.

Attention – Afin d'éviter que le rack ne

penche pendant l'installation du matériel, tirez

la barre anti-basculement du rack.

Attention – Pour éviter des températures de

fonctionnement extrêmes dans le rack,

assurez-vous que la température maximale ne

dépasse pas la fourchette de températures

ambiantes du produit déterminée par le

fabricant.

Attention – Afin d'empêcher des

températures de fonctionnement extrêmes

provoquées par une aération insuffisante,

assurez-vous de fournir une aération

appropriée pour un fonctionnement du

matériel en toute sécurité

Avis de conformité des appareils laser

Les produitsSun quifont appelaux technologieslasers sont

conformes aux normes de la classe 1 en la matière.

Attention – Ne mettez jamais des produits

Sun sous tension si leur couvercle supérieur

n'est pas mis en place. Si vous ne prenez pas

ces précautions, vous risquez de vous blesser

ou d'endommager le système.

Mise en garde relative au système en rack

La mise en garde suivante s'applique aux racks et aux

systèmes montés en rack.

Attention – Pour des raisons de sécurité, le

matériel doit toujours être chargé du bas vers

le haut. En d'autres termes, vous devez

installer, en premier, le matériel qui doit se

trouver dans la partie la plus inférieure du

rack, puis installer le matériel sur le niveau

suivant, etc.

Class 1 Laser Product

Luokan 1 Laserlaite

Klasse 1 Laser Apparat

Laser Klasse 1

Périphériques CD et DVD

L'avertissement suivant s'applique aux périphériques CD,

DVD et autres périphériques optiques:

Attention – L'utilisation de contrôles et de

réglages ou l'application de procédures autres

que ceux spécifiés dans le présent document

peuvent entraîner une exposition à des

radiations dangereuses.

Safety Agency Compliance Statements xix

Page 20

Einhaltung sicherheitsbehördlicher Vorschriften

Lesen Sie vor dem Ausführen von Arbeiten diesen

Abschnitt. Im folgenden Text werden Sicherheitsvorkehrungen beschrieben, die Sie bei der Installation eines

Sun Microsystems-Produkts beachten müssen.

Sicherheitsvorkehrungen

Treffen Sie zu Ihrem eigenen Schutzbei der Installation des

Geräts die folgenden Sicherheitsvorkehrungen:

■ Beachten Sie alle auf den Geräten angebrachten

Warnhinweise und Anweisungen.

■ Stellen Sie sicher, dass Spannung und Frequenz der

Stromversorgung den Nennleistungen auf dem am

Gerät angebrachten Etikett entsprechen.

■ Führen Sie niemals Fremdobjekte in die Öffnungen

am Gerät ein. Es können gefährliche Spannungen

anliegen. Leitfähige Fremdobjekte können einen

Kurzschluss verursachen, der einen Brand, Stromschlag oder Geräteschaden herbeiführen kann.

Je nach Netzschaltertyp an Ihrem Gerät kann eines der

folgenden Symbole verwendet werden:

Ein – Versorgt das System mit Wechselstrom.

Aus– Unterbricht die Wechselstromzufuhr

zum Gerät.

Wartezustand – Der Ein-/Standby-Netzschalter befindet sich in der Standby-Position.

Modifikationen des Geräts

Nehmen Sie keine elektrischen oder mechanischen

Gerätemodifikationen vor. Sun Microsystems ist für die

Einhaltung der Sicherheitsvorschriften von modifizierten

Sun-Produkten nicht haftbar.

Symbole

Die Symbole in diesem Handbuch haben folgende

Bedeutung:

Achtung – Gefahr von Verletzung und

Geräteschaden. Befolgen Sie die Anweisungen.

Achtung – Heiße Oberfläche. Nicht berühren,

da Verletzungsgefahr durch heiße Oberfläche

besteht.

Achtung – Gefährliche Spannungen. Befolgen

Sie die Anweisungen, um Stromschläge und

Verletzungen zu vermeiden.

Aufstellung von Sun-Geräten

Achtung – Geräteöffnungen Ihres SunProdukts dürfen nicht blockiert oder

abgedeckt werden. Sun-Geräte sollten niemals

in der Nähe von Heizkörpern oder Heißluftklappen aufgestellt werden. Die Nichtbeachtung dieser Richtlinien kann Überhitzung

verursachen und die Zuverlässigkeit Ihres

Sun-Geräts beeinträchtigen.

Lautstärke

Gemäß denin DIN 45 635 Teil1000 definiertenVorschriften

beträgt diearbeitsplatzbedingte Lautstärke dieses Produkts

weniger als 70 dB(A).

SELV-Konformität

Der Sicherheitsstatus der E/A-Verbindungen entspricht

den SELV-Anforderungen.

xx Sun Fire E2900 Systems Installation Guide • May 2006

Page 21

Anschluss des Netzkabels

Warnung bezüglich Batterien

Achtung – Sun-Geräte sind für

Stromversorgungssysteme mit einem

geerdeten neutralen Leiter (geerdeter

Rückleiter bei gleichstrombetriebenen

Geräten) ausgelegt. Um die Gefahr von

Stromschlägen zu vermeiden, schließen Sie

das Gerät niemals an andere Stromversorgungssysteme an. Wenden Sie sich an den

zuständigen Gebäudeverwalter oder an einen

qualifizierten Elektriker, wenn Sie nicht sicher

wissen, an welche Art von Stromversorgungssystem Ihr Gebäude angeschlossen ist.

Achtung – Nicht alle Netzkabel verfügen

über die gleichen Nennwerte. Herkömmliche,

im Haushalt verwendete Verlängerungskabel

besitzen keinen Überlastschutz und sind

daher für Computersysteme nicht geeignet.

Verwenden Sie bei Ihrem Sun-Produkt keine

Haushalts-Verlängerungskabel.

Die folgende Warnung gilt nur für Geräte mit StandbyNetzschalter:

Achtung – Beim Netzschalter dieses Geräts

handelt es sich nur um einen Ein/StandbySchalter. Zum völligen Abtrennen des Systems

von der Stromversorgung dient hauptsächlich

das Netzkabel. Stellen Sie sicher, dass das

Netzkabel an eine frei zugängliche geerdete

Steckdose in der Nähe des Systems angeschlossen ist. Schließen Sie das Stromkabel

nicht an, wenn die Stromversorgung vom

Systemchassis entfernt wurde.

Die folgende Warnung gilt nur für Geräte mit mehreren

Netzkabeln:

Achtung – Bei unsachgemäßer Handhabung

oder nicht fachgerechtem Austausch der

Batterien besteht Explosionsgefahr. Verwenden Sie bei Systemen mit austauschbaren

Batterien ausschließlich Ersatzbatterien

desselben Typs und Herstellers bzw. einen

entsprechenden, vom Hersteller gemäß den

Anweisungen im Service-Handbuch des

Produkts empfohlenen Batterietyp. Versuchen

Sie nicht, die Batterien auszubauen oder

außerhalb des Systems wiederaufzuladen.

Werfen Sie die Batterien nicht ins Feuer.

Entsorgen Sie die Batterien entsprechend den

Anweisungen des Herstellers und den vor Ort

geltenden Vorschriften. CPU-Karten von Sun

verfügen über eine Echtzeituhr mit integrierter Lithiumbatterie. Diese Batterie darf nur

von einem qualifizierten Servicetechniker ausgewechselt werden.

Gehäuseabdeckung

Sie müssen die Abdeckung Ihres Sun-Computersystems

entfernen, um Karten, Speicher oderinterne Speichergeräte

hinzuzufügen. Bringen Sie vor dem Einschalten des

Systems die Gehäuseabdeckung wieder an.

Achtung – Nehmen Sie Sun-Geräte nicht ohne

Abdeckung in Betrieb. Die Nichtbeachtung

dieses Warnhinweises kann Verletzungen oder

Geräteschaden zur Folge haben.

Warnungen bezüglich in Racks eingebauter Systeme

Die folgenden Warnungen gelten für Racks und in Racks

eingebaute Systeme:

Achtung – Bei Produkten mit mehreren Netzkabeln müssen alle Netzkabel abgetrennt werden, um das System völlig von der Stromversorgung zu trennen.

Achtung – Aus Sicherheitsgründen sollten

sämtliche Geräte von unten nach oben in

Racks eingebaut werden. Installieren Sie also

zuerst die Geräte, die an der untersten

Position im Rack eingebaut werden, gefolgt

von den Systemen, die an nächsthöherer Stelle

eingebaut werden, usw.

Safety Agency Compliance Statements xxi

Page 22

Achtung – Verwenden Sie beim Einbau den

Kippschutz am Rack, um ein Umkippen zu

vermeiden.

Normativas de seguridad

Lea esta sección antes de realizar cualquier operación. En

ella seexplican las medidasde seguridad que debe tomaral

instalar un producto de Sun Microsystems.

Achtung – Um extreme Betriebstemperaturen

im Rack zu vermeiden, stellen Sie sicher, dass

die Maximaltemperatur die Nennleistung der

Umgebungstemperatur für das Produkt nicht

überschreitet

Achtung – Um extreme Betriebstemperaturen

durch verringerte Luftzirkulation zu vermeiden, sollte die für den sicheren Betrieb des

Geräts erforderliche Luftzirkulation eingesetzt

werden.

Hinweis zur Laser-Konformität

Sun-Produkte, die die Laser-Technologie verwenden,

entsprechen den Laser-Anforderungen der Klasse 1.

Class 1 Laser Product

Luokan 1 Laserlaite

Klasse 1 Laser Apparat

Laser Klasse 1

Medidas de seguridad

Para su protección, tome las medidas de seguridad

siguientes durante la instalación del equipo:

■ Siga todos los avisos e instrucciones indicados en el

equipo.

■ Asegúrese de que el voltaje y frecuencia de la fuente

de alimentación coincidan con el voltaje y frecuencia

indicados en la etiqueta de clasificación eléctrica del

equipo.

■ No introduzca objetos de ningún tipo por las rejillas

del equipo, ya que puede quedar expuesto a voltajes

peligrosos. Los objetos conductores extraños pueden

producir cortocircuitos y, en consecuencia, incendios,

descargas eléctricas o daños en el equipo.

Símbolos

En este documento aparecen los siguientes símbolos:

Precaución – Existe el riesgo de que se

produzcan lesiones personales y daños en el

equipo. Siga las instrucciones.

Precaución – Superficie caliente. Evite todo

contacto. Las superficies están calientes y

pueden causar lesiones personales si se tocan.

CD- und DVD-Geräte

Die folgende Warnung gilt für CD-, DVD- und andere

optische Geräte:

Achtung – Die hier nicht aufgeführte

Verwendung von Steuerelementen,

Anpassungen oder Ausführung von

Vorgängen kann eine gefährliche

Strahlenbelastung verursachen.

xxii Sun Fire E2900 Systems Installation Guide • May 2006

Precaución – Voltaje peligroso. Para reducir

el riesgo de descargas eléctricas y lesiones

personales, siga las instrucciones.

Page 23

En función del tipo de interruptor de alimentación del que

disponga el dispositivo, se utilizará uno de los símbolos

siguientes:

Encendido – Suministra alimentación de CA

al sistema.

Apagado – Corta la alimentación de CA del

sistema.

Espera – El interruptor de encendido/espera

está en la posición de espera.

Conexión del cable de alimentación

Precaución – Los productos Sun se han

diseñado para funcionar con sistemas de

alimentación que cuenten con un conductor

neutro a tierra (con conexión a tierra de

regreso para los productos con alimentación

de CC). Para reducir el riesgo de descargas

eléctricas, no conecte ningún producto Sun a

otro tipo de sistema de alimentación. Póngase

en contacto con el encargado de las

instalaciones de su empresa o con un

electricista cualificado en caso de que no esté

seguro del tipo de alimentación del que se

dispone en el edificio.

Modificaciones en el equipo

No realicemodificaciones de tipo mecánico ni eléctrico en el

equipo. Sun Microsystems no se hace responsable del

cumplimiento de normativas en caso de que un producto

Sun se haya modificado.

Colocación de un producto Sun

Precaución – No obstruya ni tape las rejillas

del producto Sun. Nunca coloque un producto

Sun cerca de radiadores ni fuentes de calor. Si

no sigue estas indicaciones, el producto Sun

podría sobrecalentarse y la fiabilidad de su

funcionamiento se vería afectada.

Nivel de ruido

De conformidad con los requisitos establecidos en el

apartado 1000 de la norma DIN 45635, el nivel de ruido en

el lugarde trabajoproducido poreste productoes menorde

70 db(A).

Cumplimiento de la normativa para instalaciones SELV

Las condiciones de seguridad de las conexiones de entrada

y salidacumplen losrequisitos para instalaciones SELV (del

inglés Safe Extra Low Voltage, voltaje bajo y seguro).

Precaución – No todos los cables de

alimentación tienen la misma clasificación

eléctrica. Los alargadores de uso doméstico no

cuentan con protección frente a sobrecargas y

no están diseñados para su utilización con

sistemas informáticos. No utilice alargadores

de uso doméstico con el producto Sun.

La siguiente medida solamente se aplica a aquellos

dispositivos que dispongan de un interruptor de

alimentación de espera:

Precaución – El interruptor de alimentación

de este producto funciona solamente como un

dispositivo de espera. El cable de alimentación

hace las veces de dispositivo de desconexión

principal del sistema. Asegúrese de que

conecta el cable de alimentación a una toma

de tierra situada cerca del sistema y de fácil

acceso. No conecte el cable de alimentación si

la unidad de alimentación no se encuentra en

el bastidor del sistema.

La siguiente medida solamente se aplica a aquellos

dispositivos que dispongan de varios cables de

alimentación:

Safety Agency Compliance Statements xxiii

Page 24

Precaución – En los productos que cuentan

con varios cables de alimentación, debe

desconectar todos los cables de alimentación

para cortar por completo la alimentación

eléctrica del sistema.

Precaución – Por seguridad, siempre deben

montarse los equipos de abajo arriba. A saber,

primero debe instalarse el equipo que se

situará en el bastidor inferior; a continuación,

el que se situará en el siguiente nivel, etc.

Advertencia sobre las baterías

Precaución – Si las baterías no se manipulan

o reemplazan correctamente, se corre el riesgo

de que estallen. En los sistemas que cuentan

con baterías reemplazables, reemplácelas sólo

con baterías del mismo fabricante y el mismo

tipo, o un tipo equivalente recomendado por

el fabricante, de acuerdo con las instrucciones

descritas en el manual de servicio del

producto. No desmonte las baterías ni intente

recargarlas fuera del sistema. No intente

deshacerse de las baterías echándolas al fuego.

Deshágase de las baterías correctamente de

acuerdo con las instrucciones del fabricante y

las normas locales. Tenga en cuenta que en las

placas CPU de Sun, hay una batería de litio

incorporada en el reloj en tiempo real. Los

usuarios no deben reemplazar este tipo de

baterías.

Cubierta de la unidad del sistema

Debe extraer la cubierta de la unidad del sistema

informático Sun para instalar tarjetas, memoria o

dispositivos de almacenamiento internos. Vuelva a colocar

la cubierta antes de encender el sistema informático.

Precaución – Para evitar que el bastidor se

vuelque durante la instalación del equipo,

debe extenderse la barra antivolcado del

bastidor.

Precaución – Para evitar que se alcance una

temperatura de funcionamiento extrema en el

bastidor, asegúrese de que la temperatura

máxima no sea superior a la temperatura

ambiente establecida como adecuada para el

producto.

Precaución – Para evitar que se alcance una

temperatura de funcionamiento extrema

debido a una circulación de aire reducida,

debe considerarse la magnitud de la

circulación de aire requerida para que el

equipo funcione de forma segura.

Aviso de cumplimiento de la normativa para la utilización de láser

Los productos Sunque utilizantecnología lásercumplen los

requisitos establecidos para los productos láser de clase 1.

Precaución – No ponga en funcionamiento

los productos Sun que no tengan colocada la

cubierta. De lo contrario, puede sufrir lesiones

personales y ocasionar daños en el sistema.

Advertencia sobre el sistema en bastidor

Las advertencias siguientes se aplican a los sistemas

montados en bastidor y a los propios bastidores.

xxiv Sun Fire E2900 Systems Installation Guide • May 2006

Class 1 Laser Product

Luokan 1 Laserlaite

Klasse 1 Laser Apparat

Laser Klasse 1

Page 25

Dispositivos de CD y DVD

La siguiente medida se aplica a los dispositivos de CD y

DVD, así como a otros dispositivos ópticos:

Precaución – La utilización de controles,

ajustes o procedimientos distintos a los aquí

especificados puede dar lugar a niveles de

radiación peligrosos.

Nordic Lithium Battery Cautions

Norge

Advarsel – Litiumbatteri — Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten. Brukt batteri

returneres apparatleverandøren.

Sverige

Varning – Explosionsfara vid felaktigt

batteribyte. Använd samma batterityp eller en

ekvivalent typ som rekommenderas av

apparattillverkaren. Kassera använt batteri

enligt fabrikantens instruktion.

Danmark

Suomi

Advarsel! – Litiumbatteri — Eksplosionsfare

ved fejlagtig håndtering. Udskiftning må kun

ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til

leverandøren.

Varoitus – Paristo voi räjähtää, jos se on

virheellisesti asennettu. Vaihda paristo

ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan

ohjeiden mukaisesti.

Safety Agency Compliance Statements xxv

Page 26

xxvi Sun Fire E2900 Systems Installation Guide • May 2006

Page 27

Preface

This guide describes how to install and set up a Sun Fire™ E2900 system.

How This Book Is Organized

Chapter 1 contains information on installing and cabling the system.

Appendix A describes the connectors on the system.

Related Documentation

Application Title

Administration Sun Fire Entry-level Midrange System Administration Guide

Administration Sun Fire Entry-level Midrange System Controller Command Reference Manual

Service Sun Fire E2900 Systems Service Manual

xxvii

Page 28

Accessing Sun Documentation

You can view, print, or purchase a broad selection of Sun documentation, including

localized versions, at:

http://www.sun.com/documentation

Contacting Sun Technical Support

If you have technical questions about this product that are not answered in this

document, go to:

http://www.sun.com/service/contacting

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and

suggestions. You can submit your comments by going to:

http://www.sun.com/hwdocs/feedback

Please include the title and part number of your document with your feedback:

Sun Fire E2900 Systems Installation Guide, part number 817-4053-15

Tools Required

For the procedures in this document, you will need these tools:

■ Computer lifting device

■ Phillips No. 2 Screwdriver

■ 13 mm Wrench

■ 8 mm Wrench

xxviii Sun Fire E2900 Systems Installation Guide • May 2006

Page 29

CHAPTER

1

Physical Installation

Sun Fire E2900 systems can be shipped in several ways:

1. Not in a cabinet and with a slide rail mounting kit for installation in a cabinet

2. Not in a cabinet and intended upon being freestanding

3. Pre-installed in a cabinet

Following is a list of subjects covered. For method 1 begin with Section 1.1,

“Installing Slides and Rails” on page 1-2. For methods 2 and 3 begin with Section 1.4,

“Installing the Cable Management Arm” on page 1-21.

■ Section 1.1, “Installing Slides and Rails” on page 1-2

■ Section 1.2, “Installing the System in a Cabinet” on page 1-13

■ Section 1.3, “Installing Slide Rail Locking Nuts” on page 1-19

■ Section 1.4, “Installing the Cable Management Arm” on page 1-21

■ Section 1.5, “Connecting Sun Fire V1280/Netra 1280 Power Cables” on page 1-30

■ Section 1.6, “Connecting Consoles to the System Controller” on page 1-32

■ Section 1.7, “Connecting the I/O Assemblies” on page 1-35

■ Section 1.8, “Powering On the System” on page 1-35

■ Section 1.9, “Powering Off the System” on page 1-36

■ Section 1.10, “Installing Additional Hardware” on page 1-36

■ Section 1.11, “Installing Additional Peripheral Devices” on page 1-37

1-1

Page 30

Caution – The cabinet stabilizers (if applicable) must be extended whenever a Sun

Fire V1280/Netra 1280 system is pulled out of the cabinet.

Caution – The Sun Fire V1280/Netra 1280 system, with mounting cradle, weighs

approximately 286 lb (130 kg). Two people using a computer equipment lift are

required to move the system safely into the cabinet.

Caution – Pull only one Sun Fire V1280/Netra 1280 system out of the cabinet at a

time to prevent unbalancing the cabinet.

1.1 Installing Slides and Rails

Systems which are to be mounted in a cabinet utilize a slide rail mounting kit. This

kit includes the following:

■ Two slide lock spacers

■ Two slide lock nuts

■ Four rails, two inner and two outer

■ 8 MM. wrench

Note – If you received your system pre-installed in a cabinet you may proceed

directly to Section 1.4, “Installing the Cable Management Arm” on page 1-21.

This section is divided into the following:

■ Section 1.1.1, “Adjusting the Rail Assembly” on page 1-3

■ Section 1.1.2, “Installing the Inner Slides on the System” on page 1-4

■ Section 1.1.3, “Preparing the Rails for Two-Post Installations” on page 1-6

■ Section 1.1.4, “Installing the Rail Assemblies in a Sun Fire/StorEdge Cabinet” on

page 1-7

■ Section 1.1.5, “Installing the Rail Assemblies in a Sun Rack 900 Cabinet” on

page 1-9

■ Section 1.1.6, “Installing the Rail Assemblies in a 19-Inch Four-Post Cabinet” on

page 1-11

■ Section 1.1.7, “Installing the Rail Assemblies in a 19-inch Two-Post Rack” on

page 1-12

1-2 Sun Fire E2900 Systems Installation Guide • May 2006

Page 31

1.1.1 Adjusting the Rail Assembly

Each rail assembly consists of four components (FIGURE 1-1):

■ Rear bracket that attaches to the slide assembly

■ Adjustable bracket that attaches to the rear bracket (adjustable bracket is not used

in some configurations)

■ Slide assembly (with inner and outer slides)

■ Front bracket

2-Post 3" Position

2-Post 4" Position

Sunfire Cabinet

2-Post 6" Position

NGR Cabinet

Storedge Cabinet

Adjustable

bracket

Rear

bracket

Slide

assembly

Front

bracket

S

U

N

F

I

R

E

FIGURE 1-1 Rail Assembly (Standard Configuration)

Adjust the rear bracket or the adjustable bracket position to modify the length of the

assembly. The slide assembly and the rear bracket have bracket locations for specific

cabinets stamped onto the metal.

FIGURE 1-1 shows the location of the markings.

Chapter 1 Physical Installation 1-3

Page 32

1.1.2 Installing the Inner Slides on the System

1. Remove the inner slide from the slide assembly:

a. Press the latch adjacent to the green latch.

b. Pull the inner slide free from the outer slide/rail assembly.

2. Push up on the inner slide so that the locating tab, on the side of the system, clips

over the cutouts in the slide (

The spring tab should engage.

Note – The spring clips must be above the system hooks; the lip on the main body

of the inner slide must engage under and behind the system hook.

3. Secure the inner slide to the system using two 5 x 10 MM. screws for each slide.

4. Repeat Step 1 through Step 3 for the second inner slide.

FIGURE 1-2).

1-4 Sun Fire E2900 Systems Installation Guide • May 2006

Page 33

FIGURE 1-2 Spring Clips and Cutouts

Chapter 1 Physical Installation 1-5

Page 34

1.1.3 Preparing the Rails for Two-Post Installations

For two-post installations, you can dismantle and reassemble the rail assemblies

(

FIGURE 1-3). The rail assemblies can be adjusted to suit a 19-inch two-post rack that

has a post depth in the range of 3 to 6 inches (7.5 to 15.0 cm).

1. Remove the nuts that secure the adjustable bracket and discard the adjustable

bracket (

2. Remove the four nuts securing the front bracket.

FIGURE 1-1).

3. Rotate the front bracket 180 degrees and secure it facing inward (

FIGURE 1-3).

4. Remove the four nuts that secure the rear bracket.

5. Rotate the rear bracket 180 degrees so that it faces inward (

FIGURE 1-3).

6. Align the rear bracket to the appropriate markings on the slide assembly and

secure the rear bracket.

7. Repeat Step 1 through Step 6 for the second rail assembly.

Rear bracket

(facing inwards)

Front bracket

(facing inwards)

2-Post 3" Position

Slide assembly

2-Post 4" Position

Sunfire Cabinet

2-Post 6" Position

NGR Cabinet

FIGURE 1-3 Rail Assembly (Modified for Two-Post Installation)

1-6 Sun Fire E2900 Systems Installation Guide • May 2006

Storedge Cabinet

Page 35

1.1.4 Installing the Rail Assemblies in a Sun Fire/StorEdge Cabinet

Sun Fire/StorEdge™ cabinets have No. 10-32 UNF tapped screw holes in the front

and rear, which are numbered from bottom to top.

Note – The rail assemblies are reversible. They can be used on either side of the

cabinet.

1. Adjust the position of the adjustable bracket on each rail assembly.

a. Loosen the two nuts that secure the adjustable bracket.

b. Reposition the adjustable bracket to the location stamped “SUNFIRE” on the

rear bracket and secure the adjustable bracket.

2. Adjust the length of each rail assembly.

a. Loosen the four nuts that secure the rear bracket.

b. Reposition the rear bracket to the location marked “Sun Fire Cabinet” on the

slide assembly and secure the rear bracket.

1.1.4.1 Installing the Rail Assemblies in the Bottom Position

1. Insert the pins in the front bracket into cabinet holes 22 and 33 (FIGURE 1-4).

The pins will hold the bracket in place until the bracket is secured.

2. Secure the adjustable bracket into cabinet holes 24 and 31 with two No. 10-32 UNF

screws.

3. Secure the front bracket into cabinet holes 24 and 31 with two No. 10-32 UNF

screws.

4. Repeat Step 1 through Step 3 for the second rail assembly.

Note – Mounting the system in cabinet holes 24 and 31 allows for 10-inches of space

beneath the system in order to service the baseplane.

Chapter 1 Physical Installation 1-7

Page 36

1.1.4.2 Installing the Rail Assemblies in the Top Position

1. Insert the pins in the front bracket into cabinet holes 58 and 69 (FIGURE 1-4).

The pins will hold the bracket in place until it is secured.

2. Secure the adjustable bracket into cabinet holes 60 and 67 with two No. 10-32 UNF

screws.

3. Secure the front bracket into cabinet holes 60 and 67 with two No. 10-32 UNF

screws.

4. Repeat Step 1 through Step 3 for the second rail assembly.

Front bracket

secured to outer cabinet holes

FIGURE 1-4 Installing the Rails in a Sun Fire Cabinet

1-8 Sun Fire E2900 Systems Installation Guide • May 2006

Adjustable bracket

secured to inner cabinet holes

Page 37

1.1.5 Installing the Rail Assemblies in a Sun Rack 900 Cabinet

Sun™ Rack 900 cabinets have M-6 UNF tapped screw holes in the front and rear that

are numbered from bottom to top.

Note – The rail assemblies are reversible. They can be used on either side of the

cabinet.

1. Remove the adjustable bracket on each rail.

a. Loosen the two nuts that secure the adjustable bracket.

b. Discard the adjustable bracket.

2. Adjust the length of each rail assembly.

a. Loosen the four nuts that secure the rear bracket.

b. Reposition the rear bracket to the location marked “NGR Cabinet” on the slide

assembly and secure the rear bracket.

1.1.5.1 Installing the Rail Assemblies in the Bottom Position

1. Insert the pins in the front bracket into cabinet holes 22 and 33 (FIGURE 1-5).

The pins will hold the bracket in place until the bracket is secured.

2. Secure the rear bracket into cabinet holes 24 and 31 with two M-6 UNF screws.

3. Secure the front bracket into cabinet holds 24 and 31 with two M-6 UNF screws.

4. Repeat Step 1 through Step 3 for the second rail assembly.

Note – Mounting the system in cabinet holes 24 and 31 allows for 10-inches of space

beneath the system in order to service the baseplane.

Chapter 1 Physical Installation 1-9

Page 38

1.1.5.2 Installing the Rail Assemblies in the Top Position

1. Insert the pins in the front bracket into cabinet holes 58 and 69 (FIGURE 1-5).

The pins will hold the bracket in place until the bracket is secured.

2. Secure the rear bracket into cabinet holes 60 and 67 with two M-6 UNF screws.

3. Secure the front bracket into cabinet holes 60 and 67 with two M-6 UNF screws.

4. Repeat Step 1 through Step 3 for the second rail assembly.

Front bracket

secured to outer cabinet holes

FIGURE 1-5 Installing the Rails in a Sun Rack 900 Cabinet or 19-Inch Four-Post Cabinet

1-10 Sun Fire E2900 Systems Installation Guide • May 2006

Rear bracket

secured to outer cabinet holes

Page 39

1.1.6 Installing the Rail Assemblies in a 19-Inch FourPost Cabinet

The rails can be adjusted to suit a 19-inch cabinet that is compliant with either IEC

297-4 or EIA 310-D. Each rail assembly has a distance between front and rear

mounting rails from 17.7 to 30.7 inches (45.0 to 78.0 cm).

Note – The rail assemblies are reversible. They can be used on either side of the

cabinet.

Caution – It is the installer’s responsibility to ensure that the cabinet has sufficient

structural strength and stability to handle any required installations.

1. Remove the adjustable bracket on each rail assembly.

a. Loosen the two nuts that secure the adjustable bracket.

b. Discard the adjustable bracket.

2. Adjust the length of each rail assembly.

a. Loosen the four nuts that secure the rear bracket.

b. Reposition the rear bracket to the appropriate markings shown on the slide

assembly and secure the rear bracket.

3. Secure the rear bracket with two No. 10-32 UNF screws (

■ To install the system in the lowest position, insert the rackmount securing screws

no lower than 18.5 inches and 22.5 inches (47.0 cm and 57.2 cm) respectively.

Refer to the Sun Fire V1280/Netra 1280 Slide Rail Installation Instructions and

Mounting Template to determine cabinet hole locations.

FIGURE 1-5).

Note – Mounting the bracket no lower than 18.5 inches and 22.5 inches allows for

10-inches of space beneath the system in order to service the baseplane.

■ To install the system in the topmost position, insert the rackmount securing screws

no higher than 39.5 inches and 43.5 inches (100.0 cm and 110.0 cm) respectively.

Refer to the Sun Fire V1280/Netra 1280 Slide Rail Installation Instructions and

Mounting Template to determine cabinet hole locations.

4. Secure the front bracket with two No. 10-32 UNF screws (

5. Repeat Step 1 through Step 4 for the second rail assembly.

Chapter 1 Physical Installation 1-11

FIGURE 1-5).

Page 40

1.1.7 Installing the Rail Assemblies in a 19-inch TwoPost Rack

Note – The rails assemblies must be prepared. See Section 1.1.3, “Preparing the Rails

for Two-Post Installations” on page 1-6.

Note – The rail assemblies are reversible. They can be used on either side of the

cabinet.

Caution – Ensure that the rack is anchored to the floor, ceiling, or adjacent frames.

It is the installer’s responsibility to ensure that the rack has sufficient structural

strength and stability to handle any required installations.

1. Secure the front bracket with two No. 10-32 UNF screws.

Insert the rackmount securing screws no lower than 18.5 inches and 22.5 inches (47.0

cm and 57.2 cm) respectively. Refer to the Sun Fire V1280/Netra 1280 Slide Rail

Installation Instructions and Mounting Template to determine cabinet hole locations.

Note – Mounting the bracket no lower than 18.5 inches and 22.5 inches allows for

10-inches of space beneath the system in order to service the baseplane.

2. Secure the rear bracket with two No. 10-32 UNF screws.

3. Repeat Step 1 and Step 2 for the second rail assembly.

1-12 Sun Fire E2900 Systems Installation Guide • May 2006

Page 41

1.2 Installing the System in a Cabinet

This section contains the following topics:

■ Section 1.2.1, “Preparing to Install the System in the Cabinet” on page 1-13

■ Section 1.2.2, “Mounting the System in the Cabinet” on page 1-15

1.2.1 Preparing to Install the System in the Cabinet

1. Remove the front bezel doors (FIGURE 1-6).

a. Open the door and press down on the hinge pin levers to release the hinges.

b. Lift the door off of the hinge pins and store the door in a safe place.

c. Repeat Step a and Step b for the second front bezel door.

FIGURE 1-6 Releasing the Door Hinge Mechanism

Chapter 1 Physical Installation 1-13

Page 42

2. Remove the shipping cradle bolts (FIGURE 1-7).

The bolts secure the orange metal shipping cradle to the wooden pallet.

FRONT

FIGURE 1-7 Removing the Shipping Cradle Bolts

1-14 Sun Fire E2900 Systems Installation Guide • May 2006

Page 43

1.2.2 Mounting the System in the Cabinet

Caution – The Sun Fire V1280/Netra 1280 system with mounting cradle weighs

approximately 286.0 lb (130.0 kg). To prevent personal injury, two people are needed

to move the system safely into the cabinet using a computer equipment lift.

1. Extend the cabinet stabilizer and lock it in position (as applicable).

Caution – The shipping cradle must be attached when the system is lifted. Failure

to do so will result in major damage to the system.

2. Insert the forks of the lifting device fully through the shipping cradle opening

FIGURE 1-8).

(

FRONT

FIGURE 1-8 Inserting the Lifting Device into the Shipping Cradle

Chapter 1 Physical Installation 1-15

Page 44

3. Lift the system off of the wooden shipping pallet and remove the pallet.

4. Extend the outer slides from the cabinet and latch them in the extended position.

5. Lift the system until it is level with the outer slides on the cabinet.

6. Carefully move the lifting device forward until the slides on the system are fully

engaged with the outer slides on the cabinet

(FIGURE 1-9).

The latches on each side must click out, locking the slides.

Outer slides

Inner slides

FIGURE 1-9 Aligning the Slides

1-16 Sun Fire E2900 Systems Installation Guide • May 2006

Page 45

Caution – The cabinet stabilizers (if applicable) must be extended or the cabinet

might topple when the lifting device is withdrawn.

7. With the lifting device still supporting the system, loosen the four captive screws

attaching the handles of the shipping cradle to the system.

8. Loosen the four captive screws that attach the handles to the shipping cradle.

9. Pull both shipping cradle handles away from the system.

This disconnects the shipping cradle from the system.

10. Lower the shipping cradle out of the way with the lifting device.

Store the shipping cradle for future use.

FIGURE 1-10 Removing the Shipping Cradle

Chapter 1 Physical Installation 1-17

Page 46

11. Press the green latches on each slide and push the system into the cabinet

(

FIGURE 1-11).

FIGURE 1-11 Pushing the System into the System Cabinet

12. Tighten the two securing screws on the front of the system to secure the system in

the cabinet (

FIGURE 1-12).

13. Retract the cabinet stabilization mechanism (as required).

14. Reattach the front doors of the system.

Securing screw Securing screw

FIGURE 1-12 Tightening the Securing Screws

1-18 Sun Fire E2900 Systems Installation Guide • May 2006

Page 47

1.3 Installing Slide Rail Locking Nuts

Note – Slide rail locking nuts are pre installed on all units shipped from the factory

in a cabinet.

For systems not shipped pre installed in a cabinet, a slide rail mounting kit is

utilized that contains slide rail locking nuts, spacer and rails that are used to mount

and secure a system in a cabinet, see Section 1.1, “Installing Slides and Rails” on

page 1-2. Once locking nuts are installed on a system, the following is applicable:

■ Slide rail locking nuts must be loosened in order to remove a system from a

cabinet

■ Slide rail locking nuts must be securely tightened on each system prior to moving

a cabinet with one or more systems

Proceed as follows to install the slide rail locking nuts:

Note – The slide rail mounting kits contain a pair of spacers provided by the

manufacturer along with the rails. The manufacturer’s spacers must be discarded

and replaced by the Sun spacers provided in the kit.

1. Slide the system out of the system cabinet.

2. Remove and discard the manufactures spacers provided with the slide rails in the

kit.

3. From the rear of the system, insert and tighten the supplied spacers onto the

locking bolts on each slide (

The spacer shoulders must face outwards.

FIGURE 1-13).

Chapter 1 Physical Installation 1-19

Page 48

FIGURE 1-13 Inserting and Tightening the Slide Rail Spacers

4. Slide the system into the system cabinet.

5. From the rear of the system, insert and tighten the locking nuts, one for each slide

(

FIGURE 1-14).

FIGURE 1-14 Inserting and Tightening the Slide Rail Locking Nut

6. Repeat Step 1 through Step 5 for each system in the system cabinet.

1-20 Sun Fire E2900 Systems Installation Guide • May 2006

Page 49

1.4 Installing the Cable Management Arm

This section contains the following topics:

■ Section 1.4.1, “Installing the CMA–Lite” on page 1-22

■ Section 1.4.2, “Installing the CMA–800.” on page 1-23

The purpose of a cable management arm (CMA) is to support and protect cables

when a system slides into or out of a cabinet.

Two cable management arm solutions are offered: CMA-Lite and CMA-800. The

optimum choice of CMA is dependant upon the available depth in the cabinet and

the quantity or type of cable to be supported. Use the CMA-Lite if the larger CMA800 management arm does not fit your cabinet.

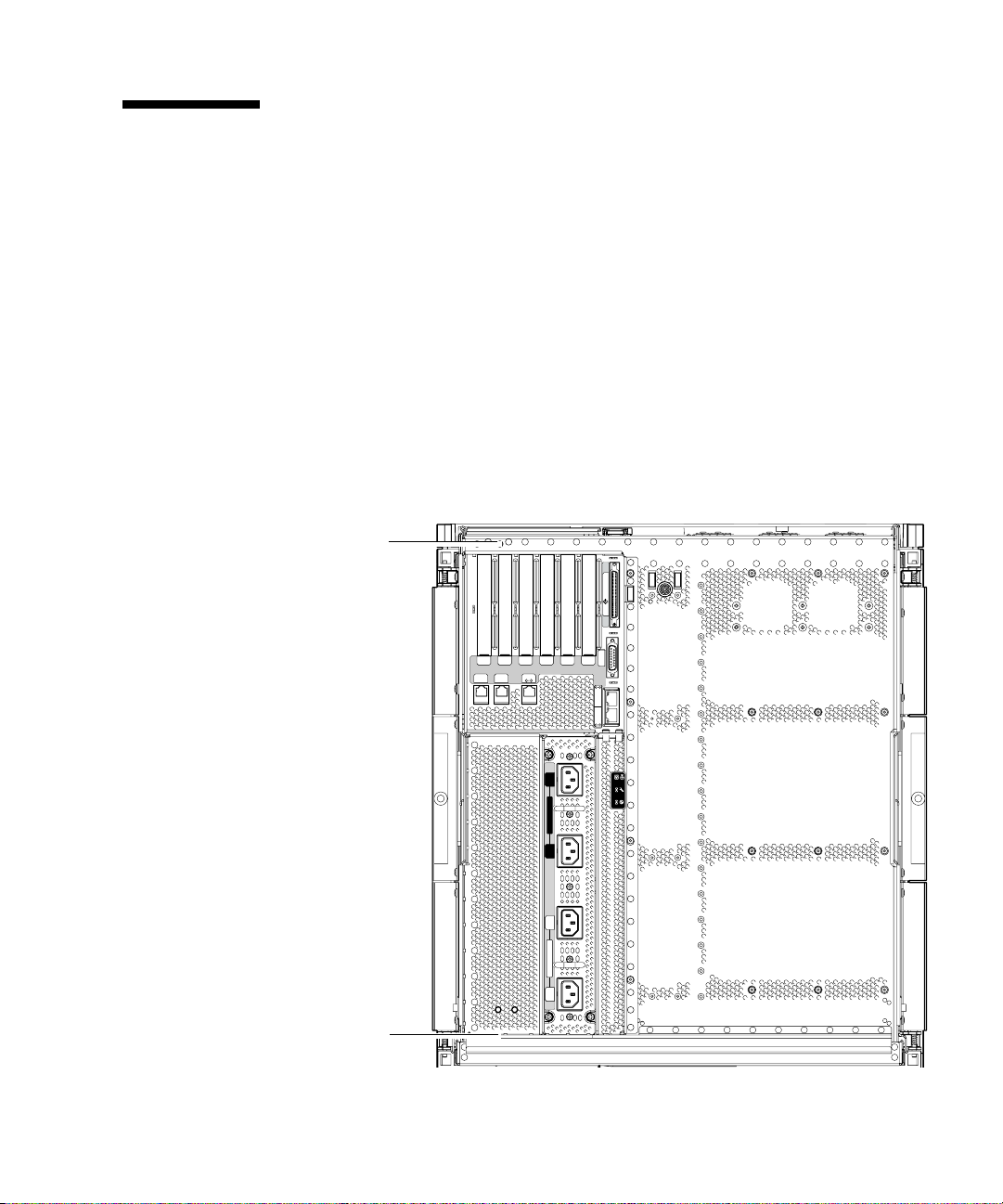

Threaded holes for attaching the CMA are provided on the rear of the system

(

FIGURE 1-15).

Upper

bracket holes

SCSI3

PCI 3

PCI 1

PCI 2

PCI 4

PCI 0

33MHz

33MHz

SSC1 SSC1

BB

A

Serial A Serial B

33MHz

PCI 5

33MHz

33MHz

66MHz

ALARMS

Link

Active

NET

0

GBit

Link

Active

NET

1

GBit

Lower

bracket holes

FIGURE 1-15 Bracket Mounting Holes

AC

3

SOURCE A

SOURCE B

AC

2

AC

1

SOURCE A

AC

0

Chapter 1 Physical Installation 1-21

Page 50

1.4.1 Installing the CMA–Lite

1. Secure the pivot at the end of the upper arm to the top rear of the system, using

the two captive screws (

2. Secure the center pivot point of the CMA to the inside rear of the left hand rail

assembly, using the two captive screws.

3. Secure the pivot at the end of the lower arm to the bottom rear of the system,

using the two captive screws.

FIGURE 1-16).

Captive

screws (2)

CMA-LIte

FIGURE 1-16 CMA–Lite Cable Management Arm

1-22 Sun Fire E2900 Systems Installation Guide • May 2006

Captive

screws (2)

Captive

screws (2)

Page 51

1.4.2 Installing the CMA–800.

t

t

To install a CMA-800 proceed as follows:

1. Refer to

CMA parts.

FIGURE 1-17, throughout the following procedures for identification of

Hinge pin

Upper pivot

bracket

Upper CMA arm

Guide bar

Hinge pin

Lower pivot

bracket

Guide slo

Left hand

T-bracket

Lower CMA arm

FIGURE 1-17 Upper/Lower CMA Arms and Left Hand/Right Hand T-Brackets

Right hand

T-bracket

Guide bar

Chapter 1 Physical Installation 1-23

Guide slo

Page 52

Note – In the following procedure all left-hand and right-hand orientation is as

viewed from the rear of the system chassis.

2. Remove the hinge pin securing the pivot bracket to the upper CMA arm, which

will facilitate attaching the bracket to the system chassis.

3. Secure the pivot bracket to the upper left hand side of the system chassis using

the two captive screws. See FIGURE 1-18 and FIGURE 1-19.

After attaching the pivot bracket to the chassis, use the hinge pin removed

previously to secure it to the upper CMA arm.

Upper pivot bracket

mounting holes

Upper pivot

bracket

Lower pivot

bracket

Lower pivot bracket

mounting holes

(hidden)

FIGURE 1-18 Upper/Lower Pivot Bracket Mounting Holes

1-24 Sun Fire E2900 Systems Installation Guide • May 2006

Page 53

Hinge pin

Upper pivot bracket

Upper CMA arm

FIGURE 1-19 Attachment of Upper CMA Arm and Pivot Bracket

Chapter 1 Physical Installation 1-25

Page 54

4. Remove the hinge pin securing the pivot bracket to the lower CMA arm, which

will facilitate attaching the bracket to the system chassis.

5. Secure the pivot bracket to the lower left hand of the system chassis using the two

captive screws, see

FIGURE 1-18 and FIGURE 1-20.

6. After attaching the bracket to the chassis, secure the lower CMA arm to the

bracket using the hinge pin removed previously.

Hinge pin

Lower pivot bracket

Lower CMA arm

FIGURE 1-20 Attachment of Lower CMA Arm and Pivot Bracket

1-26 Sun Fire E2900 Systems Installation Guide • May 2006

Page 55

7. Secure the left hand T-bracket to the left hand slide rail using two captive screws,

FIGURE 1-21.

Slide rail

Left hand T-bracket

FIGURE 1-21 Attaching Left Hand T-Bracket

Chapter 1 Physical Installation 1-27

Page 56

8. Secure the right hand T-bracket to the right hand slide rail using two captive

screws,

FIGURE 1-22.

Slide rail

Right hand T-bracket

FIGURE 1-22 Attachment of Right-Hand T-Bracket

1-28 Sun Fire E2900 Systems Installation Guide • May 2006

Page 57

9. Secure the upper CMA arm to left hand T-bracket using a single hinge pin

FIGURE 1-23.

Hinge pin

Guide bars

Hinge pin

Left hand T-bracket

Right hand T-bracket

FIGURE 1-23 Attachment of Upper/Lower CMA Arms to T-Bracket

10. Secure the lower CMA arm to the left hand T-bracket using a single hinge pin,.

FIGURE 1-23.

11. Route the cabling through the cable channels as desired and then secure both the

upper and lower CMA arms by inserting the guide bars of each arm into the slots

provided on the right hand T-bracket.

Chapter 1 Physical Installation 1-29

Page 58

1.5 Connecting Sun Fire V1280/Netra 1280 Power Cables

Caution – The Sun Fire V1280/Netra 1280 system is designed to work with power

systems having a grounded neutral conductor. Do not connect the equipment into

any other type of power system. Contact your facilities manager or a qualified

electrician to determine what type of power is supplied to your building.

Caution – Your Sun product is shipped with grounding-type (three-wire) power

cords. Always connect the cords into grounded power outlets.

Caution – The socket outlets must be installed near the equipment and easily

accessible.

1. Turn the system power switch to the Standby position.

Caution – The On/Standby power switch does not isolate the equipment. The AC

power cords are the primary means of disconnection for this product.

2. Turn the cabinet power off (in a powered cabinet).

Refer to the installation guide that came with the cabinet.

3. Label both ends of the power cords.

Two cords should be labeled Source A and two should be labeled Source B.

4. Connect the power cables to the system.

a. Connect the Source A power cords to AC0 and AC1 on the system and the

Source B power cords to AC2 and AC3 on the system.

b. Run the power cords through the CMA and secure them with tie wraps.

Make sure the CMA can extend and retract without dislodging the power cords.

1-30 Sun Fire E2900 Systems Installation Guide • May 2006

Page 59

Note – Step 3 and Step 4 will already be completed for systems that come pre

installed in a Sun Rack 900 cabinet.

5. Connect the system to the power source.

Note – It is the installer’s responsibility to ensure that the cabinet has sufficient

electrical power and redundancy to handle the required installation.

● If mounted in an unpowered cabinet:

a. Connect power cords from Source A on the system to the customer-supplied

power source A circuit breakers.

b. Connect power cords from Source B on the system to the customer-supplied

power source B circuit breakers.

● If mounted in a powered cabinet:

a. Connect power cords from Source A on the cabinet to the customer-supplied

power source A circuit breakers and Source B on the cabinet to the customersupplied power source B circuit breakers.

Refer to the installation guide that came with the cabinet for instructions on

cabinet power cabling.

b. Connect power cords from Source A on the cabinet to Source A on the system

and Source B on the cabinet to the Source B on the system.

Refer to the installation guide that came with the cabinet for instructions on

cabinet power cabling.

Chapter 1 Physical Installation 1-31

Page 60

1.6 Connecting Consoles to the System Controller

This section contains the following topics:

■ Section 1.6.1, “Connecting the Initial Administrative Console” on page 1-33

■ Section 1.6.2, “Connecting the Administrative Console” on page 1-35

The system controller (SC) is responsible for providing the Lights-Out Management

(LOM) functions, which include power on sequencing, executing module power-on

self-tests (POST), environmental monitoring, fault indication and alarms.

The LOM command-line interface and the Solaris/OpenBoot™ PROM console are

accessed by connecting an administrative console to either serial port A or the

10/100 LOM Ethernet port. The administrative console can be any external input

device (laptop computer or workstation) connected to either of these ports.

Serial port A is used to connect directly to an ASCII terminal or a network terminal

server (NTS) using a command-line interface. This port is used for the initial

administrative console. It is used to modify the default system controller settings

(usually so that the 10/100 LOM Ethernet port can be used as an administrative

console). The configuration of Serial port A cannot be changed. See Appendix A for

details on the Serial ports.

The 10/100 LOM Ethernet port is used to connect the system controller to the

network. This port is preconfigured as follows:

■ System controller configured to be on a network

■ System controller Ethernet configured for Dynamic Host Configuration Protocol

(DHCP)

■ No pre-configured system controller Ethernet IP address, Gateway, Domain name

system (DNS) domain, DNS servers

1-32 Sun Fire E2900 Systems Installation Guide • May 2006

Page 61

1.6.1 Connecting the Initial Administrative Console

For the initial configuration, connect Serial A port to the serial port on any of the

following devices:

■ ASCII terminal

■ Sun workstation

■ Terminal server (or patch panel connected to a terminal server)

Note – If the IP address assigned to the 10/100 LOM Ethernet port by DHCP is

known, the 10/100 LOM Ethernet port can be accessed without the Serial A port.

1. Connect the administrative console to the Serial A port.

The Serial A port is a DTE (data terminal equipment) port. An adapter, crossover

cable or null modem cable is required to connect the Serial A port to another DTE

port. For Serial A port connector pinouts and adaptor information, see Section A.4,

“LOM Serial Ports” on page A-6.

2. Turn the customer-supplied circuit breakers power switch to the On position.

3. Turn the system power switch to the On position.

Refer to the Sun Fire Entry-level Midrange System Administration Guide.

4. Set up the administrative console.

Refer to the Sun Fire Entry-level Midrange System Administration Guide.

Chapter 1 Physical Installation 1-33

Page 62

I/O Assembly

68-pin SCSI port

Alarms port

Serial A port

10/100 LOM

Ethernet port

Net0/Net1

Ethernet port

PCI 1

PCI 2

PCI 0

33MHz

33MHz

SSC1 SSC1

BB

A

Serial A Serial B

SCSI3

PCI 3

PCI 4

PCI 5

33MHz

33MHz

33MHz

66MHz

ALARMS

Link

Active

NET

0

GBit

Link

Active

NET

1

GBit

AC

3

SOURCE A