Page 1

Sun Fire

™

B1600

Blade System Chassis

Hardware Installation Guide

Sun Microsystems, Inc.

4150 Network Circle

Santa Clara, CA 95054 U.S.A.

650-960-1300

Part No. 817-3430-10

August 2003, Revision A

Send comments about this document to: docfeedback@sun.com

Page 2

Copyright 2003Sun Microsystems,Inc., 4150Network Circle, SantaClara, California95054, U.S.A.All rightsreserved.

Sun Microsystems,Inc. hasintellectual property rightsrelating totechnology embodiedin theproduct that is described inthis document.In

particular,and withoutlimitation, theseintellectual property rightsmay includeone ormore ofthe U.S.patents listedat

http://www.sun.com/patents andone ormore additionalpatents orpending patentapplications inthe U.S.and inother countries.

This documentand theproduct towhich itpertains are distributedunder licensesrestricting theiruse, copying,distribution, and

decompilation. Nopart ofthe productor ofthis documentmay bereproducedin anyform byany meanswithout priorwritten authorizationof

Sun andits licensors,if any.

Third-party software, includingfont technology,is copyrightedand licensedfrom Sun suppliers.

Parts ofthe productmay bederived from BerkeleyBSD systems,licensed fromthe Universityof California.UNIX isa registered trademarkin

the U.S.and inother countries,exclusively licensedthrough X/OpenCompany, Ltd.

Sun, Sun Microsystems,the Sunlogo, AnswerBook2,docs.sun.com, Netra,Netra ft,Sun Fire, andSolaris aretrademarks orregistered

trademarks ofSun Microsystems,Inc. inthe U.S.and inother countries.

All SPARCtrademarks areused underlicense andare trademarks or registered trademarksof SPARCInternational, Inc.in theU.S. andin other

countries. Productsbearing SPARCtrademarks are basedupon anarchitecture developed by Sun Microsystems,Inc. TheEnergy Starlogo isa

registered trademark of EPA.

The OPENLOOK andSun™ GraphicalUser Interfacewas developedby SunMicrosystems, Inc.for itsusers andlicensees. Sun acknowledges

the pioneeringefforts ofXerox in researchingand developingthe conceptof visualor graphicaluser interfacesfor thecomputer industry.Sun

holds anon-exclusive licensefrom Xerox tothe XeroxGraphical UserInterface, whichlicense alsocovers Sun’slicensees whoimplement OPEN

LOOK GUIsand otherwisecomply withSun’s writtenlicense agreements.

Use, duplication,or disclosure bythe U.S.Government issubject to restrictionsset forthin theSun Microsystems, Inc.license agreementsand as

provided inDFARS 227.7202-1(a)and 227.7202-3(a)(1995), DFARS 252.227-7013(c)(1)(ii) (Oct. 1998), FAR 12.212(a)(1995), FAR52.227-19, or

FAR52.227-14 (ALTIII), asapplicable.

DOCUMENTATION IS PROVIDED "AS IS" AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANYIMPLIED WARRANTY OFMERCHANTABILITY, FITNESSFOR A PARTICULAR PURPOSEOR NON-INFRINGEMENT,

ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright 2003Sun Microsystems,Inc., 4150Network Circle, SantaClara, California95054, Etats-Unis.Tous droitsréservés.

Sun Microsystems,Inc. ales droits depropriété intellectuelsrelatants à la technologie incorporée dans leproduit quiest décritdans ce

document. Enparticulier,et sansla limitation,ces droits depropriété intellectuelspeuvent inclure unou plusdes brevetsaméricains énumérés

à http://www.sun.com/patents et unou lesbrevets plus supplémentairesou lesapplications debrevet enattente dansles Etats-Uniset dans

les autrespays.

Ce produitou documentest protégé parun copyrightet distribuéavec deslicences quien restreignent l’utilisation,la copie,la distribution,et la

décompilation. Aucunepartie dece produitou documentne peutêtre reproduite sousaucune forme,parquelque moyen que ce soit, sans

l’autorisation préalableet écritede Sunet deses bailleursde licence,s’il yena.

Le logicieldétenu pardes tiers,et quicomprend latechnologie relative auxpolices decaractères, estprotégépar uncopyright etlicencié pardes

fournisseurs deSun.

Des partiesde ceproduit pourront êtredérivées dessystèmes BerkeleyBSD licenciéspar l’Universitéde Californie.UNIX estune marque

déposée auxEtats-Unis etdans d’autrespays etlicenciée exclusivementpar X/OpenCompany, Ltd.

Sun, SunMicrosystems, lelogo Sun,AnswerBook2, docs.sun.com,Netra, Netraft, SunFire, et Solaris sont desmarques defabrique oudes

marques déposéesde SunMicrosystems, Inc. aux Etats-Unis et dans d’autrespays.

Toutes lesmarques SPARC sont utilisées sous licence et sont des marques defabrique oudes marquesdéposées deSPARC International,Inc.

aux Etats-Uniset dansd’autres pays.Les produits protantles marques SPARC sont baséssur unearchitecturedéveloppée parSun

Microsystems, Inc.

L’interfaced’utilisation graphiqueOPEN LOOKet Sun™a étédéveloppée parSun Microsystems, Inc.pour sesutilisateurs etlicenciés. Sun

reconnaît lesefforts de pionniers de Xeroxpour larecherche et le développment du concept des interfaces d’utilisation visuelle ou graphique

pour l’industriede l’informatique.Sun détientune licensenon exclusivedo Xeroxsur l’interfaced’utilisation graphiqueXerox, cette licence

couvrant égalementles licenciéesde Sunqui mettenten placel’interface d’utilisation graphiqueOPEN LOOKet quien outrese conforment

aux licencesécrites deSun.

LA DOCUMENTATION EST FOURNIE "EN L’ÉTAT" ET TOUTES AUTRES CONDITIONS, DECLARATIONS ET GARANTIES EXPRESSES

OU TACITES SONT FORMELLEMENTEXCLUES, DANSLA MESUREAUTORISEE PARLA LOIAPPLICABLE, YCOMPRIS NOTAMMENT

TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE UTILISATION PARTICULIERE OU A

L’ABSENCE DE CONTREFAÇON.

Please

Recycle

Page 3

Contents

1. Preparing for the Installation 1–1

1.1 Checklist of Rackmounting and Setup Tasks 1–2

1.2 Contents of the Ship Kit 1–3

1.3 Tools and Equipment Needed 1–4

1.4 System Chassis Dimensions 1–4

1.5 Site Preparation 1–8

1.5.1 System Cooling Requirements 1–8

1.5.1.1 General Environmental Parameters 1–8

1.5.1.2 Airflow Requirements 1–11

1.5.1.3 Estimating the Heat Dissipation 1–11

1.5.2 Operating Power Limits and Ranges 1–12

1.5.3 Estimating Power Consumption 1–12

2. Rack Options and Placement 2–1

2.1 Rack Options 2–1

2.2 Service Access 2–2

2.3 Rack and Floor Loading 2–3

2.4 Rack and Cabinet Safety 2–3

3. Installing the System Chassis In a Rack or Cabinet 3–1

Contents iii

Page 4

3.1 Installing the System Chassis In a

Four-Post Rack or Cabinet 3–1

3.1.1 Contents of the Four-Post Rackmount Kit 3–2

3.1.2 Using the Rack Buddy 3–2

3.1.3 Attaching the Brackets to the Four-Post Rack 3–3

3.1.4 Installing the System Chassis In the Four-Post Rack or Cabinet

3–6

3.2 Installing the System In a Two-Post Rack 3–11

3.2.1 Contents of the Two-Post Rackmount Kit 3–11

3.2.2 Installing the System Chassis In a Two-Post Rack 3–12

3.3 What to Do Next 3–16

4. Removing and Installing Modules 4–1

4.1 Removing and Installing Blades or Filler Panels 4–2

4.1.1 Removing Blades or Filler Panels 4–3

4.1.2 Installing a Blade or Filler Panel 4–6

4.2 Removing and Installing a PSU 4–9

4.2.1 Removing a PSU 4–10

4.2.2 Inserting a PSU 4–12

4.3 Removing and Installing a Switch and System Controller (SSC) 4–15

4.3.1 Chassis Supplied With Only One SSC 4–15

4.3.2 Removing the SSC 4–17

4.3.3 Installing the SSC 4–19

4.4 What to Do Next 4–22

5. Connecting and Managing Cables 5–1

5.1 Location of Ports and Power Inlets 5–2

5.2 Connecting the IEC Power Cords 5–3

5.3 Cable Requirements for 1000BASE-T and 10/100BASE-TX Connections

5–5

iv Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 5

5.3.1 1000BASE-T Cable Requirements 5–5

5.3.1.1 Cable Testing for Existing Category 5 Cable 5–5

5.3.2 Cable Requirements for 10/100BASE-TX Devices 5–6

5.4 Attaching the Connector Cables 5–6

5.5 Connecting to the 10/100/1000BASE-T Data Network Ports 5–7

5.6 Connecting to the 10/100BASE-T Network Management Ports 5–10

5.7 Managing Cables for Multiple System Chassis 5–12

5.8 What to Do Next 5–13

6. Connecting the RS232 Serial Port to Different Devices 6–1

6.1 Serial Port Pin Numbers 6–3

6.2 Connecting to a Terminal Server 6–4

6.3 Connecting to a VT100 Terminal or a Sun Workstation 6–5

6.4 Connecting to a Terminal That Has a

9-pin Adapter 6–6

6.5 Connecting to a Modem 6–7

6.6 Connecting the Cable to the Serial Port 6–8

6.7 Setting up a Serial Link to the System Controller Using a Laptop 6–9

6.7.1 Connecting to a Laptop 6–9

6.7.1.1 Using Microsoft Windows HyperTerminal 6–11

6.8 What to Do Next 6–12

Contents v

Page 6

vi Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 7

Figures

FIGURE 1-1 System Chassis Dimensions (Top View) 1–6

FIGURE 1-2 System Chassis Dimensions (Front View) 1–7

FIGURE 1-3 Temperature and Altitude Operating Ranges 1–9

FIGURE 1-4 Temperature and Relative Humidity Ranges 1–9

FIGURE 2-1 EIA/RETMA Mounting Hole Pattern Dimensions 2–2

FIGURE 3-1 Using the Rack Buddy 3–2

FIGURE 3-2 Sliding the Front Bracket Section Into the Back Bracket Section

(19-Inch, Four-Post Rack) 3–3

FIGURE 3-3 Connecting the Front and Back Four-Post Bracket Sections (19-Inch, Four-Post Rack) 3–4

FIGURE 3-4 Inserting the Rack Bracket Spacer 3–5

FIGURE 3-5 Removing the Module Retaining Pins 3–7

FIGURE 3-6 Aligning the System Chassis to the Brackets (19-Inch, Four-Post Rack) 3–8

FIGURE 3-7 Removing the Sacrificial Lifting Handle (19-Inch, Four-Post Rack) 3–9

FIGURE 3-8 Tightening the Captive Retaining Screws (19-Inch, Four-Post Rack) 3–10

FIGURE 3-9 Removing the Module Retaining Pins 3–12

FIGURE 3-10 Attaching the Two-Post Front Brackets to the System Chassis

(19-Inch, Two-Post Rack) 3–13

FIGURE 3-11 Attaching the Front of the System Chassis to the Rack

(19-Inch, Two-Post Rack) 3–14

FIGURE 3-12 Attaching the Back Brackets (19-Inch, Two-Post Rack) 3–15

FIGURE 4-1 B1600 System Chassis with Single-width and Double-width Blades 4–2

FIGURE 4-2 Disengaging the Blade Locking Mechanism 4–3

Figures vii

Page 8

FIGURE 4-3 Ejecting the Blade 4–4

FIGURE 4-4 Removing the Blade 4–5

FIGURE 4-5 Blade Locking Mechanism 4–6

FIGURE 4-6 Aligning and Inserting the Blade 4–7

FIGURE 4-7 Closing the Blade Lever Mechanism 4–8

FIGURE 4-8 PSU Ejector Lever 4–10

FIGURE 4-9 Removing the PSU From the System Chassis 4–11

FIGURE 4-10 Aligning the PSU 4–12

FIGURE 4-11 Sliding the PSU in the System Chassis 4–13

FIGURE 4-12 Closing the PSU Ejector Lever 4–14

FIGURE 4-13 Rear View of the Chassis Showing a Filler Module in Slot SSC1 4–16

FIGURE 4-14 SSC Ejector Lever 4–17

FIGURE 4-15 Removing the SSC From the System Chassis 4–18

FIGURE 4-16 Aligning the SSC Before Insertion 4–19

FIGURE 4-17 Inserting the SSC 4–20

FIGURE 4-18 Closing the SSC Ejector Lever 4–21

FIGURE 5-1 External Cable Ports (One SSC and PSU Shown) 5–2

FIGURE 5-2 Inserting the IEC Power Cords 5–3

FIGURE 5-3 Clipping on the Power Cord Retention Clip 5–4

FIGURE 5-4 The 10/100/1000BASE-T Data Network Ports 5–7

FIGURE 5-5 Attaching the Data Network Cables to the Network Ports 5–9

FIGURE 5-6 10/100BASE-T Network Management Ports 5–10

FIGURE 5-7 Attaching the Network Management Cables 5–11

FIGURE 5-8 Back Cable Management Rings 5–12

FIGURE 6-1 Serial Port Pin Numbers 6–3

FIGURE 6-2 Patch Panel Connections to a Terminal Server 6–4

FIGURE 6-3 Attaching the Serial Cables 6–8

FIGURE 6-4 Connecting the SSC to the Serial Port on a Laptop 6–10

viii Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 9

Tables

TABLE 1-1 System Chassis Dimensions 1–4

TABLE 1-2 Operating and Storage Specifications 1–8

TABLE 1-3 Operating Power Limits and Ranges 1–12

TABLE 1-4 Power Consumption 1–12

TABLE 2-1 Mounting Hole Pattern Dimensions 2–2

TABLE 5-1 10/100/1000BASE-T Data Network Port Pinouts 5–8

TABLE 5-2 100BASE-T Network Management Port Pinouts 5–10

TABLE 6-1 Serial Port Pinouts 6–3

TABLE 6-2 Serial Port Pinouts to a Terminal Server 6–5

TABLE 6-3 Serial Port Pin Interconnections to a Sun DB-25 (25-pin) Adapter 6–6

TABLE 6-4 Serial Port Pin Interconnections to a DB-9 (9-pin) Adapter 6–7

TABLE 6-5 Default Settings for Connecting a Modem to the Serial Port 6–7

TABLE 6-6 Pin Inter-connections Required to be Performed by the 25x9-way D-type Female-to-Female

Adapter 6–10

Tables ix

Page 10

x Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 11

Preface

This guide provides information about how to choose and prepare a location for a

Sun Fire B1600 blade system chassis, and details of how to install the system chassis

in a rack.

How This Book Is Organized

Chapter 1 describes the environmental requirements and airflow considerations for

the Sun Fire B1600 blade system chassis.

Chapter 2 explains the various rackmount options and requirements for the

system chassis.

Chapter 3 details how to install the system chassis into a rack.

Chapter 4 describes how to install a blade or filler panel in the system chassis. The

chapter also describes how to remove (and install) other components from the

system chassis.

Chapter 5 explains how to connect the IEC power supply cords and RJ-45 connectors

to the system chassis.

Chapter 6 explains how to connect the serial port to different devices.

xi

Page 12

Related Documentation

Application Title

Compliance and safety Sun Fire B1600 Blade System Chassis Compliance and Safety

Manual

Hardware installation

overview (foldout poster)

Hardware installation Sun Fire B1600 Blade System Chassis Hardware Installation

Software installation

overview (foldout poster)

Software setup Sun Fire B1600 Blade System Chassis Software Setup Guide

B100x and B200x server

blade installation and

setup

System chassis

administration and

component replacement

Switch administration Sun Fire B1600 Blade System Chassis Switch Administration

Late-breaking information Sun Fire B1600 Blade System Chassis Product Notes

Sun Fire B1600 Blade System Chassis Quick Start

Guide (this manual)

Sun Fire B1600 Blade System Chassis Software Setup Quick Start

Sun Fire B100x and B200x Server Blade Installation and Setup

Guide

Sun Fire B1600 Blade System Chassis Administration Guide

Guide

Accessing Sun Documentation

You can view or purchase a broad selection of Sun™ documentation, including

localized versions, at:

http://www.sun.com/documentation

You can also purchase printed copies of select Sun documentation from iUniverse,

the Sun documentation provider, at:

http://corppub.iuniverse.com/marketplace/sun/

xii Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 13

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and

suggestions. You can email your comments to Sun at:

docfeedback@sun.com

Please include the part number (817-3430-10) of your document in the subject line of

your email.

Preface xiii

Page 14

xiv Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 15

CHAPTER

1

Preparing for the Installation

This chapter provides the information you need to prepare for the installation of the

Sun Fire B1600 blade system chassis in the following sections:

■ Section 1.1, “Checklist of Rackmounting and Setup Tasks” on page 1-2

■ Section 1.2, “Contents of the Ship Kit” on page 1-3

■ Section 1.3, “Tools and Equipment Needed” on page 1-4

■ Section 1.4, “System Chassis Dimensions” on page 1-4

1-1

Page 16

1.1 Checklist of Rackmounting and Setup Tasks

1. Unpack the system chassis.

2. Check that you have the required parts for rackmounting.

See Section 1.2, “Contents of the Ship Kit” on page 1-3, Section 3.1.1, “Contents of

the Four-Post Rackmount Kit” on page 3-2,orSection 3.2.1, “Contents of the Two-

Post Rackmount Kit” on page 3-11.

3. Locate the rackmounting holes.

See Section 3.1.2, “Using the Rack Buddy” on page 3-2.

4. Install the rack brackets.

See Section 3.1.3, “Attaching the Brackets to the Four-Post Rack” on page 3-3 or

Section 3.2.2, “Installing the System Chassis In a Two-Post Rack” on page 3-12.

5. Install the system chassis in the rack or cabinet.

See Section 3.1, “Installing the System Chassis In a Four-Post Rack or Cabinet” on

page 3-1 or Section 3.2, “Installing the System In a Two-Post Rack” on page 3-11.

6. Install the blades, if applicable.

See Section 4.2, “Installing a Blade or Filler Panel” on page 4-5.

7. Remove and re-install the PSUs and SSCs if you want to check the serial numbers

or familiarize yourself with the installation and removal procedures.

See Section 4.3, “Removing and Installing a PSU” on page 4-8 and Section 4.4,

“Removing and Installing a Switch and System Controller (SSC)” on page 4-14.

8. Connect the power cords.

See Section 5.2, “Connecting the IEC Power Cords” on page 5-3.

9. Connect the management and data cables.

See Section 5.4, “Attaching the Connector Cables” on page 5-6.

10. Connect the serial port(s) to a serial device.

You can connect to both serial ports, if applicable. See Chapter 6 for details of how to

connect the system chassis to different devices.

11. Check that cables are managed correctly.

See Section 5.7, “Managing Cables for Multiple System Chassis” on page 5-12.

1-2 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 17

1.2 Contents of the Ship Kit

The Sun Fire B1600 blade system chassis is packaged in polyethylene foam cushions

for dynamic protection and is contained within a corrugated container with an

integrated wood pallet. The sealed corrugated container is attached to the wood

pallet at the base with cap nails. The assembly is banded to the wood pallet for

additional strength and protection.

The top panels of the container include instructions about how to unpack the

system. No special tools are required. One box contains the necessary

documentation and software, and the other box holds the rackmount hardware.

The modules shipped within the system chassis depend on the configuration

ordered.

The ship kit box accompanying the system contains some or all of the following

items:

■ Manuals:

■ Sun Fire B1600 Blade System Chassis Hardware Installation Guide

■ Sun Fire B1600 Blade System Chassis Compliance and Safety Manual (Multilingual)

■ Sun Fire B1600 Blade System Chassis Software Setup Guide

■ Sun Fire B1600 Blade System Chassis Software Quick Start Poster

■ Sun Fire B1600 Blade System Chassis Hardware Quick Start Poster

■ Sun Fire B100x and B200x Server Blade Installation and Setup Guide (supplied only

if the chassis contains B100x and/or B200x server blades)

■ CD: Sun Fire B1600 Platform Documentation, Drivers, and Installation CD

■ 19 Inch four post rackmount kit

■ Cables and connectors

Note – The operating system software kit must be ordered as a separate item. The

manuals and CD shipped with the system chassis are all that you need to install the

system chassis hardware.

Use the instructions in this guide and the Sun Fire B1600 Blade System Chassis

Product Notes (if present) to unship and mount the system.

Two people are required to lift a fully populated Sun Fire B1600 blade system chassis

into a four-post rack, and three people for a two-post rack. The system chassis

weighs approximately 45 kg (99lb) when fully equipped.

Chapter 1 Preparing for the Installation 1-3

Page 18

Do not remove any modules (blades, filler panels, PSUs, SSCs) from the system

chassis prior to rack installation as this may result in deformation of the chassis and

system chassis failure.

Ensure that doorways, corridors, and aisles are wide and high enough to

accommodate the system while you are maneuvering it into position.

1.3 Tools and Equipment Needed

You need the following equipment to install a Sun Fire B1600 blade system chassis:

■ A suitable host rack or cabinet.

■ The appropriate rackmount kit for the host rack or cabinet

■ Category 5 RJ-45 cabling. A maximum of 20 cables are required for a fully

populated system chassis

■ IEC power cabling. Two cables are required per system chassis

You will also need the following tools:

■ No. 2 Phillips screwdriver

■ The correct screwdriver for the rackmounting screws being attached to, and

supplied with, the host rack or cabinet

■ A cage nut insertion tool (only for racks or cabinets using caged nuts)

1.4 System Chassis Dimensions

The shipping dimensions of the Sun Fire B1600 blade system chassis are listed in

TABLE 1-1 and shown in FIGURE 1-1 and FIGURE 1-2.

TABLE 1-1 System Chassis Dimensions

Dimension US Measurement

Overall width 17.64 in. 448.0mm

Overall width, including sacrificial lifting handles 20.08 in. 510.0mm

Depth 26.81 in. 681.0mm

1-4 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Metric

Measurement

Page 19

TABLE 1-1 System Chassis Dimensions (Continued)

Dimension US Measurement

Metric

Measurement

Overall height 5.16 in. 131.0mm

Overall height, including sacrificial lifting handles 6.22 in. 158.0mm

Weight (fully populated) 99lb 45kg

Chapter 1 Preparing for the Installation 1-5

Page 20

26.81 in.

24 in.

(681.0mm) (609.6mm)

Orange sacrificial lifting handle

17.64 in.

(448.0mm)

20.08 in.

(510.0mm)

FIGURE 1-1 System Chassis Dimensions (Top View)

The system chassis is designed to fit in a 800mm rack. If you want to install the

system chassis in a rack less than 800mm deep, check the suitability of the rack

before you start the installation.

1-6 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 21

5.16 in.

6.22 in.

(131.0mm)

(158.0mm)

Orange sacrificial lifting handle

FIGURE 1-2 System Chassis Dimensions (Front View)

Chapter 1 Preparing for the Installation 1-7

Page 22

1.5 Site Preparation

This section contains information about the following system and site requirements

for the Sun Fire B1600 blade system chassis:

■ Section 1.5.1, “System Cooling Requirements” on page 1-8

■ Section 1.5.2, “Operating Power Limits and Ranges” on page 1-12

■ Section 1.5.3, “Estimating Power Consumption” on page 1-12

1.5.1 System Cooling Requirements

This section provides the general environmental parameters and airflow

requirements for the Sun Fire B1600 blade system chassis.

Note – The Sun Fire B1600 blade system chassis uses front-to-back forced air

cooling.

1.5.1.1 General Environmental Parameters

You can operate and store the system safely in the conditions detailed in TABLE 1-2,

FIGURE 1-3 and FIGURE 1-4.

TABLE 1-2 Operating and Storage Specifications

Specification Operating Storage

Ambient temperature 5˚C to 35˚C

maximum ambient

temperature is derated by 1˚C

per 500m altitude above 500m

Relative humidity 10% to 90% RH non-

condensing, 27˚C max wet

bulb

Altitude -400m up to 3000m -400m up to 12000m

1-8 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

-40˚C to 65˚C

up to 93% RH noncondensing, 38˚C max wet

bulb

Page 23

35

Temperature, ˚C

5

-400

106

500

95

3000

70

Altitude, m

Pressure, kPa

FIGURE 1-3 Temperature and Altitude Operating Ranges

27˚C wet bulb temperature

90% RH

Moisture content

10% RH

5

35

Dry bulb temperature, ˚C

FIGURE 1-4 Temperature and Relative Humidity Ranges

Chapter 1 Preparing for the Installation 1-9

Page 24

Recommended Environment Parameters

Your environmental control system must provide intake air for the server which

complies with the limits specified in “General Environmental Parameters” on

page 1-8.

To avoid overheating, do not direct warmed air:

■ towards the front of the cabinet or rack

■ towards the server access panels

Note – When you receive your system, leave it in the shipping crate at its final

destination for 24 hours in the environment in which you will install it. This is to

prevent thermal shock and condensation.

The operating environmental limits in

TABLE 1-2 reflect what the systems have been

tested to, in order to meet all functional requirements. Operating computer

equipment in extremes of temperature or humidity increases the failure rate of

hardware components. To minimize the chance of component failure, use the server

within the optimal temperature and humidity ranges.

Ambient Temperature

An ambient temperature range of 21˚C to 23˚C is optimal for system reliability. At

22˚C it is easy to maintain safe relative humidity levels. Operating in this

temperature range provides a buffer in the event of the environmental support

systems failing.

Ambient Relative Humidity

Ambient relative humidity levels between 45% and 50% are the most suitable for

data processing operations in order to:

■ prevent corrosion

■ provide an operating time buffer in the event of environmental control system

failure

■ help avoid failures caused by the intermittent interference from static discharges

that occur when relative humidity is too low.

Electrostatic discharge (ESD) is easily generated and less easily dissipated in areas

where the relative humidity is below 35%, and becomes critical when levels drop

below 30%.

1-10 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 25

1.5.1.2 Airflow Requirements

The Sun Fire B1600 blade system chassis has been designed to function in a natural

convection airflow when mounted in a rack or cabinet and uses front-to-back forced

air cooling. To meet the declared environmental specification follow these

guidelines:

■ The Sun Fire B1600 blade system chassis uses PSU fans that can achieve a

maximum airflow of 160cfm in free air. Ensure that there is sufficient airflow

through the rack or cabinet.

■ The rack or cabinet in which the system chassis is mounted must provide inlet air

at the front of the system chassis. The airflow exhausts horizontally from the PSU

and SSC modules located at the back of the system chassis and must be able to

leave the cabinet.

■ Inlet and exhaust ventilation must both have a minimum open area of

■ The use of perforated or solid door panels must allow adequate airflow to the

2

22in

(142 cm2) for each system chassis.

system chassis when the cabinet doors are closed.

1.5.1.3 Estimating the Heat Dissipation

To estimate the heat generated by a Sun Fire B1600 blade system chassis convert the

figure for the system’s power consumption from watts to BTU/hr.

The formula to convert from watts to BTU/hr is to multiply the power in watts by

3.415. For example:

total power consumption of blades + total power consumption of SSCs + total power

consumption of PSUs x 3.415 = xxxxx BTU/hr

For power consumption figures for the SSC, the PSU and blades, see “Estimating

Power Consumption” on page 1-12

Note – Do not install multiple Sun Fire B1600 blade system chassis in a four-post

rack or cabinet unless your cooling system is capable of dissipating in excess of the

total thermal load. For example:

(5 x 700W each system) x 3.415 = 11952.5 BTU/hr

Chapter 1 Preparing for the Installation 1-11

Page 26

1.5.2 Operating Power Limits and Ranges

TABLE 1-3 Operating Power Limits and Ranges

Description Operating Limit or Range

Maximum operating current

Maximum power supply rating

Maximum in-rush current

Operating input voltage range

(auto-ranging)

Voltage frequency range 47 to 63Hz

Power factor 0.8 to 1.0

BTU/Hr rating 3415 BTU/Hr

* Each power cord provides approximately one half of the input current during normal system operation.

† Currents up to the maximum power supply rating might be required for future product upgrades

‡ The in-rush current decays to the normal operating current inless than 200 milliseconds. Sequencing of power

to multiple units is not required, as the peak current is less than seven times the operating current.

*

†

‡

16A @ 110VAC

8A @ 240VAC

12A @ 110VAC

6A @ 240VAC

20A

110 to 240 VAC

1.5.3 Estimating Power Consumption

To estimate the total power consumption for one or more Sun Fire B1600 blade

system chassis installed in a single rack or cabinet, add together the individual

power requirement figures for each system chassis you have installed, using the

values in

One blade + one SSC + two PSUs

TABLE 1-4 Power Consumption

System Chassis Components Power Consumption (max)

one SSC Add 65W per SSC

one PSU Add 110W per PSU

one B100s Blade Add 35W per blade

one B100x Blade Add 48W per blade

one B200x Blade Add 126W per blade

1-12 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

TABLE 1-4. A minimum system configuration would be:

Page 27

CHAPTER

2

Rack Options and Placement

This chapter provides details about the racks and cabinets into which you can install

a Sun Fire B1600 blade system chassis, and contains the following sections:

■ Section 2.1, “Rack Options” on page 2-1

■ Section 2.2, “Service Access” on page 2-2

■ Section 2.3, “Rack and Floor Loading” on page 2-3

■ Section 2.4, “Rack and Cabinet Safety” on page 2-3

2.1 Rack Options

You can install the Sun Fire B1600 blade system chassis into these 19-inch and

23-inch racks:

■ 19-inch two-post rack with a post depth between 3in. (76.2 mm) and

6in. (152.4mm)

■ 19-inch four-post IEC297/EIA310-D rack with a distance between mounting rails

from 24.6in. (625 mm) to 36.4in. (925 mm)

■ 23-inch two-post rack with a post depth of 5 in. (127mm). These are intended for

use with telco seismic frames

■ 23-inch four-post rack

Note – You can also install the system into a cabinet, subject to adequate cabinet

ventilation, power and floor loading considerations. Read this chapter for further

details.

2-1

Page 28

The vertical mounting hole pattern of the rack must conform to the standard

dimensions given in

TABLE 2-1 Mounting Hole Pattern Dimensions

Standard Pattern

IEC297/EIA310/

RETMA (RU)

IEC917/ETSI (SU) Constant pitch of 0.98 in. (25 mm)

1U

FIGURE 2-1 EIA/RETMA Mounting Hole Pattern Dimensions

TABLE 2-1 and shown in FIGURE 2-1.

Repeating pattern of 5/8 in. (15.7mm), 5/8in. (15.7 mm),

in. (12.7 mm)

1/2

1/2 in. (12.7mm)

5/8 in. (15.7mm)

5/8in. (15.7mm)

1/2in. (12.7mm)

2.2 Service Access

The bottom of lowest of the five system chassis must be mounted no lower than

2.95 in. (75mm) above the bottom of the rack or cabinet to enable removal and fitting

of the orange sacrificial lifting handle.

Ensure that units or cables above a Sun Fire B1600 blade system chassis do not

protrude beyond the front face of the system chassis to enable proper airflow.

Access to the front and back of the Sun Fire B1600 blade system chassis is required

for installation and system maintenance.

Note – If you are installing the system chassis into a cabinet that has a door, you

might need to swing the door back 180 degrees, or remove the door altogether.

2-2 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 29

2.3 Rack and Floor Loading

The rack or cabinet must be capable of supporting a static load of 99 lb (45kg) for

each fully configured Sun B1600 blade system chassis. Dynamic load considerations

are subject to site location and application. You must account for the weight of any

cables attached to systems within the rack, as well as additional hardware installed

within the rack (power boxes, and so on).

See your manufacturer’s loading guidelines to avoid overloading the rack or cabinet.

Check the maximum floor loading weight for the installation area before calculating

the number of system chassis to install in a rack or cabinet.

2.4 Rack and Cabinet Safety

Racks or cabinets that contain Sun Fire B1600 blade system chassis must be anchored

to the floor or to adjacent frames, using the manufacturer’s instructions.

Free-standing racks or cabinets with a footprint of less than 23.6in. x 23.6in.

(600mm x 600 mm) are likely to be unstable and should be treated with caution.

Where several system chassis are fitted in a rack or cabinet, only one of them should

be withdrawn for service at any one time.

See the Sun Fire B1600 Blade System Chassis Compliance and Safety Manual for further

safety information.

Caution – If the system chassis is installed in a closed or multi unit rack assembly,

the operating ambient temperature of the rack or cabinet environment might exceed

the room ambient. Ensure that rack environment ambient temperature does not

exceed 95˚ F (35˚ C).

Caution – Mounting of the system chassis in a rack or cabinet should be such that a

hazardous condition is not created due to uneven mechanical loading or weight

distribution.

Chapter 2 Rack Options and Placement 2-3

Page 30

2-4 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 31

CHAPTER

3

Installing the System Chassis In a Rack or Cabinet

This chapter provides instructions for installing the Sun Fire B1600 blade system

chassis into a rack or cabinet. See Chapter 2 for information about which racks you

can use with the Sun Fire B1600 blade system chassis.

This chapter contains the following sections:

■ Section 3.1, “Installing the System Chassis In a Four-Post Rack or Cabinet” on

page 3-1

■ Section 3.2, “Installing the System In a Two-Post Rack” on page 3-11

■ Section 3.3, “What to Do Next” on page 3-16

3.1 Installing the System Chassis In a Four-Post Rack or Cabinet

This section contains instructions for installing a Sun Fire B1600 blade system chassis

in a four-post rack or cabinet.

The system chassis is shipped with orange sacrificial lifting handles which assist in

handling the system chassis. The handles must be stored in a safe place after the

system chassis is installed in a rack or cabinet.

Note – The figures in this section are simplified to show only the rails to which the

rack brackets are attached.

3-1

Page 32

3.1.1 Contents of the Four-Post Rackmount Kit

The 19-inch, four-post rackmount kit comprises:

■ One Rack Buddy

■ Two rackmount brackets

■ One set of 10-32 UNF and M6 Sun Microsystems rackmounting screws for Sun

racks

■ Four M4 screws

■ One rack bracket spacer

You must supply the appropriate screws to attach the brackets to any rack not

supplied by Sun Microsystems.

3.1.2 Using the Rack Buddy

The Rack Buddy card helps you to find out which rackmount holes are appropriate

for installing the system chassis.

1. Hold the Rack Buddy to the rack so that the bottom of the Rack Buddy is either

just above the top of a system already installed in the rack or above the bottom of

the rack (

FIGURE 3-1).

FIGURE 3-1 Using the Rack Buddy

3-2 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 33

2. Note which holes are in alignment with the Rack Buddy recesses.

Use these holes when you attach the rack brackets to the rack. Continue with

Section 3.1.3, “Attaching the Brackets to the Four-Post Rack” on page 3-3.

3.1.3 Attaching the Brackets to the Four-Post Rack

1. If required, slide together the front and back sections of the rack brackets

(

FIGURE 3-2).

Back section

Front section

FIGURE 3-2 Sliding the Front Bracket Section Into the Back Bracket Section

(19-Inch, Four-Post Rack)

2. Extend each rack bracket to the length required to fit in the rack or cabinet.

3. Insert two M4 screws (supplied with the rack mount kit) to each bracket, and

finger tighten to connect the front and back bracket sections together (

FIGURE 3-3).

Note – Insert one screw through the slot furthest away from the front of the rack

bracket. Insert the other screw through a suitable slot nearest the front edge of the

back bracket section. Spacing the screws as far apart as possible provides greater

bracket rigidity (see FIGURE 3-3).

Chapter 3 Installing the System Chassis In a Rack or Cabinet 3-3

Page 34

Front of rack bracket

Front edge of back

bracket section

FIGURE 3-3 Connecting the Front and Back Four-Post Bracket Sections (19-Inch, Four-Post

Rack)

4. Attach each end of the bracket to the rack or cabinet using the screws appropriate

to the rack or cabinet. Do not fully tighten the screws.

Use the rack holes you noted as part of Section 3.1.2, “Using the Rack Buddy” on

page 3-2.

The mounting holes in the rack bracket are oversized to allow installation in most

racks or cabinets.

3-4 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 35

5. Insert the rack bracket spacer in the front of the rack brackets.

Push the rack spacer location pins fully in the middle hole of each rack bracket

(

FIGURE 3-4).

FIGURE 3-4 Inserting the Rack Bracket Spacer

6. Tighten the front rack bracket screws fully and remove the rack bracket spacer.

7. Repeat Step 5 through Step 6 for the back of the bracket.

8. Fully tighten the M4 screws in the middle of the brackets to complete the bracket

installation.

Chapter 3 Installing the System Chassis In a Rack or Cabinet 3-5

Page 36

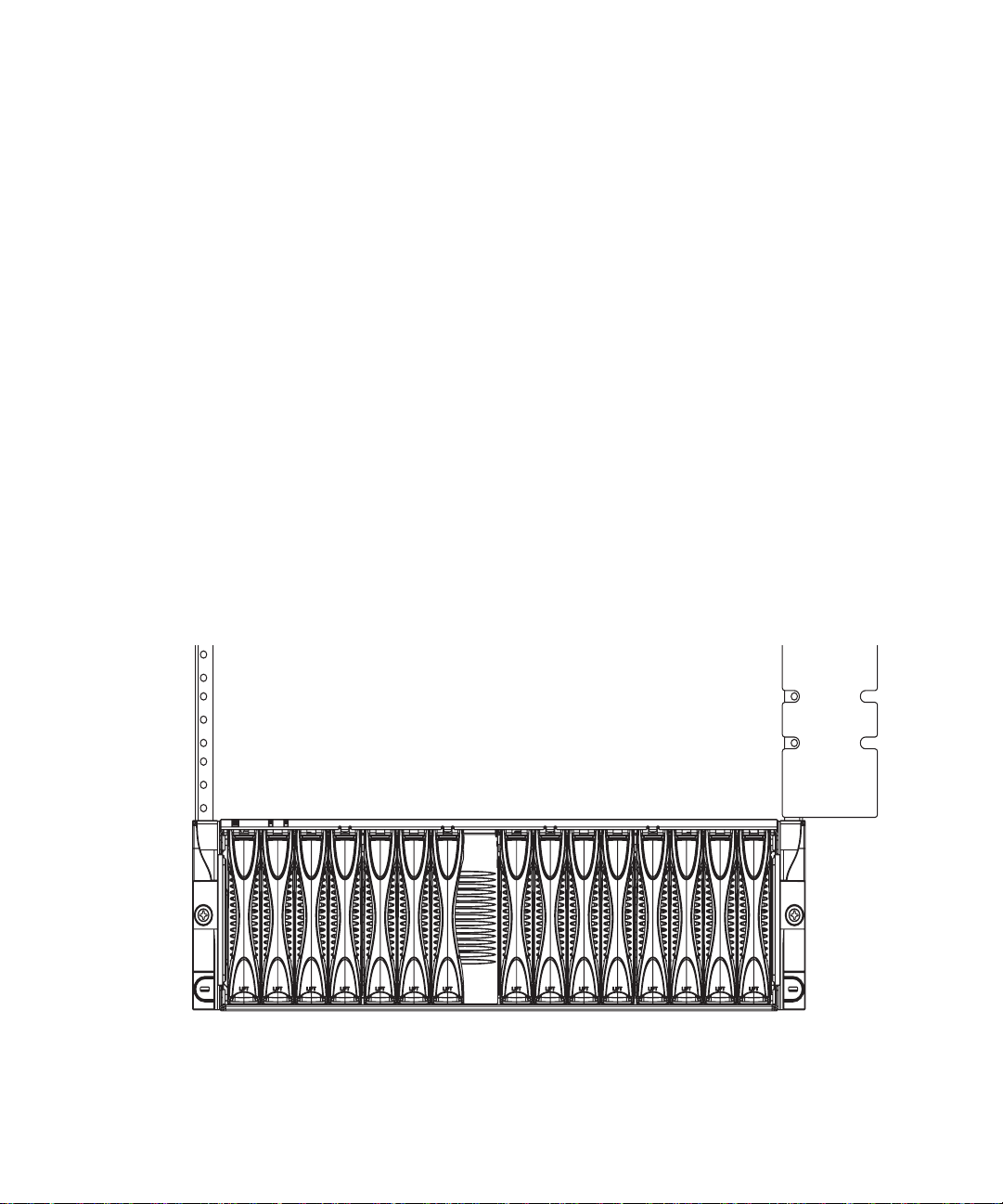

3.1.4 Installing the System Chassis In the Four-Post Rack or Cabinet

Caution – To reduce the possibility of tipping the rack or cabinet during installation

ensure that the rack stability features are in use if the rack or cabinet is not bolted

down.

Caution – Keep the system chassis in the horizontal position when lifting it by the

sacrificial lifting handles. The handles are not designed to hold a system that is

tipped from the horizontal position.

Caution – When inserting the system chassis into the rack, it is essential that the

chassis is kept parallel to the front of the rack. On final insertion into the rack, apply

equal force to both sides of the system chassis to ensure correct installation.

1. Take the system chassis out of the packaging and place it on a flat surface.

Use the orange sacrificial lifting handles to lift the system chassis.

Caution – Do not attempt to lift a populated system chassis by yourself. A fully

populated system chassis weighs approximately 99lb (45kg) and must be lifted by at

least two people.

3-6 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 37

2. Remove the module retaining pins (FIGURE 3-5).

FIGURE 3-5 Removing the Module Retaining Pins

3. Disengage the back sacrificial lifting handle (FIGURE 3-6).

Slide the sacrificial lifting handle toward the back of the system chassis and then

push the handle down.

Chapter 3 Installing the System Chassis In a Rack or Cabinet 3-7

Page 38

4. Lift the system chassis up to the rack or cabinet.

Use one hand to grasp the orange front sacrificial lifting handle, and hold the bottom

of the system chassis with your other hand. Do not lift the system chassis

5. Align the system chassis to the rack brackets (

FIGURE 3-6).

Step 4

Step 3

FIGURE 3-6 Aligning the System Chassis to the Brackets (19-Inch, Four-Post Rack)

6. Slide the system chassis into the rack (FIGURE 3-7).

3-8 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 39

7. Remove the front sacrificial lifting handle (FIGURE 3-7).

Slide the sacrificial lifting handle toward the back of the system chassis and then

pull down.

FIGURE 3-7 Removing the Sacrificial Lifting Handle (19 -Inch, Four-Post Rack)

8. Push the system chassis fully into the rack.

Take care to keep the system chassis straight during insertion.

Chapter 3 Installing the System Chassis In a Rack or Cabinet 3-9

Page 40

9. Tighten the captive retaining screws located at the front of the system chassis

(

FIGURE 3-8).

JB

O

S

3

0

0

0

FIGURE 3-8 Tightening the Captive Retaining Screws (19-Inch, Four-Post Rack)

10. Go to Section 3.3, “What to Do Next” on page 3-16.

3-10 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 41

3.2 Installing the System In a Two-Post Rack

This section contains instructions for installing a Sun Fire B1600 blade system chassis

into a non-specific two-post rack. These instructions are for both 19-inch and

23-inch rackmount options.

The system chassis is shipped with orange sacrificial lifting handles for handling the

system chassis. The handles must be stored in a safe place after the system chassis is

installed in a rack or cabinet.

Note – The figures in this section are simplified to show only those rails to which

the system chassis rack brackets are attached.

3.2.1 Contents of the Two-Post Rackmount Kit

The two-post rackmount kit comprises:

■ The Rack Buddy

■ Four rackmount brackets

■ One set of 10-32 UNF Sun Microsystems rackmounting screws for Sun racks

You must supply the appropriate screws to attach the brackets to any rack not

supplied by Sun Microsystems.

Chapter 3 Installing the System Chassis In a Rack or Cabinet 3-11

Page 42

3.2.2 Installing the System Chassis In a Two-Post Rack

1. Place the system chassis on a flat surface and remove the sacrificial lifting handles.

Slide the sacrificial lifting handle toward the back of the system chassis and then

push the handle down.

2. Remove the module retaining pins (

FIGURE 3-9).

FIGURE 3-9 Removing the Module Retaining Pins

3-12 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 43

3. Attach the front brackets to the system chassis (FIGURE 3-10).

J

BO

S 3000

FIGURE 3-10 Attaching the Two-Post Front Brackets to the System Chassis

(19-Inch, Two-Post Rack)

Chapter 3 Installing the System Chassis In a Rack or Cabinet 3-13

Page 44

4. Hold the system chassis up to the rack and attach the front brackets (FIGURE 3-11).

Inner rack bracket

screw holes

FIGURE 3-11 Attaching the Front of the System Chassis to the Rack

(19-Inch, Two-Post Rack)

Caution – A fully populated system chassis weighs 99 lb (45 kg) approximately and

must be lifted by at least two people. A third person is required to attach the front

brackets to the rack.

Note – The two inner rack bracket screw holes are the rackmount holes identified

by the Rack Buddy. See Section 3.1.2, “Using the Rack Buddy” on page 3-2.

3-14 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 45

5. Attach the back brackets to the system chassis and to the two-post rack

(

FIGURE 3-12).

FIGURE 3-12 Attaching the Back Brackets (19-Inch, Two-Post Rack)

6. Go to Section 3.3, “What to Do Next” on page 3-16.

Chapter 3 Installing the System Chassis In a Rack or Cabinet 3-15

Page 46

3.3 What to Do Next

The Sun Fire B1600 blade system chassis can be installed as:

■ A fully populated system

■ A populated system chassis that requires the installation of blades

If you have installed a system chassis that requires blade installation, continue with

Chapter 4.

If you have installed a fully populated Sun Fire B1600 blade system chassis, continue

with Section 5.1, “Location of Ports and Power Inlets” on page 5-2.

3-16 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 47

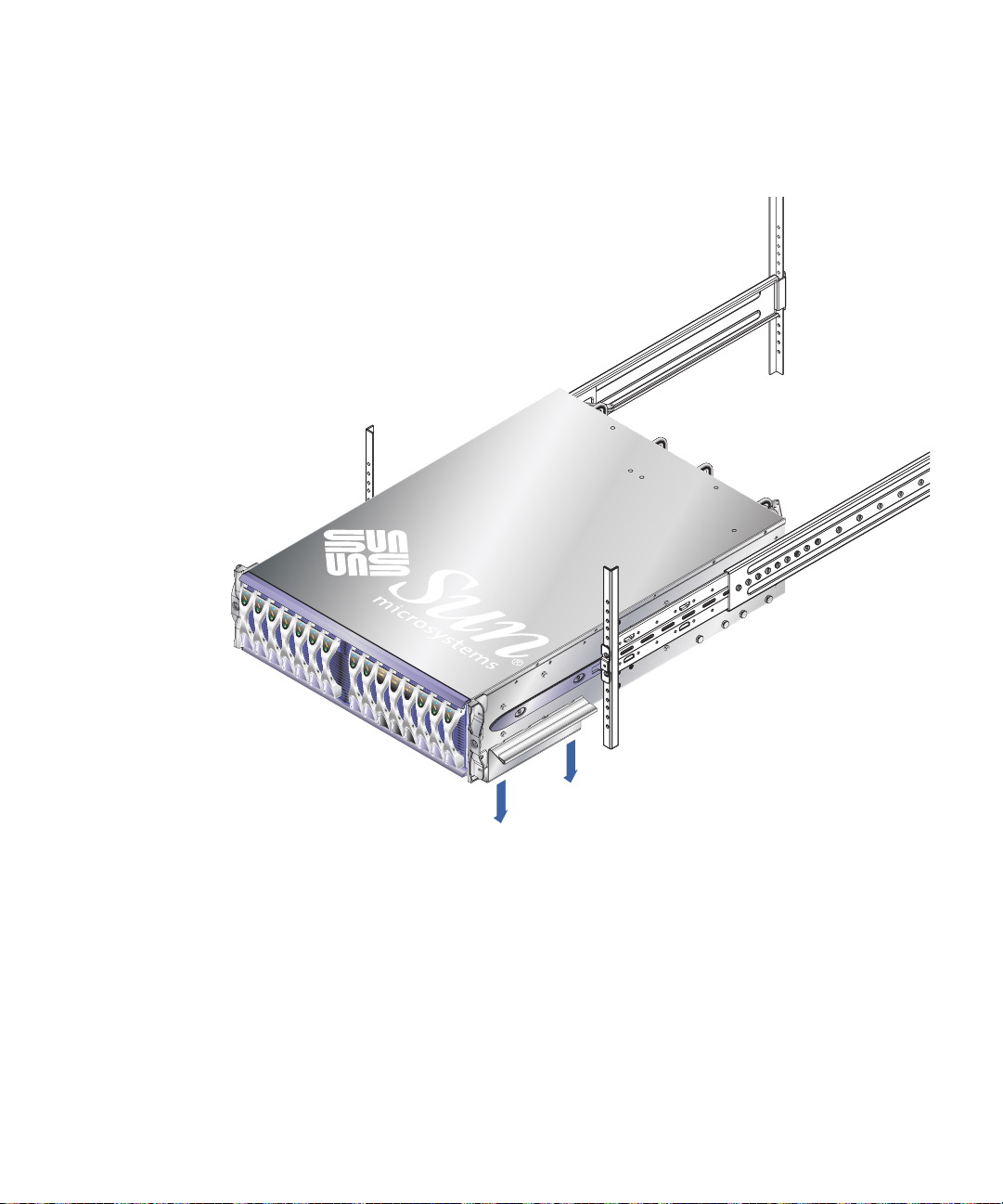

CHAPTER

4

Removing and Installing Modules

This chapter provides instructions for installing Sun Fire B1600 server blades of filler

panels, Power Supply Units (PSUs) and Switch and System Controllers (SSC).

The Sun Fire B1600 blade system chassis can be ordered in two configuration

options:

■ A fully populated system chassis

A fully populated system chassis contains two Power Supply Units (PSUs),

two Switch and System Controllers (SSCs), and a combined total of up to 16

blades and filler panels.

■ A partially populated system chassis that requires the installation of blades

A partially populated system contains two Power Supply Units (PSUs), two

Switch and System Controllers (SSCs), and 16 filler panels.

This chapter provides the procedures for removing filler panels, if necessary, and

installing blades in the system chassis. It also provides instructions for removing and

inserting PSUs and SSCs while the system is powered down. It contains the

following sections:

■ Section 4.1, “Removing and Installing Blades or Filler Panels” on page 4-2

■ Section 4.2, “Removing and Installing a PSU” on page 4-9

■ Section 4.3, “Removing and Installing a Switch and System Controller (SSC)” on

page 4-15

■ Section 4.4, “What to Do Next” on page 4-22

Note – The procedures contained in this section assume that the system chassis is

unpowered. See the Sun Fire B1600 Blade System Chassis Administration Guide for

instructions on removing a module from a powered system chassis.

4-1

Page 48

4.1 Removing and Installing Blades or Filler Panels

The system chassis contains 16 slots. It can hold a combination of single-width

blades, double-width blades and filler panels. Double-width blades occupy two

adjacent slots in the system chassis.

FIGURE 4-1 shows a system chassis containing single-width blades and a

double-width blade.

Note – Be aware that the system chassis contains three internal dividing walls.

Double-width blades must be installed in two available slots between these internal

dividing walls.

FILLER

PAN

EL

FILLER

PAN

EL

FILLER

PANEL

Double-Width Blade

Single-Width Blade

FIGURE 4-1 B1600 System Chassis with Single-width and Double-width Blades

4-2 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 49

4.1.1 Removing Blades or Filler Panels

The steps in this section refer to removal of a single-width blade. The same steps

apply when installing a double-width blade or filler panel.

1. Insert your finger in the pull recess located at the bottom front of the blade lever

and pull gently to disengage the locking mechanism (

FIGURE 4-2).

JBOS 3000

FIGURE 4-2 Disengaging the Blade Locking Mechanism

Chapter 4 Removing and Installing Modules 4-3

Page 50

2. Pull the lever in a forward and upward motion, causing the blade lever to unlatch

and eject the blade partially from the system chassis (

FIGURE 4-3).

JBOS 3000

FIGURE 4-3 Ejecting the Blade

4-4 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 51

3. Pull the lever to remove the blade from the system chassis (FIGURE 4-4).

Support the bottom of the blade with your free hand while lifting the blade clear of

the system chassis.

JBOS 3000

FIGURE 4-4 Removing the Blade

Chapter 4 Removing and Installing Modules 4-5

Page 52

4.1.2 Installing a Blade or Filler Panel

Note – Operating the system chassis with empty blade slots might disrupt airflow

through the system chassis and will compromise EMC compliance.

Note – Be aware that the system chassis contains three internal dividing walls.

Double-width blades must be installed in two available slots between these internal

dividing walls.

The steps below refer to installation of a single-width blade. The same steps apply

when installing a filler panel or double-width blade.

1. If required, open the blade lever by inserting a finger in the pull recess located in

lower portion of the blade lever and pull the lever in a forward and upward

motion, causing the lever to unlatch (

FIGURE 4-5).

Pull recess

FIGURE 4-5 Blade Locking Mechanism

4-6 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 53

2. Align the blade with the empty slot.

Ensure that the blade connector is facing towards the system chassis, with the hinge

point of the lever mechanism at the top. Support the bottom of the blade with your

free hand while lifting the blade up to the system chassis (

FIGURE 4-6).

JBOS 3000

FIGURE 4-6 Aligning and Inserting the Blade

3. Insert the blade into the empty slot.

Caution – Ensure that the blade engages with the system chassis guidance system.

Failure to align the blade correctly can result in damage to the chassis midplane or

the blade connection.

4. Gently push the blade into the slot until the blade latch ears, on top of the lever,

are positioned in the chassis.

Chapter 4 Removing and Installing Modules 4-7

Page 54

5. Close the blade lever fully by pushing it down until you feel the latch click in

place. This engages the blade into the chassis slot (

FIGURE 4-7).

JBOS 3000

FIGURE 4-7 Closing the Blade Lever Mechanism

4-8 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 55

4.2 Removing and Installing a PSU

Use the procedures in this section to remove and install a PSU. These are optional

procedures for you to familiarize yourself with the mechanism or to check the PSU

Serial Number.

Note – The procedures contained in this section assume that the system chassis is

unpowered. See the Sun Fire B1600 Blade System Chassis Administration Guide for

instructions on removing a PSU from a powered system chassis.

Caution – To ensure that it remains within an acceptable range of operating

temperatures the Sun Fire B1600 system chassis requires two PSUs.

Chapter 4 Removing and Installing Modules 4-9

Page 56

4.2.1 Removing a PSU

1. Squeeze the green PSU ejector lever to unlatch it and pull the lever towards you

to disconnect the PSU from the system chassis (

FIGURE 4-8).

FIGURE 4-8 PSU Ejector Lever

2. Check that the ejector lever is open fully and clear of the PSU module.

4-10 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 57

3. Remove the PSU from the system chassis by pulling on the vertical handles

attached to the rear of the PSU (

FIGURE 4-9).

Support the bottom of the PSU while removing the module from the system chassis.

Vertical Handles

FIGURE 4-9 Removing the PSU From the System Chassis

Chapter 4 Removing and Installing Modules 4-11

Page 58

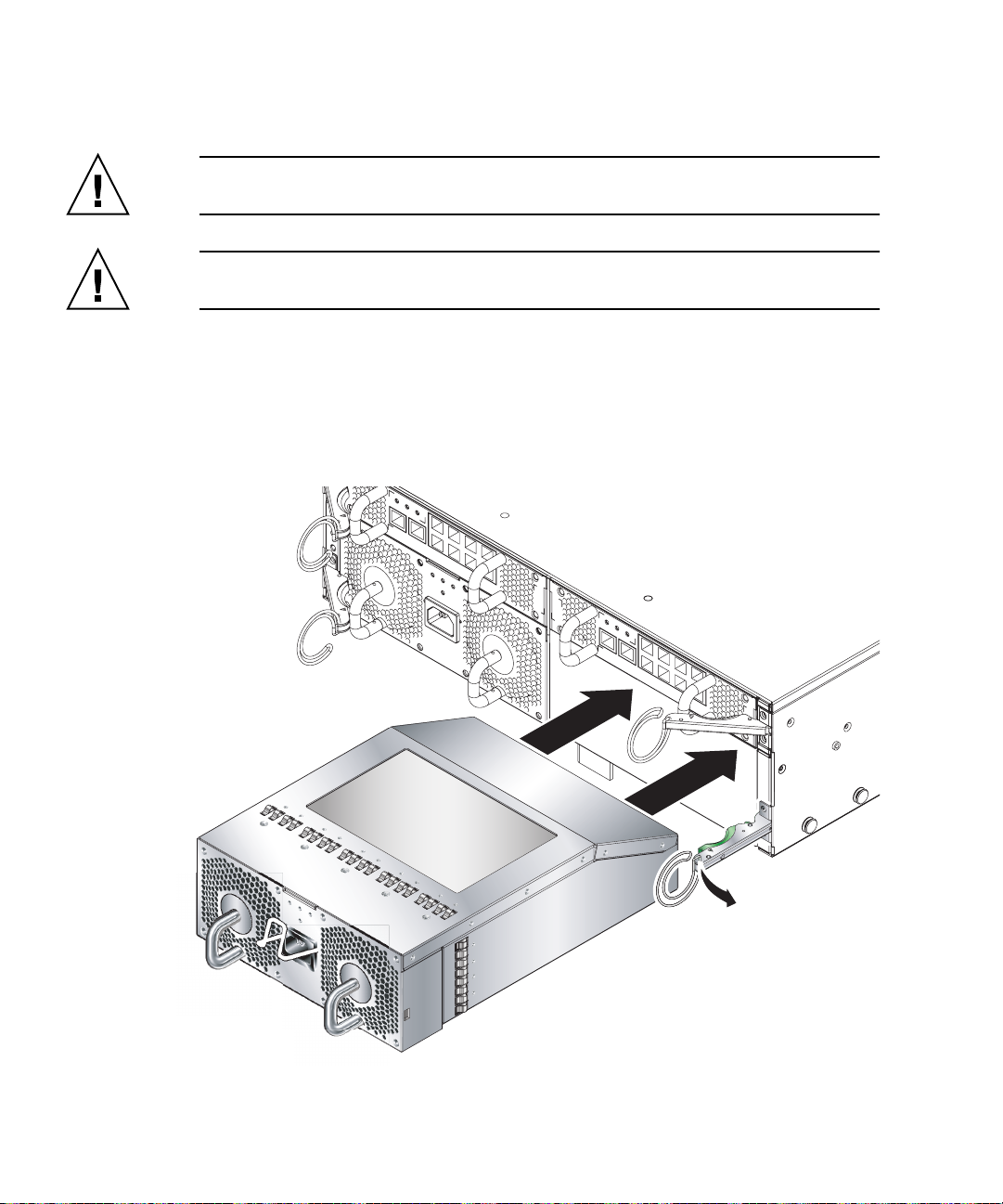

4.2.2 Inserting a PSU

Caution – To ensure that it remains within an acceptable range of operating

temperatures the Sun Fire B1600 system chassis requires two PSUs.

Caution – Do not install a PSU with the IEC power cord already attached. Only

connect the power cord when the PSU is installed.

1. Correctly align the PSU with the empty PSU slot in the system chassis.

PSU connectors must face towards the system chassis and be located on the lower

half of the PSU (

2. Check that the chassis ejector lever is opened fully and does not obstruct the

opening to the PSU slot (

FIGURE 4-10).

FIGURE 4-10).

FIGURE 4-10 Aligning the PSU

4-12 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 59

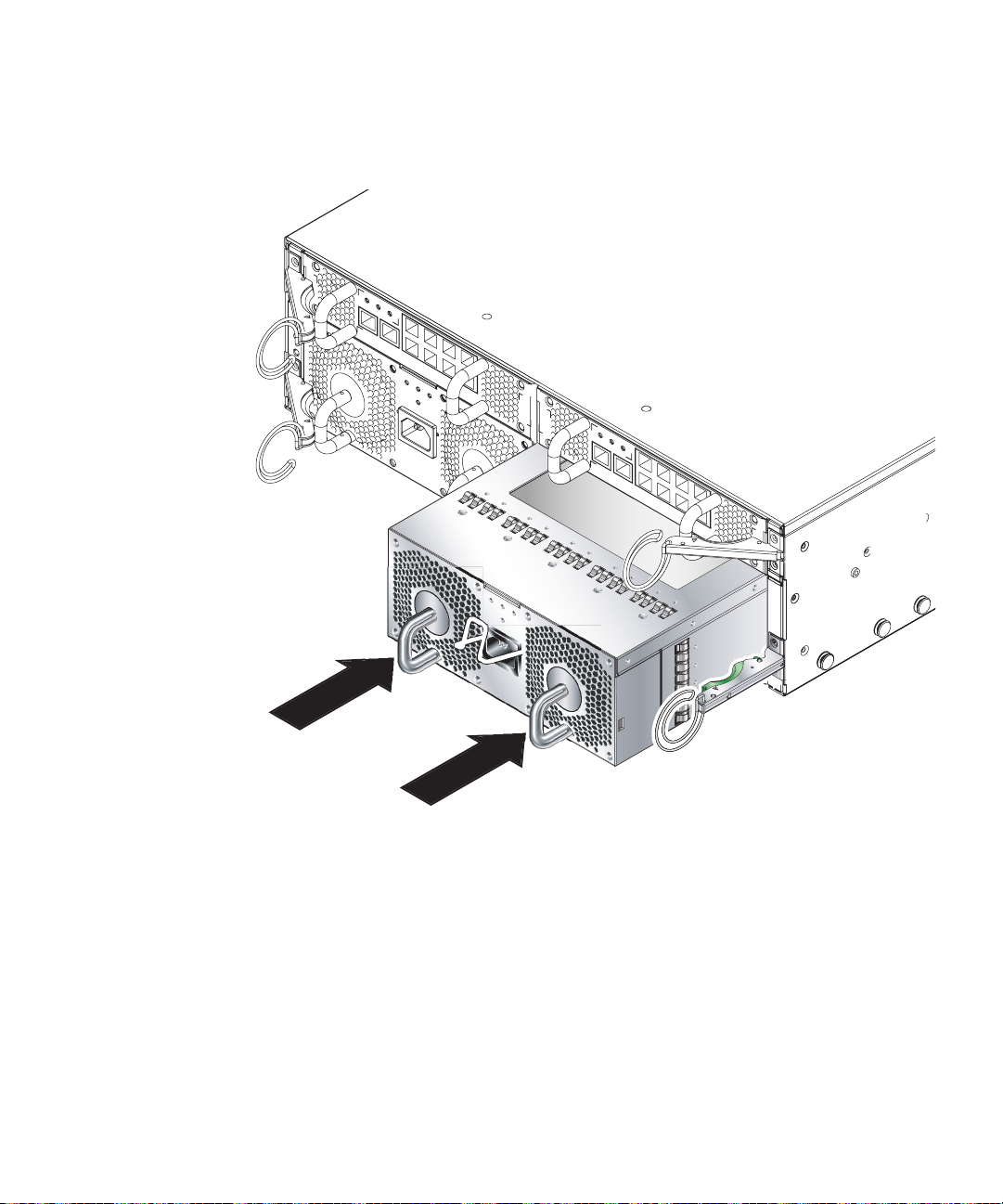

3. Slide the PSU into the empty PSU slot.

Push the PSU into the slot until the ejector lever engages (

FIGURE 4-11).

You must push the PSU firmly to raise the system flap within the system chassis.

FIGURE 4-11 Sliding the PSU in the System Chassis

Chapter 4 Removing and Installing Modules 4-13

Page 60

4. Complete the installation by closing the ejector lever fully.

Check that the ejector lever engages onto the PSU pull handle. This engages the PSU

into the system chassis (

FIGURE 4-12).

FIGURE 4-12 Closing the PSU Ejector Lever

4-14 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 61

4.3 Removing and Installing a Switch and System Controller (SSC)

Use the procedures in this section to remove and install an SSC. These are optional

procedures to enable you to familiarize yourself with the mechanism, or to check the

SSC Serial Number.

Note – The procedures contained in this section assume that the system chassis is

not connected to the network and is not powered up. See the Sun Fire B1600 Blade

System Chassis Administration Guide for instructions on removing an SSC from a

networked and powered system chassis.

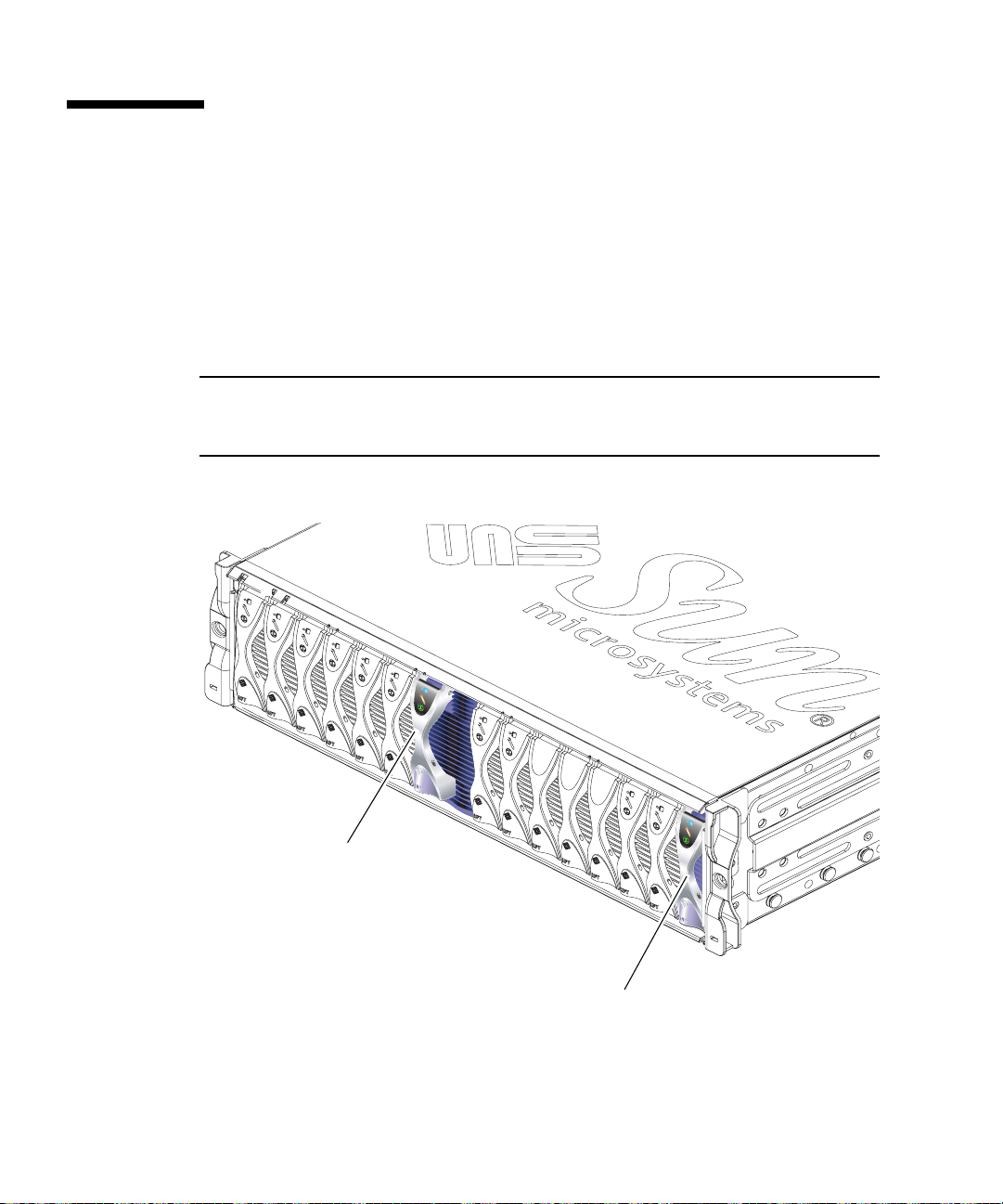

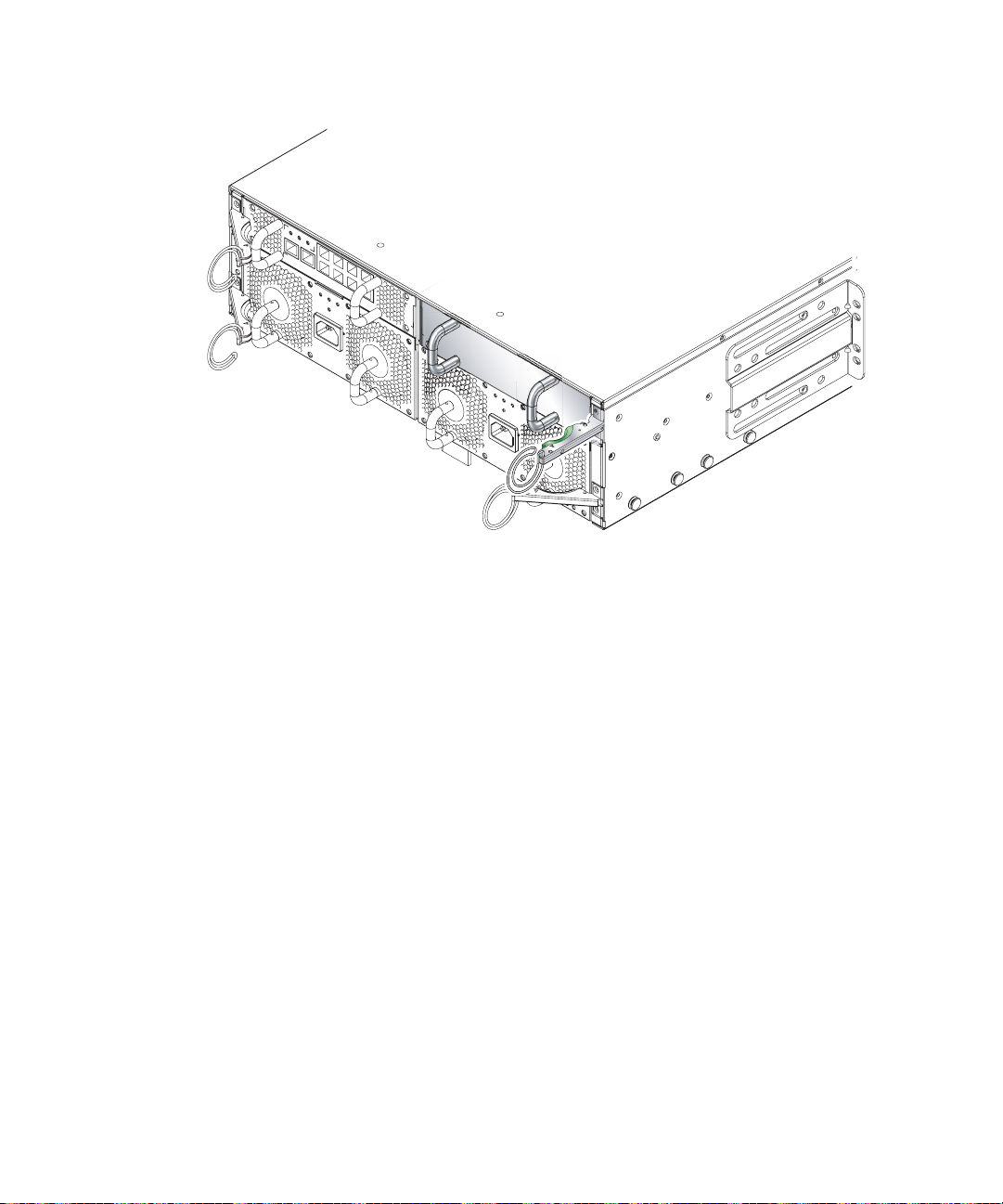

4.3.1 Chassis Supplied With Only One SSC

If you have purchased a chassis containing only a single SSC, then the module in

slot SSC1 will be an SSC filler module (see

enclosure; it contains no functioning system hardware and you cannot connect a

serial cable or any network cables to it (it has no connectors).

Note – If you are removing a filler panel and replacing it with a new SSC, make sure

the currently installed SSC is using release 1.2 (or later) of the System Controller

firmware. (Also, if the module you are installing as a redundant SCC is not a new

one but is taken from another chassis and does not have release 1.2 firmware

installed on it, you need to upgrade it on the old chassis before installing it as a

redundant SSC.) Release 1.2 is the first firmware release to support failover (in other

words, to support the ability of two System Controllers to monitor each other’s

health, and of the standby System Controller to take over from the active one in the

event of a critical failure).

FIGURE 4-13). This is an empty metal

For full instructions about replacing an SSC filler module with a new SSC module,

and about upgrading the System Controller firmware on an SSC, refer to the Sun Fire

B1600 Blade System Chassis Administration Guide.

The mechanical procedures for removing and installing an SSC filler module are the

same as those for removing and installing an actual SSC module. They are described

in the remainder of this section.

Chapter 4 Removing and Installing Modules 4-15

Page 62

FIGURE 4-13 Rear View of the Chassis Showing a Filler Module in Slot SSC1

4-16 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 63

4.3.2 Removing the SSC

1. Squeeze the green SSC ejector lever to unlatch it, and then pull the lever towards

you to disconnect the SSC from the system chassis (

FIGURE 4-14).

FIGURE 4-14 SSC Ejector Lever

2. Check that the ejector lever is open fully and clear of the SSC module

(

FIGURE 4-14).

Chapter 4 Removing and Installing Modules 4-17

Page 64

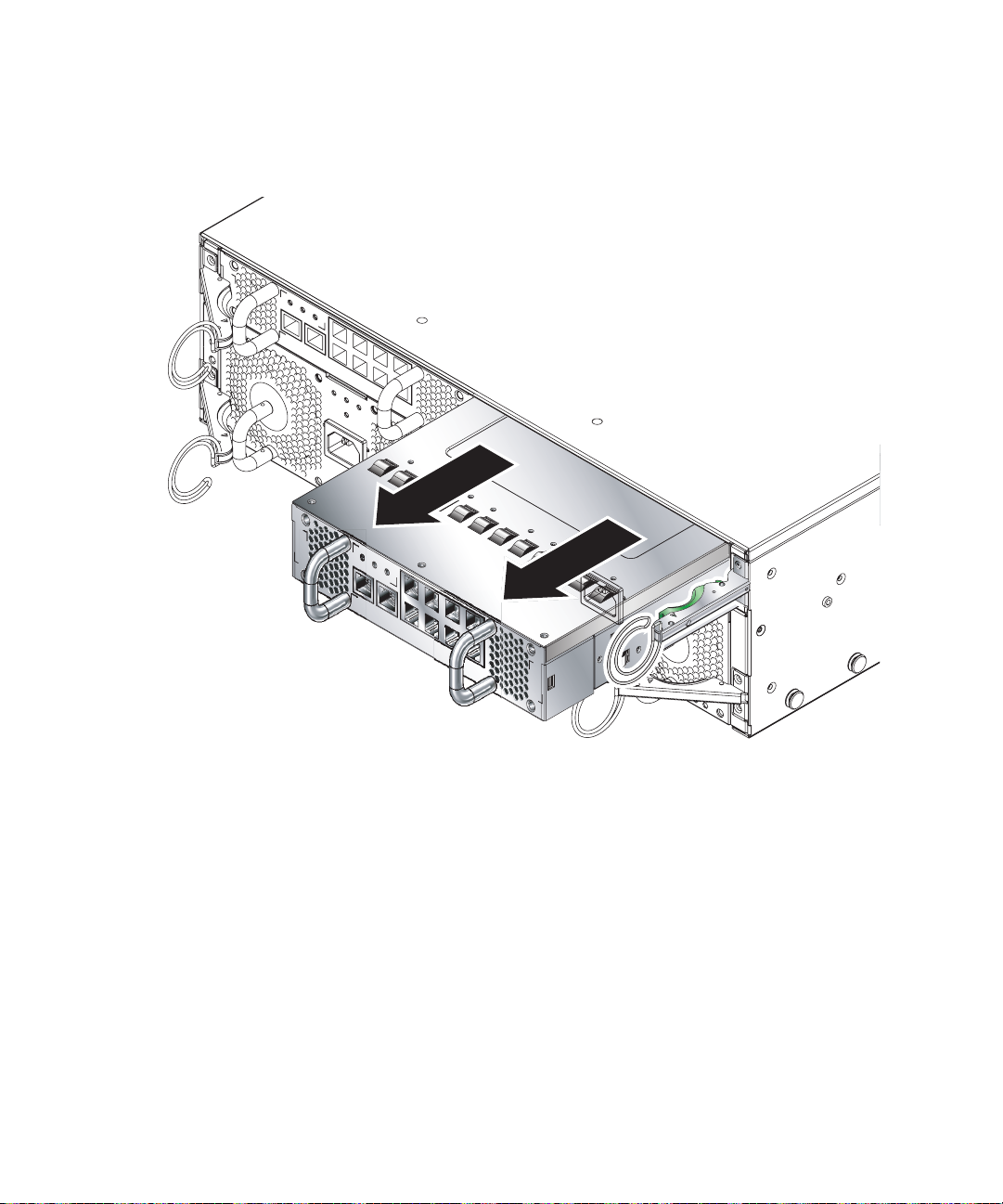

3. Remove the SSC from the system chassis by pulling on the vertical handles

attached to the back of the SSC (

FIGURE 4-15).

Support the bottom of the SSC while removing the module from the system chassis.

FIGURE 4-15 Removing the SSC From the System Chassis

4-18 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 65

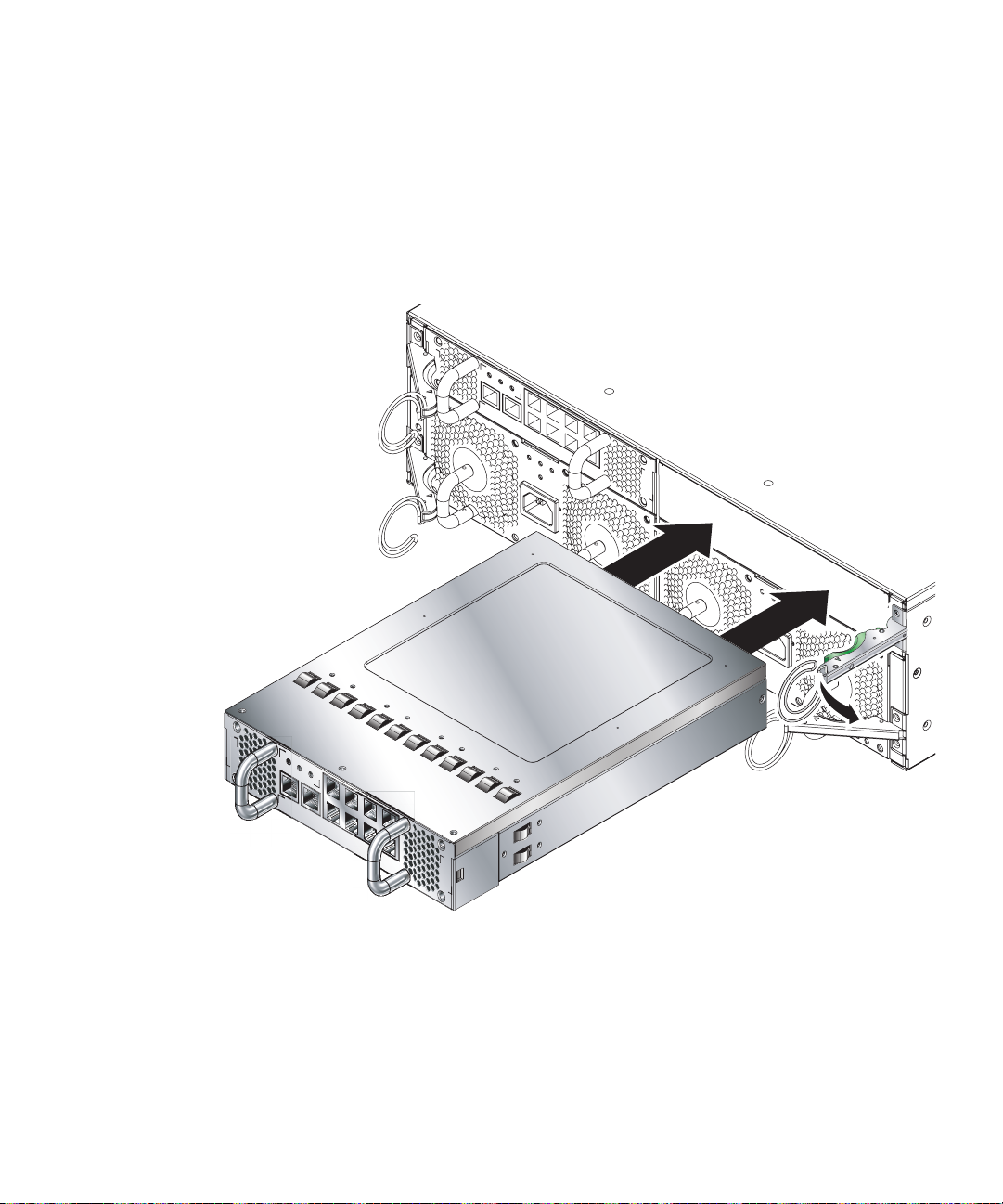

4.3.3 Installing the SSC

1. Align the SSC with the system chassis.

SSC connectors must face towards the system chassis and be located on the lower

half of the SSC.

2. Ensure that the chassis ejector lever is opened fully and does not obstruct the

chassis opening (

FIGURE 4-16).

FIGURE 4-16 Aligning the SSC Before Insertion

Chapter 4 Removing and Installing Modules 4-19

Page 66

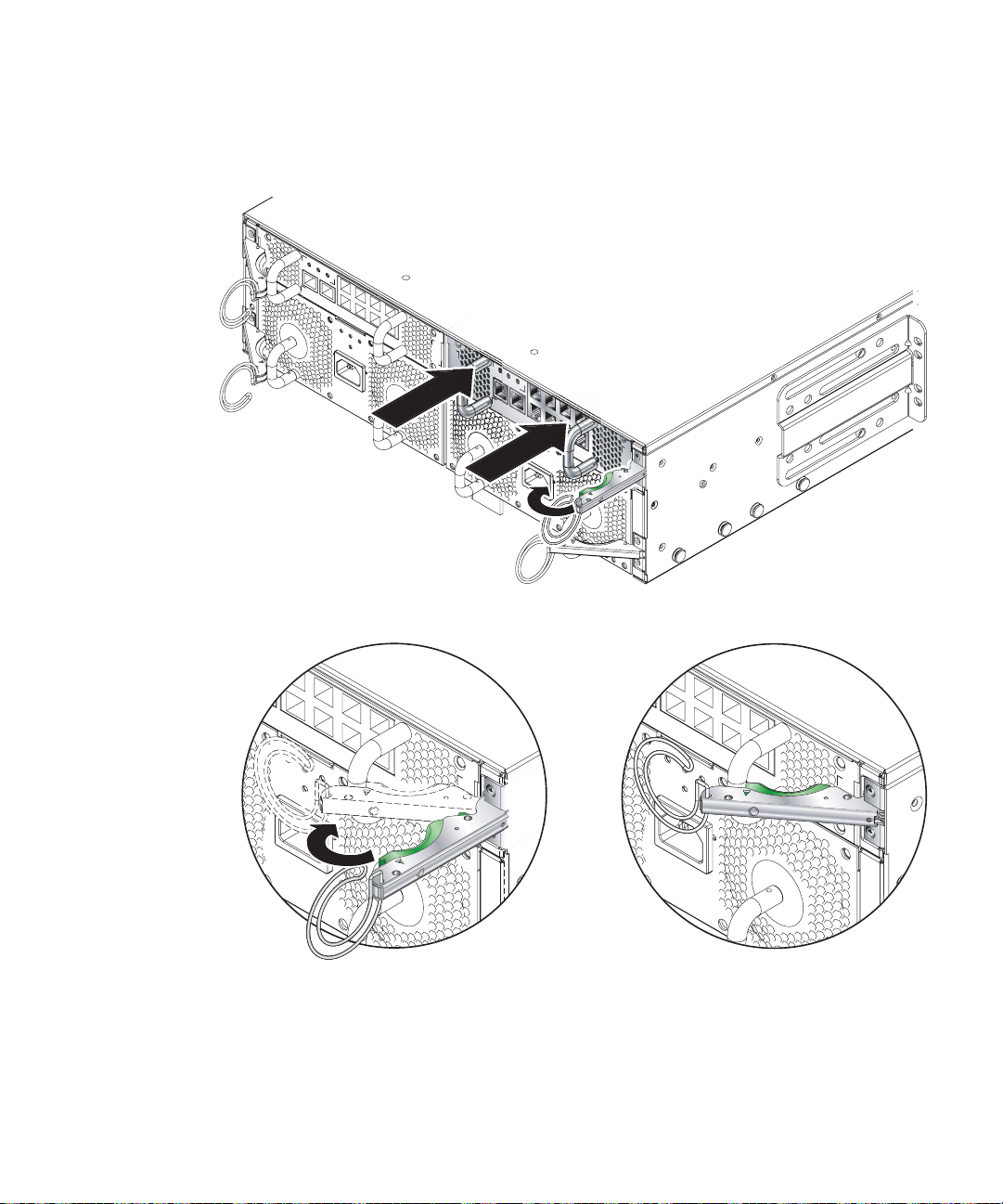

3. Slide the SSC into the empty chassis slot.

Push the SSC into the slot until the ejector lever engages (

FIGURE 4-17).

FIGURE 4-17 Inserting the SSC

4-20 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 67

4. Complete insertion by closing the ejector lever.

Check that the latch engages onto the SSC pull handle. This engages the SSC into the

system chassis (

FIGURE 4-18).

FIGURE 4-18 Closing the SSC Ejector Lever

Chapter 4 Removing and Installing Modules 4-21

Page 68

4.4 What to Do Next

Now you have a fully populated Sun Fire B1600 blade system chassis, continue with

Section 5.1, “Location of Ports and Power Inlets” on page 5-2.

4-22 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 69

CHAPTER

5

Connecting and Managing Cables

This chapter contains the following sections:

■ Section 5.1, “Location of Ports and Power Inlets” on page 5-2

■ Section 5.2, “Connecting the IEC Power Cords” on page 5-3

■ Section 5.3, “Cable Requirements for 1000BASE-T and 10/100BASE-TX

Connections” on page 5-5

■ Section 5.4, “Attaching the Connector Cables” on page 5-6

■ Section 5.5, “Connecting to the 10/100/1000BASE-T Data Network Ports” on

page 5-7

■ Section 5.6, “Connecting to the 10/100BASE-T Network Management Ports” on

page 5-10

■ Section 5.7, “Managing Cables for Multiple System Chassis” on page 5-12

■ Section 5.8, “What to Do Next” on page 5-13

See Chapter 6 for details of Serial Port connections to other devices.

5-1

Page 70

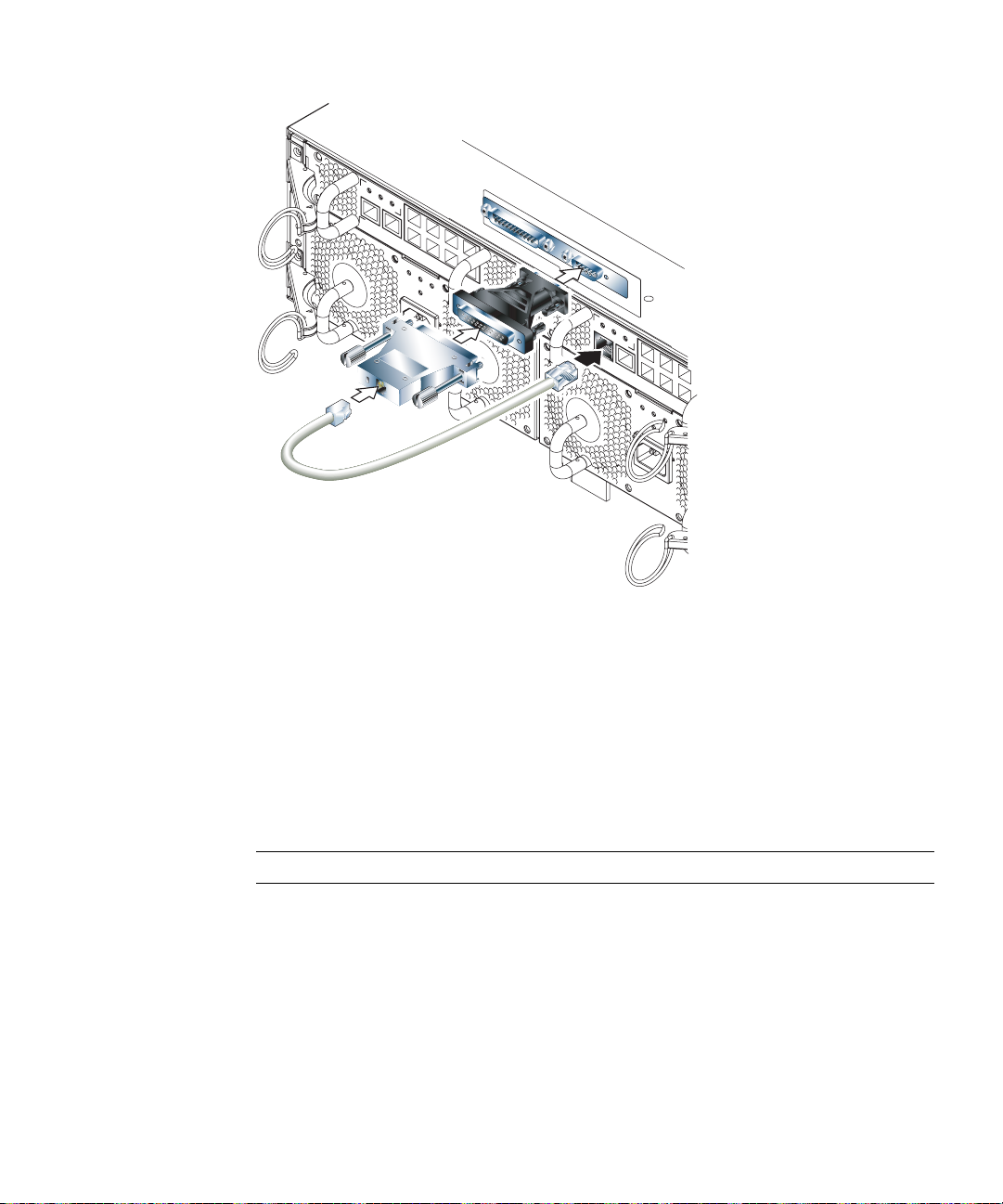

5.1 Location of Ports and Power Inlets

FIGURE 5-1 shows the ports and power inlets at the back of the Sun Fire B1600 blade

system chassis.

10/100BASE-T network management port

RS232 serial console port

SSC 0

IEC power inlet

FIGURE 5-1 External Cable Ports (One SSC and PSU Shown)

10/100/1000BASE-T data

network ports

Caution – Do not connect a telephone jack connector to a RJ-45 port. This can

damage the switch. Instead, use only twisted-pair cables with RJ-45 connectors that

conform with FCC standards, and make sure you follow local national wiring or

electrical regulations.

5-2 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 71

5.2 Connecting the IEC Power Cords

You must connect an IEC power cord to each of the PSUs before you attach any

other cables. Connecting each power cord to a separate circuit breaker will ensure

that failure of one circuit does not compromise the system.

1. Connect the power cord to the IEC power inlet (

Note – The Sun B1600 blade system chassis powers on when the power cords are

connected. Connection of the power cord provides a reliable earth to ground.

FIGURE 5-2).

FIGURE 5-2 Inserting the IEC Power Cords

Chapter 5 Connecting and Managing Cables 5-3

Page 72

2. Confirm that the PSU LEDs are in the correct state.

If the PSU fans run at high speed and the blue and amber LEDs are lit on the PSU,

the unit might not be fully inserted into the system enclosure. See Section 4.3,

“Removing and Installing a PSU” on page 4-8 for details of how to install the PSU

correctly.

Caution – Do not attempt to install a PSU with the power cord attached.

3. Use the power cord retention clip to hold the power cord in position (

FIGURE 5-3).

FIGURE 5-3 Clipping on the Power Cord Retention Clip

4. Repeat Step 1 through to Step 3 for the other PSU.

5-4 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 73

5.3 Cable Requirements for 1000BASE-T and 10/100BASE-TX Connections

This section provides details of the 1000BASE-T and 10/100BASE-TX cable

requirements when connecting to a Sun Fire B1600 blade system chassis.

5.3.1 1000BASE-T Cable Requirements

All Category 5 UTP cables that are used for 100BASE-TX connections should also

work for 1000BASE-T connections, providing that all four wire pairs are connected.

However, for all critical connections or any new cable installations, use

Category 5E (enhanced Category 5) cable. The Category 5E specification includes

test parameters that are only recommendations for Category 5. Therefore, the first

step in preparing existing Category 5 UTP cable for running 1000BASE-T is a simple

test of the cable installation to confirm that it complies with the IEEE 802.3ab

standards.

5.3.1.1 Cable Testing for Existing Category 5 Cable

Installed Category 5 UTP cables must pass tests for Attenuation, Near-End Crosstalk

(NEXT), and Far-End Crosstalk (FEXT). This cable testing information is specified in

the ANSI/TIA/EIA-TSB-67 standard. Additionally, cables must also pass test

parameters for Return Loss, skew and Equal-Level Far-End Crosstalk (ELFEXT).

These tests are specified in the ANSI/TIA/EIA-TSB-95 Bulletin, “The Additional

Transmission Performance Guidelines for 100 Ohm 4-Pair Category 5 Cabling.”

Chapter 5 Connecting and Managing Cables 5-5

Page 74

5.3.2 Cable Requirements for 10/100BASE-TX Devices

The data ports on the SSC are designed to operate at an optimal speed of 1000 Mbps

but can be connected to 10 or 100 Mbytes/sec devices. The SSC also includes a

10/100BASE-TX management port. For 10/100BASE-TX connections, twisted-pair

cable can have two or four pairs of wires. Each wire pair is two different colors. For

example, one wire might be red, and the other red with white stripes. When

connecting the SSC to a device at 10 or 100 Mbytes/sec, use unshielded twisted-pair

(UTP) cable with RJ-45 connectors at both ends. For 100BASE-TX connections,

Category 5 cable is required. For 10BASE-T connections, Category 3, 4 or 5 cable can

be used.

Note – Twisted-pair cables must not exceed 100 meters (328 feet) in length.

Note – When connected to a shared collision domain (such as a hub with multiple

workstations), switch ports must be set to half-duplex mode and back pressure flow

control must be disabled to avoid propagating jamming packets throughout the

segment.

5.4 Attaching the Connector Cables

You must connect the power cords to the PSUs before you attach the remaining

cables:

■ RJ-45 10/100/1000BASE-T data network connectors

(see Section 5.5, “Connecting to the 10/100/1000BASE-T Data Network Ports” on

page 5-7 for further information)

■ RJ-45 10/100BASE-T network management connectors

(see Section 5.6, “Connecting to the 10/100BASE-T Network Management Ports”

on page 5-10 for further information)

■ RS232 serial connectors (see “Connecting the RS232 Serial Port to Different

Devices” on page 6-1 for further information)

Attach the RJ-45 connectors by inserting the connector into the relevant port until

the connector clicks in place.

5-6 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 75

The SSC is designed to connect to IEEE 802.3ab compliant devices. For most

applications, the external ports on the SSC will be connected to other switches in the

network backbone. It might also be connected directly to Gigabit Ethernet network

cards in PCs or servers.

Caution – Do not connect a telephone jack connector to any RJ-45 port. This can

damage the switch. Instead, use only twisted-pair cables with RJ-45 connectors that

conform with FCC standards, or local national wiring or electrical regulations.

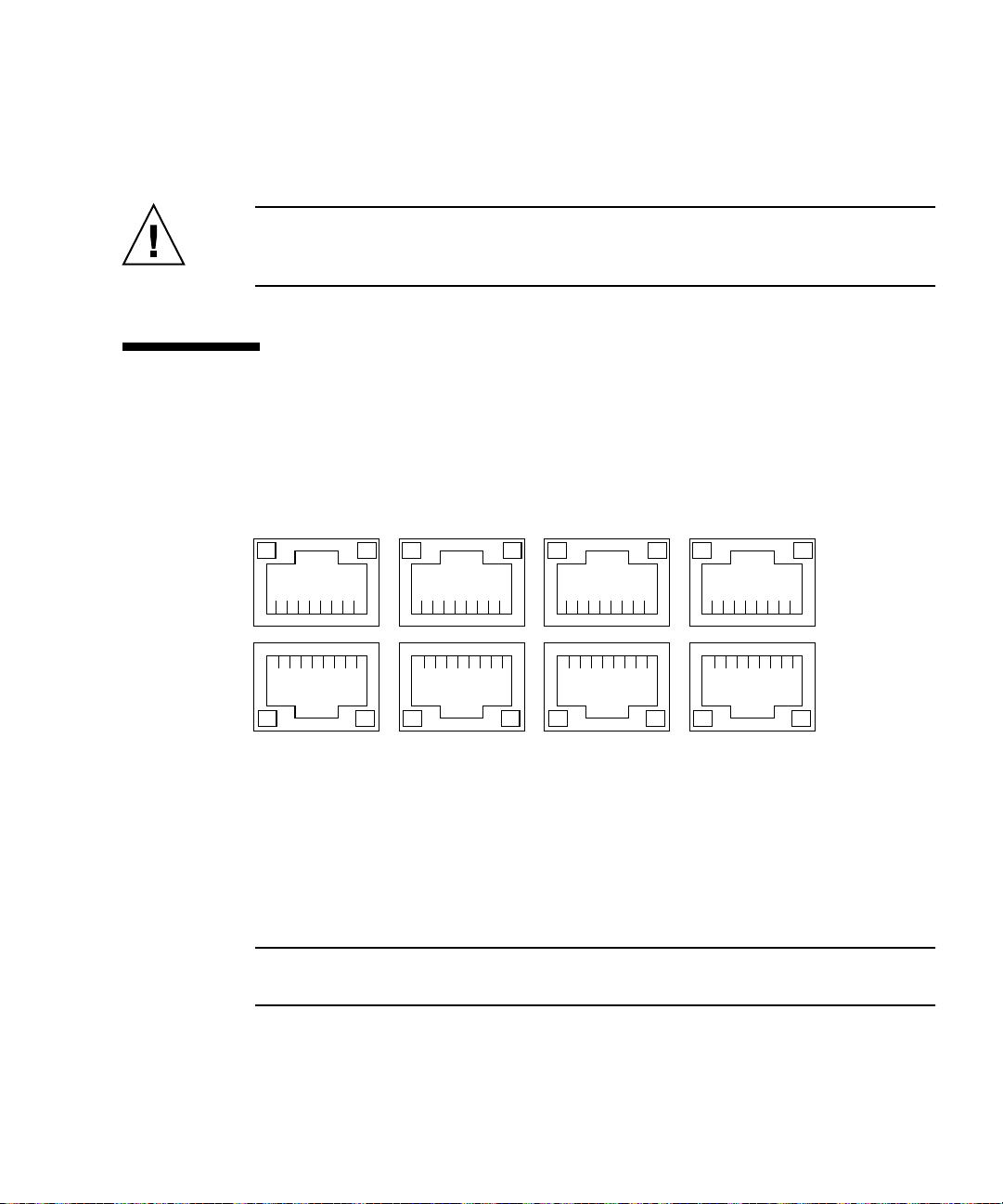

5.5 Connecting to the 10/100/1000BASE-T Data Network Ports

4567

A B

81

81

BA

A B

81

81

BA

A B

81

81

BA

A B

81

81

BA

0123

FIGURE 5-4 The 10/100/1000BASE-T Data Network Ports

The RJ-45 ports are arranged as a 4x2 array and provide the connection from the

Switch and System Controller (SSC) to the network.

Each port has integral green Link Present/Active and Link Speed LED indicators.

Note – The Link Present/Active indicator is always on the left, regardless of the

orientation of the RJ-45 port.

Chapter 5 Connecting and Managing Cables 5-7

Page 76

Note – The ce0 interface of each blade is connected to the switch in SSC0 and the

ce1 interface of each blade is connected to the switch in SSC1. Both switches run in

parallel, but separately.

TABLE 5-1 10/100/1000BASE-T Data Network Port Pinouts

Pin 1 TRD0+ Pin 2 TRD0-

Pin 3 TRD1+ Pin 4 TRD2+

Pin 5 TRD2- Pin 6 TRD1-

Pin 7 TRD3+ Pin 8 TRD3-

LED A Link

Present/

Active

LED B Link Speed:

On = 1000BASE-T

Off = 100BASE-T

When LED A is illuminated constantly it indicates that a link is established, but no

packets are being transferred. When LED A is flashing it indicates that a link is

established, and packets are being transferred.

FIGURE 5-5 shows how to connect the data network cables to the system chassis.

If you intend to configure your system chassis with redundant data connections, see

Chapter 3 of the Sun Fire B1600 Blade System Chassis Software Setup Guide for details

of how to duplicate connections from the SSC to your network.

5-8 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 77

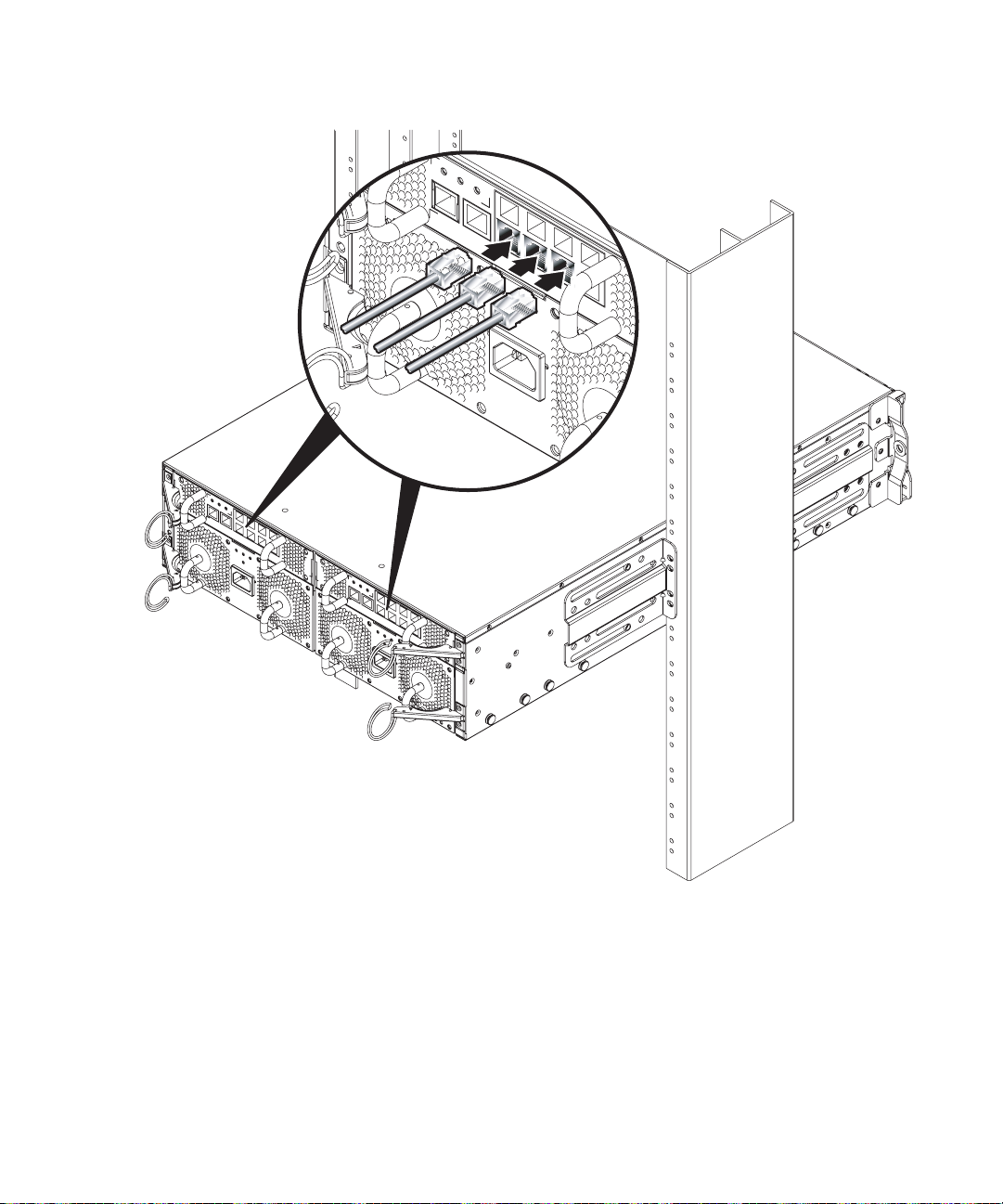

FIGURE 5-5 Attaching the Data Network Cables to the Network Ports

Chapter 5 Connecting and Managing Cables 5-9

Page 78

5.6 Connecting to the 10/100BASE-T Network Management Ports

These ports are labelled NET MGMT and are 10/100 Mbytes/sec Ethernet ports for

carrying network management traffic only. If you are concerned about the security of

your management network, we recommend strongly that you place the Network

Management port on a different subnet from the Data Network ports.

The port has integral green Link Present/Active and Link Speed indicators.

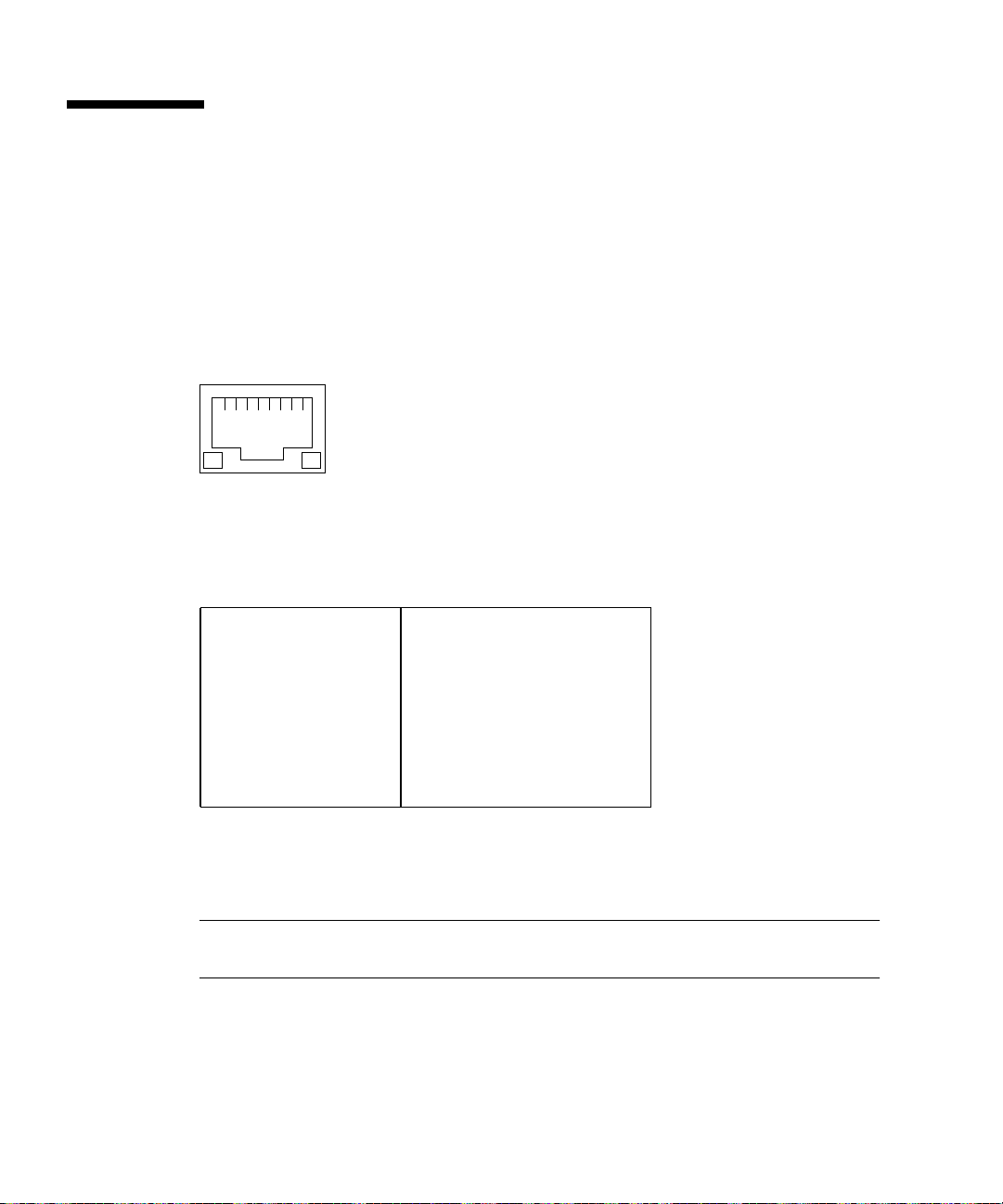

81

BA

FIGURE 5-6 10/100BASE-T Network Management Ports

TABLE 5-2 100BASE-T Network Management Port Pinouts

Pin 1 TXD+ Pin 2 TXD-

Pin 3 RXD+ Pin 4 4T_D3P

Pin 5 4T_D3P Pin 6 RXD-

Pin 7 4T_D4P Pin 8 4T_D4P

LED A Link

Present/

Active

LED B Link Speed:

On = 100BASE-T

Off = 10BASE-T

When LED A is illuminated constantly it indicates that a link is established, but no

packets are being transferred. When LED A is flashing it indicates that a link is

established and packets are being transferred.

Note – 4T_D3P and 4T_D4P pins provide a common-mode termination for unused

lines.

FIGURE 5-7 shows how to connect the network management cables to the system

chassis.

5-10 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 79

FIGURE 5-7 Attaching the Network Management Cables

Chapter 5 Connecting and Managing Cables 5-11

Page 80

5.7 Managing Cables for Multiple System Chassis

A Sun Fire B1600 blade system chassis that uses every available connection has

22 cables (including power cords) attached to the back of the system. When multiple

system chassis are installed within the same rack you must use effective cable

management to avoid blocking airflow through the system chassis.

Check that:

■ Cables are of an adequate length

■ There is adequate clearance at the back of the system chassis

■ The cabling from multiple system chassis does not block the back vents of any

system chassis that is installed beneath them

Cable management rings are attached to the module ejector handles on each PSU

and SSC. Use each ring to gather the cables from each module and to keep them

clear of the back system vents (

FIGURE 5-8).

SSC cable

management rings

PSU cable

management rings

FIGURE 5-8 Back Cable Management Rings

5-12 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 81

Caution – Failure to keep the vents at the back of the system chassis clear might

cause the system chassis to overheat and lead to system shutdown.

5.8 What to Do Next

See Chapter 6 for details of how to connect the Serial Port to different types of device

such as a:

■ Terminal server

■ VT100 terminal or Sun Workstation

■ Terminal that has a 9-pin adapter

■ Modem

Chapter 5 Connecting and Managing Cables 5-13

Page 82

5-14 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 83

CHAPTER

6

Connecting the RS232 Serial Port to Different Devices

To perform the initial configuration when you have installed and applied power to

the blade system chassis, you must either set up a serial connection to SSC0 or you

must set up a DHCP server to perform the IP configuration of the chassis’ active

System Controller automatically. If you set up a DHCP server to do this, you can

then telnet into the active System Controller to set up the chassis for the first time.

For information about configuring a DHCP server to enable you to connect to the

chassis’ active System Controller for the first time over a telnet instead of a serial

connection, see the Sun Fire B1600 Blade System Chassis Software Setup Guide.

Note – When both SSCs in the chassis are powered and working normally and

neither is damaged, by default SSC0 contains the active System Controller and SSC1

contains the standby System Controller. This means that, to set up the chassis for the

first time using a serial connection, you need a serial connection to at least SSC0.

However, for day-to-day operation of the blade system chassis, we recommend you

set up serial connections to both SSCs. This ensures that, if the active SSC fails for

any reason, you do not lose serial connectivity to the chassis.

This chapter contains the following sections:

■ Section 6.1, “Serial Port Pin Numbers” on page 6-2

■ Section 6.2, “Connecting to a Terminal Server” on page 6-3

■ Section 6.3, “Connecting to a VT100 Terminal or a Sun Workstation” on page 6-4

■ Section 6.4, “Connecting to a Terminal That Has a 9-pin Adapter” on page 6-5

■ Section 6.5, “Connecting to a Modem” on page 6-6

■ Section 6.6, “Connecting the Cable to the Serial Port” on page 6-7

■ Section 6.7, “Setting up a Serial Link to the System Controller Using a Laptop” on

page 6-8

6-1

Page 84

6.1 Serial Port Pin Numbers

When viewing the Sun Fire B1600 blade system chassis from the back, pin 1 of the

RJ-45 serial port is on the left, and pin 8 is on the right.

81

FIGURE 6-1 Serial Port Pin Numbers

TABLE 6-1 Serial Port Pinouts

Pin number on System

Chassis

Pin 1 RTS

Pin 2 DTR

Pin 3 TXD

Pin 4 Signal Ground

Pin 5 Signal Ground

Pin 6 RXD

Pin 7 DSR

Pin 8 CTS

Signal

6-2 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

Page 85

6.2 Connecting to a Terminal Server

For this connection, you can use the standard RJ-45 patch cable and DB-25 adapter

supplied with the system chassis.

The serial port is a DTE port. You must be aware that if you are connecting a SSC’s

serial port to another DTE port - the pinouts for the serial ports on the SSCs

correspond with the pinouts for the RJ-45 ports on Cisco terminal servers. This

means that if you are using a Cisco AS2511-RJ terminal server you can:

■ Connect a rollover cable directly to the Sun Fire B1600 blade system chassis.

■ Connect a rollover cable to a patch panel and use a straight-through patch cable

to connect the patch panel to the Sun Fire B1600 blade system chassis (see

FIGURE 6-2).

Note – You do not have to use a Cisco terminal server. For other terminal servers,

see the manufacturer’s documentation to confirm whether the pinouts of the serial

ports on the terminal server match the pinouts of the Sun Fire B1600 system chassis.

If they do not, write down which pins on the terminal server’s serial ports carry the

signals listed in the right-hand column in

taking each of the pins on either SSC’s serial port to the correct pin on the terminal

server’s serial port.

TABLE 6-2. Then make a rollover cable

Terminal

server

Straight-through cable

Patch panel

Rollover cables

Sun Fire B1600

FIGURE 6-2 Patch Panel Connections to a Terminal Server

Chapter 6 Connecting the RS232 Serial Port to Different Devices 6-3

Page 86

TABLE 6-2 Serial Port Pinouts to a Terminal Server

Pin number on

System Chassis

Pin 1 RTS CTS

Pin 2 DTR DSR

Pin 3 TXD RXD

Pin 4 Signal Ground Signal Ground

Pin 5 Signal Ground Signal Ground

Pin 6 RXD TXD

Pin 7 DSR DTR

Pin 8 CTS RTS

Signal Terminal Server Signal

Connection

6.3 Connecting to a VT100 Terminal or a Sun Workstation

For this connection, you can use the standard RJ-45 patch cable supplied with the

chassis, but you must also use the DB-25 adapter that is supplied as well.

To configure the chassis directly from a VT100 terminal or a Sun workstation:

1. Connect one end of the serial cable to the serial port on the SSC.

2. Insert the other end of the serial cable into the DB-25 adapter

(part number 530-2889).

3. Plug the adapter into the DB-25 serial connector on the VT100 terminal or Sun

workstation you intend to use.

The DB-25 adapter supplied with your system chassis enables you to connect to any

Sun system. The pin interconnections are listed in

6-4 Sun Fire B1600 System Chassis Hardware Installation Guide • August 2003

TABLE 6-3.

Page 87

TABLE 6-3 Serial Port Pin Interconnections to a Sun DB-25 (25-pin) Adapter

Serial Port (RJ-45 Connector) Pin 25-pin Connector

Pin 1 (RTS) Pin 5 (CTS)

Pin 2 (DTR) Pin 6 (DSR)

Pin 3 (TXD) Pin 3 (RXD)

Pin 4 (Signal Ground) Pin 7 (Signal Ground)

Pin 5 (Signal Ground) Pin 7 (Signal Ground)

Pin 6 (RXD) Pin 2 (TXD)

Pin 7 (DSR) Pin 20 (DTR)

Pin 8 (CTS) Pin 4 (RTS)

6.4 Connecting to a Terminal That Has a 9-pin Adapter

The pinouts for the chassis serial ports correspond with the pinouts for the RJ-45

ports on the Cisco AS2511-RJ terminal server. For terminal servers from other

manufacturers, you might need to obtain a suitable rollover cable (see Section 6.2,

“Connecting to a Terminal Server” on page 6-3).

1. Connect one end of the serial cable to the serial port on the SSC.

2. Insert the other end of the serial cable into the DB-9 adapter.

Chapter 6 Connecting the RS232 Serial Port to Different Devices 6-5

Page 88

3. Plug the adapter into the DB-9 serial connector on the terminal you intend to use.

The DB-9 (9-pin) adapter must perform the pin interconnections listed in

TABLE 6-4 Serial Port Pin Interconnections to a DB-9 (9-pin) Adapter

Serial Port (RJ-45 Connector) Pin 9-pin Connector

Pin 1 (RTS) Pin 8 (CTS)

Pin 2 (DTR) Pin 6 (DSR)

Pin 3 (TXD) Pin 2 (RXD)

Pin 4 (Signal Ground) Pin 5 (Signal Ground)

Pin 5 (Signal Ground) Pin 5 (Signal Ground)

Pin 6 (RXD) Pin 3 (TXD)

Pin 7 (DSR) Pin 4 (DTR)

Pin 8 (CTS) Pin 7 (RTS)

6.5 Connecting to a Modem