Page 1

Sun Fire

Systems Service Manual

™

6800/4810/4800/3800

Sun Microsystems, Inc.

www.sun.com

Part No. 805-7363-15 v2

May 2008, Revision A

Submit comments about this document at: http://www.sun.com/hwdocs/feedback

Page 2

Copyright 2008Sun Microsystems, Inc., 4150 Network Circle, SantaClara, CA 95054 USA. All rights reserved.

This product ordocument is protected by copyright and distributed under licenses restricting its use, copying, distribution, and decompilation.

No partof this product or document may be reproduced inany form by any meanswithout prior written authorization of Sun and its licensors,

if any. Third-party software, includingfont technology, is copyrighted and licensedfrom Sun suppliers.

Parts ofthe product may be derived from BerkeleyBSD systems, licensed from the University ofCalifornia. UNIX is a registered trademark in

the U.S.and other countries, exclusively licensedthrough X/Open Company, Ltd.

Sun, SunMicrosystems, the Sun logo, AnswerBook2, docs.sun.com, Sun Fire, and Solaris are trademarks, registered trademarks, or service

marks ofSun Microsystems, Inc. in the U.S. and other countries. All SPARC trademarksare usedunder license and are trademarks or registered

trademarks ofSPARCInternational, Inc. in the U.S.and other countries.Products bearing SPARC trademarks are based upon an architecture

developed bySun Microsystems, Inc .

The OPENLOOK and Sun™ Graphical UserInterface was developedby Sun Microsystems, Inc. for its users and licensees. Sun acknowledges

the pioneeringefforts of Xerox in researching and developing the concept of visual or graphical user interfaces forthe computer industry. Sun

holds anon-exclusive license from Xerox to the Xerox Graphical User Interface, which license also covers Sun’s licensees who implement OPEN

LOOK GUIsand otherwise comply with Sun’swritten license agreements.

U.S. GovernmentRights-Commercial use. Government users are subject tothe Sun Microsystems, Inc. standard license agreement and

applicable provisions ofthe FAR and its supplements.

DOCUMENTATION IS PROVIDED “AS IS” AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NONINFRINGEMENT, ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright 2008Sun Microsystems, Inc., 4150 Network Circle, SantaClara, CA 95054 Etats-Unis. Tous droits réservés.

Ce produit oudocument est protégé par un copyright etdistribué avec des licences qui en restreignent l’utilisation, la copie,la distribution, et la

décompilation. Aucunepartie de ce produit ou document ne peut être reproduite sous aucune forme, par quelque moyenque ce soit, sans

l’autorisation préalableet écrite de Sun etde ses bailleurs de licence,s’il y en a. Le logiciel détenu par des tiers, et qui comprend la technologie

relative aux polices de caractères, est protégé par un copyright etlicencié par des fournisseurs deSun.

Des partiesde ce produit pourront être dérivées des systèmes Berkeley BSD licenciés par l’Université de Californie. UNIX estune marque

déposée aux Etats-Unis et dans d’autres pays et licenciée exclusivement par X/Open Company, Ltd.

Sun, SunMicrosystems, le logo Sun, AnswerBook2, docs.sun.com, Sun Fire, et Solaris sont des marques defabrique ou des marques déposées,

ou marques deservice, de Sun Microsystems, Inc. aux Etats-Unis et dans d’autres pays. Toutes les marques SPARC sont utilisées sous licence et

sont desmarques defabrique oudes marques déposées de SPARC International, Inc. aux Etats-Unis et dans d’autres pays. Les produits portant

les marques SPARC sont basés sur unearchitecture développée par Sun Microsystems, Inc.

L’interfaced’utilisation graphique OPEN LOOK et Sun™ a été développée par Sun Microsystems,Inc. pour ses utilisateurs et licenciés. Sun

reconnaît les efforts depionniers de Xerox pour la recherche et le développementdu concept des interfaces d’utilisation visuelle ou graphique

pour l’industriede l’informatique. Sun détient unelicence non exclusive de Xerox surl’interface d’utilisation graphique Xerox, cette licence

couvrant également les licenciés deSun qui mettent en placel’interface d’utilisation graphique OPEN LOOKet qui en outre se conforment aux

licences écritesde Sun.

CETTE PUBLICATION EST FOURNIE "EN L’ETAT" ET AUCUNE GARANTIE, EXPRESSE OU IMPLICITE, N’EST ACCORDEE, Y

COMPRIS DES GARANTIES CONCERNANT LA VALEUR MARCHANDE, L’APTITUDE DE LA PUBLICATION A REPONDRE A UNE

UTILISATION PARTICULIERE, OU LE FAIT QU’ELLE NE SOIT PAS CONTREFAISANTE DE PRODUIT DE TIERS. CE DENI DE

GARANTIE NE S’APPLIQUERAIT PAS, DANS LA MESURE OU IL SERAIT TENU JURIDIQUEMENT NUL ET NON AVENU.

Please

Recycle

Page 3

Contents

Preface xxi

1. Safety and Tools Requirements 1–1

1.1 Safety Precautions 1–1

1.2 Symbols 1–2

1.3 System Precautions 1–3

1.3.1 Captive Screws 1–3

1.3.2 Fan Speed Message 1–3

1.3.3 Sun Fire Cabinet Fan Tray Power Switches 1–4

1.3.4 Firmware On Replacement Boards and Assemblies 1–4

1.3.5 Switzerland Caution 1–4

1.4 Filler Boards and Filler Panels 1–5

1.5 Periodic Maintenance 1–5

1.6 Tools Required 1–6

2. Powering Off and On 2–1

2.1 Powering Off the System 2–1

2.2 Powering On the System 2–6

3. FrameManager 3–1

3.1 FrameManager Description 3–1

iii

Page 4

3.2 FrameManager LEDs 3–2

3.3 Replacing the FrameManager 3–2

4. Power 4–1

4.1 Power Supplies 4–1

4.1.1 Power Supply Slot Locations 4–2

4.1.2 Power Supply LEDs 4–7

4.1.3 Replacing a Sun Fire 6800/4810 System Power Supply 4–7

4.1.4 Replacing a Sun Fire 4800 System Power Supply 4–9

4.1.5 Replacing a Sun Fire 3800 System Power Supply 4–11

4.2 AC Input Box 4–13

4.2.1 Replacing the AC Input Box 4–16

4.3 Redundant Transfer Unit (RTU) and Redundant Transfer Switch (RTS) 4–

17

4.3.1 Replacing the RTS Modules 4–20

4.3.2 Replacing the RTU Assembly 4–21

5. Patch Panel 5–1

5.1 Patch Panel 5–1

5.2 Replacing the Patch Panel 5–2

6. Fan Trays 6–1

6.1 Fan Tray Slot Numbering 6–2

6.2 Fan Tray LEDs 6–5

6.3 Replacing Fan Trays in Sun Fire 6800/4810/4800 Systems 6–5

6.3.1 Removing a Fan Tray 6–5

6.3.2 Installing a Fan Tray 6–6

6.4 Replacing Fan Trays in a Sun Fire 3800 System 6–7

6.4.1 Removing a Fan Tray 6–7

6.4.2 Installing a Fan Tray 6–8

iv Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 5

6.5 Cabinet Fan Trays 6–9

6.5.1 Replacing the Cabinet Fan Trays 6–10

7. System Controller Board 7–1

7.1 Handling Boards and Assemblies 7–1

7.2 System Controller Board 7–2

7.2.1 System Controller Board Slot Locations 7–4

7.2.2 System Controller Board LEDs 7–8

7.2.3 Resetting the System Controller Board 7–9

7.2.4 Replacing a System Controller Board 7–10

8. CPU/Memory Boards and Components 8–1

8.1 Handling Boards and Assemblies 8–1

8.2 Filler Panels and Filler Boards 8–3

8.3 CPU/Memory Boards 8–3

8.3.1 Replacing CPU/Memory Boards 8–7

8.3.2 Replacing DIMMs 8–13

8.4 CPU/Memory Board EMI Springfingers Clip 8–18

8.4.1 Replacing the EMI Springfingers Clip for Sun Fire 6800/4810/4800

Systems 8–18

9. PCI I/O Assemblies and Components 9–1

9.1 Handling Boards and Assemblies 9–1

9.2 Filler Boards and Filler Panels 9–3

9.3 PCI I/O Assemblies 9–4

9.3.1 PCI I/O Assembly Location Requirements 9–4

9.3.2 I/O Assembly LEDs 9–8

9.3.3 Replacing PCI I/O Assemblies 9–8

9.3.4 Replacing PCI Cards 9–11

10. CompactPCI I/O Assemblies and Components 10–1

Contents v

Page 6

10.1 Handling Boards and Assemblies 10–1

10.2 Filler Panels and CompactPCI Filler Cards 10–3

10.3 CompactPCI I/O Assembly 10–3

10.3.1 CompactPCI I/O Assembly Location Requirements 10–4

10.3.2 I/O Assembly Status LEDs 10–8

10.3.3 Replacing CompactPCI I/O Assemblies 10–9

10.3.4 Replacing CompactPCI Cards 10–11

11. Repeater Board 11–1

11.1 Handling Boards and Assemblies 11–1

11.2 Filler Boards 11–2

11.3 Repeater Board 11–2

11.3.1 Replacing Repeater Boards 11–7

12. Centerplane and ID Boards 12–1

12.1 Replacing the Centerplanes in a Sun Fire 6800 System 12–1

12.1.1 Removing the System Centerplane 12–2

12.1.2 Removing the Fan Centerplane 12–8

12.1.3 Removing the Power Centerplane 12–9

12.1.4 Installing the System Centerplane 12–12

12.1.5 Installing the Fan Centerplane 12–12

12.1.6 Replacing the Power Centerplane 12–13

12.2 Replacing the Centerplanes in a Sun Fire 4810 System 12–14

12.2.1 Removing the System Centerplane or the Power Centerplane 12–

14

12.2.2 Installing the System Centerplane or the Power Centerplane 12–

18

12.3 Replacing the Centerplane in a Sun Fire 4800 System 12–20

12.3.1 Removing the Centerplane 12–20

12.3.2 Installing the Centerplane 12–29

vi Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 7

12.4 Replacing the Centerplane in a Sun Fire 3800 System 12–30

12.4.1 Removing the Centerplane 12–30

12.4.2 Installing the Centerplane 12–38

12.5 Replacing the Sun Fire 3800 System LED Board 12–41

12.5.1 Removing the LED Board 12–41

12.5.2 Installing the LED Board 12–43

12.6 Replacing the ID Boards 12–44

12.6.1 Removing the ID Board From the Sun Fire 6800 System 12–44

12.6.2 Installing the ID Board in the Sun Fire 6800 System 12–46

12.6.3 Removing the ID Board From the Sun Fire 4810 System 12–47

12.6.4 Installing the ID board in the Sun Fire 4810 System 12–49

12.6.5 Removing the ID board From the Sun Fire 4800 System 12–49

12.6.6 Installing the ID board in the Sun Fire 4800 System 12–50

13. Periodic Maintenance 13–1

13.1 Cleaning the Air Intake Screen 13–2

13.2 Air Intake Screen for the Sun Fire 6800 System 13–2

13.2.1 Replacing the Sun Fire 6800 Air Intake Screen 13–3

13.3 Air Intake Screen for the Sun Fire 4810 System 13–4

13.3.1 Replacing the Sun Fire 4810 Air Intake Screen 13–5

13.4 Air Intake Screen for the Sun Fire 4800 System 13–6

13.4.1 Replacing the Sun Fire 4800 Air Intake Screen 13–7

A. Functional Description A–1

A.1 System Overview A–1

A.2 System Packaging A–2

A.2.1 Sun Fire 6800 System A–2

A.2.2 Sun Fire 4810 System A–4

A.2.3 Sun Fire 4800 System A–5

Contents vii

Page 8

A.2.4 Sun Fire 3800 System A–6

A.3 Software A–8

A.3.1 System Controller Software A–8

A.3.2 FrameManager Software A–8

A.4 Device Hot-Plug Procedures A–9

A.5 CPU/Memory Board A–10

A.5.1 CPU Processors A–12

A.5.2 Ecache Modules A–12

A.5.3 DIMMs A–12

A.6 I/O Assemblies A–12

A.6.1 PCI I/O Assembly A–13

A.6.2 Compact PCI I/O Assembly A–14

A.7 Power Supplies A–16

A.8 Fan Trays A–18

A.9 System Controller Board A–19

B. System Serial Number Locations and Rules for System Configuration B–1

B.1 System Serial Number Locations B–1

B.1.1 Location for the Sun Fire 6800 System B–1

B.1.2 Location for the Sun Fire 4810 System B–3

B.1.3 Location for the Sun Fire 4800 System B–4

B.1.4 Location for the Sun Fire 3800 System B–4

B.2 Boards and Assemblies B–7

B.2.1 CPU/Memory and CPU/Memory+ Boards B–7

B.2.2 I/O Assemblies B–8

B.2.3 Repeater Boards B–9

B.2.4 System Controller Board B–9

B.3 Filler Boards and Filler Panels B–10

B.4 Fan Trays B–11

viii Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 9

B.5 Power Supplies B–11

B.6 Connecting Cables B–12

B.6.1 Ethernet B–12

B.6.2 Serial Port B–12

C. Illustrated Parts Breakdown C–1

C.1 List of Replacement Parts C–1

C.1.1 Sun Fire 6800 System Replacement Parts C–2

C.1.2 Sun Fire 4810 System Replacement Parts C–5

C.1.3 Sun Fire 4800 System Replacement Parts C–7

C.1.4 Sun Fire 3800 System Replacement Parts C–10

C.1.5 CPU/Memory Board Replacement Parts C–12

C.1.6 I/O Assembly Replacement Parts C–13

C.1.7 Repeater Board Replacement Part C–15

C.1.8 System Controller Board C–16

C.1.9 Power Supply Replacement Parts C–17

C.1.10 Filler Boards and Filler Panels Replacement Parts C–19

C.1.11 Cables Replacement Parts C–20

Glossary Glossary–1

Index Index–1

Contents ix

Page 10

x Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 11

Figures

FIGURE 2-1 Sun Fire System Cabinet Showing FrameManager—Top View 2-1

FIGURE 2-2 AC Input Boxes—Sun Fire 6800 System—Rear View 2-2

FIGURE 2-3 AC Input Box—Sun Fire 4810 System—Front View 2-2

FIGURE 2-4 AC Input Box—Sun Fire 4800 System—Rear View 2-3

FIGURE 2-5 Sun Fire 3800 System Power Supplies—Rear View 2-4

FIGURE 2-6 Redundant Transfer Switches (RTS)—Sun Fire 6800 System 2-5

FIGURE 2-7 Redundant Transfer Switches (RTS)—Sun Fire 4810 System 2-5

FIGURE 2-8 Sun Fire Cabinet RTU Circuit Breakers and RTS Power Switch 2-6

FIGURE 2-9 Cabinet Fan Tray Power Switch—Sun Fire 6800 System Rear View 2-7

FIGURE 3-1 FrameManager 3-1

FIGURE 3-2 FrameManager Removal—Step 1 3-3

FIGURE 3-3 FrameManager Removal—Step 2 3-3

FIGURE 3-4 FrameManager Cable Location 3-4

FIGURE 4-1 Power Supply Locations—Sun Fire 6800 System—Front View 4-3

FIGURE 4-2 Power Supplies in Power Grid 0 and Power Grid 1—Sun Fire 6800 System 4-4

FIGURE 4-3 Power Supply Locations—Sun Fire 4800 System—Front View 4-5

FIGURE 4-4 Power Supply Locations—Sun Fire 4810 System—Front View 4-5

FIGURE 4-5 Power Supply Locations—Sun Fire 3800 System—Front View 4-6

FIGURE 4-6 Removing or Replacing a Power Supply—Sun Fire 6800 System 4-8

FIGURE 4-7 Removing or Replacing a Power Supply—Sun Fire 4800 System 4-10

xi

Page 12

FIGURE 4-8 Removing or Replacing a Power Supply—Sun Fire 3800 System 4-12

FIGURE 4-9 AC Input Box—Sun Fire 6800 System 4-14

FIGURE 4-10 AC Input Box—Sun Fire 4800 System 4-14

FIGURE 4-11 AC Input Box—Sun Fire 4810 System 4-15

FIGURE 4-12 AC Input Boxes—Sun Fire 6800 System—Rear View 4-15

FIGURE 4-13 Two Captive Screws on the AC Input Box—Sun Fire 6800 System 4-16

FIGURE 4-14 Removing the AC Input Box—Sun Fire 6800 System 4-17

FIGURE 4-15 RTU and RTS Modules 4-18

FIGURE 4-16 RTS Modules—Sun Fire 4810 System—Rear View 4-20

FIGURE 4-17 RTS Modules—Sun Fire 6800 System 4-20

FIGURE 4-18 RTU Assembly 4-21

FIGURE 5-1 Patch Panel Location—Rear View 5-1

FIGURE 6-1 Front and Rear Fan Trays—Sun Fire 6800 System 6-3

FIGURE 6-2 Fan Trays—Sun Fire 4810 System 6-3

FIGURE 6-3 Fan Trays—Sun Fire 4800 System 6-4

FIGURE 6-4 Fan Trays—Sun Fire 3800 System 6-4

FIGURE 6-5 Removing or Replacing a Front Fan Tray—Sun Fire 6800 System 6-6

FIGURE 6-6 Removing or Replacing a Fan Tray—Sun Fire 3800 System 6-8

FIGURE 6-7 Cabinet Fan Trays 6-9

FIGURE 6-8 Cabinet Fan Tray Power Switch and Connectors 6-10

FIGURE 6-9 Cabinet Fan Tray Top Plate 6-11

FIGURE 7-1 System Controller Board for Sun Fire 6800/4810/4800 Systems 7-3

FIGURE 7-2 System Controller Board for the Sun Fire 3800 System 7-3

FIGURE 7-3 System Controller Board Slot Assignments for the Sun Fire 6800 System—Front View 7-5

FIGURE 7-4 System Controller Board Slot Assignments for the Sun Fire 4810 System—Front View 7-6

FIGURE 7-5 System Controller Board Slot Assignments for the Sun Fire 4800 System—Rear View 7-7

FIGURE 7-6 System Controller Board Slot Assignments for the Sun Fire 3800 System—Front View 7-8

FIGURE 7-7 Reset Switch on a System Controller Board 7-10

xii Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 13

FIGURE 7-8 Loosening the Captive Screws and Ejector Levers 7-12

FIGURE 7-9 Removing and Replacing a System Controller Board—Sun Fire 6800 System 7-13

FIGURE 7-10 Removing and Replacing a System Controller Board—Sun Fire 3800 System 7-14

FIGURE 7-11 Tightening the Captive Screws and Locking the Ejector Levers 7-15

FIGURE 8-1 CPU/Memory Board With the Cover Installed 8-4

FIGURE 8-2 CPU/Memory Board Slot Assignments—Sun Fire 6800 System—Front View 8-5

FIGURE 8-3 CPU/Memory Board Slot Assignments—Sun Fire 4810 System—Front View 8-6

FIGURE 8-4 CPU/Memory Board Slot Assignments—Sun Fire 4800 System—Rear View 8-6

FIGURE 8-5 CPU/Memory Board Slot Assignments—Sun Fire 3800 System—Front View 8-7

FIGURE 8-6 Unlocking the Ejector Levers 8-9

FIGURE 8-7 Removing or Replacing a CPU/Memory Board—Sun Fire 6800 System 8-10

FIGURE 8-8 Removing and Replacing a CPU/Memory Board—Sun Fire 3800 System 8-11

FIGURE 8-9 DIMM Slot Numbers 8-14

FIGURE 8-10 Removing a DIMM 8-16

FIGURE 8-11 Installing a DIMM 8-17

FIGURE 8-12 Removing a CPU/Memory Board EMI Springfingers Clip 8-19

FIGURE 8-13 Installing a CPU/Memory Board EMI Springfingers Clip 8-21

FIGURE 9-1 I/O Assemblies for the Sun Fire 6800 System—Rear View 9-5

FIGURE 9-2 I/O Assemblies for the Sun Fire 4810 System—Front View 9-6

FIGURE 9-3 I/O Assemblies for the Sun Fire 4800 System—Rear View 9-7

FIGURE 9-4 PCI I/O Assembly 9-9

FIGURE 9-5 Removing or Inserting an I/O Assembly—Sun Fire 4810 System 9-10

FIGURE 9-6 Removing a PCI Card From the I/O Assembly 9-12

FIGURE 10-1 I/O Assemblies for the Sun Fire 6800 System—Rear View 10-5

FIGURE 10-2 I/O Assemblies for the Sun Fire 4810 System—Front View 10-6

FIGURE 10-3 I/O Assemblies for the Sun Fire 4800 System—Rear View 10-7

FIGURE 10-4 I/O Assemblies for the Sun Fire 3800 System—Front View 10-8

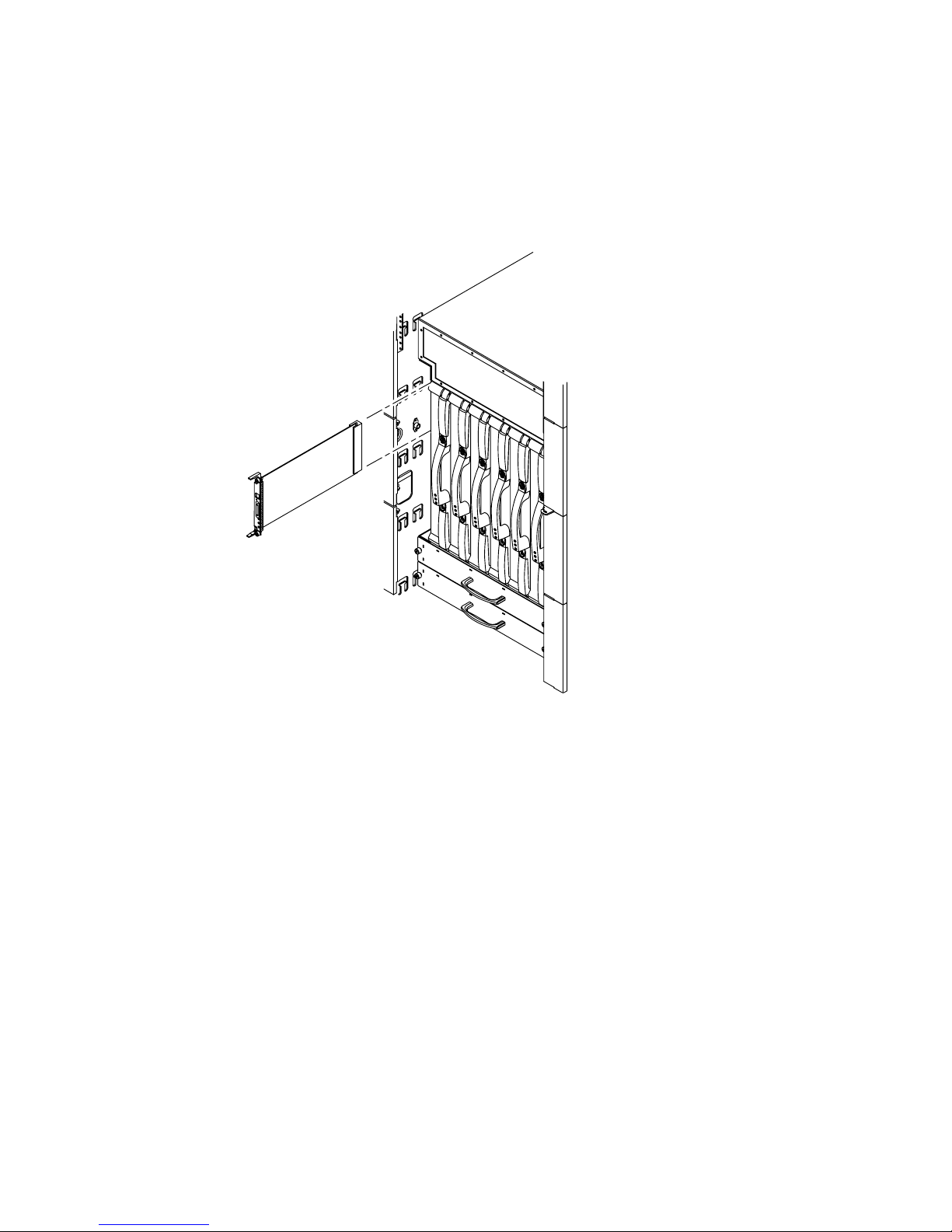

FIGURE 10-5 Removing or Inserting a CompactPCI I/O Assembly—Sun Fire 3800 System 10-10

Figures xiii

Page 14

FIGURE 10-6 Removing a CompactPCI Card 10-13

FIGURE 10-7 Replacing a CompactPCI Card 10-15

FIGURE 11-1 Repeater Board Slot Assignments for the Sun Fire 6800 System—Rear View 11-3

FIGURE 11-2 Repeater Board Slot Assignments for the Sun Fire 4810 System—Front View 11-4

FIGURE 11-3 Repeater Board Slot Assignments for the Sun Fire 4800 System—Rear View 11-4

FIGURE 11-4 Repeater Board LEDs 11-6

FIGURE 11-5 Unlocking the Ejector Levers 11-8

FIGURE 11-6 Removing and Replacing a Repeater Board—Sun Fire 6800 System 11-9

FIGURE 12-1 Removing the Door—Sun Fire 6800 System 12-2

FIGURE 12-2 Removing All Components From the Front of the Sun Fire 6800 System 12-3

FIGURE 12-3 Removing the Bus Bar Access Panels 12-4

FIGURE 12-4 Loosening the Bus Bar Captive Screws—Sun Fire 6800 System 12-5

FIGURE 12-5 Disconnecting the Two Cables From the System Centerplane—Sun Fire 6800 System 12-6

FIGURE 12-6 Removing the Screws Securing the System Centerplane—Sun Fire 6800 System 12-6

FIGURE 12-7 Moving the System Centerplane Forward Off the Guide Pins—Sun Fire 6800 System 12-7

FIGURE 12-8 Removing the System Centerplane—Sun Fire 6800 System 12-7

FIGURE 12-9 Disconnecting the Fan Tray Centerplane Cables 12-8

FIGURE 12-10 Removing the Screws Securing the Fan Centerplane 12-9

FIGURE 12-11 Centerplane Cables—Sun Fire 6800 System 12-10

FIGURE 12-12 Disconnecting the Screws Securing the Power Centerplane Bus Bars 12-11

FIGURE 12-13 Removing All Boards, Fan Trays, AC Input Box, and Power Supplies From the Front of the

Sun Fire 4810 System 12-15

FIGURE 12-14 Rear Screen Panel—Sun Fire 4810 System 12-16

FIGURE 12-15 Disconnecting the Signal Cable—Sun Fire 4810 System 12-16

FIGURE 12-16 Removing the Screws Securing the Cover to the Bus Bar and Removing the Bus Bar

Insulator—Sun Fire 4810 System 12-17

FIGURE 12-17 Removing the Bus Bar—Sun Fire 4810 System 12-17

FIGURE 12-18 Removing the System Centerplane— Sun Fire 4810 System 12-18

FIGURE 12-19 Removing the Bottom Fan Tray, CPU/Memory Boards, and I/O

Assemblies—Sun Fire 4800 System 12-21

xiv Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 15

FIGURE 12-20 Removing the Front Door—Sun Fire 4800 System 12-22

FIGURE 12-21 Removing a Power Supply at the Front of the Sun Fire 4800 System 12-23

FIGURE 12-22 Disconnecting Cables From the Connectors on the Centerplane—Sun Fire 4800

System 12-24

FIGURE 12-23 Removing the Top and Bottom Power Supply Supports—Sun Fire 4800 System 12-25

FIGURE 12-24 Removing the Cable Guide—Sun Fire 4800 System 12-26

FIGURE 12-25 Removing the Screws Securing the Centerplane to the System—Sun Fire 4800 System 12-

27

FIGURE 12-26 Removing the Centerplane and Insulator—Sun Fire 4800 System 12-28

FIGURE 12-27 Removing the Boards—Sun Fire 3800 System 12-31

FIGURE 12-28 Disconnecting the LED Cable—Sun Fire 3800 System 12-32

FIGURE 12-29 Removing a Fan Tray—Sun Fire 3800 System 12-33

FIGURE 12-30 Removing a Power Supply—Sun Fire 3800 System 12-34

FIGURE 12-31 Removing the Clamp—Sun Fire 3800 System 12-35

FIGURE 12-32 Removing the Subchassis 12-36

FIGURE 12-33 Removing the Lower Bulkhead 12-36

FIGURE 12-34 Removing the Centerplane—Sun Fire 3800 System 12-37

FIGURE 12-35 Removing the I/O Assembly—Sun Fire 3800 System 12-42

FIGURE 12-36 Disconnecting the LED Cable From the Centerplane—Sun Fire 3800 System 12-42

FIGURE 12-37 Removing IB9 I/O Assembly—Sun Fire 6800 System 12-45

FIGURE 12-38 Removing the ID Board From the Centerplane—Sun Fire 6800 System 12-46

FIGURE 12-39 Removing IB8 I/O Assembly—Sun Fire 4810 System 12-47

FIGURE 12-40 Removing the ID board From the Centerplane—Sun Fire 4810 System 12-48

FIGURE 13-1 Air Intake Screen Location for the Sun Fire 6800—Front View 13-2

FIGURE 13-2 Air Intake Screen Location for the Sun Fire 4810—Front View 13-4

FIGURE 13-3 Air Intake Screen Location for the Sun Fire 4800—Front View 13-6

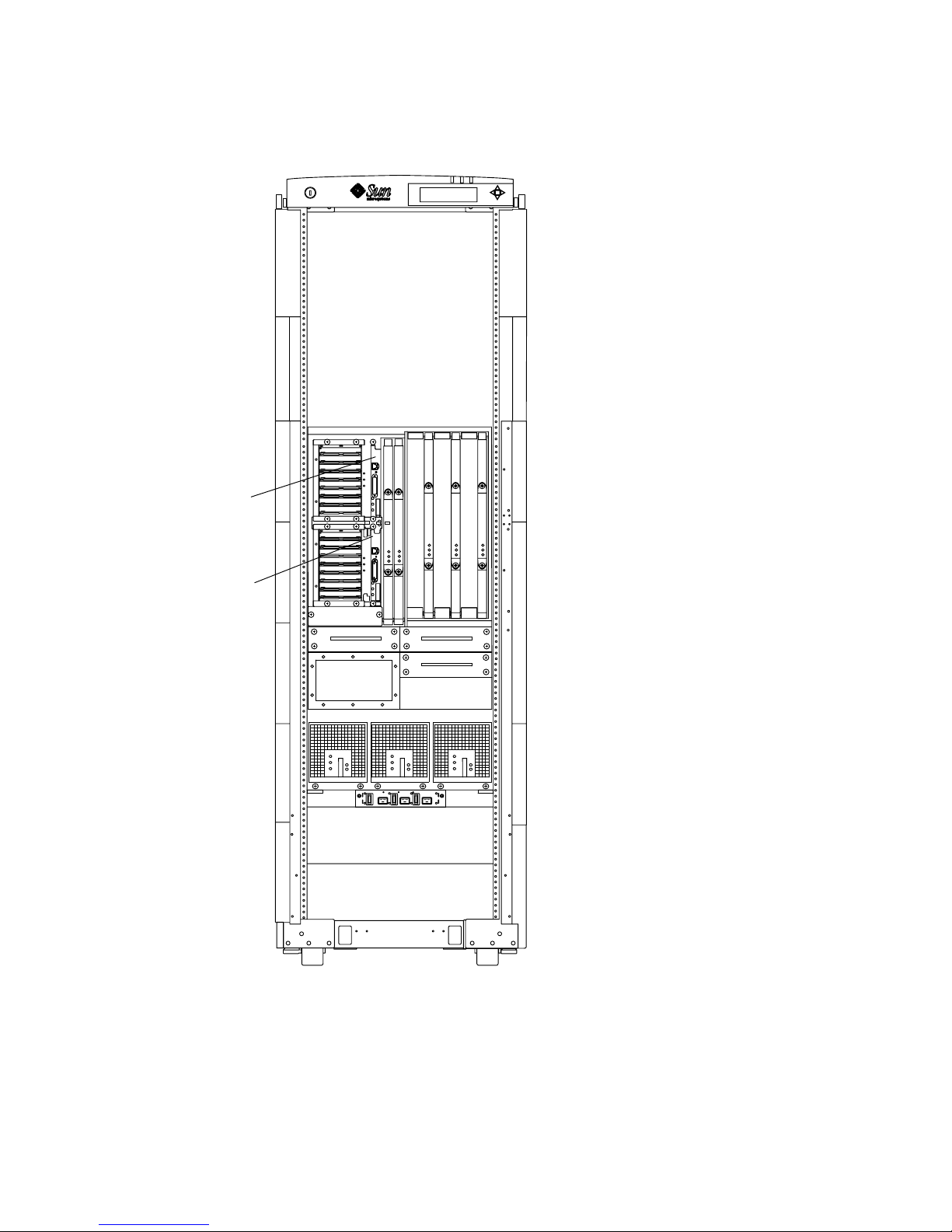

FIGURE A-1 Sun Fire 6800 System—Front and Rear Views A-3

FIGURE A-2 Sun Fire 4810 System Mounted in Sun Fire Cabinet—Front and Rear Views A-4

FIGURE A-3 Sun Fire 4800 System—Front and Rear Views A-5

Figures xv

Page 16

FIGURE A-4 Sun Fire 3800 System—Front View A-6

FIGURE A-5 Sun Fire 3800 System—Rear View A-7

FIGURE A-6 FrameManager Software Release 1.2 LCD Display A-9

FIGURE A-7 CPU/Memory Board With the Cover Removed A-11

FIGURE A-8 PCI I/O Assembly A-13

FIGURE A-9 PCI Card A-14

FIGURE A-10 CompactPCI I/O Assembly—Sun Fire 3800 System A-14

FIGURE A-11 CompactPCI I/O Assembly—Sun Fire 6800/4810/4800 Systems A-16

FIGURE A-12 Power Supply for the Sun Fire 6800 and Sun Fire 4810 Systems A-17

FIGURE A-13 Power Supply for the Sun Fire 3800 System A-17

FIGURE A-14 Power Supply for the Sun Fire 4800 System A-18

FIGURE A-15 System Controller Board—Sun Fire 6800/4810/4800 Systems A-20

FIGURE A-16 System Controller Board—Sun Fire 3800 System A-20

FIGURE B-1 Serial Number Location for the Sun Fire 6800 System—Rear B-2

FIGURE B-2 Serial Number Location for the Sun Fire 4810 System—Front B-3

FIGURE B-3 Serial Number Location for the Sun Fire 4800 System—Rear B-4

FIGURE B-4 Serial Number Location for the Sun Fire 3800 System—Rear B-5

FIGURE B-5 Sun Fire Cabinet System Serial Number Location—Rear B-6

FIGURE C-1 Sun Fire 6800 System—Front and Rear Views C-2

FIGURE C-2 Sun Fire 6800 System Cabinet C-4

FIGURE C-3 Sun Fire 4810 System Mounted in Optional Sun Fire Cabinet—Front View C-5

FIGURE C-4 Sun Fire 4800 System—Rear View C-7

FIGURE C-5 Sun Fire 4800 System—Front View C-8

FIGURE C-6 Sun Fire 3800 System—Front View C-10

FIGURE C-7 Sun Fire 3800 System—Rear View C-11

FIGURE C-8 CPU/Memory Board C-12

FIGURE C-9 PCI I/O Assembly C-13

FIGURE C-10 CompactPCI I/O Assembly for the Sun Fire 3800 System C-13

xvi Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 17

FIGURE C-11 CompactPCI I/O Assembly for the Sun Fire 6800/4810/4800 Systems C-14

FIGURE C-12 Repeater Board C-15

FIGURE C-13 System Controller Board—Sun Fire 6800/4810/4800 Systems C-16

FIGURE C-14 System Controller Board—Sun Fire 3800 System C-16

FIGURE C-15 Power Supply for the Sun Fire 6800/4810 Systems C-17

FIGURE C-16 Power Supply for the Sun Fire 3800 System C-18

FIGURE C-17 Power Supply for the Sun Fire 4800 System C-18

Figures xvii

Page 18

xviii Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 19

Tables

TABLE P-1 Typographic Conventions xxiii

TABLE 1-1 Safety Precautions 1–1

TABLE 1-2 Symbols 1–2

TABLE 1-3 Overheating Precautions Using Filler Boards 1–5

TABLE 3-1 FrameManager LED Major Functions 3–2

TABLE 4-1 Specifications for the Power Supplies 4–2

TABLE 4-2 Power Supply Slot Locations 4–2

TABLE 4-3 Power Supply LED Functions 4–7

TABLE 4-4 RTS LED Functions 4–19

TABLE 4-5 Self-Test LED Functions 4–19

TABLE 6-1 Fan Trays and Their Slot Numbers 6–2

TABLE 6-2 Fan Tray LED Functions 6–5

TABLE 6-3 Default Fan Tray Configuration 6–9

TABLE 7-1 System Controller Board Slot Locations for All Systems 7–4

TABLE 7-2 System Controller Board LED Functions 7–8

TABLE 8-1 CPU/Memory Board LED Functions 8–3

TABLE 8-2 CPU/Memory Board Slot Locations 8–5

TABLE 9-1 Description of the PCI I/O Assembly 9–4

TABLE 9-2 Location of the I/O Assemblies 9–4

TABLE 9-3 I/O Assembly Status LED Functions 9–8

xix

Page 20

TABLE 10-1 Description of the CompactPCI I/O Assembly 10–3

TABLE 10-2 Location of the I/O Assemblies 10–4

TABLE 10-3 I/O Assembly Status LED Functions 10–8

TABLE 10-4 I/O Card Status LED Functions 10–12

TABLE 11-1 Repeater Board Slot Locations 11–3

TABLE 11-2 Repeater Board LED Functions 11–5

TABLE 12-1 Default Fan Tray Configuration 12–40

TABLE A-1 Sun Fire 6800 System Components A–2

TABLE A-2 FrameManager LCD Displays A–8

TABLE A-3 FrameManager LED Functions A–9

TABLE A-4 CPU/Memory Board Slot Locations A–11

TABLE A-5 I/O Assembly Slot Locations A–12

TABLE A-6 I/O Assemblies A–15

TABLE A-7 Number of Fan Trays, CPU Fan Trays, and Blower Assemblies A–18

TABLE B-1 Overheating Precautions Using Filler Panels and Filler Boards B–10

xx Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 21

Preface

This document describes how to remove and install field-replaceable units (FRUs).

This document also presents a functional description of the systems, configuration

rules, and illustrated parts breakdowns for each system.

Who Should Use This Document

Caution – This document is written for qualified service-trained maintenance

providers. If you are not a qualified service-trained maintenance provider and you

service the system, your warranty on the system will be void.

xxi

Page 22

How This Document Is Organized

This document contains the following chapters and appendixes:

Chapter 1 describes the safety precautions and tools you will need.

Chapter 2 describes how to power on and power off the system.

Chapter 3 describes how to install and remove the FrameManager.

Chapter 4 describes how to install and remove the power supplies, the AC input

box, the redundant transfer unit (RTU), and the redundant transfer switches (RTS).

Chapter 5 describes how to install and remove the patch panel.

Chapter 6 describes how to install and remove the fan trays.

Chapter 7 describes how to install and remove the System Controller board.

Chapter 8 describes how to install and remove the CPU/Memory board, DIMMs

(Dual Inline Memory Modules), and EMI springfingers clip.

Chapter 9 describes how to install and remove the PCI I/O assembly and how to

install and remove the cards in the I/O assembly.

Chapter 10 describes how to install and remove the CompactPCI I/O assembly and

how to install and remove the CompactPCI cards in the I/O assembly.

Chapter 11 describes how to install and remove the Repeater board.

Chapter 12 describes how to install and remove the centerplane.

Chapter 13 describes how to perform the periodic maintenance tasks for Sun Fire

systems.

Appendix A presents a functional description of the systems; the card cage layout

and the layout of various boards, such as the CPU/Memory board and the I/O

assembly.

Appendix B describes system serial number locations and rules for system

configuration.

Appendix C provides illustrations of the field-replaceable units.

xxii Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 23

Typographic Conventions

TABLE P-1 Typographic Conventions

Typeface Meaning Examples

AaBbCc123 The names of commands, files,

and directories; on-screen

computer output

AaBbCc123 Document titles, new words or

terms, words to be emphasized

Edit your .login file.

Use ls -a to list all files.

Read Chapter 6 in the User’s Guide.

These are called class options.

You must be superuser to do this.

Related Documentation

Application Title

Installation Sun Fire 6800 System Getting Started

Sun Fire 4810/4800/3800 Systems Getting Started

Sun Fire 6800 System Installation Guide

Sun Fire 4810/4800/3800 Systems Installation Guide

Sun Fire 4810/4800/3800 Systems Cabinet Mounting Guide

Operation Sun Fire Cabinet Installation and Reference Guide

Software Sun Fire Midrange Systems Platform Administration Manual

Sun Fire 6800/4810/4800/3800 Systems Overview Manual

Sun Fire Midrange Systems Controller Command Reference Manual

Sun Fire Midrange Systems Dynamic Reconfiguration User Guide

Preface xxiii

Page 24

Accessing Sun Documentation

You can view, print, or purchase a broad selection of Sun documentation, including

localized versions, at:

http://www.sun.com/documentation

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and

suggestions. You can email your comments to Sun at:

http://www.sun.com/hwdocs/feedback

Please include the part number (805-7363-15) of your document in the subject line of

your email.

Contacting Sun Technical Support

If you have technical questions about this product which are not answered in this

document, go to:

http://www.sun.com/service/contacting

xxiv Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 25

Notes and Cautions

Note – Procedures contained in this document must be performed by qualified

service-trained maintenance providers. Before you begin, carefully read each of the

procedures in this manual. If you have not performed similar operations on

comparable equipment, do not attempt to perform these procedures.

Caution – This equipment contains lethal voltage. Accidental contact with

centerplane, card cage, and drive areas can result in serious injury or death.

Caution – Improper handling by unqualified personnel can cause serious damage

to this equipment. Unqualified personnel who tamper with this equipment may be

held liable for any resultant damage to the equipment.

Individuals who remove any outer panels or open covers to access this equipment

must observe all safety precautions and ensure compliance with skill level

requirements, certification, and all applicable local and national laws.

For system compliance class and conformity information, refer to the system

installation guide that came with your system.

United States Export Control Laws

Notice

Product covered by and information contained in this service manual are controlled

by U.S. Export Control laws and may be subject to the export or import laws in other

countries. Nuclear, missile, chemical biological weapons, or nuclear maritime end

uses or end users, whether direct or indirect, are strictly prohibited. Export or reexport to countries subject to U.S. embargo or to entities identified on U.S. export

exclusion lists, including but not limited to the denied persons and specially

designated nationals lists is strictly prohibited. Use of any spare or replacement

CPUs is limited to repair or one-for-one replacement of CPUs in products exported

in compliance with U.S. export laws. Use of CPUs as product upgrades unless

authorized by the U.S. Government is strictly prohibited.

Preface xxv

Page 26

xxvi Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 27

CHAPTER

1

Safety and Tools Requirements

This chapter describes the safety and system precautions you must take when

servicing the system. It also lists the tools and equipment you will need.

1.1 Safety Precautions

For your protection, observe the following safety precautions when servicing your

equipment:

■ Follow all cautions, warnings, and instructions marked on the equipment.

■ Never push objects of any kind through openings in the equipment as they may

touch dangerous voltage points or short out components that could result in fire

or electric shock.

■ Refer servicing of equipment to qualified personnel.

To protect both yourself and the equipment, observe the following safety

precautions:

TABLE 1-1 Safety Precautions

Item Problem Precaution

ESD wrist or

foot strap

ESD mat ESD Using an approved ESD mat provides protection from static damage

Electro-Static

Discharge (ESD)

Connect the ESD banana connector to your system and wear the wrist

strap or foot strap when handling printed circuit boards. Each system

except for the Sun Fire 3800 has an ESD socket.

when used with a wrist strap or foot strap. The mat also cushions and

protects small parts that are attached to printed circuit boards.

1-1

Page 28

1.2 Symbols

TABLE 1-2 Symbols

Symbol Description Meaning

CAUTION

CAUTION

CAUTION

SYSTEM,

POWER

COMPONENT

ACTIVATED

FAULT

Hazardous voltages are present. To reduce the risk of electrical

shock and danger, follow the instructions.

Risk of personal injury. To reduce the risk, follow the instructions.

Risk of equipment damage. To reduce the risk, follow the instructions.

CAUTION: Hot surfaces. Avoid contact. Surfaces are hot and may cause

personal injury if touched.

System is receiving DC power. When the power LED is lit, the system is

operating normally.

Component is activated when the green activated LED on the

system component is lit.

System has detected a hardware failure. When the fault LED

(amber) is lit, the system has detected hardware failure.

OK TO

REMOVE

1-2 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

You can safely remove board or component from the system when

the OK to remove LED (amber or blue) is lit.

Page 29

1.3 System Precautions

Ensure that the voltage and frequency of the power outlet to be used matches the

electrical rating labels on the equipment.

Wear an ESD wrist/foot strap when handling any magnetic storage devices,

CPU/Memory boards, or other printed circuit boards.

Use only properly grounded power outlets as described in the installation guides.

Caution – DO NOT make mechanical or electrical modifications to the system or

the cabinet. Sun Microsystems is not responsible for regulatory compliance of

modified cabinets.

Caution – The chassis AC power cord(s) must remain connected to ensure a proper

ground.

1.3.1 Captive Screws

Caution – Completely loosen all captive screws before ejecting the System

Controller board, power supplies, and I/O assemblies. Captive screws that have not

been completely loosened may cause damage to the System Controller board, power

supplies, or I/O assemblies.

1.3.2 Fan Speed Message

The fan speed message states “WARNING” instead of “NOTICE” when the fan

changes speed. Fans will go from low to high speed if all of the system fans are not

providing cooling, or when the environmental threshold is exceeded for the CPU.

Use the showenv -v command to obtain CPU environmental threshold

information. Refer to the Sun Fire 6800/4810/4800/3800 System Controller Command

Reference Manual for correct usage of the showenv command. The system is OK and

is still within the thermal specification when this “WARNING” message appears.

Chapter 1 Safety and Tools Requirements 1-3

Page 30

1.3.3 Sun Fire Cabinet Fan Tray Power Switches

If the Sun Fire cabinet fan trays are not operating, make sure that the fan trays are

switched on. The fan tray power switches are located in the back of each cabinet fan

tray, below the power cord socket.

1.3.4 Firmware On Replacement Boards and

Assemblies

After installing a board or assembly, use the showboards -p proms command to

determine if the firmware needs to be updated. If an update is required, use either

the system controller flashupdate -f or flashupdate -c command. Refer to

the Sun Fire 6800/4810/4800/3800 System Controller Command Reference Manual for

correct usage of the flashupdate command.

Note – Do not use the flashupdate -u command as shown in onscreen messages.

Using flashupdate -u can result in incompatibility issues that require a reboot of

the system controller and domains.

You can find a list of the most current patches for bug fixes and system firmware

upgrade on SunSolve Online

patches, including Year 2000 patches, to all users. Other product and OS patches are

available to SunSpectrum

Care Center or your service provider if you need assistance in accessing the list of

current patches and system firmware upgrades.

sm

. SunSolve provides recommended and security

sm

contract customers. Contact your local Sun Customer

1.3.5 Switzerland Caution

Caution – The Sun Fire Sun Fire 3800 system exceeds the rating requirements in

Switzerland for pluggable type A equipment. To comply with national requirements,

customers in Switzerland who receive a standalone Sun Fire Sun Fire 3800 system

(shipped without a rack) must provide a means to connect the system to a pluggable

type B power circuit.

1-4 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 31

1.4 Filler Boards and Filler Panels

Filler boards and filler panels are used for EMI protection and to ensure proper air

flow in order to prevent the system from overheating.

TABLE 1-3 describes the precautions you must take when you remove boards or

assemblies from a system.

TABLE 1-3 Overheating Precautions Using Filler Boards

If you have... Do the following

Empty PCI card slots Install PCI filler boards in all empty PCI card slots.

Empty CompactPCI

I/O slots

CPU/Memory board Install a filler board in a system to prevent the system from

System Controller

board

Empty power supply

slots

Empty fan tray slots Install fan tray filler panels in empty fan tray slots within one

Install CompactPCI I/O filler boards in all unused CompactPCI

slots.

overheating if the system is to be operating without the CPU/

Memory board installed. If two CPU/Memory boards must be

removed, use a CPU filler panel over one board slot and install a

filler board in the second board slot in order to prevent the system

from overheating. Do not install two filler panels. The filler panels

are for short term use only (CPU/Memory board replacement).

A filler board occupies the empty slot for one of the System

Controller boards. If you install a redundant System Controller

board, remove the System Controller filler board.

Install power supply filler panels in empty power supply slots

within one minute in a powered-on system.

minute in a powered-on system.

1.5 Periodic Maintenance

The Sun Fire 6800/4810/4800 systems have been designed such that the air intake

screens can be cleaned or changed without the need to power off the system. The

Sun Fire 3800 system does not have any air intake screens.

The Sun Fire 6800/4810/4800 systems each have one air intake screen that requires

periodic inspection and cleaning. Inspecting the air intake screen for debris and

trapped particles should be done every three months of operation. The level of

Chapter 1 Safety and Tools Requirements 1-5

Page 32

debris found on the screen and surrounding area should be considered in the

decision of when to remove and clean the air intake screen. See Section 13.1

“Cleaning the Air Intake Screen”.

If the air intake screen collects a substantial amount of debris in less than three

months, investigate the air supply system for sources of contamination and take

corrective action. In addition, notify and update account management, as required.

Have spare air intake screens onsite so that replacements are available when needed

for cleaning.

1.6 Tools Required

For the procedures in this document, you will need these tools:

■ Screwdriver, Phillips No. 1 with six-inch shank

■ Screwdriver, Phillips No. 2 with six-inch shank

■ Screwdriver, Phillips No. 2 with 10-inch shank

■ Screwdriver, straight slot with six-inch shank

■ Needlenose pliers

■ ESD mat

■ ESD grounding wrist strap or foot strap

1-6 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 33

CHAPTER

2

Powering Off and On

This chapter describes how to power the system off and on. These systems do not

have a physical keyswitch. Before physically powering off the system, you must halt

the Solaris operating environment in each domain and then power off the domain.

2.1 Powering Off the System

1. Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

step-by-step commands for powering off the domains and the system.

2. If your Sun Fire 4810/4800/3800 system is not in a Sun Fire™ cabinet, skip to Step

3. For Sun Fire 6800 system or Sun Fire 4810/4800/3800 systems mounted in a Sun

Fire cabinet, turn the keyswitch on the FrameManager to the off position

(

FIGURE 2-1).

FrameManager

keyswitch

FIGURE 2-1 Sun Fire System Cabinet Showing FrameManager—Top View

2-1

Page 34

3. Turn off the AC input box(es) (FIGURE 2-2, FIGURE 2-3, FIGURE 2-4).

The Sun Fire 3800 system does not have an AC input box.

AC input box

FIGURE 2-2 AC Input Boxes—Sun Fire 6800 System—Rear View

AC input box

AC input box

FIGURE 2-3 AC Input Box—Sun Fire 4810 System—Front View

2-2 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 35

AC input box

FIGURE 2-4 AC Input Box—Sun Fire 4800 System—Rear View

Chapter 2 Powering Off and On 2-3

Page 36

4. If you have a Sun Fire 3800 system, turn off the power switch located on each

power supply (

FIGURE 2-5).

Power switch

Power supply

FIGURE 2-5 Sun Fire 3800 System Power Supplies—Rear View

5. For Sun Fire 6800 system or Sun Fire 4810/4800/3800 systems mounted in a Sun

Fire cabinet, turn off the redundant transfer switches (RTS) (

FIGURE 2-7).

FIGURE 2-6 and

2-4 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 37

RTS

RTS

RTS RTS

System rear System front

FIGURE 2-6 Redundant Transfer Switches (RTS)—Sun Fire 6800 System

RTS RTS

FIGURE 2-7 Redundant Transfer Switches (RTS)—Sun Fire 4810 System

System rear

Chapter 2 Powering Off and On 2-5

Page 38

2.2 Powering On the System

1. If your Sun Fire 4810/4800/3800 system is not in a Sun Fire cabinet, skip to Step 3.

For the Sun Fire 6800 system or Sun Fire cabinet, turn on the RTS modules

(

FIGURE 2-8).

It will take 30 seconds to one minute for the RTS modules to power on.

2. Check that all of the circuit breakers on each side of the RTU are on.

Circuit breakers

RTS0 module power switch

FIGURE 2-8 Sun Fire Cabinet RTU Circuit Breakers and RTS Power Switch

3. Turn on the AC input box(es).

FIGURE 4-10 on page 4-14, FIGURE 4-11 on page 4-15,orFIGURE 4-12 on page 4-15.

See

The Sun Fire 3800 system does not have an AC input box.

4. If you have a Sun Fire 3800 system, turn on the power switch located on each

power supply (

FIGURE 2-5).

5. For Sun Fire 6800 system or Sun Fire 4810/4800/3800 systems mounted in a Sun

Fire cabinet, make sure that the rack fan trays are switched on.

This switch is located in the back of the cabinet, below the power cord socket on

each rack fan tray (

FIGURE 2-9).

6. If your Sun Fire 4810/4800/3800 system is not in a Sun Fire cabinet, skip this step.

For Sun Fire 6800 system or Sun Fire 4810/4800/3800 systems mounted in a Sun

Fire cabinet, turn the keyswitch on the FrameManager to the on position

(

FIGURE 2-1).

2-6 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 39

7. Power on the system.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering on the system.

Power switch

FIGURE 2-9 Cabinet Fan Tray Power Switch—Sun Fire 6800 System Rear View

Chapter 2 Powering Off and On 2-7

Page 40

2-8 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 41

CHAPTER

3

FrameManager

This chapter provides procedures for field-replaceable FrameManager units within a

Sun Fire 6800 system cabinet. The following sections are included in this chapter:

■ Section 3.1 “FrameManager Description” on page 3-1

■ Section 3.2 “FrameManager LEDs” on page 3-2

■ Section 3.3 “Replacing the FrameManager” on page 3-2

3.1 FrameManager Description

The FrameManager is a set of hardware and software intergated into the Sun Fire

cabinet and the Sun Fire 6800 system. It performs concurrent monitoring and control

of the

the top front of the cabinet (

FrameManager

fan trays, RTS modules, and RTU assemblies. The FrameManager is located on

FIGURE 3-1).

FIGURE 3-1 FrameManager

3-1

Page 42

3.2 FrameManager LEDs

The LEDs indicate the status of the individual device. The FrameManager has three

LEDs: power, fault, and service (

TABLE 3-1 FrameManager LED Major Functions

LED Function Operation

TABLE 3-1).

Green LED

Amber LED

Amber LED

Power On when the RTS has been commanded to enable

switched power.

Fault On when a fault condition exists in the FrameManager,

fan trays, RTS module, or RTU assembly.

Service

FrameManager, fan trays, RTS module, or RTU assembly

can safely be removed from a powered-on system when

the Service LED (amber) is lit.

3.3 Replacing the FrameManager

1. Loosen the screws at the back of the assembly (FIGURE 3-2).

Note – You may have to remove the two middle screws and reinstall them after you

slide the replacement assembly into place.

Note – Note the current position of the keyswitch before removing the

FrameManager. The replacement FrameManager keyswitch must be in the same

position.

3-2 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 43

FIGURE 3-2 FrameManager Removal—Step 1

2. Slide the assembly forward and carefully flip it onto the top of the cabinet to

access the cable connector on the rear of the assembly (

FIGURE 3-3 FrameManager Removal—Step 2

FIGURE 3-3).

3. Disconnect the five cables from the assembly (FIGURE 3-4).

Chapter 3 FrameManager 3-3

Page 44

FIGURE 3-4 FrameManager Cable Location

4. Remove the assembly from the top of the cabinet.

Caution – Make sure that the keyswitch of the replacement FrameManager is in the

same position as the keyswitch of the removed FrameManager. Not doing so could

cause the system to be inadvertently powered off when the replacement

FrameManager is reconnected to the five cables.

5. Install the replacement assembly by reversing Step 1 through Step 4.

3-4 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 45

CHAPTER

4

Power

This chapter describes how to remove and replace power supplies and the AC input

box. Location information on the RTS modules is also provided.

To protect both yourself and the equipment, make sure you follow the safety

precautions in Chapter 1 “Safety and Tools Requirements.”

This chapter contains the following sections:

■ Section 4.1 “Power Supplies” on page 4-1

■ Section 4.1.1 “Power Supply Slot Locations” on page 4-2

■ Section 4.1.2 “Power Supply LEDs” on page 4-7

■ Section 4.1.3 “Replacing a Sun Fire 6800/4810 System Power Supply” on

page 4-7

■ Section 4.1.4 “Replacing a Sun Fire 4800 System Power Supply” on page 4-9

■ Section 4.1.5 “Replacing a Sun Fire 3800 System Power Supply” on page 4-11

■ Section 4.2 “AC Input Box” on page 4-13

■ Section 4.2.1 “Replacing the AC Input Box” on page 4-16

■ Section 4.3 “Redundant Transfer Unit (RTU) and Redundant Transfer Switch

(RTS)” on page 4-17

■ Section 4.3.1 “Replacing the RTS Modules” on page 4-21

■ Section 4.3.2 “Replacing the RTU Assembly” on page 4-22

4.1 Power Supplies

The Sun Fire 6800 and Sun Fire 4810 systems use the same interchangeable power

supplies. The Sun Fire 4800 system and the Sun Fire 3800 system each have

specialized power supplies that cannot be interchanged with each other or with any

other Sun Fire systems.

4-1

Page 46

Each board in the systems has localized DC-to-DC converters to provide the correct

voltages.

TABLE 4-1 lists the specifications for the power supplies.

TABLE 4-1 Specifications for the Power Supplies

System Type

Sun Fire 6800

Sun Fire 4810

Sun Fire 4800

Sun Fire 3800

Power Supplies

per System

65656

35656

35656

35656

Main Voltage

Output DC

There are four alternating current (AC) power cords for the Sun Fire 6800 system.

There are three AC power cords for the Sun Fire 4810 and the Sun Fire 4800 systems.

Each power supply in the Sun Fire 3800 system has its own power cord. The

software monitors the status of the AC power source. For more information on the

power supplies, see Appendix A.

4.1.1 Power Supply Slot Locations

TABLE 4-2 Power Supply Slot Locations

System Slot Numbers Slot Location Default Slot Numbers

Auxiliary Voltage

Output DC

Sun Fire 6800

Sun Fire 4810

Sun Fire 4800

Sun Fire 3800

PS0 to PS5 Front PS0 to PS5

PS0, PS1, PS2 Front PS0

PS0, PS1, PS2 Front PS0

PS0, PS1, PS2 Rear PS0

The Sun Fire 6800 system has two independent power grids, grid 0 and grid 1. For

the Sun Fire 6800 system, power supplies PS0, PS1, and PS2 are assigned to power

grid 0 and power supplies PS3, PS4, and PS5 are assigned to power grid 1. See

(

FIGURE 4-1).

4-2 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 47

PS0

PS1

PS3

PS4

PS2

FIGURE 4-1 Power Supply Locations—Sun Fire 6800 System—Front View

PS5

Chapter 4 Power 4-3

Page 48

FIGURE 4-2 illustrates the power supplies in power grid 0 and power

grid 1.

PS0

PS1

PS2

PS3

PS4

PS5

Power supplies in power grid 0

FIGURE 4-2 Power Supplies in Power Grid 0 and Power Grid 1—Sun Fire 6800 System

Power supplies in power grid 1

4-4 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 49

In the Sun Fire 4800 and Sun Fire 4810 systems, install the power supplies in this

order: PS0, PS1, and PS2.

PS2

PS0

PS1

FIGURE 4-3 Power Supply Locations—Sun Fire 4800 System—Front View

PS2

PS0

PS1

FIGURE 4-4 Power Supply Locations—Sun Fire 4810 System—Front View

Chapter 4 Power 4-5

Page 50

In the Sun Fire 3800 system, install the power supplies in this order: PS0, PS1, and

PS2.

PS2 PS1 PS0

FIGURE 4-5 Power Supply Locations—Sun Fire 3800 System—Front View

4-6 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 51

4.1.2 Power Supply LEDs

There are three LEDs on each power supply. TABLE 4-3 notes the LED functions.

TABLE 4-3 Power Supply LED Functions

LED Name and Location On Off

Activated LED

(green)

Fault LED

(amber)

OK to remove

LED (amber)

Power supply activated and

operating normally

Internal fault No internal fault

Power supply can be

removed

Power supply deactivated

Power supply cannot be

removed

4.1.3 Replacing a Sun Fire 6800/4810 System Power

Supply

4.1.3.1 Removing a Sun Fire 6800 or Sun Fire 4810 System Power

Supply

1. Power off the appropriate power supply.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures forpowering off the power supply.

Note – When the green Activated LED on the power supply is off (not lit) and the

amber OK to remove LED is on (lit), it is safe to continue. You do not have to power

off the power grids, AC input box, or RTS module(s).

2. Have a power supply filler panel or replacement power supply available.

Chapter 4 Power 4-7

Page 52

3. Loosen the two captive screws (FIGURE 4-6).

Ejector lever

Captive screws

FIGURE 4-6 Removing or Replacing a Power Supply—Sun Fire 6800 System

4. Unlock the ejector by pulling the ejector down.

5. Slide the power supply out.

6. If no replacement, install a power supply filler panel to cover the empty slot.

Tighten the captive screws.

4.1.3.2 Installing a Sun Fire 6800 or Sun Fire 4810 System Power

Supply

1. Remove the power supply filler panel if present.

2. Slide the power supply into the slot (

3. Lock the ejector by pushing the ejector up.

4. Tighten the two captive screws.

Note – Install power supply filler panels to cover any empty slots.

5. Make sure that the appropriate power switch on the AC input box for the new

power supply is on.

6. Turn on the power supply using the system controller software.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering on the power supply.

FIGURE 4-6).

4-8 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 53

Note – Make sure the green Activated LED is on (lit). If the green Activated LED is

not on, check to see if the power supply is seated properly and the power supply is

turned on.

4.1.4 Replacing a Sun Fire 4800 System Power Supply

4.1.4.1 Removing a Sun Fire 4800 System Power Supply

1. Power off the appropriate power supply.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures forpowering off the power supply.

Note – When the green Activated LED on the power supply is off (not lit) and the

amber OK to remove LED is on (lit), it is safe to continue. You do not have to power

off the power grids, AC input box, or RTS module(s).

2. Have a power supply filler panel available.

3. Loosen the two captive screws, one on the top of the power supply and one on the

bottom of the power supply (

FIGURE 4-7).

Chapter 4 Power 4-9

Page 54

Ejectors

Captive screw

FIGURE 4-7 Removing or Replacing a Power Supply—Sun Fire 4800 System

4. Unlock the ejectors by pushing the ejectors outward.

5. Slide the power supply out.

6. If no replacement, install a power supply filler panel to cover the empty slot.

4.1.4.2 Installing a Sun Fire 4800 System Power Supply

1. Remove the power supply filler panel if present.

2. Remove the protective cover from the power supply connector.

3. Hold the power supply vertically, with one hand gripping the bottom of the unit,

and the other hand gripping the handle, (

the chassis until it stops.

FIGURE 4-7) slide the power supply into

4. Lock the ejectors by pushing them inward.

5. Tighten the two captive screws.

6. Make sure that the appropriate power switch on the AC input box for the new

power supply is on.

4-10 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 55

7. Turn on the power supply by using the system controller software.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering on the power supply.

8. Make sure the green Activated LED is lit.

If the green Activated LED is not on, check to see if the power supply is seated

properly and the power supply is turned on.

4.1.5 Replacing a Sun Fire 3800 System Power Supply

4.1.5.1 Removing a Sun Fire 3800 System Power Supply

1. Power off the appropriate power supply.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures forpowering off the power supply.

Note – When the green Activated LED on the power supply is off (not lit) and the

amber OK to remove LED is on (lit), it is safe to continue. You do not have to power

off the power grids, AC input box, or RTS module(s).

2. Have a power supply filler panel available.

3. Loosen the power cable lock strap, and disconnect the power cable from the

power supply.

4. Loosen the two captive screws (

5. Holding the power supply handle, slide the power supply partially out of the

system.

FIGURE 4-8).

Caution – The power supply is heavy, do not remove it completely from the system

while only holding the handle of the power supply.

Chapter 4 Power 4-11

Page 56

6. Holding the power supply with both hands, slide the power supply completely

out of the system.

Captive screws

FIGURE 4-8 Removing or Replacing a Power Supply—Sun Fire 3800 System

7. If no replacement, install a power supply filler panel to cover the empty slot.

Tighten the captive screws.

4-12 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 57

4.1.5.2 Installing a Sun Fire 3800 System Power Supply

1. Remove the power supply filler panel if present.

2. Remove the protective cover from the output connector.

3. Holding the power supply handle with one hand on the handle and the other

hand supporting the base, slide the power supply completely into the system

until it is fully engaged.

4. Tighten the two captive screws.

5. Connect the power cable to the power supply, and secure it with the power cable

lock strap.

6. Toggle the power supply switch to on.

7. Turn on the power supply using the system controller software.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering on the power supply.

8. Make sure the green Activated LED is lit.

Note – Make sure the green Activated LED is on (lit). If the green Activated LED is

not on, check to see if the power supply is seated properly and the power supply is

turned on.

4.2 AC Input Box

There are two AC input box types. The single input type AC input box is in the Sun

Fire 6800 system (

Fire 4810 and Sun Fire 4800 systems. The Sun Fire 3800 system does not have an AC

input box. For the location of the AC input box(es), see

FIGURE 4-11 on page 4-15, and FIGURE 4-12 on page 4-15.

FIGURE 4-9), and the multiple input type AC input box is in the Sun

FIGURE 4-10 on page 4-14,

Chapter 4 Power 4-13

Page 58

FIGURE 4-9 AC Input Box—Sun Fire 6800 System

AC input

box

FIGURE 4-10 AC Input Box—Sun Fire 4800 System

4-14 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 59

FIGURE 4-11 AC Input Box—Sun Fire 4810 System

AC input box

AC input box

FIGURE 4-12 AC Input Boxes—Sun Fire 6800 System—Rear View

AC input box

Chapter 4 Power 4-15

Page 60

4.2.1 Replacing the AC Input Box

4.2.1.1 Removing the AC Input Box

1. Power off the system.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering off the system.

Note – The Sun Fire 4810 and 4800 AC input boxes have three power cord locks

each.

2. Loosen the power cord lock(s).

3. Disconnect the power cord(s).

Caution – Disconnecting the power cord removes system ground.

4. Loosen the two captive screws on the AC input box (

Captive screws

FIGURE 4-13 Two Captive Screws on the AC Input Box—Sun Fire 6800 System

5. Slide the AC input box out of the chassis (FIGURE 4-14).

FIGURE 4-13).

4-16 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 61

FIGURE 4-14 Removing the AC Input Box—Sun Fire 6800 System

4.2.1.2 Installing the AC Input Box

1. Slide the AC input box into the system.

2. Tighten the two captive screws.

3. Connect the power cord to the AC input box.

4. Power on the system.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering on the system.

4.3 Redundant Transfer Unit (RTU) and

Redundant Transfer Switch (RTS)

The Sun Fire 6800 system has two RTUs. Each RTU contains two RTS modules. The

primary configuration is the left RTS module with the right RTS module as

secondary for redundancy. The RTUs function as power sequencers.

Each RTS module within an RTU is connected to a separate power source.

Chapter 4 Power 4-17

Page 62

Note – If two separate AC power sources (primary and secondary) are not available,

and a single AC power source is used, connect ONLY RTS0 (and RTS2 for Sun Fire

6800 systems) to the power source. Connecting all RTSs to a single AC power source

(even if separate circuit breakers are used) is not supported and will adversely affect

reliability.

Unswitched outlet (powered)

Circuit breaker

Switched

outlets

Each RTS module has three LEDs (

FIGURE 4-15 and TABLE 4-4).

The unswitched outlet on each side of the RTU is active only if an RTS is installed on

the same side. If only one RTS is installed, the unswitched outlet on the same side

will have power and the unswitched outlet on the other side will not have power.

These outlets are normally reserved to power the system cabinet fan trays at the top

of the cabinet. If only one RTS is installed then one fan tray must be powered by an

unswitched outlet and the other fan tray by a switched outlet (

LEDs

Unswitched outlet (unpowered)

FIGURE 4-15).

Switched

outlets

FIGURE 4-15 RTU and RTS Modules

4-18 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

RTS0 module

Page 63

TABLE 4-4 describes the RTS LED functions.

TABLE 4-4 RTS LED Functions

LED Position Color Status Meaning

Left

Middle

Right

Green On The source is present and is within specifications.

Off The source either is not present or is below

specifications.

Flashing The source is above specifications.

Green On The module relay is energized and the module is

connected to the outlets.

Off The module relay is de-energized and the module

is seated.

Flashing The module relay is de-energized and the module

is not properly seated.

Amber On The module has a fault.

Off The module does not have a fault.

During a self-test when you power on the system, the LEDs function as described in

TABLE 4-5.

TABLE 4-5 Self-Test LED Functions

LEDs Flashing Pattern Meaning

All

All

Middle

FIGURE 4-16 and FIGURE 4-17 show the location and numbering of the RTS modules.

Three times Self-test is complete

Right, middle, left LED test is complete

Flashing for three seconds Seating test in progress

Chapter 4 Power 4-19

Page 64

RTS0

FIGURE 4-16 RTS Modules—Sun Fire 4810 System—Rear View

RTS1

RTS2

RTS3

Front view

FIGURE 4-17 RTS Modules—Sun Fire 6800 System

4-20 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

RTS0

RTS1

Rear view

Page 65

4.3.1

Replacing the RTS Modules

1. For systems with redundant RTS modules, skip to Step 3.

2. For systems with non-redundant RTS modules, power off the system.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering off the system.

Power off the RTS module that is to be replaced (

3.

Power off the wall circuit breaker connected to the RTS module that is to be

4.

replaced.

Remove the power cord from the RTS module that is to be replaced.

5.

Loosen the screw on the bottom of the RTS module.

6.

RTS modulePower switch (each module)

RTS module screw

FIGURE 4-18

).

FIGURE 4-18

Pull the module straight out.

7.

8.

Install the replacement unit by reversing Step 1 through Step 7.

Ensure proper engagement of the connector in the rear of the module when inserting

the replacement module into the RTU.

RTU Assembly

Chapter 4 Power 4-21

Page 66

4.3.2 Replacing the RTU Assembly

1.

Notify users that the system will be powered off.

2.

Power off the system.

3.

Power off the wall circuit breaker connected to the RTS module(s) that are to be

removed.

Label and remove all cabling.

4.

5.

Remove the RTS module(s), see previous section.

Note – Do not attempt to remove the RTU without first removing the RTS modules.

6. Remove the four screws holding the RTU to the cabinet (

7. Firmly pull out the RTU.

8. Install the replacement RTU Assembly by reversing Step 1 through Step 6.

The assembly is self-aligning.

FIGURE 4-18).

4-22 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 67

CHAPTER

5

Patch Panel

This chapter provides procedures for the field-replaceable patch panel within the

Sun Fire 6800 system cabinet. The following sections are included in this chapter:

■ Section 5.1 “Patch Panel” on page 5-1

■ Section 5.2 “Replacing the Patch Panel” on page 5-2

5.1 Patch Panel

There is one patch panel in the Sun Fire 6800 system cabinet. The patch panel

provides an interface between the system controllers and the system. The patch

panel is located in the rear of the cabinet directly above the AC input boxes and

RTU.

Patch panel

FIGURE 5-1 Patch Panel Location—Rear View

5-1

Page 68

5.2 Replacing the Patch Panel

1. Label and remove all cabling.

2. Loosen the four captive screws.

3. Remove the Patch Panel unit.

4. Install the replacement unit by reversing Step 1 through Step 3.

5-2 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 69

CHAPTER

6

Fan Trays

This chapter describes how to remove and replace fan trays. To protect both yourself

and the equipment, make sure you follow the safety precautions in Chapter 1.

This chapter contains the following sections:

■ Section 6.1 “Fan Tray Slot Numbering” on page 6-2

■ Section 6.2 “Fan Tray LEDs” on page 6-5

■ Section 6.3 “Replacing Fan Trays in Sun Fire 6800/4810/4800 Systems” on

page 6-5

■ Section 6.4 “Replacing Fan Trays in a Sun Fire 3800 System” on page 6-7

■ Section 6.5 “Cabinet Fan Trays” on page 6-9

All systems have multiple fan trays that provide redundant cooling if one fan tray

fails. The Sun Fire 6800 system has four fan trays that collectively cool the system.

The Sun Fire 4810 and Sun Fire 4800 systems have three fan trays that also

collectively cool the system. The Sun Fire 3800 system has four fan trays in the rear

of the system that provide front-to-back cooling. The power supplies of all the

systems have their own fans for internal cooling. The Sun Fire 6800 system and the

Sun Fire cabinet also have two fan trays mounted on top of the cabinets.

6-1

Page 70

6.1 Fan Tray Slot Numbering

TABLE 6-1 lists the fan trays, their slot numbers, and identifies the redundant fan tray

for each system.

TABLE 6-1 Fan Trays and Their Slot Numbers

System Fan Tray Location

Sun Fire 6800 system FT0

FT1

FT2

FT3

Sun Fire 4810 system FT0

FT1

FT2

Sun Fire 4800 system FT0

FT1

FT2

Sun Fire 3800 system FT0

FT1

FT2

FT3

FIGURE 6-1, FIGURE 6-2, FIGURE 6-3, and FIGURE 6-4 illustrate the locations of the fan

Rear

Front

Rear

Front (redundant)

Rear

Rear (redundant)

Front

Rear (redundant)

Front

Rear

Rear (redundant)

Rear

Rear

Rear

trays in each system.

6-2 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 71

FT1

FT3

FT0

FT2

FIGURE 6-1 Front and Rear Fan Trays—Sun Fire 6800 System

FT2

FT0

FIGURE 6-2 Fan Trays—Sun Fire 4810 System

FT1

Chapter 6 Fan Trays 6-3

Page 72

FT0

FT1

FT2

FIGURE 6-3 Fan Trays—Sun Fire 4800 System

FT0

FT2

FIGURE 6-4 Fan Trays—Sun Fire 3800 System

6-4 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

FT1

FT3

Page 73

6.2 Fan Tray LEDs

There are three LEDs on each fan tray. TABLE 6-2 describes the LED functions.

TABLE 6-2 Fan Tray LED Functions

LED On Off

Activated LED

(green)

Fault LED

(amber)

OK to remove

LED (amber)

Device is activated; you cannot

remove the fan tray when this

LED is on.

Internal fault. No internal fault.

Device is deactivated; you can

remove the fan tray when this

LED is on.

Device is deactivated; you can

remove the fan tray when this

LED is off.

Device is activated; you cannot

remove the fan tray when this

LED is off.

6.3 Replacing Fan Trays in Sun Fire 6800/

4810/4800 Systems

6.3.1 Removing a Fan Tray

Caution – Within one minute of removing the fan tray, install a filler panel to

prevent the system from overheating.

1. Make sure you have a replacement fan tray or filler panel available.

2. Power off the defective fan tray.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering off the fan tray.

Note – When the green Activated LED on the fan tray is off (not lit) and the amber

OK to remove LED is on (lit), it is safe to continue.

Chapter 6 Fan Trays 6-5

Page 74

3. If you are removing the top fan tray, FT1, from a Sun Fire 4800 system, remove the

bezel by snapping it off.

4. Loosen the captive screws.

5. Slide the fan tray out (

6. If no replacement, install a filler panel.

Note – For the Sun Fire 4800, only FT0 has a filler panel.

7. Tighten the captive screws.

Captive screw

FIGURE 6-5).

Captive screw

FIGURE 6-5 Removing or Replacing a Front Fan Tray—Sun Fire 6800 System

6.3.2 Installing a Fan Tray

Caution – Within one minute of removing the filler panel, install a fan tray to

!

6-6 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

prevent the system from overheating.

1. Loosen the captive screws on the filler panel.

2. Remove the filler panel and save it.

3. Slide the replacement fan tray into the slot.

Page 75

4. Tighten the captive screws.

If you are installing the top fan tray, FT1, into a Sun Fire 4800 system, replace the

bezel by snapping it on.

5. Turn on the fan tray using the system controller software.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering on the fan tray.

6.4 Replacing Fan Trays in a Sun Fire 3800

System

6.4.1 Removing a Fan Tray

Caution – Within one minute of removing the fan tray, install a replacement or a

filler panel to prevent the system from overheating.

1. Make sure you have a replacement fan tray or filler panel available.

2. Power off the defective fan tray.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering off the fan tray.

3. Wait until the LEDs indicate that the fan tray is ready to be removed.

Note – After powering off the fan tray, the green Activated LED on the fan tray

must be off (not lit) and the amber OK to remove LED must be on (lit). You do not

have to power off the power grids, AC input box, or RTS module(s).

4. Loosen the two captive screws.

Chapter 6 Fan Trays 6-7

Page 76

5. Slide the fan tray out.

FIGURE 6-6 Removing or Replacing a Fan Tray—Sun Fire 3800 System

6. If no replacement, install a filler panel.

7. Tighten the captive screws.

6.4.2 Installing a Fan Tray

Caution – Within one minute of removing the filler panel, install a fan tray to

!

prevent the system from overheating.

1. Loosen the captive screws on the filler panel if present.

2. Remove the filler panel and save it.

3. Slide the fan tray into the slot.

■ Install the two bottom fan trays, FT2 and FT3, with the captive screws on top.

6-8 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Page 77

■ Install the top two fan trays, FT0 and FT1, with the captive screws on the bottom.

The default configuration is three fan trays installed in the order shown in

TABLE 6-3 Default Fan Tray Configuration

Top Left Top Right Bottom Left Bottom Right

Filler panel, FT0 Fan tray, FT1 Fan tray, FT2 Fan tray, FT3

4. Tighten the two captive screws.

5. Turn on the fan tray using the system controller software.

Refer to the Sun Fire Midrange Systems Platform Administration Manual for complete

procedures for powering on the fan tray.

6.5 Cabinet Fan Trays

Two fan trays provide additional cooling for the Sun Fire 6800 system. Both are

located on the cabinet top immediately behind the FrameManager (

TABLE 6-3.

FIGURE 6-7).

Cabinet fan trays

FIGURE 6-7 Cabinet Fan Trays

Chapter 6 Fan Trays 6-9

Page 78

Note – Each RTU has two “unswitched” power outlets (the topmost outlets on each

side of the RTU). By default these unswitched outlets provide power to the fan trays.

If a cabinet has only one RTS installed, then only the associated unswitched outlet

will have power and the remaining fan tray must be connected to one of the

“switched” power outlets.

6.5.1 Replacing the Cabinet Fan Trays

1. Ensure that the power switch is set to off (FIGURE 6-8).

Rear view

Fan trays (2)

FIGURE 6-8 Cabinet Fan Tray Power Switch and Connectors

2. Open the rear door for easier access.

3. Disconnect and then remove the two connectors from the rear of the fan tray

(

FIGURE 6-8).

6-10 Sun Fire 6800/4810/4800/3800 Systems Service Manual • May 2008

Connectors (2)

Page 79

4. Loosen and then remove the two screws from the fan assembly top plate

(

FIGURE 6-9).

Screws (2)

Top plate

FIGURE 6-9 Cabinet Fan Tray Top Plate

5. Remove the fan assembly top plate.

This will reveal two captive screws.

6. Loosen the two captive screws.

7. Remove the fan tray assembly by supporting the fan tray with one hand while

raising the end containing the connectors and then pulling slightly forward.

8. Install the replacement unit by reversing Step 1 through Step 7.

Chapter 6 Fan Trays 6-11

Page 80