Page 1

Sun™Datacenter Switch 3456

Installation Guide

Sun Microsystems, Inc.

www.sun.com

Part No. 820-4730-11

December 2008, Revision A

Submit comments about this document at: http://www.sun.com/hwdocs/feedback

Page 2

Copyright 2008Sun Microsystems,Inc., 4150Network Circle, SantaClara, California95054, U.S.A.All rightsreserved.

Sun Microsystems,Inc. hasintellectual property rightsrelating totechnology embodiedin theproduct that is described in this document. In

particular,and withoutlimitation, theseintellectual property rights may include one or more ofthe U.S.patents listedat

http://www.sun.com/patents and one ormore additionalpatents orpending patentapplications inthe U.S.and inother

countries.Unpublished -rights reservedunder theCopyright Lawsof theUnited States..

This distributionmay includematerials developedby thirdparties.Parts ofthe product maybe derivedfrom BerkeleyBSD systems,licensed

from theUniversity ofCalifornia. UNIXis aregistered trademark in the U.S. and in other countries, exclusively licensed through X/Open

Company, Ltd.

Sun, SunMicrosystems, theSun logo,SunService, andThe Networkis theComputer are trademarksor registered trademarksof Sun

Microsystems, Inc.in theU.S. andother countries.TheOPEN LOOKand Sun(TM)Graphical UserInterface wasdeveloped bySun

Microsystems, Inc.for itsusers andlicensees.

Sun acknowledgesthe pioneeringefforts ofXerox in researchingand developingthe conceptof visualor graphicaluser interfacesfor the

computer industry.Sun holdsa non-exclusivelicense from Xeroxto theXerox Graphical User Interface, which license also covers Sun’s

licensees whoimplement OPENLOOK GUIsand otherwisecomply withSun’s writtenlicense agreements.

Use ofany spareor replacement CPUsis limitedto repairor one-for-one replacementof CPUsin products exportedin compliancewith U.S.

export laws.Use ofCPUs asproduct upgradesunless authorizedby theU.S. Governmentis strictlyprohibited.

DOCUMENTATION IS PROVIDED "AS IS" AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OFMERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT,

ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright ©2008 SunMicrosystems, Inc.,4150 NetworkCircle, Santa Clara, California 95054, Etats-Unis. Tous droits réservés.

Sun Microsystems,Inc. détientles droits depropriété intellectuelsrelatifs à la technologie incorporée dans le produit qui est décrit dans ce

document. Enparticulier,et cesans limitation,ces droits de propriété intellectuellepeuvent inclure un ou plus des brevetsaméricains listésà

l’adresse http://www.sun.com/patent set un ou les brevets supplémentairesou lesapplications debrevet en attente aux Etats - Unis et

dans lesautres pays.Nonpublie -droits réservés selon la législation des Etats-Unis sur le droit d’auteur.

Cette distributionpeut comprendre descomposants développéspar destierces parties.Desparties dece produit pourrontêtre dérivées des

systèmes BerkeleyBSD licenciéspar l’Universitéde Californie.UNIX estune marquedéposée auxEtats-Unis etdans d’autres payset licenciée

exclusivement parX/Open Company, Ltd.

Sun, Sun Microsystems, le logo Sun, SunService, et The Network is the Computer sont des marques defabrique oudes marques déposées de

Sun Microsystems,Inc. auxEtats-Unis etdans d’autres pays.L’interface d’utilisation graphiqueOPEN LOOKet Sun(TM)a étédéveloppée par

Sun Microsystems,Inc. pourses utilisateurset licenciés.

Sun reconnaîtles efforts depionniers deXerox pourla recherche etle développementdu conceptdes interfacesd’utilisation visuelle ou

graphique pourl’industrie del’informatique. Sundétient unelicense nonexclusive deXerox surl’interface d’utilisationgraphique Xerox, cette

licence couvrantégalement leslicenciés deSun quimettent enplace l’interfaced’utilisation graphiqueOPEN LOOKet qui,en outre,se

conforment auxlicences écritesde Sun.

L’utilisationde piecesdetachees oud’unites centralesde remplacement est limitee aux reparations oua l’echangestandard d’unites centrales

pour lesproduits exportes,conformement ala legislationamericaine enmatiere d’exportation. Sauf autorisation par les autorites des EtatsUnis, l’utilisationd’unites centralespour procedera desmises ajour deproduits est rigoureusement interdite.

LA DOCUMENTATION EST FOURNIE "EN L’ETAT" ET TOUTES AUTRES CONDITIONS, DECLARATIONS ET GARANTIES EXPRESSES

OU TACITES SONT FORMELLEMENTEXCLUES, DANSLA MESUREAUTORISEE PARLA LOIAPPLICABLE, YCOMPRIS NOTAMMENT

TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE UTILISATION PARTICULIERE OU A

L’ABSENCE DE CONTREFACON.

Please

Recycle

Page 3

Contents

Preface xi

1. Cautions and Considerations 1

Chassis Weight 1

Moving the Chassis 1

Loading by the Chassis 2

Chassis Activity Dimensions 3

Heat Considerations 3

Air Temperature 3

Surface Temperature 4

Other Objects’ Temperatures 4

Hot and Cold Aisles 4

Electrical Considerations 4

Main Power 4

Bus Power 5

Pin Power 5

2. Partial Configuration 7

Complete and Base Configurations 7

Configuration Considerations 8

iii

Page 4

Filler Panels 8

Line Card Distribution 8

Power Supplies 8

Component Distribution 9

3. Preparing for Installation 11

Final Location Checklists 11

Power Checklist 11

Network Checklist 12

Cabling Checklists 12

Power Cabling Checklist 12

Network Cabling Checklist 12

Spacing Checklist 12

Loading Checklist 13

Environmental Checklist 13

Personnel Checklist 13

Tools Checklists 13

Installation Tools Checklist 14

Administration Tools Checklist 14

Maintenance Tools Checklist 14

Path to Final Location 15

Security Systems 15

Signage 15

Carpets 15

Grades 16

Elevators 16

Doors 16

Thresholds and Gaps 17

Path 17

iv Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 5

Surface 17

Turns 17

Receiving Area 18

Equipment 18

Cleanliness 18

Personnel 18

Number of People 19

Tasks and Roles 19

Mindset 20

Safety 20

Methodical Approach 20

Diligent Attitude 21

Installation and Maintenance Tools 21

Standard Tools 21

4. Installation Sequence 23

Installation Sequence 23

5. Unpacking the Chassis 25

Unpacking the Chassis 25

▼ To Remove Shipping Crate Components 26

▼ To Remove the Plastic Envelope 29

▼ To Fit the Ramp 30

▼ To Unsecure the Chassis 31

▼ To Roll Out the Chassis 32

6. Installing the Chassis 35

Installing the Chassis 35

▼ To Move to the Final Location 35

▼ To Level the Chassis 36

Contents v

Page 6

▼ To Secure the Chassis 39

▼ To Remove the Power Supply Filler Panels 39

▼ To Remove the Line Card Filler Panels 40

▼ To Install the Line Card Filler Panels 41

Inspecting the Chassis 43

▼ To Verify Electrical Leakage 43

▼ To Verify Electrical Continuity 45

7. Inspecting and Repairing Pins 47

Midplane Filler Strips 47

Inspecting Pins 48

Tools 48

▼ To Inspect the Pins on the Rear Side of the Midplane 48

▼ To Inspect the Pins on the Front Side of the Midplane 51

Repairing and Replacing Pins 54

Tools 54

▼ To Remove Pins 54

▼ To Remove a Pin With Needle-Nose Pliers 56

▼ To Insert Pins 57

8. Installing Fabric Cards 59

Fabric Card Considerations 59

Inspecting Fabric Cards 60

▼ To Inspect the Fabric Card iTRAC Connectors 60

▼ To Inspect the Fans 61

▼ To Inspect the Retainers 62

Installing Fabric Cards Into the Chassis 63

▼ To Install the Midplane Stiffener 63

▼ To Install the Fabric Cards 65

vi Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 7

▼ To Remove the Midplane Stiffener 66

Fabric Card Administrative Commands 68

▼ To Enable Fabric Cards 68

▼ To Disable Fabric Cards 68

▼ To Enable Fabric Card IPMB Buses 69

▼ To Disable Fabric Card IPMB Buses 69

▼ To Enable Fabric Card Standby Power 69

▼ To Disable Fabric Card Standby Power 69

▼ To Fully Power On Fabric Cards 70

▼ To Power Down Fabric Cards to a Standby State 70

▼ To Read Fabric Card FRUID Information 70

9. Installing Line Cards 73

Line Card Considerations 73

Inspecting Line Cards 74

▼ To Inspect the Line Card iTRAC Connectors 74

▼ To Inspect the iPASS Connectors 75

▼ To Inspect the Retainers 76

Installing Line Cards Into the Chassis 77

▼ To Install the Line Cards 77

Line Card Administrative Commands 78

▼ To Enable Line Cards 78

▼ To Disable Line Cards 79

▼ To Enable Line Card IPMB Buses 79

▼ To Disable Line Card IPMB Buses 79

▼ To Enable Line Card Standby Power 79

▼ To Disable Line Card Standby Power 80

▼ To Fully Power On Line Cards 80

▼ To Power Down Line Cards to a Standby State 80

Contents vii

Page 8

▼ To Read Line Card FRUID Information 81

10. Powering On 83

Installing Power Supplies 83

▼ To Install Power Supplies 83

Preparing Power Supplies 85

▼ To Attach Power Cables 85

Power Supply Administrative Commands 86

▼ To Power On Power Supplies 86

▼ To Power Down Power Supplies 87

▼ To Verify Power Supply Status 87

Working With CMCs 87

Powering On the CMCs 88

▼ To Cable CMCs to the Management Console 88

▼ To Access the CMC From the Serial Management Port 88

▼ To Access the CMC From the Network Management Port 89

▼ To Verify CMC Status 90

Powering On the Sun Datacenter Switch 3456 91

▼ To Power On the Sun Datacenter Switch 3456 91

11. Cabling the Switch 93

Installing Cable Guides 93

▼ To Install Cable Plates 93

▼ To Remove Cable Plates 94

▼ To Install Cable Trees 95

▼ To Remove Cable Trees 96

▼ To Install Cable Trays 97

▼ To Remove Cable Trays 98

Cabling the Switch 98

viii Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 9

Cable Cautions 99

▼ To Attach Cables to the Sun Datacenter Switch 3456 99

▼ To Remove Cables From the Sun Datacenter Switch 3456 102

▼ To Check Link Status 103

Index 105

Contents ix

Page 10

x Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 11

Preface

This installation guide provides comprehensive instructions for installing the Sun

Datacenter Switch 3456 switch.

This document is written for service personnel, and users who have advanced

knowledge and experience installing and configuring computing machines. Topics

include cautions, preparations, unpacking, and installation tasks.

Using UNIX Commands

This document might not contain information about basic UNIX®commands and

procedures such as shutting down the system, booting the system, and configuring

devices. Refer to the following for this information:

■ Software documentation that you received with your system

■ Solaris™ Operating System documentation, which is at:

http://docs.sun.com

xi

Page 12

Shell Prompts

Shell Prompt

C shell machine-name%

C shell superuser machine-name#

Bourne shell and Korn shell $

Bourne shell and Korn shell superuser #

Typographic Conventions

*

Typeface

AaBbCc123 The names of commands, files,

AaBbCc123 What you type, when contrasted

AaBbCc123 Book titles, new words or terms,

* The settings on your browser might differ from these settings.

Meaning Examples

Edit your.login file.

and directories; on-screen

computer output

with on-screen computer output

words to be emphasized.

Replace command-line variables

with real names or values.

Use ls -a to list all files.

% You have mail.

% su

Password:

Read Chapter 6 in the User ’s Guide.

These are called class options.

Yo u must be superuser to do this.

To delete a file, type rm filename.

Related Documentation

The documents listed as online are available at:

xii Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 13

http://docs.sun.com/app/docs/prod/switch.3456

Application Title Part Number Format Location

Product Notes Sun Datacenter Switch 3456 Product Notes 820-4727-10 PDF Online

Unpacking Sun Datacenter Switch 3456 Unpacking Guide 820-4736-10 PDF

Printed

Site Planning Sun Datacenter Switch 3456 Site Planning Guide 820-4728-10 PDF Online

Installation Sun Datacenter Switch 3456 Installation Guide 820-4730-10 PDF

Printed

Administration Sun Datacenter Switch 3456 Administration Guide 820-4731-10 PDF Online

Service Sun Datacenter Switch 3456 Service Manual 820-4733-10 PDF Online

Reference Sun Datacenter Switch 3456 Reference Manual 820-4734-10 PDF Online

Regulatory Sun Datacenter Switch 3456 Safety and Compliance

Guide

820-4735-10 PDF Online

Shipping crate

Online

Shipping kit

Online

Documentation, Support, and Training

Sun Function URL

Documentation http://www.sun.com/documentation/

Support http://www.sun.com/support/

Training http://www.sun.com/training/

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and

suggestions. You can submit your comments by going to:

http://www.sun.com/hwdocs/feedback

Please include the title and part number of your document with your feedback:

Sun Datacenter Switch 3456 Installation Guide, part number 820-4730-11.

Preface xiii

Page 14

xiv Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 15

CHAPTER

1

Cautions and Considerations

This chapter describes the challenges in preparing the site and installing the Sun

Datacenter Switch 3456. This chapter contains the following topics:

■ “Chassis Weight” on page 1

■ “Chassis Activity Dimensions” on page 3

■ “Heat Considerations” on page 3

■ “Electrical Considerations” on page 4

Note – A hard copy version of the Sun Datacenter Switch 3456 Installation Guide is

shipped inside the switch shipping crate. You can also access the guide at this URL:

http://docs.sun.com/app/docs/prod/switch.3456

Chassis Weight

As shipped, the Sun Datacenter Switch 3456 switch chassis and crate weighs

approximately 1800 pounds (820 kg). This section describes the effects and behavior

of that much mass.

Moving the Chassis

When moving the chassis from the truck to the unpacking area and to the final

location, consider the implications of the chassis weight:

■ Traversing any grade will require additional force and personnel to safely move

the Sun Datacenter Switch 3456.

1

Page 16

■ The Sun Datacenter Switch 3456 casters all swivel freely. The chassis responds to

the greater of applied forces. This means that a person pushing on one corner to

move the chassis will also cause the chassis to rotate. So at least two people

should push equally on adjacent corners to move the Sun Datacenter Switch 3456.

■ When rolling the Sun Datacenter Switch 3456 off of the shipping pallet and down

the shipping ramp, the chassis will catch at the junction of the pallet and ramp,

and will have a tendency to rotate. Expect and prepare for this behavior.

■ To accelerate the Sun Datacenter Switch 3456 to a walking speed requires effort,

time, and distance. To stop the Sun Datacenter Switch 3456 from moving requires

the same or more. To accelerate, transport, or stop a Sun Datacenter Switch 3456

requires slow methodical movement, a clear and safe path, and sufficient

personnel aware of their actions.

Caution – The Sun Datacenter Switch 3456 chassis cannot be safely moved by one

person alone. Never allow any person near the direct path of the Sun Datacenter

Switch 3456. Personnel moving the Sun Datacenter Switch 3456 should consciously

keep their feet away from the bottom edge of the Sun Datacenter Switch 3456,

because this is a pinch point and can cause injury. Personnel moving the Sun

Datacenter Switch 3456 should stand to either side of the chassis or behind its

direction of motion.

Loading by the Chassis

The Sun Datacenter Switch 3456 can only be located on surfaces that can

accommodate its weight. The four casters on the Sun Datacenter Switch 3456 chassis

have a total contact area of 8 square inches or a loading of 225 psi. This load should

not be of concern, if the surfaces or foundations are concrete or reinforced.

Unreinforced wood surfaces cannot support the weight of the Sun Datacenter Switch

3456, and even if only temporary during movement, might flex enough to cause

bottoming out.

Carpeted surfaces might not be able to survive the stress of the Sun Datacenter

Switch 3456 casters, especially when turning. Additionally, movement over carpet is

difficult.

2 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 17

Chassis Activity Dimensions

TABLE 1-1 provides Sun Datacenter Switch 3456 chassis dimensions, and the

minimum dimensions needed for unpacking, moving, and the final location.

TABLE 1-1 Approximate Minimum Chassis Activity Dimensions

Item Length Width Height Comment

Sun Datacenter

Switch 3456

chassis

Unpacking space 35 ft (10.7 m) 10 ft (3 m) 9 ft (2.7 m) To accommodate rollout

Moving perimeter 15 ft (4.6 m) 10 ft (3 m) 6 ft (1.8 m) For stopping distance and

Installation at

final location

Final location 8 ft (2.4 m) 10 ft (3 m) 6 ft (1.8 m) Dimensions outside of

6 ft (1.8 m) 4 ft (1.2 m) 5 ft (1.5 m) Dimensions of chassis.

and crate shell movement

safety margin.

12 ft (3.7 m) 12 ft (3.7 m) 6 ft (1.8 m) To accommodate line card

and fabric card

installation.

cable guides, access space

only.

Heat Considerations

This section describes the heat output of the Sun Datacenter Switch 3456 and its

potential safety hazard for personnel. This section also describes keeping an open

area at the exhaust side, and considerations for other systems and equipment in the

area.

Air Temperature

The calculated approximate air temperature output of the Sun Datacenter Switch

3456 is 36° F (20°C) hotter than the air going in. While this output temperature is not

hot enough to burn, this temperature is sufficient to dehydrate and render useless

any cooling device in the vicinity.

Chapter 1 Cautions and Considerations 3

Page 18

Surface Temperature

During operations, the exhaust surfaces, such as the fans mounted to the fabric

cards, are at a higher temperature than the exhaust air. Bear this situation in mind

when replacing a failed fan, because its temperature will be even greater.

Other Objects’ Temperatures

No object should be in direct contact with the exhaust air. However, occasional

hanging cables or drop lamps might happen to be in the stream. Any objects in the

exhaust air stream will be at an elevated temperature because of this exposure.

Hot and Cold Aisles

The heat output of a fully configured Sun Datacenter Switch 3456 is approximately

40 KW. The Sun Datacenter Switch 3456s’s air mass flow is calculated to

approximately 3400 cfm (1.6 m

switch is 36°F (20°C) degrees hotter than the air going in. As such, the hot aisle for

the Sun Datacenter Switch 3456 should be configured to accommodate this heat

output and in no way compromise the cooling of other equipment. Do not store any

objects in the switch hot aisle. Such objects would interfere with proper air

circulation, and might become a safety hazard.

3

/s), which means that the air exhausted from the

Electrical Considerations

This section describes the voltages present and the exposure to active lines during

component installation.

Main Power

Caution – The 16 Sun Datacenter Switch 3456 power supplies require 200 -240 VAC.

Take all precautions normally associated with these voltages.

4 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 19

Bus Power

Caution – When servicing the Sun Datacenter Switch 3456, bus power is active. Bus

power is a low voltage, but very high current. Even the smallest form of short circuit

can cause physical injury and severe damage to the Sun Datacenter Switch 3456.

Pin Power

Caution – When servicing the Sun Datacenter Switch 3456, pin power and signals

are active. While not a shock or burn threat, there is the possibility of damage to the

pin, midplane, fabric card, and line card, should a short or grounding take place.

Use all precautions associated with working with active signal conductors when

servicing the Sun Datacenter Switch 3456.

Chapter 1 Cautions and Considerations 5

Page 20

6 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 21

CHAPTER

2

Partial Configuration

This chapter describes configuring the Sun Datacenter Switch 3456 with less than a

complete configuration. Topics include:

■ “Complete and Base Configurations” on page 7

■ “Configuration Considerations” on page 8

■ “Component Distribution” on page 9

Complete and Base Configurations

For maximum functionality, the Sun Datacenter Switch 3456 is designed to be

operated in a fully configured state:

■ 24 line cards

■ 18 fabric cards

■ 16 power supplies

■ 2 CMCs

If necessary, fewer components can be installed. For example, the base configuration

of the switch is:

■ 1 line card

■ 18 fabric cards

■ 6 power supplies

■ 2 CMCs

For the base configuration or a partial configuration, filler panels must be installed

where there are empty line card and power supply slots.

7

Page 22

Caution – Do not configure the Sun Datacenter Switch 3456 with fewer than 18

fabric cards installed. Thermal requirements will not be satisfied.

Configuration Considerations

Filler Panels

To maintain proper airflow for adequate cooling, filler panels must be installed in

vacant line card and power supply slots. Besides directing airflow, the filler panels

close openings to the Sun Datacenter Switch 3456 chassis, preventing intrusion of

objects and contaminants to the chassis interior.

Line Card Distribution

Line cards are installed from the center out, across the available slots. The vacant

slots must have filler panels installed. For example, if only 12 line cards are to be

installed, they would occupy slots 6 through 17. Filler panels are installed in the

vacant slots (0 through 5 and 18 through 23).

Power Supplies

Power supplies are configured in a need+1 redundancy. A fully configured Sun

Datacenter Switch 3456 with 24 line cards and 18 fabric cards needs 14 power

supplies. Two power supplies act as redundant, one for each power bus. The power

supply slots are hard-wired to two power buses. Power supplies installed in the

lower row (PS0, PS1, and so on to PS7), provide power to line card slots 0 to 11 and

fabric card slots 9 to 17. Power supplies installed in the upper row (PS8, PS9, and so

on to PS15), provide power to line card slots 12 to 23 and fabric card slots 0 to 8.

8 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 23

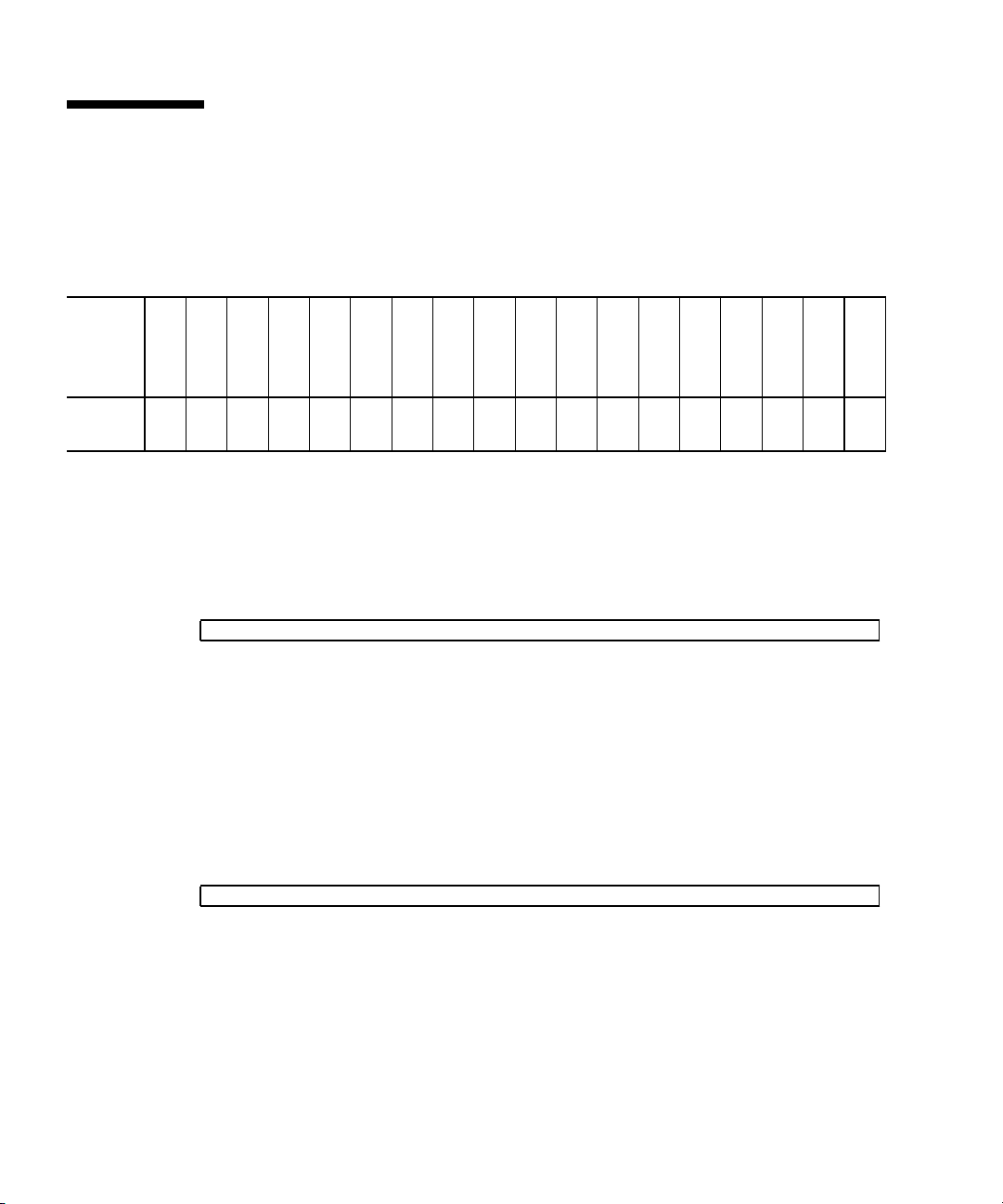

TABLE 2-1 lists the maximum number of line cards that are supported for a given

number of power supplies.

TABLE 2-1 Maximum Quantity of Line Cards for Quantity of Power Supplies

Quantity of Power Supplies Maximum Supported Line Cards

62

86

10 10

12 16

14 20

16 24

Component Distribution

If you are configuring less than a complete Sun Datacenter Switch 3456, you can

incrementally add and distribute line cards and power supplies to the empty slots in

the left-to-right order described by

TABLE 2-2:

TABLE 2-2 Incremental Configuration

1 2 3456789101112131415161718192021222324

Line

Card Slot

Power

Supply

Slots

11 12 10 13 9 14 8 15 7 16 6 17 5 18 4 19 3 20 2 21 1 22 0 23

2, 4, 6, 9,

11, 13

0, 15 7, 8 3, 12 1, 14 5, 10

For example, if you were to configure the switch with only one line card, you would

install the line card into slot 11. You would also install power supplies into slots 2, 4,

6, 9, 11, and 13, in that order.

If you were to configure the switch with ten line cards, you would install the line

cards into slots 11, 12, 10, 13, 9, 14, 8, 15, 7, and 16, in that order. You would also

install power supplies into slots 2, 4, 6, 9, 11, 13, 0, 15, 7, and 8, in that order.

Quantity of Line Cards

Chapter 2 Partial Configuration 9

Page 24

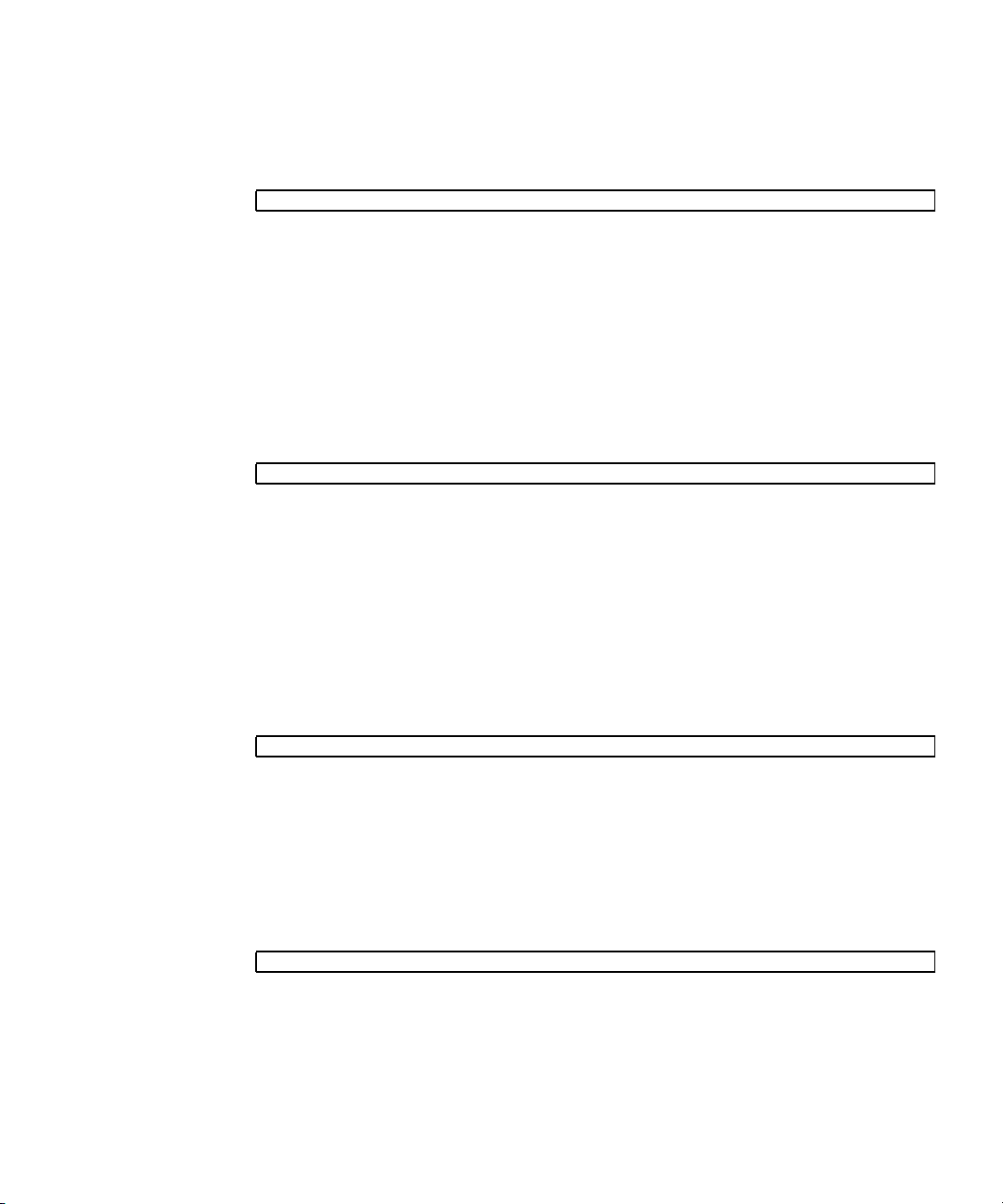

TABLE 2-3 provides suggested configurations, based upon a fraction of the complete

configuration.

TABLE 2-3 Suggested Configurations

Configuratio

n

Quantity

of Line

Cards Line Card Slots Power Supply Slots

Base 1 11 2, 4, 6, 9, 11, 13

1/8 3 11, 12, 10 2, 4, 6, 9, 11, 13, 0, 15

1/4 6 11, 12, 10, 13, 9, 14 2, 4, 6, 9, 11, 13, 0, 15

3/8 9 11, 12, 10, 13, 9, 14, 8, 15, 7 2, 4, 6, 9, 11, 13, 0, 15, 7, 8

1/2 12 11, 12, 10, 13, 9, 14, 8, 15, 7, 16, 6, 17 2, 4, 6, 9, 11, 13, 0, 15, 7, 8, 3, 12

5/8 15 11, 12, 10, 13, 9, 14, 8, 15, 7, 16, 6, 17, 5, 18, 4 2, 4, 6, 9, 11, 13, 0, 15, 7, 8, 3, 12

3/4 18 11, 12, 10, 13, 9, 14, 8, 15, 7, 16, 6, 17, 5, 18, 4, 19,

2, 4, 6, 9, 11, 13, 0, 15, 7, 8, 3, 12, 1, 14

3, 20

7/8 21 11, 12, 10, 13, 9, 14, 8, 15, 7, 16, 6, 17, 5, 18, 4, 19,

3, 20, 2, 21, 1

2, 4, 6, 9, 11, 13, 0, 15, 7, 8, 3, 12, 1, 14,

5, 10

Because the line cards are equally distributed across the available slots, cabling rules

and lengths still apply. See “Cabling the Switch” on page 98 and the Sun Datacenter

Switch 3456 Site Planning Guide .

10 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 25

CHAPTER

3

Preparing for Installation

This chapter describes tasks to be accomplished before actually installing the Sun

Datacenter Switch 3456. Topics include:

■ “Final Location Checklists” on page 11

■ “Path to Final Location” on page 15

■ “Receiving Area” on page 18

■ “Personnel” on page 18

■ “Installation and Maintenance Tools” on page 21

Final Location Checklists

This section includes a checklist that the installers can use to ensure that they are

ready for installation. This checklist covers power, air conditioning, network cabling,

spacing, loading, and other topics.

Power Checklist

■ ____ Are correct power cables used?

■ ____ Is power routed through circuit breakers to code?

■ ____ Is power conditioned before the chassis?

■ ____ Is the power turned off?

■ ____ Has a backup solution been implemented?

11

Page 26

Network Checklist

■ ____ Has the network topology been determined?

■ ____ Has the blueprint been determined?

■ ____ Has the IB support network been configured?

Cabling Checklists

Power Cabling Checklist

■ ____ Have the cables been routed from facility power to backup, through conduits

to breakers to conditioner to switch?

■ ____ Have the cables been labeled for their respective connections?

■ ____ Have the cables been properly bundled?

■ ____ Have the cables been given enough slack for installation?

■ ____ Have appropriate connectors been fitted?

Network Cabling Checklist

■ ____ Have the cables been routed between IB switches and the Sun Datacenter

Switch 3456?

■ ____ Have the cables been labeled for their respective ports?

■ ____ Have the cables been properly bundled?

■ ____ Have the cables been given enough slack for installation?

Spacing Checklist

■ ____ Has enough work area been cleared for receiving the chassis and

components?

■ ____ Is this area clean?

■ ____ Has enough space been allocated for the path to the final location?

■ ____ Are doors set open?

■ ____ Are doors, hallways, and elevators large enough to accommodate the Sun

Datacenter Switch 3456?

■ ____ Are carpets covered with hard surfaces?

■ ____ Are gaps and thresholds appropriately prepared?

12 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 27

■ ____ Is there sufficient spacing at the final location for installation activities?

■ ____ Is there sufficient spacing at the final location for operation and air flow

management?

Loading Checklist

■ ____ Can the final location accommodate the weight of the fully configured

chassis?

■ ____ Can the path to the final location accommodate the weight of the chassis?

■ ____ Have reinforcements to the flooring been installed?

■ ____ Can the elevator accommodate the weight of the chassis?

Environmental Checklist

■ ____ Can the environmental control system support the thermal demands of the

switch?

■ ____ Have additional cooling systems been installed and tested operational?

■ ____ Have the air flow characteristics of the final location been analyzed?

■ ____ Has the air flow management been configured for the Sun Datacenter Switch

3456’s additional heat load?

Personnel Checklist

■ ____ Have the appropriate personnel for installation, administration, and

maintenance been determined?

■ ____ Do the personnel understand their responsibilities?

■ ____ Have the personnel read and understood the Sun Datacenter Switch 3456

documentation respective to their activities?

■ ____ Are the personnel properly equipped for their tasks?

■ ____ Are the personnel available to perform their tasks?

Tools Checklists

Are the tools readily available for installation, administration, and maintenance?

Chapter 3 Preparing for Installation 13

Page 28

Installation Tools Checklist

■ ____ Socket extension

■ ____ Socket

■ ____ Ratchet

■ ____ Small needlenose pliers

■ ____ Phillips screwdrivers

■ ____ Adjustable wrenches

■ ____ Wire strippers

■ ____ Molex pin repair kit

■ ____ Flashlights

■ ____ Gloves

■ ____ Digital multimeter

■ ____ Beam level

■ ____ Scissors

■ ____ Pocket knife or box cutter

Administration Tools Checklist

■ ____ InfiniBand network subnet manager software stack

■ ____ Host server for software stack

■ ____ Server for CMC interface

■ ____ Serial terminal for CMC interface

Maintenance Tools Checklist

■ ____ Socket extension

■ ____ Socket

■ ____ Ratchet

■ ____ Molex pin repair kit

■ ____ Flashlights

■ ____ Gloves

■ ____ Digital multimeter

14 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 29

Path to Final Location

This section address obstructions or hindrances along the route from the unpacking

site to the final location.

Security Systems

The path to the final location might need the Sun Datacenter Switch 3456 to move

through a secure area. Sensors for intrusion, movement, doors opening, and so on,

must be disabled, or else a false alarm might sound.

Consider the impact of the path to the final location on the security of the building.

Are the personnel entering or passing through an area that they are not authorized

to do so?

Consult with the security services before moving the Sun Datacenter Switch 3456.

This way, security is not surprised if intrusion and door alarms are activated.

Additionally, security might be able to provide an alternative route that has less

impact to building security.

Signage

If the path to the final location has high foot traffic, consider posting signs and

providing email informing personnel of the move. This action alerts uninvolved

personnel to avoid the path, which eases the movement of the Sun Datacenter

Switch 3456 and reduces the possibility of complications or injuries.

Carpets

The Sun Datacenter Switch 3456 chassis will not roll on carpet without great effort.

Plan a path to the final location that avoids carpeted areas. If carpeting cannot be

avoided, place sheet metal or masonite panels over the carpeting to make the chassis

roll more easily.

You do not need to place panels on the entire carpeted path. Use enough to support

the chassis and provide the chassis a surface to roll on. For example, if you use 3 ft x

5 ft (0.91 m x 1.52 m) masonite panels, three panels will support the chassis, while a

Chapter 3 Preparing for Installation 15

Page 30

fourth panel can be laid in front of the chassis in the direction of travel. Once the

chassis has rolled off the rear-most panel, lift that panel and move it to the front.

Repeat this process down the path over carpeting.

Grades

The Sun Datacenter Switch 3456 chassis weighs 1433 pounds (650 kg) as shipped.

Any grade along the path requires additional effort to move the chassis, or prevent

the chassis from moving. Do not attempt to move the chassis up or down a grade

greater than 3%.

Additionally, the Sun Datacenter Switch 3456 chassis is equipped with antitilt bars

that are mounted at the centerline. The presence of the bars limits the clearance

movement to 0.5 inch (12 mm). When a chassis peaks a grade of 3% or greater, the

antitilt bars bottom out.

Elevators

If the path to the final location requires use of an elevator, ensure that the elevator

can safely accommodate the weight of the Sun Datacenter Switch 3456 chassis and

the personnel moving it.

The elevator doors must be wide enough to allow the Sun Datacenter Switch 3456 to

pass, ideally with personnel alongside. The doors might need to be held open, either

physically, or by pressing the door open button within the elevator.

Verify that the threshold at the elevator doors permits the chassis to enter and exit

the elevator. The gap between the floor and elevator should not be too large, nor

should there be any height difference. Check this gap at both the entering and

exiting floors. If there are any minor discrepancies, a metal sheet or masonite panel

can be used to compensate.

Doors

Doors must open wide enough to accommodate the Sun Datacenter Switch 3456

chassis and personnel alongside. Additional personnel can hold doors open, or the

doors can be securely propped open using wedges or catches. Do not hold doors

open with chairs or other easily available objects. Such objects do not guarantee a

secure door and can diminish the space for moving the chassis.

16 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 31

Thresholds and Gaps

The path to the final location might have building expansion joint gaps, carpet

runners, door thresholds, or other inconsistencies in an otherwise smooth surface.

When these obstructions cannot be avoided, use metal plates or masonite panels to

compensate for the irregularities. If a gap is too great, or a threshold too high, the

panel might break. In this situation, an alternative path to the final location must be

found.

Path

Surface

The path, regardless of surface, should be clean and free of any obstructions.

Obstructions include trash, cables, fasteners (screws, nuts, paper clips, thumbtacks,

tie wraps, and so on), any scrap (pencils, pens, papers, and so on), or small object

that might hinder movement. A quick sweeping of the path to the final location

before moving the Sun Datacenter Switch 3456 can remove most objects that might

later prove troublesome.

Turns

Ensure that any turns in the path to the final location allow unhindered movement

of the chassis. Avoid narrow hallways and tight turns, because they create

opportunities for injury.

Check the path before moving the Sun Datacenter Switch 3456. If you are in doubt of

the chassis’ ability to navigate a certain section of a building, a make-shift

framework, constructed of duct-taped sticks for example, can give an idea of the

path’s viability. Walk the framework through the path to the final location. If there is

any situation where the framework binds, then the chassis will also.

If a tight turn cannot be avoided, consider adding protection to the walls of the

inside corners of the turn. Additionally, consider adding protection to the corners of

the Sun Datacenter Switch 3456 chassis.

Chapter 3 Preparing for Installation 17

Page 32

Receiving Area

This section lists the equipment used in the receiving area or loading dock and the

condition and state of the area.

Equipment

To receive and unpack the Sun Datacenter Switch 3456, the following equipment is

required.

■ Forklift or pallet jack rated for at least 2000 lbs

■ Large flat-blade screwdrivers (one for each person unpacking)

■ Claw hammer (one for each person unpacking)

■ Adjustable wrench (two for each person unpacking)

■ Scissors

■ Gloves (for each person unpacking)

■ Bin for parts collection

Cleanliness

The unpacking area must be clean and uncluttered. Personnel will be working

closely and activity. The personnel must be free to move about without distraction or

the possibility of tripping or slipping.

The task of unpacking produces packing material waste and wood shavings. This

debris should be removed and swept away before the chassis is rolled out.

After rollout, the crate can be reassembled and stored. The unpacking area should be

swept again.

Personnel

This section describes the personnel needed for the installation, what their tasks are,

and their mindset.

18 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 33

Number of People

The minimum number of people involved with the installation of the Sun Datacenter

Switch 3456 is two. Many tasks involve two people to maintain safety. While some

tasks only require one person, three people is ideal as it provides redundancy in

some situations and makes many tasks easier. Four people can make a couple of

tasks very easy. Yet in most situations, four or more people are detrimental, as they

might end up interfering with each other’s work.

Tasks and Roles

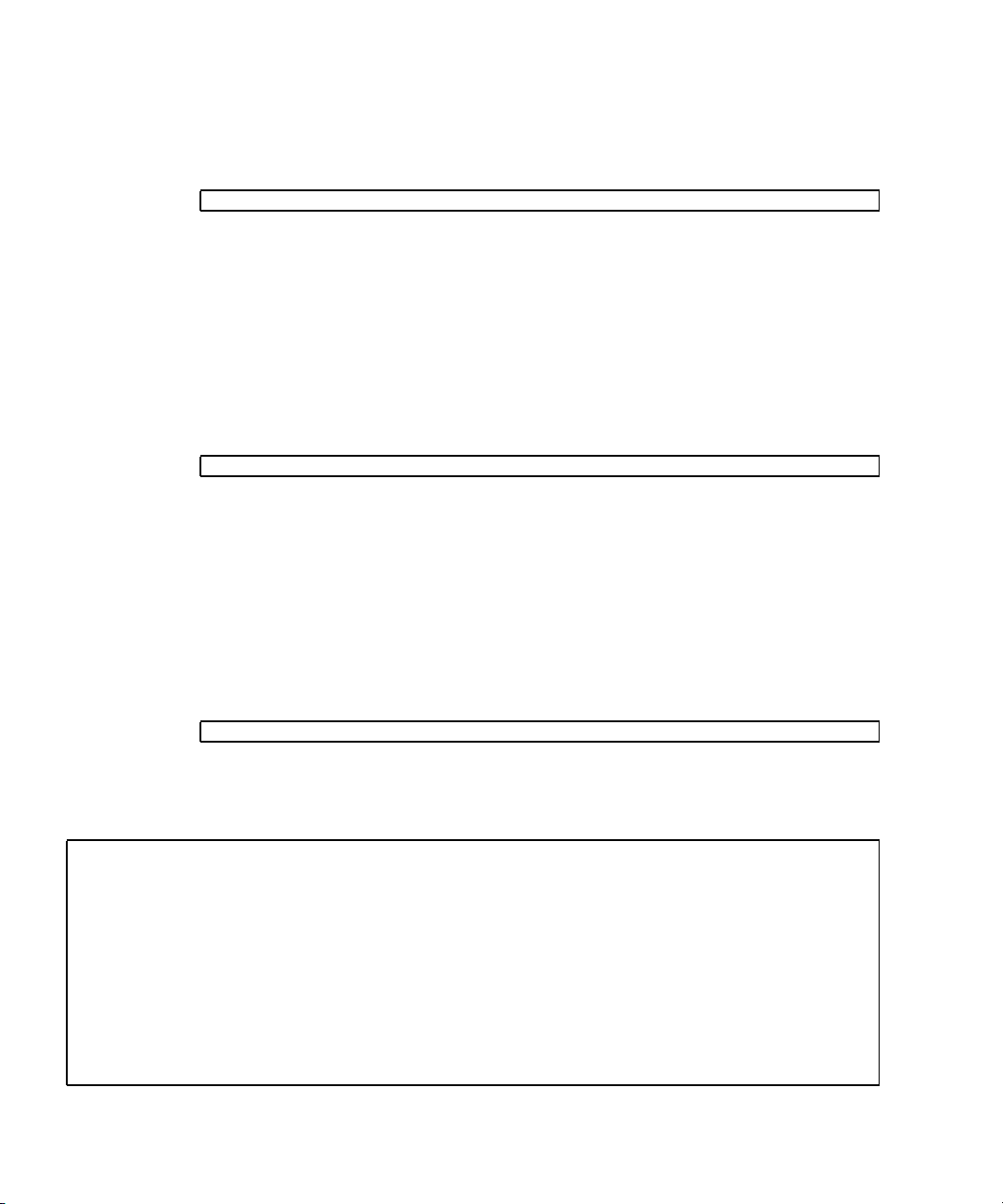

TABLE 3-1 describes the tasks involved with installing the Sun Datacenter Switch

3456, the ideal number of people, and their roles for that task.

TABLE 3-1 Tasks and Roles

Task

Unloading crate from truck 1 Only one person can operate a forklift or pallet jack.

Moving crate to unpacking area 2 The operator of the forklift or pallet jack, and another person to

Unpacking Sun Datacenter Switch

3456

Moving Sun Datacenter Switch

3456 to final location

Inspecting chassis 4 One person can accomplish this task, but a person at each corner

Inspecting pins 2 One person can accomplish this task, but a person on each side can

Cabling chassis management

controller (CMC)

Cabling power supplies 2 One person can accomplish this task. Two people, working from the

Installing fabric cards 2 The synchronized procedures of installing the fabric cards requires

No. of

People Roles for Task

offer guidance and feedback when moving the crate.

4 Two people can do this task, however, more people can speed up

the tasks. Additionally, tasks can happen at the four corners of the

chassis in parallel.

3 At least two people, one to push, the other to steer. With three

people, one pushes, the other two push and steer. With four, all

push and steer. Additionally, a non-pushing person can handle

situations that might need correction, such as a propped door

coming loose or caterpillaring the panels over carpet.

can speed things up greatly.

speed things up greatly.

1 A simple cable connection requires only one person.

outer sides to the center, can speed up the task.

two people for lifting the cards into place. Insertion is better

handled by two people, though one person can accomplish the task.

Chapter 3 Preparing for Installation 19

Page 34

TABLE 3-1 Tasks and Roles (Continued) (Continued)

Task

Installing line cards 2 The synchronized procedures of installing the line cards requires

Running diagnostics 1 Only one person is needed.

Cabling line cards 4 One person can achieve this task, though it can be greatly

Administration 1 Only one person is needed.

Servicing fans, power supplies,

and CMCs

Servicing fabric and line cards 2 The synchronized procedures of removing and installing the cards

Maintenance 1 A service or maintenance person performs tasks that only need one

No. of

People Roles for Task

two people for lifting the cards into place. Insertion is better

handled by two people, though one person can accomplish the task.

accelerated if two teams work on opposite ends of the chassis,

working towards each other. One team member can route the IB

cables through the guides, while the other person secures the

connectors.

1 The components can be easily replaced by one person.

requires two people for lifting the cards into place. Insertion and

ejection are better handled by two people, though one person can

accomplish the task.

person.

Mindset

Because of the cost and importance of the Sun Datacenter Switch 3456, the personnel

installing the switch must have a certain mindset.

Safety

The Sun Datacenter Switch 3456 is heavy. Moving it might cause injury and damage

to property. The personnel must be attentive to their own and others’ actions. The

personnel must be focused. The personnel must understand the purpose of their task

and responsibility that goes with it.

Methodical Approach

The Sun Datacenter Switch 3456 is complex and delicate. Processes described in this

documentation have been developed from actual installation experiences. There are

no shortcuts or optional tasks. Procedures are to be done exactly as described. The

personnel should realize the time for procedures and be willing to commit that time.

20 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 35

Any situation that doesn’t look right, operation that doesn’t function smoothly, or

behavior that is not as expected, must be investigated immediately.

Check and recheck your work. Unknowingly making a mistake yet correcting it is

permissible and good practice. Covering up a known uncertainty can cause serious

damage.

Diligent Attitude

Many of the procedures for installation might require repeated efforts. There might

be situations that mean undoing tasks that were accomplished hours ago. The

personnel installing the Sun Datacenter Switch 3456 must realize the importance of

correctly installing the switch.

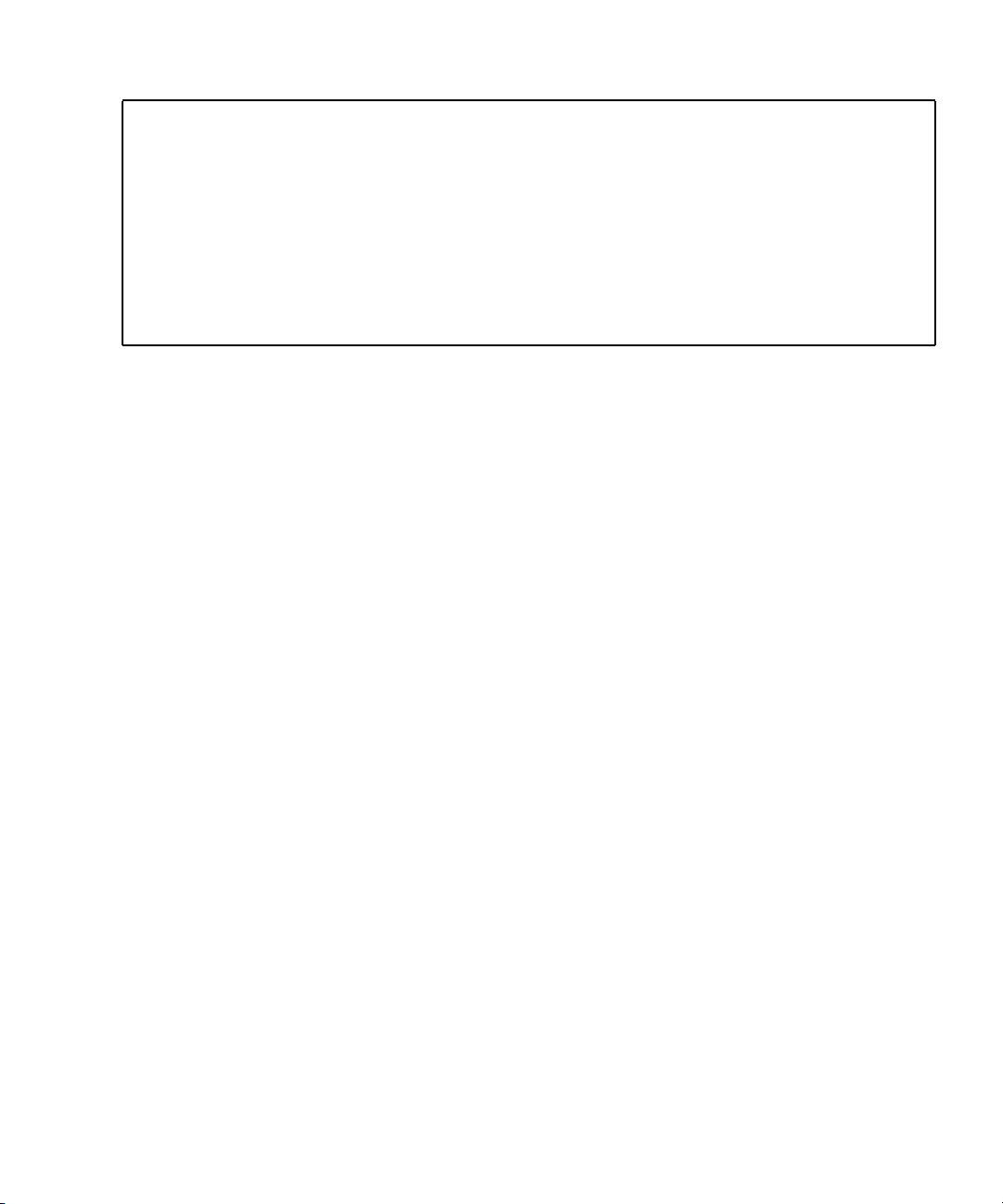

Installation and Maintenance Tools

This section lists the tools to be used for the installation.

Standard Tools

TABLE 3-2 describes the tools required for the installation and maintenance of the Sun

Datacenter Switch 3456.

TABLE 3-2 Standard Tools for Installation

Tool Purpose

Socket extension Extends reach of socket to the line and fabric cards, especially when the

Sun Datacenter Switch 3456 is fully configured.

Socket Inserts and ejects line and fabric cards from the chassis.

Ratchet Drives the socket and extension.

Claw hammer For uncrating the chassis.

Small needle

nose pliers

Phillips

screwdrivers

Flat-blade

screwdrivers

For straightening bent pins and handling small items.

To tighten and loosen Phillips screws.

To pry klimp fasteners and for basic utility.

Chapter 3 Preparing for Installation 21

Page 36

TABLE 3-2 Standard Tools for Installation (Continued) (Continued)

Tool Purpose

Adjustable

Removing nuts, bolts, and other packing hardware.

wrenches

Molex pin repair

To repair or replace broken, bent, or damaged midplane pins.

kit

Flashlights For inspecting pins, connectors, and chassis fittings.

Gloves To protect hands during unpacking and moving.

DMM To check continuity and leakage during installation.

Beam level To level the Sun Datacenter Switch 3456 chassis.

22 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 37

CHAPTER

4

Installation Sequence

This chapter outlines the sequence of events that occur to receive the Sun Datacenter

Switch 3456, uncrate it, transport it to the final location, inspect the chassis, install

components, attach power, cable it, and begin administration.

■ “Installation Sequence” on page 23

Installation Sequence

TABLE 4-1 describes the installation task sequence and provides cross-references to

those procedures.

TABLE 4-1 Sun Datacenter Switch 3456 Installation Sequence

Step Task Cross-Reference

1 Remove the Sun Datacenter Switch 3456 from its crate. “Unpacking the Chassis” on page 25

2 Remove the fabric cards, line cards, and cabling hardware

from their boxes.

3 Transport the Sun Datacenter Switch 3456 to the final location. “To Move to the Final Location” on page

35

4 Level the chassis. “To Level the Chassis” on page 36

5 Secure the chassis. “To Secure the Chassis” on page 39

6 Remove the filler panels (if installed). “To Remove the Power Supply Filler

Panels” on page 39

“To Remove the Line Card Filler Panels”

on page 40

7 Inspect the chassis. “Inspecting the Chassis” on page 43

23

Page 38

TABLE 4-1 Sun Datacenter Switch 3456 Installation Sequence (Continued)

Step Task Cross-Reference

8 Inspect midplane back pins. Repair or replace them if

necessary.

“Inspecting Pins” on page 48

“Repairing and Replacing Pins” on page

54

9 Install midplane stiffener. “To Install the Midplane Stiffener” on

page 63

10 Install fabric cards. Chapter 8

11 Remove midplane stiffener. “To Remove the Midplane Stiffener” on

page 66

12 Inspect midplane front pins. Repair or replace them if

necessary.

“Inspecting Pins” on page 48

“Repairing and Replacing Pins” on page

54

13 Install line cards. Chapter 9

14 Install filler panels in any vacant slots. “To Install the Line Card Filler Panels” on

page 41

15 Install cable trees and cable plates. “Installing Cable Guides” on page 93

16 Install additional power supplies. “To Install Power Supplies” on page 83

17 Attach power cables. “Preparing Power Supplies” on page 85

18 Configure the CMC. “Working With CMCs” on page 87

19 Power up the power supplies. “Powering On the Sun Datacenter Switch

20 Power on the fabric cards and line cards.

3456” on page 91

21 Verify component status.

22 Bring cables to the switch.

23 Install the first line card cable tray in the lowest slot. “To Install Cable Trays” on page 97

24 Cable first line card. “Cabling the Switch” on page 98

25 Repeat Step23 for remaining line cards, working your way up.

26 Check link status. “To Check Link Status” on page 103

24 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 39

CHAPTER

5

Unpacking the Chassis

This chapter describes unpacking the Sun Datacenter Switch 3456 chassis.

Unpacking the Chassis

The chassis unpacks from the shipping crate perpendicular to the long edge of the

shipping crate. A rectangular area, approximately 10 by 20 feet (3 by 6 meters) is

needed for unpacking the chassis.

crate should be oriented to the area for unpacking.

FIGURE 5-1 shows where and how the shipping

FIGURE 5-1 Shipping Crate in Unpacking Area

25

Page 40

▼ To Remove Shipping Crate Components

The shipping crate separates into seven pieces; two shells, two ramps, a cap, a

sub-cap, and a pallet.

1. Using the scissors or knife, cut the straps that secure the cap and shells to the

pallet.

2. Lift the cap from the shells.

See

FIGURE 5-2.

FIGURE 5-2 Lifting the Cap From the Shells

Note – The sub-cap is flush with the shells and is removed with the shells, not the

cap.

3. Release the shells from eachother

FIGURE 5-3.

See

26 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 41

FIGURE 5-3 Releasing the Shells From Eachother

4. Seperate the shells and the sub-cap from the pallet.

FIGURE 5-4.

See

Chapter 5 Unpacking the Chassis 27

Page 42

FIGURE 5-4 Separating the Shells and Sub-Cap From the Pallet

5. Remove the two bolts securing the each ramp to the pallet, then set the ramps

and bolts aside.

See

FIGURE 5-5.

FIGURE 5-5 Removing the Ramps

28 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 43

6. Remove the documentation and shipping kit from the pallet.

▼ To Remove the Plastic Envelope

● Using the scissors, carefully cut the plastic envelope around the perimeter of

the chassis at the base.

See

FIGURE 5-6.

FIGURE 5-6 Cutting the Plastic Envelope

Note – Pull out on the envelope as you cut, so that you do not damage the chassis

surface.

▼ To Fit the Ramp

● Attach the ramps to the side of the pallet

FIGURE 5-7.

See

Note – Ensure that the guides on the ramps are towards the center.

Chapter 5 Unpacking the Chassis 29

Page 44

FIGURE 5-7 Fitting the Ramp to the Pallet

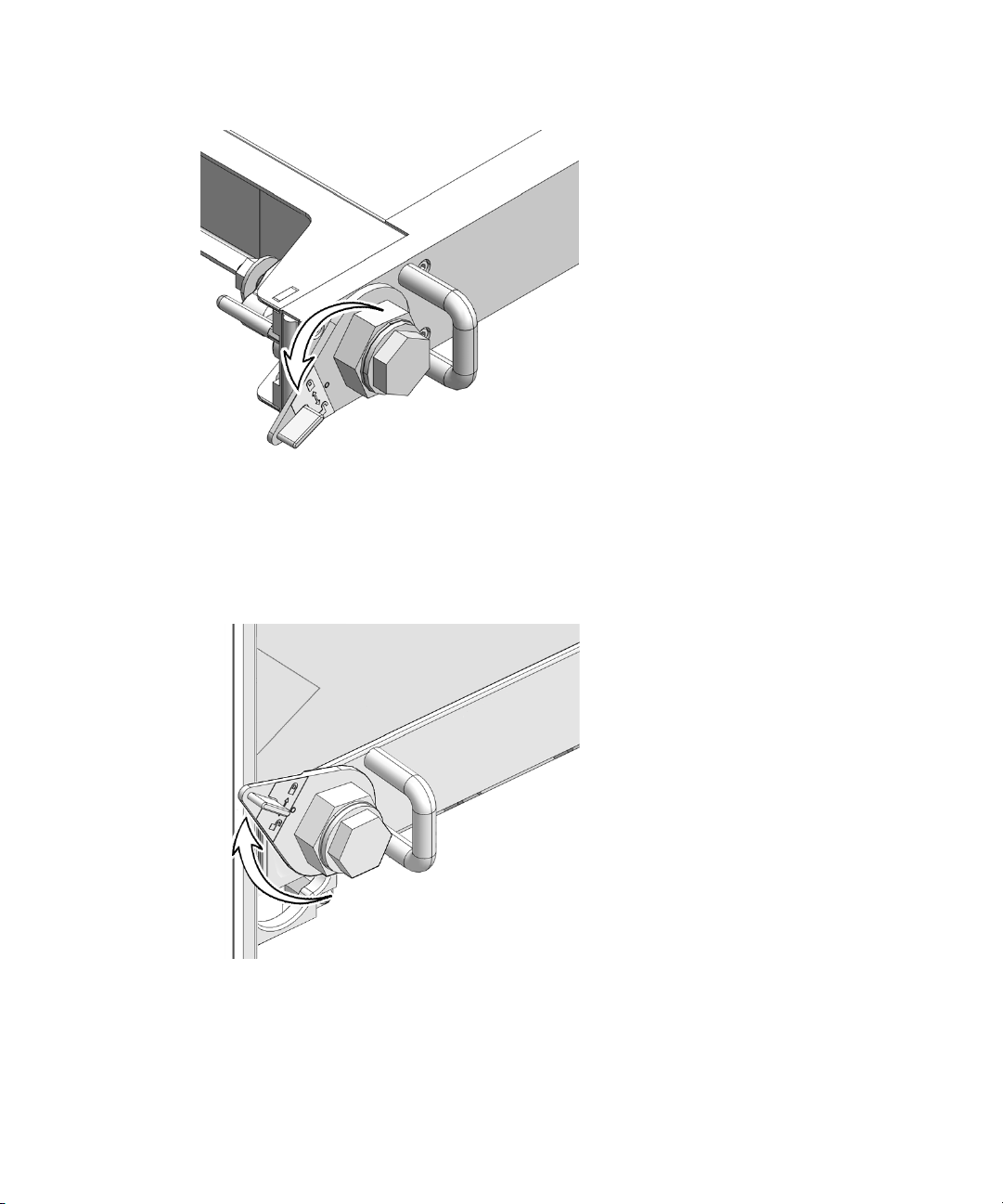

▼ To Unsecure the Chassis

1. Use the adjustable wrenches to remove the bolts securing the corner brackets to

the pallet.

See

FIGURE 5-8.

FIGURE 5-8 Removing the Bracket Securing Bolts

2. Prepare the corner brackets for transport.

30 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 45

a. Loosen the screws that secure the brackets to the chassis.

FIGURE 5-8.

See

b. Raise the brackets all the way.

c. Tighten the screws to secure the brackets to the chassis.

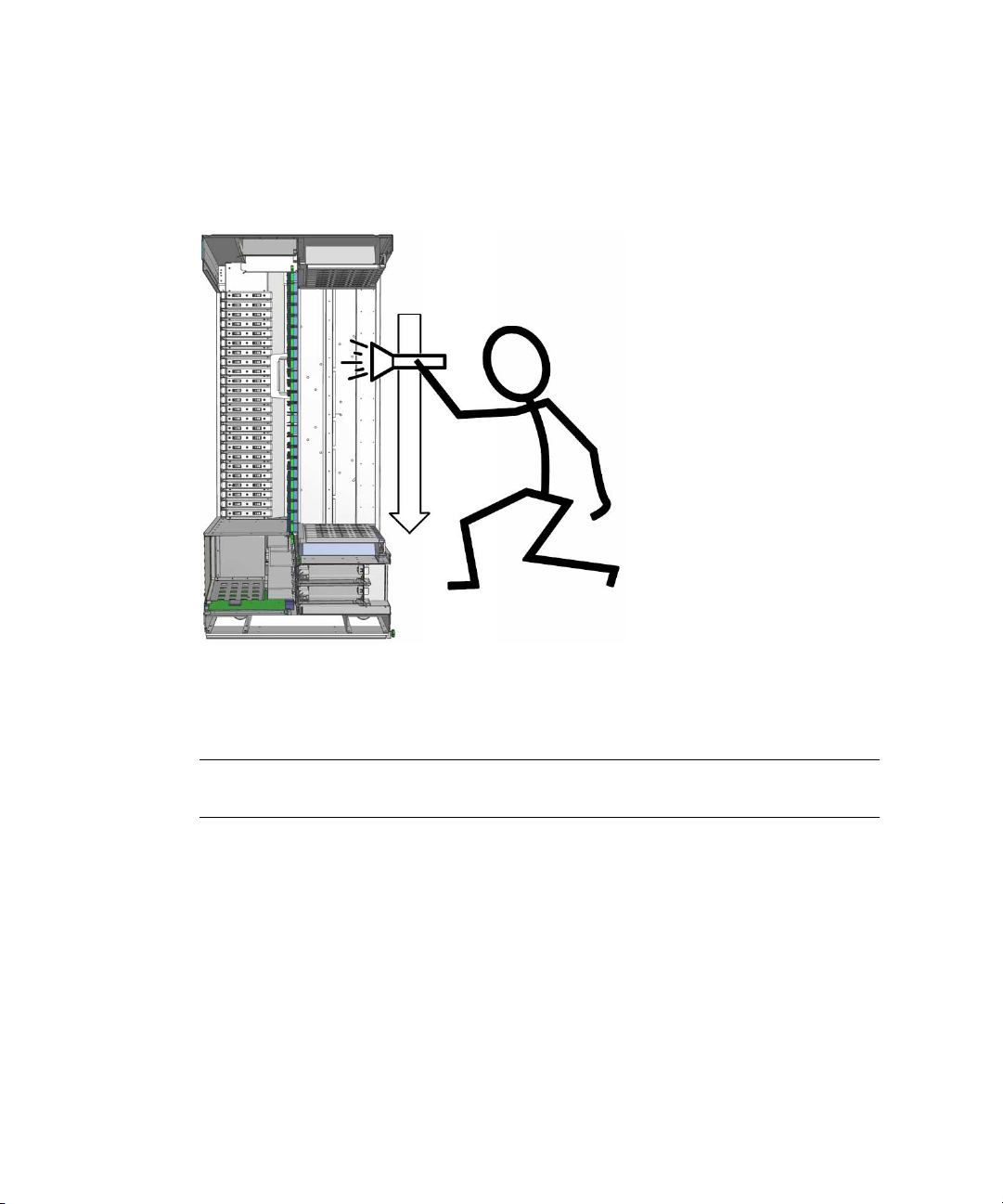

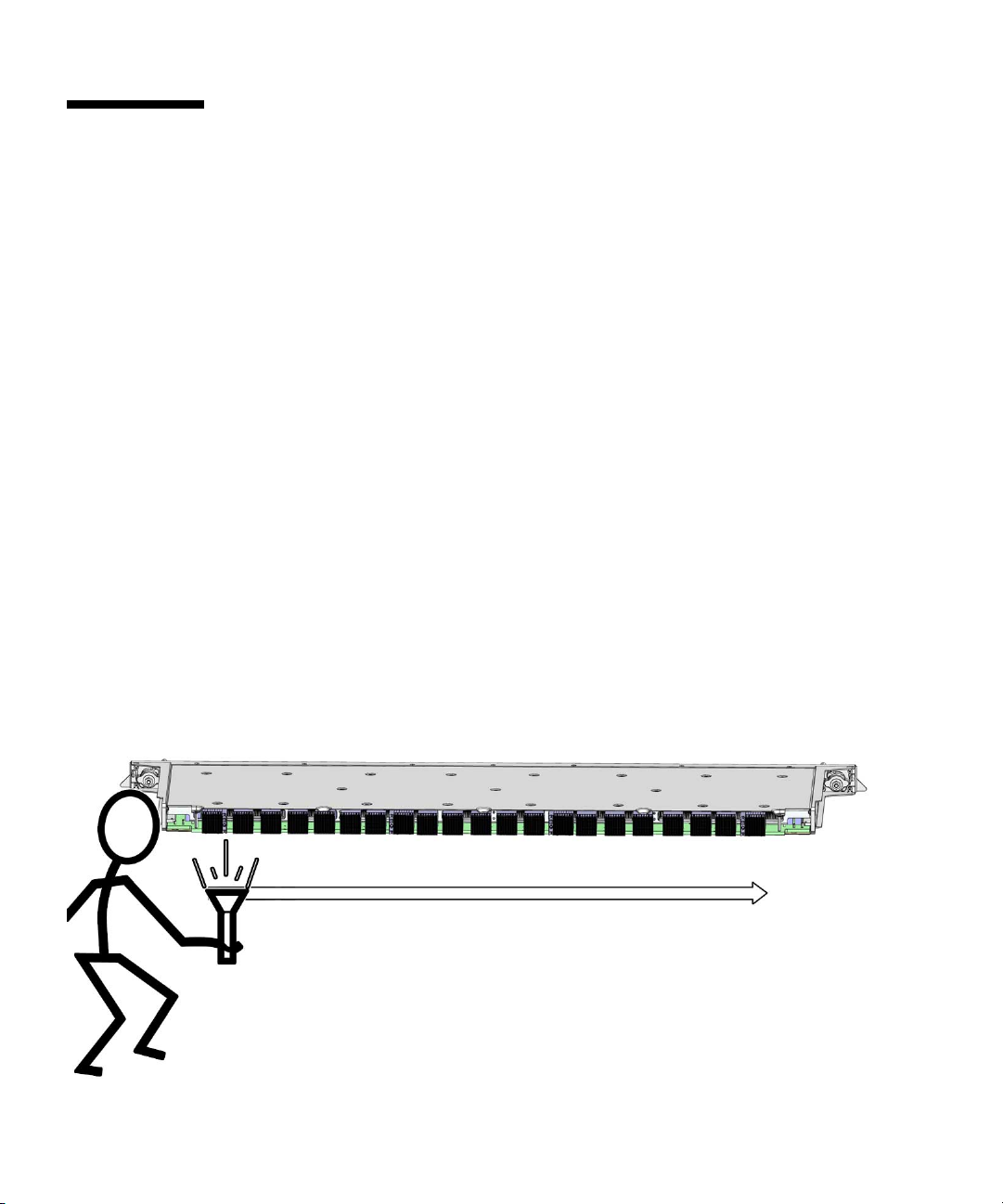

▼ To Roll Out the Chassis

1. Ensure that the floor space up to 5 feet (1.5 m) from the end of the ramp is clear.

2. Prepare the personnel.

■ One person (pusher) will push the chassis off the pallet from the end opposite

the ramps.

■ One person (guider) at the left of the chassis (left side of ramps) will guide the

chassis off the pallet and brake its roll down the ramps.

■ One person (guider) at the right of the chassis (right side of ramps) will guide

the chassis off the pallet and brake its roll down the ramps.

See

FIGURE 5-9.

Chapter 5 Unpacking the Chassis 31

Page 46

FIGURE 5-9 Rolling Out the Chassis

3. The pusher begins the rollout as the guiders steer the chassis.

Halfway off the pallet, the chassis might bottom out on the pallet edge because of

the antitilt bar. In this situation:

a. The pusher continues to push, flexing the pallet load surface with the

pusher’s weight.

b. The guiders move the chassis side-to-side in a concerted fashion.

Once the antitilt bar has cleared the pallet edge, the chassis will begin rolling

down the ramps under its own weight.

4. The pusher stops pushing and moves to the end of the ramps to assist the

guiders.

5. The guiders control the descent of the chassis down the ramps and onto the

floor.

Note – Though not recommended, rollout is possible with just two people. At Step

b, the guider must repeatedly switch sides until the chassis moves free. Additionally,

the pusher will take the side opposite the guider in Step 4.

6. (Optional) Reassemble the crate.

a. Remove the ramps from the side of the pallet.

32 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 47

b. Lay the ramps and their bolts onto the pallet.

c. Return the shells to the pallet and secure them together.

d. Set the sub-cap into the shells.

e. Set the cap onto the shells.

Chapter 5 Unpacking the Chassis 33

Page 48

34 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 49

Chapter 5 Unpacking the Chassis 35

Page 50

CHAPTER

6

Installing the Chassis

This chapter describes procedures for installing and inspecting the Sun Datacenter

Switch 3456 chassis. Topics include:

■ “Installing the Chassis” on page 35

■ “Inspecting the Chassis” on page 43

Installing the Chassis

This section describes getting the chassis to the final location.

▼ To Move to the Final Location

This procedure assumes that you have the final location ready for receiving the Sun

Datacenter Switch 3456 chassis, and that the chassis has been unpacked from the

shipping crate.

1. Walk the path to the final location.

■ Prop open any doors that must be passed.

■ Take preparatory steps if security must be overridden.

■ Post signs for directions and information for others not involved with the

movement.

■ Sweep the path and check the floor surfaces for objects that might hinder

movement, and remove those objects.

■ Check for folds or loose ends of carpeting (if traveling over carpeting).

■ Have metal sheets or masonite panels ready for thresholds, gaps, or carpeting.

■ Remove any obstructions from the path.

35

Page 51

■ Check the elevators in path, if any.

2. Verify that the leveling feet are in the fully raised position.

3. With one person as the pusher and at least one other person as a guider, begin

moving the chassis on the path.

Caution – The guider can cross to either side of the chassis, but should never

remain in the path of motion.

4. Move the chassis as slow as reasonably possible.

Note – When approaching intersections, doorways, or places where interaction with

others or collision might occur, announce your presence.

5. When you arrive at the final location, position the chassis for leveling and

securing.

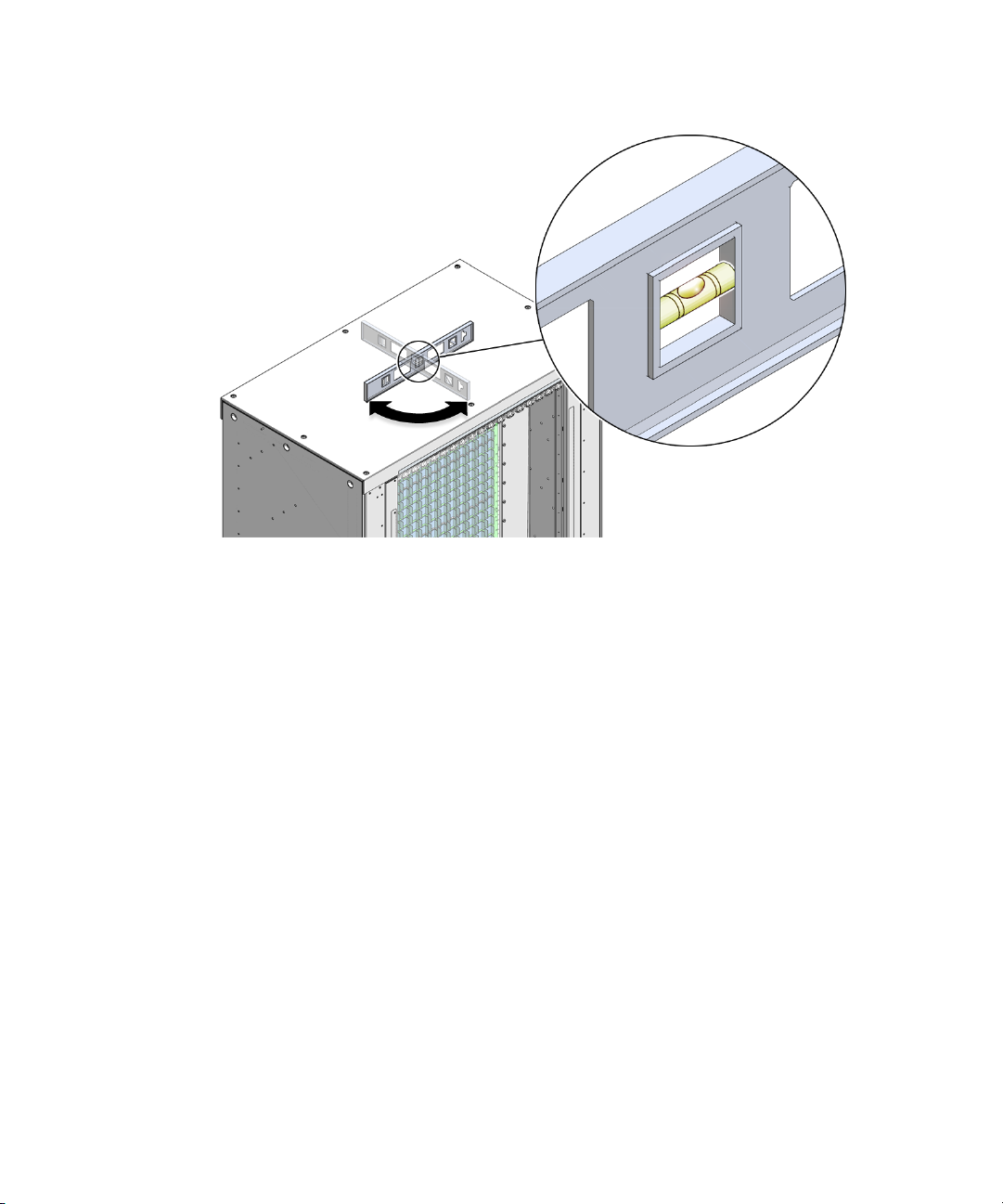

▼ To Level the Chassis

Once the chassis is at the final location, you must level the chassis. The chassis does

not need to be perfectly level. However, the load borne by the casters should now be

distributed between the casters and the leveling feet.

Note – The directions indicated in this procedure are referenced from the front or

line card side of the chassis.

1. Position the Sun Datacenter Switch 3456 in the final location.

2. Using the adjustable wrench, lower the first leveling foot so that it contacts the

floor and you begin to feel resistance.

See FIGURE 6-1.

36 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 52

FIGURE 6-1 Lowering the Feet

3. Repeat Step 2 for each leveling foot.

4. Lower each foot two additional turns.

5. Place a beam level at the center of the chassis, running right to left.

See

FIGURE 6-2.

Chapter 6 Installing the Chassis 37

Page 53

FIGURE 6-2 Setting the Level

6. Note the position of the bubble.

7. Rotate the beam level 90 degrees, now running front to rear.

See

FIGURE 6-2.

8. Note the position of the bubble.

9. Consider your next step:

■ If the bubble favored the right and the front, raise the right front foot or lower

the left rear foot.

■ If the bubble favored the right and the rear, raise the right rear foot or lower

the left front foot.

■ If the bubble favored the left and the front, raise the left front foot or lower the

right rear foot.

■ If the bubble favored the left and the rear, raise the left rear foot or lower the

right front foot.

10. Adjust the appropriate leveling foot.

11. Repeat Step 5 to Step 10 until the chassis is level.

■ If the adjustment causes a caster to lift from the floor, go to Step 12.

■ If the adjustment causes a foot to lift from the floor, go to .

■ Otherwise, go to Step 19.

38 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 54

12. Raise all feet equally by one quarter turn.

13. Repeat Step 12 until the caster seats.

14. If completing Step 13 makes the chassis unlevel, stop.

15. Go to Step 19.

16. Lower all feet equally by one quarter turn.

17. Repeat Step 16 until the foot seats.

18. If completing Step 17 makes the chassis unlevel, stop.

19. The present state is sufficient.

▼ To Secure the Chassis

Some building codes might require securing the Sun Datacenter Switch 3456 to its

final location. You can use the brackets removed when unpacking to help secure the

Sun Datacenter Switch 3456 to the floor.

1. Using an adjustable wrench, loosen the screws securing the corner brackets to

the chassis.

2. Using the brackets as a template, mark the floor for fastener locations.

3. Remove the corner brackets.

4. Prepare the floor as appropriate for building codes.

5. Reattach the corner brackets to the chassis.

6. Secure the brackets to the floor, using washers or shims where appropriate.

▼ To Remove the Power Supply Filler Panels

The Sun Datacenter Switch 3456 ships with power supply filler panels installed. If

power supplies are to be installed, the filler panels should be removed first.

1. Swing the release lever of the power supply filler panel out and to the right.

2. Pull the handle of the filler panel to remove it from the chassis.

3. Set the filler panel aside.

4. Repeat from Step 1 for all remaining filler panels.

Chapter 6 Installing the Chassis 39

Page 55

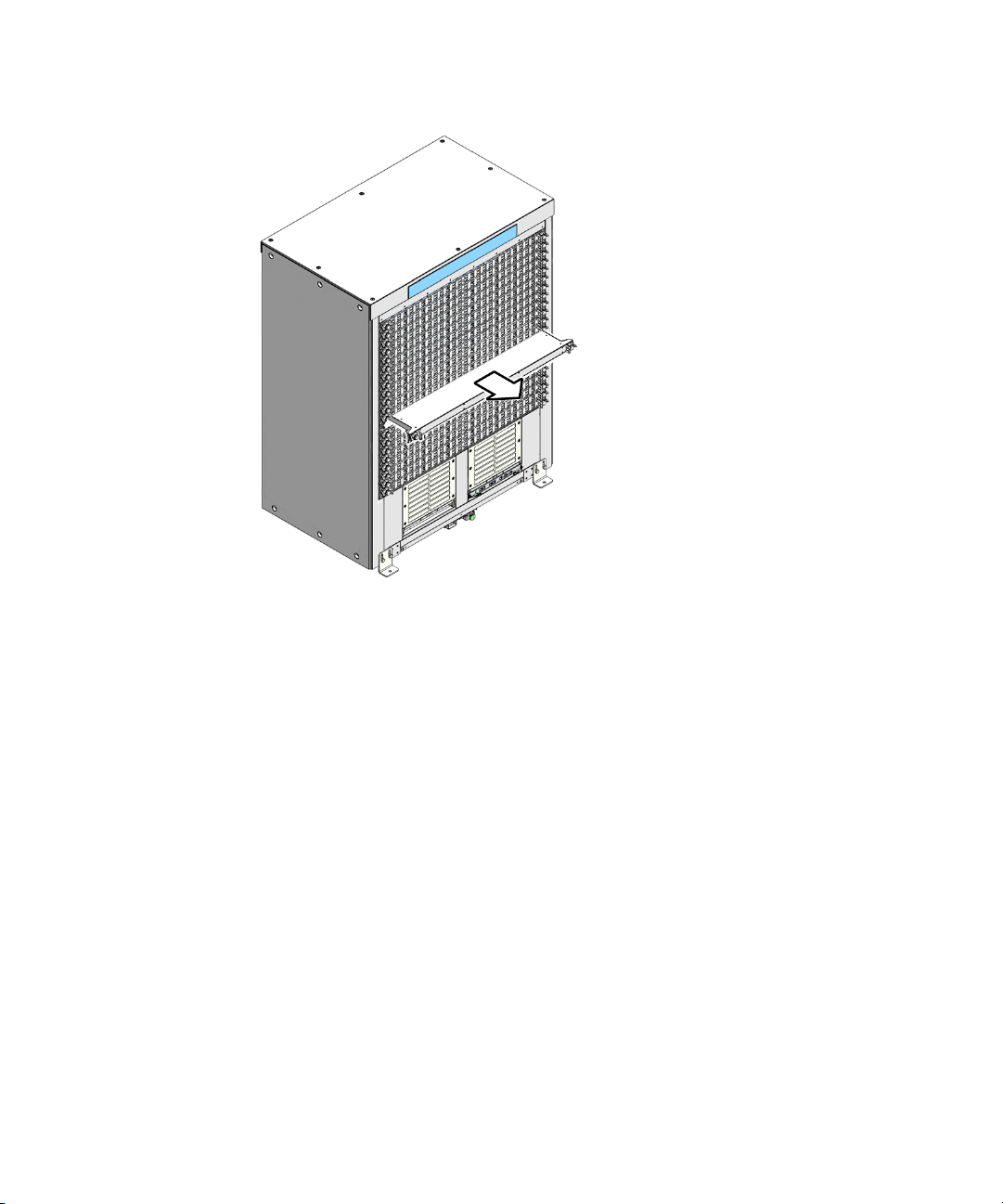

▼ To Remove the Line Card Filler Panels

Your Sun Datacenter Switch 3456 might ship with line card filler panels installed.

You must remove the filler panel where a line card will install.

1. Grasp the locking levers at each end of the filler panel.

See

FIGURE 6-3.

FIGURE 6-3 Turning Filler Panel Lock Levers

2. Turn the levers counter-clockwise to the unlocked position.

FIGURE 6-3.

See

3. Pull the filler panel away from the chassis by the handles.

See

FIGURE 6-4.

40 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 56

FIGURE 6-4 Removing the Filler Panel

4. Repeat from Step 1 for any other filler panels to be removed.

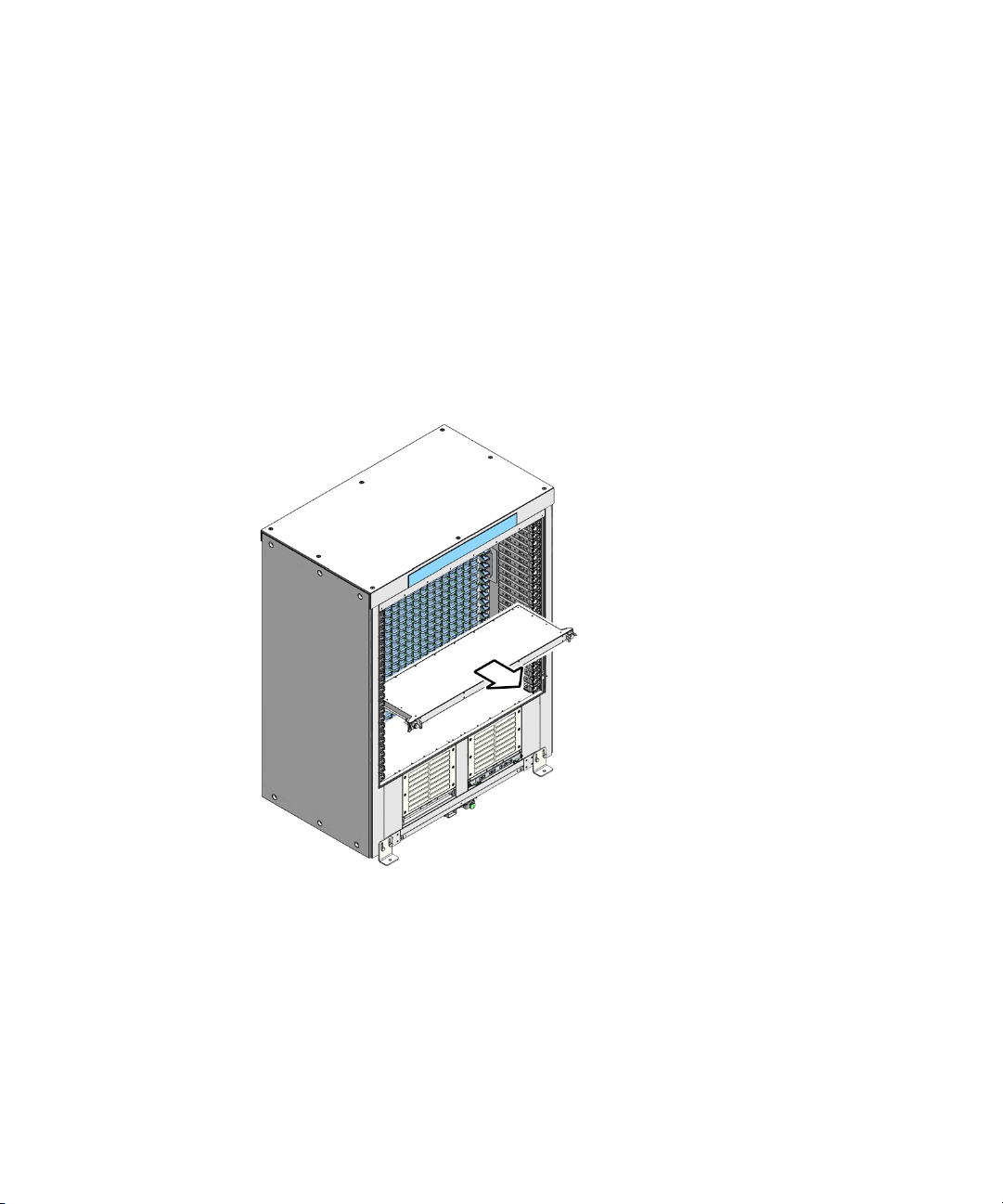

▼ To Install the Line Card Filler Panels

If the Sun Datacenter Switch 3456 is to be configured with less than 24 line cards, the

vacant slots must have filler panels installed to maintain proper airflow and thermal

management.

1. Grasp the handles at each end of the filler panel and lift the panel to the vacant

slot.

2. Slide the filler panel half-way into the chassis.

3. Turn the levers counter-clockwise to the unlocked position.

See

FIGURE 6-5.

Chapter 6 Installing the Chassis 41

Page 57

FIGURE 6-5 Turning Filler Panel Lock Levers Counter-Clockwise

4. Slide the filler panel into the chassis until it stops.

5. Turn the levers clockwise to the locked position.

See

FIGURE 6-6.

FIGURE 6-6 Turning Filler Panel Lock Levers Clockwise

6. Repeat from Step 1 for any remaining vacant slots.

42 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 58

Inspecting the Chassis

The weight of the Sun Datacenter Switch 3456 promotes a susceptibility to vibration

and movement. It is good practice to inspect the chassis as an early part of the

installation process.

▼ To Verify Electrical Leakage

Use a DMM for this verification test.

1. Grasp the release lever of power supply 0 and pull to release the power supply.

See

FIGURE 6-7.

FIGURE 6-7 Releasing the Power Supply

2. Continue to pull the power supply halfway out, but do not remove it.

3. Repeat from Step 1 for all power supplies.

4. Set the DMM for ohms.

If the DMM is not autoranging, set it for the highest resistance.

5. Touch the black probe of the DMM to the chassis ground.

See

FIGURE 6-8.

Chapter 6 Installing the Chassis 43

Page 59

FIGURE 6-8 Verifying Electrical Leakage

6. Touch the red probe to each one of the line card power connectors on the right

side.

The resistance should be no less than 1 megohm.

7. Move the black probe to a screw on the midplane stiffener.

See

FIGURE 6-8.

8. Repeat Step 6.

9. Move the black probe to a bus bar screw that is floating in the bus bar.

See

FIGURE 6-8.

10. Repeat Step 6.

11. Move the black probe to a line card power connector on the left side.

See

FIGURE 6-8.

12. Repeat Step 6.

13. If you read less than 1 megohm on any of these tests, investigate why.

14. Continue to “To Verify Electrical Continuity” on page 45.

▼ To Verify Electrical Continuity

Use a DMM for this verification test.

44 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 60

1. Set the DMM for ohms.

If the DMM is not autoranging, set it for the lowest resistance.

2. Touch the black probe of the DMM to the chassis ground.

FIGURE 6-9.

See

FIGURE 6-9 Verifying Electrical Continuity

3. Touch the red probe to each one of the line card power connectors on the left

side.

The resistance should be no greater than 50 ohm.

4. Move the black probe to a screw on the midplane stiffener.

See

FIGURE 6-9.

5. Repeat Step 3.

6. Move the black probe to a bus bar screw that is floating in the bus bar.

See

FIGURE 6-9.

7. Repeat Step 3.

8. Move the black probe to a line card power connector on the left side.

See

FIGURE 6-9.

9. Repeat Step 3.

10. If you read more than 50 ohm on any of these tests, investigate why.

Chapter 6 Installing the Chassis 45

Page 61

11. Slide power supply 0 back in its slot until the release lever begins to move.

FIGURE 6-10.

See

FIGURE 6-10 Securing the Power Supply

12. Swing the power supply release lever to the left to secure the power supply.

13. Repeat Step 11 for all power supplies.

46 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 62

CHAPTER

7

Inspecting and Repairing Pins

This chapter describes procedures to inspect and repair the midplane pins. Topics

include:

■ “Midplane Filler Strips” on page 47

■ “Inspecting Pins” on page 48

■ “Repairing and Replacing Pins” on page 54

Midplane Filler Strips

The Sun Datacenter Switch 3456 ships with plastic filler strips affixed to the

midplane. These strips protect the pins of the midplane connectors during the

installation process. The filler strips are secured in place by short pieces of rubber

tubing, which are inserted over the midplane alignment pins. See

FIGURE 7-1 Midplane Filler Strips

FIGURE 7-1.

47

Page 63

Inspecting Pins

Before installing the fabric cards and line cards, you must inspect the pins of the

midplane connectors. Inspection is a meticulous process, and cannot be hurried.

Expect about 30 minutes for each side of the midplane. To shorten this time, one

person might inspect the pins on the fabric card side (rear) of the midplane, while

another inspects the pins on the line card side (front) of the midplane.

Tools

For inspection, you need the following tools:

■ Pin gauge block

■ Bright flashlight

■ Magnifying glass or loupe

■ Notepad and pen

▼ To Inspect the Pins on the Rear Side of the Midplane

The primary tool used to check the midplane pins is the pin gauge block. This tool

effortlessly slides over the straight pins of an iTRAC connector that is in good

condition. If there is any resistance, a pin is bent and requires further examination.

1. Remove the rubber tubes that secure the filler strip for fabric card slot 0.

Set the tubes aside.

2. Remove the filler strip for slot 0.

Set the filler strip aside.

3. Using the pin gauge block, gently insert it into the iTRAC connector at the top.

4. If you feel any resistance to insertion, note the connector number on the

notepad.

See

FIGURE 7-2.

48 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 64

FIGURE 7-2 Fabric Card Connector Nomenclature

The connector number is located above each connector and is unique. For

example, the upper-left connector number is FC-R23-F0. The lower-right

connector number is FC-R0-F17. The connector number is decoded as follows:

■ FC – Fabric card.

■ Ra – Row a, where a is 0 through 23.

■ Fb – Frame b, where b is 0 through 17.

The origin of this coordinate system is the lower-left corner, FC-R0-F0. In

FIGURE 7-2, the connector identified is FC-R13-F15.

5. Continue down to the next connector and repeat from Step 3.

6. After you have checked the bottom connector, visually inspect any connectors

you noted previously.

Chapter 7 Inspecting and Repairing Pins 49

Page 65

7. Using the magnifying glass and the flashlight positioned above you, look at the

pins of the connector.

Look at the pins straight on. See

FIGURE 7-3 Inspecting the Pins (Fabric Card)

FIGURE 7-3.

8. Look for any light reflection inconsistencies.

A bent pin reflects light differently, either brighter or darker than the surrounding

pins.

Note – Do not look at the individual pins, rather look at all of the connector ’s pins

as a whole. A bent pin will be apparent.

9. Identify the pin that needs repair or replacement and note this.

10. Look for any contaminants that might be present.

These contaminants might appear as light dots near the pins.

11. Move your head to the next suspect connector and inspect its pins, repeating

Step 7 through Step 10.

12. Continue in this manner for all suspect connectors.

13. Repeat Step 1 to Step 12 for fabric card slot 1 to fabric card slot 17.

50 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 66

14. If a pin needs repair or replacement, see “Repairing and Replacing Pins” on

page 54.

▼ To Inspect the Pins on the Front Side of the Midplane

The primary tool used to check the midplane pins is the pin gauge block. This tool

effortlessly slides over the straight pins of an iTRAC connector that is in good

condition. If there is any resistance, a pin is bent and requires further examination.

1. Remove the rubber tubes that secure the filler strip for line card slot 0.

Set the tubes aside.

2. Remove the filler strip for slot 0.

Set the filler strip aside.

3. Using the pin gauge block, gently insert it into the iTRAC connector on the left

side.

4. If you feel any resistance to insertion, note the connector number on the

notepad.

See

FIGURE 7-4.

Chapter 7 Inspecting and Repairing Pins 51

Page 67

FIGURE 7-4 Line Card Connector Nomenclature

The connector number is located above each connector and is unique. For

example, the lower-left connector number is LC-C17-L0. The upper-right

connector number is LC-C0-L23. The connector number is decoded as follows:

■ LC – Line card.

■ Cc – Column c , where c is 0 through 17.

■ Ld – Level d , where d is 0 through 23.

The origin of this coordinate system is the lower right corner, LC-C0-L0. In

FIGURE 7-4, the connector identified is LC-C14-L10.

5. Continue right to the next connector and repeat from Step 3.

6. After you have checked the far right connector, visually inspect any connectors

you noted previously.

52 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 68

7. Using the magnifying glass and the flashlight positioned above you, look at the

pins of the connector.

Look at the pins as straight on. See

FIGURE 7-5 Inspecting the Pins (Line Card)

FIGURE 7-5.

8. Look for any light reflection inconsistencies.

A bent pin reflects light differently, either brighter or darker than the surrounding

pins.

Note – Do not look at the individual pins, rather look at all of the connector ’s pins

as a whole. A bent pin will be apparent.

9. Identify the pin that needs repair or replacement and note this.

10. Look for any contaminants that might be present.

These contaminants might appear as light dots near the pins.

11. Move your head to the next suspect connector and inspect its pins, repeating

Step 7 through Step 10.

12. Continue in this manner for all suspect connectors.

13. Repeat Step 1 to Step 12 for line card slot 1 to line card slot 23.

14. If a pin needs repair or replacement, see “Repairing and Replacing Pins” on

page 54.

Chapter 7 Inspecting and Repairing Pins 53

Page 69

Repairing and Replacing Pins

If you find a bent pin, it might be possible to straighten it. If the bend is too severe,

the pin must be replaced.

Tools

To repair or replace a pin, you need the following tools:

■ Molex pin replacement tool

■ Replacement pins (extracted from a spare iTRAC connector)

■ Head-mounted magnifier

■ Flashlight

Another person to assist you can make the task much easier.

▼ To Remove Pins

Before you can attempt to straighten a bent pin, you must remove the pins

surrounding the bent pin. See

1. Locate the bent pin.

See

FIGURE 7-6.

FIGURE 7-6.

54 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 70

FIGURE 7-6 Locating the Bent Pin and Surrounding Pins

2. Use the Molex tool to remove the pin (if any) above the bent pin.

a. Slide the Molex tool completely over the pin.

b. Activate the lock to grasp the pin.

c. Press the trigger to pull the pin out.

d. Push the ejector back in to release the pin and reset the tool.

3. Set the pin aside.

4. Use the Molex tool repeating Step 2 to remove the pin (if any) below the bent

pin.

5. Set the pin aside.

6. Repeat Step 2 to remove the pins to the left and right sides of the bent pin (if

any).

7. Set these pins aside.

The bent pin is now exposed.

Chapter 7 Inspecting and Repairing Pins 55

Page 71

8. Flip the Molex tool over and use the tube in attempt to straighten the pin.

If the pin cannot be straightened satisfactorily, or might break if straightened,

replace it.

9. Remove the pin following Step 2.

10. If the pin is too bent for the Molex tool, see “To Remove a Pin With

Needle-Nose Pliers” on page 56.

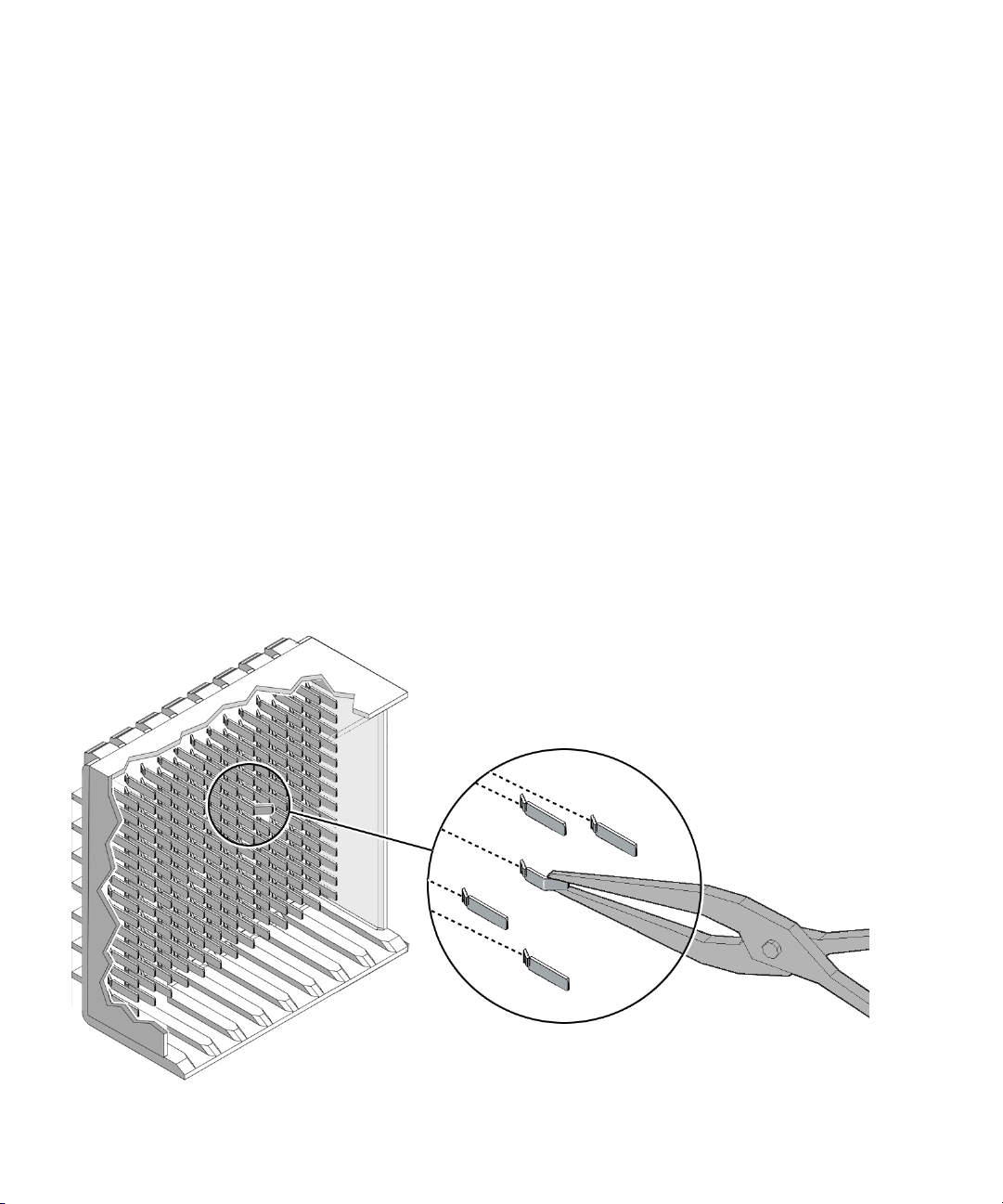

▼ To Remove a Pin With Needle-Nose Pliers

Perform this procedure only when the Molex tool is incapable of removing the pin.

You need micro-tipped needle-nose pliers.

1. With one hand, grasp the pin with the very tip of the needle-nose pliers.

2. Squeeze the pliers sufficiently to grip the pin for extraction.

3. With the other hand, steady the pliers in a position for perpendicular

extraction.

See

FIGURE 7-7.

FIGURE 7-7 Using Pliers to Pull a Pin

56 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 72

4. In one motion, use both hands to pull the pin out of the connector.

5. Dispose of the pin.

▼ To Insert Pins

When inserting pins, work from the top down. Repeat Step 1 through Step 5 for each

pin that needs to be inserted.

1. Ready the Molex tool for a pin insertion.

a. Press the trigger on the Molex tool to release the ejector.

b. Slide a pin into the opening.

A portion of the pin protrudes.

c. Activate the lock to grasp the pin.

2. Position the Molex tool over the hole in the connector where you want to insert

the pin.

3. Holding the Molex tool perpendicular to the plane of the connector, insert the

pin into the connector.

4. Slowly press the ejector in until it stops.

The pin is inserted.

5. Carefully deactivate the lock and withdraw the Molex tool from the connector.

Chapter 7 Inspecting and Repairing Pins 57

Page 73

58 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 74

CHAPTER

8

Installing Fabric Cards

This chapter describes inspection and installation procedures, and administrative

commands for fabric cards. Topics include:

■ “Inspecting Fabric Cards” on page 60

■ “Installing Fabric Cards Into the Chassis” on page 63

■ “Fabric Card Administrative Commands” on page 68

Fabric Card Considerations

Caution – The thermal management of the switch chassis is compromised when a

fabric card slot is vacant. You must install a filler panel or replacement fabric card

immediately after removing one.

Though the fabric cards are not heavy, they should be installed by two people. This

method ensures that proper alignment can be achieved before the fabric card

retainers are locked. Improper alignment can bend midplane connector pins.

Fabric cards use high-density iTRAC connectors that interface with the midplane

pins. If these connectors are damaged, the pins of the midplane connector can also

be damaged upon fabric card insertion.

You must inspect the fabric card connectors, fans, and retainers before installing the

fabric card into the switch chassis.

59

Page 75

Inspecting Fabric Cards

Inspect the fabric cards to see if they are ready for installation.

▼ To Inspect the Fabric Card iTRAC Connectors

The iTRAC connectors on fabric cards are the receptacles for the midplane connector

pins. These connectors are checked just as meticulously as the midplane connector

pins. However, you must verify that no connectors are damaged and no holes are

blocked.

You need the following tools:

■ Bright flashlight

■ Magnifying glass or loupe

■ Dental type metal pick

1. Unwrap the fabric card from its antistatic packaging.

2. Place the fabric card on a work surface with the iTRAC connectors facing you.

3. Using the flashlight positioned to the side and above you, look at the holes of

the left-end connector.

Look at the holes straight on. See

FIGURE 8-1.

FIGURE 8-1 Inspecting Fabric Card Connectors

60 Sun Datacenter Switch 3456 Installation Guide • December 2008

Page 76

Note – Do not look at the individual holes, rather look at all of the connector ’s holes

as a group. A damaged or contaminated hole will be apparent.

4. Look for any closed over or contaminated holes.

A closed-over or contaminated hole appears brighter than the surrounding holes.

If you see any closed-over or contaminated holes, use the magnifying glass and

pick to remove the contamination or open the closed-over hole.

Verify that the contamination has been removed from the connector and the

connector surface is clean. Use a spare midplane connector pin to verify the

resistance to insertion.

■ If there is great resistance, but the pin does enter the hole properly, investigate

why.

■ If the pin does not enter the hole at all, reject the fabric card. Contact your

SunService

SM

representative.

5. Look for any enlarged or cracked holes.

An enlarged or cracked hole appears darker than the surrounding holes.

If you see any enlarged or cracked holes, use a spare midplane connector pin to

verify the resistance to insertion.

■ If the insertion gives a little resistance and the pin does not wobble in the hole,

the connector is still acceptable.

■ If there is no resistance to insertion and the pin can wobble in the hole, reject