Page 1

Sun Netra™CP3250

Blade Server User’s Guide

Sun Microsystems, Inc.

www.sun.com

Part No. 820-5195-11

April 2009, Revision 01

Submit comments about this document at: http://www.sun.com/hwdocs/feedback

Page 2

Copyright ©2009 SunMicrosystems, Inc.,4150 NetworkCircle, Santa Clara, California 95054, U.S.A. All rights reserved.

This distributionmay includematerials developedby thirdparties.

Parts ofthe productmay bederived from BerkeleyBSD systems,licensed fromthe Universityof California.UNIX isa registered trademarkin

the U.S.and inother countries,exclusively licensedthrough X/OpenCompany, Ltd.

Sun, SunMicrosystems, theSun logo,Netra, SunRay, the Netra logo and the Solaris logo are trademarks or registered trademarksof Sun

Microsystems, Inc.,or itssubsidiaries, inthe U.S.and othercountries.

All SPARC trademarks areused underlicense andare trademarksor registered trademarksof SPARC International, Inc.in theU.S. andother

countries. Productsbearing SPARC trademarks arebased uponarchitecture developed by Sun Microsystems,Inc.

Use ofany spareor replacement CPUsis limitedto repairor one-for-one replacementof CPUsin products exportedin compliancewith U.S.

export laws.Use ofCPUs asproduct upgradesunless authorizedby theU.S. Governmentis strictlyprohibited.

DOCUMENTATION IS PROVIDED "AS IS" AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OFMERCHANTABILITY, FITNESS FORA PARTICULAR PURPOSE OR NON-INFRINGEMENT,

ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Copyright ©2009 SunMicrosystems, Inc.,4150 NetworkCircle, Santa Clara, California 95054, Etats-Unis. Tous droits réservés.

Cette distributionpeut comprendre descomposants développéspar destierces parties.

Des partiesde ceproduit pourront êtredérivées dessystèmes BerkeleyBSD licenciéspar l’Universitéde Californie.UNIX estune marque

déposée auxEtats-Unis etdans d’autrespays etlicenciée exclusivementpar X/OpenCompany, Ltd.

Sun, SunMicrosystems, lelogo Sun,Netra, SunRay, le logo Netra et le logo Solaris sont des marques de fabrique ou des marques déposéesde

Sun Microsystems,Inc., ouses filiales,aux Etats-Uniset dansd’autres pays.

Toutes les marques SPARC sont utilisées sous licence et sont des marquesde fabriqueou desmarques déposées de SPARCInternational, Inc.

aux Etats-Uniset dansd’autres pays.Les produits portantles marquesSPARC sontbasés surune architecture développéepar Sun

Microsystems, Inc.

L’utilisationde piecesdetachees oud’unites centralesde remplacement est limitee aux reparations oua l’echangestandard d’unites centrales

pour lesproduits exportes,conformement ala legislationamericaine enmatiere d’exportation. Sauf autorisation par les autorites des EtatsUnis, l’utilisationd’unites centralespour procedera desmises ajour deproduits est rigoureusement interdite.

LA DOCUMENTATION EST FOURNIE "EN L’ETAT" ET TOUTES AUTRES CONDITIONS, DECLARATIONS ET GARANTIES EXPRESSES

OU TACITES SONT FORMELLEMENT EXCLUES, DANS LA MESURE AUTORISEE PAR LA LOI APPLICABLE, YCOMPRIS NOTAMMENT

TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE UTILISATION PARTICULIERE OU A

L’ABSENCE DE CONTREFACON.

Please

Recycle

Page 3

Contents

Preface xiii

1. Overview 1–1

1.1 Overview 1–2

1.2 Features 1–2

1.3 Physical Description 1–4

1.3.1 Front Panel Components 1–4

1.3.2 Blade Server Diagram 1–6

1.4 System Configurations 1–7

1.4.1 AMC 1–8

1.4.2 Advanced Rear Transition Module 1–8

1.5 Hot-Swap Support 1–11

1.6 System Components 1–11

1.6.1 Required Hardware Components 1–11

1.6.2 Optional Hardware Components 1–12

1.6.3 Software Components 1–12

1.7 Technical Support and Warranty 1–13

1.7.1 Locating the Part Number and Serial Number Information 1–13

1.7.2 Viewing the Electronic Blade Server ID Information 1–14

iii

Page 4

2. Hardware Installation and Service 2–1

2.1 Safety and Tool Requirements 2–2

2.1.1 Equipment and Operator Safety 2–2

2.1.2 Materials and Tools Required 2–3

2.2 Installing the Blade Server 2–4

2.2.1 Preparing for the Installation 2–4

2.2.1.1 Check Power, Thermal, Environmental, and Space

Requirements 2–4

2.2.1.2 Local Network IP Addresses and Host Names

Worksheet 2–5

2.2.1.3 Installation Procedure Summary 2–6

2.2.2 Configuring the Hardware 2–6

2.2.2.1 Verify Chassis Fan Tray Upgrade 2–6

2.2.2.2 Installing Optional Components 2–7

2.2.2.3 Configuring the Advanced Rear Transition Module

(ARTM) 2–7

2.2.3 Installing the Netra CP3250 Blade Server in an ATCA Shelf 2–8

2.2.3.1 Installing an Advanced Rear Transition Module

(ARTM) 2–8

2.2.3.2 Installing the Blade Server Into the Shelf 2–11

2.2.4 Connecting External I/O Cables 2–13

2.2.4.1 Connecting Cables to a System Console Running the

Solaris OS 2–13

2.2.4.2 Connecting Cables to the System Console Not Running

the Solaris OS 2–15

2.2.4.3 Netinstall Boot Device Map 2–15

2.3 Service Procedures 2–17

2.3.1 Hot-Swapping the Netra CP3250 Blade Server 2–17

2.3.2 Powering Off the Netra CP3250 Blade Server 2–17

2.3.3 Removing the Netra CP3250 Blade Server 2–18

2.3.4 Powering On the System 2–18

iv Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 5

2.3.5 Automatic Power-Off Events 2–18

2.3.6 Servicing DIMMs 2–19

2.3.6.1 DIMM Requirements 2–19

2.3.6.2 Installing a DDR2 DIMM 2–21

2.3.6.3 Removing a DDR2 DIMM 2–23

2.3.7 Installing the Optional Compact Flash Card 2–24

2.3.8 Installing Optional AMC 2–27

2.3.9 Adding or Replacing the Battery 2–30

2.3.10 Changing Jumper Settings 2–31

2.3.10.1 Clearing the CMOS Setting Using Jumper 2 2–31

2.3.10.2 Changing the OOS LED Color Using Jumper 13 2–32

2.3.11 Checking DIP Switch Settings 2–33

2.3.12 Resetting the Netra CP3250 Blade Server 2–34

3. Hardware Architecture 3–1

3.1 Block Diagram 3–2

3.2 Intel Processors 3–3

3.3 Intel San Clemente MCH 3–3

3.4 Memory 3–4

3.5 Networking and I/O 3–5

3.5.1 ICH9 I/O Controller Hub 3–5

3.5.2 PCI Express Bus 3–5

3.5.3 LPC Bus Interface 3–6

3.5.4 Redundant BIOS 3–6

3.5.5 Trusted Platform Module (TPM) 3–7

3.5.6 IPMC 3–7

3.5.7 RS-232 Serial Ports 3–7

3.5.8 Broadcom 5715C Gigabit Ethernet 3–8

Contents v

Page 6

3.5.9 Sun Dual 10-Gbit Ethernet/Quad 1-Gbit RGMII Network Interface

Chip 3–8

3.6 I/O Components 3–8

3.6.1 AMC Slot 3–8

3.6.2 EIDE/ATA for Compact Flash 3–9

3.6.3 SAS/SATA 3–9

4. Software Configuration 4–1

4.1 Operating Systems 4–2

4.2 Software Updates 4–2

4.3 SunVTS Software 4–3

4.4 Configuring Sun Netra CP3250 blade server For 1 GbE or 10 GbE

Switches 4–4

5. Configuring and Using BIOS Firmware 5–1

5.1 About BIOS Settings 5–2

5.1.1 Navigating BIOS Screens 5–2

5.1.2 BIOS Option ROMs 5–2

5.1.3 Description of the BIOS Screens 5–3

5.2 Changing the Configuration of a BIOS Menu Item 5–3

5.3 Setting the Boot Device Using BIOS Setup Screens 5–4

5.4 Setting Supervisor and User Passwords 5–5

5.5 Resetting the System Time and System Date 5–6

5.6 Updating the BIOS 5–6

5.7 Secondary BIOS Image 5–7

5.8 Perform a Live Firmware Upgrade 5–8

5.9 Power-On Self-Test 5–8

5.10 Changing POST Options 5–9

A. BIOS Screens A–1

vi Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 7

B. Physical Characteristics B–1

B.1 Form Factor B–2

B.2 Power and Thermal Metrics B–2

B.3 Connectors and Pinouts B–2

B.3.1 Front Panel Connectors B–2

B.3.1.1 Ethernet Port B–3

B.3.1.2 USB Ports B–4

B.3.1.3 Serial Port B–5

B.3.2 AMC Connector B–5

B.3.3 Power Connector (Zone 1) B–6

B.3.4 Data Transport Connector (Zone 2) B–8

B.3.5 Advanced Rear Transition Module (ARTM) Connector (Zone 3)

B–9

B.3.5.1 Zone 3 (J30) Connector Pin Assignments B–10

B.3.5.2 Zone 3 (J31) Connector PIN Assignments B–11

B.3.5.3 Zone 3 (J32) Connector PIN Assignments B–12

B.3.5.4 Zone 3 (J33) Connector PIN Assignments B–13

B.3.5.5 Zone 3 Signal Descriptions B–14

C. ShMM CLI and Commands C–1

C.1 Shelf Manager Command-Line Interface C–2

C.2 Shelf Manager CLI Commands C–3

Index Index–1

Contents vii

Page 8

viii Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 9

Figures

FIGURE 1-1 Netra CP3250 Blade Server (Front View) 1–4

FIGURE 1-2 Netra CP3250 Blade Server (Component Side View) 1–6

FIGURE 1-3 Netra CP3250 Blade Server in Shelf Enclosure 1–7

FIGURE 1-4 Netra CP3250 Blade Server, Backplane, and Relationship to ARTM 1–9

FIGURE 1-5 Netra CP3250 Blade Server Barcode Labeling 1–14

FIGURE 2-1 Installing a Netra CP32x0 ARTM 2–9

FIGURE 2-2 Injector/Ejector Latch and Locking Screw on the ARTM 2–10

FIGURE 2-3 Engaging the Netra CP3250 Blade Server Latch 2–12

FIGURE 2-4 Serial Port on the Netra CP3250 Blade Server 2–14

FIGURE 2-5 Locating DIMM Slots 2–20

FIGURE 2-6 Installing a DIMM 2–22

FIGURE 2-7 Removing a DIMM 2–24

FIGURE 2-8 Opening the Door to Access Compact Flash 2–25

FIGURE 2-9 Compact Flash Location 2–26

FIGURE 2-10 Removing an AMC Filler Panel 2–28

FIGURE 2-11 Installing an AMC 2–29

FIGURE 2-12 Jumper 2 in the Default Run Position 2–31

FIGURE 2-13 SW1 Default DIP Switch Settings 2–33

FIGURE 2-14 SW4 Default DIP Switch Settings 2–33

FIGURE 2-15 SW5 Default DIP Switch Settings 2–34

ix

Page 10

FIGURE 2-16 Netra CP3250 Blade Server Front Panel 2–35

FIGURE A-1 BIOS Main Menu A–2

FIGURE A-2 Advanced Configuration Menu A–3

FIGURE A-3 CPU Configuration Menu A–4

FIGURE A-4 IDE Configuration Menu A–5

FIGURE A-5 USB Configuration Menu A–6

FIGURE A-6 Event Log Control Menu A–7

FIGURE A-7 IPMI 2.0 Configuration Menu A–8

FIGURE A-8 Remote Access Configuration Menu A–9

FIGURE A-9 PCI Option ROM Configuration Menu A–10

FIGURE A-10 Trusted Computing Menu A–11

FIGURE A-11 Boot Settings Menu A–12

FIGURE A-12 Boot Device Priority Configuration Menu A–13

FIGURE A-13 Security Settings Menu A–14

FIGURE A-14 Exit Menu A–15

FIGURE B-1 Ethernet RJ-45 Connector B–3

FIGURE B-2 Front Panel USB Connector B–4

FIGURE B-3 Front Panel Serial RJ-45 Connector B–5

FIGURE B-4 Power Distribution Connector (Zone 1) P10 B–6

FIGURE B-5 Zone 2 Connector B–8

FIGURE B-6 Zone 3 Connector B–10

x Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 11

Tables

TABLE 1-1 I/O Configurations 1–10

TABLE 1-2 FRU ID Areas 1–15

TABLE 2-1 Local Area Network Information 2–5

TABLE 2-2 Netinstall Boot Device Table 2–15

TABLE 2-3 Extra MAC Addresses for Virtual LAN Configuration 2–16

TABLE 2-4 Pin Functions on Jumper 2 2–31

TABLE 5-1 BIOS Setup Screens Summary 5–3

TABLE 5-2 POST Options 5–9

TABLE B-1 Ethernet Port Connector Pin Assignments B–3

TABLE B-2 USB Port Pin Assignments B–4

TABLE B-3 Serial Port Mini DIN 8-pin Connector Pinouts B–5

TABLE B-4 Power Distribution Connector Pin Assignments B–6

TABLE B-5 Zone 2 Connector Pin Assignments B–8

TABLE B-6 J30 Pin Connector Assignments B–10

TABLE B-7 J31 Connector Pin Assignments B–11

TABLE B-8 J32 Connector Pin Assignments B–12

TABLE B-9 J33 Connector Pin Assignments B–13

TABLE B-10 Zone 3 Signal Descriptions B–14

TABLE C-1 Shelf Manager CLI Command Summary C–3

xi

Page 12

xii Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 13

Preface

The Sun Netra CP3250 Blade Server User’s Guide describes the hardware specifications,

function, and physical properties of the Sun Netra™ CP3250 blade server. It also

provides detailed information on the system firmware.

The Sun Netra CP3250 Blade Server User’s Guide is written for system integration

engineers, field applications and service engineers, and others involved in the

integration of this blade server into systems. This guide is written for personnel who

are familiar with the Solaris™ Operating System, the Linux operating systems and

Advanced Telecommunications Computing Architecture (ATCA) computing

environment.

How This Document Is Organized

Chapter 1 provides an overview of the Sun Netra CP3250 blade server.

Chapter 2 provides instructions on hardware installation.

Chapter 3 provides information on hardware architecture.

Chapter 4 provides information on the supported operating systems and on the Sun

Validation Test Suite (SunVTS™) software.

Chapter 5 provides information on the BIOS (Basic Input Output System).

Appendix A provides first-level and second-level BIOS menu illustrations.

Appendix B provides information on the Sun Netra CP3250 blade server physical

characteristics.

Appendix C provides a list of the most commonly used ShMM commands.

xiii

Page 14

Using UNIX Commands

This document might not contain information about basic UNIX®commands and

procedures such as shutting down the system, booting the system, and configuring

devices. Refer to the following for this information:

■ Software documentation that you received with your system

■ Solaris™ Operating System documentation, which is at:

http://docs.sun.com/app/docs/prod/solaris

Shell Prompts

Shell Prompt

C shell machine-name%

C shell superuser machine-name#

Bourne shell and Korn shell $

Bourne shell and Korn shell superuser #

xiv Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 15

Typographic Conventions

*

Typeface

AaBbCc123 The names of commands, files,

AaBbCc123 What you type, when contrasted

AaBbCc123 Book titles, new words or terms,

* The settings on your browser might differ from these settings.

Meaning Examples

Edit your.login file.

and directories; on-screen

computer output

with on-screen computer output

words to be emphasized.

Replace command-line variables

with real names or values.

Use ls -a to list all files.

% You have mail.

su

%

Password:

Read Chapter 6 in the User’s Guide.

These are called class options.

Yo u must be superuser to do this.

To delete a file, type rm filename.

Related Documentation

For additional information about the Sun Netra CP3250 blade server or the Netra

CP32x0 advanced rear transition module (ARTM), refer to the following documents

The following table lists the documentation for this product. The online

documentation is available at:

http://docs.sun.com/app/docs/prod/cp3250.brd#hic

Application Title Part Number Format Location

Installation

and Service

Pointer

Doclette

Sun Netra CP3250 Blade Server

User’s Guide (this manual)

Netra CP3250 Blade Server Getting

Started Guide

820-5195 PDF,

HTML

820-5197 Printed,

PDF,

HTML

Online

Shipkit

Preface xv

Page 16

Application Title Part Number Format Location

Late-breaking

Information

Safety

Information

Safety

Information

.

Application Title Part Number Format Location

Installation and

Configuration

Installation and

Configuration

Installation and

Configuration

Netra CP3250 Blade Server Product

Notes

Netra CP3250 Blade Server Safety

and Compliance Guide

Important Safety Information for

Sun Hardware Systems

820-5194 PDF,

HTML

820-5198 PDF,

HTML

816-7190 Printed Shipkit

Online

Online

The following table lists the documentation that is related to this product.

Sun Netra CP32x0 SAS Storage

Advanced Rear Transition Module,

Dual HD User’s Guide

http://docs.sun.com/app/docs/prod/cp32x0.sas#hic

Sun Netra™ CP32x0 Quad GbE,

Dual Fibre Channel, Advanced Rear

Transition Module, User’s Guide

http://docs.sun.com/app/docs/prod/cp32x0.4gbefc?l=en#hic

Sun Netra™ CP32x0 10GbE

Advanced Rear Transition Module,

Dual Port User’s Guide

http://docs.sun.com/app/docs/prod/cp32x0.10gbee?l=en#hic

820-3147 PDF,

HTML

820-3148 PDF,

HTML

820-3150 PDF,

HTML

Online

Online

Online

Documentation, Support, and Training

Sun Function URL

Documentation http://docs.sun.com/

Support http://www.sun.com/support/

Training http://www.sun.com/training/

xvi Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 17

Third-Party Web Sites

Sun is not responsible for the availability of third-party web sites mentioned in this

document. Sun does not endorse and is not responsible or liable for any content,

advertising, products, or other materials that are available on or through such sites

or resources. Sun will not be responsible or liable for any actual or alleged damage

or loss caused by or in connection with the use of or reliance on any such content,

goods, or services that are available on or through such sites or resources.

Sun Welcomes Your Comments

Sun is interested in improving its documentation and welcomes your comments and

suggestions. You can submit your comments by going to:

http://www.sun.com/hwdocs/feedback

Please include the title and part number of your document with your feedback:

Sun Netra CP3250 Blade Server User’s Guide, part number 820-5195.

Preface xvii

Page 18

xviii Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 19

CHAPTER

1

Overview

This chapter provides an overview of the features, configurations, and system

requirements of the Sun Netra CP3250 blade server.

This chapter contains the following sections:

■ Section 1.1, “Overview” on page 1-2

■ Section 1.2, “Features” on page 1-2

■ Section 1.3, “Physical Description” on page 1-4

■ Section 1.4, “System Configurations” on page 1-7

■ Section 1.5, “Hot-Swap Support” on page 1-11

■ Section 1.6, “System Components” on page 1-11

■ Section 1.7, “Technical Support and Warranty” on page 1-13

1-1

Page 20

1.1 Overview

The Sun Netra CP3250 blade server is a dual-socket quad-core Intel-based ATCA

blade for high performance ATCA x86 applications in wireless infrastructure and

central office consolidation.

This blade server complies with the AdvancedTCA specification and is a new

addition to SUN's ATCA product family.

The ATCA standard comprises the PICMG 3.0, 3.1, 3.2, and 3.3 versions of the

standard. The Sun Netra CP3250 blade server complies with the following

specifications:

■ PICMG 3.0, the base specification that defines the mechanical, power distribution,

system management, data transport, and regulatory guidelines.

■ PICMG 3.1, which builds on the PICMG 3.0 base specification and on IEEE

802.3-2003.

1.2 Features

The blade server ’s primary features are as follows:

■ ATCA card 322.25 mm x280 mm, 1.2 inch slot height

■ Two Harpertown Processor Sockets, QuadCore version @2.135 GHz and up to

40W per CPU

■ Intel San Clemente North Bridge and Intel ICH9R I/O controller hub

■ DDR2 (registered, with ECC) at 667 MHz, up to six modules/cards, up to 4 GB

per DIMM, in very-low-profile design (0.72 inch height)

■ Two 1000MBASE-T Ethernet base fabric (PICMG 3.0) interface ports (using

BCM5715C) from PCIe x4

■ Two 10 Gb XAUI Ethernet extended fabric (PICMG 3.1) interface ports (using Sun

Neptune) from PCIe x8

■ One AMC.1 Type 8S2E2 expansion slot (PCIe x8) supporting I/O expansion with

signaling to the advanced rear transition module (ARTM)

■ One Asynchronous serial port routed to front panel and ARTM from SuperIO

1-2 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 21

■ Dual USB 2.0/1.1 ports on front panel

■ One 10/100/1000MHBASE-T management port on front panel, with second

management LAN sent to ARTM (from BCM 5715C); these are not directly tied

into IPM controller.

■ SATA to EIDE master to support one Compact Flash Type II socket up to 16 GB of

user Flash. Socket is only accessible when blade is removed from chassis

■ Redundant BIOS, 8MB

■ Management support using on-board IPM controller (Renesas H8) that provides

dual IPMB bus. The IPMB bus is to be monitored by the shelf manager, providing

redundant IPMI channels

■ Rear I/O expansion/connectivity provided to an optional ARTM. Compatible

with Sun’s current ARTM architecture with upgrade capability to support PICMG

working group ARTM.0 standard (Zone 3 Interface)

■ SAS connectivity from ARTM to AMC slot

■ Contains TPM (Trusted Platform module) chip

■ 225W delivered max power for the complete card (including 25W ARTM) via

dual, redundant -48 VDC nominal rails

■ Certified NEBS compliant in Sun’s Netra CT 900 system

Chapter 1 Overview 1-3

Page 22

1.3 Physical Description

1.3.1 Front Panel Components

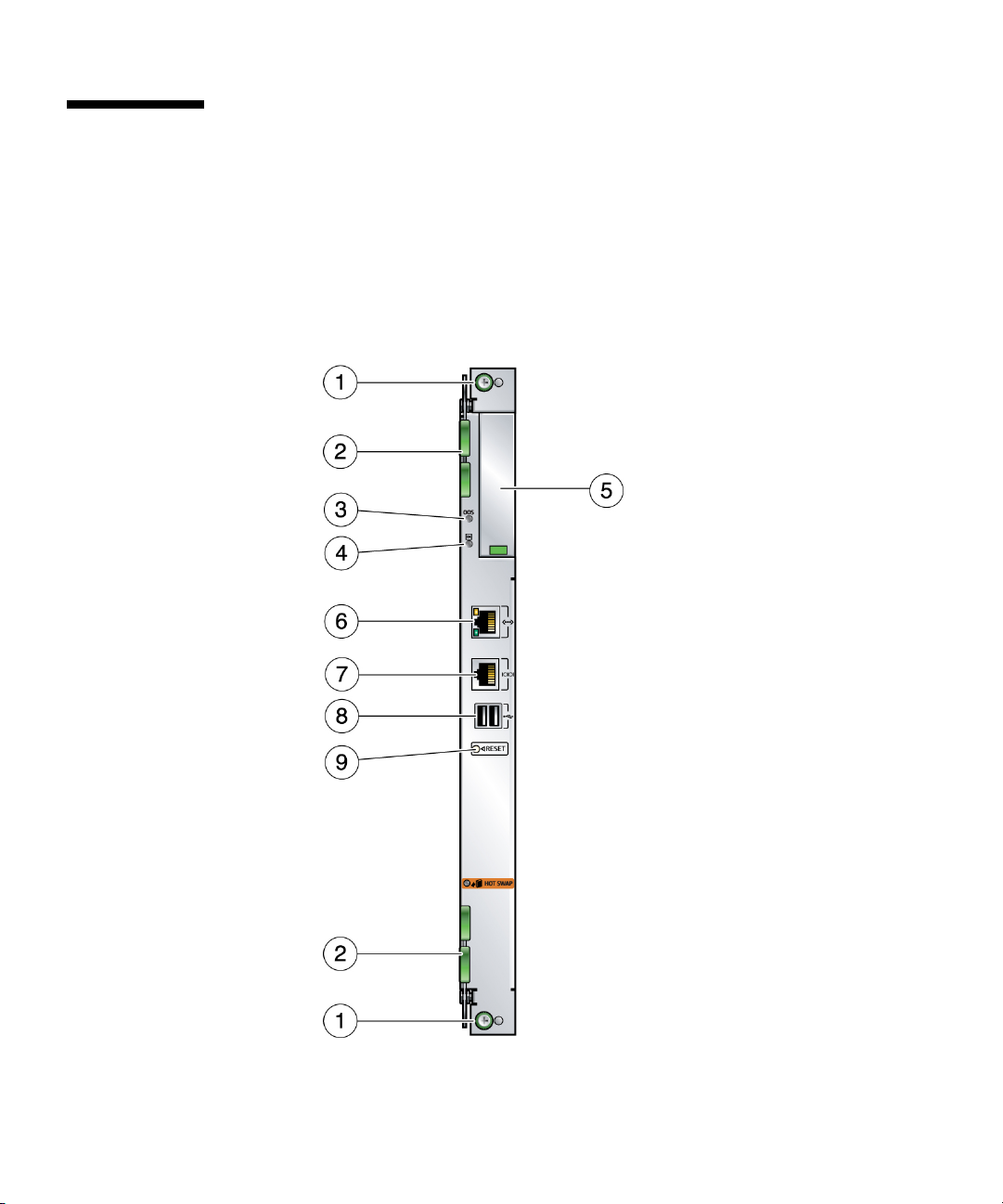

FIGURE 1-1 Netra CP3250 Blade Server (Front View)

1-4 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 23

Figure Legend

1 Locking screws

2 Latches

3 Out-of-service (OOS) LED

4 OK LED

5 AMC slot

6 10/100/1000 Ethernet management port

7 Serial port

8 USB port

9 Reset button

Chapter 1 Overview 1-5

Page 24

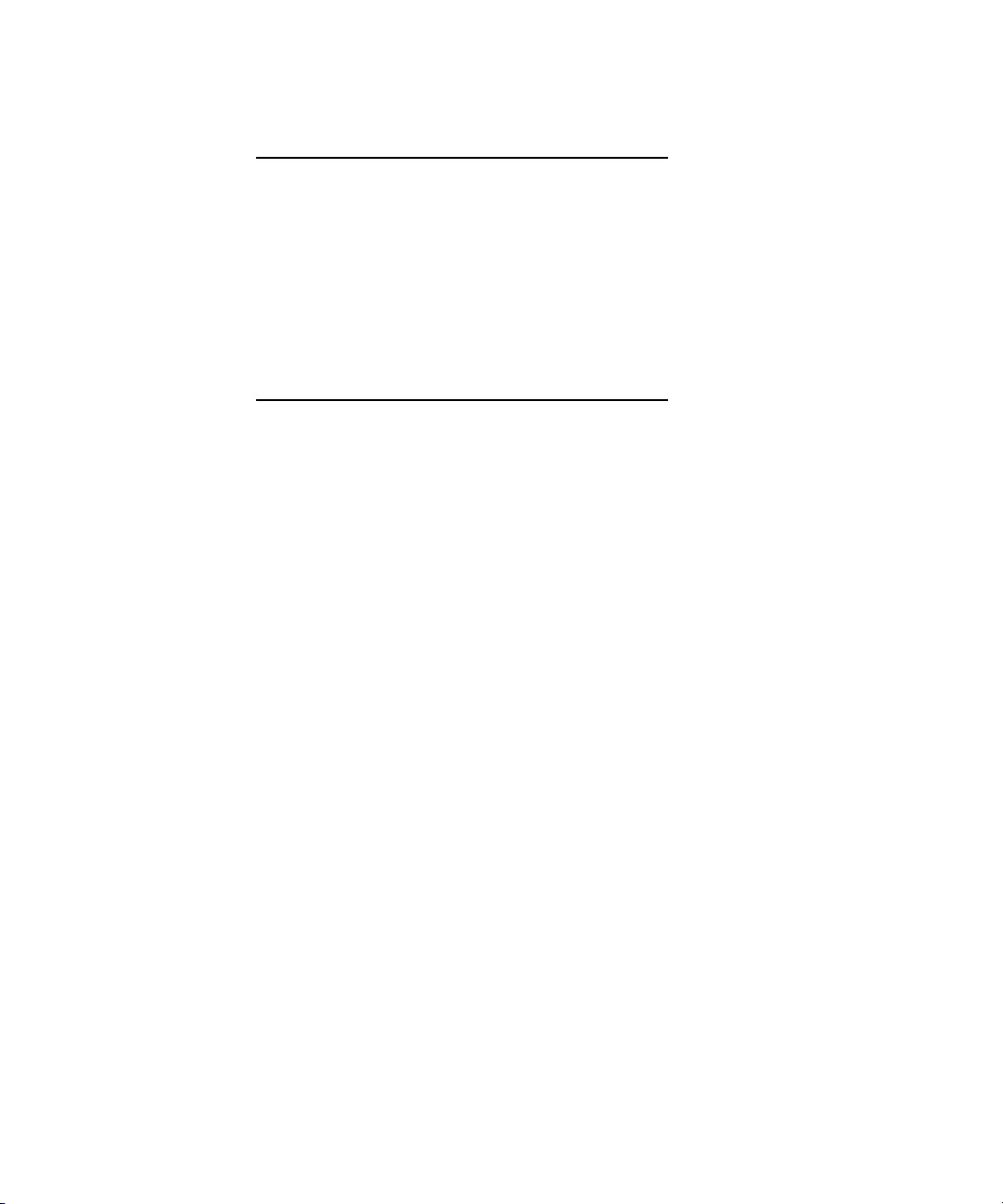

1.3.2 Blade Server Diagram

FIGURE 1-2 Netra CP3250 Blade Server (Component Side View)

Figure Legend

1 CF card slot 4 Zone 1 power connector

2 Zone 3 connectors 5 DIMMs

3 Zone 2 connectors 6 CPU heatsinks

1-6 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 25

1.4 System Configurations

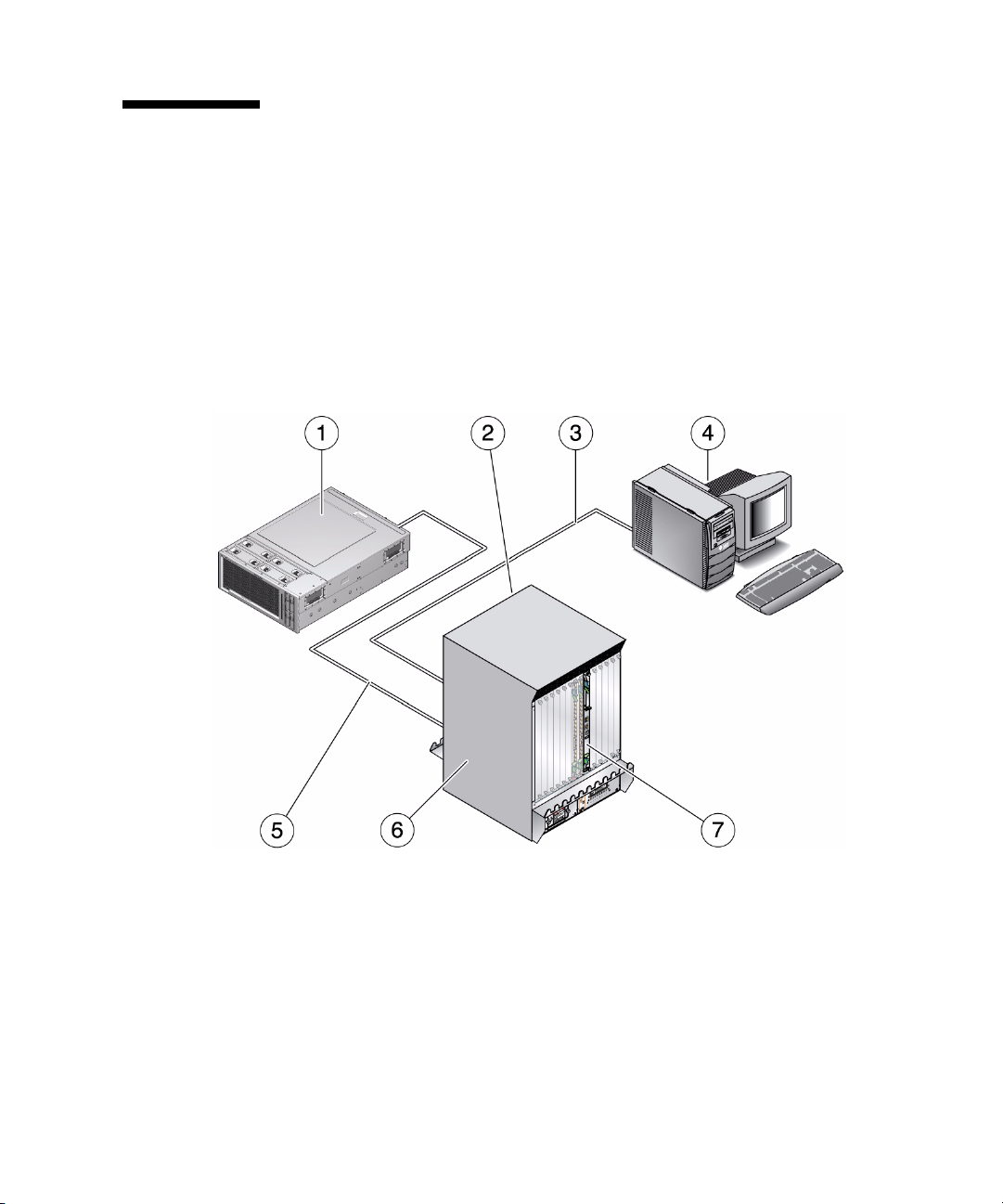

Sun Netra CP3250 blade servers can be installed into an ATCA shelf (chassis), as

shown in

configurations to suit user requirements. For example, the blade server can be

configured to boot from a network as a diskless client with either a front panel or

ARTM network connection. The Sun Netra CP3250 blade server has an optional

Compact Flash card and connectors for additional memory.

FIGURE 1-3 Netra CP3250 Blade Server in Shelf Enclosure

FIGURE 1-3. The blade servers can be deployed in various electrical

Chapter 1 Overview 1-7

Page 26

1.4.1 AMC

The Sun Netra CP3250 blade server has one AMC slot, with eight lanes of PCIe, to

provide additional I/O to the front panels or to the rear of the enclosure when used

with an ARTM.

The Sun Netra CP3250 blade server supports AMC mid-height, single wide cards, as

defined by the AMC specification.

1.4.2 Advanced Rear Transition Module

You can install one of the optional Netra CP32x0 advanced rear transition modules

(ARTMs) into the rear of the ATCA shelf, opposite the Sun Netra CP3250 blade

server.

For more information, refer to the following documentation: Sun Netra CP32x0 SAS

Storage Advanced Rear Transition Module, Dual HD User’s Guide (820-3147)

(ARTM-HD)

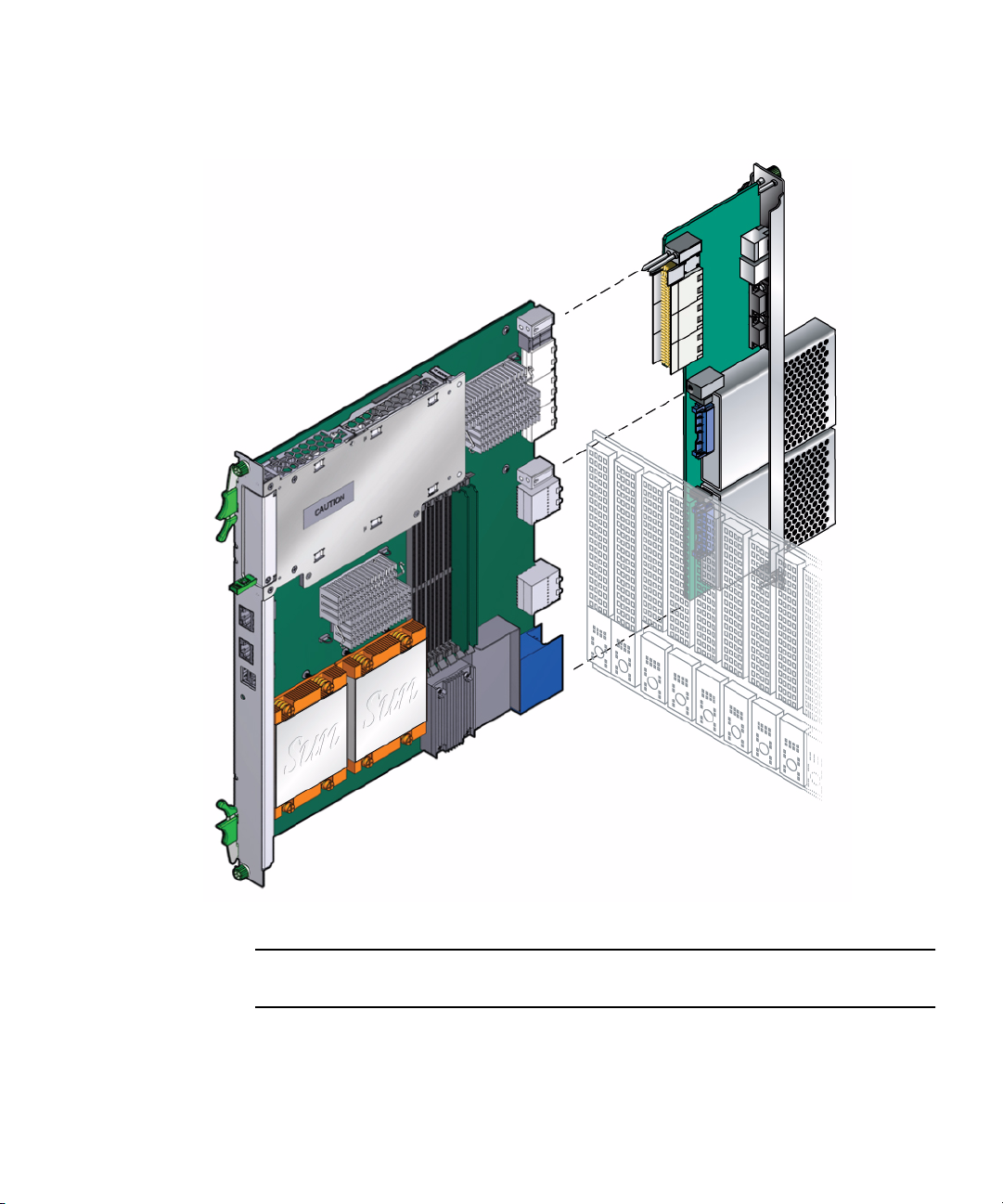

FIGURE 1-4 shows the physical relationship between the Sun Netra CP3250 blade

server, the ARTM, and the backplane in a typical ATCA system.

1-8 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 27

FIGURE 1-4 Netra CP3250 Blade Server, Backplane, and Relationship to ARTM

Note – When using the ARTM with the Sun Netra CP3250 blade server, use cables

of less than 10 meters in length for serial I/O ports.

Chapter 1 Overview 1-9

Page 28

You can order a Netra CP32x0 ARTM, build a custom module, or buy one from an

IHV. You must set up a minimal set of I/O for a boot path for the host blade server

and for a path for console I/O to deliver commands and read blade server and

system status.

Possible boot and console configurations are described in

Microsystems provides the Sun Netra CP3250 blade server and, optionally, a

compatible Netra CP32x0 ARTM. The ARTM provides one 10/100/1000BASE-T per

second Ethernet RJ-45 port from the host to the rear of the system. This port can be

used to accomplish, optionally, a network boot as a diskless client. The other

configurations require IHV hardware.

TABLE 1-1 I/O Configurations

I/O Hardware Required Description

Ethernet Netra CP32x0 ARTM, as an

option for rear access

SAS Netra 146-GB hard disk and the

Netra CP32x0 ARTM-HD

Zone 3 ARTM

Zone 3 ARTM

Serial data

Serial data

Compact

Flash

Sun Netra CP3250 blade server

Netra CP32x0 ARTM

IDE Compact Flash card Sun Netra CP3250 blade server supports one, optional IDE

The default boot path uses an Ethernet port; the blade server

runs in a diskless client configuration

Available with the optional Netra CP32x0 ARTM-HD or

through an AMC with SAS capabilities. When the optional

ARTM is installed, connect to the drive(s) via SAS ports on the

ARTM.

Serial port A on the front panel provides the path of the default

console I/O.

When an optional Netra CP32x0 ARTM is installed, the

module’s serial port A will become the path of the default

console I/O (

Compact Flash drive, either 8-Gbyte or 16-Gbyte, installed in a

Type II CF socket on the blade server.

TABLE 1-1. Sun

FIGURE 1-4).

1-10 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 29

1.5 Hot-Swap Support

Hot-swap support for inserting and extracting blade servers is provided in

accordance with the ATCA PICMG 3.0 and 3.1 standards.

Hot-swap of the CP3250, ARTM, and AMC is supported in the Netra CT 900 server.

1.6 System Components

This section contains the system-level hardware and software components, required

and optional, for the Sun Netra CP3250 blade server.

1.6.1 Required Hardware Components

The Sun Netra CP3250 blade server cannot be used as a stand-alone system. It is

designed to be used in an ATCA chassis for 8U boards. The minimum hardware

requirements needed to use the Sun Netra CP3250 blade server are:

■ ATCA system enclosure for 8U boards (includes shelf, backplane, hub/switch

board, shelf manager and power supply)

■ Console output device or serial terminal

■ Boot device (such as hard drive, network, or Compact Flash card)

■ Peripheral device for network access

■ IPMC (built in)

■ Cables for terminal and network connections

■ Netra CT 900 server fan tray upgrade kit (PN 594-4953-01). If you are installing

the Sun Netra CP3250 blade server in a Netra CT 900 server that has lower-speed

fan trays, you must upgrade the Netra CT 900 server fan trays to support the

additional cooling needs of the Sun Netra CP3250 blade server. For more

information on the Netra CT 900 server fan tray upgrade kit (PN 594-4953-01), see

the Netra CT 900 Server Upgrade Guide (820-3255).

Caution – You can damage the Sun Netra CP3250 blade server components if you

install the blade server in a chassis that does not provide sufficient cooling. For more

information, see Section 2.2.1.1, “Check Power, Thermal, Environmental, and Space

Requirements” on page 2-4.

Chapter 1 Overview 1-11

Page 30

Note – Use only serial cables that are less than 10 meters in length.

1.6.2 Optional Hardware Components

Sun Microsystems provides the following items for customer order:

■ Compact Flash card

■ AMCs

■ Netra CP32x0 ARTM (optional)

The ARTM is optional and must be ordered separately from the Sun Netra

CP3250 blade server.

The optional ARTM enables rear system I/O access to the following:

■ Network

■ Boot device

■ Two hot-swappable SAS hard disk drives (optional)

■ Console terminal (FIGURE 1-3).

■ Sun Netra CP3240 switch (optional)

The Sun Netra CP3240 switch is capable of operating at 10 GbE, but is set by

default to operate at 1GbE. To use the switch at 10 GbE, perform a one-time

configuration procedure, available in the Sun Netra CP3x40 Switch Product Notes

(820-3260).

1.6.3 Software Components

The following OSs are certified for use on Sun Netra CP3250 blade server:

■ Solaris™ 10 (05/08) Operating System (Solaris OS)

■ WindRiver Linux 3.1

■ RedHat Linux 5.2

■ Windows 2003

Additional OSs are being tested and will be supported after they are certified.

Refer to the Netra CP3250 Blade Server Product Notes (820-5194) for more Solaris OS

information, including a list of any required Netra software patches and support for

subsequent versions of Solaris and other OSs. You can view and download the latest

version of the product notes at the following web site:

http://docs.sun.com

1-12 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 31

Additionally, VMware is a software component certified to work with the Sun Netra

CP3250 blade server. It is listed on VMware’s HCL at:

http://www.vmware.com/resources/compatibility/search.php?action=

search&deviceCategory=server&productId=1&keyBasic=

netra&maxDisplayRows=50&key=netra&release%5B%5D=-1&datePosted=

-1&stepping=&nsockets=&ncores=&max_mem=

1.7 Technical Support and Warranty

Should you have any technical questions or support issues that are not addressed in

the Sun Netra CP3250 blade server documentation set or on the technical support

web site, contact your local Sun Services representative. This hardware carries a

one-year return-to-depot warranty.

For customers in the U.S. or Canada, call 1-800-USA-4SUN (1-800-872-4786).

For customers in the rest of the world, please find the World Wide Solution Center

nearest you at the following web site:

http://www.sun.com/contact/services_solutions.jsp

When you call Sun Services, be sure to indicate if the Sun Netra CP3250 blade server

was purchased separately, and is not associated with a system. Please have the blade

server identification information ready. For proper identification of the blade server,

be prepared to give the representative the blade server part number, and serial

number.

1.7.1 Locating the Part Number and Serial Number Information

The Sun Netra CP3250 blade server part number, serial number, revision number,

and media access control (MAC) address are printed on stickers located on the Sun

Netra CP3250 blade server (

The Sun barcode label provides the following information:

■ Blade server serial number (for example, 1005LCB-07296R0912), which is on the

barcode label

The part number/dash/revision/date code label provides the following

information:

FIGURE 1-5).

Chapter 1 Overview 1-13

Page 32

■ Blade server part number (for example, 3753529), which is the first seven digits on

the part number label

■ Product dash number (for example, -01)

■ Revision number (for example, REV: 01)

The MAC address label contains the base MAC address for the blade server in

printed and barcode form. It is an orange label located on the Zone 1 connector.

FIGURE 1-5 Netra CP3250 Blade Server Barcode Labeling

Part number label

Serial number label

1.7.2 Viewing the Electronic Blade Server ID Information

The Sun Netra CP3250 blade server can be electronically identified through its IPMI

FRU ID PROM, which is accessible through standard fru utilities.

The IPMI FRU ID PROM format follows the Intel Specification IPMI Platform

Management FRU Information Storage Definition, v1.0 Document, Revision 1.1,

September 27, 1999.

1-14 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 33

The IPMI FRU ID manufacturing records match Sun part number and serial number

labels on the product. For more information about part number and serial number

labels, see Section 1.7.1, “Locating the Part Number and Serial Number Information”

on page 1-13.

The IPMI FRU ID contains six FRU ID areas, which are defined in

TABLE 1-2 FRU ID Areas

FRU Area Description

COMMON

HEADER

INTERNAL USE

AREA

CHASSIS INFO

AREA

BOARD INFO

AREA

PRODUCT INFO

AREA

MULTIRECORD

INFO AREA

Contains header and pointers to other FRUID sections and is used

by fru utility software

Not present

Not present

Contains the manufacturing record without memory (FRU part

number) for the FRU level assembly of the blade server. This

assembly level is equivalent to the FRU replacement that is received

from Sun Service.

• Mfg Date/Time = (Date/Time of blade server assembly}

• Manufacturer = {manufacturer name)

• Product Name = CP3250

• Serial Number = XXXXXXX-XXXXXXXXXX (Sun 18-digit format)

• Part Number = 000000000PPPPPPPDDRR (Sun Part Number)

where 0 = Leading zeroes, P= Part Number, D=Dash, R=Rev

Contains manufacturing record for configured blade server with

memory. This assembly level includes the base blade server (FRU)

plus memory.

• Manufacturer = (manufacturer name)

• Product Name = CP3250

• Part/Model Number = 000000000PPPPPPPDDRR (Sun Part

Number) where 0 = Leading zeroes, P= Part Number, D=Dash, R=

Rev

• Product Version = XXXX (dash/rev)

• Serial Number = XXXXXXX-XXXXXXXXXX (Sun 18-digit format)

Sun Internal Use Only

TABLE 1-2.

Chapter 1 Overview 1-15

Page 34

1-16 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 35

CHAPTER

2

Hardware Installation and Service

This chapter describes the Sun Netra CP3250 blade server hardware installation and

service procedures.

This chapter contains the following sections:

■ Section 2.1, “Safety and Tool Requirements” on page 2-2

■ Section 2.2, “Installing the Blade Server” on page 2-4

■ Section 2.3, “Service Procedures” on page 2-17

2-1

Page 36

2.1 Safety and Tool Requirements

2.1.1 Equipment and Operator Safety

Refer to the Important Safety Information for Sun Hardware Systems (816-7190) for

general safety information and to the Netra CP3250 Blade Server Safety and Compliance

Guide (820-5198) for specific safety information.

Read the following safety statements that are specific to the Sun Netra CP3250 blade

server carefully before you install or remove any part of the system.

Caution – Depending on the particular chassis design, operations with open

equipment enclosures can expose the installer to hazardous voltages with a

consequent danger of electric shock. Ensure that line power to the equipment is

disconnected during operations that make high voltage conductors accessible.

The installer must be familiar with commonly accepted procedures for integrating

electronic systems and the general practice of Sun systems integration and

administration. Although parts of these systems are designed for hot-swap

operation, other components must not be subjected to such stresses. Work with

power connected to a shelf only when necessary, and follow these installation

procedures to avoid equipment damage.

This equipment is sensitive to damage from electrostatic discharge (ESD) from

clothing and other materials. Use the following antistatic measures during an

installation:

■ If possible, disconnect line power from the shelf when servicing a system or

installing a hardware upgrade. If the shelf cannot be placed on a grounded

antistatic mat, connect a grounding strap between the facility electrical input

ground (usually connected to the shelf) and facility electrical service ground.

■ Use an antistatic wrist strap when performing the following tasks:

■ Removing a blade server from its antistatic bag

■ Connecting or disconnecting blade servers or peripherals

2-2 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 37

The other end of the antistatic wrist strap lead should be connected to one of the

following:

■ A ground mat

■ The chassis metal as a ground

The grounded mat or the chassis must be connected to a facility ground to

prevent a floating ground.

■ Keep blade servers in the antistatic bags until they are needed.

■ Remove a blade server from its antistatic bag only when wearing a properly

connected ground strap.

■ Place circuit blade servers that are out of their antistatic bags on an antistatic mat

if one is available and the mat is grounded to a facility electrical service ground.

Do not place blade servers on top of an antistatic bag unless the outside of the bag

also has antistatic protective properties.

2.1.2 Materials and Tools Required

The tools required for installation and service are as follows:

■ Phillips screwdrivers: No. 1 (required), No. 2 (optional)

■ Antistatic wrist strap

■ Terminal console

■ Serial cable of less than 10 meters in length to connect the Sun Netra CP3250

blade server with a system console

Refer to Section 1.6, “System Components” on page 1-11 for information on

hardware requirements.

Chapter 2 Hardware Installation and Service 2-3

Page 38

2.2 Installing the Blade Server

2.2.1 Preparing for the Installation

Prepare for installation by reading and performing the following steps.

1. Become familiar with the contents of the documentation referenced in the steps.

2. Verify that all listed hardware and software are available (see Section 1.6, “System

Components” on page 1-11).

3. Check power, thermal, environmental, and space requirements (see

Section 2.2.1.1, “Check Power, Thermal, Environmental, and Space Requirements”

on page 2-4).

4. Verify that local area network (LAN) preparations are completed (see

Section 2.2.1.2, “Local Network IP Addresses and Host Names Worksheet” on

page 2-5).

5. Ensure that the host names and their network IP addresses are allocated and

registered at the site. Record this information in

2.2.1.1 Check Power, Thermal, Environmental, and Space Requirements

TABLE 2-1.

Observe that your environment meets the following requirements:

■ Your enclosure specifications can support the sum of the specified maximum

blade server power loads. (See Section B.2, “Power and Thermal Metrics” on

page B-2).

■ Facility power loading specifications can support the rack or enclosure

requirements.

■ Your enclosure specifications can support the cooling airflow requirements.

The Sun Netra CP3250 blade server fits into a standard ATCA shelf. If your

installation requirements are different, contact your field applications engineer.

2-4 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 39

2.2.1.2 Local Network IP Addresses and Host Names Worksheet

Collect the information listed in TABLE 2-1 to connect hosts to the LAN. Ask your

network administrator for help, if necessary. This information is not needed for a

stand-alone installation.

TABLE 2-1 Local Area Network Information

Information Needed Your Information

IP address*and host name for each Sun

Netra CP3250 blade server client

Domain name

Type of name service and corresponding

name server names and IP addresses—for

example DNS and NIS (or NIS+)

Subnet mask

Gateway router IP address

Network File System (NFS) server names

and IP addresses

Web server URL

* Local IP addresses are not needed if they are assigned by a network Dynamic Host Configuration Protocol

(DHCP) server.

You might need the MAC (Ethernet) addresses of the local hosts to make name

server database entries. You can see the MAC address in the console output while

booting the blade server. You can also find it on the barcode label on the node blade

server (see Section 1.7.1, “Locating the Part Number and Serial Number

Information” on page 1-13).

Chapter 2 Hardware Installation and Service 2-5

Page 40

2.2.1.3 Installation Procedure Summary

This section summarizes the high-level procedures that are required to install the

Sun Netra CP3250 blade server. Ensure that you are familiar with the information in

Section 2.2.2, “Configuring the Hardware” on page 2-6 through the end of Chapter 2

before installing the blade server.

The process to set up and configure a Sun Netra CP3250 blade server in a system

includes the following procedures:

1. Configuring the blade server’s physical hardware.

For example, install the AMC and set switches, as necessary (Section 2.2.2,

“Configuring the Hardware” on page 2-6).

2. Physically installing the advanced rear transition module (ARTM) as necessary

(Section 2.2.3.1, “Installing an Advanced Rear Transition Module (ARTM)” on

page 2-8).

3. Physically installing the Sun Netra CP3250 blade server, and any peripheral

boards into the ATCA shelf Section 2.2.3, “Installing the Netra CP3250 Blade

Server in an ATCA Shelf” on page 2-8).

4. Connecting the nodes to a local network. (Section 2.2.4, “Connecting External I/O

Cables” on page 2-13).

5. Downloading and installing SunVTS (Section 4.1, “Operating Systems” on

page 4-2), if you are running the Solaris Operating System on the Sun Netra

CP3250 blade server and want to verify system integrity.

2.2.2 Configuring the Hardware

This section lists hardware installation and settings that might apply to your blade

server configuration. Read and perform the procedures, as necessary, before

installing the Sun Netra CP3250 blade server into the ATCA shelf.

2.2.2.1 Verify Chassis Fan Tray Upgrade

Caution – The Netra CT 900 server fan tray upgrade kit (594-4953) must be

installed in the chassis before the Sun Netra CP3250 blade server is installed. This

fan tray upgrade is required to provide adequate cooling and prevent the system

from overheating or shutting down due to an over temperature condition that can

occur with the older or mismatched fan trays.

2-6 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 41

● To verify if the fan tray upgrade is installed on a Netra CT 900 server, log into

the Shelf Manager and issue the following command for fan trays 1,2, and 3:

# clia fruinfo fan_tray 1 | grep "Product Part"

If the “Product Part/Model Number” is 370-7764-xx, the fan trays must be replaced

with high-speed fan trays. Refer to the Netra CT 900 Server Upgrade Guide (820-3255)

for more information.

If the “Product Part/Model Number” is 371-3033-xx or newer, an upgraded fan tray

is already installed.

2.2.2.2 Installing Optional Components

Use the following table to locate your options and installation instructions.

DIMMs “DIMM Requirements” on page 2-19

“Installing a DDR2 DIMM” on page 2-21

Compact Flash card “Installing the Optional Compact Flash Card” on page 2-24

AMC “Compact Flash Location” on page 2-26

2.2.2.3 Configuring the Advanced Rear Transition Module (ARTM)

If you are using one of the Netra advanced rear transition modules (ARTMs), refer to

the documentation: Netra CP32x0 SAS Storage Advanced Rear Transition Module, Dual

HD User’s Guide (820-3147) (ARTM-HD)

See Section B.3, “Connectors and Pinouts” on page B-2 for detailed connector pin

assignments for the Sun Netra CP3250 blade server.

Chapter 2 Hardware Installation and Service 2-7

Page 42

2.2.3 Installing the Netra CP3250 Blade Server in an ATCA Shelf

If you install the Sun Netra CP3250 blade server with an ARTM, the ARTM must be

installed first.

Note – Slots 1 through 6 and 9 through 14 are available for Sun Netra CP3250 blade

servers. Slots 7 and 8 are reserved for the switch card.

2.2.3.1 Installing an Advanced Rear Transition Module (ARTM)

A compatible ARTM must be used with the Sun Netra CP3250 blade server for rear

I/O access. The ARTM enables access to the network, a boot device, and a console

terminal. You can use one of the Netra CP32x0 ARTMs or you can design your own

ARTM-compatible transition module. For more information, see Section 1.4.2,

“Advanced Rear Transition Module” on page 1-8.

1. Verify that you have taken the necessary antistatic precautions.

See Section 2.1.1, “Equipment and Operator Safety” on page 2-2.

2. From the rear of the system, choose the corresponding slot for the ARTM.

The rear transition module must be installed, inline, behind a compatible Netra

blade server.

For example, if the Sun Netra CP3250 blade server will be installed in slot 3, the

corresponding rear transition module must be installed at the back of the system

in slot 3 (

Netra CP3250 blade server in corresponding slots, the system will recognize the

Sun Netra CP3250 blade server and not the rear transition module.

FIGURE 2-1). If you do not install the rear transition module and the Sun

Note – Slots 1 through 6 and 9 through 14 are available for Sun Netra CP3250 blade

servers. Slots 7 and 8 are reserved for the switch card.

2-8 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 43

FIGURE 2-1 Installing a Netra CP32x0 ARTM

3. Remove the slot filler panel from the selected slot, if necessary.

4. Retrieve the advanced rear transition module (ARTM) from the ship kit.

5. Prepare the rear transition module by opening the injector/ejector latch at the

top of the module (

FIGURE 2-2).

Chapter 2 Hardware Installation and Service 2-9

Page 44

FIGURE 2-2 Injector/Ejector Latch and Locking Screw on the ARTM

6. Carefully align the edges of the ARTM with the card guides in the appropriate

slot.

Look into the enclosure to verify correct alignment of the rails in the guides.

7. Keep the ARTM aligned in the guides, and slide the module in until the

injector/ejector latches engage the card cage.

8. Push the ARTM into the backplane connectors, and close the latch.

9. Tighten the locking screws to ensure that the module is secured into the ATCA

shelf.

2-10 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 45

10. Install the Sun Netra CP3250 blade server into the front of the ATCA shelf in

the corresponding slot.

See Section 2.2.3.2, “Installing the Blade Server Into the Shelf” on page 2-11 for

instructions.

2.2.3.2 Installing the Blade Server Into the Shelf

Note – You can install the Sun Netra CP3250 blade server in any available slot in the

ATCA shelf except for slots 7 and 8.

1. If you have installed an advanced rear transition module (ARTM), go to the

front of the system and locate the corresponding slot number of the ARTM.

2. Remove the filler panel from the blade server slot, if necessary.

The filler panel is secured to the card cage using two screws, one at the top of the

filler panel, the other at the bottom. Store the filler panel in a safe place; you

might need to use it again if you remove a blade server for an extended time.

3. Prepare the Sun Netra CP3250 blade server by opening the injector/ejector

latches.

4. Carefully align the edges of the blade server with the guides in the appropriate

slot.

Look into the enclosure to verify correct alignment of the rails in the guides.

5. Keep the blade server aligned in the guides and slide the blade server in until

the injector/ejector latches engage the card cage.

6. Push the blade server slightly into the backplane connectors and close the

latches to seat the blade server in the connectors (

Push the upper latch lever to engage the blade server. When the upper and lower

levers are engaged properly, the blue Hot-Swap LED blinks while the blade server

is initializing. The blue LED turns off and the green OK LED lights when the

blade server is ready for use.

FIGURE 2-3).

Note – If the hot-swap LED does not light, then wiggle and push the latch so it

engages the hot-swap switch.

Chapter 2 Hardware Installation and Service 2-11

Page 46

FIGURE 2-3 Engaging the Netra CP3250 Blade Server Latch

7. Tighten the locking screws and the top and the bottom of the Sun Netra CP3250

blade server to ensure that it is secured to the ATCA shelf (

The blade server is now completely installed and will power on automatically.

8. Configure the switches accordingly as described in Section 4.4, “Configuring

Sun Netra CP3250 blade server For 1 GbE or 10 GbE Switches” on page 4-4.

2-12 Sun Netra CP3250 Blade Server User’s Guide • April 2009

FIGURE 2-2).

Page 47

2.2.4 Connecting External I/O Cables

Front panel ports are typically used for maintenance and troubleshooting purposes

in installed and running systems. External I/O cables are connected to the Sun Netra

CP3250 blade server or to the Netra CP32x0 rear transition module when a rear

transition module is used.

To connect each of these following cables:

■ For Ethernet connections, Category 5e or better, network cable is required.

Connect one end of the Ethernet cable to a suitable 10/100/1000 MBASE-T

Ethernet switch and the other end to one of the Ethernet ports on the Sun Netra

CP3250 blade server or the Netra CP32x0 ARTM.

■ Attach asynchronous serial I/O cables from serial communication devices to the

RJ-45 serial ports on the Sun Netra CP3250 blade server or Netra CP32x0 ARTM.

2.2.4.1 Connecting Cables to a System Console Running the Solaris OS

1. Connect a RJ-45 style serial cable to the serial console port on the front panel of

the Sun Netra CP3250 blade server (

transition module.

Serial access (both front and rear) is through the same serial interface controller. If

both ports are connected at the same time, console input and output can be

performed through both, however, this configuration is not recommended. If both

access interfaces are not connected at the same time, console input/output can be

performed through NetConsole session via the ShMM.

FIGURE 2-4) or the Netra CP32x0 rear

2. Connect the other end of the serial cable to the serial port of the system serving

as the serial console.

Chapter 2 Hardware Installation and Service 2-13

Page 48

FIGURE 2-4 Serial Port on the Netra CP3250 Blade Server

Serial port

3. Use one of the following to establish a full-duplex serial terminal connection

with the Sun Netra CP3250 blade server:

■ The tip utility

■ The minicom utility

2-14 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 49

■ A telnet utility (Connect to the proper port on a Network Terminal Server to

which the Sun Netra CP3250 blade server is connected.)

■ Another suitable serial communications program on the system console

For example, if you are using a UNIX system as the system console, at the UNIX

prompt in a command tool or shell tool, or serial port A, type:

# tip -9600 /dev/ttya

2.2.4.2 Connecting Cables to the System Console Not Running the Solaris OS

1. Connect a serial cable to the serial console port on the front panel of the Sun

Netra CP3250 blade server (

FIGURE 2-4) or the Netra CP32x0 rear transition

module.

2. Connect the other end of the serial cable to the serial port of the system serving

as the system console.

3. Set the serial communications settings to 9600 baud, 8 bit, 1 stop bit, no parity,

and no handshake.

2.2.4.3 Netinstall Boot Device Map

TABLE 2-2 provides a map of netinstall boot devices. You may need this information

to understand which MAC address is associated with the system IP address on the install

server.

For example, the Base Fabric interface is connected to the switch model-number in

slot 8 of the ATCA shelf. To install to this device, select the xxx Ethernet interface

from the BIOS setup menus.

TABLE 2-2 Netinstall Boot Device Table

MAC Address Solaris

Device

00:14:4f:xx.yy.zz+0 bge0 (BMC5715C) Base Fabric 0 Slot 7

00:14:4f:xx.yy.zz+1 bge1 (BMC5715C) Base Fabric 1 Slot 8

00:14:4f:xx.yy.zz+2 bge2 (MCP55)and

00:14:4f:xx.yy.zz+3 bge3 (MCP55)and

Hardware

Device Connects to...

mgtA (front panel)

(BCM5715C)

mgtB (rear panel)

(BCM5715C)

Chapter 2 Hardware Installation and Service 2-15

Switch Slot

Connection

Page 50

TABLE 2-2 Netinstall Boot Device Table (Continued)

MAC Address Solaris

Device

Hardware

Device Connects to...

00:14:4f:xx.yy.zz+4 nxge0 (Sun 10 GbE

Multithreaded

Networking

Technolgy 10 GB)

0:14:4f.xx.xn+5 nxge1 (Sun 10 GbE

Multithreaded

Networking

Technolgy 10 GB)

0:14:4f.xx.xn+6 nxge2 (Sun 10 GbE

Multithreaded

Networking

Technolgy 1 GB)

0:14:4f.xx.xn+7 nxge3 (Sun 10 GbE

Multithreaded

Networking

Technolgy 1 GB)

The Sun Netra CP3250 blade server supports virtual LAN configuration for the Sun

10 GbE Multithreaded Networking Technolgy ports (MAC addresses 4, 5, 6, and 7).

When configured, the virtual LAN feature enables the assignment of multiple MAC

address to one port.

TABLE 2-3 lists the extra MAC addresses available for the Sun 10

GbE Multithreaded Networking Technolgy ports.

Switch Slot

Connection

Extended Fabric 0 Slot 7

Extended Fabric 1 Slot 8

AMC and ARTM

AMC and ARTM

TABLE 2-3 Extra MAC Addresses for Virtual LAN Configuration

Primary MAC Address Additional MAC Addresses

0:14:4f.xx.xn+4 0:14:4f.xx.xn+8 through 0:14:4f.xx.xn+14

0:14:4f.xx.xn+5 0:14:4f.xx.xn+15 through 0:14:4f.xx.xn+21

0:14:4f.xx.xn+6 0:14:4f.xx.xn+22 through 0:14:4f.xx.xn+28

0:14:4f.xx.xn+7 0:14:4f.xx.xn+29 through 0:14:4f.xx.xn+35

2-16 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 51

2.3 Service Procedures

2.3.1 Hot-Swapping the Netra CP3250 Blade Server

You can remove the Sun Netra CP3250 blade server without powering off the entire

chassis by performing these steps.

1. Power off the blade server.

See Section 2.3.2, “Powering Off the Netra CP3250 Blade Server” on page 2-17.

2. Remove the blade server.

See Section 2.3.3, “Removing the Netra CP3250 Blade Server” on page 2-18.

2.3.2 Powering Off the Netra CP3250 Blade Server

1. Shut down the operating system.

Log in and shut down any OS operating on the blade server or its companion

ARTM.

2. Deactivate the blade server.

Log in to the shelf manager and deactivate the blade server in the target slot.

For example, to shut down the blade server in slot 3, log in to the shelf manager

and type:

# clia deactivate board 3

Wait for the blue Hot-Swap LED to light steadily before removing the blade

server.

Chapter 2 Hardware Installation and Service 2-17

Page 52

2.3.3 Removing the Netra CP3250 Blade Server

1. Power off the Sun Netra CP3250 blade server.

Use the instructions in Section 2.3.2, “Powering Off the Netra CP3250 Blade

Server” on page 2-17.

2. If installed, remove all cables from the front of the Sun Netra CP3250 blade

server.

3. Loosen the locking screws to release the blade server from the ATCA shelf.

4. When the blue Hot-Swap LED lights steadily, release the upper latch and the

lower latch at the same time to unseat the blade server from the connectors.

5. Remove the blade server from the ATCA shelf and place the blade server on an

antistatic mat.

2.3.4 Powering On the System

Sun Netra CP3250 blade servers are powered on automatically via the H8 BMC

when you install the blade server into a slot in the ATCA shelf. Once installed, the

blade server sequences through power-on states until it is fully powered on.

2.3.5 Automatic Power-Off Events

A power-off sequence is initiated either by a request from the shelf manager or a

fault condition. The Sun Netra CP3250 blade server shuts down to standby power

mode when the following upper critical threshold conditions are met:

■ Detection of DC input (both -48V A and -48V B) drop for more than 5ms

■ Processor thermal trip drops to standby mode

Thermal trip of DC brick turns off all local power (standby included)

2-18 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 53

2.3.6 Servicing DIMMs

2.3.6.1 DIMM Requirements

The Sun Netra CP3250 blade server supports a total of six DIMMs and the maximum

memory capacity of 24 GB (using four 4 GB DIMMs). The Sun Netra CP3250 blade

server accommodates the following DIMMs and configurations:

■ Up to six standard DDR2 SDRAM registered/ECC DIMMs

■ DIMMs must be installed in matching pairs

■ 2 GB and 4 GB DDR2 modules are supported

■ Maximum of 24 GB in six slots

The Sun Netra CP3250 blade server supports DIMMs that have the following

characteristics:

■ A 144-bit wide data bus DDR2 interface (2x64-bit data + 2x8-bit ECC)

■ DDR2 DIMM: 4.4 - 7.0 watts (1.8 V)

■ Very low profile (VLP) with a maximum height of 0.72 inch (18.3 mm)

Chapter 2 Hardware Installation and Service 2-19

Page 54

FIGURE 2-5 Locating DIMM Slots

Populate DIMMs in matching pairs, starting with Pair 0, then adding Pair 1, then

Pair 2.

There are two channels, Channel A and Channel B. DIMMs are identified as A0, B0,

A1, B1, A2, and B2. Where Pair 0 would be A0 and B0, and so on.

2-20 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 55

2.3.6.2 Installing a DDR2 DIMM

The following procedure provides a general guide for installing additional memory.

However, for specific directions on installing DIMMs on the Sun Netra CP3250 blade

server, refer to the documentation that shipped with the DIMMs.

1. Access the blade server by performing one of the following procedures:

■ If the Sun Netra CP3250 blade server is installed in an ATCA shelf, remove the

blade server from the shelf as explained in Section 2.3.3, “Removing the Netra

CP3250 Blade Server” on page 2-18.

■ Remove the Sun Netra CP3250 blade server from its antistatic envelope and place

it on an ESD mat near the ATCA shelf.

2. Take antistatic precautions: Attach and electrically ground the wrist strap.

Caution – Always wear a grounded antistatic wrist strap when handling DIMMs.

3. Locate the DIMM connectors on the Sun Netra CP3250 blade server.

Select the connectors where you will install the DIMM. See

slot locations.

Caution – Do not remove the DIMM from its antistatic container until you are

ready to install the DIMM on the Sun Netra CP3250 blade server. Handle the DIMM

only by its edges. Do not touch DIMM components or metal parts. Always wear a

grounded antistatic wrist strap when handling DIMM.

FIGURE 2-5 for DIMM

4. Remove the DIMM from its protective packaging, holding the module only by

the edges.

Note – Before installing a replacement DIMM, verify that the new DIMM is the

same size as its paired DIMM.

5. Holding the DIMM upright to the blade server, insert the bottom edge of the

DIMM into the bottom of the slot’s hinge-style connector (

FIGURE 2-6).

Caution – Evenly engage the DIMM in its hinge-style slot; uneven contact can

cause shorts that will damage the Sun Netra CP3250 blade server. Do not rock the

DIMM into place. Ensure that all contacts engage at the same time. You will feel or

hear a click when the DIMM properly seats in the connector.

Chapter 2 Hardware Installation and Service 2-21

Page 56

The socket and module are both keyed, which means that the DIMM can be installed

only one way. With even pressure, push simultaneously on both upper corners of the

DIMM until its bottom edge (the edge with the gold fingers) is firmly seated in the

connector.

FIGURE 2-6 Installing a DIMM

6. Press the top edge of the DIMM toward the blade server until the retainer clips

click into place in the notches on the DIMM sides (

FIGURE 2-6).

The small metal retainer clips on each side of the DIMM slot are spring-loaded, and

they should click into place in the notches on the sides of the DIMM.

2-22 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 57

2.3.6.3 Removing a DDR2 DIMM

If you are returning the DIMM or the blade server for service, or if you are replacing

a DIMM with another DIMM, remove the DIMM from the Sun Netra CP3250 blade

server.

Note – Safely store the original factory-shipped DIMM and related DIMM

packaging. Store any removed DIMM in the new DIMM packaging.

To remove a DIMM from the Sun Netra CP3250 blade server, perform the following

steps:

1. Access the blade server by performing one of the following procedures:

■ If the Sun Netra CP3250 blade server is installed in an ATCA shelf, remove the

blade server from the shelf as explained in Section 2.3.3, “Removing the Netra

CP3250 Blade Server” on page 2-18.

■ Remove the Sun Netra CP3250 blade server from its antistatic envelope and place

it on an ESD mat near the ATCA shelf.

If an ESD mat is not available, you can place the blade server on the antistatic

envelope in which it was packaged.

Caution – Do not place blade servers on top of an antistatic bag unless the outside

of the bag also has antistatic protective properties.

2. Take antistatic precautions: Attach and electrically ground the wrist strap.

Caution – Always wear a grounded antistatic wrist strap when handling DIMMs.

3. Simultaneously pull both spring retainer clips outward from the slot for the

DIMM you want to remove.

4. Grasp the DIMM by the edges, and carefully pull it out of its connector.

Place it in an antistatic bag.

Chapter 2 Hardware Installation and Service 2-23

Page 58

FIGURE 2-7 Removing a DIMM

5. If you are replacing the DIMM you removed with a new DIMM, install it as

described in Section 2.3.6.2, “Installing a DDR2 DIMM” on page 2-21.

2.3.7 Installing the Optional Compact Flash Card

An IDE Compact Flash card can be installed on the Sun Netra CP3250 blade server.

The Compact Flash card is not hot-swappable, and there is no access to the Compact

Flash card once the Sun Netra CP3250 blade server is installed in an ATCA shelf.

1. Access the blade server by performing one of the following procedures:

■ If the Sun Netra CP3250 blade server is installed in an ATCA shelf, remove the

blade server from the shelf as explained in Section 2.3.3, “Removing the Netra

CP3250 Blade Server” on page 2-18.

■ Remove the Sun Netra CP3250 blade server from its antistatic envelope and place

it on an ESD mat near the ATCA shelf.

If an ESD mat is not available, you can place the blade server on the antistatic

envelope in which it was packaged.

Caution – Do not place blade servers on top of an antistatic bag unless the outside

of the bag also has antistatic protective properties.

2-24 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 59

2. Push where indicated on door that provides access to the Compact Flash, then

open the door.

FIGURE 2-8 shows the door.

FIGURE 2-8 Opening the Door to Access Compact Flash

3. Locate the Compact Flash connector.

The connector is located on the blade server, behind the sheet metal door

protecting the AMC slot B1 (

FIGURE 2-9).

Chapter 2 Hardware Installation and Service 2-25

Page 60

FIGURE 2-9 Compact Flash Location

4. To install the Compact Flash card, use the arrow on the card as a guide to insert

the card into the Compact Flash connector.

Note – Sun Compact Flash cards have a life time of 2,000,000 write/erase cycles.

Users are responsible for ensuring that the operating system and applications do not

exceed this limitation.

2-26 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 61

2.3.8 Installing Optional AMC

An Advanced Mezzanine card (AMC) is a card or module that provides additional

functionality to the Sun Netra CP3250 blade server. The blade server contains one

AMC slot in which you can install an optional AMC device. An AMC device can be

installed and removed via a cutout in the front panel while the Sun Netra CP3250

blade server is installed in the chassis.

Note – The following procedure provides a general set of instructions for installing

an AMC on the Sun Netra CP3250 blade server. Refer to the AMC manufacturer’s

documentation for specific instructions on installing these devices.

1. Retrieve the wrist strap from the shipping kit.

2. Attach the adhesive copper strip of the antistatic wrist strap to the metal

chassis.

Wrap the other end twice around your wrist, with the adhesive side against your

skin.

3. Remove the AMC slot filler panel from the blade server ’s front panel

(

FIGURE 2-10).

Chapter 2 Hardware Installation and Service 2-27

Page 62

FIGURE 2-10 Removing an AMC Filler Panel

4. Retrieve the AMC from its shipping kit and place it on an antistatic surface.

5. Insert the AMC through the cutout and into the AMC slot (

2-28 Sun Netra CP3250 Blade Server User’s Guide • April 2009

FIGURE 2-11).

Page 63

FIGURE 2-11 Installing an AMC

Caution – Do not use excessive force when installing the AMC into the slot. You

might damage the AMC connector on the Sun Netra CP3250 blade server, causing

permanent damage to the AMC or the blade server. If the AMC does not seat

properly when you apply even pressure, remove the AMC and carefully reinstall it.

Chapter 2 Hardware Installation and Service 2-29

Page 64

6. Carefully push the AMC into the AMC connector.

7. Refer to the AMC documentation for software and cabling installation

instructions.

2.3.9 Adding or Replacing the Battery

The Sun Netra CP3250 blade server does not ship with the battery. If you want

CMOS settings to be preserved in the event of power loss, obtain and install the

battery.

The battery must be type CR1632, with a minimum of 4ma abnormal charging

current rating (for example; a Renata CR1632).

Caution – Risk of explosion if the battery is replaced by an incorrect type. Dispose

of used batteries properly in accordance with manufacturer’s instructions and local

regulations.

To install the battery:

1. Remove the old battery, if necessary.

2. Slide the new battery into the holder with the side labeled “+” facing up.

2-30 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 65

2.3.10 Changing Jumper Settings

Jumpers and their switches are located near the heatsink on the blade server.

2.3.10.1 Clearing the CMOS Setting Using Jumper 2

Reset jumper 2 to clear the CMOS settings, which restores the default BIOS settings.

Jumper 2 is shown in

FIGURE 2-12. The jumper housing should be stored in the P2/P3

position, which is the run position.

FIGURE 2-12 Jumper 2 in the Default Run Position

TABLE 2-4 provides information on the pin functions on jumper 2.

TABLE 2-4 Pin Functions on Jumper 2

Pin Number Purpose

Pin 1 Battery Feed

Pin 2 VCC_RTC (destination for battery

power)

Pin 3 BATT_CLR (resistor to GND, used to

drain capacitive charge and clear the

CMOS memory)

Chapter 2 Hardware Installation and Service 2-31

Page 66

To reset the jumper and return the CMOS settings to the default settings, perform

the following steps:

1. Remove the jumper housing from the run position (P2/32) and move it to the

reset position (P1/P2).

2. Wait at least one second for the CMOS settings to reset and then move the

jumper housing back to the run position (

3. Reinstall the blade server.

Use the procedure in Section 2.2.3.2, “Installing the Blade Server Into the Shelf”

on page 2-11.

FIGURE 2-12).

Note – The blade server will operate normally only when the jumper housing is in

the run position.

2.3.10.2 Changing the OOS LED Color Using Jumper 13

The color of the Out-of-service (OOS) LED can be set to red or amber by moving

jumper 13 to the appropriate position. Amber is the default color for the OOS LED.

To change the Jumper 13 position to display a red OOS LED:

1. Remove the jumper housing from the default (amber) position (P2/P3) and

move it to the red position (P1/P2).

2. Reinstall the blade server.

Use the procedure in Section 2.2.3.2, “Installing the Blade Server Into the Shelf” on

page 2-11.

2-32 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 67

2.3.11 Checking DIP Switch Settings

DIP switch settings are set by default at the factory. The following settings are

required for normal operation of the blade server.

FIGURE 2-13 SW1 Default DIP Switch Settings

FIGURE 2-14 SW4 Default DIP Switch Settings

Chapter 2 Hardware Installation and Service 2-33

Page 68

FIGURE 2-15 SW5 Default DIP Switch Settings

2.3.12 Resetting the Netra CP3250 Blade Server

Caution – Do not operate the ATCA shelf without all fans, component heatsinks, air

baffles, and covers installed. Severe damage to components can occur if the ATCA

shelf is operated without adequate cooling mechanisms.

1. Use a spudger tool or other stylus to press and release the recessed Reset

button on the front of the Sun Netra CP3250 blade server (

2. Confirm the progress of the reset by monitoring the BIOS POST messages.

2-34 Sun Netra CP3250 Blade Server User’s Guide • April 2009

FIGURE 2-16).

Page 69

FIGURE 2-16 Netra CP3250 Blade Server Front Panel

Reset button

Chapter 2 Hardware Installation and Service 2-35

Page 70

2-36 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 71

CHAPTER

3

Hardware Architecture

This chapter describes the hardware components and architecture of the Sun Netra

CP3250 blade server.

This chapter contains the following sections:

■ Section 3.1, “Block Diagram” on page 3-2

■ Section 3.2, “Intel Processors” on page 3-3

■ Section 3.3, “Intel San Clemente MCH” on page 3-3

■ Section 3.4, “Memory” on page 3-4

■ Section 3.5, “Networking and I/O” on page 3-5

■ Section 3.6, “I/O Components” on page 3-8

3-1

Page 72

3.1 Block Diagram

3-2 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 73

3.2 Intel Processors

The Sun Netra CP3250 blade server supports dual 64-bit low voltage Intel Xeon

(Harpertown) processors at 2.13 GHz with 12 MB of L2 cache and a 1066 MHz

system bus. This processor is designed for high-performance, low-power

communication, storage, and embedded applications. It is built on Intel’s new 65nm

topology. The following are the key features of the Harpertown processor:

■ Quad-Core processor optimized for high performance, low-power

communication, storage, and embedded applications.

■ Four complete execution cores in a single processor

■ Dual processor support (eight high-performance cores per Sun Netra CP3250

blade server)

■ FSB Parity Protection providing key reliability and data integrity features

■ Intel Smart Cache Technology

■ Enhanced 36-bit memory addressing

■ FSB address, data, and response parity protection

■ Enhanced Intel Speedstep Technology

■ Intel¨ Advanced Thermal Manager

■ Streaming SIMD Extensions 3 (SSE3) Support

■ Embedded life cycle support

3.3 Intel San Clemente MCH

The architecture of the Intel E7520 Memory Controller Hub (MCH) provides the

performance and feature set required for performance servers, with configuration

options that facilitate optimization of the platform for workloads characteristic of

communication, presentation, storage, performance computation, or database

applications. To accomplish this, the MCH has numerous Reliability, Availability,

Serviceability, Usability and Manageability (RASUM) features on multiple interfaces.

The following list provides key features on the MCH:

■ Supports two processors on dual independent point-to-point system buses

operating at 266MHz (1066MTS) or 333MHz (1333MTS)

■ Six PCI Express x4 ports. Each of these ports can be configured as x4, x8, or x16

ports interfaces

Chapter 3 Hardware Architecture 3-3

Page 74

■ Enterprise South Bridge Interface (ESI) to ICH9 device

■ Maximum memory bandwidth using DDR2-667 is 10.6GB per slot for two DDR2

channels

3.4 Memory

The Sun Netra CP3250 blade server supports 4-Gbyte registered DDR2-667 memory,

for up to 24 Gbytes memory total. When four DIMM slots or less are populated, the

DIMM clock rate will be set to the max clock rate of up to 333 Mhz. When six

DIMMs slots are populated, the DIMM clock rate will be set to a max clock rate of

up to 267 Mhz.

For optimal performance, memory DIMMs must be installed in like pairs. The

controller supports 1 bit per byte ECC and supports DDR2 667 registered DRR

SDRAM modules. For more information on supported DIMM configurations, see

Section 2.3.6.1, “DIMM Requirements” on page 2-19.

Additional features of the Sun Netra CP3250 blade server’s memory architecture

include:

■ Very low profile (0.72 inch) DIMM support

■ Memory bandwidth up to 5.3 Gbyte/sec

■ DDR2 power requirements 4.4W to 7.0W (1.8V)

Although single channel operation is defined by the Intel Memory Controller and

will function, this configuration will not be qualified, tested, or supported on the

Sun Netra CP3250 blade server.

The supported configuration is dual channel, which follows the DIMM loading

order: Pair 0 (first) -> Pair 1 (second) -> Pair 2 (third).

DIMMs must be loaded by pairs in the order indicated. Install DIMMs in pairs of

like memory types.

3-4 Sun Netra CP3250 Blade Server User’s Guide • April 2009

Page 75

3.5 Networking and I/O

Networking and I/O are provided by the following chips and interconnects:

■ ICH9 I/O controller hub

■ PCI Express Bus

■ LPC bus interface

■ Redundant BIOS

■ Trusted Platform Module

■ Broadcom 5715C Gbit Ethernet chip

■ Sun 10 GbE Multithreaded Networking Technolgy Dual 10-Gbit + Dual 1-Gbit

Ethernet chip

3.5.1 ICH9 I/O Controller Hub

The ICH9 I/O provides legacy function support similar to that of previous

ICH-family devices, but with extensions in Serial-ATA technology and 64-bit/66

MHz PCI-X support. The ICH9 I/O also includes integrated USB 2.0 and USB 1.0

support, an LPC interface, a system management interface, a power management

interface, PECI interface, integrated Gigabit Ethernet controllers (not used on Sun

Netra CP3250 blade server), and an integrated DMA controller.

3.5.2 PCI Express Bus

PCI Express 1.0 (PCIe) is a high-speed, point-to-point dual simplex chip

interconnect. It is the latest extension of the PCI bus. PCIe operates at 2.5 GHz and

supports land widths of x1, x2, x4, x8, x16, and x32. Additional features include:

■ Serial point-to-point interconnect between two devices

■ Each lane supports two differential signal pairs, one pair for each data direction

■ 2.5-Gbyte/sec transfer rate

■ Scalable performance based on the number of lanes implemented per interconnect

Chapter 3 Hardware Architecture 3-5

Page 76

3.5.3 LPC Bus Interface

The LPC bus is a multiplexed (command, address, and data) serialized 4-bit bus

with optional side band signals. It replaces the ISA/X-bus and reduces pin count

(approximately 40) over the ISA/X-bus.