Page 1

StorageTek

Virtual Tape Storage System

®

(VTSS) for VSM5

Planning and System Assurance Guide

Part Number: 96257

Revision: A

Page 2

Page 3

Virtual Tape Storage

Subsystem (VTSS)

for VSM5

Planning and System Assurance Guide

®

Page 4

Information in this publication may be updated at any time without notice. Please direct comments about this document

to the Sun Learning Services (SLS) e-mail feedback system at:

slsfs@sun.com

>> Or write to:

Sun Learning Services

Storage Technical Publications

Sun Microsystems

One StorageTek Drive

Louisville, CO 80028-3256 USA

T o ensure proper handling of your comments, specify the publication name, part number, edition number, and applicable

page(s) in all correspondence. If you would like a personal response, include your contact information. Submitted content becomes the sole property of Sun Microsystems.

Export Destination Control Statement

These commodities, technology or software were exported from the United States in accordance with the Export Administration Regulations. Diversion contrary to U.S. law is prohibited.

Disclaimer of Warranties and Limitation of Liability

Sun Microsystems, Inc. (Sun) has no liability for your use of this publication or any associate d hardw are, software or

spare parts. You are responsible for any damage resulting from use of this publication, and associated hardware, software or spare parts, including loss of data. Y ou are responsible for backing up your data. Use of this publication, and associated hardware, software and spare parts, should be in accordance with this publication and all other product specifications and instructions, and in compliance with all applicable terms, conditions, laws, rules and regulations.

SUN MAKES NO WARRANTIES OF ANY KIND AND EXPRESSLY DISCLAIMS ALL EXPRESS AND IMPLIED WARRANTIES, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. SUN SHALL NOT BE LIABLE FOR ANY DIRECT , INDIRECT, SPECIAL, CONSEQUENTIAL, INCIDENT AL OR

PUNITIVE DAMAGES RESULTING FROM USE OF THIS PUBLICA TION OR ANY ASSOCIA TED HARDWARE, SOFTWARE OR SPARE PARTS, INCLUDING LOSS OF DATA, EXCEPT FOR PERSONAL INJURY DIRECTLY CAUSED

BY USE OF THIS PUBLICATION.

Proprietary Information Statement

Information in this document, including any associated software program, may not be reproduced, disclosed or distributed in any manner without written consent from Sun.

If you find this publication, please return it to Sun Microsystems, One StorageTek Drive, Louisville, CO 80028-5214,

USA. Return postage will be paid by Sun.

Revision A (September 2006)

This document contains 118 pages. “Revision History / Summary of Changes” on page v lists release dates, part numbers, and editions for this document, plus a brief summary of significant content changes.

Sun, Sun Microsystems, the Sun logo, StorageTek, the S torageT ek logo, Virtual S torage Manager, and VSM are brands,

trademarks or registered trademarks of Sun Microsystems, Inc. in the United States and other countries.

© 2001-06 by Sun Microsystems, Inc. All rights reserved.

iv Sun Confidential: Internal Only 96257

Revision A

Page 5

Revision History / Summary of Changes

EC Doc PN

133687 96257 A

SAP

Revision

Release

Date

September

2006

Supported Versions / Summary of Changes

New document created for FRS release of VSM5-VTSS

system (Phase 1), including 2Gb back-end FC loops,

VCF3 cards, 146GB drives, detached operator panel, etc.

96257 Sun Confidential: Internal Only v

Revision A

Page 6

Content s

Revision History / Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Warranty Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Class 1 Laser Product Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Cabling Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Hazardous Materials Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Standards Conformance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Product Safety Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Internal Code License Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Safety / Fiber Optic / ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Electrostatic Discharge Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Fiber Optic Component Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Providing Feedback About This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Optimizing Content For Electronic Viewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Notational and Typographic Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xix

Where to Find Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

VSM Engineering Website . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Customer Resource Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

Product-Specific Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxi

Product Education and Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxi

SE Support Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Global Services Field Support Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Storage Sales Community . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Partners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

‘Documents on CD’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

Colophon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

1: Planning and Implementation Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Creating Planning Teams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

Planning / Readiness / Implementation T imelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

2: Configuration Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Defining Customer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

VSM Sizer Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

MVC Sizer Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

MVC Migration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

CDS Sizer Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

VTSS Configuration Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

VSM5-VTSS Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

vi Sun Confidential: Internal Only 96257

Revision A

Page 7

VSM5-VTSS Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Model Numbers / Configurations / Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Prerequisites for FICON Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Additional Prerequisites for FICON RTDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Native FICON Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

FICON Data Transfer Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

FICON Cabling — Short-Wave vs. Long-Wave Co nn ec tio ns . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

VCF3 (FICON) Card Configuration Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Fibre Channel Cables — Available Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

AC Source Power Specifications and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

DC Power Supply Voltage Ripple Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

3: Implementation Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

4: Site Readiness Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Site Evaluation – External Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Site Evaluation – Internal Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Transfering Equipment Point-to-Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Structural Dimensions and Obstructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Elevator Lifting Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Floor-Load Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Ramp Inclines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Data Center Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Emergency Power Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Fire Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

Site Power Distribution Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Equipment Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Source Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Dual Independent Source Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Transient Electrical Noise and Power Line Disturbances . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

HVAC Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Environmental Requirements and Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Floor Construction Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Floor Loading Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Floor Loading Specifications and References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

Raised-Floor Lateral Stability Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Raised-Floor Panel Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Raised-Floor Pedestal Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Physical Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

A: Specifications and Additional Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-57

Motherboard and FRU Interconnections – Side 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-58

Motherboard and FRU Interconnections – Side 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-59

Power Safety Grounding Diagram – Side 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-60

Power Safety Grounding Diagram – Side 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-61

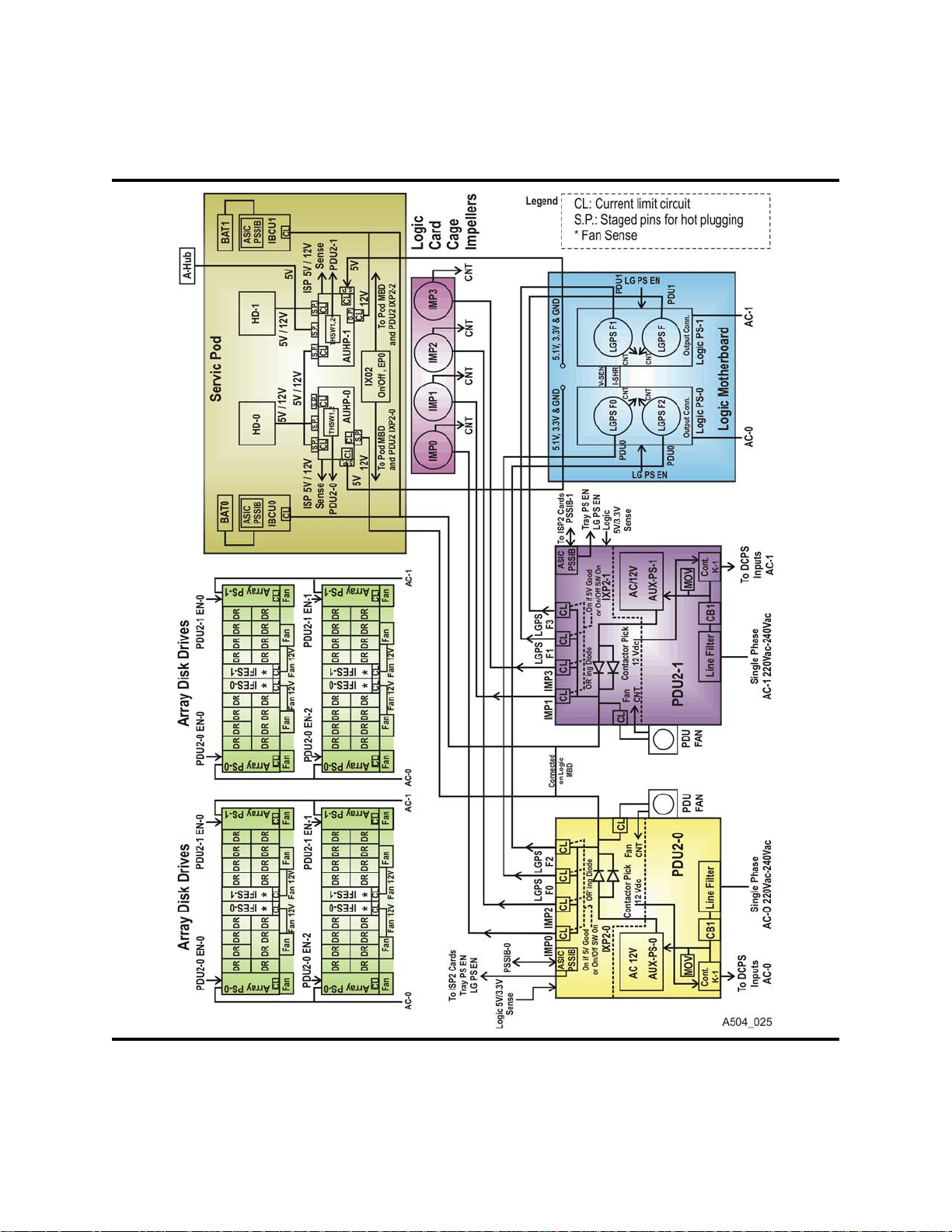

Power System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-62

Data Paths and Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-63

Fiber Optic Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-64

VShell Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-64

96257 Sun Confidential: Internal Only vii

Revision A

Page 8

Sample IOCP Gen for FICON Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-65

Virtual Tape Drive Mapping and Host Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-66

FRU Identifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-67

Array Drive Module Status Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-72

B: FICON Channel Extension Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-75

Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-76

General Channel Extension Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-77

FICON Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-78

Placement of Extension Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-78

Interoperability Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-78

FICON Channel Extension – Sample Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-79

McData/CNT Channel Extension Interoperability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-81

Cisco Systems Channel Extension Interoperability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-83

B: Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-85

D: Forms and Reference Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-99

96257 Sun Confidential: Internal Only viii

Revision A

Page 9

Figures

Figure 1-1. System Assurance Process Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Figure 2-1. VSM Quick Tool – Tool Selection Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Figure 2-2. VSM Sizer Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Figure 2-3. MVC Sizer Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Figure 2-4. MVC Migration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Figure 2-5. CDS Sizer Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Figure 2-6. Native FICON Attachment Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Figure 2-7. FICON Channel Card Configuration – 4 VCF Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Figure 2-8. FICON Channel Card Configuration – 6 VCF Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Figure 2-9. FICON Channel Card Configuration – 8 VCF Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Figure 4-1. Site Electrical Power Distribution System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Figure 4-2. Transient Electrical Grounding Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

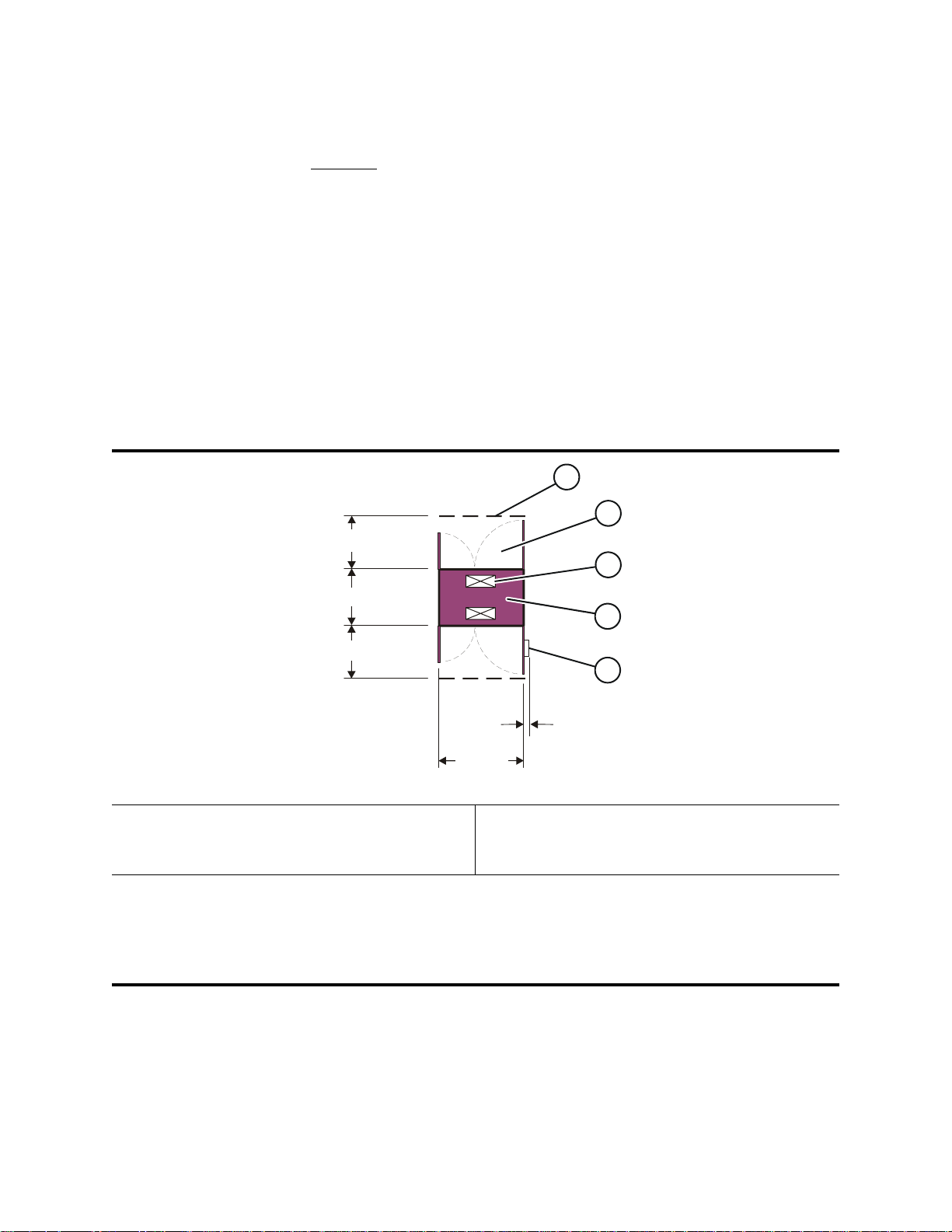

Figure 4-3. VSM5-VTSS Cabinet Weight Distribution and Leveler Locations . . . . . . . . . . . . . . . . . . . 4-54

Figure 4-4. VSM5-VTSS Cabinet Dimensions for Physical Space Planning . . . . . . . . . . . . . . . . . . . . 4-55

Figure A-1. VSM5-VTSS Motherboard and FRU Interconnections – Side 0 . . . . . . . . . . . . . . . . . . . . A-58

Figure A-2. VSM5-VTSS Motherboard and FRU Interconnections – Side 1 . . . . . . . . . . . . . . . . . . . . A-59

Figure A-3. VSM5-VTSS Power Safety Grounding Diagram – Side 0 . . . . . . . . . . . . . . . . . . . . . . . . . A-60

Figure A-4. VSM5-VTSS Power Safety Grounding Diagram – Side 1 . . . . . . . . . . . . . . . . . . . . . . . . . A-61

Figure A-5. VSM5-VTSS Power System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-62

Figure A-6. VSM5-VTSS Data Paths and Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-63

Figure A-7. Sample IOCP Gen for FICON Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-65

Figure A-8. Array Drive Module States and Relationships . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-72

Figure B-1. Host-to-VTSS Channel Extension – Direct Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . B-79

Figure B-2. Host-to-VTSS Channel Extension – Behind Single FICON Switch / Director . . . . . . . . . . B-79

Figure B-3. Host-to-VTSS Channel Extension – Between Cascaded FICON Switches / Directors . . . B-79

Figure B-4. VTSS-to-RTD Channel Extension – Direct Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . B-80

Figure B-5. VTSS-to-RTD Channel Extension – Between Cascaded FICON Switches / Directors . . . B-80

Figure B-6. VTSS-to-VTSS Channel Extension – Between Cascaded FICON Switches / Directors . . B-81

96254 Sun Confidential: Internal Only ix

Revision A

Page 10

Tables

Table 2-1. Configuration Planning Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Table 2-2. VSM5-VTSS Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

Table 2-3. VSM5-VTSS Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

Table 2-4. VSM5-VTSS Model Numbers / Configurations / Capacities . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Table 2-5. Single-Mode vs. Multi-Mode FICON Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Table 2-6. Fibre Channel Cables – Available Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

Table 2-7. VSM5-VTSS AC Source Power Specifications and Connectors . . . . . . . . . . . . . . . . . . . . . .2-41

Table 2-8. VSM5-VTSS DC Power Supply Voltage Ripple. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

Table 2-9. VSM5-VTSS Power Requirements — Single AC Source Power Cable Operation . . . . . . . .2-42

Table 2-10. VSM5-VTSS Power Requirements — Dual AC Source Power Cable Operation . . . . . . . .2-42

Table 3-1. Implementation Planning Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-43

Table 4-1. Site Readiness Planning Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-45

Table 4-2. Source Power Requirements for VSM5 Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-50

Table 4-3. VSM5-VTSS Floor Loading Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-53

Table 4-4. VSM5-VTSS Cabinet Superimposed Floor Loading Example. . . . . . . . . . . . . . . . . . . . . . . .4-53

Table 4-5. Raised Flooring Horizontal Force Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-54

Table A-1. Fiber Optic Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-64

Table A-2. VShell Command Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-64

Table A-3. Mapping Parameters for 256 Virtual Tape Drives (VTDs). . . . . . . . . . . . . . . . . . . . . . . . . . A-66

Table A-4. VSM5-VTSS FRU Identifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-67

Table A-5. Array Drive Module Status Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-73

96254 Sun Confidential: Internal Only x

Revision A

Page 11

Notices

■ W arranty Notice

This document neither extends nor creates warranties of any nature, expressed or implied. Sun cannot accept any responsibility for your use of the information in this document, or for your use of any associated software programs. Sun assumes no responsibility

for data corruption or erasure resulting from use of the information in this docum ent, or

use of software programs. You are responsible for backing up your data. You should ensure that your use of this information complies with all applicable laws, rules and regulations of the jurisdiction(s) where the information is used.

Any changes or modifications made to this equipment which are not expressly approved

in advance by Sun will void the warranty, and may cause the equipme nt to create harmful

interference.

■ Class 1 Laser Product Notice

Laser transceivers are classified as Class 1 Laser Product, and have an output less than

70 microwatts and a wavelength of 850 nm. Sun Class 1 Laser Products comply with EN

60 825-1(+A-11) and with sections 21 CFR 1040.10 and 1040.11 of the Food and Drug

Administration (FDA) regulations. The following translations are provided to identify laser

safety and classification:

Finnish

French

Swedish

DANGER !!

Lasers and high-frequency signals used in optical fiber cables can cause eye

injury if safety precautions are not followed. To prevent injury, observe these

precautions: Never look directly into an optical fiber cable, laser transceiver,

or connector; ensure that all transceiver optical ports are terminated with a

cable or cover; and comply with all warning labels on fiber optic components.

: Luokan 1 laserlaite

: appariel A laser de classe 1

: klasse 1 laser apparat

■ Cabling Notice

Cables that connect peripherals to the VSM system must be shielded and grounded. Operation of peripheral equipment with cables that are not shielded and correctly grounded

may result in interference to radio and TV reception.

xi Sun Confidential: Internal Only 96257

Revision A

Page 12

■ Hazardous Materials Handling

Lead-acid battery packs and lithium-battery cards used in the VSM-VTSS are classified as

hazardous materials. Sun personnel are required to comply with U.S. Department of

Transportation (DOT), International Civil Aviation Organization (ICAO) and International

Maritime Dangerous Goods (IMDG) Code requirements for shipping, recycling, and disposal of hazardous materials. If you have questions ab out these requirements, cont act the

Sun Environmental Health and Safety (EHS) group in Louisville, Colorado (USA).

■ Standards Conformance

This VSM5-VTSS system conforms to all necessary North American (U.S./Canada) and

international standards for product safety, electromagnetic compatibility (EMC), body

schemes, and binary multiples as defined below.

Product Safety Standards

This VSM5-VTSS system complies with the following product safety standards:

• Underwriters Laboratories (UL)

mation Technology Equipment, Third Edition

• Canadian St andar ds Association (CSA)

CAN/CSA C22.2 No. 950-95, Information Technology Equipment, Third Edition

• International Electrotechnical Commission (IEC)

Safety Information Technology Equipment through TUV (Technischer Ueberwachungsverein)

– Listed by Underwriters Laboratories UL 1950, Infor-

Electromagnetic Compatibility

This VSM5-VTSS system complies with the following referenced standards for electromagnetic compatibility (EMC):

United States: Federal Communications Commission (FCC)

with FCC Title 47, Part 15 Subpart B, Unintentional Radiators Class A.

FCC Compliance Statement

limits for Class A digital devices pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed in accordance with the instruction manual, may cause harmful interference to radio communications. Opera tion of this equipment in a residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at his or her own expense.

: This equipment has been tested and found to comply to the

– Certified to Canadian St andards Asso ciation,

– Complies with IEC Publication 950,

– This equipment complies

Canada: Canadian Department of Communications (CDC)

with Canadian EMC law CDC ICES-003.

European Union (CE Mark)

Directive 89/336 (as amended).

96257 Sun Confidential: Internal Only xii

– This equipment complies with Electromagnetic Compatibility

Revision A

– This equipment complies

Page 13

Australia/New Zealand

1995.

China – This equipment complies with CNS 13438.

Korea

– This equipment complies with Korean EMC Law.

– This equipment complies with EMC Framework—AS/NZS 3548:

Japan: Voluntary Control Council for Interference (VCCI)

VCCI (Japan) Class A (C15PR22).

VCCI Compliance Statement (Japanese translation)

VCCI Compliance St atement (English translation)

the Technical Requirement of the Volunt ary Control Council for Interference (VCCI) by

information technology equipment. In a domestic environment, this product may

cause radio interference, in which case the user may be required to take corrective

action.

Taiwan: Bureau of Commodity Inspection and Quarantine (BCIQ)

plies withBCIQ EMC Law—Taiwan: CNS13438.

The following warning label statement pertains to BSMI regulations in Taiwan, R.O.C.:

Taiwan Warning Label Statement (Taiwanese translation)

– This equipment complies with

:

: This is a Class A product based on

– This equipment com-

:

Taiwan Warning Label Statement (English translation)

domestic environment, this product may cause radio interference, in which case the

user may be required to take adequate measures.

CISPR 22 and EN55022 Warning

this product may cause radio interference in which case the user may be required to take

adequate measures.

xiii Sun Confidential: Internal Only 96257

– This is a Class A product. In a domestic environment

Revision A

: This is a Class A product. In a

Page 14

■ Internal Code License Statement

NOTICE

INTERNAL CODE LICENSE

PLEASE READ THIS NOTICE CAREFULLY BEFORE INSTALLING AND OPERATING THIS EQUIPMENT. THIS NOTICE IS A LEGAL

AGREEMENT BETWEEN YOU (EITHER AN INDIVIDUAL OR ENTITY), THE END USER, AND SUN MICROSYSTEMS, INC. (‘SUN’),

THE MANUFACTURER OF THE EQUIPMENT. BY OPENING THE PACKAGE AND ACCEPTING AND USING ANY UNIT OF EQUIPMENT DESCRIBED IN THIS DOCUMENT, YOU AGREE TO BECOME BOUND BY THE TERMS OF THIS AGREEMENT. IF YOU

DO NOT AGREE WITH THE TERMS OF THIS AGREEMENT, DO NOT OPEN THE PACKAGE AND USE THE EQUIPMENT. IF YOU

DO NOT HAVE THE AUTHORITY TO BIND YOUR COMPANY, DO NOT OPEN THE PACKAGE AND USE THE EQUIPMENT. IF YOU

HAVE ANY QUESTIONS, CONTACT THE AUTHORIZED SUN DISTRIBUTOR OR RESELLER FROM WHOM YOU ACQUIRED THIS

EQUIPMENT. IF THE EQUIPMENT WAS OBTAINED BY YOU DIRECTLY FROM SUN, CONTACT YOUR SUN REPRESENTATIVE.

1.Definitions:

a. “Derivative works” are defined as works based upon one or more pre-

existing works, such as a translation or a musical arrangement, or any

other form in which a work may be recast, transformed, or adapted. A

work consisting of editorial revision, annotations, elaboration, or other

modifications which, as a whole, represent an original work of authorship, is a Derivative work.

b. “Internal Code” is Microcode that (i) is an integral par t of Equipment, (ii)

is required by such Equipment to perform its data storage and retrieval

functions, and (iii) executes below the user interface of such Equipment. Internal code does not include other Microcode or software, including data files, which may reside or execute in or be used by or in

connection with such Equipment, including, without limitation, Maintenance Code.

c. “Maintenance Code” is defined as Microcode and other software, in-

cluding data files, which may reside or execute in or be used by or in

connection with Equipment, and which detects, records, displays, and/

or analyzes malfunctions in the Equipment.

d. “Microcode” is defined as a set of instructions (software) that is either

imbedded into or is to be loaded into the Equipment and executes below

the external user interface of such Equipment. Microcode includes both

Internal Code and Maintenance Code, and may be in magnetic or other

storage media, integrated circuitry, or other media.

2. The Equipment you have acquired by purchase or lease is manufactured

by or for Sun and contains Microcode. By accepting and operating this

Equipment you acknowledge that Sun or its licensor(s) retain(s) ownership of all Microcode, as well as all copies thereof, that may execute in or

be used in the operation of servicing of the Equipment and that such Microcode is copyrighted by Sun or its licensor(s).

3. Sun hereby grants you, the end user of the Equipment, a personal, nontransferable (except as permitted in the transfer terms in paragraph 7 below), nonexclusive license to use each copy of the Internal Code (or any

replacement provided by Sun or your authorized Sun distributor or reseller) which license authorizes you, the end user, to execute the Internal

Code solely to enable the specific unit of Equipment for which the copy of

Internal Code is provided to perform its data storage and retrieval functions in accordance with Sun’s (or its licensor’s) official published specifications.

4. Your license is limited to the use of the Internal Code as set forth in paragraph 3 above. You may not use the Internal Code for any other purpose.

You may not, for example, do any of the following:

(a) access copy, display, print, adapt, alter, modify, patch, prepare Deriv-

ative works of, transfer, or distribute (electronically or otherwise) or

otherwise use the Internal Code;

(b) reverse assemble, decode, translate, decompile, or otherwise reverse

engineer the Internal Code (except as decompilation may be expressly permitted under applicable European law solely for the purpose of

gaining information that will allow interoperability when such information is otherwise not readily available); or

(c) sublicense, assign, or lease the Internal Code or permit another per-

son to use such Internal Code, or any copy of it.

If you need a backup or archival copy of the Internal Code, Sun, or your

authorized Sun distributor or reseller, will make one available to you, it being acknowledged and agreed that you have no right to make such a copy.

5. Nothing in the license set forth in paragraph 3 above or in this entire Notice shall convey, in any manner, to you any license to or title to or other

right to use any Maintenance code, or any copy of such Maintenance

Code. Maintenance Code and Sun’s service tools and manuals may be

kept at your premises, or they may be supplied with a unit of Equipment

sent to you and/or included on the same media as Internal Code, but they

are to be used only by Sun’s customer service personnel or those of an

entity licensed by Sun, all rights in and to such Maintenance Code, service tools and manuals being reserved by Sun or its licensors. You agree

that you shall not use or attempt to use the Maintenance Code or permit

any other third party to use and access such Maintenance Code.

6. You, the end user, agree to take all appropriate steps to ensure that all of

your obligations set forth in this Notice, particularly in paragraphs 4 and

5, are extended to any third party having access to the Equipment.

7. You may transfer possession of the Internal Code to another party only

with the transfer of the Equipment on which its use is authorized, and your

license to use the Internal Code is discontinued when you are no longer

an owner or a rightful possessor of the Equipment. You must give such

transferee all copies of the Internal Code for the transferred Equipment

that are in your possession, along with a copy of all provisions of this Notice. Any such transfer by you is automatically (without further action on

the part of either party) expressly subject to all the terms and conditions

of this Notice passing in full to the par ty to whom such Equipment is transferred, and such transferee accepts the provisions of this license by initial

use of the Internal Code. You cannot pass to the transferee of the Equipment any greater rights than granted under this Notice, and shall hold Sun

harmless from any claim to the contrary by your transferee or its successors or assigns. In addition, the terms and conditions of this Notice apply

to any copies of Internal Code now in your possession or use or which you

hereafter acquire from either Sun or another party.

8. You acknowledge that copies of both Internal Code and Maintenance

Code may be installed on the Equipment before shipment or included with

the Equipment and other material shipped to you, all for the convenience

of Sun’s service personnel or service providers licensed by Sun, and that

during the warranty period, if any, associated with the Equipment, and

during periods in which the Equipment is covered under a maintenance

contract with Sun or service providers licensed by Sun, both Internal

Code and Maintenance Code may reside and be executed in or used in

connection with such Equipment, and you agree that no rights to Maintenance Code are conferred upon you by such facts. Sun or the licensed

service provider may keep Maintenance Code and service tools and

manuals on your premises but they are to be used only by Sun’s customer

service personnel or those of service providers licensed by Sun. You further agree that upon (i) any termination of such warranty period or maintenance contract period; or (ii) transfer of possession of the Equipment to

another party, Sun and its authorized service providers shall have the

right with respect to the affected Equipment to remove all service tools

and manuals and to remove or disable all Maintenance Code and/or replace Microcode which includes both Internal Code and Maintenance

Code with Microcode that consists only of Internal Code.

96257 Sun Confidential: Internal Only xiv

Revision A

Page 15

Safety / Fiber Optic / ESD Precautions

The following precautions must be followed during all phases of equipment installation,

operation, and servicing. Equipment users are responsible for following warnings and

cautions, and for taking other appropriate steps to assure safe equipment operation. Sun

assumes no liability for failure to comply with these requirements.

■ Safety Precautions

To prevent hazardous conditions and personal injury, follow these safety precautions:

Verify Proper Equipment Grounding

Ensure cabinet frames are properly connected to an electrical earth ground. AC power

supplies require a three-conductor power cable. Source powe r cables must be plugged in to approved three-contact electrical outlets. Power cable jacks and mating plugs must

meet electrical code requirements for the intended area of u se an d a lso comply with Inter national Electrotechnical Commission (IEC) safety standards.

Avoid Electric Shocks

Only qualified personnel may remove equipment covers for servicing. Before starting a

service procedure, remove conductive met al objects from your person including rings,

watches, necklaces, and badge chains. Use a conductive wrist strap and work mat

grounded to a jack or unpainted met al surface on a cabinet frame. Never touch exposed

connector pins or sockets, or leave ‘live’ cable ends exposed.

Use Only Approved Tools and Test Equipment

Use only approved tools and test equipment supplied in the standard CSE tool kit. Always

ground test equipment to a grounding jack on the cabinet frame. Repair or replace any

damaged tools or test equipment prior to use.

Be Aware of Your Operating Environment

Never operate electrical or electronic equipment in the presence of flammable gases or

fumes, as these can create an explosion hazard.

Never Service or Adjust Equipment Alone

Never service or adjustment equipment unless another person capable of rendering first

aid and resuscitation is present.

Do Not Substitute Parts or Modify Equipment

To assure equipment safety featur es ar e main tained, and to avoid introducing additional

hazards, never install substitute p arts or mod ify Sun equipment without explicit permission

from Sun technical support personnel. Never remove, cut, or relocate raised-floor tiles

without first receiving customer permission.

Provide Adequate Equipment Clearances

Make sure there is sufficient clearance around equipment to facilitate airflow and heat dissipation, and to maintain ambient system temperatures within recommended operating

ranges. Provide clearances that allow cabinet doors to open at least 90 degrees, and to

be easily removed for servicing equipment or in emergency situations.

xv Sun Confidential: Internal Only 96257

Revision A

Page 16

Strictly Comply With Caution and Warning Messages

To prevent injury and equipment damage, comply with all caution and warning messages

in this document. Also employ any and all other precautions which you deem necessary

for safe operation of equipment in your specific operating environment.

Carefully Follow Procedural Steps

Always complete procedural steps in listed order. Performing steps out of order can expose you to potentially hazardous or lethal conditions.

Protect Yourself From Moving Parts

Restrict loose clothing and long hair to avoid becoming ent angled in moving p art s such as

fans, impellers, and blowers.

Promptly Reinstall Covers and Doors

After completing service procedures, promptly reinst all cabinet cove rs, and close and lo ck

cabinet doors to maintain proper cabinet airflow , prevent overheating, and restrict accessibility to energized FRUs.

Miscellaneous Safety Precautions

To prevent tipovers, never tilt a cabinet beyond a 15-degree angle (e.g., when ascending

or descending ramps). Use caution when working near open floor tiles. Use good housekeeping practices to avoid fire hazards and to reduce the potential for mishaps.

■ Electrostatic Discharge Precautions

Electrostatic discharge (ESD)-sensitive components must always be handled under protected conditions, and ESD-preventive equipment must be used when servicing equipment. Employees who handles ESD-sensitive parts must be aware of the damage that

ESD can cause, and must take the following precautions to prevent it.

Use ESD-Preventive Equipment

Always use Field Service Grounding Kit P/N 4711 when installing or servicing Sun equipment. Always use a conductive wrist strap and antistatic work mat, and ensure those are

grounded to a jack or unpainted metal on the cabinet frame when working.

Regularly Check and Clean ESD-Preventive Equipment

Regularly (at least monthly during frequent use) verify the resistance of wrist-strap

grounding cords to be between 0.8M ohm (Ω) and 1.2M ohm (Ω), and work ma t co rd s to

be less than 1.2M ohm (Ω); replace damaged cords or any that do not meet these specifi-

cations. Regularly (at least monthly during frequent use) clean antistatic work mats; ACL

Conductive Cleaner is preferred for this purpose since it leaves no residue, but isopropyl

alcohol or a mild detergent and water solution can also be used.

Remove Conductive Personal Items

Before beginning service procedures inside a cabinet, remove all conductive metal objects from your person including rings, watches, neckla ces, and badge chains.

Handle ESD-Sensitive Components Carefully

Keep circuit cards, ASICs, and other ESD-sensitive components away fr om ESD sources

and extraneous electrical currents. Keep parts in ESD-protective packaging until installation, and store removed ESD-sensitive parts in protective packaging.

96257 Sun Confidential: Internal Only xvi

Revision A

Page 17

■ Fiber Optic Component Handling Precautions

To prevent damage to optical fiber cables and connectors, and to mitigate inherent hazards from laser-light emissions, always follow these general handling precautions:

Protect Your Eyes

Never aim the output of a laser, or of an optical fiber connected to a laser , directly into your

eyes. Do not examine an optical connector on any cable that is still attached to its data

transmission port, since laser light may be present in the cable. Befor e examining the en d

of an optical fiber, verify that no laser-light signals are present. Always cap unused data

transmission ports on channel interface cards.

Handle Fiber Optic Components Gently

Handle fiber cables and connectors gently to prevent damage. Ne ver grasp cables or connectors with pliers or grippers, or attach pulling devices to them. Never bend fiber cables

(e.g., when routing along cable paths or guides) to a radius of <12 mm (<0.5 in.), and do

not coil cables to <96 mm (<3.74 in.) in diameter. Use strain-relief mechanisms to prevent

the weight of cables from damaging fibers. Protect cables from sharp edges or protrusions, heat sources, and other damaging conditions. Ensure that equ ipment openings and

floor cutouts have protective edging at cable contact points.

Prevent Contamination of Cable Ends

Avoid touching the core of optical cables, as this can contaminate fibers and prevent light

transmission. If a cable-end becomes contaminated, remove any loose debris using

canned air or by gently tapping the connector, then clean the cable-end with an approved

cleaning kit. Leave protective caps on cable-ends until cables are attached to a connector;

after disconnecting cables, always reinstall clean protective caps.

xvii Sun Confidential: Internal Only 96257

Revision A

Page 18

About This Guide

About This Guide

■ Product Overview

The Sun StorageTek Virtual Storage Manager® (VSM®) is a disk-based virtual tape system that provides enterprise-class storage management capabilities for MVS-based systems. Its scalable design, which includes Virtual Tape Control System (VTCS) host software and an intelligent Virtual Tape Storage Subsystem (VTSS) disk buffer, optimizes

streaming workloads and backup and recovery functions, reduces management overhead, and maximizes tape capacity utilization to reduce data protection costs in a wide

range of storage environments.

■ Intended Audience

This document is intended for use by Sun Microsystems personnel and other qu alified service providers (QSPs)

tification, servicing, and technical support of VSM5 system equipment.

Users of this document should have a working knowledge of the following concepts and

technologies: virtualization; Ethernet; FICON, fibre channel, and network topologies; tape

storage (tape drives and tape libraries); and disk storage.

1

involved with site planning, installation, configuration, testing, cer-

■ Providing Feedback About This Document

Your feedback helps ensure the accuracy and completeness of this document. Please direct all comments regarding this publication to the Sun Learning Services e-mail feedback

system at

To assure proper handling of your correspondence, specify the publication name, part

number , edition number, and referenced page(s) in your e-mail. If you would like a personal response, you must also include your contact information. Submitted content becomes

the sole property of Sun.

slsfs@sun.com.

■ Optimizing Content For Electronic Viewing

If a digitized photograph, screen capture, line drawing, or oth er graphic h as been r educed

to fit in this document, small text in the image may be unreadable when viewed in an Adobe Acrobat

®

PDF file at 100% or lower scaling on some electronic displays.

To correct this problem, use Acrobat Reader scaling tools to increase the image size until

affected text becomes legible. The amount of ‘upscaling’ required will depends on several

factors, including: the original point size of the text; the original dimensions and resolution

of the image; and how much the image was scaled down.

1. Third-party contractors certified and authorized by Sun to work with systems and equipment described in this guide.

xviii Sun Confidential: Internal Only 96257

Revision A

Page 19

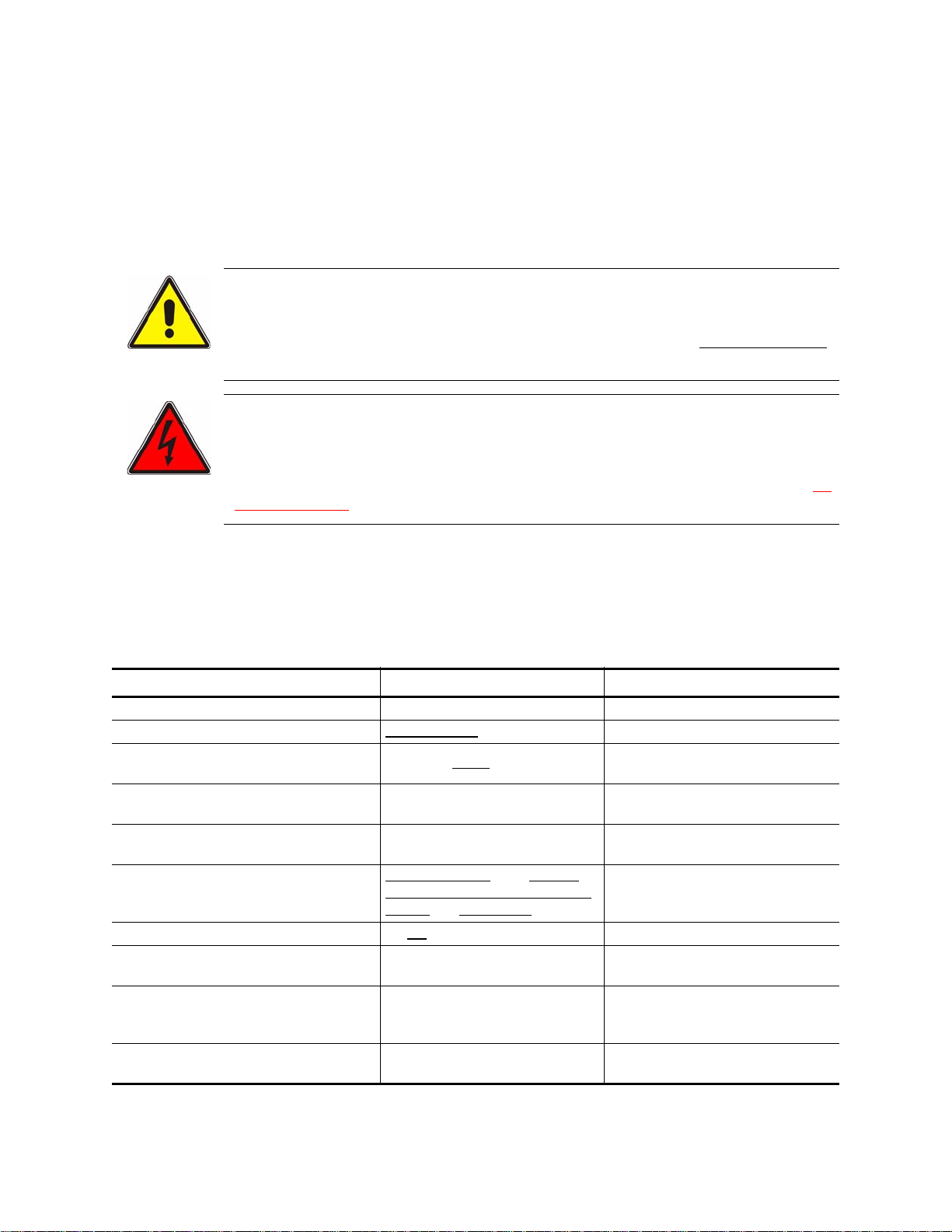

■ Alert Messages

Alert messages used within this document are presented as follows:

Note: A note provides emphasis or additional useful detail about a topic or proce-

dure, and can either precede or follow the information it references.

CAUTION !

A caution directs urgent attention to an action or condition which could damage equipment or corrupt data or system software if the accompanying procedure is not completed or is performed incorrectly. A caution always precedes

the information it references.

DANGER !!

A danger message directs urgent attention to an action or condition that has

potential to create a hazardous situation or to cause immediate, severe, and

possibly fatal injury or adverse long-term health effects if the accompanying

procedure is not completed or is performed incorrectly. A danger message always precedes the information it references.

■ Notational and Typographic Conventions

The following notational and typographic conventions are us ed throughout this document

to highlight special words, phrases, and actions.

Item Example(s) Description of Convention

Publications; course titles Installation and Service Guide Italic font

MS Windows or GUI screen titles Ethernet Setup screen Italic underlined font

Computer keyboard input keys Press the [Enter

User-keyed non-variable inputs; system-

generated outputs

User-keyed variable inputs

E-mail and IP addresses; URLs; file and

folder names; active fields and icons in

GUI windows

Emphasized text Do not

Physical VTSS labels for FRUs, LED indi-

cators, ports, or switches

Hypertext link (in PDF file) to a figure, ta-

ble, procedure step, or section heading

Text references to numbered callouts in

accompanying artwork

show systemstate

Name = <

glsfs@sun.com

www.support.storagetek.com

cli.exe

POWER ON indicator; ETH0 port;

POWER ENABLE switch

See Figure 2-1 on page 2-27; R e-

peat Step 3; See “Assigning Pass-

words” on page 4-11.

Pull the D-ring handle [3]. Bold font in bold square brackets [ ]

system name

file; 129.80.64 subnet

touch exposed wiring... Underlined font

] key.

>

; click Submit;

Monospaced underlined font in

square brackets [ ]

Monospaced bold font

Monospaced italic bold font in an-

gled brackets < >

;

Monospaced underlined font

Bold caps font

Blue font (prints black in black and

white photocopies)

96257 Sun Confidential: Internal Only xix

Revision A

Page 20

About This Guide

■ Where to Find Additional Information

Additional information about the complete line of Sun S tor ageTek products and services is

provided through various media, as described below.

Reference Documents

The VSM5 Virtual Tape Storage Subsystem (VTSS) is one of several hardware and software components that link together to create the VSM5 system. Besides this document, it

may be useful to consult some or all of the reference documents listed below to complete

planning, system assurance, installation, and se rvice tasks fo r other VSM component s designed for a specific customer site.

Document Name and Part Number Availability

VSM Hardware

VTSS for VSM5 – Planning and System Assurance Guide, 96257 1

VTSS for VSM5 – Installation and Service Guide, 96254 1

T9x40 Tape Drive Planning and Migration Guide, MT6004 1

Nearline Physical Planning Guide, ML0041 1

Nearline Enterprise 9310/4410/9360 LSM System Assurance Guide, ML6500 1

TimberWolf 9740 Library Storage Module System Assurance Guide, MT5100 1

VSM Software

VTCS n.n * Quick Reference Guide 1, 2

VTCS n.n * Installation and Configuration Guide 1, 2

VTCS n.n * Administrator’s Guide 1, 2

VTCS n.n * Command and Utility Reference 1, 2

VTCS n.n * Messages and Codes 1, 2

VTCS n.n * XML Reference 1, 2

Remote Service and Support

Service Delivery Platform System Assurance Guide 1, 3

Service Delivery Platform Installation and Configuration Guide 1, 3

Notes:

1. Sun StorageTek Customer Resource Center (CRC) website: www.support.storagetek.com.

2. Sun StorageTek Software Manufacturing and Distribution – Web

CRC T ools click Software Manufacturing and Distribution; E-mail

U.S. (outside Colorado) and Canada 1.800.436.5554, International and within Colorado 1.303.673.8562.

3. Sun StorageTek Hardware Manual Scheduling – Phone

• * Use document s labeled as version 6.0 or higher , which is the minimum host software level required for compatibil-

ity with VTSS back-end FICON channels.

: 1.303.673.6241.

: www.support.storagetek.com, then under

: LSVSMD-list@louisville.stortek.com; Phone :

xx Sun Confidential: Internal Only 96257

Revision A

Page 21

VSM Engineering Website

Extensive and detailed information about VSM, including engineering do cuments, Redbooks, White Papers, and standards, is available through the VSM Engineering website at

http://vsm.stortek.com. Website access is restricted to Sun employees.

Customer Resource Center

The Sun StorageTek Customer Resource Center (CRC) website at www.support

.storagetek.com provides resources including product documents, software keys, code

downloads, SE tools, and information on product education and training. Website access

is restricted to Sun employees, registered customers with a current warranty or maintenance service agreement, and registered partners.

Product-Specific Documentation

The latest editions of documents for all Sun S torage Tek products can be printed from PDF

files available on the CRC website; see ”Customer Resource Center” above for more information. VSM documents, including those for VTCS software and VTSS hardware, are

available through the path Current Products > Tape Products > Virtual Storage Manager

on the CRC website.

VTCS software documents, including a Quick Reference Guide, Installation and Configu-

ration Guide, Administrator’s Guide, Command and Utility Reference, Messages and

Codes, and XML Reference) also are provided on a CD-ROM that ships with each VSM

system. To order additional CDs, contact Sun StorageTek Software Manufacturing and

Distribution (SMD) at 800.436.5554, 303.673.8600, or

request the VTCS Information CD. To order individual software documents in bound-book

format, contact the SMD group.

www.support.storagetek.com, and

Product Education and Training

The Sun Storage Tek Learning Network website at http://learning.stortek.com provides

education and training courses for all Sun products, including the VTSS for VSM5. Website access is restricted to Sun employees. Courses for the VSM5 system include:

• CRS100178

• CRS100267 – VSM MVS System Administration for customers

• CRS-102711 – Detached Operator Panel (DOP) webinar

• CRS101

• CRS100014

• CRS101182

96257 Sun Confidential: Internal Only xxi

– VSM MVS System Administration for employees

nnn – VTSS for VSM5 Differences

– SVA9500 and VSM Installation and Maintenance

– FICON Native - T9X40 Tape Drive.

Revision A

Page 22

About This Guide

SE Support Tools

SE tools, white papers, and other content for use with Sun StorageTek products, including

VSM5 system equipment, are available through the SE Support Tools website at

http://setools. Website access is restricted to Sun employees.

Global Services Field Support Tools

Resources to assist with sales and support of VSM5 system equipment and other Sun

StorageTek products and services are located on the Global Services Field Support Tools

website at

cess is restricted to Sun employees.

http://sunsolve.central.sun .com/handbook_internal/FieldTools/. Website ac-

Storage Sales Community

Marketing collaterals and configuration documents for all Sun StorageTek products, including VSM5 system equipment, are available on the Storage Sales Community website

at

https://portal.storagetek.com/sales. Website access is restricted to Sun employees.

Partners

The Sun StorageTek Partners website at https://members.storagetek.com provides information about products, services, customer support, upcoming events, training programs, and sales tools to support Sun Partners. Website access is restricted to Sun employees and registered Sun partners.

‘Documents on CD’

Documents on CD is a set of CD-ROMs that contain documents for many Sun

StorageTek tape, disk, and storage networking products, and is shipped quarterly to field

offices. Contact your manager to obtain a current copy.

■ Colophon

This document was created using Adobe FrameMaker 7.0 publishing software, and was

converted to a PDF (portable document format) file using Adobe Acrobat Writer 6.0 document conversion software. Acrob at Reader software (Version 4.0 or higher)

view PDF versions of this document.

1

is required to

1. This software can be downloaded free from www.adobe.com.

xxii Sun Confidential: Internal Only 96257

Revision A

Page 23

Planning and Implementation

END

Proposal Acceptance

Entry Forms Complete

SA = System Assurance

S

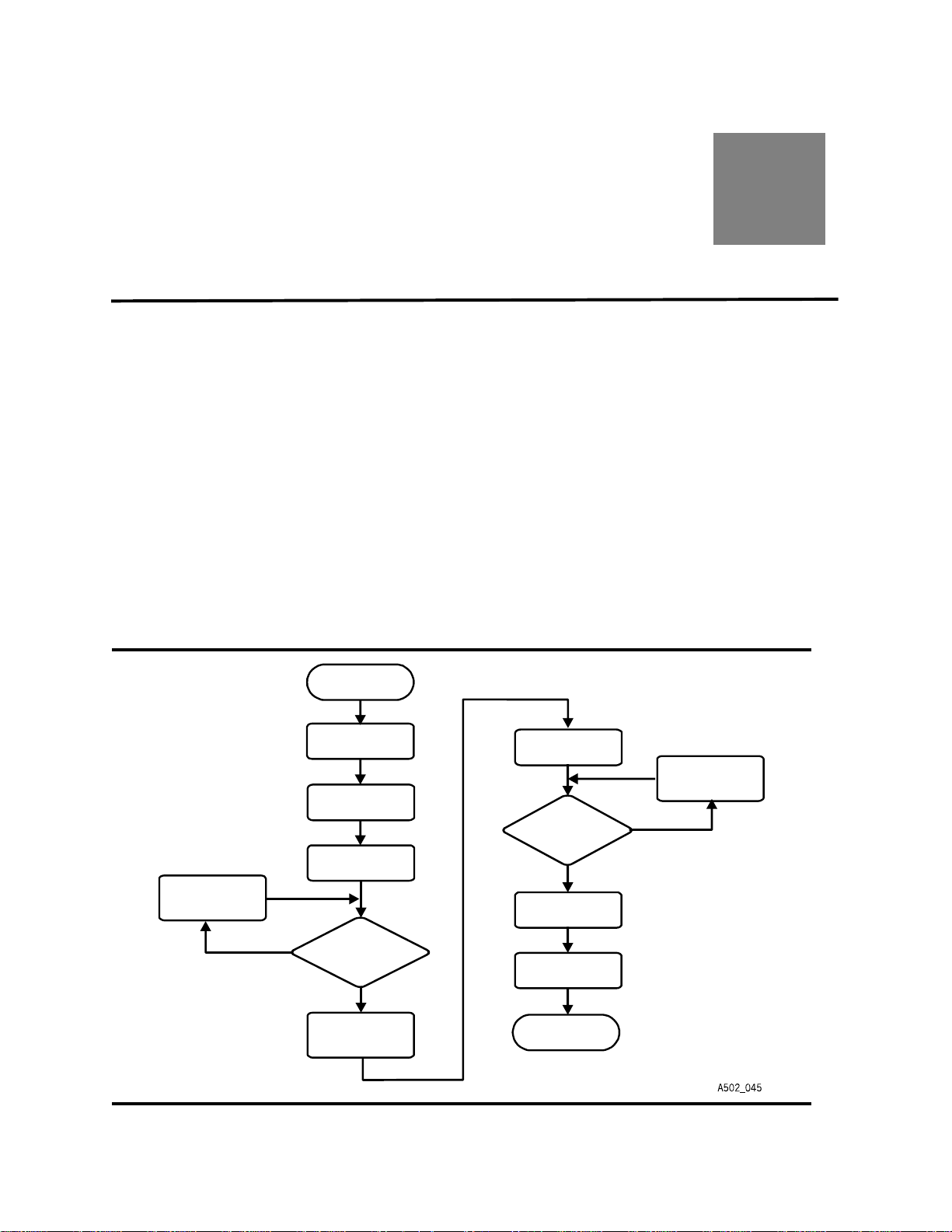

Overview

This chapter provides an overview of key participants, timelines, and activities involved in

planning for and implementing a VSM5 system.

Successful implementation requires regular communication and coordination between

customer personnel and the Sun account team. This ongoing collaboration helps ensure

that all factors critical to the implementation are identified and addressed before equipment is delivered to the site. The primary goals of the planning process are to:

• Ensure the VSM5 system is properly designed to meet the requirements of the customer, and that it is ordered, deliver ed, installed, configured, tested, certified, and turned

over with a minumum of disruptions and problems

• Ensure the installation site infrastructure is equipped to handle the power, data-handling,

and environmental requirements of VSM5 system equipment, and that customer personnel are trained to assist with delivery , inst allation, configuration, testing, certification, and

operation of the VSM5 system equipment.

Figure 1-1. System Assurance Proces s Flow

1

or OM Contacts

SSC

SA Team for

More Information

= Shared Ser Center

SC vices

OM = Orders Management

NO

START

System

Assurance

Planning Meetings

Ord Placementer

Are

Order

Worksheets or Sales

and Correct

?

YES

SSC

or OM Approves

the Order and

Assigns

a Ship Date

System

Assurance

Planning Meetings

Are the

Pre-Installation

Checklists Complete

and Correct

?

YES

Installation

Post installation

Follow-up

NO

SA Team Corr ects

Pre-installation

Checklists

96257 Sun Confidential: Internal Only 1-23

Revision A

Page 24

Planning and Implementation Overview

■ Creating Planning Teams

Once a sales proposal has been accepted, the Sun customer service manager (CSM)

should confer with customer-site personnel including the network administrator, data center manager, and facilities manager to identify which individuals who should be involved

with implementation planning, site readiness planning, and delivery and installation planning.

Customer and Sun personnel who particip ate in these p lanning teams jointly own and control the various processes, activities, and deliverables of those teams.

Once the team participants h ave been identified, one customer team member and one

Sun team member should be selected to act as coordinators for each team. Re gular meetings should be scheduled to:

• Define roles and responsibilities for all team members

• Define required implementation activities and task completion dates

• Identify and address issues that could impede delivery, installation, or implementation of

system equipment.

Forms and worksheets in Appendix D can be used by both customer and Sun planning

team members to record key system hardware and software information, identify p lanning

factors and considerations, and record completion dates for critical planning and implementation activities.

Customer

of:

• Persons who will determine the configuration and location of VSM5 system equipment,

including but not limited to: the data center manager; one or more network administrators; the facilities manager; the site engineer, etc.

• Persons who will be directly involved with installation, testing, certification, and operation

of VSM5 system equipment, including but not limited to: facilities personnel; system operators; network/IT personnel, etc.

• Persons who will be involved with delivery and dock-to-data center transit of VSM5 system equipment, including but not limited to: the dock manager; dock personnel; facilities

personnel, etc.

Sun

representative (SR); the local customer services manager (CSM); a systems engineers

(SE); a system support specialist (SSS); a technical support specialist (TSS); a professional services (PS) consultant; and a customer service engineer (CSE).

membership for the various planning and implementation teams should consist

membership for the various teams may include some or all of the following: the sales

1-24 Sun Confidential: Internal Only 96257

Revision A

Page 25

Planning / Readiness / Implementation Timelines

■ Planning / Readiness / Implementation Timelines

The following activity guidelines allow sufficient time for planning, readiness, and implementation tasks to be completed prio r to delive ry of VSM5 system e quip ment to a customer site.

1. Three months

• The network administrator, data center manager, and Sun account representative,

systems engineer (SE), and technical support specialist (TSS) define a system configuration that best addresses customer requirements.

• The site engineer, facilities manager, and Sun Professional Services consultant review site factors that present existing or potential safety and environmental hazards

which could negatively affect the operation of the VSM5 system. See “Site Evalua-

tion – External Considerations” and “Site Evaluation – Internal Considerations” on

page 4-46.

• The facilities manager and Sun Professional Services review equipment transfer requirements and define a compliance plan as needed. See “Transfering Equipment

Point-to-Point” on page 4-47.

• The facilities manager and Sun Professional Services consultant review power supply and cabling requirements, and evaluate compliance to requirements. See “Site

Power Distribution Systems” on page 4-49.

• The site engineer, facilities manager, and structural engineer (if needed) review floor

construction and load ratings, and evaluate compliance. See “Floor Construction Re-

quirements” and “Floor Loading Requirements” on page 4-52.

• The network administrator, data center manager, and Sun technical support specialist review data cabling requirements for the VSM5 system configuration, and evaluate compliance to requirements. See “Fibre Channel Cables — Available Lengths”

on page B-166.

before the scheduled delivery date for the VSM5 system equipment:

• After completing reviews of power, environment al, floor ing, and network connectivity

requirements, the site engineer and facilities manager schedule needed facilities upgrades, targeting completion for not later than

equipment (two weeks is preferable).

2. Two months

• The site engineer and facilities manager create a floorplan/layout for all VSM5 system equipment, and review it with the Sun Professional Services consulta nt. See

“Physical Space Requirements” on page 4-55.

Note: A copy of the final floorplan/layout should be given to the Sun sales represen-

tative to attach to the sales order.

• The facilities manager and Sun technical support specialist measure and record cable-layout distances between AC source power locations, host systems, network

servers, remote support devices, and VSM5 system hardware components.

96257 Sun Confidential: Internal Only 1-25

before the scheduled delivery date for the VSM5 system equipment:

Revision A

one week before delivery of system

Page 26

Planning and Implementation Overview

• The dock manager and/or facilities manager and Sun customer service manager

identify any special shipping requirements, and notify the Sun manufacturing group

as needed.

• The Sun sales representative completes and submits the equipment sales order, including all necessary cabling and spare parts.

• The network administrator and data center manager select appropriate personnel for

VSM5 system training, targeting completion for no later than one week before delivery of equipment.

3. One month

• The network administrator, data center manager, and Sun sales representative verify

that all required components in the specified configuration, and all cables of the required length, have been ordered.

• The Sun customer service manager reconfirms the scheduled system delivery date

with the Sun manufacturing facility.

• The facilities manager verifies compliance of input power systems and power cabling

in the data center. See “Site Power Distribution Systems” on page 4-49.

• The facilities manager verifies environmental compliance and HVAC systems readiness in the delivery, staging, and installation areas.

• The site engineer and structural engineer verify floor loading compliance along the

delivery path and at the data center installation location. See “Floor Construction Re-

quirements” and “Floor Loading Requirements” on page 4-52.

• The Sun customer services manager identifies which Sun personnel will perform the

VSM5 system installation at the customer site.

4. Two weeks

• The Sun sales representative verifies that all parts and bills of material (BOM) have

been delivered to the site to allow hardware and software conversions and featu re

changes in previously-installed equipment.

before the scheduled delivery date for the VSM5 system equipment:

before the scheduled delivery date for the VSM5 system equipment:

• The facilities manager and Sun customer service manager verify the delivery dock

and data center personnel, and Sun CSEs who will be available to accept delivery of

the system equipment, and assist in unpackaging, point-to-point transfer, and installation of system equipment.

• The facilities manager, data center manager, and Sun customer service manager

agree on firm dates and timeframes for delivery, installation, certification, and operational testing of system equipment.

1-26 Sun Confidential: Internal Only 96257

Revision A

Page 27

Configuration Planning

This chapter provides an overview of configuration planning considerations and activities

that are used to design a VSM5 system tailored to customer requirements, and to ensure

proper implementation of the system.

Designing an optimized VSM5 system to meet specific customer requirements requires

close collaboration between Sun personnel (the account represent ative (AR), systems engineers (SEs), and technical support specialists (TSSs)) and key customer decisionmakers (network administrators, data center managers, etc.) who are involved with selecting

and implementing the system.

Planning for more complex system implementations may require consult ation with the Sun

Global Professional Services group.

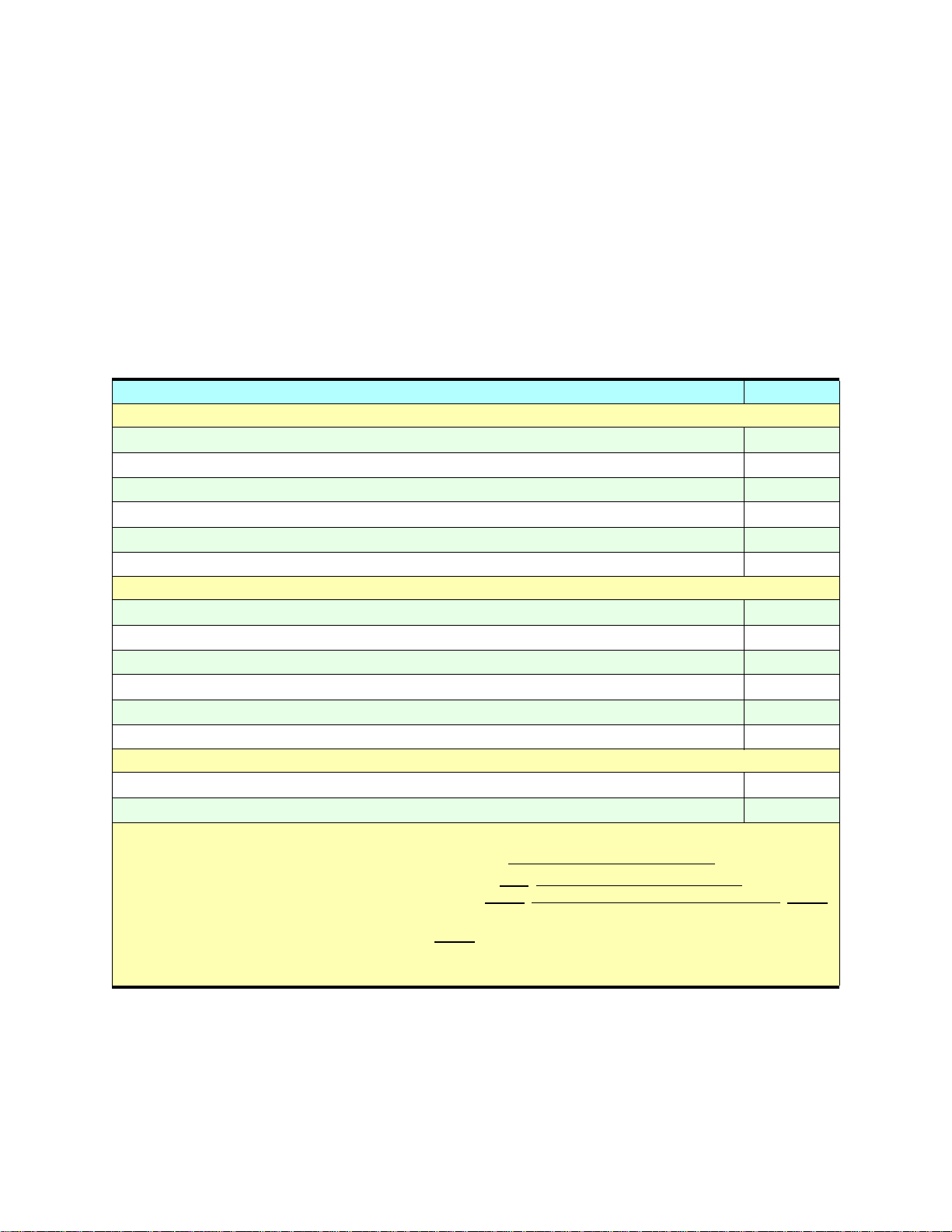

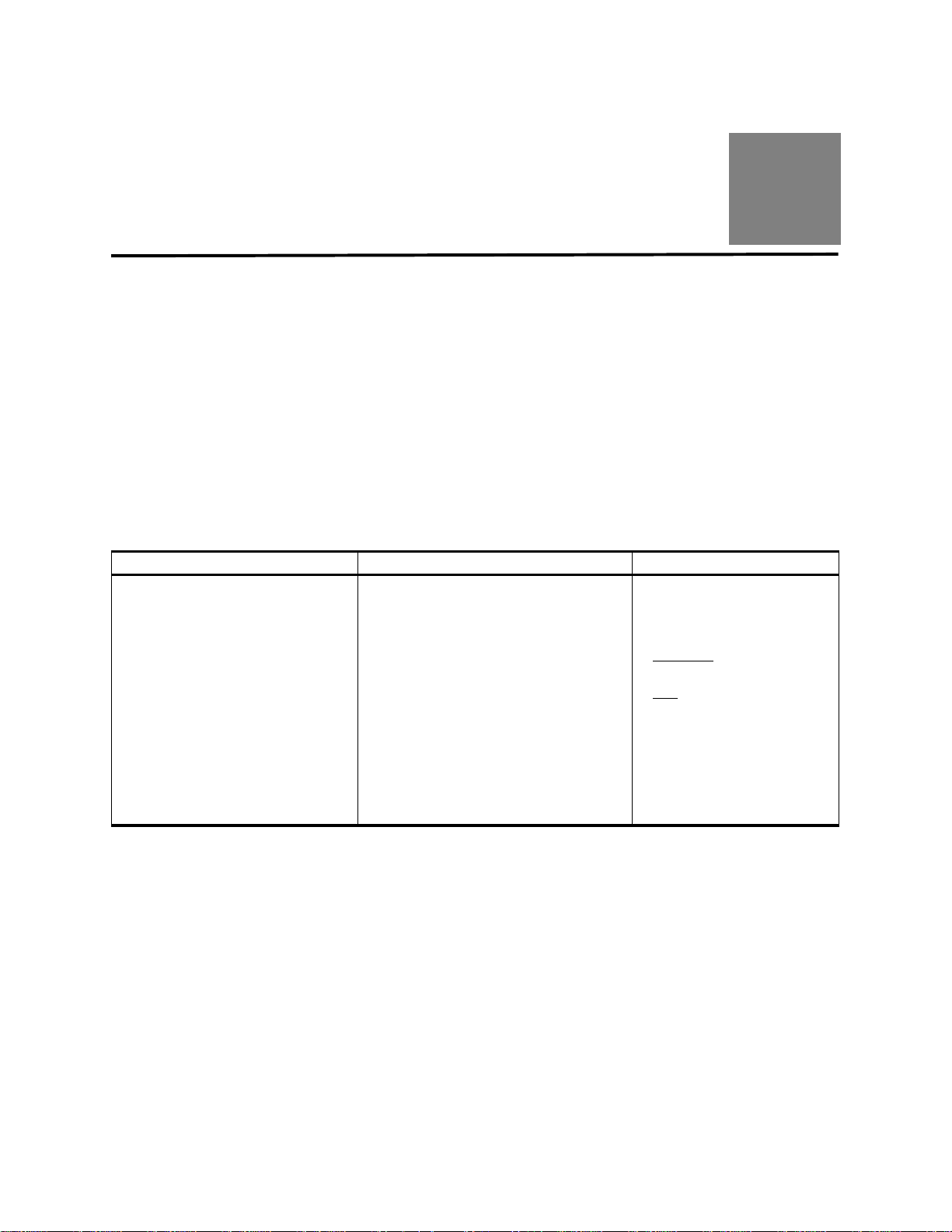

Table 2-1.Configuration Planning Overview

Key High-Level Activities Key Sub-Tasks Key Participants

• Use sizing tools to estimate requirements and propose a VSM5 system

configuration

• Define customer requirements.

• Assess budget ary constraints.

• Design an optimized VSM5 system

based on defined requirements

and constraints.

• Create high-level conceptual diagram

of proposed VSM5 system configuration

• Create det ailed engineering diagram of

proposed VSM5 system configuration

• Present VSM5 system physical and

functional configuration plans to key decisionmakers

• Complete applicable Appendix D worksheets

•Customer

trator; data center manager

: account representative;

•Sun

systems support specialist;

technical support specialist;

systems engineer

2

: network adminis-

96257 Sun Confidential: Internal Only 2-27

Revision A

Page 28

Configuration Planning

■ Defining Customer Requirements

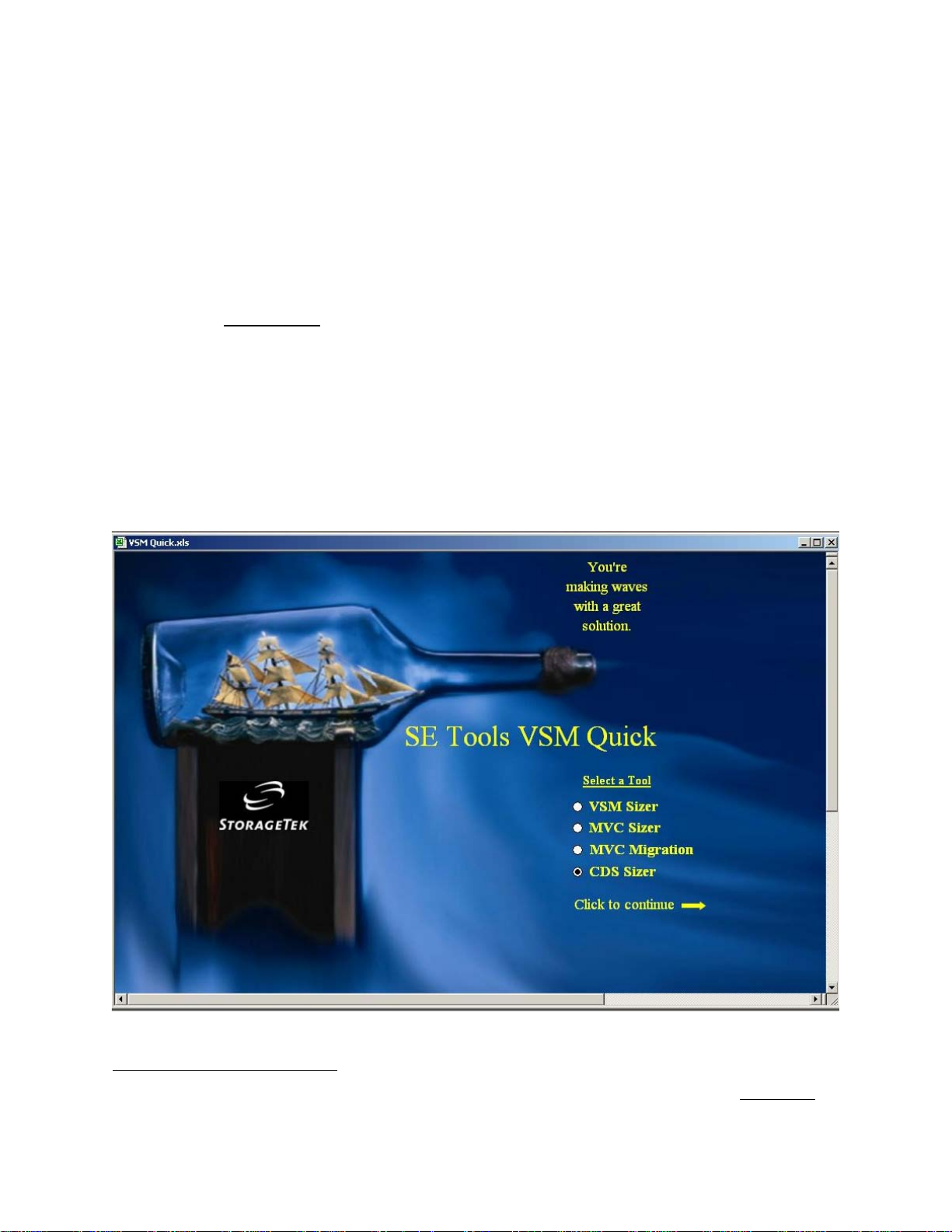

Customized tools are available to assist Sun personnel with estimating customer requirements and configuring a unique VSM5 system to meet those needs.

VSM Quick is a pre-sales tool package designed for use by SEs and ARs. It provides potential customers with a quick estimate of the size and scope of a VSM5 system that is tailored to their requirements.

VSM Quick and other VSM-related tools are available on the SE Tools website at

http://setools. Use of VSM Quick requires a Pentium system with a minimum of 128MB

RAM (256MB+ recommended), 8MB of free disk space, Windows 2000 or XP operating

system, and the MS Office Suite 2000 (or later).

The VSM Quick tool package currently consists of four discrete tools: the VSM Sizer tool,

MVC Sizer tool, MVC Migration tool, and CDS Sizer tool, as described in the following

pages. Figure 2-1 shows the VSM Quick tool selection screen.

Detailed information on how to use each tool is available in the help file th at accompanies

the download of the VSM Quick program.

1

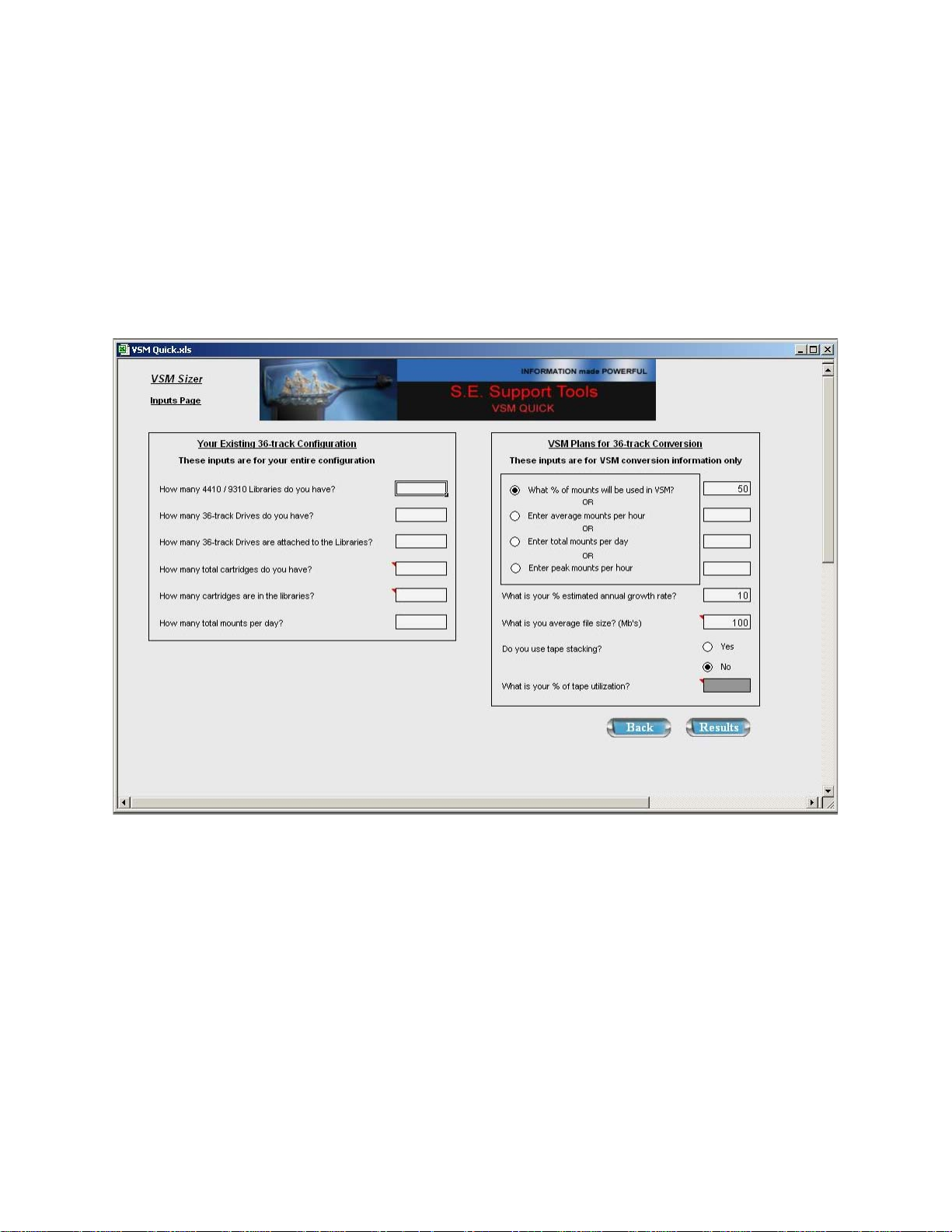

Figure 2-1. VSM Quick Tool – Tool Selection Screen

1. Also, a CD-ROM with SE tools for many other StorageTek products is available on the SE tools website at http://setools, or

from the StorageTek Software Manufacturing and Distribution (SMD) group.

2-28 Sun Confidential: Internal Only 96257

Revision A

Page 29

VSM Sizer Tool

As shown in Figure 2-2, the VSM Sizer tool requests input s on mount activity, file size, the

estimated growth rate of data, and the current configuration of libraries, transports, and

cartridges to determine customer requir eme nts for a VSM5 syst em .

Based on the results of its calculations, the tool identifies an optimum VSM5-VTSS configuration and minimum number of RTDs to meet the defined requirements. The tool also

suggests possible hardware reductions that could result from installing the proposed

VSM5 system.

Defining Customer Requirements

Figure 2-2. VSM Sizer Tool

96257 Sun Confidential: Internal Only 2-29

Revision A

Page 30

Configuration Planning

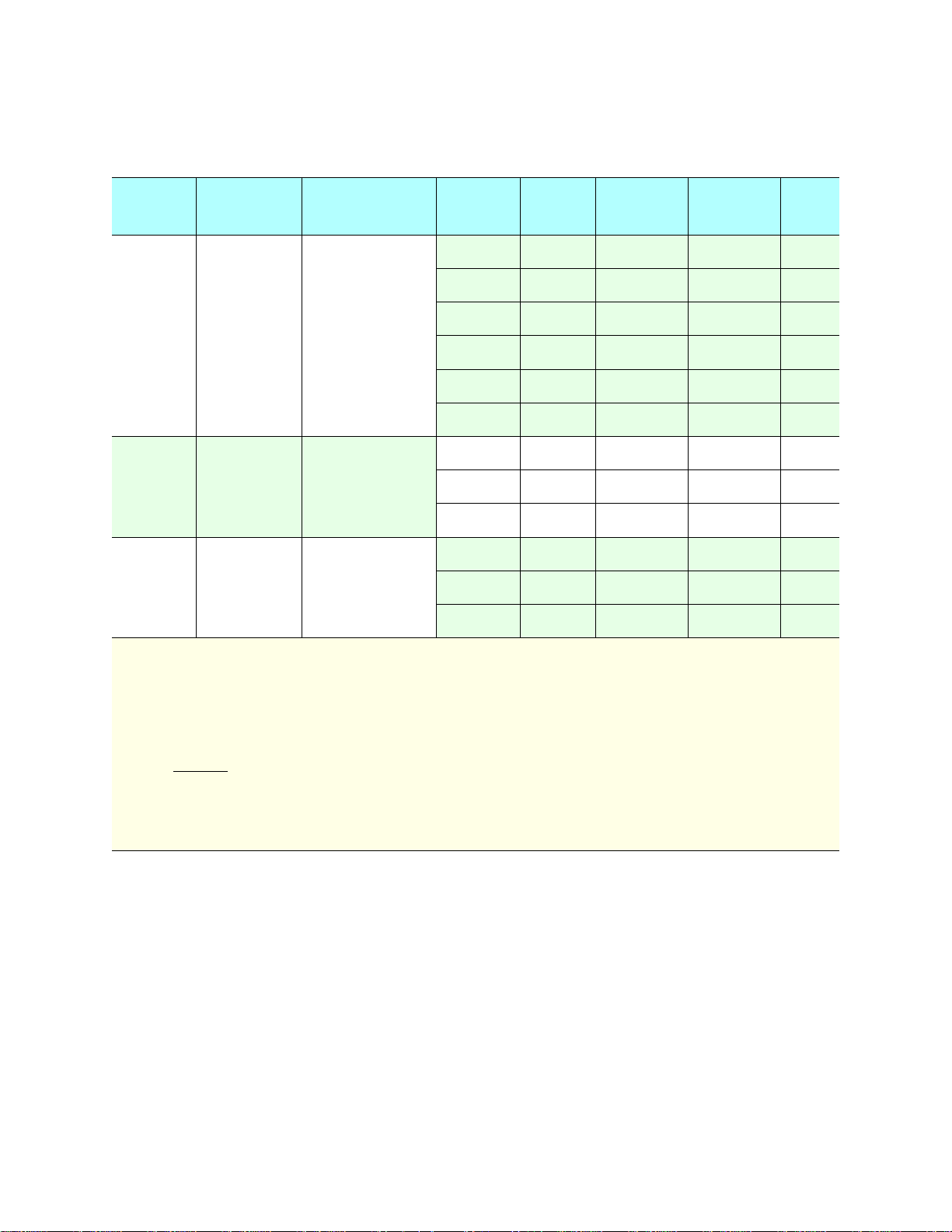

MVC Sizer Tool

As shown in Figure 2-3, the MVC Sizer tool estimates the number of Multiple Volume Cartridges (MVCs) required for a VSM installation a t intervals of 90 d ays, 180 days, 27 0 days,

one year, two years, and three years, based on mount activity and average file size.

The tool also reports estimated hours needed for daily reclaim activity, and the aver age

number of MVCs to be added on a monthly basis after the first 90 days.

Figure 2-3. MVC Sizer Tool

2-30 Sun Confidential: Internal Only 96257

Revision A

Page 31

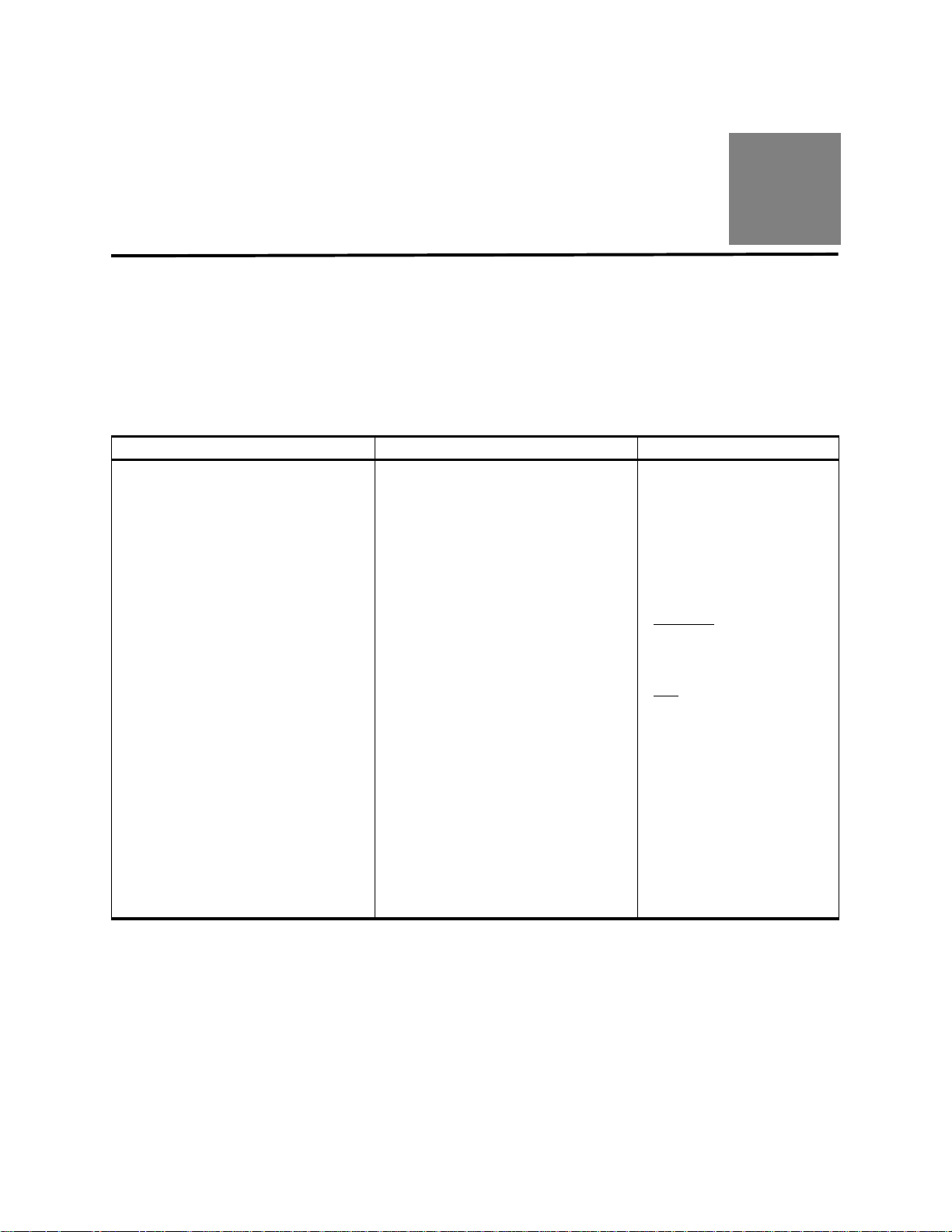

MVC Migration Tool

As shown in Figure 2-4, the MVC Migration tool evaluates existing tape systems, tape media, channels, and data set size to estimate the number of Multiple Volume Cartridges

(MVCs) required for a VSM installation at intervals of 90 days, 180 days, 270 days, one

year, two years, and 3 years, and the amo unt of time needed to mig rate data from existing

manual or Nearline tape devices to the proposed VSM5 system.

Defining Customer Requirements

Figure 2-4. MVC Migratio n Tool

96257 Sun Confidential: Internal Only 2-31

Revision A

Page 32

Configuration Planning

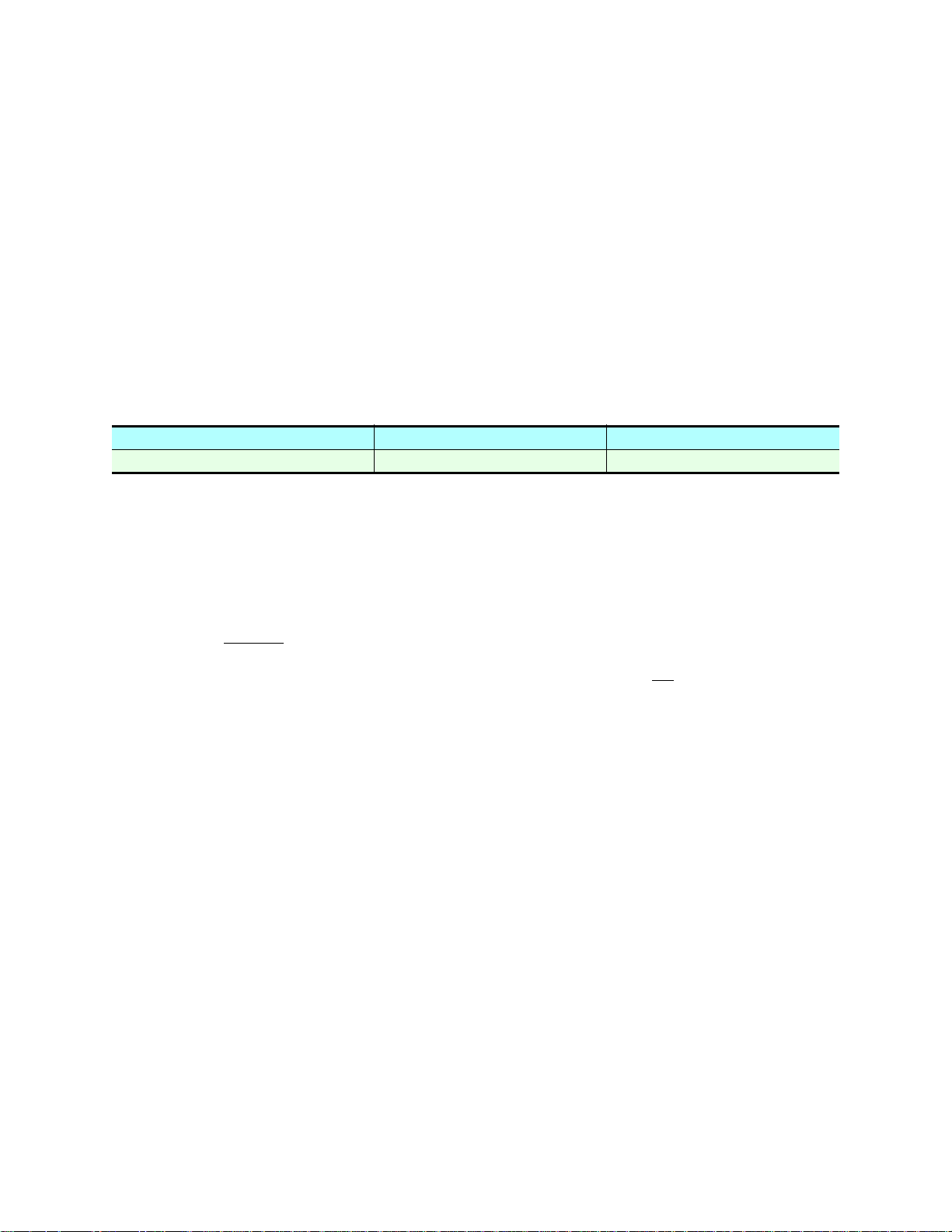

CDS Sizer Tool

As shown in Figure 2-5, the CDS Sizer is used to determine size requirements for the

HSC control data set (CDS) based on a specific VSM5 system configuration.

The tool requests detailed inputs about the VSM configuration (num ber of LSMs, VTVs,

MVCs, VTSSs, configured MVC ranges, and configured VTV ranges), then ca lculates the

number of 4K blocks needed in the HSC database to accommodate the LSM and VSM

configurations.

Figure 2-5. CDS Sizer Tool

2-32 Sun Confidential: Internal Only 96257

Revision A

Page 33

■ VTSS Configuration Planning

VTSS Configuration Planning

A VSM5 system consists of Virtual Tape Control System (VTCS) host software, Virtual

Tape Storage Subsystem (VTSS) disk hardware (tape buffers)

1

, real tape drives (RTDs)

which attach to an Automated Cartridge System (ACS), and automated ca rtridge system s

(ACSs), a.k.a. tape libraries.

A VSM5-VTSS connects to IBM S/390-equivalent data-streaming ar chitectures and related hardware

2

, and has front-end and back-end FICON connections. ESCON connections

are not available for VSM5-VTSS.

VSM5-VTSS Environmental Requirements

Table 2-2. VSM5-VTSS Environmental Requirements

Environmental

Factor

Temperature

Thermal Change

(maximum rate/hr)

Humidity

Notes:

• Abbreviations key: C = Centigrade; F = Fahrenheit; ft. = foot / feet; m = meter(s)

• * The shipping environment must not exceed the storage environment limits longer than 10 days.

#

•

The storage environment must not exceed the operating environment limits longer than 60 days.

•‡ Humidity specifications exclude conditions that may cause condensation on disk drives.

‡

Altitude

Shipping Environment

Limits*

o

C to +60oC

-40

o

F to +140o F)

(-40

15 C

(27o F)

10% to 80% 10% to 80% 20% to 80%

0m to 15,240m

(0 ft. to 50,000 ft.)

Storage Environment

10

o

(50

0m to 3050m

(0 ft. to 10,000 ft.)

#

Limits

o

C to 40 C

F to 104o F)

15oC

(27o F)

Operating Environment

(0 ft. to 8000 ft.)

(60

Limits

o

16

C to 32oC

o

F to 90o F)

5oC

(9o F)

0m to 2439m

VSM5-VTSS Physical Characteristics

Table 2-3. VSM5-VTSS Physical Characteristics

Physical Attribute Specification

Height 154.94cm (61.0 in.)

Width (with both side covers attached) 92.1cm (36.24 in.)

Depth (with front and rear doors attached) 77.1cm (30.34 in.)

Maximum Weight (with 64 array drives) 445kg (982 lbs.)

Footprint 7093.7cm2 (1099.5 in2)

Recommended Service Clearance, Front/Rear (door swing radius) 54.1cm (21.3 in.)

Recommended Left/Right Side Clearance (optional) 6.4cm (2.5 in.)

1. Both a primary VTSS and secondary VTSS can be used within a single system configuration.