Page 1

SPARCcenter2000EPowerSupply InstallationManual

A Sun Microsystems, Inc. Business

2550 Garcia Avenue

Mountain View, CA 94043 U.S.A.

415 960-1300 FAX 415 969-9131

Part No.: 802-2700-10

Revision -A, April 1995

Page 2

1995Sun Microsystems, Inc.

2550 Garcia Avenue, Mountain View,California 94043-1100 U.S.A.

All rights reserved.This productand related documentationare protectedby copyright and distributed under licenses

restrictingits use, copying, distribution, and decompilation. No part of this product or related documentation may be

reproducedin any form by any means without prior written authorization of Sun and its licensors, if any.

Portions of this product may be derived from the UNIX

®

and Berkeley 4.3 BSD systems, licensed from UNIX System

Laboratories, Inc., a wholly owned subsidiary of Novell, Inc., and the University of California, respectively.Third-partyfont

softwarein this product is protected by copyright and licensed from Sun’s font suppliers.

RESTRICTED RIGHTS LEGEND: Use, duplication, or disclosure by the United States Government is subject to the restrictions

set forth in DFARS252.227-7013 (c)(1)(ii) and FAR52.227-19.

The product described in this manual may be protected by one or more U.S. patents, foreignpatents, or pending applications.

TRADEMARKS

Sun, the Sun logo, Sun Microsystems, Solaris are trademarks or registered trademarks of Sun Microsystems, Inc. in the U.S.

and certain other countries. UNIX is a registered trademark in the United States and other countries, exclusively licensed

throughX/Open Company,Ltd. OPEN LOOK is a registered trademark of Novell, Inc. PostScript and Display PostScript are

trademarks of Adobe Systems, Inc. All other product names mentioned herein are the trademarks of their respective owners.

All SPARCtrademarks, including the SCD Compliant Logo, are trademarks or registered trademarks of SPARCInternational,

Inc. SPARCstation,SPARCserver, SPARCengine, SPARCstorage,SPARCware, SPARCcenter,SPARCclassic,SPARCcluster,

SPARCdesign, SPARC811, SPARCprinter, UltraSPARC, microSPARC, SPARCworks,and SPARCompiler are licensed

exclusively to Sun Microsystems, Inc. Products bearing SPARCtrademarks are based upon an architecturedeveloped by Sun

Microsystems,Inc.

The OPEN LOOK

®

and Sun™ Graphical User Interfaces were developed by Sun Microsystems, Inc. for its users and licensees.

Sun acknowledges the pioneering efforts of Xerox in researching and developing the concept of visual or graphical user

interfaces for the computer industry.Sun holds a non-exclusive license from Xerox to the Xerox Graphical User Interface,

which license also covers Sun’s licensees who implement OPEN LOOK GUIs and otherwise comply with Sun’s written license

agreements.

Please

Recycle

X Window System is a product of the Massachusetts Institute of Technology.

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, OR NON-INFRINGEMENT.

THIS PUBLICATIONCOULD INCLUDE TECHNICAL INACCURACIES OR TYPOGRAPHICAL ERRORS. CHANGES ARE

PERIODICALLY ADDED TO THE INFORMATION HEREIN; THESE CHANGES WILL BE INCORPORATED IN NEW

EDITIONS OF THE PUBLICATION. SUN MICROSYSTEMS, INC. MAYMAKE IMPROVEMENTS AND/OR CHANGES IN

THE PRODUCT(S) AND/OR THE PROGRAM(S) DESCRIBED IN THIS PUBLICATION AT ANY TIME.

Page 3

Contents

1. Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2. Power Supply Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Operating System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Open Boot PROM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Powering Down the System . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.4 Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Installing the Bottom Power Supply . . . . . . . . . . . . . . . . . 2-4

2.5.1 Identifying a Redundant-Capable Cabinet . . . . . . . 2-4

2.5.2 Installing the Supply. . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6 Restarting the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.7 Reading Boot Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

A. Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

iii

Page 4

A.1 Removal Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.1.1 Opening the Hinged Door . . . . . . . . . . . . . . . . . . . . . A-1

A.1.2 Removing the Vented Front Panels. . . . . . . . . . . . . . A-2

A.1.3 Removing the Side Panels . . . . . . . . . . . . . . . . . . . . . A-3

A.1.4 Removing the EMI Shield . . . . . . . . . . . . . . . . . . . . . A-4

A.1.5 Rear Screen Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

A.2 Closing the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A.2.1 EMI Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A.2.2 Rear Screen Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A.2.3 Vented Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

A.2.4 Side Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

iv SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 5

Figures

Figure 2-1 Key Switch Positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-2 AC Distribution Unit Power Switch. . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-3 Removing the Power Supply Compartment EMI Panel . . . . . 2-5

Figure 2-4 Disconnecting the Top Power Supply Power Cord . . . . . . . . . 2-6

Figure 2-5 Removing the Power Supply Cage Cover Panel. . . . . . . . . . . . 2-7

Figure 2-6 AC Distribution Unit Removal and Replacement . . . . . . . . . . 2-7

Figure 2-7 Removing the Power Breaker Box . . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 2-8 Freeing the Filter Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-9 Installing the Bottom Power Supply. . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-10 Installing the Power Supply Mounting Screws. . . . . . . . . . . . . 2-11

Figure 2-11 Installing the Bottom Cover Panel . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-12 Installing the Main Bus Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-13 Installing Power Harness on the Top and Bottom Power Supply

Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-14 Installing the Main Bus Bar and the Power Harness . . . . . . . . 2-14

Figure 2-15 Plugging the Filter Cable into the Bottom Power Supply . . . . 2-15

Figure 2-16 Replacing the Power Breaker Box . . . . . . . . . . . . . . . . . . . . . . . . 2-16

v

Page 6

Figure 2-17 Connecting the Power Cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-18 Removing the Jumper-Connector and Installing the Sense Cable

2-18

Figure 2-19 Replacing the Power Supply Compartment EMI Panel . . . . . 2-19

Figure 2-20 Local/Remote Switch Location . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-21 System Reset Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Figure 2-22 Front Panel Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Figure 2-23 Power Supply Adapter Board LEDs. . . . . . . . . . . . . . . . . . . . . . 2-25

Figure 2-24 Opening the Hinged Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Figure 2-25 Removing the Vented Front Panels . . . . . . . . . . . . . . . . . . . . . . A-3

Figure 2-26 Removing the Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Figure 2-27 Removing the EMI Shield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Figure 2-28 Rear Screen Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

vi SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 7

Tables

Table 1-1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 2-1 LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

vii

Page 8

viii SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 9

Preface

This manual provides instructions for installing a power supply in a

redundant-capable SPARCcenter™2000™or SPARCcenter 2000E™system.

These instructions are designed for an experienced service provider.

How This Book Is Organized

Chapter 1, “Before You Start,” is an overview of the tasks involved. Read this

chapter to become familiar with the overall upgrade process.

Chapter 2, “Power Supply Installation,” explains how to perform the

installation.

Appendix A, “Access” details how to remove and replace system covers.

ix

Page 10

Related Documents

The following documents contain information that may be helpful after the

upgrade is installed.

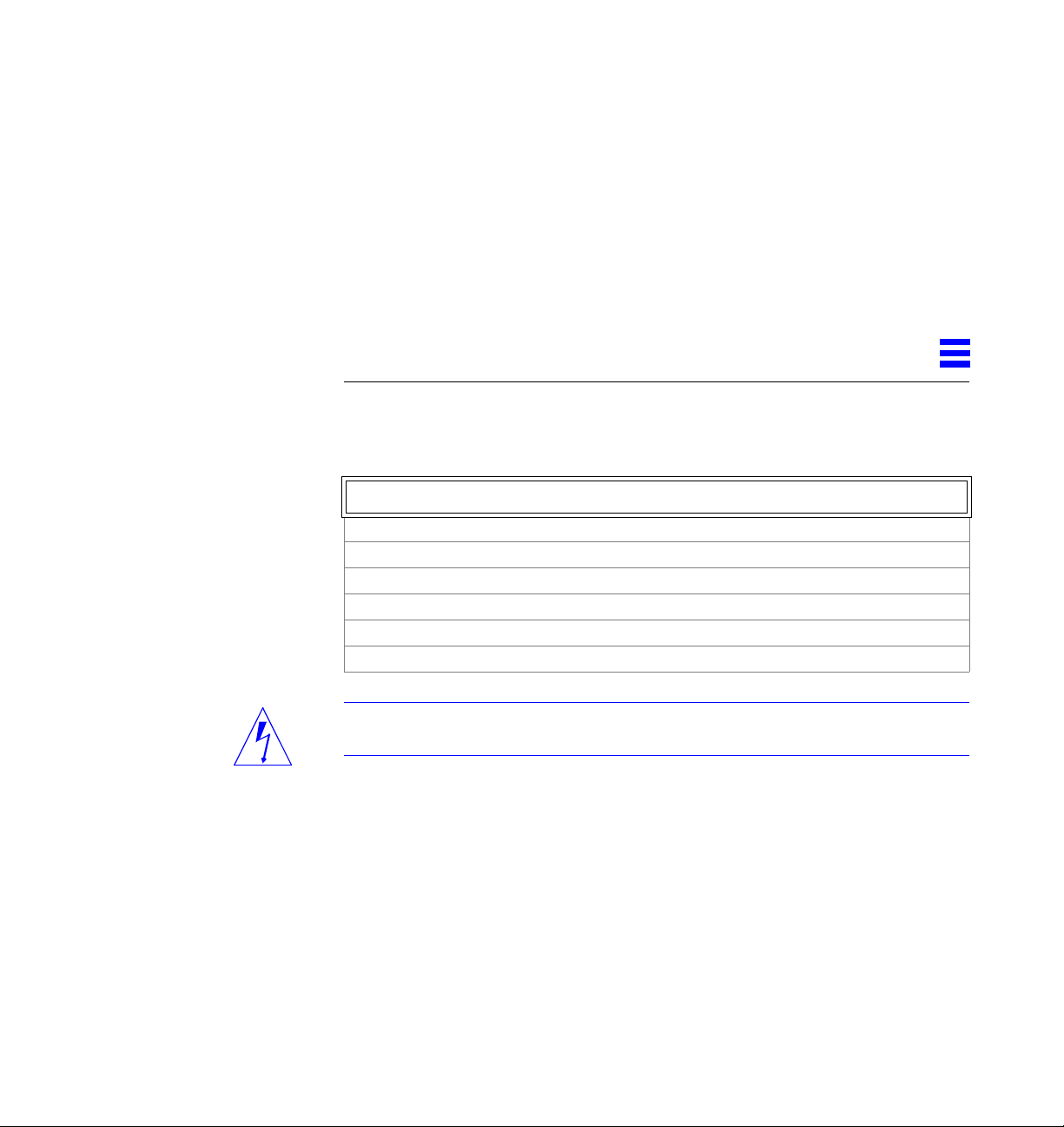

Table P-1 Related Documents

Application Title Part Number

Safety SPARCcenter 2000 Regulatory Compliance Manual 801-3051

Installation SPARCcenter 2000 Installation Manual 800-6975

Diagnostics SPARCcenter 2000 Post User’s Guide 800-7481

OpenBoot Command Reference 800-6076

User’s Guides SPARCcenter 2000 Storage Device User ’s Guide 800-7009

150MB Tape Drive User’s Guide 800-7020

5.0 GB 8mm Tape Drive User’s Guide 800-7022

10 Gbyte 8mm Tape Drive User’s Guide 801-7652

14 Gbyte 8mm Tape Drive User’s Guide 802-1850

20 Gbyte 4 mm Internal Tape Auto-Loader User’s Guide 801-4977

Service SPARCcenter 2000 ServiceManual 801-2007

x SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 11

What Typographic Changes Mean

The following table describes the typographic changes used in this book.

Table P-2 Typographic Conventions

Typeface or

Symbol Meaning Example

AaBbCc123 The names of commands,

files, and directories;

on-screen computer output

AaBbCc123 What you type, contrasted

with on-screen computer

output

AaBbCc123 Command-line placeholder:

replace with a real name or

value

AaBbCc123 Book titles, new words or

terms, or words to be

emphasized

Shell Prompts in Command Examples

The following table shows the default system prompt and superuser prompt

for the C shell, Bourne shell, and Korn shell.

Table P-3 Shell Prompts

Shell Prompt

C shell prompt machine_name%

Edit your .login file.

Use ls -a to list all files.

machine_name% You have mail.

machine_name% su

Password:

To delete a file, type rm filename.

Read Chapter 6 in User’s Guide.

These are called class options.

You must be root to do this.

C shell superuser prompt machine_name#

Bourne shell and Korn shell

prompt

Bourne shell and Korn shell

superuser prompt

Preface xi

$

#

Page 12

Notes, Cautions, and Warnings

Warning – This equipment contains lethal voltage. Accidental contact can

result in serious injury or death.

Caution – Improper handling by unqualified personnel can cause serious

!

damage to this equipment. Unqualified personnel who tamper with this

equipment may be held liable for any resultant damage to the equipment.

Individuals who remove any outer panels or open covers to access this

equipment must observe all safety precautions and ensure compliance with

skill level requirements, certification, and all applicable local and national

laws.

Procedures contained in this document must be performed by qualified

service-trained maintenance providers.

Note – Before you begin, carefully read each of the procedures in this manual.

If you have not performed similar operations on comparable equipment, do

not attempt to perform these procedures.

xii SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 13

BeforeYouStart

This manual provides procedures for installing a power supply in a redundantcapable SPARCcenter 2000 or 2000E system cabinet.

1.1 Safety Precautions

For your protection, observe the following safety precautions when setting up

your equipment:

• Follow all cautions, warnings, and instructions marked on the equipment.

• Ensure that the voltage and frequency rating of the power outlet you use

• Use properly grounded power outlets only.

• Never push objects of any kind through openings in the equipment as they

• Refer servicing of equipment to qualified personnel.

1

matches the electrical rating label on the equipment and video monitor.

may touch dangerous voltage points or short out components that could

result in fire or electric shock.

1-1

Page 14

1

To protect both yourself and the equipment, observe the following precautions:

Table 1-1 Safety Precautions

Item Problem Precaution

Springfingers Personal injury The springfingers have sharp edges. Use care when handling springfinger-

equipped cabinet screens and system boards.

RFI leakage Keep springfinger-equipped screens and panels in place when the system is

running. These assemblies suppress radio frequency interference (RFI) and

are required by law in many localities.

Damaged

springfingers

Wrist strap or

Foot strap

ESD mat ESD An approved ESD mat provides protection from static damage when used

Cover panels System damage

Filler panels System damage

SBus slot covers System damage

ESD Wear a conductive wrist strap or foot strap when handling printed circuit

and overheating

and overheating

and overheating

Look for any broken or twisted springfingers and replace any damaged

screen or board with a new assembly.

boards.

with a wrist strap or foot strap. The mat also cushions and protects small

parts that are attached to printed circuit boards.

Attach all cabinet cover panels after performing service work on the system.

Install card cage filler panels in all unused card cage slots. Open slots

severely reduce the cooling capability of the system.

Install SBus slot covers in all unused system board SBus slots. Openings on

the backs of system boards reduce the cooling capability of the system.

1.2 Symbols

The following symbols mean:

WARNING Risk of electrical shock.To reduce

the risk, follow the instructions.

WARNING Risk of personal injury. To reduce the

risk, follow the instructions.

!

1-2 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 15

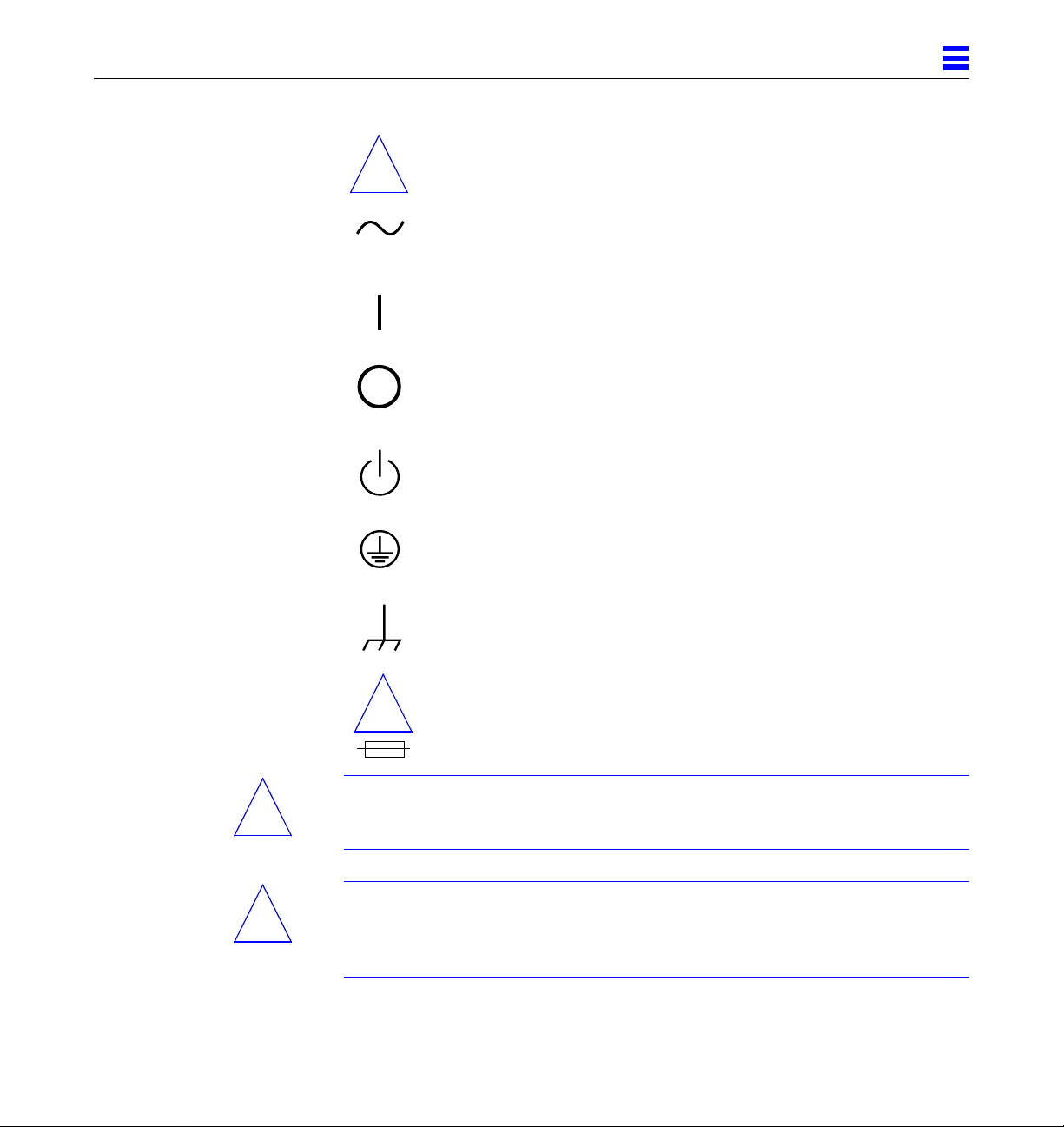

1

CAUTION Risk of equipment damage. To reduce

the risk, follow the instructions.

!

AC A terminal to which alternating

current or voltage may be applied.

ON The principal and stand-by switches

are in the ON position.

OFF The principal switch is in the OFF

position.

STAND-BY The stand-by switch is in the

STAND-BY position.

PROTECTIVE EARTH Protective earth conductor.

CHASSIS Frame or chassis terminal.

FUSE REPLACEMENT For continued protection against risk

!

Caution – DO NOT make mechanical or electrical modifications to the cabinet.

!

!

Sun Microsystems is not responsible for regulatory compliance of modified

cabinets.

Caution – Power off the cabinet and all equipment connected to it before

performing any of the procedures described in this book.

The system chassis power must be turned off, and the AC power cord must

remain plugged in to ensure a proper ground.

BeforeYouStart 1-3

MARKING of fire and electric shock, replace

ONLY with same type and rating of

fuse.

Page 16

1

Warning – This equipment contains lethal voltages. Accidental contact can

result in serious injury or death.

Caution – Improper handling by unqualified personnel can cause serious

!

!

damage to this equipment. Unqualified personnel who tamper with this

equipment may be held liable for any resulting damage to the equipment.

Persons who remove any of the outer panels to access this equipment must

observe all safety precautions and ensure compliance with skill level

requirements, certification, and all applicable local and national laws.

All procedures contained in this document must be performed by qualified

service-trained maintenance providers.

Caution – Before you begin, carefully read each of the procedures in this

manual. If you have not performed similar operations on comparable

equipment, do not attempt to perform these procedures.

1.3 Tools Required

The following list represents the minimum of tools and test equipment

required to service the system cabinet:

• Screwdriver, slotted, 3/16 inch

• Screwdriver, Phillips #2

• Screwdriver, Phillips #1

• Hex driver, M-4

• Hex driver, 3/16 inch

• Hex driver, 9 mm

• Wrench, 13 mm

• DIP/IC extraction tool

• ESD mat, Sun P/N 250-1088, or equivalent

• Grounding wrist strap

• Needlenose pliers

1-4 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 17

PowerSupplyInstallation

This chapter provides the complete upgrade procedures.

Perform these tasks in order to install a system power supply.

Safety Precautions page 1-1

Powering Down the System page 2-2

Removal Procedures page A-1

Installing the Bottom Power Supply page 2-4

Closing the System page A-6

Restarting the System page 2-20

Warning – Risk of electric shock. Do not work inside the cabinet while power

is applied to the system. Power down using the procedure which follows.

2

2-1

Page 18

2

2.1 Operating System

The correct operating system must be installed to support dual power supply

operation. The operating system must be:

Solaris 2.4 or higher, or

Solaris 2.3 with the patch: ID# 101318-59 or later revision level (obtain this

patch through your normal service channels)

Check to see which operating system is running on your machine. If necessary,

load one of the correct Solaris versions listed here before proceeding.

2.2 Open Boot PROM

The system boards require the Open Boot PROM version -10 or higher to

support dual power supply operation. If necessary, install new PROMs on all

system boards before proceeding.

2.3 Powering Down the System

Halt the operating system before turning off system power. Proceed below.

1. Notify users that the system is going down.

2. Be sure that the system files and data have been backed up.

3. Halt the system using the appropriate commands.

The halt procedure varies for different types of operating systems. Refer to

the documentation for your operating system for the correct halt procedure.

4. Wait for the system-halted message and the boot monitor prompt.

5. Turn the key switch to the (standby) position.

See Figure 2-1.

6. Turn AC power off:

Turn the AC distribution unit power switch to Off. The switch is at the rear

of the cabinet. See Figure 2-2.

2-2 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 19

2

On

Standby

Figure 2-1 Key Switch Positions

Diagnostics

Secure

↓

Off

Main Power

Figure 2-2 AC Distribution Unit Power Switch

Power Supply Installation 2-3

Page 20

2

2.4 Access

Remove all system cover panels before proceeding with the upgrade. For these

procedures, refer to Appendix A, “Access.”

2.5 Installing the Bottom Power Supply

Note – Read and follow all safety and ESD instructions found in Section 1.1,

“Safety Precautions.”

2.5.1 Identifying a Redundant-Capable Cabinet

Note – The cabinet in question is a redundant-capable cabinet if:

• The power supply cover panel on this chassis is long as shown in Figure 2-3.

This panel reaches to the bottom of the frame. In contrast, the cover panel on

the non redundant-capable chassis reaches about half the way down the frame

• The cabinet is configured with the power supply adapter board. This board,

if present, can be viewed by looking through the EMI screen on the front of the

system.

2-4 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 21

2.5.2 Installing the Supply

2.5.2.1 Preparation

1. Remove the power supply compartment EMI panel Part No. 340-3134-xx

covering both power supplies. See Figure 2-3.

Remove twelve 10-32 screws securing the panel in place and set aside.

2

Screws

Figure 2-3 Removing the Power Supply Compartment EMI Panel

2. Disconnect the top power supply power cord.

This is in the lower-center of the top supply. See Figure 2-4.

Power Supply Installation 2-5

Page 22

2

Power cord

Figure 2-4 Disconnecting the Top Power Supply Power Cord

3. Remove the power supply cage cover panel.

Remove six screws securing the panel, Part No. 340-3157-xx to the power

supply cage and remove the panel (it will not be reused). See Figure 2-5.

2-6 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 23

Remove screws, 6 places

Figure 2-5 Removing the Power Supply Cage Cover Panel

Remove the AC Distribution Unit

1. Disconnect all AC cables plugged into the unit, and disconnect cables

from connectors J2 and J3.

See Figure 2-6.

2

Cage cover panel

Springfingers (2 each)

Power supply cable

#6 Phillips screws

Phillips screws

AC distribution unit

Figure 2-6 AC Distribution Unit Removal and Replacement

Power Supply Installation 2-7

Page 24

2

Note – J3 is located on the top of the AC distribution unit, J2 is on the backside.

2. Remove the three Phillips screws and two #6-32 Phillips screws.

3. Carefully remove the power distribution unit from the system chassis.

Remove the Breaker Box

1. Remove the power breaker box. See Figure 2-7.

a. Unplug the power cord from the breaker box going to the top power

supply.

b. Remove two screws from holes in the bottom lip of the breaker box

which secure it to the bottom power supply. Set the screws aside.

c. Unscrew two captive screws at the top of the breaker box securing it to

the top power supply.

d. Remove the box and set aside.

Captive screws (2 places)

Screws (2 places, hidden)

Figure 2-7 Removing the Power Breaker Box

2-8 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 25

Filter Cable

1. Free the filter cable.

a. On the inside of the power supply cage, cut the tie wrap and uncoil the

cable. See Figure 2-8.

b. Pass the cable connector through the rectangular hole in the power

supply cage and allow it to hang.

Filter cable

Tie wrap

2

Rectangular hole (hidden)

2.5.2.2 Power Supply Physical Installation

Figure 2-8 Freeing the Filter Cable

1. Install the springfingers, Part No. 340-2415-xx (two each — included with

the kit) on the new power supply.

Install each springfinger (shown in Figure 2-9) using three screws.

2. Place the supply on the power supply shelf at a slight angle so the left-

edge enters the power supply cavity first.

Power Supply Installation 2-9

Page 26

2

3. Shove the supply into the cavity — flush against the sheet metal in the

left-interior of the power supply cage.

See Figure 2-9.

Power supply cage

Power supply

Springfingers (2 each):

Install using 3 screws

each

Figure 2-9 Installing the Bottom Power Supply

4. Install six screws to secure the power supply to the power supply cage.

Use screws Part No. 340-1372-xx. See Figure 2-10.

2-10 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 27

Screws (6 places)

2

Figure 2-10 Installing the Power Supply Mounting Screws

Power Supply Installation 2-11

Page 28

2

5. Install the bottom cover panel.

Position the panel Part No. 340-3190-xx and install 12 screws

Part No. 240-1372-xx to secure the panel to the cabinet. See Figure 2-11.g

Screws (12 places)

Bottom cover panel

Part No. 340-2190-xx

Figure 2-11 Installing the Bottom Cover Panel

2.5.2.3 Main Bus Bar Installation

Install the main bus bar Part No. 340-3136-xx to connect the top and bottom

power supply busses.

1. Orient the bus bar as shown in Figure 2-12.

2. Place the bus bar flush against the top and bottom power supplies so

holes in the tabs slide over all bolts on the supplies: eight on the top

supply and eight on the bottom.

3. Loosely install in the order given the following on each bolt: a flat washer,

a lock washer and a nut.

See Figure 2-12.

4. Loosely install four M6 screws through holes in the bus bar to secure the

bus bar to the top and bottom cover panels.

The screw Part No. is 240-2083-xx. See Figure 2-12.

5. Tighten all nuts and screws installed in Step 3 and Step 4.

2-12 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 29

Screws, M6 (4 places)

Nuts backed by lock and flat

washers (16 places)

Main bus bar,

Part No. 340-3136-xx

2

Tabs (8 each)

Figure 2-12 Installing the Main Bus Bar

2.5.2.4 Power Harness Installation

Install the power harness, Part No. 530-2164-xx (comprised of four bus wires)

to connect the two power supplies.

1. Orient the power harness as shown in Figure 2-13.

2. Connect the power harness to the top power supply.

Push four spade connectors onto the spade lugs. See Figure 2-13.

3. Connect the power harness to the bottom power supply.

Push four spade connectors onto the spade lugs.

4. Secure the power harness to the cover panels.

Clip the power harness into nylon retainers in the top and bottom power

supply cover panels. See Figure 2-14.

Power Supply Installation 2-13

Page 30

2

+12V

A

+12V Return

C

–12V

E

–12V Return

G

Power harness Part

No. 530-2164-xx

+12V

B

D

+12V Return

F

–12V

H

–12V Return

Figure 2-13 Installing Power Harness on the Top and Bottom Power Supply Terminal

Cover panel

Power harness Part

No. 530-2164-xx

Powerharness

retainers

Main bus bars

Figure 2-14 Installing the Main Bus Bar and the Power Harness

2-14 SPARCserver 2000E Power Supply Installation Manual—April 1995

Blocks

Page 31

2.5.2.5 Cabling

Filter Cable, Breaker Box and AC Distribution Unit

1. Plug in the filter cable.

Form a service loop in the cable and plug the connector into J2 (the top

connector) on the power supply. See Figure 2-15.

2. Replace the power breaker box. See Figure 2-15.

c. Insert the filter cable service loop into the hole in the back side of the

breaker box (Figure 2-15).

Note – Insert filter cable loop into the hole in breaker box that is surrounded

by springfingers.

Service loop

2

Rectangular hole

Breaker box

(cutaway view)

Figure 2-15 Plugging the Filter Cable into the Bottom Power Supply

Power Supply Installation 2-15

Page 32

2

d. Place the breaker box against power supply cage.

Align the captive screws with the bottom two holes in the top power

supply. See Figure 2-16.

e. Loosely thread the two captive screws at the top of the breaker box into

holes in the top power supply.

f. Loosely thread two screws through holes in the bottom lip of the

breaker box into holes in the bottom power supply.

g. Tighten all four screws to secure the power breaker box in place.

Note – Ensure the filter cable does not become crimped between the breaker

box and the power supply cage.

Captive screws (2 places)

Screws (2 places, hidden)

Figure 2-16 Replacing the Power Breaker Box

3. Replace the AC distribution unit. a. Place the power distribution unit against the chassis with all four holes

aligned with those in the chassis.

2-16 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 33

b. Replace the three Phillips screws and two #6-32 Phillips screws.

c. Replace cables in connectors J2 and J3.

1. Plug in the three power cords:

See Figure 2-17.

a. Plug the main power cord into the AC distribution box J2 and the other

end into breaker box J1 (bottom-right jack).

b. Plug power cord Part Number 530-2160-xx into breaker box J2 (top

jack) and the other end into the top power supply AC input.

c. Plug power cord Part Number 530-2160-xx into breaker box J3 (bottom-

left jack) and the other end into the bottom power supply AC input.

Top power supply

Breaker box

2

J3

AC distribution unit

Bottom power supply

Power cords

J2 (hidden)

Figure 2-17 Connecting the Power Cords

Note – Examine the breaker box to ensure both circuit breakers are ON. Set

them to ON if required.

Power Supply Installation 2-17

Page 34

2

2.5.2.6 Power Supply Sense Cable

1. Remove the jumper-connector from the power supply adapter board.

You will find this device plugged into the connector nearest the outside

edge of the cabinet. Remove it. See Figure 2-18.

2. Plug the sense cable for the bottom power supply into the power supply

adapter board.

Plug it into the near-most connector — from which the jumper-connector

was removed in Step 2.

3. Plug the other end of the sense cable into the sense connector on the

bottom power supply.

Plug it into J1 near the top of the supply.

Jumper connector: Remove to allow the

lowerpower supply cablesensecableto be

plugged into this connector.

Figure 2-18 Removing the Jumper-Connector and Installing the Sense Cable

2-18 SPARCserver 2000E Power Supply Installation Manual—April 1995

Power supply sense cable

for bottom power supply

Power supply

adapter board

Page 35

2.5.2.7 Restorethe System

1. Replace the power supply compartment EMI panel. See Figure 2-3.

Position the panel against the cabinet and secure using 12 screws.

2

Screws

Figure 2-19 Replacing the Power Supply Compartment EMI Panel

Power Supply Installation 2-19

Page 36

2

2.6 Restarting the System

Note – As the system starts up, watch for error messages from the POST

diagnostic program. If a terminal is not already part of the system, install a

TTY terminal before continuing the start up. See the SPARCcenter 2000

Installation manual for terminal settings.

1. The system key switch must be turned to (the standby position).

See Figure 2-1.

Caution – The outlet must be a 200-240 Vac 30-ampere circuit, intended solely

!

for use by the server cabinet, as described in the site preparation instructions in

the SPARCcenter 2000 Installation manual. The electrical receptacle must be

grounded, and the grounding conductor serving this receptacle must be

connected to the earth ground at the service equipment.

2. Turn the Local/Remote switch down, to Local. See Figure 2-20.

3. Turn on the power switch on the AC distribution unit.

See Figure 2-2.

4. Turn on power to the terminal.

A terminal is required for viewing system messages.

5. Turn the key switch to (the power-on position). See Figure 2-1.

Several things will happen:

• The DC-powered blower fan in the top of the cabinet begins turning.

• The left front panel LED (green) turns on immediately to indicate the DC

power supply is functioning.

• The middle front panel LED (yellow) lights immediately and should turn

off after approximately 60 seconds.

• The right front panel LED (green) lights after POST has ended to show

that booting is successful.

• The terminal beep indicates that the system is ready.

• The terminal screen lights up upon completion of the internal self test.

2-20 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 37

Remote

Local

2

Figure 2-20 Local/Remote Switch Location

Caution – Never move the system cabinet or the expansion cabinets when

!

system power is on. Excessive movement can cause catastrophic disk drive

failure. Always power the system OFF before moving cabinets.

Power Supply Installation 2-21

Page 38

2

6. Watch the terminal screen for any POST error messages.

At the conclusion of testing, POST automatically configures the system,

omitting any devices that have failed diagnostics. After POST ends, the

system will boot using the new configuration.

If the middle front panel LED remains lit after the system has booted, the

system has failed POST.

If you system has two power supplies and one fails, the system will

continue to operate. If POST, OBP or the operating system detects the power

supply failure, a warning message similar to the one below will be

displayed to the console:

Power supply maintenance should be scheduled.

Note – POST does not test drives or internal parts of SBus cards. To test these

devices, run OpenBoot PROM (OBP) diagnostics manually after the system has

booted. Refer to the OpenBoot Command Reference manual for instructions.

7. To start POST again, or if the system hangs, press the reset switch on the

back of the front panel.

See Figure 2-21.

2-22 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 39

Reset switch

2

Figure 2-21 System Reset Switch

8. If the system displays “not responding” or “no carrier” messages, the

Link Integrity Test may be set incorrectly.

2.7 Reading Boot Messages

Use the boot software messages to verify the presence of options in the system.

After POST completes the system self-test, a message similar to the following

will appear on your screen. The message lists hardware detected in the system.

Power Supply Installation 2-23

Page 40

2

Note – The following screen display is an example only. The actual message

displayed on the screen will vary with the software running on the system.

<<<< SPARCsystem 2000XX POST VX.X >>>>

...(various test messages)...

SPARCsystem 2000 Series (2 X XXXXXX), No Keyboard

ROM Rev. -.-, --- MB Memory installed, Serial #---.

Ethernet address -:-:--:-:--:--, Host ID: ------.

Note – When a system is started for the first time, or if the master board is

replaced, OBP will prompt you to select a system board to be the new system

master. The system master is normally in slot 0.

If there is no terminal on this system, you must check the system status by

inspecting LEDs on the front panel and if present) on the power supply

adapter board. See Figure 2-22 and Figure 2-23.

Table 2-1 summarizes LED status conditions during and after POST.

DC power (green)

Fault (yellow)

System running (green)

Figure 2-22 Front Panel Status LEDs

2-24 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 41

Sense cable to bottom power supply

Power supply adapter board

LEDs (2 each)

2

Sense cable to top power supply

Sense cable to backplane

Bottom

Power Supply

Figure 2-23 Power Supply Adapter Board LEDs

Table 2-1 LED Status Indicators

Location LED Condition

Front panel Left LED

(green)

Middle LED

(yellow)

Right LED

(green)

All system boards Lower 8 LEDs During POST, LEDs cycle on and off in irregular pattern.

Master system board only Lower 8 LEDs After POST, LEDs display cyclic pattern.

All slave system boards Lower 8 LEDs After POST, LEDs display solid pattern until boot is ended, then LEDs

On — DC power supply is receiving AC current.

Off — There is no DC power.

On — (first 60 seconds) Self tests are running.

Off — (after self tests end) No hardware failures.

On — (after self tests end) Hardware failure was detected.

Off — (first 60 seconds) Self tests are running.

On — (after self tests end) System is running.

Off — (after self tests end) System cannot run; repair is needed.

display same cycling pattern as master board. After boot ends, for boards

without SPARC modules, LEDs continue to display solid pattern. After

boot ends, LEDs on failed boards should be OFF.

Top

Power Supply

Power supply adapter

board (redundantcapable chassis only)

Left LED

Right LED

Power Supply Installation 2-25

On — bottom power supply failed, or the circuit breaker (breaker box)

tripped.

Off — top power supply fail, or the circuit breaker (breaker box) tripped.

Page 42

2

2-26 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 43

Access

A.1 Removal Procedures

Remove panels to afford access to the power supplies and related components.

A.1.1 Opening the Hinged Door

1. Grasp the door at the upper-right corner and pull towards you firmly.

See Figure 1-1.

The door is secured closed by clips and ball-studs at the side opposite of the

hinge. The door is released and swings open if pulled firmly.

A

A-1

Page 44

A

Figure 1-1 Opening the Hinged Door

A.1.2 Removing the Vented Front Panels

1. Grasp the panel under the vent at one end and pull it outward

approximately 1 inch (2-3 centimeters) to disengage the ball studs.

See Figure 1-2.

2. Repeat this procedure at the opposite side to free the panel.

A-2 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 45

A

Figure 1-2 Removing the Vented Front Panels

A.1.3 Removing the Side Panels

To remove the left and right side panels:

1. Loosen two slot-head captive screws near the panel base.

2. Tilt the panel bottom out.

Access A-3

Page 46

A

3. Lift the panel up until free of the tabs at the top of the chassis. Set the panel aside.

Panel notches

Chassis tabs

Side panel

Captive screws

Figure 1-3 Removing the Side Panels

A.1.4 Removing the EMI Shield

The EMI shield is located behind the front panels.

1. Remove the Phillips screws securing the EMI shield to the chassis.

See Figure 1-4.

2. Grab the handle at the panel top to tilt the panel out to remove it.

A-4 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 47

A

EMI shield

#10 Phillips screws

Figure 1-4 Removing the EMI Shield

A.1.5 Rear Screen Panel

1. Remove the two #10 Phillips screws securing the panel to the frame.

See Figure 1-5.

Access A-5

Page 48

A

2. Tilt the panel top out and lift it free of the chassis. Set the panel aside.

There is a flange on the bottom of the rear screen.

Rear screen panel

#10 Phillips screws

Kick panel

Figure 1-5 Rear Screen Panel Removal

A.2 Closing the System

A.2.1 EMI Panel

1. Hold the panel by the handle at the top. Position the panel in the opening

so the bottom flange fits over the lip at the bottom of the opening.

2. Tilt the panel flush against the chassis. Install and tighten all screws.

A.2.2 Rear Screen Panel

1. Insert the panel so the bottom flange engages behind the top of the kick panel.

2. Tilt the panel flush against the frame and secure using two screws.

A-6 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 49

A.2.3 Vented Front Panel

♦ Place the panel against the chassis with ball studs aligned with catches on

the panel.

At both ends, tap or press the panel into place.

A.2.4 Side Panels

1. Place the panel against the cabinet so the notches on the panel inside

align with tabs at the chassis top.

2. Lower the panel into place and allow it to hang flush against the chassis.

3. Tighten the two captive screws at the panel base.

A

Access A-7

Page 50

A

A-8 SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 51

RevisionHistory

Revision Dash Date Comments

802-2700-10 -A April 1995 First Customer Ship

Page 52

SPARCserver 2000E Power Supply Installation Manual—April 1995

Page 53

Reader Comments

We welcome your comments and suggestions to help improve this manual. Please let us

knowwhat you thinkabout the SPARCserver2000E PowerSupplyInstallation Manual,

part number 802-2700-10.

■ The procedures were well documented.

Strongly Strongly Not

Agree Agree Disagree Disagree Applicable

❑❑❑❑❑

Comments

■ The tasks were easy to follow.

Strongly Strongly Not

Agree Agree Disagree Disagree Applicable

❑❑❑❑❑

Comments

■ The illustrations were clear.

Strongly Strongly Not

Agree Agree Disagree Disagree Applicable

❑❑❑❑❑

Comments

■ The information was complete and easy to find.

Strongly Strongly Not

Agree Agree Disagree Disagree Applicable

❑❑❑❑❑

Comments

■ Do you have additional comments about the SPARCserver 2000E Power Supply

Installation Manual?

Name:

Title:

Company:

Address:

Telephone:

Email address:

Page 54

BUSINESS REPLY MAIL

FIRST CLASS MAIL PERMIT NO. 1 MOUNTAIN VIEW, CA

POSTAGE WILL BE PAID BY ADDRESSEE

SUN MICROSYSTEMS, INC.

Attn: Manager, Hardware Publications

MS MPK 14-101

2550 Garcia Avenue

Mt. View, CA 94043-9850

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

Loading...

Loading...