Sun-Mar CENTREX 2000 series, CENTREX 2000 AC/DC, CENTREX 2000, CENTREX 2000 NE Owner's Manual

Serial # ________________

CENTREX 2000 FAMILY

OWNER’S MANUAL

RATED CAPACITY

Weekend & Vacation Use

(Cottage Use)

NE Units; 6 Adults

Electric Units; 7 Adults

Residential & Continuous Use

NE units: 3 Adults

Electric Units; 4 Adults

Standard 41

Certified for liquid

containment, odors, and solid

end products in cottagel use

Certified to NSF/ANSI Standard 41

CENTREX 2000

CENTREX 2000 AC/DC

CENTREX 2000 NE

OWNER’S MANUAL

CONTENTS

I

ntroduction

Chapter 1

Chapter 2

Chapter 3

How your composting

toilet Works

How Composting Works

The Composting Chamber

Compost Finishing Drawer

Evaporation Chamber

Winter Use

CENTREX 2000 Family Part Numbers

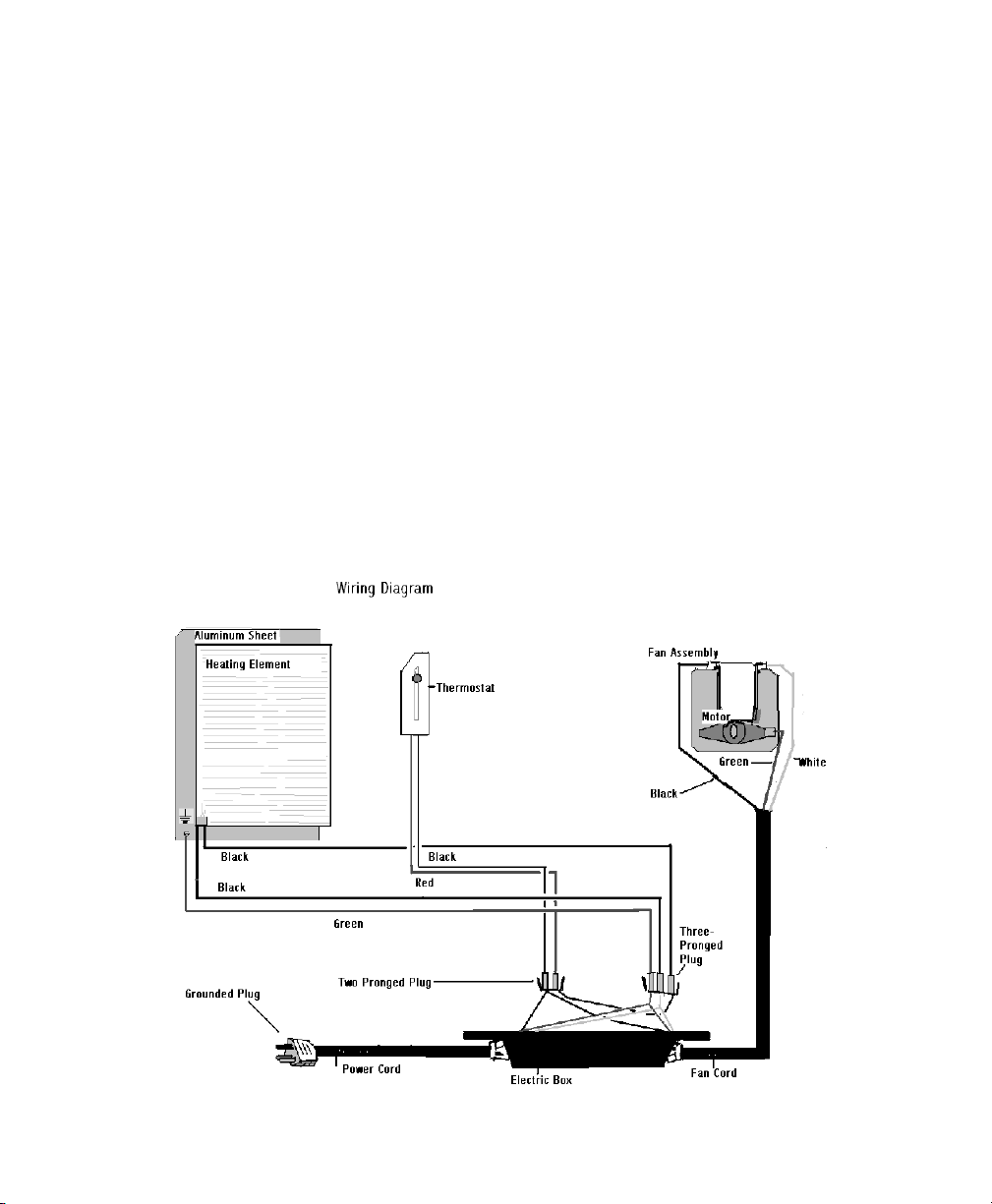

Wiring Diagram

CENTREX 2000 Family Explosion

Drawing

Inspection

Check for Damage

Check for Parts and Functionality

Placement of unit

Installation

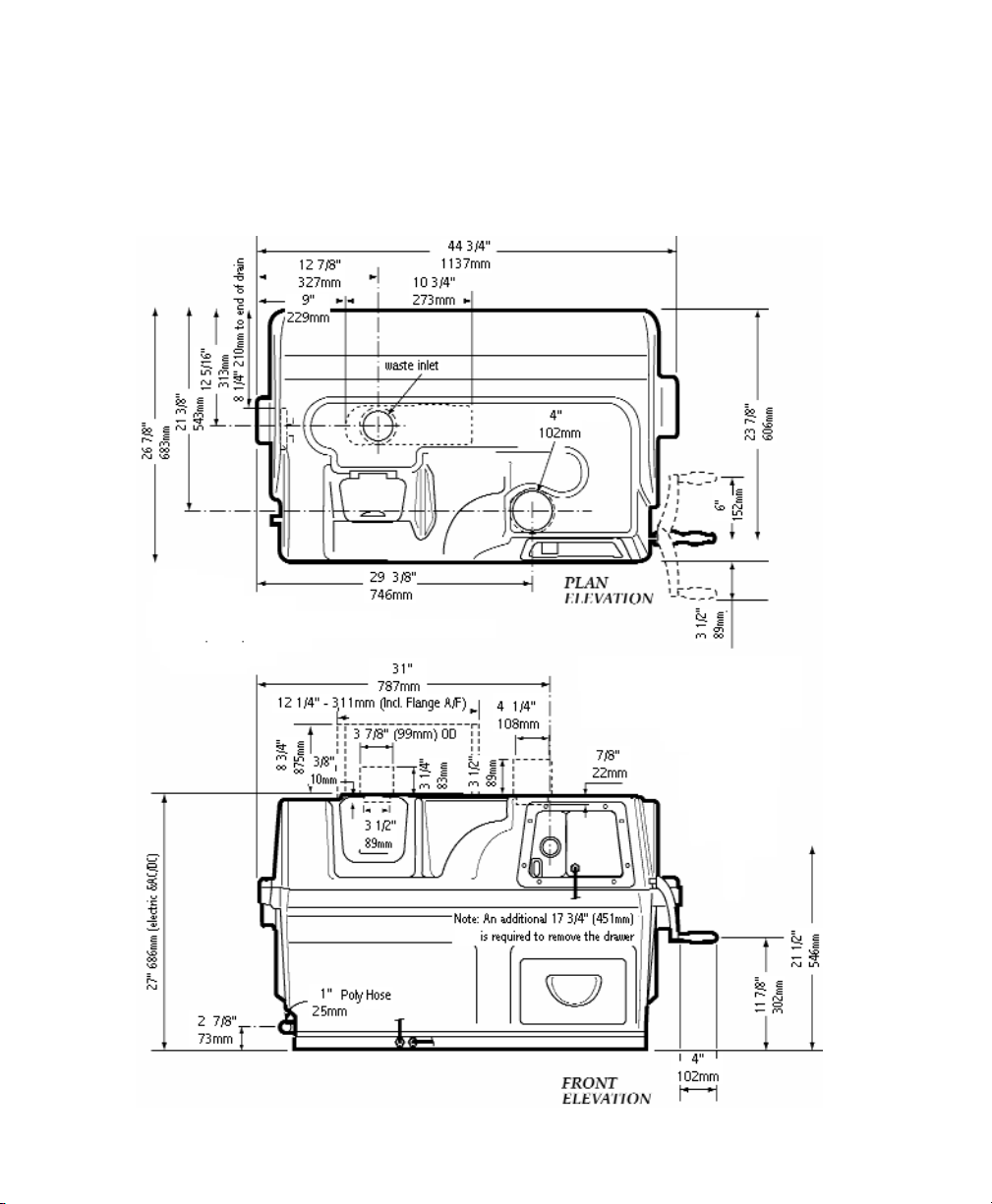

CENTREX 2000 Rough in Dimensions

Included in your kit

Installing the 1 Pint(500ml)

Low-Flush Toilet

Installation Considerations for

The Waste Pipe

The 3” (75mm) Waste Inlet

Drain Installation

Handling Effluent

Vent Pipe Location

Adjusting the Fan Gate

Vent Pipe Installation

Leading the Vent through the roof

The Diffusor

Electrical Considerations

12 Volt Fan Installation

Start Up and Use

Initial System Start Up

2-5

2

2

2

3

3

4

5

6

6

6

6

7-12

7

8

8

9

9

9

9

10

10

10

10

11

11

11

12

13-15

13

Chapter 4

Chapter 5

Annual Start Up

Periodic Check Up

Ongoing Maintenance

Compost

Troubleshooting

Aerobic Compost Requirements

Compost Too Wet

Compost Too Dry

Waste not Breaking Down

Lumps

Drum Too Full

Flies

Mechanical

Troubleshooting

Urine Odor In Washroom

Occasional Urine Odor Outside

Sewage Odor when drum turns

Fan Noisy

Fan Not Working

Liquid Buildup/

Lack of Evaporation

Overflowing Liquid

Heating System Not Working

Liquid In Finishing Drawer

Drum Will Not Stay Vertical

Drum Will Not Turn

Drum Door Not Opening/

Closing

Waste Not Exiting Waste Pipe

Composting

Accessories

WarrantyInformation

Basic Maintenance

Electrical Specifications

14

14

15

16-19

16

17

17

17

18

18

19

20-24

20

21

21

21

22

22

22

23

23

23

24

24

24

25

26

27

28

- 1 -

Introduction

HOW YOUR COMPOSTING TOILET WORKS

The key to the success of the “CENTREX 2000 Family” lies in it’s three chamber design. Each of the three chambers; composting, compost finishing, and evaporation have their own independent environments for optimum efficiency.

Composting is a natural recycling process where human

waste and toilet paper are broken down by microbes

into minerals and converted back to earth. Heat, oxygen, organic material and moisture are needed to

transform this waste into good fertilizing soil, perfect for

your flower beds.

Oxygen is provided by the ventilation system, and by

tumbling the composting drum. Additional organic

material is introduced by adding “Compost Sure Blue”

(or 100% non-antibacterial wood shavings). The waste

entering the toilet is approximately 90% water content.

Any excess liquid which is not absorbed will collect on

the floor of the unit (evaporation chamber) where it

may be evaporated into water vapor and carried back

to the atmosphere through the venting system. The

remaining waste material is transformed into an inoffensive earth-like substance.

The Composting Chamber

The composting chamber is in the form of a Bio-drum

which holds the natural compost heat, provides the necessary mass to maintain a good compost, and is rotated by turning the handle to achieve perfect mixing and

aeration.

During mixing, both the input door and the output doors

will remain closed. When the drum returns to the top

dead centre position ready to receive more waste, the

input doors remains open.

Compost is removed from the drum periodically, by

pulling the white drum locker button (on the handle side

of the composting unit)out, and turning the handle

counter-clockwise so that the drum rotates clockwise.

When this is done, the output door stays open, and

compost falls into the second chamber;-the compost

finishing drawer.

To ensure that the compost remains moist, but does not

get too wet (between 40 and 60% moisture content is

ideal), any excess liquid which the compost cannot

absorb drains through a screen in the rear of the drum

directly onto an evaporating tray beneath the screen,

and from there, overflows into the evaporating chamber.

The evaporating tray can be removed periodically to

remove peat moss debris that has accumulated.

Compost Finishing Drawer

The compost finishing drawer is at the extreme right of

the unit below the composting drum, and just above the

evaporating chamber. Compost from the drum is isolated in the drawer where it is allowed to ‘finish’ composting. For seasonally used units, several drawers of finished compost are normally removed at the beginning

of the season. Otherwise some composted material can

be extracted into the drawer and left there for 3-4

weeks until it is time to remove more compost from the

drum.

- 2 - - 27 -

Evaporating Chamber

The third chamber is the floor of the Sun-Mar “CENTREX

2000 Family” which forms the evaporation chamber

from where excess liquids may be evaporated. You will

always see liquid in this area, which is waiting to be

evaporated.

In electric and AC/DC units, air is pulled through intake

holes at the rear of the unit; over the evaporating

chamber, and up the 2”(50mm) vent stack which exits

from the front of the composting unit when AC power is

being used.

On non-electric or AC/DC units, when AC power is

unavailable, natural draft caused by the chimney effect

of the 4”(100mm) vent and assisted by the 12 volt fan

draws air into the unit and up the 4”(100mm)vent

stack.

In the electric mode, the evaporation process is further

assisted by a thermostatically controlled heating element in a separate sealed compartment under the

evaporating chamber. This heater is on when there is

liquid in the evaporating chamber, and mostly off when

the chamber is dry. The heating system maintains

warmth in the evaporating chamber, and the indirect

warmth assists the composting process, without the

compost drying out. A safety drain exits from the side

of the composter which drains off any excess liquid to a

cess pool, recycling bed, or other approved facility.

Winter Use

Because "Sun-Mar" units are made largely of fiberglass

and high grade stainless steel, freezing temperatures

will not damage the composting unit. Composting action

decreases as the temperature drops, so for continuous

use, the composting unit should be kept constantly at or

above 55-60 degrees F (13-15 C). All exposed vent

stack should be insulated (right up to 2" or 5cm below

the diffusor) to minimize the condensation in the pipe

and avoid ice blockages. Drain pipe should be insulated or, in extreme temperatures, heat tape used to prevent ice blockages.

In extreme temperatures, an additional source of heat

will also be required.

If the compost is frozen in the drum, the unit may be

used periodically as a "holding tank", until the compost

warms up and the microbes emerge from dormancy.

Space should be made in the drum prior to freezing to

accommodate winter use. The drum should NOT be

rotated when the compost is frozen.

Make sure that the composting unit is protected from

snow and ice accumulation to ensure that moisture

doesn't get into the heater base. It is a good idea to

put a tarp over the composting unit to protect it from

snow.

- 3 -

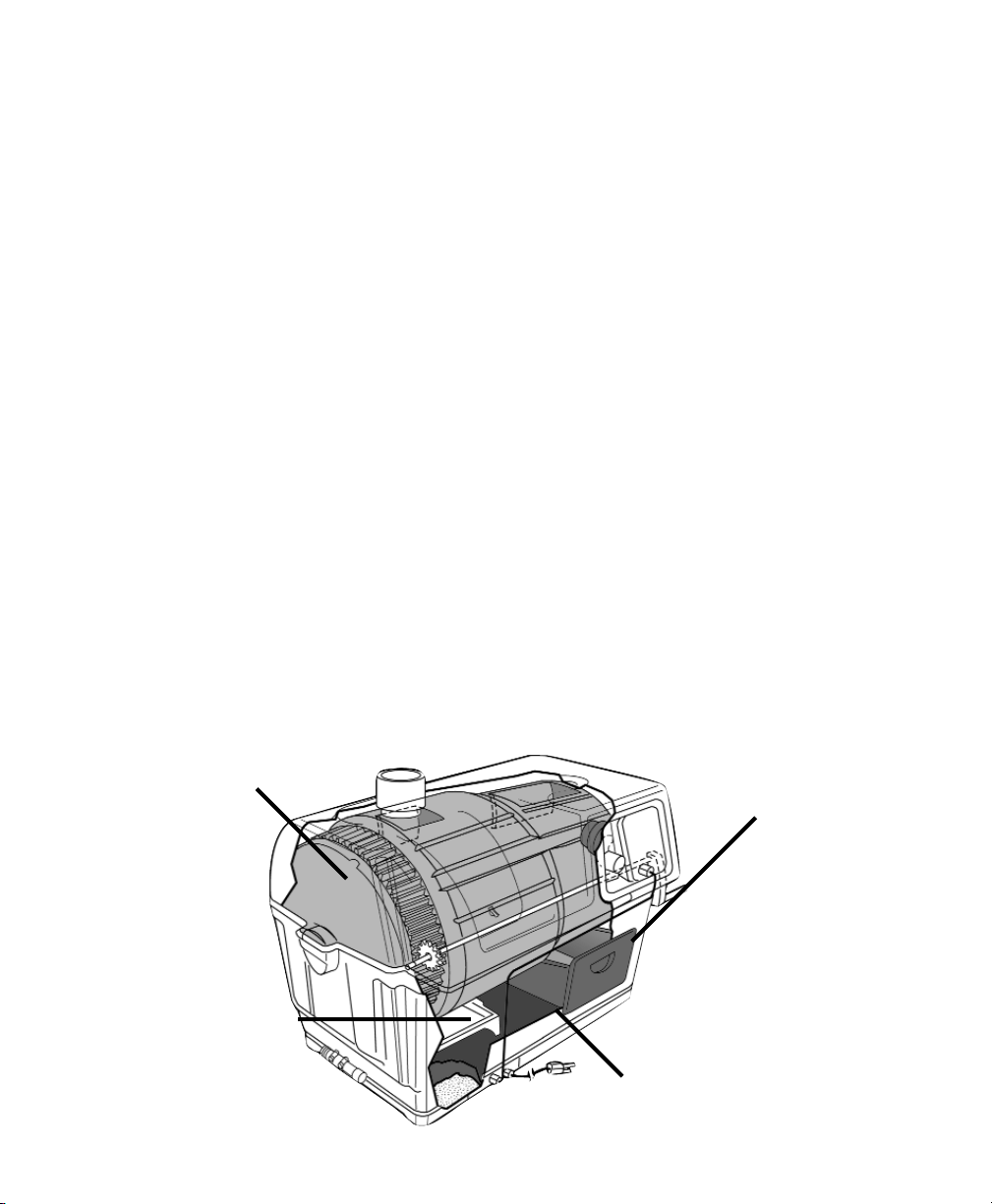

Composting Drum:

Waste and bulking mix-

Finishing Drawer: Where

compost is put to ‘finish’

Evaporation Chamber: This is

where you will frequently see liquid collecting.

Evaporation Tray: Extends

the surface area of the

evaporation chamber

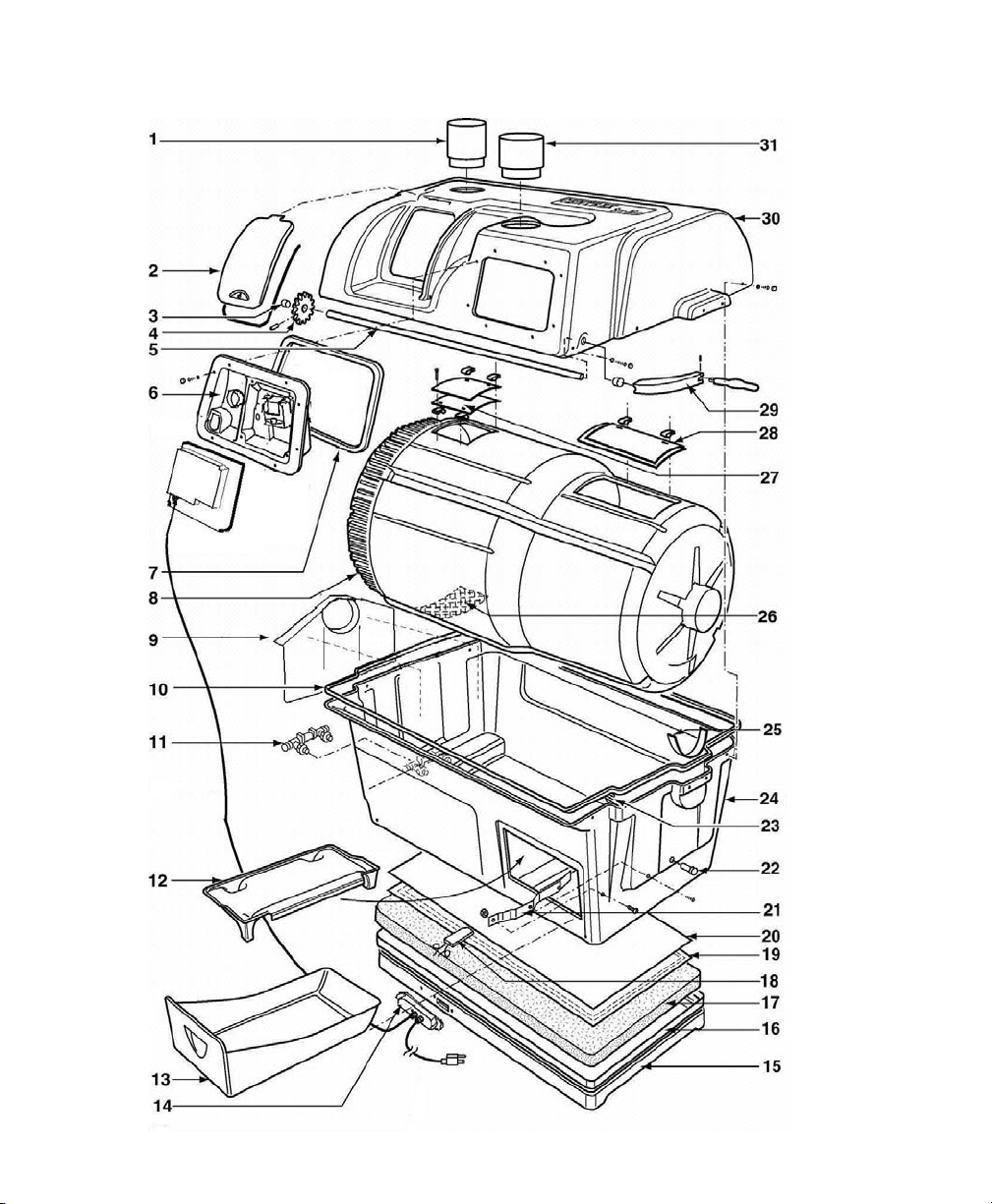

EXPLOSION DRAWING OF COMPOSTING UNIT

- 4 - - 25 -

CENTREX 2000 FAMILY PART NUMBERS & DESCRIPTIONS

# PART DESCRIPTION # PART DESCRIPTION

1

PP-INLEP-0207CX Centrex Waste Inlet

17

(Incl. In Heating Element Kit) Insulation

2

AO-ACCEP-0481BX Access Port

18

AO-THERA-0001AX Thermostat

3

PP-BUSH0-0812XX Bushing Threaded

19

AO-HEATE-0311XX Heating Element C9286-1

4

AO-SMALL-0440XX Nylon Drive Gear

20

PM-ALUMS-0811EX Aluminum Sheet

5

AO-SHAFA-0851XX SS Shaft Kit

21

AO-DRUML-0469BX Drum Locker

6

AO-FAN_A-0315KX Fan Assembly (Electric & AC/DC)

22

PP-SCRE00-0821EX Drum Locker Knobt

7

PP-GASK0-0188XX Rubber Gasket

23

PP-INTAV-0797XX Air Intake Vent

8

PP_DRUM0-0624CX Centrex 2000 Drum

24

PF-TANKC-0761EX Centrex 2000 Tank

9

PP-BEARP-0758RX Bearing Plate

25

PP-BEARS-0787CX Drum Bearing Strip

10

PP-GASK0-0188BX Rubber U Channel

26

AM-DRUMS-0329EX Drum Screen

11

AP-DRAI0-0306EX Drain Assembly

27

AO-DRUMD-2004EX Drum Door

12

PF-EVAPT-0789EX Evaporating Tray

28

AO-DRUMD-2004EX Drum Door

13

PF-DRAW1-0764EX Centrex 2000 Drawer

29

AO-HANDL-3000EX Swivel Handle

14

P0-ELECB-0001AX Electric Box Assembly (Electric and AC/DC)

30

PP-TOPC2-0802BX Centrex 2000 Top Kit

15

PF-HEAT1-0760EX Centrex 2000 Heater Tray

30

PP-TOPC2-0802DX Centrex 2000 NE Top

16

PP-GASK0-0188BX Rubber U Channel

30

PP-TOPC2-0802CX Centrex 2000 AC/DC Top

31

PP-INLEP-0207CX Waste Inlet Pipe

Chapter 1

Inspection

This chapter describes how to inspect your new Centrex 2000 prior to installation for damage and make

sure you have received all of the parts.

Inspecting

the unit for

damage

i) If there is any visible damage to the carton

the contents of car ton MUST be inspected before signing bill of lading. Damaged units

should be refused. Call Sun-Mar immediately.

Before signing the shipping papers and dismissing the driver.

ii)

ensure that the carton contents have been inspected.

If the shipper has left-

iii)

Report the damage immediately to the transport company and call Sun-Mar.

Soon after delivery, remove the Centrex 2000 carefully

iv)

from the carton

-

If there is hidden damage, or for any service Questions, contact Sun-Mar to determine

the best course of action.

-

-

Check Carton

Contents

and

Familiarize

Yourself with

the

Centrex 2000

Placement of

Unit

Check that the carton contains the vent stack (pipe, fittings, roof flashing and diffusor);

“Compost Sure”, rake, drain hose and fittings, etc. Notify Sun-Mar if you are missing anything.

i) Turn the drum handle clockwise to rotate the Bio-Drum for mixing and aeration. (The drum

rotates counter-clockwise and the drum door closes).

TThhiiss iiss hhooww yyoouu wwiillll rroottaattee tthhee ddrruumm..

ii) Lift and remove the access door and rotate the drum until the drum opening is visible

through the the access door opening for adding “Compost Sure Blue”.

aadddd ““CCoommp

poosstt SSuurree BBlluuee””ppeeaatt mmoossss mmiixxttuurree ttoo tthhee ddrruumm

TThhiiss iiss hhooww yyoouu wwiillll

iii) Plug the unit’s electrical cord (Electric and AC/DC units) into a standard three-prong elec-

trical outlet, and feel the air movement from the vent outlet at the front of the unit to

ensure the vent system is working properly.

v) Pull out the compost finishing drawers at the bottom right of the unit.

vi) After the unit has been plugged in for ten minutes, place a hand on the floor of the

evaporating chamber (the area under the finishing drawer) to check it is warm to the

touch, and that the heater is working properly.

vii) Affix the “WARNING/CLEANING” sticker to the underside of the toilet seat cover, and check

that another is on the access port of the composting unit.

The unit should be installed so that the base is protected from weather. The rubber “u” channel at the bottom of the unit is well-sealed with silicone, but if the unit is sitting in water, has

snow melting against it, or rain pouring on it, this may eventually wear through and short out

the heating element. Install your unit with a protective cover of some kind around this area,

and do not install the unit in a pit where water can accumulate around it.

- 6 - - 23 -

- 7 -- 22 -

Chapter 2

Installation

ROUGH IN DIMENSIONS

Included

In Your Kit

1- Owners Manual 1- 1 1/2” (38mm)Roof Flashing (Electric & AC/DC)

1- Warranty Card 1- 4” (100mm)Roof Flashing (NE & AC/DC)

1- Evaporation Tray 6- 2” x 30” (50760mm)PVC Pipe (Electric & AC/DC)

1- 8’ 4” (254cm)Drain Pipe 2- Compost Sure

1- Rake 1- 4” Diffusor (100mm)(Electric & AC/DC)

1- 3” (76mm)Centrex 2000 Inlet 1- 6” (150mm) Diffusor (NE & AC/DC)

5- 4” x30” (100x 700mm)ABS Pipe (NE & AC/DC) 1- Centrex 2000 Hardware Kit

1- 12 Volt 2.4 Watt Fan (NE & AC/DC) 1- Centrex NE Hardware Kit (NE & AC/DC)

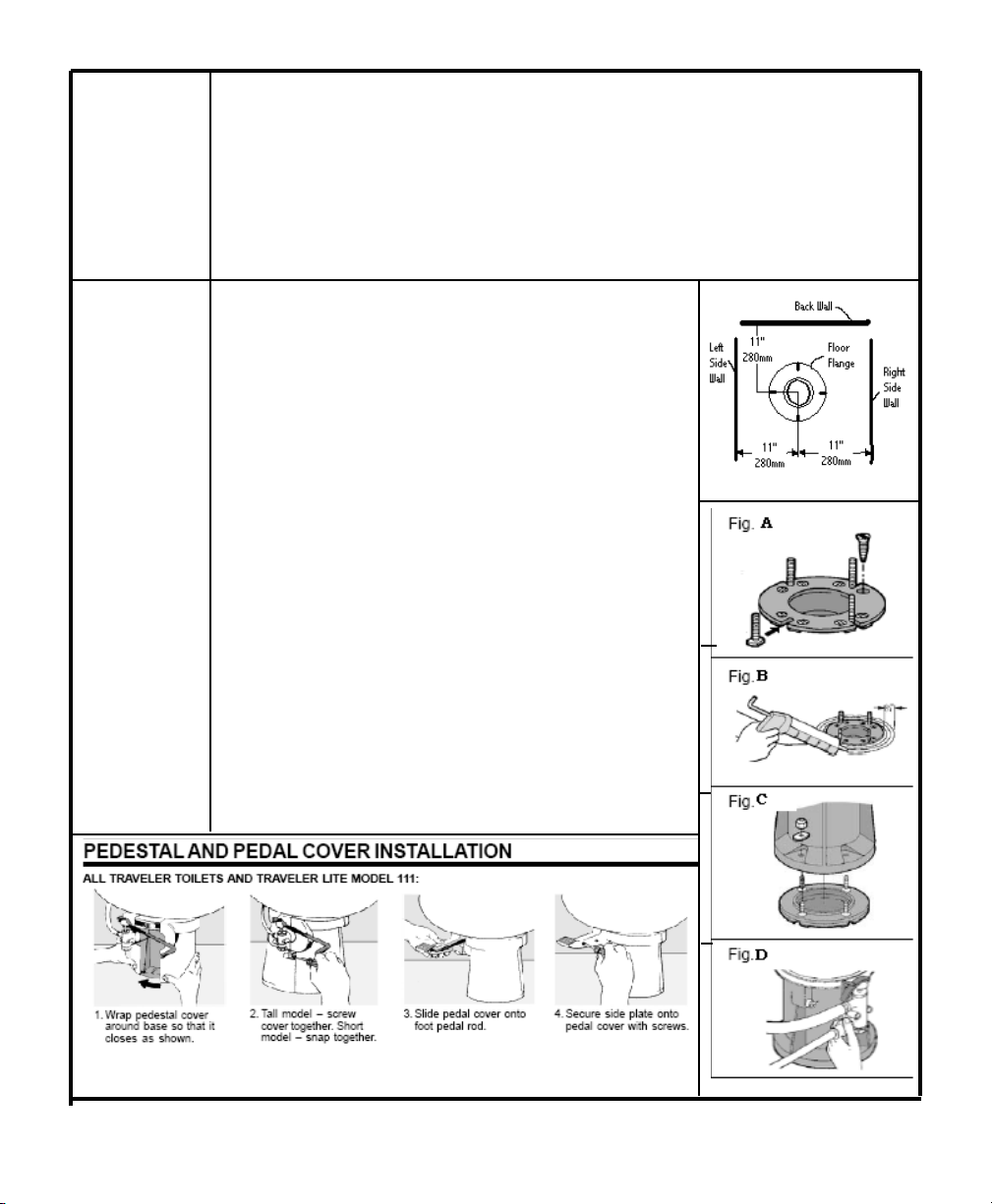

Installing the

“1 Pint” Low

Flush Toilet

1. Make sure the center of the floor flange is at least 11 inches

(280mm) from the back wall.

2. When Installing a new floor flange, make certain that the toilet

mounting bolts align properly with Sealand Traveler toilet mounting pattern.

3. Secure flange to floor using flat head screws through countersunk holes in flange. Insert bolts into slotted holes in flange

(Fig. A)

4. If toilet is being installed in a shower stall, apply a 1/4”(6mm) thick

by 3/4”(19mm) wide bead of glazing compound around the

circumference of the floor flange (Fig B).

5. Position floor seal by pressing the floor bolts up through the

holes in the seal.

6. Set toilet in place with bolts protruding up through mounting holes

in base (Fig C).

7. Install washers and hex nuts provided with toilet. Tighten nuts

down equally with standard 7/17” (12mm) open end wrench.

Remove excess Glazing compound from around base.

8. Connect water supply line to water valve (1/2” or 13mm MPT) inlet

using appropriate fittings (Fig D)

9. Turn on water supply and flush toilet to test for leaks.

10. Attach pedestal and pedal covers to toilet base. See instructions

below.

- 8 -

Loading...

Loading...