Sun-Mar centrex 2000 af, centrex 2000 af ac/dc, centrex 2000 af ne Owner's Manual

Serial # ________________

CENTREX 2000 AF FAMILY

OWNER’S MANUAL

PO-MANU0-0829EX

March 2008

Rev D3

Product Info: (905) 332-1314 Fax: (905) 332-1315 Tech. Service: (888) 341-0782

E-mail: compost@sun-mar.com http://www.sun-mar.com

600 Main St 5370 South Service Rd.

Tonawanda NY Burlington, ON

14150-0888 USA L7L 5L1 CANADA

RATED CAPACITY

Weekend & Vacation Use

(Cottage Use)

NE Units; 5 Adults or families of 7 or

Electric Units; 6 Adults or families of 8

Residential & Continuous Use

NE units; 3 Adults or a family of 5 or

Electric Units; 4 Adults or families of 6

Standard 41

Certified for liquid containment,

odors, and solid end products in

both residential and cottage use

Certified to NSF/ANSI Standard 41

CENTREX 2000 AF

CENTREX 2000 AF AC/DC

CENTREX 2000 AF NE

Electrical Specifacations 2000 2000 NE 2000

AC/DC

Maximum Amps 2.4 NA 2.4/NA

Fan Watts

35 req. 1.4 opt.

(Required or Optional 35 req./

Hook-up) 1.4 opt.

Heater Watts

370 NA 370

(When on)

Average Power Use 200 NA 200

In Watts (Heater on

1/2 time)

- 34 -

- 33 - - 2 -

OWNER’S MANUAL

CONTENTS

Chapter 3

Chapter 4

Chapter 5

I

ntroduction

Chapter 1

Chapter 2

How your composting

toilet Works

How Composting Works

The Composting Chamber

Compost Finishing Drawer

Evaporation Chamber

Winter Use

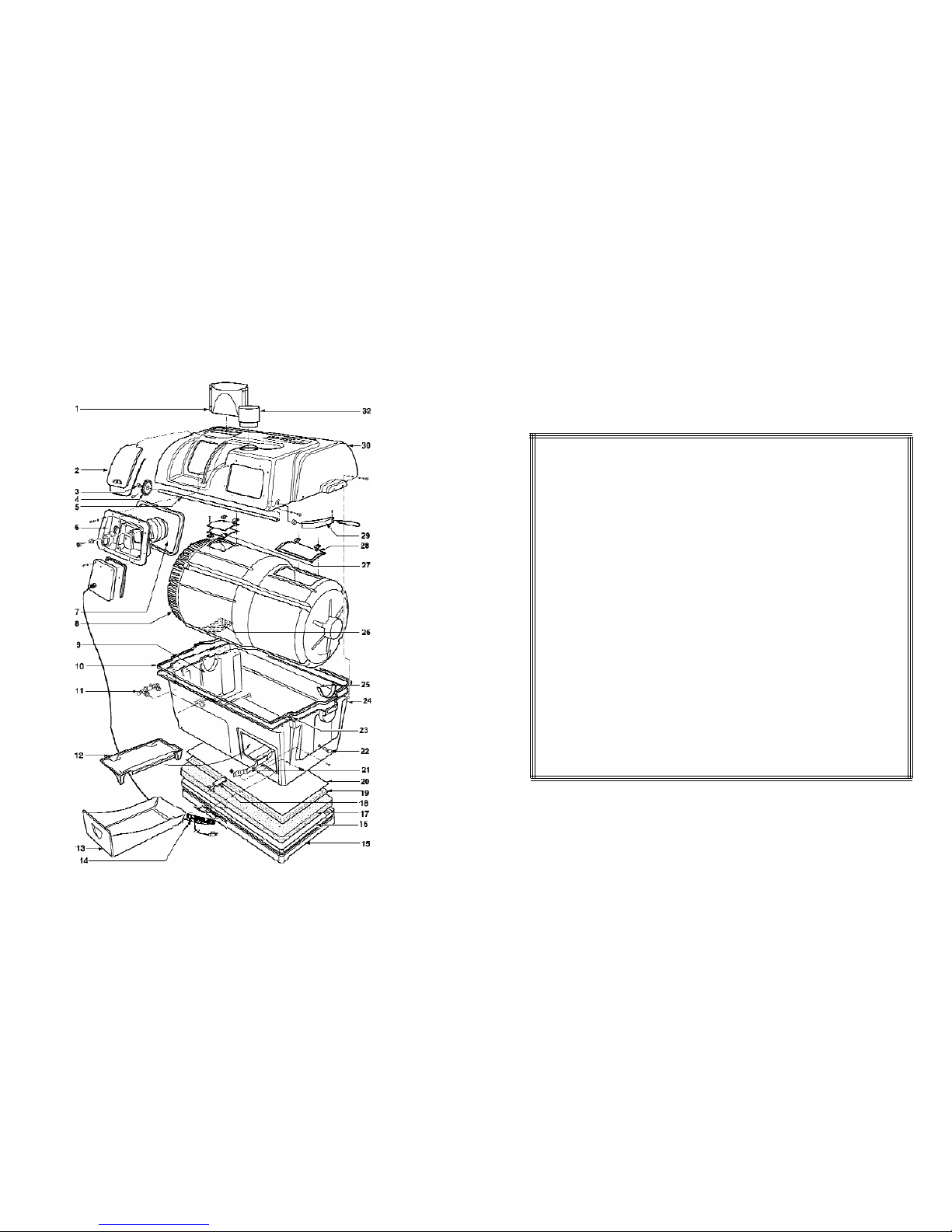

CENTREX 2000 AF Family Explosion

Drawing

CENTREX 2000 AF Family

Part Numbers

Wiring Diagram

Dry Toilet Explosion Diagram

Inspection

Check for Damage

Check for Parts and Functionality

Placement of AF Dr y Toilet

Installation

CENTREX 2000 AF

Rough in Dimensions

AF Dry Toilet Rough In Dimensions

Included in Your Kit

Installing the AF Toilet Base

The Transition Piece

Determining if an Extention Pipe

Piece is Needed

Assembling Extension Pipe Pieces

Finishing the AF Toilet Installation

Adjusting the Air Intake

Installing optional Vent on Toilet

Cutting Holes in the Toilet Chute

Drain Installation

Handling Effluent

Vent Piping Location

Adjusting the Fan Gate

Vent Piping Installation

Leading the Vent Through the Roof

The Diffusor

Electrical Considerations

12 Volt Fan Installation

3-7

3

3

3

4

4

5

6

6

7

8

8

8

8

9-15

9

10

11

11

11

12

12

12

13

13

13

13

14

14

14

14

15

15

15

16

Start Up and Use

Initial System Start Up

Annual Start Up

Periodic Check Up

Ongoing Maintenance

Compost

Troubleshooting

Aerobic Compost Requirements

Compost Too Wet

Compost Too Dry

Waste not Breaking Down

Lumps

Drum Too Full

Flies

Mechanical

Troubleshooting

Urine Odour In Washroom

Occasional Urine Odour Outside

Sewage Odour when drum tur ns

Fan Noisy

Fan Not Working

Liquid Buildup/

Lack of Eva poration

Overflowing Liquid

Heating System Not Working

Liquid In Finishing Drawer

Drum Will Not Stay Vertical

Drum Will Not Turn

Drum Door Not Opening/

Closing

Waste Not Exiting Waste Pipe

Warranty Information

Basic Maintenance

17-19

17

18

18

19

20-23

20

21

21

22

22

22

23

24-29

24

25

25

25

26

26

26

27

28

28

28

29

29

30

31

Introduction

HOW YOUR COMPOSTING TOILET WORKS

Composting is a natural recycling process where human

waste and toilet paper are broken down by microbes

into minerals and converted back to ear th. Heat, oxygen, organic material and moisture are needed to transform this waste into good fertilizing soil, perfect for your

flower beds.

Oxygen is provided by the ventilation system, and by

tumbling of the composting drum. Additional organic

material is introduced by adding a compost bulking mixture. The waste entering the toilet is approximately

90% water content. Any excess liquid which is not

absorbed will collect on the floor of the unit (evaporation chamber) where it may be evaporated into water

vapor and carried back to the atmosphere through the

venting system. The remaining waste material is transformed into an inoffensive ear th-like substance.

The Composting Chamber

The composting chamber is in the form of a Bio-drum

which holds the natural compost heat, provides the necessary mass to maintain a good compost, and is rotated by turning the handle to achieve perfect mixing and

aeration.

During mixing, both the input door and the output doors

will remain closed. When the drum retur ns to the top

dead centre position ready to receive more waste, the

doors will remain open.

A drum stopper, on the right side of the unit (handle

side) automatically holds the Bio-drum in a top dead

center position so that it is always positioned to receive

new material.

To ensure that the compost remains moist, but does not

get too wet (between 40 and 60% moisture content is

ideal), any excess liquid which the compost cannot

absorb drains through a screen in the bottom of the

drum directly onto an evaporating tray beneath the

screen, and from there, overflows into the larger evaporating chamber. The eva porating tray can be removed

periodically to remove peat moss debris that has accumulated.

Compost Finishing Drawer

The compost finishing drawer is at the extreme right of

the unit below the composting drum, and just above the

evaporating chamber. Compost from the drum is isolated in the drawer where it is allowed to ‘finish’ composting. For seasonally used units, several drawer s of

finished compost are normally removed at the beginning of the season. Otherwise some composted material can be extracted into the drawer and left there for

2 months until it is time to remove more compost from

the drum.

Evaporating Chamber

The third chamber is the floor of the Sun-Mar “CENTREX 2000 AF” which forms the evapor ation chamber

from where excess liquids are evapor ated. You will frequently see liquid in this area.

- 3 - - 32 -

The key to the success of the “CENTREX 2000 AF Family” lies in it’s three chamber design. Each of the three chambers; composting, compost finishing, and evaporation have their own independent environments for optimum efficiency.

In Electric or AC/DC units, air is pulled through intake

holes at the rear of the unit and down the toilet; over

the evaporating chamber, and up the 2”(50mm) vent

stack which exits from the front of the composting unit

when AC power is being used.

When using the NE or AC/DC units and AC power is

unavailable, natural draught caused by the chimney

effect combined with a 12 volt fan draws air into the unit

and up the 100mm vent stack.

In Electric or AC/DC units using the AC mode, the evaporation process is further assisted by a thermostatically controlled heating element in a separate sealed compartment under the evaporating chamber. This heater

is on when there is liquid in the evaporating chamber,

and largely off when the chamber is dry. The heating

system maintains warmth in the evaporating chamber,

and the indirect warmth assists the composting

Winter Use

Because “Sun-Mar” units are made of fiberglass and

high grade stainless steel, freezing temperatures will

not damage the composting unit. Composting action

decreases as the temperature drops, so for extended

use, the toilet should be kept constantly at or above

55-60 F(13-15 C) degrees. All exposed 2“(50mm)

vent stack should be insulated to minimize the condensation in the pipe and avoid ice blockages.

In extreme temperatures, an additional source of heat

will also be required. It is also advisable for residential

applications in extreme climates to install an electric

plumbing tape inside the 2”(50mm) vent to prevent

icing.

If the compost is frozen in the dr um, the unit may be

used periodically as a “holding tank”, until the compost

warms up and the microbes emerge from dor mancy.

Space should be made in the drum to accommodate

winter use. The drum should NOT be rotated when the

compost is frozen.

- 4 -- 31 -

Basic Maintenance Instructions

Sealand toilet and 'Centrex Family' Central Units

The toilet is porcelain and should be cleaned with hot water or bio-degradable products to avoid damage

to the compost. If required 'Compost Quick' or Baking Soda can be used diluted in hot water.

Three times a week weekly maintenance:

Turn drum to reveal waste inlet hole through access por t and add compost mix at the rate of 1 cup

(250ml) per person per day. (Scoop provided is 2 cups or 500ml)

Rotate handle clockwise to mix contents of Bio-drum and give 6 complete revolutions of the drum - (3640 rotations of the handle). Ensure that the drum door opening is in the vertical position at the end

after hearing the 'click' of the catch.

Check compost volume and condition in Bio-ddrum

and:

If the waste in the Bio-drum is too wet add wood shavings to improve aeration.

If composting is too slow add a compost accerant every second week, and ensure that the dr um is not

more than 1/2 full. If it is, follow the instructions for the emptying cycle.

Monthly maintenance and emptying cycle:

Rake out evaporation chamber with rake provided. For units with one, (Centrex 1000, 2000, & 3000

units) the black evaporating tray should be removed, solid matter tipped into the finishing tray and then

replaced beneath the drum screen.

Empty out the collection chamber ready to receive fresh material.

Attention: the composting unit must remai

n plugged in to an electrical outlet continuously to function

odourlessly. The AC/DC units should have both fans running while used in electric mode to prevent recirculation

between vent stacks. If you will be away from the residence where the composting unit is

installed for longer than three days, the power may be disconnected while the composting unit lays dormant.

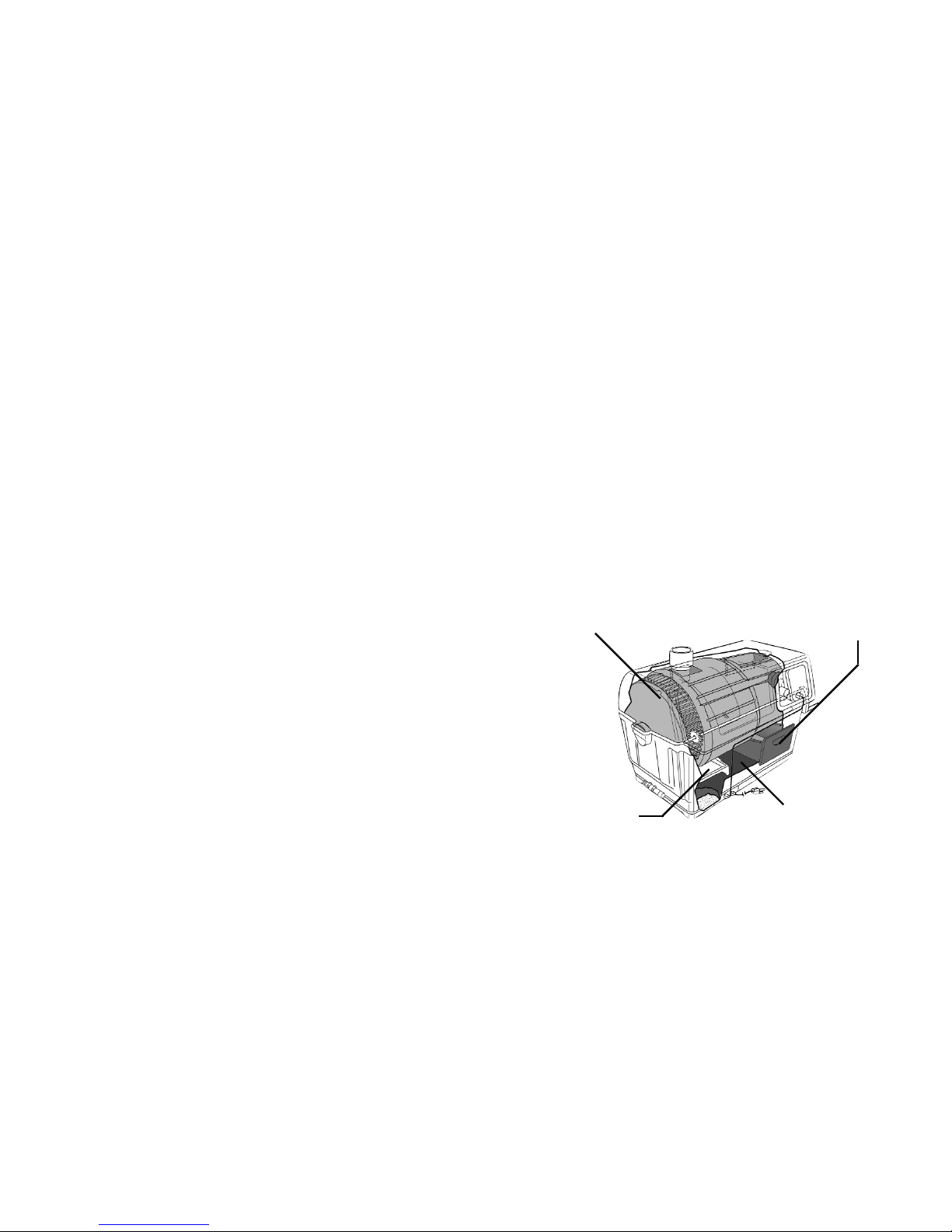

Composting Drum: Waste and

bulking mixture collect for

decomposition

Finishing Drawer: Where

compost is put to ‘finish’

Evaporation Tray: Extends the

surface area of the evaporation chamber

Evaporation Chamber: This is

where you will frequently see liquid collecting.

- 5 - - 30 -

WARRANTY

EXPLOSION DRAWING OF COMPOSTING UNIT

SUN-MAR Corp. warrants the original purchaser that this toilet is free from defects in material and workmanship under normal house or cottage use. SUN-MAR Corp. will furnish new

parts for any par t that fails within three years provided that our inspection shows that

such failure is due to defective material or workmanship. Any part supplied by us to

replace another part is warranted for the balance of the original warranty period.

This warranty does not cover:

1. Damage resulting from neglect, abuse, accident or alteration; or damage caused by

fire, flood, acts of God or any other casualty.

2. Parts and accessories not sold or manufactured by SUN-MAR Corp. or any damage

resulting from the use of such items.

3. Damage or failure resulting from failure of the purchaser to follow normal operating

procedure outlined in the Owner’s Manual or in any other printed instructions.

4. Labor and services charges incurred in the removal and replacement of any par ts

found defective under the terms of this warranty.

5. All returns to the factory must by made freight prepaid. All shipments from the factory

are made F.O.B. the factory.

This warranty is in lieu of all other warranties expressed or implied, and no per son is

authorized to enlarge our warranty responsibility, which is limited to the terms of this certificate. The Company reserves the right to change, improve or modify its products without

obligation to install these improvements on equipment previously manufactured.

Loading...

Loading...