Page 1

© 2017 by Snow Joe®, LLC

All rights reserved. Original instructions.

SAVE THESE INSTRUCTIONS

A Division of Snow Joe®, LLC

OPERATOR’S MANUAL

Model LJ602E Form No. SJ-LJ602E-880E-M

R

ELECTRIC LOG SPLITTER

15-AMP | HYDRAULIC | 5-TON

IMPORTANT!

Safety Instructions

All Operators Must Read These

Instructions Before Use

Always follow these safety guidelines. Failure to do so may

result in serious bodily injury or death.

General Safety Warnings!

When using the log splitter, basic safety precautions should

always be followed to reduce the risk of re, electric shock,

and personal injury, including the following:

mWARNING! The use of any other accessory or

attachment might increase the risk of injury.

TRAINING

Before using the log splitter, take the time to familiarize

yourself with the controls, especially how to stop the log

splitter in an emergency. Only individuals who have read these

instructions and have a thorough understanding of these

instructions shall operate the log splitter. Never allow children

to operate the log splitter.

Retain this manual for future reference and reread it at the start

of each log splitting season.

1. Read, understand, and follow all instructions on the

log splitter and in the manual(s) before attempting to

assemble and operate. Save this manual for reference and

ordering replacement parts.

2. Never allow children under 18 years old to operate this

machine. Children 18 years old and over should be

trained and supervised by an adult who understands the

operation of the log splitter.

3. Never allow an untrained individual to operate the log

splitter.

4. Understand the function of all the controls and their

proper operation. Know how to stop the machine in case

of emergency.

PREPARATION

Work Area

1. Plan your log splitting pattern to avoid discharge of

material toward people, pets, and property. Thrown

objects can cause serious personal injury.

2. Always inspect the area where the log splitter is to

be used. Ensure the surface the machine is on is

23.6 inch – 29.5 inch (60 cm – 75 cm) high, stable, level

and free from overhanging items such as limbs, wires etc.

3. All visitors: children, adults, and pets, should be kept at a

distance from working area, at least 16.5 ft. (5 m) from the

log splitter while it is in operation. Stop the log splitter if

people or pets enter the discharge area.

4. Always observe the surface conditions to avoid slipping,

falling, and unexpected objects.

5. Avoid Dangerous Environments – Don’t use appliances in

damp or wet locations. Do not operate the log splitter in

the rain or wet conditions.

6. Operation of the log splitter where temperatures are

below 41ºF (5ºC) or above 104ºF (40ºC), at a high altitude

and/or high humidity may result in a malfunction of the

machine. Do not use the log splitter in poor environmental

conditions.

7. Ensure electrical conditions meet requirements (see

Electric Safety).

8. Do not use the machine where gasoline, natural gas or

other ammable vapors are present. The electric motor

may spark and cause an explosion or re.

Protective Clothing

1. Thrown objects can cause serious injury to the eyes and

exposed body. Always wear safety glasses or eye shields

during operation and while performing an adjustment or

repair. Always use face or dust mask if operation is dusty.

2. Use of rubber gloves and substantial footwear is

recommended when working outdoors. Wear protective

hair covering to contain long hair.

3. Always operate wearing adequate protective garments.

Dress Properly – Do not wear jewelry or other loose

clothing, which could become entangled in moving parts.

Wear footwear that provides protection for the feet and

ensures sure footing.

4. Always use ear protection if the noise level exceeds 85

dB. Observe any noise prevention regulations and laws.

5. Inspect the log splitter for worn, missing or damaged

parts and safety labels. See maintenance section for

detailed instructions.

6. Use the Right Appliance – Do not use this appliance for

any job except that for which it is intended.

1

Page 2

Wood Condition

1. Do not split oversized logs (max. log diameter: 10 inch,

max log length: 20.5 inch). Do not attempt to split “hard”

wood that requires more than 5 seconds to split.

2. Ensure the log is free from items that may be projected or

cause damage to the machine (ie.: nails, wire).

3. Ensure the end of the log is cut square and all branches

have been cut ush.

OPERATION

Operator Requirements

1. Only one person shall operate the log splitter. All other

individuals and animals shall maintain a safe distance

during operation (see safety warning in Preparation).

2. Always operate the machine in a standing position and in

a location that is not in the path of projected debris. The

location of the machine should provide safe footing and

balance for the operator.

3. Do not operate the machine while under the inuence of

alcohol, drugs or physically, mentally fatigued. Always be

alert and watch what you are doing!

4. Contact with the moving parts can amputate body parts.

Do not put any part of your body near moving parts.

Workload Requirements

1. Never exceed the operating capacity of the log splitter.

2. Always split the log in the direction of the grain. Do not

place a log across the log splitter.

3. Never split more than one log at a time.

4. Do not load a log when the ram is moving.

Log Splitting

1. Remove any keys and adjusting wrenches before turning

the machine ON.

2. Do not use accessories or attachments that are not

recommended in this manual.

3. Place the log on the log retention brackets. Do not hold or

secure the log with your hands.

4. Do not split wood that takes more than 5 seconds to split.

Doing so will apply excessive pressure on the ram cylinder

and damage the machine.

5. Do not push/force the log onto blade. Always let the blade

initiate splitting the log.

6. If the log moves during operation, stop and reset.

7. If a log is jammed do not request assistance of a second

person. Ensure the machine power is disconnected and

built up pressure released before attempting to release

log.

8. Ensure the machine is turned OFF when not in use. If the

machine is left unattended then disconnect power to the

machine.

MAINTENANCE AND STORAGE

1. Maintain or replace safety and instruction labels. Ensure

safety guards are in place.

2. Disconnect the power and ensure built up pressure has

been released from the tool before cleaning, repairing, or

inspecting the log splitter.

3. For best operation keep the blade sharp, moving parts

lubricated and the machine cleaned.

4. Always check for damaged or worn parts, alignment of

moving parts, and tightness of bolts and screws before

each use.

5. Replace oil as specied in the Maintenance section.

Follow all local regulations and laws concerning disposal

of waste oil.

6. Qualied mechanics and electricians must carry out

repairs.

7. When not in use, always store the machine in a secure

location that children cannot access. Store the machine

in a dry environment. The machine can be transported or

stored in the ambient temperature between 77ºF – 131ºF

(25ºC – 55ºC).

Electrical Safety

1. Ground fault circuit interrupter (GFCI) protection should

be provided on the circuit(s) or outlet(s) to be used for the

log splitter. Receptacles are available having built-in GFCI

protection and may be used for this measure of safety.

2. To reduce the risk of electric shock, this appliance has

a polarized plug (i.e. one blade is wider than the other).

Use this appliance only with a polarized, UL-listed (CSA

certied in Canada) extension cord recommended for

outdoor use. The appliance plug will t into a polarized

extension cord only one way.

If the appliance plug does not t fully into the extension

cord, reverse the plug. If the plug still does not t, obtain

a correct polarized extension cord. A polarized extension

cord will require the use of a polarized wall outlet. The

extension cord plug will t into the polarized wall outlet

only one way. If the plug does not t fully into the wall

outlet, reverse the plug. If the plug still does not t,

contact a qualied electrician to install the proper wall

outlet. Do not modify the appliance plug, extension cord

receptacle, or extension cord plug in any way.

3. To prevent electric shock, use only with an extension cord

suitable for outdoor use, such as SW, SOW, STW, STOW,

SJTW, or SJTOW.

Before use, check that the extension cord is in good

condition. When using an extension cord, make sure to

use one heavy enough to carry the current your product

will draw. For lengths less than 50 feet, a No. 14 AWG

extension cord should be used. An undersized cord will

cause a drop in line voltage resulting in loss of power and

overheating.

2

Page 3

m WARNING m

Electric shock may cause SEVERE INJURY or

DEATH. Heed these warnings:

• Do not allow any part of the log splitter to make

contact with water while it is in operation. If the

appliance becomes wet while turned o, wipe dry

before starting.

• Use only a UL-, CSA-, or ETL-rated extension cord for

outdoor, all-weather use, such as the Snow Joe

Sun Joe

with lighted end (Model PJEXT50-B). Visit snowjoe.

com to purchase this extension cord online or, to order

by phone, call 1-866-SNOWJOE (1-866-766-9563).

• Do not use an extension cord over 100 ft (30 m).

• Do not touch the appliance or its plug with wet hands

or while standing in water. Wearing rubber boots

oers some protection.

®

SJTW-A 14-gauge 50-foot extension cord

EXTENSION CORD CHART

®

+

Extension Cord

Length

Wire Gauge (A.W.G.):

4. To prevent the appliance cord from disconnecting from

the extension cord during operation, make a knot with the

two cords as shown in Table 1.

Table 1. Method of Securing Extension Cord

Cord set

(A) Tie cord as shown

(B) Connect plug and receptacle

5. Do not abuse the cord. Never pull the log splitter by the

cord or yank the cord to disconnect it from the receptacle.

Keep the cord away from heat, oil, and sharp edges.

Up to 50 ft

(15 m)

14 12

+50 ft - 100 ft

(+15 m - 30 m)

Appliance cord

3

Page 4

Safety Symbols

The following table depicts and describes safety symbols that may appear on this product. Read, understand, and follow all

instructions on the machine before attempting to assemble and operate.

Symbols SymbolsDescriptions Descriptions

To reduce the risk of injury, user

must read instruction manual.

Wear heavy-duty gloves and

steel-toed boots when using the

machine and handling debris.

WARNING! Do not expose or

operate the unit in rain or wet

conditions. Keep dry.

Moving parts can crush and cut

hands and ngers. Keep hands

clear of the ram plate, wedge, and

logs while splitting.

Disconnect the mains plug if the

cord is damaged or entangled.

SAFETY ALERT – Indicates a

precaution, a warning, or a danger.

Wear eye and hearing protection. For

protection against injury, wear ear

defenders and safety goggles.

Keep bystanders and children

a safe distance away.

WARNING! Always be aware of

the movement of the log splitter.

Keep you hands away from splits

and cracks which open in the log. Do

not remove jammed logs with you

hands.

4

Page 5

Know Your Electric Log Splitter

Read the owner’s manual and safety instructions carefully before operating the log splitter. Compare the illustration below

to the log splitter in order to become familiar with the location of the various controls and adjustments. Save this manual for

future reference.

13

15

14

THE OTHER SIDE

1 2

11

12

10

9

1. Log pusher

2. Log rail

3. Splitting wedge

4. Bleed screw

16

5. Oil drain bolt

6. Lifting handle

7. Supporting leg

8. Log retaining plates

8

3

4

5

6

7

9. Motor

10. Appliance cord

11. On/O switch

12. Switch box

13. Rear wheels

14. Hydraulic control lever

15 Control lever guard

16. Max. pressure limit screw

Technical Data

Rated Voltage 120 V AC 60 Hz 1500 W

Splitting Force (Max) 5 ton

Ram Force/ 5 ton

Continuous Force

Material Steel

Log Length (Max) 20.5 in. (52 cm)

Log Diameter (Max) 10 in. (25.4 cm)

Wedge 5 in. (12.8 cm)

Beam 5.5 in. (14 cm)

Hydraulic Cylinder Size 29.7 in. x 2.3 in.

(Length x Diameter) (75.5 cm x 5.9 cm)

Hydraulic Rod Size 30.2 in. x 1.2 in.

(Length x Diameter) (76.8 cm x 3 cm)

Hydraulic Capacity 1.1 gal (4.2 l)

Wheel Size 6 in. (15.2 cm)

Weight 92.6 lbs (42 kg)

5

Page 6

Unpacking

Carton Contents

• Electric log splitter

• Lifting handle

• Supporting leg

• Bolts, nuts and washers (4 sets)

• Manuals and registration card

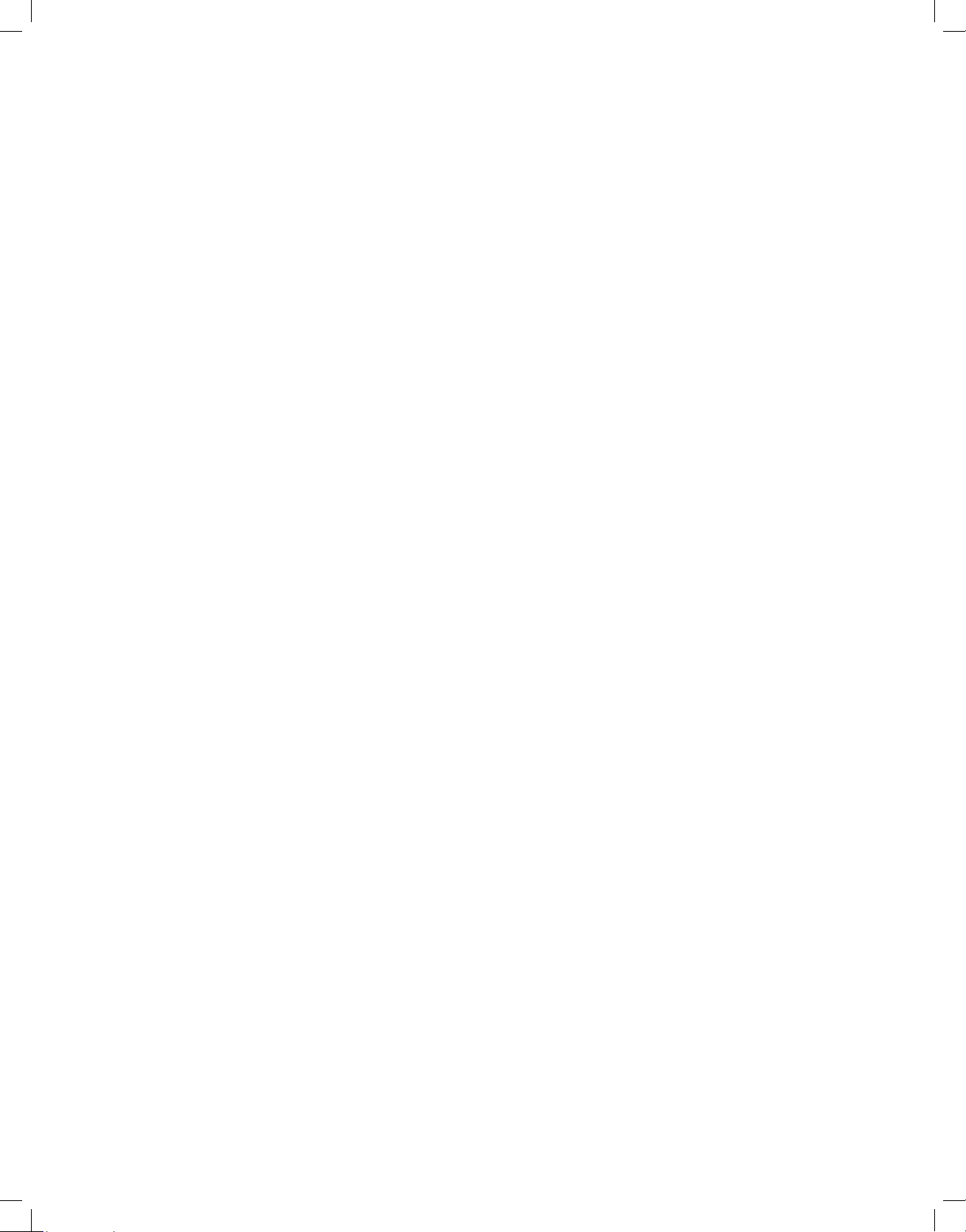

1. Place the lifting handle on the supporting leg, x them

together with the provided bolts, nuts and washers.

Tighten securely (Fig. 1).

Fig. 1

Bolts

1. Carefully remove the log splitter and check to see that all

of the above items are supplied.

2. Inspect the product carefully to make sure no breakage

or damage occurred during shipping. If you nd damaged

or missing parts, DO NOT return the unit to the store.

Please call the Snow Joe® + Sun Joe® customer service

department at 1-866-SNOWJOE (1-866-766-9563).

NOTE: Do not discard the shipping carton and packaging

material until you are ready to use your new electric log

splitter. The packaging is made of recyclable materials.

Properly dispose of these materials in accordance with

local regulations.

IMPORTANT! The equipment and packaging material are not

toys. Do not let children play with plastic bags, foils, or small

parts. These items can be swallowed and pose a suocation

risk!

Assembly

mWARNING! Do not connect to the power supply

until assembly is complete. Failure to comply could result in

accidental starting and serious personal injury.

mWARNING! The product must be fully assembled

before operation. Do not use a product that is only partially

assembled or assembled with damaged parts.

NOTE: Before using the log splitter, follow these instructions to

assemble the lifting handle and the supporting leg.

Nuts

Lifting handle

Washer

Supporting leg

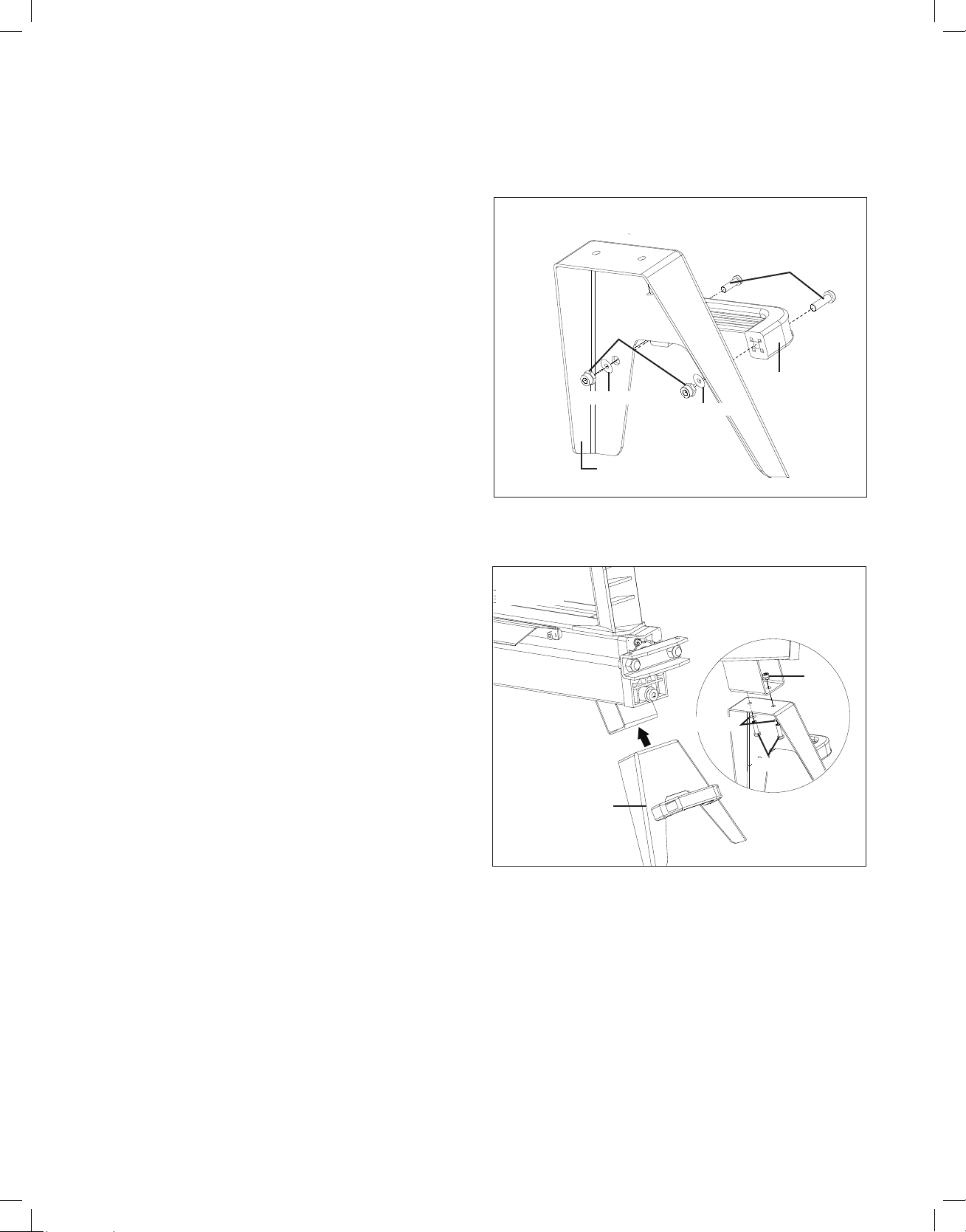

2. Attach the leg with handle assembly on the bottom of the

log splitter, secure with the other 2 sets of bolts, nuts and

washers. Tighten securely (Fig. 2).

Fig. 2

Leg with handle

assembly

Washer

Nut

Washers

Bolts

6

Page 7

Operation

mWARNING! Before using the log splitter, review the

instructions below and all safety information. Failure to follow

these instructions may result in property damage or injury to

the operator or bystanders.

mWARNING! Before the initial operation, the bleed screw

should be adjusted to allow air to go in and out of the oil tank.

(loosen three to four turns). Airow should be detectable during

operation. To avoid leaking oil close the bleed screw when

moving the machine.

Important! Failure to open the bleed screw during operation

will result in permanent damage to the log splitter.

mWARNING! Do not adjust the max. pressure limiting

screw. This was set at the factory so the log splitter works

under the maximum pressure limit of 5 tons. Tampering

with the screw will result in hydraulic pump failure. Only a

professional mechanic shall adjust the max. pressure limiting

screw.

Splitting Operation

Follow these instructions to operate the log splitter:

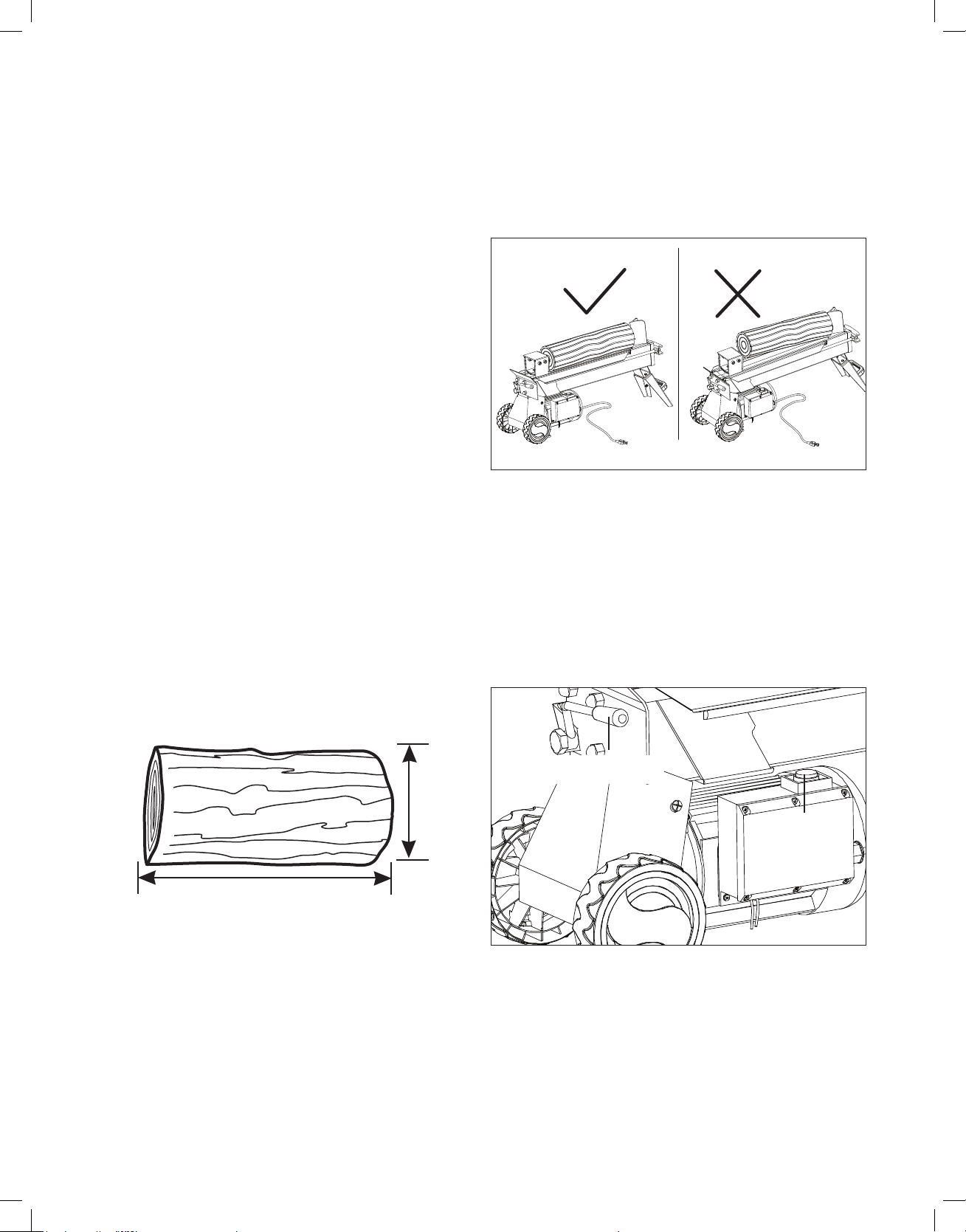

1. Ensure all logs meet the proper size requirements

[(max log diameter: 10 in. (25.4 cm); max log length:

20.5 in. (52 cm)].

IMPORTANT! Logs vary in hardness and structure. Small

logs with knots or harder wood may be more dicult to

split. Larger logs with less hardness may not be dicult to

split. Do not force the log splitter if the log fails to split on

the rst attempt.

mWARNING! Always set logs rmly on the log retaining

plates and the log rail. Make sure logs will not twist, rock or

slip while being split. Do not force the blade by splitting the

log on the upper part. This will break the blade or damage the

machine (Fig. 3).

Fig. 3

mWARNING! Never load or unload logs while the log

pusher is moving.

6. Plug the appliance cord into an appropriate power outlet.

7. Engage the log pusher by using your left hand to push the

hydraulic control lever and your right hand to push the

On/O switch (Fig. 4).

NOTE: This log splitter is equipped with ZHB control

system, which requires both the On/O switch and the

hydraulic control lever to be engaged simultaneously to

start the machine.

Fig. 4

10 in. (25.4 cm)

20.5 in. (52 cm)

2. When loading or positioning a log, always handle the bark

side; never handle the ends. Never place your hands or

body parts between the log and the splitter.

3. Make sure all moving parts is completely stop. Never load

or unload logs while the log pusher is moving.

4. Check that bleed Screw is open.

5. Load the log lengthwise into the unit between the wedge

and the log pusher. Be sure that the split will be along the

grain. Check to make sure the log is xed stably.

Hydraulic control

lever

On/O switch

8. The log pusher will move forward and the log will be split

by the splitting wedge.

mWARNING! If the log cannot be split within 5 seconds,

do not engage the log pusher any more, otherwise the log

splitter will be damaged. For extremely hard logs, rotate it by

90° to see if it can be split in a dierent direction. If the log

still cannot be split, its hardness exceeds the capacity of the

machine and thus that log should be discarded to protect the

log splitter.

7

Page 8

mWARNING! Break log in the direction of its growing

grain. Do not place log across the log splitter for splitting. It

may be dangerous and may seriously damage the machine.

mWARNING! Do not attempt to split 2 log pieces at the

same time. A piece may y up and cause personal injury.

mWARNING! Accidents occur when there is more than

one person involved in loading and operating the log splitter;

only one person should operate the splitter. If a second person

is assisting in loading the splitter, NEVER allow an assistant to

hold the log in place while the operator is using the unit.

9. Release both the hydraulic control lever and the On/O

switch, the log pusher will move to the original position.

Wait until the wood pusher completely stops, and remove

the split log.

Fig. 6

Maintenance

Removing A Jammed Log

If the log gets stuck on the wedge base, or the wedge

becomes embedded in the log and will not completely split or

separate from the log, follow the directions below to remove

the log.

m WARNING! Do not attempt to remove the jammed

log with your hands or knock it o. It may cause serious injury

or damage to the machine.

1. Release both the hydraulic control lever and the On/O

switch.

2. After the log pusher moves back and completely stops

at its starting position, insert a wedge wood under the

jammed log (Fig. 5).

Fig. 5

Wedged wood

3. Start the log splitter to push the wedge wood to go

completely under the jammed one.

4. Repeat above instructions 2 - 3 with a sharper sloped

wooden wedge as needed until the log is free.

mWARNING! Do not try to knock the jammed log o. It

will damage the machine or may launch the log and cause an

accident or injury (Fig. 6).

mWARNING! Always disconnect the power and ensure

built up pressure has been released from the tool before

cleaning, repairing, or inspecting the log splitter.

General

• Periodically apply a light coat of rust resistant oil, such as

3-in-1 oil or WD-40, to the springs to keep them in proper

working order.

• Periodically check all fasteners for tightness.

• Annually clean and lightly lubricate parts.

• Use a glossy enamel spray paint to touch up scratched or

worn painted metal surfaces.

• Never exceed the load capacity rating of 5 tons; it will

damage the log splitter and void the manufacturer's

warranty.

• Periodically sharpen the wedge. Use a ne tooth le, take

o burrs and smooth rough sections of the cutting edge.

IMPORTANT! If a part needs replacement, only use parts

that are specically recommended by the manufacturer.

Replacement parts that do not meet these specications

may result in a safety hazard, may compromise the tool's

performance, and will void the manufacturer's warranty.

Replacing the Hydraulic Oil

After every 150 hours of use, the hydraulic oil needs to

be replaced. The following hydraulic oils or equivalent are

recommend for the log splitter’s hydraulic transmission

system.

• SHELL Tellus 22

• MOBIL DTE 11

• ARAL Vitam GF 22

• BP Energol HLP-HM 22

To replace the hydraulic oil, follow the instructions below.

1. Turn o and unplug the log splitter. Make sure all moving

parts have come to a complete stop.

2. Unscrew to remove the oil drain bolt with dipstick (Fig. 7).

8

Page 9

Fig. 7

Oil drain bolt

with dipstick

3. Turn the log splitter and let it stand on the supporting leg

to drain the hydraulic oil o (Fig. 8).

5. Clean the oil drain bolt before thread them back. Make

sure it is tightened to avoid leakage before place the log

splitter horizontally.

Storage

• Before storing, make sure the log splitter is clean and dry.

Such upkeep is necessary to ensure years of trouble-free

performance.

• Lightly lubricate all metal surfaces before storing.

• Store the machine in a secure location that children

cannot access. Store the machine in a dry environment.

The machine can be transported or stored in the ambient

temperature between 77ºF – 131ºF (25ºC – 55ºC).

• Examine the log splitter thoroughly for worn, loose, or

damaged parts. Should you need to repair or replace a

part, contact an authorized Snow Joe® + Sun Joe® dealer

or call the Snow Joe® + Sun Joe® customer service center

at 1-866-SNOWJOE (1-866-766-9563) for assistance.

Fig. 8

Supporting leg

4. Turn the log splitter and let it stand on the rear wheels,

and rell the hydraulic oil into the hole behind the oil drain

bolt with dipstick (Fig. 9).

Fig. 9

Rell oil here

Service + Support

If your Sun Joe® LJ602E electric log splitter requires service or

maintenance, please call 1-866-SNOWJOE (1-866-766-9563)

for assistance.

Model + Serial Numbers

When contacting the company or reordering parts, you will

need to provide the model and serial numbers of your product.

These are found on the decal axed to the housing or handle

of your log splitter. Copy these numbers into the space

provided below.

Record the following numbers from the housing or handle of your

new product:

L J 6 0 2 E

Model #:

Serial #:

Rear wheel

9

Page 10

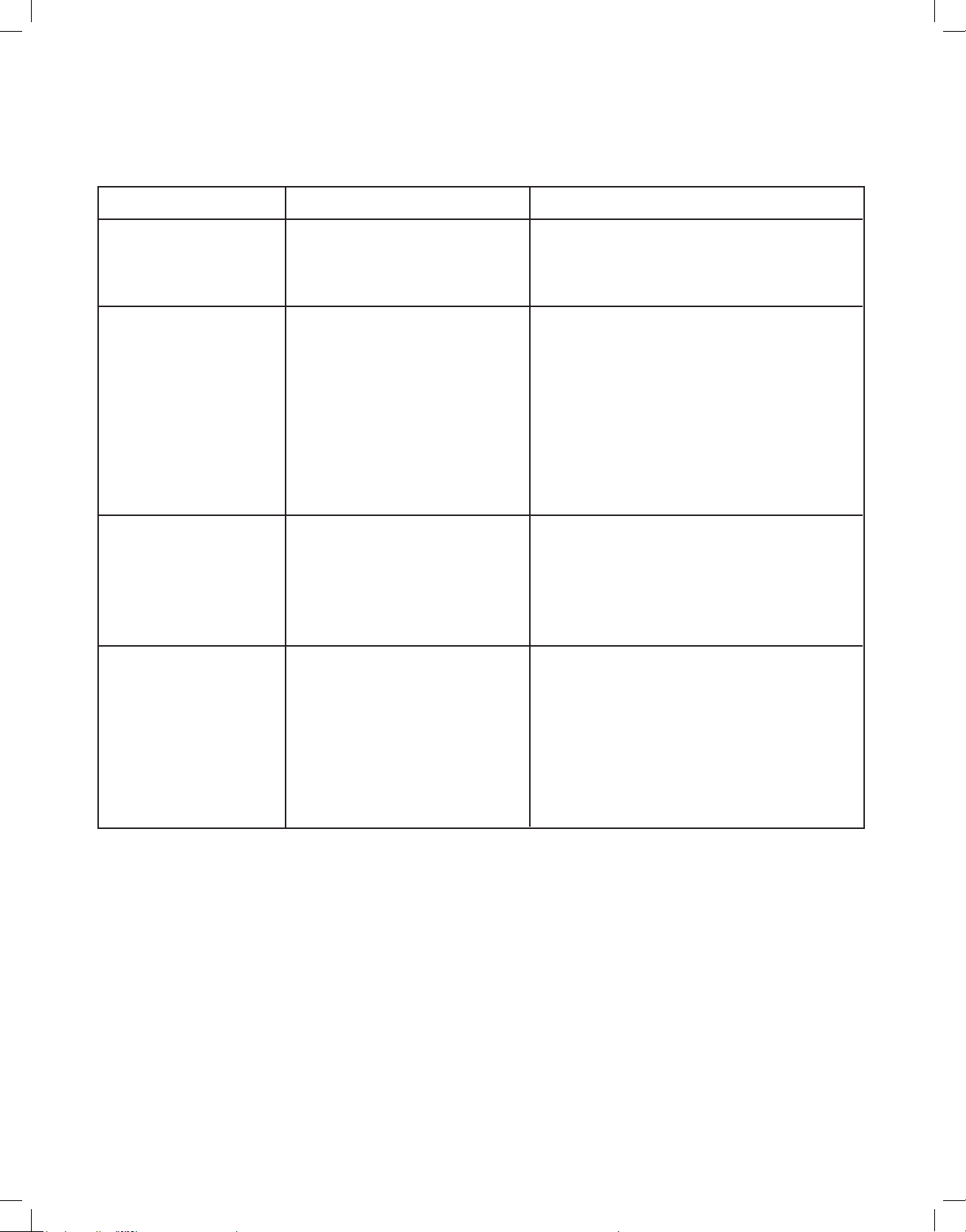

Troubleshooting

Problem Possible Causes

Motor does not run

The machine fails to

split logs

The log pusher moves

jerkily, generating

unusual noise or

vibrating a lot

• Overload protection device

disengaged to protect the log

splitter from being damaged

• Log is improperly positioned.

• The sizes or hardness of the

log exceeds the capacity of the

machine

• Wedge cutting edge is blunt

• Oil leaks

• Unauthorized adjustment was

made on Max. Pressure Limiting

Screw. Lower max pressure rating

was set.

• Lack of hydraulic oil and

excessive air in the hydraulic

system.

Recommended Remedy

• Contact a qualied electrician for opening

the switch box to engage the overload

protection device inside.

• Reload the log

• Reduce the log size

• Locate leak(s) and call the Snow Joe

Sun Joe

®

customer service department at

1-866-SNOWJOE (1-866-766-9563).

®

• Call the Snow Joe

+ Sun Joe® customer

service department at 1-866-SNOWJOE

(1-866-766-9563).

• Check oil level. Rell the hydraulic oil

if needed.

®

+

Oil leaks around the

ram or from other

points.

• Air sealed in hydraulic system

while operating.

• Bleed screw is not tightened

before moving the log splitter.

• Oil drain bolt with dipstick is

not tightened.

• Hydraulic control valve

assembly and/or seal(s) is

• Loosen bleed screw by 3 ~ 4 rotations before

operating the log splitter.

• Tighten the bleed screw up before moving the

log splitter.

• Tighten the oil drain bolt with dipstick.

®

• Call the Snow Joe

+ Sun Joe® customer

service department at 1-866-SNOWJOE

(1-866-766-9563).

worn.

Only a company specialist may be able to correct faults that cannot be rectied with the aid of this table. Please call the

Snow Joe® + Sun Joe® customer service center at 1-866-SNOWJOE (1-866-766-9563).

10

Page 11

Optional Accessories

mWARNING! ALWAYS use only authorized Snow Joe

replacement parts or accessories that are not intended for use with this tool. Contact Snow Joe® + Sun Joe® if you are unsure

whether it is safe to use a particular replacement part or accessory with your tool. The use of any other attachment or accessory

can be dangerous and could cause injury or mechanical damage.

®

+ Sun Joe® replacement parts and accessories. NEVER use

ModelAccessories Item

1

Snow Joe® + Sun Joe® SJTW-A 14-gauge

50-foot extension cord with lighted end

NOTE: Accessories are subject to change without any obligation on the part of Snow Joe® + Sun Joe® to provide notice of such

changes. Accessories can be ordered online at snowjoe.com or via phone by contacting the Snow Joe® + Sun Joe® customer

service center at 1-866-SNOWJOE (1-866-766-9563).

PJEXT50-B

11

Page 12

NOTES

12

Page 13

NOTES

13

Page 14

NOTES

14

Page 15

SNOW JOE® + SUN JOE® CUSTOMER PROMISE

ABOVE ALL ELSE, Snow Joe® + Sun Joe® are dedicated to you, our customer. We strive to make your experience as pleasant

as possible. Unfortunately, there are times when a product does not work or breaks under normal operating conditions. We

think it’s important that you know what you can expect from us. That’s why we created the Snow Joe® + Sun Joe® promise.

OUR PROMISE: Snow Joe® + Sun Joe® warrant new products for two years from the date of purchase. If your product does

not work, or there’s an issue with a specic part, we will x this by either sending you a free replacement part or by sending

you a new or comparable product at no charge. How cool is that! Before you know it, you’ll be back in action cutting,

sawing, mowing, washing and…?

PRODUCT REGISTRATION:

Snow Joe®, LLC (“Snow Joe® + Sun Joe®”) strongly encourages

you to register your purchase. You can register online at

snowjoe.com/ProductRegistration, or by printing and mailing

in a registration card available online from our website, or

calling our Customer Service Department at 1-866-SNOWJOE

(1-866-766-9563), or by e-mailing us at help@snowjoe.com.

Failure to register your product purchase will not diminish your

warranty rights. However, registering your purchase will allow

Snow Joe® + Sun Joe® to better serve you with any of your

customer service needs.

WHO CAN SEEK WARRANTY COVERAGE?

This Warranty is extended by Snow Joe® + Sun Joe® to the owner

of this Machine (a “Machine” consists of a product powered by

a motor) for residential and personal household use only. This

Warranty does not apply to products used for commercial, rental

or re-sale purposes. Should ownership of this machine change

during the 2-year period, please update the Machine’s owner

information at snowjoe.com/ProductRegistration.

WHAT IS COVERED?

Snow Joe® + Sun Joe® warrants to the owner that if this Machine

fails within 2 years from the date of purchase due to a defect in

material or workmanship or as a result of normal wear and tear

from ordinary household use, Snow Joe® + Sun Joe® will send a

replacement part or product, as needed, free of charge and with

free shipping to the original purchaser.

If, in Snow Joe® + Sun Joe®’s sole discretion, the failed Machine

cannot be repaired with a part, Snow Joe® + Sun Joe® will elect to

either (A) send a new Machine at no charge and with free shipping

or (B) refund the full purchase price to the owner.

WHAT IS NOT COVERED?

This Warranty does not apply to the Machines that have been used

commercially or in non-household applications. This Warranty

does not cover cosmetic changes that do not aect performance.

This Warranty is only valid if the Machine is used and maintained

in accordance with the instructions, warnings and safeguards

contained in the owner’s manual. Snow Joe® + Sun Joe® will not

be responsible for the cost of any unauthorized warranty repairs.

This warranty does not cover any cost or expense incurred by

the purchaser in providing substitute equipment or service during

reasonable periods of malfunction or non-use of this product

while waiting for a replacement part or unit under this warranty.

Wearing parts like belts, augers, chains and tines are not covered

under this warranty, and can be purchased at snowjoe.com or

by calling 1-866-SNOWJOE (1-866-766-9563). Batteries are

covered in full for 90-days from the date of purchase.

Repair, replacement or refund of the purchase price are the

exclusive remedies of purchaser and the sole liability of Snow Joe®

+ Sun Joe® under this warranty. No employee or representative

of Snow Joe® + Sun Joe® is authorized to make any additional

warranty or any modication to this warranty which may be

binding upon Snow Joe® + Sun Joe®. Accordingly, purchaser

should not rely upon any additional statements made by any

employee or representative of Snow Joe® + Sun Joe®. In no event,

whether based on contract, indemnity, warranty, tort (including

negligence), strict liability or otherwise, shall Snow Joe® +

Sun Joe® be liable for any special, indirect, incidental, or

consequential damages, including, without limitation, loss of

prot or revenue.

Some states do not allow limits on warranties. In such states, the

above limitations may not apply to you.

Outside the USA, other warranties may apply.

15

Page 16

snowjoe.com

mWARNING! This product or its power cord contains chemicals, including lead, known to the State

of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

For more information go to www.P65Warnings.ca.gov.

mWARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known [to the State of California] to cause cancer, birth defects, or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specically designed to lter out microscopic particles.

For more information go to www.P65Warnings.ca.gov.

Loading...

Loading...