Sunje SRB-1300, SRB-1200, SRB-1100, SRB-1800, SRB-1600 Instruction Manual

...

It is recommended that only persons who have sufficient knowledge and experience such as system

designers and responsible persons deal with this product after carefully reading the product manual.

1

The matters of safety

01 02 03

Instruction Manual

SRB Series

Eng

04

2

Check the package contents

▶ Product compositions

The package includes the following products composition.

Ion Bar

SRB Series / 2ea

Power Controller

SRC-2P / 1ea

3

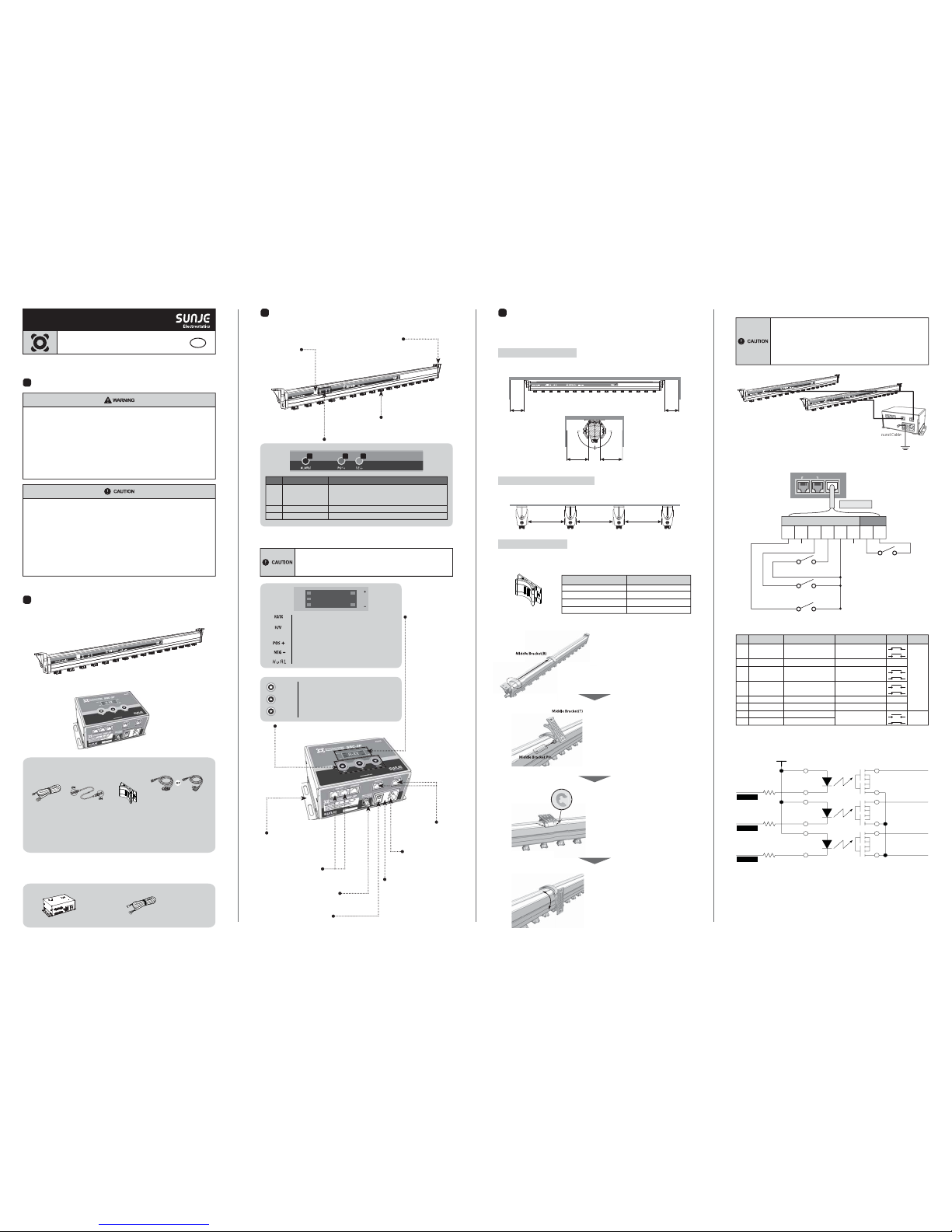

Nomenclatures of parts

▶ Ion Bar (SRB Series)

Discharge Needle

The needles for

generating +/- ions.

Indicator Light

Side Bracket

A bracket to fix the item

on the facing target.

Mounting Bracket

The bracket for

mounting SRC-2P.

Input Terminal

This terminal is for

controlling and power

supply of a ion bar.

Output Terminal

This terminal is for controlling

and power supply of a ion bar

#1 and #2.

4

Installation and connection

▶ Ion bar installation

When you install the ion bar, Please check the distance between ion bar and object.

※ Please, handle with care when you carry or install not to break or bend an ion bar.

If there is any conductive object close to ion bar, SRB Series may not operate properly.

Please install it with reference to figure below.

Interference by Grounding Matters

Side to Side Installation (More than two sets)

When the more than two ion bars are installed, to avoid interference,

the range between two ion bars should be more than 400mm.

Min 400mm Min 400mm Min 400mm

Installation by Middle Brackets

The middle bracket is used to protect bending problem by the weight of ion bar. Please fix the middle

bracket with M4 bolts. The number of supporting middle bracket will differ from the models.

Middle Bracket

※ Ion Bar Middle Bracket Quantity

SRB-1100 ~ 1300

SRB-1500 ~ 1800

SRB-2000 ~ 2300

SRB-2500 ~ 3200

-

1ea

2ea

3ea

Model Middle Bracket Quantity

▶ Power Controller (SRC-2P)

▶ Option

If you require extra functions with the basic accessories we provided, you need to purchase optional

items in below for further assistant.

Signal Cable

SUC-MT-2-001

10m

RMS Controller

RMSU

1 32

Display

Can check the status of

the ion bar's operation.

RMS(Real Monitoring System)

Communication Terminal

Used to RMS(Real Monitoring System)

communication.

Power Switch

The switch to turn on/off the power.

Fuse

250V, 1A Glass Type

Power Input

Used to power supply.

(AC 100V~240V, 50/60Hz)

Ground Terminal

Used to connect the ground cable.

Settings Buttons

Min 200mmMin 200mm

90.0°

90.0°

Min 150mmMin 150mm

* If the equipment is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

* Do not let the water touch the product. It may cause electric shock or fire due to malfunction.

* When you check or maintain the product, make it sure you turn off the power.

It may cause electric shock or fire due to malfunction.

*

Secure the product firmly when you want to secure it. There is a possibility of accident due to fall-over or malfunction, etc.

*

Secure working space when you install the product. If working space is not secured, the checking or maintenance of

the product is made impossible leading to failure of the product.

* Do not use the product at the place where dangerous material such as inflammable or ignitable material exists.

This product is not the product of anti-explosive type.

* This device is made only for industrial uses. You need to ground the device beforehand.

Otherwise, there are in case of malfunction, electric shock, or fire damage.

*

Do not contact the discharge needle or terminal with power applied. There is a possibility of electric shock or malfunction.

* Handle the discharge needle with care as its tip is very sharp.

* Connect wires referring to the product manual. Wrong connection can cause failures.

*

Take precautions as cables of the adaptor, the power line and communication line of each product may disconnect.

If the cable is damaged, replace it immediately.

* Do not install the device where the vibration can be detected.

Any minor impact or vibration on the device, the malfuction or danger of accident might happen.

* Do not use the product for the purpose outside of the range of the product use.

If the product is used for the purpose outside of the range of the use,

it can result in the trouble or the shortened service life. Or an unexpected problem may occur.

* The ionizer generates ozone(below 0.05ppm).

If you sense the smell of ozone when you use more than two units, ventilate the air.

* When installing or transporting the ion bar, be prepare not to bend the item during the process.

*

Please try to input your power connection with an exclusive power controller(SRC-2P)

of SRB Series.

*

The composition of a package(1set) can be consisted of a controller and two ion bars.

We recommand you to purchase and install as a package as a unit.

NO

1

2

3

Alarm LED

POS(Positive) LED

NEG(Negative) LED

When H/V unit has some problem to generate high-voltage,

alarm LED is turned on.

(When it shows the difference more than about ±30% with setting value.)

(+) high voltage normal operating signal.

(

-

) high voltage normal operating signal.

Name Function

When H/V unit has some problem to generate high-voltage,

H/V LED is turned on. (When it shows the difference

more than about ±30% with setting value.)

The LED for RMS(Real Monitoring System) operating.

(+) high voltage normal operating signal.

When H/V unit has some problem to generate high-voltage.

(-) high voltage normal operating signal.

H/V

NEG

POS

RX/TX

8.8.8.8.

UP

DOWN

SET

Use it when you increase the setting value.

Use it when you decrease the setting value.

This button is used for various settings.

(Address, Output Time, Output Voltage)

■ Middle Bracket Installation

a. Adjust a "Middle Bracket(B)" to set an ion bar in your

expected area of installation.

b. Assemble "Middle Bracket(T)" and

"Middle Bracket Pin" as shown in the figure.

c. Place two "E rings(Middle Bracket Pin fixing)" into a

"Pin side" to install a middle bracket.

d. After assembling a middle bracket, face the ion bar

using a middle bracket that can point to the proper

target area.

E ring

(Middle Bracket Pin fixing)

Ground Cable

Length : 1m / Ø4-Ø4[mm]

Output Cable

Max Length : 10m

Output Cable

Max Length : 10m

* If you use a power controller without an exclusive SRB Series componenet,

it might cause product malfunction.

* The composition of a package(1set) can be consisted of a controller and two ion bars.

If you only use one ion bar to the specified controller, it might not function properly.

We recommand you to purchase and install as a package as a unit.

* The maximum installation length from an ion bar to controller is 10 meter.

If it exceeds, it might not function properly.

▶ How to connect the power controller

▶ Interface

▶ Circuit (Photo Relay Output)

INTERFACERMSLINK

Not Used

Remote

(Close : Stop, Open : Run)

Run/Stop State

(Close : Run, Open : Syop State)

H/V Abnormal 1

(Close : Alarm, Open : Normal)

H/V Abnormal 2

(Close : Alarm, Open : Normal)

1 2 3 4 5 6 7 8

Remote, Alarm

Output Input

Not Used

No RemarksColor Function Input / Output

Run/Stop State

Photo Relay Output

(Run-Close, Stop-Open)

Photo Relay Output

(Normal-Open, Alarm-Close)

Photo Relay Output

(Normal-Open, Alarm-Close)

Remote

(Close : Stop, Open : Run)

Not Used

Remote 1

Remote 2

Not Used -

Common

-

-

-

-

-

High Voltage Abnormal 1

High Voltage Abnormal 2

Picture

Output

Input

Orange

White & Orange

Green

Blue

White & Blue

White & Green

3

4

6

7

8

2

1

5

White & Brown

Brown

Normal

Alarm

Run

Stop

Normal

Alarm

Run

Stop

※ The device must be grounded to prevent electric shock in order to function well.

RUN/STOP

H/V Alarm 1

H/V Alarm 2

+5V

1. Run/Stop State

3. H/V Abnormal Alarm 1

4. H/V Abnormal Alarm 2

5. Common

Power Cable

SPC-MT-1-001

AC 100V, 50/60Hz, 1.8m / 1ea

or

Power Cable

SPC-MT-2-001

AC 220V, 50/60Hz, 1.8m / 1ea

*

*

Output Cable

SOC-RB-1-001

10m / 2ea

Middle Bracket

SBR-B7-2-001

0~3ea

Ground Cable

SGC-MT-2-001

1m /Ø4-Ø4[mm]

/ 1ea

▶ Power Controller (SRC-2P)

05 06 07 08

8

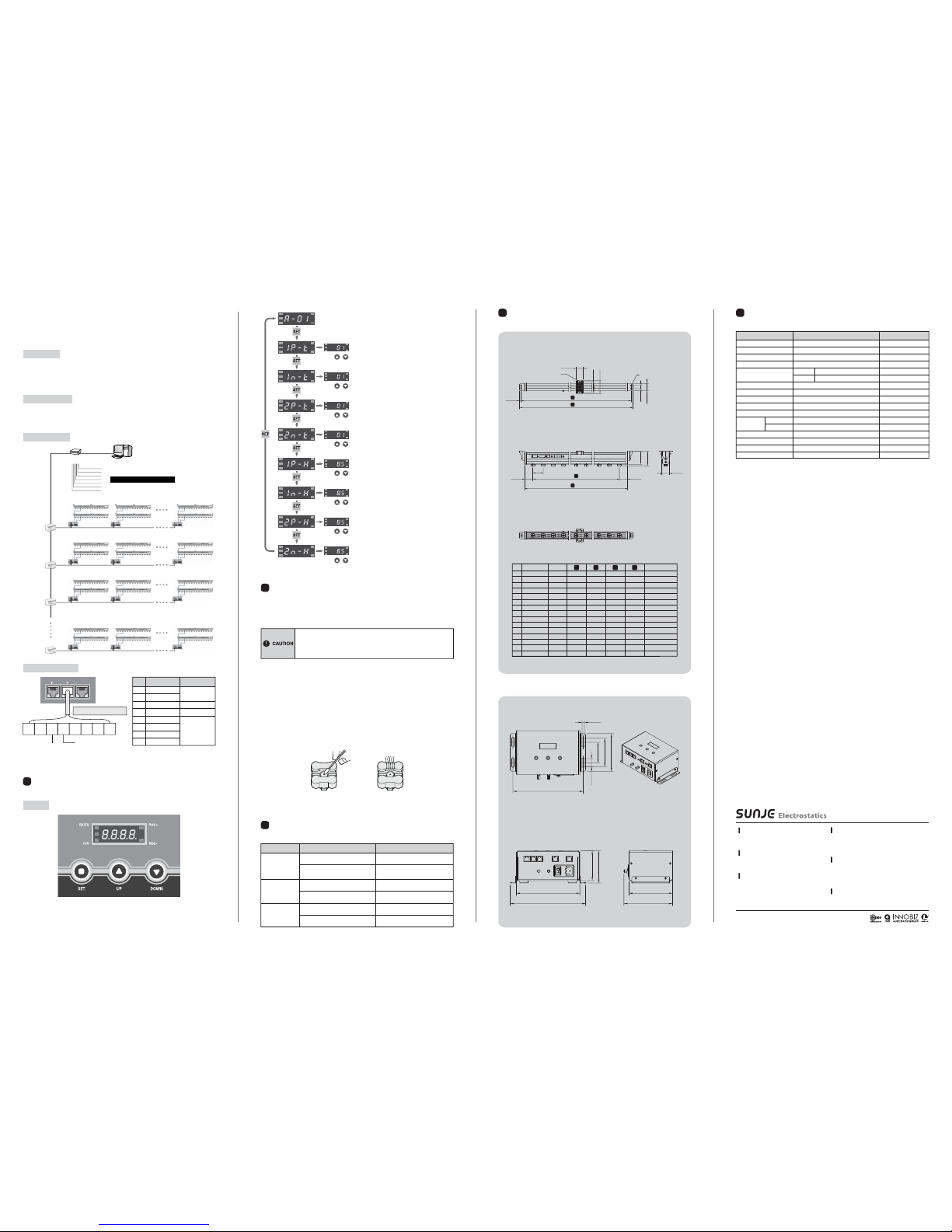

Dimensions

▶ Ion Bar (SRB Series) / Power Controller (SRC-2P)

9

Specification

※ The appearance and specification of the product may be changed without prior notice for the

improvement of the product.

Input Power

Power Consumption

Current Consumption

Ion-Generation Method

Electrode Material

Electrode Replacement

Operation Circumstance

Dimensions

Function

Alarm Function

Interface

Mounting Method

Warranty

AC 100 ~ 240V, 50/60Hz

Max. 15W

Max. 68mA

Corona Discharge Pulse AC

Tungsten

Cartridge type

0℃ ~ +50℃(32℉ ~ 122℉), 35% ~ 85% RH

See the accompanying drawing paper

Remote Control

Positive 1 ~10 Sec. / Negative 1 ~ 10 Sec.

Positive 4 ~ 11kV / Negative 4 ~11kV

H/V Abnormal

Run, Stop, RS-485, Alarm(H/V Abnormal)

Bolt Mounting with Bracket

1 year

AC 220V

Level V0

RJ45

SRB Series

SRC-2P

Non-Flammable ABS

EGI

Parameter Description / Value Remarks

Period [Sec.]

Voltage [kV]

Main Body Material

Adjust

Function

FRONT SIDE

TOP

110.0

122.5

177.0

51.5

71.5

95.0

20.0

6.0

160.0

190.0

81.0

75.0

▶ Ion Bar (SRB Series)

BOTTOM

FRONT SIDE

TOP

±2.5

C

±2.5

D

40.0

65.0

78.0

10.0

18.0

40.0

4-Ø5X9L SLOT HOLE

2-Ø5X10L SLOT HOLE

49.0 49.0

60.0

A

±2.5

B

77.5

89.2

46.0

Settings

5

How to set

▶ SRC-2P

a. Max. 4,096 sets of ion bar.

b. Real Time Monitoring of ion bar condition. (Signal checking cycle : max. 1min)

c. Record, revise and cancelation of managed history by operator.

d. Ion bar checking and abnormal history.

RMS Features

RMS Configuration

RMS UTP Specifications

a. Provide fine display view.

b. Equipment ID, equipment name, maker, ion bar state, maintenance history.

c. Detailed data checking in several groups.

Monitoring Function

No Color Descriptions

Not Used

Not Used

RS-485+

RS-485-

Orange

White & Orange

Green

Blue

White & Blue

White & Green

3

4

6

7

8

2

1

5

White & Brown

Brown

▶ RMS (Option)

Monitoring operation and abnormal conditions of the installed ionizer for static elimination in real time from the PC connected to the network management system that can fit a large amount of

static electricity; trends for operating device in the management of unmanned removing is highly

recommended for the customers.

INTERFACERMSLINK

RS-485+

RS-485-

1 2 3 4 5 6 7 8

RMS(Real Monitoring System)

Power Controller #1

Address #01 Address #02 Address #16

Address #01 Address #02 Address #16

Address #01 Address #02 Address #16

Address #01 Address #02 Address #16

Power Controller #2 Power Controller #16

Power Controller #1 Power Controller #2 Power Controller #16

Power Controller #1 Power Controller #2 Power Controller #16

Power Controller #1 Power Controller #2 Power Controller #16

RMSU

RMSU

RMSU

RMS Controller #1

RMS Controller #2

RMS Controller #3

RMS Controller #32

RMSU

1 Group

2

3

4

5

6

7

8

Group

PC

Maximum Set : 8 Groups, 4,096 Set

MULTI-PORT

(8 Port)

< SRC-2P Controller Panel >

Maintenance is an essential item for maintaining its capacity. Please conduct a routine

maintenance according to the below description. The life time of a discharge needle can be a

difference depending on using circumstance. SRB Series needs a routine maintenance and

cleaning in case of bad circumstance. (high humidity or dust)

▶ Discharge needle cleaning

The contamination level of discharge needle is different among the areas where the user installs,

please maintain own cleaning period that suits your environment.

▶ Discharge needle cleaning order

a. Be sure to power off before cleaning the ion bar.

b. Soak the cotton swab with alcohol. (do not use acetone)

c. Put the swab on the discharge needle and wipe it turning the swab right and left.

(take precautions not to apply severe force to the discharge needle.)

d. Replace the damaged discharge needle.

e. After the cleaning, let the alcohol applied to the discharge needle surface evaporate completely

and then operate the ion bar.

f. Please record the cleaning process as a reference in the file.

▶ Discharge needle maintenance

If the discharge needle broken or severely damaged, please replace the needle socket immediately.

6

Maintenance

※ After setting the device, the set value is automatically

saved in 3 seconds.

Address Set Up / Running

- The possible setting range for communication address is 1~16.

-

Press up/down buttons to select the expected address which you are willing to use.

※ To set "Address", you need to set channel(#1 & #2) first.

Positive(+) Time[sec.] Set Up (Channel 1)

- Setting range for Positive(+) Time is 1~10 seconds.

- Press up/down buttons to select proper output time.

Negative(

-

) Time[sec.] Set Up (Channel 1)

- Setting range for Negative(

-

) Time is 1~10 seconds.

- Press up/down buttons to select proper output time.

Positive(+) Time[sec.] Set Up (Channel 2)

- Setting range for Positive(+) Time is 1~10 seconds.

- Press up/down buttons to select proper output time.

Negative(

-

) Time[sec.] Set Up (Channel 2)

- Setting range for Negative(

-

) Time is 1~10 seconds.

- Press up/down buttons to select proper output time.

Positive(+) Voltage[kV] Set Up (Channel 1)

- Setting range for Positive(+) Voltage is 4~11kV.

- Press up/down buttons to select proper output voltage.

Negative(

-

) Voltage[kV] Set Up (Channel 1)

- Setting range for Negative(

-

) Voltage is 4~11kV.

- Press up/down buttons to select proper output voltage.

Positive(+) Voltage[kV] Set Up (Channel 2)

- Setting range for Positive(+) Voltage is 4~11kV.

- Press UP/DOWN buttons to select proper output voltage.

Negative(

-

) Voltage[kV] Set Up (Channel 2)

- Setting range for Negative(

-

) Voltage is 4~11kV.

- Press up/down buttons to select proper output voltage.

▶ Checklist before called

7

Problem solving

The product

does not work

Is your power cable still plugged in?

Please re-plug the power cable

and then turn the device on again.

Was the proper voltage level applied

for this set-up?

Please use the proper level of power

input for the device.

(AC 100~240V, 50/60Hz)

There is no

ionization

Is there any conductive material

around the device?

Please refer to 「Installation & Connection」 for

setting the proper target distance from device.

Does the installed environment have too

high/low level of humidity or temperature?

Please install the device upon

the proper working specification.

The ionizing

performance

has been

decreased.

Any damages or cut on the cables?

You need to replace the cables

if it gets cut or damaged.

Any contamination on the discharge needle?

Please refer to 「Maintenance」 for

cleaning the discharge needle.

Problem Identifying Problem Solution

*

This device uses the high level of voltage. When operating maintenance, please power off

and unplug the device. Otherwise, there might be in case of electric shock or fire damage.

* The discharge needle is very sharp at the edge.

Do not phsically(directly) touch the discharge needle.

Copyright 2017. SUNJE Hi-Tek Co., Ltd. All Rights Reserved.

Sunje (SHANGHAI) Trading Co.,Ltd.

Room 312, Jiurun Business Building 3rd Floor,No. 298,

Yindu Road, Xuhui District, Shanghai, China 200000

T) +86-21-5433-9761 F) +86-21-5433-9762

Sunje Technology Co., Ltd.

2F, No.6, Lane.102, Sinhe Rd, Sinfong Township,

Hsinchu County, Taiwan 30472

T) +886-3-568-7891 F) +886-3-568-7950

Sunje Japan Co., Ltd.

3-11-16-321 Higashimikuni, Yodogawa-ku, Osaka, Japan

T) +81-6-4866-5202 F) +81-6-6399-9290

Head Office & Factory (Busan)

8 ,Cheonggwang-gil, Ilgwang-Myeon, Gijang-Gun,

Busan, Korea

T) +82-51-720-7500 F) +82-51-720-7501

Southern Sales Office (Chilgok)

35-2, Seojungni 3-gil, Seokjeok-eup, Chilgok-gun,

Gyeongsangbuk-do, Korea

T) +82-54-476-9033 F) +82-54-476-9034

Central Sales Office (Hwaseong)

3F, Ilshin B/D, 4, Namnyeoul 2-gil, Hwaseong-si,

Gyeonggi-do, Korea

T) +82-31-203-9034 F) +82-31-202-9034

Customer Center +82-70-7714-9033

Sales Contact +82-31-203-9034

www.sunstat.com

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

SRB-1100

SRB-1200

SRB-1300

SRB-1500

SRB-1600

SRB-1800

SRB-2000

SRB-2100

SRB-2200

SRB-2300

SRB-2500

SRB-3000

SRB-3200

SRB-3400

SRB-3600

1020

1140

1260

1380

1500

1740

1980

2100

2220

2280

2520

2940

3120

3300

3480

1118

1238

1358

1478

1598

1838

2078

2198

2318

2378

2618

3038

3218

3398

3578

1160

1280

1400

1520

1640

1880

2120

2240

2360

2420

2660

3080

3260

3440

3620

1180

1300

1420

1540

1660

1900

2140

2260

2380

2440

2680

3100

3280

3460

3640

-

-

1

1

1

2

2

2

2

3

3

3

3

4

MODEL No. MIDDLE BKT Q’TY

18

20

22

24

26

30

34

36

38

39

43

50

53

56

59

TIP Q’TY No.

A

B C D

Loading...

Loading...