SunGrabber

IN-GROUND

- SOLAR POOL HEATER -

TM

INSTALLATION AND OPERATION MANUAL

TABLE OF CONTENTS

How Does the SunGrabberTM System Work?...............................

Why is SunGrabber

What’s Needed to Install Your SunGrabber

Installing your SunGrabber

Heating Your Pool………….……………………………………...…

ATTENTION: THIS MANUAL PROVIDES A DETAILED STEP-BY-STEP PROCEDURE FOR THE INSTALLATION OF THE SUNGRABBER

POOL HEATING SYSTEM. THE DIRECTIONS SHOULD BE FOLLOWED PROPERLY AND ONLY RECOMMENDED SUNGRABBER

AND HARDWARE SHOULD BE USED IN ORDER TO PROVIDE A TROUBLE FREE SYSTEM. READ THIS MANUAL COMPLETELY BEFORE

STARTING. IF YOU HAVE ANY INSTALLATION PROBLEMS OR QUESTIONS, CONSULT YOUR LOCAL SUNGRABBER

CONFORM TO LOCAL BUILDING CODES.

CAUTION:

FAMILIAR WITH WORKING ON ROOFS AND HAVE THE PROPER LADDERS AND SAFETY EQUIPMENT FOR SUCH WORK, YOU SHOULD HIRE

SOMEONE WITH THE NECESSARY EXPERIENCE TO DO THE INSTALLATION. FAILURE TO OBSERVE SAFE PRACTICES ON A ROOF OR OTHER

ELEVATED STRUCTURE MAY RESULT IN FALLING, LEADING TO SERIOUS INJURY. WHEN INSTALLING COLLECTORS ON THE GROUND, DO

NOT BUILD A RACK SUPPORT THAT CAN ALLOW CHILDREN TO ACCESS THE POOL.

TM

Your Best Choice?.....................................

TM

………………..………………………

SOLAR COLLECTORS ARE OFTEN INSTALLED ON THE ROOF OF BUILDINGS OR RESIDENTIAL HOMES. UNLESS YOU ARE

TM

……………………..

Page 2

Page 2

Page 3 & 4

Page 4-7

Page 8

Winterizing Your SunGrabber

Troubleshooting……..…………………….……..

Frequently Asked Questions……………….…..

Customer Support………….……………………

Warranty……………………..…………………...

TM

….…………....

TM

COMPONENTS

TM

DEALER. ALWAYS

TM

SOLAR

Page 8

Page 8

Page 9

Page 9

Page 9

Congratulations!

SUBPLENUM

METERING HOLES

CROSS-SECTION

OF HEADER

PANEL TUBES

SUBPLENUM

METERING HOLES

CROSS-SECTION

OF HEADER

PANEL TUBES

You are about to install a SunGrabber

U.S.A., the manufacturer of SunGrabber

TM

In-ground Solar Pool Heater - The best solar pool heater made! Based right here in the

TM

pioneered polymer solar pool heaters over 30 years ago, and today takes great pride in

being the largest and oldest manufacturer in the world. Backed by the longest and best warranty in the industry, your SunGrabber

is state-of-the-art in solar pool heating technology, and will provide years of FREE HEAT

installed correctly, a SunGrabber

TM

can raise your pool temperatures up by 10°F, and extend your swimming season.

Regular use of a solar blanket will enhance the performance of your new SunGrabber

for your pool! In fact, when sized and

TM

and allow you to enjoy a

warmer pool!

HOW DOES THE SUNGRABBERTM SYSTEM WORK?

x The system is designed to be installed horizontally (20’ long panels) or vertically (10’ and 12’ long panels)

x Pool water moves through the solar panel(s) picking up the sun’s solar heat along the way.

x Warmed pool water is then returned back to the pool.

x During the day, between 2°F and 5°F of heat is added each time your pool water circulates through the solar panel(s).

62/$5+($7

&22/

:$7(572

62/$5

3$1(/

62/$5+($7

&22/

&22/

:$7(572

:$7(572

62/$5

62/$5

3$1(/

3$1(/

62/$5+($7

62/$5+($7

62/$5+($7

62/$5+($7

62/$5+($7

62/$5+($7

62/$5+($7

62/$5+($7

TM

:$50

:$7(5

),/7(5$1'

3803

&22/ :$50

6:,00,1*322/

72322/

),/7(5$1'

),/7(5$1'

3803

3803

6:,00,1*322/

&22/ :$50

&22/ :$50

6:,00,1*322/

If your pool water is too warm, circulate the pool water through the solar panel at night to cool your pool!

WHY IS SUNGRABBERTM YOUR BEST CHOICE?

SunGrabberTM’s patented tube-to-tube construction and water metering system provides even flow

and heating along the entire width and length of the solar panel. These features eliminate

inefficient hot spots associated with other solar brands.

1. Pool water enters the header and travels through the metering holes into the

subplenum without creating excessive additional backpressure on the pool pump.

2. The subplenum evenly distributes pool water simultaneously to

every panel tube.

3. The pool water then flows down the panel creating a fully-wetted

surface that is in touch with the sun’s solar heat.

:$50

:$50

:$7(5

:$7(5

72322/

72322/

4. A balanced fully-wetted surface optimizes transfer of the sun’s

available solar heat to your pool water.

2

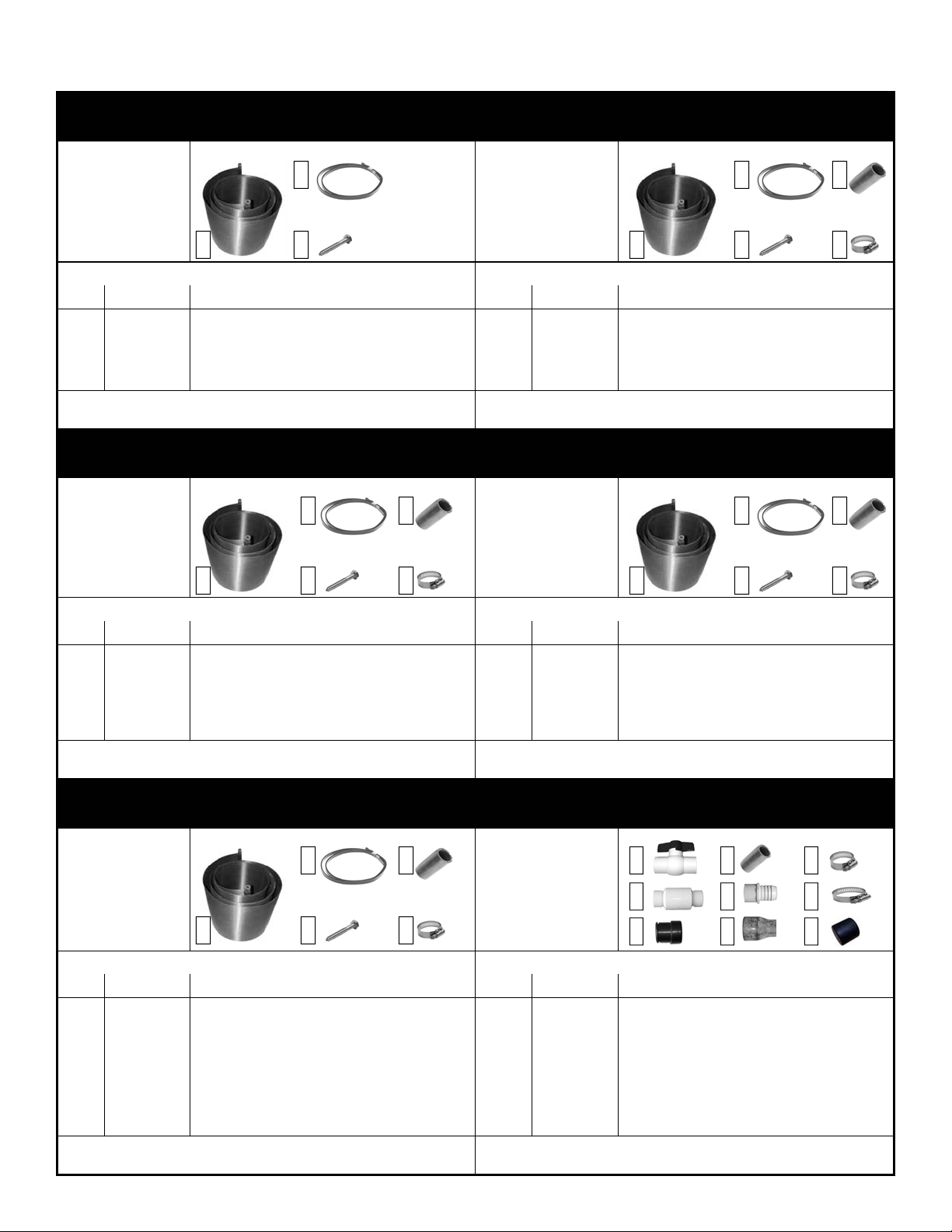

WHAT’S NEEDED TO INSTALL YOUR SUNGRABBERTM?

SunGrabber

Product

P/N 260-1

P/N 260-5

40,000 BTU’s

Box Contents Box Contents

Item Quantity Description Item Quantity Description

A

B

C

Additional Parts Required: (1) - System Kit, PVC Solvent Primer/Cement, Teflon

Tape, Roofing Mastic, and plumbing from roof to pool equipment.

SunGrabber

Product

P/N 270-2

P/N 280-2

TM

Box Contents by Item

(Manual and Warranty Card Not Shown)

SunGrabber

Product

P/N 260-2

B

A

1

3

6

2’ x 20’ in-ground solar panel

36” mounting straps

2” x 1/4” mounting screws

TM

(Manual and Warranty Card Not Shown)

C

Box Contents by Item

P/N 260-6

80,000 BTU’s

A

B

C

D

E

TM

Additional Parts Required: (1) - System Kit, PVC Solvent Primer/Cement, Teflon

Tape, Roofing Mastic, and plumbing from roof to pool equipment.

SunGrabber

Product

P/N 280-3

DB

TM

(Manual and Warranty Card Not Shown)

A E

2

3

9

2

4

2’ x 20’ in-ground solar panel

60” mounting straps

2” x 1/4” mounting screws

1 1/2” rubber coupler

1 1/2” hose clamp

TM

(Manual and Warranty Card Not Shown)

40,000 BTU’s

40,000 BTU’s

Box Contents Box Contents

Item Quantity Description Item Quantity Description

A

B

C

D

E

Additional Parts Required: (1) - System Kit, PVC Solvent Primer/Cement, Teflon

Tape, Roofing Mastic, and plumbing from roof to pool equipment.

SunGrabber

2

3

9

2

4

Product

A E

2’ x 10’ in-ground solar panel

60” mounting straps

2” x 1/4” mounting screws

1 1/2” rubber coupler

1 1/2” hose clamp

TM

C A E

Box Contents by Item

(Manual and Warranty Card Not Shown)

Includes P/N 267

System Kit

A

B

C

D

E

TM

Additional Parts Required: PVC Solvent Primer/Cement, Teflon

Mastic, and plumbing from roof to pool equipment.

2

3

9

2

4

1

SunGrabber

Product

2’ x 10’ in-ground solar panel

60” mounting straps

2” x 1/4” mounting screws

1 1/2” rubber coupler

1 1/2” hose clamp

P/N 267 System Kit

TM

(Manual and Warranty Card Not Shown)

Box Contents by Item

B

C

Box Contents by Item

C

TM

Tape, Roofing

Box Contents by Item

D

TM

DB

P/N 272-2

DB

P/N 267

A

B

46,000 BTU’s

Box Contents Box Contents

Item Quantity Description Item Quantity Description

A

B

C

D

E

Additional Parts Required: (1) - System Kit, PVC Solvent Primer/Cement, Teflon

Tape, Roofing Mastic, and plumbing from roof to pool equipment.

2

3

9

2

4

A E

2’ x 12’ in-ground solar panel

60” mounting straps

2” x 1/4” mounting screws

1 1/2” rubber coupler

1 1/2” hose clamp

C

SYSTEM KIT

A

B

C

D

E

F

G

H

I

TM

Additional Parts Required: (1) - System Kit, PVC Solvent Primer/Cement, Teflon

Tape, Roofing Mastic, and plumbing from roof to pool equipment.

1

1

1

6

2

1

14

1

1

C

1 1/2” ball valve

1 1/2” check valve

Vacuum relief valve (VRV)

1 1/2” rubber coupler

1 1/2” male rib adapter (MRA)

1 1/2” x 2” bell reducer rubber coupler

1 1/2” hose clamp

2” hose clamp

1 1/2” rubber cap

3

D

E

F

G

H

I

TM

WHAT’S NEEDED TO INSTALL YOUR SUNGRABBERTM? (CONTINUED)

Additional parts required other than P/N 267 System Kit can be purchased at you local hardware store.

TOOLS REQUIRED

Cordless drill

1/8” drill bit

7/16” socket and driver

1/2” ratchet

Flathead and Phillips screwdriver

1/4” socket driver

Tape measure

Marking pencil

Hack saw or PVC pipe cutter

AVAILABLE SUNGRABBER

P/N 241-2 1 1/2” X 2” Panel Add-on Adapter Kit

P/N 250-1 High Wind Roof/Rack Mounting Kit (1 required per (2) 2’ panels

plus 1 additional per system)

P/N 261-2 Panel Add-on Kit

P/N 262 Panel Repair Kit

For more information on accessories, please contact your nearest SunGrabber

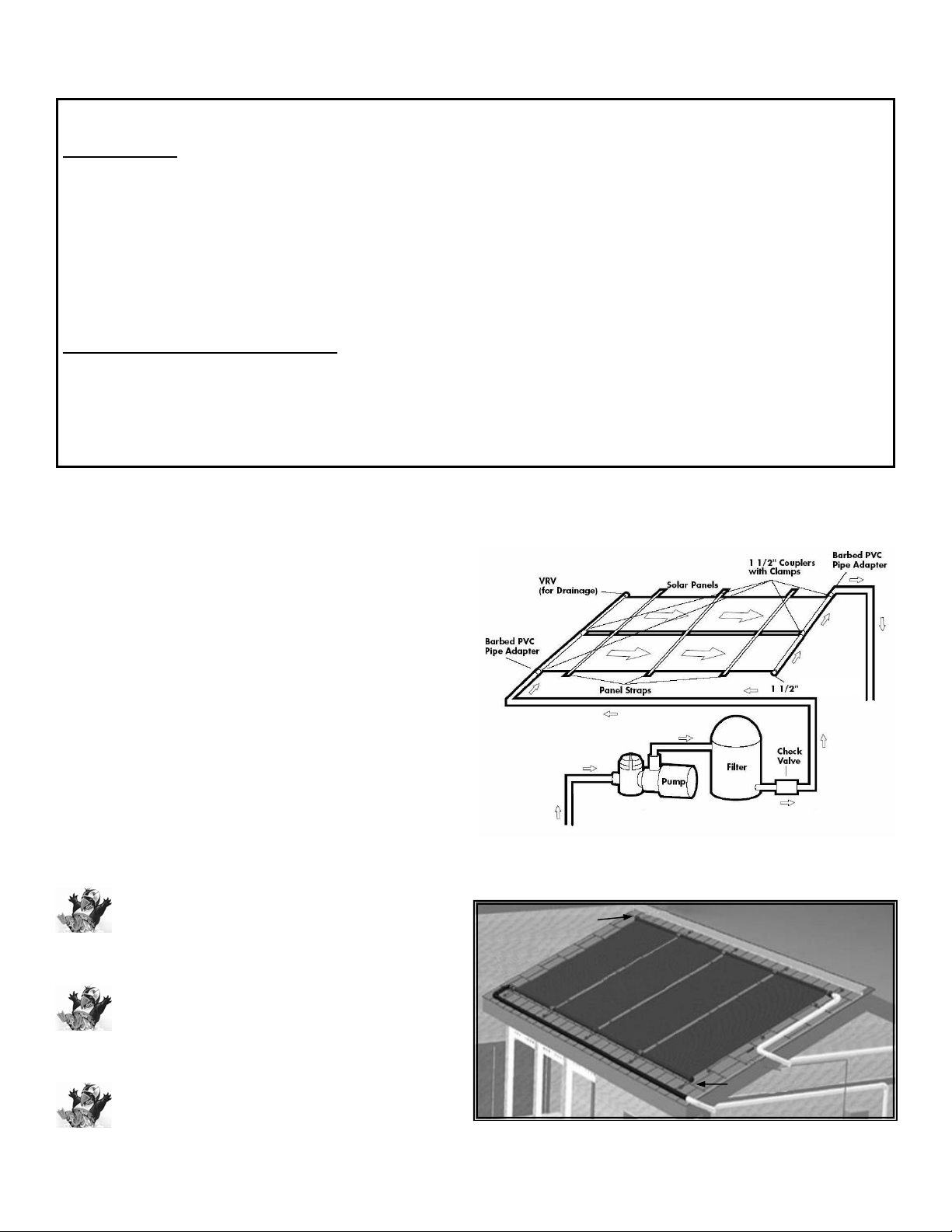

INSTALLING YOUR SUNGRABBER

The ideal location for your SunGrabber

TM

ACCESSORIES

TM

TM

system is a south-facing

TM

pitched roof closest to your pool equipment with enough space to

mount your panel(s). West-facing would be a second choice

followed by east with north being the least desirable. Be certain

that trees or other structures do not shade the location you select.

The effectiveness of your SunGrabber

TM

system is dependent on

the amount of direct sunlight. Survey the roof to confirm a proper

fit.

A 3/4 to 1 1/2 horsepower pump will generally handle installations

up to 30 feet away from the pool equipment and one story high.

Large systems and remote installation may require a pump with

more horsepower. If your pool has a gas heater or heat pump,

plumb the solar system in between the filter and gas heater/heat

pump. You should see a reduction in your monthly energy bill!

dealer or visit us on the web at www.sungrabber.com

Rubber Cap

Typical Horizontal Installation

You can install up to (12) 2’ wide solar panels either

horizontally (20’ panels) or vertically (10’ and 12’

panels).

When transporting panel(s) to the roof or rack and

while positioning panel(s) before mounting, be sure

they are not dragged over any sharp surfaces.

Each SunGrabber

TM

solar panel is water pressure

tested and drained at the factory so it is common for

some residual water to be present in your solar

panel upon delivery.

VRV

(for drainage)

1 1/2” Rubber Cap

Typical Vertical Installation

4

TM

::$50

:$7(5

72322/

&&22/

:$7(572

62/$5

3$1(/

),/7(5$1'

3803

&&22/ :$50

6:,00,1*322/

662/$5+($7

662/$5+($7

INSTALLING YOUR SUNGRABBER

(CONTINUED)

HORIZONTAL INSTALLATION ON SHINGLE ROOF [P/N’S 260-1, 260-2, 260-5, 260-6]

CAUTION: VERTICAL INSTALLATION OF THESE MODELS WILL VOID THE WARRANTY

1. Determine the location of your panel(s). Lay out your

system so that it declines slightly (a minimum of 1/4 inch of

P

L

L

A

F

F

O

H

C

N

I

4

/

1

F

O

M

U

M

I

N

I

M

A

T

E

E

F

0

1

R

E

fall every 10 feet) toward the bottom corner of the panel that

feeds from your pool equipment. This is needed to ensure

proper drainage during daily use and for winterizing.

2. The three mounting straps provided should be positioned

with one in the center of the panel, and one 5” in from each

header. Mark the bottom row lag screw locations. Position

the first strap with 10” of under-hang below the lag screw

location, drill an 1/8” pilot hole, remove strap, apply adhesive

to the pilot hole, re-position the strap, and screw the lag

screw through the strap into the roof. Install remaining two

straps the same way. In Step 8, you will use the 10”

underhang strapping and the same lag screw to secure

supply piping. (see photos 2)

3. If this is a multiple panel system, connect all the panels

using the rubber couplers and hose clamps provided with

your system. Make sure each coupler is pushed on at least

an inch past the raised ribs of the header adapters. Position hose clamps 1/4” from the end of the couplers and tighten. (see

photo 3)

4. Install the rubber cap and stainless steel clamp over the header adapter at the bottom corner of the system that will not have

plumbing running to it. (see photo 4)

5. Install the VRV and bell reducer as shown onto the upper most corner of the top panel that will

not have plumbing running to it. (see photo 5)

6. Install rubber couplers and clamps on the opposite corners that will receive plumbing. Insert 11/2” Male Ribbed Adapters (MRAs) with barbs into the coupler and secure with a hose clamp.

(see photo 6)

7. Follow Steps 1 and 2 for mounting remaining straps.

8. Construct plumbing as shown. Use extra strapping at the bottom to hold supply piping.

(see photos 8)

ATTENTION: P/N 250-1 HIGH WIND ROOF/RACK MOUNTING KITS may be purchased from your

dealer and used in high wind applications in addition to the roof/rack mounting hardware

included in your system. One kit is required for every two panels used in a system; one

additional kit is required to complete the system. (Example: A system with (8) 2’ panels requires

5 kits)

4.

6.

2.

2.

3.

8. 5. 8.

5

TM

:$50

:$7(5

72322/

&&22/

:$7(572

62/$5

3$1(/

),/7(5$1'

3803

&22/ :$50

6:,00,1*322/

662/$5+($7

62/$5+($7

62/$5+($7

62/$5+($7

::$50

:$7(5

72322/

&&22/

:$7(572

62/$5

3$1(/

),/7(5$1'

3803

&&22/ :$50

6:,00,1*322/

662/$5+($7

62/$5+($7

62/$5+($7

62/$5+($7

INSTALLING YOUR SUNGRABBER

(CONTINUED)

VERTICAL INSTALLATION ON SHINGLE ROOF [P/N 270-2, 272-2, 280-2, 280-3]

ATTENTION: HORIZONTAL INSTALLATION OF THESE MODELS IS ACCEPTABLE

M

I

N

I

M

1. Determine the location of your panel(s). Lay out your system

so that it declines slightly (a minimum of 1/4 inch of fall every

10 feet) toward the bottom corner of the panel that feeds from

your pool equipment. This is needed to ensure proper

drainage for winterizing.

2. Lay out all panels and connect them together using the rubber

couplers and hose clamps provided. Make sure the couplers

are pushed onto the header adapter at least an inch past the

raised barb, position the hose clamps 1/4” from the ends of

the couplers, and tighten.

3. Install the rubber cap and stainless steel clamp over the

header adapter at the bottom corner of the system that will not

have plumbing running to it. (see photo 4)

4. Install the VRV and bell reducer as shown onto the upper

most corner of the top panel that will not have plumbing

running to it. (see photo 5)

A

T

E

E

F

0

1

R

E

P

L

L

A

F

F

O

H

C

N

I

4

/

1

F

O

M

U

5. Install rubber couplers and clamps on the opposite corners

that will receive plumbing. Insert 1-1/2” Male Ribbed Adapters

(MRAs) with barbs into the coupler and secure with a hose

clamp. (see photo 6)

6. The three mounting straps provided should be positioned with one in the center of the panel, one 3” down from the top header and

one 5” up from the bottom header.

7. Starting with the strap at the top of the panel, mark the position of the first lag 2” off the edge of

the panel, position the strap over the mark with one inch overhanging the lag screw location.

Drill an 1/8” pilot hole, remove the strap, apply roofing mastic over the pilot hole, re-position the

strap, and screw lag screw through the strap into the roof. (see photos 2 & 7)

8. Position the panel under the strap, pull the strap tight across the panel and install the second

lag screw.

9. Continue until all the panels are installed then construct plumbing from the panels to the pool

7.

equipment.

ATTENTION: P/N 250-1 HIGH WIND ROOF/RACK MOUNTING KITS may be purchased from your dealer and used in

high wind applications in addition to the roof/rack mounting hardware included in your system. One kit is required

for every two panels used in a system; one additional kit is required to complete the system. (Example: A

system with (8) 2’ panels requires 5 kits)

REQUIREMENTS FOR ROOF TYPES OTHER THAN SHINGLE ROOF

Flat Tile or Barrel Tile Roofs: Use 1-1/4” TAPCON Hex Head Screws (available at any local hardware store) in place of the provided

lag screws. This requires drilling a pilot hole with a 3/16 inch masonry drill bit in the tile before inserting the screw. Do not drill into the

substrate below the tile; doing so can promote a roof leak if not done correctly. The mounting screws should be positioned 1” to 2”

above the bottom edge of the tile. This will allow a space between the tile and the substrate due to the overlap in the tiles. On barrel tile

roofs, try to lay out the panels so that the mounting holes are on the peak or top of the barrel tile. Be sure that the tiles that the panels

are fastened to are secure. For high wind prone areas or where roof tiles are loose, consult your dealer for an alternate method.

6

INSTALLING YOUR SUNGRABBERTM (CONTINUED)

REQUIREMENTS FOR ROOF TYPES OTHER THAN SHINGLE ROOF (CONTINUED)

Cedar Shake Roofs: If the cedar shakes are installed on top of a plywood surface, use a galvanized metal flashing (approximately 4”

x 4”) under each shake where the mounting screw will penetrate. Center the flashing under the penetration location before installing

the screw. Drill a pilot hole and apply a generous amount of sealant into the hole. If the cedar shakes are installed on fir strips,

contact your dealer for alternate mounting instructions.

Flat Built-up Gravel Roofs: Use caution when installing on this type of roof. The roof must be in good condition and be completely

dry. If you are uncertain of the condition of the roof, consult a professional. At each mounting location remove the loose gravel in an

area approximately 6“ x 6”. At the exact location of the penetration, remove the gravel which is embedded into the tar surface of the

roof using a chisel or the back of a claw hammer. Scrap back the gravel until you have a smooth tar surface approximately 2“ x 2”.

Apply a generous amount of sealant under the mounting hardware and over the head of the screw once installed. Using a 2” to 2½”

fender washer under the mounting hardware will provide additional mounting surface. The screw must be tightened to hold the

hardware securely to roof surface; however, use extreme caution not to over tighten and strip the screw in the plywood. An alternate

method is to have a roofing contractor install roof curbs where the mounting hardware will be installed.

Open Beam Roofs: Any ceiling with exposed beams must be checked to avoid the screw ends from penetrating into the interior

space. Call for alternate installation method.

Metal Roofs: If the metal roof is installed on a plywood surface, you may proceed using the normal installation method. If the metal

roof is installed on fir strips, the mounting hardware must penetrate into the fir strip to insure a good seal and to avoid bending the

metal surface. If screw heads protrude above the surface of the roof, a substrate must be used to prevent damage to the panels.

Rubber or Asphalt Modified: This type of roof is typically installed flat. Using a 2” to 2½” fender washer under the mounting

hardware will provide additional mounting surface. Be sure to use a generous amount of sealant under the washer, between the

washer and the mounting hardware, and on top of the mounting screw.

Roof or Ground Mounted Rack Systems: Rack systems can be made from pressure treated wood or aluminum. For roof mounted

racks aluminum is preferred for its additional strength and longevity. See your dealer for rack mounting options.

CONNECTING TO POOL EQUIPMENT

Install check valve and by-pass ball valve as shown.

The check valve prevents the water in the panels from

flowing backwards through filter and back-flushing into

the pool. The by-pass ball valve allows you to

manually activate and deactivate your solar system

daily. When turning the system on, regulate flow using

the by-pass ball valve. The solar system works best at

flow rates ranging from 1 to 4 gpm per panel. To

regulate flow, simply document the pressure on the

pressure gauge of the filter with the by-pass valve open

and the pool pump running. Then throttle the by-pass

ball valve closed until the pressure on the filter gauge

has increased (for a maximum 12 panel system) more

than what you originally documented. Give the system

about 10 minutes to normalize, and then check the

pressure gauge again. Additional fine-tuning may be

required. Once set, mark the location of the by-pass

ball valve handle so that you can simply and accurately

activate and deactivate the solar system daily.

FROM

POOL

PUMP

FILTER

ISOLATION

BALL VALVE

(OPTIONAL)

CHECK

VALVE

TO

SOLAR

FROM

SOLAR

BYPASS

BALL

VALVE

OUTLET

TEE

BY-PASS VALVE

(OPTIONAL)

HEATER

ISOLATION

BALL VALVE

(OPTIONAL)

ISOLATION

CHECK VALVE

(OPTIONAL)

HEATER

OR

TO

POOL

True Union isolation ball valves are recommended to make Winterizing your system easier. NOTE: A MOTORIZED VALVE AND AN

AUTOMATIC SOLAR CONTROL ARE OPTIONAL ITEMS AVAILABLE FROM YOUR LOCAL POOL DEALER.

7

HEATING YOUR POOL

When the system starts up you will notice tiny air bubbles flowing into your pool. This is the plumbing and solar panel(s) being purged

of any air. This is normal and should last a few minutes. To check the performance of the system, turn off the pool pump. Wait 10

minutes and feel the surface of the solar panel. It should be hot to the touch. Now turn the pool pump back on and feel the panel

getting cooler to the touch. The difference in temperature is FREE

Warning: If the panel is full of water and has been sitting in the sun without the pump running, the water can get

very hot. Hot water can cause burns, so be sure everyone is away from the pool inlet each time the system is

turned on.

For best results, turn on your solar system whenever your solar panels are in the sun. Turn the solar system off at night or when it’s

raining to prevent cooling the pool. If your pool system has a timer, set it to operate from 9 a.m. until 5 p.m. This is the best solar

heating period. Using a solar blanket in addition to your solar pool heater will hold the warmth in the pool and help it heat more

quickly. It is particularly important to use the blanket at night or when it’s windy. If your pool becomes too warm during the season,

turn the pump and solar on at night to help cool the pool.

solar heat being added to your pool water!

WINTERIZING YOUR SUNGRABBER

A vacuum relief valve (VRV) is provided with your SunGrabber

TM

TM

system to allow the panels to drain when the pump is off. All

plumbing designs should allow for full drainage. Turn by-pass valve and pool pump off, and allow 30 to 40 minutes for drainage.

Undo the isolation valves, remove the VRV, and allow the system to drain. Reattach your VRV. SunGrabber

TM

panels are designed

to be left in place through the winter months as long as they are drained. If you question the drainage of your system you should

disconnect each panel and raise each one up to check and see that no water is present.

Freeze damage is not covered under warranty.

TROUBLESHOOTING

If you are having an issue with your SunGrabber

follows. Usually a resolution can be found in these two sections. If your particular issue is not found, please visit us on the web at

www.sungrabber.com or contact our customer support department at 1-866-SUNGRAB (786-4722).

Issue: My system doesn’t seem to be working.

Resolution: Turn off your pool pump midday in bright sunlight. After 10 minutes have passed, feel the solar panel. It should be quite warm to the

touch. Turn your pool pump back on. Wait another 10 minutes and feel the solar panel again. It should be cool to the touch. The difference in

temperature is the heat being added to your swimming pool and indicates that your system is functioning properly. Also, the water entering the

pool from the solar panel through the pool inlet should be warmer than the surrounding pool water.

TM

, please review this section and the Frequently Asked Question section that

Issue: My pool is not warm enough.

Resolution: Your system should be up and running for five days to reach optimum temperature. Be sure the system is turned off during the night,

or this will cool your pool. Be sure your solar system is getting sun the entire day or at least 4 to 6 hours of afternoon sun, preferably on a southfacing pitched roof.

Issue: Flow from my pool inlet seems greatly reduced and filter pressure excessive.

Resolution: There will be some increase in backpressure on the filter and pump when the solar system is on. Check to see that your pool filter is

properly cleaned.

8

FREQUENTLY ASKED QUESTIONS

TM

The following questions are those asked most frequently by our SunGrabber

your SunGrabber

Question: Should I use a solar pool cover with my solar system?

Answer: Yes. A solar pool cover prevents evaporation and heat loss, especially at night when the outside temperature is cooler. If you do not

use one, there is a good chance that the heat you added during the day will be lost at night.

Question: Can above ground pool solar panels be used to heat my in-ground pool?

Answer: SunGrabberTMdoes not recommend using above ground solar panels on in-ground pools.

TM

, your answer may be found below.

customers. If you have a question or concern about

Questions: Can I add on more panels if I want my pool warmer?

Answer: Absolutely. The more panels—the warmer your pool! Your SunGrabber

TM

system’s modular design accepts additional panels very

easily.

Question: Can I use my SunGrabber

Answer: If you have a gas heater or heat pump installed on your pool currently, simply install your SunGrabber

TM

with a gas heater or heat pump?

TM

between the filter and the gas

heater/heat pump. You will notice a reduction in your monthly energy bill!

Questions: How should I time my automatic pool cleaner?

Answer: Set your pool cleaner to turn on after the solar system. This prevents air from entering and possibly damaging pool-cleaning equipment

during startup of your solar system.

Question: I left my solar panel full of water through the winter and now some of the tubes are leaking. Can it be repaired?

Answer: Yes it can. You will need to order our “Panel Repair Kit” from your local dealer. It is very important that your SunGrabber

winterized each year. (Reference the “Winterizing Your SunGrabber

TM

” section of this manual, page 8)

TM

is properly

CUSTOMER SUPPORT

If your issue was not addressed in our Troubleshooting or Frequently Asked Questions sections, please visit us on the web at

www.sungrabber.com or contact our customer support department at 1-866-SUNGRAB (786-4722).

WARRANTY

Your SunGrabber

TM

is backed by a limited 10-year warranty.

9

Notes

Notes

P/N 07347C 3/06

TM

SunGrabber

866-SUNGRAB • 866-786-4722

435 Otterson Drive

Chico, CA 95928

www.sungrabber.com

Loading...

Loading...