SUNFAR E300 SERIES

Manual

E300 Series Mini-type Integrated

Universal Inverter Manual

1

SHENZHEN SUNFAR ELECTRIC TECHNOLOGIES CO.,LTD

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

2

PREFACE

Thanks very much for choosing E300 series mini-type integrated universal inverter.

This manual provides guidance of using inverter safely and carefully, containing

introduction of installation, wiring, parameters list, routine maintenance, operating rules

and cautions, etc.

In order to make good use of inverter properly and safely, please read this manual

thoroughly before using. It may lead to abnormal operation or failure, reduce using life,

even damage equipment and cause personal injury if you it wrongly.

This manual is attachment together with the inverter. Please keep it well and it would be

available to engineering and installation personnel, repairing and maintaining during

product functioning period. SUNFAR has the right to modify and ameliorate products, data

and dimensions without notice, so this manual is updated and all the contents in this

manual are subject to change without any notice.

SHENZHEN SUNFAR ELECTRIC TECHNOLOGIES CO., Ltd.

E300 Series Mini-type Integrated Universal Inverter Manual

Version: v1.0

Time: Feb. 2009

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

CONTENT

3

1. INTRODUCTION……………………………………………………

1.1. Model Explanation…………………………………………

1.2. Inverter Model………………………………………………

1.3. Appearance………………………………………………

1.4. Specification Data…………………………………………

2. INSTALLATION……………………………………………………

2.1. Environmental Requirements ………………………………

2.2. Installation Dimension……………………………………

3. WIRING………………………………………………………………

3.1. Precautions……………………………………………………

7

7

7

7

8

10

10

10

12

12

3.2. Wiring of External Components……………………………

3.3. Basic Wiring………………………………………………

3.4. Wiring of Main Loop Terminal ………………………………

3.5. Wiring of Control Loop Terminal…………………………

3.6. Wiring of RS485 Interface and External Keyboard ………

4. PANEL OPERATION………………………………………………

4.1. Key Function Description……………………………………

4.2. Panel Operational Method……………………………………

4.3. State Monitor Parameter List………………………………

E300 Series Mini-type Integrated Universal Inverter Manual

12

13

14

14

15

17

17

18

18

SUNFAR E300 SERIES

4

4.4. Inverter Simple Operation……………………………………

5. PARAMETER LIST…………………………………………………

6. FAULT DIAGNOSIS AND COUNTERMEASURES……………

6.1. Protective Function and Countermeasures…………………

6.2. Fault Record Inquiry……………………………………………

6.3. Reset……………………………………………………………

AppendixⅠRS485 COMMUNICATION PROTOCOL……………

1.1. Summary………………………………………………………

1.2. BUS Structure and Protocol Description ……………………

1.3. Frame Format Description……………………………………

19

21

23

23

24

24

25

25

25

29

1.4. Example…………………………………………………………

Appendix Ⅱ MODBUS PROTOCOL ………………………………

1.1. Protocol Format Explanation………………………………

1.2. Example…………………………………………………………

Appendix Ⅲ BRAKING RESISTOR………………………………

32

36

36

39

41

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

5

PRECAUTIONS

In order to use inverter properly and safely, please read this manual carefully before using.

You should follow the requirements of this manual to move, install, run, operate and repair

etc.

1. Opening

Please check any damage that may have occurred during transportation.Ⅰ

Please check whether the nameplate data of iⅡ nverter is in accordance with your

order, if anything wrong, please contact supplier immediately.

Our product is manufactured, packed and transported in the strict quality system. But in

case there is any error, please contact with our company or local agent, we will solve the

problem as quickly as possible.

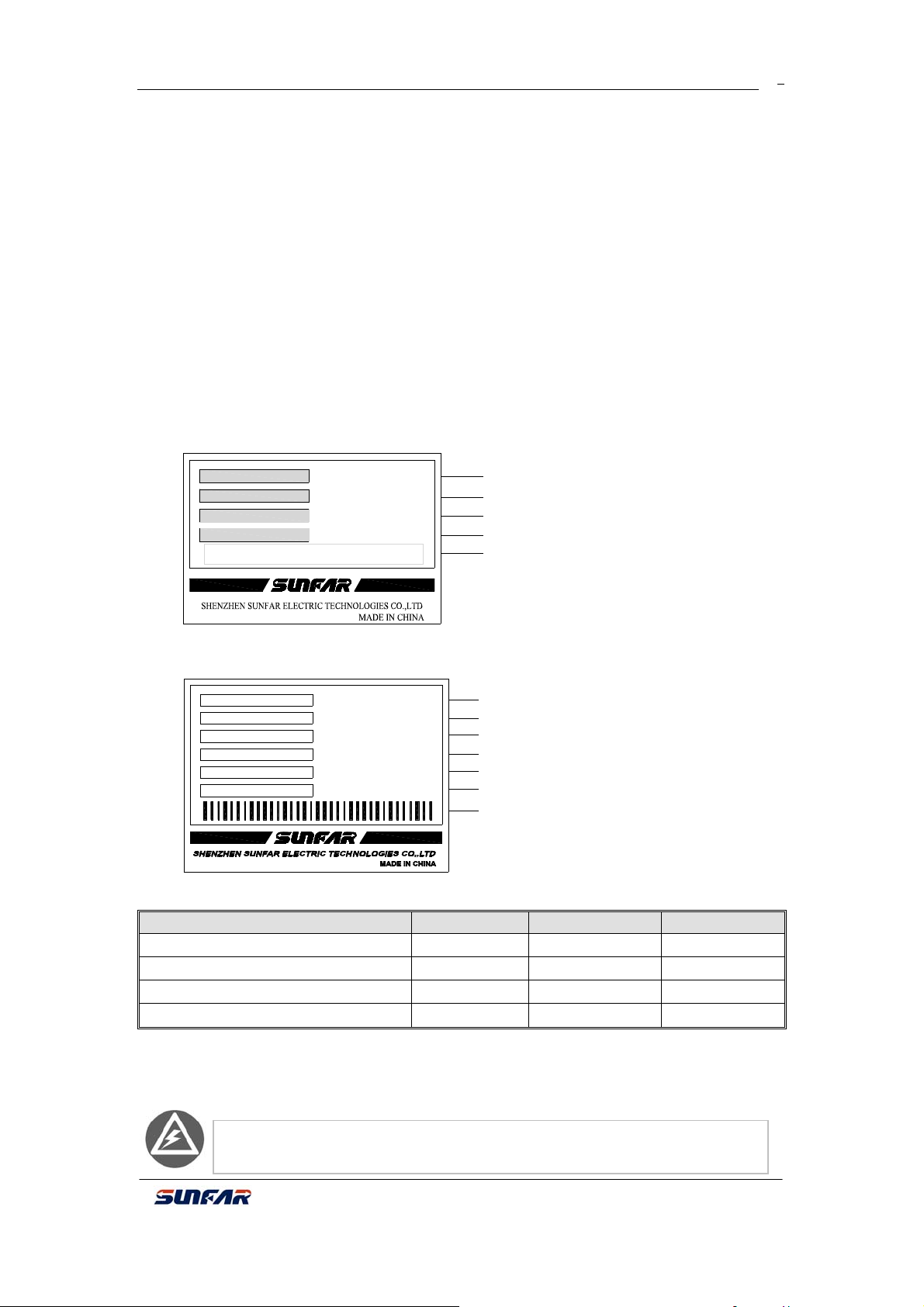

Inverter’s nameplate data

TYPE:

SOURCE:

OUTPUT:

SERIAL No.:

E300-2S0007

1PH 220V 50/60Hz

1.7KVA 4.5A

XXXXXXXXXX

Model

Rated Parameters

Rated output capacity and current

Product serial No.

Bar code

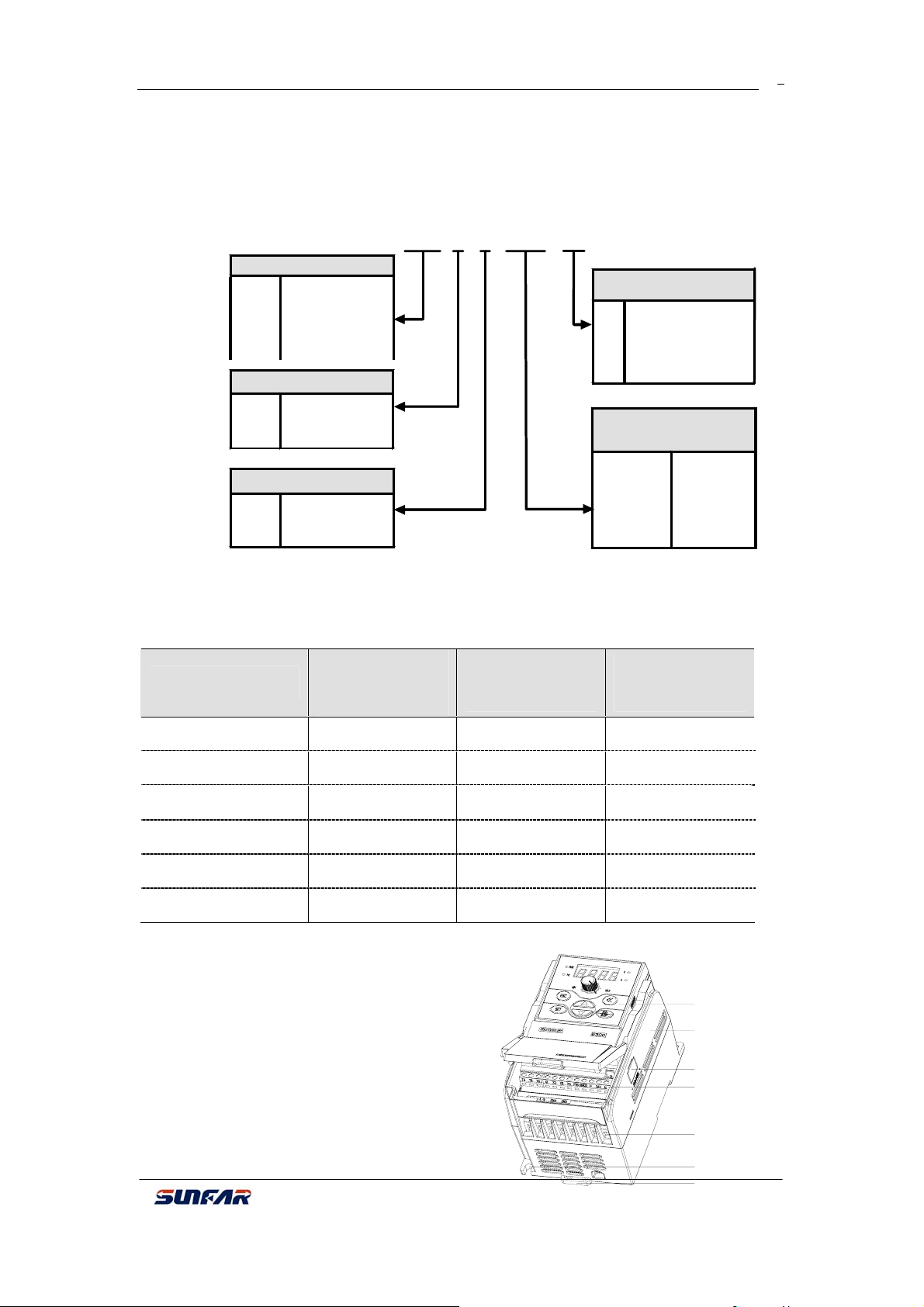

Fig-1 Nameplate

Package data

TYPE:

TYPE:

SOURCE:

SOURCE:

NET WEIGHT:

GROSS WEIGHT:

VOLUME:

SERIAL No.:

E300-2S0007

1PH 220V 50/60Hz

KG

KG

(mm)

XXXXXXXXXX

Model

Rated Parameters

Net Weight

Gross Weight

V

olume

Serial No.

Bar Code

Dimension

Model Net Weight Gross Weight Dimension

E300-2S0002/E300-2S0002(B) 0.78 0.97 195×115×175

E300-2S0004/E300-2S0004(B) 0.82 1.00 195×115×175

E300-2S0007/E300-2S0007(B) 1.43 1.66 203×135×180

E300-2S0015/E300-2S0015(B) 1.52 1.82 203×135×180

2. Safety Regulations

There are four kinds of symbols being related with cautions as following:

Danger: If user does not operate according to requirements, it will lead to

death, grievous bodily harm or severe property loss.

E300 Series Mini-type Integrated Universal Inverter Manual

6

p

1. D

B

t

i

ith filt

g

Warning: If user does not operate according to requirements, it will lead to

inverter injury or damage.

This symbol will hint some useful information.

This symbol will hint some items that need to be noticed in operation.

SUNFAR E300 SERIES

2.1 Installing

Do not install inverter on combustible material.

Do not install in the explosive ambient.

Do not drop other material into the inverter.

It is forbidden to disassemble and refit inverter.

2.2 Wiring

2.2.1. It must be operated by professional worker when wiring.

2.2.2. Please be sure to turn off the power supply at least 10 min before wiring.

2.2.3. Inverter and motor must be grounded correctly.

2.2.4. Be sure to wire and inspect after power-off at least10 minutes.

2.2.5. Electron components are sensitive about static electricity, so do not drop other

material in inverter or touch the main circuit.

It is forbidden to connect AC power supply with the U, V

and W out

ut terminals directly.

2.3 Maintenance

o not touch the radiator after power-off at least 10 minutes.

2. The earth terminal of inverter must be connected to ground reliably.

3. Attention Notes:

3.1. Be sure to install inverter in a well-ventilated ambient.

3.2. Motor temperature at inverter control will be higher than at main supply control,

which is normal phenomenon.

3.3. Ordinary motor cannot run at low speed for a long time, so user should select

special motor for inverter or reduce motor load under low speed.

3.4. When the altitude is over 1000m, inverter will be valid to decrease rated current,

and rated current will decrease 10% when attitude is increased 1500m.

e sure not to connec

other sur

e absorbers.

nverteroutput terminalsw

er capacitors and

4 Dispose:

When you dispose inverter and its parts, please pay attention to:

Capacitor: The capacitors in inverter may explode when they are burned.

Plastic: Poisonous gas may be generated when front panel is burned, please pay

attention to waste gas when plastic parts are burned.

Method: Please dispose inverter as industry rubbish.

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

/

7

1 INTRODUCTION

1.1 Model Explanation

E300

Product

Mini-type

integrated

universal

inverter

Volt Class

4

2

380V

220V

Power Phase

T

S

3 PH

1 PH

1.2 Inverter Model

Rated Capacity

Model

E300- 4 T 0007 (B)

Rated Output

(KVA)

Current (A)

Derivative Model

Built-in braking

B

unit and RS485

communication

Applied Motor Power

(KW )

0002

0004

0007

0015

0.2

0.4

0.7

1.5

Applied Motor

Power (KW)

E300-2S0002 0.69 1.8 0.25

E300-2S0004 0.95 2.5 0.4

E300-2S0007 1.7 4.5 0.75

E300-2S0015 2.9 7.5 1.5

E300-4T0007 1.6 2.5 0.75

E300-4T0015 2.8 4.2 1.5

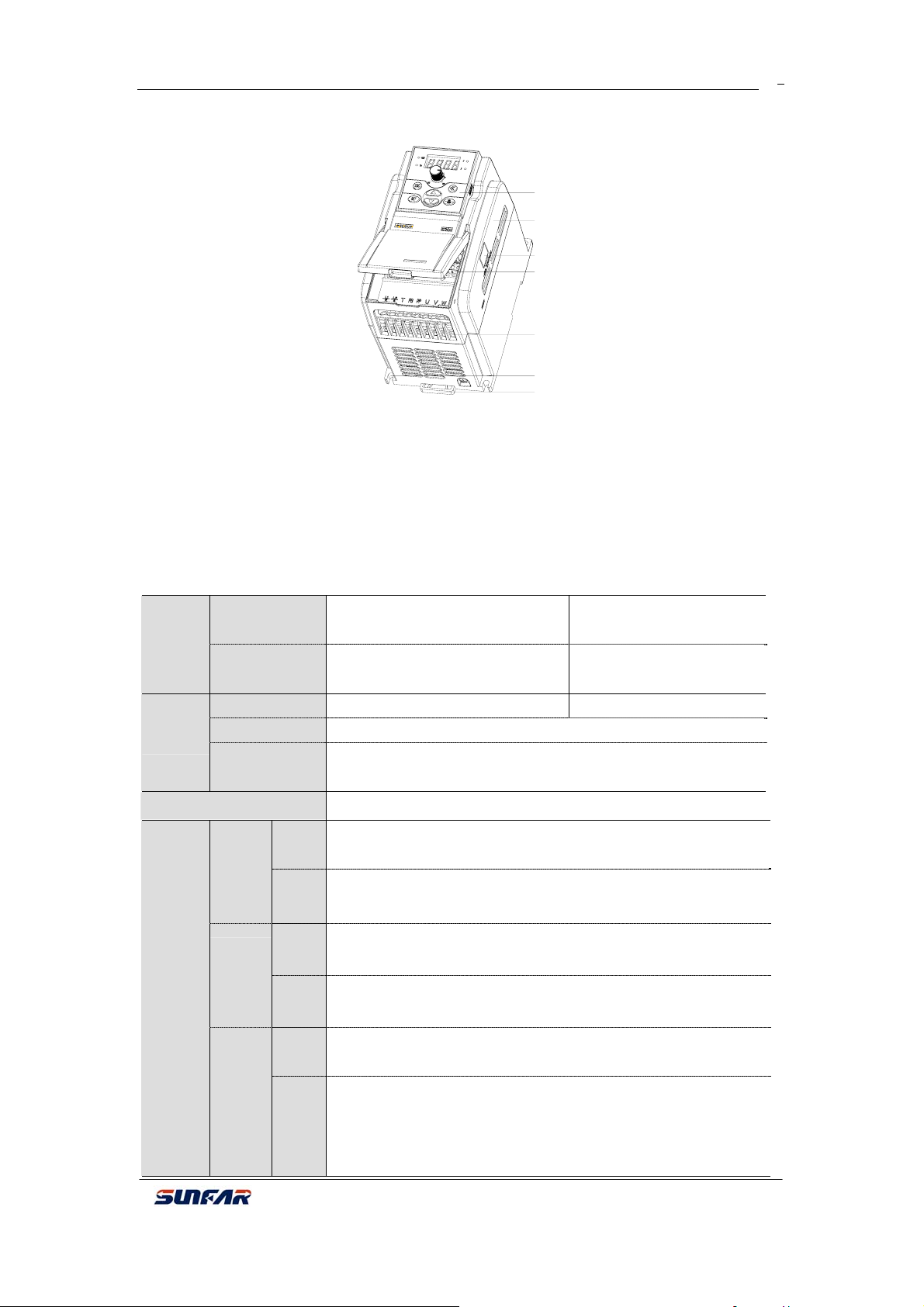

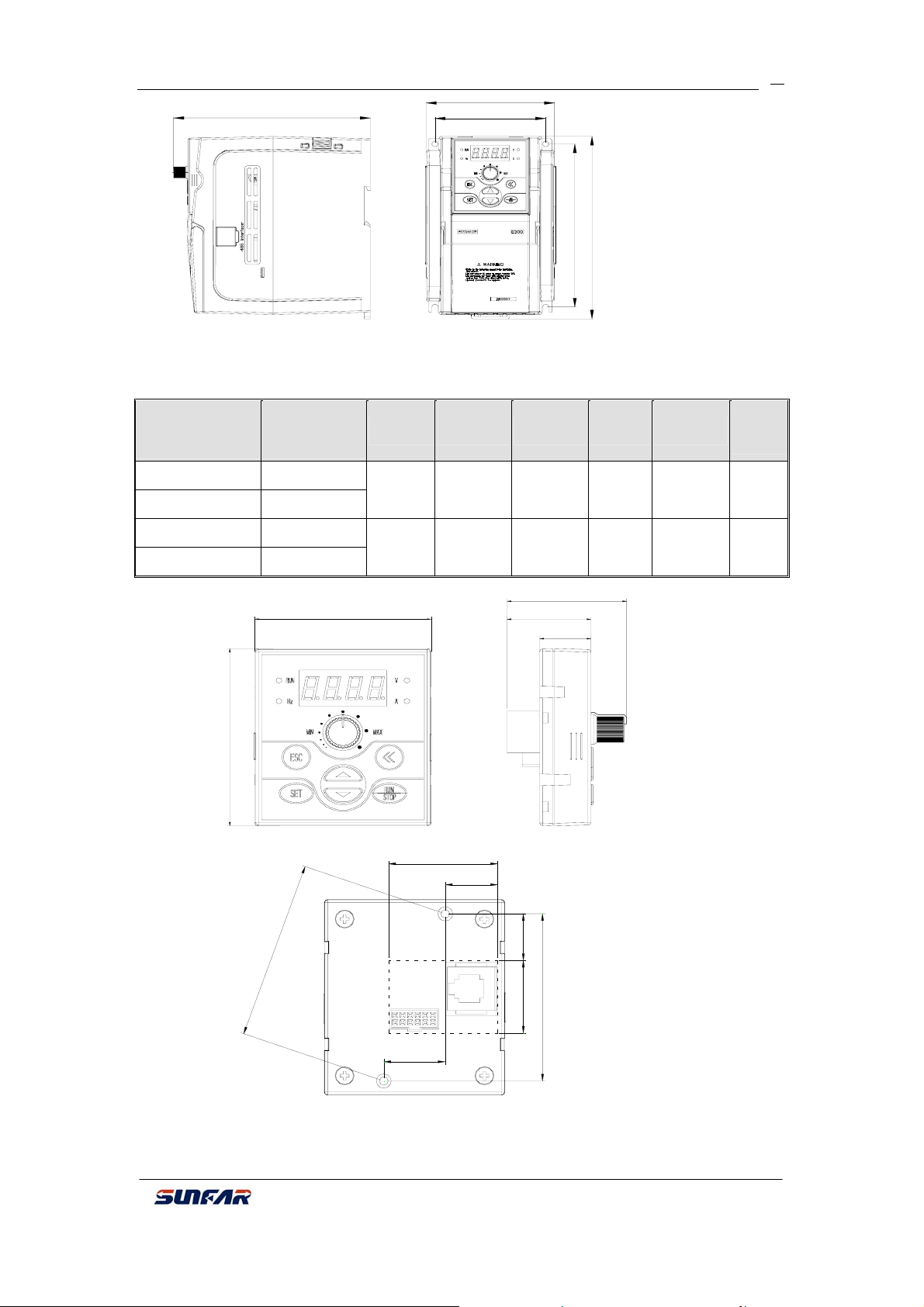

1.3 Appearance

1.3.1 Type One

Suitable model:E300-2S0002

E300

Fig 1-1 Type Ⅰ

E300-2S0004

Series Mini-type Integrated Universal Inverter Manual

Operation

panel

Cover

RS485

inte rfa c e

Control loop

cable input

M a in loop

cable input

Bo tto m

installation hole

Bo tto m side by-side button

SUNFAR E300 SERIES

A

8

1.3.2 Type Two

Operation

panel

Cover

interface

RS485

Control loop

cable input

Main loop

cable input

Fig 1-2 TypeⅡ

1.4 Specification Data

E300 series power range:2S0002 ~2S0015 and 4T0007 ~4T0015。

E300 series specification data and typical function:

Rated volt and

Input

Permissible

volt range

Output

Overload

Endurance

Control Mode V/F control

Suitable model: E300-2S0007~

E300-2S0015/

3 PH(4T****)380V

freq

50/60 Hz

320V ~ 460V 170V ~ 270V

Volt 0 ~ 380V 0~220V

Freq 0~1000 Hz

110% for long-term;150% for 1m; 180% for 2s

Bottom

installation hole

Bottom side-byside buttome

1 PH(2S****)220V

50/60 Hz

on

Analog

Input

Digital

Input

Analog

Input

0.4% of maximum output freq

0.1 Hz

Within 0.4% of maximum output freq

Control

Freq

setting

Resoluti

Freq

Precisio

Characte

ristics

V/F

control

n

Digital

Input

Torque

boost

uto

current

/volt

Within 0.1% of setting freq

Manual set: 0.0~20.0% of rated output

It will check motor stator current and volt automatically based

on special arithmetic to control within allowable range to

ensure minimum failure during acc/ dec or stable running.

limit

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

9

Multi-speed

control

RS485

communication

(E300B series)

Analog

Freq

setting

input

Digital

input

Seven programmable multi-speed control, three multi-speed

control terminal

Standard built-in RS485 interface, RS485 communication

protocol and MODBUS for choice

Panel potentiometer setting, DC volt 0~10V,DC current 0~

20mA

Operation panel setting,RS485 interface setting, UP/DW

terminal control

Relay

and

Typical

Function

Output

Signal

output

Analog

output

Acc /dec time

setting

One OC output and one relay output (TA, TB, TC) as many

OC

as 9 types of choice

One 0~10V volt signal

0.1~600s continuous setting, S curve and linear mode for

choice

DC braking Action freq 0~500.0 Hz, action time 0~20.0 S

Low noise

running

Running

function

Operati

Display

on

panel

display

Protection / warning

function

Runnin

g state

Warnin

Carrier wave freq 1.5 KHz ~ 12.0 KHz continuous

adjustments to ensure the lowest motor noise.

Upper and Lower freq setting, reversal operating restriction,

RS485 communication,, freq increasing/decreasing control

etc.

Output freq, current and volt,motor rotate speed,freq

setting, module temperature,analog I/O

Last four times failure record, output freq, current, volt and

g

DC volt of last fault trip for running parameter record

Over current,over volt, under volt, overheating, short circuit

etc.

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

2 WIRING

2.1 Environmental Requirements:

10

¾ Ambient temperature should be in range of-10 ºC-40 ºC.

¾ Please avoid putting inverter in a high temperature and moist location.

The humidity is less than 90% and non-condensing.

¾ Avoid sunshine directly.

¾ Keep away from combustible, explosive material and caustic gas or

liquid.

¾ No dust, floating fiber and metal particles.

¾ It must be installed in a firm and no vibration location.

¾ Keep away from electromagnetic disturbance.

If users demand any special installation, please contract us firstly.

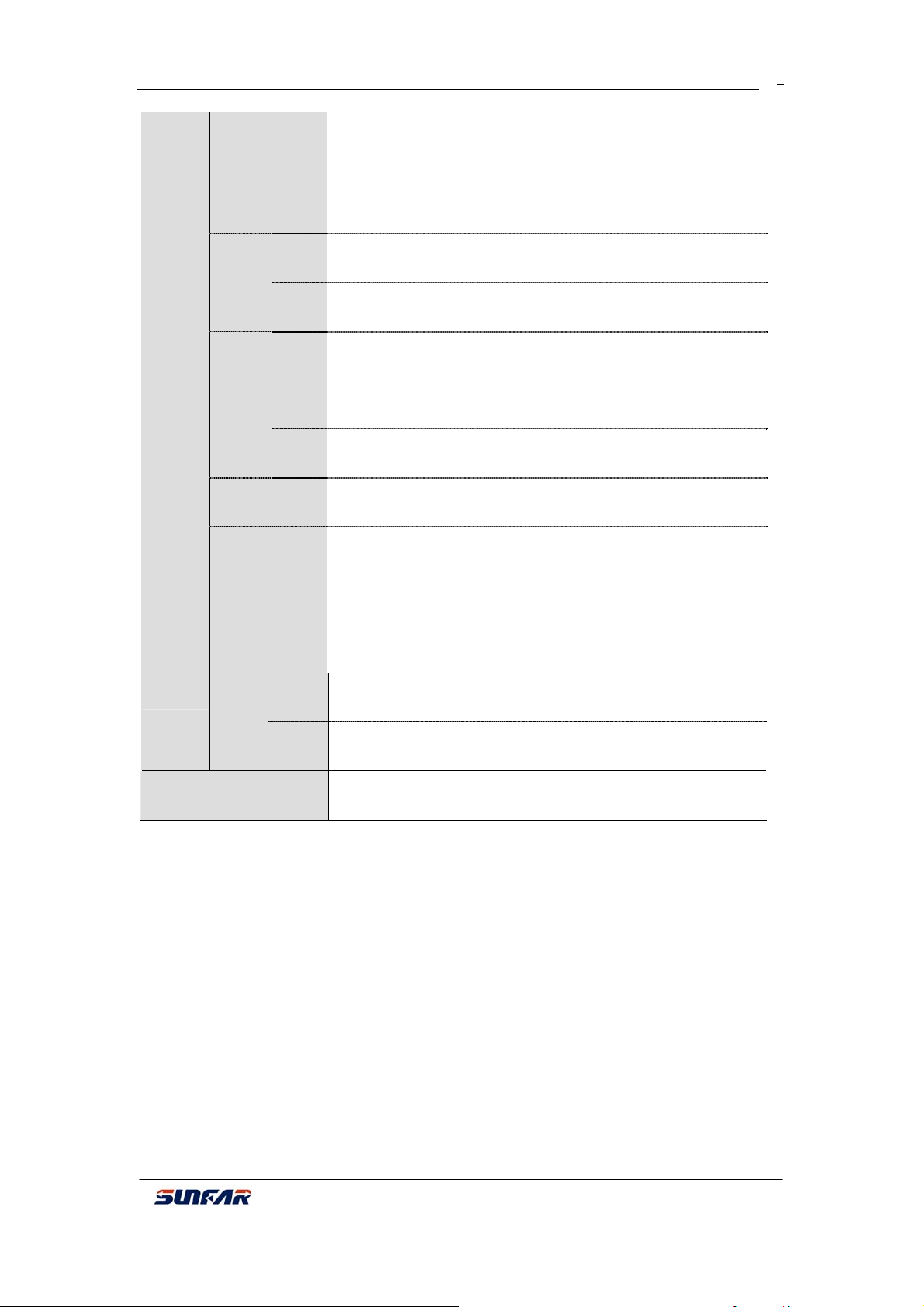

Installation space and distance of single inverter shows as fig 2-1-A that ambience should

be enough space. For several inverter installations, it should adopt guide clapboard to

ensure better cooling between each inverter shown as fig 2-1-B.

Above 50mm

Fan

ventilation

WARNING

!

1.Refer to the instruction manual before installation

and operation.

2.Do not connect AC power to output terminals UVW.

3.Do not remove any cover while applying power

and at least 10min. after disconnecting power.

4.Securely ground(earth) the equipment.

Above 120mm

Above 50mm

Above 120mm

Fig 2-1-A Installation space distance Fig 2-1-B Installation for several inverters

2.2 Installation Dimension

2.2.1 Dimension

Suitable model:E300-2S0002/ E300-2S0004 as fig

D

Fig 2-2-A Inverter installation

E300 Series Mini-type Integrated Universal Inverter Manual

W

W1

H1

H

SUNFAR E300 SERIES

Suitable model:E300-2S0007~2S0015/ E300-4T0007~4T00015 as fig 2-2-B.

D

Fig 2-2-B Inverter installation

E300 series installation dimension:

Model

Model

W1 W H1 H D

(3PH 380V)

(1PH 220V)

W

W1

H

H1

11

Screw

spec

E300-2S0002

67.5 81.5 132.5 148 134.5 M4

E300-2S0004

E300-4T0007 E300-2S0007

86.5 101.5 147.5 165 154.5 M4

E300-4T0015 E300-2S0015

2.2.2 Options Installation Size

68.7

2

.

2

6

Fig 2-2-D Small keypad base installation size

60.7

Fig 2-2-C Small keypad installation size

36.7

17.6

20.7

41.1

28.8

17.6

16.425.5

58.7

Note: When using screw M3, please pay attention to hole place in broken line and hole

size.

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

12

3 WIRING

3.1 Precautions

(1)Install a middle breaker between inverter and power supply avoiding enlarging

accident.

(2)For reducing electromagnetic interface (EMI), please connect surge absorber to

coil of electromagnetic contactors, relays etc.

(3)Freq setting terminal AI, instrument circuit(AO)etc., these analog signals wire

should be over 0.3mm² shield wire. Shield layer is connected with ground terminal CM

less than 30m.

(4)Wiring of relay input and output loop (X1 ~ X3) should choose over 0.75mm²

intertwist or shield wire. Shield layer should be connected to control terminal CM less than

50m.

(5)Separate control wire from main loop wire, parallel wiring should be part over

10cm, and across wiring should be vertical.

(6)Wire of Inverter and motor should be less than 30m. When it is over 30m, it

should decrease inverter carrier wave freq properly.

(7)All down-lead should be tightened with terminals to ensure well-contact.

(8)Compressive resistance of all down-lead should match with inverter volt.

¾ Inverter output terminal U、V、W should not add absorber capacitor or other

RC absorber shown as fig.3-1.

Motor

M

Inverter

U

V

W

RC absorber

Fig 3-1 Output terminal does not allow connecting RC absorber

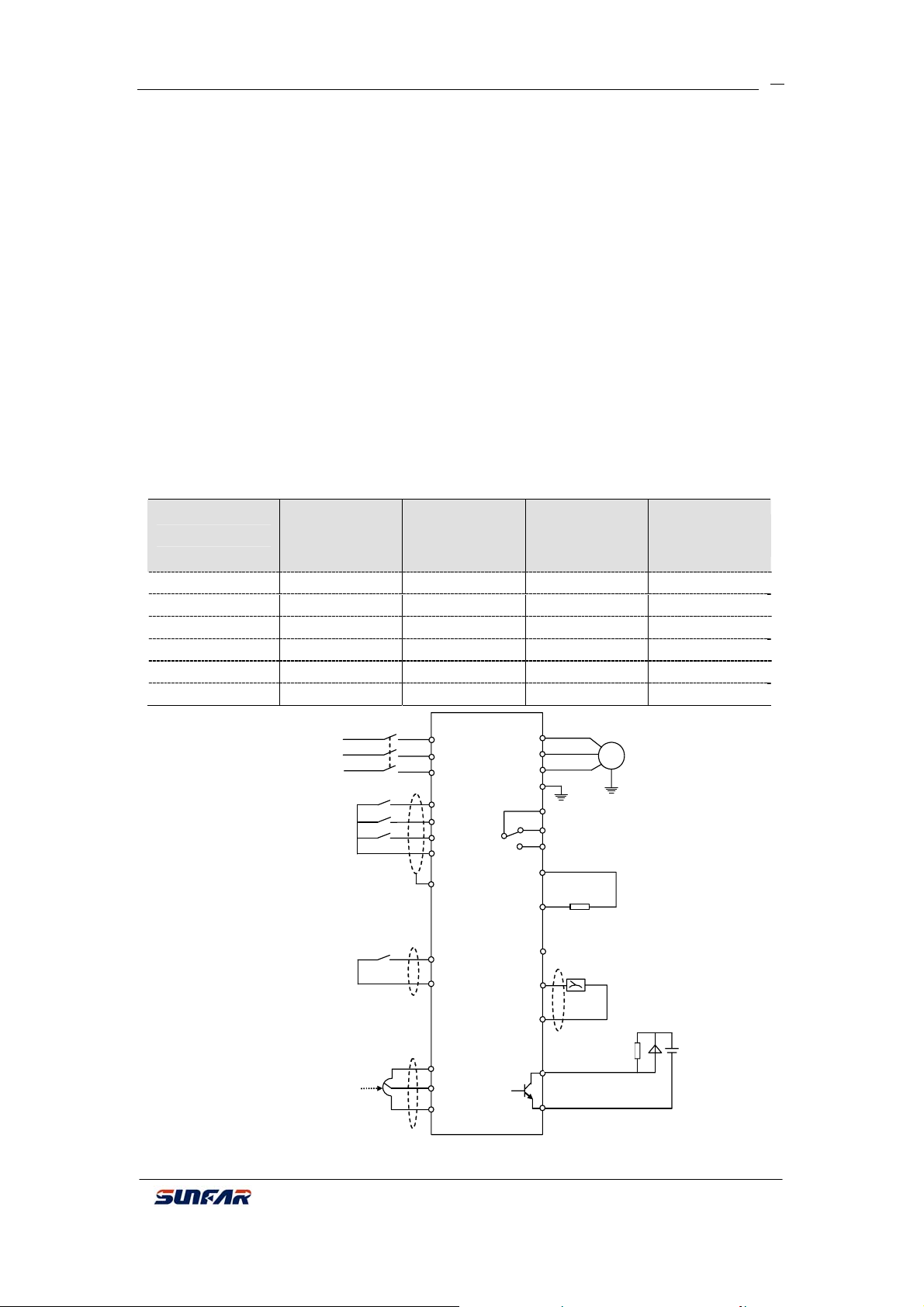

3.2 Wiring of External Components

AC pow er

Air-breaker switch

Contactor

AC re a c to r

Fig 3-2 Inverter wiring

E300 Series Mini-type Integrated Universal Inverter Manual

Braking resistor

PP PB

R/L1

S/L2

! WARNING

1.Refe r to th e in str u ct i on m a nu al b e fore inst alla ti o n

and operation.

2.Do not connect A C power to ou tput term inals UVW .

3.Do not rem ove any c over wh ile appl ying p owe r

T

and at least 10min. a fter disconn e cting pow er.

4.Securely ground(eart h) the equipm ent.

E300

U

V

W

Motor

SUNFAR E300 SERIES

A

M

T

T

T

A

r

A

g

13

Power

Please follow this manual for appointed input power specification.

Air-breaker switch

1. When inverter is in maintenance or long-time nonuse, air-breaker switch isolates

inverter and power supply.

2. When inverter input side has failure of short circuit or power low-volt, air-breaker

switch can take protection.

Contactor

Control power-on and power-off of inverter and load motor.

AC reactor

1. Increase power factor;

2. Reduce power network harmonic wave input from inverter;

3. Weaken imbalance effect on three phase power volt.

Breaking resistor

In the situation of regenerative braking, avoiding bringing volt too high.

Recommended specification for the devices as following:

Wire spec

(main circuit)

(mm2)

Air-breaker

(A)

Magnetic

contactor (A)

Model

pplied motor

(KW)

E300-2S0002 0.25 1.5 10 6

E300-2S0004 0.4 1.5 16 6

E300-2S0007 0.75 2.5 20 12

E300-2S0015 1.5 2.5 32 18

E300-4T0007 0.75 1.0 10 6

E300-4T0015 1.5 1.5 16 12

3.3 Basic Wiring

3PH power

supply

Programmable

input terminal

0~10V(0~20mA)

Freq setting

3PH breaker

×

×

×

FWD

R

S

T

X1

X2

X3

CM

E

FWD

CM

10V

I

CM

U

V

W

E

a

b

Failure alarm output

c

PP

PB

24V Auxiliary DC power

O

CM

Open-circuit

collector output

OC

CM

Motor

~

GND

External brakin

resistor

Vol tmet e

(0~10V)

Fig 3-3 Inverter basic wiring

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

A

A

A

3.4 Wiring of Main Loop Terminal

(1) TypeⅠ(Suitable model: E300-4T0007~E300-4T0015)

Terminal description:

R S T PB PP U V W E

3PH power input

Braking resistor

Motor

Terminal Function Terminal Function

14

GND

Braking resistor can be

connected between PP

and PB.

Connect 3PH AC 380V

motor

PP

R、S、T

Positive terminal of

DC negative

Connect 3PH AC

380V power supply

PB

U、V、W

E GND

(2)Type Ⅱ(Suitable model: E300-2S0002~E300-2S0015)

:

L1

C 220V power

supply input

L2

PB

PP U EW

Braking

resistor

V

Motor

GND

Terminal description:

Terminal Function Terminal Function

Braking resistor can be

connected between PP and

PB.

PP

Positive terminal of DC

negative

PB

L1、L2

Connect 1PH AC 220V power

supply

U、V、

W

Connect 3PH AC 220V

motor

E GND

3.5 Wiring of Control Loop Terminal

(1)Control loop terminal:

TC

X1

X3 CM

OC

FWDTA TB

I10V

E300 Series Mini-type Integrated Universal Inverter Manual

24V

O X2

SUNFAR E300 SERIES

(2)Function description of control loop terminal:

Type Terminal Function Note

Provide +10V(0~20mA)

power

Provide +24V(0~50mA)

power(CM terminal as

this power grounding)

Volt(current)signal input

terminal

Public terminal of input

(output)signal(10V

and 24V power

grounding)

Multi-function input

terminal 1

Multi-function input

terminal 2

Multi-function input

terminal 3

FWD order input

terminal

Programmable volt

signal output terminal

and external voltmeter

(set by [F1.4])

Programmable

open-circuit collector

output set by [F1.11]

Normal TA-TB close and

TA-TC open appointed

function is valid; TA-TB

open and TA-TC close.

Parameter [F1.12]

selects output function.

Power supply

Analog input

Control terminal

Analog output AO

OC

output

Programmable output

10V

24V

AI

CM

X1

X2

X3

FWD

OC

TA

TB

TC

15

0~10V(0~20mA)

Specific function for

multi-function input

terminals, please

refer to parameter

[F1.7] ~ [F1.9] for

setting. Terminal

and CM terminal

close that is valid.

FWD-CM decides

running direction

when panel control

mode. It’s valid when

close with CM

terminal.

Volt signal output 0~

10V

Max load current

150mA, max

endurable volt 24V

Contactor capacity:

AC 250V, 1A resistive

load.

3.6 Wiring of RS485 Interface and External Keyboard

(1)Wiring mode of RS485 interface:

(2)RS485 interface adopts 8P“ crystal pin”

phone line and external keyboard interface

adopts 8P“crystal pin” net line.

Suitable model:E300-2S0002~E300-2S0015/E300-4T0007/E300-4T0015

E300 Series Mini-type Integrated Universal Inverter Manual

-(B)

+(A)

Ext

Ext

ernal keyboard interface

!

WARNING

1.Refer to the instruction manual before installation

and operation.

2.Do not connect AC power to output terminals UVW.

3.Do not remove any cover while applying power

and at least 10min. after disconnecting power.

4.Securely ground (earth) the equipment.

¾ E300B series has communication function. For this using, please refer to

appendix explanation.

¾ When inverter failure, RUN/STOP light on cover will display.

SUNFAR E300 SERIES

RS485 interface

Fig 3-4-A Wiring mode Ⅰ

ernal keyboard interface

Fig 3-4-B Wiring mode Ⅱ

16

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

i

4 PANEL OPERATION

17

Running indicate light

LED display

RUN

Hz

V

A

Return

Up

Set

MIN MAX

ESC

SET

RUN

STOP

LED display data un

sec

%

rmp

Panel potentiometer

Switch

Run, stop, reset

Down

Fig 4-1 Operation panel layout

Note:E300 series keyboard interface can not be compatible with other Sunfar series keyboard. Please do

not use confusedly.

4.1 Key Function Description

Key Function

LED display Display inverter current running state parameter and set parameter.

A、Hz、V

RUN

Data modification key for modifying function code or parameter.

Return key. During normal monitor mode, press this key and enter

ESC

SET

Run and stop order key. When order channel chooses panel control

RUN

STOP

Switch key. During any state for modifying data by data, press this key

Panel potentiometer. When inverter running freq is set by potentiometer

MAXMIN

Corresponding unit of main LED display data

Operation indicator light means there is output volt from output terminal

U, V, W during inverter running.

During monitor mode, if freq order channel is digital set mode [F0.0]=0),

press this key directly to modify freq setting value.

non-normal monitor mode/ monitor parameter check mode which can

check inverter running state parameter. During any operation state,

only press this key that can return to last state.

Set key ensures current state or parameter(parameter stores in inner

storage)and enters next function menu.

[F0.2] =###0), this key is valid. It is trigger key. During inverter stop

state, press this key and start inverter running. During inverter running

state, press this key to input stop order for running. During inverter

failure state, this key as failure reset key.

to choose modified data which may display.

(F0.0=3), you may decrease and increase running freq by rotating

potentiometer knob.

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

N

4.2 Panel Operational Method

(1)State parameter check (eg.)

Return

to

normal

control

ormal monitorDisplay:45.0 Output freq

control

State parameter

check

ESC

State parameter

check

Display:d.0 Monitor code

Display: d.2 Function code

ESC

Parameter check Di sp la y:383 Output volt

Enter p aram eter mo dify

mode (refer to next chapter)

Parameter check

mod e

Display:F0.0 Function code

(2)Parameter check and modify (eg.)

Normal

monitor mode

Display: 45.0 Output freq

Parameter

check

Display:F0.0 F u nction co de

Modify

parameter for

requirement

tore modified

parameter

ESC

Parameter

check

ESC

Parameter

check

Parameter

modify

SET

Parameter

store

Display:F0.1 Function code

Display:45.0 Parameter data

Display:50.0 Parameter data

Display: F 0.1 Function code

4.3 State Monitor Parameter List

SET

18

ESC

Select checked

state parameter

Confirm checked

SET

state parameter

ESC

SET

Select checked/

modified parameter

SET

ESC

ESC

C

o

n

t

i

n

u

e

m

G

i

v

e

u

p

m

o

d

i

f

i

c

a

t

i

o

n

o

d

i

f

y

o

r

r

e

t

u

r

n

Monitor code Content Unit

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

M

19

d-0 Inverter current output freq Hz

d-1

d-2

Inverter current output current(virtual value)

Inverter current output volt(virtual value)

A

V

d-3 Motor rotate speed rpm

d-4 Inverter inner DC volt V

d-5

Inverter input AC volt(virtual value)

V

d-6 Set freq Hz

d-7 Analog input AI V

d-8 Running linear speed

d-9 Set linear speed

d-10 Input terminal state

d-11 Module temperature ºC

d-12 Analog output AO V

d-13 Reserved

d-14 1st failure record

d-15 2nd failure record

d-16 3rd failure record

d-17 4th failure record

d-18 Output freq of last failure Hz

d-19 Output current of last failure A

d-20 Output volt of last failure V

d-21 DC volt of last failure V

4.4 Inverter Simple Operation

4.4.1 Inverter initialization set

(1)Freq input channel selection([F0.0])

Inverter initialization set is different based on each model. Set this parameter as 0, inverter

freq is set by panel number.

(2)Operation input channel selection([F0.2])

Inverter initialization set is different based on each model. Set this parameter as [F0.2]

=###0, inverter stop and startup is controlled by the key of operation panel

4.4.2 Simple Operation

Forbid connect power supply to inverter output terminals U/V/W.

PH power

upply

3PH breaker

×

×

×

R

S

T

U

V

W

E

Motor

GND

Fig 4-2 Wiring of simple running

RUN

STOP

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

20

① Please wire as fig 4-2;

② Be sure correct wiring then power on. Inverter displays “P.oFF”, then “0”;

Be sure [F0.0] = 0③ ;

④ Based on inverter nameplate data for applied motor, please set parameter [F0.12] and

[F0.13];

⑤ Press key to start inverter, and inverter outputs freq 0 and displays “0.0”;

RUN

STOP

⑥ Press key for UP function to increase set freq. Inverter output freq increases and

motor rotate speed increases;

⑦ Check motor running is normal or not. If any abnormal, please stop running immediately

and power-off. Then, check the reasons and run again;

Press key for DOWN function to decrease set freq⑧ ;

⑨ Press key again to stop running and power-off.

Manufacture setting value of carrier wave freq is fixed between 1.5-12KHz. If

motor without load and under high carrier wave freq running, it may cause

slight shock. So, please decrease carrier wave freq value (parameter [F0.8]).

RUN

STOP

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

r

A

A

A

5. PARAMETER LIST

Function Code Name Setting range

0: Digital setting

Freq input channel / mode

F0. 0

selection

F0. 1 Freq digital setting 0.00 ~ upper freq 0.1

Operation channel and mode

F0. 2

selection

F0. 3 Lower freq 0.0 Hz ~ [F0.4] 0.1

F0.4 Upper freq [F0.3] ~ 1000 Hz 0.1

F0.5 Acc time 0.1 ~ 600.0 S 0.1

F0.6 Dec time 0.1 ~ 600.0 S

F0.7 Acc/ dec characteristics paramete

Basic operation parameter unit

F0.8 Carrier wave freq 1.5 ~ 12.0 Khz

F0. 9 Modulate mode 0: Asynchronism 1: Synchronization

F0. 10 Parameter read-in protection

F0. 11 Torque boost

F0. 12 Basic running freq 5.0 Hz ~ upper freq 0.1 50.0

F0. 13 Max output volt 25 ~ 250V, 50 ~500V 1 220, 440

I input lower volt

F1. 0

F1. 1 AI input upper volt

F1. 2 Min setting freq

F1. 3 Max setting freq

F1. 4 Analog output selection 0: Output freq 1: Output current 2: Output volt

O output lower limit 0.0V ~ [F1.6]

F1. 5

O output upper limit [F1.5] ~ 10.0V

F1. 6

Function selection of input terminal

F1. 7

1 (0 ~ 12)

Function selection of input terminal

F1. 8

2 (0 ~ 12)

Function selection of input terminal

F1. 9

I/O Parameter Unit

3 (0 ~ 12)

Reserved

F1. 10

Output terminal OC function

F1. 11

selection

Relay output TA/TB/TC function

F1. 12

selection

1: External input signal (0~10V / 0~20mA)

2: Serial communication terminal (1)

3: Panel potentiometer

4: External terminal selection

1st part of LED:Operation channel selection

0:Control by keypad

1:Control by external terminal

2: Serial communication terminal (1)

2nd part of LED:Operation mode selection

0:Two-line mode 1

1:Two-line mode 2

2:Three-line mode

3rd part of LED:Reversal avoidance

0: Invalid 1: Valid

4th part of LED: Self-startup when power-on

0: Prohibit 1: Allow

0: Linear acc/ dec

1: S curve acc/ dec

1: Only allow to modify parameter F0.1 and this

parameter

2: Only allow to modify this parameter

Other data: all parameter can be allow to modify

0.0 ~ 20.0 (%)

0.0V ~ [F1.1]

[F1.0] ~ 10.0V

0.0 Hz ~ [F1.3]

[F1.2] ~ 1000 Hz

0: Control terminal idle

1: Multi-speed control 1

2: Multi-speed control 2

3: Multi-speed control 3

4: FWD jog control

5: REV jog control

6: Freq setting channel selection 1

7: Freq setting channel selection 2

8: Free stop control

9: Three-line mode running control

10: DC braking control

11: REV control

12: Failure reset

0: During inverter running

1: Freq reach

2: Freq level check (FDT)

3: Overload check out

4: Freq reaches upper limit

5: Freq reaches lower limit

6: During zero speed running

7: Low-volt stop

8: Inverter failure

21

Minimum

Manufacture

Unit

1

1

0.1

1

0.1

1

1 0

0.1 6.0

0.1

0.1 10.0

0.1 0.0

0.1 50.0

1

0.1 0.0

0.1 10.0

1 11

1 1

1 2 ×

1 0

1 8

Setting

3

0.0

1000

0.0

50.0

10.0

10.0

0

8.0

0

0.0

0

Modify

Limit

×

×

×

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

F1.13 Freq reach check out amplitude 0.0~ 20 Hz 0.1 5.0

F1.14 FDT (freq level) set 0.0~1000 Hz 0.1 10.0

F1.15 FDT output delay time 0.0~ 20.0 S 0.1 2.0 ×

F1.16 Overload warning level 50~200(%) 1 110

F1.17 Overload warning delay time 0.0 ~ 20.0 S 0.1 2.0 ×

F2.0 Startup freq 0.0 ~ 50.0 Hz 0.1 1.0

F2.1 Startup freq lasting time 0.0 ~ 20.0 S 0.1 0.0 ×

F2.2 Stop mode 0: Dec stop 1: Free stop 1 0

F2.3 DC braking initial freq when stop 0.0 ~ 500.0 Hz 0.1 3.0

F2.4 DC braking action time when stop 0.0 ~ 20.0 S 0.1 0.0 ×

F2.5 DC braking action volt when stop 0 ~ 50 (%) 1 10

F2.6 FWD jog freq 0.0 Hz~ upper freq 0.1 10.0

F2.7 REV jog freq 0.0 Hz ~ upper freq 0.1 10.0

F2.8 Acc moment level 110 ~ 200 (%) 1 170

Auxiliary running parameter unit

F2.9 Motor overload protection coefficient50 ~ 110 (%) 1 100

Initial volt of dynamic braking

F2.10

(E300B series)

F3.0 Multi-speed freq 1

F3.1 Multi-speed freq 2

F3. 2 Multi-speed freq 3

F3. 3 Multi-speed freq 4

F3. 4 Multi-speed freq 5

F3. 5 Multi-speed freq 6

F3. 6 Multi-speed freq 7

F3. 7 Linear speed coefficient setting

F3. 8 Monitor parameter selection 0 ~ 21 1 0

Parameter check and modification

F3. 9

authority

F3. 10 Parameter initialization

F3. 11 Low-volt protection level

Multi-speed and senior running parameter unit

F3. 12 Over-volt limitation action level

F3. 13 Current limit amplitude level 150 ~ 250 (%) 1 200

F3. 14 Program version 1800 ~ 1899 1 1800

Communication setting (E300B

F4.0

series)

F4.1 Master address (E300B series) 0 ~ 30 1 1

F4.2 Master response delay 0 ~ 1000 ms 1 5

Communication auxiliary function

F4.3

setting

Communication overtime checkout

F4.4

Communication function parameter unit

time (E300B series)

F4.5 Linkage setting proportion 0.1 ~ 10.0 0.1 1.0

300 ~400V

600 ~ 800V

0.0 Hz ~ upper freq

0.0 Hz ~ upper freq

0.0 Hz ~ upper freq

0.0 Hz ~ upper freq

0.0 Hz ~ upper freq

0.0 Hz ~ upper freq

0.0 Hz ~ upper freq

0.01 ~ 10.00

0 ~ 9999 1 1700

0: No action

1: Standard initialization

2: Eliminate failure record

3: Complete initialization

180 ~ 230V

360 ~ 460V

350 ~ 400V

700 ~ 800V

st

part of LED: Baud rate selection

The 1

0: Reserved 1: 1200 bps 2: 2400 bps

3: 4800 bps 4: 9600 bps 5: 19200 bps

The 2nd part of LED: Data format selection

0: No check 1: Even check 2: Odd check

The 3rd part of LED: Protocol selection

0: RS485 protocol

1: MODBUS communication protocol

The 4th part of LED: Reserved

The 1st part of LED: Inverter master and slave set

0: This inverter as slave

1: This inverter as master

The 2ndpart of LED: Action selection if

communication failure

0: Stop 1: Keep state

The 3rd and 4th part of LED: Reserved

0.0 ~ 50.00 Hz 0.01 3.00

1

0.1 35.0

0.1 15.0

0.1 3.0

0.1 20.0

0.1 25.0

0.1 30.0

0.1 35.0

0.01 1.00

1 0 ×

1

1

1 0114

1 0010

370

740

200

400

380

760

22

F4.6 Reserved

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

6 FAULT DIAGNOSIS AND COUNTERMEASURES

6.1 Protective Function and Countermeasures

Code Fault Probable Cause Solution

Fu.01

Fu.02

Fu.03

Fu.04

Fu.05

Fu.06

Fu.07

Fu.08

Over-current

during inverter

acc running

Over-current

during inverter

dec running

Over-current

during inverter

running or stop

Over-volt during

inverter add

ruuning

Over-volt during

inverter dec

running

Over-volt during

inverter running

Over-volt when

inverter stop

Low-volt during

inverter running

1. Acc time is short

2. Motor direct startup during

rotation

3. Set high for torque boost

4. Power supply volt is low

Dec time is short Increase dec time

1. Load occurs mutation

2. Power supply volt is low

1. Input volt is high

2. Power supply is switched

on-off frequently

1. Dec time is short

2. Input volt is abnormal

1. Power supply volt is

abnormal

2. It has energy feedback

load

Power supply volt is

abnormal

1. Power supply volt is

abnormal

2. It has heavy load startup

in power net

1. Prolong acc time

4. Start after motor stop

5. Decrease torque boost volt

6. Check power supply volt and

decrease power

1. Decrease load fluctuation

2. Check power supply volt

1. Check power supply volt

2. Decrease acc torque set

1. Prolong dec time

2. Check power supply volt

3. Install braking resistor or

select braking resistor again

1. Check power supply volt

2. Install braking unit, braking

resistor or select braking

resistor again

Check power supply volt

1. Check power supply volt

2. Power supply separately

23

Fu.09 Reserved

Fu.10 Reserved

Fu.11

Fu.12 Inverter overload

Fu.13 Motor overload

Fu.14

Inverter

disturbance

Inverter

over-heat

Wrong act due to

electromagnetism

disturbance

1.Heavy load

2.Acc time is short

3.Torque boost is high

4.Power supply volt is low

1.Heavy load

2.Acc time is short

3.Protection coefficient set is

low

4.Torque boost is high

1.Fan duct obstruct

2.Environment temperature

is high

3.Fan damaged

1. Reduce load or change for

2. Prolong acc time

3. Decrease torque boost volt

4. Check power supply volt

1. Reduce load

2. Prolong acc time

3. Increase motor overload

protection coefficient [F2.9]

4. Decrease torque boost

1.Clear fan duct or improve

ventilation condition

2. Improve ventilation condition

and decrease carrier wave freq

3.Change fan

Add absorb circuit to inverter

disturbance source

higher power range inverter

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

r

24

Fu.15

-Fu.19

Fu.20

Fu.21

Fu.40

Reserved

Current check

wrong

Reserved

Inner data

memorizer

wrong

Current check equip or

circuit damaged

Control parameter read-in

wrong

1. Check socket line

2. Refer to manufacturer

Refer to manufacturer

6.2 Fault Record Inquiry

E300 series inverter records recent four times failure code and last inverter failure output

parameter in order to find out the reasons.

Please refer to keypad operation way to look for information.

Monitor Item Content Monitor Item Content

d-14 Record of 1st failure d-18 Output freq of last failure

d-15 Record of 2nd failure d-19 Output current of last failure

d-16 Record of 3rd failure d-20 Output volt of last failure

d-17 Record of 4th failure d-21 DC volt of last failure

6.3 Reset

When inverter failure, you may select below ways for resuming normal running:

Ⅰ:When display failure code, press key

Ⅱ:Close external multi-funciton terminal X? (failure reset) and CM, then cutoff.

Ⅲ:Send failure reset order through RS485 interface.

Ⅳ:Cut power off.

¾ Be sure to check failure reasons and exclude it before reset, which may

cause inverter permanent damage.

¾ If can not reset or failure again after reset, please find out reasons. If not, it

may damage inverter.

¾ When overload or ove

-heat protection, please prolong 5 minute to reset.

RU

STONP

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

25

AppendixⅠ:RS485 COMMUNICATION PROTOCOL

1.1 Summary

E300 series derivative models, E300B series supports standard RS485 communication

interface through PC/PLC to reach centralized monitor(send operation order, set inverter

running parameter and read inverter running state) to meet special using requirement. This

protocol is design for above function.

1.1.1 Protocol Content

This serial communication protocol defines transmission information and use format and it

includes master-polling (or broadcasting) format, master coding method. Content includes

function code of action, transferring data and error check. Slave response is the same

structure, and it includes action confirmation, returning data and error check etc. If slave

causes any error while receiving information or cannot finish action by master, it will send

one fault signal to master as a response.

1.1.2 Using Application

1. Suitable product

The protocol is suitable for all Sunfar product series ranges inverter(C300 series, C320

series, E350 series, E380 series, E300 series etc.), which also can be suitable for

communication protocol of some other inverter brands.

2. Suitable mode

(1) Inverter connects to PC/PLC control net of “single master multi-slave” with RS485.

(2) Inverter connects to PC/PLC monitor background of “point to point” with RS485/

RS232 (transition interface).

1.2 BUS Structure and Protocol Description

1.2.1 BUS structure

1. Interface mode

RS485(RS232 for choice, but need level translator)

2. Transmission mode

Asynchronism serial and semiduplex transmission mode. At the same time, only master or

only slave can send data, and the other only can receive data. Data during serial

Asynchronism communication, it would send by a frame to a frame as form of message.

3. Topological mode

In single-master system, there are 32 sites at most, one as master site and 31 slave sites.

The setting range of slave address is 0~30, 31 (1FH) is broadcast communication address.

Slave address must be exclusive in the network. Point to point mode is a special

application as single master and multi-slaves topological mode, which is only one slave

condition.

1.2.2 Protocol description

RS485 communication protocol is a kind of serial master-slave communication protocol,

and only an equipment as master can build protocol in network (named as

“Inquire/Command”). Other equipments as slaves only can provide data to correspond

master “Inquire/Command” or corresponding action for master’s “Inquiry/Command”.

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

26

Master is PC, industrial machine or programmable controller etc, and slave is inverter.

Master not only visits some slave, but also sends broadcast information to all slaves. For

single master “Inquiry/Command”, all slaves will return a signal as response; for broadcast

information provided by master, slave no need offer any feedback to master.

1.Data structure

Three kinds of data transmission for choice:

(1)1 bit start-bit, 8 bit data bits, 1 bit stop-bit and no check bit.

(2)1 bit start-bit, 8 bit data bits, 1 bit stop-bit and even check bit(manufacturing

setting).

(3)1 bit start-bit, 8 bit data bits, 1 bit stop-bit and odd check bit.

2.Baud rate

Five baud rate for choice: 1200bps, 2400 bps, 4800 bps, 9600 bps, 19200 bps

3.Communication mode

(1)Adopt master “poll”, slave “response” point to point communication.

(2)Use inverter keypad sets inverter serial interface communication parameter, including

local address, baud rate and data format.

Master set must be same as inverter baud rate and data format.

4.Communication rule

(1) There are at least 5-byte startup interval time between data frames, only the

message with stated startup internal time is valid.

(2) Mater waiting time and inverter longest corresponding time is 8-byte transmission

time. If longer time, judge as communication failure.

(3) If inverter does not receive any message after communication overtime checkout

time (function code: F4.4), judge as wire-break. Then, based on communication

auxiliary function setting (function code: F4.3), it decides slave running state. (If

receive any message during this time, it will control under it.)

1.2.3 Message structure

Length of each message is between 11~18 bytes(based on data format),Character type

can be ASC code and hex.Ⅱ

Data showing rule: hex, high number before and low number after. Shown as bellow:

(1)ASC code of data 3800HⅡ :

Data place

Data value(hex)

( 2 ) Hex of 3800H: (invalid place as“0”)

Data place

Data value(hex)

9 10 11 12

Set data Set data Set data Set data

33 38 30 30

9 10 11 12

Set

data

Set

data

Set

data

Set

data

00 00 38 00

1. Master command frame

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

yp

sum

Slave

State

State

27

sequence

Definit

This communication protocol defines: 2AH (ASC code of character) and 5AH are Ⅱ

available. When header is 2AH, all data behind header is ASC code. When header is Ⅱ

5AH, all data behind header is hex code and invalid byte fill 0. Unaided headers of 2AH

and 5AH aren’t rightful header. There need waiting time above five bytes before sending

header.

Set range of inverter address:0~30,31(1FH)as broadcast communication address.

(3)Order type

Order type is during master sending data frame for defining action of this frame data.

Based on different order type, frame length is different shown as below:

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Send

Slave

Slave

Header

Slave

ion

2.Slave corresponding frame

General data definition description for data frame

sequence

Send

efinition

(1)Header

(2)Slave addr.

addr.

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Header

Data Operation

0 Read slave state and characteristics information

1 Read slave running parameter

2 Read function code parameter

t

e

Slave

Slave addr.

O n

Operation

peratio

Order

order

order

Order area Addr. area Data area Check area 0DH

feedbac

corresp

Slave

feedbac

Corresponding

area

Data type

Data addr.

Data addr.

Set data

Set data

Set data

Set data

R nninu

R nninu

R nninu

Data

Data

Data

Addr.

area

Data area Check area 0DH

R nunni

C k hec

C k hec

C k hec

C k hec

C k hec

C k hec

Check

Check

Tail

Tail

3

4 Send control order

5

6~F

(4)Operation order

Master gives control order to slave and it exists in all types of data frame (master sends

4th and 5th)shown as bellow:

Data Operation Data Operation

00H Invalid order 10H Set slave running freq

01H FWD running startup 11H

Modify inverter RAM area function code parameter, it will not

save if power-off (no storage)

Modify inverter EPROM area function code parameter, it will save

if power-off

Reserved

FWD running startup with running freq

set

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

28

02H REV running startup 12H

REV running startup with running freq

set

03H Stop 13H Stop with running freq set

04H Slave FWD jog 14H FWD jog running with running freq set

05H Slave REV jog 15H REV jog running with running freq set

06H Jog running stop 16H Jog stop with running freq set

…

…

…

…

20H Slave failure reset 30H Reserved

21H Slave urgent stop 31H Reserved

(5)Slave correspond

Slave data correspond to master is for action feedback of master order frame. It exists in

all type data frame shown as below:

Data Definition Data Definition

Slave receives data for normal

0

operation

Slave running prohibit modifying

2

data

1

3

Receive data beyond range

Data modification prohibited by

password

Try to read, reserve or hide

4

parameter

5

Reserved

When adopt ASC code Ⅱ

Appointed parameter code or

6

invalid address(beyond limitation)

Invalid order type or operation

8

order

When slave corresponding byte data is “6~8”, frame length of corresponding

frame is 11 byte.

7

9~F

transmission data, it exists

invalid ASC code characterⅡ

Reserved

Frame format is shown as below:

correspo

Slave

nd

Definition

0 1 2 3 4 5 6 7 8 9 10

addr.

Slave

addr.

Slave

Header

Slave addr.

corres

pond

Slave

0 0

Order/ corresponding

area

sum

Check

sum

Check

sum

Check

sum

Check area 0DH

Check

Tail

(6)State feedback

Slave sends back slave basic running state to master, which exists in all type data frame.

(Slave feedback 4

th

and 5th)shown as below:

Data Operation Data Operation

00H

Slave DC volt does not

prepare well

10H Reserved

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

Sl

01H Slave FWD running 11H FWD acc

02H Slave REV running 12H REV acc

03H Slave stop 13H Abrupt stop then startup

04H Slave FWD jog running 14H FWD dec

05H Slave REV jog running 15H REV dec

06H Reserved 16H Slave is during DC braking state

20H Slave is during failure state 21H Slave urgent stop

(7)Check sum

ASC code value (ASC code format) / hex data sum from slave address to set data/ ⅡⅡ

running data.

(8)Tail

Hex“0DH”,that’s ASC code of “CR”Ⅱ 的 ASCⅡ

When slave failure and state feedback data is“20H”, feedback data frame 7th and 8th

data(data addr.)as failure code.

29

1.3 Frame Format Description

1.3.1 Order type 0 ―Read slave state and characteristics information

Master sends frame length 14 byte, slave corresponding frame length 18 byte.

Note: Slave offer different feedback of character information because of different

When master sends header, tail or check sum of data frame abnormal, slave maybe

can not be normal correspond.

Master send

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Header

addr.

Slave

addr.

Slave

0

Operatio

n order

Operatio

n order

type

Data

sum

Check

sum

Check

sum

Check

sum

Check

00

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Slave addr.

ave

Header

Slave addr.

Slave

State

Data type

State

Character

Character

Character

Character

Character

Check sum

Character

Check sum

Check sum

data value of master sending frame.

Tail

Check sum

Tail

Data Type

(master send)

Character Information(slave correspond)

6 7 8 9 10 11 12

0

Read

slave

Volt class 0 Power Power Power Power

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

yp

yp

p

data

30

model

info.

Read

1

slave

model

Reserved Reserved Reserved Reserved Reserved Reserved

info.

Read

2

slave

Reserved Reserved # # # #

version

Read

3

slave

operation

Master

control

Master

freq set

Reserved Reserved Reserved Reserved

info.

4~

Reserved # # # # # #

F

Eg. If master sending frame data value is zero, slave corresponding information is 400015.

It means: 4 as volt class, 380V;0 as charater information value;0015 as power, 1.5Kw.

1.3.2 Order type 1―――Read slave running parameter

Master sending frame length is 14 byte, and slave corresponding frame length is 18 bytes.

send

Header

addr.

Slave

addr.

Slave

1

order

on

Operati

order

on

Operati

0

C k

hec

sum

Check

Data

t

t

e

e

C k

Data

sum

hec

sum

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Master

corres

ond

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Slave

Header

Slave addr.

correspond

feedback

Slave

feedback

State

State

Data type

Data type

R ng

R ng unni

data

R ng

unni

unni

Check sum

Check sum

Running

Check sum

Slave addr.

0

Data type: For inverter monitor parameter item, E300 series monitor parameter item as

follow:

Monitor Item Data type Slave Feedback Value

d.0 00 Output freq

d.1 01 Output volt

...

d.15 15 The 2nd failure record

..

.

...

..

.

...

..

.

sum

Check

Check sum

Tail

Tail

d-21 21 The last failure DC current

Please refer to E300 series manual chapter four, 4.3 state monitor unit to check

inverter monitor parameter.

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

M

t

Slave

eedbac

Ch

k

Slave

F

31

1.3.3 Order type 2―――Read function code parameter

Master sending frame length is 14 byte, and slave corresponding frame length is 18 byte.

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Slave addr.

Slave

Slave addr.

correspon

Slave

order

2

f

State

k

Header

as

er

correspond

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Slave

H eread

Please refer to order type 3 and 5 for data type and data addr.

Operation

State

order

Data type

Operation

Data addr.

Data type

Data addr.

Data addr.

Pa ter rame

Data addr.

Pa ter rame

Check sum

Pa ter rame

Check sum

Pa ter rame

Check sum

C k hec

Check sum

C k hec

Tail

C k hec

1.3.4 Order type 3―Modify RAM area function code parameter

1.3.5 Order type 5―Modify EPROM area function code parameter

Master sending frame length is 18 byte, and slave corresponding frame length is 18 byte.

Master send

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Op on erati

Operation

Header

Slave

Slave

3

order

Data

or

5

Data type

Data

Set data

Set data

Set data

S ta et da

C k

hec

sum

C k

hec

Check

Tail

ec

Check

Tail

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Slave

Header

Slave

correspon

Slave

State

State

Data type

Data addr.

Data addr.

Set data

Set data

Set data

S ta et da

C k

hec

C k hec

Data type definition:

Function

code unit

F1 F2 F3 F4 F5 F6 F7 F8 F9 FC FE FF FH FL FP

Data type 01 2 3 4 5 6 7 8 9 A B C D E F

Function code relative addr.: eg. Data addr. of F0.8、F1.8、F2.8、F#.8 is 8, but different data

type.

Note: When slave can not finish master order, feedback setting data is 0000.

1.3.6 Order type 4―――Send control order

Master sending frame length is 15 byte, and slave corresponding frame length is 18 byte.

For normal operation, this kind of frame is most suitable.

e

r

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

C k hec

Check

Tail

E300 Series Mini-type Integrated Universal Inverter Manual

C

p

Slave

r

sum

heck

C k

hec

32

SUNFAR E300 SERIES

Operatio

Operatio

Header

corres

ond

Set data of master sending frame is set freq from master sending to slave.

Running data of slave corresponding frame is master sending running parameter which

decides by set content from monitor item (function code: [F3.8]) in inverter function

parameter unit, meantime, slave feedback this item monitor value.

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

Slave

H er ead

Please refer to E300 series manual chapter five, function parameter unit, to check inverter

function parameter unit.

addr.

Slave

Slave

addr.

Slave

Slave

4

correspon

State

n order

n order

State

Set data

M or

onit

0

Set data

M or

onit

Set data

Set data

sum

R ng

R ng

unni

R ng

unni

unni

C

sum

heck

R ng

unni

C

sum

heck

C k

hec

Check

C k

hec

Tail

Check

Tail

1.4 Example

1.4.1 Read slave state and character information (order type 0)

Data set: read slave model.

Master

Explain Header Addr. 00 0 order No data type Adding hex Tail

Data return: model is 2S0004.

Slave

return

Digit 1 2 1 2 1 6 4 1

Explain Head

Header

send

Digit 1 2 1 2 1 2 4 1

2A 30 30 30 30 31 30 30 30 0D

Eg.

5A 00 00 00 00 01 00 00 00 0D

Head Slave State Data Character

er addr. feedback type information

2A 30 30 30 30 33 30 0D

Eg.

5A 00 00 00 00 03 00 0D

er

Slave Order Operation Data

addr. type order type

Running

startup

Slave

corresp Check sum Tai l

ond

0

slave

return

Slave

receive

data

Slave stop

state

No

data

type

Data type Check sum Ta i l

32 30 30 30 32

30 30 34 34 39

02 00 00 00 00

00 00 04 00 09

02-volt class 2S

04 - powe

0.4KW

Adding hex or

adding algorism

30 31

38 31

00 00

00 01

Ta il

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

1.4.2 Read slave running parameter (order type 1)

Data set: read d-6(present set freq).

33

Master

send

Explain Header Addr. 00 1 order

Data return: return to present set freq 50.0 Hz.

Slave

return

Explain Header

Header

Digit 1 2 1 2 1 2 4 1

Eg.

Digit 1 2 1 2 1 2 4 4 1

Eg.

2A 30 30 31 30 30 30 30 36 30 31 38 37 0D

5A 00 00 01 00 00 00 00 06 00 00 00 07 0D

Header

2A 30 30 30 30 33 30 30 36

5A 00 00 00 00 03 00 00 06

Slave

addr.

Slave

addr.

0 slave

return

Order

type

Slave

correspond

Slave

receive

data

Operation

order

Invalid

order

State

feedback

Slave

stop[

Data type Data type Check sum Ta il

D

parameter

unit

Display

parameter

D

Parameter

unit

D

parameter

Data

type

No data

type

Adding hex Tail

Running

data

30 31

46 34

00 00

01 F4

Set freq

50.0 Hz

Adding

Check

sum

30 32

36 34

00 00

00 FE

hex

Ta il

0D

0D

Ta il

1.4.3 Read function code parameter (order type 2)

Data set: read parameter [F0.8]

Master

send

Explain Header Addr. 00 2 order

Data return: carrier wave freq [F0.8]=8.0KHz.

Slave

return

Header

Digit 1 2 1 2 1 2 4 1

2A 30 30 32 30 30 30 30 38

Eg.

5A 00 00 02 00 00 00 00 08

Header

Digit 1 2 1 2 1 2 4 4 1

2A 30 30 30 30 33 30 30 38

Eg.

5A 00 00 00 00 03 00 00 08

Slave

addr.

Slave

addr.

Order type

Slave

correspond

Operation

order

Invalid

control

order

State

feedback

Data type Data addr.

F

parameter

unit

Data type

Data

type

F

parameter

Return

data

30 30

35 30

00 00

00 50

Check

sum

30 31

38 41

00 00

00 0A

Adding

hex

Check

sum

30 32

35 30

00 00

00 5B

Ta il

0D

0D

Ta il

Ta il

0D

0D

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

34

Explain Header

0 slave

return

Slave

receive

data

Slave

stop

state

F0

Parameter

unit

F0.8

Return

data as

8.0KHz

Adding

hex

Ta il

1.4.4 Modify RAM area function code parameter (order type 3)

Data set: modify data set freq [F0.1]=50.0Hz, not keep when stop.

Master

send

Digit 1 2 1 2 1 2 4 4 1

Explain Header

Data return: data correct set.

Slave

return

Explain Header

Header

2A 30 30 33 30 30 30 30 31

Eg.

5A 00 00 03 00 00 00 00 01

Header

Digit 1 2 1 2 1 2 4 4 1

Eg.

Slave

addr.

Addr.

Slave

2A 30 30 30 30 33 30 30 31

5A 00 00 00 00 03 00 00 01

0 slave

return

00

addr.

Order

3 order

Operation

type

Slave

correspond

Slave

receive

data

order

Invalid

control

order

feedback

Slave

Data type Data type Set data

F0

Parameter

unit

State

stop

state

Data type

Parameter

F0. 1

Parameter

Data

addr.

F0

F0.1

unit

30 31

46 34

00 00

01 F4

Set freq

50.0Hz

Set data

30 31

46 34

00 00

01 F4

Set data

50.0HZ

Check

sum

30 32

35 46

00 00

00 F9

Adding

hex

Check

sum

30 32

35 46

00 00

00 F9

Adding

hex

Ta il

0D

0D

Ta il

Ta il

0D

0D

Ta il

1.4.5 Send control order (order type 4)

Data return: set slave 0 inverter FWD running freq 10.0 Hz.

Master

send

Digit 1 2 1 2 4 4 1

Eg.

Explain Header Addr. 00 4 order

Data return: 0 inverter receives data normally.

Slave

return

Digit 1 2 1 2 1 2 4 4 1

Header Slave addr. Order type

2A 30 30 34 31 31

5A 00 00 04 00 11

Header

Slave

addr.

Slave

correspond

feedback

State

Operation

order

FWD with

freq set

0

Set data Check sum Tail

30 30

36 34

00 00

00 64

Set freq

10.0 Hz

Monitor

item

Running

30 31

43 30

00 00

00 79

Adding hex Tail

Check

data

sum

0D

0D

Ta il

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

35

2A 30 30 30 30 31 30 30 30

Eg.

5A 00 00 00 00 01 00 00 00

Explain Header

0

slave

return

Slave

receive

data

Slave

FWD

running

Fixed

data

Present

display

monitor

d-0

30 30

36 34

00 00

00 64

Data set

successfully

30 32

34 42

00 00

00 65

Adding

hex

0D

0D

Ta il

1.4.6 Modify EEPROM parameter (order type 5)

Data send: modify torque boost [F0.11]=6.0, store when stop.

Master

send

Digit 1 2 1 2 1 2 4 4 1

Explain Header

Header

2A 30 30 35 30 31 30 30 41

Eg.

5A 00 00 05 00 01 00 00 0B

Slave

addr.

Addr.

Order

type

00 5 order

Operation

order

Slave

FWD

running

Data type Data type

F0

Parameter

unit

F0.11

Parameter

Set

data

30 30

33 43

00 00

00 3C

Data

set

Check

sum

30 32

36 44

00 00

00 4D

Adding

hex

Tail

0D

0D

Tail

Data return: slave receives data normally.

Slave

return

Explain Header

Header

Digit 1 2 1 2 1 2 4 4 1

Eg.

Slave

addr.

2A 30 30 30 30 31 30 30 41

5A 00 00 00 00 01 00 00 0B

0 slave

return

Slave

correspond

Slave

receive

data

State

feedback

Slave

FWD

running

Data type

F0

Parameter

unit

Data

addr.

F0.11

Set data

30 30

33 43

00 00

00 3C

Data set

successfully

Check

sum

30 32

36 38

00 00

00 48

Adding

hex

Ta il

0D

0D

Ta il

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

r

36

AppendixⅡ:MODBUS PROTOCOL

1. Communication Set

F4.0=X1XX, choose MODBUS RTU protocol;

F4.0=X0XX, choose RS485 protocol.

Note: X means as random number.

2. Communication Function

It is for master and inverter communication, including sending inverter operation order,

modification function code parameter and read inverter running state, monitor parameter,

failure information and function code parameter.

3. Protocol Format

code

ADU

PDU

Data

CRC

checkout

>3.5 character

transmission

interval

MODBUS RTU format

>3.5 character

transmission

interval

Slave addr.

Function

1.1 Protocol Format Explanation

1. Slave addr.

0 as broadcast addr., and slave addr. can be set as 1~30.

2. PDU part

(1)Function code 03: Read several inverter function parameter, running state,

monitor parameter and failure information at most for reading six addr. serial

inverter parameter.

Master send:

PDU part 03

Data length (Byte) 1 1 1 1 1

Slave correspond:

PDU part 03

Data length (Byte) 1 1 2* register number

(2)Function code 06: Modify single inverter operation order, running freq and

function parameter.

Master send:

PDU part 06

Data length (Byte) 1 1 1 1 1

Register initial addr. Register number

High order Low order High order Low order

Read byte number(2* registe

number)

Register initial addr. Register data

High order Low order High order Low order

Read content

Slave correspond:

PDU part 06

Data length (Byte) 1 1 1 1 1

Register initial addr. Register data

High order Low order High order Low order

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

(3)Function code 10: Modify several inverter operation order, running freq

and function parameter.

Master send:

37

Register initial addr. Register number

PDU part 10

Data length

(Byte)

Slave correspond”

PDU part 10

Data length(Byte)

Note: Inverter stores from register of lowest addr. to highest addr. at most six function

code. If any wrong, slave will correspond demurral.

Demurral correspond:

PDU part Demurral code

Data length (Byte) 1 1

Demurral code means failure type:

Demurral code Corresponding failure

01 Invalid function code

02 Invalid data addr.

03 Data beyond limitation

04 Slave invalid operation

20 Read too much parameter

21 Read stored and hided parameter

22 Slave running prohibits modification data

23 Data modification by password protection

24 Read parameter failure

CRC checkout:

High

order

1 1 1 1 1 1

1 1 1 1 1

Low

order

Register initial addr. Register number

High order Low order High order Low order

0x80+ function code

High

order

Low

order

Content byte

number

Register

content

2* register

number

CRC checkout CRC low order CRC high order

Data length (Byte) 1 1

CRC checkout function as follow:

unsigned int crc_chk_value(unsigned char *data_value, unsigned char length)

{

unsigned int crc_value=0xFFFF;

int i;

while(length--)

{ crc_value^=*data_value++;

for(i=0;i<8;i++)

{ if(crc_value&0x0001)

crc_value=( crc_value>>1)^0xA001;

else

crc_value= crc_value>>1;

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

}

}

return(crc_value);

}

3. Communication Parameter Addr. Definition

Inverter parameter addr. distribution

Register definition Register addr. space

High order as function code unit number, and low order as

Function parameter

(1)

function code tab. Eg., F1.11, the register addr. is F10B.

38

Monitor parameter

Operation order

(2)

High order as 0xD0, and low order as monitor tab. Eg., d.12,

the register addr. is D00C.

0x1001

Freq set 0x1002

Inverter state

Failure information

(3)

(4)

0x2000

0x2001

Note: (1) EEPROM may decrease its using life if write function code parameter frequently.

For some parameter communication mode, it no need to store and only modify RAM value

is ok. When write function parameter RAM value, only change F in register high order addr.

into 0. If write RAM value of F1.11, the register addr. Should be 010B, but figured way of

this register addr. can not use for reading inverter function parameter.

(2) Corresponding operation order of operation order code:

Operation order code Operation order

0x0000 Invalid order

0x0001 FWD running startup

0x0002 REV running startup

0x0003 Stop

0x0004 Slave FWD jog

0x0005 Slave REV jog

0x0006 Jog running stop

0x0020 Slave failure reset

(3) Inverter state:

Inverter state code Meaning

0x0000 Slave DC volt unprepared well

0x0001 During slave FWD running

0x0002 During slave REV running

0x0003 Slave stop

0x0004 During slave FWD jog running

0x0005 During slave REV jog running

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

0x0011 During FWD acc

0x0012 During REV acc

0x0013 Instantaneous stop then startup

0x0014 FWD dec

0x0015 REV dec

0x0016 Slave during DC braking state

0x0020 Slave during failure state

(4) High order of failure information code is 0, and low order corresponds to behind tab of

inverter failure code Fu., eg. Failure information code is 0x000C, which means inverter

failure code is Fu.12.

39

1.2 Example

1.Start 1# inverter FWD running

Master claim:

Slave

addr.

01 06 10 01 00 01 1D 0A

Slave correspond: Inverter FWD running returns to same data for master claim.

2. Set inverter running freq as 50. 0 Hz

Master claim:

Slave

addr.

01 06 10 02 01 F4 2C DD

Slave correspond: inverter running for 50.0 Hz returns to same data for master claim.

3. Read inverter current running freq, output current, inverter corresponding freq 50.0 Hz

and output current 1.1A.

Master claim:

Slave

addr.

01 03 D0 00 00 02 FC CB

Function code

Function code

Function code

Register initial addr. Register data CRC checkout

High

order

Register initial addr. Register data CRC checkout

High

order

Register initial addr. Register number CRC checkout

High

order

Low

order

Low

order

Low

order

High

order

High

order

High

order

Low

order

Low

order

Low

order

Low

order

Low

order

Low

order

High

order

High

order

High

order

Slave correspond:

Slave

addr.

01 03 04 01 F4 00 0B FB FA

4. Start 1# inverter FWD running and set inverter running freq as 40 Hz.

Master claim:

Slave Function

Function

code

Register Register

Read

character

number

1st register data 2nd register data CRC checkout

High

order

Low

order

Content

High

order

1st register 2ndregister CRC

Low

order

Low

order

High

order

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

40

initial addr. number data data checkout

addr. code

01 10 10 01 00 02 04 00 01 01 90 AF 9F

Slave correspond:

Slave

addr.

01 10 10 01 00 02 14 C8

High

Low

order

order

Function code

High

Low

order

order

Register initial addr. Register number CRC checkout

High

order

byte

number

Low

order

High

order

High

order

Low

order

Low

order

High

order

Low

order

Low

order

Low

order

High

order

High

order

E300 Series Mini-type Integrated Universal Inverter Manual

SUNFAR E300 SERIES

41

Appendix BRAKING RESISTORⅢ

During inverter running, if speed of controlled motor decreases too fast or shock of motor

load too fast, its feedback energy may generate power into inverter capacitance that

would cause damage of inverter itself. Inverter inner control will restrict based on load. If

braking performance can not reach requirement, it needs external braking resistor to

achieve energy release in time. External braking resistor as energy consuming mode

would consume for power braking resistor. If so, power of braking resistor should select

suitably. Below is SUNFAR recommended braking resistor power and resistor value.