Page 1

DROPS

D4.1

Air / Water

Heat Pump

Operating manual and assembly

Version 1.2 19012017

Effect from serial number: 164010111

Page 2

Page 3

-3-

Table of contents

1. Description of Heat Pump 4

2. Construction of Heat Pump 4

3. Installation of Heat Pump 5

3.1 Precautions during installation of the device 5

3.2 Installation recommendations 5

3.3 Connection of hydraulic circuit 5

3.4 Connection of air ducts 5

3.5 Electrical connection 7

3.6 Installation diagram 7

4. Description of controller functions 7

4.1 Control of actuators 8

4.2 Safety 8

4.3 Clock settings 8

4.4 Date settings 8

4.5 Screen settings 8

4.5.1 Screen brightness 8

4.5.2 Screen saver brightness 8

4.6 Programme information 8

5. Installer menu 8

5.1 Tank set point temperature 8

5.2 Anti-freezing 8

5.3 Weekly schedule active 9

5.4 Weekly control of heat pump operation with different levels of temperature 9

5.5 Circulation pump 9

5.6 Language 9

5.7 Service menu 9

5.8 Manual operation 11

5.9 LEGIONELLA settings 11

5.9.1 LEGIONELLA temperature 11

5.9.2 LEGIONELLA duration 11

5.9.3 Maximum LEGIONELLA time 11

5.9.4 LEGIONELLA reminder 11

5.10 Evaporator defrost 11

5.11 Minimum operating temperature 11

5.12 Hysteresis of minimum operating temperature 12

5.13 Heater operation below minimum operating temperature 12

5.13.1 Hysteresis of set point temperature 12

5.13.2 ECO-ECO PLUS threshold temperature 12

5.13.3 Hysteresis of ECO-ECO PLUS threshold 12

5.14 Installation protection 12

5.15 Emergency temperature 12

5.16 Delay compressor 12

5.17 Clear alarm of control temperature 12

5.18 Edit service phone number 12

5.19 Change service code 12

5.20 Factory settings 12

5.21 Sleep Mode 13

6. Security and Alarms 13

7. Maintenance 13

8. SG Ready function 13

9. The procedure after the shelf life of the device 13

10. Hydraulic diagrams 14

10.1 Refrigerant circuit illustration 16

11. Technical data 17

12. Start-up protocol ( 19

13. Start-up protocol ( 21

Copy for the Investor)

Copy for the Manufacturer)

Page 4

Heat pump DROPS D4.1 is a device for utility water heating. It uses the rotary compressor optimised for high

condensation temperatures, i.e. High heating temperatures of utility water. The air flow via the finned coil is forced by

modern, powerful and energy efficient EBM PAPST fan. Water heating is in the SWEP plate exchanger of stainless

steel, and a water circulation is forced by the installed in the heat pump the WILO circulating pump adapted also to work

directly with utility water. The correct operation of the heat pump is ensured by the controller with algorithm optimized for

the heat pump DROPS D4.1 construction. The housing is made of ABS plastic. All the above mentioned

characteristics/components comprise the high quality and efficiency of the heat pump.

Any operations not described in this manual must be carried out in accordance with the accepted rules of installation

knowledge.

1. Description of Heat Pump

2. Construction of Heat Pump

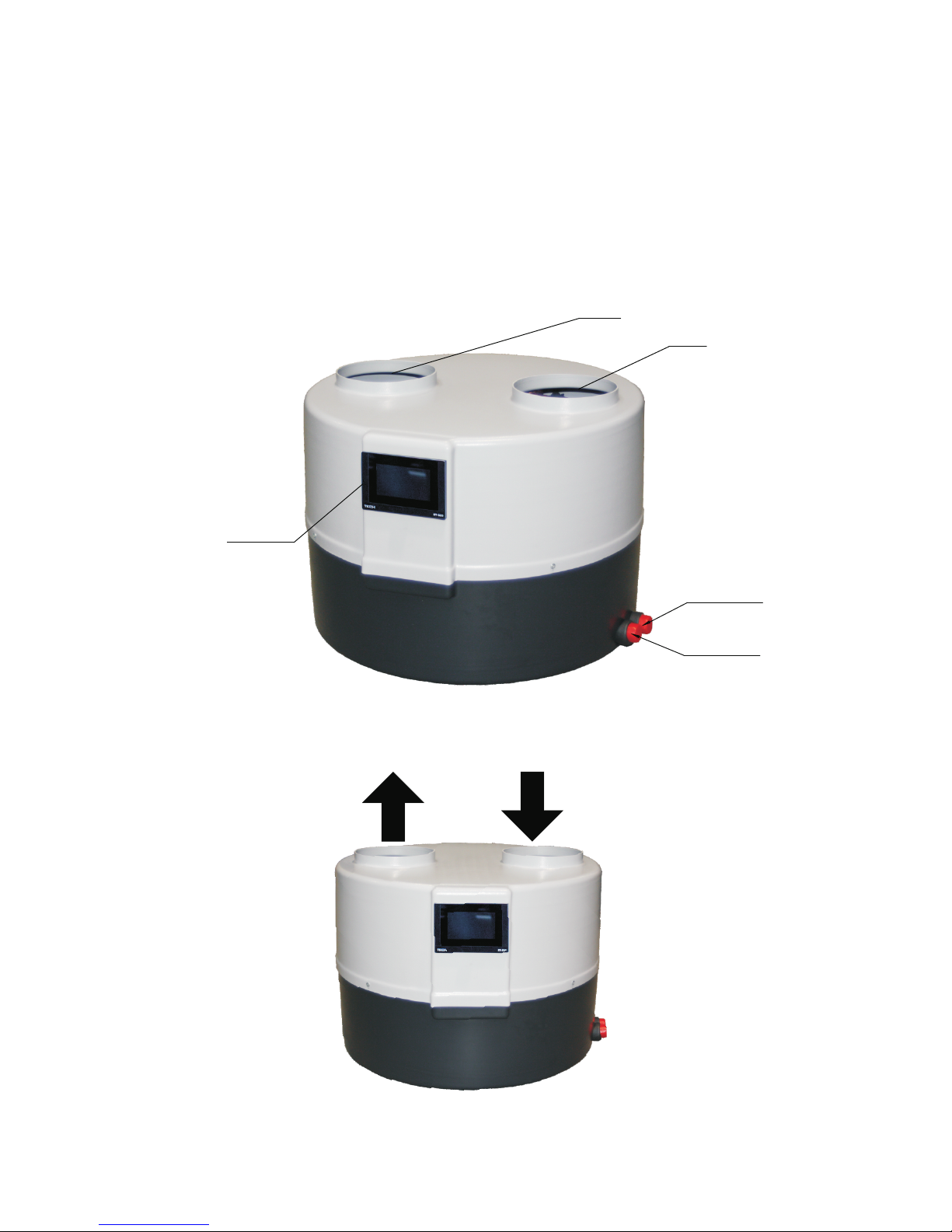

Control panel

Air inlet

Air outlet

Hot water outlet

Cold water inlet

The power cord is located on the back of the unit

Air outlet Air inlet

-4-

Page 5

The heat pump DROPS D4.1 should be installed in a room where the temperature does not drop below + 5°C. Where

there is a risk of the temperature drop below 5°C, drain the water circulation between the heat pump and the storage

tank and blow out well the installation, e.g. with compressed air.

Level the heat pump during the assembly with the legs of adjustable height. Failure to comply with this

recommendation may result in a defective work and eventually damage to the equipment.

Keep away from divisions (walls ceilings etc.) for smooth maintenance work on the pump heat.

In the lower part of the pump heat housing there is a condensate discharge nozzle to which the hose outlet should be

connected. It is recommended to drain the condensate to the sewage system and to use a siphon.

The heat pump has a built-in automatic air vent that ensures the condenser venting and also the whole heating loop.

The pipeline between the heat pump and the storage tank must have an internal diameter of 20 mm.

On the water return to the heat pump pipeline install an angled filter!!!

The pipelines should be isolated on the whole length!!!

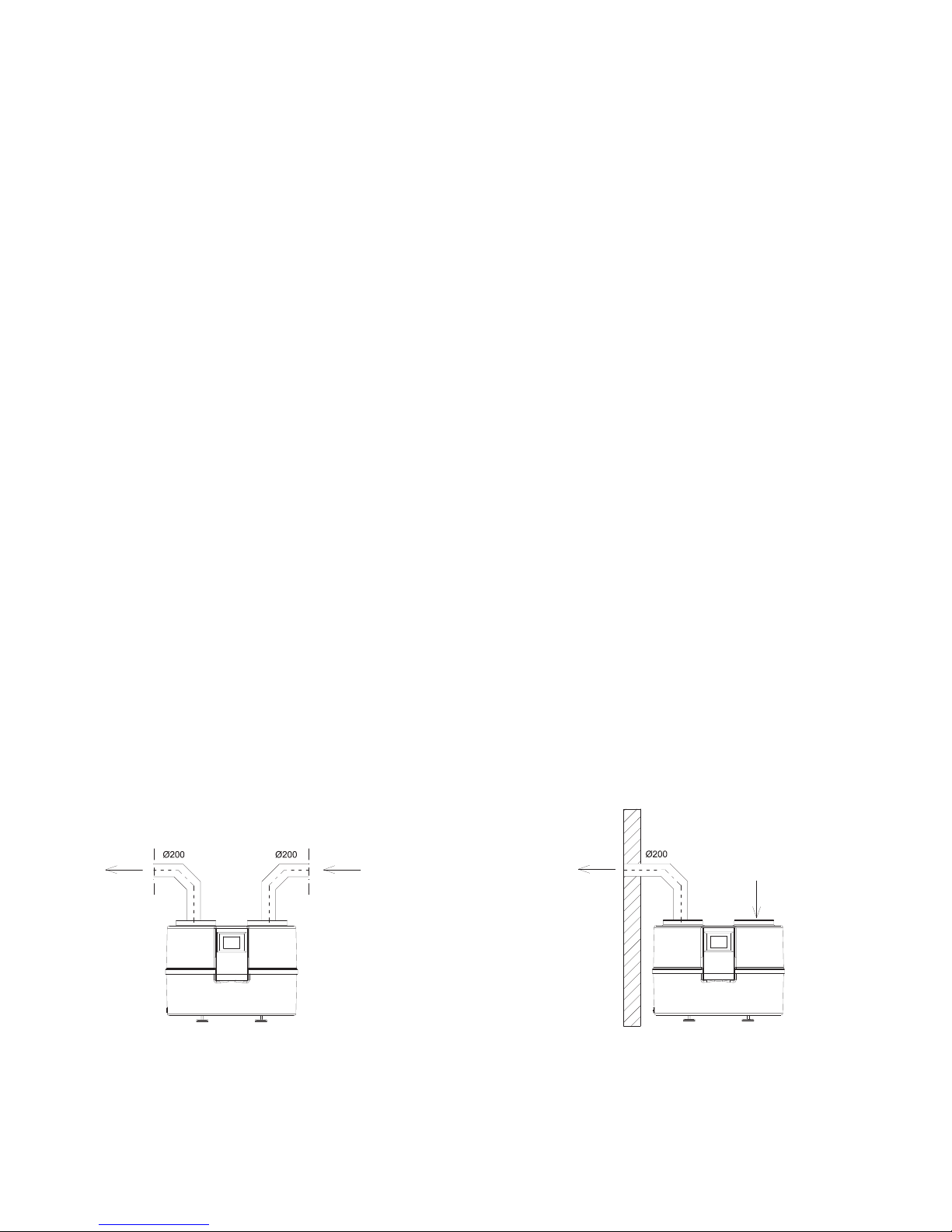

The heat pump has two connectors for connecting the air ducts. The internal diameter of the air ducts must be min.

200mm.

The maximum lengths of the air tubes: 8m

In case of connecting air ducts outside a building one should protect against the air circulation in the winter/

period of sub-zero conditions, when the heat pump is excluded from use.

Installation of the heat pump should be carried out by a person with appropriate qualifications in the field of heating and

cooling devices.

During the installation, one should observe the health and safety regulations which applies in a given country.

3. Installation of Heat Pump

3.2. Installation recommendations

3.3. Connection of hydraulic circuit

3.4. Connection of air ducts

3.1. Connection of air ducts

-5-

AIR ABSORBED FROM ONE ROOM AND DISCHARGED INTO

ANOTHER ONE

AIR ABSORBED FROM THE ROOM AND DISCHARGED

OUTSIDE THROUGH THE WALL

OUTSIDE

AIR

INSIDE

ROOM

Page 6

-6-

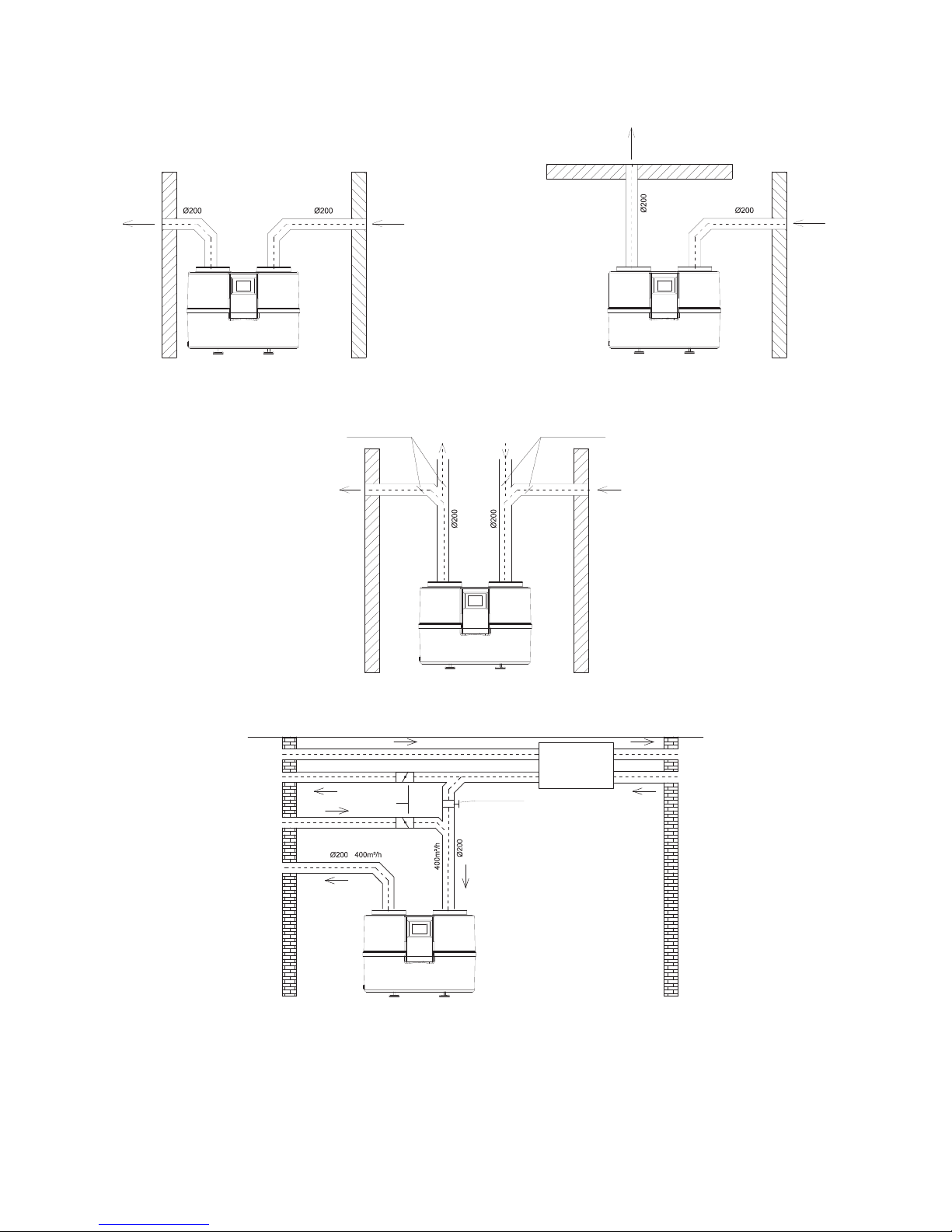

Note: Furthermore the air intake and discharge is allowed from the room in which the pump is installed. But it can result

in reduced energy efficiency.

HEAT PUMP COOPERATING WITH RECUPERATOR

AIR ABSORBED FROM OUTSIDE THROUGH WALL

AND DISCHARGED OUTSIDE THROUGH ROOF

INSIDE ROOM

OUTSIDE

AIR

DISTRIBUTION OF AIR INLET AND DISCHARGED

OUTSIDE

AIR

OUTSIDE

AIR

THROTTLE THROTTLE

INTERNAL

ROOM 1

INTERNAL

ROOM 2

AIR ABSORBED FROM OUTSIDE THROUGH WALL AND

DISCHARGED OUTSIDE THROUGH WALL

OUTSIDE

AIR

OUTSIDE

AIR

OUTSIDE

AIR

OUTSIDE

AIR

AIR SUPPLIED TO

3

ROOMS 150 - 250 m /h

AIR DISCHARGED

FROM ROOMS

Heat pump and recuperative central are working independently of another one so that's why air ducts also

should be separated. The point is, that in time when recuperative is working, but heat pump isn't working this

air freely flow to ventilation box, but not to the heat pump. This would reduce efficiency of the fan recuperative

central.

CHECK VALVE

THROTTLE VALVE

Page 7

The heat pump is powered by 1~230V/50 Hz. As a standard it has a plug with a cable of 1.5 m length.

Important: It is recommended that the electric supply circuit of the heat pump was equipped in the circuit breaker of the

characteristic C and residual current device with rated differential current transmission of 0.03A.

Note: All work related with the installation of these elements should be performed by personnel with the appropriate

permissions and qualifications.

3.5 Electrical connection

3.6 Installation diagram

4. Description of controller functions

-7-

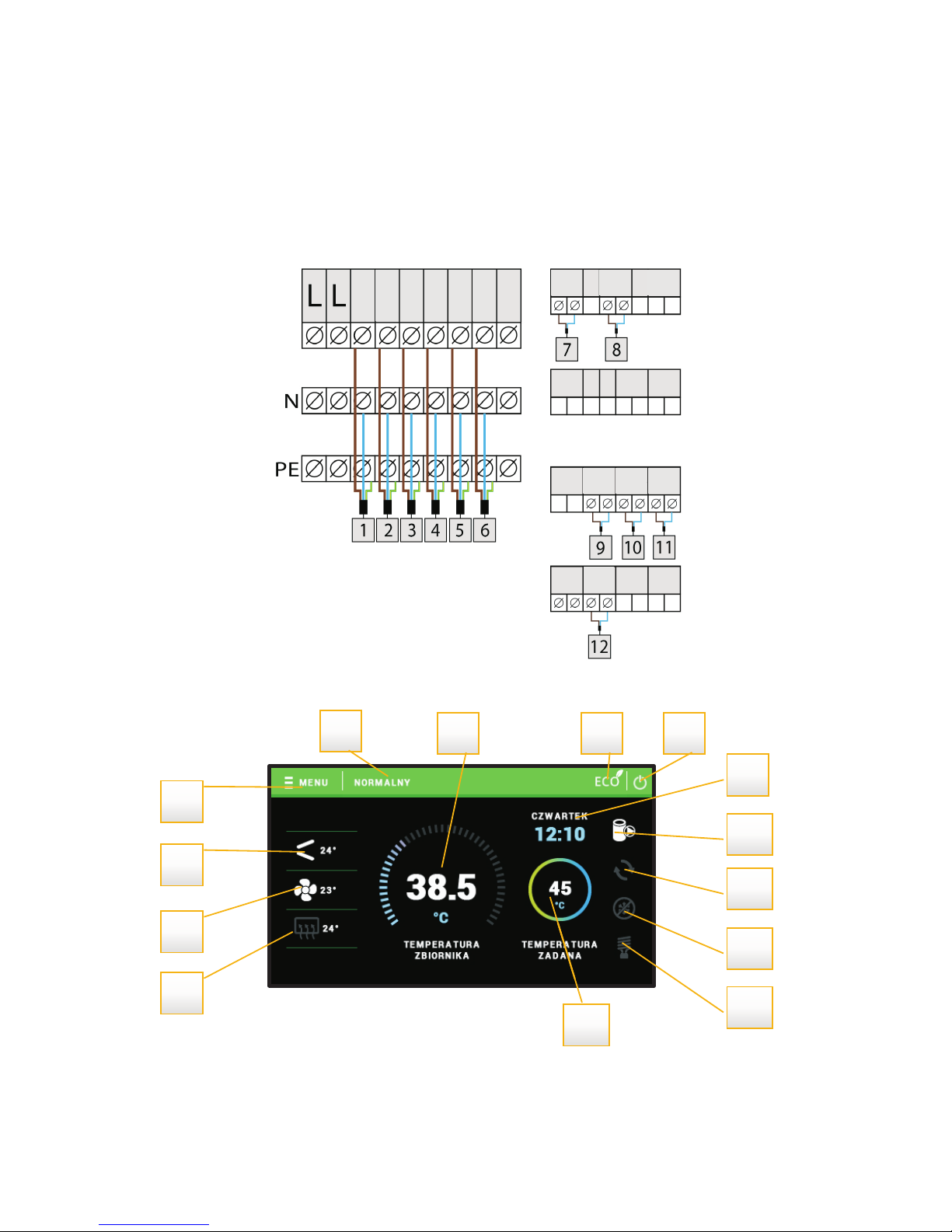

HEATER

VENTILATOR

COMPRESSOR

TANK PUMP

HIGH

PRESSURE

SWITCH

LOW

PRESSURE

SWITCH

SG

SWITCH

EXTERNAL

SENSOR

TANK

SENSOR

CONTROL

SENSOR

EVAPORATOR

SENSOR

DEFROST VALVE

CIRCULATION

PUMP

1

5

4

3

2

6 7 8

9

10

11

12

13

14

1. Evaporator temperature

2. External temperature

3. Control temperature

4. Enter the controller menu

5. Heat pump operation mode

6. Current tank temperature

7. ECO / ECO PLUS mode

8. STANDBY mode icon

9. Current time and day of the week

10. Tank pump icon

11. Circulating pump icon

12. Defrost mode icon

13. Heater icon

14. Pre-set tank temperature

Page 8

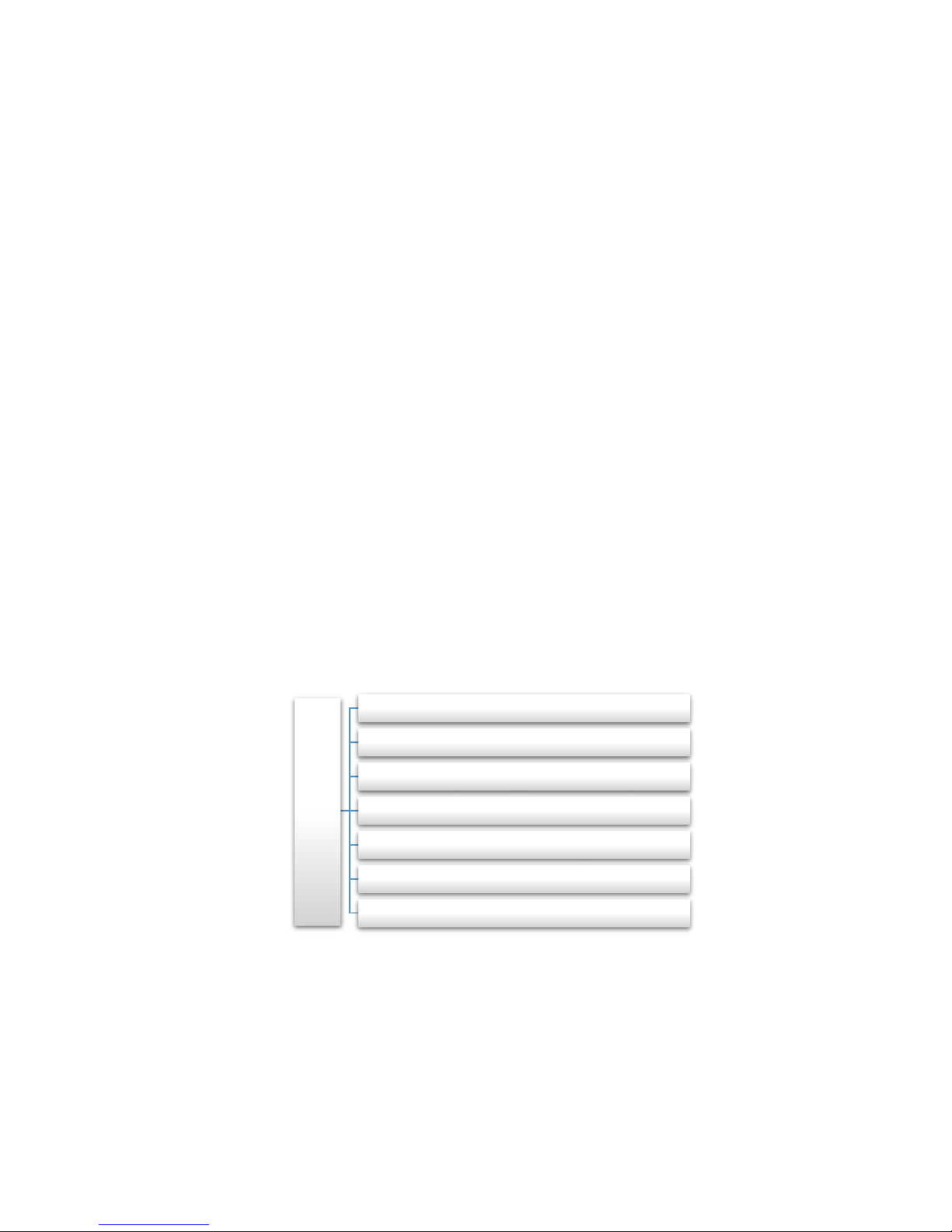

Installer menu

Tank set point temperature

Anti-freezing

Weekly schedule active

Weekly schedule

Circulation pump

Language

Service menu

The controller controls the operation of the compressor, ventilator, integrated circulation pump, additional circulation

pump and electrical heater. The compressor is activated with a delay in relation to the circulation pump and ventilator compressor delay parameter.

The electrical heater operates above the ECO-PLUS temperature and in the event of a breakdown.

For the protection of the device against unwanted changes in settings e.g. by children, you can activate the lock - to

operate the controller you must enter the access code.

After selecting the option of Active Protection the controller after a specified period of inactivity (setting Lock Delay)

locks access to the menu functions of the controller. To unlock the driver must enter the four digit code which can be

defined in the PIN Code Change option.

The option allows you to set the current time.

The option allows you to set the current date.

The function allows you to define the brightness of the display during the edit and view of the controller functions in the

range of 10-100%.

The function allows you to define the brightness of the display during the dimming, which is activated in 30 seconds

after the end of the edit and view of the controller functions in the range of 5-100%.

The function allows you to preview the controller information - name of the manufacturer, software number, and service

telephone number.

This function is used to set the tank set-point temperature. The ventilator, the compressor and the pump work until the

tank setpoint temperature is reached.

With this function the user specifies anti-freezing operations, which serve to protect the installation against freezing.

When the temperature drops below a certain temperature threshold (factory set limit is 5°C) the heat pump or the heater

engages permanently; it disengages when the temperature in the circuit reaches a value of temperature threshold

4.1 Control of actuators

4.2 Security

4.3 Clock settings

4.4 Date settings

4.5 Screen brightness

4.5.1 Screen brightness

4.5.2 Screen brightness

4.6 Programme information

5.1 Tank set point temperature

5.2 Anti-freezing

5 Installer menu

-8-

Page 9

increased by 3°C (i.e. in the case of factory settings it will be the value 8°C).

After pressing the encoder the user switches to define the anti-freezing functions. First by turning the encoder selects

the device that is to engage when the temperature drops below a certain threshold: the heater of the heat pump. Next

sets the temperature threshold.

This option allows to enable / disable the activity of weekly control operation. After engaging the functions of weekly

control the pump will work during the selected days of the week and the hours in comfort mode and during the rest in

reduced mode.

The set-point temperatures in modes are not editable and are respectively for the reduced mode: 40°C and for the

comfort mode: 50°C.

The controller is equipped in SG function - in certain conditions (a short circuit of SG) the controller enables a comfort

mode regardless of the weekly programme.

The weekly control will operate correctly after setting the current time and day of the week.

The controller allows to select the settings of two set-point temperature levels of hot utility water - daily and night. The

setpoint temperatures declared for each day of the week in accordance with the specified time periods. For each day

there are two time periods for the daily temperature and two time periods for the night temperature.

The first step when editing the weekly settings is selection of day for which we want to clarify the individual settings. By

turning the encoder the user can select one of the following days of the week, all day (“Entire week"), working days or

weekends ("Saturday and Sunday")

The next step is to select the hours in which the pump has to run in reduced mode and in which in comfort mode. By

turning the encoder move over an hour the setting you want to change and press the encoder. The screen displays the

additional menu:

• Change - selecting this option will change the settings of the selected hour (reduced / comfort mode)

• Copy - will copy settings (reduced / comfort mode) to the adjacent hours - just press the encoder and then turn it

- the settings are copied to subsequent hours.

• Accept - accepts settings for all hours. After pressing this option the screen of Installer Menu is displayed again.

This function is used to activate the connected circulation pump and define individual settings.

After pressing the encoder just select "ON". On the controller display appears a screen for setting the desired operating

time and then the break time.

Next the user selects the days of circulation pump activity: selected day of the week, weekdays or weekends.

The next step is to select hours in which the circulation pump is to be active.

This function allows to set the language of the controller.

To start the service menu of the controller the four-digit access code must be entered. If necessary this code can be

changed to another in the service menu.

5.3 Weekly schedule active

5.4 Weekly control of heat pump operation with different levels of temperature

5.5 Circulation pump

5.6 Language

5.7 Service menu

-9-

Page 10

Service menu

Manual operation

Compressor

Ventilator

Heater

Tank pump

Circulation pump

Defrost valve

Legionella settings

LEGIONELLA temperature

LEGIONELLA duration

LEGIONELLA maximum time

LEGIONELLA reminder

Defrost

Manual defrost

Defrost supervision

Evaporator temperature

Final evaporator temperature

External temperature

Maximum defrost duration

Minimum operating temperature

Hysteresis of minimum operating temperature

Heater operation below minimum operating

temperature

Hysteresis of set point temperature

ECO-ECO PLUS threshold temperature

Hysteresis of ECO-ECO PLUS threshold

Installation protection

Emergency temperature

Delay compressor

Clear alarm of control temperature

Edit service phone number

Change service code

Factory settings

-10-

Page 11

The function allows to enable individual devices regardless to other to verify its operation. Enable individual devices by

pressing the encoder when highlighted: ventilator, compressor, heater, main pump, circulation pump and additional

pump.

LEGIONELLA function is used to disinfect the tank. In the service menu you can configure individual parameters of this

function.

When editing set the desired value by turning the encoder, accept the choice by pressing the encoder.

The function allows to define the set-point temperature of disinfection.

Using this function sets the duration of the disinfection (in minutes) in which the set-point temperature of disinfection

stays at a constant set level (Legionella temperature).

This is the maximum total duration of disinfection (LEGIONELLA function) since the engagement (regardless of the

temperature during the engagement). In the case when the tank does not reach the set-point temperature or does not

maintain for the duration of the LEGIONELLA function set-point temperature, then after a maximum time the controller

will return to the basic operating mode.

When the user activates this function, the controller displays the reminder of disinfection function. The message

appears after 10 days from the last engagement of this function.

Defrosting can occur when the external temperature drops below the T defrost parameter - a parameter set in the

serviceevaporator defrost tab and when the temperature of the evaporator reaches the set value. Defrost is carried out

until the evaporator reaches the end evaporator defrost temperature - a parameter to set in the service tab. Defrost is

limited in time by the max defrost duration parameter. If during this time the evaporator cannot be effectively

defrosted, the heat pump switches to the 10 minute pre-heating cycle, and then again a process of defrosting. After 3

unsuccessful attempts of defrosting the defrost error message is displayed. The heat pump is locked. All the protection

functions remain active. The heat pump reset takes place e.g. when power is disconnected.

Additionally in the controller there is available function of manual defrost - service tab Manual defrosting

should be used in emergency situations (strong evaporator frosting).

In the tab defrost parameter - service, the user can set the following parameters:

evaporator temperature (range from +5°C to -15°C)

final evaporator temperature (range from +5°C to +25°C )

external temperature (range from +10°C to +2°C )

At the certain external temperature or below this temperature thawing is carried out at the set evaporator

temperature or below this temperature. Evaporator temperature at which the thawing is carried out should maintain for

the min. 15s. After this time the evaporator defrost is activated.

In the Service - defrost parameter tab there is located LP monitoring function (low pressure switch) during

defrosting. Functions to select: No LP monitoring, LP monitoring active. In the case of active function of No LP

monitoring the signal from the low pressure switch is not taken into account by the controller during the evaporator

defrost.

5.8 Manual operation

5.9 LEGIONELLA settings

5.9.1 LEGIONELLA temperature

5.9.2 LEGIONELLA duration

5.9.3 LEGIONELLA maximum time

5.9.4 LEGIONELLA reminder

5.10 Evaporator defrost

-11-

This function is used to set the minimum temperature (threshold) of the heat pump activation.

5.11 Minimum operating temperature

Page 12

Hysteresis of minimum operating temperature introduces a tolerance for the activation threshold temperature

preventing unwanted oscillations at activation low temperature fluctuations. This is the difference between the heat

pump activation temperature and the temperature of its deactivation (after the temperature drop).

Example: when the minimum operating temperature is set to 5°C and the hysteresis is set at 2°C, the heat pump

activates at 5°C, but when the temperature drops to a value of 3°C the pump is deactivated.

The user can decide whether the heater is to be enabled below the minimum air temperature.

This option is used to set the tank temperature hysteresis. This is the difference between the set point temperature

(desired on a boiler - when the heat pump turns off) and a temperature of the heat pump return to work.

The ECO - ECO PLUS threshold is a tank temperature at which the generator is turned off and further tank post heating

starts to be carried out using the heater or/and an additional heat source.

This option is used to set the temperature hysteresis for the ECO - ECO PLUS threshold (disconnection of the unit and

the engagement of an additional heat source), in order to prevent unnecessary oscillations. This is the difference

between the temperature of threshold disengagement of the generator and the temperature of the generator return to

work (after the temperature drop below the ECO - ECO PLUS threshold).

The operation of the installation protection depends on the pressure switch (the pressure sensor).

In the event of the engagement of this function, the signal of the pressure switch with too high pressure disables the

pump and triggers the alarm.

The emergency temperature is a parameter protecting the compressor and the generator from overheating. In the

event of a dangerous increase in the temperature of the control sensor (up to an emergency temperature) 3 times within

an hour the generator disengages permanently. In this case the restart of the device is only possible via the heat pump

manufacturer service.

After starting the heat pump, first engages the ventilator and the pump, and then after a few seconds, the compressor.

This setting adjusts the time delay of the compressor engagement after the ventilator and the pump. When the pump is

about to disengage (e.g.: the ECO - ECO PLUS threshold temperature is to be reached), first the compressor is

disengaged and after a set time delay, the ventilator and the pump.

This parameter is closely linked with the emergency temperature function. If the control temperature exceeds the

emergency threshold 3 times within an hour, it is possible to heat only with the heater.

Using this setting it is possible to edit the service phone number, which is displayed in the user menu: Information. Set

the desired value by turning the encoder, accept the choice by pressing the encoder.

With this function you can change the access code to the service menu. Set the desired value by turning the encoder,

accept the choice by pressing the encoder.

The controller is pre-configured to work. However, it should be adjusted to your needs. You can return to the factory

settings at any time. When enabling the option of factory settings all custom settings of the heat pump are lost (stored in

user menu) to the settings stored by the controller manufacturer. From this point you can re-set your own service

parameters of the heat pump.

5.12 Hysteresis of minimum operating temperature

5.13 Heater operation below minimum operating temperature

5.13.1 Hysteresis of set point temperature

5.13.2 ECO-ECO PLUS threshold temperature

5.13.3 Hysteresis of ECO-ECO PLUS threshold

5.14 Installation protection

5.15 Emergency temperature

5.16 Delay compressor

5.17 Clear alarm of control temperature

5.18 Edit service phone number

5.19 Change service code

5.20 Factory settings

-12-

Page 13

When you press and hold for a few seconds the sleep mode button (standby) on the main screen of the controller, the

installation actuators are disconnected. The anti-freezing function remains active - in the event of temperature drop

below the certain threshold the heat pump or the heater enables. This button is used when it is necessary to shut off

immediately all the devices.

In order to ensure the maximum safe and defect-free operation the regulator has several security features. In the event

of an alarm the audible signal enables and a corresponding message appears on the display.

In the ST-520 controller before and during the heating season check the technical condition of the wiring. Check also

the controller mounting, clean of dust and other pollutants.

User of device are requested at lest in a year to make service activities, which should including for example:

• cleaning of vaporizer

• cleaning case and the base of heat pump

• cleaning filter localized in hydraulic instalation

• check of electric patches

Attention: Before start service activities you should disconnect heat pump and electric grid!

Heat pump is protected by pressure switches with automatic reset, installed in refrigerant circuit by side of low and high

pressure. Pressure switches are connected direct to the driver. Freeing any of the pressure switches cause stop

working of circulation pump and appearance sound signal.

Additional air-compressor is safed by the sensor of hot gas.

The heat pump DROPS D4.1 was designed to work with the installations of photovoltaic panels and operating in energy

tariffs. The controller has an additional potential-free NO contact. After triggering the contact the heat pump and HUW

tank loading is enabled up to the daily set-point temperature.

After the shelf life of the device, you should contact a person with the appropriate permissions in the field of recovery

and disposal/utilization of controlled substances.

After emptying the device from the refrigerant the device can be given to disposal/utilization and / or individual

components can be recycled.

5.21 Sleep Mode

6. Security and Alarms

7. Maintenance

8. SG Ready function

9. The procedure after the shelf life of the device

CAUSE

Generator

breakdown

All the devices except

the heater are disabled

- exceeding the maximum

temperature in the system

The alarm clears itself when

the temperature drops

- defective external sensor

Replace the external sensor

Installation

failure

All the devices except

the heater are disabled

Too high pressure in the

system

The alarm clears itself when

the pressure drops

Tank sensor

failure

No device is operating

Defective tank sensor

Replace the tank sensor

Control sensor

failure

- On the main display

appears an appropriate

message

Defective control sensor

Replace the control sensor

-13-

Page 14

10. Hydraulic diagrams

-14-

CHUW

HUW

TO INLET Ø200

1 – HEAT PUMP

2 – BALL VALVE

3 – CIRCULATION PUMP

4 – CHECK VALVE

5 – DIAPHRAGM PRESSURE EXPANSION VESSELS

6 – SECURITY VALVE

7 – HUW TANK

8 – SECURITY VALVE

9 - DIAPHRAGM PRESSURE EXPANSION VESSELS

10 – INLET STRAINER

TO OUTLET Ø200

CW

Page 15

-15-

CHUW

HUW

TO INLET Ø200

TO OUTLET Ø200

1 – HEAT PUMP GELBI

2 – BALL VALVE

3 – CIRCULATION PUMP

4 – CHECK VALVE

5 – DIAPHRAGM PRESSURE EXPANSION VESSELS

6 – SECURITY VALVE

7 – HUW TANK

8 – INLET STRAINER

CW

Page 16

-16-

10.1. Refrigerant circuit illustration

Page 17

-17-

11. Technical data

The above values of COP and heating times were established in the following conditions: Drawn air temperature: 20°C.

The pump connected directly to the water tank. The air drawn directly from the room. In different conditions the above

values may change.

Scope

External temperature

min/max [°C]

+

5

/ +43

The temperature of hot water with the heat pump MAX °C 60

°C

60

The temperature of the hot water with the electrical heater.

°C

75

Minimum installation area

Heat-carrying agent

Electrical power supply:

2

m

1

Water

1/N/PE 220-240V/50Hz

-

-

Electrical parametres

Recommended security

COP, water heating 10 ÷ 40°C:

COP, water heating 10 ÷ 45°C:

COP, water heating 10 ÷ 50°C:

COP, water heating 10 ÷ 55°C:

Heating time for 100 L water at 10 ÷ 40°C:

Heating time for 100 L water at 10 ÷ 45°C:

Heating time for 100 L water at 10 ÷ 50°C:

Heating time for 100 L water at 10 ÷ 55°C:

Maximum heating capacity for drawn air

temperature of 20°C:

Average heating capacity for drawn air

temperature of 20°C and water heating

from 10 to 55 °C:

Energy consumption for drawn air temperature

of 20°C:

A

A

A

W

W

C6

min 0,29kW, max. 0,560kW

1,98 kW

1,49 kW

4,33

3,98

3,55

3,22

2h:27min

3h:07min

3h:57min

4h:38min

Max. starting electricity of the heat pump

Max. work electricity of the heat pump

Power of absorb

15,2

3

90

fan

max 55

circulation pump

Page 18

-18-

The above values of COP and heating times were established in the following conditions: Drawn air temperature: 35°C.

The pump connected directly to the water tank. The air drawn directly from the room. In different conditions the above

values may change.

Scope

External temperature

min/max [°C]

+

5

/ +43

The temperature of hot water with the heat pump MAX °C 60

°C

60

The temperature of the hot water with the electrical heater.

°C

75

Minimum installation area

Heat-carrying agent

Electrical power supply:

2

m

1

Water

1/N/PE 220-240V/50Hz

-

-

Electrical parametres

Recommended security

COP, water heating 10 ÷ 40°C:

COP, water heating 10 ÷ 45°C:

COP, water heating 10 ÷ 50°C:

COP, water heating 10 ÷ 55°C:

Heating time for 100 L water at 10 ÷ 40°C:

Heating time for 100 L water at 10 ÷ 45°C:

Heating time for 100 L water at 10 ÷ 50°C:

Heating time for 100 L water at 10 ÷ 55°C:

Maximum heating capacity for drawn air

temperature of 35°C:

Average heating capacity for drawn air

temperature of 35°C and water heating

from 10 to 55 °C:

Energy consumption for drawn air temperature

of 35°C:

A

A

A

W

W

C6

min 0,29kW, max. 0,65kW

2,57 kW

1,9 kW

6,9

6,6

5,7

4,9

1,5h

1,9h

2,6h

3,4h

Max. starting electricity of the heat pump

Max. work electricity of the heat pump

Power of absorb

15,2

3

90

fan

max 55

circulation pump

Working factor

Refrigerant/ quantity type/kg

R134a/ 0,6 kg

Maximum permissible pressure (low pressure)

bar

7

Maximum permissible pressure (high pressure)

bar

23

Dimensions

Diameter

Ø mm

668

Height

mm

512

Weight

kg

45

Heating circuit parameters

Connectors for the heating circuit

cal

2xGW 3/4"

Minimum tube inside diameter

mm

20

Flow

3

m /h

0,280

Working factor

-

water/propylene glycol

Compressor type

Type of the air-compressor oil

rotary

ATMOS-RB68EP/FVC68D Quantity: 320 ml ±20

The producer is reserving the right for changes of included information in the instruction

Page 19

-19-

Copy for the Investor

Device serial no

Name and address of the Investor

Name and surname of

the actuating person

Place of installation

(e.g. cellar)

Air ducts

Diameter: Material:

Heating pipeline

Diameter: Material:

Heating diagram corresponding

with the operating instructions

HUW tank capacity

Feed temp. - heat pump*

Return temp. - heat pump*

.............................................. ...................................................... ........................................

Stamp/signature of dealer Stamp/signature of installing company Signature of investor

Diagram no: Other:

Start-up protocol of the heat pump DROPS D4.1

Condensate drainage

method

Electrical connection

Name and surname of

the person performing

Overcurrent Protection

Residual-current

device

Cross-section of

the power cord

Heater Yes No Circulation pump Yes No

Notes

Start-up date

* Note the temperature of the storage container down during the measurement. The temperature of the storage

container during the measurement should not be lower than 30ºC.

Page 20

-20-

Page 21

-21-

Start-up protocol of the heat pump DROPS D4.1

Copy for the Manufacturer of a device1

.............................................. ...................................................... ........................................

Stamp/signature of dealer Stamp/signature of installing company Signature of investor

1

In the event of malfunction of the heat pump “The start-up protocol” is attached to the complaint notification, to be sent

to the manufacturer. The Protocol is the basis for defining the correctness of the selection and installation method of

the device.

Device serial no

Name and address of the Investor

Name and surname of

the actuating person

Place of installation

(e.g. cellar)

Air ducts

Diameter: Material:

Heating pipeline

Diameter: Material:

Heating diagram corresponding

with the operating instructions

HUW tank capacity

Feed temp. - heat pump*

Return temp. - heat pump*

Diagram no: Other:

Condensate drainage

method

Electrical connection

Name and surname of

the person performing

Overcurrent Protection

Residual-current

device

Cross-section of

the power cord

Heater Yes No Circulation pump Yes No

Notes

Start-up date

* Note the temperature of the storage container down during the measurement. The temperature of the storage

container during the measurement should not be lower than 30ºC.

Page 22

-22-

Page 23

-23-

Page 24

Loading...

Loading...