SILVANTIS®

PHOTOVOLTAIC

MODULES

F-SERIES and R-SERIES

72-Cell High Wattage Modules

INSTALLATION GUIDE

F-SERIES and R-SERIES 72-Cell Installation Guide

1.0 Introduction

1.0 Introduction 2

1.1 Models Covered by Installation Guide 2

2.0 Safety 3

2.1 General Safety 3

2.2 Mechanical Safety 3

2.3 Electrical Safety 3

3.0 Mechanical Installation 4

3.1 Planning and Design 4

3.2 Module Installation Options 5

3.3 Module Installation Using Center

Mounting Brackets 5

3.4 Additional Mounting Methods 7

4.0 Electrical Installation 8

4.1 Planning and Design 8

4.2 Module Wiring 8

4.3 Grounding 9

4.3 Option A: Metal Lug 10

4.3 Option B: Racking Manufacturer

Integrated Grounding Methods 11

4.3 Option C: Bolt Wire Assembly 11

4.3 Option D: Alternative Grounding 11

5.0 Maintenance 12

5.1 String Grounding 12

6.0 Disclaimer of Liability 13

7.0 Appendix 14

7.1 Module Details 14

7.2 Center Clamp Module Installation

Illustrations 15

7.3 Module Clamp Drawings 15

Thank you for choosing SunEdison's Silvantis modules. This

guide provides information regarding the proper installation

and handling of Silvantis modules.

Silvantis modules consist of a series of electrically

interconnected monocrystalline solar cells that are sealed

within a laminated sheet of tempered, low glare antireflective coating (ARC) glass superstrate, and EVA back

sheet substrate. These laminates are secured inside an

aluminum frame to provide rigidness and a mounting

mechanism to affix to sub-structures. Do not modify or

remove frames.

Please review all the sections that pertain to proper

installation of modules listed in this guide. The instructions

detailed in this guide must be followed throughout the

module’s lifetime deployment. If you need additional

information about the safe, proper use and handling of

SunEdison photovoltaic module products, please contact

SunEdison.

1.1 Models Covered by Installation Guide

Silvantis Monocrystalline Modules

Silvantis F-Series

F310BzC F315BzC F320BzC

F325BzC F330BzC F335BzC

Silvantis F-Series U.S. Tariff-Free

F310BzD F315BzD F320BzD

F325BzD F330BzD F335BzD

Silvantis R-Series

R330BzC R335BzC R340BzC

R345BzC R350BzC R355BzC

z indicates manufacturing location: M = Malaysia, X = Mexico, K = Korea

P = China, T = Taiwan

For product parameters and specifications see Section 7.0.

© 2015 SunEdison 2

2.0 Safety

Ensure to follow all safety guidelines stated below. Failure

to do so can cause injury, damages, or a void in the

module warranty.

2.1 General Safety

• Modules are intended for outdoor use.

• Do not submerge modules in water at any time.

• The front and back of each module is labeled with

a product bar code. Do not cover, remove or deface

labels as they are necessary for product identification.

• Do not allow unauthorized persons near the installation

site or module storage area.

• Troubleshooting should include planning, checking,

disconnecting, cause seeking, replacement and

record keeping.

• Do not wear rings, jewelry, watches or other metallic

items while working with photovoltaic modules.

2.2 Mechanical Safety

• Damage to the glass surface or its anti-reflective coating

will impact the power output and overall efficiency of the

system. Scratches, handling marks or any other damage

to the glass surface must be avoided.

• To avoid these and other performance prohibitive

issues, keep the front side of the module clean and free

of obstructions including covers, tape, adhesives, paint

and debris.

• Packaged modules must be stored indoors; in a dry and

ventilated area.

• Once opened, continue to store modules in a dry and

ventilated room.

• To safely keep modules stored, they must remain

packaged on the provided pallets, and must not be

stacked more than two pallets high.

• Do not place or drop objects on the modules, including

other modules.

• Do not twist the module frame.

• Do not stand, step, walk or jump on the module.

• Do not mark the modules with sharp instruments.

• Do not leave a module unsupported or unsecured.

• Do not modify module in any way, which includes the

frame, glass, eva, etc.

• Upon unpacking, only carry a module by its frame with

two or more people. Do not carry a module by the wires

or junction box.

• All modules are manufactured with a sealed junction

box, pre-attached cables and locking connectors. These

components should not be modified or tampered with

in any way. If connectors are not hooked up right away,

SunEdison recommends attaching protective caps to

prevent damage to the connectors.

• Do not install or handle the modules or their

components when they are wet or during periods

of high wind.

• Do not attempt to disassemble, repair or open

any part of the module; including the junction box

or sub-components.

• Do not artificially concentrate sunlight on a module.

• Do not install or handle broken modules. If a module

is broken, or the back sheet is torn, contact with the

surface or frame can cause an electrical shock.

2.3 Electrical Safety

• All installations must be performed in compliance

with all applicable regional and local electrical codes

or other applicable national and international electrical

standards.

• Use only insulated tools during installation,

troubleshooting and maintenance of the modules.

• Wear suitable protection to prevent direct contact with

module’s electrical output and mechanical sharp edges.

• Cover the front of the modules with an opaque material

to stop production of electricity when installing or

working with a module or wiring.

WARNING: Precautions should be taken to avoid damage to the glass surface when unpacking, handling or

storing the modules since any damage to the glass surface may impact the power output of the modules.

© 2015 SunEdison 3

F-SERIES and R-SERIES 72-Cell Installation Guide

• Modules connected in a series should not be

disconnected under illumination. Disconnecting

modules under illumination may cause electrical arcing,

which may result in burns, fires or other injuries and

damages.

• Photovoltaic modules produce DC electrical energy

from sunlight. When illuminated, each module can

have a DC potential of over 45 V and should be

handled with care.

• Always use a wire management system that keeps

wires and cables out of direct contact with edged

surfaces, which could cut or damage the insulation. Do

not allow wires to rest on the ground or roof surface.

3.0 Mechanical Installation

3.1 Planning and Design

• Before installation, check to ensure the sub-structure

will accommodate expected system loads. This

includes and is not limited to roof, foundations,

mechanical structure and mechanical connections.

• All Silvantis solar modules have a module fire resistance

rating of Class C. According to the UL1703 test

protocol, revised in 2014, all Silvantis solar modules

also have a module fire resistance rating of Class A

for spread of flame, and fire performance of either

Type 1 or Type 2 classification as specified on the

module label. Per UL, the fire rating of this module is

valid only when mounted in the manner specified in

the mechanical mounting instructions. The system fire

rating is determined by the module, rack and roofing

materials. SunEdison recommends not mixing module

fire performance type within a system.

• Mechanical structures should not contact the module

back sheet, any racking or the microinverter under any

expected load conditions.

• Consider the following factors during system design,

which will influence performance:

a. SunEdison solar modules produce the most

power when they are pointed directly at the

sun, and should be tilted for optimum system

performance.

b. Proximity to obstructions have the potential to

shade or damage the modules (examples below):

• walls

• buildings

• trees

• groundcover

• snow cover

• dust and debris

c. Designs should allow adequate airflow across

the back of the module because elevated

temperatures will decrease energy yield.

d. Allow a minimum spacing of 10 mm between

modules for thermal expansion.

© 2015 SunEdison 4

3.2 Module Installation Options

For bolt and clamp mounting locations and allowable load

capacities, please refer to the table on pages 6-7.

• Each module should be mounted using four bolts

through the mounting holes on the rear side of the

module, or with four clamps over the front side, within

the region specified as shown in the mounting diagram

below.

• Depending on the desired load capability of the array,

modules may be mounted either perpendicular or

parallel to the structure rails. Clamps can be mounted

anywhere inside of the safe mounting range for each

case illustrated in the table on pages 6-7.

• If using bolts, use a bolt stack no smaller than ¼"-20

or M6, with two flat washers and a locking washer as

shown in Appendix 7.1.

• To ensure an adequate clamping area, all clamps must

be able to clamp within the range specified in the table

on pages 6-7. All fasteners used to fix the modules with

clamps should be no smaller than ¼”-20 or M6.

• To provide adequate fixing or clamping force, torque the

fasteners to the manufacturers torque specifications.

• For all cases, the area of the supporting structure in

contact with rear side of the module must comply with

the dimensions specified in Appendix 7.1.

• All other structural dimensions, such as clamp and rail

thickness, should be sized appropriately for the intended

site load.

3.3 Module Installation Using Center

Mounting Brackets

• Modules may also be mounted using center clamps as

shown in Appendix 7.2, for use with trackers.

• Center mounting clamps must meet SunEdison

approved extrusion and hardware requirements.

• For module loads higher than 2400 Pa, module clamps

and hardware must be pre-approved by SunEdison.

• SunEdison approved center clamps utilizing M8 bolts

are to be tightened to 9.2-11.9 N·m (6.8-8.8 ft·lbs).

• Mechanical structures should not contact the module

backsheet under any expected load conditions.

• Ensure that frame weep holes (see Appendix 7.1) are

not obstructed by the mechanical installation.

• Mechanical installation of the module shall not cause

the frame to torque more than 38 mm.

• A minimum clearance of 152 mm is required between

the roof and bottom of the module frame.

© 2015 SunEdison 5

F-SERIES and R-SERIES 72-Cell Installation Guide

A

A

C

C

B

C

B

FIGURE 1(a): MOUNTING CONFIGURATIONS

MODULE

ILLUSTRATION

FRONT VIEW

BACK VIEW

CASE 1

Bolt Mount

Locations

Clamp Mount

Locations:

Fixed clamp

location for

5400 Pa

front load

FRONT VIEW

BACK VIEW

CASE 2

Bolt Mount

Locations

Clamp Mount

Locations:

Clamp mount

allowable

range

CASE 3

Clamp Mount Locations:

Clamp mount allowable range

Case 3, option 1

BACK VIEW

OR Case 3, option 2

BACK VIEW

LOAD

PARAMETERS

DETAILS

Maximum

Rear Load:

2400 Pa

(50 psf)

Maximum

Front Load:

5400 Pa

(113 psf)

CASE 1: Structural rails

running perpendicular to

the length of the module

should be fixed via bolts at

the mounting holes between

each long side frame, or

Clamps can be mounted

at the Fixed Clamp Mount

location as shown in the

color code key. See 7.3 for

minimum clamp dimensions.

Maximum

Rear Load:

2400 Pa

(50 psf)

Maximum

Front Load:

5400 Pa

(113 psf)

CASE 2: Structural rails

running parallel to the

length of the module should

be fixed via bolts at the

mounting holes on each

long side frame, or Clamps

can be mounted anywhere

within the Clamp Mount

Range as shown in the color

code key.

Maximum

Rear Load:

2400 Pa

(50 psf)

Maximum

Front Load:

2400 Pa

(50 psf)

CASE 3: Structural rails

running perpendicular to the

length of the module should

be fixed via bolts at the

mounting holes between each

long side frame, or Clamps

can be mounted anywhere

within the Clamp Mount

Range as shown in the color

code key.

Mounting Color Code: Mounting Hole Location Module Rail Fixed Clamp Mount Clamp Mount Range

Fixed Clamp Mount location:

Clamp mount allowable range:

A – 394 mm

B – 248 mm

C – 444 mm

© 2015 SunEdison 6

FIGURE 1(b): MOUNTING CONFIGURATIONS

AP90 V1.5/ATI TRACKER

MOUNTING

CASE 4: Structural rails running parallel

to the length of the module should be

attached within the Mounting Range

on each long side frame as shown in

the color code key.

NEXTRACKER CENTER

MOUNTING WITH BOLTS

CASE 5: The NexTracker mounting

structure is authorized for use with

SunEdison PV modules. Special

mounting holes have been provided

on the long rail of the module frame as

shown in Appendix 7.1. Use of these

mounting holes for anything other than

NexTracker is prohibited.

Maximum

Rear Load:

2400 Pa (50 psf)

Maximum

Front Load:

2400 Pa (50 psf)

Maximum

Rear Load:

2400 Pa (50 psf)

CASE 5 CASE 4

Maximum

Front Load:

2400 Pa (50 psf)

Mounting Color Code: Mounting Hole Location Mounting Range Module Rail

D – 400 mm E – 1,188 mm F – 200 mm

3.4 Additional Mounting Methods

Use of the PanelClaw system (Polar Bear® III) is

recommended with Silvantis modules. Structures

manufactured by PanelClaw Inc. use a special clamp, or

Use of the SunEdison AP90 Single Axis Tracker is

authorized for use as well. Please refer to the AP90

installation guide for specific instructions. Installation

guides can be found on the SunEdison website.

"claw" designed to attach to the flange of the module at all

four corners, on the two short frame ends.

For proper placement, attach a claw over the module

frame flange at each of the four designated locations and

tighten the screw so that the claws are flush with the

long and short ends of the module flange. This mounting

method has been tested to a maximum rating of 50 psf in

the negative and positive direction. Refer to case two in

Figure 1(a), as well as the PanelClaw installation guide for

information on the installation of the clamps.

© 2015 SunEdison 7

F-SERIES and R-SERIES 72-Cell Installation Guide

4.0 Electrical Installation

4.1 Planning and Design

All modules are manufactured with a sealed junction

box, pre-attached cables and locking connectors. These

components should not be modified or tampered with

in any way.

Note: Installers shall ensure that the polarized locking

connectors are from the same supplier. Do not mix

polarized interlocking connectors from different

manufacturers—including connections at the inverter,

combiner boxes and modules. Doing so will void the

warranty. Refer to the corresponding data sheet for

connector types.

• Ensure connectors are clean and dry before

establishing connection.

• Ensure that all wire, fusing and disconnects are

appropriately sized for the system design according

to national, regional, and local codes.

• Electrical characteristics are within plus or minus 5% of

rated values for Isc, Voc, Impp and Vmp. Pmax ranges

between 0% to +3% (R-Series) and 0 W to +5 W

(F-Series) of rated Pmax at standard test conditions

(STC). However, modules will operate under conditions

that may be significantly different than STC. SunEdison

suggests multiplying specified ratings by a minimum of

1.25 or more when designing the system and balance

of system components. Refer to local codes before

planning and designing the system.

• Determine the maximum number of modules that may

be connected in series using the following formula

Ns = Vmaxs/Vocm

Where:

Ns equals the maximum modules in series.

Vmaxs equals the maximum system voltage.

Please refer to module data sheet for actual Vmax

rating, as some models are rated for 1000 V UL and

1000 V IEC.

Vocm equals the module open circuit voltage at

coldest conditions for the site (refer to local codes).

4.2 Module Wiring

• The module includes wires and polarized locking

connectors from the junction box on the back of the

module. Field replacement of connectors or cables

must be avoided and will void the product warranty.

Polarized locking connectors of the same type, make

and manufacturer are required for all series string

wiring. The maximum operating temperature of the

wires and connectors should not exceed 85 C.

• When installing modules in landscape orientation, use

the 1.3 meter lead lengths to ensure enough cable

length to make adjacent module-to-module string

connections (assumes a maximum spacing of 50 mm

between adjacent modules).

• Always wire modules so that proper polarity is

maintained. Avoid placing excessive tension on

the cables.

• There is no limit to the maximum number of series

strings that can be combined in parallel. However,

each string must include overcurrent protection with a

maximum rating of 15 A. SunEdison recommends the

use of DC rated fuses or overcurrent protection devices

with the appropriate maximum voltage rating.

• Do not connect modules directly to a parallel bus.

• The cross-sectional areas of cable and the connector

type must be selected to align with the overall system

design, and should include the maximum short

circuit current of the system, maximum operating

temperatures and cable run lengths.

• For field connections, use at a minimum #12 AWG/4

mm2 wires; insulated for a minimum of 85 C. Use

copper wire only.

WARNING: Installers shall adhere to all applicable local, regional, and national codes and regulations when designing

and constructing the photovoltaic system

Note: In colder climates, it may be necessary to further reduce the maximum number of modules in a series by using

Vocm at the minimum expected operating temperature.

© 2015 SunEdison 8

4.3 Grounding

Module frames and structures grounding must be

compliant with all national and local regulations.

SunEdison recommends grounding all module frames

and associated structures in order to maintain a zerovoltage potential between the electrically conductive

equipment and the earth in all scenarios.

SunEdison modules use a coated aluminum frame

for corrosion resistance. In order to ensure proper

grounding the coating must be penetrated by the

grounding method. A copper grounding wire with a

minimum gauge of 12 AWG is recommended to carry

the electrical ground load. Consult applicable codes

to ensure the appropriate conductor diameter is used

for the system. The grounding method must not allow

direct contact of dissimilar metals with the frame of the

module, as this would result in galvanic corrosion. UL

1703 recommends metal combinations not to exceed a

voltage potential of 0.5.

The frame has predrilled holes marked with a grounding

sign as illustrated in Figure 2. These holes should be used

exclusively for grounding. Do not drill additional holes

or modify existing holes in the frame.

Figure 2: Image of the grounding holes

© 2015 SunEdison 9

F-SERIES and R-SERIES 72-Cell Installation Guide

4.3 Option A: Metal Lug

SunEdison recommends copper or tin plated grounding

lugs rated for outdoor use and used with a #12 or

larger wire. The use of a copper split bolt connector is

authorized for well.

Attach the grounding lug to the frame by referring to

Figure 3 and the following steps:

Figure 3: Option A Grounding Lug Assembly

Use stainless steel metric or English sets only. Please

refer to the following list for the minimum hardware

requirements for each set.

Metric set

- Stainless Steel Bolt M4

- Stainless Steel Nut M4

- Stainless Steel Flat Washer M4

- Stainless Steel Spring Washer M4

- Stainless Steel Lock-Toothed Washer M4

- Stainless Steel Slotted Washer M4

English set

- Stainless Steel Bolt #8-32

- Stainless Steel Nut #8-32

- Stainless Steel Flat Washer #8-32

- Stainless Steel Spring Washer #8-32

- Stainless Steel Lock-Toothed Washer #8-32

- Stainless Steel Slotted Washer #8-32

Step 1: Place the grounding lug over the grounding hole

on the exterior of the module frame.

Step 2: Place a star washer directly between the bottom

of the grounding lug and the exterior surface of

the frame.

Step 3: Place a bolt through the lug, star washer and

frame grounding hole.

Step 4: Secure the lug to the frame using a flat washer,

split washer and nut.

Step 5: Torque the bolt stack to approximately 1.5

N·m (1.1–1.7 ft·lbs) to ensure the star washer

penetrates the anodized frame.

–2.3

© 2015 SunEdison 10

4.3 Option B: Racking Manufacturer

Integrated Grounding Methods

Integrated grounding methods must be appropriately

certified to UL standards and must be in accordance

with the specified instructions of the respective

manufacturer. SunEdison modules can be grounded

by bonding modules to a grounded racking system.

SunEdison recommends using its internally developed

integrated grounding clip, PN: 720256 with its piloted

bolt, PN: 720230. The grounding clip utilizes a 304

stainless steel KEP nut to make the ground connection,

and the geomet finished bolt carries the current to the

grounded structure. The torque specification for the bolt

and clip is 14.9 N·m (11 ft·lbs).

Figure 4: Option B Grounding Lug Assembly

4.3 Option C: Bolt Wire Assembly

Step 1: Attach grounding lug at one of the designated

aforementioned grounding hole locations. Using

only stainless steel hardware, insert a stainless

steel bolt first through the stainless steel cup

washer, and then through the grounding hole.

Step 2: Loosely add a stainless steel backing nut and

a toothed lock washer to the bolt.

Step 3: Bend the EGC into an Omega (Ω) shape to tightly

fit between the partially installed bolt head

and cup washer. The EGC will be exclusively in

contact with the steel.

Step 4: Tighten the bolt to approximately 4 N·m (35 in·lbs)

of torque. The toothed washer must penetrate

the coated aluminum.

Step 5: Route the correctly sized ECG wire without

bringing the wire into contact with the module

frame.

Figure 5: Option C Bolt Wire Assembly

Mounting Rail Here

If the clip is not available, SunEdison also recommends

using the BURNDY WEEBs integrated rack grounding,

part numbers WEEB-ADC, WEEB-ADR, WEEB-WMR1 and

WEEB-WMR2. These devices are made of 304 stainless

steel that properly ground the modules with specialized

teeth that penetrate both module and structure. Should

you choose a rack integrated method that is not approved

by UL please contact SunEdison before proceeding to

determine compatibility.

4.3 Option D: Alternative Grounding

To use other code compliant frame grounding methods

that are UL certified contact SunEdison for approval.

© 2015 SunEdison 11

F-SERIES and R-SERIES 72-Cell Installation Guide

5.0 Maintenance

Check the modules for any damages to the glass

surfaces and frames on a regular basis. Routinely

inspect all modules for safe electrical connections,

sound mechanical connections, and for any shading or

corrosion issues. If dirt or debris becomes built-up clean

the glass using only a soft cloth, with a mild, non-abrasive

detergent and water. SunEdison recommends using mild

cleaning liquids; a neutral pH in the range of 6.0 to 8.0

is recommended. Chemicals with pH less than 6.0 or

greater than 8.0 should be avoided as it may damage the

glass surface and/or the anti-reflective coating. Please

consult with the system designer to determine the

best cleaning and inspection schedule based on local

environmental conditions.

Do not power wash, use harsh cleaning materials or

coarse objects such as scouring powder, steel wool,

scrapers, blades or other sharp instruments to clean the

module. Use of any such methods and materials will void

the product warranty. Do not wash modules with water

that is more than 20 C cooler than the surface of the

module. Doing so can cause the glass to crack.

WARNING: Use caution when cleaning the back surface

of the module to avoid scratching the substrate materials.

5.1 String Grounding

Silvantis F-series modules come in two types, PID-free

and PID-resistant. PID-free panels have a “PID-free”

designation on the nameplate label (Figure 6a) as

well as a “P” on the right side of the bar code label

(Figure 6b). String grounding requirements for the two

types of modules are:

• PID-free modules do not require string grounding

and are fully compatible with floating ground

transformerless and micro-inverters, as well as with

galvanically isolated inverters.

• PID-resistant modules: For string voltages greater

than 100 V PID-resistant modules must be used with

galvanically isolated inverters with the negative end

of the string held at ground potential. Floating ground

transformerless string inverters may not be used with

PID-resistant modules. PID-resistant modules are fully

compatible with microinverters where string voltage

is less than 100 V, in which case string grounding is

not required.

Figure 6: PID-free module designations

(a)

(b)

© 2015 SunEdison 12

6.0 Disclaimer of Liability

International Product Certifications:

The information in this manual is based on SunEdison’s

knowledge and experience and is believed to be accurate.

However, the information in this manual (without

exception) including recommendations and specifications

does not constitute a warranty, expressed or implied.

SunEdison reserves the right to change the manual, the

module, or specifications without prior notice.

The product warranty will be voided if:

• Handling and installation does not conform to

SunEdison’s written installation instructions.

• The product has been modified in a manner not

previously authorized by SunEdison in writing.

• The product is installed in an environment for which it

was not designed.

• There may be other conditions that could void the

warranty. Please check the applicable product warranty.

SunEdison will not be held liable for special, indirect,

consequential, contingent or incidental damages related

to or arising from the installation or use of the product by

purchaser under any circumstances.

SunEdison assumes no responsibility for any product

application or use that is beyond SunEdison’s direct

control. SunEdison does not accept responsibility

and expressly disclaims liability for loss, damage, or

expense arising out of or in any way connected to such

installation, operation or maintenance of the product.

Certification • IEC 61215 certified by TÜV SÜD

• IEC 61730 certified by TÜV SÜD

to ensure electrical safety

• UL 1703 listed by CSA for US

and Canada

Environmental AB8 (−50 C to +40 C)

Module Fire

Type 1 or Type 2 available

1

Performance

Fire Resistance

Class C

Rating

IEC 61215, IEC 61730, CE, UL 1703 and Safety Class II

certifications ensure that SunEdison solar products operate

safely and comply with applicable national and global

electrical, performance, reliability and fire safety codes.

SunEdison modules are certified by:

1

Refer to design package and module label for specific Fire Performance Type.

© 2015 SunEdison 13

F-SERIES and R-SERIES 72-Cell Installation Guide

7.0 Appendix

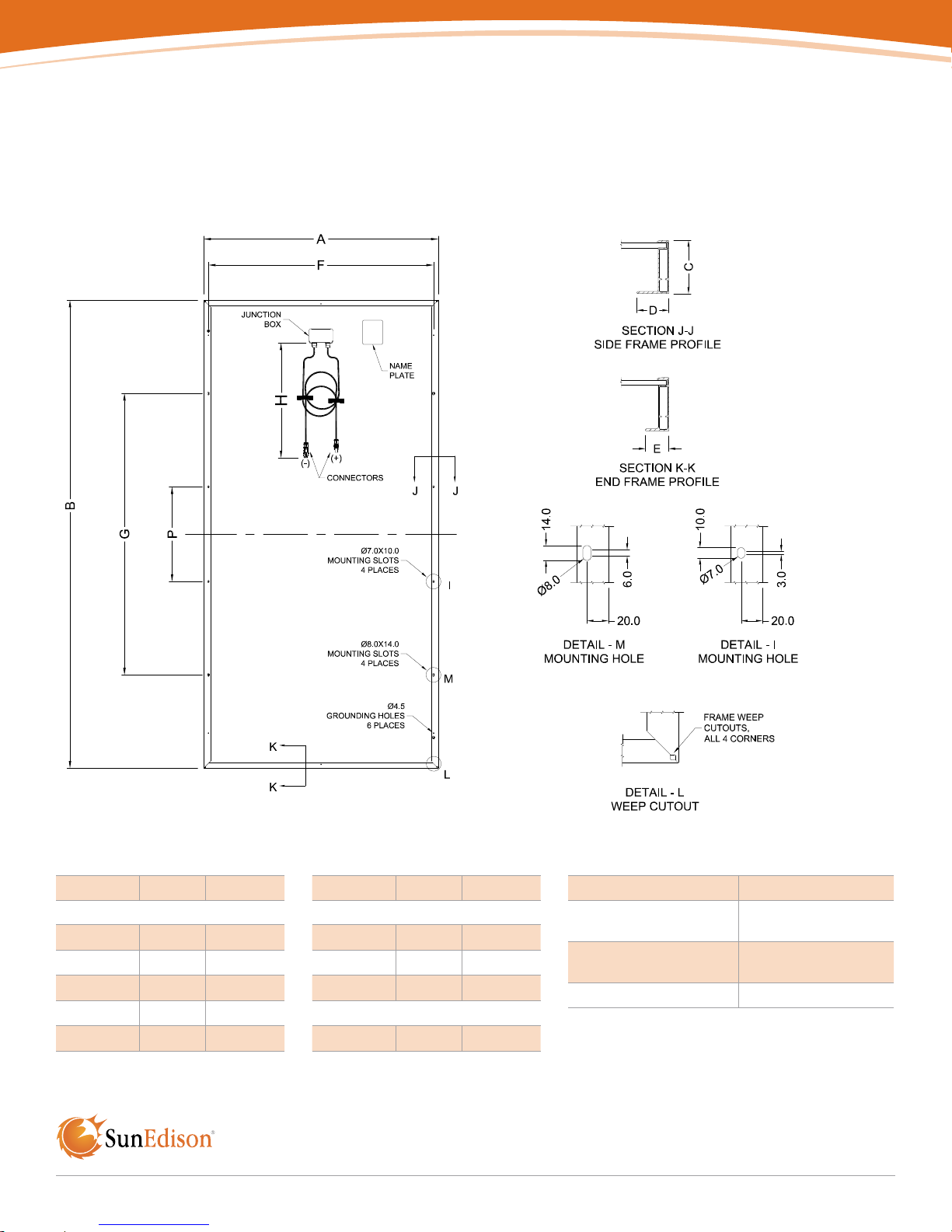

7.1 Module Details

PHYSICAL PARAMETERS

Dimension mm inch

Module Dimensions

A 990 39.0

B 1,976 77.8

C 50 2.0

D 30 1.2

E 22 0.9

Dimension mm inch

Mounting Hole Spacing

F 950 37.4

G 1,188 46.8

P 400 15.7

Cable Length

H 1,300 51.2

© 2015 SunEdison 14

Module Weight 22 kg

Frame Material

Tempered ARC Glass

Thickness

Connector Types Amphenol H4 (-39)

Anodized aluminum

alloy

3.2 mm

7.2 Center Clamp Module Installation Illustrations

7.3 Module Clamp Drawings

Bolt Stack Details Center Mount Option

PHYSICAL PARAMETERS

Dimension mm inch

Module Clamp Dimensions

A 6.35 0.25

B 38 1.5

Minimum Clamp Dimensions

C 50 1.97

D 15 0.59

© 2015 SunEdison 15

SunEdison Delivers Solar

Solutions Around the World

Australia

Brazil

Bulgaria

Canada

Chile

China

France

Germany

Greece

India

Indonesia

Israel

Italy

Japan

Jordan

Malaysia

Mexico

South Africa

South Korea

Spain

Taiwan

Turkey

U.A.E

United Kingdom

U.S.A.

www.sunedison.com

600 Clipper Drive Belmont, CA 94002

Phone: 866-786-3347 or 650-453-5600 Fax: 443-909-7150

©2015 SunEdison Products Singapore Pte. Ltd.; A SunEdison Company. All rights reserved. SunEdison and the SunEdison logo are registered trademarks or trademarks of SunEdison

Products Singapore Pte. Ltd. and/or its affiliates in the United States and certain other countries. All other trademarks mentioned in this document are the property of their respective

owners.

LWI-19389 TF_F_R72_GD_50mm_v4 07.2015

Loading...

Loading...