SUNDYNE

LMV-801 PUMPS

Instruction and Operation Manual

January 2009

14845 W. 64th Avenue • Arvada, Colorado 80007 USA • +1-303-425-0800 • FAX: +1-303-425-0896 • www.sundyne.com

Sundyne Europe • Dijon (Longvic) • France • +33 (0) 3.80.38.33.00 • FAX: +33 (0)3.80.38.33.66

Sundyne Nikkiso • 27-10, Ebisu 2-Chome, Shibuya-Ku • Tokyo 150-0013, Japan • +81-3-3444-6475 • FAX: +81-3-3444-6806

ANSIMAG • ANYSPEED • CASTER • GSP • HMD/KONTRO • MASO/SINE • SUNDYNE COMPRESSORS • SUNDYNE • SUNFLO

Copyright

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any

form or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior permission of

Sundyne Corporation.

© 2009 Sundyne Corporation

Warranty

Sundyne Corporation warrants to Buyer for a period of twelve (12) months from the date of being placed in service

(but not to exceed eighteen (18) months after the date of shipment) that the equipment at the time of shipment will

be free from defects of design, material and workmanship. If any defect s or m a lperformance occur during the

warranty period, Sundyne’s sole obligation shall be limited to alteration, repair or replacement at Sundyne’s

expense, F.O.B. Factory, of parts or equipment, which upon return to Sundyne and upon Sundyne’s examination

prove to be defective. Equipment and accessories not manufactured by Sundyne are warranted only to the extent of

and by the original manufacturers’ warranty. Sundyne shall not be liable for damage or wear to equipment caused by

abnormal conditions, vibration, failure to properly prime or to operate equipment without flow or caused by

corrosives, abrasives or foreign objects. THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED INCLUD I NG AN Y WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. In no event shall Sundyne be liable

for consequential or incidental damages.

14845 W. 64th Avenue • Arvada, Colorado 80007 USA • +1-303-425-0800 • FAX: +1-303-425-0896 • www.sundyne.com

Sundyne Europe • Dijon (Longvic) • France • +33 (0) 3.80.38.33.00 • FAX: +33 (0)3.80.38.33.66

Sundyne Nikkiso • 27-10, Ebisu 2-Chome, Shibuya-Ku • Tokyo 150-0013, Japan • +81-3-3444-6475 • FAX: +81-3-3444-6806

ANSIMAG • ANYSPEED • CASTER • GSP • HMD/KONTRO • MASO/SINE • SUNDYNE COMPRESSORS • SUNDYNE • SUNFLO

Contents

CONTENTS .........................................II

INTRODUCTION.................................. 1

Sundyne Centrifugal Pumps .............. 1

Extended Motor Shaft Option............. 1

Text Symbols ......................................... 1

Equipment and Safety Precautions.. 2

Wearing Personal Protective

Equipment .............................................2

Using Forklifts....................................... 2

Ensuring Electrical Safety................... 2

Testing Equipment............................... 2

Using Chemicals .................................. 3

Protection from Falling ........................ 3

Preventative Machine Guards............ 3

EXPLOSION/FIRE HAZARD.............. 3

Pre-Commission Checklist ................. 3

Familiarizing Yourself with the Pump 3

Driver Instructions................................ 3

Verifying Auxiliaries.............................. 3

Installing a Seal Environmental

Control System..................................... 4

Checking Driver Rotation.................... 4

Piping Connections.............................. 4

Storing Your Pump Long-Term ..........6

Suction and Discharge Piping............7

Seal Environmental Control System.7

Liquid Buffer System............................8

START UP ........................................... 9

Start-Up Procedures .............................9

Controlling the Pump During Startup9

Single Operation................................... 9

Parallel Operation................................. 9

OPERATION & CONTROL................ 10

Operation of Sundyne Pumps

Suction Conditions............................. 10

Minimum Flow Conditions................. 10

Entrained Gases................................. 10

System Head Curve........................... 10

Parallel Operation............................... 11

MAINTENANCE................................. 12

Disassembling the LMV-801..............12

..........10

Start Up Checklist................................. 4

Pressurizing the Fluid Loop................ 4

Setting the Valves................................ 4

Control Checklist................................... 4

Verifying Operating Conditions.......... 4

Installation and Start-Up Checklist... 5

INSTALLATION................................... 6

Inspection ............................................... 6

Storing Your Pump Short-Term......... 6

Sundyne Corporation http://www.sundyne.com

Inspection, Cleaning, & Shimming the

Extended Motor Shaft.........................15

Shaft and Lip Seal.............................. 15

Extended Motor Shaft - Shoulder

Dimension............................................ 15

Shaft Sleeve........................................ 16

Mechanical Seal................................. 16

Reassembling the LMV-801...............17

TROUBLESHOOTING.......................21

Pump Diagnostics ...............................21

ii

Pump Mechanical Seal Diagnostics 23

SPECIFICATIONS.............................25

Common Parts List..............................26

Single Seal Arrangement and Parts.27

Double Seal Arrangement and Parts

..................................................................29

Tandem Seal Arrangement and Parts

..................................................................31

Inducer & Parts.....................................33

Diffuser Cone Extension....................34

Integral Centrifugal Separator..........35

Extended Motor Shaft Adapter.........36

Recommended Spare Parts List.......37

INDEX................................................40

Sundyne Corporation http://www.sundyne.com

iii

Instruction and Operation Manual

INTRODUCTION

Sundyne Centrifugal Pumps

Sundyne pumps provide high-energy

performance and competitive efficiencies in an

industrial quality, compact unit that is simple to

maintain. Sundyne pumps are single stage.

Designed to increase the pressure of a

continuous flow of fluid by applying centrifugal

action, Sundyne pumps are most commonly

used in HPI, CPI, and Boiler Feed applications.

Commonly applied in refineries, petrochemical

plants, and power generation plants, Sundyne

pumps are used in high-head, low-to-medium

flow processes. This manual presents

installation, servicing, troubleshooting,

maintenance, and spare parts information for the

latest configuration of Sundyne centrifugal

pumps.

Extended Motor Shaft Option

Adapter for extended

motor shafts

Note: Parenthetical numbers included in the

text correspond to item numbers on the

illustrated figures. The correct spare

part can be ordered for any generation

pump by referencing the item and serial

numbers.

Note: If the pump has a bearing box, the

instructions are in a separate manual.

The bearing box manual and the pump

manual are designed to be used

together.

Sundyne offers an extended motor shaft for use in

extreme temperature conditions. The extended motor

shaft and motor adapter separate the motor from the

pump. This option is recommended when the process

temperature is below 0° F (-18° C) or above 300° F

(149° C). This option can be utilized on existing units

through a field retrofit.

Text Symbols

The following symbols may be found in the text

of this manual. They have the following

meanings:

WARNING: Text accompanied by this

symbol indicates that failure to follow

directions could result in bodily harm or

death.

ELECTRICAL HAZARD: Text

accompanied by this symbol indicates

that failure to follow directions could result

in electrical damage to equipment or

electrical shock.

RECOMMENDED: Text accompanied by

this symbol indicates recommended

usage.

REMINDER: Text accompanied by this

symbol indicates a reminder to perform

an action.

EQUIPMENT USE ALERT: Text

accompanied by this symbol indicates

that failure to follow directions could result

in damage to equipment.

1

Instruction and Operation Manual

Equipment and Safety Precautions

Sundyne Corporation manufactures centrifugal

pumps to exacting International Quality

Management System Standards (ISO 9001) as

certified and audited by Lloyd’s Register Quality

Assurance Limited. Genuine parts and

accessories are specifically designed and tested

for use with these products to ensure continued

product quality and performance. Sundyne

cannot test all parts and accessories sourced

from other vendors, incorrect design and/or

fabrication of such parts and accessories may

adversely affect the performance and safety

features of these products. Failure to properly

select, install or use authorized Sundyne pump

parts and accessories is considered misuse and

damage or failure caused by misuse is not

covered by Sundyne’s warranty. Additionally,

modification of Sundyne products or removal of

original components may impair the safety of

these products and their effective operation.

CAUTION

Sundyne pumps may handle hazardous,

flammable, and/or toxic fluids. Proper personal

protective equipment should be worn.

Precautions must be taken to prevent physical

injury. Pumpage must be handled and disposed

of in accordance with applicable environmental

regulations.

Note: Safety procedures must be applied

prior to any installation, maintenance,

or repair of a Sundyne pump. Failure to

follow safety precautions may lead to

injury!

Wearing Personal Protective

Equipment

To ensure safety, protective equipment must be

worn at all times when installing, performing

maintenance or repairing equipment. The

following safety recommendations must be

adhered to for optimum safety:

• Hearing protection is strongly

recommended at all times when noise

levels exceed 85 dB during an eight

(8.0) hour period.

Note: Chemical resistant gloves must be used

if chemical use is required (refer to

Using Chemicals for additional

information).

Note: A dust mask respirator must be worn if

chemicals have warning labels

regarding fumes, dust or mists.

When using more than one piece of protective

equipment, consider their compatibility. For

example, safety glasses will not interfere with

hearing protection seals. Be sure to clean all

pieces of personal protective equipment

immediately after each use.

Using Forklifts

Any persons operating a forklift must have an

active recognized operator license.

Note: Before initializing forklift operation,

verify that the lift is in a safe operating

position.

Ensuring Electrical Safety

All electrical sources must be powered-off

before installation, service or repair of

equipment occurs.

Note: Sundyne recommends that a Lock-

out/Tag-out program be followed prior

to altering the equipment. Locks or

tags must be provided to warn

employees that equipment is

temporarily unavailable.

Once all work has been completed, the person

installing the lock or tag must remove it

according to company procedure.

• Safety glasses, with the minimum

requirement of side shields, must be

worn at all times.

• Steel-toed shoes must be worn when

lifting equipment greater than 15 pounds

(7 kg) or if pallet jacks or forklifts are

operated.

Testing Equipment

Prior to performing a test on newly installed,

maintained or repaired equipment, all personnel

in the immediate area must be warned.

Note: Follow company procedures prior to

equipment testing at all times.

2

Instruction and Operation Manual

Using Chemicals

Any chemicals to be used must be accompanied

by a relevant material safety data sheet (MSDS),

in accordance with government legislation. If

applicable, use chemical proof gloves.

Note: An eye wash station (or equivalent)

should be available in the event of

injury. If any hazardous or flammable

chemicals pass through the equipment,

a complete decontamination of the

equipment is required.

Protection from Falling

Fall protection and associated preventative

measures is required when working on

equipment located six feet or higher from the

ground.

Note: Follow company fall prevention

procedures prior to working on

equipment.

Preventative Machine Guards

Preventative guards must remain in place on all

equipment.

Note: Only remove the guards while

performing maintenance or repair.

Replace the guards immediately after working

on the equipment and prior to start up.

EXPLOSION/FIRE HAZARD

Note: Never use an acetylene torch, open

flame, or heat to attempt to remove

parts that have seized together in

Sundyne equipment. Any residual

process gas or liquid that is flammable

can result in an explosion or fire with

potential for serious injury or death.

Pre-Commission Checklist

Familiarizing Yourself with the Pump

Before servicing and starting up the Sundyne

pump, carefully review all information on the

product, including:

• Specification sheets

• Outline drawings

• Performance curves

• Instruction and related manuals

• System P&ID/Process Flow Diagram

(Clients equipment)

• Control system and operational

philosophy/narrative (Client)

Familiarize yourself with the pump configuration

before starting and operating the pump.

Driver Instructions

Carefully follow all installation and starting

instructions provided by the driver manufacturer.

This information is included in the final data

package.

Verifying Auxiliaries

Before start up, verify that the following

auxiliaries are met:

• Check the utility connections

• Verify that the auxiliary piping conforms

to Sundyne standards, as indicated in

the detailed specifications

• Verify all switch and instrument

connections

• Verify that all switch and instrument

settings are set to normal operating

standards

• Calibrate all measurement equipment,

such as flow meters, ampere meters,

and pressure meters, etc.

3

Instruction and Operation Manual

Installing a Seal Environmental Control

System

Install a system to control the seal environment.

Also, verify that port 1 is properly vented.

If required, install drain piping overhead to

ensure that the environment operates under

normal conditions. For more information,

contact Sundyne Corporation.

Checking Driver Rotation

Rotation must be counter-clockwise when

looking at the end of the motor.

Start Up Checklist

Pressurizing the Fluid Loop

Pressurize the double seal buffer loop or

external seal flush, if applicable, prior to

admitting fluid into the pump casing.

Piping Connections

Verify that the following bolted or threaded

connections are tight:

• Pump flange bolts

• Seal environment piping and port

connections

• Pump case drain plug

Setting the Valves

To set the pump to the designated operating

point, start the pump with the suction valve in

the open position while throttling the discharge

valve.

Control Checklist

Verifying Operating Conditions

Verify the following parameters against the

specifications on the Specification sheet:

• Suction pressure

• Suction temperature

• Discharge pressure

• Total head

• Flow rate

• Power consumption

• Specific gravity

• Viscosity

• Net Positive Suction Head (NPSH)

The status of these conditions will significantly

alter performance of the pump if they are not in

accordance with the specification sheet.

Check with your Sundyne representative if the

operation conditions of your pump must run

under different parameters than indicated by the

specification sheet.

4

Instruction and Operation Manual

Installation and Start-Up Checklist

Note: Lock out all switch gears, including main driver, and instrumentation before working on this

equipment.

This checklist is NOT intended to be inclusive. You must read and follow: instruction manuals, outline

drawings, specification sheets and curves for this equipment during installation, commissionin g, and

operation. Your total satisfaction is our goal. Please call with any questions or comments. Be sure to have

the unit serial number that is imprinted on the pump nameplate, and request “Sundyne Field Service”.

Is all the information underlined above readily available?

Are the following bolted/threaded connections tight?

• Pump flange bolts?

• Seal environment piping and port connections?

• Pump case drain plug?

Is a check valve installed in the discharge line?

Is Port 1 open to atmosphere, or piped to safety drain or flare vent header? (Back pressure must

not exceed 5 psig).

Note: A drip leg must be used if the Port 1 connection rises from the seal housing.

Are all other seal system ports identified and connected according to the outline drawings?

Do process conditions, suction pressure, suction temperature, discharge header pressure, and

specific gravity agree with specification sheet information? DO NOT test the pump on water

unless it is designed for water. Check with your representative or Sundyne Corporation if you

must test on a different fluid than shown on the specification sheet.

Prior to starting the unit, have you opened the suction valve fully and discharge throttled to allow

design flow, typically 40-50% open? Check the control valve to be sure it is functional. Inspect the

case drain, ports, and flanges for leaks. Has the pump been vented through Port 6. Check suction

pressure to be sure it agrees with the specification sheet.

Unlock the main driver circuit and bump the motor. Rotation is CCW, as viewed from the top end

of the motor. Is rotation correct? Once rotation is verified start the main driver. After

commissioning, bumping the motor is not required.

If pressure control is being used, throttle the discharge valve immediately after start-up. Does the

discharge pressure agree with the specification sheet? If flow control is being used, adjust the

valve until flow agrees with the design value listed on the specification sheet.

Listen for any unusual noises or pressure fluctuations.

Note: If you have any questions or concerns about these procedures or the information supplied,

please call your representative or Sundyne Corporation.

5

Instruction and Operation Manual

INSTALLATION

Inspection

Immediately inspect your Sundyne product upon

receipt of the equipment. Check for any

damage, which may have occurred during

shipment. Notify the carrier and Sundyne

immediately if damage is evident.

Storing Your Pump Short-Term

If your Sundyne pump is not to be installed

immediately, protect it from exposure to

moisture and dust. Do not remove the factory

installed shipping covers for casing flanges and

Storing Your Pump Long-Term

In addition to the precautions in the short-term

section above, additional precautions are

required for long-term storage.

If your Sundyne pump will not be operated for a

period of time exceeding six months from the

date of shipment, long-term storage conditions

must be met to ensure minimum corrosion

damage to the fluid-end components.

Note: Sundyne does not accept liability for

equipment damaged during the storage

period. Sundyne does not guarantee

the quality of equipment during and

after the storage period.

To ensure the original quality of the Sundyne

pump after storage, all components must be

inspected by an authorized Sundyne service

engineer. Components that are not

manufactured by Sundyne (except mechanical

seals) must be inspected by its own

manufacturer.

Note: Any inspection fees are the sole

responsibility of the purchaser.

Factors which affect the quality of a Sundyne

pump, when stored, are:

Note: The input shaft on the pump may not

seal ports. Ensure that the shipping covers be

kept securely in place.

Note: Observe the storage instructions

Long-term storage methods must prevent

damaging conditions from making contact with

the internal components of the equipment. When

the equipment is stored in strong chemical

environments or near salt water, protection must

occur immediately upon receipt of the

equipment.

Recommended Long-Term Storage

Procedures

Sundyne recommends that you do the following

to prevent damage to your pump during longterm storage:

1. Store your pump only in an indoor, climate

2. Perform inert gas purging of component

3. Use desiccant bags.

turn freely due to seal drag. If the input

shaft does turn freely, and if rotation is

“not smooth,” damage may have

occurred during shipping.

provided by the driver manufacturer.

• Humidity

• Temperature

• Surrounding chemicals

controlled building. These conditions will

maintain constant temperature and humidity.

internals.

6

Instruction and Operation Manual

Note: Because long-term storage of

equipment is of a highly critical nature,

it is recommended that Sundyne be

Suction and Discharge Piping

Please adhere to the following best practices for

installing and maintaining suction and discharge

piping:

1. Install a suction strainer (12 mesh - .062" or

1.6mm opening) and clean the suction line

prior to starting the pump. This procedure

will protect the impeller from damage by mill

scale, welding slag, or other foreign particles

during initial startup.

Note: Sundyne recommends installation of a

differential pressure instrument across

strainer to indicate strainer condition.

2. When installing piping to the pump, ensure

that all piping is supported independently

from the pump.

3. All piping must always line up with the pump

flanges.

Note: Never use force to position piping into

place at the flanged suction and

discharge connection locations. Failure

to have piping properly aligned may

impose excessive strains on the unit.

contacted to provide more details on

the above procedures.

4. Sundyne recommends using a straight pipe

assembly of at least three times the length

of the pipe diameter.

Note: Carefully select the size of pipe and

fittings to be installed so that friction

losses will remain low.

5. Never use a suction pipe that is smaller in

diameter than the pump suction inlet.

6. Sundyne recommends installation of a

discharge check valve to prevent reverse

rotation.

7. Use block valves (both suction and

discharge) when isolating the pump during

shutdown. This practice will minimize

process leakage and prevent possible

reverse rotation from pump back-flow.

8. It is recommended that suction and

discharge pressure gauges be installed on

any pump that is not flow controlled. If no

flow measuring device is installed there is no

way to determine accurately where on its

curve the pump is operating.

Seal Environmental Control System

A seal environmental control system may be

required depending upon the pump seal

arrangement and application.

Always maintain the pump seal environment as

detailed on the specification sheet that

accompanies each unit.

Note: For most applications, a standard

control system can be obtained from

the factory.

Ensure that the specified seal environmental

control system is properly installed and that the

ports are open (or plugged) as indicated in

Figure 1.

Note: Port 1 must always be open so that it is

free to drain.

7

Instruction and Operation Manual

Figure 1. Seal Housing Port Identification

Liquid Buffer System

For double liquid seals and tandem liquid seals,

a liquid buffer system is used. Introduce the

buffer liquid into port 7, which will flow through

the seal cavity, and out from port 2.

Buffer flow should be 0.5 to 3 gpm (2 to 12

liters/min) with an inlet temperature of 60

o

120

F (16o to 49oC), and inlet pressure as

o

to

indicated on the pump specification sheet. The

liquid must be clean to 5μ microns.

8

Instruction and Operation Manual

START UP

Start-Up Procedures

Perform the following tasks to start the Sundyne

pump.

1. Run-in of pump: If the pump is to be run

under conditions which are considerably

different from those conditions listed on the

spec sheet (such as a change in specific

gravity, suction pressure, flow rate, etc.) the

factory should be consulted to ensure that

the run-in conditions are compatible with the

pump.

2. Check to ensure that the driver has been

serviced per instructions provided by the

driver manufacturer.

3. Auxiliaries - Check utility connections; verify

that auxiliary piping is per Sundyne

drawings; verify switch and instrument

connections and set points; calibrate flow

instruments and other transmitters.

Controlling the Pump During Startup

4. Flushing screens should be installed in all

field assembled piping connections.

5. Check the pump specification sheet and

outline drawings for seal environment

requirements. Be sure seal housing port

piping is properly connected. If double seals

are used, buffer fluid must be pressurized

before suction pressure is applied to the

pump. Port 1 must be open. Maximum

allowable backpressure on port 1 is 5 psig

(0.35 kg/cm²). If port 6 is not used for a seal

flush, it is recommended that a hand bleed

valve be installed at this location. Bleed air

and vapor before starting.

6. Jogging is used to verify proper direction of

rotation for the main driver.

Note: Never start the pump against a closed

discharge valve. Always check to

ensure that the discharge valve is

partially open.

To ensure control of the pump during start up,

follow the start up procedures for your desired

configuration.

Single Operation

1. Start the pump with the suction valve open

while throttling the discharge valve. This will

ensure that the pump will reach the design

flow operating point.

2. If the process fluid is near its vapor

pressure, open the supply vessel seal cavity

vent so that the pump can fill with liquid.

Parallel Operation

To prevent back-flow, place the check valves in

the discharge piping of each pump.

Note: Sundyne recommends installing

separate bypass loops around each

pump for additional operational

flexibility.

1. Start the first unit as described in the

Single Operation instructions.

2. Start the second unit with the bypass

valve set to maintain the flow above

minimum flow.

3. Open the discharge valve on the second

unit so that the design flow of both units

is maintained.

Note: Do not operate the pumps at their peak

head capability.

Sundyne recommends that separate flow

controls be used on each pump to provide a

lower minimum flow range than is achieved by

pressure control.

9

Instruction and Operation Manual

A

y

2

A

OPERATION & CONTROL

Operation of Sundyne Pumps

Under normal operation, several factors must be

taken into consideration to ensure successful

pump operation. Experienced pump operators

will be aware of jeopardizing factors and their

effects.

Suction Conditions

Improper flow of liquid into the impeller is the

most common operational abuse of centrifugal

pumps. Two conditions must exist to prevent

turbulence at the eye of the impeller.

• Proper suction piping, see suction piping

section.

• Liquid reaching the impeller eye must

have enough vapor pressure to prevent

the fluid from flashing to a gas in the

impeller. If this condition occurs, it will

cause cavitation, which can damage the

impeller and inducer. When centrifugal

pumps cavitate the noise sounds like

the pump is “pumping gravel”. In high

speed, single stage pumps, this sound

may not be discernable. Cavitation can

be prevented by maintaining suction

pressure at a high enough level and

suction temperatures low enough to

maintain Net Positive Suction Head

(NPSHa) available greater than Net

Positive Suction Head (NPSHr) required

by the pumps.

Minimum Flow Conditions

Vibration and noise will occur during operation of

centrifugal pumps if either of two conditions

exist:

• Internal flow separations

• Recirculation at low flow conditions

If the operator is noticing excessive noise or

vibration, operation must be suspended until the

cause is determined and corrected. Continued

use may cause damage to the pump.

Resonance in the discharge line can accentuate

noise, vibration, and damage to the pump,

primarily when a control valve is located an

excessive distance downstream from the pump.

Entrained Gases

The head and capacity of centrifugal pumps will

be reduced by gas that is drawn in with the

liquid. Under normal operating conditions,

centrifugal pumps can tolerate up to 2% of gas

(by volume). Entrained gases can cause

damage to mechanical seals with the exception

of double seals. If you have entrained gas,

contact Sundyne for further instruction.

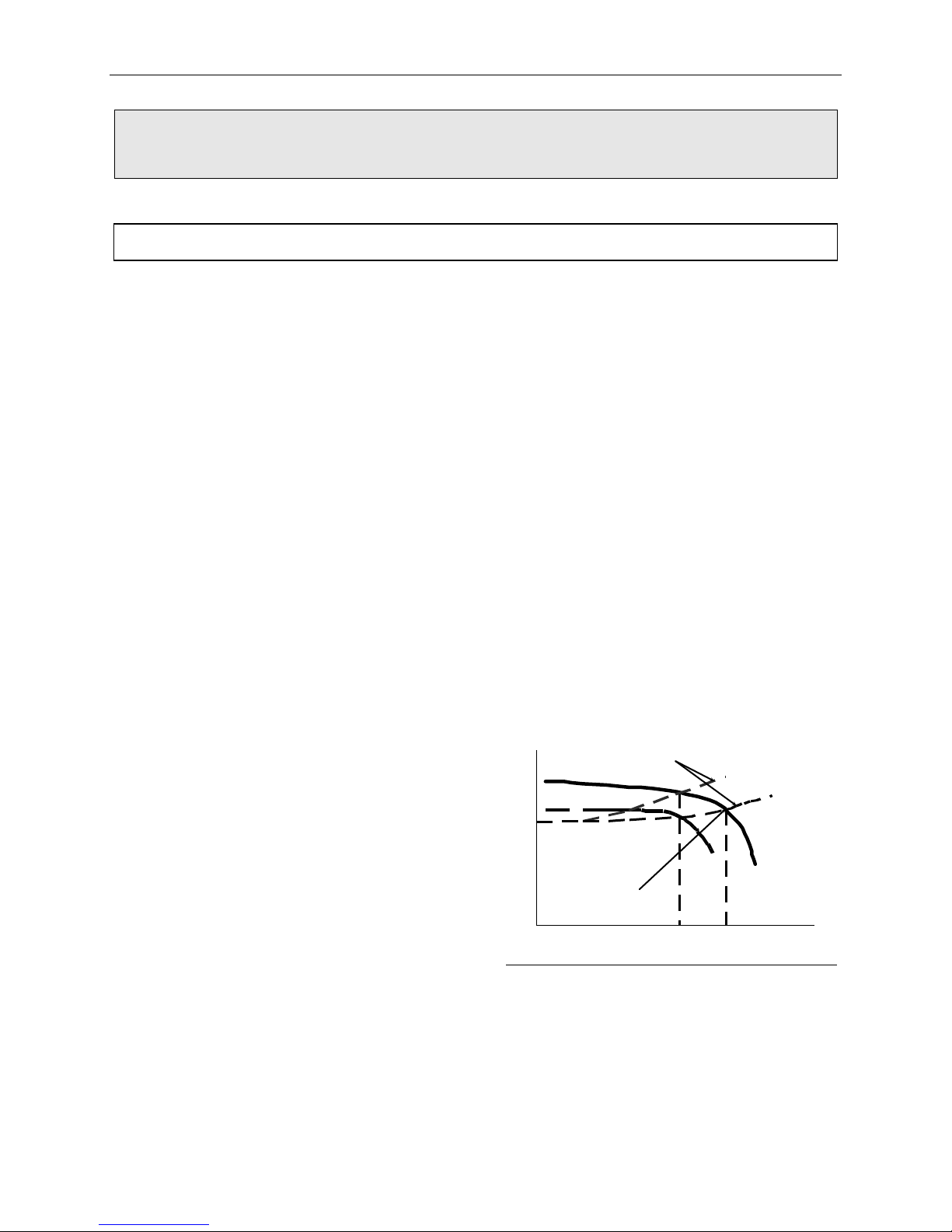

System Head Curve

The point of intersection between the system

curve and the pump characteristic curve

determines the flow or operation for the

centrifugal pump. For steady flow to occur, the

system curve must intersect the pump

characteristic curve at a significant angle. The

following diagram gives examples of satisfactory

and unsatisfactory angles of intersection.

Figure 2. Typical Operation

System (Head) Curves

B

Good

HEAD

ngle of

I ntersection

FLOW

Note: The curve for pump A has a significant

angle of intersection with system curves

D and E. The system curve D could

represent a system with the control

valve wide open while curve E could

represent the same system but with the

throttle valve closed to reduce flow from

flow 1 to flow 2. Pump curve B, on the

other hand, will provide only flow 2,

Valve Partiall

E

1

D

Closed

Valve

Wide

Open

10

Instruction and Operation Manual

even with the control valve wide open

(curve D). When the control valve is

partially closed to create system curve

E, the curve E and lower pump curve B

are practically parallel. The lack of a

significant angle of intersection means

that the system is unstable; pump flow

is likely to fluctuate erratically and not

respond to control valve position.

Parallel Operation

Maximizing control is critical when operating

centrifugal pumps in parallel. One pump can

overpower the other in regards to head at a

lower total flow. If a simple, unrestricted manifold

connects two pumps at the discharge head, the

discharge head of one pump is imposed on the

other. All pumps will see the same discharge

head at a given time. This is demonstrated on

the following diagrams.

The characteristic curves of two pumps

designated A and B are demonstrated in the

Parallel Operation

figure.

Figure 3. Parallel Operation

FLOW

Figure 4. Parallel Units Common Valve

Since no two pumps will have exactly the same

performance, it is assumed that pump A

produces a slight amount more head than pump

B. The pumps are arranged with a common

manifold as shown in Parallel Units Common

Valve figure.

The pressure in the manifold is set at P1; the

flow through pump A indicated as A1 on the

preceding curve. At the same time, the flow

through pump B is indicated as B1. However, if

the throttle valve is closed to cause the manifold

pressure P to rise to P2, then flows through

pump A and B are A2 and B2 respectively. If the

throttle valve were closed even further, then

pump B would cease to flow entirely. Since

pump B would effectively be deadheaded, the

fluid in it would heat up and boil. During internal

boiling, it could encounter liquid slugging and

probable damage to the pump. Proper selection

of a control system can prevent this situation.

11

Instruction and Operation Manual

MAINTENANCE

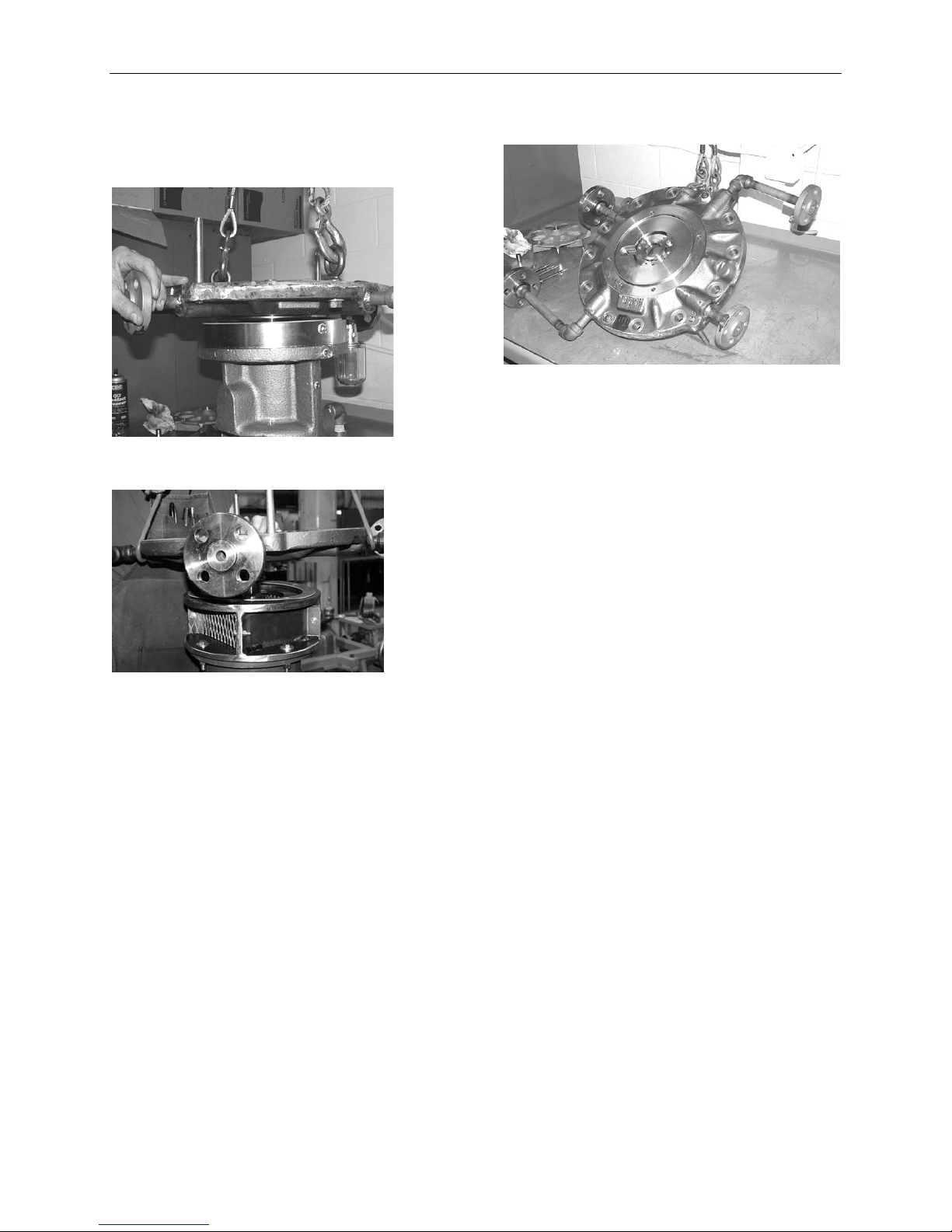

Disassembling the LMV-801

The following procedures apply to all

configurations of the LMV-801 process pump

including the extended motor shaft and bearing

box options. Refer to the specification sheet to

determine your specific pump configuration and

optional equipment included. Disassembly

should be done only to the extent necessary for

repair.

Note: The following replacement parts will be

required as a result of pump

disassembly and seal housing removal:

PART ITEM NO. QTY.

Impeller Tab washer 5 1

O-ring Repair Kit -- 1

Thermal Barrier Gasket 87A 1

STEP 1

Remove the motor, bearing box and/or extended

motor shaft adapter (if applicable), and seal

housing from the pump casing.

STEP 2

Remove the inducer or impeller bolt.

Note: Left hand thread.

Note: Restricting the impeller from moving will

be necessary.

STEP 3

Remove the impeller by prying gently with two

screwdrivers.

Bearing box

Adapter for

extended

motor shaft

Note: The impeller is dynamically balanced

and should be replaced if it shows any

sign of damage.

12

Instruction and Operation Manual

STEP 4

Remove the diffuser cover.

STEP 5

Remove the lower seal rotating face.

STEP 7

Remove the lower process seal.

STEP 8

Remove the lower shaft sleeve and o-ring.

STEP 6

Remove the lower process seal bolts.

STEP 9

Remove the seal housing bolts.

13

Instruction and Operation Manual

STEP 10

Remove the seal housing from the motor,

bearing box or extended motor shaft adapter,

as applicable.

Seal housing with bearing box shown.

STEP 11

Remove upper process seal or the throttle

bushing.

Seal housing with extended motor shaft

adapter shown.

14

Instruction and Operation Manual

Inspection, Cleaning, & Shimming the Extended Motor Shaft

Shaft and Lip Seal

Inspect the lip seal (115A) and driver shaft for

wear. Replace the lip seal and repair the shaft if

required. Shaft size in the lip riding area to be

1.750 ± 0.003 inches (44.45 ± 0.076mm)

diameter with 16 RMS or better surface finish.

Check the driver shaft for proper axial position.

The shaft shoulder, which controls the position

of the shaft sleeve, seal rotating face and

impeller, must be recessed .092 ± .030 inches

above the flange face as shown in the figure

below. Impeller rub and seal leakage will result if

this dimension is not held.

Figure 5. Driver Shaft Position

Dimension A

Figure 6. Shoulder Dimension

Measure depth A to shaft shoulder

(Range will be 0.068" to 0.108")

Installed adapter housing

A

EXTENDED

SHAFT

MOTOR

(AD02AA21) mounted with

no shims

Number of 0.010”

(0.25mm) Shims

Required

Shims added here

Extended Motor Shaft - Shoulder

Dimension

This section to be used with Reassembling the

LMV-801 section, steps 3 and 4.

The shaft shoulder dimension A as shown in

figure 6 must be measured as described below.

The motor must be positioned vertically with the

shaft pointing upwards.

Measure the shaft shoulder dimension A, from

the face of the motor adapter to the shaft

shoulder. This dimension can be measured

using a parallel bar and depth micrometer or tool

# T-GA-010.

Dimension A is then used to determine the

number of shims required per table in figure 6.

0.098” to 0.108” incl

(2.49mm to 2.74mm incl)

0.088” to 0.097” incl

(2.24mm to 2.48mm incl)

0.078” to 0.087” incl

(1.98mm to 2.23mm incl)

0.068” to 0.077” incl

(1.73mm to 1.97mm incl)

0

1

2

3

15

Instruction and Operation Manual

Shaft Sleeve

Ensure that there are no high spots on the end

surfaces of the shaft sleeve or the impeller hub.

High spots will distort the seal rotating face due

to the clamping force of the impeller bolt. Ensure

that shaft sleeve end faces are parallel within

0.0003” (.0076mm). Shaft sleeve end faces can

be lapped to achieve the flatness required.

Replace or lap the seal rotating face if the wear

track is rough or worn to a depth greater than 2

helium light bands.

A combined total of 0.010 inch (0.25mm)

maximum may be removed from the surfaces of

the seal rotating faces. Excess material removal

will result in incorrect seal face loading causing

increased seal leakage.

Remove any high spots on the end surfaces of

Note: Shaft sleeve ends that are out of parallel

beyond specification can contribute to

mechanical seal leakage due to mating

the shaft sleeve and impeller hub to insure that

the seal rotating face will not be distorted by

clamping force of the impeller bolt.

ring clamped against sleeve being out of

square.

Reassemble the seal, throttle bushing, if used

seal housing, and impeller using an o-ring repair

Mechanical Seal

Carefully inspect the seals for abrasive particles,

excessive seal face wear and any binding of the

seal face washer.

Replace or rebuild a faulty mechanical seal.

Seals may be rebuilt by replacing the seal face

washer, wedge rings, o-ring, and springs. A seal

repair kit is available.

kit. All o-rings that were disturbed by

disassembly should be replaced. During

reassembly, carefully check the torque values

listed in Table 3.

The impeller may rub on the diffuser cover plate

(15) until o-rings (936D and 936E) are

compressed by tightening hex nuts (914A).

Check the shaft for freedom of rotation after the

pump is assembled and all bolts are tightened

per Table 3.

16

Instruction and Operation Manual

Reassembling the LMV-801

The following procedures apply to the LMV-801

process pump single seal arrangement. For

differences in the double and tandem seal

arrangements see the seal arrangement

drawings later in this manual. Refer to the

specification sheet to determine your specific

pump configuration and optional equipment

included.

STEP 1

Install throttle bushing.

STEP 2 (Extended shaft motors only)

Mount the adapter to the motor.

Note: Ensure there are no shims or thermal

barrier gaskets between the motor and

the adapter.

STEP 3 (Extended shaft motors only)

Check the shaft shoulder dimension to

determine number of shims required.

See previous section and figure 6, for method

and table to determine the correct number of

shims.

STEP 4 (Extended shaft motors only)

Install the alignment pin into the adapter. Install

thermal barrier gasket and shims as required.

Alignment pin

Torque bolts to 40 ft-lb.

Installing the shim.

17

Instruction and Operation Manual

STEP 5

Install shaft sleeve on motor, bearing box or

extended shaft motor adapter, as applicable.

STEP 6

Install the thermal barrier gasket (if not

previously installed) and seal housing on the

bearing box or extended shaft motor adapter.

Torque to 40 ft-lbs.

STEP 7

Install the lower shaft sleeve o-ring.

STEP 8

Install the lower process seal and bolts.

Seal housing being installed onto bearing box.

Seal housing being installed onto extended

motor shaft adapter.

Lower process seal.

Tightening the bolts on the lower process seal.

18

Instruction and Operation Manual

STEP 9

Install the lower seal rotating face.

STEP 10

Install the inducer cover and o-rings, 936D and

936E.

STEP 11

Install the inducer or impeller bolt and 936G oring.

STEP 12

Install diffuser and o-rings 936B and 936C.

STEP 13

Install the seal housing and bearing box or

extended motor shaft adapter (as applicable)

onto the pump casing.

Pump, seal housing, and bearing box shown.

Torque impeller or inducer to 36-40 ft-lbs.

19

Instruction and Operation Manual

Figure 7. Service Check Points

20

Instruction and Operation Manual

TROUBLESHOOTING

Pump Diagnostics

Several system factors may aff ect the

performance of the pump. These factors are:

• Temperature

• Specific gravity

• Suction pressure

• Driver speed

These factors as well as internal problems must

be considered when analyzing pump system

performance. The following table gives

diagnostic information that can be useful when

analyzing pump performance problems.

• Flow rate

• Control characteristics

Table 1. Pump Diagnostics

Situation/Symptom Possible Cause Investigative/Corrective Action

No flow, no pressure at

start-up.

Pump not completely filled with liquid. Bleed all vapor or air from port 6.

Allow more cool-down time if pumping low

temperature fluid.

Check suction line for air leak if suction

pressure is lower than atmospheric.

NPSH actually lower than NPSH requirement listed on

specification sheet.

Suction line blocked – check suction screen

and valve.

Excessive pressure drop through suction

piping.

Flow restricted by vapor pockets in high points

of suction line.

Suction tank level or pressure too low.

Entrained air or vapor in pumped fluid.

NPSH reduced by presence of more volatile

fluid in process fluid.

Failure of drive component, such as interconnecting

shaft or impeller key, or item missing from assembly.

Reverse direction of rotation. Direction of driver shaft rotation must be as

Insufficient total head.

Flow too high. Check total head and flow rate against

Wrong direction of driver shaft rotation. (It is possible

for the pump to develop greater than 50 percent

design total head in this condition).

NPSH actually lower than NPSH requirement listed on

specification sheet.

Flow too low, causing overheating of fluid resulting in

internal boiling and unstable pump operation.

Diffuser discharge throat partially plugged or

impeller damaged by passage of a solid particle.

Disassemble and inspect.

shown by arrow on pump casing. Note: Impeller

and driver rotate in the same direction.

performance curve.

Direction of driver shaft rotation must be as

shown by arrow on pump casing. Note: Impeller

and driver rotate in the same direction.

Refer to solutions listed under “No flow, no

pressure at start-up”.

Increase through-flow rate.

Bypass part of pump discharge to supply tank.

Clean these areas of all obstructions and restore

surfaces to a smooth polished finish free of all

corrosion pitting. Edge of diffuser throat must be

sharp.

21

Instruction and Operation Manual

Situation/Symptom Possible Cause Investigative/Corrective Action

Insufficient total head

cont.

Driver overloaded.

Corrosion and/or erosion of diffuser throat (may

also be accompanied by corrosion/ erosion of

diffuser and cover surface adjacent to impeller).

Excessive recirculation from discharge to inlet. Check flow through external plumbing.

Process fluid specific gravity or viscosity different

from values shown on specification sheet.

Driver speed too low. Check speed against value listed on

Pressure gauges or flow meters in error Calibrate instrumentation.

Fluid specific gravity or viscosity higher than values

listed on specification sheet.

Electrical failure in electric driver. Check circuit breaker heater size and setting.

If edge of throat is no longer sharp and smooth

or has opened in size, head-rise may be

reduced. Opening of the inlet area of the throat

will result in higher flow rate and horsepower

consumption. Corrosion/erosion of diffuser and

cover surfaces will result in a significant

horsepower increase.

Pump o-ring (936C) damaged or missing.

Integral centrifugal separator orifice worn.

Check actual viscosity and specific gravity at

operating temperature. Viscosity higher than five

centipoise will cause reduced head and flow and

increased power consumption.

specification sheet.

Check actual viscosity and specific gravity

against value listed on specification sheet.

Check voltage and voltage balance between

phases.

Current for each phase should be balanced

within three percent.

Excessive discharge

pressure pulsations.

Mechanical failure in driver or pump. Remove driver and check for freedom of rotation,

Corrosion pitting on surface of diffuser cover or

diffuser, adjacent to impeller blades. Head rise is

also reduced by this condition.

Flow rate too low. Increase flow rate through pump. Add bypass to

Insufficient NPSH available. Refer to solution for insufficient NPSH under “No

Defective flow control valve. Check control valve.

correct spacing

of pump shaft assemblies.

Remove fluid end and search for any mechanical

failure.

Disassemble pump and inspect. Rough or

pitted surfaces can cause friction losses which

will significantly increase horsepower

consumption. Clean these areas of all

obstruction and restore surfaces to a smooth

polished finish. Check diffuser throat area at

the inlet; erosion or corrosion resulting in

roughness or increased area will increase

horsepower consumption. Note: A larger throat

size than design will allow a higher flow and

horsepower for a given head rise.

suction tank if necessary.

flow, no pressure at startup,” above.

22

Instruction and Operation Manual

g

Pump Mechanical Seal Diagnostics

The following table contains diagnostic

information that is applicable to single seal,

double seal, and tandem seal equipped units.

Repair procedures for mechanical seals are

listed in this manual under Maintenance.

Table 2. Pump Mechanical Seal Diagnostics

Situation/Symptom Possible Cause Investigative/Corrective Action

Sudden increase in seal

leakage.

Severe cavitation or loss of suction causing

vibration and bouncing of seal face.

Seal icing on low temperature pumps or icing

when handling fluids which vaporize at a

temperature of less than +32°F (0°C) at

atmospheric pressure

Solid particles in seal cavity or seal spring area

(seal faces usually have rough scratched

appearance).

Correct pump suction condition causing

cavitation. Bleed vapor from seal cavity and

restart.

Install double seal if loss of suction cannot be

prevented.

Quench with compatible fluid which will not

freeze at pump temperature through seal drain

port 2 or 7 to prevent ice formation on

atmospheric side of seal during start-up and in

running condition.

Use purge of dry nitrogen gas through ports

2 or 7.

Install double or tandem seal if ice is caused by

water in process fluid or supply external seal

flush of compatible fluid which does not contain

water.

Inspect for clogged integral centrifugal separator

orifices. Clean orifices if necessary (plan 31 if so

equipped.)

Supply external clean seal flush or double seal if

particles cannot be removed by separator.

Seal stationary face spring action is rough and

sticky.

Worn or damaged seal. Disassemble seal and rebuild or replace per

Wear pattern on seal rotating faces not uniform. Lightly lap surfaces of shaft sleeve and impeller

Wear pattern on stationary face smooth but not

uniform.

Edges of stationary face chipped and seal face

worn. (Vapor flashing in seal cavity will cause

excessive wear and/or cracking of rotating face.)

Seal rotating face cracked or broken. May be

caused by damage at assembly or thermal shock

caused by seal running dry.

If parts are corroded, replace with parts made

from compatible materials.

If formation of solids causes sticky seal analyze

fluid properties. Use external seal flush or double

seal arrangement.

instructions in maintenance section.

hub which contact rotating seal face to remove

hi

h spots. Install new seal faces.

Lap flat or replace seal.

Install seal cavity bypass to suction tank.

Prevent loss of pump suction.

Supply cool seal flush.

Install double seal.

Prevent loss of pump suction or supply

continuous external seal flush.

Install double seal.

23

Instruction and Operation Manual

Situation/Symptom Possible Cause Investigative/Corrective Action

Chemical attack of seal faces, seal parts or

o-rings.

Investigate fluid properties and determine

suitable materials for replacement.

Damage to mechanical seal secondary seal

(Teflon® wedge or U-cup or elastomer o-ring).

Check for erosion and/or corrosion attack.

Install seal flush or double seal arrangement.

24

Instruction and Operation Manual

SPECIFICATIONS

Table 3. Torque Values

Gearbox

Sundyne Standard Steel Screws & Bolts and NACE Compliant Steel Screws/Bolts (BG Material)

Torque Values

Item # Location Size English Metric

905H Oil Filter Manifold 3/8 - 16 x 1/2 22 - 25 ft-lbs 30 - 34 N-m

905L Gearbox Seal 1/4 - 20 x 1/2 75 - 80 in-lbs 8.5 - 9.0 N-m

905M, N Journal Bearings #10 - 24 x 1 35 - 40 in-lbs 4.0 - 4.5 N-m

905T Chemical Barrier Gasket 1/4 - 20 x 5/8 75 - 80 in-lbs 8.5 - 9.0 N-m

909B Gearbox Halves 1/2 - 13 x4 60 - 65 ft-lbs 81 - 88 N-m

909C Gearbox Halves, Alignment 5/8 - 18 x 4 17/64 60 - 65 ft lbs 81 - 88 N-m

906B Sight Glass #8 - 32 x 1/2 10 - 12 in-lbs 1.0 - 1.4 N-m

Pumps & Compressors*

Sundyne Standard Steel Screws and Bolts

Item # Location Size English Metric

3 Impeller Bolt/Inducer:

LMV/BMP-801, 802, 806, 322, 311, 331 1/2 - 20 36 - 40 ft-lbs 49 - 54 N-m

LMV/BMP-341, 346 1/2 - 20 65 - 70 ft-lbs 88 - 95 N-m

LMV-313, 343, BMP-338, 348 (High Flow) 3/4 - 10 85 - 90 ft-lbs 115-122 N-m

LMC/BMC 3X1P, 3X1F, 3X3, 3X6P, 3X7 1/2 - 20 36 - 40 ft-lbs 49 - 54 N-m

906D Diffuser Attaching Screws 1/4 - 20 95 - 102 in-lbs 11 - 11.5 N-m

905E Mechanical Seal No. Spacer 1/4 - 20 x 12 95 - 102 in-lbs 11 - 11.5 N-m

905F Throttle Bushing/Mechanical Seal 1/4 - 20 x 12 95- 102 in-lbs 11 - 11.5 N-m

905G Double Seal with Spacer 1/4 - 20 x 3/4 95 - 102 in-lbs 11 - 11.5 N-m

914A Case Nuts 3/4 - 10 250 - 275 ft-lbs 340 - 375 N-m

914A Case Nuts 7/8 - 9 300 - 330 ft-lbs 405 - 445 N-m

905A Seal Housing to Gearbox 3/8 - 16 x 1 3/4 35 - 40 ft-lbs 47 - 54 N-m

905P Separator 1/4 - 20 x 5/8 95 - 102 in-lbs 11 - 11.5 N-m

Pumps & Compressors

NACE Compliant Steel Screws / Bolts (BG Material)

Torque Values

Item # Location Size English Metric

3 Impeller Bolt/Inducer:

LMV/BMP-801, 802, 806, 322, 311, 331 1/2 - 20 36 - 40 ft-lbs 49 - 54 N-m

LMV/BMP-341, 346 1/2 - 20 65 - 70 ft-lbs 88 - 95 N-m

LMV-313, 343, BMP-338, 348 (High Flow) 3/4 - 10 85- 90 ft-lbs 115 - 122 N-m

LMC/BMC 3X1P, 3X1F, 3X3, 3X6P, 3X7 1/2 - 20 36 - 40 ft-lbs 49 - 54 N-m

906D Diffuser Attaching Screws 1/4 - 20 70 - 75 in-lbs 8.0 - 8.5 N-m

905E Mechanical Seal No. Spacer 1/4 - 20 70 - 75 in-lbs 8.0 - 8.5 N-m

905F Throttle Bushing/Mechanical Seal 1/4 - 20 70 - 75 in-lbs 8.0 - 8.5 N-m

905G Double Seal with Spacer 1/4 - 20 70 - 75 in-lbs 8.0 - 8.5 N-m

914A Case Nuts 3/4 - 10 160 - 200 ft-lbs 217 - 270 N-m

914A Case Nuts 7/8 - 9 225 - 245 ft-lbs 305 - 332 N-m

905A Seal Housing to Gearbox 3/8 - 16 x 1 3/4 27 - 30 ft-lbs 37 - 40 N-m

905P Separator 1/4 - 20 x 5/8 70 - 75 in-lbs 8.0 - 8.5 N-m

* When using Teflon® o-rings, allow 15 minutes between torquing for the Teflon® to cold flow. Repeat torquing until

there is no change in torque.

Torque Values

Note: When using PTFE o-rings, allow 15 minutes between repeated torquing for the PTFE to cold flo w.

Repeat until there is no change in the torque value.

25

Instruction and Operation Manual

Common Parts List

(Not Dependent on Seal Arrangement)

Table 4. Common Parts List

Item

No.

1 Pump Casing 1 911 Stud 12

2 Impeller 1 914A Hex Nut 12

3 Impeller Bolt 1 916S Washer 4

4 Impeller Key *1 918A Pin 1

5 Impeller Tab Washer *1 924B Bull Plug 1

9 Inducer (Optional) 1 924D Bull Plug 1

10 Inducer Stud (Optional) 1 936A O-ring Packing *1

13 Diffuser 1 936B O-ring Packing *1

14A Locating Pin 2 936C O-ring Packi ng *1

15 Diffuser Cover 1 936D O-ring Packing *1

914B Hex Nut 4 936E O-ring Packing *1

115A Shaft Seal 1 936F O-ring Packing *1

30 Seal Housing 1 936G O-ring Packing *1

87A Spacer (or Thermal Barrier

Gasket)

Part Name Qty Item

No.

1 981 Baffle Plate 1

Part Name Qty

905A Hex Head Cap Screw 4

*Recommended spare parts.

26

Instruction and Operation Manual

Single Seal Arrangement and Parts

Figure 8. Single Seal Arrangement

27

Instruction and Operation Manual

Table 5. Single Seal Arrangement

Item No. Part Name Qty. Item No. Part Name Qty.

21B Throttle Bushing (Upper) *1 62A - Seal Face Washer **1

50 Slinger Sleeve Assembly *1 63A - Seal Spring Backup Disc **1

51A Seal Rotating Face *1 64A - Seal Retaining Ring **1

60A Mechanical Seal *1 65A - Seal Spring **6

61A - Retainer and Drive

Sleeve Assembly

62A - Seal Face Washer **1 905E Hex Head Cap Screw 3

63A - Seal Spring Backup Disc **1 905F Hex Head Cap Screw 3

64A - Seal Retaining Ring **1 916A Washer 3

65A - Seal Spring **6 916B Washer 3

68A - Seal Wedge Ring **1 936H O-ring Packing *2

60A Mechanical Seal (Alternate) *1 936J O-ring Packing *1

61A - Retainer and Drive

Sleeve Assembly

1 69A - O-ring Packing **1

1

*Recommended Spare Parts

**Recommended Seal Spare Component Parts (Contained in Mechanical Seal Repair Kit)

28

Instruction and Operation Manual

Double Seal Arrangement and Parts

Figure 9. Double Seal Arrangement

29

Instruction and Operation Manual

Table 6. Double Seal Arrangement

Item No. Part Name Qty. Item No. Part Name Qty.

50A Shaft Sleeve (Lower) *1 61B - Retainer & Drive Sleeve

1

Assembly

50B Shaft Sleeve (Upper) *1 62B - Seal Face Washer **1

51C Seal Rotating Face *1 63B - Seal Spring Backup Disc **1

52 Seal Spacer 1 64B - Seal Retaining Ring **1

60A Mechanical Seal (Lower) *1 65B - Seal Spring **6

61A - Retainer & Drive Sleeve

1 68B - Seal Wedge Ring **1

Assembly

62A - Seal Face Washer **1 60B Mechanical Se al (Alternate) *1

63A - Seal Spring Backup Disc **1 61B - Retainer & Drive Sleeve

1

Assembly

64A - Seal Retaining Ring **1 62B - Seal Face Washer **1

65A - Seal Spring **6 63B - Seal Spring Backup Disc **1

68A - Seal Wedge Ring * *1 64B - Seal Retaining Ring **1

60A Mechanical Seal (Alternate) *1 65B - Seal Spring **6

61A - Retainer & Drive Sleeve

1 69B - O-ring Packing **1

Assembly

62A - Seal Face Washer **1 905F Hex Head Cap Screw 3

63A - Seal Spring Backup Disc **1 905G Hex Head Cap Screw 3

64A - Seal Retaining Ring **1 916A Washer 3

65A - Seal Spring * *6 916B Washer 3

69A - O-ring Packing **1 936H O-ring Packing *2

60B Mechanical Seal (Upper) *1 936J O-ring Packing *2

*Recommended Spare Parts

**Recommended Seal Spare Component Parts (Contained in Mechanical Seal Repair Kit)

30

Instruction and Operation Manual

Tandem Seal Arrangement and Parts

Figure 10. Tandem Seal Arrangement

31

Instruction and Operation Manual

Table 7. Tandem Seal Arrangement

Item No. Part Name Qty. Item No. Part Name Qty.

50A Shaft Sleeve (Lower) *1 64B - Seal Retaining Ring **1

50B Shaft Sleeve (Upper) *1 65B - Seal Spring **6

51A Seal Rotating Face *1 68B - Seal Wedge Ring **1

51C Seal Rotating Face *1 60B Mechanical Seal (Alternate) *1

60A Mechanical Seal (Lower) *1 61B - Retainer & Drive Sleeve

1

Assembly

61A - Retainer & Drive Sleeve

1 62B - Seal Face Washer **1

Assembly

62A - Seal Face Washer **1 63B - Seal Spring Backup Disc **1

63A - Seal Spring Backup Disc **1 64B - Seal Retaining Ring **1

64A - Seal Retaining Ring **1 65B - Seal Spring **6

65A - Seal Spring **6 69B - O-ring Packing **1

68A - Seal Wedge Ring **1 60B Mechanical Seal (Gas Seal) *1

60A Mechanical Seal (alternate) *1 61B - Seal Retainer 1

61A - Retainer & Drive Sleeve

1 62B - Seal Face Washer **1

Assembly

62A - Seal Face Washer **1 65B - Garter Spring **1

63A - Seal Spring Backup Disc **1 68B - Backing Ring **2

64A - Seal Retaining Ring **1 69B - O-ring Packing **1

65A - Seal Spring **6 905E Hex Head Cap Screw 3

69A - O-ring Packing **1 905F Hex Head Cap Screw 3

60B Mechanical Seal (Upper) *1 916A Washer 3

61B - Retainer & Drive Sleeve

1 916B Washer 3

Assembly

62B - Seal Face Washer **1 936H O-ring Packing *2

63B - Seal Spring Backup Disc **1 936J O-ring Packing *3

*Recommended Spare Parts

**Recommended Seal Spare Component Parts (Contained in Mechanical Seal Repair Kit)

32

Instruction and Operation Manual

Inducer & Parts

Figure 11. Optional Equipment

Table 8.

Item

Number

9 Inducer 1

10 Inducer Stud 1

14B Alignment Pin 2

86 Cover Gasket 1

106 Chemical Barrier Gasket 1

Part Name QTY.

33

Instruction and Operation Manual

Diffuser Cone Extension

Figure 12. Diffuser Cone Extension

Table 9.

Item

Number

1 Pump Case 1

13 Diffuser 1

16 Diffuser Extension 1

Part Name Qty.

34

Instruction and Operation Manual

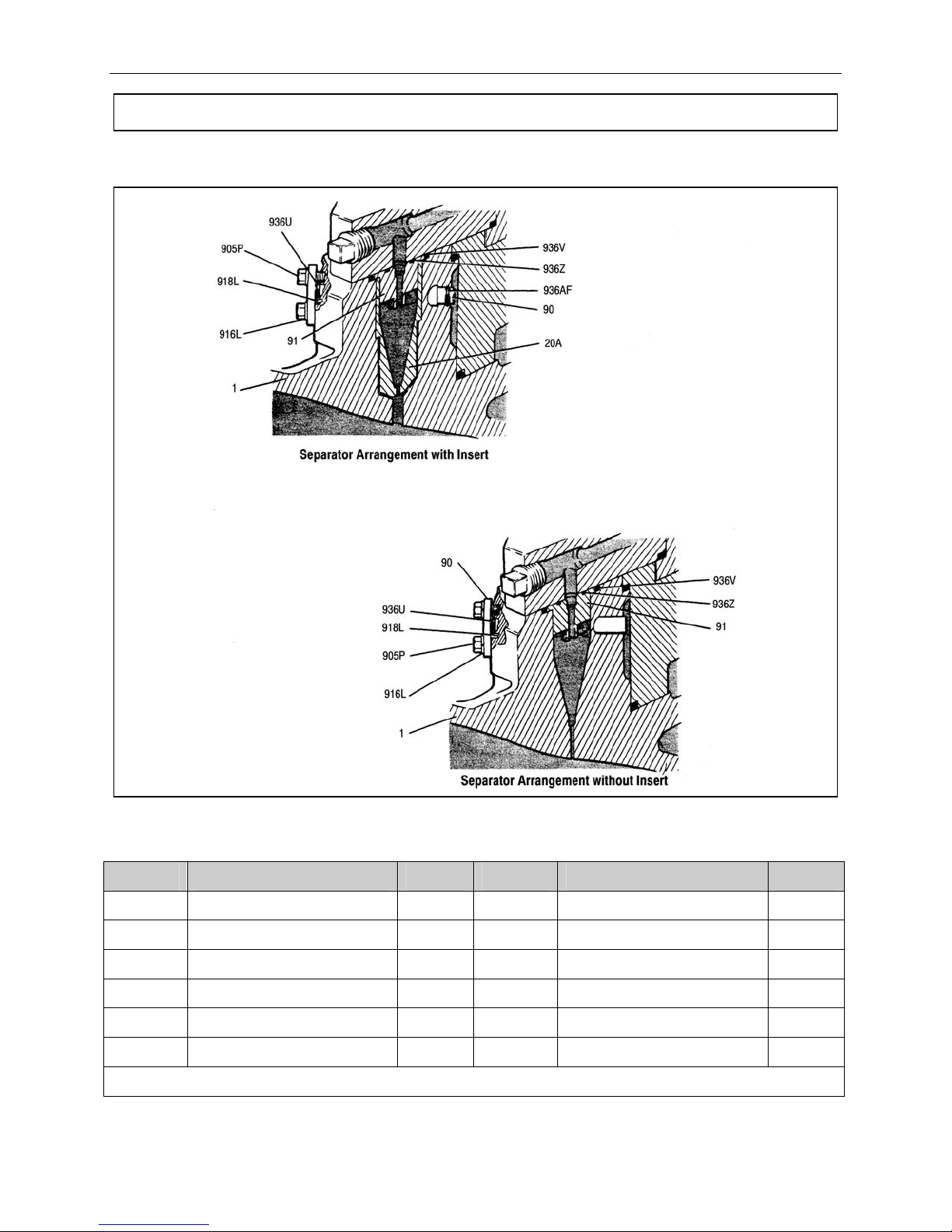

Integral Centrifugal Separator

Figure 13. Integral Centrifugal Separator

Item No. Part Name Qty. Item No. Part Name Qty.

1 Pump Casing 1 918L Pin 1

20A Separator Insert 1 936U O-ring Packing *1

90 Separator Orifice 1 936V O-ring Packing *1

91 Separator Fitting 1 936Z O-ring Packing *1

905P Hex Head Ca p Screw 2 936AF O-ring Packing *1

916L Washer 2

*Recommended Spare Parts

Table 10. Integral Centrifugal Separator Parts List

35

Instruction and Operation Manual

Extended Motor Shaft Adapter

Figure 14. Extended Motor Shaft Adapter

101

914B

916S

102

87A

916S

905A

Table 11. Extended Motor Shaft Adapter Parts List

Item No. Part Name Qty.

101 Adapter, Extended Motor Shaft 1

102 Shims As required

87A Thermal Barrier Gasket 1

905A Hex He ad Cap Screw 4

916S Washer, lock 3/8” 4

916S Washer, flat 3/8” 4

914B Nut, hex 3/8”-16 4

36

Instruction and Operation Manual

Recommended Spare Parts List

Table 12. Recommended Spare Parts List

ITEM NO. PAGE NO.

4

3 (or 10)

87A

115A

RKORP801

936A

936D

936E

936F

936G

936H

936J

936V

936Z

5

21B

50

51A

60A

936H

936J

DESCRIPTION

PUMP

Impeller Key

Impeller Bolt (or Inducer Stud)

Thermal Barrier Gasket

Lip Seal

O-ring Repair kit (Includes following)

- O-ring Packing

- O-ring Packing

- O-ring Packing

- O-ring Packing

- O-ring Packing

- O-ring Packing

- O-ring Packing

- O-ring Packing

- O-ring Packing

- Impeller Tab Washer

SINGLE SEAL

Throttle Bushing

Slinger Sleeve

Seal Rotating Face

Mechanical Seal

O-ring

O-ring

CLASS

1 2 3

QTY QTY QTY

1

1

1

1

1

1

2

2

1

2

2

1

2

2

1

1

1

1

2

1

1

2

1

1

8

8

4

2

2

1

50A

50B

51C

60A

60B

936H

936J

50A

50B

51A

60A

60B

60B

51C

936H

936J

DOUBLE SEAL

Shaft Sleeve (Lower)

Shaft Sleeve (Upper)

Seal Rotating Face

Mechanical Seal (Lower)

Mechanical Seal (Upper)

O-ring

O-ring

TANDEM SEALS

Shaft Sleeve (Lower)

Shaft Sleeve (Upper)

Seal Rotating Face

Mechanical Seal (Lower)

Mechanical Seal (Upper)

Mechanical Seal (Upper Gas)

Seal Rotating Face

O-ring

O-ring

37

1

1

1

1

2

1

1

2

1

1

2

1

1

8

8

4

4

4

2

1

1

1

1

2

1

1

2

1

1

2

1

1

2

1

1

2

1

1

8

8

4

6

6

3

Instruction and Operation Manual

Notes: Seal repair kits for standard seals are

available. O-rings for standard units are

available as a packaged o-ring Kit. The

o-ring repair kit does not include o-rings

936B and 936C.

Class 1: Minimum recommended spare

parts necessary to perform a

startup, and inspection of a new

unit.

Class 2: Minimum recommended spare

parts necessary to cover 1-2

years of normal operation.

Class 3: Minimum recommended spare

parts stock necessary for critical

services or units that will be

installed in remote locations.

38

Instruction and Operation Manual

Figure 15. Pump Exploded View

39

Instruction and Operation Manual

INDEX

Auxiliaries, 3

Chemical Use, 3

Common Parts List, 25

Control Checklist, 4

Controlling the Pump During Startup, 9

Diffuser Cone Extension, 33

Disassembling the LMV-801, 12

Double Seal Arrangement and Parts, 28

Driver Instructions, 3

Driver Rotation, 4

Driver Shaft Position Figure, 15

Electrical Safety, 2

Entrained Gases, 10

Environmental Control System, 4

Equipment and Safety Precautions, 2

Extended Motor Shaft, 1

Extended Motor Shaft - Shoulder Dimension, 15

Extended Motor Shaft Adapter, 35

Fall Protection, 3

Inducer & Parts, 32

Inspection, 6

Inspection, Cleaning, & Shimming the Extended

Motor Shaft, 15

INSTALLATION, 6

Installation and Start-Up Checklist, 5

Integral Centrifugal Separator, 34

ISO 9001, 2

Liquid Buffer System, 8

Machine Familiarization, 3

MAINTENANCE, 12

Mechanical Seal, 16

Minimum Flow Conditions, 10

Operating Conditions, 4

OPERATION & CONTROL, 10

Operation of Sundyne Pumps, 10

Parallel Operation, 9, 11

Parallel Operation Figure, 11

Parallel Units Common Valve Figure, 11

Personal Protective Equipment, 2

Piping Connections, 4

Pre-Commission Checklist, 3

Pressurizing Fluid Loop, 4

Preventative Machine Guards, 3

Pump Diagnostics, 21

Pump Exploded View Figure, 38

Pump Mechanical Seal Diagnostics, 23

Reassembling the LMV-801, 17

Recommended Spare Parts List, 36

Seal Environmental Control System, 7

Seal Housing Port Identification Figure, 8

Service Check Points Figure, 20

Setting the Valves, 4

Shaft and Lip Seal, 15

Shaft Sleeve, 16

Shoulder Dimension Figure, 15

Single Operation, 9

Single Seal Arrangement and Parts, 26

SPECIFICATIONS, 24

START UP, 9

Start Up Checklist, 4

Start-Up Procedures, 9

Storing Your Pump Long-Term, 6

Storing Your Pump Short-Term, 6

Suction and Discharge Piping, 7

Suction Conditions, 10

Sundyne Centrifugal Pumps, 1

System Head Curve, 10

Tandem Seal Arrangement and Parts, 30

Testing Equipment, 2

Text Symbols, 1

Torque Values, 24

TROUBLESHOOTING, 21

Typical Operation Figure, 10

Using Forklifts, 2

40

14845 W. 64th Avenue • Arvada, Colorado 80007 USA • +1-303-425-0800 • FAX: +1-303-425-0896 • www.sundyne.com

Sundyne Europe • Dijon (Longvic) • France • +33 (0) 3.80.38.33.00 • FAX: +33 (0)3.80.38.33.66

Sundyne Nikkiso • 27-10, Ebisu 2-Chome, Shibuya-Ku • Tokyo 150-0013, Japan • +81-3-3444-6475 • FAX: +81-3-3444-6806

ANSIMAG • ANYSPEED • CASTER • GSP • HMD/KONTRO • MASO/SINE • SUNDYNE COMPRESSORS • SUNDYNE • SUNFLO

Loading...

Loading...