SUNDYNE

LMC 341F COMPRESSOR

Instruction and Operation Manual

August 2007

Effective: August 2007 Visit our website at www.sundyne.com

COPYRIGHT

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise without the prior permission

of Sundyne Corporation.

© 2007 Sundyne Corporation

WARRANTY

Sundyne Corporation warrants to Buyer for a period of twelve (12) months from the

date of being placed in service (but not to exceed eighteen (18) months after the

date of shipment) that the equipment at the time of shipment will be free from

defects of design, material and workmanship. If any defects or malperformance

occur during the warranty period, Sundyne’s sole obligation shall be limited to

alteration, repair or replacement at Sundyne’s expense, F.O.B. Factory, of parts or

equipment, which upon return to Sundyne and upon Sundyne’s examination prove to

be defective. Equipment and accessories not manufactured by Sundyne are

warranted only to the extent of and by the original manufacturers’ warranty. Sundyne

shall not be liable for damage or wear to equipment caused by abnormal conditions,

vibration, failure to properly prime or to operate equipment without flow or caused by

corrosives, abrasives or foreign objects. THE FOREGOING WARRANTY IS

EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER

EXPRESSED OR IMPLIED INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. In no

event shall Sundyne be liable for consequential or incidental damages.

INTRODUCTION AND SAFETY.....................................................................................1

Text Symbols.............................................................................................................................................................1

Equipment and Safety Precautions .....................................................................................................................1

EXPLOSION/FIRE HAZARD.......................................................................................... 2

USING THIS MANUAL:..................................................................................................3

1. INSTALLATION..........................................................................................................4

INTRODUCTION TO THE SUNDYNE COMPRESSOR ................................................. 5

Inspection...................................................................................................................................................................5

Short-term Storage...................................................................................................................................................5

Long-term Storage ...................................................................................................................................................5

Installing the Suction and Discharge Piping - Guidelines.............................................................................6

Seal Environment Control System.......................................................................................................................7

Baseplate Grouting.................................................................................................................................................. 9

Horizontal Unit Gearbox Support Bracket .........................................................................................................9

Driver and Coupling................................................................................................................................................. 9

2. LUBRICATING OIL SYSTEM..................................................................................... 9

3. START-UP................................................................................................................ 13

Compressor Control During Start-Up................................................................................................................14

Run-In of the Compressor....................................................................................................................................14

4. SERVICING ..............................................................................................................15

Regular Maintenance.............................................................................................................................................15

5. MAINTENANCE OF THE SEALS AND PROCESS END DISASSEMBLY .............. 16

Tandem Seal Configurations...............................................................................................................................16

Double Seal Configurations.................................................................................................................................16

Procedure for Disassembling Process End.....................................................................................................16

Vertical units without a driver stand..................................................................................................................17

Vertical units with a driver stand........................................................................................................................17

BMC Units.................................................................................................................................................................17

Tandem Seal Disassembly...................................................................................................................................19

Impeller/Diffuser Cover Alignment.....................................................................................................................24

Impeller/Diffuser Clearance Calculation...........................................................................................................27

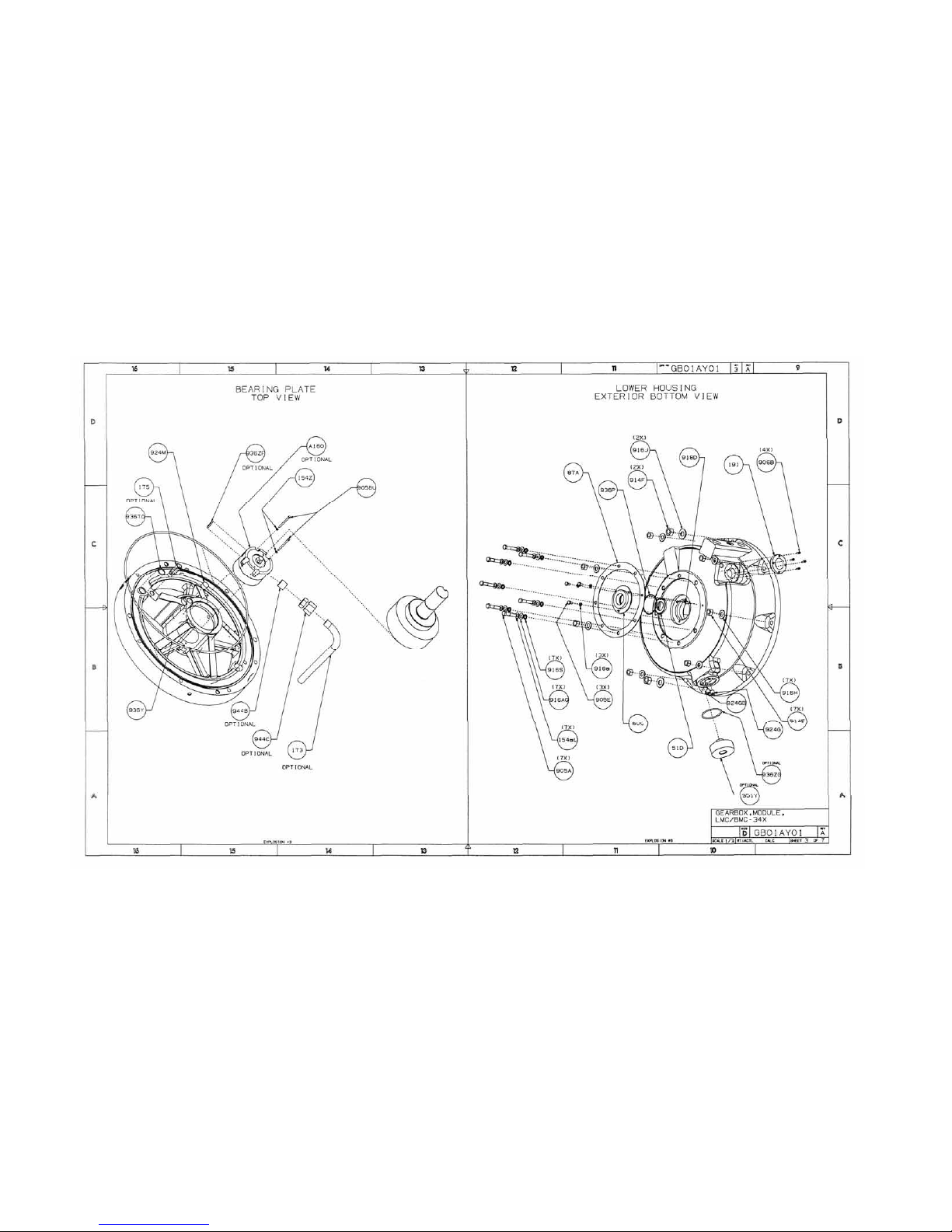

6. GEARBOX DISASSEMBLY .....................................................................................30

7. INSPECTION OF DISASSEMBLED HARDWARE...................................................44

8. CHECKING AND SETTING HIGH SPEED SHAFT END PLAY...............................48

9. GEARBOX AND PROCESS END REASSEMBLY.................................................. 50

Gearbox Auxiliary Hardware Installation..........................................................................................................53

10. TROUBLESHOOTING............................................................................................54

11. OPERATION........................................................................................................... 57

12. SPARE PARTS.......................................................................................................58

13. SUNDYNE COMPRESSOR WARRANTY.............................................................. 62

Critical Start-up Checklist ....................................................................................................................................62

Lock-out/Tag-out Guidelines...............................................................................................................................64

SINGLE SEAL ARRANGEMENT..........................................................................................................................65

DOUBLE SEAL ARRANGEMENT........................................................................................................................66

TANDEM SEAL ARRANGEMENT........................................................................................................................67

PHOENIX COMPRESSOR DRAWINGS ...................................................................... 68

Introduction and Safety

Text Symbols

The following symbols may be found in the text

of this manual.

They have the following meanings:

WARNING: Text accompanied by this

symbol indicates that failure to follow

directions could result in bodily harm or

death.

ELECTRICAL HAZARD: Text

accompanied by this symbol indicates

that failure to follow directions could result

in electrical damage to equipment or

electrical shock.

Equipment and Safety Precautions

Sundyne Corporation manufactures

compressors to exacting International Quality

Management System Standards (ISO 9001) as

certified and audited by Lloyd’s Register Quality

Assurance Limited. Genuine parts and

accessories are specifically designed and tested

for use with these products to ensure continued

product quality and performance. Sundyne

cannot test all parts and accessories sourced

from other vendors; incorrect design and/or

fabrication of such parts and accessories may

adversely affect the performance and safety

features of these products. Failure to properly

select, install or use authorized Sundyne pump

parts and accessories is considered misuse and

damage or failure caused by misuse is not

covered by Sundyne’s warranty. Additionally,

modification of Sundyne products or removal of

original components may impair the safety of

these products and their effective operation.

RECOMMENDED: Text accompanied by

this symbol indicates recommended

usage.

REMINDER: Text accompanied by this

symbol indicates a reminder to perform

an action.

EQUIPMENT USE ALERT: Text

accompanied by this symbol indicates

that failure to follow directions could

result in damage to equipment.

CAUTION

Sundyne compressors may handle hazardous,

flammable, and/or toxic fluids. Proper personal

protective equipment should be worn.

Precautions must be taken to prevent physical

injury. Residual fluids must be handled and

disposed of in accordance with applicable

environmental regulations.

Note: Safety procedures must be applied

prior to any installation, maintenance,

or repair of a Sundyne compressor.

Failure to follow safety precautions may

lead to injury!

1

Wearing Personal Protective

Equipment

To ensure safety, protective equipment must be

worn at all times when installing, performing

maintenance, or repairing equipment. The

following safety recommendations must be

adhered to for optimum safety:

• Safety glasses, with the minimum

requirement of side shields, must be worn

at all times.

• Steel-toed shoes must be worn when

lifting equipment greater than 15 pounds

(7 kg) or if pallet jacks or forklifts are

operated.

• Hearing protection is strongly

recommended at all times when noise

levels exceed 85 dB during an eight (8.0)

hour period.

Note: Chemical resistant gloves must be used

if chemicals are utilized (refer to Using

Chemicals for additional information).

Note: A dust mask respirator must be worn if

chemicals have warning labels

regarding fumes, dust, or mists.

When using more than one piece of protective

equipment, consider their compatibility. For

example, safety glasses will not interfere with

hearing protection equipment. Be sure to clean

all pieces of personal protective equipment

immediately after each use.

Using Forklifts

Any persons operating a forklift must have an

active recognized operator license.

Note: Before initializing forklift operation,

verify that the lift is in a safe operating

position.

Once all work has been completed, the person

installing the lock or tag must remove it

according to company procedure.

Testing Equipment

Prior to performing a test on newly installed,

maintained, or repaired equipment; all personnel

in the immediate area must be warned.

Note: Follow company procedures prior to

equipment testing at all times.

Using Chemicals

Any chemicals to be used must be accompanied

by a relevant material safety data sheet (MSDS),

in accordance with government legislation. If

applicable, use chemical proof gloves.

Note: An eye wash station (or equivalent)

should be available in the event of

injury. If any hazardous or flammable

chemicals pass through the equipment,

a complete decontamination of the

equipment is required.

Protection from Falling

Fall protection and associated preventative

measures are required when working on

equipment located six feet or higher from the

ground.

Note: Follow company fall prevention

procedures prior to working on

equipment.

Preventative Machine Guards

Preventative guards must remain in place on all

equipment.

Note: Only remove the guards while

performing maintenance or repair.

Replace the guards immediately after working

on the equipment and prior to start up.

EXPLOSION/FIRE HAZARD

Ensuring Electrical Safety

All electrical sources must be powered-off

before installation, service, or repair of

equipment occurs.

Note: Sundyne recommends that a Lock-

out/Tag-out program be followed prior

to altering the equipment. Locks or

tags must be provided to warn

employees that equipment is

temporarily unavailable.

Note: Never use an acetylene torch, open

flame, or heat to attempt to remove

parts that have seized together in

Sundyne equipment. Any residual

process gas or liquid that is flammable

can result in an explosion or fire with

potential for serious injury or death.

2

Using This Manual:

Organization

This manual is part of the final data package for the Sundyne LMC/BMC Phoenix compressor. In addition

to this manual, the final data package includes such information as the following:

Drawings, Sundyne specification sheet with test performance curves, test data, inspection data, material

certificates if required; and auxiliary equipment information. When using the specification sheet, section 1

of the final data package, and drawings, last section of final data package, in this manual compare the

release date with those in the maintained final data package to ensure that you are using the most

current information. This manual explains procedures for the Sundyne compressor, including how to:

install it, maintain it, service it, troubleshoot problems; and order parts. Whenever you talk or write to your

Sundyne representative, provide your compressor’s unique serial number.

This manual contains the following sections:

1. Installation

Describes how to install the compressor and how to store it until you install it.

2. Lubricating Oil System

Provides the following information: how to prepare the gearbox for start-up; how the lubricating oil

system works; and specifications for gearbox lubricants.

3. Start-up

Provides a procedure for starting and controlling the compressor. A critical start-up checklist is

included as Reference A.

4. Servicing

Provides procedures for servicing the compressor.

5. Maintenance of the Seals and Process End Disassembly

Provides procedures for disassembling the LMC/BMC compressor and its seal housings.

6. Gearbox Disassembly

Provides procedures for disassembling & reassembling the gearbox of the compressor.

7. Inspection of Disassembled Hardware

Provides procedure for inspecting the disassembled hardware.

8. Checking and Setting High Speed Shaft End Play

Provides procedure for checking and setting high speed shaft end play.

9. Gearbox and Process End Reassembly

Provides detailed reassembly procedure of gearbox and process end.

3

10. Troubleshooting

Provides tables for the following:

a) Looking up a problem.

b) Identifying the possible cause.

c) Selecting the corrective action.

11. Operation

Provides general guidelines for controlling a compressor such as surge control, suction throttling,

discharge throttling, and speed control.

12. Spare Parts

Contact and reference information.

13. Sundyne Compressor Warranty

Provides a warranty statement for the compressor/gearbox unit.

Reference A

Critical Start-up Checklist

Reference B

Lock-out/Tag-out Guidelines

Reference C

Seal Arrangement Drawings for single, double, and tandem configuration

Reference D

Phoenix Compressor/Gearbox Drawings

1. Installation

This section provides an introduction to the compressor, procedures for inspecting and installing it, and

procedures for storing it if you are not installing it immediately. It contains a subsection on each of the

following:

Introduction:

Inspection:

Short-term Storage:

Long-term Storage:

Suction and Discharge Piping:

Seal Environment Control System:

even if you use the standard system supplied by the factory.

Baseplate Grouting:

Horizontal Unit Gearbox Support Bracket:

support bracket on a horizontal unit.

Driver and Coupling:

grouting, and before you connect the piping for suction and discharge.

This provides a brief description about the compressor and how it is used.

As soon as you receive the compressor, inspect it thoroughly.

If the unit will be installed within 6 months follow these procedures.

If the unit will not be installed within 6 months follow these procedures.

Follow these procedures to set up the piping for suction and discharge.

Follow these procedures to set up the seal environment controls,

Use this information for applying grouting to the baseplate.

Follow these procedures to drill and pin the gearbox

Follow these procedures to align the driver and the compressor. Do this after

4

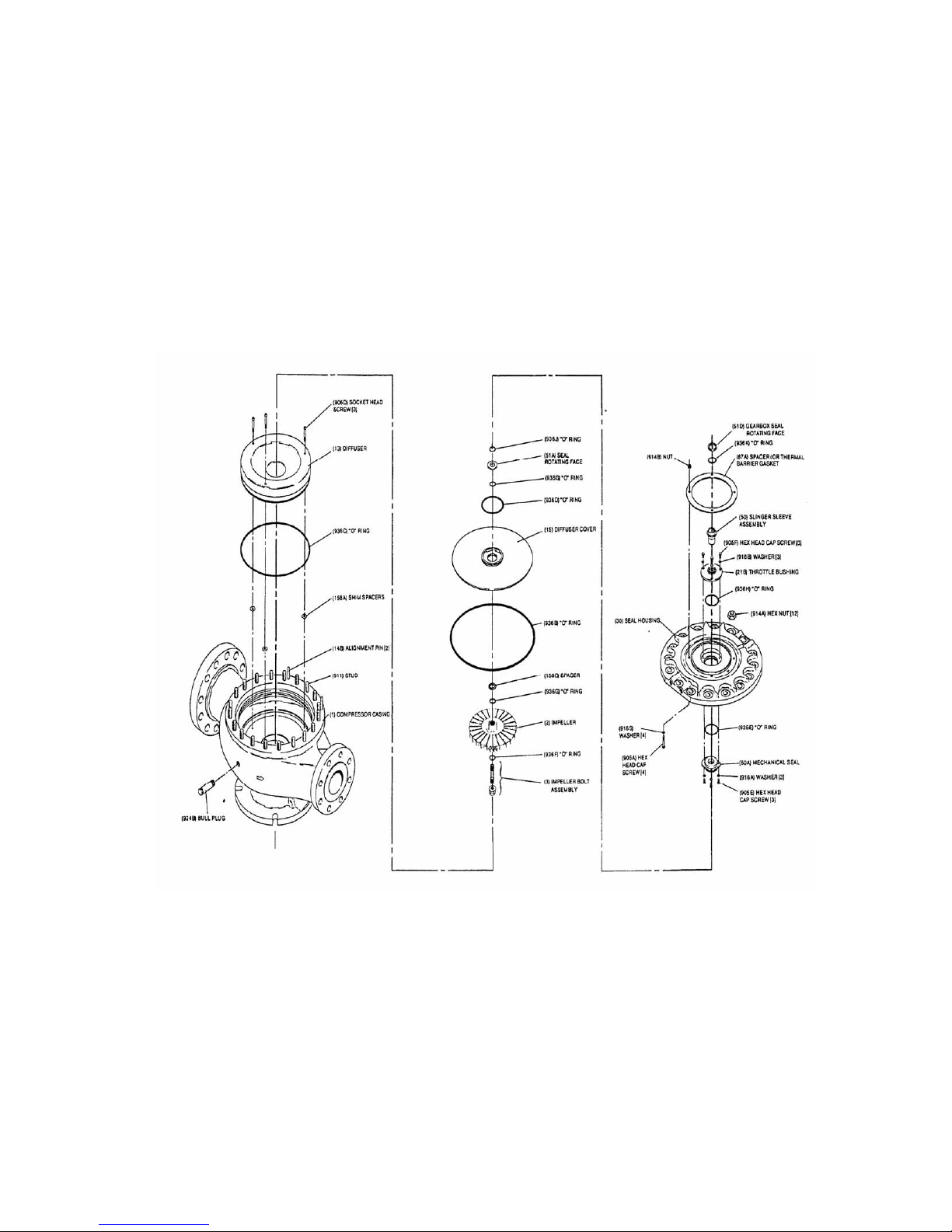

Introduction to the Sundyne Compressor

Sundyne LMC/BMC compressors have a single stage with an integral gearbox. It increases the pressure

of a continuous flow gas by applying centrifugal action. Sundyne LMC/BMC compressors are most

commonly used in chemical process plants to increase the pressure in a recycle loop. They are also used

in refineries, petrochemical plants, and power generation plants. Within these facilities, Sundyne

Compressors are used in booster, regeneration, vapor recover, boil-off, and other gas process

applications.

Sundyne LMC/BMC compressors offer industrial quality in a compact unit that is simple to assemble. It

provides high-energy performance and competitive efficiencies. For detailed specifications for Sundyne

LMC/BMC compressors, see the specification sheet and bill of materials or consult Sundyne

Compressors. For the primary components, see Reference D, compressor /gearbox module

drawings.

Inspection

1. When you receive the Sundyne LMC/BMC compressor, check for any damage. If you find any, inform

the carrier and Sundyne promptly.

2. Use Outline drawings in the final data package to ensure that all auxiliary items are properly included.

3. Check the gearshaft carefully. Seal drag may cause it not to turn freely at first. This is normal. But if

the gearshaft binds, it may be damaged, or it may need adjusting.

Short-term Storage - 1 day to 6 months

1. If the compressor is to be stored near strong chemicals or salt water, protect it immediately. To do

this, follow steps 5 through 11 from the long-term storage procedures below.

2. Protect the unit from moisture and dust.

3. Make sure that the factory’s shipping covers for the housing flanges and the seal ports are securely

in place.

4. Carefully follow the instructions provided by the manufacturer of the motor or turbine driver.

Long-term Storage - 6 months or more

If you store the LMC/BMC compressor for a long period of time, the methods you use are very important.

Please contact Sundyne at (303)-425-0800 USA and ask for the Field Service Department for further

instructions.

1. Be sure the storage area has: Humidity below 65%; and temperature range from 45° to 85°F

(7°C to 29°C).

2. Do not allow contact of airborne chemicals with the internal components of the unit.

3. If the unit is being stored near strong chemicals or salt water, protect it immediately.

4. Protect the unit from moisture and dust.

5. Make sure that the factory’s shipping covers for housing flanges and seal ports are securely in place.

5

6. Prevent corrosion to the components of the gearbox and the fluid-end.

7. Store the unit indoors.

8. Keep the room temperature and humidity constant.

9. Use desiccant bags to absorb moisture.

Either of the following:

10. Purge the internal components with an inert gas.

or

11. Oil flooding of component internals

Review Long Term Storage Instructions supplied with Final Data Package. Should you have any

questions, contact the factory in Arvada, Colorado.

After long-term storage, have an authorized Sundyne service engineer inspect all components and

supervise any necessary repair to be sure that they work properly. Any components not made by

Sundyne (except mechanical seals) must be inspected or replaced as determined by the

manufacturer’s authorized personnel, at the purchaser’s expense. Any Field Service work must be

clearly stated at the time of purchase to validate an Extended Warranty.

Because storage location and unknown factors at the site or storage are beyond our control,

Sundyne does not accept any liability for damage to the equipment during storage, nor do we

guarantee the quality of the equipment during and after the storage period. An Extended Warranty

will be null and void if the proper equipment preparation is not maintained.

Installing the Suction and Discharge Piping - Guidelines

Step 1: Clean the suction line.

Step 2: Install a strainer to protect the impeller from damage by mill scale, welding slag, or other

foreign particles.

Step 3: Make sure that the piping is aligned with the compressor flanges.

Step 4: Support all piping independently of the compressor.

Step 5: When you move the piping into place, never use excessive force at the flanged suction and

discharge connections. This could strain the unit.

Step 6: Use suction pipe that has a diameter at least as large as the diameter of the suction inlet of

the compressor.

Step 7: Make sure that the suction and discharge piping have no unnecessary elbows, bends, and

fittings. These increase the losses caused by friction. Also, be sure that all piping and fittings

are large enough to minimize losses caused by friction.

Step 8: Before you connect the piping to the compressor, tighten the hold down-bolts on the

compressor.

Step 9: Do not use elbow parts near the suction flange. A straight pipe run of at least 3 times the pipe

diameter is desirable between an elbow and the suction flange.

6

Step 10: Use block valves on both suction and discharge pipes to isolate the compressor during

shutdown, minimize process leakage, and reduce the likelihood of backflow through the

compressor, which can cause reverse rotation.

Seal Environment Control System

For the seal used with the compressor, always maintain the environment shown on the specification

sheet for your unit. For some arrangements and applications, you may need a system to control the seal

environment. For many applications, you can obtain a standard system from the factory. Make sure that

the system is installed properly and that the ports are open or plugged, as applicable. See Outline

drawing in the Final Data Package. Always be sure to leave port 1 free to drain leakage from the

gearbox oil seal and vent the gas seal.

You must vent case drain port 1 to atmospheric pressure and allow it to gravity drain properly. Otherwise

oil could contaminate the outboard gas seal. This port can be attached to a flare line, but should not have

back-pressure in excess of 5 psi.

A. GAS BUFFER SYSTEM – A gas buffer system must be used with double gas seals to prevent

process gas leakage out of the compressor. The buffer must be a cooled, dry, filtered gas, which

is compatible with the process gas and the compressor metallurgy. The buffer is introduced into

seal port 7 at a pressure range of 40 to 80 psi (2.8 to 5.6 kg/cm

suction pressure (max. of 160 psig – 11.2 kg/cm

2

) and at an average temperature no higher than

250°F (121°C). Part of the buffer flows across the lower seal into the process gas and part flows

across the upper seal and is vented from port 1. A buffer flow of 1.0 to 2.0 scfm (0.028 to 0.056

3

Nm

/min) must be maintained through the seal cavity, and should be regulated by a valve or

orifice on port 2. It is also acceptable to provide a buffer into port 2 and regulate by a valve or

orifice out of port 7. The buffer system must be in operation prior to starting the compressor.

Refer to compressor specification sheet for specific buffer requirements.

A buffer gas may also be used between tandem seals to reduce process leakage when buffer

contamination of the process gas is not permissible. Contact the factory for buffer pressure and

flow requirements.

B. LIQUID BUFFER SYSTEM – A liquid buffer system is used with double liquid seals and is

functionally identical to a gas buffer. The buffer liquid is introduced into port 7 or 2, allowed to flow

through the seal cavity, and out the opposing port.

Buffer flow should be 0.5 to 3 gpm (2 to 12 liters/min) with an inlet temperature of 60° to 120°F

(16° to 49°C), and inlet pressure a minimum of 20 psi (1.4 kg/cm

pressure.

If a closed loop buffer system is used, the buffer must be cooled prior to returning to port 7.

Otherwise, heat generated by seal friction will build up in the buffer, resulting in shorter seal life. If

an open loop system is used, an orifice or valve on port 2 should be used to regulate flow to

proper value.

NOTE

The compressor casing of units with double liquid seals must be drained prior to starting.

C. SEAL FLUSH – An optional seal flush system is available for use with single or tandem gas seal

arrangements when the process gas is contaminated with dust, dirt, or any other types of solid

particles. A clean, cool gas, either from external sources or cooled, filtered gas throttled from the

discharge is introduced into port 5 or 6 at a pressure slightly higher than suction pressure. Thus,

only clean gas will contact the seal face minimizing erosion and seal deterioration.

A flush is not required with a double gas seal due to the flushing action of the buffer leakage

across the lower seal.

2

) greater than compressor

2

) above process suction

7

D. PORT 1 PIPING – Units equipped with gas seals must vent case drain port 1 to atmospheric

pressure and allow it to gravity drain properly. Otherwise oil could contaminate the outboard gas seal.

This port can be attached to a flare line, but should not have back-pressure in excess of 5 psi.

8

Baseplate Grouting

A rigid concrete mounting base is recommended for all installations. Use a non-shrink grouting to fill the

baseplate grout-fill holes. The concrete foundation should have minimum deflections and freedom from

resonant frequencies in the operating range of the equipment being supported. The stand shall be

secured in position by one inch diameter bolts. The bolts shall be installed in the foundation with sufficient

length to protrude one quarter inch above the nut. The customer shall provide a 4” x 4” x 1/4” steel plate

under each leveling screw.

BMC UNITS WITH HORIZONTAL STANDS: The base plate should be leveled prior to grouting. Grout

shall set for the time limit as determined by the grout manufacturer.

LMC UNITS WITH VERTICAL STANDS: The top of the stand (driver mounting surface) should be

leveled by shimming under the base prior to grouting. The channels are to be filled with grout through the

access holes. The nuts on the foundation bolts should not be tightened until the grout has set as

determined by the grout manufacturer.

Horizontal Unit Gearbox Support Bracket

A gearbox support bracket (BK01AW04) is attached to the gearbox bearing plate and provides support to

the gearbox in the horizontally mounted configuration. The bracket is a two-piece slotted hole design

attaching the two pieces to provide adjustability in the field during field installation alignment. A shim (1/4”

thickness preferred) should be placed under the bracket and alignment completed. The bracket should

then be drilled and pinned (3/8” minimum pin diameter) in two locations to prevent possibly shifting of the

bracket during operation of the unit.

Driver and Coupling

Lock out starting switch on driver prior to working on coupling, following lock-out/tag-out

procedure.

UNITS WITH VERTICAL OR HORIZONTAL STANDS - ALIGNMENT--

If other than Sundyne supplied couplings are used, they must be flexible disc or gear type couplings

capable of tolerating parallel and angular misalignment of .005 inch maximum as well axial end play of

.060 inch maximum. Always refer to the coupling manufacturers recommendations for installation and

maintenance.

The motor and compressor coupling hubs are normally installed at the factory. For alignment

specifications, see Coupling Manufacturers Bulletin in the Final Data Package. Align the driver and

compressor after grouting and before you connect the suction and discharge piping. After you install the

piping, inspect the alignment again.

2. Lubricating Oil System

Oil Specification

The oil used in Sundyne gearboxes must meet the specifications presented in Field Engineering

Bulletin 40.2.04. In general, an ISO viscosity grade 32 oil will meet these specifications. Before using any

oil, you should verify its properties by consulting its manufacturer.

.

9

Field Engineering Bulletin

Sundyne & Sunflo & HMP Gearbox Lubricant Recommendations

EFFECTIVE : MAY 2006 Rev: E

For years the preferred gearbox lubricant for Sundyne pumps and compressors has been automotive

automatic transmission fluid (ATF). However, over time the additives in automatic transmission fluid have

changed to coincide with the technical improvements in automobile transmissions. The additives in the

new formulations of ATF, such as Dexron III, have been found to have negative effects on Sundyne

gearboxes and could compromise mechanical integrity and reliability of the equipment.

ISO Viscosity Grade 32 or 46 general purpose or synthetic oils are the recommended lubricants for

Sundyne gearboxes as shown in Table 1 below. ISO VG 46 lubricants are now recommended for high

horsepower gearbox models 33X and 34X with spherical roller bearings and high ambient temperature

installations. Gearbox lube oil should be changed twice yearly or more frequently in severe environments

which may be detrimental to the lubricant. Oxidized oil is frequently characterized by a darkening and/or

thickening of the oil. Operating of gearboxes with oxidized lubricant should be avoided.

Synthetic oils possess different characteristics than conventional mineral oils which make them desirable

for various extreme conditions such as high and low temperature operation. Synthetic oils offer very low

pour points, high temperature oxidation stability and a higher viscosity index.

The operation of Sundyne equipment in high or low ambient conditions may require special consideration

of gearbox lubricant and/or supplemental protective equipment such as heat exchangers or gearbox

heaters.

The lubricant chosen must be compatible with gearbox elastomers, Viton and Buna N. Any oil that

contains an inert additive such as PTFE, molybdenum disulfide or silicon should not be used in Sundyne

gearboxes. Use of lubricants containing inert additives will void the product warranty.

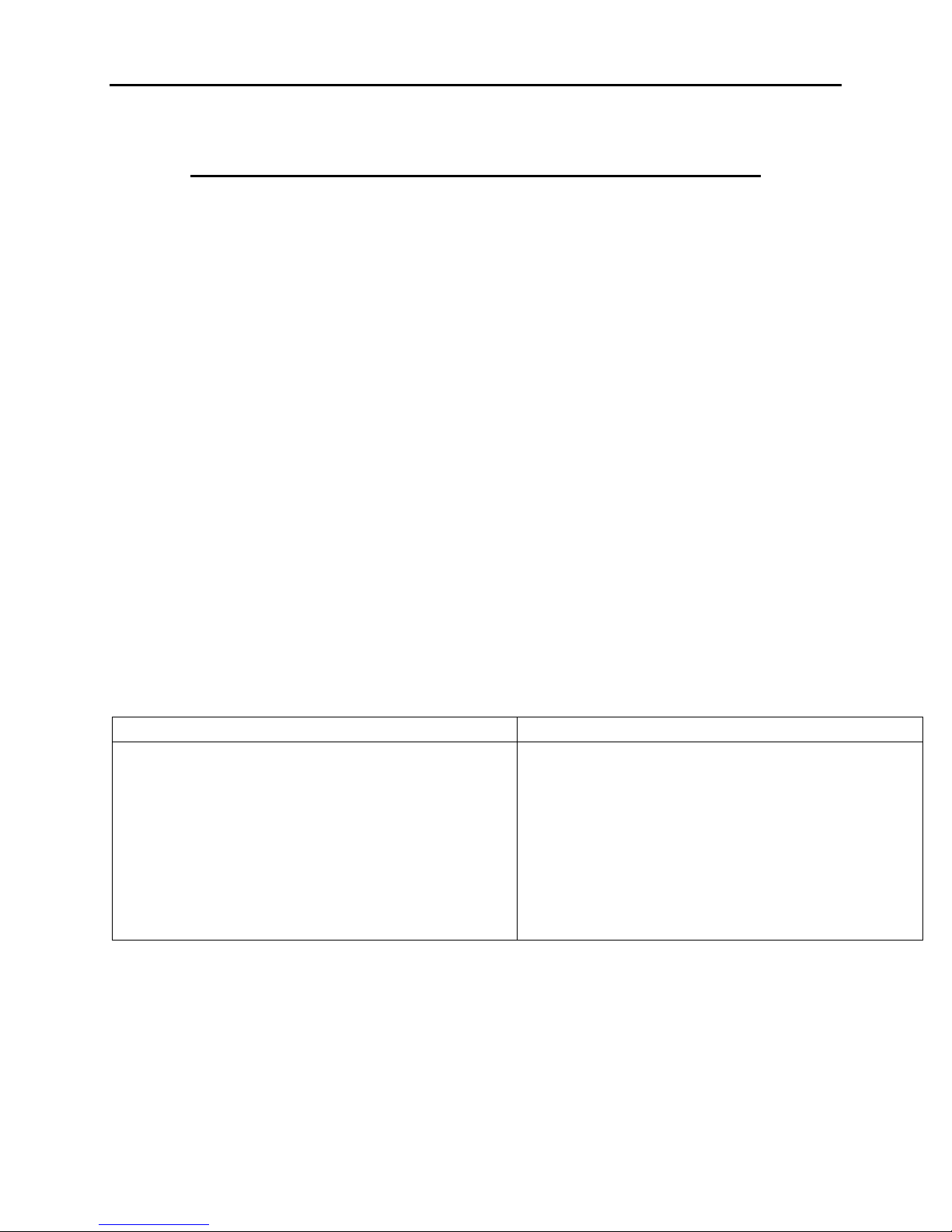

Table 1:

Use ISO Viscosity Grade 32 Lubricant ** Use ISO Viscosity Grade 46 Lubricant

Models: LMV/BMP-311

LMC/BMC-311F

LMC-BMC-311

LMV/BMP-313

LMC/BMC-313

LMV-322

All Sunflo Gearboxes

HMP-3000

HMP-5000

** Use ISO VG 46 lubricant for high ambient temperatures above 40 °C (100 °F).

10

Models: LMV/BMP-331 LMV/BMP-341

LMC/BMC-331F LMC/BMC-341F

LMC/BMC-331P LMC/BMC-341P

LMV/BMP-333 LMV/BMP-343

LMC/BMC-333 LMC/BMC-343

LMC/BMC-337 LMV-346

BMP-338 LMC/BMC-347

BMP-348

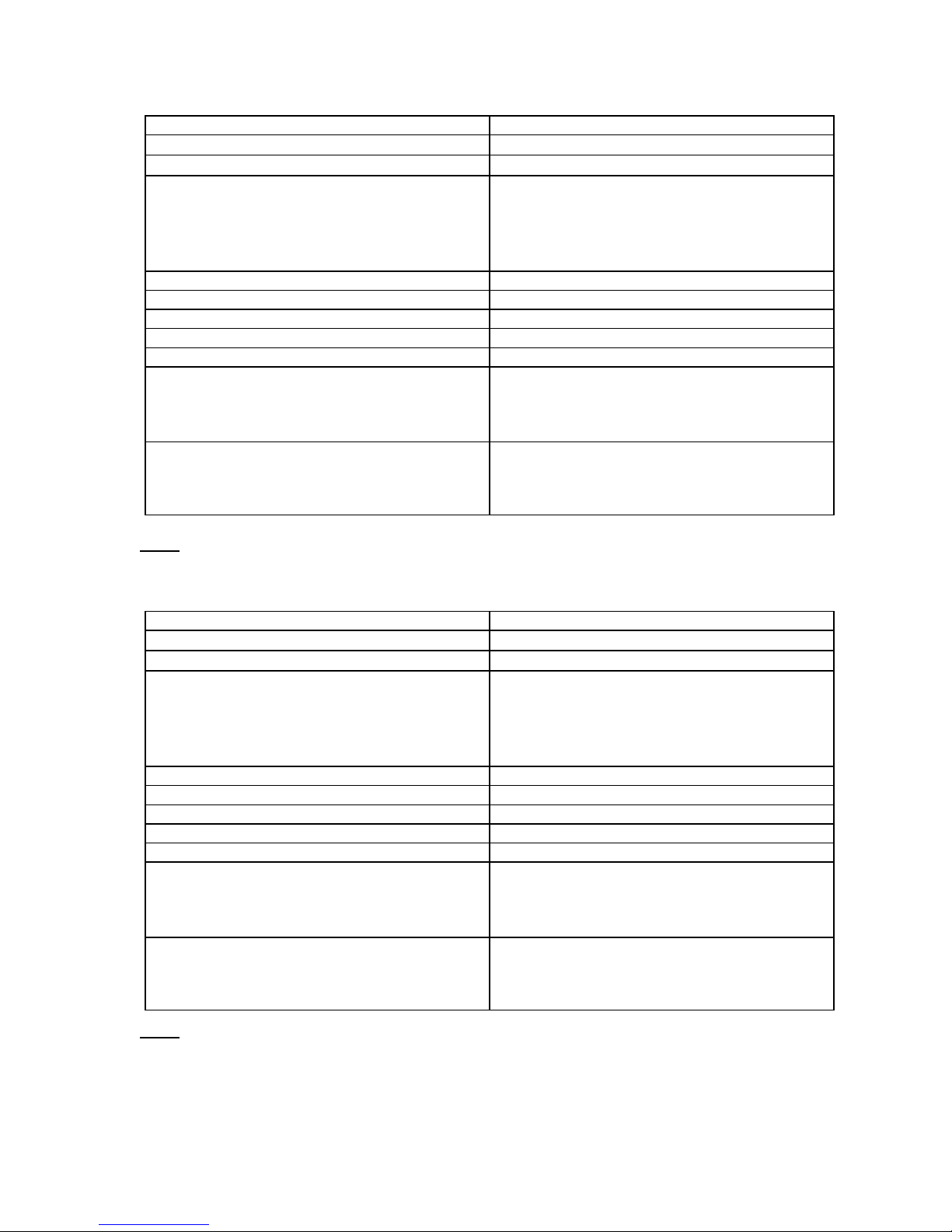

Recommended ISO VG 32 gearbox lube oil specifications:

Gravity, API 28 - 37

Pour Point, °C (°F)

Flash Point, °C (°F)

Viscosity,

cSt at 40°C

cSt at 100°C

SUS at 100°F

SUS at 210°F

-7 (20) max.

204 (400) min.

28.8 to 35.2

5.2 min.

150 to 180

44 min.

Viscosity Index 95 min.

ISO Viscosity Grade 32

Color, ASTM D 1500 1.5

Neutralization Number, Maximum 0.20

Rust Protection, ASTM D 665, A & B Pass

Demulsibility, ASTM D 1401

Time to 0 ml emulsion

at 54°C (130°F) after 30 min.

at 82°C (180°F) after 60 min.

Foam Limits, ASTM D 892

Sequence 1

Sequence 2

Sequence 3

Pass

Pass

25/0 max.

50/0 max.

25/0 max.

No other additives are recommended.

Note:

Recommended ISO VG 46 gearbox lube oil specifications:

Gravity, API 28 - 37

Pour Point, °C (°F)

Flash Point, °C (°F)

Viscosity,

cSt at 40°C

cSt at 100°C

SUS at 100°F

SUS at 210°F

-7 (20) max.

204 (400) min.

41.4 to 50.6

6.5 min.

217 to 260

48.8 min.

Viscosity Index 95 min.

ISO Viscosity Grade 46

Color, ASTM D 1500 2.0

Neutralization Number, Maximum 0.25

Rust Protection, ASTM D 665, A & B Pass

Demulsibility, ASTM D 1401

Time to 0 ml emulsion

at 54°C (130°F) after 30 min.

at 82°C (180°F) after 60 min.

Foam Limits, ASTM D 892

Sequence 1

Sequence 2

Sequence 3

Pass

Pass

25/0 max.

50/0 max.

25/0 max.

Note: No other additives are recommended.

11

Lube Oil System

The integral Sundyne lube oil system consists of the following major components: gearbox sump,

main lube pump, oil heat exchanger (if necessary), and oil filter. Oil is taken from the sump by the

lube pump, then passed through internal passages to an external integrally mounted manifold,

through the heat exchanger, then through the filter and back into the gearbox to the bearings. After

passing through the bearings, the oil drains back to the sump.

The gearbox sump holds approximately seven U.S. quarts (7.4 liters) of oil not including auxiliary

piping and heat exchanger. For wet sump gearboxes, fill gearbox within ¼” from top of oil level sight

glass. DO NOT overfill gearbox, as this will cause excessive foaming and overheating of the oil.

The main lube pump is a constant displacement gear type pump directly driven by the input shaft.

The standard heat exchanger is a shell and tube water cooled type mounted on the gearbox

manifold. Some low speed or low temperature units do not require a heat exchanger. For units having

a heat exchanger, cooling water should be provided at 150 psig (11 kg/cm

the specification sheet for cooling water requirements. Coolant flow should be controlled by a hand

valve installed in the cooling fluid discharge line to maintain a gearbox sump temperature between

140°F to 200°F (60°C to 93°C). Approximately one hour may be required to stabilize temperature.

The oil filter is a disposable pleated paper element type. Gearbox oil and filter should be changed

every six months.

2

) maximum pressure. See

Optional Lube Oil System Auxiliaries

A. LUBE OIL PRIMING KIT – A pre-lube system is required on units operating at high speed,

high pressure, or high horsepower conditions. It is also mandatory with the use of certain

auxiliary equipment. The kit consists of a motor driven positive displacement pump, check

valve, gages, and necessary piping. To start compressor, operate the pre-lube pump at least

30 seconds with a minimum of 7 psig (0.492 kg/cm

driver.

The pre-lube pump is to shut down only after main driver is at full operating speed.

B. REMOTE HEAT EXCHANGER – Some large water-cooled and all air-cooled heat

exchangers are mounted off the gearbox. Except for packaged units, the interconnecting

piping is the purchaser’s responsibility. The heat exchanger MUST be mounted lower than

the oil filter; otherwise, air pockets may be present in the lube oil lines at start-up, causing oil

starvation at the bearings. Equivalent length of piping and fitting must not exceed 20 feet

(6m), using minimum of 3/4” (19mm) I.D. tubing or pipe. If greater pipe lengths are required,

pipe diameter must be increased accordingly.

C. GEARBOX SUMP HEATER – A sump heater is required when ambient temperatures may

fall below the temperature at which the gearbox oil becomes too viscous for proper lube

pump operation. Both steam and electric sump heaters are available. The lube oil priming

pump must be operated anytime the sump heater is in operation.

2

) indication prior to starting the main

12

3. Start-up

If a Sundyne supplied control panel is to be used with the Sundyne LMC/BMC compressor, use the

control panel recommended start-up procedure in addition to the steps below. Before starting the

LMC/BMC compressor, complete the following procedure in the order in which the steps are

provided:

Step 1:

Check motor rotation before installing coupling.

Step 2: For the auxiliaries: Check the connections of the utilities; verify that the auxiliary piping

Step 3: Install flushing screens in all field-assembled piping connections. Clean these screens

Step 4:

Step 5: Prime the lubricating system, as follows:

Step 6: Turn on the cooling water to lubrication systems heat exchanger (if applicable), or turn on

Step 7: For double seal configurations, the buffer system must be pressurized to the pressure

Step 8: Charge the compressor with process gas.

Step 9: Start compressor, following process control startup procedures.

Step 10: Once the gearbox oil temperature has stabilized, adjust cooling water supply until the oil

Make sure that the driver has been serviced as per manufacturer recommendations.

meets the requirements shown in the Outline Drawing.

prior to commissioning. Check frequently for cleanliness and clean as needed.

Drain any liquids (blow-down) from the compressor and inlet pipe.

• Fill the oil reservoir with lubricating oil in accordance with the Field Engineering

Bulletin Gearbox Lubricant Recommendations.

• Add oil as necessary through the fill opening.

• With wet sump compressors, add oil as necessary until the oil level stabilizes at

the top of the bull’s eye in the sight glass. With dry sump, check oil level at

reservoir sight glass.

• Start the auxiliary lubricating pump, and run it until the oil reaches the correct

pressure and temperature. Add oil as necessary until the oil level stabilizes 3/4

of the way from the bottom of the sight glass.

• Allow lube pump to operate for at least 30 seconds with a minimum of 7 psig

(0.492 kg/cm^2) indication prior to starting the main driver.

air cooled heat exchanger. Verify high points (e.g. heat exchanger and filters) have been

vented.

specified on the spec sheet and on outline drawings prior to pressurizing the unit.

temperature to the bearings is 120º - 160ºF on units equipped with water cooled heat

exchangers. Maximum recommended temperature is 180ºF.

13

Compressor Control During Start-Up

Single Units:

A. Suction throttling (preferred method). Start compressor with the discharge valve open

while throttling the suction valve to bring the compressor to the design operating

point.

B. Discharge throttling. Start the compressor with the suction valve completely open

while throttling the discharge valve to bring the compressor to the design operating

point.

C. Other Methods – Insure that the compressor does not go into surge (flow too low) or

that the design horsepower is not exceeded (flow too high) while starting or operating

the compressor. Check units specification sheet for flow limits

Series Operation:

In series operation, it is necessary to have a bypass from the discharge of the second stage

back to the suction of the first stage. A check valve should be placed in the discharge line

downstream of the bypass. Typical start-up procedure is as follows:

A. Open the suction and discharge block valves and the bypass valve.

B. Start the second stage unit and maintain stable operation.

C. Start the first stage unit and maintain design flow to both units.

D. When sufficient pressure is being produced to overcome system back-pressure, the

check valve will open and the units will be on stream.

E. Close the bypass valve, being sure that the flow to the compressor is above the

surge point.

Parallel Operation:

Check valves must be placed in the discharge piping of each compressor to prevent backflow when one unit is started prior to the others. It is advantageous to install separate bypass

loops around each compressor for additional operational flexibility.

The first unit may be started as described above for single units. However, prior to starting

the second unit, it is preferable that the on-stream unit not be operating near its peak head

capability. This will lessen the chance of surging when the second unit is started.

Run-In of the Compressor

If the compressor is to be run-in or mechanically tested under conditions which are

considerably different from those that the unit is designed for (such as gas molecular weight,

suction pressure, flow rate, etc.) Sundyne should be consulted to insure that the run-in

conditions are compatible with the compressor.

14

4. Servicing

General Requirements

To increase the operating life of your compressor and keep it in good operating condition, you should

inspect and service it regularly. Measure all of the operating parameters documented in the specific

maintenance procedures and log your measurements. Make sure that all major equipment, such as

lubricating pumps, heat exchangers, and instrumentation, perform according to the manufacturer’s

recommendations. Whenever you find a deviation from specifications, identify its source immediately,

and take any corrective steps that are required to bring the unit into manufacturer’s specifications.

Regular Maintenance

Gearbox Oil

Check the level of the oil in the gearbox immediately before and after initial start-up, and regularly

while the compressor is running. Be sure to keep the level of the oil within the gearbox design limit.

The oil level must be maintained within the MIN/MAX range on the sight glass.

You can add oil to the wet sump gearbox while the compressor is running. See tagging information

on gearbox for where to add oil during operation. This location is different from the initial fill location.

Each must be used for its tagged purpose. Overfilling the gearbox will cause excess foaming and

overheating and should be avoided at all times.

Oil may be added to the external reservoir of the dry sump gearbox at the fill port.

Oil Pressure

The correct oil pressure from the main pump of the gearbox depends on the configuration of the

bearings and the characteristics of the lubricating oil used. In the normal operation, the oil pressure

supplied to the gearbox should be between 18-60 psig (1.2 - 4.2 Kg/cm

shutdown).

Changing the gearbox oil and filter

Change the oil in the reservoir and the oil filter elements every 6 months. SFHC recommended

synthetics may go for a longer period of time before an oil change out is required. For dual oil filter

units with a transfer valve, vent and fill the idle oil filter before operating the transfer valve.

Seal Leakage

Seal leakage out of port 1 should be checked periodically. Seals should be replaced if leakage

increases to an unacceptable level. With double seals, buffer pressure and usage should be

monitored to insure that seals are functioning properly.

Driver

Inspect the driver to make sure that it performs according to the manufacturer’s specifications.

Coupling

Inspect the coupling according to the manufacturer’s specifications. Never operate the compressor

without first checking the coupling guard. A compressor with a missing or incorrectly installed guard

could cause serious or fatal injury.

2

) (15 psi alarm, 10 psi

15

5. Maintenance of the Seals and Process End Disassembly

This section provides the procedure for disassembling the LMC/BMC compressor and its seal

housings for maintenance of the seals. The gearbox assembly is shown in Reference D, gearbox

module drawing.

Follow your organization’s Lock-out/Tag-out instructions before working on the

compressor. Failure to follow adequate Lockout/Tag-out procedures could cause serious injury.

Follow your organization’s procedures for blocking in or isolating the compressor from the process,

for depressurizing, and for decontamination before disassembly.

Tandem Seal Configurations

Depressurize the seal buffer system before depressurizing the compressor, otherwise reverse

pressure may cause the inboard seal to fail.

Double Seal Configurations

The compressor must be depressurized before the seal buffer system is depressurized, otherwise

reverse pressure may cause the inboard seal to fail.

Item numbers refer to the numbers in Reference D, gearbox module drawings.

The following procedures apply to all configurations of the Sundyne LMC/BMC compressors. Refer to the

specification sheet to determine the specific configuration and optional equipment included in your unit.

Parenthetical numbers in the text correspond to item numbers in the illustrations and parts lists.

Procedure for Disassembling Process End

The following replacement parts will be required as a result of compressor disassembly and seal

housing removal:

Table 5.1

PART DESCRIPTION ITEM

O-Ring Packing 936B 1

O-Ring Packing 936C 1

O-Ring Packing 936D 1

O-Ring Packing 936E 1

O-Ring Packing 936F 1

O-Ring Packing 936G 1

O-Ring Packing 936H 2

O-Ring Packing 936J 3

Single Seal 60A 1

Double Seal 60A, 60B 2

Tandem Seal 60A, 60B 2

Thermal Barrier Gasket 87A 1

NUMBER

QUANTITY

NOTE:

An O-Ring repair kit is available. This kit contains the O-Rings required to replace the gearbox

and compressor mechanical seals.

16

Step 1

Remove the driver and gearbox from the compressor housing as follows:

(3X2 compressor case shown in photo)

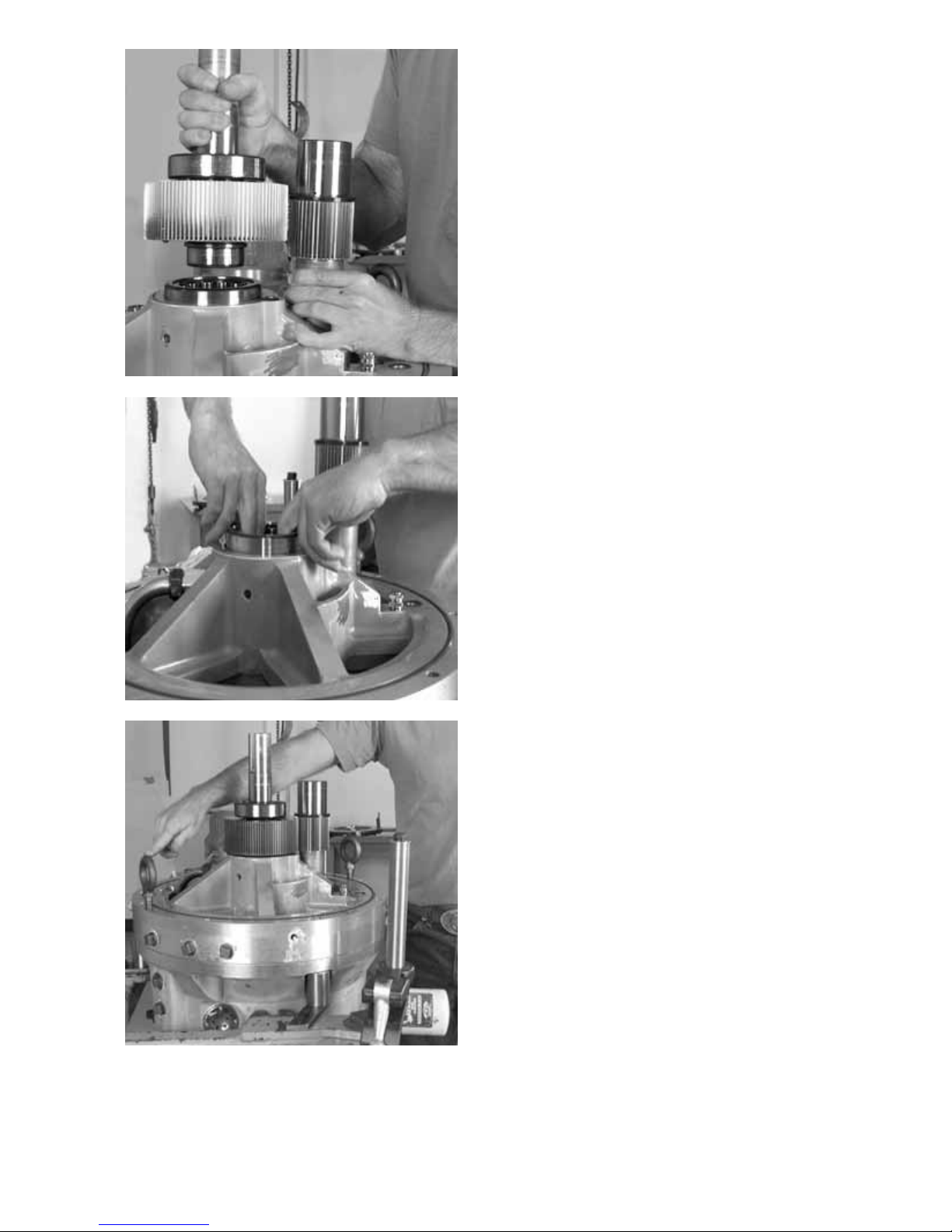

Vertical units without a driver stand (shown here)

Remove attaching hardware and lift driver from gearbox. Remove nuts (914A) from compressor

casing studs. Lift the gearbox and seal housing from the compressor casing, taking care not to

damage the impeller. Place the gearbox on a suitable support with the impeller inclined upward.

Vertical units with a driver stand

Remove bolts (909D) securing the coupling guard. Remove the coupling guard. Disengage both ends

of the spacer coupling and remove the floating shaft. Remove nuts (914A) from the compressor

casing studs and release the stiffening brackets. Attach the integral turnbuckles to the gearbox

bearing plate (102). Using the turnbuckles, lift the gearbox and seal housing from the compressor

casing. Exercise care to prevent damage to the impeller. Place the gearbox on a suitable support with

the impeller inclined upward.

BMC Units

Remove bolts (909D) securing the coupling guard. Remove the coupling guard. Disengage both ends

of the spacer coupling and remove the floating shaft. Attach a hoist to the gearbox using eyebolts in

the tapped holes on the bearing plate. Eyebolts can also be placed in the gearbox input housing as in

above photo. Remove nuts (914A) from the compressor casing studs and disconnect gearbox

bracket (BK01AW04) from the main base. Store any shims between the bracket foot and the main

base. Remove the gearbox and seal housing from the compressor casing by moving them toward the

driver until the impeller clears the compressor casing. Place gearbox on a suitable support with the

impeller facing upward.

17

NOTE: The gearbox can be worked on while in a horizontal position. However, the

diffuser cover must be prevented from falling off when the impeller is removed. If the cover

falls from its location severe damage to cover and output shaft (high speed shaft) will

occur.

Step 2 Prevent impeller from rotating and

remove impeller bolt (3).

NOTE: Impeller bolt may have either a

left-hand or a right-hand thread

depending on impeller rotation direction.

Left-hand rotation impellers will have a

left-hand thread impeller bolt and righthand rotation impellers will have a righthand thread impeller bolt.

(full emission impeller shown) Compressors that utilize clockwise

impeller rotation when viewed from the

(full emission impeller shown)

inlet, have left hand thread impeller bolts,

and counterclockwise rotating impellers

have right hand thread bolts.

Step 3 Remove impeller (2). It may be

necessary to pry under the impeller and

cover (15) to loosen it from the shaft. Pry

on opposite sides of the impeller so that

the impeller is removed evenly.

The impeller is dynamically

balanced and should be replaced or

rebalanced if it shows any sign of

damage.

(full emission impeller shown)

Step 4 Remove diffuser cover (15) from seal

18

housing (30).

Use a flat blade screw driver

inserted into pry slot of cover (15) to help

lift cover from seal housing (30).

Tandem Seal Disassembly

Step 1 Remove the seal rotating face (51a).

NOTE:

Tandem Seal Arrangement shown here. See

Reference C, Seal Arrangement Drawings, for

single and double arrangements.

Step 2

Remove hex head cap screws (905E),

washers (916A) and remove lower

mechanical seal (60A) of the tandem seal

arrangement from the seal housing.

19

Step 3 Remove spacer sleeve (60A).

Step 4 Remove o-ring (936J).

Step 5 Remove upper seal rotating face (51C).

Use two small screw drivers to lift

up the rotating face.

20

Step 6 Remove the hex head cap screws

(905A), lock washers (154AT), flat

washers (916AG), and seal washers

(916S) from seal housing (30).

Step 7 Install two 3/4” eye-bolts, approximately

180° from each other, through the seal

housing flange face.

21

Step 8 Use hoist and equal length chain

hooks to lift seal housing off the gear

box.

Step 9 Turn seal housing (30) over so you can

see the upper Tandem seal, and remove

the Thermal Barrier Gasket (87A).

It may help to have to people on

hand to help rotate seal housing.

22

Step 10 If upper seal from Tandem seal

arrangement requires removal; remove

hex head cap screws (905F), and lock

washers (916B).

Step 11 Remove upper mechanical seal (60B).

seals for abrasive particles, excessive

seal face in the retainer. Replace or

rebuild any faulty mechanical seal.

Seals may be rebuilt by replacing the

carbon seal nose, o-ring, and springs,

providing retainer is not damaged or

heavily worn. A seal repair kit is

available; contact your customer

representative or the factory. Replace or

lap the seal rotating face if the wear

track is rough or worn to a depth greater

than .0002-inch.

& Carefully inspect the

Step 12 Remove spacer sleeve (50B) from high

speed shaft. Note o-ring (936J) will be

lifted off high speed shaft along with

spacer sleeve (50B).

unusual wear or damage. Replace all

worn parts.

Clean and inspect all items for

23

Impeller/Diffuser Cover Alignment

The following replacement items will be required as a result of compressor disassembly and diffuser

removal:

Table 5.2

PART DESCRIPTION ITEM NUMBER QUANTITY

Impeller Spacer 158C Series AR

O-Ring Packing 936A 1

O-Ring Packing* 936C 1

O-Ring Packing 936E 1

O-Ring Packing 936F 1

O-Ring Packing 936G 1

*Required only if diffuser is removed.

Step 1

Remove impeller bolt (3), and impeller (2).

Step 2

Inspect impeller and procure a new one if required.

Step 3

Inspect diffuser for signs of damage (i.e. gouging in the bowl areas due to erosion or mechanical

damage)

Step 4

The impeller spacer (158C) is required to align the blade side of the impeller shroud flush with the

diffuser cover (15). The impeller spacer (158C) thickness (“D” dimension of Figure 5.1) must be

determined and the correct spacer installed during the replacement of any one of the following

components: gearbox assembly, gearbox high speed shaft (A130), or high speed shaft bearings

(151A or B), impeller (2), seal housing (30), diffuser cover (15).

NOTE:

The original clearances for your compressor as shipped from the factory for the impeller and

diffuser are recorded and supplied as part of the final data package.

Step 5

The Impeller to Diffuser Cover Alignment Procedure

Align the impeller (2) with the diffuser cover (15) as follows:

The Impeller to Diffuser Cover Alignment Procedure requires multiple assemblies of the stacked

rotating elements mounted on the end of the high speed shaft assembly. The procedure is attempted

after the gearbox is completely assembled with the shaft end play checked and within its specification

of 0.015” +/- 0.002”. This procedure also assumes that all components have been checked and are in

good order. If not, then new parts must be procured.

The 1st assembly includes only the mating rings, shaft sleeves, impeller spacer (158C), and impeller

(2) and is done without any o-rings, mechanical seal, seal housing (30) or diffuser cover (15). The

purpose of the 1st assembly is to ensure that all stacked components are compressed and fit tight

when the impeller is torqued to specification. A visual and physical check of these stacked

components is required to ensure that they cannot be spun in relation to the shaft.

The 2nd assembly requires that all components be installed, except the Item #936G O-Ring between

the impeller spacer (158C) and impeller (2). The purpose of this assembly is to check the impeller (2)

24

shroud height in relation to the diffuser cover (15) and to determine the correct thickness of the

impeller spacer (158C).

In the 3rd assembly, once the correct impeller spacer (158C) is determined, the impeller spacer

(158C), the o-ring (936G) between the impeller spacer (158C) and the impeller (2), and the impeller

(2) are assembled for the final time to complete the assembly.

5a. Assemble the gearbox, less the gearbox mechanical seal and mating ring, the process

mechanical seal(s) and mating ring(s), the seal housing (30), the diffuser cover (15), and impeller

(2). Ensure end float is within recommended limits; i.e., 0.015” +/- 0.002”.

5b. With the diffuser cover (15) removed from the seal housing (30), set the diffuser cover bottom

side up on a work bench. Set the impeller (2) in the recessed portion of the diffuser cover and

measure the distance from the outside flat surface of the diffuser cover to the front or blade side

of the impeller shroud as close to the outside edge of the shroud, as possible. The impeller

should be recessed into the diffuser cover a minimum of 0.025”. If the dimension is less than

0.025”, contact Sundyne Compressors in Arvada, Colorado.

5c. Place the gearbox upside down on a workbench or gearbox stand so the end of the high speed

shaft (A130) protrudes upward. All checks from this step on, should take place with the high

speed shaft resting down on its upper thrust washer or upper thrust tilt pad bearings.

5d. Assemble the seal component stack-up onto the high speed shaft (A130) without using the

mechanical seals, O-Rings, seal housing (30), or diffuser cover (15). With the high speed shaft

(A130) extending upward, slide on the gearbox mating ring (51D), and then the following parts:

For double seals, assemble the upper shaft sleeve (50B), the process mating ring (51C), the

lower shaft sleeve (50A), the impeller spacer (15C) and the impeller (2).

For single seals, assemble the shaft sleeve (50), the process mating ring (51A), the impeller

spacer (158C), and the impeller (2).

For tandem seals, assemble the upper shaft sleeve (50B), the upper process mating ring (51C),

the lower shaft sleeve (50A), the lower process mating ring (51A), the impeller spacer (158C), and

the impeller (2).

5e. To install the impeller (2):

-Check the shaft OD pilot fits and the impeller bore pilot fits and ensure that they are clean and free of

burrs. Clean up, deburr and polish, as needed, to prevent damage to each during assembly.

-Heat the impeller in an oven heated to 350ºF for 30-60 minutes.

-Apply a very small amount of anti-seize compound onto the shaft pilot fits to ease the installation and

removal of the impeller and to prevent galling.

-Lower the heated impeller onto the shaft on top of the stacked up parts, place a soft metal washer

over the impeller, install the impeller bolt (Item #3), and torque per Table 8.1. A soft metal washer is

placed between the impeller and the impeller bolt to prevent damage to the end surfaces of each

part.

-Allow the impeller to cool. This process can be accelerated by blowing shop air past the heated

wheel.

5f. During the cooling process, retorque the impeller bolt (3) 3-4 separate times to 50 ft. Ibs. When

the impeller is cool, retorque one final time per Table 8.1.

5g. Once the impeller is installed and cool, recheck the stacked components to ensure that they are

all tight and cannot rotate in relation to one another.

25

NOTE:

Steps 5d-5g serve to check that all stacked components are tight and not loose during

assembly. There is no way to check these stacked components with the seal housing

installed. Since the impeller to shaft fit is not a loose or slip fit, it is possible to assemble the

stacked components and achieve the required torque, even though the stacked components

could remain loose and free to turn in relation to the shaft. This could lead to component

damage if allowed to operate in this condition.

5h. Remove the impeller (2).

5i. Remove all stacked components, except the gearbox mating ring (51D).

5j. Reinstall the same components, only this time, include all O-Rings, mechanical seals, the seal

housing (30), and the impeller spacer (158C). Leave out the 936G O-Ring between the impeller

bolt (3) and the impeller. Place a soft metal washer between the impeller bolt and impeller to

prevent galling while torquing the impeller bolt.

5k. Before installing the diffuser cover (15), remove the o-ring (936E) from behind the diffuser cover,

then install the diffuser cover, without the o-ring, on to the seal housing (30).

5L. Reinstall the impeller using the same procedure described in step 5e above.

5m. Measure the distance between the top of the impeller shroud and the diffuser cover (15) per

(Figure 5.1). The impeller shroud should extend .000-.030” beyond or above the diffuser cover

(with the gearbox upside down). This is the “E” dimension in (Figure 5.1). If the shroud height is

measured out of tolerance, determine the correct impeller spacer thickness and replace it with

one of the correct size to ensure the proper shroud height (“E” dimension).

Table 5.3

Part Number

SP01AD02XXF 0.018”

SP01AD02XXA 0.030”

SP01AD02XXG 0.040”

SP01AD01XXB 0.050”

SP01AD01XXH 0.060”

SP01AD01XXC 0.070”

SP01AD01XXD 0.090”

SP01AD01XXE 0.110”

SP01AD01XXJ 0.020”

Thickness

5n. Remove the impeller (2).

5o. Remove the diffuser cover (15), reinstall the diffuser cover O-Ring (936E) behind the diffuser

cover, and reinstall the diffuser cover, with O-Ring, onto the seal housing.

5p. Install the impeller spacer (158C) with the correct thickness and the o-ring (936G) between the

impeller spacer and the impeller.

5q. Install the impeller (2) as described in step 5 above.

5r. Recheck the alignment of the impeller (2) shroud to the diffuser cover (15); i.e., Dimension “E” in

Figure 5.1.

26

5s. When the impeller is completely cooled, remove the impeller bolt (3) and the soft metal washer

and then reinstall the impeller bolt, without the soft metal washer

and torque per Table 8.1.

5t. Record the thickness of the impeller spacer (158C) and the impeller shroud to diffuser cover

alignment (Dimension “E” in Figure 5.1) for future reference.

Impeller/Diffuser Clearance Calculation

The clearance between the impeller and diffuser must be checked and, if necessary, adjusted after

the replacement of any of the following parts: gearbox assembly, gearbox high speed shaft (A130),

gearbox high speed shaft bearings (151A or B), diffuser (13), impeller (2), compressor casing (1),

seal housing (30).

Step 1

The required impeller to diffuser clearance is 0.035 - 0.055 inches, see (“A”) dimension in

(Figure 5.1). This clearance is obtained by installing shim spacers (158A) between the diffuser and

compressor casing, see (“B”) dimension in the (Figure 5.1). The recommended procedure for

determining shim spacer requirements is as follows:

Step 2

Refer to (Figure 5.1). The seals, seal housing, diffuser cover, and impeller must be installed on the

gearbox. The diffuser must be bolted into the compressor case (1).

Step 3

Using electrical solder, make a ring that is slightly smaller in diameter than the impeller blade

diameter. Place the solder ring on the diffuser and center it around the inlet eye. Use tape to hold the

solder in place.

Step 4

Install the complete compressor assembly and gearbox in to the compressor case and tighten four

equally spaced seal housing nuts (914A) onto the case studs. Use the proper torque given in Table

8.1. Then remove the seal housing nuts and carefully lift out the compressor assembly from the

compressor case.

Step 5

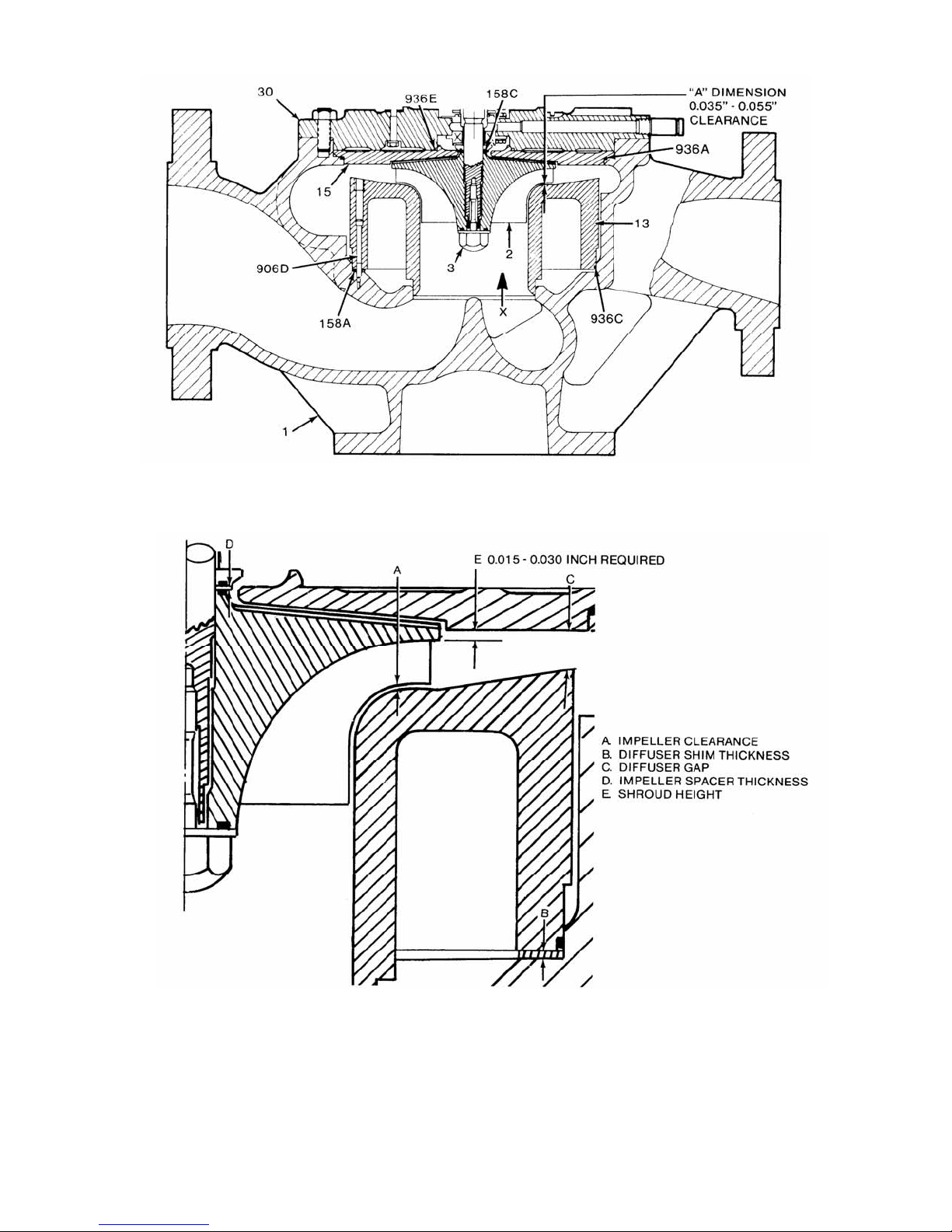

Measure the thickness of the solder ring at points where it contacted the impeller blades and record

the average thickness. This is the “A” dimension in (Figure 5.1). This impeller to diffuser clearance

must be between 0.035 and 0.055 inch (0.089 and 0.140 mm).

Step 6

If the impeller clearance is not within the proper range, calculate the required change in shims. Add

or remove diffuser spacers (158A) to adjust the clearance to the correct range.

27

Figure 5.1. Compressor Cross-Section and Clearances

28

NOTE:

The shim spacers are available in sets of five, including one each of:

Table 5.4

0.005 inch (0.13 mm)

0.010 inch (0.25 mm)

0.015 inch (0.38 mm)

0.020 inch (0.51 mm)

0.030 inch (0.76 mm)

Step 7

Install the spacers (158A) in compressor case (1).

Step 8

Install O-Ring (936C) on the diffuser (13).

Step 9

Install diffuser in compressor case and tighten the three screws (906D) per torque Table 8.1.

NOTE:

If a PTFE O-Ring (936C) was installed, perform the following steps, (10) through (14) prior to

final assembly of the compressor casing to the seal housing (30). If an elastomer O-Ring was

used, proceed to Step 15.

Step 10

Place casing (1), with diffuser (13) installed, on solid work surface.

Step 11

Place three of the compressor casing attaching hex nuts (914A) or other suitable spacers on upper

surface of diffuser.

Step 12

Lower the gearbox assembly onto the hex nuts. Install four of the compressor casing nuts (914A) and

tighten. This step is necessary to compress the PTFE O-Ring (935C) and maintain the proper final

impeller-to diffuser clearance.

Step 13

Remove the gearbox assembly from the case and remove the hex nuts that were used as spacers.

Retorque three screws (906D) to proper torque values.

Step 14

Reassemble the compressor with another solder ring and recheck the impeller clearance.

Step 15

Record the new diffuser spacers (158A) thickness (“B” dimension) and the impeller to diffuser

clearance (“A”) dimension in (Figure 5.1). Remove the compressor assembly from the compressor

case and place short strips or coils of electrical solder taped out on the flat portion of the diffuser.

Step 16

Reinstall the compressor assembly and retighten the case nuts. Loosen the nuts and remove the

assembly. Measure the solder at the flattened portion and record the diffuser to cover clearance

(“C” dimension) in (Figure 5.1). This dimension must be within 10% of the as shipped “C” dimension

as shown in the final data package.

29

Step 17

Reassemble the compressor installing all the O-Rings into the proper positions. Tighten the

compressor case nuts to the proper torque listed in Table 8.1.

CAUTION: When PTFE O-Rings are being used, special consideration must be taken to

allow for cold flow. Retorquing may be required to obtain proper torque value.

6. Gearbox Disassembly

Note: In order to disassemble gearbox it is necessary to complete steps 1

through 16 of Maintenance of the Seals and Process End

Disassembly.

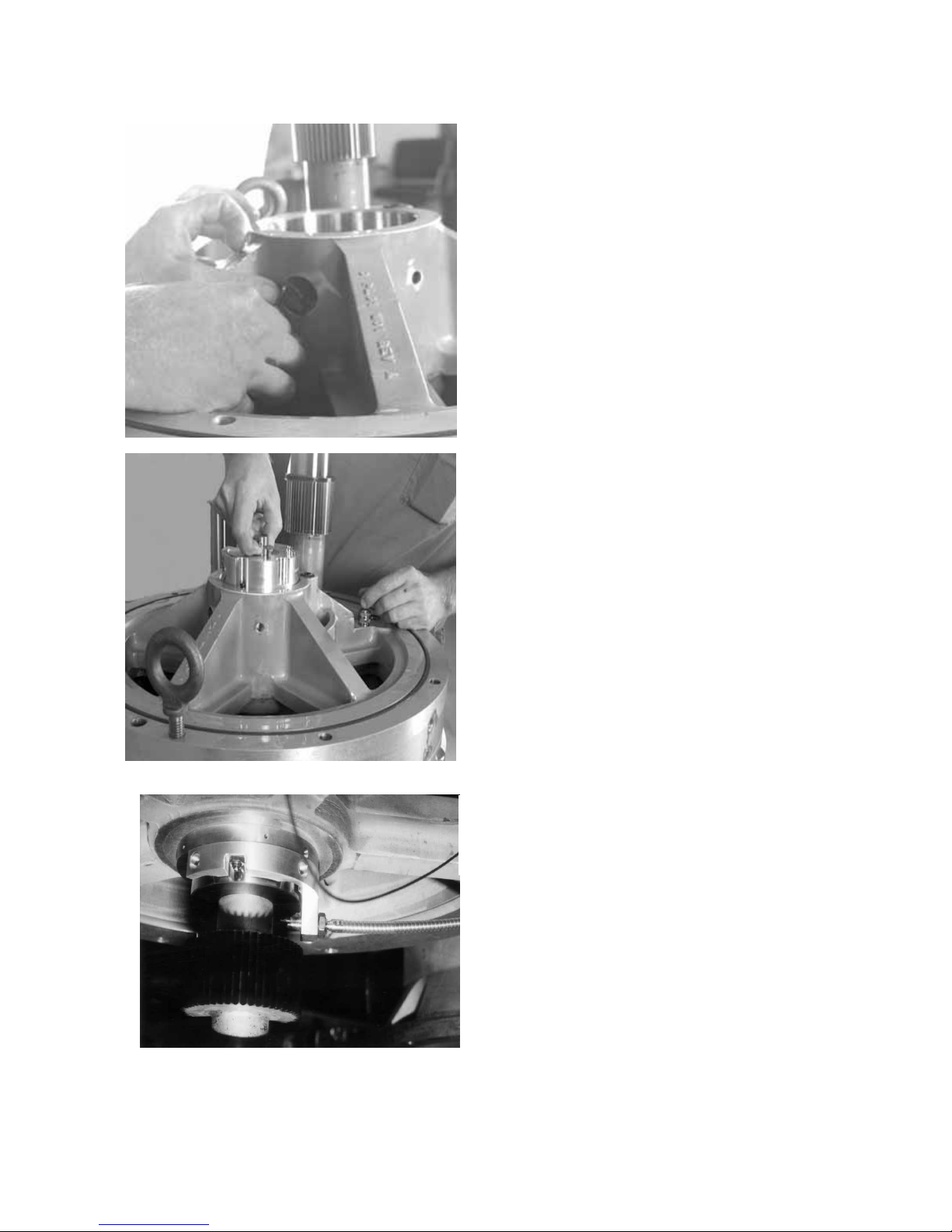

Step 1 If you have not drained

the oil from the gearbox you should do so

now! Remove hex head cap screws

(905E) and lock washers (916A) from the

gearbox seal flange.

Step 2 Remove gearbox seal (60C).

It is helpful to use a small flat

blade screw driver to lift the seal flange

up from the aluminum gearbox face.

30

Step 3 Carefully inspect the seals for abrasive

particles, excessive seal face wear and

any binding of the carbon seal nose.

Replace or rebuild any faulty mechanical

seal. Seals may be rebuilt by replacing

the carbon seal nose, o-ring, and spring

providing the retainer is not damaged or

heavily worn.

Step 4 Remove o-ring (936P).

Step 5 Remove rotating face (51D).

Use two small flat blade screw

drivers to help lift rotating face out of

pocket in the gearbox taking care not to

damage the gearbox seal o-ring chamfer.

Inspect the rotating face for any cracks,

chips, or grooves. If any cracks or chips

are present replace the rotating face.

31

Step 6 Rotate gearbox in holding device so that

the input shaft (A120) is now pointing up.

Make certain that the gearbox is steady

and held in place by clamps. Remove nuts

(914F) and (914E), remove flat washers

(916J) and (916H). Next remove bolts

(909C) and (909B), and flat washers

(916H) and (916J) making sure that the

alignment bolts are removed first. Loosen

four round hex head socket screws

located on the top of the input seal (115).

result in damage to either the input seal

(115) or the input shaft (A120).

Failure to loosen these screws will

Step 7 Install two 5/8” eye bolts into the top of

the upper gearbox housing (101B). Use

hoist to lift the upper gearbox housing

(101B) away from the other gearbox

housings.

upper gearbox housing (101B) and watch

to see if the input shaft assembly (A120)

roller bearing outer race and rollers stay

with the upper gearbox housing (101B). If

the bearing does stay with the upper

gearbox housing (101B), the mechanic

should try to keep the bearing from falling

out of the upper gearbox housing (101B)

by reaching into the housing and holding

the bearing in place. After the mechanic

rests the upper gearbox housing (101B)

on a bench or table remove the outer

race and rollers sliding them back onto

the input shaft assembly (A120). Remove

the input seal (115) from the upper

gearbox housing (101B). Inspect seal. If

it was leaking or is damaged replace

input seal (115) with a new seal.

It is a good idea to look into the

32

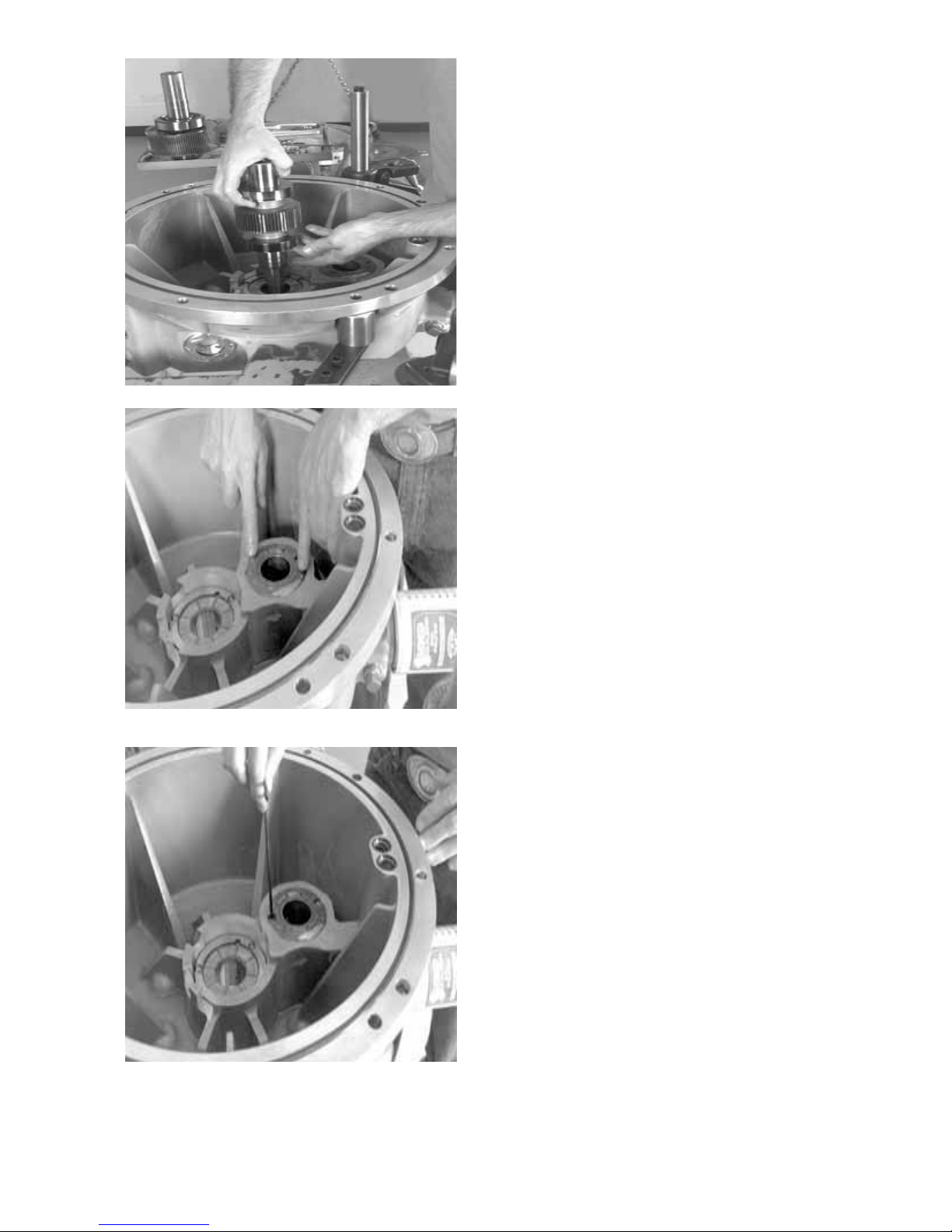

Step 8 Remove the input shaft assembly (A120).

To accomplish this the mechanic must

first lift up the idler shaft assembly (A140)

and tilt it away from the input shaft

assembly (A120). The mechanic should

grasp the input shaft assembly by the top

of the shaft and lift straight up and away

from the bearing plate (102). The lower

outer race and rollers from the input shaft

assembly (A120) will be in the bearing

plate (102). Pull the outer race and rollers

out of the bearing plate (102) and keep

with the input shaft assembly (A120).

Step 9 Install two 5/8” eye bolts into the top face

of the bearing plate (102). The mechanic

will use these to lift the bearing plate from

the lower housing (101A).

33

Step 10 a. Remove the sump tube (173). First

loosen the nut on the compression

fitting (944C) with a wrench.

NOTE: If dry sump design, unit will

not have an internal lube pump and

sump tube.

Step 10 b. Then hand spin the nut free. Pull the

sump tube (173) out of the

compression fitting (944C).

Step 11a. Remove compression fitting (944C).

Loosen the fitting with a wrench.

34

Step 11 b. Hand spin the fitting off the 2.0” x 3/4”

pipe nipple (944B).

Step 12 Remove the 2.0” x 3/4” pipe nipple

(944B) using a pipe wrench. Be careful

the pipe nipple (944B) screws into the

aluminum lube pump housing (A160) and

do not force the pipe nipple (944B) or you

may strip or pull the threads in lube pump

assembly (A160).

Step 13 Remove socket head cap screws

(905BU), 10-24 x 2.5” long screw, from

the lube pump assembly (A160). There

are two screws that hold the lube pump

in place and two screws that hold the

lube pump together. If by chance when

removing (905BU) you loosen the shorter

screws, replace immediately and move to

the next screw on the lube pump

assembly (A160).

Note: If gearbox is of dry sump

configuration, then a spacer is installed

instead of the lube pump. The procedure

for removing the spacer is the same as

for removing the lube pump.

35

Step 14 Install two 1/4-20 screws into the top of

the lube pump assembly (A160). These

screws are used to turn the lube pump

assembly (A160) around in the bearing

plate (102).

Note: with the dry sump gearbox, a

spacer with O-ring seal is installed

Spacer with O-ring seal

for dry sump gearbox

O-ring

instead of the lube pump.

Step 15 a. Using the 1/4-20 screws in step 14,

turn the lube pump assembly around in

either CCW or CW rotation so you can

see the o-ring (936Z) in the hole in the

bearing plate (102) where the 2.0” x

3/4” pipe nipple (944B) was inserted.

36

Step 15 b. Remove the o-ring (936Z) after you can

see it through the hole in bearing plate

(102). Use a sharp scribe or needle

vise and poke the point into the o-ring

(936Z) and twist it out of its seat in the

lube pump (A160) and through the hole

in bearing plate (102). Replace o-ring

with new item. Remove the o-ring

(936Y) and (936TQ) from the bearing

plate (102) replace with new items.

Step 16

Remove the lube pump assembly (A160)

from the bearing plate (102). To achieve

this, the mechanic must grasp the top of

the lube pump shaft with their fingers and

pull straight up and out on that shaft.

Remove the pressure relief valve (175)

from the top of the bearing plate (102)

Inspect the pressure relief valve (175) for

any foreign matter. If any particles or

sludge is found replace with a new

pressure relief valve (175). Remove 1/2”

NPT pipe plug (924M) from the top of the

bearing plate (102).

(underside of bearing plate shown)

Step 17 Remove the vibration key-phasor probe

from the bearing bracket and then remove

gearbox bearing plate (102).

37

Step 18 Remove the bearing plate (102) from the

lower gearbox housing (101A). Make

certain you use the 5/8” eye bolts to lift

It is a good idea to use a hoist

with equal length chains and hooks to

facilitate an even lift of the bearing plate

(102). If the bearing plate (102) is not

lifted evenly it will catch the upper high

speed journal bearing (151B) on the high

speed shaft (A130) and possibly damage

the shaft or the bearing.

38

Step 18 a. Remove and inspect the upper high

speed journal bearing (151B) and the

upper thrust washer (155B) from the

bearing plate (102). First remove hex

head cap screws (905N) and lock

washers (154E). Next pull high speed

journal bearing (151B) from bearing

plate (102). Save shim (158). When

inspecting the bearing look for rub

marks or uneven wear marks. If the

bearing has scratches or dings or any

unusual wear replace the upper high

speed journal bearing with a new item

(151B). If the upper high speed journal

bearing checks good tag the bearing

as upper high speed journal bearing

(151B). This will help insure it does not

become mixed up with the lower high

speed journal bearing. Inspect the

thrust washer (155B). If there are any

burns or rubs replace the thrust

bearing (155B).

Step 19 Remove idler shaft (A140). To do this the

mechanic must lift the high speed shaft

(A130) slightly while pulling the idler shaft

(A140) up and away from the high speed

shaft (A130).

39

Step 20 Remove the high speed shaft (A130).

Step 21 Remove socket head cap screws

(905AA) from lower idler journal bearing

(151C).

40

Step 22 Insert a 1/2” square drive 1.0” socket

down into the center of the lower idler

journal bearing. This socket is used as a

spacer/guide for the jack screw. Make

certain the 1/2” square drive hole is

pointing toward the thrust face of the

lower idler journal bearing (151C).

Step 23 Remove lower idler journal bearing. Use

a bearing puller. Thread two screws 1/420 into the two top holes in the lower idler

journal bearing (151C). Screw the jack

bolt on the bearing puller down against

the 1.0” socket, and then jack (pull) the

bearing out of its location. Inspect the top

thrust face and the interior of the lower

idler journal bearing. If there are any

burns, rubs, deep scratches, replace the

bearing with a new item (151C).

41

Step 23 (continued)

Step 24 Remove socket head cap screws (905M)

and lock washers (154D) from lower high

speed journal bearing (151A). Remove

thrust washer (155A) by lifting up and off

the lower high speed journal bearing

(151A). Inspect the thrust washer for any

burns, scratches or rubs. If any of these

conditions are found, replace the thrust

washer with a new item (155A).

Step 25 Remove the lower high speed bearing

(151A) by tapping (with a soft mallet) on