Page 1

S M T 9 6 5 0 User Guide

3 . 0

2 9 D ec 2006

1 of 36

SMT9650

USER GUIDE

Copyright © Sundance

All rights reserved. No part of this document may be reproduced, translated, stored

in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without prior written permission

of the owner.

Note:

If this copy is no longer in use, return to sender.

Document No.

Revision

Date

Page

Page 2

S M T 9 6 5 0 User Guide

3 . 0

2 9 D ec 2006

2 of 36

APPROVAL PAGE

Name Signature Date

AUTHOR/S

Name Signature Date

Peter Robertson 4 Dec 2006

Document No.

Revision

Date

Page

Page 3

S M T 9 6 5 0 User Guide

3 . 0

2 9 D ec 2006

3 of 36

DOCUMENT HISTORY

Date Initials Revision Description of change

6 Dec 2006 PSR 0.1 Initial Draft

22 Dec 2006 PSR 1.0 Various corrections and extra pictures added

26 Dec 2006 PSR 2.0 Updated and extra demo description added

29 Dec 2006 PSR 3.0 Revised extra demos

Document No.

Revision

Date

Page

Page 4

S M T 9 6 5 0 User Guide

3 . 0

2 9 D ec 2006

4 of 36

TABLE OF CONTENTS

1 INTRODUCTION ................................................................................................................................................................... 5

2 PREREQUISITES .................................................................................................................................................................. 5

3 OVERVIEW ............................................................................................................................................................................ 5

4 CONSTRAINTS ...................................................................................................................................................................... 6

1.1 SIZE CONSTRAINT .................................................................................................................................................................... 6

1.2 ORDERING CONSTRAINT ............................................................................................................................................................ 6

5 LABVIEW INTERFACE ....................................................................................................................................................... 7

6 DEMONSTRATION 1 ........................................................................................................................................................... 8

1.3 SIMULINK MODEL .................................................................................................................................................................. 10

1.4 PARS MODEL ..................................................................................................................................................................... 10

1.5 THE PRE-BUILT TASKS ........................................................................................................................................................... 11

1.5.1. Config364 .................................................................................................................................................................. 11

1.5.2. silo2switch ................................................................................................................................................................. 12

1.5.3. chan2mux .................................................................................................................................................................. 13

1.6 BUILDING THE DEMONSTRATION .............................................................................................................................................. 14

1.7 RUNNING THE DEMONSTRATION ............................................................................................................................................... 14

1.8 INTERNAL DETAILS ................................................................................................................................................................ 16

7 DEMONSTRATION 2 ......................................................................................................................................................... 17

8 DEMONSTRATION 3 ......................................................................................................................................................... 23

9 ACRONYMS AND ABBREVIATIONS ............................................................................................................................. 25

10 KNOWN ISSUES ................................................................................................................................................................ 25

11 COPYRIGHT ...................................................................................................................................................................... 26

12 LICENSE AGREEMENT .................................................................................................................................................. 27

13 INSTALLATION ................................................................................................................................................................ 30

14 ACKNOWLEDGEMENT .................................................................................................................................................. 36

Document No.

Revision

Date

Page

Page 5

S M T 9 6 5 0 User Guide

3 . 0

2 9 D ec 2006

5 of 36

1 INTRODUCTION

The SMT9650 is a software package that allows Labview to be used with code executing on hardware

made up from combinations of DSP and FPGA modules. The code is generated from Simulink models

using PARS, a development tool that uses 3L Diamond to create multiprocessor applications.

2 PREREQUISITES

You need the following software to have been installed before you can use the SMT9650:

● Labview (version 8.0 or later)

● Matlab & Simulink

● PARS

● 3L Diamond DSP & 3L Diamond FPGA (V3.1.4 or later)

This document assumes that you are familiar with these software components.

3 OVERVIEW

An application built with the SMT9650 comprises two parts: a Labview front-end running on a PC and a

DSP application1 running in attached hardware.

The Labview front-end uses custom Virtual Instruments (VIs) to load the DSP application and

communicate with it. The nature of the communication between the PC and the attached hardware is

invisible to the user; the various combinations permitted by Sundance hardware (host comport or USB

connection, for example) are managed by the underlying systems software.

1

To keep the text simple, this document will use the term “DSP application” to mean an application suitable for a

multiprocessor system comprising both DSP and FPGA components.

Document No.

Revision

Date

Page

Page 6

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

6 of 36

4 CONSTRAINTS

Labview and Simulink have different models of computation, and two constraints are necessary in order

to allow them to cooperate.

1.1 SIZE CONSTRAINT

The size of arrays handled by Labview VIs is determined by the source of the data; for the input

instruments this will be Simulink (from the DSPs) and for the output instrument it will be Labview. When

running a system entirely within either the Simulink or Labview environments, matching of data sizes is

mostly done for you. In the hybrid environment of the SMT9650, you must make sure that array sizes

match the requirements of the data destination manually.

1.2 ORDERING CONSTRAINT

The code generated by Simulink imposes a strict ordering constraint on the application; all input sources

will be read before all output sinks are written. This means that the loop in Labview communicating with

the DSP system must ensure that all the SMT9650 output VIs are executed before all of the input VIs. The

simplest way to achieve this is to use a flat sequence and make sure that all your output VIs appear in one

frame and all the input VIs appear in the next.

Document No.

Revision

Date

Page

Page 7

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

7 of 36

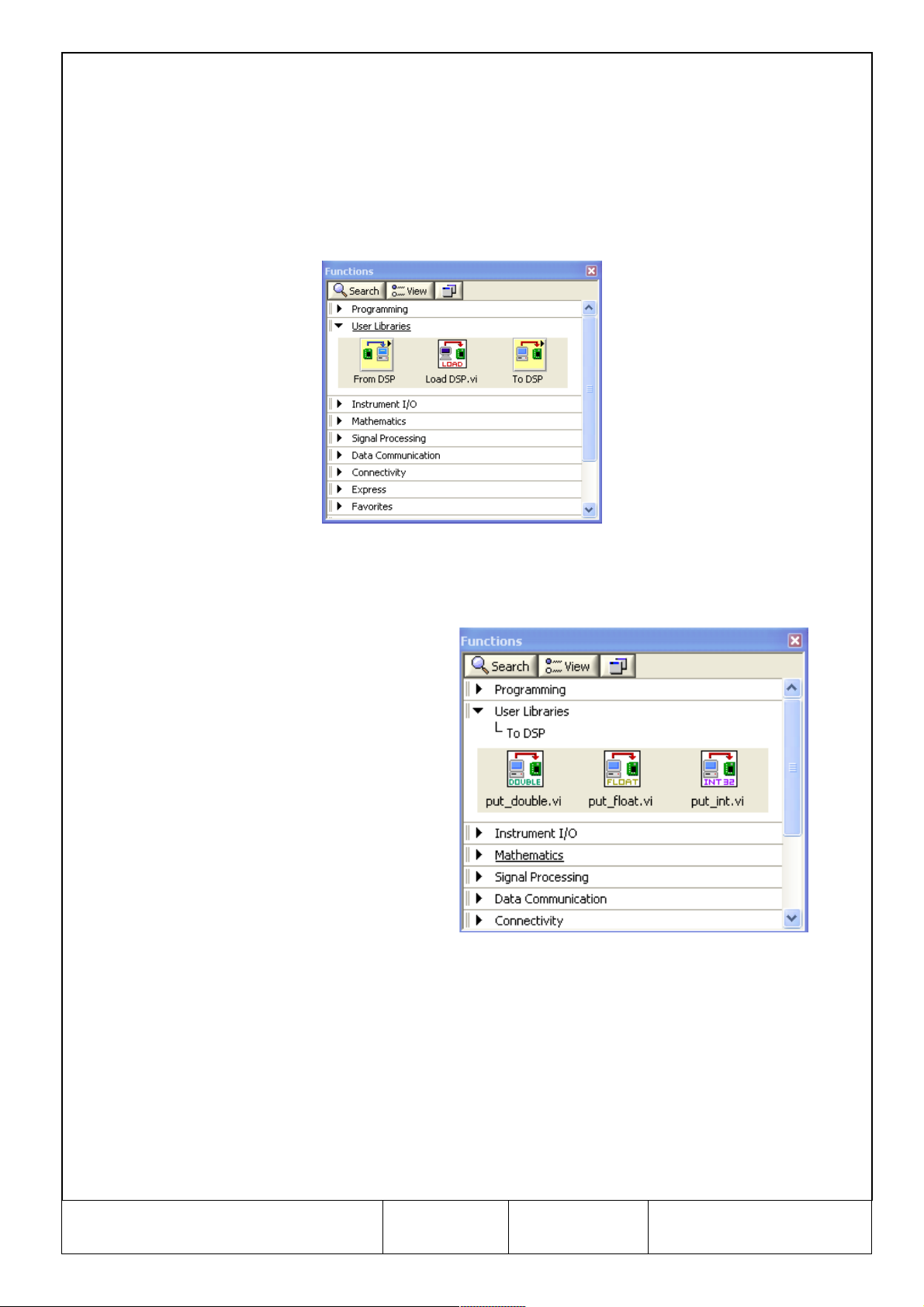

5 LABVIEW INTERFACE

The Labview interface is presented as seven virtual instruments: one to load the Sundance hardware, three

to get data from the DSP application, and three to send data to the DSP application. These instruments

appear as User Libraries in the Labview Functions palette. You can display this palette by going to the

Block Diagram window and selecting View/Functions Palette.

From DSP is a folder with the three input instruments and To DSP is a folder with the three output

instruments. LOAD DSP.vi is the instrument used to send an application to the Sundance hardware.

The “get_...” instruments receive data from the DSP application in the form of arrays of values of the

selected type; the size of array is determined by the DSP. For example, get_int.vi returns an array of

32-bit integers.

The “put_...” instruments send arrays of the selected type to the DSP application. For example,

put_float.vi sends arrays of 32-bit floating point values. The size of array transmitted must match

the expectation of the receiving DSP code.

Document No.

Revision

Date

Page

Page 8

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

8 of 36

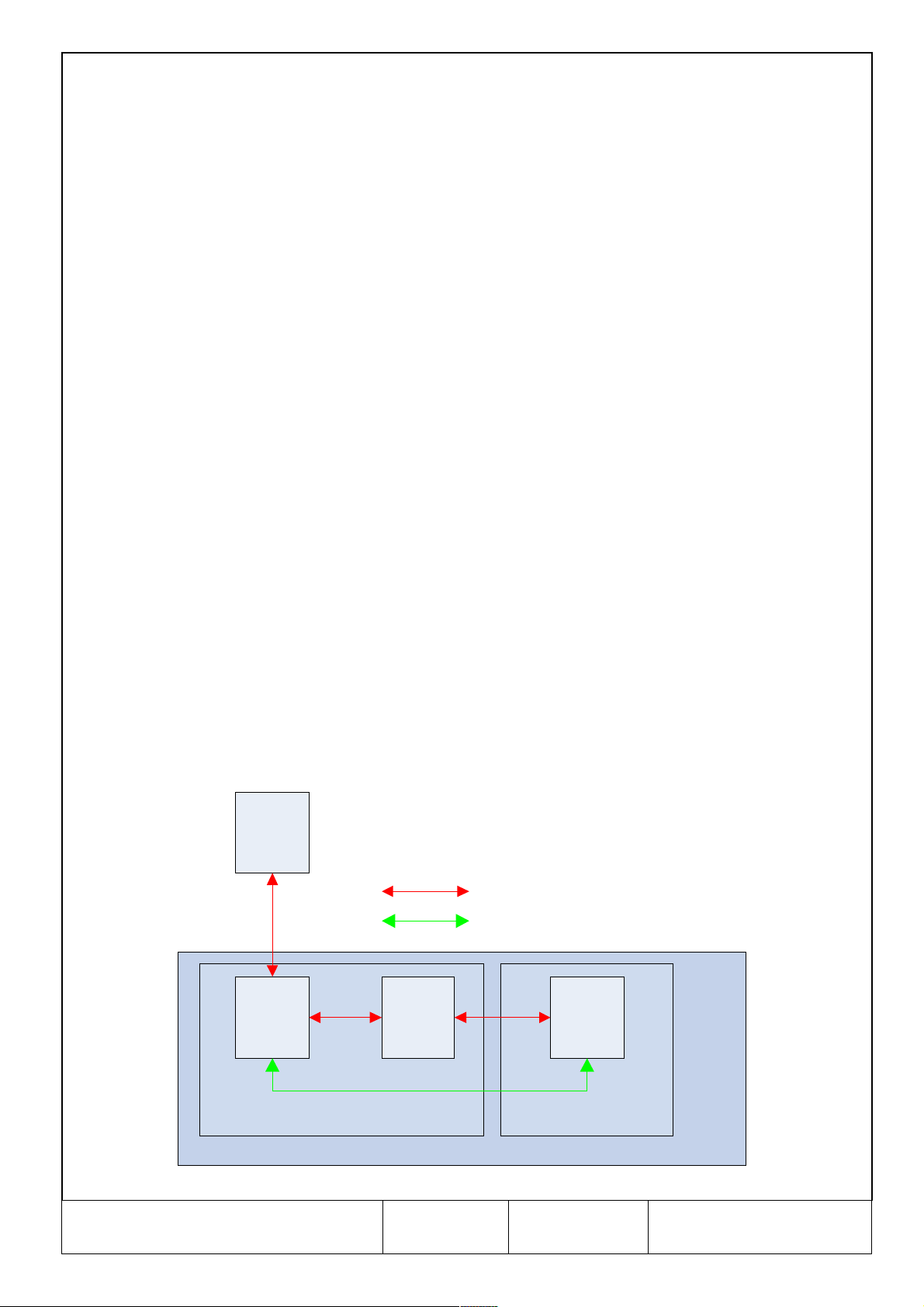

6 DEMONSTRATION 1

This demonstration shows how a simple DSP application generated using PARS can be combined with a

front-end developed under Labview. TIt can be found in the \Demos\Demo1\ sub-folder of the SMT9650

installation folder; this will be C:\SundanceDSP\SMT9650\Demos\Demo1\ by default.

The hardware needed for this demonstration is pictured below.

There are two Sundance TIMs mounted on an SMT310Q carrier board: an SMT374 dual C6713 DSP

module (root & node) and an SMT364 4-channel ADC module. Data are carried between these modules

over comports and SDBs. The comport connections are built into the carrier, and an SMT596 SHB

connector is used to join the SDBs of the two modules.

The logical connections are shown in the following diagram:

SMT310Q

SMT364SMT374

roo t nod e ADC

Host PC

3

41 1

0

compo rt conn ection

SDB conne ction

4

Document No.

Revision

Date

Page

Page 9

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

9 of 36

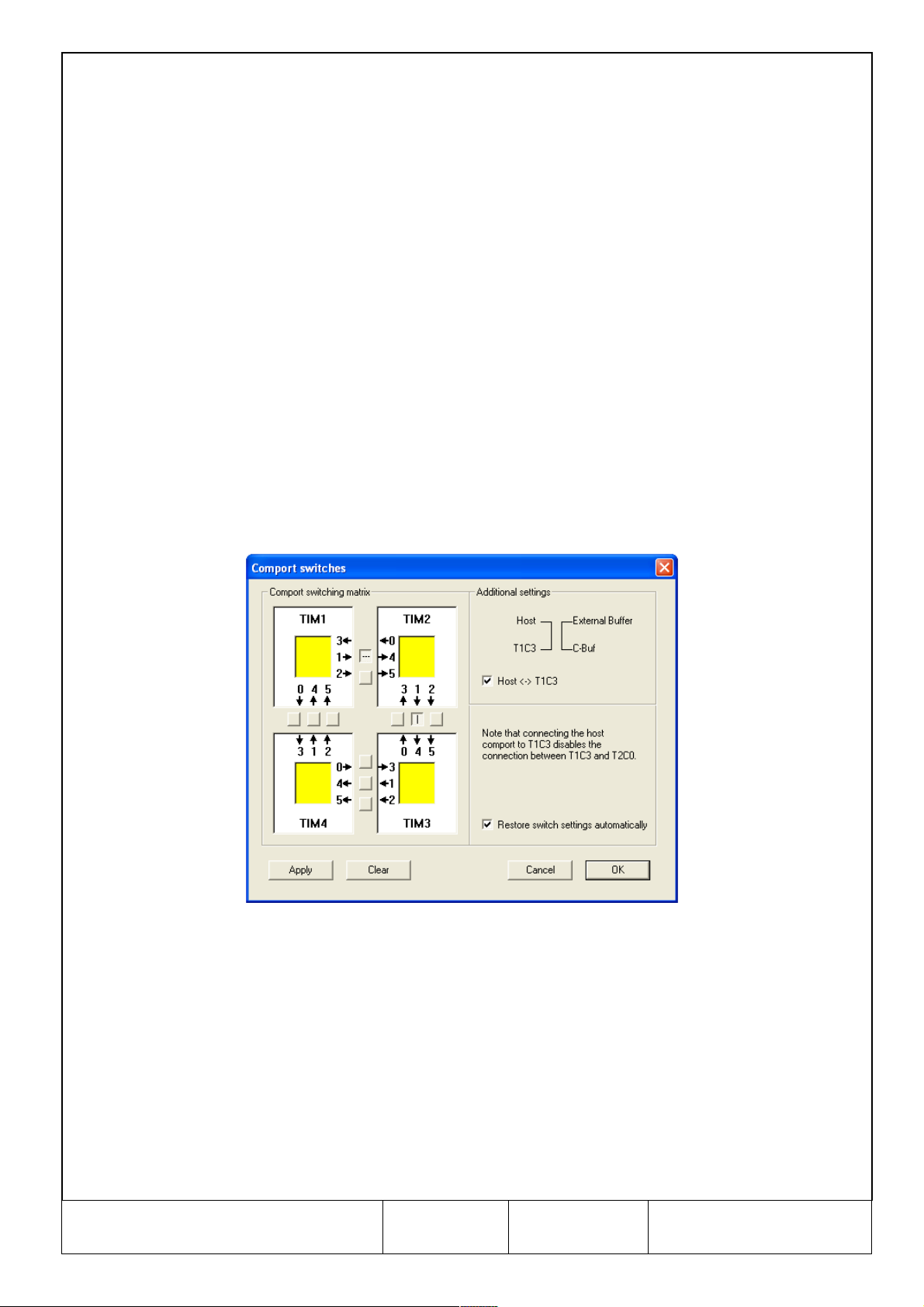

The on-board comport connection between the STM374 and the SMT364 (CP:1 to CP:4) is enabled using

the Sundance BoardInfo utility:

Select Tools and then Comport Switch. This will bring up the following display:

Click the square between TIM1 comport 1 and TIM2 comport 4 to make it display as ... as in the picture

above, if necessary. This enables the required comport connection. Click OK and then OK again.

The demonstration can be tailored to run on different combinations of hardware modules and carrier

boards by changing parameters in the model, as described in the PARS documentation.

Document No.

Revision

Date

Page

Page 10

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

10 of 36

1.3 SIMULINK MODEL

1.4 PARS MODEL

The demonstration is an SMT364 ADC TIM communicating with an SMT374 TIM running three user

tasks on two DSPs. Config364 runs on the node DSP and starts the ADC running as a counter. The

remaining tasks run on the root DSP: Silo2switch gathers the ADC data and passes them to

chan2mux which splits out two channels of data. These two channels are then passed to the Host

Task which uses Labview to display the data.

Document No.

Revision

Date

Page

Page 11

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

11 of 36

1.5 THE PRE-BUILT TASKS

The demonstration uses three PARS pre-built (PB) tasks that have been developed to provide access to

the SMT364 ADC: config364, silo2switch, and chan2mux.

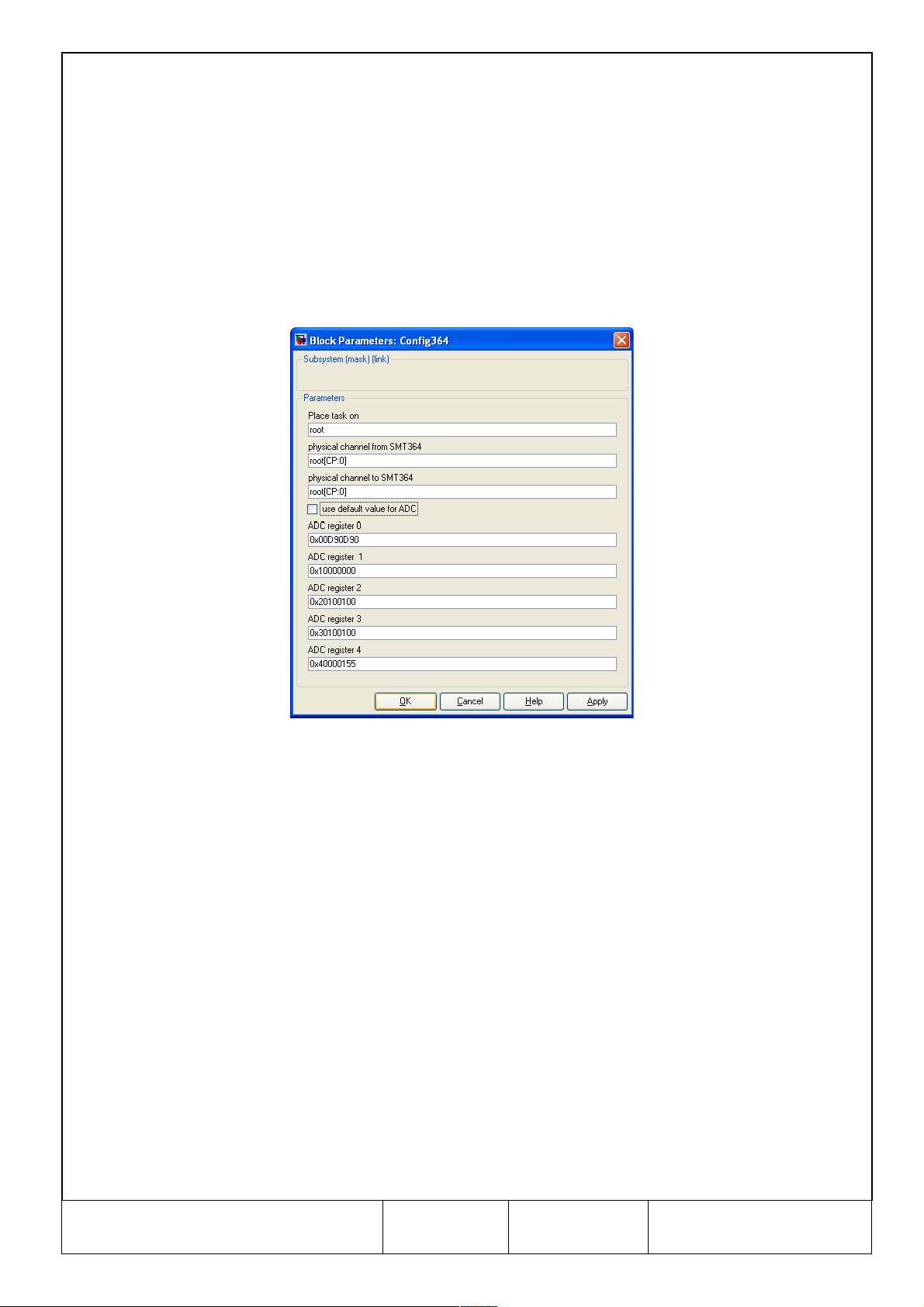

1.5.1. Config364

This PB task configures an SMT364 ADC board. For more information about the SMT364, please refer to

its user manual. This PB task is a wrapper around the Config364 tasks shipped with the SMT6045. For

more information about how the task works and its parameters, please refer to the SMT6045

documentation. This PB tasks takes the following parameters:

Figure 1: Parameters window for Config364 task.

● Place task on: specify which processor this task should be placed on.

● Physical channel from SMT364. Define the physical channel connecting the SMT364 to the

processing board.

● Physical channel to SMT364. Define the physical channel connecting the SMT364 to the

processing board. Normally this is the same as the previous parameter.

● Use default values for ADC. If selected, any parameters entered for ADC registers are ignored

and the default values will be used.

● ADC registers 0 to 4: values for ADC registers. Please refer to the SMT364 User Guide for an

explanation of these registers.

Document No.

Revision

Date

Page

Page 12

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

12 of 36

1.5.2. silo2switch

This is a wrapper for a task with the same name from the SMT6045. It is a task that reads data from a

physical channel and buffers them and allows a slow data sink to work with an SMT364 ADC.

Figure 2: Parameter window for silo2switch task

● Place task on: specify which processor this task should be placed on.

● Task memory size: the amount of memory that will be assigned to this task for stack and heap.

Since this task needs a lot of memory to buffer input data, you need to make sure that enough

memory is assigned to this task.

● Input channel: Physical channel that connects to the ADC board.

● Sample type: this depends on the ADC settings and could be 16-bit integer or 16-bit unsigned

integer.

● Sample per frame: the number of samples in one frame.

● Number of Frames: the number of frames that the task allocates for buffering.

Document No.

Revision

Date

Page

Page 13

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

13 of 36

1.5.3. chan2mux

This is a wrapper for a task with the same name from the SMT6045. This task multiplexes input data into

several outputs.

Figure 3: Parameter window for chan2mux task.

● Place task on: specify the processor on which this task should be placed.

● Task memory size: the amount of memory that will be assigned for this task's stack and heap.

Since this task allocates a lot of memory to buffer input data, you need to make sure that enough

memory is assigned.

● Input channel: If a value is entered in this field, PARS will use it as an input for task (the

Simulink model is changed and the input will disappear). If no value is entered in this field, then a

virtual channel is assumed for input.

● Sample per line: the number of samples in each line.

● Lines per frame: the number of lines in each frame.

● Number of output channels: the number of output channels into which the input will be divided.

Document No.

Revision

Date

Page

Page 14

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

14 of 36

1.6 BUILDING THE DEMONSTRATION

You should start by reading the PARS documentation to understand the build process.

1. Open Matlab and give the command PARSOptions at the >> prompt, then use the resulting

dialogue to select and then Accept your DSP hardware. In this example it will be

SMT374_6713_300.

2. Give the command PARS at the >> prompt.

3. In the PARS window, click on >> and browse to the demonstration model demo1.mdl.

4. Select the file, click Open, and then click the PARS command Open model. The should open a

demo1_PARS window.

5. Click Generate in the PARS window. This should start the build process which will continue with

activity in several windows. Eventually it should finish and report “System generation

successfully finished”. Click OK to dismiss the report.

6. The file demo1_PARS.app should have been created in a new sub folder, demo1_PARS, of the

folder containing the original model.

1.7 RUNNING THE DEMONSTRATION

Start Labview and select File/Open, then browse to the folder containing the demonstration VI,

Demo1.vi. Double click on Demo1.vi to open it. This should bring up the following window:

Document No.

Revision

Date

Page

Page 15

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

15 of 36

Type in the name of the PARS application you wish to execute. The filename you supply here can be

relative to the directory containing the VI itself. For this demonstration you can use

demo1_PARS/demo1_PARS.app. Now click the run button, the arrow below and to the left of View.

This will start the demonstration running and bring up the following dialogue:

PARS has been used to generate a Diamond application that contains all the code for the DSP part of the

demonstration, and Labview is attempting to load that application. To do this, it needs to be told which

DSP hardware to use. In this case there is only one recognised Sundance carrier board in the system, so

click OK to select it.

The demonstration should now load and start to execute:

You can stop the demonstration by pressing the STOP button.

Document No.

Revision

Date

Page

Page 16

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

16 of 36

1.8 INTERNAL DETAILS

You can investigate the internal details of the demonstration by going to the front panel Window menu

and opening the block diagram (Show Block Diagram):

You will see that the diagram is made up from two frames which will execute from left to right. The left

frame is responsible for loading the application into the DSP. It uses the LOAD instrument which is given

the name of the application. The only output from LOAD is a boolean signal that is true should an error

occur while sending the application to the Sundance hardware; this will cause the demonstration to stop.

The right frame is the body of the demonstration. It is a loop that continually requests two streams of data

from the DSPs and displays them. Each stream is made up of arrays of integers brought in through the

INT32 instruments. Each of these instruments is given an integer that selects the number of the DSP's

output port that has been specified in PARS as presenting the data. In this example the DSPs use only two

output ports, 1 and 2. The output from the INT32 instruments will be arrays of integers. The frame also

implements the STOP button.

Document No.

Revision

Date

Page

Page 17

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

17 of 36

7 DEMONSTRATION 2

This demonstration can be found in the \Demos\Demo2\ sub-folder of the SMT9650 installation folder;

this will be C:\SundanceDSP\SMT9650\Demos\Demo2\ by default. It takes four channels of data from

the SMT364 and passes them through SDBs to an SMT361Q; an SMT374 is used to configure the

SMT364. The data values are scaled by different constant amounts and then displayed.

There are two variants of this demonstration: one using an SMT310Q carrier and one using an SMT148.

The SMT310Q hardware for this demonstration is shown in the picture below:

There are three Sundance TIMs mounted on an SMT310Q carrier board: a 4-processor SMT361Q, an

SMT374 dual C6713 DSP module, and an SMT364 4-channel ADC module; slot two is unused. Data

are carried between these modules over comports and SDBs. The comport connections are either built

into the modules or are realised using FMS cables on the back of the carrier. An SMT596 SHB

connector is used to join the SDBs using the SHB connectors on the SMT374 and the SMT3634;

individual SHB cables can also be used.

The logical connections are shown in the following diagram:

SMT310Q

SMT364SMT374

AD C

Host PC

comp ort connection

SD B con ne ction

4

SMT361Q

0

1

3

4dsp3b

01

3

4

dsp 3d

roo t

0 1

3

4

0

013

dsp3c

dsp4a01

2

3

dsp4b

2

3

4

5

3

2

Revision

Date

Page

Document No.

Page 18

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

18 of 36

The application in this demonstration configures the SMT364 to generate four streams of 16-bit data on

the four SDB outputs of the ADC. These streams are passed to the simple tasks on each of the four

SMT361Q processors to be multiplied by different factors. Finally, the results are sent to Labview to be

displayed.

For the SMT310Q variant, PARSOptions should be set to SPAWAR 4ch (Board 1 Configuration, EXT

COMPORT).

The files for this demonstration can be found in demos/demo2/SMT310Q.

Document No.

Revision

Date

Page

Page 19

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

19 of 36

The Simulink model above is converted into the PARS model below, with the silo2switch tasks

placed on each processor of the SMT361Q, along with their corresponding “Gain” tasks. The

configuration of the pre-built tasks silo2switch and Config364 have been described for the

previous demonstration.

The PC side of the application is the following Labview VI; it can be loaded by double-clicking the file

Demo2/SMT310Q/Demo2.vi in the demonstration folder.

Document No.

Revision

Date

Page

Page 20

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

20 of 36

You can type in the name of the demonstration application file (demo2_PARS/demo2_PARS.app)

and then execute the VI by pressing the right-arrow below View. File names are be relative to the folder

containing the VI.

When the application runs, the following output will be displayed:

The application is loaded into the DSP system and starts to run. The four channels of integer data are read

by four INT32 VIs. Note that Simulink will generate these streams of data and expect them to be read in

the strict sequence that is echoed by the placement of the VIs into sequential frames within the main loop.

The received data are then sent to be displayed.

Document No.

Revision

Date

Page

Page 21

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

21 of 36

There is a variant of the demonstration that uses an SMT148 carrier.

This can be selected by setting PARSOptions as follows:

The files for this demonstration can be found in demos/demo2/SMT148.

Document No.

Revision

Date

Page

Page 22

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

22 of 36

The configuration is similar to the SMT310Q configuration with the exception that the root processor is

now the second DSP on the SMT374, and this communicates with the host using a USB connection. This

change in host communication is handled for you automatically.

The application can be executed by double-clicking demo2/SMT148/demo2.vi.

SMT148

SMT364SMT374

ADC

Host PC

compo rt conne ction

SDB conne ction

4

SMT361Q

0

1

3

4dsp3b

01

3

4

dsp 3d

dsp 3a

0 14

0

013

dsp3c

dsp4a

0

1

2

3

roo t

2

3

4

5

3

2

0

USB conne ction

Document No.

Revision

Date

Page

Page 23

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

23 of 36

8 DEMONSTRATION 3

This demonstration can be found in the \Demos\Demo3\ sub-folder of the SMT9650 installation folder;

this will be C:\SundanceDSP\SMT9650\Demos\Demo3\ by default. It takes four channels of 16-bit data

from the SMT364 and passes them through an SMT398 which multiplexes them into a single output

stream. This stream is passed to an SMT374 which demultiplexes it and displays the resulting four

streams.

The SMT148 hardware for this demonstration is shown in the picture below2:

The Simulink model for this demonstration is as follows:

2

The SMT361Q is not used in this demonstration.

Document No.

Revision

Date

Page

Page 24

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

24 of 36

The hardware profile for this demonstration is:

Note that this profile will reconfigure the SMT398 with firmware from the file fpga20.rfd. This file is

present in the demo3 folder, but a copy needs to exist in the demo3_PARS folder.

Once this has been set, PARS can create the following model:

The application can be executed by double-clicking demo3/demo3.vi.

Document No.

Revision

Date

Page

Page 25

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

25 of 36

9 ACRONYMS AND ABBREVIATIONS

ADC Analog to Digital Converter

DSP Digital Signal Processor

FPGA Field Programmable Gate Array

PARS Parallel Application from Rapid Simulation

SDB Sundance Digital Bus

TIM Texas Instruments Module

USB Universal Serial Bus

VI LabVIEW Virtual Instrument

10 KNOWN ISSUES

Users should be aware of the following issues:

1. Labview can get into a strange state when an application fails or is stopped. This appears in two

forms:

a) When attempting to re-run an application or run a different application, Labview terminates.

b) When an application hangs or fails, Labview starts to close but ends up in a minimal state that

can only be cleared by using Task Manager to kill Labview.

2. When launching a VI by means of an executable, the VI starts to execute before the user can type

an application name. Cancelling the selection of the hardware results in a notification of failure to

load the application. The application name can now be given and the VI started manually.

3. The pre-built tasks must be allocated enough memory. Failure to do so will result in the

application hanging. Details of the required memory can be found in doc/*.txt in the smt6045

installation directory.

4. The current release does not support logging.

5. Host output port numbers are allocated sequentially from top to bottom of the Host task, starting at

1. Host input port numbers are allocated in the same manner.

Document No.

Revision

Date

Page

Page 26

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

26 of 36

11 COPYRIGHT

Matlab and Simulink are trademarks of The MathWorks.

LabVIEW is a trade mark of National Instruments.

Document No.

Revision

Date

Page

Page 27

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

27 of 36

12 LICENSE AGREEMENT

END-USER LICENSE AGREEMENT for

SMT9650

Sundance Digital Signal Processing Inc.

Referred to hereafter as (SDSP)

IMPORTANT - READ CAREFULLY: This END-USER LICENSE AGREEMENT

(Or "AGREEMENT") is a Legal Agreement between you (either an individual or entity) and SDSP.

The "LICENSED MATERIALS" subject to this Agreement include the enclosed software programs and

documentation and any "on-line" or electronic documentation associated with the software programs. The

"LICENSED MATERIALS" (collectively referred to as the "SOFTWARE") may include certain SDSP

proprietary software programs that. By installing, copying or otherwise using the "LICENSED

MATERIALS", you agree to abide by the following provisions.

You assume responsibility for the selection of the SOFTWARE to achieve your intended results, and for

the installation, use and results obtained from the SOFTWARE.

1. SOFTWARE LICENSE - The Licensed Materials are protected by copyright laws, international

copyright treaties, and trade secret laws, as well as other intellectual property laws and treaties. The

Licensed Materials are licensed, not sold to you, and can only be used in accordance with the terms of

this Agreement. SDSP retains title and ownership of the Licensed Materials, including all intellectual

property rights.

a) Restrictions - This license is for a single-user host computer. You may not install the Licensed

Materials on a network server or otherwise use the Licensed Materials on more than one host

computer at the same time. Additionally, if this package contains multiple versions of the Licensed

Materials, you may only use one version of the Licensed Materials on a single host computer. You

may either make one copy of the Licensed Materials for archival purposes or copy the Licensed

Materials to another medium and keep the original Licensed Materials for archival purposes. Other

than as expressly set forth in Section 1(b) below, you may not otherwise copy or reproduce the

Document No.

Revision

Date

Page

Page 28

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

28 of 36

Licensed Materials. In no event may you use two copies or versions of the Licensed Materials on

more than one host computer at the same time.

b) Copy, modify, and merge - You may copy the SOFTWARE into any machine-readable or printed

form for backup purposes in support of your use of the SOFTWARE on the single-user machine.

You may not modify the SOFTWARE. You may merge it into another program for your use on

the single-user machine. Any portion of this SOFTWARE merged into another program will

continue to be subject to the terms and conditions of this Agreement. You must reproduce and

include the copyright notice (s) on any copy, modification, or portion merged into another

program. The license entitles the user to 20 runtime licenses. To obtain additional runtime licenses

please contact SDSP.

c) Termination - This license is effective until terminated. Without prejudice to any other rights,

SDSP may terminate your right to use the Licensed Materials and any applications generated using

the Licensed Materials under this Agreement if you fail to comply with the terms of this

Agreement. In such event, you must destroy all copies of the SOFTWARE and all of its

component parts.

2. INTELLECTUAL PROPERTY RIGHTS. The Licensed Materials contain copyrighted material, trade

secrets and other proprietary information. In order to protect the Licensed Materials, and except as

specifically permitted by statute, you may not decompile, reverse engineer, disassemble or otherwise

translate the object code versions of the software programs included in the Licensed Materials to

human-perceivable form. If you are a corporation you agree you will use your best efforts to prevent

your employees and contractors from decompiling, reverse engineering, disassembling, modifying or

translating the Licensed Materials. In no event may you alter, remove or destroy any copyright notice

included in the Licensed Materials. SDSP reserves all rights not specifically granted under this

Agreement.

3. APPLICABILITY. This license only applies to the version of the SOFTWARE for which it was

issued. It does not automatically entitle the licensee to software advancements and functionality to be

offered in future versions of the software. The licensee can obtain future versions of the SOFTWARE

by prior agreement with SDSP.

4. LIMITATIONS. SDSP MAKES NO WARRANTY OF ANY KIND, EITHER EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE ENTIRE RISK AS

TO THE QUALITY AND PERFORMANCE OF THE SOFTWARE IS WITH YOU. SHOULD THE

SOFTWARE PROVE DEFECTIVE, YOU (NOT SDSP) ASSUME THE ENTIRE COST OF ALL

NECESSARY SERVICING, REPAIR, OR CORRECTION.

Document No.

Revision

Date

Page

Page 29

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

29 of 36

5. IN NO EVENT WILL SDSP BE LIABLE TO YOU FOR ANY DAMAGES, INCLUDING ANY

LOST PROFITS, LOSS OF BUSINESS INFORMATION, BUSINESS INTERRUPTION, LOST

SAVINGS OR OTHER INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF

THE USE OR INABILITY TO USE SUCH SOFTWARE, EVEN IF SDSP HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY ANY OTHER PARTY.

6. YOU ACKNOWLEDGE THAT YOU HAVE READ THIS AGREEMENT, UNDERSTAND IT,

AND AGREE TO BE BOUND BY ITS TERMS AND CONDITIONS. YOU FURTHER AGREE

THAT IT IS THE COMPLETE AND EXCLUSIVE STATEMENT OF THE AGREEMENT

BETWEEN YOU AND SDSP WHICH SUPERSEDES ANY PROPOSAL OR PRIOR

AGREEMENT, ORAL OR WRITTEN, AND ANY OTHER COMMUNICATIONS BETWEEN US

RELATING TO THE SUBJECT MATTER OF THIS AGREEMENT.

7. EXPORT CONTROL. The re-export of United States origin software and documentation is subject to

the Export Administration Act of 1969 as amended. Compliance with such regulations is your

responsibility.

8. U.S. GOVERNMENT RESTRICTED RIGHTS. This computer software and documentation are

provided with RESTRICTED RIGHTS. Use, duplication, or disclosure by the Government is subject

to restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer

Software clause at DFARS 252.227-7013 (Oct. 1988) or if provided under a contract or subcontract

with NASA or a civilian agency of the Government, to the restrictions set forth is such contract or

subcontract.

9. Should you have any questions concerning this Agreement, or if you desire to contact SDSP for any

reason, please contact SDSP.

Copyright (C) 1999-2006, Sundance Digital Signal Processing Inc.

Document No.

Revision

Date

Page

Page 30

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

30 of 36

13 INSTALLATION

Before installing the SMT9650:

● Make sure that all the required software components have been installed and configured properly;

● Close any instances of Matlab.

To install the SMT9650, run SMT9650_setup_vX_X.exe from the installation CD, where X_X

denotes the SMT9650 version number. For example, use SMT9650_setup_v4_0.exe to install

SMT9650 version 4.0.

You should see the following window.

Figure 4: Setup step 1, Password page.

Enter your password and press next. Please contact your reseller if you have not been given a password.

Press Next> to continue to the welcome page, and then press Next> again.

Document No.

Revision

Date

Page

Page 31

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

31 of 36

Figure 5: Setup step 2, welcome page.

Figure 6: Setup step 3, accepting the end user license agreement.

Please read the End User License Agreement (EULA) carefully. You can find the text of this agreement in

the previous section of this User Guide. If you agree with the terms of the license, select the accept option

Document No.

Revision

Date

Page

Page 32

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

32 of 36

and press Next>. If you do not agree with the terms and conditions, Cancel the installation and contact

your reseller.

Figure 7: Setup step 4, user name and company name.

Enter your user name and company name, then press Next>.

Document No.

Revision

Date

Page

Page 33

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

33 of 36

Figure 8: Setup step 5, selecting the installation directory.

The SMT9650 will usually be installed into the folder c:\SundanceDSP\SMT9650\.

If you want to use a different folder, select change and browse to the correct location.

Click Next> when you have chosen the installation folder.

Document No.

Revision

Date

Page

Page 34

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

34 of 36

Figure 9: Setup step 6, checking installation setting.

Press <Back if you want to change any settings before starting the installation process by

clicking Install.

Figure 10: Setup step 7, Installation in progress.

Do not turn your computer off until the “Installshield Wizard Complete” message has appeared.

Document No.

Revision

Date

Page

Page 35

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

35 of 36

Figure 11: Setup step 8, Installation completed window.

This window shows that the installation of SMT9650 has finished.

Document No.

Revision

Date

Page

Page 36

S M T 9 6 5 0 U s e r G u i d e

3 . 0

2 9 D e c 2 0 0 6

36 of 36

14 ACKNOWLEDGEMENT

This work was accomplished under the US Navy contract #N65236-06-P-2514 and Sundance would

like to acknowledge this support.

Document No.

Revision

Date

Page

Loading...

Loading...