Page 1

SMT8090

User Manual

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 2

Version 0.9 Page 2 of 10 SMT8090 User Manual

Revision History

Date Comments Engineer Version

18/02/04 First release PSR 0.9

Page 3

Version 0.9 Page 3 of 10 SMT8090 User Manual

Table of Contents

Revision History.......................................................................................................... 2

Table of Contents ....................................................................................................... 3

Contacting Sundance. ................................................................................................ 4

Notes. ......................................................................................................................... 4

Precautions................................................................................................................. 4

Outline description...................................................................................................... 5

Architecture. ............................................................................................................... 6

Hardware involved...................................................................................................... 7

Hardware installation. ................................................................................................. 7

Software applications. ................................................................................................ 9

3L application.......................................................................................................... 9

Description of the functions in the test software menu............................................ 9

“Resetting SMT390 FPGA”.................................................................................. 9

“SMT390 FPGA DLLs Reset” .............................................................................. 9

“Configuring Clock Synthesizers” ........................................................................ 9

“Clock Selection” ............................................................................................... 10

“ADC Output Format” ........................................................................................ 10

“Capture Data – Both Channels” ....................................................................... 10

Matlab application ............................................................................................. 10

Pegasus application (to be done).......................................................................... 10

Page 4

Version 0.9 Page 4 of 10 SMT8090 User Manual

Contacting Sundance.

You can contact Sundance for additional information by sending email to

support@sundance.com

.

Notes.

- SHB stands for Sundance High-speed Bus.

- CommPort denotes an 8-bit communication port following the TI C4x

standards.

Precautions

In order to guarantee that Sundance’s boards function correctly and to protect the

module from damage, the following precautions should be taken:

- They are static sensitive products and should be handled accordingly.

Always place the modules in a static protective bag during storage and

transition.

- When operating, make sure that the heat generated by the system is

extracted e.g. a fan extracting heat or air blower. It is vital for the SMT390

daughter module.

Page 5

Version 0.9 Page 5 of 10 SMT8090 User Manual

Outline description.

The SMT8090 is a dual-C6713 based module (SMT374) combined with a dual highspeed ADC module (SMT390).

SMT374 characteristics:

⇒ Dual TMS320C6713 processor running at 225MHz

⇒ Six 20MB/s communication ports (comm.-ports)

⇒ 128MBytes of SDRAM (100MHz)

⇒ 8MByte Flash ROM for boot code and FPGA programming

⇒ Global expansion connector

⇒ General purpose I/O connector

⇒ High bandwidth data I/O via 2 Sundance High-speed Buses (SHB).

SMT390 characteristics:

⇒ Two 12-bit ADCs (AD9430-210

) sampling at up to 210MHz,

⇒ Two Sundance High-speed Bus (SHB) connectors,

⇒ Two 4-channel Rocket Serial Link (RSL

) connector – 2.5Gbits/second each,

⇒ Two 20 MegaByte/s communication ports,

⇒ Low-jitter on-board system clock,

⇒ Xilinx Virtex-II Pro FPGA,

⇒ 50-Ohm terminated analogue inputs and outputs, external triggers and

clocks via MMCX (Huber and Suhner) connectors,

⇒ User defined pins for external connections,

⇒ Compatible with a wide range of Sundance SHB modules,

⇒ TIM standard compatible.

The SMT8090 is a demonstration software for the evaluation of the SMT374 and

rd

SMT390 modules. It can be used for prototyping 3G (3

generation) systems and

high-speed data acquisition system with or without digital processor. This document

is an installation guide for the SMT8090 demonstration system.

The SMT8090 application gets the DSP on the SMT374 to configure the SMT390

FPGA and control clock frequencies, clock routings, data format and data capture.

The DSP grabs data from both channels and stores them into a file, which can be

read by a Matlab application for data displaying and FFT processing.

Page 6

Version 0.9 Page 6 of 10 SMT8090 User Manual

Architecture.

The following diagram shows the architecture of the SMT8090 system:

Analogue

Connection

SMT374

Module #1

Global Bus

Connection

DSP

TIM site 1

Data

SMT516

Data

SHB

Connection

SMT390

DAQ

Module #2

TIM site 2

Control

Comm

Port

Data

SDB

Connection

Spare

TIM site 3

Data

Comm

Port

Spare

MMCX to BNC cables

Processing

SMT310Q

TIM site 4

PC

Host

Page 7

Version 0.9 Page 7 of 10 SMT8090 User Manual

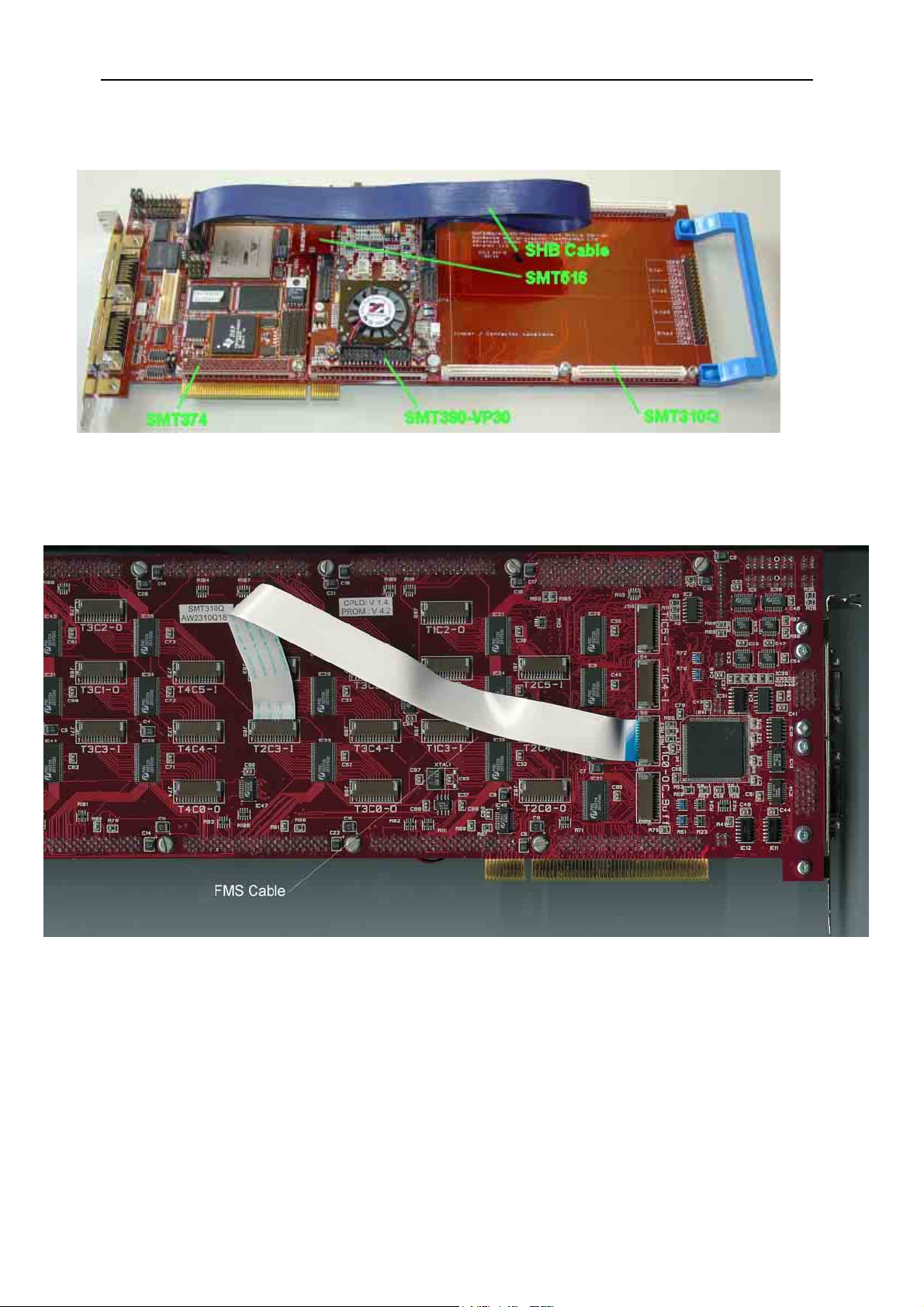

Hardware involved.

The SMT8090 is built around two main modules but also involves a carrier board and

some cables to interconnect them and allow them to communicate with each other

and to access the PC.

⇒ 1x SMT310Q: PCI carrier

⇒ 1x SMT374: Dual-C6713 based module; to be plugged on site 1 of

SMT310Q.

⇒ 1x SMT390: Dual-ADC module; to be plugged on site 2 of SMT310Q.

⇒ 1x FMS cable (20cm): to connect T1C0 to T2C3 at the back of the

SMT310Q.

⇒ 1x SMT516 (SHB to SHB PCB): to connect SHBA (SMT374) to SHBA

(SMT390).

⇒ 4x MMCX to BNC cables to connect an external analogue signal source to

J1 to J4 and an external clock source (when using external sampling clock) to J5 and

J6.

Hardware installation.

Here are the steps to follow to install the SMT8090 system.

1 – Place the SMT374 on TIM site 1 of the carrier board (SMT310Q).

2 – Place the SMT390 on TIM site 2 of the carrier board (SMT310Q).

3 – Make sure that the boards are firmly seated, then provide the 3.3V to the boards

by screwing in the bolts and screws through one of the mounting holes on the

SMT374 and SMT390.

4 – Connect CommPort 0 of the SMT374 to CommPort 3 of the SMT390 (T1C0 to

T2C3) via an FMS cable at the back of the SMT310Q.

5 – Connect SHBA on the SMT374 to SHBA on the SMT390 via the SMT516.

6 – Connect external sources to J1, J4, J5 and J6 via MMCX-BNC cables. Make sure

that the external signal meet the input characteristics of the SMT390 described in the

SMT390 User Manual.

7 – Place the carrier board in the host system.

Page 8

Version 0.9 Page 8 of 10 SMT8090 User Manual

The following picture shows how connections are made at the top of the system:

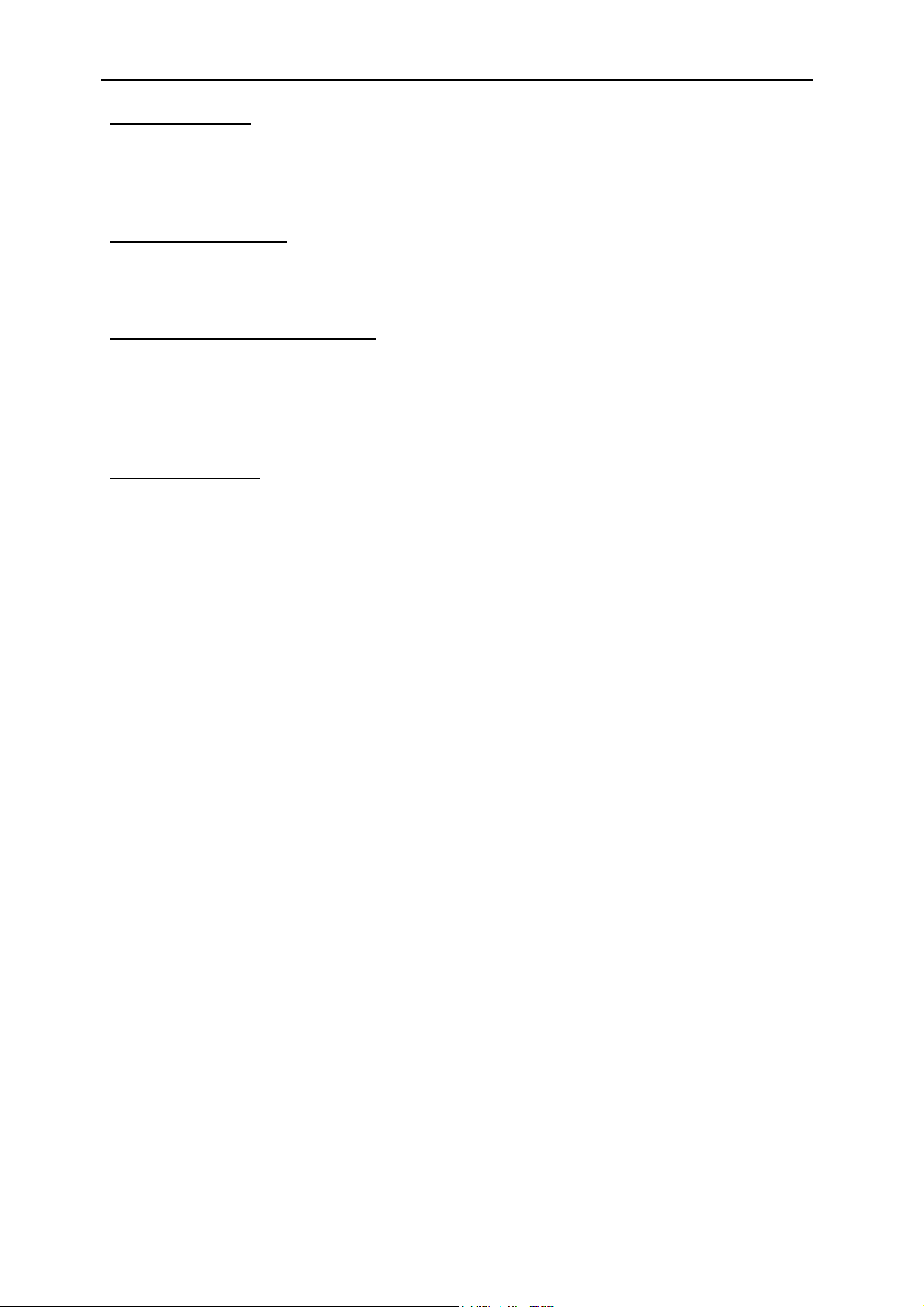

The following picture shows the CommPort connection at the back of the SMT310Q.

Note that the FMS are ‘twisted’, i.e. one end should be blue and the other should

show silver pins.

Page 9

Version 0.9 Page 9 of 10 SMT8090 User Manual

Software applications.

3L application.

In a sub-folder labelled 3L, you will find a C (Test.c), a configuration (Test.cfg) and a

make (nmake) files.

In a DOS prompt window, simply type nmake to generate the 3L application file,

which can be loaded into the SMT374 by using the 3L Server (3L Diamond needs to

be installed first).

This application allows the user to execute simple commands such as configuring the

ADC (output format and scale), the clock synthesizers, clock routing, capturing data,

etc.

Description of the functions in the test software menu.

The 3L application provided with the system allows the following option. Some will

prompt for a value. Before sending the control word to the SMT390. In some case

and where available, the internal control register is not only set up but also read-back

straight after to make sure it has been programmed properly. The value read-back is

displayed in the main window.

“Resetting SMT390 FPGA”

This command keeps the configuration of the FPGA but resets all its internal

registers.

“SMT390 FPGA DLLs Reset”

The FPGA implements two DLLs (one per ADC channel). When the sampling

frequency or the clock routing is being changed, DLLs can run out of step. To avoid

that problem and re-lock them, a DDL Reset operation is necessary. Writing any

value into the reset register will reset both DDLs.

“Configuring Clock Synthesizers”

This function loads with the value specified (in decimal, not hexadecimal) and starts

the on-board clock synthesizer.

Fsynthesized = M / N, with 200 < M < 400 and N=0 (div by 2), 1 (div by 4), 2 (div by

8) or 3 (div by 1).

For example, to generate 100 MHz: 400/4=100, which gives M=400 and N=4

M is coded on 9 bits and N on 2 bits. Here (400)d=(110010000)b and N=(2)d=(10)b

The value in binary is obtained by gathering N and M : 10110010000

Simply convert this value into decimal (1424) and enter it when prompted.

Page 10

Version 0.9 Page 10 of 10 SMT8090 User Manual

“Clock Selection”

This command routes the clocks to the ADC depending on whether they are external

or internal. Enter 0 for External, 1 for Internal or 2 for External from Opposite

Channel. The selection is prompted for Channel A first and then Channel B

“ADC Output Format”

The ADC can output the data in either binary or 2’s Complement format. The function

allows the selection and also the scale (half or full).

“Capture Data – Both Channels”

This command captures data from both channels, one after the other (not

simultaneously). Data are then stored into two separate files into the directory where

the application has been started. Files are called CAPTUREA0.txt and

CAPTUREB0.txt

Matlab application

In the same folder as the 3L application, you can find a Matlab application (test.m).

Under Matlab set up the current folder into the path in order for the application to

open the two data files and run the application.

It will open 4 windows, which are respectively ChannelA – Time Domain, ChannelA –

Frequency Domain, ChannelB – Time Domain and Channel B - frequency domain.

Once data are captured, you can launch the Matlab application, located on

Pegasus application (to be done).

The SMT8090 is also provided with a Pegasus application (Pegasus folder), which

shows the user the dynamic performance of the system.

Loading...

Loading...