Page 1

Unit / Module Description: SMT356 + SMT365 Example Configuration

Unit / Module Number: SMT8056

Document Issue Number: 1.0

Issue Date: 24th July 2007

Original Author: G.K.Parker

User Manual

for

SMT8056

Sundance Multiprocessor Technology Ltd, Chiltern House,

Waterside, Chesham, Bucks. HP5 1PS.

This document is the property of Sundance and may not be copied

nor communicated to a third party without prior written

permission.

© Sundance Multiprocessor Technology Limited 2006

Page 2

Revision History

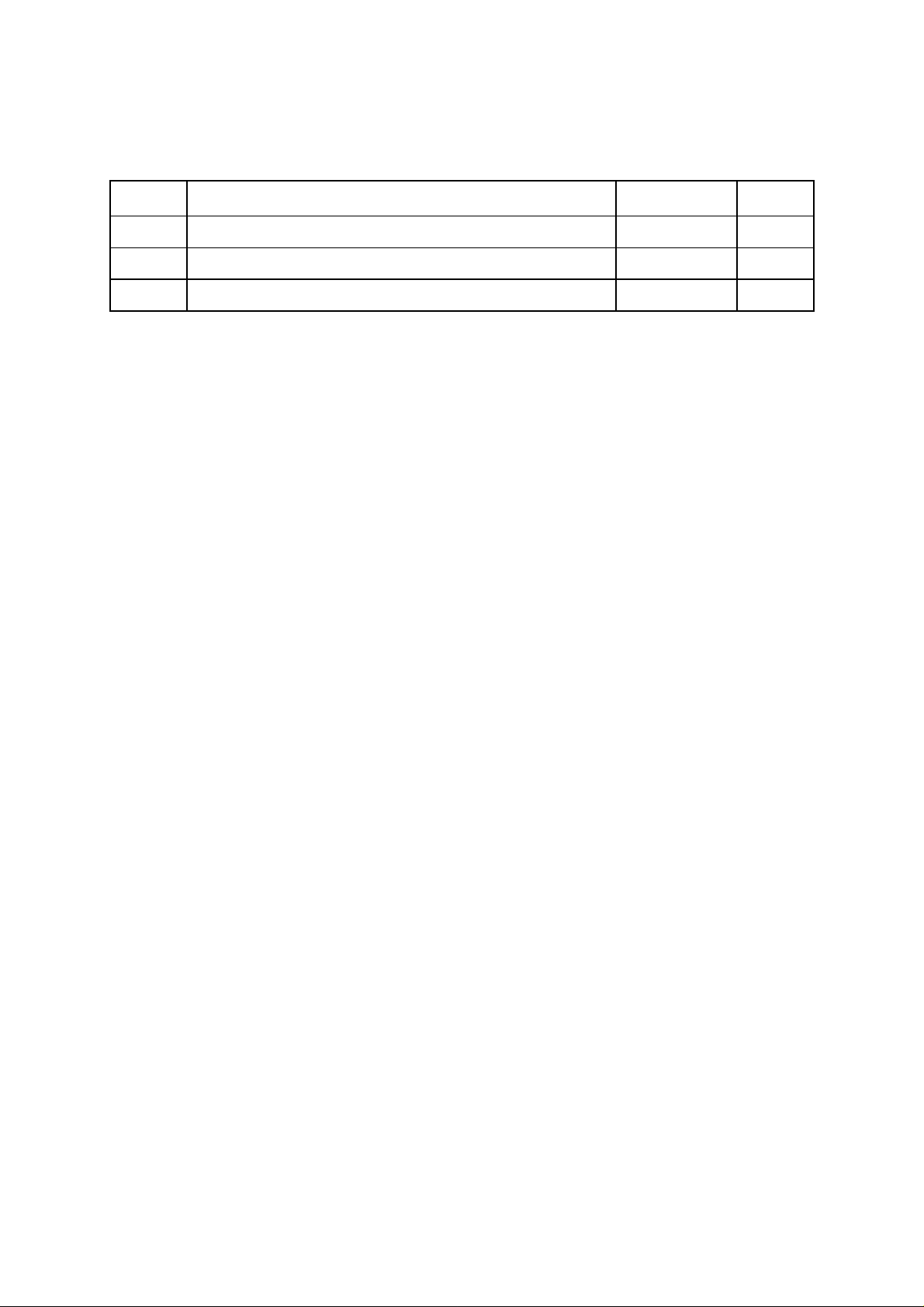

Issue Changes Made Date Initials

1.0 First release. 24/7/07 GKP

Page 3

Table of Contents

1 Introduction....................................................................................................................... 4

2 Setup.......................................................................................................................... .......... 4

2.1 Equipment Needed...................................................................................................... 4

2.2 Supplied Software....................................................................................................... 4

2.3 System Configuration - Software............................................................................ 4

2.4 System Configuration – Hardware...........................................................................5

3 Application Description ................................................................................................. 8

3.1 What Happens.............................................................................................................. 8

3.2 How It Works ............................................................................................................... 9

Page 4

1 Introduction

The SMT8056 is a demonstration system showing how the SMT356 (ADC module)

can be operated with the SMT365 (DSP module) using 3L/Diamond.

The documented example source code shows the necessary steps and func tions to

call within a Diamond application.

The example acquires data from 4 input channels and displays these graphically.

2 Setup

2.1 Equipment Needed

SMT356 8 channel ADC module.

SMT365 DSP module.

SMT310Q TIM carrier board.

FMS ComPort Cable

SHB Cable

SMT517 SHB to SDB adapter.

3L/Diamond

2.2 Supplied Software

Demo356_365.c Main example source code.

Demo356_365.app Diamond executable.

Demo356_365.cfg Configuration file.

Display.c, Display.h Supplementary source and header files.

graph3l.h, graph3l.lib

makefile Project makefile.

v-top.mcs SMT356 FPGA configuration file.

Distribution A folder containing necessary DLL files.

2.3 System Configuration - Software

The DLL files from within the distribution folder should be copied to the

WINDOWS\SYSTEM32 directory. They may already be present.

The remainder of the files should be copied into a single folder.

If only the executable is needed, then this must be accompanied by the v-top.mcs

file also.

Page 5

2.4 System Configuration – Hardware

The SMT365 DSP module should be placed in site 1 of the SMT310Q. This module

should be secured using both mounting screws (or nuts depending upon SMT310Q

configuration).

The SMT356 ADC module should be placed in site 2 of the SMT310Q. This module

should be secured using both mounting screws (or nuts depending upon SMT310Q

configuration).

An FMS ComPort cable must be connected between T1C0 and T2C3. Note that one

end of the cable should show the silver pins, and the other end should show the

blue plastic.

Page 6

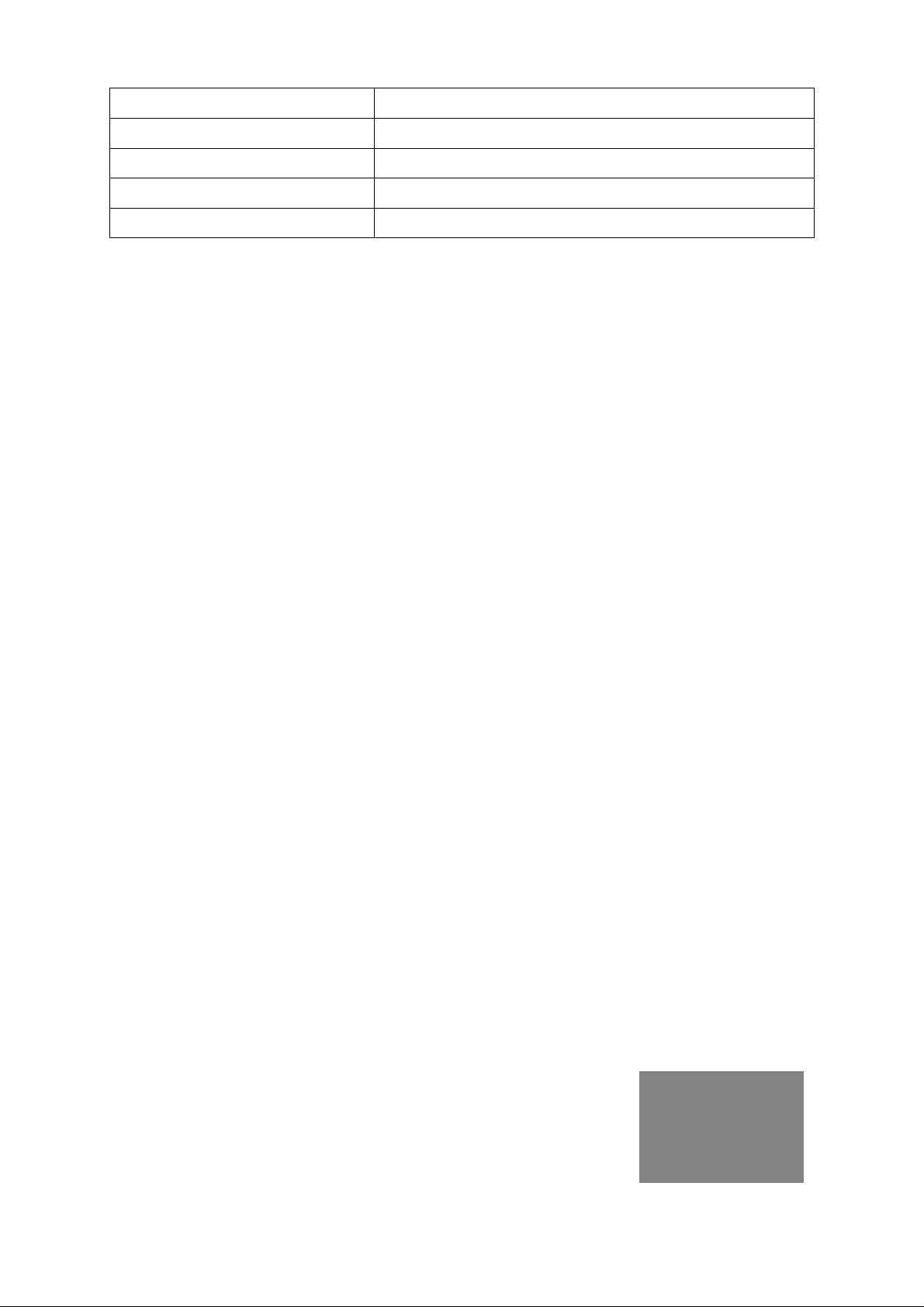

The SMT356’s jumpers should be set up as shown here;

This selects the following;

Control ComPort number 3.

SDB clock = 50MHz.

Clock divider enabled.

Internal capture trigger.

On-board 10MHz sample clock source.

Page 7

An SMT517 and SDB cable should be connected between the two TIM modules. The

SDB cable must be in the position shown on the SMT517. This is for SDB port 0.

Page 8

3 Application Description

3.1 What Happens

When the .app file is executed Diamond will typically send a RESET signal to the

carrier (and all modules). The DONE LEDs on the 365 (D6) and 356 (LED5) will

illuminate. This indicates that both FPGAs have been un-configured.

Diamond will then load and run the application. The SMT365’s DONE LED will

extinguish.

The first part of the application is to draw the 4 output windows which will contain

the sampled ADC data. These windows can be positioned anywhere on screen.

The program will then configure the SMT356’s FPGA; its DONE LED will extinguish.

The screen should look similar to;

Page 9

3.2 How It Works

The system works by using two main interfaces;

A ComPort, and

An SDB

There are several ways of using both of these interfaces within Diamond. The

following is just one of these approaches.

For the application to utilise the SDB, one must be ‘claimed’ – see demo356_365.c

line 79.

Sdb0 = SMT_SDB_Claim(0);

Configuration of the SMT356 mode is performed using a ComPort. These interfaces

do not need to be claimed, but using the following approach, one must be careful

not to use a ComPort that is already being used by the rest of the system.

The SMT356 control word must be composed following the details in the SMT356

User Manual. This control word is then sent to the SMT356;

link_out_word(ctrl_word, 0);

Firstly, the control word must be sent with the internal trigger enable bit clear. After

this word has been sent, any further words sent with the trigger bit set will cause an

acquisition to start.

Immediately after the start control word has been sent, an SDB read instruction can

be performed;

SMT_SDB_Read(Sdb0, sizeof(Data), Data);

This defines the source interface as Sdb0 (a pointer returned in the SMT_SDB_Claim

call earlier), the length of data, and the destination.

This function will wait until all of the data has been received before execution

continues. A properly designed multi-threaded application would not have this

limitation. It is only used here for simplicity.

When the data has been received, it can be converted into floats and then sent to the

display tasks.

Loading...

Loading...