Page 1

Unit / Module Name:

Dual channel 14-bit DAC – 840 MSPS

Unit / Module Number:

Used On:

Document Issue:

Date:

SMT381

SMT338-VP, SMT320, SMT310Q, SMT327, SMT300Q

1.6.0

23/09/2004

CONFIDENTIAL

Approvals Date

Managing Director

Software Manager

Design Engineer

Sundance Multiprocessor Technology Ltd, Chiltern House, Waterside, Chesham, Bucks. HP5 1PS.

This documents is the property of Sundance and may not be copied nor communicated to a third party

without the written permission of Sundance. © Sundance Multiprocessor Technology Limited 1999

Page 2

Revision History

01/06/04

28/06/04

15/07/04

16/07/04

11/08/04

20/09/04

23/09/04

Changes Made Issue Initials

First release 1.0.0 LPS

Updated analog output circuit and PCB placement 1.1.0 LPS

General Updated to Document 1.2.0 LPS

Updated ext clock input description and updated part

1.3.0 LPS

descriptions

Added figure indicating test points on SMT381 1.4.0 LPS

General Updates to Document 1.5.0 MRV

Added waveform performance specifications 1.6.0 MRV

Page 3

List of Abbreviations

Abbreviation Explanation

ATP Acceptance Test Procedure

BCD Binary Coded Decimal

BER Bit Error Rate

BOM Bill Of Materials

CDR Clock and Data Recovery

CPCI Compact PCI

DAC Digital to Analog Converter

DDR Double Data Rate

DLL Delay Lock Loop

DSP Digital Signal Processor

FPGA Field Programmable Gate Array

GSPS Giga Sample Per Second

LSB Least Significant Bit

LVDS Low Voltage Differential Signalling

LVPECL Low Voltage Positive ECL

MSB Most Significant Bit

NA Not Applicable

PC Personal Computer

PCB Printed Circuit Board

PCI Peripheral Component Interconnect

POR Power On Reset

RSL Rocket Serial Link

RSLCC Rocket Serial Link Communications Channel

SDRAM Synchronous Dynamic Random Access Memory

SHB Sundance High-speed Bus

SI Serial Interface

SMT Sundance Multiprocessor Technology

SPI Serial Peripheral Interface

TBD To Be Determined

TI Texas Instruments

VCO Voltage Controlled Oscillator

Page 4

Table of Contents

1 Introduction...........................................................................................................10

1.1 Overview ........................................................................................................10

1.2 Module Features.............................................................................................10

1.3 Possible Applications......................................................................................10

1.4 Related Documents........................................................................................11

2 Functional Description...........................................................................................12

2.1 Module Overview............................................................................................12

2.2 Communication Ports (ComPorts) ..................................................................13

2.3 Sundance High-Speed Bus (SHB)..................................................................13

2.4 Main Analogue characteristics........................................................................14

2.5 Data stream description..................................................................................14

2.5.1 Description of internal FPGA blocks ............................................................15

2.6 Clock Structure...............................................................................................17

2.7 Trigger Structure.............................................................................................18

2.8 Power Supply and Reset Structure.................................................................19

2.9 MSP430 Functionality.....................................................................................20

2.10 FPGA Configuration......................................................................................22

2.11 Analogue output section...............................................................................22

2.12 DAC Settings................................................................................................24

3 Description of interfaces........................................................................................24

3.1 DAC Control Interface.....................................................................................24

3.2 DAC Data Interface ........................................................................................25

3.3 Memory Interface............................................................................................25

3.4 MSP430 Interface...........................................................................................25

3.5 Serial Number ................................................................................................25

3.6 PLL Interface..................................................................................................25

3.7 Clock Synthesizer Interface............................................................................26

3.8 TIM Interface..................................................................................................26

3.9 External Trigger..............................................................................................26

3.10 Daughter card Interface................................................................................26

3.11 RSL Interface (RSL not yet available)...........................................................33

3.11.1 RSL Connector and Pinout Definition.....................................................33

3.11.2 RSL Cable Definition..............................................................................35

3.12 SHB Interface...............................................................................................35

4 Firmware Description............................................................................................39

4.1 Main States ....................................................................................................39

4.2 Configuring the FPGA.....................................................................................40

4.3 Setting up the FPGA.......................................................................................40

5 Control Register Settings......................................................................................41

5.1 Control Packet Structure.................................................................................41

5.2 Reading and Writing Registers.......................................................................42

5.3 Memory Map ..................................................................................................43

5.4 Register Descriptions......................................................................................45

Page 5

5.4.1 The Reset Register..................................................................................45

5.4.2 Firmware Version Register (Read Add 0x000) .........................................45

5.4.3 Temperature Registers (Read Add 0x020, 0x021, 0x028,0x029).............46

5.4.4 Serial Number Registers (Read Add 0x022 – 0x025 and 0x02A – 0x02D)

.........................................................................................................................46

5.4.5 DAC Clock Source Registers (Write Add 0x801)......................................47

5.4.6 Clock Synthesizer Setup Register (Write Add 0x800)...............................47

5.4.7 PLL Setup Registers (Write Add 0x802 – 0x809) .....................................48

5.4.8 DAC Setup Registers (Write Add 0x900 – 0x905)....................................48

6 PCB Layout...........................................................................................................50

6.1 SMT381 PCB View.........................................................................................50

6.2 Assembly Drawings........................................................................................51

6.3 SMT338-VP Assembly Drawings....................................................................53

6.4 SMT381 PCB View.........................................................................................54

7 General Properties................................................................................................58

7.1 FPGA Mounted on SMT338-VP......................................................................58

7.2 Design Resource Usage.................................................................................58

7.3 Power Supply.................................................................................................58

7.4 Module Dimensions........................................................................................59

7.5 FPGA/JTAG Connector..................................................................................60

8 System Setup........................................................................................................61

8.1 How to connect the SMT381 to SMT338-VP ..................................................61

9 Module Performance.............................................................................................65

9.1 Introduction.....................................................................................................65

9.2 LVDS Data interface.......................................................................................65

9.3 Waveform Memory.........................................................................................66

10 Firmware Building Blocks....................................................................................70

10.1 Introduction...................................................................................................70

10.2 Clock Synthesizer......................................................................................... 70

10.3 DAC serial setup...........................................................................................71

10.4 PLL Configuration.........................................................................................74

11 Test Points..........................................................................................................77

12 APPENDIX A – Waveform Memory Setup ..........................................................78

12.1 Introduction...................................................................................................78

10.2 System Setup...............................................................................................78

10.2 Software Setup.............................................................................................78

Page 6

Table of Tables

Table 1. Main analogue characteristics of the SMT381............................................14

Table 2. Daughter Card Interface Power Connector and Pinout...............................29

Table 3. Register Memory Map (DAC registers not yet fixed in firmware).................45

Table 4. Table of Connector Locations on SMT381. ................................................56

Table 5. Table of Component Locations on SMT381................................................57

Table 6. Virtex-II Pro IO Count.................................................................................58

Table 7. Virtex-II Pro Device Utilization Summary....................................................58

Table 8. SMT381 Power Supply Voltages................................................................59

Table 9. SMT381-VP Power Supply Voltages..........................................................59

Table 10. Internal Power Supply Voltages................................................................59

Table 11. SMT381-VP Dimensions..........................................................................60

Table 12. Clock Synthesizer Test Output.................................................................70

Table 13. Clock Synthesizer Division Setup.............................................................71

Table 14. Configuration of the DACSerialSetupReg register....................................73

Page 7

Table of Figures

Figure 1. Functional Block diagram of SMT381........................................................12

Figure 2. Internal Data path of the SMT338-VP........................................................15

Figure 3. Clock tree of the SMT381..........................................................................17

Figure 4. Trigger structure of the SMT381 and SMT338-VP.....................................19

Figure 5. Power Generation and distribution............................................................20

Figure 6. Microcontroller State Machine...................................................................21

Figure 7. Option 1 for the SMT381 analog output stage...........................................23

Figure 8. Option 2 for the SMT381 analog output stage...........................................23

Figure 9. Combined analog output circuit.................................................................24

Figure 10. Daughter card connector interface..........................................................27

Figure 11. Daughter Card Interface: Data Signals Connector and Pinout (Bank A).30

Figure 12. Daughter Card Interface: Data Signals Connector and Pinout (Bank B).31

Figure 13. Daughter Card Interface: Data Signals Connector and Pinout (Bank C).32

Figure 14. Rocket Serial Link Interface. ...................................................................33

Figure 15. Rocket Serial Link Interface Connector and Pinout (RSL A)....................34

Figure 16. Rocket Serial Link Interface Connector and Pinout (RSL B)....................35

Figure 17. Samtec HFEM Series Data Cable...........................................................35

Figure 18. Possible SHB Configurations. .................................................................36

Figure 19. SHB Connector Configuration 1 Pinout...................................................37

Figure 20. SHB Connector Configuration 2 Pinout...................................................38

Figure 21. SMT381-VP Firmware State Diagram.....................................................39

Figure 22. Setup Packet Structure. ..........................................................................41

Figure 23. Packet Structure – Defined Commands. .................................................42

Figure 24. Control Register Read Sequence............................................................42

Figure 25. Reset Register (Write Only).....................................................................45

Figure 26. Firmware Version Register (Read Only)..................................................45

Figure 27. Temperature Registers (Read Only)........................................................46

Figure 28. Serial Number Registers (Read Only).....................................................46

Figure 29. Serial Number Registers Cont. (Read Only)............................................47

Figure 30. Clock Source Selection Table (Write Only)..............................................47

Figure 31. Clock Source Register (Write Only).........................................................47

Figure 32. Clock Synthesizer Setup Register (Write Only). ......................................47

Figure 33. PLL Setup Registers (Write Only). ..........................................................48

Figure 34. DAC Setup Registers (Write Only). .........................................................48

Figure 35. SMT 381 PCB layout - TOP. ...................................................................50

Figure 36. SMT 381 PCB layout – BOTTOM............................................................50

Figure 37. SMT381 Top Assembly Drawings. ..........................................................51

Figure 38. SMT381 Bottom Assembly Drawings......................................................51

Figure 39. Main Module Top Assembly Drawing......................................................53

Figure 40. Main Module Bottom Assembly Drawing.................................................54

Figure 41. Side view of SMT381-VP (Height)...........................................................54

Figure 42. Side view of SMT381-VP. .......................................................................55

Figure 43. Top view of SMT381-VP. ........................................................................55

Page 8

Figure 44. Connector Location on SMT381,.............................................................56

Figure 45. FPGA/JTAG connector for the SMT381-VP. ...........................................60

Figure 46. SMT381 to SMT338-VP Interconnection.................................................61

Figure 47. Components Used to Connect the SMT381 to the SMT338-VP..............62

Figure 48. Fitting of Nylon Screws and Nuts to the SMT338-VP. .............................63

Figure 49. Securing the SMT338-VP onto a Sundance Carrier................................63

Figure 50. Connecting the SMT381 to the SMT338-VP............................................64

Figure 51. Time View Captures of LVDS Interface Data...........................................65

Figure 52. Measurements of Time View Capture. ....................................................65

Figure 53. Waveform Memory - Time View Capture – 1000MHz sample frequency

(500MHz VCO Clock) – 125MHz analog output................................................66

Figure 54. Measurements of Capture – 1000MHz sample frequency (500MHz VCO

Clock) – 125MHz analog output........................................................................66

Figure 55. Waveform Memory - FFT – 1000MHz sample frequency (500MHz VCO

Clock) – 125MHz analog output – Channel A....................................................67

Figure 56. Waveform Memory - FFT – 1000MHz sample frequency (500MHz VCO

Clock) – 125MHz analog output – Channel B....................................................67

Figure 57. Waveform Memory - FFT – 1400MHz sample frequency (700MHz

Synthesizer Clock) – 175MHz analog output – Channel A................................68

Figure 58. Waveform Memory - FFT – 1400MHz sample frequency (700MHz

Synthesizer Clock) – 175MHz analog output – Channel B................................68

Figure 59. Waveform Memory - FFT – 600MHz sample frequency (300MHz VCO

Clock) – 75MHz analog output – Channel A......................................................69

Figure 60. Waveform Memory - FFT – 600MHz sample frequency (300MHz VCO

Clock) – 75MHz analog output – Channel B......................................................69

Figure 61. Clock Synthesizer Register.....................................................................70

Figure 62. Clock Synthesizer Frequency Calculation. ..............................................71

Figure 63. DAC serial write operation.......................................................................72

Figure 64. DAC serial read operation.......................................................................72

Figure 65. State machine of the DAC for the SMT381..............................................73

Figure 66. Register Setup for PLL............................................................................74

Figure 67. PLL Configuration Sequence...................................................................75

Figure 68. State Machine Driving the PLL Serial Interface. ......................................76

Figure 69. Test point locations on the SMT381........................................................ 77

Figure 70. Test Program Main Menu........................................................................ 78

Figure 71. SMT338-VP Sub-Menu...........................................................................79

Figure 72. SMT381 Sub-Menu.................................................................................80

Figure 73. Waveform Memory Setup Sequence.......................................................81

Page 9

Precautions (Please Read this!).

In order to guarantee that the SMT381-VP functions correctly and

to protect the module from damage, the following precautions

should be taken:

The SMT381-VP is a static sensitive product and should be

handled accordingly. Always place the module in a static protective

bag during storage and transition.

When operated, make sure that the heat generated by the system

is extracted e.g. by the use of a fan extractor or an air blower.

SHB and RSL connectors are similar but their use is really

different. Do NOT connect an SHB and an RSL connectors

together with and SHB cable! This would cause irreversible

damages to the modules.

Naming Conventions.

The SMT381 refers to a dual channel, 14-bit, 840MSPS DAC

daughter card.

The SMT338-VP refers to a single width Virtex-II Pro based FPGA

module with a Sundance LVDS Bus interface (used for connecting

TIM modules to daughter cards)

The SMT381-VP refers to the SMT381 plugged onto the SMT338VP forming a complete module DAC + FPGA Module.

Page 10

1 Introduction

1.1 Overview

The SMT381-VP is a single width expansion module that plugs onto the SMT338-VP.

It is capable of converting two external digital inputs coming form the SMT338-VP at

840 MSPS with a resolution of 14 bits, or from internal memory at 1GSPS. A Fujitsu

dual channel DAC (MB86064) performs the digital to analogue conversion.

The SMT381 (daughter card) is plugged into the SMT338-VP (main module). Digital

data is then supplied from the SMT338-VP via the daughter card connector over the

Sundance LVDS Bus to the SMT381 which converts the digital data stream to an

analogue signal.

The SMT338-VP controls data transfers via ComPorts, Sundance High-speed Bus

(SHB) or the Rocket Serial Link (RSL) (The RSL interface is not yet implemented).

These interfaces are compatible with a wide range of Sundance processor and I/O

modules.

A very important aspect must be kept in mind by the user. The DAC is rated for

1 GSPS but the SMT338-VP’s FPGA can only supply data to the DAC at 840MHz. It

is however possible to load data into the onboard memory on the DAC. This internal

data can be converted at 1GSPS.

1.2 Module Features

The main features of the SMT381 are listed underneath:

• Dual channel DAC

• 1 GSPS conversion frequency from internal memory

• 840MSPS conversion frequency for data coming from the SMT338-VP

• 14 Bit data resolution

• Custom Clock and Trigger inputs via external connectors

• Internal Waveform generator

• Standard Sundance ComPorts and SHB interfaces for easy interconnection to

Sundance products (interfaces for data sample and non-real-time processing)

1.3 Possible Applications

The SMT381-VP can be used for the following applications (this non-exhaustive list

should be taken as an example):

• Broadband cable modem head-end systems

• 3G Radio transceivers

• High-data-rate point-to-point radios

• Medical imaging systems

• Spectrum analyzers

Page 11

1.4 Related Documents

[1] Sundance High-speed Bus (SHB) specifications – Sundance.

ftp://ftp2.sundance.com/Pub/documentation/pdffiles/SHB_Technical_Specification_v1_0.pdf

[2] RocketIO Serial Links (RSL) specifications – Sundance.

ftp://ftp2.sundance.com/Pub/documentation/pdffiles/RSL_Technical_Specification_v1_0.pdf

[3] TIM specifications.

ftp://ftp2.sundance.com/Pub/documentation/pdf-files/tim_spec_v1.01.pdf

[4] Sundance LVDS Bus (SLB) specifications – Sundance.

http://www.sundance.com/docs/SLB%20-%20Technical%20Specifications.pdf

[5] Virtex-II Pro FPGA datasheet - Xilinx.

http://direct.xilinx.com/bvdocs/publications/ds083.pdf

[6] Fujitsu MB86064 DAC datasheet.

http://www.fme.fujitsu.com

[7] ComPort specification – Texas Instruments.

http://focus.ti.com/lit/ug/spru63c.pdf

Page 12

2 Functional Description

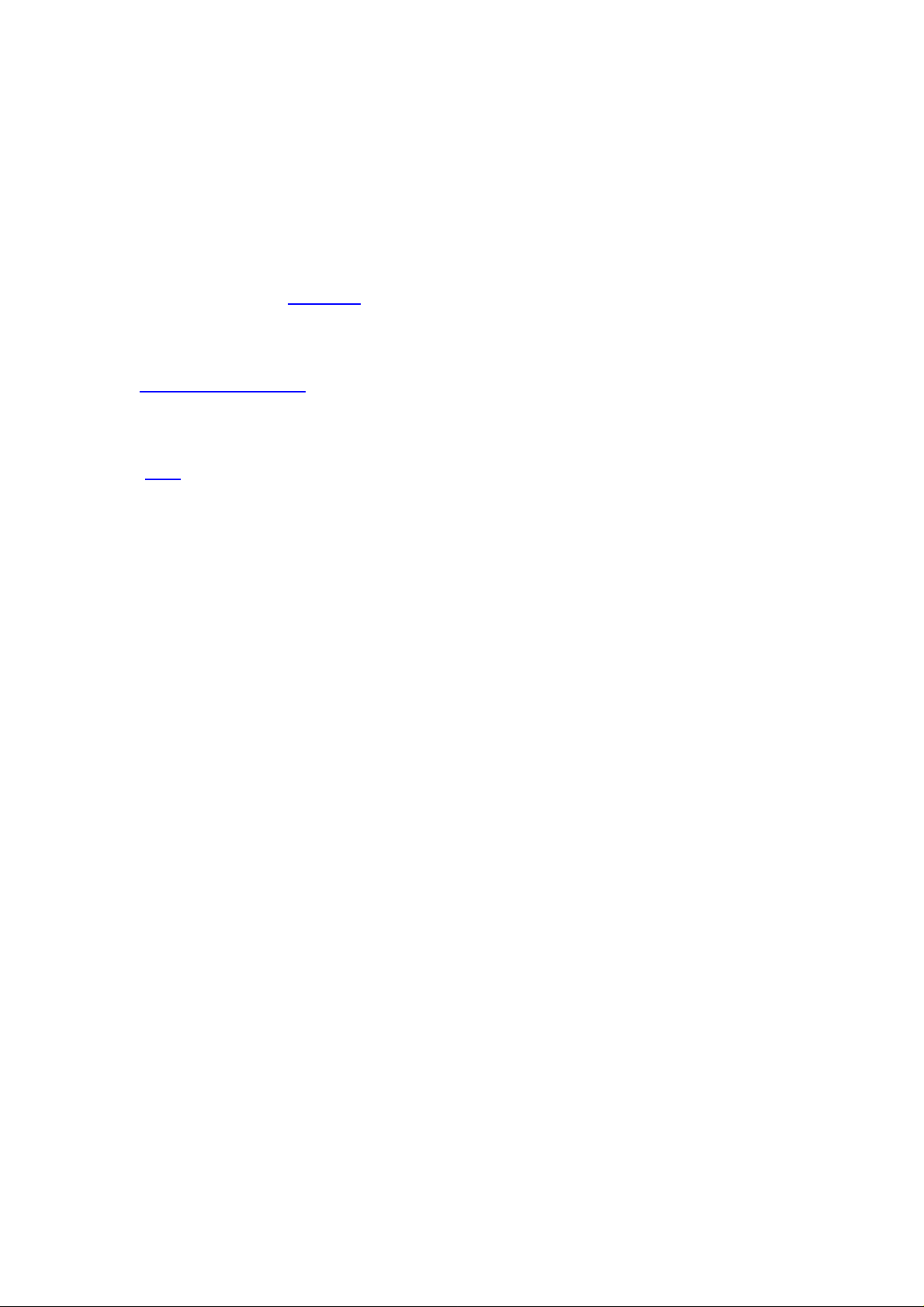

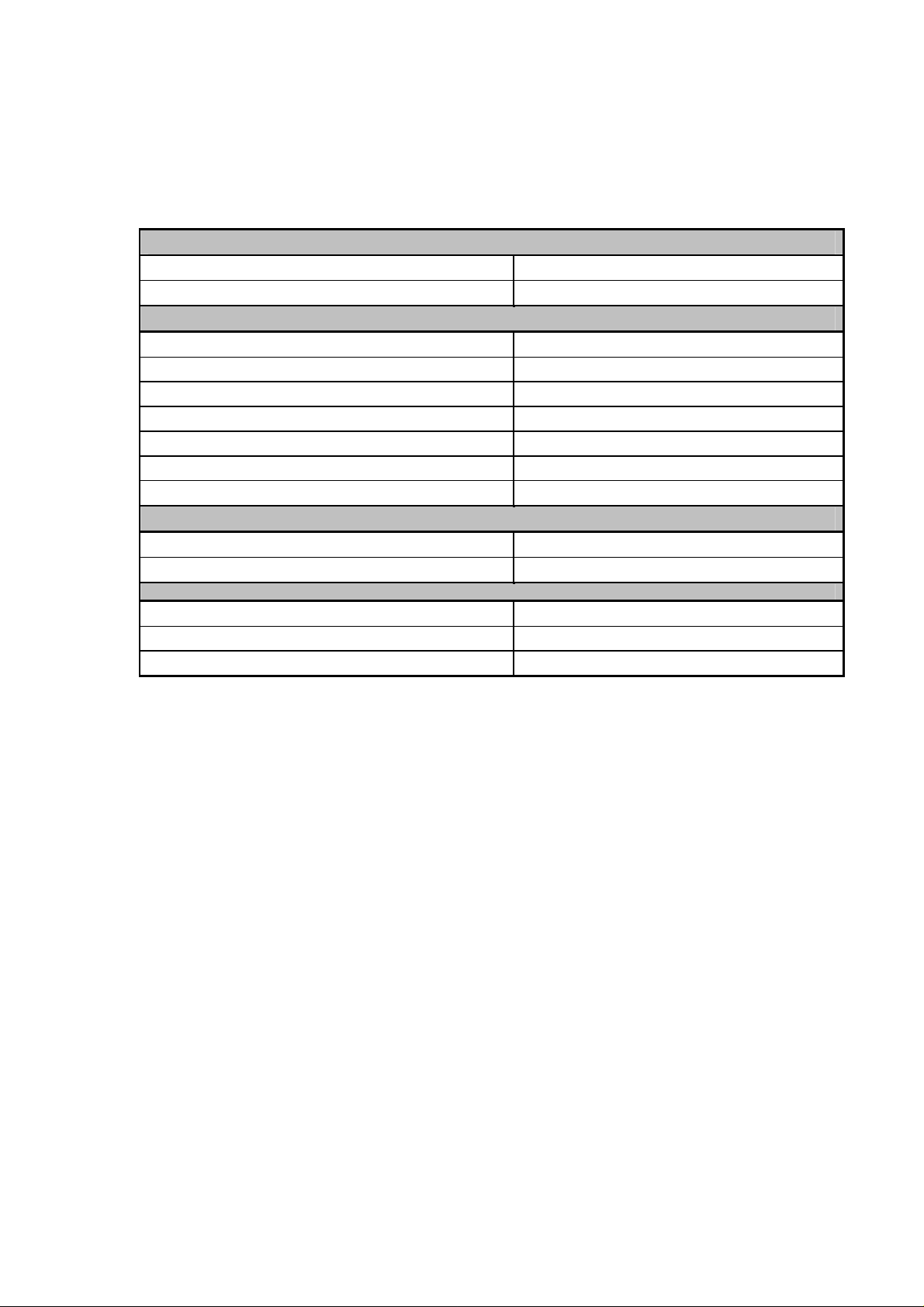

2.1 Module Overview

600MHz 1200MHz

VCO

div

2

SMT338

FPGA

Ext

Trigger

(1d)

Daughter

Card

Connector

The numbers in brackes denote the

Notes:

amount of FPGA IO pins requires.

'd' is used for differential pairs. 1d

Will thus requre 2 IOs

Data Sync Clock (1d)

Data Channel A (14d)

Data Channel B (14d)

Loop Clock (1d)

Loop Clock (1d)

SMT381SMT338-VP

Ext

Trigger

Ch A and Ch B

div

Input Clock (1d)

8

1V8

Convertor

circuit

Figure 1. Functional Block diagram of SMT381.

Clock Generation

Distribution

Digital to Analog

(MB86064)

Control (4)

LVPECL

and

Input Clock

Convertor

25MHz 400MHz

Clock Synth

(1d)

External Clock

Signal

Conditioning

Signal

Conditioning

Output

CHA

Output

CHB

Ch

A

Ch

B

The SMT338-VP sends the digital data to the module via the daughter card

connector. Data is clocked out of the FPGA on both edges of the DAC clock (DDR).

The user can provide this clock by means of the VCO, Clock synthesizer or custom

external clock. The external clock can be provided as an LVPECL clock or as an RF

clock (two separate inputs).

All digital functions on the module are controlled by the SMT338-VP. There are two

14-bit LVDS ports on the DAC which converts the data on a DDR clock. The sampled

data can either be supplied to the DAC cores externally via the LVDS data bus or

internally from the Waveform Memory Module. The data may be routed to the DAC

cores through a number of paths. The most direct path routes data straight from the

LVDS input buffers to the DAC core input latches.

There are two DAC cores present in the MB86064. Thus two channels are available

for outputs. The outputs of the DAC are differential currents, which are converted to a

voltage by the analogue output stage. Details on the set up will be discussed later.

The design of the SMT381 is split over two PCBs. The main PCB (main module –

SMT338-VP) contains the FPGA and the digital connector interfaces (TIM, SHB and

Page 13

RSL). The main memory as well as the MSP430 microprocessor is also located on

this PCB. The second PCB (daughter card – SMT381) contains all the analog

circuitry. The clock generation, trigger control, analog signal conditioning and DAC is

located on this PCB. The SMT381-VP refers to the combination of the SMT338-VP

and the SMT381.

The depth of the SMT381-VP is 21 mm. If the SMT381-VP is mated with a PCI

carrier two PCI slots will be required for the Module + Carrier combination. If the

SMT381-VP is mated with a cPCI carrier the Module + Carrier will require two cPCI

slots.

The FPGA gets control words over a ComPort interface following the Texas

Instruments C4x ComPort standard. The FPGA receives data through the onboard

memory or SHB interface. It is then sent to the DAC cores over two 14-bit LVDS

busses according to the SLB standard. The DACs convert the data and sends the

data to the output connectors.

Two full (60-pin) SHB connectors are accessible from the FPGA. Their main function

is to receive digital samples from other modules. Please refer to the SHB

specification for more details about the way connectors can be configured.

A global reset signal is mapped to the FPGA from the bottom TIM connector via the

MSP430 microcontroller.

2.2 Communication Ports (ComPorts)

The SMT381-VP provides two ComPorts – ComPort 0 and ComPort 3. Both of these

ComPorts are connected to the FPGA on the SMT338-VP. ComPort 3 is also

connected to the MSP430 microprocessor. The microprocessor is the master of this

ComPort after reset and configures the FPGA with configuration data received over

this link. After configuration the microprocessor releases the ComPort to the FPGA.

These ComPorts are driven at 3.3V levels.

2.3 Sundance High-Speed Bus (SHB)

Two SHB connectors are used to transmit data to the SMT381-VP from the external

world. Both SHB busses are identical and 60-bits wide. See the SHB specification

for more information.

Page 14

2.4 Main Analogue characteristics

The main analogue characteristics are listed in the following table:

Analogue outputs

Output current range 20mA

Data Format Analogue current

External sampling clock inputs (The clock frequency is divided by 2 on the SMT381 for a DDR clock for the DAC)

LVPECL Clock

Signal format LVPECL

Frequency range 25MHz to 1000 MHz

RF Clock

Signal format Sinus wave

Frequency range 25MHz to 1000 MHz

Amplitude 0dBm Typ

External trigger inputs

Signal format LVPECL

Frequency range DC to 100 MHz

ADC Performance @ Single tone at -1dBFS, 800MSa/s, DC to 400MHz (From DAC datasheet)

Spurious Free Dynamic Range (SFDR) @ 20MHz

Spurious Free Dynamic Range (SFDR) @ 300MHz

Cross-talk 4 tone test, each tone at -15dBFS, centred at 276MHz

75dBc

58dBc

67dBc

Table 1. Main analogue characteristics of the SMT381.

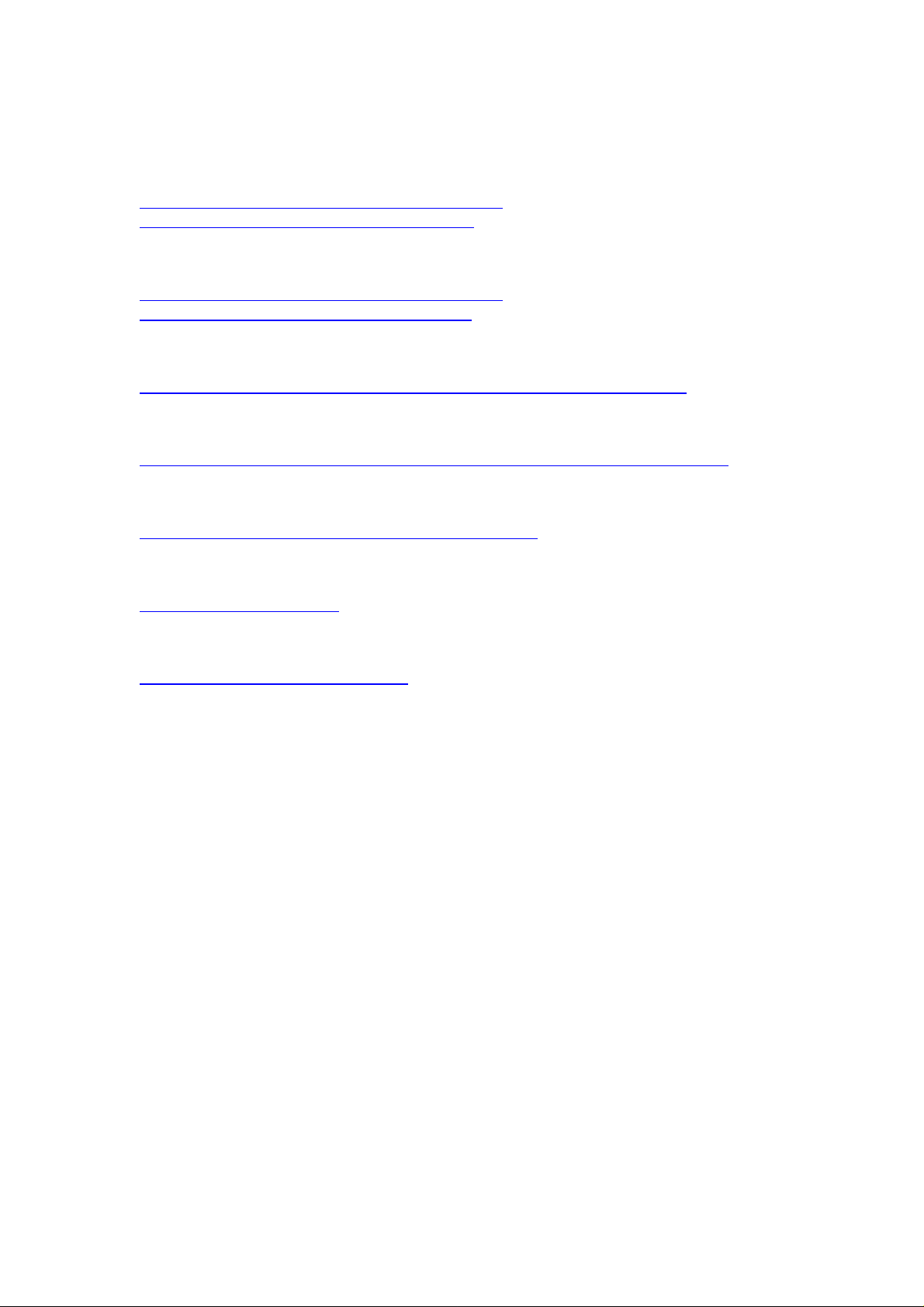

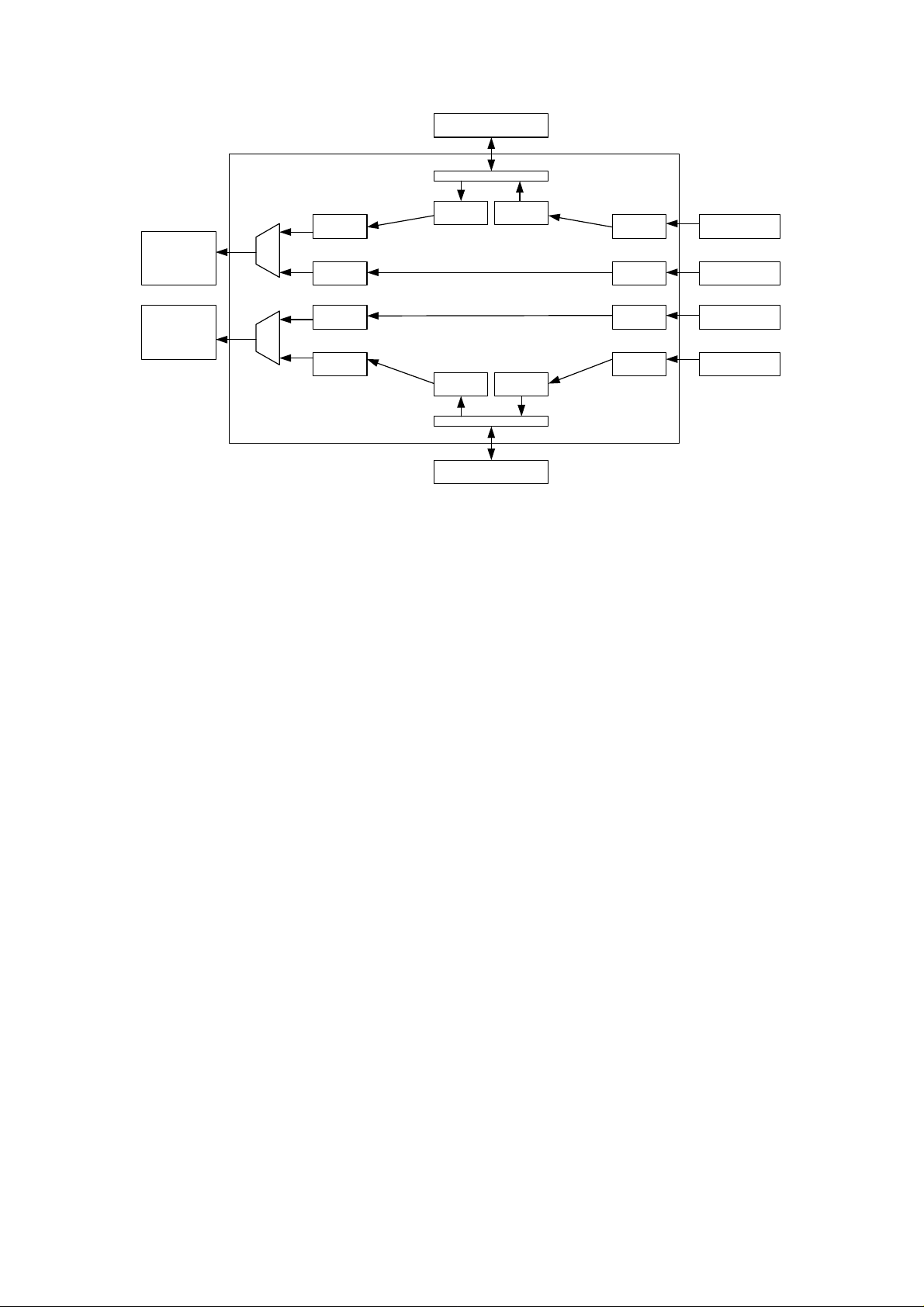

2.5 Data stream description

The data paths for both channels on the module are the same. The DAC is driven by

a single clock either generated on the module or provided by the user through an

MMBX connector. As only a single clock is present on the module the two data-paths

will always be in exact synchronization. As the data path on this module finds its

origin in the SMT338-VP’s FPGA the internal data path of the FPGA must also be

explained. Figure 2 shows the SMT338-VP’s FPGA data path.

Page 15

DDR SDRAM

Memory Interface

DAC

Channel A

DAC

Channel B

Mux

Mux

Pre-process

Data

Pre-process

Data

Pre-process

Data

Pre-process

Data

Retrieve from

Memory

Retrieve from

Memory

Memory Interface

DDR SDRAM

Store in

Memory

Store in

Memory

SHB

Interface

SI

SI

SHB

Interface

SHB for Channel A

RSL for Channel A

RSL for Channel B

SHB for Channel B

Figure 2. Internal Data path of the SMT338-VP.

The digital data stream is received from two interfaces. The first data stream is a

direct RSL interface for real-time type applications (RSL is not yet implemented).

While the second stream comes from the DDR SDRAM memory for non-real-time

type module transmits (the memory is initialized over the SHB interface).

Each data stream is then conditioned and sent to the SMT381 via the daughter card

connector. A multiplexer selects between the two data streams.

2.5.1 Description of internal FPGA blocks

Pre-processing Data

The user can implement his own type of processing on the data stream if required.

SI

The Serial Interface block takes the high-speed serial input data stream and converts

it into a parallel data stream (Not yet implemented).

Mux

The multiplexer connected to the RSL and SHB/memory interfaces selects between

these two data streams to send to the SMT381.

Store in Memory

The store in memory block takes the incoming data stream from the SHB and stores

the data into DDR SDRAM. This block will only transfer data from the memory to the

SMT381 when a valid trigger command is received. The amount of data that must be

stored is configurable.

Page 16

Memory Interface

The memory interface block is the DDR SDRAM controller. This block is responsible

to all write and read transactions to and from the DDR SDRAM.

Retrieve from Memory

The retrieve from memory block retrieves stored data in the DDR SDRAM when it

receives a valid read command. The read command specifies the location and

amount of data that needs to be retrieved.

SHB Interface

The data received from the SHB interface is stored in memory. The SHB interface

controls the SHB bus between the SMT338-VP and any module connected to the

SHB sending the data.

In addition to the above interface blocks the FPGA also implements the following

functions (not indicated on the diagram):

Trigger Interface

Handles all triggers. Triggers may be received from the external hardware trigger

connectors (two separate triggers – one for each channel), or by receiving a trigger

command over the ComPort (also separate commands for each channel). When a

trigger is received data is sent to the SMT381 from the memory on the SMT338-VP.

DAC Control Interface

Control interface for writing setup information to the DAC on the SMT381 to configure

it for any selected mode of operation. Data is received over the ComPort interface

and written out to the DAC over a serial interface.

Clock Synthesizer Interface

Control interface for writing setup information to the clock synthesizer on the SMT381

to configure its clock output frequency. Data is received over the ComPort interface

and written out to the clock synthesizer over a serial interface.

PLL Interface

Control interface for writing setup information to the PLL on the SMT381 to configure

the VCO output voltage. Data is received over the ComPort interface and written out

to the PLL over a serial interface. The PLL drives one VCO circuit. This VCO + PLL

circuit generates the main system clock and is configurable between 600 and 1200

MHz. The side is called the RF side. This clock is then divided by two which enables

the DAC to have a very stable PLL + VCO clock ranging from 300 to 600MHz.

DAC Interface

The DAC interface sends a high speed data stream from the FPGA to the DAC

present on the SMT381. There are two channels available on the DAC and data is

latched into the DAC on the rising and falling edge (DDR) of the DAC’s input clock

which is clocked into the FPGA to make data synchronization easier. The inputs are

14bit data streams which is clocked out of the FPGA at a maximum frequency of

420MHz (on both edges, thus 840MSPS).

Page 17

Clock Tree Setup Interface

There are various clock routing configurations available for the SMT381. This

interface configures the clock tree.

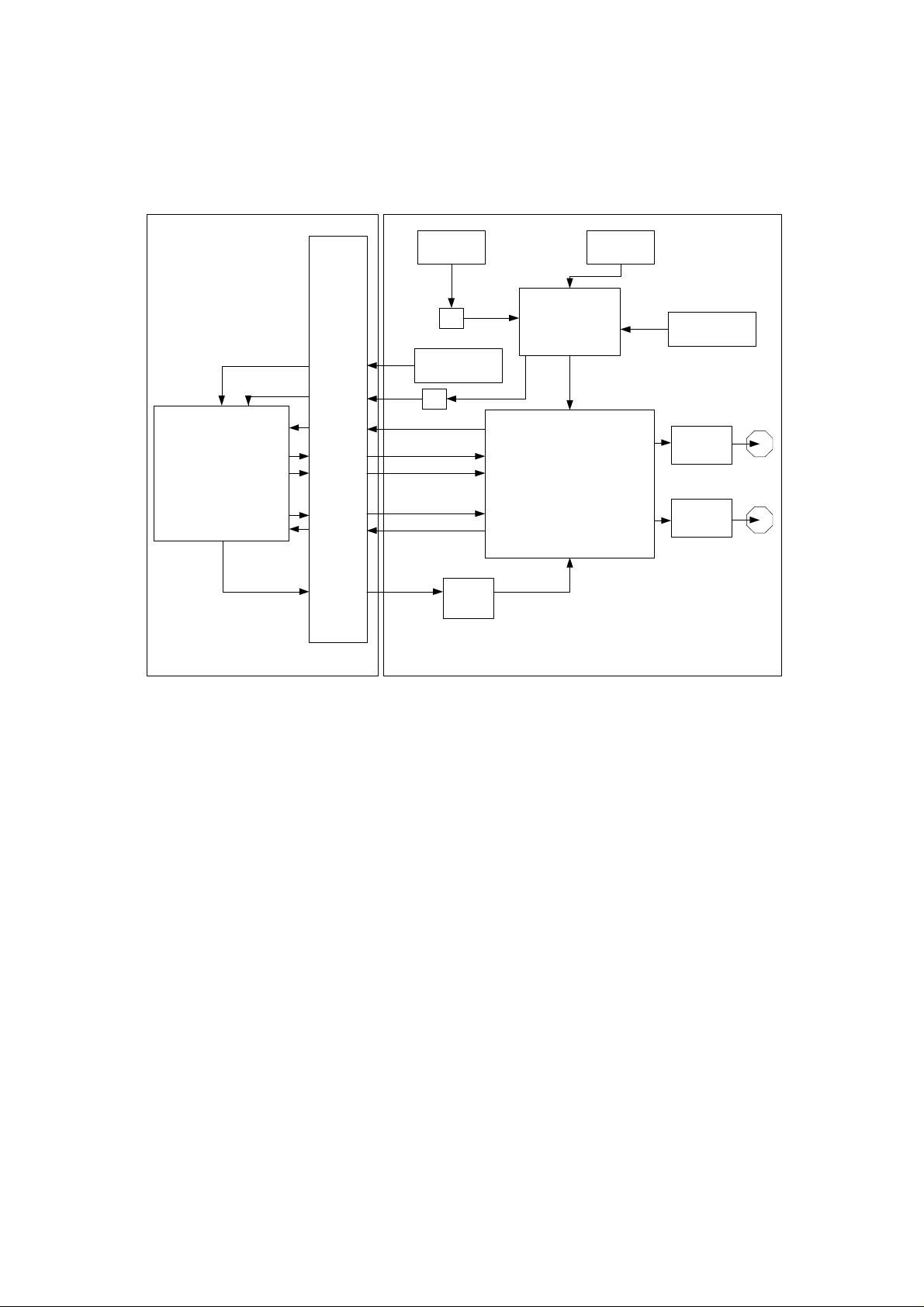

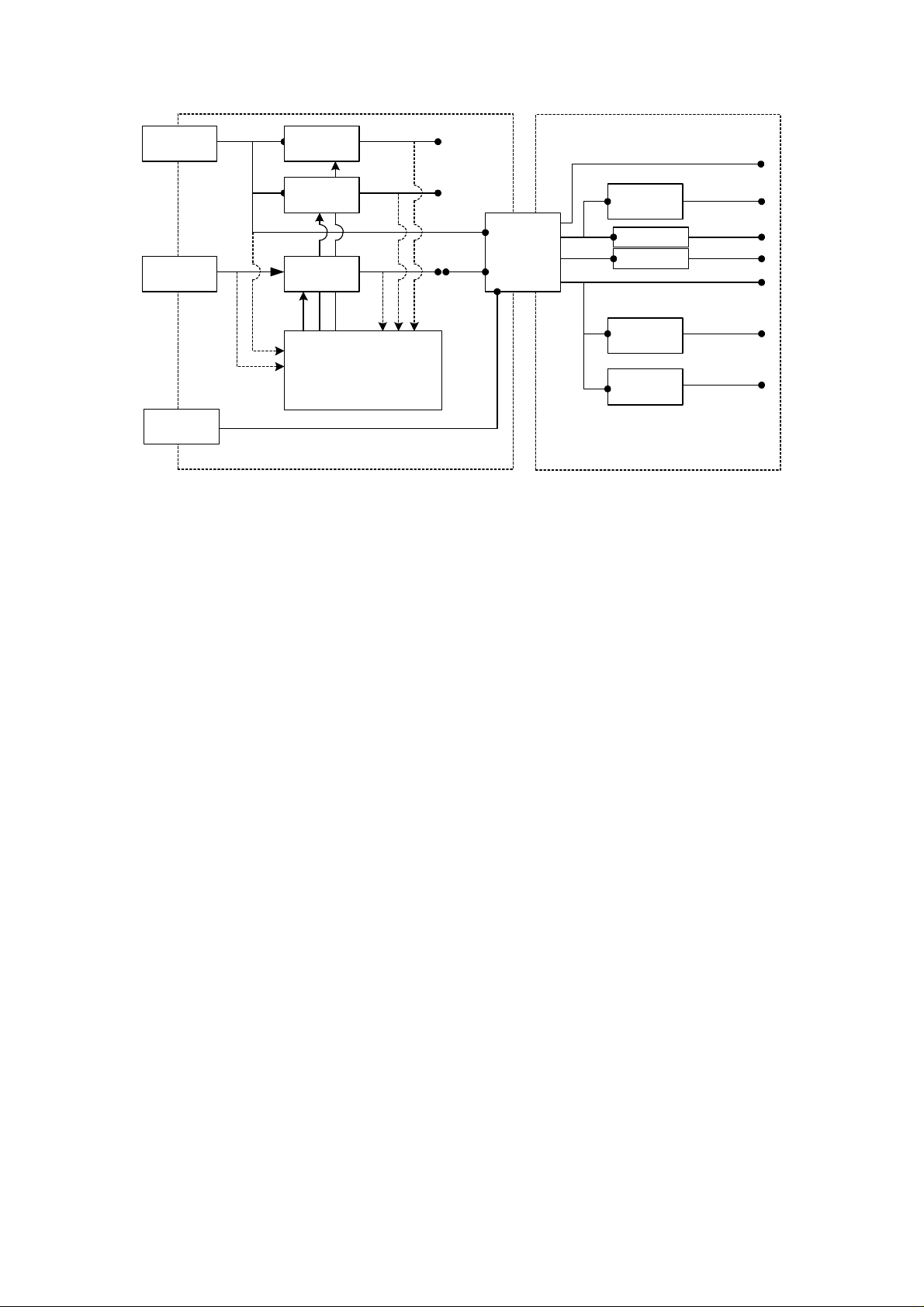

2.6 Clock Structure

There are two integrated clock generators on the module. The user can either use

these clocks or provide the module with an external clock (input via MMBX

connectors). The following figure shows the SMT381 clock tree.

External Clocks

Ext RF

Clock

Input

(MMBX)

ECL

Comp-

arator

2:1 Mux

Clock Div 2

External Trigger

External Trigger Input

(MMBX)

Ext

LVPECL

Clock

Input

(MMBX)

ECL

Reciever/

Driver

Clock

Div 8

Clk Synth (25MHz -

400MHz)

Clk Synth

LVPECL

Buffer

3:1 Mux with Dual Output

Fanout

Buffer

DAC

VCO (600MHz -

1200MHz)

PLL

Voltage Controlled

Oscillator

Comparator

div 2

TTL to LVPECL

Loop

Clock

DAC clock

output

(MMBX)

LVPECL

Buffer

PLL

SMT338

Data

Clock

Clock

Control

Figure 3. Clock tree of the SMT381.

The main clock tree of the SMT381 consists of two clock sources to achieve the

DAC’s full range of input frequencies (DC – 500MHz). The first clock source is a

MICREL clock synthesizer which has a range from 50MHz to 950MHz. This source’s

disadvantage however is that it has a jittery output and thus the clock is not that

stable. Its advantage however is that it can attain a wide range of frequencies,

especially the lower frequencies. The output clock is LVPECL.

Page 18

The second clock source is a voltage controlled oscillator with a phase lock loop.

This combination has a very stable output. However a limited frequency range can be

attained by this combination (300MHz – 600MHz). This is achieved by taking a

600MHz -1200MHz VCO and dividing the output by 2. The output clock must also be

scaled to LVPECL.

Alternatively the user can provide the module with an external LVPECL clock or an

external RF clock. The user can select between any of these input clocks.

The selected clock then drives the DAC and is also distributed to the main module

(SMT338-VP) for data synchronization purposes. On the FPGA of the SMT338-VP a

PLL synchronizes the clock with the data being sent by using the supplied clock and

looping that same clock to the DAC and back. This technique synchronizes the clock

to the data is being sent out on (SMT338-VP side) even further with the clock used in

the DAC. Synchronization issues become a bigger factor as the clock frequencies get

bigger.

All the clock control is done on the SMT338-VP side in firmware on the FPGA. The

multiplexer selects the clock and this clock is then used inside the DAC and SMT338VP for data transmitting purposes. The set up of the clock packages is also done in

firmware.

Finally an external trigger is supplied to the SMT338-VP and the multiplexed clock

divided by 8. The trigger can be used for memory storing and retrieving functions etc.

while the clock divided by 8 is mainly for debugging purposes.

2.7 Trigger Structure

There are two main data-paths (per channel) for data received either from RSL

interface (not yet implemented) or SHB/memory interface. The first data path is

directly connected to the DAC interface and sends the data as is. The second data

path is either a direct link to the DAC interface or to memory. The trigger settings

differ depending on the path used.

There are two main sources for the trigger. The first is an LVPECL trigger received

over the MMBX connector (triggered on rising edge). The second is a trigger

command. The trigger command can be received either over the RSL interface or via

the ComPorts.

The following trigger settings are possible for the RSL interface (RSL not yet

implemented):

• Start transmitting data when a trigger is received. Stop transmitting when the

next trigger is received.

• Transmit a pre-determined amount of samples when a trigger is received.

• Ignore all triggers and transmit data continuously (cycle through memory).

The following trigger settings are possible for the DDR SDRAM data-path:

Page 19

• Transmit a pre-determined amount of samples when a trigger is received, and

carry on cycling through them.

The following diagram is a graphical representation of the trigger structure and

sources on the SMT381 and SMT338-VP:

FPGAExternal Trigger

RSL CDR Interface

RSL Rx Cmd State

Trigger Generation

External Trigger Input

(MMBX)

LVPECL

Buffer

SMT338-VP

ComPort Interface

ComPort Rx Cmd

State Machine

Trigger Generation

SMT381

Trigger Setup

Register

Figure 4. Trigger structure of the SMT381 and SMT338-VP.

Machine

Trigger

Distribution

2.8 Power Supply and Reset Structure

The SMT381 uses the following voltages: 12V, -12V, 5V, -5.2V, 3.3V and 1.8V. Only

two voltages must be generated on the SMT381 as the rest are supplied by the

carrier. The voltages that must be generated are -5.2V and 1.8V. -5.2V is used for

the comparator and op amp in the clock circuitry while 1.8V is used for the serial

control interface on the DAC.

All the other voltages are supplied by the carrier and thus present on the SMT338-

VP. The required voltages are then supplied to the SMT381 by a daughter card

power connector present on the SMT338-VP and SMT381. The SMT381 plugs into

this power connector and thus has power for all its modules.

Pin X_RESET is the only reset option on the SMT381. This pin resides on the DAC.

On the falling edge of X_RESET the DAC is reset and all registers are set to their

default values. After a reset most parts of the device are powered down.

The following figure shows the power structure of the SMT338-VP and SMT381:

Page 20

TIM Connector

D+5V0_IN

Vccaux

DC / DC

Converter

D+2V5

Daughter Card

D+5V0

TIM

Mounting Hole

D+3V3_IN

TIM Connector

D+12V0 and

D-12V0

Voltage

Measure

Vccint

DC / DC

Converter

Analog Power

Switch

Microprocessor

On / Off

Control

MSP430

D+1V5

D+3V3

Voltage

Measure

Main Module to

Daughter Card

Power

Connector

Low Dropout

Regulator

Analog Filter

Analog Filter

Analog Filter

Low Dropout

Regulator

D-5V2

D-12V0

D+12V0

D+3V3

A+3V3

D+1V8

Main Module

Figure 5. Power Generation and distribution.

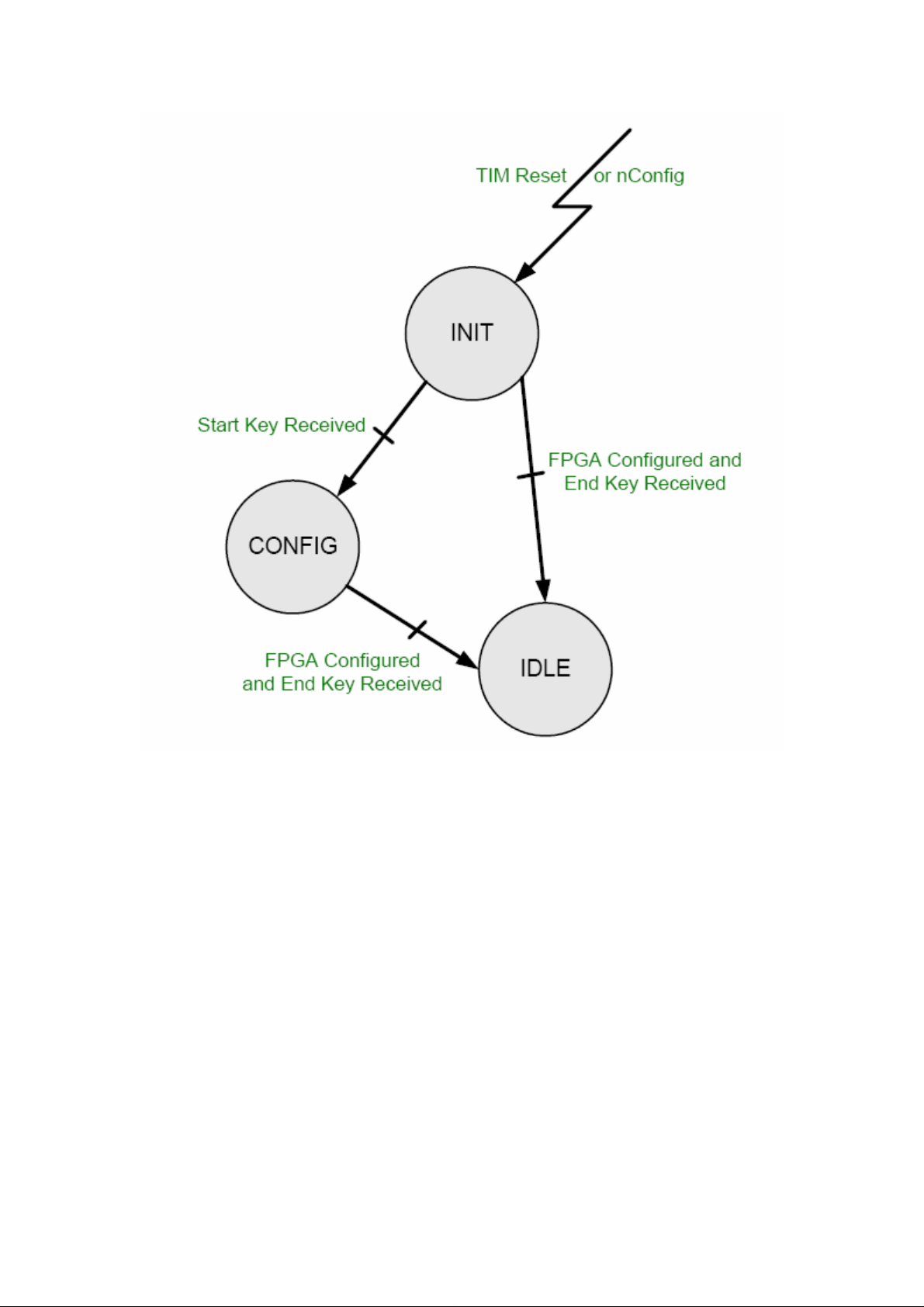

2.9 MSP430 Functionality

The MSP430 implements analog control functionality that is difficult to implement in

the FPGA. The microprocessor

• Controls the power start-up sequence

• Controls the reset structure on the module

Page 21

Figure 6. Microcontroller State Machine.

At power-up or on a TIM Reset or on a nConfig line going low, the state machine

goes into an INIT State. TIM Reset and nConfig lines are available on the carrier

module – see TIM Specifications for location on TIM connectors).

From there, it has two choices depending on the state of the FPGA (configured i.e.

DONE pin high or un-programmed i.e. DONE Pin Low). To configure the FPGA,

simply send a Start Key followed by the bitstream and then and End Key. To re-start

the FPGA with the current bitstream loaded, simply send a End Key.

Start Key = 0xBCBCBCBC and End Key = 0xBCBCBC00.

A TIM Reset can be issued to reconfigure the FPGA at anytime, but may reset other

modules as well. In the case of reconfiguring a particular module, the nConfig line is

used.

Page 22

MSP430 is connected to ComPort 3 of the TIM. With the standard firmware

implementation ComPort 3 is used to communicate with the FPGA. ComPort 0 is

open for custom applications as it is not used by the SMT381-VP.

2.10 FPGA Configuration

In a typical Sundance system a carrier and host module (most likely a DSP module)

is needed to configure the SMT381-VP.

After a hardware reset the FPGA of the SMT381-VP is un-configured and the

microprocessor (MSP430) waits for a data stream. At this point the microprocessor is

in control of ComPort 3. The host can then send a data stream over ComPort 3

starting with a STARTKEY, then the data, and ending with an ENDKEY. This will

configure the FPGA via the microprocessor, and after configuration the

microprocessor will release ComPort3 so that the host can talk straight to the FPGA.

If at any time the host want to reset the FPGA the host must send a reset command

to it the SMT381-VP over the ComPort – Any hardware resets coming over the TIM

site will be caught by the microprocessor but will not be passed on to the FPGA.

If the FPGA is configured, but the host restarts its application, it must send an

ENDKEY only. This will ‘wake up’ the FPGA and the uP will release ComPort 3 so

that the host can use it for FPGA communication.

If the host want to reconfigure the FPGA it must toggle the nConfig line on the TIM

site. This will give control of the ComPort back to the microprocessor, but it will not

un-configure the FPGA. If the host then start sending a new bit-stream starting with a

STARTKEY, the FPGA will be un-configured and the new bit-stream will load. If after

toggling the nConfig line, if the host does not want to re-configure the FPGA, it must

send an ENDKEY like described above.

The above structure makes it possible to:

• Reset only the FPGA in the system and

• Make sure that the FPGA is not un-configured every time the host application

is re-run as it takes time for the FPGA to re-configure (approximately 35

seconds).

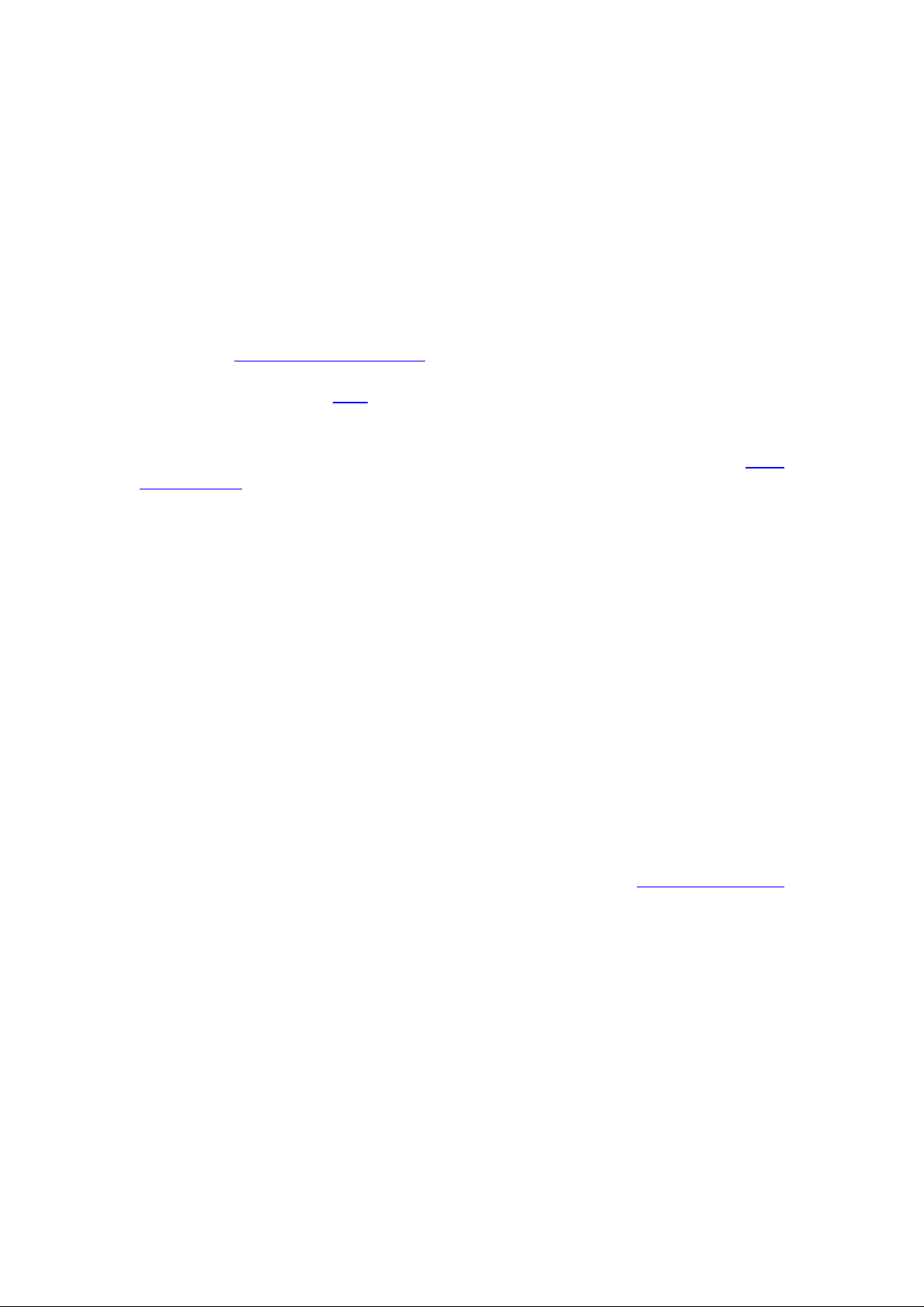

2.11 Analogue output section

Two options are hardwired into the design. The options are shown below with a

figure of each.

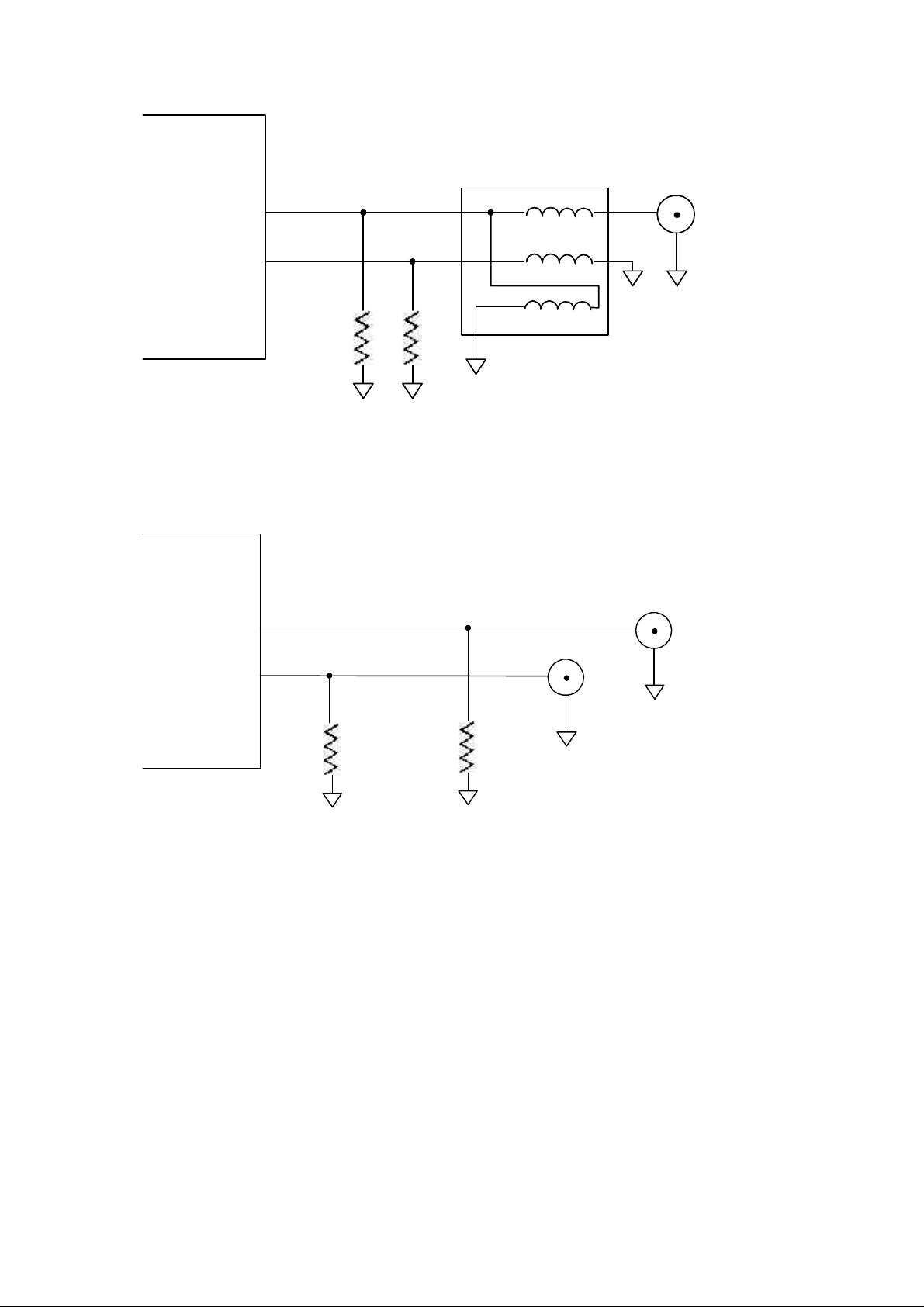

Option 1

Single ended AC coupled output with Macom TP-101 transformer.

Page 23

TP101

+

Output

Connector

-

R1 R1

Figure 7. Option 1 for the SMT381 analog output stage.

Option 2

Differential DC coupled output with + and – channels going to separate connectors

+

Output

Connector

-

R2

Figure 8. Option 2 for the SMT381 analog output stage.

R2

Output

Connector

Page 24

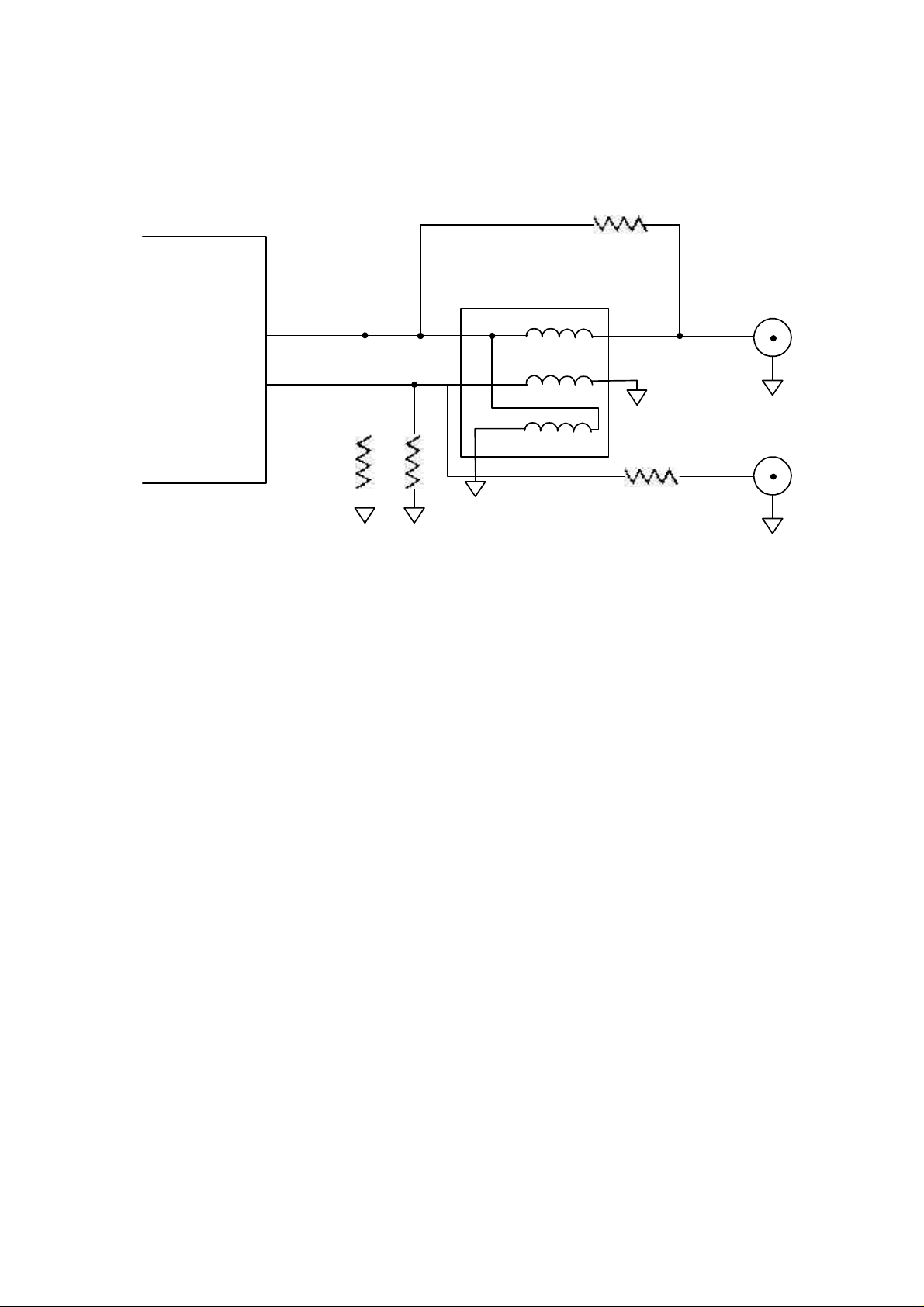

Combined circuit

The two combined:

+

-

0 ohm

TP101

R3 R3

0 ohm

Figure 9. Combined analog output circuit.

Depending on whether an AC or DC coupled version is ordered the board will be

assembled accordingly to either give the AC or DC coupled circuit shown above.

For more information consult the Fujitsu (MB86064) DAC datasheet [6].

2.12 DAC Settings

All DAC settings are controlled and implemented by the 4 wire serial control

interface. The serial interface uses pins SERIAL_IN, SERIAL_OUT, SERIAL_CLK

and SERIAL_EN. Programmed settings are stored in a number of registers which are

individually accessible using either a 7-bit (WMM Registers) or 10-bit (DAC Core

Registers) address/control word. Data may be written to or read from each of these

registers.

For more information consult the Fujitsu (MB86064) DAC datasheet [6].

3 Description of interfaces

3.1 DAC Control Interface

A four wire uni-directional control interface is implemented between the FPGA and

the DAC. This interface is used for clocking configuration information into the DAC.

Page 25

Note 1: The serial interface on the DAC side uses 1.8V signalling levels. These

control lines are however connected unto a 3.3V bank on the FPGA with additional

pull-up resistors on the SMT381 to 1.8V. For this reason the FPGA firmware may

never drive ‘1’ out on these pins as it will drive the DAC at 3.3V and thus damage it.

The firmware may only drive ‘0’ for ‘0’ and ‘Z’ for ‘1’. Because of the pull-up resistor

the ‘Z’ will be pulled up to 1.8V. This approach works well and any used wishing to

develop his own firmware is advised to take a look at the SMT381 example firmware

before developing his own.

3.2 DAC Data Interface

The output of each channel from the SMT338-VP to the DAC is a 14 bit LVDS data

bus clocked on the synchronized DAC clock.

Note 1: The data bus between the FPGA and the DAC is wired in a strange way to

assist routing. If a user wants to develop his own VHDL design and not use the

example design he is advised to take a look at the wiring of the example design to

assist him with his own design.

Note 2: On Rev 01 of the SMT381 the positive and negative data pairs of the LVDS

bus between the FPGA and the DAC is swapped for one of the two channels. This

results in a data flip. This issue is corrected in firmware by inverting the data before

writing it out over the interface. Once again any user wanting to do his own design is

advised to take a look at the example firmware design.

3.3 Memory Interface

Two groups of two 16 bit Micron DDR SDRAMs form the volatile sample storage

space of the module. Each DDR SDRAM is 256 MBits in size. This provides the

module with a total of 64Mbytes (or 32 Mega samples) of storage space per channel.

Each channel contains a 32 bit DDR SDRAM controller. This interface is capable of

data transfer at 1 GBytes / s. It is thus fast enough to write the outgoing DAC data

stream.

3.4 MSP430 Interface

After configuration the microprocessor communicates with the FPGA using the IO

pins of the FPGA Slave Select Configuration interface. The MSP is the master of the

interface and will continually write the serial number and the measured on-board

voltages to the FPGA. A system host can then read this data from the FPGA over the

ComPort interface.

3.5 Serial Number

A Maxim 1-Wire silicon serial number device is located on the SMT381 and the

SMT338-VP. This is used to assign a unique serial number to each module.

3.6 PLL Interface

A three wire uni-directional control interface is implemented between the FPGA and

the PLL on the daughter card. This PLL sets and controls the voltage for the VCO

that generates the main clock.

Page 26

3.7 Clock Synthesizer Interface

A three wire uni-directional control interface is implemented between the FPGA and

the Micrel clock synthesizer on the daughter card. The clock synthesizer can

generate a variable 50 – 950 MHz clock. The jitter on this clock is higher than on the

main PLL+VCO clock, but it is convenient for testing.

3.8 TIM Interface

The SMT381-VP implements ComPorts 0 and 3. There are no DIP switches on the

module and all configuration data is received and transmitted over these two ports.

The ComPorts are not used for DAC data transfer. ComPort 3 is implemented as a

bi-directional transceiver interface for FPGA configuration and control operations.

ComPort 0 is available but not used in the default firmware provided with the board.

The Global Bus Interface is not implemented on the SMT381. Refer to [3] for a more

detailed description of the TIM interface.

3.9 External Trigger

The external trigger input is received by a LVPECL input buffer on the SMT381. The

buffered signal is passed down as a differential LVPECL signal to the FPGA on the

SMT338-VP. For compatibility reasons with other daughter card modules there are

no ECL termination resistors mounted on the SMT338-VP. For this reason the pulse

width of the input trigger must be at least 1uS before the FPGA will register it.

As this might be a problem for some applications this issue has been resolved on the

newer SMT338-VP modules and appropriate termination resistors are provided to

improve the response time of the FPGA to an external trigger.

For most systems it is likely that there will be a system host (DSP Module). For this

reason it is also possible to send a software trigger to the SMT381-VP over ComPort

3. There will however be a latency from the time that the command is sent to the time

that data is read from the memory.

3.10 Daughter card Interface

The daughter-card interface is made up of two connectors. The one is a 0.5mm pitch

differential Samtec connector. This connector is for transferring digital LVDS data to

the DAC from the main module. The second one is a 1mm pitch Samtec header type

connector. This connector is for providing power to the daughter-card.

The figure underneath illustrates this configuration. The bottom view of the daughter

card is shown on the right. This view must the mirrored to understand how it

connects to the main module.

Page 27

Top Primary TIM Connector

Bank A Bank B Bank C

Power Connector

DDR266 SDRAM

Samsung

DDR266 SDRAM

Samsung

Power

Data Connectors

Power Connector

RSL

SHB

B

Xilinx

Virtex-II Pro

XC2VP30-6

FF896 Package

B

FPGA

Config

Global Bus Connector

SMT338-VP SMT381

RSL

SHB

A

A

Figure 10. Daughter card connector interface

The female differential connector is located on the main module. The Samtec Part

Number for this connector is QTH-060-01-F-D-DP-A.

The female power connector is located on the main module. The Samtec Part

Number for this connector is BKS-107-01-F-V-A

The male differential connector is located on the daughter card. The Samtec Part

Number for this connector is QSH-060-01-F-D-DP-A

The male power connector is located on the daughter card. The Samtec Part Number

for this connector is BKT-107-03-F-V-A

The mated height between the main module and the daughter card is 5 mm.

Each pin on the power connector can carry 1.5 A. Digital 5V (D+5V0), digital 3V3

(D+3V3), digital 12V0 (D+12V0), digital -12V0 (D-12V0) and digital ground (DGND) is

provided over this connector. D+3V3 and D+5V0 are assigned four pins each while

D+12V0 and D-12V0 are assigned two each. The daughter card can thus draw a

total of 6A for the D+3V3 and D+5V0 supplies while D+12V0 and D-12V0 can only

supply 3A. The integral ground plane on the differential connector provides additional

grounding. The following table shows the pin assignment on the power connector:

Page 28

Pin Number Pin Name Description of Signal

1 D+3V3 Digital 3.3 Volts

2 DGND Digital Ground

3 D+3V3 Digital 3.3 Volts

4 DGND Digital Ground

5 D+3V3 Digital 3.3 Volts

6 DGND Digital Ground

7 D+3V3 Digital 3.3 Volts

8 DGND Digital Ground

9 D+5V0 Digital 5.0 Volts

10 DGND Digital Ground

11 D+5V0 Digital 5.0 Volts

12 DGND Digital Ground

13 D+5V0 Digital 5.0 Volts

14 DGND Digital Ground

15 D+5V0 Digital 5.0 Volts

16 DGND Digital Ground

17 D+12V0 Digital 12.0 Volts

18 DGND Digital Ground

19 D+12V0 Digital 12.0 Volts

20 DGND Digital Ground

21 D-12V0 Digital -12.0 Volts

22 DGND Digital Ground

23 D-12V0 Digital -12.0 Volts

24 DGND Digital Ground

25 DGND Digital Ground

26 NC

27 NC

28 NC

29 NC

30 NC

Page 29

31 TDI Loop with TDO

32 TDO Loop with TDI

33 DGND Digital Ground

Table 2. Daughter Card Interface Power Connector and Pinout.

The following few pages describes the signals on the data connector between the

main module and the daughter card. Bank A on the connector is used for the DAC

Channel A data bus. Bank C is used for the DAC channel B data bus. Bank B is used

for system clock and trigger signals, DAC control signals and general system control

signals. The general system control signals include: clock control interface (for the

clock modules present on the SMT381), daughter card sense signal, daughter card

ID signals, low drop out regulator control signals and daughter card DAC reset signal.

All reserved signals are connected to the FPGA on the main module for future

expansion.

Page 30

Bank A Bank B Bank C

1 3 5 7 41 43 81 83

2 4 6 8

Bank A

Pin No Pin Name Signal Description Pin No Pin Name Signal Description

Dir Main Module to Daughter Card Dir Main Module to Daughter Card

1 DOAI0p Data In 0 Channel A, pos. 2 DOBI0p Data In 1 Channel A, pos.

3 DOAI0n Data In 0 Channel A, neg. 4 DOBI0n Data In 1 Channel A, neg.

Dir Main Module to Daughter Card Dir Main Module to Daughter Card

5 DOAI1p Data In 2 Channel A, pos. 6 DOBI1p Data In 3 Channel A, pos.

7 DOAI1n Data In 2 Channel A, neg. 8 DOBI1n Data In 3 Channel A, neg.

Dir Main Module to Daughter Card Dir Main Module to Daughter Card

9 DOAI2p Data In 4 Channel A, pos. 10 DOBI2p Data In 5 Channel A, pos.

11 DOAI2n Data In 4 Channel A, neg. 12 DOBI2n Data In 5 Channel A, neg.

Dir Main Module to Daughter Card Dir Main Module to Daughter Card

13 DOAI3p Data In 6 Channel A, pos. 14 DOBI3p Data In 7 Channel A, pos.

15 DOAI3n Data In 6 Channel A, neg. 16 DOBI3n Data In 7 Channel A, neg.

Dir Main Module to Daughter Card Dir Main Module to Daughter Card

17 DOAI4p Data In 8 Channel A, pos. 18 DOBI4p Data In 9 Channel A, pos.

19 DOAI4n Data In 8 Channel A, neg. 20 DOBI4n Data In 9 Channel A, neg.

Dir Main Module to Daughter Card Dir Main Module to Daughter Card

21 DOAI5p Data In 10 Channel A, pos. 22 DOBI5p Data In 11 Channel A, pos.

23 DOAI5n Data In 10 Channel A, neg. 24 DOBI5n Data In 11 Channel A, neg.

Dir Main Module to Daughter Card Dir Main Module to Daughter Card

25 DOAI6p Data In 12 Channel A, pos. 26 DOBI6p Data In 13 Channel A, pos.

27 DOAI6n Data In 12 Channel A, neg. 28 DOBI6n Data In 13 Channel A, neg.

Dir Reserved Dir Reserved

29 Reserved Reserved 30 Reserved Reserved

31 Reserved Reserved 32 Reserved Reserved

Dir Daughter Card to Main Module Dir Main Module to Daughter Card

33 ClkOIp Output Ready, I channel,

pos

35 ClkOIn Output Ready, I channel,

neg

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

37 SysClockp System clock, pos. 38 ExtTriggerIp External Trigger A, pos.

39 SysClockn System clock, neg. 40 ExtTriggerIn External Trigger A, neg.

34 DOIRIp Loop back clock to DAC, pos.

36 DOIRIn Loop back clock to DAC, neg.

Figure 11. Daughter Card Interface: Data Signals Connector and Pinout (Bank A).

Page 31

Bank A Bank B Bank C

1 3 5 7 41 43 81 83

2 4 6 8

Bank B

Pin No Pin Name Signal Description Pin No Pin Name Signal Description

Type MSP system signals Type MSP system signals

Dir Bi-Directional Dir Bi-Directional

41 SMBClk TmpCntrl0 42 SMBData TmpCntrl1

43 SMBnAlert TmpCntrl2 44 SerialNo Serial Number

45 Reserved Reserved 46 Reserved Reserved

47 Reserved Reserved 48 Reserved Reserved

49 D3V3Enable D3V3Enable 50 D1V8Enable D1V8Enable

Type FPGA system signals Type FPGA system signals

Dir Bi-Directional Dir Bi-Directional

51 DACCntrl0 DAC Control 0 52 DACCntrl0 DAC Control 1

53 DACCntrl0 DAC Control 2 54 DACCntrl0 DAC Control 3

55 DACCntrl0 DAC Control 4 56 AdjClkSClk AdjClockCntrl0

57 AdjClkSData AdjClockCntrl1 58 AdjClkSLoad AdjClockCntrl2

59 AdjClkTest AdjClockCntrl3 60 PllClk PllCntrl0

61 PllData PllCntrl1 62 PllLe PllCntrl2

63 PllFoLd PllCntrl3 64 AdcAClkSel AdcAClkSel

65 AdcBClkSel AdcBClkSel 66 IntClkDivEn IntClkDivEnable

67 IntClkDivnReset IntClkDivnReset 68 IntExtClkSel IntExtClkSel

69 IntExtClkSelnReset IntExtClkSelnReset

Type FPGA JTAG Type FPGA JTAG

Dir Bi-Directional Dir Bi-Directional

71 FpgaTck FpgaTck 72 FpgaTms FpgaTms

73 FpgaTdi FpgaTdi 74 FpgaTdo FpgaTdo

Type MSP JTAG Type MSP JTAG

Dir Bi-Directional Dir Bi-Directional

75 MspVref MspVref 76 MspTck MspTck

77 MspTms MspTms 78 MspTdi MspTdi

79 MspTdo MspTdo 80 MspnTrst MspnTrst

70 FpgaVref FpgaVref

Figure 12. Daughter Card Interface: Data Signals Connector and Pinout (Bank B).

Page 32

Bank A Bank B Bank C

1 3 5 7 41 43 81 83

2 4 6 8

Bank C

Pin No Pin Name Signal Description Pin No Pin Name Signal Description

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

81 DOAQ0p Data In 0 Channel B, pos. 82 DOBQ0p Data In 1 Channel B, pos.

83 DOAQ0n Data In 0 Channel B, neg. 84 DOBQ0n Data In 1 Channel B, neg.

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

85 DOAQ1p Data In 2 Channel B, pos. 86 DOBQ1p Data In 3 Channel B, pos.

87 DOAQ1n Data In 2 Channel B, neg. 88 DOBQ1n Data In 3 Channel B, neg.

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

89 DOAQ2p Data In 4 Channel B, pos. 90 DOBQ2p Data In 5 Channel B, pos.

91 DOAQ2n Data In 4 Channel B, neg. 92 DOBQ2n Data In 5 Channel B, neg.

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

93 DOAQ3p Data In 6 Channel B, pos. 94 DOBQ3p Data In 7 Channel B, pos.

95 DOAQ3n Data In 6 Channel B, neg. 96 DOBQ3n Data In 7 Channel B, neg.

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

97 DOAQ4p Data In 8 Channel B, pos. 98 DOBQ4p Data In 9 Channel B, pos.

99 DOAQ4n Data In 8 Channel B, neg. 100 DOBQ4n Data In 9 Channel B, neg.

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

101 DOAQ5p Data In 10 Channel B, pos. 102 DOBQ5p Data In 11 Channel B, pos.

103 DOAQ5n Data In 10 Channel B, neg. 104 DOBQ5n Data In 11 Channel B, neg.

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

105 DOAQ6p Data In 12 Channel B, pos. 106 DOBQ6p Data In 13 Channel B, pos.

107 DOAQ6n Data In 12 Channel B, neg. 108 DOBQ6n Data In 13 Channel B, neg.

Dir Reserved Dir Reserved

109 Reserved Reserved 110 Reserved Reserved

111 Reserved Reserved 112 Reserved Reserved

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

113 ClkOQp Output Ready, Q channel,

pos

115 ClkOQn Output Ready, Q channel,

neg

Dir Daughter Card to Main Module Dir Daughter Card to Main Module

117 RslClockp Rsl Clock, pos. 118 ExtTriggerQp External Trigger A, pos.

119 RslClockn Rsl Clock, neg. 120 ExtTriggerQn External Trigger A, neg.

114 DOIRQp Loop back clock to FPGA, pos.

116 DOIRQn Loop back clock to FPGA, neg.

Figure 13. Daughter Card Interface: Data Signals Connector and Pinout (Bank C).

Page 33

3.11 RSL Interface (RSL not yet available)

3.11.1 RSL Connector and Pinout Definition

The Rocket Serial Link (RSL) is a serial based communications interconnection

standard that is capable of transfer speeds of up to 2.5GBit/s per link. Up to four links

can be combined to form a Rocket Serial Link Communications Channel (RSLCC)

that is capable of data transfer up to 10GBit/s.

Each RSL is made up of a differential Tx and Rx pair. A single RSL can thus transfer

data at 2.5GBit/s in both directions at the same time. Rocket Serial Link

interconnections are based on the RocketIO standard used on Xilinx Virtex-II Pro

FPGAs. Rocket Serial Links uses Low Voltage Differential Signaling (LVDS).

The SMT381-VP uses a subset of the RSL specification. Four RSLs are combined to

form a 10GBit/s RSLCC. One RSLCC per DAC channel is implemented on the

SMT381-VP. The RSLCC is thus capable to transfer a raw data stream to the DAC in

real time.

The connector used for the RSL interface is a 0.8mm pitch differential Samtec

connector. The part number for this connector is: QSE-014-01-F-D-DP-A. The RSL

connector takes the place of the optional 3rd and 4th SHB connector on a TIM module.

The following diagram shows the position of the RSL connectors on the SMT381-VP:

Daughter Card

Power Conn

DDR266 SDRAM

Top Primary TIM Connector

Daughter Card Expansion Connector

DDR266 SDRAM

Power

Samsung

Samsung

RSL

RSL

A

B

SHB

SHB

A

Bottom Primary TIM Connector

B

Figure 14. Rocket Serial Link Interface.

There are two additional RSL footprints underneath the module (by default not

mounted) in the same place as top RSL connectors. By mounting these two

connectors and not the top two it is possible to plug the SMT381-VP straight onto an

RSL enabled carrier without having to interconnect the links with cables.

Page 34

2 4 6 8

1 3 5 7

RSL A

Pin No Pin Name Signal Description Pin No Pin Name Signal Description

Dir Carrier / Other Module to SMT381-VP Dir SMT381-VP to Carrier / Other Module

1 RxLink0p Receive Link 0, positive 2 TxLink0p Transmit Link 0, positive

3 RxLink0n Receive Link 0, negative 4 TxLink0n Transmit Link 0, negative

Dir Carrier / Other Module to SMT381-VP Dir SMT381-VP to Carrier / Other Module

5 RxLink1p Receive Link 1, positive 6 TxLink1p Transmit Link 1, positive

7 RxLink1n Receive Link 1, negative 8 TxLink1n Transmit Link 1, negative

Dir Carrier / Other Module to SMT381-VP Dir SMT381-VP to Carrier / Other Module

9 RxLink2p Receive Link 2, positive 10 TxLink2p Transmit Link 2, positive

11 RxLink2n Receive Link 2, negative 12 TxLink2n Transmit Link 2, negative

Dir Carrier / Other Module to SMT381-VP Dir SMT381-VP to Carrier / Other Module

13 RxLink3p Receive Link 3, positive 14 TxLink3p Transmit Link 3, positive

15 RxLink3n Receive Link 3, negative 16 TxLink3n Transmit Link 3, negative

Dir Reserved Dir Reserved

17 Reserved Reserved 18 Reserved Reserved

19 Reserved Reserved 20 Reserved Reserved

Dir Reserved Dir Reserved

21 Reserved Reserved 22 Reserved Reserved

23 Reserved Reserved 24 Reserved Reserved

Dir Reserved Dir Reserved

25 Reserved Reserved 26 Reserved Reserved

27 Reserved Reserved 28 Reserved Reserved

Figure 15. Rocket Serial Link Interface Connector and Pinout (RSL A).

RSL B

Pin No Pin Name Signal Description Pin No Pin Name Signal Description

Dir Carrier / Other Module to SMT381-VP Dir SMT381-VP to Carrier / Other Module

1 RxLink0p Receive Link 0, positive 2 TxLink0p Transmit Link 0, positive

3 RxLink0n Receive Link 0, negative 4 TxLink0n Transmit Link 0, negative

Dir Carrier / Other Module to SMT381-VP Dir SMT381-VP to Carrier / Other Module

5 RxLink1p Receive Link 1, positive 6 TxLink1p Transmit Link 1, positive

7 RxLink1n Receive Link 1, negative 8 TxLink1n Transmit Link 1, negative

Dir Carrier / Other Module to SMT381-VP Dir SMT381-VP to Carrier / Other Module

9 RxLink2p Receive Link 2, positive 10 TxLink2p Transmit Link 2, positive

11 RxLink2n Receive Link 2, negative 12 TxLink2n Transmit Link 2, negative

Page 35

Dir Carrier / Other Module to SMT381-VP Dir SMT381-VP to Carrier / Other Module

13 RxLink3p Receive Link 3, positive 14 TxLink3p Transmit Link 3, positive

15 RxLink3n Receive Link 3, negative 16 TxLink3n Transmit Link 3, negative

Dir Reserved Dir Reserved

17 Reserved Reserved 18 Reserved Reserved

19 Reserved Reserved 20 Reserved Reserved

Dir Reserved Dir Reserved

21 Reserved Reserved 22 Reserved Reserved

23 Reserved Reserved 24 Reserved Reserved

Dir Reserved Dir Reserved

25 Reserved Reserved 26 Reserved Reserved

27 Reserved Reserved 28 Reserved Reserved

Figure 16. Rocket Serial Link Interface Connector and Pinout (RSL B).

3.11.2 RSL Cable Definition

The matching cable for the RSL connector is a Samtec High Speed Data Link Cable

(Samtec HFEM Series). The cable may be ordered with different length and mating

connector options. The following diagram shows such a typical cable:

Figure 17. Samtec HFEM Series Data Cable.

3.12 SHB Interface

The SMT381-VP implements a subset of the full SHB implementation. Two

configurations are possible

Configuration 1: SHB A is configured to receive 32-bit data words for channel A and

SHB B is configured to receive 32-bit data words for channel B. Both SHB interfaces

Page 36

are configured as inputs only. Control and configuration data is received over

ComPort 3. The SHB interface is clocked by the SMT338-VP system clock of 53MHz.

Configuration 2: Either SHB A or SHB B is configured to receive two 16-bit halfwords. The first 16-bits is used for data for channel A and the second 16-bits is used

for data for channel B. (This option is not implemented in firmware.)

The first configuration is ideal for higher speed data transfer. The second

configuration can be used if just one SHB is available on a module that the SMT381VP interfaces to. The two possible configurations are illustrated in the following

figure:

Channel A

Data Stream SHB for

Channel B

Data Stream

SHB A

Interface

SHB B

Interface

Channel A

SHB for

Channel B

32 Bit Channel A

or

16 Bit Channel A and

16 Bit Channel B

32 Bit Channel B

or

16 Bit Channel A and

16 Bit Channel B

Figure 18. Possible SHB Configurations.

The connector used for the SHB interface is a 0.5mm Samtec QSH Type connector.

The full part number for this connector is: QSH-030-01-L-D-A-K

The pinout information for the two possible configurations for both SHB connectors is

given in the following table:

Page 37

2 4 6

1 3 5

SHB A and SHB B, Configuration 1 (X = A for SHB A, X = B for SHB B)

Pin No Pin Name Direction Signal Description Pin No Pin Name Direction Signal Description

1 ChXClk To 381 Ch X, Word Clock 31 ChXD29 To 381 Ch X, Word Data 29

2 ChXD0 To 381 Ch X, Word Data 0 32 ChXD30 To 381 Ch X, Word Data 30

3 ChXD1 To 381 Ch X, Word Data 1 33 ChXD31 To 381 Ch X, Word Data 31

4 ChXD2 To 381 Ch X, Word Data 2 34 ChXWen To 381 Ch X, Write Enable

5 ChXD3 To 381 Ch X, Word Data 3 35 ChXReq Reserved Not Implemented

6 ChXD4 To 381 Ch X, Word Data 4 36 ChXAck Reserved Not Implemented

7 ChXD5 To 381 Ch X, Word Data 5 37 Reserved Reserved Reserved

8 ChXD6 To 381 Ch X, Word Data 6 38 Reserved Reserved Reserved

9 ChXD7 To 381 Ch X, Word Data 7 39 Reserved Reserved Reserved

10 ChXD8 To 381 Ch X, Word Data 8 40 Reserved Reserved Reserved

11 ChXD9 To 381 Ch X, Word Data 9 41 Reserved Reserved Reserved

12 ChXD10 To 381 Ch X, Word Data 10 42 Reserved Reserved Reserved

13 ChXD11 To 381 Ch X, Word Data 11 43 Reserved Reserved Reserved

14 ChXD12 To 381 Ch X, Word Data 12 44 Reserved Reserved Reserved

15 ChXD13 To 381 Ch X, Word Data 13 45 Reserved Reserved Reserved

16 ChXD14 To 381 Ch X, Word Data 14 46 Reserved Reserved Reserved

17 ChXD15 To 381 Ch X, Word Data 15 47 Reserved Reserved Reserved

18 ChXD16 To 381 Ch X, Word Data 16 48 Reserved Reserved Reserved

19 ChXD17 To 381 Ch X, Word Data 17 49 Reserved Reserved Reserved

20 ChXD18 To 381 Ch X, Word Data 18 50 Reserved Reserved Reserved

21 ChXD19 To 381 Ch X, Word Data 19 51 Reserved Reserved Reserved

22 ChXD20 To 381 Ch X, Word Data 20 52 Reserved Reserved Reserved

23 ChXD21 To 381 Ch X, Word Data 21 53 Reserved Reserved Reserved

24 ChXD22 To 381 Ch X, Word Data 22 54 Reserved Reserved Reserved

25 ChXD23 To 381 Ch X, Word Data 23 55 Reserved Reserved Reserved

26 ChXD24 To 381 Ch X, Word Data 24 56 Reserved Reserved Reserved

27 ChXD25 To 381 Ch X, Word Data 25 57 Reserved Reserved Reserved

28 ChXD26 To 381 Ch X, Word Data 26 58 Reserved Reserved Reserved

29 ChXD27 To 381 Ch X, Word Data 27 59 Reserved Reserved Reserved

30 ChXD28 To 381 Ch X, Word Data 28 60 Reserved Reserved Reserved

Figure 19. SHB Connector Configuration 1 Pinout.

Page 38

2 4 6

1 3 5

SHB A and SHB B, Configuration 2

Pin No Pin Name Direction Signal Description Pin No Pin Name Direction Signal Description

1 ChAClk To 381 Ch A, ½Word Clock 31 Reserved Reserved Reserved

2 ChAD0 To 381 Ch A, ½Word Data 0 32 Reserved Reserved Reserved

3 ChAD1 To 381 Ch A, ½Word Data 1 33 Reserved Reserved Reserved

4 ChAD2 To 381 Ch A, ½Word Data 2 34 Reserved Reserved Reserved

5 ChAD3 To 381 Ch A, ½Word Data 3 35 Reserved Reserved Reserved

6 ChAD4 To 381 Ch A, ½Word Data 4 36 Reserved Reserved Reserved

7 ChAD5 To 381 Ch A, ½Word Data 5 37 ChBClk To 381 Ch B, ½Word Clock

8 ChAD6 To 381 Ch A, ½Word Data 6 38 ChBD0 To 381 Ch B, ½Word Data 0

9 ChAD7 To 381 Ch A, ½Word Data 7 39 ChBD1 To 381 Ch B, ½Word Data 1

10 ChAD8 To 381 Ch A, ½Word Data 8 40 ChBD2 To 381 Ch B, ½Word Data 2

11 ChAD9 To 381 Ch A, ½Word Data 9 41 ChBD3 To 381 Ch B, ½Word Data 3

12 ChAD10 To 381 Ch A, ½Word Data 10 42 ChBD4 To 381 Ch B, ½Word Data 4

13 ChAD11 To 381 Ch A, ½Word Data 11 43 ChBD5 To 381 Ch B, ½Word Data 5

14 ChAD12 To 381 Ch A, ½Word Data 12 44 ChBD6 To 381 Ch B, ½Word Data 6

15 ChAD13 To 381 Ch A, ½Word Data 13 45 ChBD7 To 381 Ch B, ½Word Data 7

16 ChAD14 To 381 Ch A, ½Word Data 14 46 ChBD8 To 381 Ch B, ½Word Data 8

17 ChAD15 To 381 Ch A, ½Word Data 15 47 ChBD9 To 381 Ch B, ½Word Data 9

18 ChAUser0 Reserved Not Implemented 48 ChBD10 To 381 Ch B, ½Word Data 10

19 ChAUser1 Reserved Not Implemented 49 ChBD11 To 381 Ch B, ½Word Data 11

20 ChAUser2 Reserved Not Implemented 50 ChBD12 To 381 Ch B, ½Word Data 12

21 ChAUser3 Reserved Not Implemented 51 ChBD13 To 381 Ch B, ½Word Data 13

22 ChAWen To 381 Ch A, Write Enable 52 ChBD14 To 381 Ch B, ½Word Data 14

23 ChAReq Reserved Not Implemented 53 ChBD15 To 381 Ch B, ½Word Data 15

24 ChAAck Reserved Not Implemented 54 ChBUser0 Reserved Not Implemented

25 Reserved Reserved Reserved 55 ChBUser1 Reserved Not Implemented

26 Reserved Reserved Reserved 56 ChBUser2 Reserved Not Implemented

27 Reserved Reserved Reserved 57 ChBUser3 Reserved Not Implemented

28 Reserved Reserved Reserved 58 ChBWen To 381 Ch B, Write Enable

29 Reserved Reserved Reserved 59 ChBReq Reserved Not Implemented

30 Reserved Reserved Reserved 60 ChBAck Reserved Not Implemented

Figure 20. SHB Connector Configuration 2 Pinout.

Page 39

4 Firmware Description

4.1 Main States

At reset, the FPGA is in the INIT state where internal memory and registers are reset.

It then waits for data from the SHB interface to write to the DDR memory (state

“STORE”). Once the memory is full, upon a trigger, data is read back and written to

the DAC (state “READ BACK”). When the whole memory has been read back the

FPGA can carry on cycling through the memory, or go back into the “WAIT START

CMD” state and wait for a new data from the SHB interface. The following diagram

describes the sequence of events during an acquisition:

Figure 21. SMT381-VP Firmware State Diagram.

Page 40

4.2 Configuring the FPGA

The default for the FPGA configuration mode is using ComPort3. Configuring the

FPGA from ComPort 3 makes it possible not to have to use a JTAG cable. Having a

direct ComPort link enhances debugging and testing and therefore reduces the

products time to market.

The configuration data can be downloaded into a DSP TIM module external memory

(SMT6001) along with the DSP application, or configuration data can be sent from a

PC application using a Sundance carrier with a DSP host (SMT6500).

The bitstream is presented on ComPort 3 and the microcontroller embedded on the

SMT381-VP provides the mechanism to deliver it to the Virtex-II Pro device

(configuration takes about 35 seconds and the process is similar to the configuration

of the SMT398. For more into refer to the SMT398 User Manual).

After configuration the ComPort is available to the FPGA for data transfers.

4.3 Setting up the FPGA

• Configure the FPGA over ComPort 3 like described above

• Initialize the SMT381-VP registers with the required values. See Control

Register Settings section underneath for the description of these registers

• Store data in the memory on the SMT381-VP by writing it over the SHB bus.

• The SMT381-VP is waiting for a trigger to start transferring data to the DAC.

This command can come either from the external trigger connectors, or from

ComPort 3 (see transfer trigger register section for more information).

• Once it receives a trigger command, the SMT381-VP will read data from the

memory and pass it on to the DAC.

Page 41

5 Control Register Settings

The Control Registers in the SMT381 example firmware control the complete

functionality of the SMT381-VP. These Control Registers are setup via ComPort 3.

The settings of the DAC, the trigger settings, the clock settings, the configuration of

the SHB and RSL interfaces and the internal FPGA data path settings can be

configured via the Control Registers.

5.1 Control Packet Structure

The data passed on to the SMT381 over the ComPorts must conform to a certain

packet structure (for compatibility with example firmware). Only valid packets will be

accepted and only after acceptance of a packet will the appropriate settings be

implemented. Each packet will start with a certain command indicating a write (0x1)