Page 1

SMT300Q

SMT300Q User Guide V1.6

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 2

Page 2 of 61 SMT300Q SMT300Q User Guide V1.65

Date Comments

Engineer Version

30-09-02 Original Document SP 1.1

23/04/04 PLL register SP 1.2

21/05/04 Power connector part number correction TJW 1.3

16/11/04 Added: TIM sites location SM 1.4

26/11/05 Corrected: location Pin 1 of J21 SM 1.5

7/12/05 Removed SDB references AJP 1.6

Page 3

Page 3 of 61 SMT300Q SMT300Q User Guide V1.65

Table of Contents

1 Introduction ..................................................................................................................................... 8

2 Functional Description .................................................................................................................... 9

2.1 Block Diagram......................................................................................................................10

2.2 ComPort Switching Matrix.................................................................................................... 11

2.3 TIM Sites location.................................................................................................................12

3 Setting Up the SMT300Q.............................................................................................................. 13

4 Host Memory Map......................................................................................................................... 14

4.1 CompactPCI Bridge Chip Internal Register (BAR0)............................................................. 14

4.2 I/O Space Register Assignments (BAR1) ............................................................................ 14

4.3 Memory Space Assignments(BAR2).................................................................................... 15

5 DSP Resource Memory Map........................................................................................................ 16

6 Shared Memory Resource............................................................................................................ 17

7 ComPorts...................................................................................................................................... 18

7.1 ComPort Switching (Quick Switches)................................................................................... 18

7.2 Buffered ComPort................................................................................................................. 19

8 ComPort to CompactPCI Interface ............................................................................................... 23

8.1 ComPort Registers (Offset 0x10, BAR1).............................................................................. 23

8.2 Control Register (Offset 0x14, BAR1).................................................................................. 23

8.3 Status Register (Offset 0x14, BAR1 , Read-Only)............................................................... 24

8.4 Interrupt Control Register (Offset 0x18, BAR1) ................................................................... 25

9 PLL................................................................................................................................................ 26

9.1 PLLREG1 (BAR1 Offset 6016).............................................................................................. 26

9.2 PLLREG2 (BAR1 Offset 6416).............................................................................................. 26

9.3 Frequency Select (Bank 2, 3 and 4)..................................................................................... 26

9.4 Phase Shift Select (Bank 2) ................................................................................................. 27

9.5 Phase Shift Select (Bank 3 and 4)....................................................................................... 27

10 JTAG Controller ............................................................................................................................ 28

11 Using the SMT300Q External/Internal JTAG with TI Tools.......................................................... 30

12 Firmware Upgrades ...................................................................................................................... 31

13 Global/Local Bus Transfers, DSP <-> CompactPCI.................................................................... 33

13.1 Mailbox Accesses................................................................................................................. 33

13.1.1 Doorbell Interrupts....................................................................................................... 34

13.2 DSP Interrupt Control...........................................................................................................34

13.3 DSP To Local Aperture 0 control and Accessing................................................................. 35

13.3.1 Global bus access protocol ......................................................................................... 36

14 Interrupts....................................................................................................................................... 40

14.1 SMT300Q-To-CompactPCI Interrupts.................................................................................. 40

14.2 CompactPCI-To-SMT300Q Interrupts.................................................................................. 41

14.3 Interrupt Registers................................................................................................................ 41

14.3.1 CompactPCI Interrupt Configuration Register(Offset 0x4C, BAR0)............................ 41

14.3.2 CompactPCI Interrupt Status Register(Offset 0x48, BAR0)........................................ 43

14.3.3 Local Bus Interrupt Mask Register(Offset 0x77, BAR0).............................................. 44

Page 4

Page 4 of 61 SMT300Q SMT300Q User Guide V1.65

14.3.4 Local Bus Interrupt Status Register(Offset 0x76, BAR0) ............................................ 45

14.3.5 CompactPCI Mailbox WRITE/READ Interrupt Control Register(Offset: Write 0xD0,

BAR0 Read 0xD2, BAR0)............................................................................................................. 45

14.3.6 Local Bus Mailbox WRITE/READ Interrupt Control Register(Offset Write 0xD4, BAR0

Read 0xD6, BAR0) ....................................................................................................................... 46

14.3.7 Mailbox Write/Read Interrupt Status Register(Offset: Write 0xD8, BAR0 Read 0xDA,

BAR0) 47

14.3.8 INTREG Register(Offset 0x40, BAR1)........................................................................ 47

14.4 Example ............................................................................................................................... 48

14.4.1 An Interrupt service routine must be set up, in this the following register will need to be

cleared 48

15 Stand-Alone Mode........................................................................................................................ 50

16 Performance Figures .................................................................................................................... 51

16.1 Relative JTAG speeds.......................................................................................................... 52

17 Mechanical Dimensions................................................................................................................ 53

18 Power consumption ...................................................................................................................... 53

19 Cables and Connectors ................................................................................................................ 54

19.1 ComPorts ............................................................................................................................. 54

19.2 Buffered ComPort Cabling ................................................................................................... 54

19.3 JTAG back panel cabling ..................................................................................................... 56

20 Where’s that Jumper?................................................................................................................... 58

21 Expansion Header (J2)................................................................................................................. 59

22 JTAG Interface circuits.................................................................................................................. 60

22.1 Signal Description ................................................................................................................ 60

Page 5

Page 5 of 61 SMT300Q SMT300Q User Guide V1.65

Table of Figures

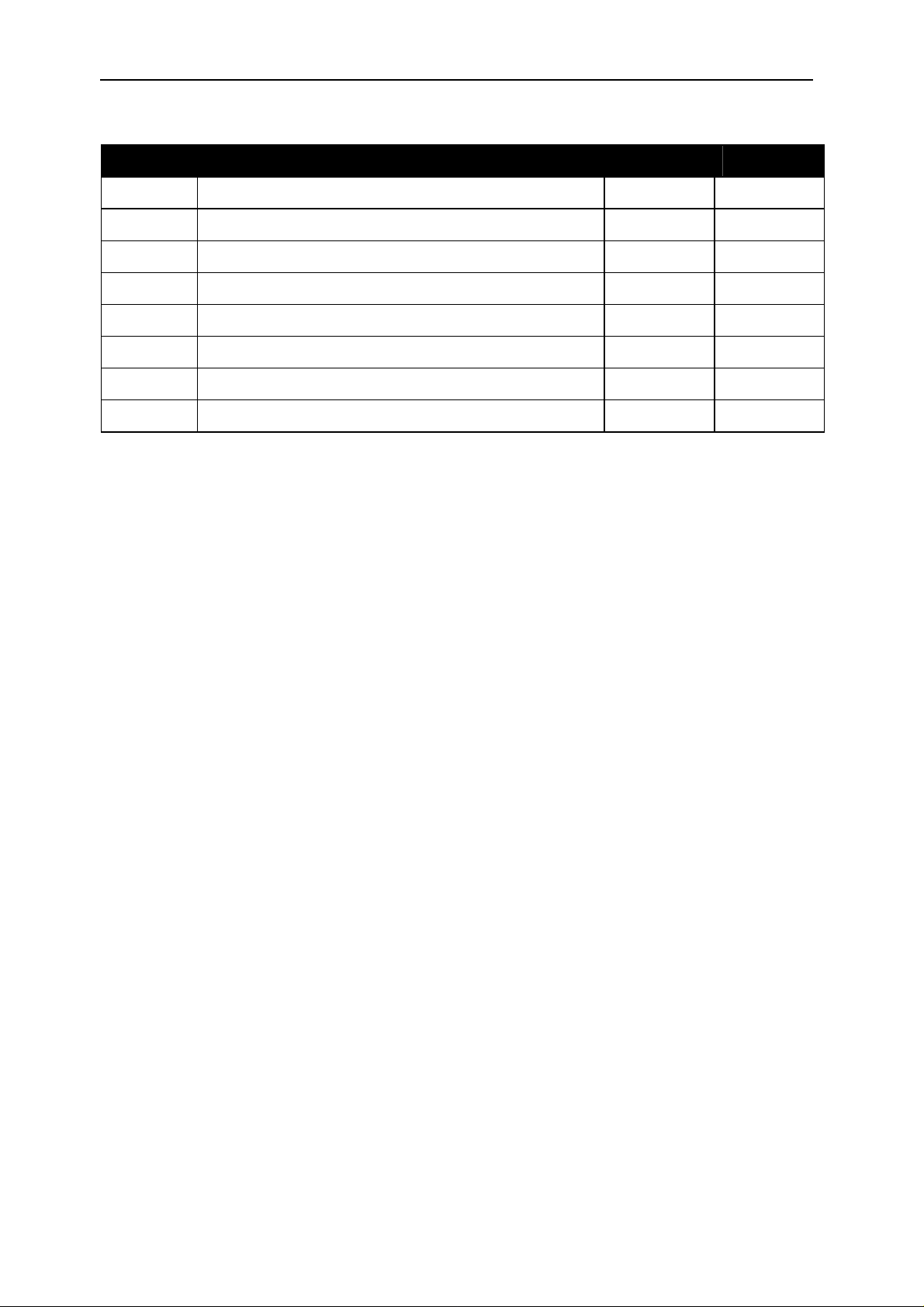

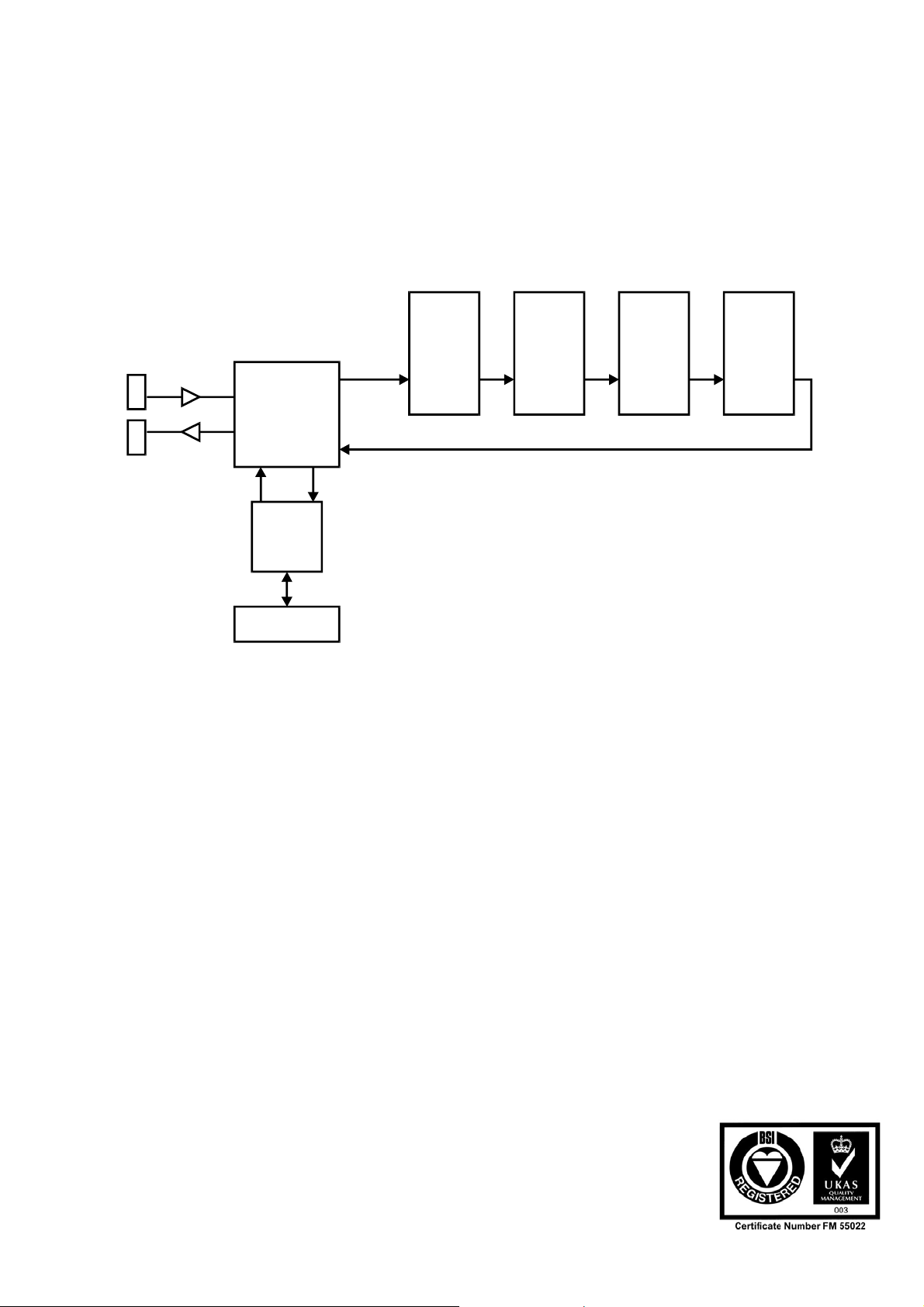

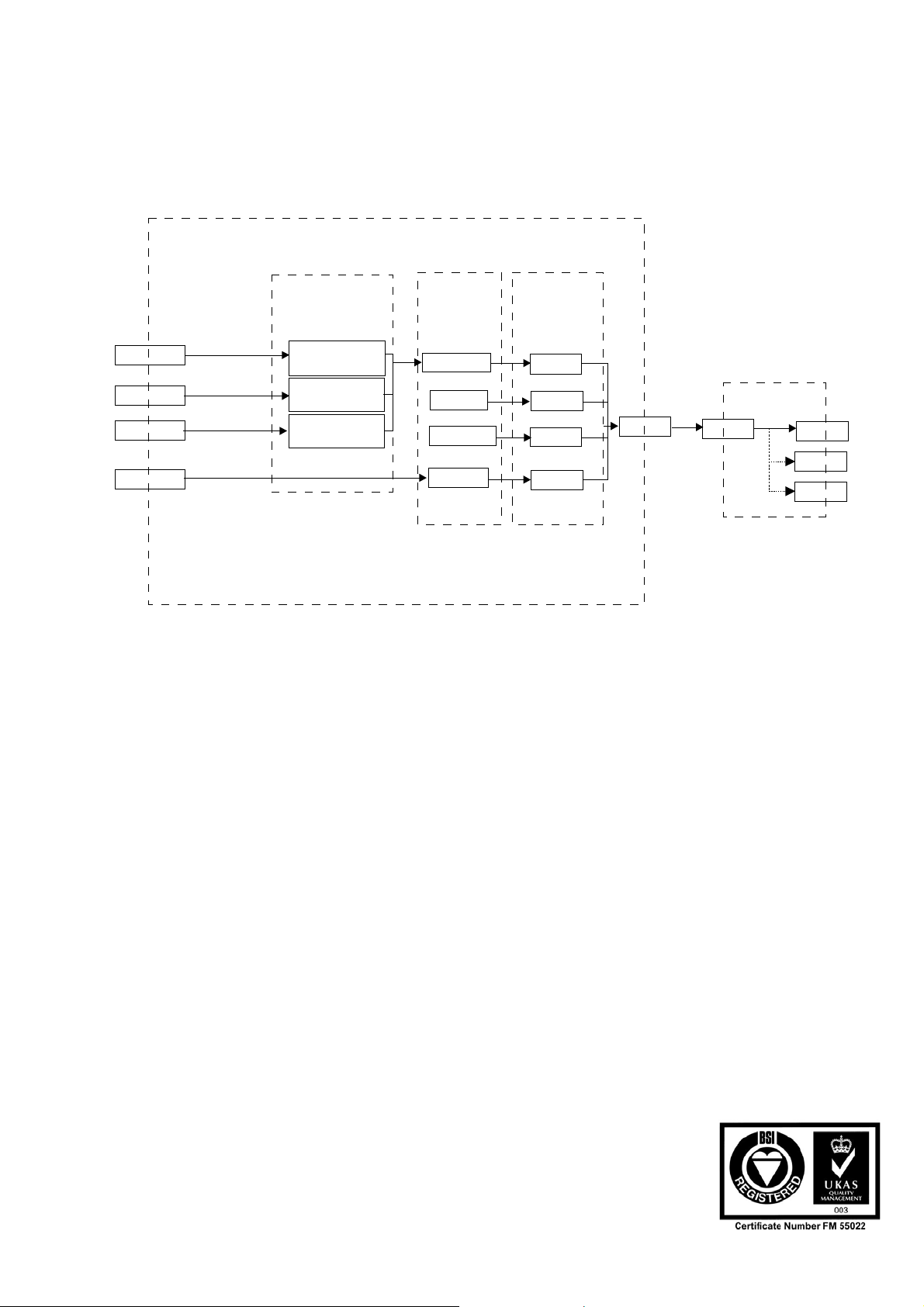

Figure 1 : Block Diagram for SMT300Q (Master site only) ........................................10

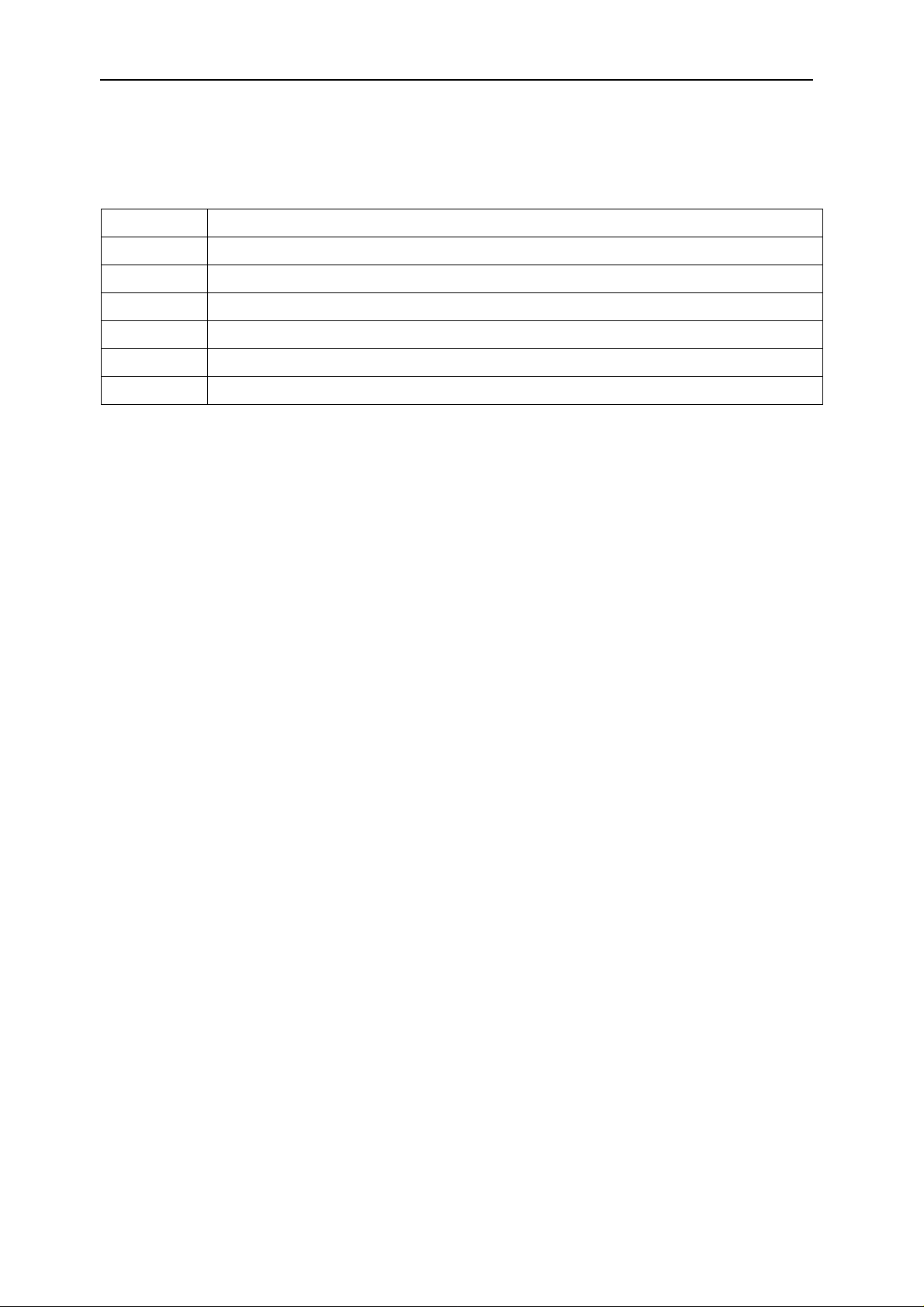

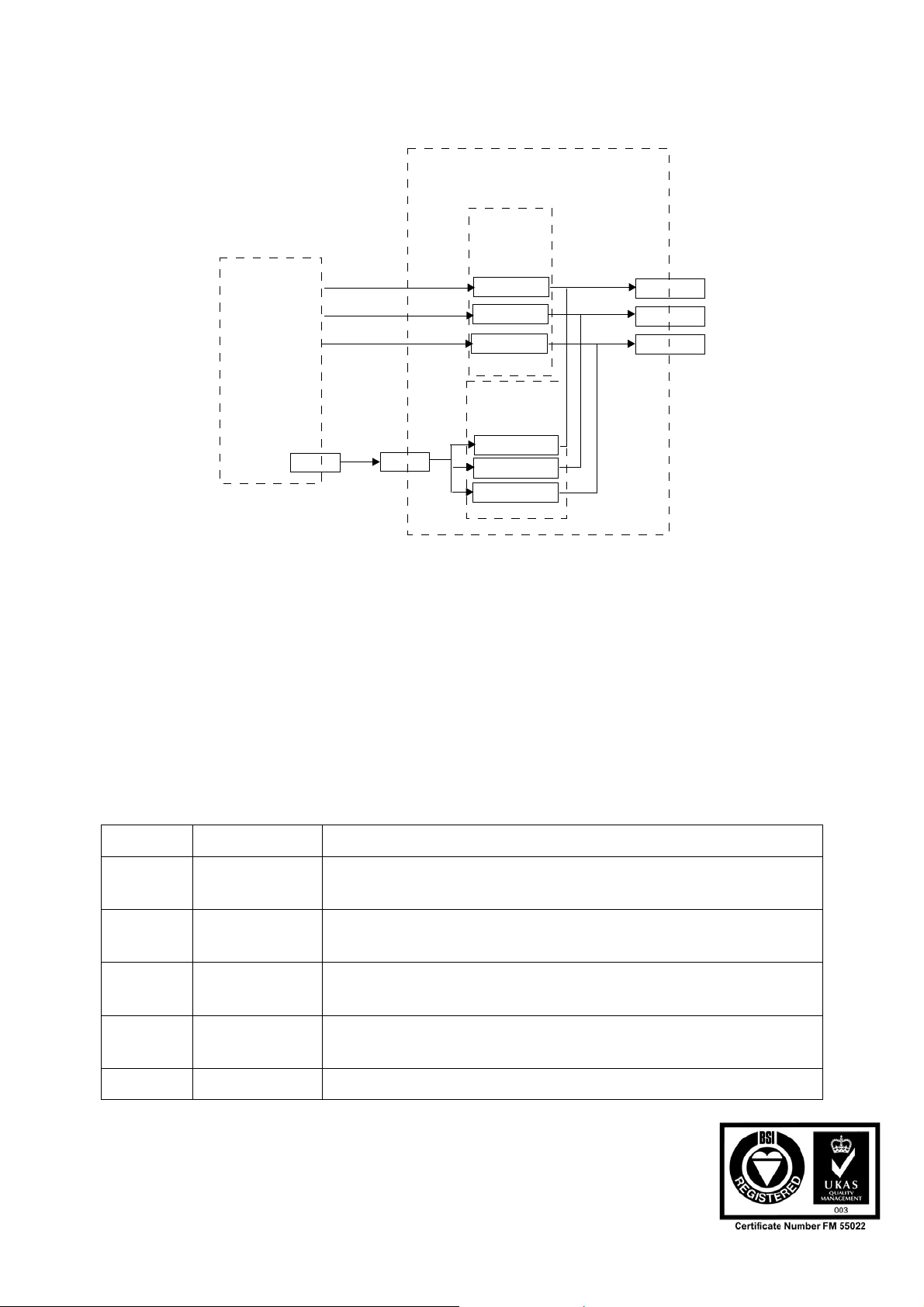

Figure 2: ComPort Switching Matrix ..........................................................................11

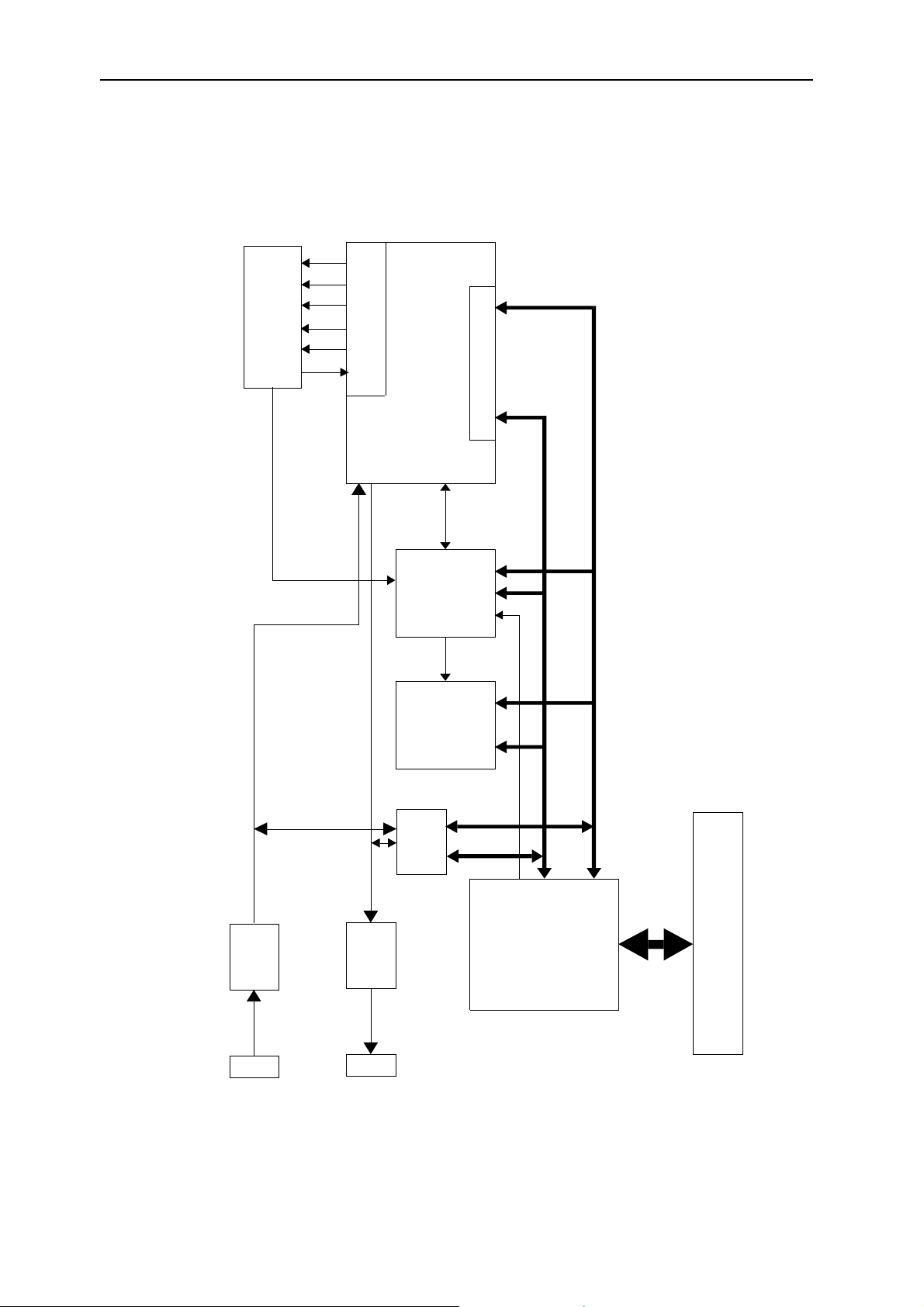

Figure 3: TIM sites location........................................................................................12

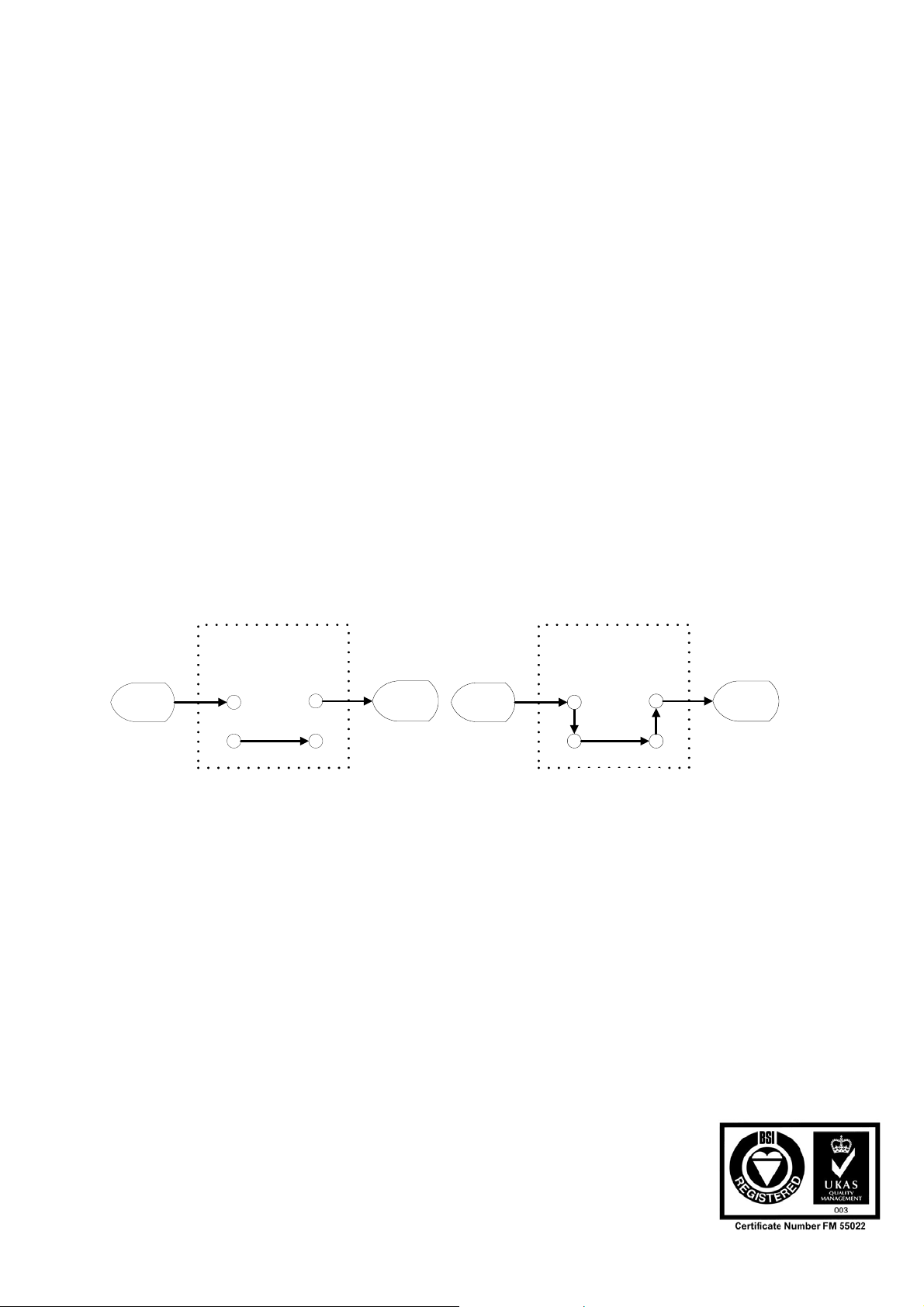

Figure 4 : Operation of quick switches.......................................................................18

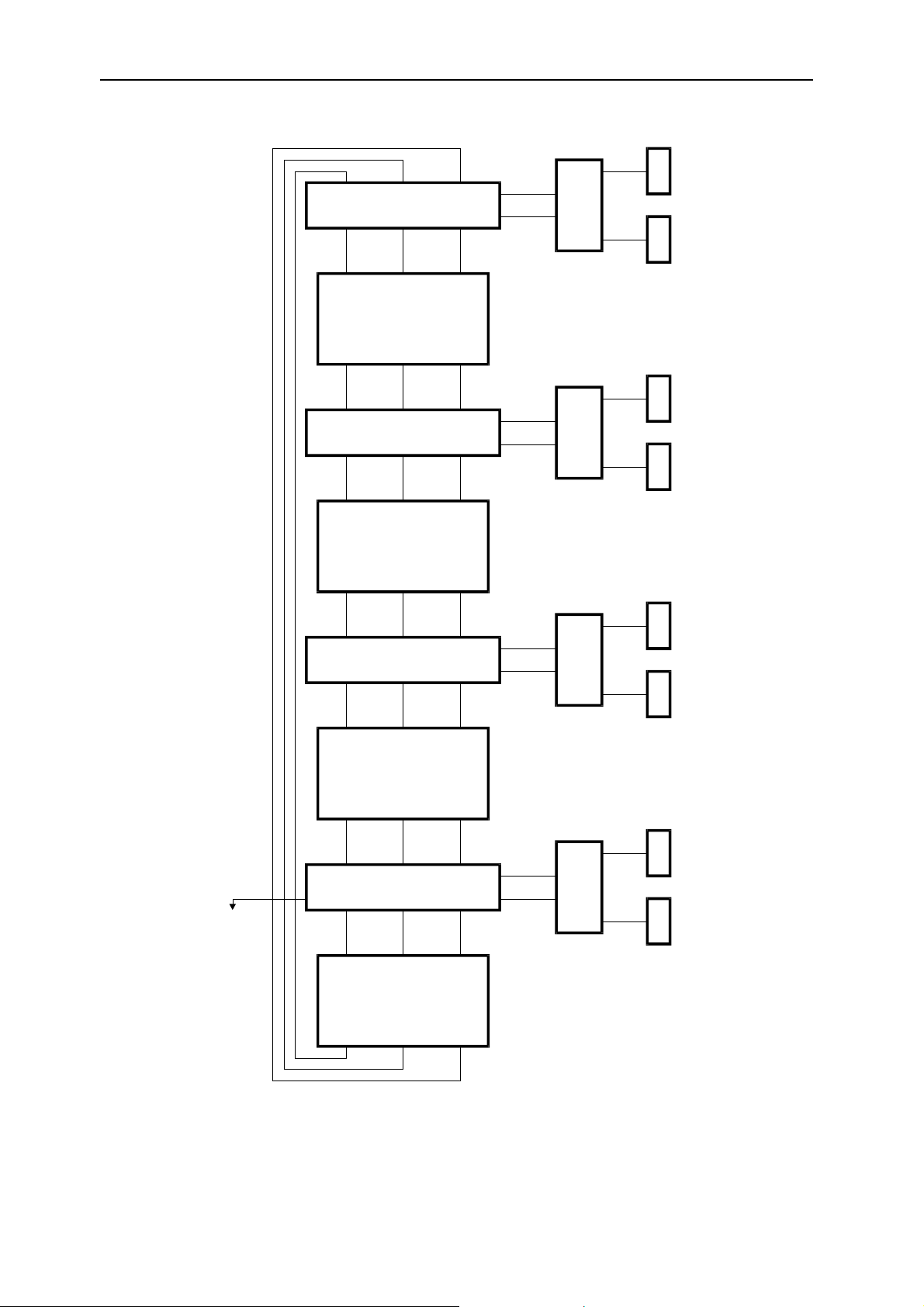

Figure 5 : TBC Data Routing .....................................................................................28

Figure 6 : JTAG header pin numbers.........................................................................32

Figure 7 : Local Bus to DSP Connectivity..................................................................33

Figure 8 : DSP Transfer via the Local Aperture 0......................................................36

Figure 9 : Timing diagram for DSP local bus access.................................................38

Figure 10 : SMT300Q to CompactPCI Interrupts.......................................................40

Figure 11 : CompactPCI to SMT300Q Interrupts.......................................................41

Figure 12 : Auxiliary Power Connector ......................................................................50

Figure 13 : JTAG speed Comparison chart ...............................................................52

Figure 14 : Jumper Finder Diagram...........................................................................58

Figure 15 : Expansion Header Pin Out Diagram........................................................59

Figure 16 : JTAG Slave circuit...................................................................................61

Page 6

Page 6 of 61 SMT300Q SMT300Q User Guide V1.65

Table of Tables

Table 1 : Table of Abbreviations..................................................................................7

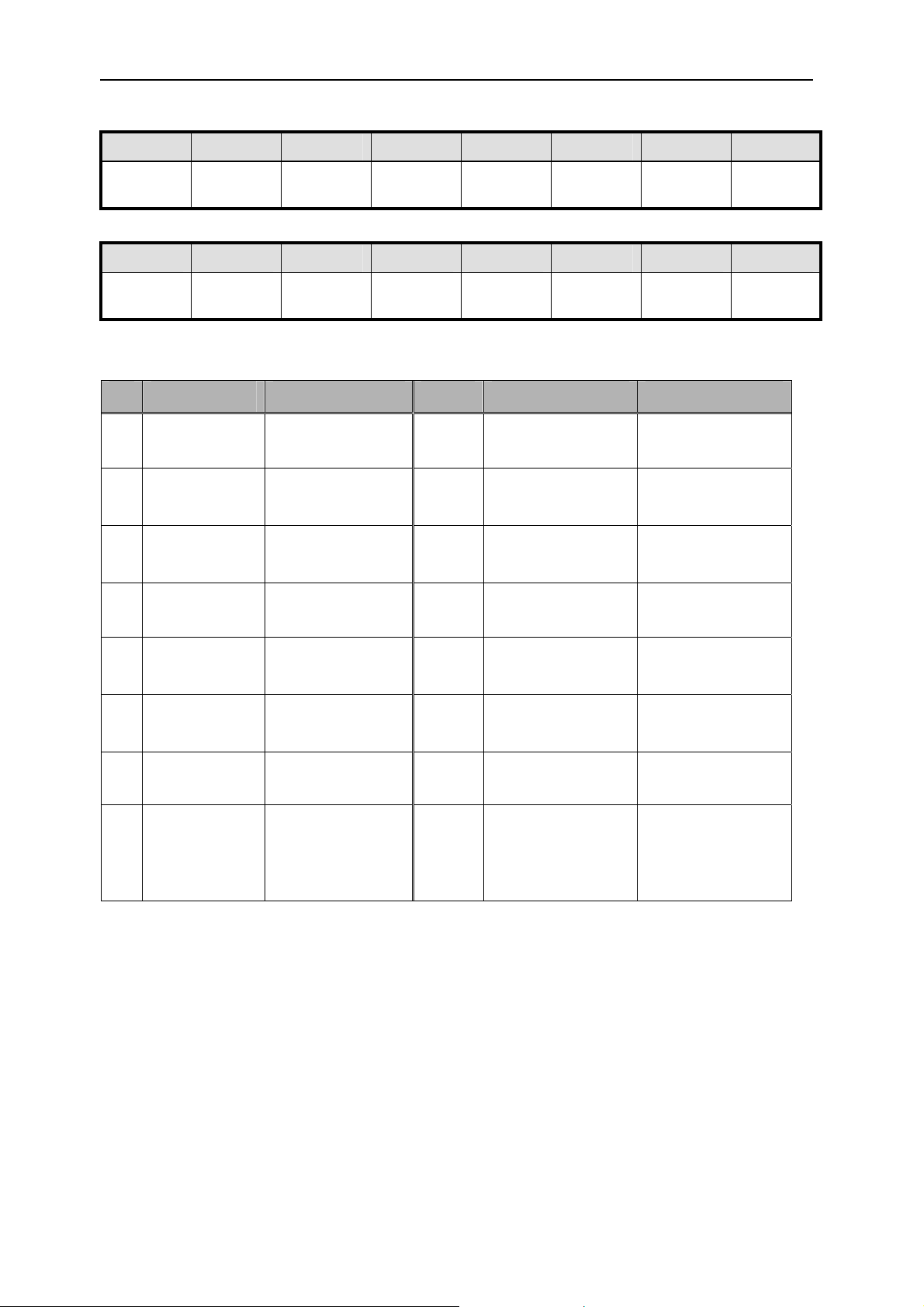

Table 2 : I/O address space map...............................................................................14

Table 3 : Memory space map....................................................................................15

Table 4 : Memory space map....................................................................................16

Table 6 : COM-SWITCH Register..............................................................................19

Table 7: Buffered ComPort 1 connections.................................................................20

Table 8: Buffered ComPort 2 connections.................................................................20

Table 9: Buffered ComPort 3 connections.................................................................20

Table 10: Buffered ComPort 4 connections...............................................................20

Table 11: Buffered ComPort 5 connections...............................................................21

Table 12: Buffered ComPort 6 connections...............................................................21

Table 13: Buffered ComPort 7 connections...............................................................21

Table 14: Buffered ComPort 8 connections...............................................................22

Table 15 : Buffered ComPort Additional Signals........................................................22

Table 16 : Control Register........................................................................................ 23

Table 17 : Status Register.........................................................................................24

Table 18 : Interrupt Control Register..........................................................................25

Table 19 : PLLREG1 Register ...................................................................................26

Table 20 : PLLREG2 Register ...................................................................................26

Table 21 : PLL Frequency Select ..............................................................................26

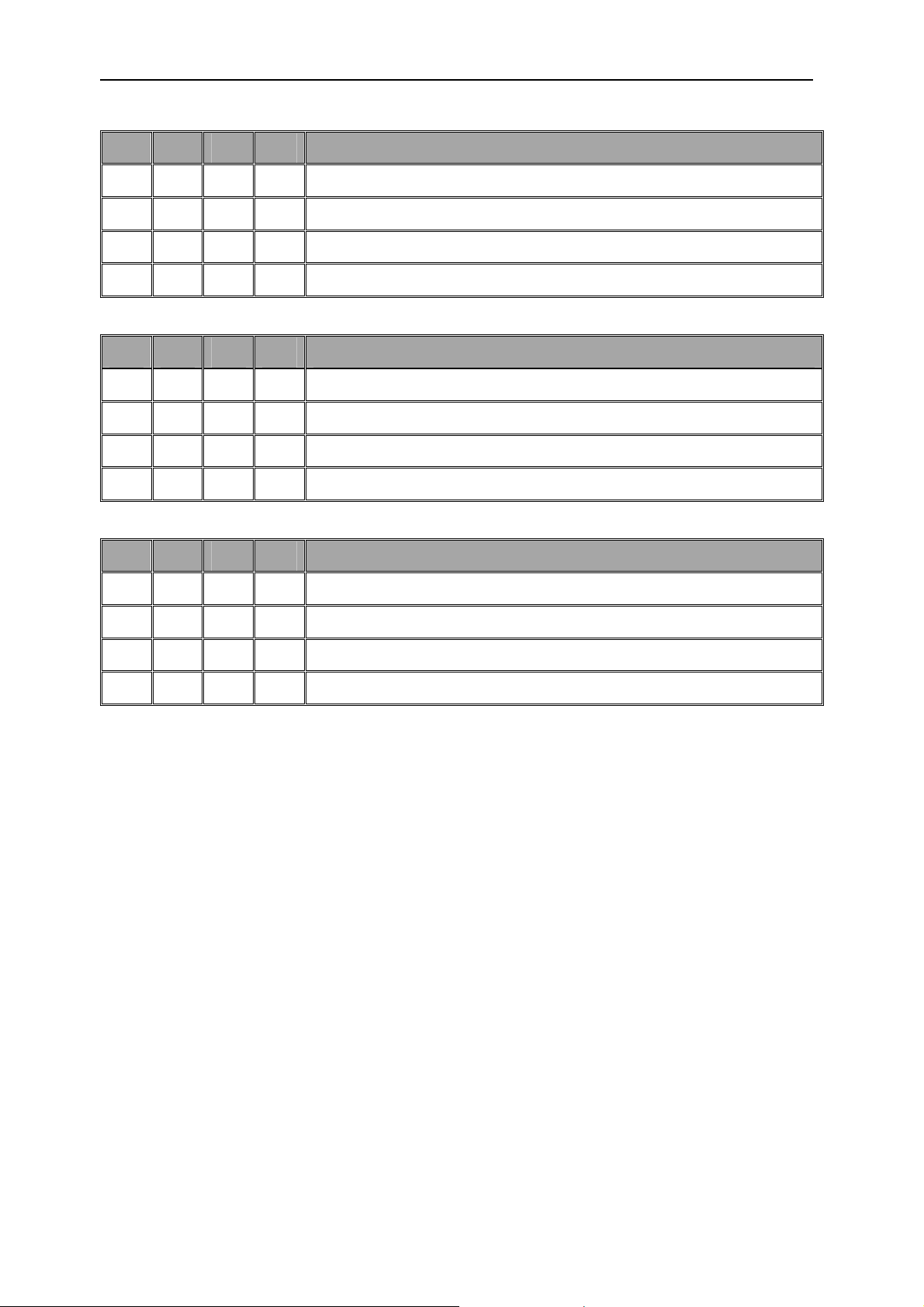

Table 22 : PLL Phase Shift Select (Bank 2)...............................................................27

Table 23 : PLL Phase Shift Select (Bank 3 and 4).....................................................27

Table 24 : JTAG Header pin function.........................................................................32

Table 25 : CompactPCI Interrupt Configuration Register...........................................43

Table 26 : CompactPCI Interrupt Status Register......................................................44

Table 27 : Local Bus Interrupt Mask Register...........................................................45

Table 28 : Local Bus Interrupt Status Register..........................................................45

Table 29 : CompactPCI Mailbox WRITE/READ Interrupt Control Register................46

Table 30 : Local Bus Mailbox WRITE/READ Interrupt Control Register....................46

Table 31 : Mailbox Write/Read Interrupt Status Register...........................................47

Table 32 : INTREG Register......................................................................................48

Table 33 : Performance Figures ................................................................................ 51

Table 35 : Buffered ComPort connector pin out.........................................................55

Table 36 : Buffered JTAG connector pin functionality as JTAG source.....................56

Table 37 : Buffered JTAG connector pin functionality as JTAG master.....................57

Page 7

Page 7 of 61 SMT300Q SMT300Q User Guide V1.65

Table Of Abbreviations

BAR Base Address Region

DMA Direct Memory Access

EPLD Electrically Programmable Logic Device

CompactPCI Compact Peripheral Component Interconnect

SRAM Static Random Access Memory

TBC Test Bus Controller

TIM Texas Instruments Module

Table 1 : Table of Abbreviations

Page 8

1 Introduction

The SMT300Q is a quad-site module carrier board that provides access to TIM

modules over the CompactPCI bus.

The carrier can hold up to four ‘C6x modules and these can exchange data using

ComPorts. A ComPort routing matrix, using electronic “quick switches”, is provided to

allow module connectivity without external cables.

The first TIM on the carrier is known as the “Master Module” and an enhanced

CompactPCI interface allows data packets to be exchanged between this module

and the CompactPCI bus at burst speeds in the range of 60–100MB/s. The DSP has

access to the CompactPCI Bridge internal registers to control DMAs, mailbox events,

and interrupts.

1MB of SRAM is mapped on to the Global Bus and can be accessed as a global

resource by the Host system across the CompactPCI Bridge or by the Master

Module.

An on-board JTAG controller allows systems to be debugged using Code Composer

Studio. This JTAG controller also has buffered outputs and inputs that can be

accessed using connectors on the carrier’s back panel. This allows off-board devices

to be connected into the JTAG chain.

Headers are provided for RESET_IN and RESET_OUT to allow multiple SMT300Q

carriers to be connected together and synchronised.

The board requires a 3.3-volt supply that is taken from the CompactPCI connector

and is made available at the fixing pillars for each module.

The SMT300Q may also be used with ‘C4x-based TIMs. When using these ‘C4x

modules you must ensure that a Master ‘C4x Module does not use its global memory

(if any is available) as this will prevent the SMT300Q from working.

If your SMT300Q does not have the Global Interface connector fitted (an ordering

option), the Master Module will still be able to use its global bus resources. The

module will not have access to the SMT300Q global resources, such as SRAM and

CompactPCI Bridge, but full ComPort and JTAG control will still be available.

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 9

2 Functional Description

Figure 1 gives the block diagram of the SMT300Q. The Slave Module sites (2–4) are

not shown, as they do not have any direct interface to the CompactPCI Bus, SRAM,

ComPort or JTAG sections of the design. The connectivity of slave sites is shown in

Figure 2.

The CompactPCI interface connects to a Quick Logic EPC363 bridge device. It has a

32-bit 33MHz CompactPCI interface that supports I2C control, mailbox register

access, and direct memory reads and writes. The CompactPCI bus is translated to a

Local bus, which is connected to the following devices:

• Shared SRAM 1MB

• Control EPLD that manages ComPort access

• JTAG controller

• Module Global Bus

• CompactPCI Bridge device

An on-board arbitration unit controls which device, Master Module or CompactPCI

Bridge, has access to this local bus resource.

The local bus has a 33MHz clock to control transfers between the various resources.

This is available on the CLKIN pin on the Master site and should be selected in

preference to the on-board oscillator to allow the DSP to synchronise its accesses to

and from the CompactPCI Bridge registers. The CompactPCI Bridge has an input

and output FIFO capable of transferring 256 32-bit words of data to and from the

DSP at 33MHz, thus bursting a maximum local bus transfer rate of 132MB/s.

The Master Module can access the SRAM over the local bus at transfer rates up to

100MB/s. The number of wait states required by the Master Module will vary

depending on the speed of the module. Maximum access rates use a 20ns strobe

cycle.

The JTAG controller is based on the TI 8990 device, and drivers can be supplied for

Code Composer Studio (Part Number SMT6012

module site causes its SENSE pin to switch the module into the JTAG chain.

ComPort communication from the Host to the Master Module site is switched through

a quick-switch, as illustrated in Figure 1. This allows the following connectivity:

). The presence of a TIM in a

• Connect the Host to the Master Module’s ComPort 3 (T1C3) and connect the

FMS (C_BUF) directly to the external buffered ComPort. This allows any of

the ComPorts on sites 1—4 to be connected to the external buffered ComPort

with an FMS cable; or

• Connect the Host to the external buffered ComPort and connect ComPort 3 of

the Master site to the FMS connector (C_BUF).

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 10

Page 10 of 61 SMT300Q SMT300Q User Guide V1.65

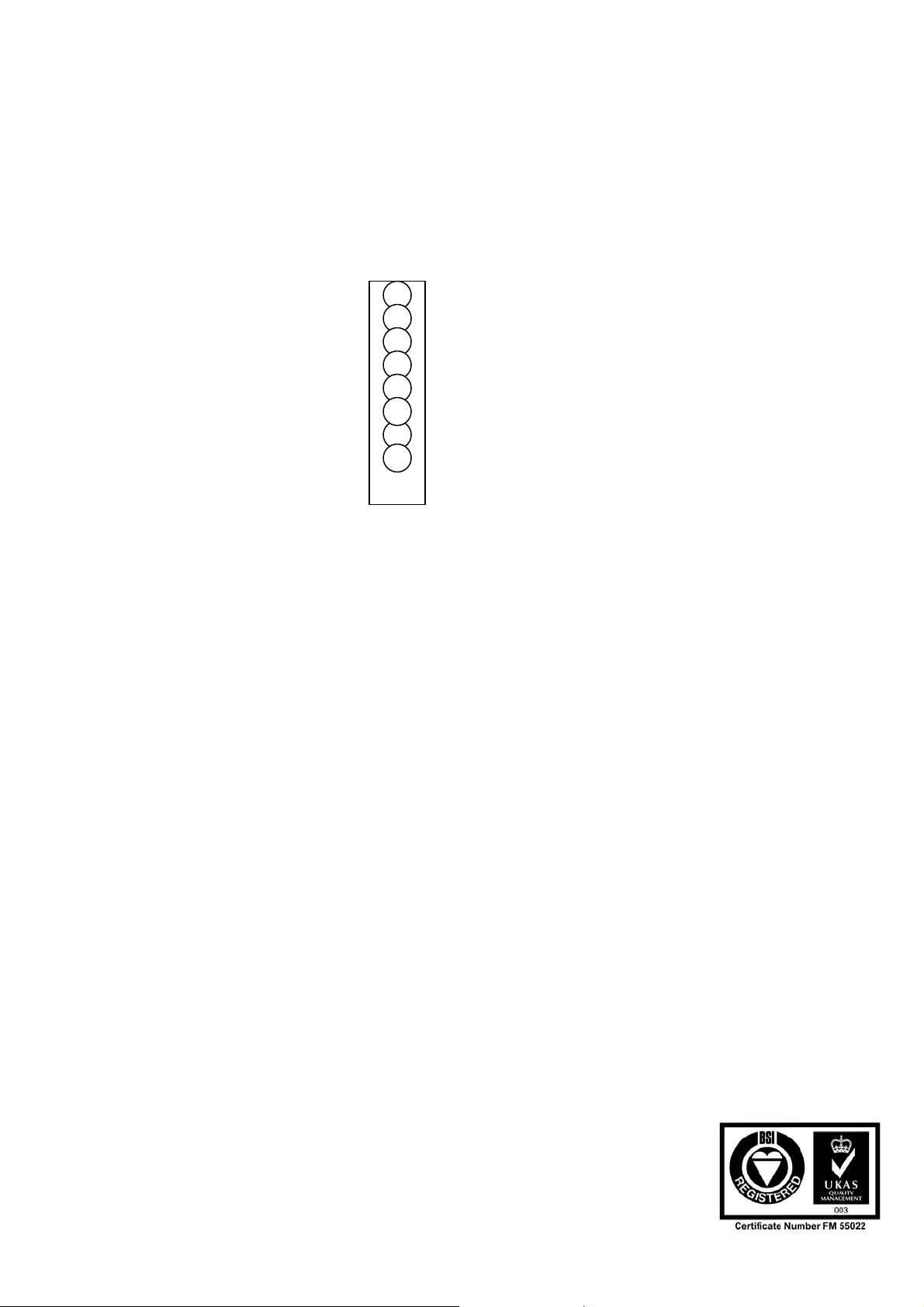

2.1 Block Diagram

Figure 1 shows the block diagram of the SMT300Q. For simplicity, only CompactPCI,

JTAG, and Buffered ComPort connectivity to the Master site is illustrated.

Connectivity between the Master site and the three other sites is shown in the

ComPort Switching Matrix block diagram, Figure 2.

ComPort Routing M atri x

340215

ComPor ts

Module Site

G lobal Bu s

HOST

ComPort

PCI Brid g e Da t a Bus (32 Bit )

Control

1 MB

PCI Bri dge Address Bus

EPLD

SRAM

8990

Buf f e r

Buf f e r

PCI Brid g e

CPCI Connector

Buf f e re d

Buf f e re d

JTAG IN

Figure 1 : Block Diagram for SMT300Q (Master site only)

JTAG OUT

Page 11

Page 11 of 61 SMT300Q SMT300Q User Guide V1.65

2.2 ComPort Switching Matrix

Cross Bar switch

1

4

2

5

Cross Bar switch

1

4

2

5

Buffer

CPLD

3

0

Buffer

CPLD

3

0

Front Panel Sockets Front Panel SocketsFront Panel Sockets

To cPCI CPLD

Cross Bar switch

Buffer

1

4

2

5

3

0

Cross Bar switch

Buffer

1

4

Figure 2: ComPort Switching Matrix

Site 1 Site 2 Site 3 Site 4

2

5

3

0

CPLD

CPLD

Comm 1 Comm 2 Comm 3 Comm 4 Comm 6Comm 5 Comm 7 Comm 8

Front Panel Sockets Front Panel SocketsFront Panel Sockets

Page 12

Page 12 of 61 SMT300Q SMT300Q User Guide V1.65

2.3 TIM Sites location

cPCI

Connector

TIM Site 4 TIM Site 3

TIM Site 1

MASTER MODULE

TIM Site 2

Figure 3: TIM sites location

Page 13

Page 13 of 61 SMT300Q SMT300Q User Guide V1.65

3 Setting Up the SMT300Q

The SMT300Q should be set up in the following way.

• Turn the PC off and insert the card into a spare CompactPCI slot.

• Switch on PC and wait for the O/S to boot up.

• Windows 95/98/NT/2000 will detect new hardware.

• Windows should automatically find the drivers from the CD, if not browse to the

CD or if you downloaded from the ftp site to the folder where you unzipped the

SMT6300 software.

• You can run the SMTBoardInfo application to detect the number of SMT300Qs in

your system and report their slot positions and I/O addresses. This information is

required when setting up code composer for the board.

Page 14

4 Host Memory Map

All address information is given in bytes :

4.1 CompactPCI Bridge Chip Internal Register (BAR0)

Please see V363EPC Local Bus CompactPCI Bridge User Manual

(http://www.quicklogic.com/home.asp?PageID=223&sMenuID=114#Docs) for details

of internal registers.

Where required, registers from the V3 datasheet have been included.

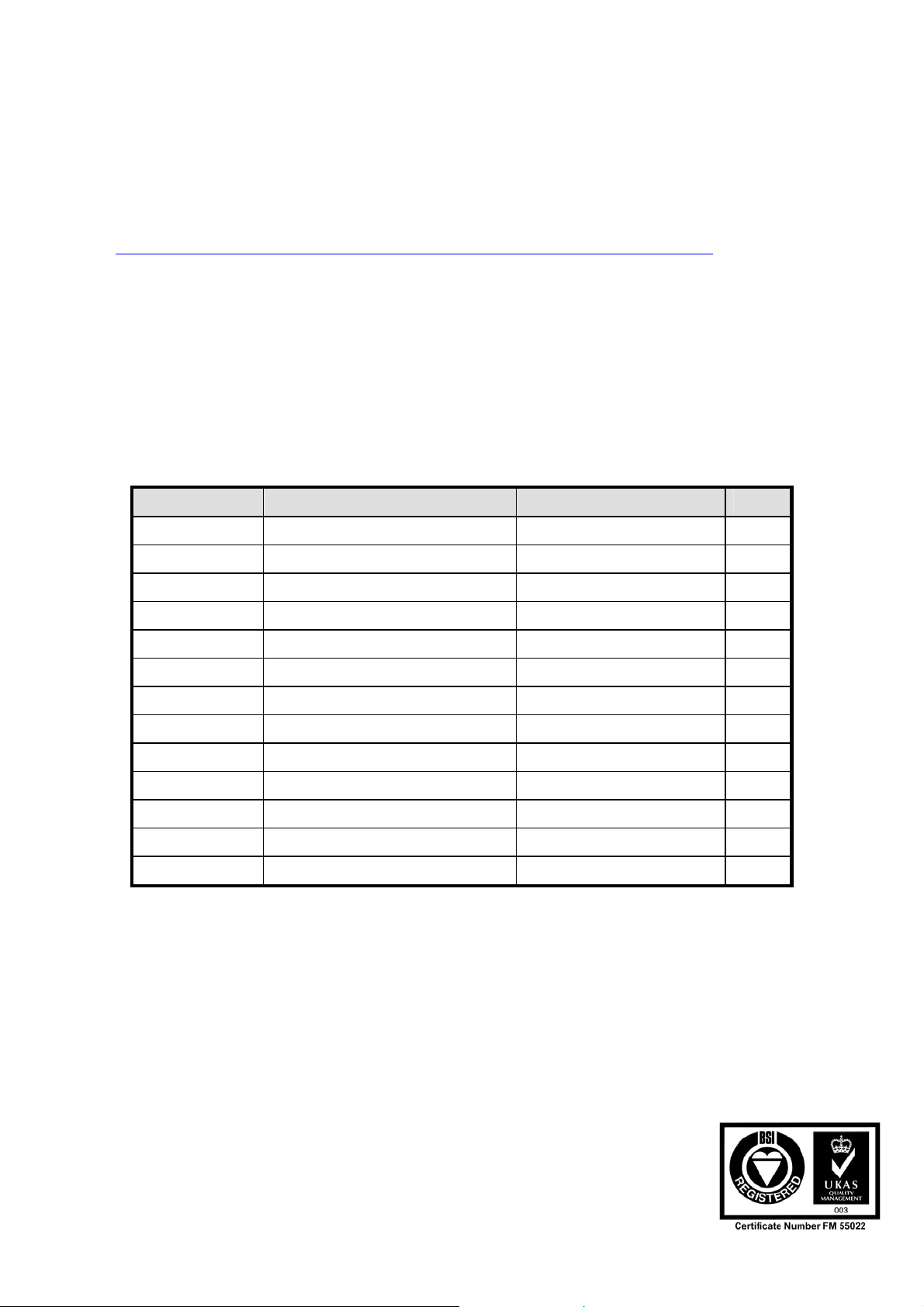

4.2 I/O Space Register Assignments (BAR1)

In target mode, a host device accesses the SMT300Q across the CompactPCI bus,

which gives access to the target mode registers. The operating system or BIOS will

normally allocate a base address for the target mode registers of each SMT300Q.

Access to each register within the SMT300Q is then made at offsets from this base

address as shown in the table below.

Offset (Hex) Register(Write) Register(Read) Width

0x00 - -

0x04 - -

0x08 - -

0x0C - -

0x10 COMPORT_OUT COMPORT_IN 32

0x14 CONTROL STATUS 32

0x18 INT_CONTROL 32

0x1C - -

0x20 to 0x3F COMPORT Configuration COMPORT Configuration

0x24 COM_SWITCH COM_SWITCH 16

0x2C COM_SWITCH_EX COM_SWITCH_EX 32

0x40 INTREG INTREG 16

0x80 to 0xAF TBC Write TBC Read 16

Table 2 : I/O address space map

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 15

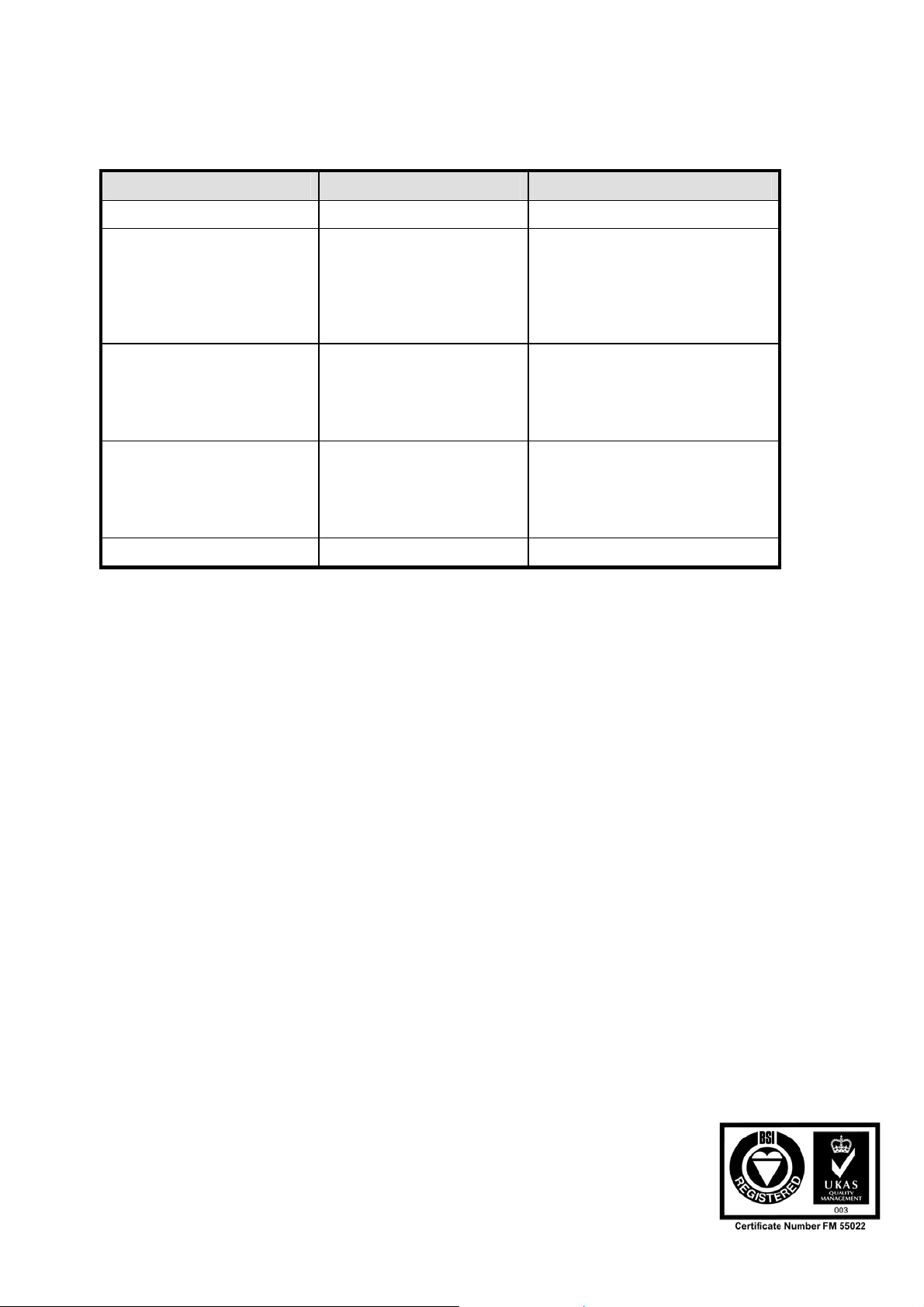

4.3 Memory Space Assignments(BAR2)

Address (Hex) Description Notes

0x0000 0000 – 0x000F FFFF Shared Memory Bank 1MB SRAM

0x00200090 ComPort Data

Mirror

Mirror of COMPORT_OUT /

COMPORT_IN in

I/O Space

Register Assignments

(BAR1)

See Note 2

0x00200094 ComPort Status

Mirror

0x00200098 ComPort Int_Control

Mirror

Mirror of Control / Status in

Space Register

Assignments (BAR1)

See Note 2

Mirror of Int_Control in

I/O

Space Register

I/O

Assignments (BAR1)

See Note 2

0x0020 0000-0x0020 007F Global Bus See Note 1

Table 3 : Memory space map

Note 1: In order for the TIM to respond to accesses for this area address line

GADD30 and GADD19 of the TIM site connector must be decoded as high and

GADD7 and GADD5 must be decoded as low.

Note 2: These mirrors of Addresses in the I/O Space (BAR1) allow increased transfer

speeds across the host ComPort link (in excess of 10X increase).

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 16

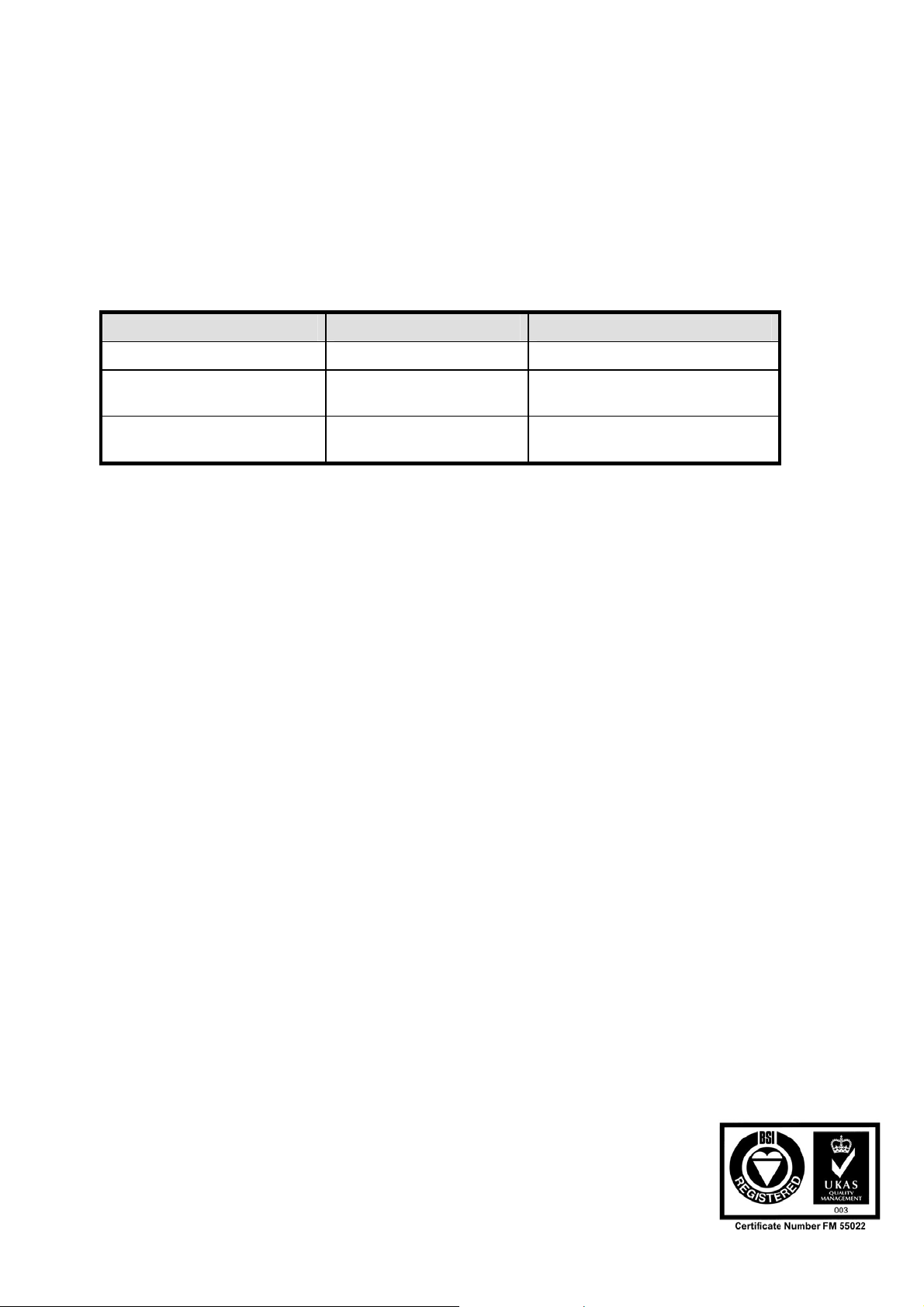

5 DSP Resource Memory Map

The Master module on the SMT300Q can access the various board resources,

including the Shared SRAM and the CompactPCI Bridge. This allows the DSP to

control the CompactPCI Bridge’s DMA engine and manipulate mailbox registers. The

table below illustrates the resources and their corresponding address region when

accessed by the Master module.

C60 Address Access Description Notes

0xD000 0000 – 0xD00F FFFF Shared Memory Bank 1MB SRAM

0x1C00 0000 – 0x1C00 00FF CompactPCI Bridge

Registers

0x1800 0000 – 0x183F FFFF Local-to-CompactPCI

Aperture 0

Table 4 : Memory space map

CompactPCI Bridge Internal

resisters

CompactPCI Bridge Aperture 0

Space

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 17

6 Shared Memory Resource

The SMT300Q has 1 MB of shared SRAM that can be accessed by both the

CompactPCI host and the Master module. This allows applications to transfer data

between the host PC and the DSP at data rates approaching 100MB/s. The address

of the shared memory is shown in the memory map.

The CompactPCI Bridge DMA processor sees the shared memory at a different

address from that used for normal accesses. For normal memory access the memory

base address register offset is 0x0000 0000. For DMA access address line A28 (On

hardware interface) must be high, therefore DMA memory access starts at 0x4000

0000 (Not 0x1000 0000 as addressing is in bytes).

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 18

7 ComPorts

Figure 2 shows how the ComPorts of each TIM site are connected.

The SMT300Q gives access to all six ComPorts on each of the four TIM sites. All of

the ComPorts can be connected buffered connectors on the front panel of the carrier

card.

There is a connection from the CompactPCI interface to ComPort 3 on TIM site 1 for

booting the TIM. This connection can be severed with a quick switch (COM-SWITCH

register offset 0x24, BAR1 bit 15)

7.1 ComPort Switching (Quick Switches)

Several of the TIM ComPorts can be linked together without the need for external

cables. This is done using quick switches controlled by the COM-SWITCH register

(BAR1, offset 0x24)

For all of the quick switches expect the one controlled by bit 15 of the COM-SWITCH

register, the following diagrams show the effects of setting or clearing the control bit.

CPa

Quick Switch Off (0)

CPb

CPa

Quick Switch On (1)

CPb

Figure 4 : Operation of quick switches

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 19

Page 19 of 61 SMT300Q SMT300Q User Guide V1.65

D15 D14 D13 D12 D11 D10 D9 D8

CompactP

CI-T1C3

T3C3-

T4C0

T3C2-

T4C5

T3C1-

T4C4

T2C3-

T3C0

T2C2-

T3C5

T2C1-

T3C4

D7 D6 D5 D4 D3 D2 D1 D0

T1C2-

T2C5

T1C1-

T2C4

T4C3-

T1C0

Table 5 : COM-SWITCH Register

T4C2-

T1C5

T4C1-

T1C4

T4C3-

T1C0

T4C2-

T1C5

Bit Clear (0) Set (1) Bit Clear (0) Set (1)

D0

D1

D2

D3

Not

Connected

Not

Connected

Not

Connected

Not

Connected

T4C1—T1C4

T4C2—T1C5

T4C3—T1C0

T1C4—T4C1

D8

D9

D10

D11

Not Connected

Not Connected

Not Connected

Not Connected

T1C3—T2C0

T2C1—T3C4

T2C2—T3C5

T2C3—T3C0

T1C3-

T2C0

T4C1-

T1C4

D4

D5

D6

D7

Not

Connected

Not

Connected

Not

Connected

Not

Connected

T1C5—T4C2

D12

T1C0—T4C3

D13

T1C1—T2C4 D14

T1C2—T2C5 D15

Not Connected

Not Connected

Not Connected

CompactPCI—

T1C3

T3C1—T4C4

T3C2—T4C5

T3C3—T4C0

CompactPCI—

External

Buffered

ComPort 2

7.2 Buffered ComPort

The buffered ComPorts on the front panel can be connected to ComPorts of the Tim

Sites. Four of the buffered ComPorts are output only (BUF 2,4,6 and 8) and four are

input only (BUF 1,3,5 and 7).

Page 20

Page 20 of 61 SMT300Q SMT300Q User Guide V1.65

Connection is controlled by COM_SWITCH_EX register (BAR1, Offset 0x2C,), shown

below,

D3 D2 D1 D0 Buffered ComPort 1 Connection (Input Only)

0 X X X Buffered ComPort 1 Disabled

1 0 1 1 Buffered ComPort 1 Connected to TIM Site 1 ComPort 3

1 1 0 0 Buffered ComPort 1 Connected to TIM Site 2 ComPort 4

1 1 0 1 Buffered ComPort 1 Connected to TIM Site 2 ComPort 5

Table 6: Buffered ComPort 1 connections

D7 D6 D5 D4 Buffered ComPort 2 Connection (Output Only)

0 X X X Buffered ComPort 2 Disabled

1 0 0 0 Buffered ComPort 2 Connected to TIM Site 2 ComPort 0

1 0 0 1 Buffered ComPort 2 Connected to TIM Site 1 ComPort 1

1 0 1 0 Buffered ComPort 2 Connected to TIM Site 1 ComPort 2

Table 7: Buffered ComPort 2 connections

D11 D10 D9 D8 Buffered ComPort 3 Connection (Input Only)

0 X X X Buffered ComPort 3 Disabled

1 0 1 1 Buffered ComPort 3 Connected to TIM Site 2 ComPort 3

1 1 0 0 Buffered ComPort 3 Connected to TIM Site 3 ComPort 4

1 1 0 1 Buffered ComPort 3 Connected to TIM Site 3 ComPort 5

Table 8: Buffered ComPort 3 connections

D15 D14 D13 D12 Buffered ComPort 4 Connection (Output Only)

0 X X X Buffered ComPort 2 Disabled

1 0 0 0 Buffered ComPort 4 Connected to TIM Site 3 ComPort 0

1 0 0 1 Buffered ComPort 4 Connected to TIM Site 2 ComPort 1

1 0 1 0 Buffered ComPort 4 Connected to TIM Site 2 ComPort 2

Table 9: Buffered ComPort 4 connections

Page 21

Page 21 of 61 SMT300Q SMT300Q User Guide V1.65

D19 D18 D17 D16 Buffered ComPort 5 Connection (Input Only)

0 X X X Buffered ComPort 5 Disabled

1 0 1 1 Buffered ComPort 5 Connected to TIM Site 3 ComPort 3

1 1 0 0 Buffered ComPort 5 Connected to TIM Site 4 ComPort 4

1 1 0 1 Buffered ComPort 5 Connected to TIM Site 4 ComPort 5

Table 10: Buffered ComPort 5 connections

D23 D22 D21 D20 Buffered ComPort 6 Connection (Output Only)

0 X X X Buffered ComPort 6 Disabled

1 0 0 0 Buffered ComPort 6 Connected to TIM Site 4 ComPort 0

1 0 0 1 Buffered ComPort 6 Connected to TIM Site 3 ComPort 1

1 0 1 0 Buffered ComPort 6 Connected to TIM Site 3 ComPort 2

Table 11: Buffered ComPort 6 connections

D27 D26 D25 D24 Buffered ComPort 7 Connection (Input Only)

0 X X X Buffered ComPort 7 Disabled

1 0 1 1 Buffered ComPort 7 Connected to TIM Site 4 ComPort 3

1 1 0 0 Buffered ComPort 7 Connected to TIM Site 1 ComPort 4

1 1 0 1 Buffered ComPort 7 Connected to TIM Site 1 ComPort 5

Table 12: Buffered ComPort 7 connections

Page 22

D31 D30 D29 D28 Buffered ComPort 8 Connection (Output Only)

0 X X X Buffered ComPort 8 Disabled

1 0 0 0 Buffered ComPort 8 Connected to TIM Site 1 ComPort 0

1 0 0 1 Buffered ComPort 8 Connected to TIM Site 4 ComPort 1

1 0 1 0 Buffered ComPort 8 Connected to TIM Site 4 ComPort 2

Table 13: Buffered ComPort 8 connections

The front panel mounted connector is a 26 pin 3M type, (3M part number 102265212JL).

As well as the 12 C4x ComPort signals and signal grounds, there are 6 additional

signals. Note that these signals are NOT essential for communications:

Name Description

I/O_OUT Output high when port is outputting data, output low when

port is receiving data.

I/O_IN Input which prevents bus contention if connected to I/O_OUT

/RST_OUT Active low open collector copy of the board reset drive.

/RST_IN Active low board reset input, pulled up to 3.3V by 100 ohms.

VCC 1 AMP +5 Volt supply, with resetable 1 Amp fuse, to power a

remote buffer, if required.

SHIELD Overall cable shield, connected to plug shells and chassis.

Table 14 : Buffered ComPort Additional Signals

The /RST_OUT is intended to allow synchronised reset of a number of boards by

driving the /RST_IN input.

The SMT502-Buffer is the recommended cable assembly for the buffered Comport

and can be purchased separately.

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 23

8 ComPort to CompactPCI Interface

The ComPort interface is memory mapped to the CompactPCI Bridge as illustrated in

table 1 : I/O address space map. The ComPort uses the Control and Data registers to

detect the state of the input and output FIFOs. The following section describes the bit

definitions for these registers.

8.1 ComPort Registers (Offset 0x10, BAR1)

The host is connected to the first TIM site using Comport 3 (T1C3). This port is bidirectional and will automatically switch direction to meet a request from either the

host or the DSP. Both input and output registers are 32 bits wide. Data can only be

written to COMPORT_OUT when STATUS[OBF] is 0. Data received from the DSP is

stored in COMPORT_IN and STATUS[IBF] is set to 1. Reading COMPORT_IN will

clear STATUS[IBF] and allow another word to be received from the DSP.

8.2 Control Register (Offset 0x14, BAR1)

The CONTROL register can only be written. It contains flags, which control the boot

modes of the first TIM site.

7-5 4 3 2 1 0

notNMI IIOF2 IIOF1 IIOF0 RESET

RESET Write a 1 to this bit to assert the reset signal to the TIM

module on the SMT300Q.

IIOF0

IIOF1

These bits connect to the corresponding pins on the TIM site

1. Writing 0 causes the corresponding IIOF line to go low.

IIOF2

NotNMI A 0 written to this bit will assert the active low NMI to the

TIM.

Table 15 : Control Register

Note. On CompactPCI system reset, RESET is asserted to the TIM site.

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 24

8.3 Status Register (Offset 0x14, BAR1 , Read-Only)

31:22 21 20 19 18 17 16 15:12 11 10 9 8

CONFIG_L TBC

RDY

0 MASTER IBF OBF

IM2 IM1 IM0 INTD

7 6 5 4 3 2 1 0

C40 INT TBC INT IBF INT OBE INT C40 IE TBC IE IBF IE OBE IE

OBE IE Set if ComPort output buffer empty interrupts enabled.

IBF IE Set if ComPort input buffer full interrupts enabled

TBC IE Set if JTAG interrupts enabled

C40 IE Set if interrupt from TIM DSP enabled

OBE INT Set if the ComPort output buffer becomes empty. Cleared by writing a

1 to the corresponding bit in the interrupt control register.

IBF INT Set if the ComPort input buffer receives a word. Cleared by writing a

1to the corresponding bit in the interrupt control register

TBC INT Set when the TBC asserts its interrupt. Cleared by removing the

source of the interrupt in the TBC.

C40 INT Set when the TIM DSP sets its host interrupt bit. Cleared by writing a

1 to the corresponding bit in the interrupt control register.

INTD The logical OR of bits 7—4 in this register gated with each one’s

enable bit.

OBF Set when a word is written to the ComPort output register. Cleared

when the word has been transmitted to the DSP.

IM0 Interrupt mask 0. Returns Interrupt Control Register Bit 8.

IM1 Interrupt mask 1. Returns Interrupt Control Register Bit 9.

IM2 Interrupt mask 2. Returns Interrupt Control Register Bit 10.

IBF Set when a word is in the ComPort input register.

MASTER Set when the SMT300Q bridge owns the ComPort interface token.

TBC RDY Reflects the current state of the TBC RDY pin. This bit is active high

and therefore and inversion of the TBC pin.

CONFIG_L Reflects the state of the TIMs’ CONFIG signal. Active low.

Table 16 : Status Register

INTD is the input interrupt into the CompactPCI Bridge from the SMT300Q, this can

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 25

Page 25 of 61 SMT300Q SMT300Q User Guide V1.65

be routed to either INTA, INTB, or INTC using the CompactPCI Interrupt

Configuration Register (offset 0x4C, BAR0)

8.4 Interrupt Control Register (Offset 0x18, BAR1)

This write-only register controls the generation of interrupts on the CompactPCI bus.

Each interrupt source has an associated enable and clear flag. This register can be

written with the contents of bits 7:0 of the Status Register.

10 9

DSP-PC IIOF2 En DSP-PC IIOF1 En

8 7 6 5 4 3 2 1 0

DSP-PC

IIOF0 En

CLEAR

C40 INT

0 CLEAR

IBF INT

CLEAR OBE

INT

C40 IE TBC IE IBF IE OBE IE

DSP-PC IIOF2 En Enables DSP-PC interrupts on IIOF2

DSP-PC IIOF1 En Enables DSP-PC interrupts on IIOF1

DSP-PC IIOF0 En Enables DSP-PC interrupts on IIOF0

IBF IE ComPort Input Buffer Full Interrupt Enable. Allows an

interrupt to be generated when the host ComPort input

register is loaded with data from the C40.

OBE IE ComPort Output Buffer Empty Interrupt. Allows an interrupt to

be generated when the host ComPort register has transmitted

its contents.

TBC IE Test Bus Controller Interrupt Enable. Interrupts from the

Texas JTAG controller are enabled when set.

C40 IE C40 Interrupt Enable. Allows a programmed interrupt to be

generated by the C40 when set.

CLEAR OBE INT Write a one to this bit to clear the interrupt resulting from a

ComPort output event.

CLEAR IBF INT Write a one to this bit to clear the interrupt event resulting

from ComPort input.

CLEAR C40 INT Write a one to this bit to clear down the C40 INT event.

Table 17 : Interrupt Control Register

The JTAG controller, which generates TBC INT, must be cleared of all interrupt

sources in order to clear the interrupt.

Page 26

9 PLL

The PLL produces three programmable clocks that are available on the user-defined

pins of the TIM connectors (Bank2CLK pin 1 on J24, Bank3CLK pin 3 on J24,

Bank4CLK pin 8 on J23).

These clocks are programmable through registers PLLREG1 and PLLREG2 (BAR1

Offset 6016 and 6416).

9.1 PLLREG1 (BAR1 Offset 6016)

D15 D14 D13 D12 D11 D10 D9 D8

Bank3CLK Frequency Select Bank3CLK Phase Shift Select

D7 D6 D5 D4 D3 D2 D1 D0

Bank2CLK Frequency Select Bank2CLK Phase Shift Select

Table 18 : PLLREG1 Register

9.2 PLLREG2 (BAR1 Offset 6416)

D7 D6 D5 D4 D3 D2 D1 D0

Bank4CLK Frequency Select Bank4CLK Phase Shift Select

Table 19 : PLLREG2 Register

9.3 Frequency Select (Bank 2, 3 and 4)

Frequency (MHz) MSB LSB

66 / 1 0 1 0 1

66 / 3 0 1 1 1

66 / 8 1 1 0 1

66 / 12 1 1 1 1

Table 20 : PLL Frequency Select

Each clock output has a programmable phase shift in steps of tu.

Where tu = 1 / (F

F

= 66 MHz

NOM

NOM

* N)

N = 32

So tu = 473.5 ps

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 27

Page 27 of 61 SMT300Q SMT300Q User Guide V1.65

9.4 Phase Shift Select (Bank 2)

Phase Shift MSB LSB

-4 tu 0 1 0 1

-2 tu 0 1 1 1

+2 tu 1 1 0 1

+4 tu 1 1 1 1

Table 21 : PLL Phase Shift Select (Bank 2)

9.5 Phase Shift Select (Bank 3 and 4)

Phase Shift MSB LSB

-8 tu 0 1 0 1

-6 tu 0 1 1 1

+6 tu 1 1 0 1

+8 tu 1 1 1 1

Table 22 : PLL Phase Shift Select (Bank 3 and 4)

Page 28

10 JTAG Controller

The SMT300Q has an on board Test Bus Controller (TBC), an SN74ACT8990 from

Texas Instruments. The TBC is controlled from the CompactPCI bus giving access to

the on-site TIMs and/or any number of external TIMs. Please refer to the Texas

Instruments data sheet for details of this controller. The TBC is accessed in I/O space

BAR1 offset 0x80.

Buffered

JTAG

Connectors

Test Bus

Switching

Matrix

Buffers

Test Bus

Controller

PCI bridge

Site 1 Site 2 Site 3 Site 4

Figure 5 : TBC Data Routing

The SMT300Q can operate in two TBC modes; Master mode and Slave mode. In

Master mode, the Test Bus Controller on the SMT300Q drives the JTAG scan chain

through the TIM sites on the SMT300Q. If any or all the sites are not populated with a

TIM then the modules SENSE signal is used to enable a tri-state buffer connecting

the TDI and TDO (JTAG Data In and Data Out) on the specific site, maintaining the

integrity of the JTAG data path. This switching is automatic. The SMT300Q auto

detects external JTAG connections and switches the JTAG circuitry accordingly.

When the SMT300Q is configured in Slave mode, the TBC on the SMT300Q is

disabled, as the TBC is assumed to be on another device connected to the

SMT300Q.

The SMT501-JTAG is designed to connect two SMTxxx carrier boards i.e., SMT300Q

controlling an SMT328 VME carrier. The length of SMT501-JTAG is 1 meter.

There are two external JTAG connectors (JTAG IN, JTAG OUT). JTAG OUT is used

when in master mode to connect to slave devices and JTAG IN is used in slave mode

to connect master devices to the SMT300Q. Both connectors can be used at the

same time to produce a chain of boards.

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 29

Page 29 of 61 SMT300Q SMT300Q User Guide V1.65

When using the JTAG chain with multiple carriers that have a large number of vacant

TIM sites it may be necessary to reduced the speed of the JTAG clock (mater board

only) to improve reliability. This can be done by inserting jumper J7 (Figure 14 :

Jumper Finder Diagram) which halves the JTAG clock frequency.

Page 30

11 Using the SMT300Q External/Internal JTAG with TI Tools.

For details on using the SMT300Q with T.I. Code Composer range, see the SMT6012

documentation.

The SMT6012 is Sundance’s driver for the T.I. Code Composer range of products

and can be purchased separately. The SMT6012 is free of charge when the

SMT300Q is bought with the Code Composer software from Sundance.

The Texas Instruments Evaluation Module (EVM) kits can be used as stand-alone

devices with a SMT300Q as the JTAG master. When running with the EVM kits

ensure that the EVM jumper has been set up correctly. i.e. External JTAG has been

selected and the DSP boot location is valid (set for internal memory space).

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 31

r

12 Firmware Upgrades

Much of the SMT300Q’s control interface is achieved using EPLDs. Sometime

customers require slightly different interface protocols, which can be catered for by a

firmware upgrade. To upgrade firmware Xilinx JTAG programming software is

required together with a lead to connect to the SMT300Q’s header. The image below

shows the location of pin 1 of the JTAG connector J21. This connector is a 2x3 2mm

pin header.

Pin 1 JTAG Programmer

Heade

2

1

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

4

6

3

5

Page 32

Page 32 of 61 SMT300Q SMT300Q User Guide V1.65

Figure 6 : JTAG header pin numbers

Pin Number Function

1 Vcc (5v)

2 Gnd

3 TCK

4 TDO

5 TDI

6 TMS

Table 23 : JTAG Header pin function

Page 33

13 Global/Local Bus Transfers, DSP <-> CompactPCI.

The traditional global bus interface on C6x DSP modules interfaces to the SMT300Q

via a local bus. This allows Global bus transfers on the DSP to be converted into

local bus accesses. This allows direct DSP accesses to the CompactPCI Bridge chip.

The resources in the CompactPCI Bridge chip are illustrated in the figure below.

PCI Bridge Device

MailBox

Read/Write

Interrupt Control

Local To PCI Bus

Apperture Control

LOCAL <-> PCI

Apperture 0

16MB Address

Space

Local Bus

Arbitration

Unit

DSP Global

Bus Access

Figure 7 : Local Bus to DSP Connectivity

13.1 Mailbox Accesses

The mailbox registers can be used if small amounts of data or commands between

the CompactPCI bus and the DSP, via the local bus, need to be transferred. Rather

than sending ComPort data, and therefore require the DSP to be checking its

ComPort for commands, a mailbox write by the CompactPCI bus can be initialized to

generate an interrupt on an DSP IIOF line indicating, to the DSP, that data is

available. The CompactPCI Bridge device provides 16 8-bit mailbox registers, which

may be used to transmit and receive data between the DSP and Host.

The mailbox registers are accessed from the DSP through the Local-to-Internal

Register (LB_IO_BASE) aperture. As illustrated in section 5, table 4 of this document

this region is accessed by the DSP via a global bus access to the CompactPCI

Bridge Registers (Address : 0x1C00 0000).

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 34

Page 34 of 61 SMT300Q SMT300Q User Guide V1.65

The mailbox registers themselves are on byte boundaries with offsets 0xC0 -> 0xCF,

from the LB_IO_BASE. As DSP global bus accesses are carried out on WORD (32bit) boundaries a write access over the global bus to 0x1C00 0000 + 0xC0 will write

to the first 4 mailbox registers in the CompactPCI Bridge device.

The mailbox registers are accessed from the CompactPCI bus through the

CompactPCI-to-Internal Register (CompactPCI_IO_BASE) aperture. This is

accessed via the CompactPCI Bridge Chip Internal Register (BAR0), byte offset

0xC0 -> 0xCF.

13.1.1 Doorbell Interrupts

Each of the 16 mailbox registers can generate four different interrupt requests called

doorbell interrupts. Each of these requests can be independently masked for each

mailbox register. The four doorbell interrupt types are:

• DSP interrupt request on read from CompactPCI side

• DSP interrupt request on write from CompactPCI side

• CompactPCI interrupt request on read from DSP side

• CompactPCI interrupt request on write from DSP side

The CompactPCI read and DSP read interrupts are OR’d together and latched in the

mailbox read interrupt status register (MAIL_RD_STAT). Similarly, the CompactPCI

write and DSP write interrupts are OR’d together and latched in the mailbox write

interrupt status register (MAIL_WR_STAT). All of the interrupt request outputs from

the status registers are OR’d together to form a single mailbox unit interrupt request

and routed to both the Local and CompactPCI Interrupt Control Units.

When a block of mailbox registers are accessed simultaneously, for example when 4

mailbox registers are read as a word quantity, then each register affected will request

a separate interrupt if programmed to do so.

See section 14 for further information on Interrupts.

13.2 DSP Interrupt Control

Interrupts can be enabled from a number of different sources i.e. DSP-> Host and

Host -> DSP. See section 14 for a description of these functions.

Page 35

13.3 DSP To Local Aperture 0 control and Accessing

The quickest way to transfer information from the DSP to CompactPCI Bus or vice

versa is to use the Local-to-CompactPCI Aperture 0 in the CompactPCI Bridge

device. A DSP unit may be required to transfer large amounts of acquired data to the

PC host for data storage or post-processing etc. Allowing the DSP to take control of

the CompactPCI bus means that the HOST only requires to transfer data, from an

internal allocated region of memory, after the transfer has been completed by the

DSP. Alerting the Host that data has been transferred can be accomplished in a

number of ways i.e. writing to the mailbox register, which can then generate an

interrupt.

The Local-to-CompactPCI Aperture 0 is mapped as a region of addressable space

from 0x1800 0000 – 0x183F FFFF (words), as shown in Table 4, section 5.

There are a number of registers in initialise before data can be read or written via this

address space.

• Unlock the CompactPCI Bridge System register. This requires a write to the

LB_CFG_SYSTEM (offset 0x78, BAR 0) with the value 0xA05F.

• Write the upper 8 bits of your destination address (in bytes) to the upper 8 bits

of the 32-bit Local Bus to CompactPCI Map 0 register (LB_MAP0_RES, offset

in bytes 0x5c ).

• Convert you lower 24-bit address to a word aligned value.

• Write/Read data from Local-to-CompactPCI Aperture 0 .

The diagram below illustrates this procedure.

In the example below the WritetoCompactPCIregisters(offset,data) function writes

data over the DSP’s Global bus, at a base address of 0x1800 0000 (words), the first

parameter passed to this function in the offset address in words, and the second is

the data to be written.

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 36

Page 36 of 61 SMT300Q SMT300Q User Guide V1.65

Receive Target address via Com-Port

Link

i.e. 0xFE12 3000

Unlock the system register in PCI bridge

#define LB_CFG_SYSTEM (0x78>>2) (divide by 4 to word align offset address of PCI

bridge register)

WritePCIRegisters((unsigned int)LB_CFG_SYSTEM,0xA05F); // Unlock Code

WritePCIRegisters((unsigned int)LB_CFG_SYSTEM,0x22008800); // Restore Value

Write Lower 24 bits of byte TargetAddress to the LB_MAP0_RES register

#define LB_MAP0_RES (0x5C>>2)

#define LB_MAP0_MEMORY_RW 0x00060000

#define LB_MAP0_ADDRESS_MASK 0xFF000000

WritePCIRegisters((unsigned int)LB_MAP0_RES,(unsigned int)(TargetAddress &

LB_MAP0_ADDRESS_MASK ) | LB_MAP0_MEMORY_RW);

// The LB_MAP0_MEMORY_RW must be Or’ed with the data to ensure the other register in

// the 32-bit word has its correct value.

WritePCIApperture0((ByteToWord32(((TargetAddress) & ~LB_MAP0_ADDRESS_MASK))),Length,buffer);

Where

void WritePCIApperture0(unsigned int address,unsigned long Len gth,unsigned int *buffer)

{

unsigned int Index;

globalbuswriteClockMB(0x18000000 + address , Length , buffer);

}

Write WORD Aligned data to Local Aperture space 0.

Figure 8 : DSP Transfer via the Local Aperture 0

13.3.1 Global bus access protocol

In Figure 8, the WriteCompactPCIApperture function calls a function

C6xGlobalWriteClockMB().

This function enables the DSP’s global bus to transfer Length words from the DSP’s

internal memory map pointed to by buffer. The function puts the Global bust into burst

Page 37

Page 37 of 61 SMT300Q SMT300Q User Guide V1.65

mode. This interface allows a synchronous stream of data to be written to the 256

WORD input FIFO of the Local To CompactPCI aperture 0. For more information on

setting this mode from the DSP can be found in the SMT335 Users Guide. This

section concentrates on the burst mode interface and arbitration mechanism for the

DSP to CompactPCI Bridge aperture access.

The Global bus interface of the DSP uses the following signals to interface to the

local bus of the SMT300Q.

DSP Signals.

AE*, DE*, CE0*

AE*/DE* are active low address/Data enable signal driven by the SMT300Q, when

the DSP has ownership of the Bus this signal is driven low by the SMT300Q allowing

the DSP to drive the Address pins and Data pins.

CE0* is the Tri-state control for the DSP’s global bus control pins. This is permanently

tied low by the SMT300Q as the control signals are always enable.

STRB1*

This is the data strobe signal from the DSP’s global bus. It is driven low when the

DSP is carrying out an access cycle. The DSP waits for the RDY1* to be driven low

by the SMT300Q to indicate transfer has been completed. This transfer is carried out

in synchronous burst mode. The DSP signals when the burst transfer is completed

by pulling STAT0 low.

RDY1*

This is an active low transfer acknowledgement, driven by the SMT300Q to indicate

that the current transfer has been completed.

STAT0..STAT3

These comprise the DSP Status line. When all of the signals are logic ‘1’ then the

DSP Global bus interface is in an idle state. When any of these signals is driven low

the DSP is requesting ownership of the SMT300Q’s local bus. STAT0 has a special

meaning and is driven low by the DSP to indicate the last data packet transfer.

Page 38

A0..A30

The DSP’s global Bus address lines

D0..D31

The DSP’s global Bus data lines

IIOF0, IIOF1 & IIOF2

The DSP’s Interrupt signals. These are open collector signals on the SMT300Q.

They can be driven by the DSP to generate an interrupt to the host, or they can be

driven by the host to interrupt the DSP.

In the timing diagram below all signals change relative to the rising LCLK signal. This

signal is the H1 clock signal of the DSP when using the DSP global bus in

synchronous mode (see SMT335 User Guide).

TIMReq FIFO Full

LCLK

STAT[1.3]

STRB1

RDY1

STAT0

AE/DE

A[30..0]

D[31..0]

Figure 9 : Timing diagram for DSP local bus access

* LCLK Period =30nS, frequency is 33MHz.

The DSP initiates a global bus R/W by asserting the STRB1 low and STAT[1:3}

change (see TIM Spec for details of STAT[1..3]). Once the arbitration unit detects

this, it waits for the last cycle of the Local bus to be completed by the CompactPCI

Bridge, before allowing the DSP to become Bus Master. Once the DSP is Master the

arbitration unit drives AE and DE low to enable the DSP’s address and data lines.

RDY1 is driven low by the arbitor to indicate to the DSP, on the next rising LCLK, that

the data packet has been transferred. If the input FIFO (256 Words Deep) becomes

full, the arbitration logic de-asserts the RDY1 signal to indicate a hold-off state. Once

the data has been transferred from the FIFO to the CompactPCI bus RDY1 is reasserted to continue the transfer. The end of the burst access is indicated by

asserting STAT0 low. If RDY1 is not active then STAT0 should remain asserted until

ready is asserted and the final data transaction has been completed.

It is possible for a deadlock condition to arise, i.e. the CompactPCI bus is trying to

read from the SMT300Q resources while the DSP is reading from the CompactPCI

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 39

Page 39 of 61 SMT300Q SMT300Q User Guide V1.65

Bus. If this happens, the arbitration unit gives the CompactPCI Bridge device priority

and services the HOST CompactPCI access before giving bus ownership back to the

DSP.

When running code composer applications to debug the DSP a reduction in the

speed of the debugger may be noticed. The DSP has priority when accessing the

local bus and any other accesses will only occur under the following conditions.

• Burst access finishes

• A deadlock condition occurs which forces the DSP to release ownership of the

Bus.

For multi-threaded applications the length of the DSP burst can be lowered to allow

CompactPCI bus R/W cycles to snatch cycles from the DSP.

Page 40

14 Interrupts

14.1 SMT300Q-To-CompactPCI Interrupts

CONTR OL EPLD

INTERRUPT

CONTROL

REGISTER

C40 IE

IBF IE

OBE IE

TBC IE

INTD

PCI Bridge

INTD

TIMIIOF0

TIMIIO F1

TIMIIOF2

JT A G IN T

INTERRUPT

CONTROL

REGISTER

DSP IIOF0

ENABLE

DSP IIOF1

ENABLE

DSP IIOF2

ENABLE

STA TUS

REGISTER

DSP INT

IBF INT

OBE INT

TBC INT

Figure 10 : SMT300Q to CompactPCI Interrupts

Interrupts can also be caused by the SMT300Q by writing or reading the mailbox

registers in the CompactPCI Bridge.

INTA

INTB

INTC

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 41

14.2 CompactPCI-To-SMT300Q Interrupts

CONTROL CPLD

CONTROL

REGISTER

PCI

Bridge

LINT c an

be caused

by any PCI

interrupt

e.g. Mailbox

LINT

LINT

IIOF0

IIOF1

IIOF2

INTREG

REGISTER

TIMIIOF0 IE

TIMIIOF1 IE

TIMIIOF2 IE

TIMIIOF0

TIMIIOF1

TIMIIOF2

Figure 11 : CompactPCI to SMT300Q Interrupts

14.3 Interrupt Registers

The following register are used to control CompactPCI-To-DSP and DSP-ToCompactPCI interrupts:

Note that Control Register (Offset 0x14, BAR1) and Interrupt Control Register (Offset

0x18, BAR1) are also used to control interrupts.

14.3.1 CompactPCI Interrupt Configuration Register(Offset 0x4C, BAR0)

Bits Name Description

31 MAILBOX Mailbox Interrupt Enable: Enables a CompactPCI interrupt

from the mailbox unit

30 LOCAL Local Bus Direct Interrupt Enable: Enables direct local bus

to CompactPCI interrupts

29 MASTER_PI CompactPCI Master Local Interrupt Enable: (see V3

datasheet)

28 SLAVE_PI CompactPCI Slave Local Interrupt Enable: (see V3

datasheet)

27 OUT-POST I2O Outbound Post List Not Empty: (see V3 datasheet)

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 42

Page 42 of 61 SMT300Q SMT300Q User Guide V1.65

26 - Reserved

25 DMA1 DMA Channel 1 interrupt enable

24 DMA0 DMA Channel 0 interrupt enable

23-22 MODE_D INTD interrupt mode: Determines use of corresponding

interrupt pin

00 Active low level triggered input

01 High-to-low edge triggered input

10 Software cleared output. INTD pin is asserted via

an interrupt event and cleared through

CompactPCI_INT_STAT register

11 Reserved

21-20 MODE_C INTC interrupt mode (as MODE_D)

19-18 MODE_B INTB interrupt mode (as MODE_D)

17-16 MODE_A INTA interrupt mode (as MODE_D)

15 INTD_TO_LB 1=INTD will request LICU interrupts when the input is

active

0=INTD will never request LICU interrupts

14 INTC_TO_D When set INTC will act as interrupt request for INTD

output

13 INTB_TO_D When set INTB will act as interrupt request for INTD

output

12 INTA_TO_D When set INTA will act as interrupt request for INTD

output

11 INTD_TO_C When set INTD will act as interrupt request for INTC

output

10 INTC_TO_LB 1=INTC will request LICU interrupts when the input is

active

0=INTC will never request LICU interrupts

9 INTB_TO_C When set INTB will act as interrupt request for INTC

output

8 INTA_TO_C When set INTA will act as interrupt request for INTC

output

7 INTD_TO_B When set INTD will act as interrupt request for INTB

output

6 INTC_TO_B When set INTC will act as interrupt request for INTB

output

5 INTB_TO_LB 1=INTB will request LICU interrupts when the input is

Page 43

Page 43 of 61 SMT300Q SMT300Q User Guide V1.65

active

0=INTB will never request LICU interrupts

4 INTA_TO_B When set INTA will act as interrupt request for INTB

output

3 INTD_TO_A When set INTD will act as interrupt request for INTA

output

2 INTC_TO_A When set INTC will act as interrupt request for INTA

output

1 INTB_TO_A When set INTB will act as interrupt request for INTA

output

0 INTA_TO_LB 1=INTA will request LICU interrupts when the input is

active

0=INTA will never request LICU interrupts

Table 24 : CompactPCI Interrupt Configuration Register

14.3.2 CompactPCI Interrupt Status Register(Offset 0x48, BAR0)

Bits Name Description

31 MAILBOX Mailbox Interrupt:

1=Mailbox interrupt request active

0=No mailbox interrupts pending

Cleared by clearing MAIL_RD_STAT and

MAIL_WR_STAT

30 LOCAL Local bus direct interrupt:

1=Local bus master requests a CompactPCI interrupt

0=No operation

This bit is set by writing 1 and cleared by writing 0

29-28 - Reserved

27 OUT_POST I2O outbound post list not empty: (see V3 datasheet)

26 - Reserved

25 DMA1 DMA channel 1 interrupt

24 DMA0 DMA channel 0 interrupt

23-15 - Reserved

14 INTC_TO_D INTD output from INTC input: when set (1) an interrupt has

occurred on INTC

13 INTB_TO_D INTD output from INTB input: when set (1) an interrupt has

occurred on INTB

Page 44

Page 44 of 61 SMT300Q SMT300Q User Guide V1.65

12 INTA_TO_D INTD output from INTA input: when set (1) an interrupt has

occurred on INTA

11 INTD_TO_C INTC output from INTD input: when set (1) an interrupt has

occurred on INTD

10 - Reserved

9 INTB_TO_C INTC output from INTB input: when set (1) an interrupt has

occurred on INTB

8 INTA_TO_C INTC output from INTA input: when set (1) an interrupt has

occurred on INTA

7 INTD_TO_B INTB output from INTD input: when set (1) an interrupt has

occurred on INTD

6 INTC_TO_B INTB output from INTC input: when set (1) an interrupt has

occurred on INTC

5 - Reserved

4 INTA_TO_B INTB output from INTA input: when set (1) an interrupt has

occurred on INTA

3 INTD_TO_A INTA output from INTD input: when set (1) an interrupt has

occurred on INTD

2 INTC_TO_A INTA output from INTC input: when set (1) an interrupt has

occurred on INTC

1 INTB_TO_A INTA output from INTB input: when set (1) an interrupt has

occurred on INTB

0 - Reserved

Table 25 : CompactPCI Interrupt Status Register

14.3.3 Local Bus Interrupt Mask Register(Offset 0x77, BAR0)

Bits Name Description

7 MAILBOX Global mailbox interrupt enable

6 CompactPCI_RD CompactPCI read error interrupt enable

5 CompactPCI_WR CompactPCI write error interrupt enable

4 CompactPCI_INT Global CompactPCI interrupt to local interrupt

enable

3 CompactPCI_PERR CompactPCI parity error interrupt enable

2 I2O_QWR I2O inbound post queue write interrupt enable

1 DMA1 DMA channel 1 interrupt enable

Page 45

Page 45 of 61 SMT300Q SMT300Q User Guide V1.65

0 DMA0 DMA channel 0 interrupt enable

Table 26 : Local Bus Interrupt Mask Register

14.3.4 Local Bus Interrupt Status Register(Offset 0x76, BAR0)

Bits Name Description

7 MAILBOX 1=interrupt has been requested by one or more of

the mailbox registers

0=no mailbox interrupts pending

6 CompactPCI_RD See V3 datasheet

5 CompactPCI_WR See V3 datasheet

4 CompactPCI_INT See V3 datasheet

3 CompactPCI_PERR See V3 datasheet

2 I2O_QWR See V3 datasheet

1 DMA1 See V3 datasheet

0 DMA0 See V3 datasheet

Table 27 : Local Bus Interrupt Status Register

14.3.5 CompactPCI Mailbox WRITE/READ Interrupt Control Register(Offset:

Write 0xD0, BAR0 Read 0xD2, BAR0)

Bits Name Description

15 EN15 Local interrupts on CompactPCI bus writes/reads to

mailbox15 enable

14 EN14 Same as above for mailbox 14

13 EN13 Same as above for mailbox 13

12 EN12 Same as above for mailbox 12

11 EN11 Same as above for mailbox 11

10 EN10 Same as above for mailbox 10

9 EN9 Same as above for mailbox 9

8 EN8 Same as above for mailbox 8

7 EN7 Same as above for mailbox 7

6 EN6 Same as above for mailbox 6

5 EN5 Same as above for mailbox 5

4 EN4 Same as above for mailbox 4

3 EN3 Same as above for mailbox 3

Page 46

Page 46 of 61 SMT300Q SMT300Q User Guide V1.65

2 EN2 Same as above for mailbox 2

1 EN1 Same as above for mailbox 1

0 EN0 Same as above for mailbox 0

Table 28 : CompactPCI Mailbox WRITE/READ Interrupt Control Register

14.3.6 Local Bus Mailbox WRITE/READ Interrupt Control Register(Offset Write

0xD4, BAR0 Read 0xD6, BAR0)

Bits Name Description

15 EN15 CompactPCI interrupts on Local bus writes/reads to

mailbox15 enable

14 EN14 Same as above for mailbox 14

13 EN13 Same as above for mailbox 13

12 EN12 Same as above for mailbox 12

11 EN11 Same as above for mailbox 11

10 EN10 Same as above for mailbox 10

9 EN9 Same as above for mailbox 9

8 EN8 Same as above for mailbox 8

7 EN7 Same as above for mailbox 7

6 EN6 Same as above for mailbox 6

5 EN5 Same as above for mailbox 5

4 EN4 Same as above for mailbox 4

3 EN3 Same as above for mailbox 3

2 EN2 Same as above for mailbox 2

1 EN1 Same as above for mailbox 1

0 EN0 Same as above for mailbox 0

Table 29 : Local Bus Mailbox WRITE/READ Interrupt Control Register

Page 47

14.3.7 Mailbox Write/Read Interrupt Status Register(Offset: Write 0xD8, BAR0

Read 0xDA, BAR0)

Bits Name Description

15 EN15 1=Mailbox 15 has requested a CompactPCI or Local

write/read interrupt

0=Mailbox 15 has not requested a CompactPCI or Local

write/read interrupt

14 EN14 Same as above for mailbox 14

13 EN13 Same as above for mailbox 13

12 EN12 Same as above for mailbox 12

11 EN11 Same as above for mailbox 11

10 EN10 Same as above for mailbox 10

9 EN9 Same as above for mailbox 9

8 EN8 Same as above for mailbox 8

7 EN7 Same as above for mailbox 7

6 EN6 Same as above for mailbox 6

5 EN5 Same as above for mailbox 5

4 EN4 Same as above for mailbox 4

3 EN3 Same as above for mailbox 3

2 EN2 Same as above for mailbox 2

1 EN1 Same as above for mailbox 1

0 EN0 Same as above for mailbox 0

Register cleared by writing 1, writing 0 has no effect

Table 30 : Mailbox Write/Read Interrupt Status Register

14.3.8 INTREG Register(Offset 0x40, BAR1)

Bits Name Description

15 - Reserved

14 - Reserved

13 - Reserved

12 - Reserved

11 - Reserved

10 - Reserved

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 48

Page 48 of 61 SMT300Q SMT300Q User Guide V1.65

9 - Reserved

8 - Reserved

7 - Reserved

6 - Reserved

5 - Reserved

4 - Reserved

3 - Reserved

2 IIOF2EN PC to DSP TIMIIOF2 interrupt enable

1 IIOF1EN PC to DSP TIMIIOF1 interrupt enable

0 IIOF0EN PC to DSP TIMIIOF0 interrupt enable

Table 31 : INTREG Register

14.4 Example

The example below shows how the DSP can cause an interrupt on the PC by writing

to mailbox register 0.

The PC must first enable the interrupts, to do this the following register bits must be

altered, and an interrupt thread handler needs to be created.

CompactPCI Interrupt Configuration Register(Offset 0x4C, BAR0) – bit 31 must be

set.

Local Bus Interrupt Mask Register(Offset 0x77, BAR0) – bit 7 must be set.

Local Bus Mailbox WRITE/READ Interrupt Control Register(Offset Write 0xD4, BAR0

Read 0xD6, BAR0) – bit 0 of the write register (0xD4) must be set.*

An Interrupt service routine must be set up, in this the following register will need to

be cleared

Page 49

Mailbox Write/Read Interrupt Status Register(Offset: Write 0xD8, BAR0 Read 0xDA,

BAR0) – bit 0 of the write register (0xD8) must be cleared.**

Local Bus Interrupt Status Register(Offset 0x76, BAR0) – bit 7 must be cleared.

To cause the interrupt the DSP needs to write to the mailbox register in the V3 chip,

this is done by writing to address 0x1C0000C0 (this will write to the first four

mailboxes).

*These are two separate registers, one to enable interrupts on reads from the

mailbox registers the other to enable interrupts on writes to the mailbox registers.

**These are two separate registers, one shows interrupt status for reads from the

mailbox register the other to show interrupt status on writes to the mailbox registers.

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 50

)

)

)

)

)

)

)

)

15 Stand-Alone Mode

For the SMT300Q to operate in stand-alone mode Jumper J8 (Figure 14 : Jumper

Finder Diagram) must be installed and the Auxiliary power header (J1) connected.

The plug for the power connector is AMP part No 640440-8. The connector requires

wiring as shown in the pin diagram below. Wire of 0.3 mm2 core (22 AWG) should be

used.

Figure 12 : Auxiliary Power Connector

1

2

3

4

5

6

7

8

1

+12V

2

-12V

3

+5V

4

+5V

5

+3.3V

6

+3.3V

7

GND

8

GND

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 51

16 Performance Figures

The following performance figures are for the SMT300Q with the Rev. A1 V3

CompactPCI bridging device fitted and using a SMT335. Further performance figures

will be issued as faster V3 CompactPCI bridging devices become available and are

fitted to the SMT300Q.

The figures shown below may vary greatly depending on the application. Some of

the issues are:

PC Architecture and performance

Transfer parameters.

• The transfer size.

• Frequency of transfer.

• The layout of the target memory. (Scatter/Gather or contiguous)

Availability of the CompactPCI bus.

• Other devices on the CompactPCI bus.

• Debugging traffic on the bus.

• ComPort traffic.

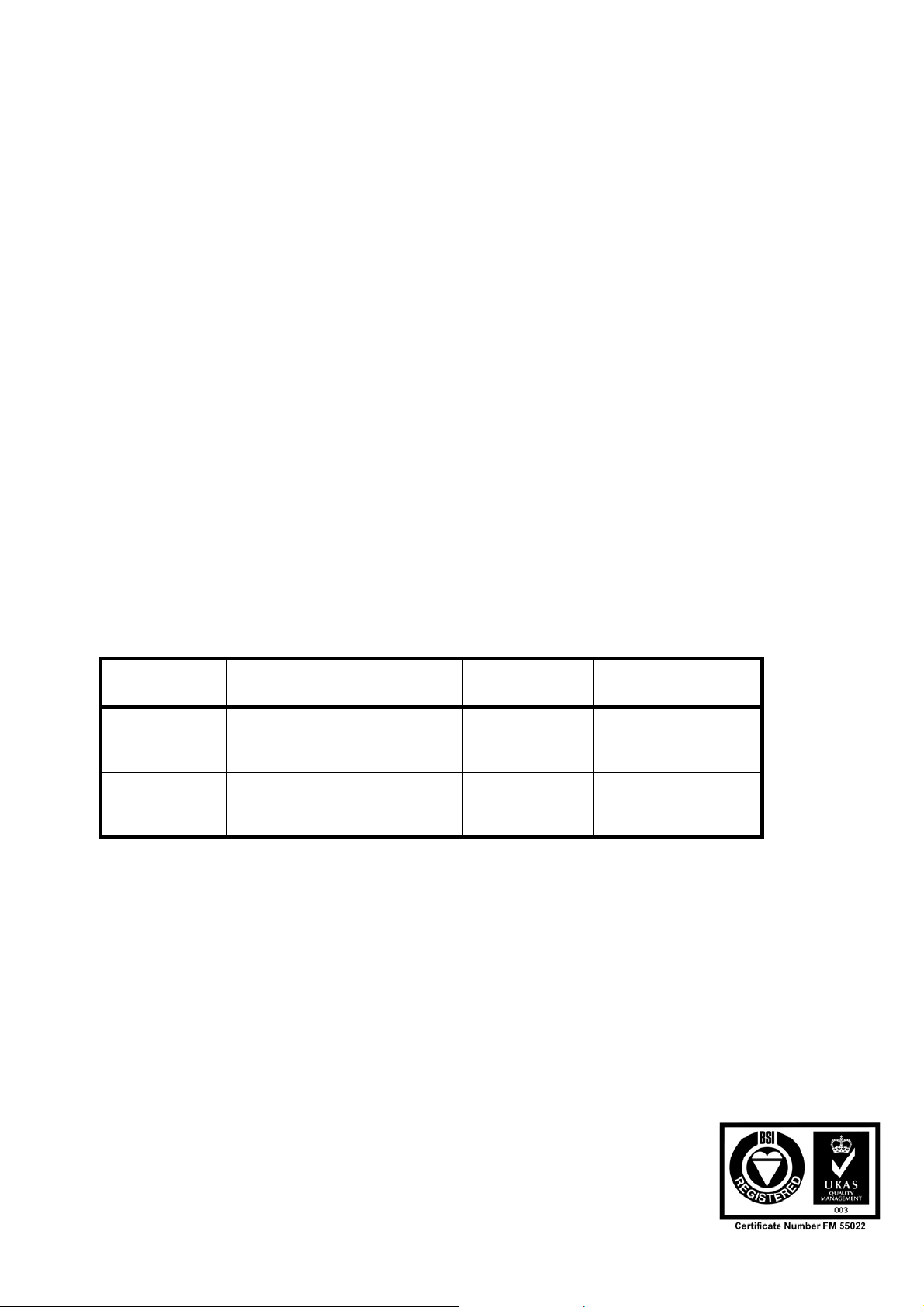

Transfer type MIN (Mb/s) MAX (Mb/s) AVERAGE

(Mb/s)

C60 Burst

Read To Host

Memory

C60 Burst

Write To Host

Memory

45 82 70 Will Vary depending

11 88 68 Will Vary depending

Table 32 : Performance Figures

Comments

on CompactPCI traffic

on CompactPCI traffic

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 52

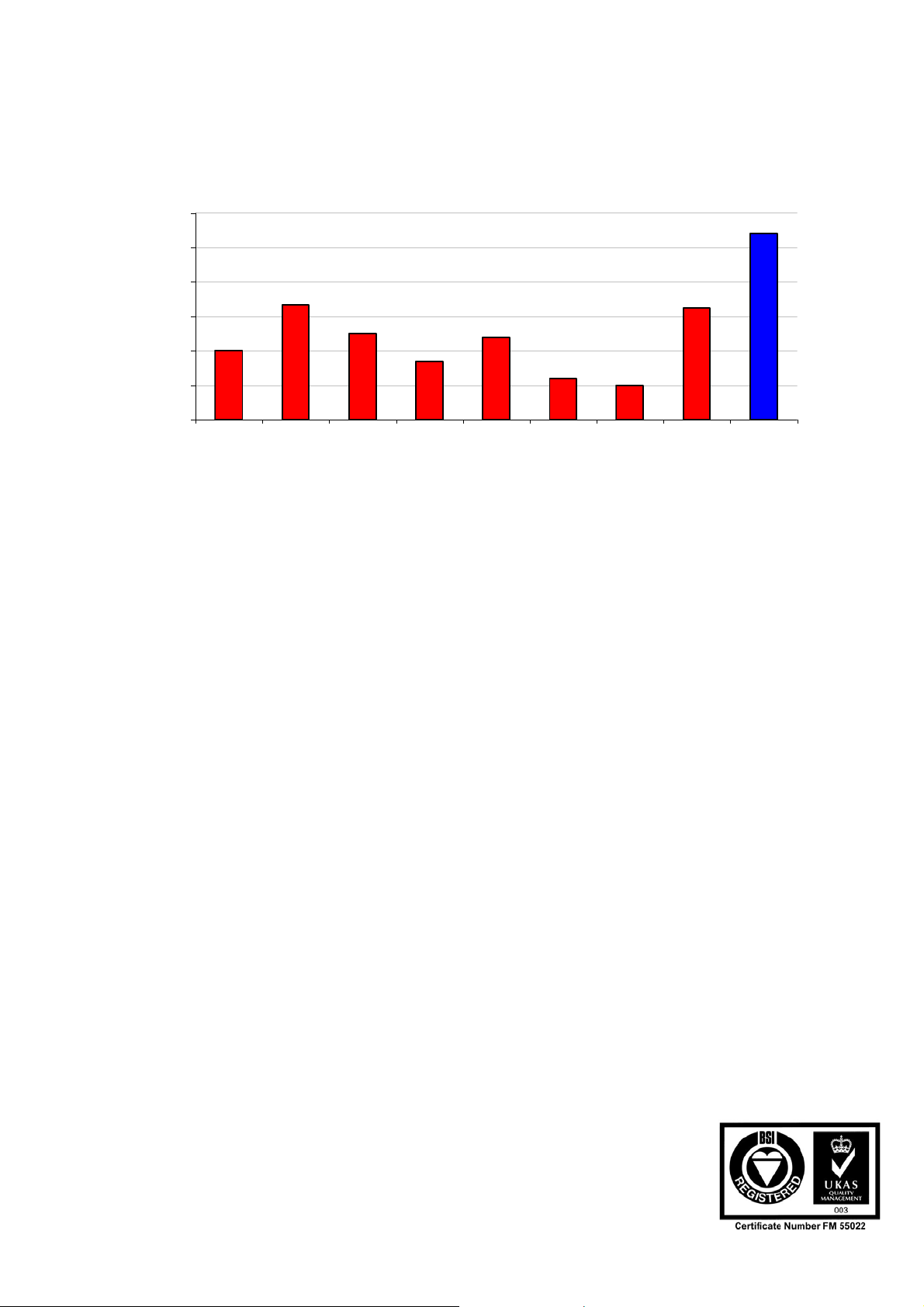

16.1 Relative JTAG speeds

Relative Emulator Speeds

3.00

2.50

2.00

1.50

1.00

1.00

0.50

Speed relative to XDS510

0.00

XDS510 FleXDS SPI525 XDS510PP

1.67

1.25

1.20

0.85

0.60

SPI515 XDS510PP Tiger SMT106 SMT310Q

Plus

Emulator

Figure 13 : JTAG speed Comparison chart

2.70

1.62

0.50

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 53

17 Mechanical Dimensions

The board size is 234 mm by 160 mm

18 Power consumption

The SMT300Q takes 3.3V and 5V power from the PC’s internal power supply. The

following current consumption figures were measured using a LEM current clamp

during a quiescent period.

Current drawn from 3.3v supply : 440 mA

Current drawn from 5v supply : 100 mA

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 54

19 Cables and Connectors

19.1 ComPorts

The cables used with FMS connectors are not supplied with the SMT300Q. You can

order them separately from Sundance with part number SMT500-FMSxx, where xx is

the cable length in centimetres.

19.2 Buffered ComPort Cabling

Connecting between buffered ComPorts requires a 1 to 1 cable; the SMT502-Buffer

is the recommended cable assembly and can be purchased separately.

Cable plugs 3M Scotchflex 10126-6000EL FES part 038740A

Plug shells 3M Scotchflex 10326-A200-00 FES part 038760D

Cable type 3M Scotchflex KUCKMPVVSB28-13PAIR FES part 038781E

This cable has 13 individual pairs, with an overall shield, and an outer diameter of

7mm. Cable length should be as short as possible. The maximum tested cable length

is 1 meter.

On reset, each ComPort initialises to being either an input or an output.

Do not connect ‘Reset to Input’ ComPorts together.

Do not connect ‘Reset to Output’ ComPorts together.

However if this should occur, no damage will result, because ComPort direction

signals disable relevant ComPorts.

The following table shows connector pin-out and cable pair connections. This is

important, as the critical signals must be paired with a ground as shown. The

allocation to twisted pairs is based on grouping the data signals because they change

at the same time, so that crosstalk is not an issue. Each control signal has its own

ground:

User Manual (QCF42); Version 3.0, 8/11/00; © Sundance Multiprocessor Technology Ltd. 1999

Page 55

Page 55 of 61 SMT300Q SMT300Q User Guide V1.65

Pin Twisted

Pair

1 1 I/O_OUT I/O_IN 15 8 D2 D2

2 1 GND GND 16 8 D3 D3

3 2 I/O_IN I/O_OUT 17 9 D4 D4

4 2 GND GND 18 9 D5 D5

5 3 /CSTRB /CSTRB 19 10 D6 D6

6 3 GND GND 20 10 D7 D7

7 4 /CRDY /CRDY 21 11 VCC VCC

8 4 GND GND 22 11 GND GND

9 5 /CREQ /CREQ 23 12 /RST_OUT /RST_IN

10 5 GND GND 24 12 GND GND

11 6 /CACK /CACK 25 13 /RST_IN /RST_OUT

12 6 GND GND 26 13 GND GND

13 7 D0 D0 SHELL - SHIELD SHIELD

14 7 D1 D1

RTI

Signal

RTO

Signal

Pin Twisted

Pair

RTI Signal RTO Signal

Table 33 : Buffered ComPort connector pin out

The overall shield is attached to the body of the metal plug shell.

The signal VCC is fused on the board at 1 amp; it automatically resets when the load

is removed.

When the buffered ComPort is reset to input, pins 1 and 23 are always driven and

pins 3 and 25 are always receivers. When the buffered ComPort is reset to output,

pins 3 and 25 are always driven and pins 1 and 23 are always receivers.

Page 56

Page 56 of 61 SMT300Q SMT300Q User Guide V1.65

19.3 JTAG back panel cabling

The 20-way JTAG connectors require the following cabling components:

Cable plugs 3M Scotchflex 10120-6000EL, FES part 038739R

Plug shells 3M Scotchflex 10320-A200-00, FES part 038759A

Cable type 3M Scotchflex KUCKMPVVSB28-10PAIR, FES part 038780G

When the SMT300Q is configured as a Slave using the Buffered JTAG connector as

a JTAG source, the buffered connector pins are used as follows:

Pin Signal Direction Description

1 TDI IN JTAG data in

2 GND

3 TDO OUT JTAG data out

4 GND

5 TMS IN JTAG Test mode select

6 GND

7 TCK IN JTAG clock, up to 10MHz

8 GND

9 TCK_RET OUT JTAG clock return

10 GND

11 /TRST IN JTAG Reset

12 GND

13 /RESET IN Board Reset in

14 PD OUT Presence detect, +5V 1A fused

15 /DETECT IN Detect external JTAG controller when grounded

16 CONFIG OPEN COLL Global open collector C4x CONFIG

17 EMU0 OUT Buffered EMU0 output

18 EMU1 OUT Buffered EMU1 output

19 SPARE1

20 SPARE2

Table 34 : Buffered JTAG connector pin functionality as JTAG source

When the SMT300Q is configured as a Master, using the Buffered JTAG connector to

connect to a JTAG slave, the buffered connector pins are used as follows:

Page 57

Page 57 of 61 SMT300Q SMT300Q User Guide V1.65

Pin Signal Direction Description

1 TDI OUT JTAG data out

2 GND

3 TDO IN JTAG data in

4 GND

5 TMS OUT JTAG Test mode select

6 GND

7 TCK OUT JTAG clock 10MHz

8 GND

9 TCK_RET IN JTAG clock return

10 GND

11 /TRST OUT JTAG Reset

12 GND

13 /RESET OUT Board Reset out

14 PD IN Presence detect when pulled high