Page 1

USER GUIDE

FOR

P

P

Parallel Application from Rapid Simulation

All rights reserved. No part of this document may be reproduced, translated,

stored in a retrieval system, or transmitted, in any form or by any means,

electronic, mechanical, photocopying, recording or otherwise, without prior

A

A

Copyright © Sundance

written permission of the owner.

Note:

R

R

S

S

If this copy is no longer in use, return to sender.

Page 2

APPROVAL PAGE

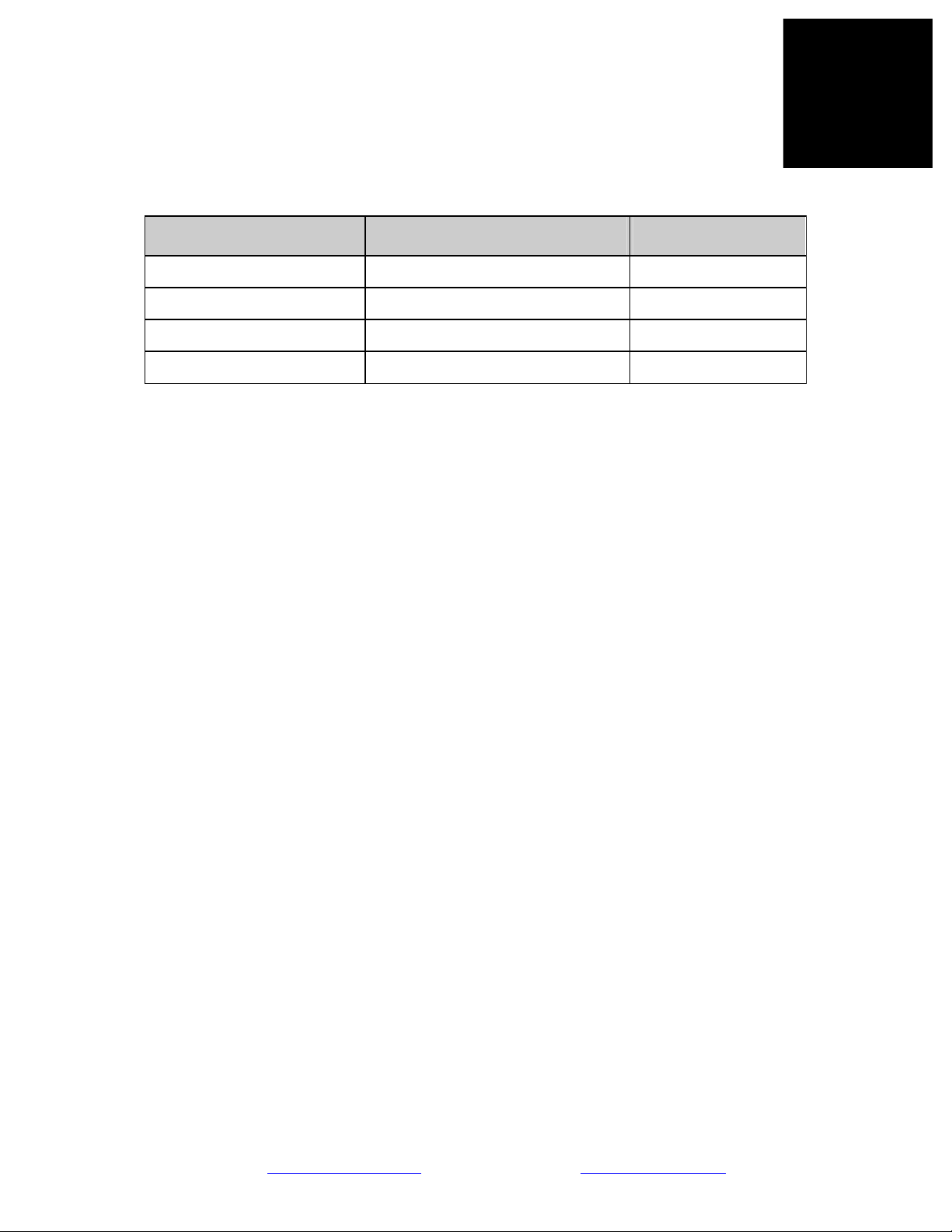

Name Signature Date

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 3

DOCUMENT HISTORY

Date Changes Made Issue Initials

Versions to accompany PARS releases < 10.2 MA, SM

29-Jul-2008 Edits during testing of PARS 10.2 6.0 NN

In Progress Rewrite for PARS 11 11-WIP BV

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 4

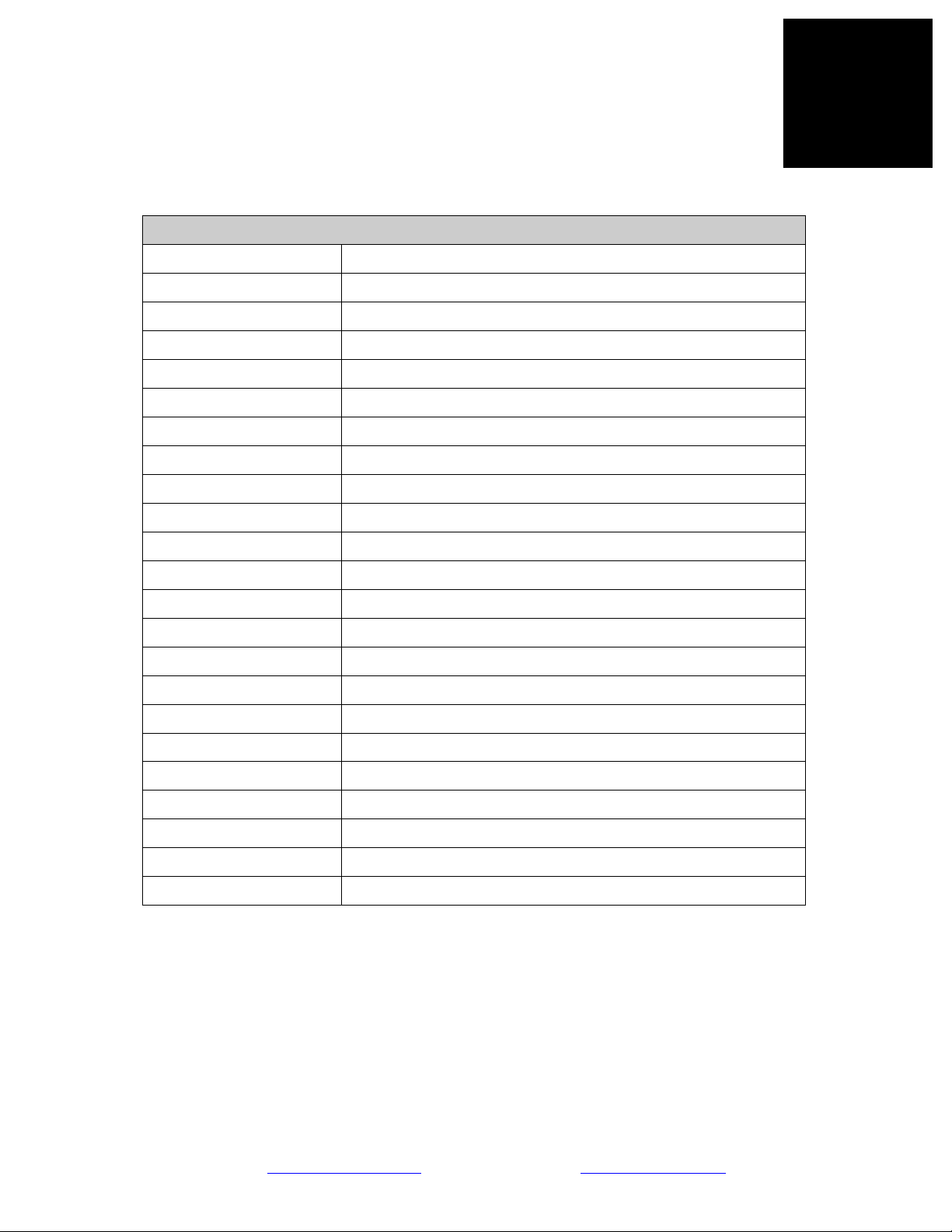

LIST OF ABBREVIATIONS

Abbreviation Explanation

CP Communications Port

DSP Digital Signal Processor

FPGA Field Programmable Gate Array

NA Not Applicable

PC Personal Computer

PCB Printed Circuit Board

PCI Peripheral Component Interconnect

PMC PCI Mezzanine Card

PrPMC Processor PMC

RF Radio Frequency

RSL RocketIO Serial Link

SDB Sundance Digital Bus

SDRAM Synchronous Dynamic Random Access Memory

SHB Sundance High-speed Bus

TBD To Be Determined

TI Texas Instruments

XMC Switched Mezzanine Card

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 5

TABLE OF CONTENTS

1. PREFACE......................................................................................................................................................... 11

1.1. INTENDED AUDIENCE ................................................................................................................................11

1.2. RELATED DOCUMENTATION ......................................................................................................................11

1.3. TRADEMARKS ...................................................................................................................................... 11

2. INTRODUCTION TO PARS.......................................................................................................................... 12

2.1. OVERVIEW............................................................................................................................................. 12

2.1.1. What is PARS?..................................................................................................................................... 12

2.1.2. Features............................................................................................................................................... 13

2.1.3. Benefits ................................................................................................................................................13

2.2. REQUIREMENTS ................................................................................................................................... 13

2.3. DEVELOPMENT FLOW ........................................................................................................................14

2.4. WALKTHRU................................................................................................................................................ 16

3. MODEL DEVELOPMENT ............................................................................................................................ 34

3.1. OVERVIEW................................................................................................................................................ 34

3.1.1. How PARS works with a model ...........................................................................................................34

3.2. PREPARING FOR CODE GENERATION ..........................................................................................................35

3.2.1. Solver Configuration ...........................................................................................................................36

3.2.2. Hardware Implementation...................................................................................................................37

3.2.3. Summary .............................................................................................................................................. 37

3.3. HARDWARE PROFILE SELECTION ...............................................................................................................38

3.4. PARTITIONING ........................................................................................................................................... 39

3.4.1. Connections between subsystems ........................................................................................................39

3.4.2. Connections between processors .........................................................................................................39

3.4.3. Data Types for Connections ................................................................................................................ 42

3.5. ALLOCATING PROCESSOR RESOURCES ...................................................................................................... 43

3.6. PRE-BUILT TASKS ..................................................................................................................................... 44

3.6.1. DSP PB Tasks......................................................................................................................................44

3.6.2. FPGA PB Tasks ................................................................................................................................... 44

3.6.3. SCOM PB Tasks ..................................................................................................................................44

3.7. HOST TESTBENCH STRATEGY ....................................................................................................................44

3.8. GENERATING APPLICATIONS ...................................................................................................................... 44

3.8.1. Pre-Compiled Libraries.......................................................................................................................44

3.8.2. FPGA Processors in Designs .............................................................................................................. 44

3.9. RUNNING THE TEST BENCH........................................................................................................................ 45

3.10. RESTRICTIONS ........................................................................................................................................... 45

3.11. COMMON ISSUES........................................................................................................................................45

3.11.1. Loop Deadlock................................................................................................................................45

3.11.2. Out-of-order Deadlock ................................................................................................................... 45

3.11.3. Rate Deadlock................................................................................................................................. 45

4. PARS COMPONENT REFERENCE ............................................................................................................46

4.1. PARS CONTROL PANEL .............................................................................................................................. 46

4.1.1. Overview..............................................................................................................................................46

4.1.2. File Menu ............................................................................................................................................46

4.1.3. PARS Menu.......................................................................................................................................... 46

4.1.4. Tool Menu............................................................................................................................................ 46

4.1.5. Help Menu ...........................................................................................................................................46

4.2. DSP TASKS............................................................................................................................................... 46

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 6

4.2.1. Overview..............................................................................................................................................46

4.2.2. Mask Options.......................................................................................................................................46

4.2.3. GRT vs. ERT ........................................................................................................................................ 47

4.3. FPGA TASKS............................................................................................................................................ 47

4.3.1. Overview..............................................................................................................................................47

4.3.2. Mask Options.......................................................................................................................................47

4.3.3. Clock Domain Considerations............................................................................................................. 47

4.3.4. HDLCoder vs. Xilinx System Generator .............................................................................................. 47

4.4. PARS DIAMOND LIBRARY........................................................................................................................47

4.4.1. Overview..............................................................................................................................................47

4.4.2. Diamond Blockset................................................................................................................................ 47

4.4.3. Device Driver Tasks ............................................................................................................................47

4.4.4. DSP Tasks............................................................................................................................................ 48

4.4.5. FPGA Tasks.........................................................................................................................................48

4.4.6. SCOM Tasks ........................................................................................................................................ 49

4.5. DSP PRE-BUILT TASKS ............................................................................................................................49

4.5.1. Overview..............................................................................................................................................49

4.5.2. Usage................................................................................................................................................... 49

4.5.3. Template of a DSP PB Task ................................................................................................................ 49

4.5.4. CPBT Operation for DSP Tasks .......................................................................................................... 49

4.5.5. Bind Input Block .................................................................................................................................. 49

4.5.6. Bind Output Block ............................................................................................................................... 49

4.5.7. Examples .............................................................................................................................................50

4.6. FPGA PRE-BUILT TASKS ......................................................................................................................50

4.6.1. Overview..............................................................................................................................................50

4.6.2. Usage................................................................................................................................................... 50

4.6.3. Template of an FPGA PB Task............................................................................................................ 50

4.6.4. CPBT Operation for FPGA Tasks ....................................................................................................... 50

4.6.5. Examples .............................................................................................................................................50

4.7. SCOM WRAPPER TASKS...........................................................................................................................50

4.7.1. Overview..............................................................................................................................................50

4.7.2. Usage................................................................................................................................................... 50

4.7.3. Hierarchy of SCOM Task Wrappers.................................................................................................... 50

4.7.4. SCOM Task Table................................................................................................................................50

4.7.5. Deriving New Variants ........................................................................................................................ 50

4.7.6. Examples .............................................................................................................................................50

4.8. HARDWARE DESCRIPTION FILE ................................................................................................................. 50

4.8.1. Overview..............................................................................................................................................50

4.8.2. Sections (.m file based input)...............................................................................................................50

4.8.3. Model Based Input (.mdl file) .............................................................................................................. 51

5. PARS GENERATED CODE .......................................................................................................................... 52

5.1. PARS HIERARCHY.................................................................................................................................... 52

5.2. DSP TASKS ...............................................................................................................................................52

5.2.1. Structure ..............................................................................................................................................52

5.2.2. Files (Production)................................................................................................................................ 52

5.2.3. Variants ............................................................................................................................................... 52

5.3. FPGA TASKS ............................................................................................................................................ 52

5.3.1. Structure ..............................................................................................................................................52

5.3.2. Common Files...................................................................................................................................... 52

5.3.3. Scalar vs. Vector Inputs....................................................................................................................... 52

5.3.4. Files .....................................................................................................................................................52

5.4. PRE-BUILT TASKS ................................................................................................................................... 53

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 7

5.4.1. Overview..............................................................................................................................................53

5.4.2. Files .....................................................................................................................................................53

5.5. PARS CONFIGURATION FILE.....................................................................................................................53

5.5.1. Overview..............................................................................................................................................53

5.5.2. Diamond Configuration Block............................................................................................................. 53

5.5.3. Sections................................................................................................................................................53

5.6. PARS APPLICATION .............................................................................................................................54

5.6.1. General Behavior ................................................................................................................................ 54

5.6.2. Boot Progression ................................................................................................................................. 54

6. HARDWARE ................................................................................................................................................... 55

6.1. PARS TARGET HARDWARE ...................................................................................................................... 55

6.1.1. Types....................................................................................................................................................55

6.1.2. Pre-Condition Requirements ...............................................................................................................55

6.1.3. Sundance Hardware ............................................................................................................................ 55

6.1.4. VMetro Hardware................................................................................................................................ 55

6.1.5. 3rd Party Board Support ..................................................................................................................... 55

7. ADVANCED FEATURES............................................................................................................................... 56

7.1. TASK CONTROL/STATUS INTERFACE......................................................................................................... 56

7.1.1. Overview..............................................................................................................................................56

7.1.2. AB105 Protocol Module ......................................................................................................................56

7.1.3. Task IDs...............................................................................................................................................56

7.1.4. Taskstate Protocol ............................................................................................................................... 56

7.1.5. Operation under HIL ...........................................................................................................................56

7.1.6. Operation in Standalone (embedded) Systems ....................................................................................56

7.2. PROFILING INTERFACE............................................................................................................................... 56

7.2.1. Overview..............................................................................................................................................56

7.2.2. PARS-Profile Module .......................................................................................................................... 56

7.2.3. Profile Report ...................................................................................................................................... 56

7.2.4. Operation under HIL ...........................................................................................................................56

7.2.5. Operation in Standalone (embedded) Systems ....................................................................................56

7.3. DEBUGGING (LOG) INTERFACE ................................................................................................................ 56

7.3.1. Overview..............................................................................................................................................56

7.3.2. Logging System Pre-Built Tasks ..........................................................................................................56

7.3.3. Tracking Task Dataflow ......................................................................................................................56

7.3.4. DSP PB Tasks......................................................................................................................................56

7.3.5. Log Report Format .............................................................................................................................. 56

7.4. DEBUGGING (JTAG EMULATORS).............................................................................................................56

7.4.1. Overview..............................................................................................................................................56

7.4.2. app2coff ............................................................................................................................................... 57

7.4.3. TI CCS Operation................................................................................................................................57

7.5. REBUILDING OUTSIDE OF PARS................................................................................................................ 57

7.5.1. Application Build Script ......................................................................................................................57

7.5.2. Changing Debugging Level................................................................................................................. 57

8. DEMOS AND EXAMPLES ............................................................................................................................ 58

8.1. ADDONE INTEGER................................................................................................................................... 58

8.1.1. Description ..........................................................................................................................................58

8.1.2. DSP Target .......................................................................................................................................... 58

8.1.3. FPGA Target .......................................................................................................................................58

8.1.4. Profiling Output...................................................................................................................................58

8.2. FILTER BANK ............................................................................................................................................58

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 8

8.2.1. Description ..........................................................................................................................................58

8.2.2. DSP Target .......................................................................................................................................... 60

8.2.3. FPGA Target .......................................................................................................................................60

8.2.4. Profiling Output...................................................................................................................................60

8.3. LEAST MEAN SQUARE ERROR ................................................................................................................... 60

8.3.1. Description ..........................................................................................................................................60

8.3.2. DSP Target .......................................................................................................................................... 60

8.3.3. FPGA Target .......................................................................................................................................60

8.3.4. Profiling Output...................................................................................................................................60

8.4. ACOUSTIC NOISE CANCELLATION.............................................................................................................. 60

8.4.1. Description ..........................................................................................................................................60

8.4.2. DSP Target .......................................................................................................................................... 60

8.4.3. FPGA Target (?)..................................................................................................................................60

8.4.4. Profile Output...................................................................................................................................... 60

8.5. FEEDBACK CONTROL SYSTEM (GM) ......................................................................................................... 60

8.5.1. Description ..........................................................................................................................................61

8.5.2. DSP Target .......................................................................................................................................... 61

8.5.3. FPGA Target .......................................................................................................................................61

8.5.4. Profiling Output...................................................................................................................................61

8.6. AEROSPACE GUIDANCE ............................................................................................................................61

8.6.1. Description ..........................................................................................................................................61

8.6.2. DSP Target .......................................................................................................................................... 61

8.6.3. Profiling Output...................................................................................................................................61

9. INSTALLATION ............................................................................................................................................. 62

9.1. RESTRICTIONS ........................................................................................................................................... 62

9.2. INSTALLED HIERARCHY ............................................................................................................................ 62

9.3. STEP-BY-STEP WALKTHRU ....................................................................................................................... 62

9.4. VERIFYING THE INSTALLATION.................................................................................................................. 62

10. ADDONS...................................................................................................................................................... 63

10.1. OVERVIEW ................................................................................................................................................ 63

10.2. SMT6045 (UNIVERSAL TARGET SERVICES)..............................................................................................63

10.2.1. Overview.........................................................................................................................................63

10.2.2. Features.......................................................................................................................................... 63

10.2.3. Installed Hierarchy......................................................................................................................... 63

10.2.4. Pre-Built Task Descriptions............................................................................................................63

10.2.5. DSP Interface Descriptions ............................................................................................................ 63

10.2.6. HOST Interface Descriptions..........................................................................................................63

10.2.7. FPGA Modules Descriptions ..........................................................................................................63

10.3. MODULES.................................................................................................................................................. 63

10.3.1. Overview.........................................................................................................................................63

10.3.2. Features.......................................................................................................................................... 63

10.3.3. Installed Hierarchy......................................................................................................................... 63

10.3.4. Pre-Built Task Descriptions............................................................................................................63

10.3.5. DSP Interface Descriptions ............................................................................................................ 63

10.3.6. HOST Interface Descriptions..........................................................................................................63

10.3.7. FPGA Modules Descriptions ..........................................................................................................64

10.4. SCOM (SUNDANCE COMMUNICATION INTERFACE) ..................................................................................64

10.4.1. Overview.........................................................................................................................................64

10.4.2. Features.......................................................................................................................................... 64

10.4.3. Installed Hierarchy......................................................................................................................... 64

10.4.4. Nomenclature.................................................................................................................................. 64

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 9

10.4.5. Pre-Defined Wrapper Interface ......................................................................................................64

10.4.6. Derivation of N-port Wrappers.......................................................................................................64

11. KNOWLEDGE BASE ................................................................................................................................ 65

11.1. DESCRIPTION............................................................................................................................................. 65

11.2. ENTRIES..................................................................................................................................................... 65

12. REFERENCES AND LINKS .....................................................................................................................66

13. LICENSING AND INTELLECTUAL PROPERTY RIGHTS ...............................................................67

14. INDEX.......................................................................................................................................................... 70

TABLE OF FIGURES and TABLES

Figure 1 - PARS Bird's Eye View.............................................................................................................................. 12

Figure 2 - PARS development cycle.......................................................................................................................... 15

Figure 3 - Invoking PARS.......................................................................................................................................... 16

Figure 4 - PARS Control Panel.................................................................................................................................. 16

Figure 5 - Invoking PARSOptions ............................................................................................................................. 17

Figure 6 - The PARSOptions dialog .......................................................................................................................... 17

Figure 7 - Select Hardware Profile............................................................................................................................. 18

Figure 8 - Select DSP task creation method............................................................................................................... 18

Figure 9 - Opening a model in PARS.........................................................................................................................19

Figure 10 - Select model file to open ......................................................................................................................... 19

Figure 11 - AddOne starting model............................................................................................................................ 20

Figure 12 - Workspace created when opening model in PARS................................................................................. 20

Figure 13 - Select blocks for grouping....................................................................................................................... 21

Figure 14 - Create a subsystem from the grouped blocks.......................................................................................... 21

Figure 15 - Subsystem created ................................................................................................................................... 22

Figure 16 - Select everything else.............................................................................................................................. 22

Figure 17 - Subsystem 2 created, but unsightly ......................................................................................................... 23

Figure 18 - Rearranged and renamed ......................................................................................................................... 23

Figure 19 - Select subsystem and create DSP Task ................................................................................................... 24

Figure 20 - Select subsystem and create HOST task .................................................................................................25

Figure 21 - AddOne model fully assigned ................................................................................................................. 25

Figure 22 - Add task mask parameters (DSP Task)................................................................................................... 26

Figure 23 - HOST task "look under mask" ................................................................................................................ 26

Figure 24 - AddOne model running (in simulation) ..................................................................................................27

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 10

Figure 25 - Generate application................................................................................................................................ 27

Figure 26 - PARS working......................................................................................................................................... 28

Figure 27 - PARS finished, testbench generated ....................................................................................................... 28

Figure 28 – Link-layer interface selection ................................................................................................................. 29

Figure 29 - AddOne model running on hardware ...................................................................................................... 29

Figure 30 - Select target with FPGA.......................................................................................................................... 30

Figure 31 - Select "HDL Coder" FPGA task creation mode...................................................................................... 30

Figure 32 - Re-assign DSP task to FPGA task........................................................................................................... 31

Figure 33 - AddOne model on FPGA task................................................................................................................. 31

Figure 34 - Simulate, then generate the re-targeted application ................................................................................ 32

Figure 35 - PARS Generates FPGA-based application.............................................................................................. 32

Figure 36 - FPGA model execution on hardware (note the error) ............................................................................. 33

Figure 37 - FPGA Execution with pipeline delay (correct) ....................................................................................... 33

Figure 38 - PARS workflow and automation............................................................................................................. 34

Figure 39 - Simulink model Solver parameters..........................................................................................................36

Figure 40 - Simulink model Hardware Implementation parameters.......................................................................... 37

Figure 41 - Selecting a hardware profile.................................................................................................................... 38

Figure 42 - Processors and wires in a hardware system............................................................................................. 40

Figure 43 - How routing is implemented between processors................................................................................... 41

Figure 44 - Setting data types on Input/Output ports................................................................................................. 42

Figure 45 - Shortcut buttons on PARS control panel................................................................................................. 43

Figure 46 - General DSP task parameters panel ........................................................................................................43

Figure 47 - Filter Bank original model....................................................................................................................... 59

Figure 48 - PARS versions as seen by Matlab........................................................................................................... 62

Table 1 - Matrix of PARS features vs. tools required................................................................................................ 14

Table 2 - Model Parameters for Code Generation ..................................................................................................... 37

Table 3 - Allowable connection data types in PARS................................................................................................. 42

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 11

Revision 11-wip-7

Page 11 of 70

1. PREFACE

This manual is a reference for generating distributed-memory multiprocessing

applications from Simulink® models.

1.1. INTENDED AUDIENCE

Before you begin, you should be familiar with developing and managing simulation models in

Simulink®. The software toolkit presented in this document will help an experienced Simulink®

architect to realize their model on special purpose digital signal processing hardware.

It will be extremely beneficial if experience with embedded digital signal processing algorithms and

tools from the Texas Instruments family of processors is available as well. For designs targeting fieldprogrammable gate array (FPGA) technology, experience with implementation of designs in very high

level hardware description language (VHDL) and tools from the Xilinx family of FPGAs will be

beneficial.

It is not necessary for the Simulink® architect to have these skills directly, but individuals should be on

hand with these skills to assist the architect with optimization options, design trade-offs and analysis of

performance results.

1.2. RELATED DOCUMENTATION

http://www.3l.com/user-guides/3l-diamond-for-sundance

http://www.3l.com/how-it-works

http://www.mathworks.com/products/rtw/

http://www.mathworks.com/products/rtwembedded/

http://www.mathworks.com/products/slhdlcoder/

http://focus.ti.com/docs/toolsw/folders/print/ccstudio.html

http://www.xilinx.com/ise/logic_design_prod/foundation.htm

http://www.xilinx.com/support/documentation/dt_sysgendsp_sysgen10-1.htm

1.3. TRADEMARKS

Simulink®, Real Time Workshop® (Embedded Coder™) and Simulink® HDL Coder™ are registered

trademarks of The MathWorks, Inc1.

PARS™ is a trademark of Sundance DSP, Inc.

VelociTI, ExpressDSP and Code Composer Studio are registered trademarks of Texas Instruments

Incorporated

XtremeDSP, Virtex and ISE are registered trademarks of Xilinx, Inc.

1

http://www.mathworks.com/company/aboutus/policies_st

atements/trademarks.html

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 12

Revision 11-wip-7

Page 12 of 70

2. INTRODUCTION TO PARS

2.1. OVERVIEW

This section introduces PARS, describes its operation, features and enumerates the

software requirements needed to use the product. A simplistic model is used to “walk thru” using

PARS.

2.1.1. What is PARS?

PARS stands for ‘Parallel Application from Rapid Simulation’ and is a toolkit for generating multip

rocessor applications from Simulink® models.

Figure 1 - PARS Bird's Eye View

The above diagram graphically illustrates how PARS enables Simulink® models to be deployed on

multi-DSP and multi-FPGA hardware.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 13

Revision 11-wip-7

Page 13 of 70

By interfacing with several toolkits, development tool chains and a distributed memory

multiprocessing operating system, PARS is able to accomplish the incredible feat of

automating the process of realizing model-based designs into deployable firmware on

embedded hardware systems.

2.1.2. Features

• Target embedded systems consisting of TI DSP (C64xx, C67xx) and Xilinx FPGA

• Manages all inter-processor communication and synchronization

• Generates test benches for Hardware-In-The-Loop simulation

• Generates stand-alone (ROM-able) applications

2.1.3. Benefits

• Maintain the system specification in model-based design space

• Complete and seamless access to wealth of visualization and diagnostic tools in Simulink

• Machine generated software and firmware eliminates time-consuming implementation effort

2.2. REQUIREMENTS

PARS requires several products, toolkits and development environments. They are enumerated below.

The MathWorks software

1. Matlab R2007B or R2008A3

2. Simulink®

3. Real Time Workshop or Real Time Workshop Embedded Coder (preferred)

4. Simulink® HDL Coder™ (optional, if targeting FPGA and not using Sysgen, below)

5. Simulink® Fixed Point and Fixed Point Blockset (optional, if targeting FPGA)

6. Signal Processing Blockset (optional, but recommended)

Texas Instruments software

7. Code Composer Studio 3.3

Xilinx software (optional, if targeting any FPGAs)

8. ISE 10.1.03i (Service Pack 3, including all IP updates)

9. Xilinx System Generator 10.1.03 (optional, if not using Simulink® HDL Coder™, above)

3L software

10. Diamond/DSP and Diamond/FPGA v3.1.10

11. Diamond Service Update 7 (provided with PARS installation)

12. SDB Hotfix (provided with PARS installation)

2

These must be properly installed and configured prior to generating code. Additionally, any hardwarevendor drivers should also be installed prior to running test benches under hardware-in-the-loop. Any

2

All Mathworks toolboxes must be consistent upon the major release. For example, R2007B+, etc.

3

PARS is distributed based on a major release of Matlab, you must use the PARS installer appropriate for your release.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 14

Revision 11-wip-7

Page 14 of 70

link-layer drivers in support of Diamond must be configured prior to attempting to run on

hardware. PARS provides an interface to link-layer drivers based on Diamond’s example

TIS project4.

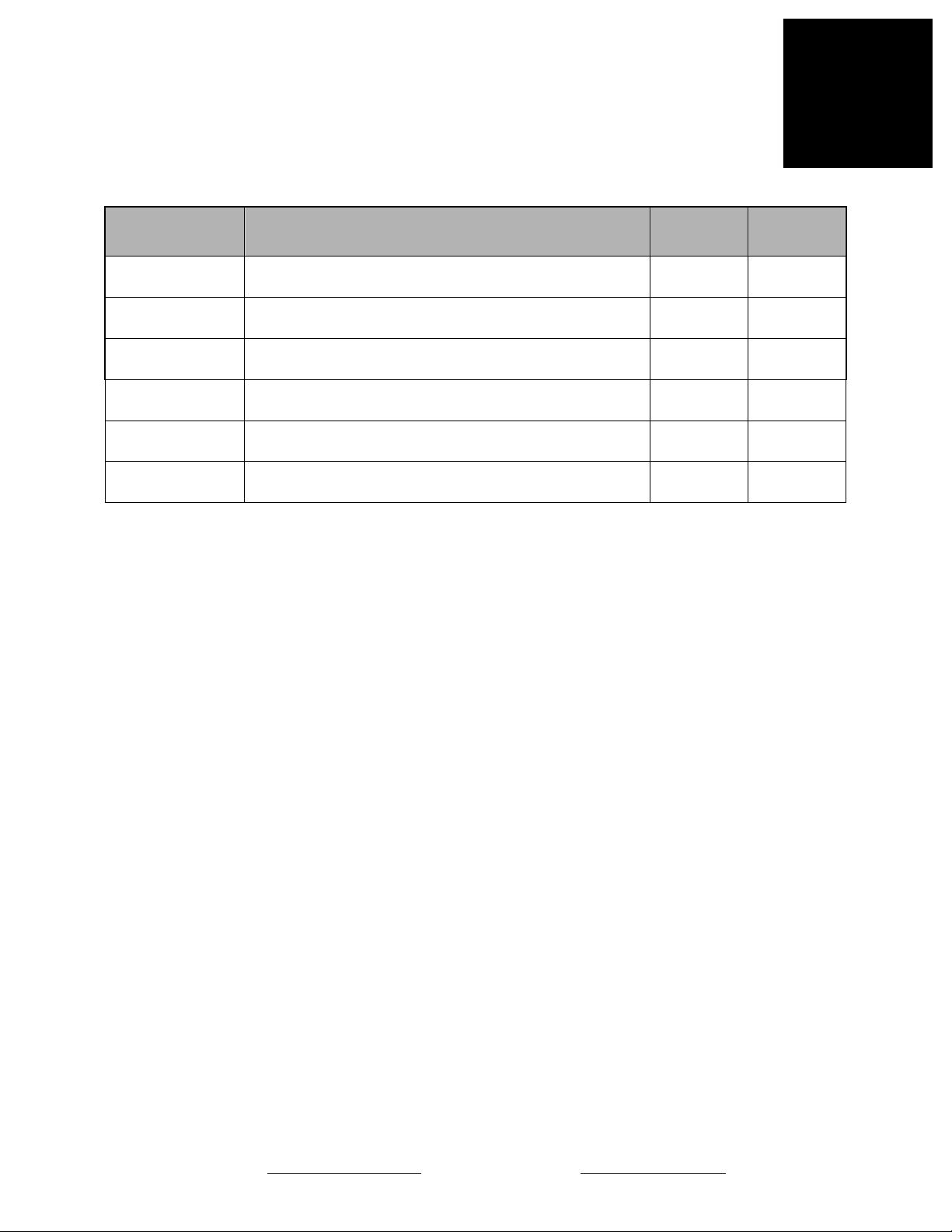

PARS The MathWorks TI Xilinx Diamond/DSP Diamond/FPGA

DSP FPGA Simulink RTW RTW-EC HDLCoder CCS ISE Sysgen Single Multi Single Multi

Single None R R O N/A R N/A N/A R O N/A N/A

Single Single

Single Multi R R O O R R O R O N/A R

None Any Not Available in PARS 11

Multi None R R O N/A R N/A N/A N/A R N/A N/A

Multi Single

Multi Multi R R O O R R O N/A R N/A R

R R O O R R O R O R O

R R O O R R O N/A R R O

Table 1 - Matrix of PARS features vs. tools required

The table above summarizes the required tools with respect to the desired number of DSPs and FPGAs.

An ‘R’ indicates a required tool. ‘O’ indicates an optional tool. ‘N/A’ indicates the tool does not

apply.

2.3. DEVELOPMENT FLOW

Generally speaking, developing with PARS is very similar to developing in Simulink®. A ‘PARS’

model is a fully-featured Simulink® model, with one important caveat: Prior to initiating code

generation, all blocks on the top level model must be organized into subsystems which have been

assigned to a processor type using the PARS Control Panel.

Organizing blocks into subsystems does not alter their behaviour in any way, so the model remains true

to the original. Assigning a subsystem to a processor type using PARS, causes the subsystem to be

‘masked’ and provides a means to control attributes for that subsystem with respect to the type of

processor you have assigned.

4

See: %DIAMOND_ROOT%\server\examples\TIS for additional details.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 15

Revision 11-wip-7

Page 15 of 70

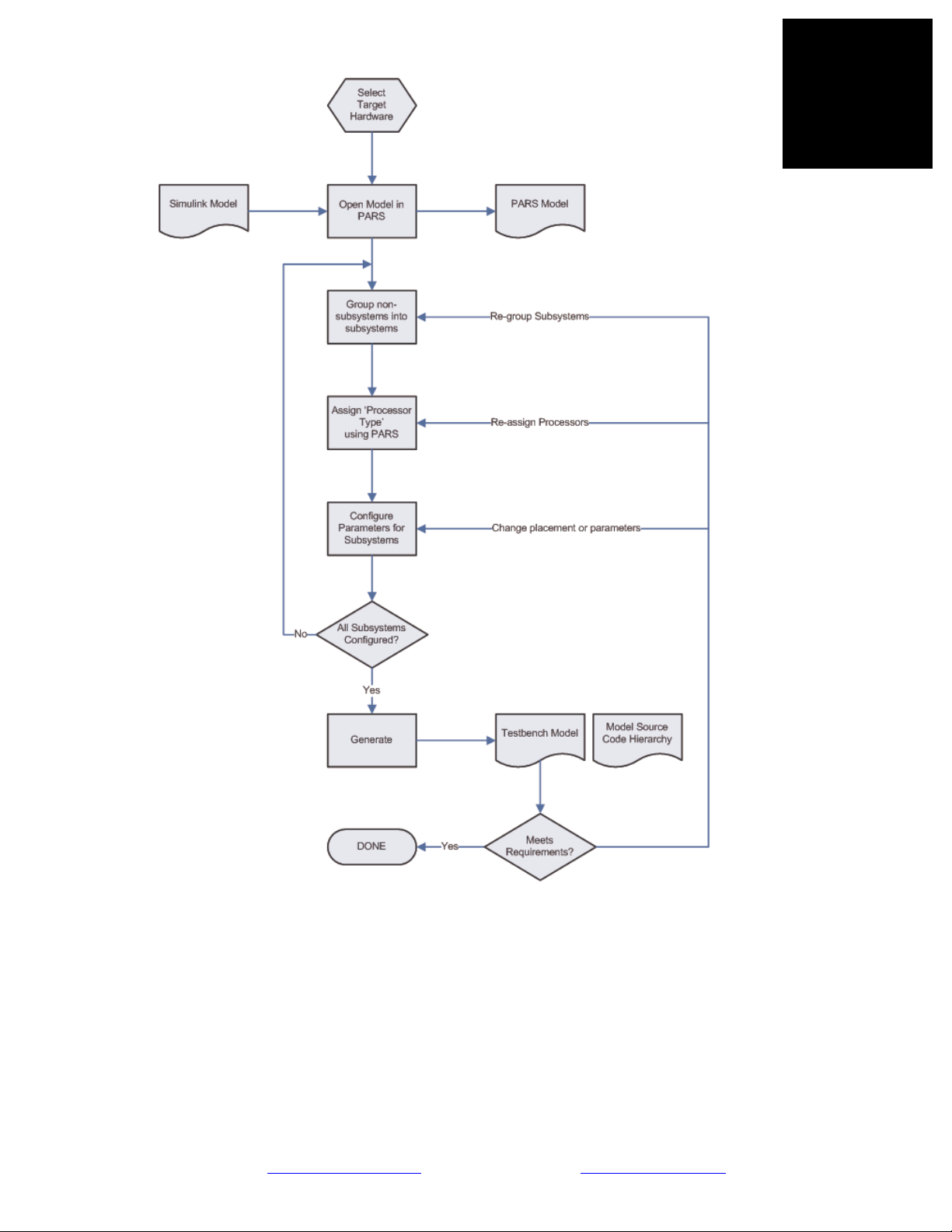

Figure 2 - PARS development cycle

You can re-assign subsystems to other processors at any time to explore trade-offs with code execution

on multi-DSP systems. You can also re-assign subsystems to other processor types (such as from DSP

to FPGA) to explore architectural trade-offs in the implementation.

The resulting application can be re-distributed or embedded into FLASH for stand-alone use.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 16

Revision 11-wip-7

Page 16 of 70

2.4. WALKTHRU

Here is a walk-through implementing a simple model with PARS.

Figure 3 - Invoking PARS

The first step is to start Matlab and invoke PARS.

Figure 4 - PARS Control Panel

The PARS control panel enables you to automate many of the steps needed to prepare a Simulink

model for code generation. It stays open on the desktop while you work in Matlab and Simulink.

Decide what your target hardware is going to be. PARS keeps a database of hardware targets that it can

use, and you can add additional ones or modify existing ones, as they are .m files. To pick a target

hardware, you invoke the ‘PARSOptions’ command.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 17

Revision 11-wip-7

Page 17 of 70

Figure 5 - Invoking PARSOptions

Figure 6 - The PARSOptions dialog

The ‘PARSOptions’ dialog allows you to pick the target hardware profile, as well as control several

features of the code generation system. These are described in detail in the section ‘PARSOptions’,

below.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 18

Revision 11-wip-7

Page 18 of 70

Figure 7 - Select Hardware Profile

For this part of the walkthrough, select a suitable DSP target and a suitable ‘DSP Task Creation’

method.

Figure 8 - Select DSP task creation method

Note that either RTW or RTW-EC must be available in order for PARS to create DSP tasks.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 19

Revision 11-wip-7

Page 19 of 70

The next step is to use the PARS control panel to open an existing Simulink model that

you would like to run on the target hardware.

Figure 9 - Opening a model in PARS

Then browse to the location of the model. This walkthrough works with one of the demonstration

models provided by PARS.

Figure 10 - Select model file to open

At this point one of three things will happen: Normally, PARS will create a new folder and make a

copy of the original model, giving it a ‘_PARS’ suffix. If the folder already exists, PARS will analyze

the modification time of the model with the ‘_PARS’ suffix versus the original model. Then, it will

either use the ‘_PARS’ model (continuing the work-in-progress) or offer to back-it-up and start over.

For the walkthrough, the ‘normal’ case is most probable.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 20

Revision 11-wip-7

Page 20 of 70

Figure 11 - AddOne starting model

This is the starting point for our work. Note the new working directory for this workspace.

Figure 12 - Workspace created when opening model in PARS

Next, we select groups of blocks that we intend to place onto the target hardware, and define

subsystems for them.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 21

Revision 11-wip-7

Page 21 of 70

Figure 13 - Select blocks for grouping

Figure 14 - Create a subsystem from the grouped blocks

We now have a subsystem for the ‘add constant’ operation. This will be come an atomic unit of

execution in the embedded system.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 22

Revision 11-wip-7

Page 22 of 70

Figure 15 - Subsystem created

Figure 16 - Select everything else

Next, we select the remainder of the blocks and create a model which consists of only subsystem

blocks at the top level. There must be one and only one HOST task present on a model in order to

generate code with (this version of) PARS. In this walkthrough, the task contains the counter and the

display blocks.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 23

Revision 11-wip-7

Page 23 of 70

Figure 17 - Subsystem 2 created, but unsightly

Figure 18 - Rearranged and renamed

After the blocks are re-arranged and cleaned up, we are ready to begin assigning resources for the

subsystems. At this point, nothing has changed in the original model, it has just been reorganized into

subsystems.

The next steps are to assign all the subsystems to processor types.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 24

Revision 11-wip-7

Page 24 of 70

Figure 19 - Select subsystem and create DSP Task

This figure shows the process of assigning a subsystem to a processor type. In the figure above, we

select the ‘Add’ subsystem, then use the PARS control panel to ‘Create DSP task’ for this subsystem.

This act masks the ‘Add’ subsystem, and enables PARS to attach several attributes needed to facilitate

code generation for the subsystem.

In the same way, the next two slides show how the ‘Host’ subsystem is assigned as the host task by

using the PARS control panel to ‘Create Host task’.

If a subsystem has been assigned, double-clicking it brings up the mask parameters which allow

manipulation of the attributes that PARS stores for each subsystem. See Figure 22, below for the

attributes that are available for the DSP task. Notably, the ‘Target Processor’ field is shown which

allows you to control the kind of DSP (fixed/floating point) you intend the subsystem to execute on.

The ‘Automatic’ is the most versatile, in which the processor type is obtained from the hardware

description, based on the assignment.

A masked subsystem must use ‘Look under mask’ in order to see the underlying blocks comprising it.

Do this for the ‘Host’ subsystem in preparation for simulation and code generation. See Figure 23,

below.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 25

Revision 11-wip-7

Page 25 of 70

Figure 20 - Select subsystem and create HOST task

Figure 21 - AddOne model fully assigned

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 26

Revision 11-wip-7

Page 26 of 70

Figure 22 - Add task mask parameters (DSP Task)

Figure 23 - HOST task "look under mask"

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 27

Revision 11-wip-7

Page 27 of 70

Figure 24 - AddOne model running (in simulation)

Now, looking at the ‘Host’ subsystem, begin the simulation. Although PARS has added some

attributes to the subsystems in preparation for code generation, the model remains a valid Simulink

model.

Begin the code generation process by stopping the simulation and invoking the ‘Generate Application’

method from the PARS control panel.

Figure 25 - Generate application

PARS begins to work and when the process is complete, will create a testbench that is configured to

load the embedded application onto the target and execute a hardware-in-the-loop simulation.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 28

Revision 11-wip-7

Page 28 of 70

Figure 26 - PARS working

Figure 27 - PARS finished, testbench generated

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 29

Revision 11-wip-7

Page 29 of 70

Figure 28 – Link-layer interface selection

When the testbench is executed, the ‘DSPLink’ block will be invoked which interfaces to the PARSsupplied link interface driver ’DSPLink.dll’. This driver is based on 3L/Diamond’s HOST

interface specification. You may use any hardware that is supported by Diamond5.

In this instance, in this example, we are communicating with an embedded system over a USB link

supported by the SMT60486 driver package.

Figure 29 - AddOne model running on hardware

The ‘AddOne’ model is now running hardware-in-the-loop.

5

Hardware vendors supporting 3L/Diamond supply link-layer drivers with their board support (BSP) packages.

6

See: http://www.sundance.com/web/files/productpage.asp?ST

RFilter=SMT6048

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 30

Revision 11-wip-7

Page 30 of 70

In this next section, we convert this model to target an FPGA instead of a DSP. Begin by

closing the model, and invoke ‘PARSOptions’ to change hardware. For this example, we

select ‘HDL Coder’ as the ‘FPGA Task Creation’ type.

Figure 30 - Select target with FPGA

Figure 31 - Select "HDL Coder" FPGA task creation mode

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 31

Revision 11-wip-7

Page 31 of 70

Open the model again and change the ‘Add’ task to FPGA task via ‘Create FPGA task’.

Figure 32 - Re-assign DSP task to FPGA task

Figure 33 - AddOne model on FPGA task

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 32

Revision 11-wip-7

Page 32 of 70

Figure 34 - Simulate, then generate the re-targeted application

Figure 35 - PARS Generates FPGA-based application

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 33

Revision 11-wip-7

Page 33 of 70

Now that the application has completed, we can execute it as before.

Figure 36 - FPGA model execution on hardware (note the error)

Notice that the FPGA-based implementation has a difference. This is due to a pipeline stage that exists

in the FPGA implementation. Effectively, the FPGA output is delayed by one simulation step.

Figure 37 - FPGA Execution with pipeline delay (correct)

Adding this delay in the testbench shows that the model is behaving in an appropriate manner.

In summary, this walkthrough has shown how to use PARS to take a Simulink model and execute it on

hardware in a very straightforward manner. It has also shown how easy it is to re-target designs from

DSP to FPGA and explore trade-offs in the implementation space.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 34

Revision 11-wip-7

Page 34 of 70

3. MODEL DEVELOPMENT

3.1. OVERVIEW

This section describes some details to guide you in developing models with PARS.

3.1.1. How PARS works with a model

PARS is a software system that automates many of the steps needed to actualize a Simulink model onto

embedded system hardware. In doing so, PARS invokes internal functions in Matlab, references

needed toolboxes, interprets and generates intermediate Simulink models and invokes external code

generation tools.

Figure 38 - PARS workflow and automation

The diagram above shows not only the process that PARS uses to generate a finished embedded

application, but also the points at which PARS provides automation.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 35

Revision 11-wip-7

Page 35 of 70

Using PARS causes changes to the model in order to manage its metadata; these changes

are non-reversible, so PARS always works with a copy of the original model. The PARS

model is derived from the original model as follows:

Given a Simulink model: <model_name>.mdl, the PARS model will be:

<model_name>_PARS\<model_name>_PARS.mdl

For example, if your Simulink model is ‘C:\test\thing.mdl’, the PARS model will be

‘C:\test\thing_PARS\thing_PARS.mdl’

You only need to open the original Simulink model, PARS will create the working space for the PARS

model, perform the needed copy and preparation of the model. When you open a Simulink model,

PARS analyzes the corresponding PARS model and takes one of the following actions:

• If the PARS model does not exist, PARS creates it by taking a copy of the original model and

then silently opens the copy.

• If the PARS model exists and has a modification date later than that of the original model, the

PARS model will be opened silently.

• Otherwise, PARS will warn you that the models are inconsistent and offer to create a backup of

the PARS model; then it derives the working model by making a copy of the original model. No

changes will be made and nothing will be opened if you decline the offer.

Backups are made according to the following procedure:

1. A new sub-folder called ‘model_backup’ will be created if necessary.

2. The existing PARS model will be moved to this folder and renamed by adding a suffix of an

underscore and the PARS model's modification date and time.

Note that PARS does not attempt to detect/prevent you from modifying the .mdl files directly, but

please be aware that inconsistencies in state can be introduced so the practice is discouraged.

3.2. PREPARING FOR CODE GENERATION

Before attempting to generate any code with PARS, it is important to ensure that the target model will

be realizable in an embedded system. In order to do this, several configuration properties of the

simulation model should be set and the model verified in simulation.

Most notably, any system must be discrete. No continuous states are possible, as the underlying

computation fabric for the (known) embedded systems are based on synchronous logic operations.

Simulink provides a function to discretize a continuous model with the function ‘sldiscmdl’. An

example that uses this function is provided in the PARS demonstration applications.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 36

Revision 11-wip-7

Page 36 of 70

3.2.1. Solver Configuration

When PARS generates code for the embedded model (for DSP targets), it uses ‘Fixed

Step, Discrete’ parameters. Therefore, it is recommended that the same settings be used

when simulating the model prior to code generation.

Figure 39 - Simulink model Solver parameters

It is also important to set the model’s stop time to ‘Inf’ before generating code. Some models will

generate different code for a non-infinite stop time; this is typically not what you want from an

autonomous embedded system.

It is also recommended to set the ‘Periodic Sample Time Constraint’ to ‘sample time independent’,

since that is precisely the kind of code that will be generated, but this is not always possible for all the

blocks that may exist in an arbitrary model.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 37

Revision 11-wip-7

Page 37 of 70

3.2.2. Hardware Implementation

The hardware implementation parameters are straightforward. The embedded systems

that PARS can currently target are based on DSP from Texas Instruments.

Figure 40 - Simulink model Hardware Implementation parameters

Select ‘Texas Instruments’ and ‘C6000’ for device vendor and type. Select byte ordering according to

your vendor hardware instructions. Note that you can leave ‘Emulation Hardware’ set to ‘None”.

3.2.3. Summary

Group Parameter Value Notes

Solver ‘SolverType’ ‘Fixed-step’

Solver ‘Solver’ ‘FixedStepDiscrete’

Solver ‘StopTime’ ‘Inf’ Recommended prior to generation

Solver ‘SampleTimeConstraint’ ‘STIndependent’ Optional

Solver ‘SolverMode’ ‘SingleTasking’ Ignored if ‘SampleTimeConstraint’ =‘STIndependent’

Hardware ‘TargetHWDeviceType’ ‘Texas Instruments->C6000’

Table 2 - Model Parameters for Code Generation

Table 2, above, summarizes the options used by PARS when generating code. They are recommended

values to configure your PARS model so that simulation can best approximate the embedded

environment.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 38

Revision 11-wip-7

Page 38 of 70

3.3. HARDWARE PROFILE SELECTION

Prior to opening a model in PARS, you need to select the target hardware profile that will

be used for the model development, allocation and generation. This enables PARS to

populate the fields for the DSP and FPGA task masks in order for you to be able to select

the processor name from the drop-down box in each of the masked subsystem.

You can do this from the PARS Control Panel via the ‘Tool’ Menu (Tool->PARS Options), or by

calling ‘PARSOptions’ in the Matlab command prompt.

Figure 41 - Selecting a hardware profile

In the PARSOptions panel, the ‘Hardware Profile’ is a drop-down box that lists the currently installed

hardware profiles you may choose from. Pick one and press ‘Accept’. This profile will remain in

effect until you change it again.

NOTE: When a PARS model is open, the ‘Tool’ menu option is grayed-out to discourage you from

changing options during an active development session. You should not change PARS options while

working with a model.

Please see Sec. 4.8. Hardware Description File, below, for additional details on adding your own

hardware profiles to your PARS installation.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 39

Revision 11-wip-7

Page 39 of 70

3.4. PARTITIONING

One of the caveats of working with PARS is that all blocks within a model be contained

in subsystems prior to code generation. Each subsystem will become an atomic unit of

execution in the embedded system.

It is important to assign all top-level objects to a subsystem. PARS does not interpret non-subsystems

in the PARS model, not even documentation objects. Typically, the documentation objects would be

placed in the ‘HOST’ subsystem, and would therefore translate to the testbench.

The goal of partitioning a model is to group tasks that might schedule independently of other

operations. For DSP applications, this means tasks which may execute on different processors, or

which may execute at different times/rates on the same processor. For FPGA applications this means

logic that can execute concurrently. The more subsystem partitions your model has, the greater

opportunity for parallelism and concurrency. The trade-off, of course, is that connections between

subsystems take a finite amount of time. This is typically not covered by simulation, unless it is

modelled by a transmission delay block.

Strictly speaking, a model is partitioned into subsystems irrespective of the underlying hardware. The

subsystems group logically related operations together. In PARS, grouping subsystems does require

some consideration of the underlying hardware communication mechanisms primarily to deal with

limited connection resources and dataflow I/O performance.

When a model is partitioned, subsystems connect to other subsystems through input and output ports.

These connections define the exchange of (numeric) data between the logic/operations implemented in

the (atomic) subsystem.

3.4.1. Connections between subsystems

Connections between subsystems on the same processor are fast. On an FPGA they are implemented

by wires connecting the output and input stages together, often with a few cycles propagation delay.

On a DSP, they are implemented by operating-system defined libraries which currently involve a buffer

copy from the output buffer to the input buffer of the peer.

You can have an unlimited number of connections between subsystems on the same processor.

3.4.2. Connections between processors

Connections between subsystems on different processors are subject to the type of link interface that

exists between them. A hardware system topology describes processors and the ‘wires’ linking them.

Each ‘wire’ declares a link interface between the two processors in a point-to-point manner. See Figure

42, below.

Hardware manufacturers provide details on pin-mappings, software drivers and/or firmware IP to

implement their link interfaces. As long as you can connect the processors using supported devices,

PARS can create applications of any complexity and any intermixture of hardware types.

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 40

Revision 11-wip-7

Page 40 of 70

The hardware topology file names both the processor and the wires connecting them.

These names may be referenced in the model to ensure that the connections between the

subsystems are established over the desired wires7.

Figure 42 - Processors and wires in a hardware system8

In the diagram, processor P2 has one link, processors P1 and P5 have two links, P4 has three links and

P3 has 4 links. The number of declared links has bearing on the flexibility afforded to the architect

when assigning subsystems to processors.

PARS ensures that all the necessary software/firmware on every processor is included in the generated

application to implement the communications that are defined by the connections described. Although

there are currently two ‘types’ of processor: DSP and FPGA, they are treated the same with respect to

declarations of wires connecting them.

Between DSPs, a special type of link termed ‘virtual’ is possible. Connections between any DSP

subsystems can be established to any other DSP subsystem. This has the effect of minimizing the need

to consider the physical system when describing a model.

7

This suggests that a naming convention be followed to allow models to reference different topologies easily

8

Courtesy of 3L/Diamond v3.1.10 User Guide, pg. 27

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com

Tel: +1 (775) 827-3103 www.sundancedsp.com

Page 41

Revision 11-wip-7

Page 41 of 70

Figure 43 - How routing is implemented between processors9

Figure 43, above, details three ways that subsystems communicate. Subsystem A and B communicate

via internal (fast) links on the same processor. Subsystem A and C communicate by using one of the

physical ‘wires’ between Processor X and Y. Subsystem B and D communicate using the ‘virtual

channel’ connection feature. PARS ensures that when the application is generated, the code necessary

to support this connection is loaded on to all the processors participating in establishing the connection;

in this case Processors X, Y and Z.

Unfortunately, this ‘virtual’ connection does not (currently) translate to the FPGA. Connections

between DSP and FPGA subsystems must be made with respect to the number and type of physical

links declared in the hardware system topology only. So for FPGA partitioning, the architect is advised

to group as much functionality onto the same FPGA as possible to minimize the number of connections

into and out of the FPGA-type processor.

9

Courtesy of 3L/Diamond v3.1.10 User Guide, pg. 33

Sundance Digital Signal Processing, Inc.

4790 Caughlin Parkway 233, Reno, NV 89519-0907, U.S.A.

email: sales@sundancedsp.com