Sunchaser Duo-Therm Rotary XL 55812.041, Duo-Therm Classic 54812.041, Duo-Therm Classic 54815.041, Duo-Therm Classic 54812.042, Duo-Therm Rotary XL 55812.042 Installation And Operating Instructions Manual

...Page 1

INSTALLATION

and OPERATING

INSTRUCTIONS

ROOF MOUNT

AIR CONDITIONER

Rotary XL (558 Series)

and Classic (548

Series)

QUICK START

SHUR START

MODELS

MODELS

54812.041

54812.042

55812.041

55812.042

54815.041

54815.042

54815.043

54815.044

55815.041

55815.042

READ THESE INSTRUCTIONS CAREFULLY, KEEP FOR FUTURE REFERENCE.

AVIS:

Cet appareil

doit

etre

repare

seulement par

un reparateur

autorise.

Modification de

I’appareil pourrait

etre

extremement

dangereuse.

CAUTION

MODIFICATION OF THIS APPLIANCE

CAN

BE

EXTREMELY

HAZARDOUS.

ALWAYS CONSULT

THE MANUFACTURER BEFORE MAKING CHANGES.

et pourrait

Causer

mal ou mort.

Form No. 19-1112-2 7-14-80

Page 2

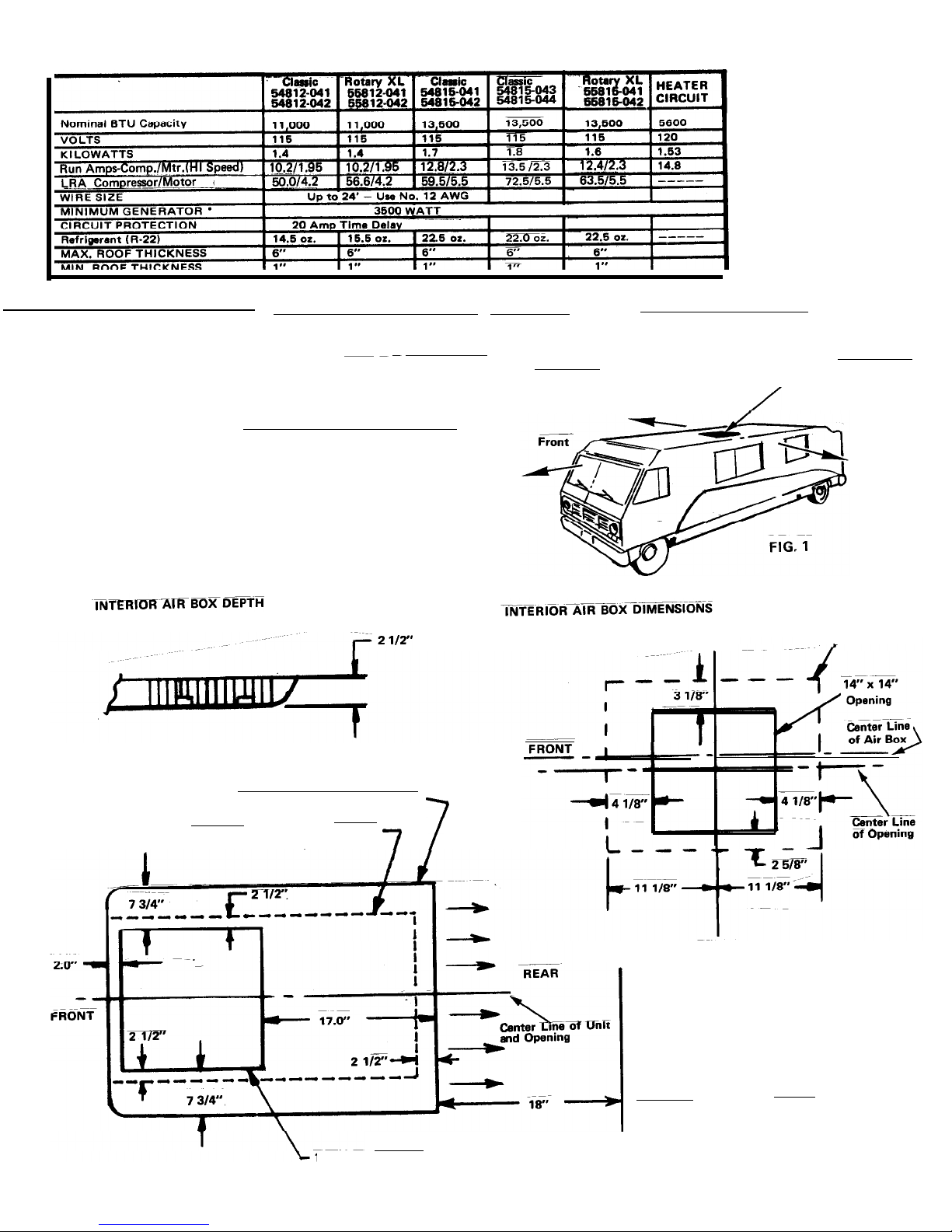

SPECIFICATIONS

* For

two units

USE

5000 watt generator

DUO-THERM TESTED UNDER ARI STANDARD 250-74

UL STANDARD 484

.

CSA STANDARD 22.2 No.

0,46

and 119

14” x 14” OPENING FROM

ROOF VENT REMOVAL

Right

1.

Normally, roof mount air conditioners are installed where

an existing roof vent has been removed. This creates the

14” x 14” opening required for installation (Fig. 1). If an

opening has to be cut, be sure to check for proper clearance

on the inside of the RV for the air box (Fig. 2) and on the

outside for the unit. (Fig. 3).

AIR

CONDITIONER DIMENSIONS

7

ROOF FLASHING DIMENSIONS

(On

Top of Vehicle)

7 I

FIG. 2

Left

RIGHT

Air Box Perimeter

I

LEFT

MINIMUM DISTANCE TO ANY

VERTICAL SURFACE (Example:

Luggage Rack) FOR CONDENSER

AIR FLOW

14” x 14” OPENING

FIG. 3

-2-

Page 3

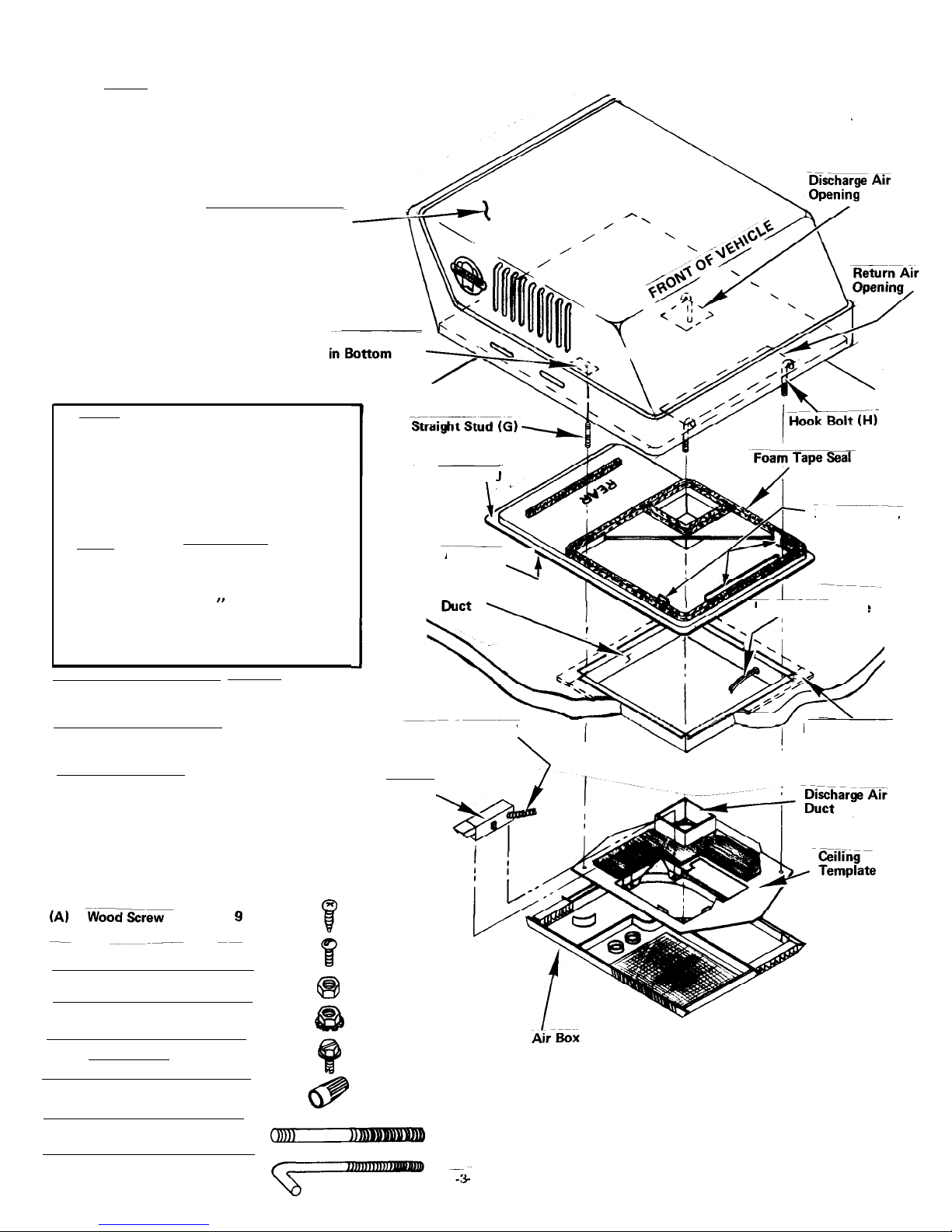

INSTALLATION LAYOUT

Fig. 4

AIR CONDITIONING

UNIT

NOTE:The anchor bolts, supplied as standard

equipment, will cover a range of 2

3/8"

to 4

1/8"

roof thickness. For roof thicknesses, other than

the standard, special Bolt Kits can be obtained by

special order. For roof sections thinner than the

standard, bolts can be cut off, care must be taken

so that threads are not damaged. Bolt Kits are

available as follows:

Threaded Hole

ROOF

KIT PART NO.

THICKNESS RANGE

3-14870(std)

2-3/8"

to 4-

1/8"

3-14867(opt)

”

1 to 2-3/8”

314868(opt)

3-3/4" to 5-1 /4"

314869(opt)

5-

1/4" to 6- 1/8"

(B)

Machine Screw

1

(Cl

Hex Nut

2

(D)

Nut & Lockwasher 4

Total No.

x

v

B

@

e

63

(E)

Self Taping Screw 4

(Blunt Point)

(F)

Wire Connector

2

(G)

Anchor Bolt (Straight)

1

(H)

Anchor Bolt (Hook) 3

OPTIONAL HEAT PACKAGE

AVAILABLE FROM DEALER

PART NUMBER 3-15603 SOLD

IN U.S.A. ONLY (UL Listed)

AIR BOX ASSEMBLY 3-13577

FOR CANADA

(CSA

Certified)

MOUNTING PARTS

Roof

Flashing

Adhesive .

Return Air

J

Conduit Attached

to Unit

\

Control

BOX

./

Guide Flanges

7

Power Supply Line

\

Framing Stock

Page 4

2.

4.

6.

Framing is required to provide adequate support and a

smooth surface for sealing. Under no circumstances should

the roof be constructed to create a low spot where water

will accumulate. Any opening between the roof and ceiling should be framed to prevent hot or cold air from being

drawn from the cavity. (Be sure to provide opening for

electrical supply line.) (See Fig. 4).

In the carton you will find the “return air duct”, an alumin-

um piece of sheet metal folded flat. Unfold and form into a

square (approximately 14” x 14”) to line the roof opening.

Form tabs approximately 1” wide along top edge to rest

against the roof.

Place duct through opening then mark

and remove any excess that protrudes beyond the ceiling.

(Hole is provided for supply line.) (See Fig. 4).

Run power line to roof opening:

If vent fan was removed,

the existing wire may be used provided it complies with

all National, State and Local wiring codes.

NOTE: Be

sure power supply is OFF.

The power line should be a

separate circuit using 12 AWG size wire and maximum

circuit protection (20 AMP time delay).

Installation of roof flashing:

(Reference Fig. 4) CAUTION:

Be sure all roof seams are sealed and surface is clean before proceding.

a. Peel

off the protective wax paper from the adhesive

a.

on the bottom of roof flashing.

Place roof flashing over 14” x 14” opening - flanges

on bottom will help assure proper alignment. Be

sure marking “REAR” is toward rear of vehicle.

b.

Once you are sure of proper alignment, press down

around outer edges to help hold in place. Seal will

be completed when unit is torqued down.

Install air conditioner on roof flashing: (Reference Fig. 4)

Using the roof flashing guide flanges, position the air condi-

tioner over the corresponding openings, CAUTION: Do not

damage the foam tape sealer on the flashing as this

makes

the sear between it ande unit. The outside

installation

is now completeand any minor positioning can be made

from inside.

(Ceiling Template)

7.

Ceiling Template Installation: Open the plastic bag of

mounting parts and use the Installation Layout on Page 3

for

reference.

a.

The control box which is permanently connected to

the unit is wrapped in cardboard and stored in the

return air opening for shipping. Pull down, being

careful not to damage coil fins, and discard wrapper.

Let hang until ceiling template is installed.

b.

Install the straight anchor bolt

(G)

into the threaded

hole located opposite the discharge air opening in

the bottom of the unit. Screw the end with

3/8”

of

thread in until finger tight. (See Fig. 5).

C.

Slide the ceiling template over this bolt andengage

the discharge air duct to check for proper alignment.

(The

upper

duct fits inside

the lower.)

Perforated

tabs may be removed for

thin

roof

sections.Remove

both tabs for roofs 1” to 2” thick; remove 1 tab

for roofs 2” to

3”thick,

and as received for roofs

3” to 4

1/4"

thick.

For roof thickness greater

than 4

1/4",

a duct adaptor (Part No. 3-13606) is

available upon request.

d.

If alignment is correct, proceed with installation; if

slight adjustments are necessary, make these before

continuing.

e.

Put Nut

(D)

on straight anchor bolt finger tight to

hold template while installing the three (3) hook

bolts

(H)

in the remaining corners. The nuts may

be installed finger tight on the bolts to aid in holding

the template. (See Fig. 5).

f.

g.

Secure ceiling template with four (4) wood screws

(A), two (2) in each end. (See Fig. 5).

Evenly tighten the four (4) anchor bolt nuts (D) to

secure the unit and insure a proper roof seal. Since

these nuts have lock washers, do not over tighten,

75 in. Ibs. or 6

1/4

ft. Ibs. torque is recommended.

Hook Bolt (H)

/

Wood Screws (A)

Page 5

8.

9.

10.

Control Box Installation: Fasten the control box to the

11.

Install Air Box: (Reference Fig. 7)

Mounting requires

ceiling template with two blunt point screws (E).

(See

four (4) wood screws (A); one (1) machine screw (B); and

Fig. 6 ).

Install one screw (A) in the junction box (part

two (2) hex nuts (C) to install the air box. (Reference

of the control box) which holds it to the ceiling.

Fig. 4).

Connect Power Supply: As mentioned previously, all wiring

must comply with the American National Standard Institute, National Electrical Codes and all local codes. NOTE:

All required installation hardware is supplied.

a.

Remove the

return

air grille held by two (2) quarter

turn fasteners.

b.

a.

The supply line should be routed to the junction box

and secured by the cable connector provided. Six

inch tails are sufficient for connection to unit wires

and ground screw. (See Fig. 6).

Remove the small cover plate at the end opposite the

return air grille, Care must be used not to break the

two mounting legs as this piece will be reinstalled

later.

C.

b.

Connect the white wire in the junction box to the

white or neutral wire from the supply line with one

of the twist type connectors provided.

NOTE: If optional heat package is to be installed, do

so before air box is installed. Refer to instructions

provided with heat package accessory 3-15603.

d.

Install air box over two weld studs on ceiling template

and secure with nuts (C).

C.

Connect the black wire in the junction box to the

black or hot

wire from the supply line with the other

twist connector.

e.

Install machine screw (B) in hole that was uncovered

by small plate. Tighten screw and nuts.

d.

Connect the ground wire to the identified ground

screw. (See Fig. 6 ).

f.

Install four (4) wood screws (A) that hold air box tight

to the ceiling.

e.

Install junction box cover with two blunt point screws

(E). (See

Fig. 6).

Reinstall cover plate and return air grille.

h.

You are now ready for operational check and many

hours of comfort!

Place thermostat sensor tube in ceiling template bracket

with small rubber grommet. (See Fig. 6 ).

Thermostat Sensor Tube

/

Bracket and Grommet

7

Plug for Optional

I

Electric Heater

Wood Screw

(A)

Wood Screw

(A)

Machine Screw (B)

Page 6

12.

FOR COOLED AND DEHUMIDIFIED AIR set the thermo-

stat dial to the desired temperature. The warmest setting

(WARM) on the dial is approximately 95 degrees;

the

coolest setting (COLD) is approximately 70 degrees.

Place blower selector switch in desired position. High-cool,

medium-cool or low-cool positions are used when air conditioning is desired. In these positions, the blower will operate

continuously and the compressor will come on when the

thermostat calls for cooling and off when the desired temperature has been

reached.

FOR CIRCULATED AIR ONLY place the selector switch in

the desired position. High Fan, Medium Fan and Low Fan

positions will circulate

inside

air and not operate the com-

pressor for cooling.

FOR HEATED AIR, with the optional heat package installed, place selector switch in the desired position. High Heat,

Medium Heat and Low Heat positions will circulate the

air

and allow the heater to cycle on the thermostat that has

been set at the desired temperature. Since actual BTU output is not affected by blower speed, it is recommended that

Low Heat position be used. NOTE: On units that do not

have the optional heat package installed, these positions

will act to circulate the inside air only.

Adjust the louvers at the air discharge openings for best air

zb&ib;tion.

(These louvers should never be completely

TO COMPLETELY SHUT DOWN THE UNIT, place the

blower switch in the “OFF” position.

NOTE: Shur-Start models have a delayed start kit installed.

When the unit is turned on, the fan will start and in approxi-

mately two (2) minutes, the compressor will start. After the

compressor has shut down, it will not restart for approxi-

mately two (2) minutes. This allows pressures to equalize

in the refrigerant system and eases the starting load for the

compressor.

Quick-Start models do not have the delayed start feature.

When the unit is turned on, the fan and compressor start at

the same time. After shutdown, wait three (3) to four (4)

minutes before restarting unit to allow pressure equalization.

13.

Air Filter - Your air conditioner will operate more effi-

ciently with a clean filter. Periodically remove and wash

the filter with soap and warm water, let dry and reinstall.

Replacement filters are available from your R.V. Dealer,

DUO-THERM Service Center or Distributor. Order

Part No. 3-8166.

Motor Lubrication

-

The motor has sealed-bearings and

with normal usage will not require oiling. On some motors

oilers may be included and can be lubricated with

non-

detergent SAE 20 motor oil if you desire.

Protective Cover

-

To keep outdoor portion of your air

conditioner free from foreign material during the

offseason, a protective vinyl cover is available as an optional item.

Order Part Number 3-9937 for the 54812,

54815, 55812 and 55815 Series.

NOTE: Be sure to

remove cover before operating the unit.

If service work is needed refer to the 19-1073 Service Directory

supplied, with the unit for the name of the_ nearest authorized

service enter. When requesting service, always give complete

model and serial numbers located on the plate

at

the rear of the

outdoor portion of the air

conditioner.

Page 7

WIRING DIAGRAM

COMPRESSOR

I

I

I

FACTORY WIRING

-

PL_

GRN

WHT

FIELD WIRING

---_

BLK

115 V.A.C. 60~ If

SHUR START ONLY

I-

CIRCUIT DIAGRAM

FAN

CAP

GRD.

Therm.

Page 8

DUO-THERM, Division of Motor Wheel Corp.,

LaGrange,

Indiana 46761

Loading...

Loading...