TM-8105005042

Solid State Kilowatt

Linear Power Amplifier

LPA-9600

Operation and Maintenance Manual (Rev. D)

WARNING

The LPA-9600 ships with internal packing material.

You MUST open the top cover and remove the

packing material BEFORE operating the unit.

3131 SW 42nd Street, Fort Lauderdale, Florida 33312 U.S.A.

www.sunairelectronics.com

LPA-9600

ii Use or disclosure of information from this document is subject to the restrictions

Proprietary/Confidentiality Notice

The information disclosed in this document, including all designs and related materials, is the property of

RIIMIC LLC dba (doing business as) Sunair Electronics (hereinafter “Sunair”) and/or its licensors. Sunair

and/or its licensors reserve all patent, copyright, and other proprietary rights to this document, including

all design, manufacturing, reproduction, use, and sales rights thereto, except to the extent said rights are

expressly granted to others. Reproduction of this document or portions thereof without prior written

approval of Sunair is prohibited.

Return Material Authorization (RMA) Procedures

In case of difficulty, please contact the Sunair Product Service Department between the hours of 8:00 a.m.

and 5:00 p.m. EST.

Telephone: (954) 400-5100

Fax: (954) 583-7337

Email: techsupport@sunairelectronics.com

To return an item for repair or replacement, a Return Material Authorization (RMA) is required from the

Product Service Department. When you receive the RMA number, carefully pack the item(s) and ship the

package(s) to the address provided by your Product Service Representative.

Write the RMA number in a visual location on the outside of the shipping container.

Retain a copy of all information sheets included with the packaging.

LPA-9600

Use or disclosure of information from this document is subject to the restrictions iii

Warranty Policy

Ground and Marine Products

Sunair Electronics warrants each piece of equipment manufactured by it to be free from defects in

material and workmanship, under normal use for the lesser of one year from the date of installation or 15

months from the date of shipment from Sunair.

Sunair will repair or replace, at its option, any defective equipment or component of the equipment

returned to it at its factory, transportation prepaid, within such warranty period. No reimbursement will be

made for non-factory repair charges.

This warranty is void if equipment is modified or repaired without authorization, subject to misuse, abuse,

accident, water damage or other neglect, or has its serial number defaced or removed.

THIS WARRANTY IS ESPECIALLY IN LIEU OF ANY AND ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. The obligation and responsibility of Sunair shall be

limited to that expressly provided herein and Sunair shall not be liable for consequential or other damage

or expense whatsoever therefore or by any reason thereof.

Sunair reserves the right to make changes in the design or additions to or improvements in its equipment

without obligation to install such additions or improvements in equipment theretofore manufactured.

Training

Sunair offers training programs of varying lengths covering operation, service and maintenance of all

Sunair manufactured equipment. For details please contact the Product Service Department.

LPA-9600

iv Use or disclosure of information from this document is subject to the restrictions

Copyright © 2011, 2012 by Sunair Electronics

All rights reserved.

Printed in the United States of America

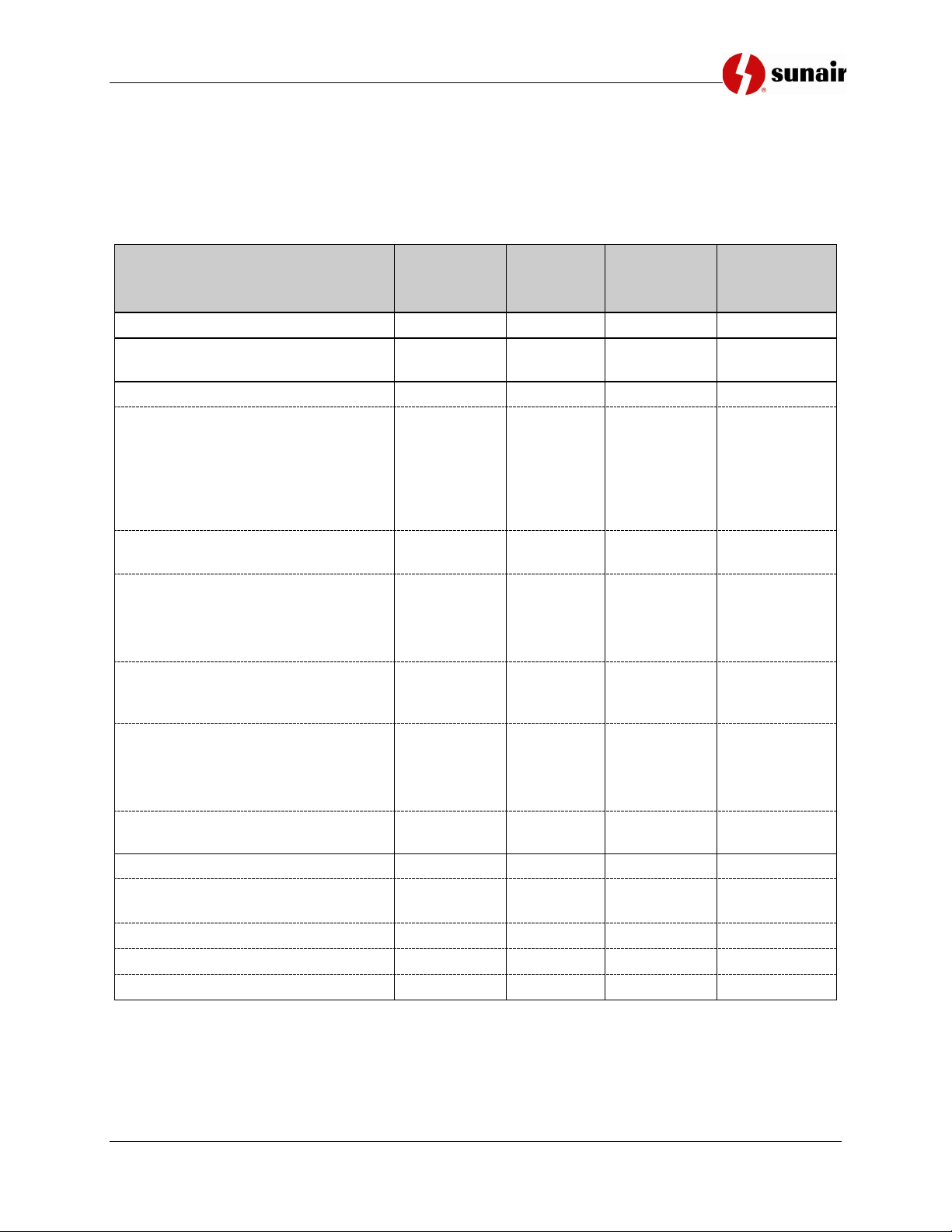

Revision

Page(s)

Manual

Revision

Date

Unit Serial No.

Effectivity

Addendum

Covered

A - First Edition - Production Changes

10/01/1990

B - Second Edition - Customer

Changes

8/29/2005

C - Third Edition

3/01/2011

N/A

N/A

• Reformatted LPA-9600 to current

standards. This includes new

numbers for Figures and Tables.

• Added temperatures in Fahrenheit.

• Replaced references to CU-9100

with CU-9150.

All

• Incorporated Service Bulletin

9600-001.

1-1, 1-2, 3-2, 5-

1, 5-2, 5-26

• Re-created several of the handdrawn diagrams using illustrating

software.

1-4, 2-3, 2-5, 2-

6, 2-8, 2-9, 4-

19, 5-22, 5-27,

5-28, 5-31, 5-

32

• Updated the contact information

with the new address and phone

numbers.

I, ii, 2-1

• Paragraph 5.5.1.1, step 3,

changed:

- +12 VDC to + 5 VDC

- A4J1 to + A4A1J4

5-10

Revised BOM for Power Amplifier

A4A3

5-49

D - Revision

02/26/2013

N/A

N/A

• Modified Rackmount Slide

Diagram (Figure 2.9-1)

2-13

• Modified Captions

All

• Modified General Glossary

xiii & xiv

• Modified CU-9150 Instructions

2-10

LPA-9600

Table of Contents

Use or disclosure of information from this document is subject to the restrictions v

1.0! General Information ............................................................................................................................ 1-1!

1.1! Purpose of Manual ..................................................................................................................... 1-1!

1.2! Purpose of Equipment ............................................................................................................... 1-1!

1.3! General Description ................................................................................................................... 1-1!

1.3.1! Physical Description ..................................................................................................... 1-1!

1.3.2! Electrical Description ................................................................................................... 1-1!

1.4! Specifications ............................................................................................................................ 1-2!

1.5! Dimensions ................................................................................................................................ 1-3!

1.6! Equipment Supplied .................................................................................................................. 1-6!

1.7! Equipment Required, Not Supplied ........................................................................................... 1-6!

1.8! Optional Equipment ................................................................................................................... 1-7!

2.0! Installation ........................................................................................................................................... 2-1!

2.1! General ...................................................................................................................................... 2-1!

2.2! Unpacking and Inspection ......................................................................................................... 2-1!

2.3! Returning Equipment to Factory ............................................................................................... 2-2!

2.4! General Installation Information ............................................................................................... 2-2!

2.4.1! Station Layout .............................................................................................................. 2-2!

2.5! Configurations ........................................................................................................................... 2-3!

2.6! Antennas and Ground Systems .................................................................................................. 2-3!

2.6.1! Random Length Non-Resonant Antennas .................................................................... 2-3!

2.6.2! Broadband 50 Ohm Antennas ...................................................................................... 2-3!

2.7! External Connections ................................................................................................................. 2-8!

2.7.1! Primary Power Connections ......................................................................................... 2-8!

2.7.2! Transceiver Connections .............................................................................................. 2-8!

2.7.3! RF Output Connections ................................................................................................ 2-8!

2.7.4! Antenna Coupler Connections ................................................................................... 2-10!

2.7.5! Station RF Ground System Connections .................................................................... 2-10!

2.8! Preliminary Checks and Adjustments ..................................................................................... 2-10!

2.9! Rack Mounting Kit Option ...................................................................................................... 2-12!

3.0! Operation ............................................................................................................................................. 3-1!

3.1! General ...................................................................................................................................... 3-1!

3.2! Function and Location of Controls and Indicators .................................................................... 3-1!

3.3! Operating the LPA-9600 ........................................................................................................... 3-3!

3.3.1! Operation with a 9000 Series Exciter/Transceiver ....................................................... 3-3!

4.0! Theory of Operation ............................................................................................................................ 4-1!

4.1! General ...................................................................................................................................... 4-1!

4.2! Control Panel Module A2 .......................................................................................................... 4-1!

4.3! Computer Assembly A3 ............................................................................................................ 4-2!

LPA-9600

Table of Contents

vi Use or disclosure of information from this document is subject to the restrictions

4.3.1! PC Assembly Computer Mother Board A3A1 ............................................................. 4-2!

4.3.2! Peripheral Board A3A2 ................................................................................................ 4-2!

4.3.3! Microprocessor Board A3A3 ....................................................................................... 4-8!

4.4! RF/PS Module A4 ................................................................................................................... 4-13!

4.4.1! RF Module Control Assembly A4A1 ......................................................................... 4-13!

4.4.2! +48 VDC Switching Power Supply A4A2 ................................................................. 4-13!

4.4.3! Power Amplifier Assembly A4A3 ............................................................................. 4-15!

4.5! Filter Module A5 ..................................................................................................................... 4-16!

4.5.1! Plug-In Filter Modules A5A1 Through A5A8 ........................................................... 4-16!

4.5.2! Plug-In Wattmeter Module A5A9 .............................................................................. 4-16!

4.5.3! Mother Board Assembly A5A10 ................................................................................ 4-17!

4.6! Output Power Combiner A6 .................................................................................................... 4-17!

4.7! Input Power Splitter Assembly A7 .......................................................................................... 4-17!

4.8! Front Panel A8 ......................................................................................................................... 4-17!

4.9! Rear Panel Connector Assembly A9 ....................................................................................... 4-17!

4.10! Auxiliary Power Supply A10 .................................................................................................. 4-17!

4.11! Block Diagrams ....................................................................................................................... 4-18!

5.0! Fault Isolation, Maintenance, and Repair ............................................................................................ 5-1!

5.1! Preventive Maintenance ............................................................................................................ 5-1!

5.1.1! Periodic Inspections ..................................................................................................... 5-1!

5.2! Corrective Maintenance ............................................................................................................. 5-1!

5.2.1! Test Equipment Required ............................................................................................. 5-1!

5.2.2! Connectors and Cables Required ................................................................................. 5-2!

5.2.3! Primary Power Input .................................................................................................... 5-2!

5.2.4! Test Conditions ............................................................................................................ 5-2!

5.3! Alignment Procedures ............................................................................................................... 5-2!

5.3.1! Preliminary ................................................................................................................... 5-2!

5.3.2! Power Up ...................................................................................................................... 5-2!

5.3.3! Keyboard ...................................................................................................................... 5-3!

5.3.4! Power Adjustment ........................................................................................................ 5-3!

5.3.5! 500 Watt Adjustment ................................................................................................... 5-4!

5.3.6! AM Power .................................................................................................................... 5-4!

5.3.7! VSWR Adjustment ....................................................................................................... 5-5!

5.4! Fault Messages .......................................................................................................................... 5-5!

5.5! Fault Isolation Procedures ....................................................................................................... 5-10!

5.5.1! RF/PS Module A4 ...................................................................................................... 5-10!

5.5.2! Peripheral Board A3A2 .............................................................................................. 5-10!

5.5.3! Filter Module A5 ........................................................................................................ 5-10!

5.5.4! Output Combiner A6 .................................................................................................. 5-11!

LPA-9600

Table of Contents

Use or disclosure of information from this document is subject to the restrictions vii

5.5.5! Input Splitter A7 ......................................................................................................... 5-11!

5.5.6! Microprocessor Board A3A3 ..................................................................................... 5-11!

5.6! Disassembly Instructions ......................................................................................................... 5-11!

5.7! Major Assembly Locations ...................................................................................................... 5-12!

5.8! Schematics and Parts Lists ...................................................................................................... 5-23!

LPA-9600

Table of Contents

viii Use or disclosure of information from this document is subject to the restrictions

THIS PAGE INTENTIONALLY LEFT BLANK

LPA-9600

List of Figures

Use or disclosure of information from this document is subject to the restrictions ix

Figure 1.5-1: LPA-9600 Outline and Mounting Dimensions .................................................................... 1-4!

Figure 1.5-2: LPA-9600 Front and Rear Panels ........................................................................................ 1-5!

Figure 2.6-1: LPA-9600 with Broadband Antenna .................................................................................... 2-4!

Figure 2.6-2: LPA-9600 with CU-9150, 35-Foot Antenna (Roof Top Installation) ................................. 2-5!

Figure 2.6-3: LPA-9600 with CU-9150, Non-Resonant Antenna ............................................................. 2-6!

Figure 2.6-4: kW Long Wire Antenna Kit ................................................................................................. 2-7!

Figure 2.7-1: Power Cable Assembly, P/N 8066002297 ........................................................................... 2-8!

Figure 2.7-2: 9000 Series Exciter/Transceiver to LPA-9600 Control Cable ............................................. 2-9!

Figure 2.8-1: Voltage Customizing - Circuit Breaker/Auxiliary Power Supply ..................................... 2-11!

Figure 2.8-2: Voltage Customizing – RF/PS Module A4 (4 Each) ......................................................... 2-12!

Figure 2.9-1: Rack Mount Slide Details .................................................................................................. 2-13!

Figure 2.9-2: Shockmount Equipment Rack with Outline Dimensions and Details ............................... 2-14!

Figure 3.2-1: LPA-9600 Controls and Indicators ...................................................................................... 3-1!

Figure 4.11-1: LPA-9600 Overall Block Diagram .................................................................................. 4-19!

Figure 4.11-2: Peripheral Board A3A2 Block Diagram .......................................................................... 4-20!

Figure 4.11-3: Microprocessor Board A3A3 Block Diagram ................................................................. 4-21!

Figure 4.11-4: Power Amplifier Assembly A4A3 Block Diagram ......................................................... 4-22!

Figure 5.7-1: Major Assembly Locations ................................................................................................ 5-13!

Figure 5.7-2: LPA-9600 Test Setup ......................................................................................................... 5-22!

Figure 5.7-3: Audio Injection Test Cable (Used in Test Setup) .............................................................. 5-22!

Figure 5.8-1: Chassis Wiring Diagram .................................................................................................... 5-27!

Figure 5.8-2: Control Panel Module A2 .................................................................................................. 5-29!

Figure 5.8-3: Computer Motherboard A3A1 ........................................................................................... 5-30!

Figure 5.8-4: Peripheral Board A3A2 ...................................................................................................... 5-33!

Figure 5.8-5: Microprocessor Board A3A3 ............................................................................................. 5-39!

Figure 5.8-6: Module Control Board A4A1 ............................................................................................ 5-45!

Figure 5.8-7: 48VDC Switching Power Supply A4A2 ............................................................................ 5-46!

Figure 5.8-8: Power Amplifier A4A3 ...................................................................................................... 5-49!

Figure 5.8-9: Filter Module A5 ................................................................................................................ 5-51!

Figure 5.8-10: PC Assembly, Band Filter 1, A5A1 ................................................................................. 5-53!

Figure 5.8-11: PC Assembly, Band Filter 2, A5A2 ................................................................................. 5-54!

Figure 5.8-12: PC Assembly, Band Filter 3, A5A3 ................................................................................. 5-55!

Figure 5.8-13: PC Assembly, Band Filter 4, A5A4 ................................................................................. 5-56!

Figure 5.8-14: PC Assembly, Band Filter 5, A5A5 ................................................................................. 5-57!

Figure 5.8-15: PC Assembly, Band Filter 6, A5A6 ................................................................................. 5-58!

Figure 5.8-16: PC Assembly, Band Filter 7, A5A7 ................................................................................. 5-59!

Figure 5.8-17: PC Assembly, Band Filter 8, A5A8 ................................................................................. 5-60!

Figure 5.8-18: PC Assembly, Watt Meter 9, A5A9 ................................................................................. 5-61!

Figure 5.8-19: PC Assembly, Mother Board, A5A10 ............................................................................. 5-62!

Figure 5.8-20: Combiner Module, A6 ..................................................................................................... 5-64!

LPA-9600

List of Figures

x Use or disclosure of information from this document is subject to the restrictions

Figure 5.8-21: Splitter Module, A7 .......................................................................................................... 5-65!

Figure 5.8-22: PC Assembly, Rear Panel Connector, A9 ........................................................................ 5-66!

Figure 5.8-23: PC Assembly, Rear Panel Connector, A9 ........................................................................ 5-67!

Figure 5.8-24: Auxiliary Power Supply, A10 .......................................................................................... 5-68!

LPA-9600

List of Tables

Use or disclosure of information from this document is subject to the restrictions xi

Table 1.6-1: LPA-9600 Equipment Supplied ............................................................................................ 1-6!

Table 1.7-1: LPA-9600 Equipment Required, Not Supplied ..................................................................... 1-6!

Table 1.8-1: LPA-9600 Optional Equipment ............................................................................................. 1-7!

Table 2.9-1: LPA-9600 Rack Mounting Kit Parts List ............................................................................ 2-13!

Table 2.9-2: LPA-9600 Shockmount Kit Equipment Rack Parts List, P/N 6032090892 ........................ 2-16!

Table 3.2-1: Front Panel Controls and Indicators ...................................................................................... 3-2!

Table 5.3-1: VRMS to Watts ..................................................................................................................... 5-4!

Table 5.4-1: Fault Messages ...................................................................................................................... 5-6!

Table 5.4-2: RF/PS Module A4 Fault Isolation Procedures ...................................................................... 5-9!

Table 5.6-1: Disassembly Instructions ..................................................................................................... 5-12!

Table 5.7-1: Peripheral Board A3A2 Fault Isolation Procedures ............................................................ 5-21!

Table 5.8-1: LPA-9600 Table of Assemblies .......................................................................................... 5-23!

Table 5.8-2: Detailed Assemblies List ..................................................................................................... 5-25!

Table 5.8-3: Detailed Assemblies List (Cont.) ........................................................................................ 5-26!

LPA-9600

List of Tables

xii Use or disclosure of information from this document is subject to the restrictions

THIS PAGE INTENTIONALLY LEFT BLANK

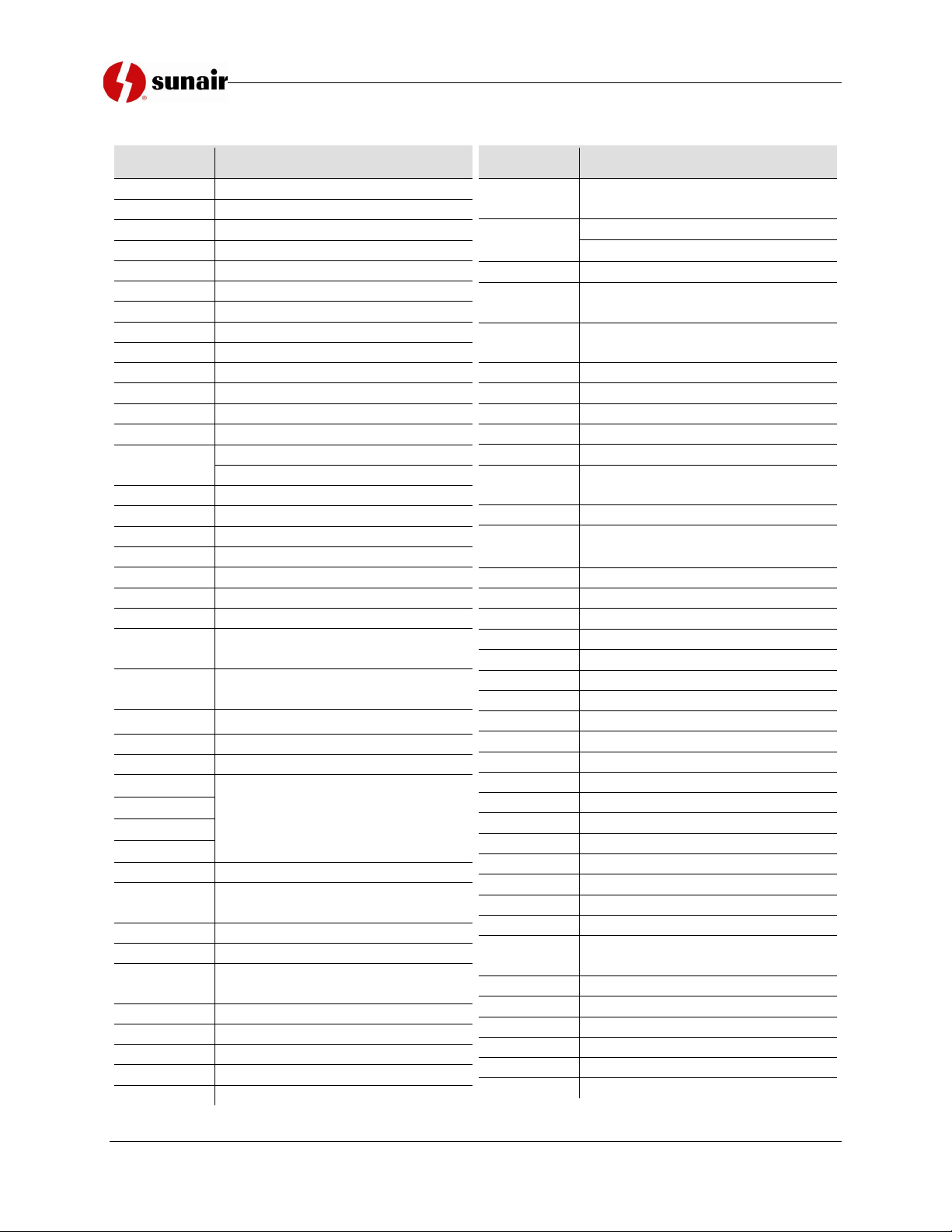

LPA-9600

General Glossary (Cont.)

Use or disclosure of information from this document is subject to the restrictions xiii

Term

Meaning

* (asterisk)

Selected function

A

Ampere (unit)

ac

Alternating current

ACC

Automatic Carrier Control

ADDR

Address

AFSK

Audio Frequency Shift Keying

AGC

Automatic Gain Control

ALC

Automatic Level Control

ALE

Address Latch Enable

ALE

Automatic Link Establishment

AIP

ASU Interconnect Panel

AM

Amplitude Modulation

AME

Amplitude Modulation Equivalent

AMP

Amplifier

Ampere (unit)

AMPL

Amplifier

ARQ

Automatic Request

ASU

Automatic Switch Unit

ATC

Air Traffic Control

AUD

Audio

AUTO

Automatic

AUX

Auxiliary

BAUD

Bd

Symbol rate (changes of signaling

events per second) (unit)

Bellcore

Bell

Telephone standards in the U.S.

BFO

Beat Frequency Oscillator

BITE

Built In Test Equipment

BRD

Board

CH

Channel

CHAN

CHL

CHN

CLR

Clear

CMOS

Complementary Metal Oxide

Semiconductor

CPLR

Coupler

CPU

Central Processing Unit (Computer)

CTCSS

Continuous Tone Coded Squelch

System

CW

Continuous Wave

dB

Decibel (unit)

dBm

Decibel referred to 1 mW (unit)

dc

Direct current

DCS

Digital Coded Squelch

Term

Meaning

DSBSC

Double Sideband Suppressed

Carrier

DSP

Display

Digital Signal Processor

DTMF

Dual Tone Multi-Frequency

DUART

Dual Asynchronous

Receive/Transmit

EEPROM

Electrically Erasable Programmable

Read Only Memory

EIA

Electronics Industry Alliance

EL

Electroluminescent

EMI

Electromagnetic Immunity

EMP

Electromagnetic Pulse

ENTR

Enter

EPROM

Erasable Programmable Read Only

Memory

ESD

Electrostatic Discharge

ETSI

European Telecommunications

Standards Institute

FAX

Facsimile

FEC

Forward Error Correction

FM

Frequency Modulation

FREQ

Frequency

FSK

Frequency Shift Keying

FWD

Forward

GRP

Group

HF

High Frequency

HPA

High Power Amplifier

HPAC

High Power Amplifier Controller

HPCU

High Power Controller Unit

HPSC

High Power Split Controller

Hz

Hertz (unit)

IC

Integrated Circuit

IF

Intermediate Frequency

IMD

Intermodulation Distortion

I/O

Input/Output

IPA

Intermediate Power Amplifier

IONCAP

Ionospheric Communications

Analysis and Prediction (Program)

ISB

Independent Sideband

kHz

Kilohertz (unit)

kW

Kilowatt (unit)

RF

Radio Frequency

LED

Light Emitting Diode

LK

Link

LPA-9600

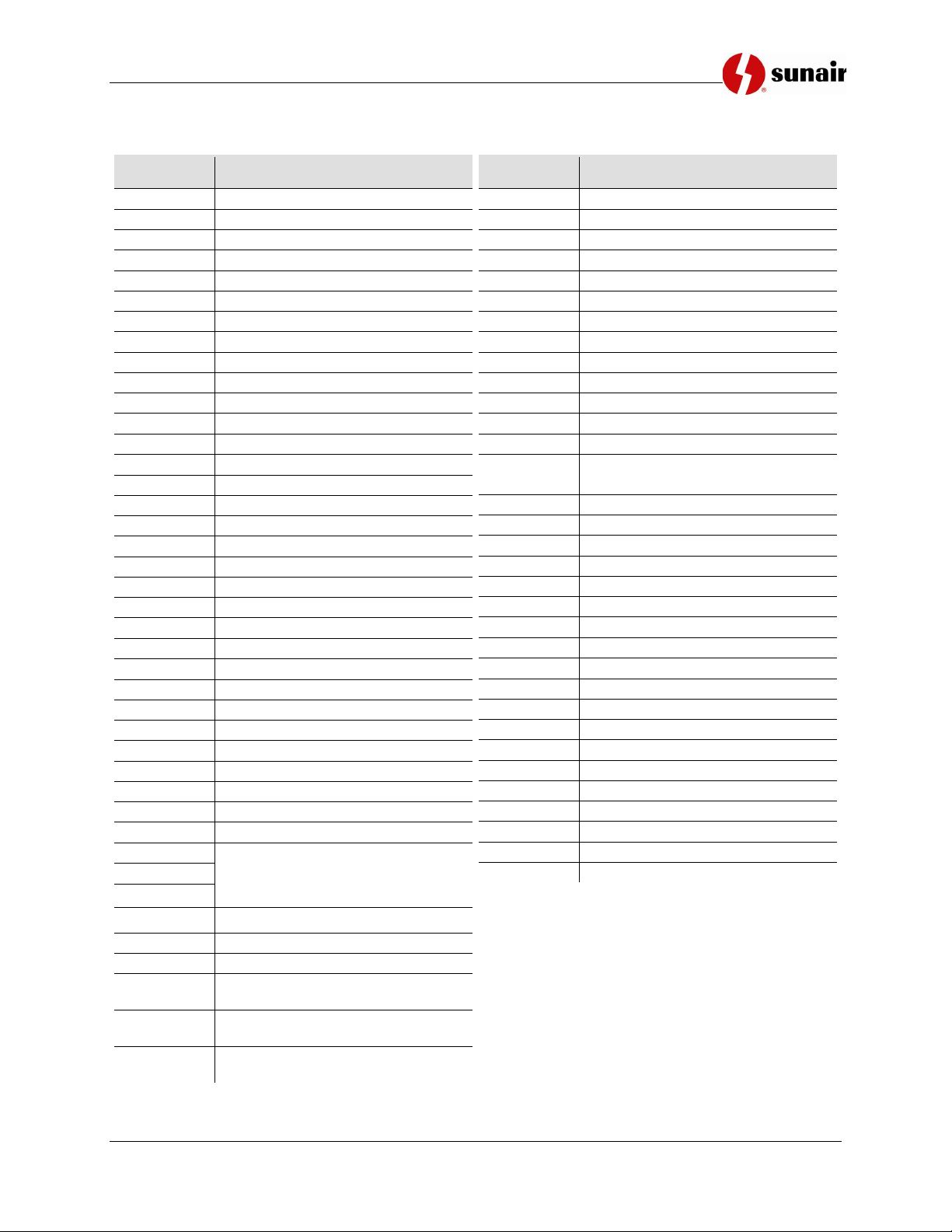

General Glossary

xiv Use or disclosure of information from this document is subject to the restrictions

Term

Meaning

LO

Local Oscillator

LCL

Local

LRU

Lowest Repairable Unit

LSB

Lower Sideband

LT

Light

MAN

Manual

LVL

Level

M CH

Manual Channel

MIC

Microphone

MHz

Megahertz (unit)

MIL-STD

Military Standard

MNL

Manual

MOV

Metal Oxide Varistor

ms

Millisecond (unit)

MTBF

Mean Time Between Failures

MTR

Meter (measuring device)

MTTR

Mean Time To Repair

NAR

Narrow

NB

Narrow Band

O.D.

Olive Drab

PA

Power Amplifier

P.C.

Printed Circuit

PEP

Peak Envelope Power

PLL

Phase-Locked Loop

P/N

Part Number

PNL

Panel

POSTSL

Post-Selector

PRESEL

Pre-Selector

PTT

Push-To-Talk

PWR

Power

RCU

Remote Control Unit

RCV

Receive

REFD

Reflected

REFL

RFL

RFI

Radio Frequency Interference

RMA

Return Material Authorization

RMT

Remote

RS232

Point-to-point comm. protocol (50

ft max. distance)

RS422

Point-to-point comm. protocol

(4,000 ft max. distance)

RS485

Multi-point comm. protocol (32

nodes max.)

Term

Meaning

RTTY

Radio Teletype

RX

Receive

RU

Rack Unit

SDR

Software Defined Radio

SEL

Select

SINAD

Signal to Noise and Distortion

SLO

Slow

SLO BLO

Time delayed fuse (slow blow)

S MTR

Signal Strength Meter

SPKR

Speaker

SPLX

Simplex

SRAM

Static Random Access Memory

SSB

Single Sideband

TCXO

Temperature Compensated Crystal

Oscillator

TFT

Thin Film Technology

TGC

Transmit Gain Control

THD

Total Harmonic Distortion

TTL

Transistor-Transistor Logic

TX

Transmit

UHF

Ultra High Frequency

USB

Upper Sideband

UTC

Universal Time Coordinated

V

Volt (unit)

Vac

Volt alternate current (unit)

VC

Voltage Control

VCO

Voltage Controlled Oscillator

Vdc

Volt direct current (unit)

VHF

Very High Frequency

VRMS

Volt Root Mean Square

VSWR

Voltage Standing Wave Ratio

W

Watt (unit)

WB

Wide Band

WPM

Words Per Minute

LPA-9600

Use or disclosure of information from this document is subject to the restrictions xv

Electrical Safe Work Practices

Accidents involving electricity can cause burns, explosions, shocks, and death. Only trained and qualified

personnel should service, install, or repair electrical equipment.

The general safety procedures for personnel servicing electronic and electrical equipment include:

• Always turn off or disconnect power before working on electric equipment, electronic circuits, or

any type of electrical item.

• Turn off and disconnect power before checking or replacing fuses.

• Locate and correct the cause of a blown fuse or tripped circuit breaker before replacing the fuse

or resetting the circuit breaker.

• Never defeat the purpose of a fuse or circuit breaker. Always install a fuse with the correct

amperage rating for the circuit. Never install a fuse with a higher rating.

• Always have a second trained and qualified person present when working on electrical systems

(protected or unprotected).

• Always remove metal jewelry, watches, rings, etc., before working on electrical circuits or any

electrical equipment.

• Do not work on electrical equipment in a wet area. Never place containers of liquid on electrical

equipment.

• Do not touch an object that may provide a hazardous path to earth ground.

• Safely discharge capacitors in equipment before working on the circuits (refer to ESD

procedures).

• Inspect cabling for defects, including frayed wiring, loose connections, or cracked insulation.

Replace defective cords and plugs.

• Always check the electrical ratings of equipment and verify that the ratings are correct.

• Never overload circuits.

• Verify grounding of equipment chassis/cabinets. Never cut off or defeat the ground connection on

a plug.

• When working at any site, always observe all safety signs and safety procedures. They exist to

protect personnel from injuries.

• All persons working on or around electrical/electronic equipment should have first aid training,

including resuscitation procedures and external cardiac compression.

LPA-9600

xvi Use or disclosure of information from this document is subject to the restrictions

Electrostatic Discharge (ESD)

Electrostatic Discharge (ESD) can severely damage sensitive components located on printed circuit cards.

Electrostatic discharge measurements as high as 35,000 volts, can occur from walking across a carpet.

To avoid potential damage to electronic equipment, follow correct electrostatic discharge preventive

procedures when handling or working with the hardware.

• Always wear an electrostatic discharge wrist strap when handling electronic hardware.

• Connect the electrostatic discharge wrist strap to a reliable earth ground.

• Replace worn or frayed electrostatic discharge wrist straps and connecting cords.

• Check your electrostatic discharge strap every month.

• Do not use electrostatic discharge straps that are out of calibration.

• Place printed circuit cards in an electrostatic discharge bag or other ESD container to avoid

damage from stray static charge.

• Do not place printed circuit cards on any surface that is not an approved electrostatic discharge

surface correctly connected to earth ground.

• Always handle printed circuit cards by the edges. Avoid touching any of the sensitive circuits on

the card.

Hazardous Materials

Hazardous materials are likely to be present at the maintenance facility. Many of the following substances

are toxic (causing illness or death): flammable materials, explosive materials, corrosive materials that

cause the skin or eyes to burn on contact, reactive materials that, when exposed to heat, air, water, or

certain other chemicals, can cause burning or release of toxic vapors.

Some hazardous substances are obvious, for example, adhesives, solvents, abrasives, fuels, and pesticides.

Other substances are less obvious, for example, toner in office copiers and printers and heavy-duty

cleaning and disinfectant products. The list of substances identified as hazardous in the workplace is

constantly increasing as new processes and new technologies create new chemicals.

Post a list of hazardous materials in each work area. In the United States, hazardous materials include a

material safety data sheet that describes the material, the health/safety risks, correct usage procedures,

recommended storage facilities, and the method(s) to treat exposure. If local codes do not require use of a

material safety data sheet, a simple list may describe the type of material, correct usage and storage

methods, and its hazard(s). Include emergency first aid procedures in the event that personnel experience

exposure to the material.

LPA-9600

Use or disclosure of information from this document is subject to the restrictions xvii

Lockout/Tagout Policy

Lockout/Tagout refers to the complete isolation of equipment during maintenance or service work. It is

good practice to require use of locks or tags as warning devices to prevent injuries to service personnel

from accidental machine start-ups.

While servicing equipment, place a red or yellow tag on the equipment, indicating it is out of use for

repairs or maintenance. Treat these tags as a lockout tag. To obtain information regarding when that piece

of equipment will become available for use, contact the person who signed the tag.

Examples of equipment/service to tag/lock out during servicing include:

• Power supplies

• Antennas

• Transmitters

• Generators

• RF equipment

• Fan systems

• Motors

Work situations where unexpected application of power or starting of equipment could occur include:

• New construction

• Installation or set-up of equipment

• Equipment that is being:

Adjusted

Inspected

Serviced

Repaired

Power types include:

• Electrical

• Mechanical

• Hydraulic

• Pneumatic

• Chemical

• Thermal

WARNING

Do not attempt to start, energize, or use a machine or equipment that is

locked out for service or maintenance.

LPA-9600

xviii Use or disclosure of information from this document is subject to the restrictions

Warnings, Cautions and Notes

Warnings, cautions, and notes alert the user to special conditions regarding safety or correct performance

of a particular step(s).

WARNINGS - Used when a procedure, technique, or restriction could result in injury or death to

personnel.

CAUTIONS - Used when a procedure, technique or restriction could result in damage to equipment.

NOTES - Used whenever emphasis or consideration for the performance of a procedural step or steps

are necessary.

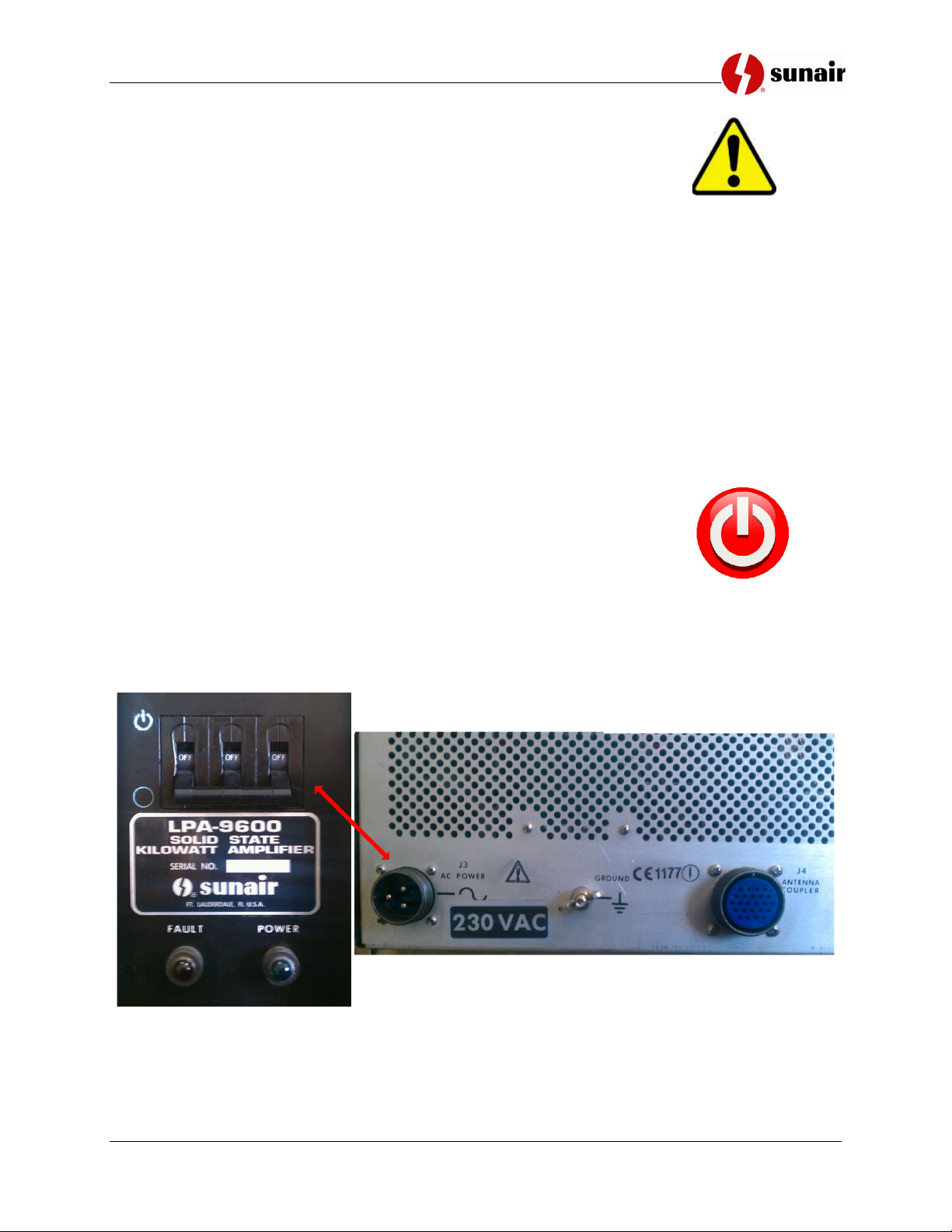

Power Disconnect Instructions

There are two ways to remove power from the unit:

• Turn off the power switch on the front of the unit.

• Disconnect the power cord from the rear of the unit (or unplug the power cord from the

power outlet).

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 1-1

CHAPTER I

1.0 General Information

1.1 Purpose of Manual

This manual describes the LPA-9600 1 kW Linear Solid State Power Amplifier and includes installation

details, operating instructions and maintenance procedures. Information in this manual applies to all

equipment configurations unless otherwise stated in the text or illustrations. The LPA-9600 is designed

specifically for operation with Sunair Transceivers and Exciters.

1.2 Purpose of Equipment

The purpose of the LPA-9600 is to amplify the low level RF output of a separate exciter to produce 1.0 kW

peak envelope power (PEP) or average power. The LPA-9600 is microprocessor controlled and operates in

the frequency range of 1.6 to 30 MHz. It is intended for a 100% unattended duty cycle for HF

communications systems networks.

1.3 General Description

1.3.1 Physical Description

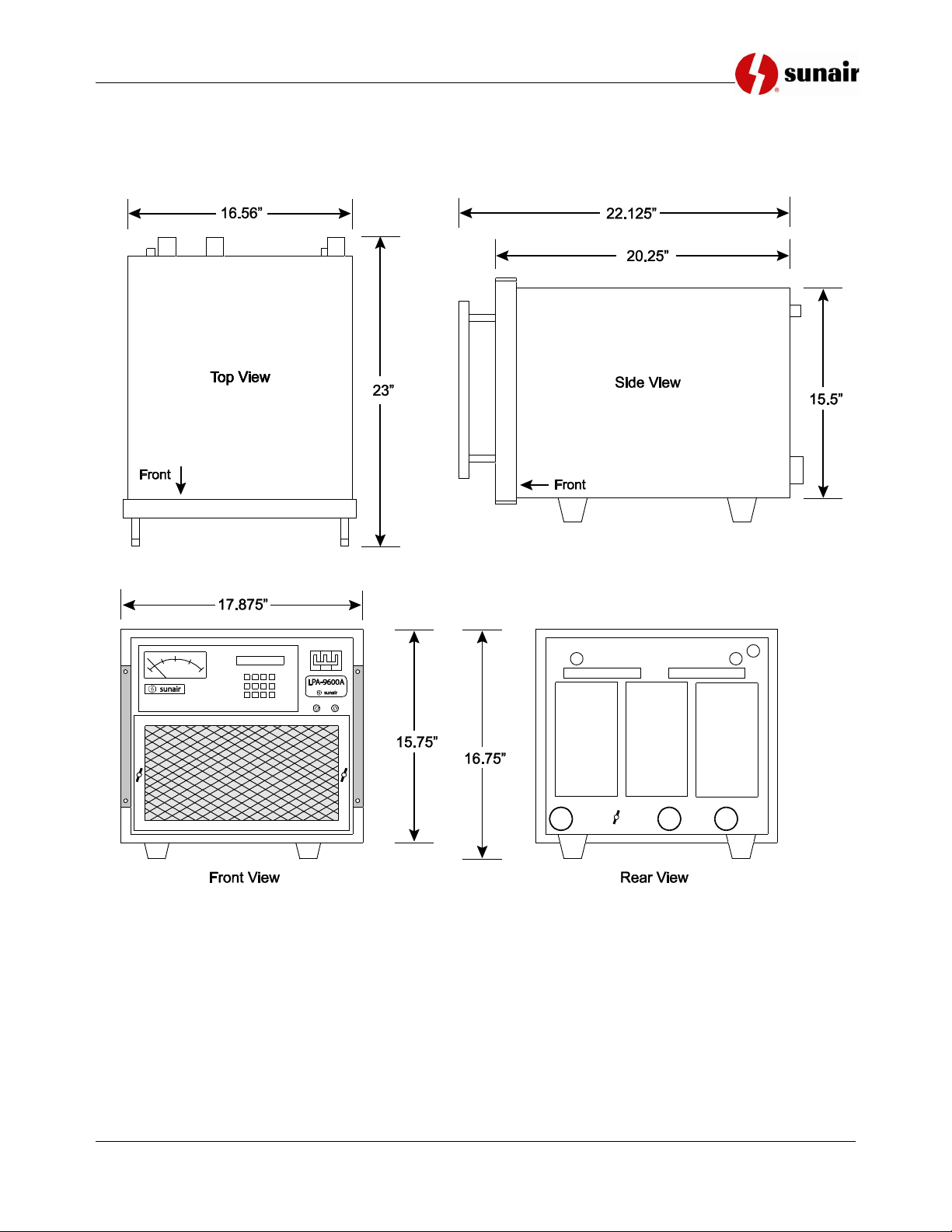

Outline and mounting dimensions for the LPA-9600 are given in Figure 1.5-1. Control, power and RF

connections to the unit are made on the rear panel.

The LPA-9600 is shown in Figure 1.5-2. The amplifier is a single enclosed unit and is smaller and much

lighter, weighing only 90 lbs., than the traditional amplifiers and power supplies contained in separate units.

Top and bottom covers provide complete access for servicing. Two blowers are provided behind the front

panel filter to force cooling air throughout the amplifier.

1.3.2 Electrical Description

The LPA-9600 1KW Solid State Linear Power Amplifier is a new generation amplifier, combining solid state

RF power amplification and microprocessor technology to produce over 1000 watts of reliable HF power into

a 50 ohm load. The unit operates in the frequency range of 1.6 to 30 MHz and at a rated output of 1.5 to 1

VSWR. Four amplifier/power supply modules, each capable of producing over 300 watts, in combination

deliver a very conservative 1000 watts of peak envelope or continuous RF output power.

The LPA-9600 operates from 115 or 230 VAC (50 to 60 Hz). It is extremely rugged and withstands

temperatures up to +65°C (+149°F) while operating at a 100% duty cycle. Forced air cooling, under

microprocessor control, is utilized to maintain safe operating temperature.

The unit is capable of providing a reduced power mode (500 watts) and a bypass mode (65 or 125 watts) that

is locally keyboard selected. Also available by keyboard are status indications of power, individual amplifier

voltages and currents. The liquid crystal display (LCD) indicates the specific function selected.

Sophisticated diagnostics, status monitoring and routine housekeeping are all under microprocessor and

software control. In the event of malfunction the LPA-9600 automatically selects the next lower safe

operating level, flashes a warning light locally, and displays the cause of the malfunction on the LCD. If the

malfunction is caused by more than one failure, the operator or technician is able to obtain detailed

diagnostics by use of the keyboard.

LPA-9600

1-2 Use or disclosure of information from this document is subject to the restrictions

1.3.2.1 Expected EMP Performance

The LPA-9600 is designed with an EMP environment in mind. All control and power lines into and out of

the LPA-9600 are filtered. This filtering on the standard unit is adequate for a mild EMP. But for full EMP

hardening, the optional EMP filter, which replaces the existing filter, is required. This filter is designed per

approved EMP techniques and decouples every input and output line (except the antenna).

Although the output elements in the LPA-9600 are solid state rather than vacuum tube, they are adequately

protected from EMP damage by shielding and specially designed filtering and decoupling of all interface

lines.

1.4 Specifications

RF Output Power: 1 kW ± 1 dB PEP and average. 500W or bypass output, front panel

keyboard selected.

RF Input Power: 75W maximum.

Frequency Range: 1.6 to 30.0 MHz.

Duty Cycle: Continuous.

Type of Emission: AM, SSB, CW or any other type within the bandwidth and power

capabilities of the amplifier.

Weight: 90 lbs. (40.8 kg).

Dimensions: CM: 45.42W X 48.26D X 40.01H

Inches: 17.88W X 19D X 15.75H

Input Impedance: 50 Ohm nominal. 2.0:1 VSWR maximum.

Output Impedance: 50 Ohm unbalanced.

Load VSWR: Rated power at 2 to 1.0, reduced power up to 3 to 1, protected above 3 to

1.

Input Voltage: 115/230 VAC ±15%, single phase, 50 to 60 Hz.

Input Power: 4.5 kVA Typical (including exciter).

Intermodulation

Distortion: 36 dB or better below PEP with a standard two tone test

signal at rated power output.

Harmonic Attenuation: 73 dB or better below carrier at rated power output into a 50 Ohm load.

Spurious: 80 dB below PEP.

Band Change Time: 10 ms maximum.

Tuning Time: 0 seconds without coupler; with an Automatic Antenna Coupler, tuning time

dependent on coupler type.

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 1-3

Temperature Range: Operating: -30ºC to +65ºC (-22ºF to +149ºF)

Storage: -40ºC to +85ºC (-40ºF to +185ºF)

Humidity: MIL-STD-810C, Method 507.1, Proc. III.

Altitude: 0-10,000 feet.

Vibration: MIL-STD-810C, Method 514.2, Equipment Category f, Table 514.2-VI for

wheeled vehicles, Figure 514.2-6, Curve V.

MTBF: 6,000 hours (calculated).

MTTR: 15 minutes.

Diagnostics: Microprocessor controlled with English Language Readout.

1.5 Dimensions

Figure 1.5-1 shows the dimensions for the LPA-9600 Power Amplifier.

LPA-9600

1-4 Use or disclosure of information from this document is subject to the restrictions

Figure 1.5-1: LPA-9600 Outline and Mounting Dimensions

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 1-5

Figure 1.5-2: LPA-9600 Front and Rear Panels

LPA-9600

1-6 Use or disclosure of information from this document is subject to the restrictions

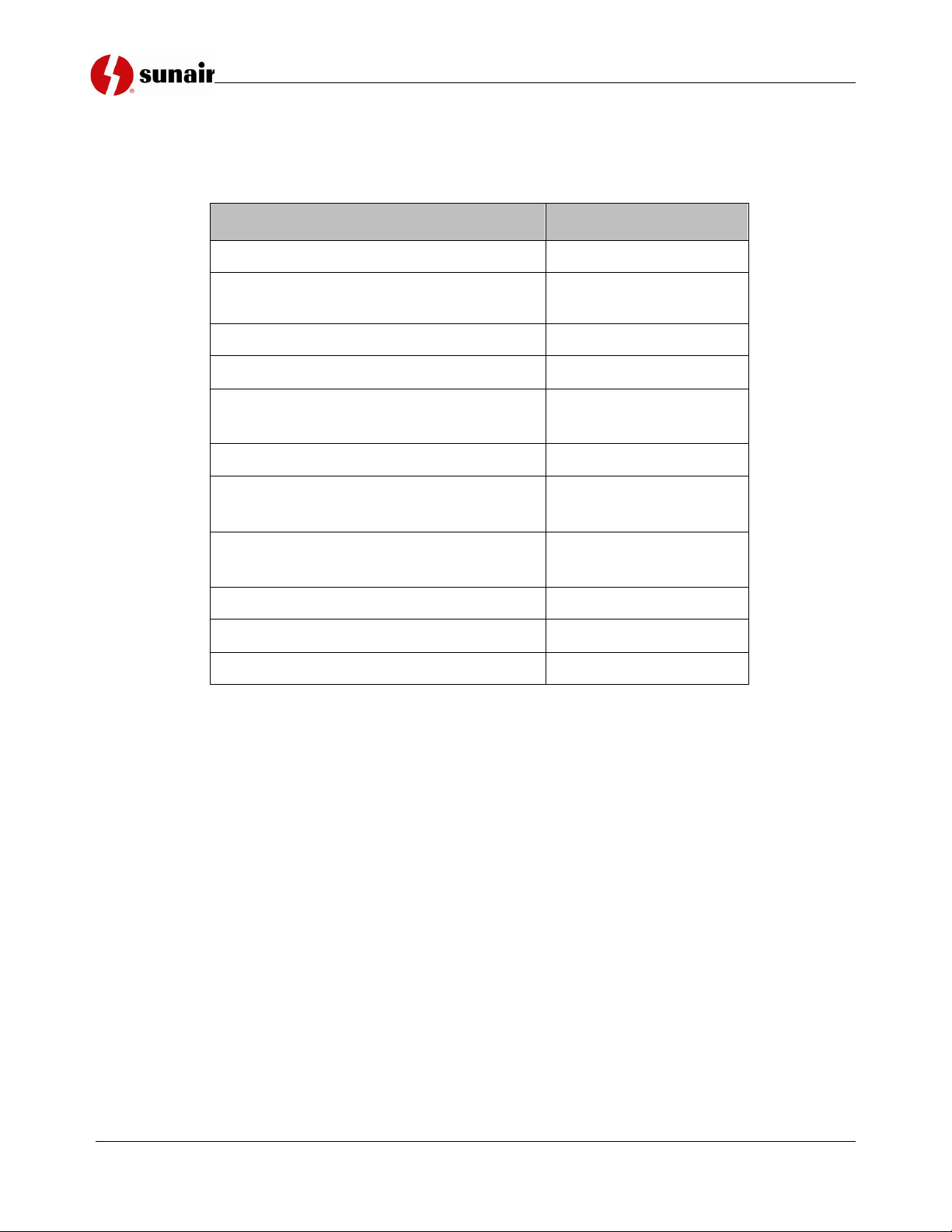

1.6 Equipment Supplied

Table 1.6-1 lists the equipment supplied with the LPA-9600.

Table 1.6-1: LPA-9600 Equipment Supplied

Equipment

Sunair Part Number

LPA-9600, 1 KW Linear Solid State Power

Amplifier

8105000059 Gray

8105000091 Green

Power Cable Assembly (10 feet)

8066002297

Operation and Maintenance Manual

TM-8105000504

Connector Kit, consisting of:

8066000294

• 2 EA Bushing, Telescoping, .56 ID

0700550054

• 2 EA Bushing, Telescoping, .62 ID

0700550062

• 2 EA Bushing, Telescoping, .75 ID

0700550071

• 1 EA Connector, RF, UHF, PL-259

0742190005

• 1 EA Connector, RF, N UG-536B/U

0747020001

• 1 EA Connector, RF, N UG-21B/U

0754140008

• 1 EA Connector, Power, 37 Pin Round

0754320006

• 2 EA Clamp, Cable, Connector

0754570002

• 1 EA Connector, Power, 24 Pin Male

1008390011

1.7 Equipment Required, Not Supplied

Table 1.7-1 lists the equipment required, but not supplied, for the LPA-9600.

Table 1.7-1: LPA-9600 Equipment Required, Not Supplied

Equipment

Sunair Part Number

External AC Power Connector

User Supplied

Transceiver or Exciter

Consult Sunair

Coaxial Cable, RG-8A/U

0588640000

Coaxial Cable, RG-58A/U

0588130001

Antenna System, 50 Ohm Nominal

User Supplied

Transceiver to LPA-9600 Control Cable

without connectors

0579240002

Transceiver to LPA-9600 Control Cable

assembly(specify length) consisting of:

• Cable 0579240002, 9000 Series

• Mating Connector and hardware

8076004098

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 1-7

1.8 Optional Equipment

Table 1.8-1 lists the optional equipment for the LPA-9600.

Table 1.8-1: LPA-9600 Optional Equipment

Equipment

Sunair Part Number

Running Spares Kit

8066900198

Service Kit (Contains PC Assembly Card

Extenders)

8066000995

Depot Spares Kit

8066900091

Field Module Kit

8066905793

CU-9150 High Speed Digital Antenna

Coupler

8120000056 Gray

8100001371 Green

LPA-9600 to CU-9150 Control Cable

8092500096

Rack Mounting Kit

8066004257 Gray

8066004290 Green

Wired Rack

8105150051 Gray

8105150093 Green

Shockmount Kit, Equipment Rack

6032090892

35 Foot Fiberglass Antenna

0715850008

KW Longwire Antenna Kit

1003090010

LPA-9600

1-8 Use or disclosure of information from this document is subject to the restrictions

THIS PAGE INTENTIONALLY LEFT BLANK

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 1-1

CHAPTER II

2.0 Installation

2.1 General

Section II contains all necessary instructions for unpacking, inspection, and, if required, reshipment of the

equipment or parts. Information regarding location and mounting considerations, power requirements, ground

system hook-ups, and cabling considerations is also provided.

2.2 Unpacking and Inspection

WARNING

The LPA-9600 ships with internal packing material.

You MUST open the top cover and remove the packing

material BEFORE operating the unit.

The LPA-9600 1 kW Linear Solid State Power Amplifier is packed in a box using double wall construction. The

packing material should be removed carefully and the contents inspected for physical damage. Any claims for

shipping damage must be filed promptly with the transportation company. If it is found necessary to file such a

claim, retain all packing material.

Do not accept a shipment when there are visible signs of damage to the shipping container until a complete

inspection is made. If there is a shortage of items or evidence of damage is noted, insist on a notation to that

effect on the shipping papers before signing the receipt from the carrier. If concealed damage is discovered after

the shipment has been accepted, notify the carrier immediately in writing and await his inspection before making

any disposition of the shipment. A full report should also be forwarded to Sunair.

Be sure to include the following information for prompt service:

• Order Number

• Model and Serial Number

• Name of Transportation Agency

• Applicable Dates

Upon receipt of this information, arrangements will be made by Sunair for repair or replacement.

LPA-9600

1-2 Use or disclosure of information from this document is subject to the restrictions

2.3 Returning Equipment to Factory

The shipping container for the LPA-9600 has been carefully designed to protect the equipment during shipping.

The container and its associated packing materials should be used to reship the unit. When necessary to return

equipment to Sunair for warranty or non-warranty repair, an authorization number is required. This number can

be obtained from our Product Services Department: 954-400-5122 or 954-400-5123.

If the original shipping carton is not available, be sure to carefully pack each unit separately, using suitable

cushioning material where necessary. Very special attention should be given to providing enough packing

material around connectors and other protrusions from the equipment. Rigid cardboard should be placed at the

corners of the equipment to protect against denting. DO NOT USE POLYSTYRENE FOAM PEANUTS FOR

PACKING PROTECTION, they may allow the unit to shift while being shipped, and become damaged.

When returning equipment to Sunair for warranty or non-warranty repair, do the following:

• Obtain a Return Material Authorization number. Refer to Return Material Authorization (RMA)

Procedures at the beginning of this manual for RMA instructions.

• Prepay shipments consigned to the address provided by the Sunair Service Department

representative.

• Use indelible ink to plainly mark the following on all documents included with the shipped

items:

US Goods Returned for Repair

Value for Customs - $(Amount) – If applicable

• Mark all sides of the package as FRAGILE – ELECTRONIC EQUIPMENT

• Carefully inspect the container to be sure it is properly and securely packaged, includes all necessary

documentation, and is properly marked.

2.4 General Installation Information

Satisfactory operation of your equipment depends on the care and thoroughness taken during installation.

2.4.1 Station Layout

The LPA-9600 must be installed in a structure which provides protection from the weather. Ambient temperature

must be maintained between - 30°C (-22°F) and +65°C (144°F).

Refer to Figure 1.5-1 to see the necessary outline dimensions required for installation. Floor load is 90 pounds.

Allow free circulation of air around the cabinet, and at least six inches air space between the back of the unit and

any wall or partition. The companion transceiver may be placed on top of the LPA-9600 for voice or CW modes

of communications. For FSK or other modes requiring a full kilowatt of average power output, the transceiver

should be located on an adjacent table and have a blower kit. The transceiver may also be rack-mounted above

the LPA-9600 if blowers are provided in the top of the rack.

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 1-3

2.5 Configurations

Figure 2.6-1 through Figure 2.6-3 are illustrations of various LPA-9600 configurations.

2.6 Antennas and Ground Systems

The LPA-9600 is designed to work with two types of antenna:

• Non-resonant antennas where an antenna coupler is used.

• Broadband antennas where the LPA-9600 is connected directly to the antenna.

Figure 2.6-1 through Figure 2.6-3 illustrate configurations where each of these two types of antennas are used.

2.6.1 Random Length Non-Resonant Antennas

The antenna impedance of non-resonant antennas is dependent on the operating frequency. An antenna coupler

must be used to match the antenna to the LPA-9600. Thirty-five foot whip antennas offer a good compromise

between practical height and good electrical performance at low operating frequencies. The performance of the

35-foot whip is greatly influenced by its ground system. For Base Station roof top installation, see Figure 2.6-2

for grounding details.

Another non-resonant antenna is the longwire. The two most popular length longwire antennas are 75 and 150

feet. Both of these antennas require an antenna coupler to match the antenna to the LPA-9600. Figure 2.6-4 is an

illustration of a 75-foot longwire installation. Note that the feed line from the antenna to the coupler is part of the

antenna’s length.

2.6.2 Broadband 50 Ohm Antennas

These are generally complex, expensive antennas requiring a large area for installation. Their use is usually

limited to high performance base station installations which must operate at diverse frequencies. As this class of

antenna has approximately 50 ohm output impedance over the rated band of frequencies, an antenna coupler is not

required. Some common types of broadband antenna are the Discone and Log-Periodic. Figure 2.6-1 is an

example of a system configuration utilizing a broadband antenna.

LPA-9600

1-4 Use or disclosure of information from this document is subject to the restrictions

Figure 2.6-1: LPA-9600 with Broadband Antenna

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 2-5

indicted on the proprietary/confidentiality page of this document.

Figure 2.6-2: LPA-9600 with CU-9150, 35-Foot Antenna (Roof Top Installation)

LPA-9600

2-6 Use or disclosure of information from this document is subject to the restrictions

indicated on the proprietary/confidentiality page of this document.

Figure 2.6-3: LPA-9600 with CU-9150, Non-Resonant Antenna

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 2-7

Figure 2.6-4: kW Long Wire Antenna Kit

LPA-9600

2-8 Use or disclosure of information from this document is subject to the restrictions

2.7 External Connections

2.7.1 Primary Power Connections

The LPA-9600 requires a primary power source that can provide up to 3.5 kVA (115 or 230 VAC).

Whenever possible, the primary power source should be connected to the amplifier through a double-pole, 30

ampere capacity, manual disconnect switch (60 ampere if primary source is 115 VAC). An arrangement of

this type will insure that all power has been removed from the unit prior to entrance for servicing. Refer to

Figure 2.7-1 primary power interconnect diagram for the line voltage connection details. The Power Cable

Assembly contains three each NO. 10 AWG conductors. The green wire connects to the station primary

power ground system. The black and the white wires connect to the 115 or 230 volt power source at the

disconnect switch previously described. The standard cable as furnished is 10 feet long.

2.7.2 Transceiver Connections

Separation between the transceiver and the amplifier may be up to 150 feet. The control cable to the

transceiver is shown in Figure 2.7-2. The transceiver accessory plug, P6, is furnished with the transceiver.

The plug P5, is furnished with the LPA-9600. The control cable 0579240002 is 37 conductor, No. 20 AWG

wire, shielded and jacketed. This cable is available in lengths specified by the customer.

The RF coaxial cable is also available in lengths specified by the customer. Type RG-58A/U, P/N

0588130001 is adequate for transceiver to amplifier spacings of less than 50 feet. For distances above 50 feet,

RG-8A/U, P/N 0588640000 should be used. Connector kits are provided with the LPA-9600 and the

transceiver.

2.7.3 RF Output Connections

The amplifier’s RF output connector is also furnished in the Connector Kit. RG-8A/U coaxial cable should

be used, regardless of the distance to the antenna or antenna coupler.

Figure 2.7-1: Power Cable Assembly, P/N 8066002297

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 2-9

Figure 2.7-2: 9000 Series Exciter/Transceiver to LPA-9600 Control Cable

LPA-9600

2-10 Use or disclosure of information from this document is subject to the restrictions

2.7.4 Antenna Coupler Connections

If an antenna coupler is not used, be sure the Connector Assembly P/N 8066007094 is installed on the rear of

the LPA-9600, J4.

NOTE: This connector links pin J4-T (Coupler Connect) to pin J4-G

(Ground).

When an antenna coupler is to be used, the buss wires on connector P/N 1008390011 must be removed before

cable construction is accomplished using this connector.

2.7.5 Station RF Ground System Connections

Grounding terminals are provided on the transceiver, LPA-9600 and antenna coupler for connection to the

station RF ground system. Use 1 or 2 inch wide copper strap or NO. 6 AWG wire or larger for this bonding.

Keep lead lengths to a minimum.

2.8 Preliminary Checks and Adjustments

Determine from the voltage customizing label the proper line voltage for the unit being installed. Connection

changes necessary to change voltage customizing are shown in Figure 2.8-1 and Figure 2.8-2. Be sure that

the Fan Voltage Switch, A10S1, is in the proper position.

If the LPA-9600 is received as a system with its companion transceiver/exciter, no adjustments should be

necessary. Otherwise, set the power levels as follows (see Figure 5.7-1 for component locations):

• Set transceiver/exciter frequency to 14.2000 MHz. Set transceiver/exciter MODE to CW, LPA-9600

to 1 kW. Key transceiver/exciter and adjust A3A2R32 for 1000 watts out.

• Set LPA-9600 to 500W. Set A3A2R33 for 500 watts out.

• Set transceiver/exciter to AM, LPA-9600 to 1 kW. Key transceiver/exciter and adjust A3A2R42 for

400 watts out.

• Set LPA-9600 to 500W. Adjust A3A2R43 for 200 watts out.

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 2-11

Figure 2.8-1: Voltage Customizing - Circuit Breaker/Auxiliary Power Supply

LPA-9600

2-12 Use or disclosure of information from this document is subject to the restrictions

Figure 2.8-2: Voltage Customizing – RF/PS Module A4 (4 Each)

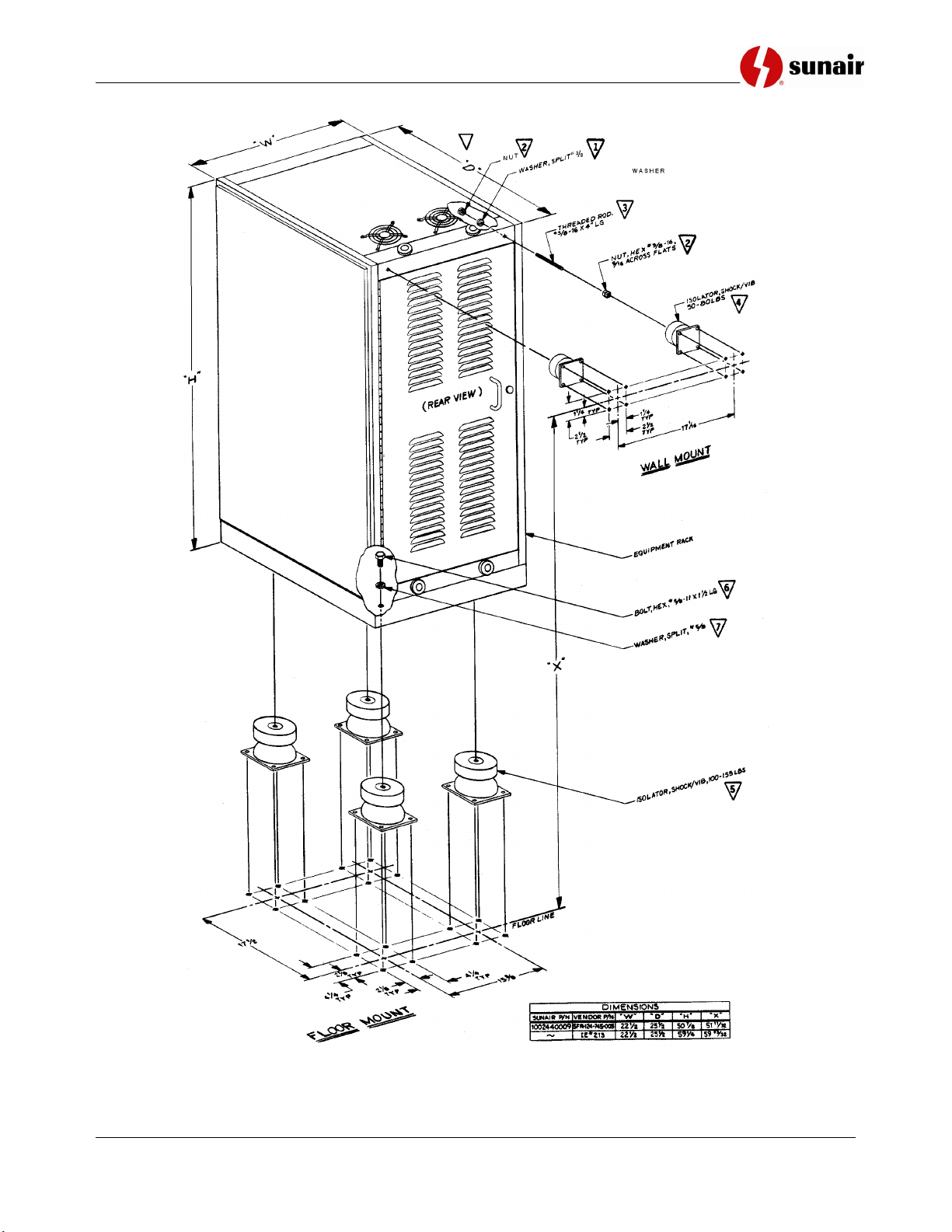

2.9 Rack Mounting Kit Option

An optional slide rack mounting kit is available to facilitate installation of the LPA-9600 in standard E.I.A.

equipment racks. See Figure 2.9-1, Figure 2.9-2, Table 2.9-1 and Table 2.9-2.

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 2-13

Figure 2.9-1: Rack Mount Slide Details

Table 2.9-1: LPA-9600 Rack Mounting Kit Parts List

Sunair Part Number

Description

80660042XX

Rack Mounting Kit

50660043XX

Bracket, Rack Mounting

6032041204

Chassis Slide

0538750006

Nut, Clip 10-32

0538870001

Screw, Ornamental 10-32 x 1/2 L

1002860032

Shim, Plate LPA/PS

LPA-9600

2-14 Use or disclosure of information from this document is subject to the restrictions

Figure 2.9-2: Shockmount Equipment Rack with Outline Dimensions and Details

(Page 1 of 2)

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 2-15

Figure 2.9-2: Shockmount Equipment Rack with Outline Dimensions and Details

(Page 2 of 2)

LPA-9600

2-16 Use or disclosure of information from this document is subject to the restrictions

Table 2.9-2: LPA-9600 Shockmount Kit Equipment Rack Parts List, P/N 6032090892

Sunair Part Number

Description

Qty

0501650008

Washer, Split 3/8

2

0501700005

Nut, Hex 3/8-16 X 9/16 AF

4

0542880644

Rod, Thd 3/8-16 X 4 Lg

2

0841810001

Isolator, Shock/Vib. 50-80 Lbs

2

1001280016

Isolator, Shock/Vib. 100-155 Lbs

4

1001290003

Bolt, Hex 5/8-11, 1½1/2 Lg

4

1001300009

Washer, Split 5/8

4

1002980011

Installation Instructions

1

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 2-1

CHAPTER III

3.0 Operation

3.1 General

This section provides information and instructions required for operation of a transceiver, the LPA-9600 1

kW Linear Solid State Power Amplifier and an automatic antenna coupler. Refer to the transceiver and the

coupler Operation and Maintenance Manuals for detailed information regarding operation of these units.

3.2 Function and Location of Controls and Indicators

Figure 3.2-1 shows the location of the LPA-9600 front panel controls and indicators. Their functions are listed

in Table 3.2-1.

Figure 3.2-1: LPA-9600 Controls and Indicators

LPA-9600

2-2 Use or disclosure of information from this document is subject to the restrictions

Table 3.2-1: Front Panel Controls and Indicators

Control or Indicator

Function

Meter, A2M1

Displays the following:

• 0 - 1400: Forward Power in watts

• 0 - 140: Reflected Power in watts

• 0 - 60V: Selected PA’s voltage

• 0 - 18A: Selected PA’s current

LCD Assembly, A2A2

This Liquid Crystal Display (LCD) displays all systems messages and

conditions.

Circuit Breaker, A8CB1

Applies primary power to the LPA-9600.

FAULT Lamp, A8DS2

A red fault lamp which, when flashing, indicates a fault in the LPA-9600.

A steady fault lamp indicates a fault external to the LPA-9600.

POWER Lamp, A8DS1

A green lamp which indicates that primary power has been applied to the

LPA-9600.

Keyboard, A2A1S1

The keyboard lets the operator/technician check individual voltage,

current and power levels. The keyboard also provides the

operator/technician with the ability to select desired power operating

levels and to read failure indications.

• Ic = Current Collector

• Vc = Voltage Collector

• PA = Power Amplifier

Ic1

When pressed, displays power supply current of PA #1 on meter.

Ic2

When pressed, displays power supply current of PA #2 on meter.

Ic3

When pressed, displays power supply current of PA #3 on meter.

Ic4

When pressed, displays power supply current of PA #4 on meter.

Vc1

When pressed, displays power supply voltage of PA #1 on meter.

Vc2

When pressed, displays power supply voltage of PA #2 on meter.

Vc3

When pressed, displays power supply voltage of PA #3 on meter.

Vc4

When pressed, displays power supply voltage of PA #4 on meter.

FWD

When pressed, displays forward output power (in watts) on meter.

REFL

When pressed, displays reflected output power (in watts) on meter.

PWR LVL

When pressed, changes output power level reading on LCD from 1 kW to

500 watts to bypass.

*

When more than one fault occurs, the LCD will read Fault: MULTIPLE..

PRESS *. Press this key to display each fault message one at a time

until all faults detected have had messages displayed.

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 2-3

3.3 Operating the LPA-9600

WARNING

The LPA-9600 ships with internal packing material.

You MUST open the top cover and remove the packing

material BEFORE operating the unit.

3.3.1 Operation with a 9000 Series Exciter/Transceiver

Insure that the transceiver/exciter and the LPA-9600 are installed properly by referring to Section II of this

manual and in the radio manual. If an antenna coupler is being used, insure its proper installation as well.

1. Apply power to the transceiver/exciter and LPA-9600. The LPA-9600 POWER lamp will light and

the LCD will display a system message.

• Without an automatic antenna coupler: kW SYSTEM OPERATIONAL, METER: FWD, PWR

LVL: 1 kW. (Instead of PWR LVL: 1 kW, it may display Bypass if it’s not programmed in the

exciter). Then kW SYSTEM OPERATIONAL appears and the system is ready to operate. If

instead the FAULT lamp on the LPA-9600 flashes, this indicates a fault in the LPA-9600. Reset

the LPA-9600 by turning the transceiver/exciter off, wait 30 seconds, then turn back on; or at the

LPA-9600 turn circuit breaker OFF then ON; or using the PWR LVL key on the keyboard, reset

the LPA-9600. If FAULT does not clear, refer to Section V of this manual.

• With a CU-9150 antenna coupler: FAULT: COUPLER UNTUNED, METER: FWD, PWR LVL:

1 kW. If there is a coupler fault, the LPA-9600 FAULT lamp will burn steadily. Follow steps 2

through 6 below.

2. Select operating frequency on transceiver/exciter.

3. If a coupler is present, press the CPLR TUNE button on the 9000 Series front panel.

4. The LCD will display system messages: COUPLER TUNING, COUPLER TUNED, and kW SYSTEM

OPERATIONAL. After tuning is complete, (maximum 2 seconds), the system is ready for operation.

5. If after a tune attempt, the FAULT lamp on the LPA-9600 burns steadily, this indicates a fault in the

coupler, antenna, or feedline. Attempt retuning. If the fault does not clear, refer to Section V of this

manual and the 9000 Series or coupler manual.

6. If the FAULT lamp on LPA-9600 flashes, this indicates a fault in the LPA-9600. Reset the LPA-

9600. If the fault does not clear, refer to Section V of this manual.

NOTE: If an antenna coupler is not used, tuning is not required when the

operating frequency of the transceiver/exciter is changed. With an

antenna coupler, coupler tuning is required with each frequency

change.

LPA-9600

2-4 Use or disclosure of information from this document is subject to the restrictions

THIS PAGE INTENTIONALLY LEFT BLANK

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 3-1

CHAPTER IV

4.0 Theory of Operation

4.1 General

See Figure 4.11-1 and Figure 5.8-1.

The LPA-9600 is an all-solid-state, self-contained, one kilowatt linear power amplifier designed for use with

9000 Series transceivers or exciters. The unit is complete in one package and includes RF amplifier modules,

power supplies, combining networks, harmonic filters and microprocessor control circuitry. Built-in

diagnostics monitor the functional operation of the unit and report malfunctions in English language on a

front panel liquid crystal alphanumeric display. In addition to reporting malfunctions, the microprocessor

reconfigures the amplifier to a safe operating power level, or shuts it down completely, providing exciter only

operation.

The RF circuitry consists of an input power splitter, four broadband RF power amplifier modules, an output

power combiner, and a harmonic low pass filter. The input power splitter divides the exciter power equally

among the four RF modules. Each RF amplifier module consists of two conservatively rated power

amplifiers combined to provide over 300 watts power output capability. The output from the four RF

amplifier modules is combined in the output power combiner, providing over 1200 watts output capability in

one feedline. The harmonic low pass filter attenuates the harmonic output of the amplifiers by at least 75 dB.

The filter is split into 8 bands, each a maximum of one-half octave frequency span (1.5 x frequency),

automatically selected by the exciter and buffered by the microprocessor circuitry, so that no tuning is

required.

Each power amplifier module consists of an RF module, a power supply, and an RF module control assembly.

The power supplies are high-efficiency switching regulators, with built-in current foldback and overvoltage

protection. The RF module control assembly provides microprocessor-controlled AC power input to the

power supplies, and regulated bias voltage to the dual amplifier, ensuring linearity.

4.2 Control Panel Module A2

See Figure 5.8-2.

The Control Panel Module is a plug-in panel arrangement on the front of the LPA-9600 which contains the

meter, the LCD Assembly, and the 3 x 4 keyboard. The LCD Assembly A2A1 is used to display the power

level selected, the diagnostic information, and the function selected to be displayed on the meter. The 3 x 4

keyboard is used to select the meter display functions. The PC Assembly Control Panel A2A2 provides the

interconnections which permit the keyboard to close the proper row to the proper column when a key is

pressed and pass the information on to the Computer Mother Board A3A1. The PWR LVL key is used to

select the desired operating power level of the LPA-9600. The * key is used to scroll through multiple fault

indications. The meter is used to display any of the four collector currents, four collector voltages, and either

forward or reflected power.

LPA-9600

3-2 Use or disclosure of information from this document is subject to the restrictions

4.3 Computer Assembly A3

4.3.1 PC Assembly Computer Mother Board A3A1

See Figure 5.8-3.

The Computer Mother Board acts as a back plane to interconnect the Peripheral Board A3A2 to the

Microprocessor Board A3A3 and to interconnect these two boards to the balance of the LPA-9600. The

Microprocessor Board plugs into A3A1J6 and A3A1J7. The Peripheral Board plugs into A3A1J8 and

A3A1J9. Connector A3A1J1 provides routing for the signals to and from the power amplifier assemblies.

Connector A3A1J2 interfaces to the Filter Module A5. Connector A3A1J3 connects to the Control Panel

Module A2. Connector A3A1J4 interfaces with the transceiver/exciter and the antenna coupler. Connector

A3A1J5 interfaces with the front panel of the LPA-9600 by transferring control signals to the front panel

lights, the bypass relay, and overtemperature fan.

4.3.2 Peripheral Board A3A2

See Figure 4.11-2 and Figure 5.8-4.

4.3.2.1 General

The Peripheral Board A3A2 contains much of the analog circuitry used to monitor and control the LPA-9600.

Many fault indicators and detectors are located on this board. These circuits are designed to inform

Microprocessor A3A3U1 when a fault has occurred in the electronic operation of the LPA-9600. Also

provided are circuits which interface it with a CU-9150 Digital 1000W Coupler.

The Peripheral Board is responsible for the following functions required for proper operation of the LPA9600:

• The signal BYPASS which causes the LPA-9600 to be bypassed in the event of a fault which in turn

inhibits it from producing its power output.

• The signals READY REMOTE , kW DETECT , FAULT REMOTE , kW POWER DETECT 1, and

kW POWER DETECT 2 operate circuits in the 9000 Series Exciter/Transceiver.

• The signal used to drive the fault lamp on the front panel of the LPA-9600.

• The signal +28 VDC TUNE ENABLE which instructs the transceiver that a CU-9150 antenna coupler

is attached and is tuning.

The Peripheral Board contains the multiplexer circuits which permit ten of the twelve front panel keys on the

keyboard to select meter functions. Contained also is a DC to DC converter to provide contrast adjustment

for the front panel LCD Assembly. Similarly, a DC to AC inverter is provided which drives the EL

(electroluminescent lamp) backlight for night time viewing of the LCD Assembly. Also provided is the

ALC/ACC Control Circuit which monitors the forward and reflected power. This circuit is responsible for

selecting and producing the proper level of ALC or ACC needed to control the 9000 Series equipment

attached to the LPA-9600.

LPA-9600

Use or disclosure of information from this document is subject to the restrictions 3-3

4.3.2.2 Temperature Sense Comparators U1, U2

The purpose of the Temperature Sense Comparators is to detect when the temperature on any of the four

heatsinks on the four individual power amplifiers has reached either of two thresholds. When the temperature

on any power amplifier heatsink reaches between 75°C and 85°C (167°F and 185°F), Microprocessor

A3A3U1 causes the fans to operate at a higher speed. If the temperature continues to increase and reaches

between 100°C to 120°C (212°F to 248°F), A3A3U1 shuts down the overheating power amplifier.

4.3.2.3 Overtemperature Buffer U3

The purpose of the Overtemperature Buffer U3 is to provide a means by which Microprocessor A3A3U1 can

monitor the temperature of power amplifier assemblies 1, 2, and 3. U3 also acts as a position from which

A3A3U1 can monitor a signal called FILTER MODULE FAULT. This signal originates in the Filter Fault

Detector U9C, U20A. If this signal is high, A3A3U1 will cause an indication on the LCD Assembly pointing

out the faulty filter module. In addition, A3A3U1 will force the LPA-9600 to BYPASS operation to protect

the filter module from damage.

4.3.2.4 Gain Fault Comparators U12

The Gain Fault Comparators are a series of four detector circuits used to monitor the power gain of the four

individual power amplifier assemblies. The input power to a particular power amplifier assembly is

compared to its output power. If the power amplifier is not producing the required amount of power,

Microprocessor A3A3U1 is alerted.

4.3.2.5 Gain Fault Buffer U7

The Gain Fault Buffer is the device by which Microprocessor A3A3U1 monitors the status of the gain of the

four power amplifier assemblies. When any of the GAIN FAULT signals go high, A3A3U1 will cause a gain

fault message to be displayed on the LCD Assembly A2A2. At the same time A3A3U1 will shut down the

defective power amplifier reducing the output power from 1000 watts to 500 watts in the LPA-9600. U7 is

also used by A3A3U1 to monitor the temperature information from power amplifier number 4 received from

the temperature sense comparators. The signal VSWR FAULT is also monitored by A3A3U1 thru U7. If this

signal goes high, A3A3U1 will reduce the power produced by the LPA-9600 from 1000 watts to 500 watts. If

VSWR FAULT is still high, A3A3U1 will place LPA-9600 in BYPASS, protecting it from the excessive

VSWR.

4.3.2.6 VC Monitor Comparators U11

The purpose of the VC Monitor Comparators comprising U11 is to monitor the individual+48V power

supplies that are mounted in each of the four power amplifier assemblies. When the voltage in a power

supply falls below +42.3 volts, the output of U11 goes high. Microprocessor A3A3U1 will sense this and

remove the defective power supply from operation.

4.3.2.7 Voltage Monitor Comparators U13

The purpose of the Voltage Monitor Comparators comprising U13 is to monitor the +28VDC and +5VDC

utilized by the logic control circuitry in the LPA-9600. Microprocessor A3A3U1 monitors the four outputs of

U13 to determine if the voltages are too high or too low.

LPA-9600

3-4 Use or disclosure of information from this document is subject to the restrictions

4.3.2.8 VC Monitor/Voltage Monitor Buffer U19

U19 is used by Microprocessor A3A3U1 to determine if any of the four +48V power supplies is producing a

voltage that is too low. U19 is also used to determine if the +28V logic control voltage is too low or if the +5

V logic control voltage is too high or too low. A3A3U1 periodically samples the inputs of U19. If any of

these inputs are high, A3A3U1 takes appropriate action and alerts the operator to the condition.

4.3.2.9 Collector Voltage Meter Conditioning Circuit U14

U14 functions as four distinct identical stages. U14A conditions the +48V from PA #1 for display on the

meter, U14C conditions the +48V for PA #2, U14B conditions the +48V for the PA #3, and U14D conditions

the +48V for PA #4. These circuits are voltage follower circuits which function identically. For example:

For PA #1, +48V is applied to U14A through a resistor divider. The resistor divider reduces the +48V to