May 2013

OPERATOR’S SAFETY MANUAL

Sumner max Jax / Beam Jax

7514 Alabonson Road

Houston, TX 77088 U.S.A

ph: 281.999.6900

fax: 281.999.6966

www.sumner.com

75 Saltsman Drive

Unit 5

Cambridge, ON N3H 4R7 Canada

ph: 519.653.5300

fax: 519-653-5305

Unit 16A

Blackpole Trading Estate East

Blackpole Road

Worcester WR3 8SG, U.K.

ph: (44) 01905 458333

fax: (44) 01905 458222

Owner’s

Reponsibilities

NOTICE: Throughout this publication, the words

WARNING, CAUTION, and IMPORTANT

will be used to alert the user to special

instructions concerning a particular

operation that may be hazardous if

performed incorrectly or carelessly.

OBSERVE THEM CAREFULLY!

These “Safety Alerts” alone cannot eliminate the

hazards that they signal. Strict compliance to these

special instructions while performing the service plus

“common sense” operation are major accident

prevention measures.

WARNING Hazards or unsafe practices which

could result in severe personal

injury or death.

CAUTION Hazards or unsafe practices which

could result in minor personal injury, product or property damage.

IMPORTANT Indicates information or instruc-

tions that are necessary for proper

operation and/or maintenance.

Copyright © 2013 by Sumner Manufacturing Co., Inc. All rights reserved. No part of

this book may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying, recording or by any information storage and

retrieval system, without permission in writing from Sumner Manufacturing Co., Inc.,

7514 Alabonson Road, Houston, TX 77088.

Max Jax / Beam Jax Operator's Manual 3

Operator Safety Instructions

Sumner’s Beam Jax and Max Jax mobile stands enable users to easily and safely move beams or pipes weighing up to

2,500 lbs (1,135 kg).

Beam Jax may be used with beams up to 24" wide.

Max Jax may be used with a pipes between 4" and 36" in

diameter.

To operate stands safely requires dexterity, mechanical skills

and sound safety habits

Although Sumner Max and Beam Jax’s are manufactured

for safe, dependable operation, it is impossible to anticipate

those combinations of circumstances which could result in

an accident. The following instructions are recommended for

safe operation of this unit:

1. Read and understand the instructions for safe

operation. Before working with a Sumner jack, understand the correct operation, applications and limitations.

Always contact Sumner when in doubt. Be particularly

aware of specic hazards. Store this safety manual in a

clean area and always at a readily available location.

Additional copies are available for download from

www.sumner.com.

2. Inspect the equipment. Prior to using Sumner jacks,

check all parts to ensure that they are in proper operating

condition. Inspect legs for bends, breaks or metal

deformation.

4 Max Jax / Beam Jax Operator's Manual

CAUTION IN THE EVENT OF ANY BENDS,

BREAKS, OR METAL DEFORMATION TO THE STANDS, DISCONTINUE USE IMMEDIATELY AND

MAKE ANY NECESSARY

REPAIRS/REPLACEMENTS

BEFORE USE.

3. Wear proper clothing. Hard hat or welding helmet,

safety shoes and welding gloves should be worn as a

precaution while operating this stand.

4. Keep work area clean. Always keep oor in work area

clear of clutter for unobstructed movement around the

stand.

5. Operate from proper position. Keep balance and

proper footing at all times.

6. Keep alert. Avoid horseplay around equipment and keep

bystanders at a safe distance. Do not allow children to

operate jacks and always keep them out of work areas.

Do not ride on stands.

CAUTION Never allow anyone under jack

stand with load.

7. Do not misuse unit. Perform only the functions for which

the jacks are designed. Never attempt to operate the

equipment at more than the recommended capacity.

WARNING Modifying the jack stand can

result in injury or death.

Max Jax / Beam Jax Operator's Manual 5

8. Operate only on level surfaces. Use the jack only on

smooth and level surfaces to avoid tipping and the

possibility of operator injury.

MAX JAX

Maximum

36" (90 cm) pipe

Minimum 4"

(10 cm) pipe

Optional

styles of

roller wheels

Large 12"

(30 cm) vee

Fine adjustment

with bearing

Optional pipe

hold down

chain

Stable and

sturdy 5-leg

construction

Quick

action

brake

Optional, large

8" (20 cm) casters

6 Max Jax / Beam Jax Operator's Manual

BEAM JAX

Max 24" (61 cm)

Min 0"

(0 cm)

Close or open

clamp from

either side.

Fine adjustment

with bearing

Stable &

sturdy 5-leg

construction

Optional 8"

(20 cm)

casters

Quick action

breaks

Max Jax / Beam Jax Operator's Manual 7

Max/Beam Jax Specications

A

C

B

Specications

Max Jax Beam Jax

Load Capacity 2,500 lb (1135 kg) 2,500 lb (1135 kg)

Basic Unit A (height)

Basic Unit with casters (height)

Beam / Vee Head height C (min.)

Beam / Vee Head height

with casters

B (width)

(width)

(max.)

(min.)

(max.)

27.0" (686 mm)

29.6" (752 mm)

36.5" (927 mm)

39.5 (1003 mm)

21.0" (533 mm)

33.0" (838 mm)

30.5" (775 mm)

42.5" (1080 mm)

B

27.8" (705 mm)

29.6" (752 mm)

37.3" (947 mm)

39.5" (1003 mm)

25.5" (648 mm)

37.5" (953 mm)

35.0" (889 mm)

47.0" (1194 mm)

8 Max Jax / Beam Jax Operator's Manual

Before you start:

1. DO check the load weight to insure that it does not

exceed stand capacity. Additional stands can be used

2. DO inspect stand thoroughly prior to use for evidence of

structural or caster damage

3. DO use the stands on rm, level surface such as pave-

ment or hard ooring

4. DO adjust head with spanner nut to allow for load

height adjustment when leveling

5. DO position heads so that they are approximately the

same height

6. DO locate stands close enough to support load length

7. DO use a minimum of two stands

WARNING Using one stand to support or

brace load can lead to a potential

injury.

8. Do position casters in same direction before placing

load on stand

WARNING Using a hammer to reposition

casters will damage wheels

resulting in injury or death.

9. Do Not lock casters before loading stands

10. Do Not drop loads on stands. Lower loads evenly onto

stands

Max Jax / Beam Jax Operator's Manual 9

General Instructions

Quick action brakes are available on all 5 casters. Use caster brakes when necessary when working on loads to ensure

a stable work surface.

Caster unlocked Caster locked

Beam Jax and Max Jax head heights may be adjusted using

the ne adjustment bearing. Stand heights may be adjusted

quickly before load is placed on stand by lifting the head off

of the base assembly, thus removing the weight of the head,

and adjusting the spanner nut higher or lower on the adjusting screw.

Spanner nut

10 Max Jax / Beam Jax Operator's Manual

Instructions for Moving Load

Max Jax

A. ALWAYS be certain Beam Jax or Max Jax stands are of a similar

height before loading.

ALWAYS be certain to place stands close enough together to t under

the length of the load.

ALWAYS use at least 2 Beam Jax or Max Jax to handle loads. NEV-

ER use a single Beam Jax or Max Jax stand alone to prop up loads.

ALWAYS place loads carefully on Beam Jax or Max Jax. NEVER drop

loads onto Beam Jax or Max Jax stands.

ALWAYS use Beam Jax and Max Jax stands on a rm, level surface

such as pavement or hard ooring. NEVER use Beam Jax and Max

Jax stands on dirt or gravel surfaces.

ALWAYS inspect Beam Jax and Max Jax stands thoroughly before

using for evidence of structural or caster damage including damaged

or bent legs, cracked welds, and cracked, bent or broken casters.

NEVER use a stand that shows signs of structural or caster damage.

IMPORTANT

For more information on general safety

practices and commonly found issues see

Sumner's Pipe Jack Safety Manual.

NEVER lock casters while loading stands.

NEVER load more than one beam or pipe on stands.

Max Jax / Beam Jax Operator's Manual 11

Hold Down Device Instructions:

1. Insert chain end of hold down device through containment loop and tighten set screw to half the length of

chain

2. Back off adjustment screw in order to have maximum

thread travel

12 Max Jax / Beam Jax Operator's Manual

3. Insert chain into slot on Hold Down Housing and

tighten adjustment screw.

4. Make sure Hold down device chain is tightly secures

load to vee.

B.Unlock casters' wheel brakes

C. Make sure all casters are in the same direction. If not

move each end of the Max Jax load in a circle to align

casters

Max Jax / Beam Jax Operator's Manual 13

D. Push load from the end where the hold down device has

secured the load to the stand

14 Max Jax / Beam Jax Operator's Manual

Beam Jax

1. Tighten Beam Jax clamps to the load before moving load

2. Unlock caster wheel brakes

3. Make sure casters are in the same direction. If not, move

each end of the Beam Jax load in circle to align casters.

4. Push the load, do not pull

5. Reposition clamp handles to move out of operator’s way

Accessories:

Base Leg Mounting Pads

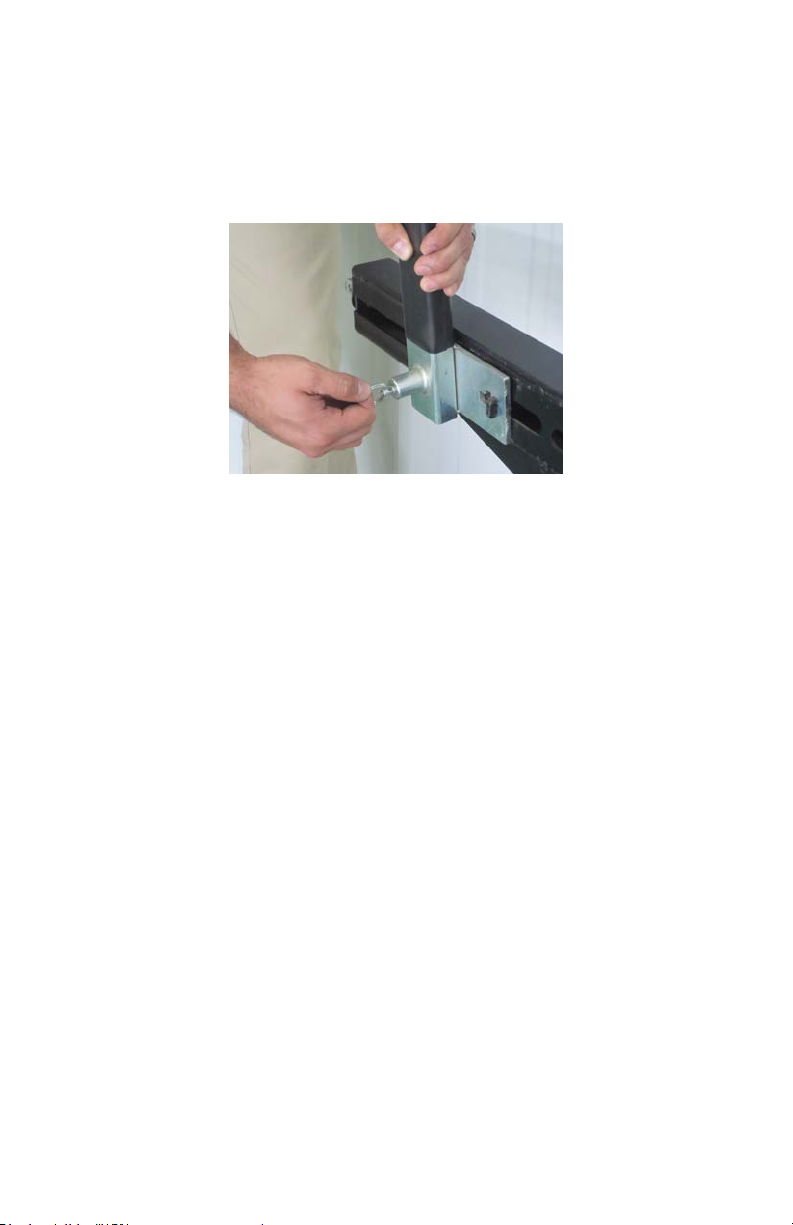

Basic Max Jax and Beam Jax come with mounting pads

that insert into the base sockets. Insert pad stem into

the base socket and secure with Allen screw and wrench

provide with the stand.

Max Jax / Beam Jax Operator's Manual 15

Caster stem inserts into base socket and must be secured with the provided Allen screw and wrench

16 Max Jax / Beam Jax Operator's Manual

Max Jax Roller Wheel Options

Instructions: All wheel kits come complete with 4 wheels,

bushing, and fastening hardware. Located on the vee head

are four holes where each wheel is mounted. It is best to

that all attaching bolts be assembled on to the vee in the

same direction.

Pn 781406 Steel wheel roller head kit

Standard roller wheel which comes with Max Jax kit# 1

Pn 781407 Stainless Steel roller head kit

Similar to standard steel wheel but with Stainless contact

Pn 781381 Large Steel roller head kit

Wide surface steel wheel provides more surface contact and

smoother rotation

Max Jax / Beam Jax Operator's Manual 17

PN 781394 Rubber wheel roller head kit

High impact molded plastic/nylon wheels for Stainless and

other exotic metals. Load rating reduced to 1,000lb/ 450 kg.

PN 781382 Stainless Steel Sleeves

Stainless sleeves bolt to the vee head providing complete

stainless surface.

PN 781383 Standard Ball Transfers

PN 781397 SS Steel Ball Transfers

Two ball transfers bolt on to each vee by tighten wing nuts.

Ball transfer can be positioned anywhere on the the vee.

18 Max Jax / Beam Jax Operator's Manual

Beam Jax Clamp Adjustment

Adjusting Beam Forks

To remove beam forks, pull out plunging attaching pin and

slide fork assembly.

To clamp narrow width loads, clamp fork should be with

plunger pin nearest to the center of the head.

Max Jax / Beam Jax Operator's Manual 19

To clamp wide loads, plunger pin on the clamp forks should

be positioned out towards the end of the head.

Loading...

Loading...